Method for preparing isohexadecane by adopting high-efficiency double-function catalyst

A bifunctional catalyst, the technology of isohexadecane, which is applied in the field of producing isoparaffins, can solve the problems of low reaction activity and isomerization selectivity, short service life of the catalyst, frequent regeneration, etc., so as to improve the reaction activity and isomerization Structuring selectivity, improving diffusion performance, and reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode 1: In this implementation mode, the method for preparing isohexadecane by using a high-efficiency dual-function catalyst is implemented according to the following steps:

[0020] The bifunctional catalyst is loaded into the constant temperature zone of the fixed-bed reactor, under H 2 Activate the atmosphere at 350-450°C for 1.0-4.0h, and then use a (trace) feed pump to continuously inject n-hexadecane into the fixed-bed reactor after dropping to the initial reaction temperature, control the reaction temperature at 260-380°C, and the reaction pressure 1.0~4.0MPa, the mass space velocity of n-hexadecane is 1.5~4.5h -1 , H 2 The volume ratio to n-hexadecane is (400-900): 1 to obtain isohexadecane;

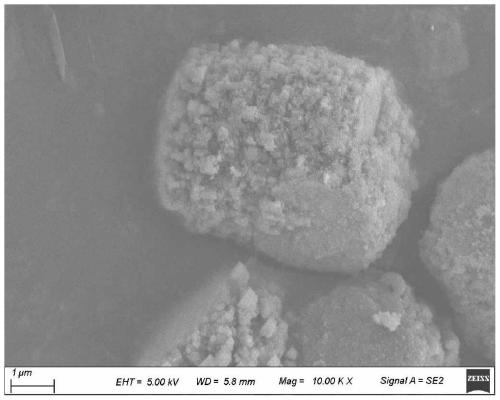

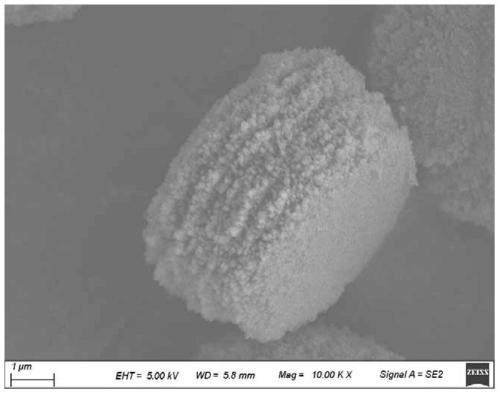

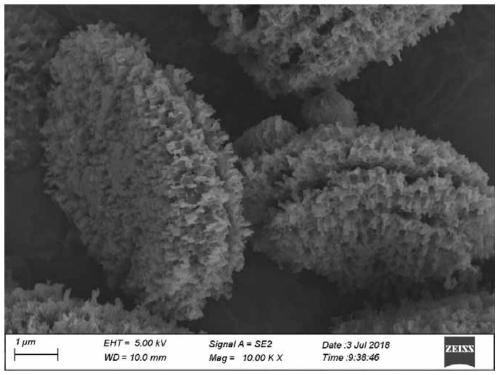

[0021] The bifunctional catalyst is formed by loading 0.02-0.09 wt.% Pd on the multi-level porous SAPO-41 molecular sieve nano sheet.

[0022] This embodiment provides a high-efficiency bifunctional catalyst prepared by carrying a small amount o...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of the described bifunctional catalyst is:

[0024] 1. 10-14g of phosphoric acid with a mass concentration of 85%, 6-8g of pseudoboehmite, 6-8g of silica sol, 12-16g of di-n-butylamine and 4.21-21.06g of crystal growth inhibitor are stirred Add to deionized water in turn, stir evenly to get the initial gel;

[0025] 2. Transfer the initial gel to a stainless steel crystallization kettle lined with polytetrafluoroethylene, crystallize at 175-195°C for 10-60 hours, collect the crystallized product and cool it to room temperature, then centrifuge, wash and dry , the dried crystallized product is placed in a muffle furnace for roasting treatment to obtain a (white) solid reaction powder that is a hierarchically porous SAPO-41 molecular sieve, and the solid reaction powder and Pd(NO 3 ) 2 The solution is impregnated to obtain a bifunctional catalyst; ...

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, 12.71g mass concentration is 85% phosphoric acid, 7.88g pseudo-boehmite, 7.67g silica sol, 15g di-n-butylamine and 4.21~ 21.06 g of crystal growth inhibitors were sequentially added into deionized water under stirring conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com