Patents

Literature

196results about How to "Extended regeneration cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the removal of nitrogen compounds from a fluid stream

ActiveUS7205448B2Increase capacityReduce accumulationMolecular sieve catalystsHydrocarbonsMolecular sieveNitrite

At lower temperatures an acidic molecular sieve adsorbent preferentially adsorbs water and basic organic nitrogen compounds over weakly basic organic nitrogen compounds such as nitrites. Elevated temperatures improve the capacity of acidic molecular sieve adsorbents to adsorb nitrites in the presence of water.

Owner:UOP LLC

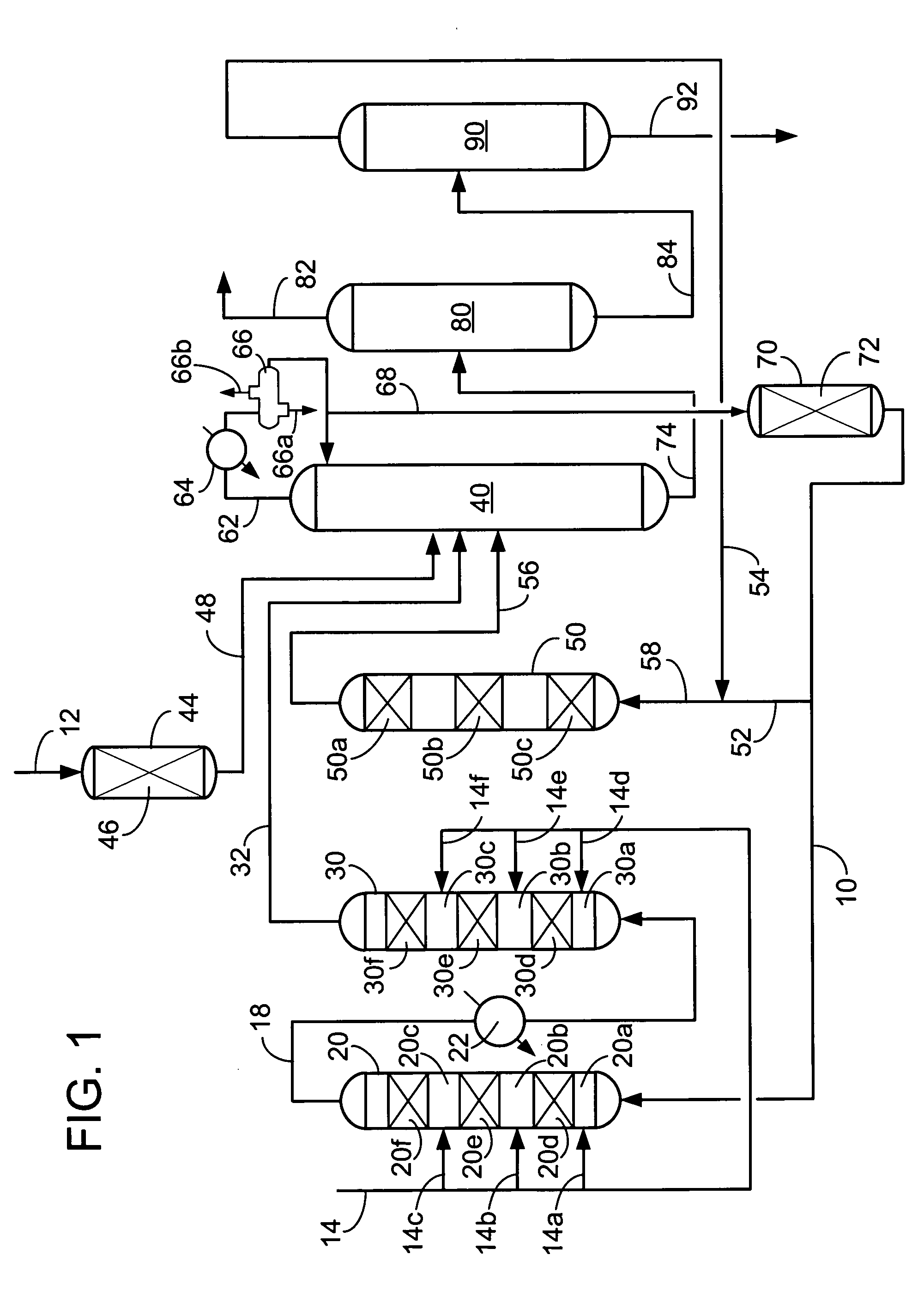

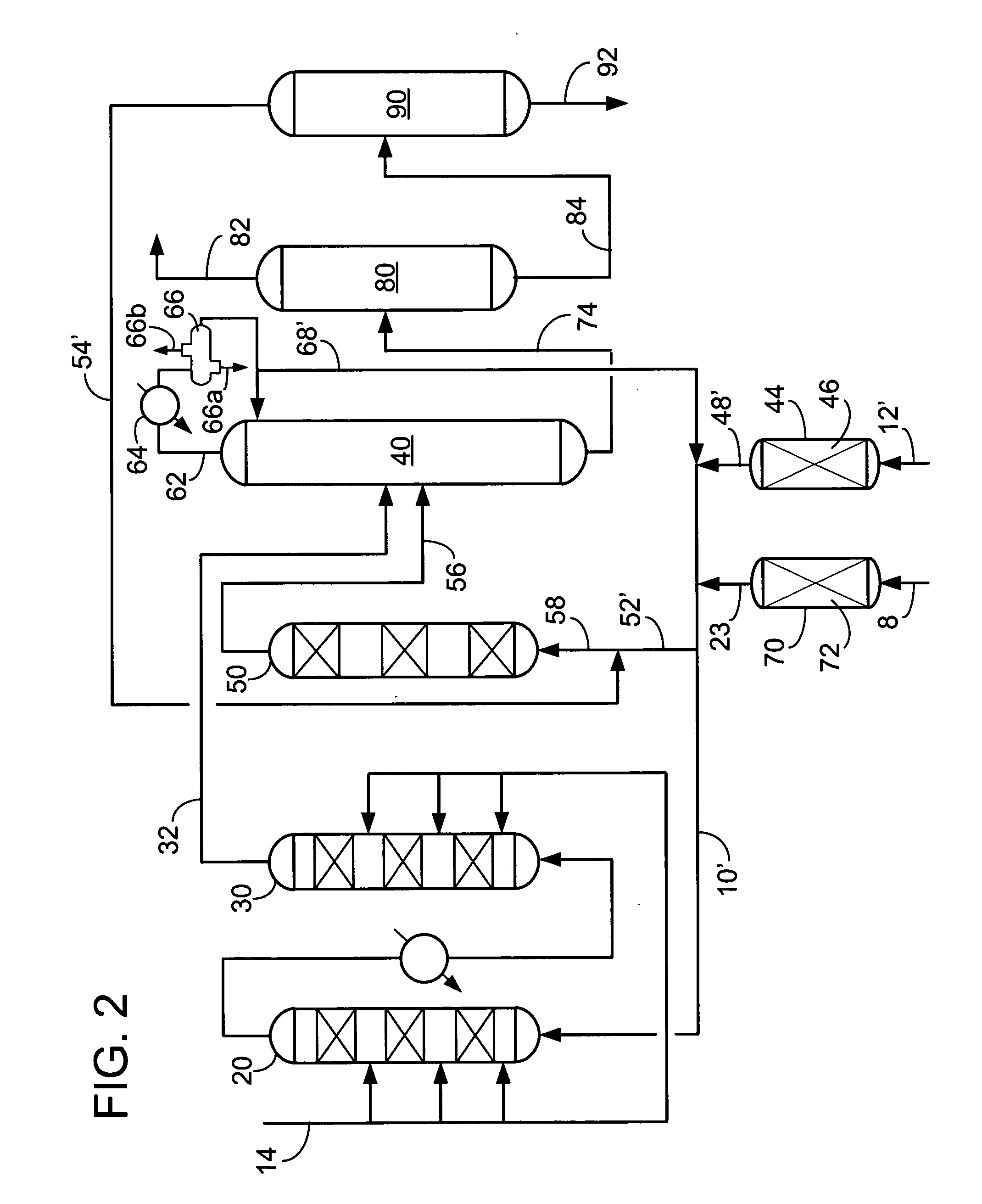

Process and apparatus for the removal of nitrogen compounds from a fluid stream

InactiveUS6894201B1Increase capacityImprove adsorption capacityHydrocarbonsAdsorption purification/separationAlkyl transferMolecular sieve

Disclosed is a process and apparatus for removing nitrogen compounds from an alkylation substrate such as benzene. A conventional adsorbent bed can be used to adsorb basic organic nitrogen compounds and a hot adsorbent bed of acidic molecular sieve can adsorb the weakly basic nitrogen compounds such as nitrites. Water facilitates the adsorption of the weakly basic nitrogen compounds. Running an alkylation substrate stream from a fractionation column of elevated temperature and suitable water concentration to the hot adsorbent bed may be advantageous.

Owner:UOP LLC

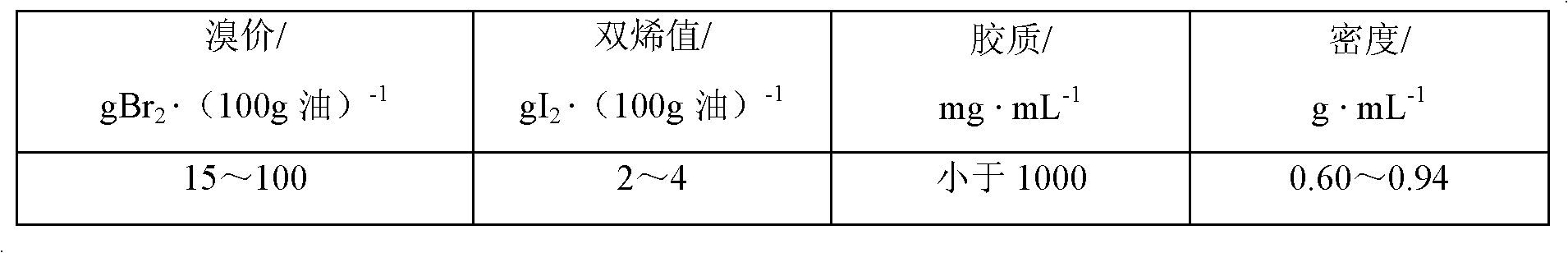

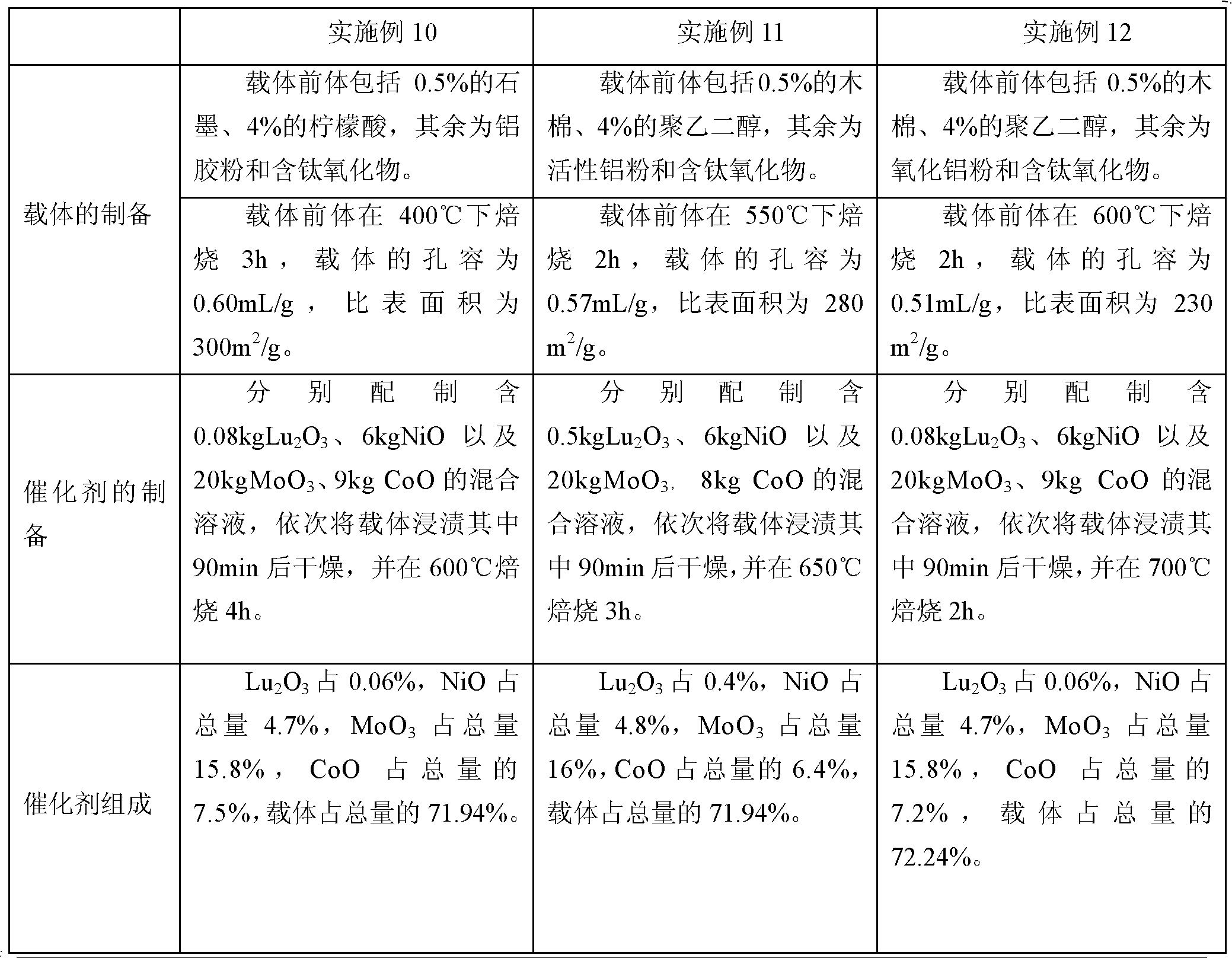

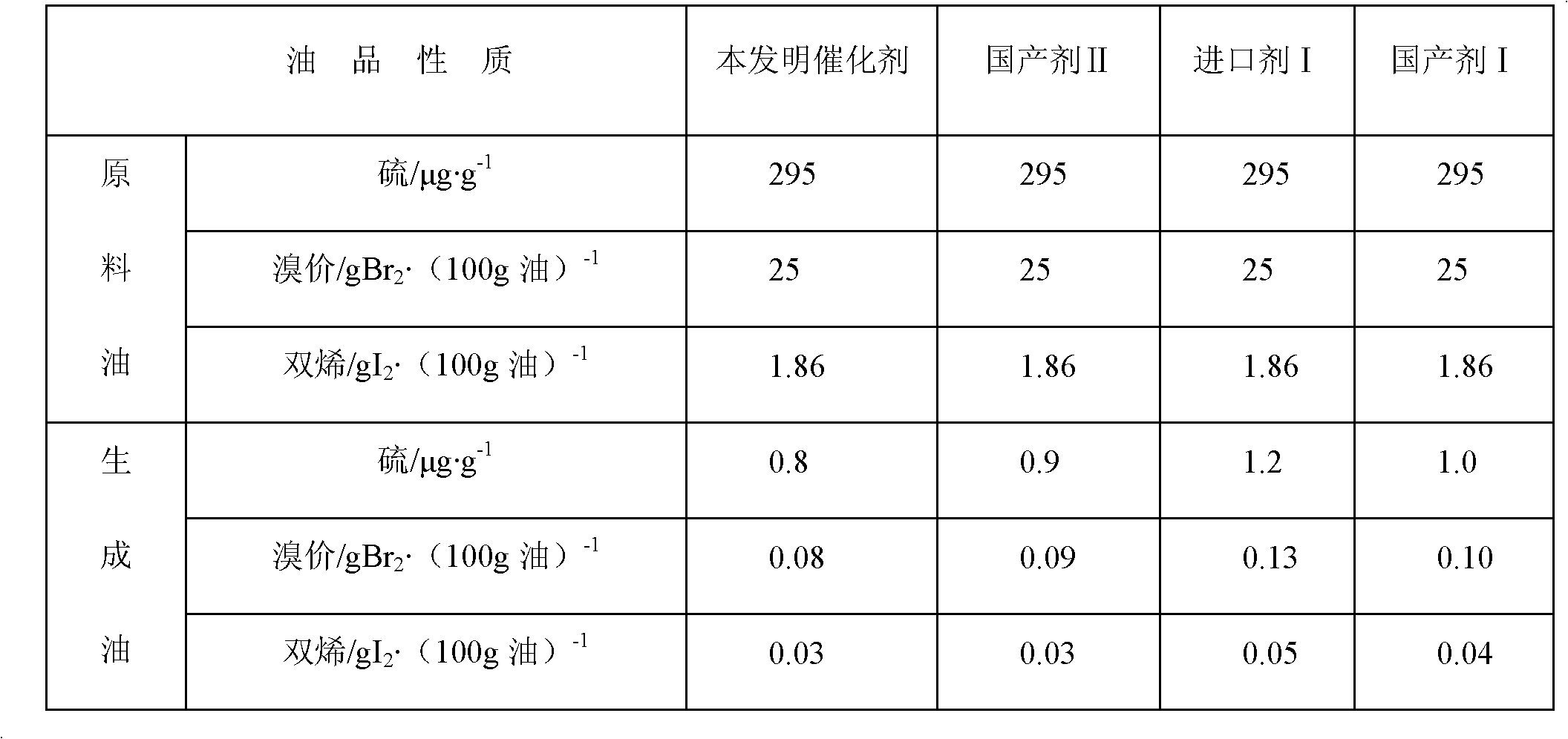

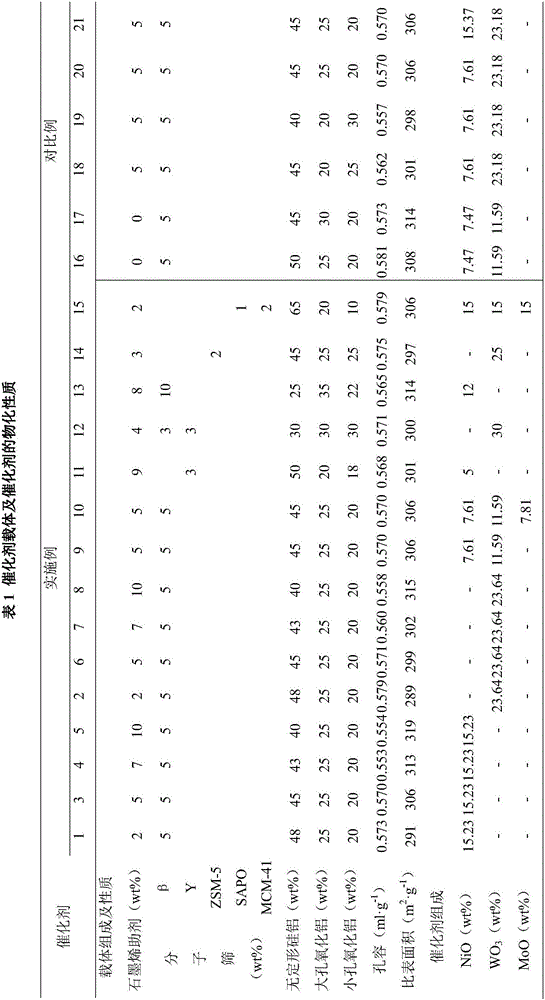

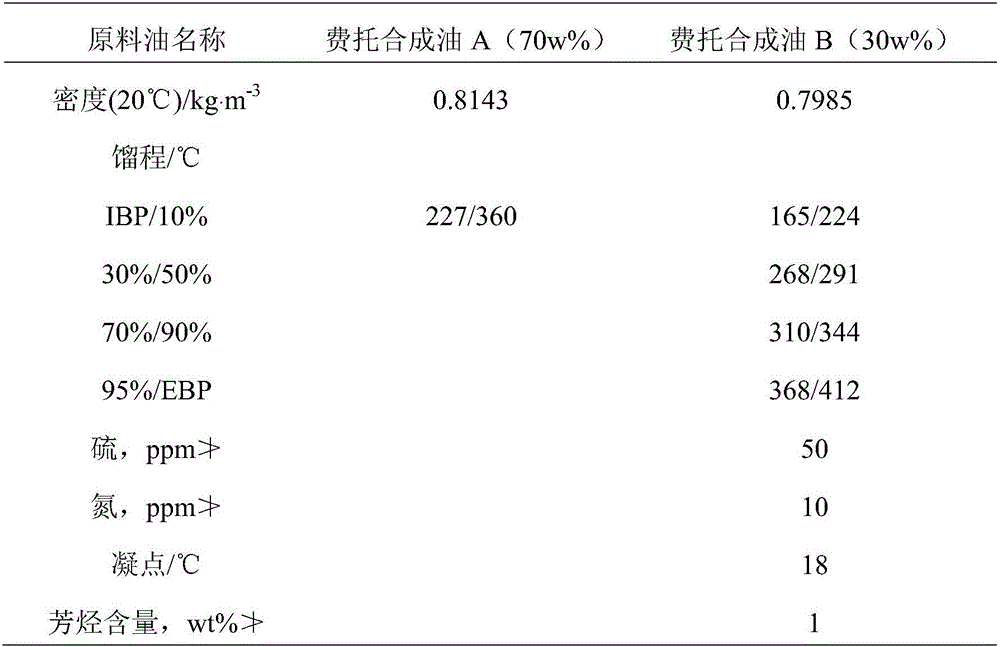

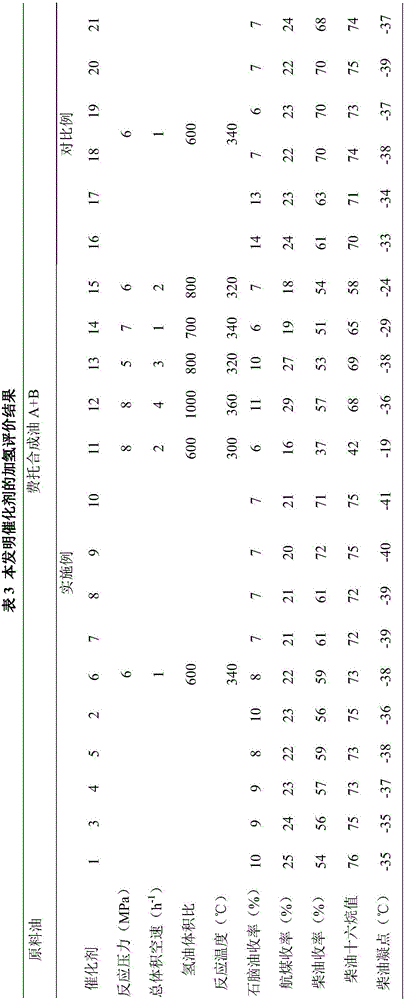

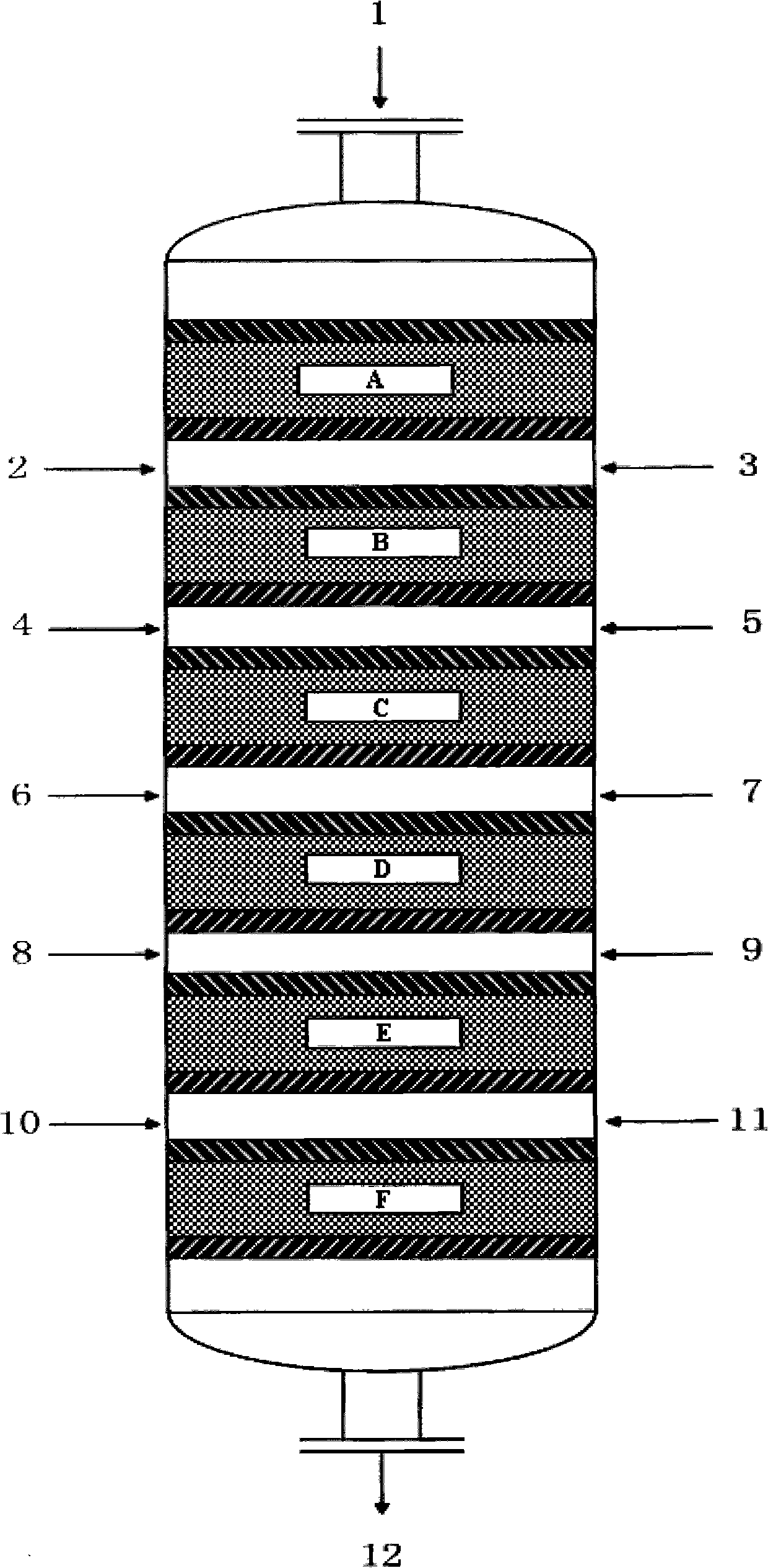

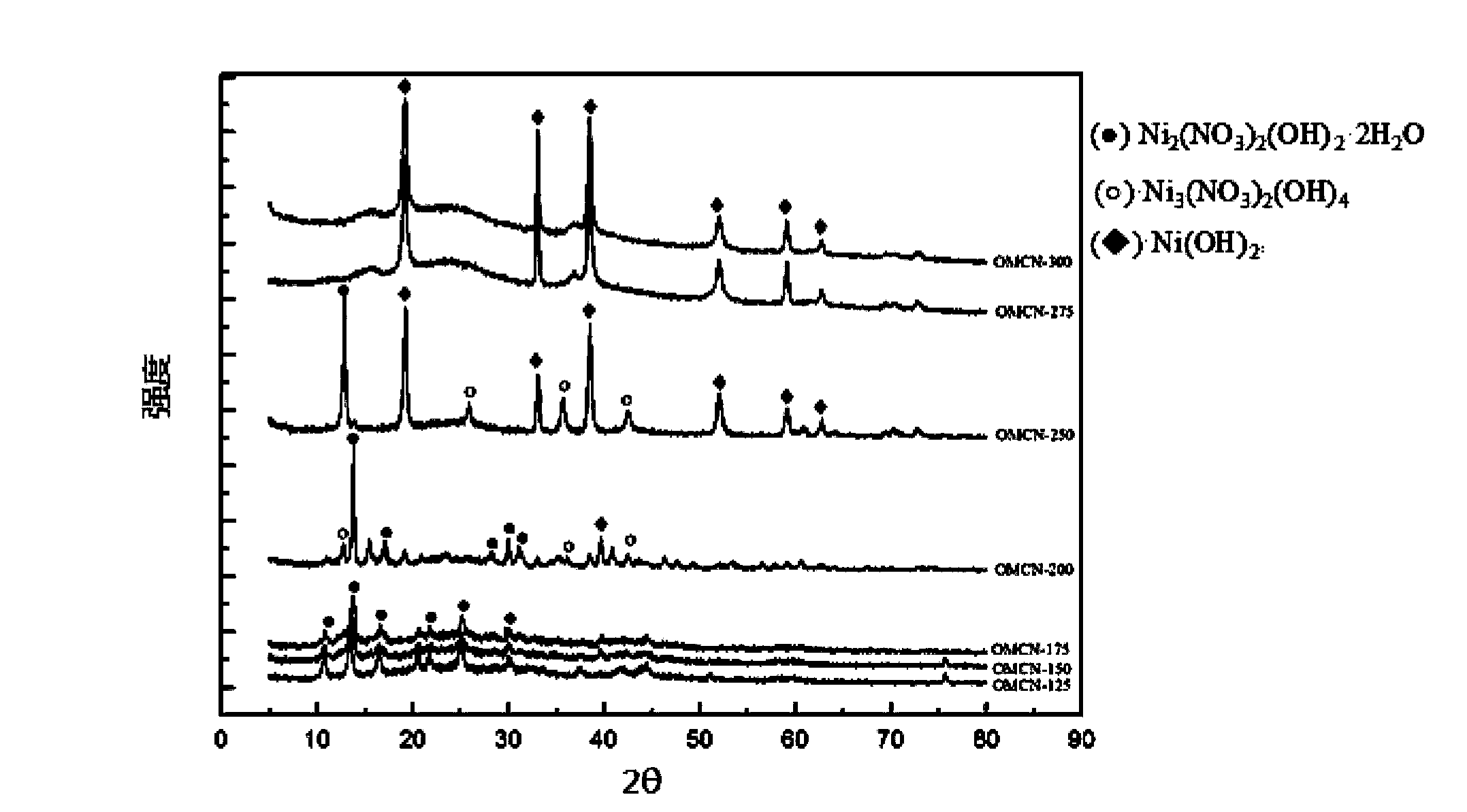

Hydrofining catalyst and preparation method thereof

ActiveCN102861593ALarge hole volumeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemical industryRare-earth element

The invention discloses a hydrofining catalyst and a preparation method thereof, belonging to the field of catalysts used in the petroleum-chemical industry. The hydrofining catalyst disclosed herein comprises a carrier, an active component and an auxiliary agent, wherein the carrier is Ti-modified gamma-alumina, the active component comprises oxides of Mo, Co and Ni, and the auxiliary agent comprises oxides of rare earth. The catalyst is characterized in that: based on 100% of the total weight of the catalyst, Co (measured in CaO) in the active component accounts for 2.0-7.5% of the total weight of the catalyst, Mo (measured in MoO3) in the active component accounts for 4.0-18.0% of the total weight of the catalyst, Ni (measured in NiO) in the active component accounts for 0.2-5.0% of the total weight of the catalyst, the auxiliary agent accounts for 0.05-1.0% of the total weight of the catalyst, and the balance consists of the carrier. According to the invention, the catalyst prepared by the formula and the method disclosed in the invention can carry out hydrogenation on saturated monoolefine while the catalyst is used for carrying out hydrodesulfurization on oils, can be suitable for technical requirements of heavy oriention, changeable sulphur content, and high air speed of hydrogenation liquid for pyrolysis gasoline two-stage hydrogenated raw materials, and simultaneously, the catalyst has the advantages of low activation temperature and low loss of aromatics in the hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP

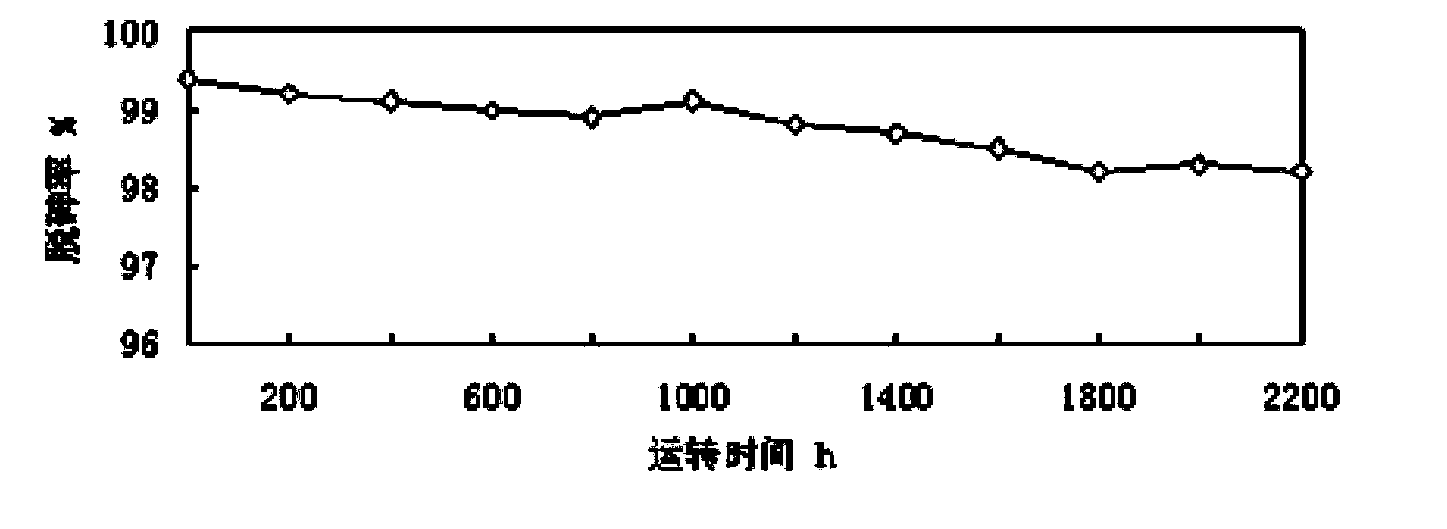

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

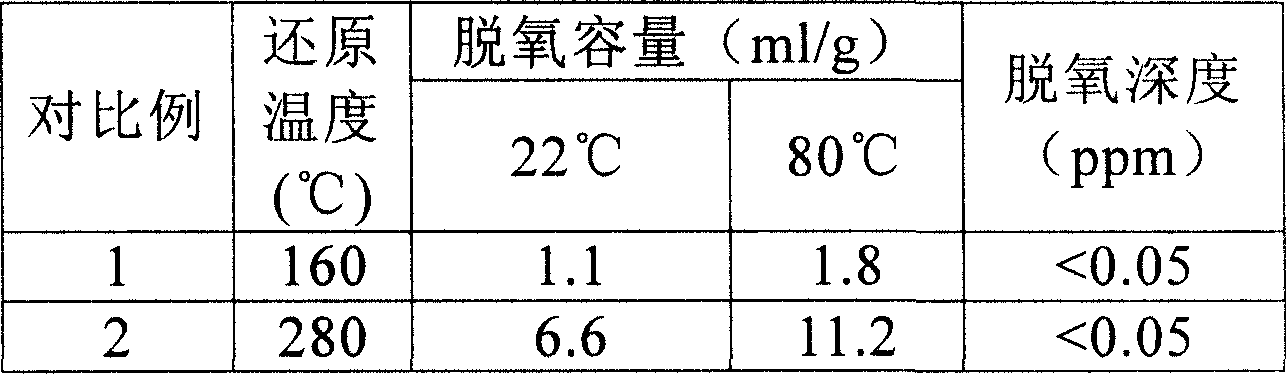

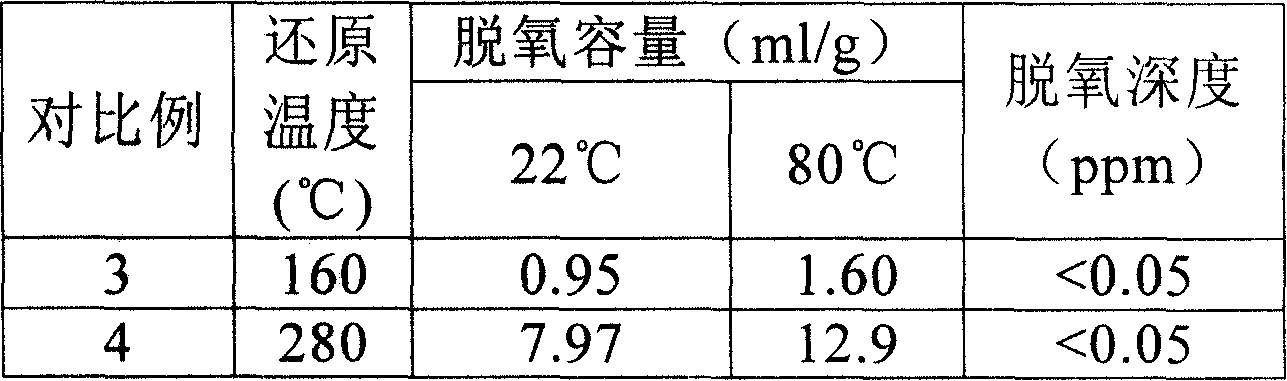

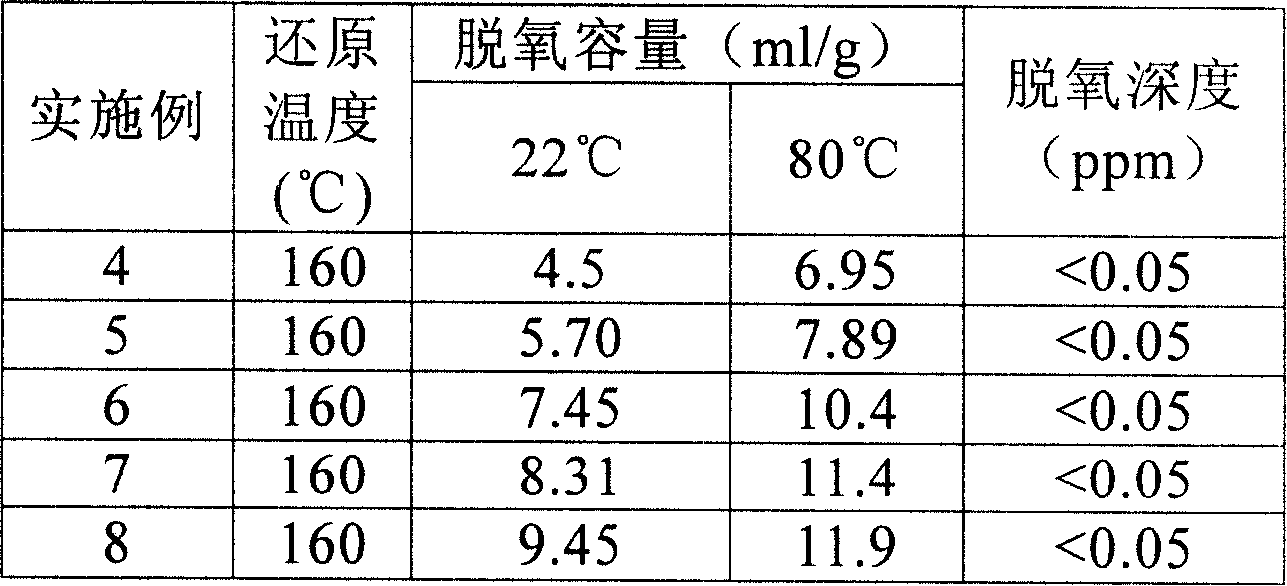

Mn-Ag double active components desoxidant, preparation method and application thereof

ActiveCN101165030AImprove deoxygenation capacityExtended regeneration cycleManganese oxides/hydroxidesSilve compoundsCalcium aluminatesPolyolefin

The present invention relates to olefin processing technology, and is especially double active component Mn-Ag deoxidizer for deoxidizing olefin and its preparation process and application. The Mn-Ag deoxidizer has Mn3O4 as main active component and small amount of Ag2O catalyst capable of lowering the temperature and decreasing the time for reducing Mn3O4 into MnO possessing deoxidizing activity. The Mn-Ag deoxidizer has calcium aluminate carrier and no other adhesive, high active component content and high deoxidizing capacity, and possesses very high compression strength. The Mn-Ag deoxidizer may be regenerated through reduction at 80-160 deg.c, and can reduce oxygen content in ethylene, propylene, etc at room temperature to below 0.05 ppm. The Mn-Ag deoxidizer is applied in industrial polyolefin production, and has long regeneration period, capacity of preventing poisoning of polymerizing catalyst and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

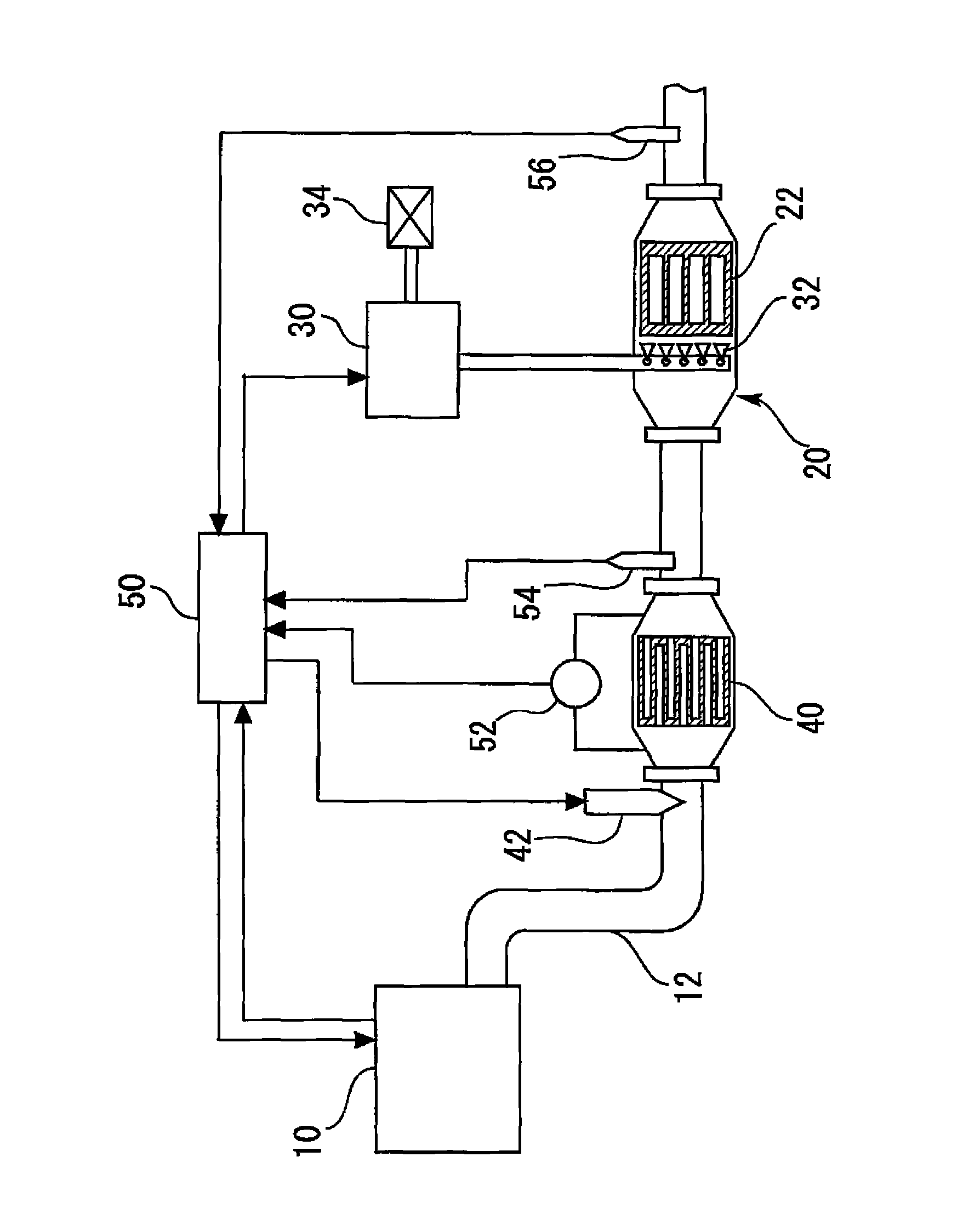

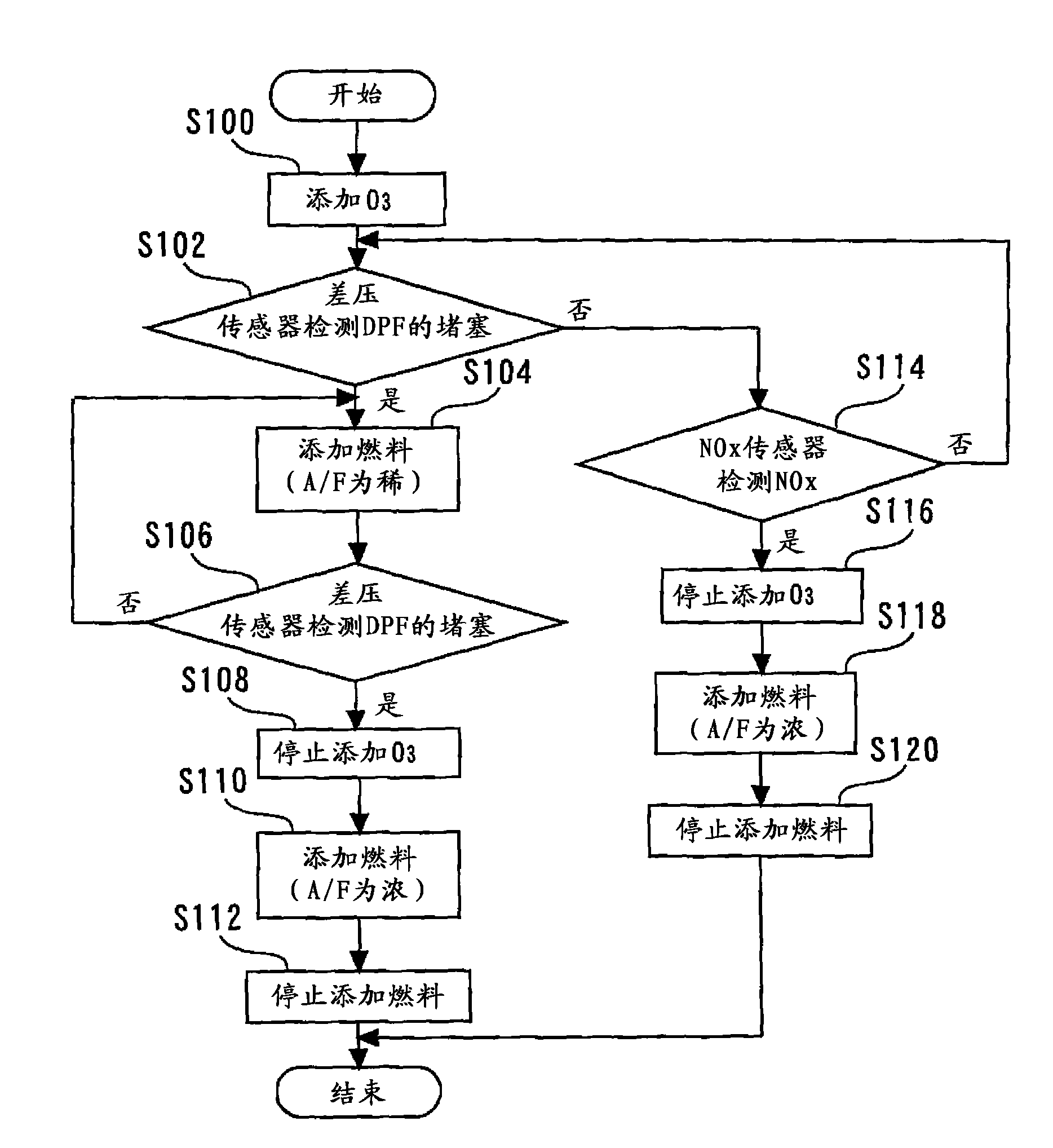

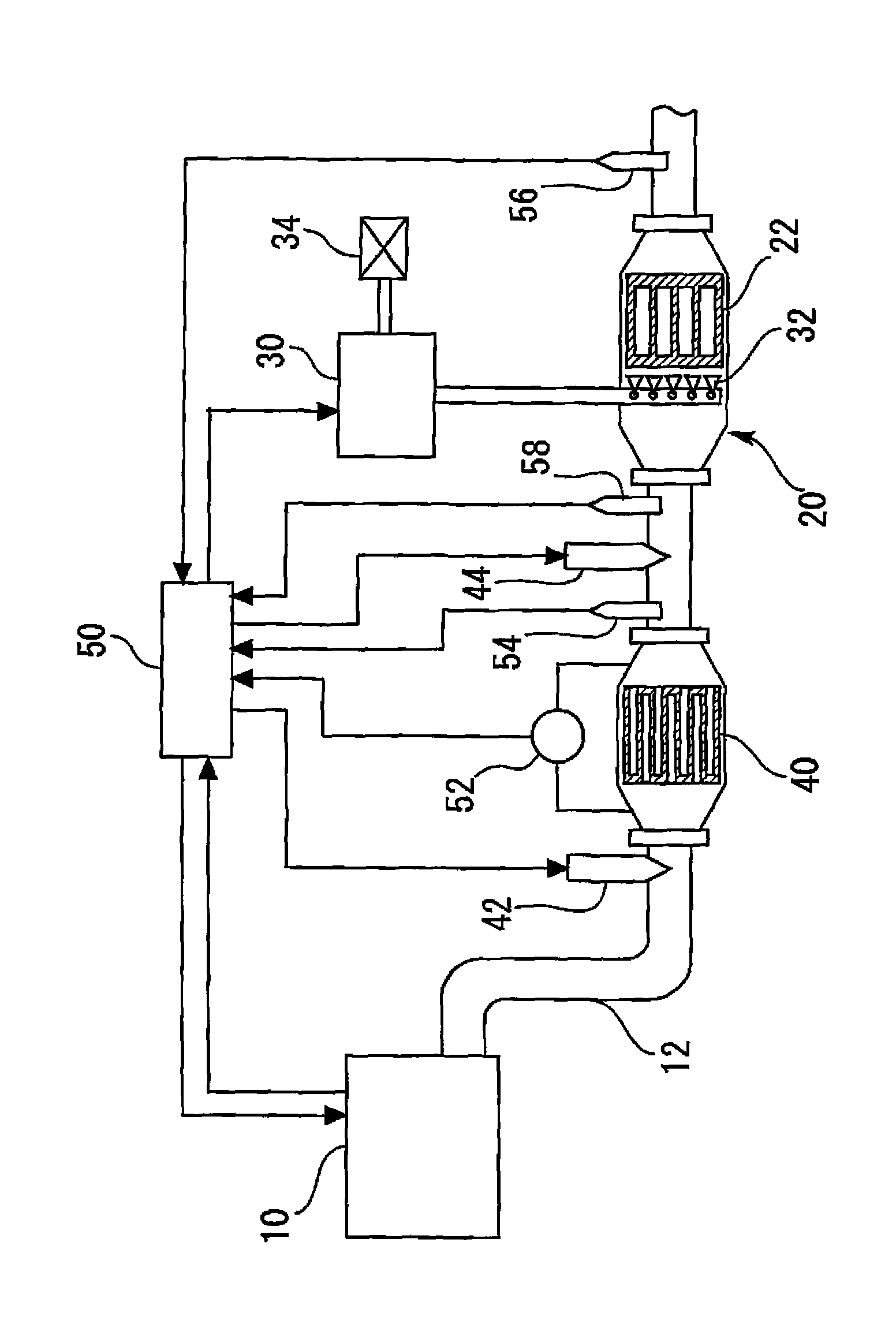

Apparatus for purifying exhaust gas of internal combustion engine

InactiveCN101636565AFacilitate occlusionFacilitate occlusion reactionGas treatmentInternal combustion piston enginesParticulatesExhaust fumes

The invention provides an exhaust gas purifying apparatus comprising a NOx storage reduction catalyst and a particulate filter, wherein the original NOx storage ability of the NOx storage reduction catalyst is sufficiently utilized. Specifically, the exhaust gas purifying apparatus comprises a filter (40) arranged in the upstream of a NOx storage reduction catalyst (22), a fuel supply means (42) for supplying a fuel so that the fuel is mixed with the exhaust gas flowing into the filter (40), and an ozone supply means (30) for supplying ozone in the downstream of the filter (40) so that ozone is mixed with the exhaust gas flowing into the NOx storage reduction catalyst (22).

Owner:TOYOTA JIDOSHA KK

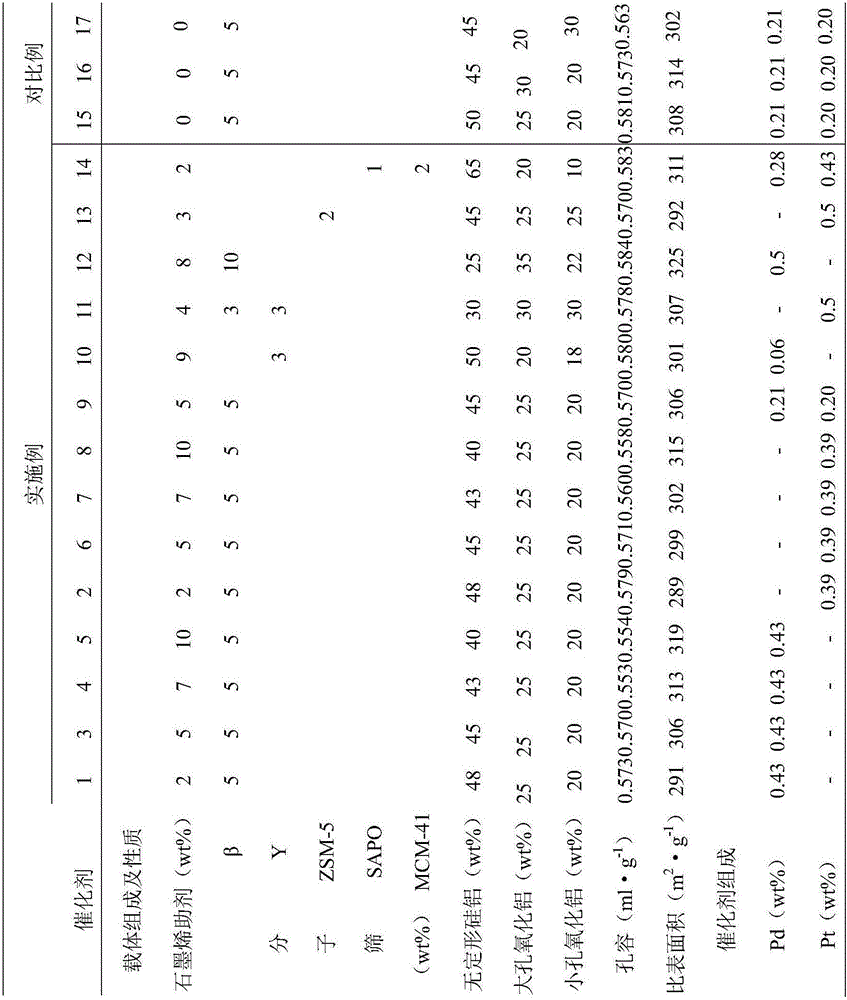

Selective hydrogenation catalyst for producing biodiesel and preparation method and application of selective hydrogenation catalyst

InactiveCN105903488AImprove thermal conductivityUniform temperature distributionMolecular sieve catalystsHydrocarbon oils refiningBiodieselFreeze-drying

The invention discloses a selective hydrogenation catalyst for producing biodiesel and a preparation method and application of the selective hydrogenation catalyst. The selective hydrogenation catalyst comprises a carrier and a main metal active ingredient loaded on the carrier, the main metal active ingredient accounts for 5-30% of the catalyst in weight and is one of or a combination of oxides containing Co, Mo, Ni and W, and the carrier is composed of, by weight, 1-8% of a molecular sieved, 25-65% of amorphous sial, 30-65% of alumina and 2-10% of a graphene auxiliary. The preparation method includes: disposing the carrier in a metal salt solution containing Co, Mo, Ni or / and W for soaking for 4-20 h to obtain a soaked carrier; freeze-drying and then calcining the soaked carrier to obtain the selective hydrogenation catalyst. With same carrying capacity of the carrier, active surface area represented by the carrier is large, the selective hydrogenation catalyst has more active sites, reaction temperature is lowered, and hydrogenation performance is improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

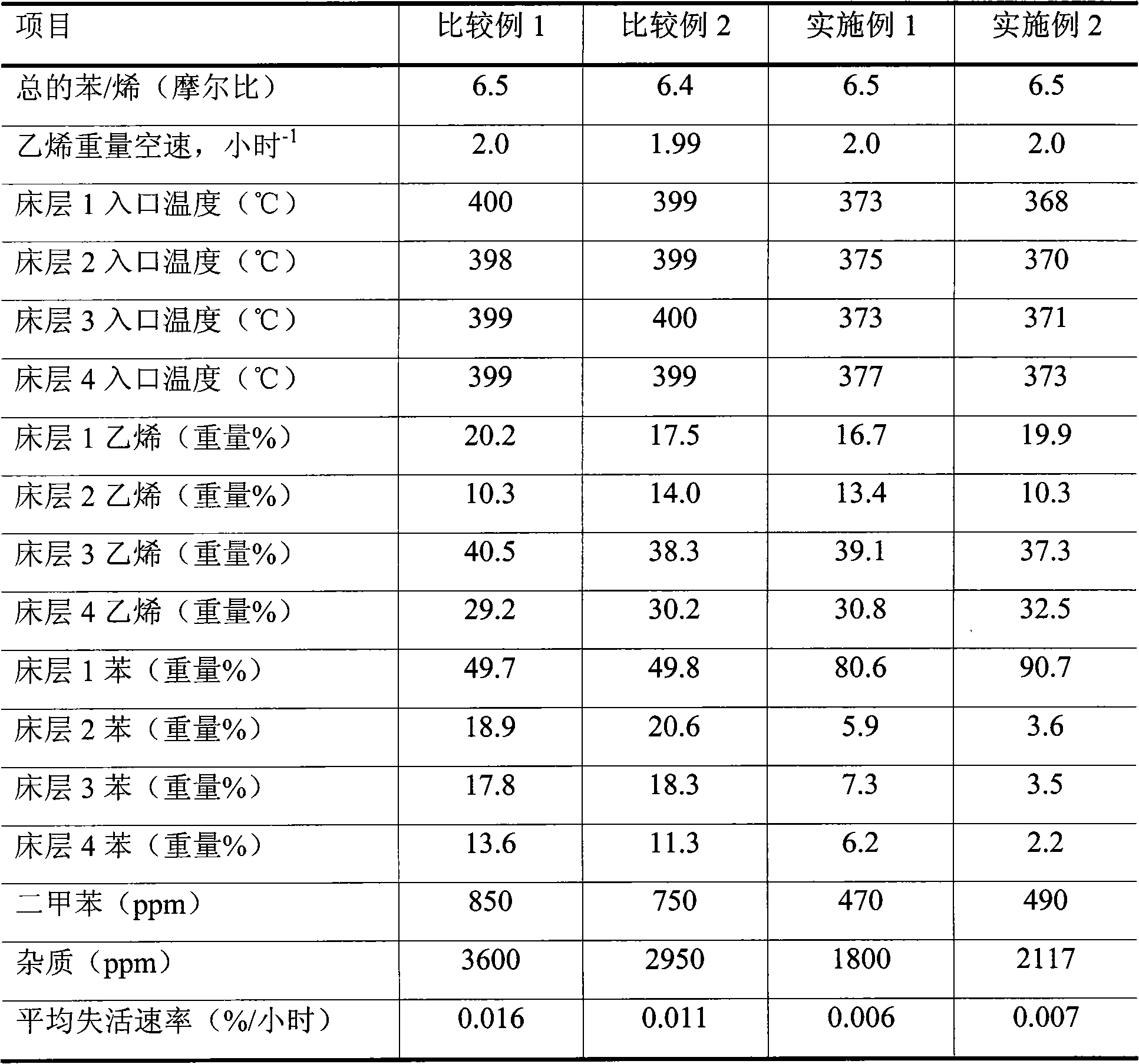

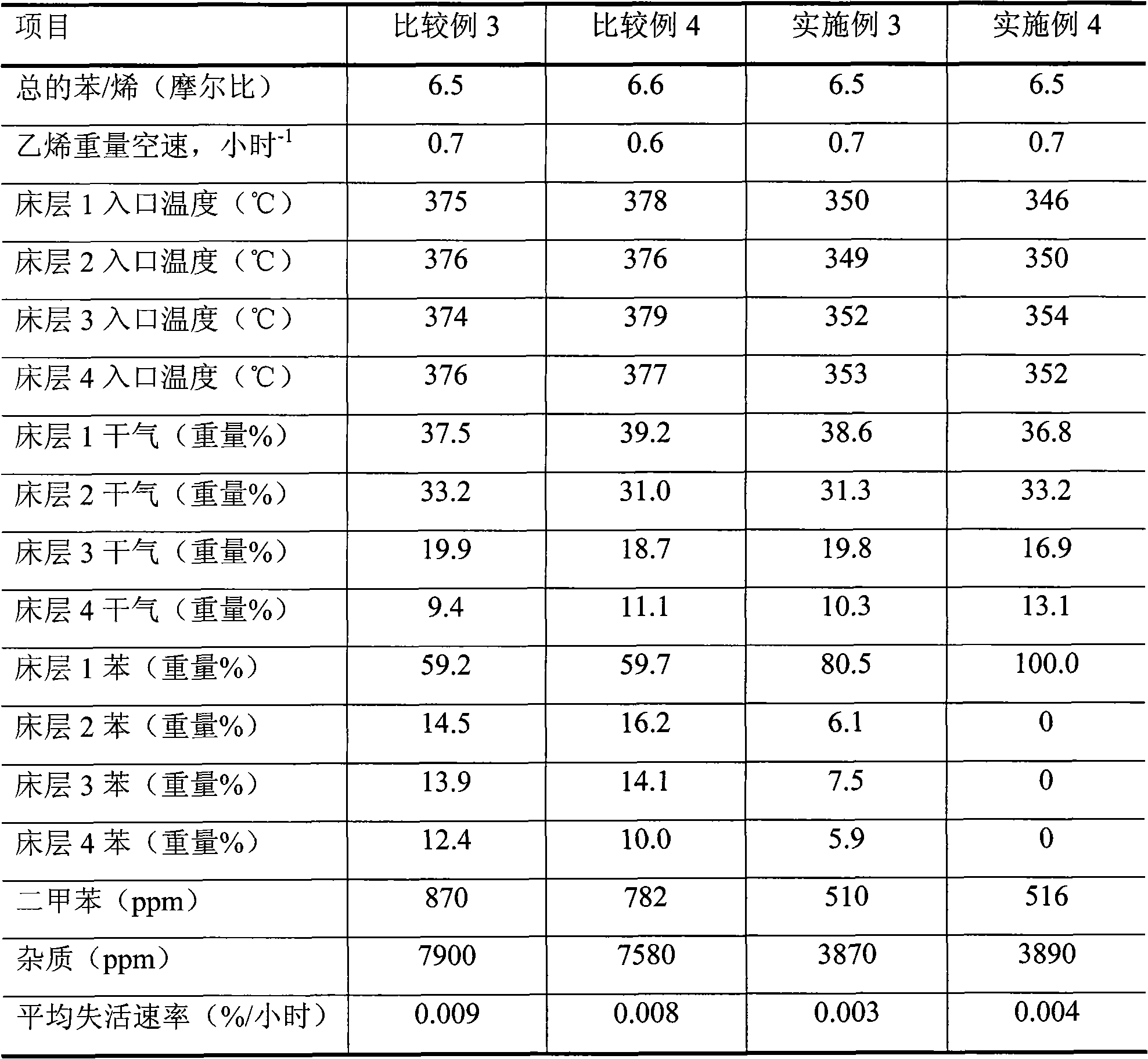

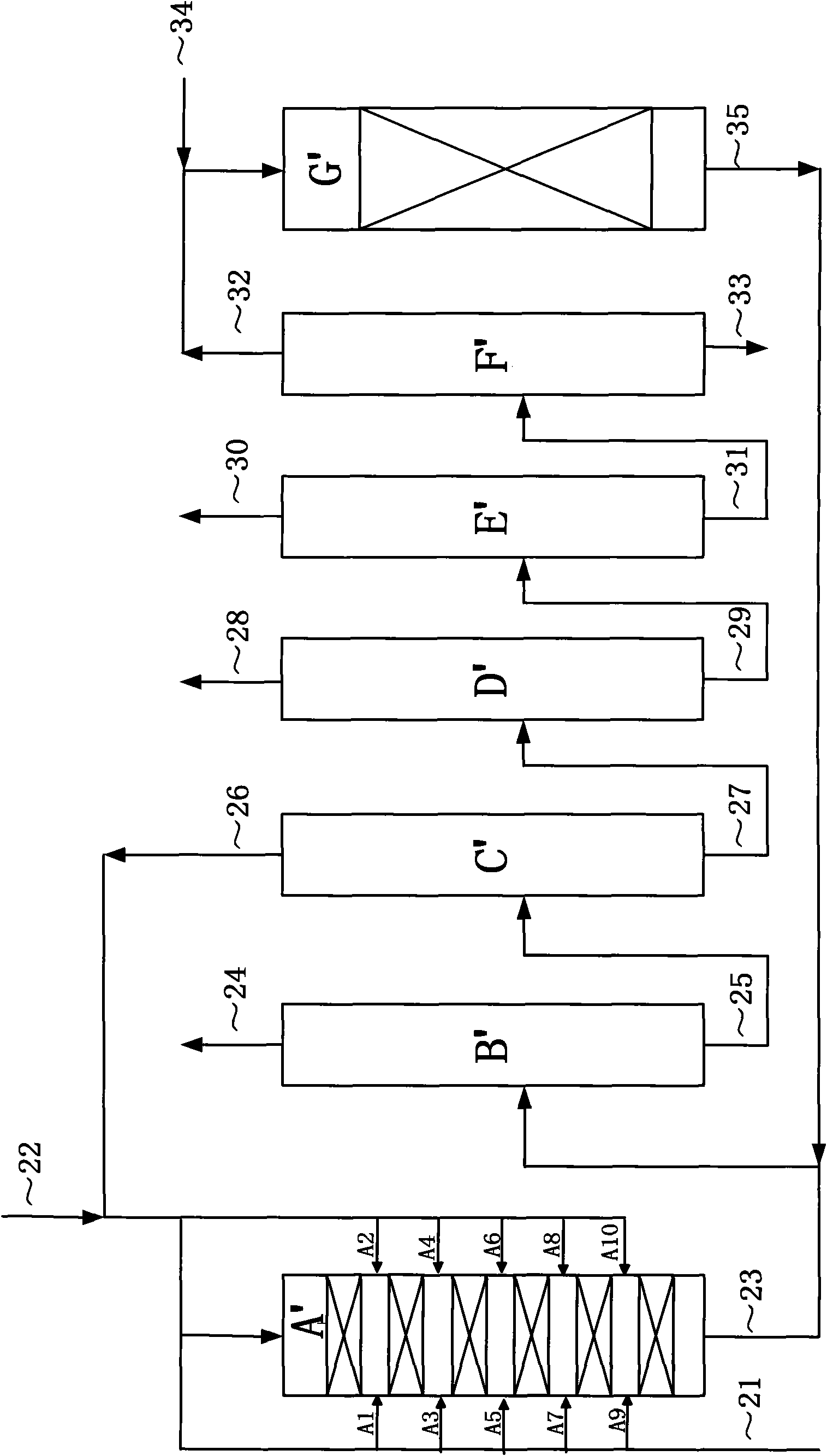

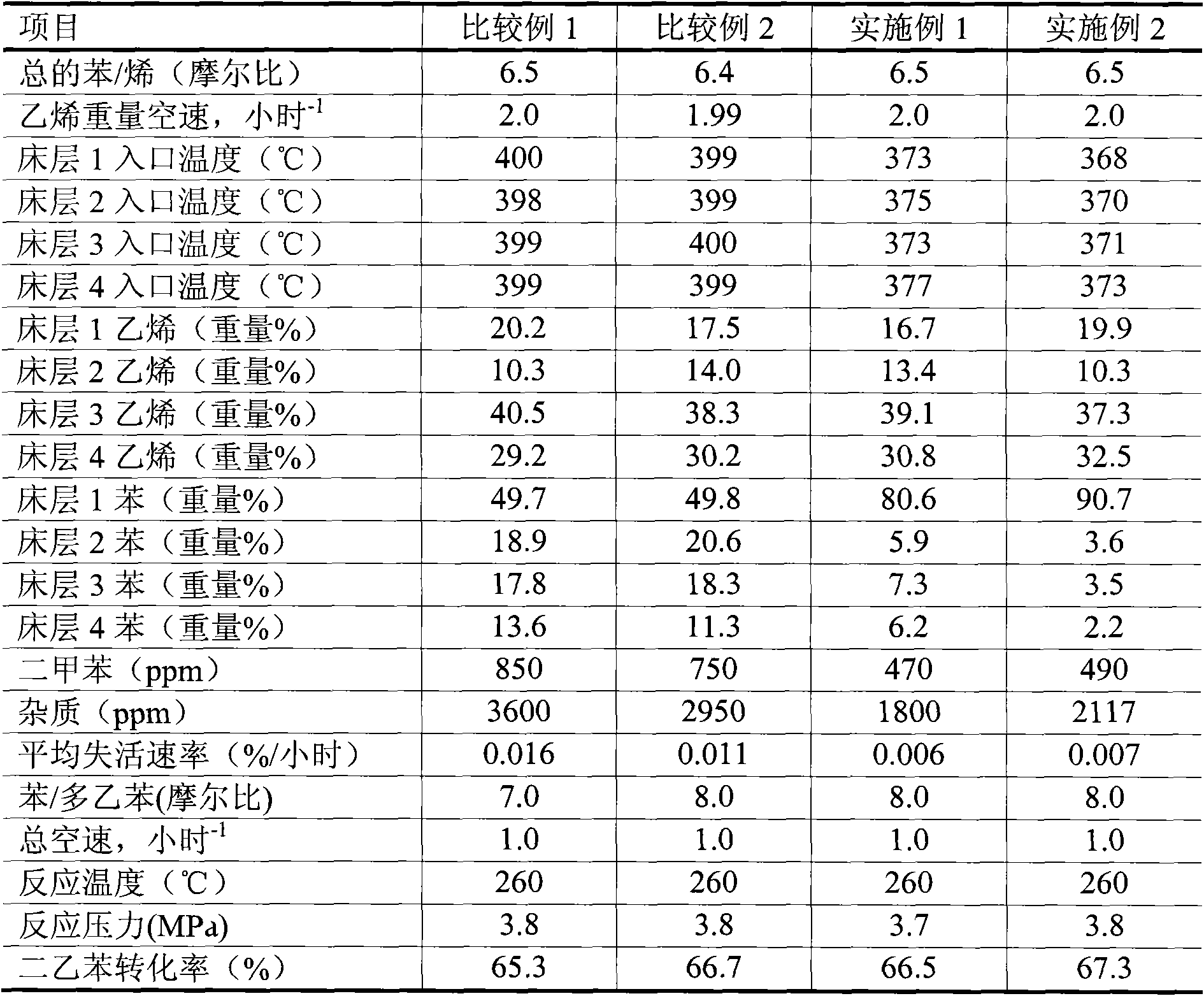

Method for preparing ethylbenzene by alkylating pure ethylene or dry gas and benzene

ActiveCN101993331AReduced service lifeReduce generationMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

The invention relates to a method for preparing ethylbenzene by alkylating pure ethylene or dry gas and benzene, which mainly solves the problem of the prior art of which the impurity dimethylbenzene content within the product ethylbenzene obtained by gas phase alkylation of pure ethylene or dry gas and benzene is high, the purity of ethylbenzene is low, the stability of the catalyst is bad, the regeneration period is short and the service life is short. The method provided by the invention solves the problem of the prior art by loading at least a section of ZSM-5 molecular sieve catalyst I which comprises SiO2 / Al2O3 with a mol ratio of 50 to 150 and at least a section of ZSM-5 molecular sieve catalyst II which comprises SiO2 / Al2O3 with a mol ratio of 160 to 300 on a fixed bed reactor, entering 30 to 70% by weight of pure ethylene or dry gas into the bed layer wherein the catalyst I is loaded, entering the residual pure ethylene or dry gas into the bed layer wherein the catalyst II isloaded, feeding 80 to 100% by weigh of benzene into the first section bed layer wherein the catalyst I is loaded from the top of the reactor, feeding the residual benzene into the following sections of catalyst bed layer, and controlling the difference between the inlet temperature of each section of catalyst bed layer and the inlet temperature on the top of the reactor in the scope of -5 DEG C to +5 DEG C. The method provided by the invention can be applied to the industrial production of ethylbenzene by alkylating pure ethylene or dry gas and benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient and environment-friendly malt syrup producing process

InactiveCN102676616AReduce manufacturing costRealize purification and removal of impuritiesSugar derivativesDisaccharidesActivated carbonUltrafiltration

The invention discloses an efficient and environment-friendly malt syrup producing process, which comprises the following steps of starch size mixing, liquefication, saccharification, cartridge filtration, membrane decontamination, membrane separation, ion exchange and vacuum concentration. The process disclosed by the invention has the advantages that glucoamylase can be recycled by an ultrafiltration membrane device, and the production cost is reduced; impurities such as colloid, protein and pigment in malt syrup can be intercepted by the ultrafiltration membrane device so as to realize the purification and decontamination of the malt syrup, and an activated carbon decoloring procedure in the existing process is replaced; and at the same time the load of ion exchange resin is reduced, the exchange capacity of the resin is improved, the regeneration period of the ion exchange resin is prolonged, the discharge of regenerated sewage is reduced, and the pollution of the environment is small.

Owner:四川绿沃创新环保工程有限公司

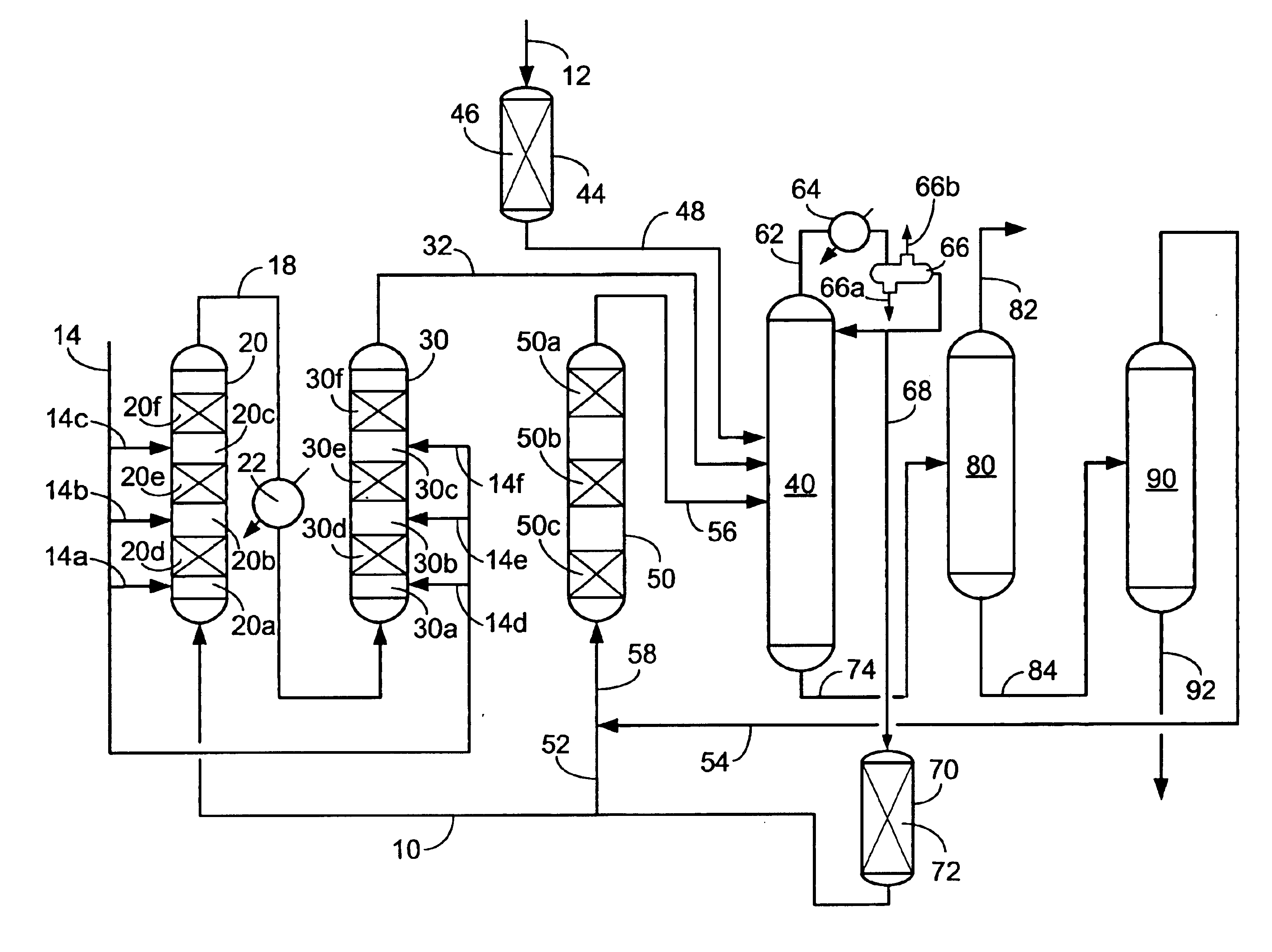

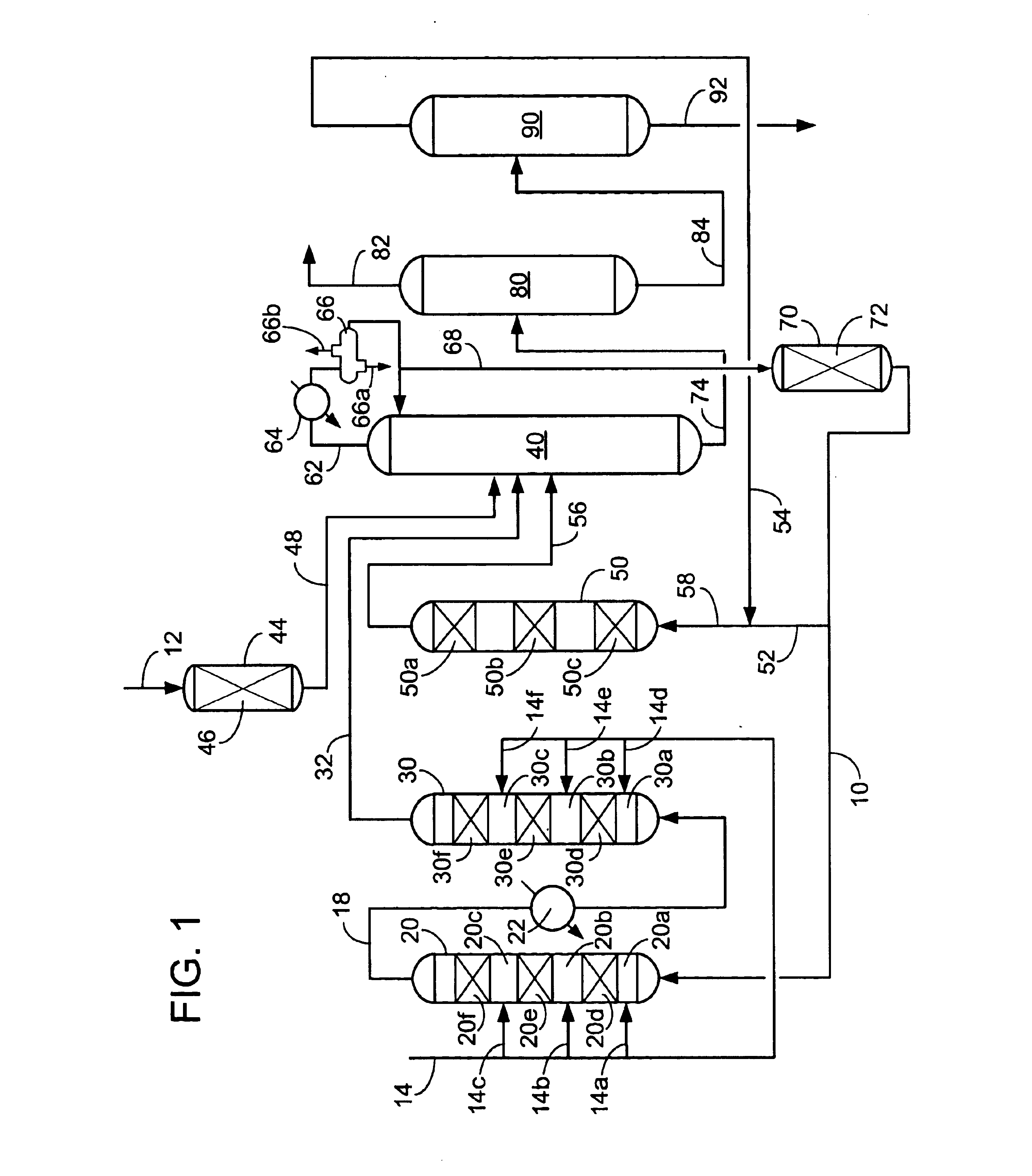

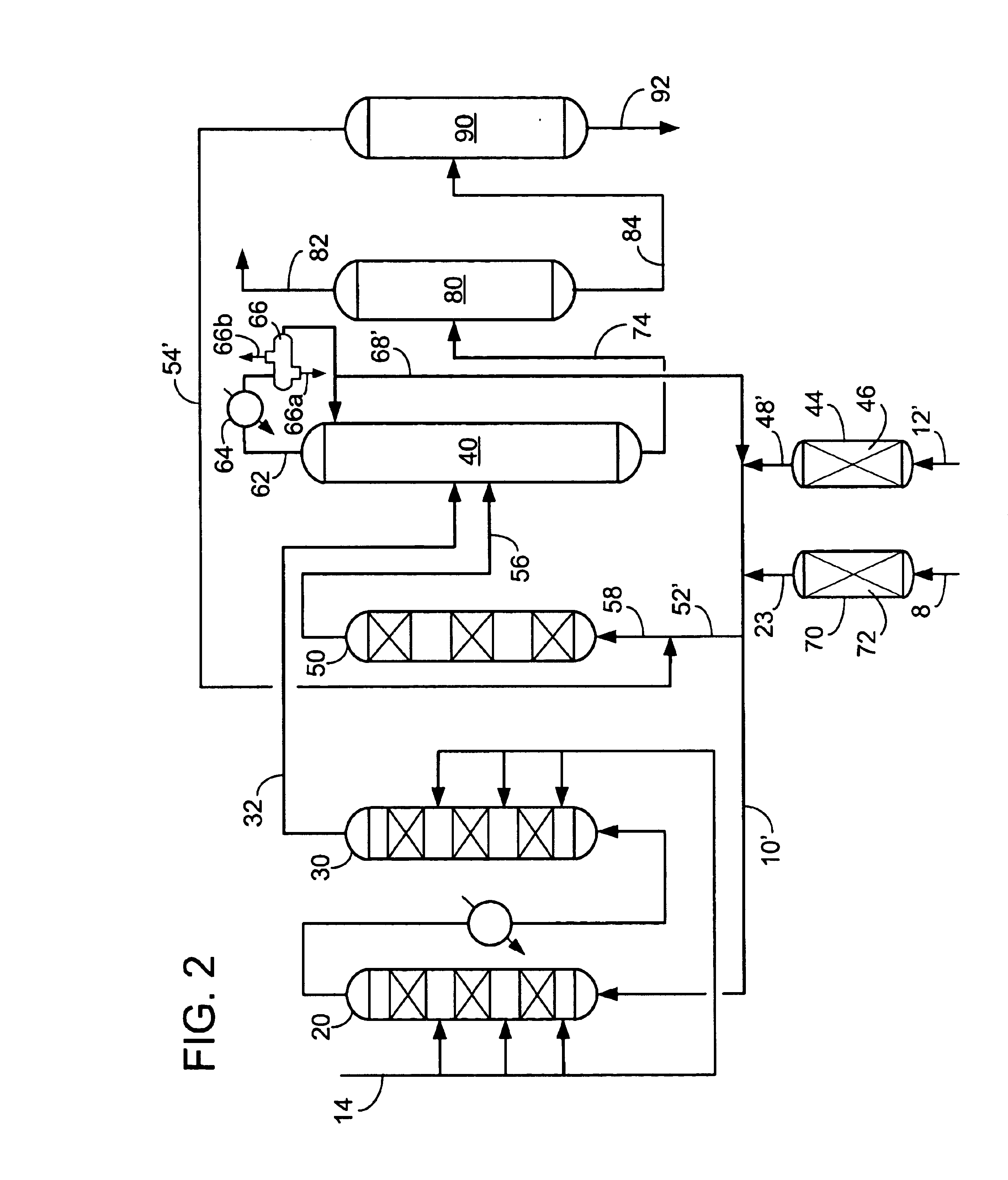

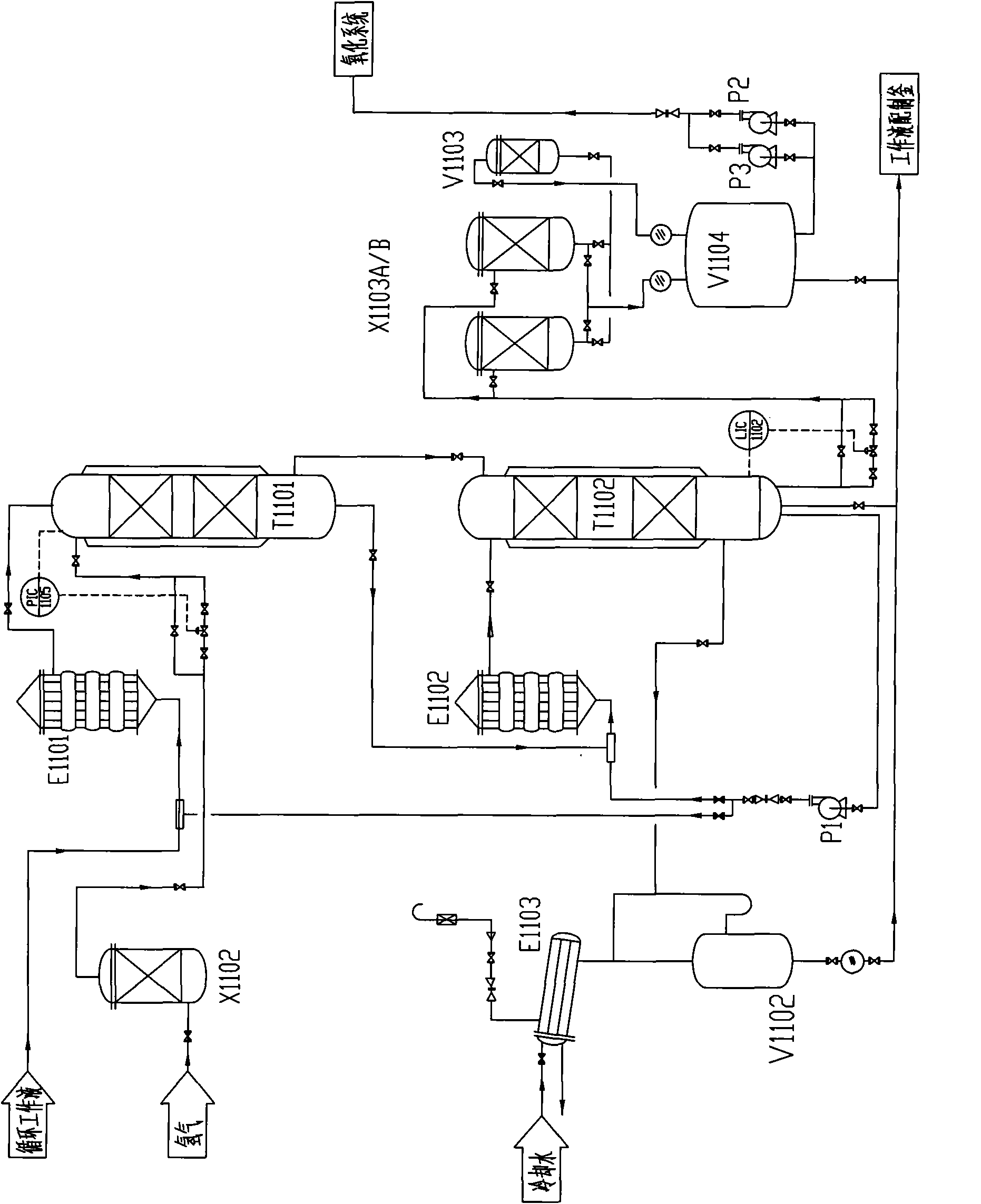

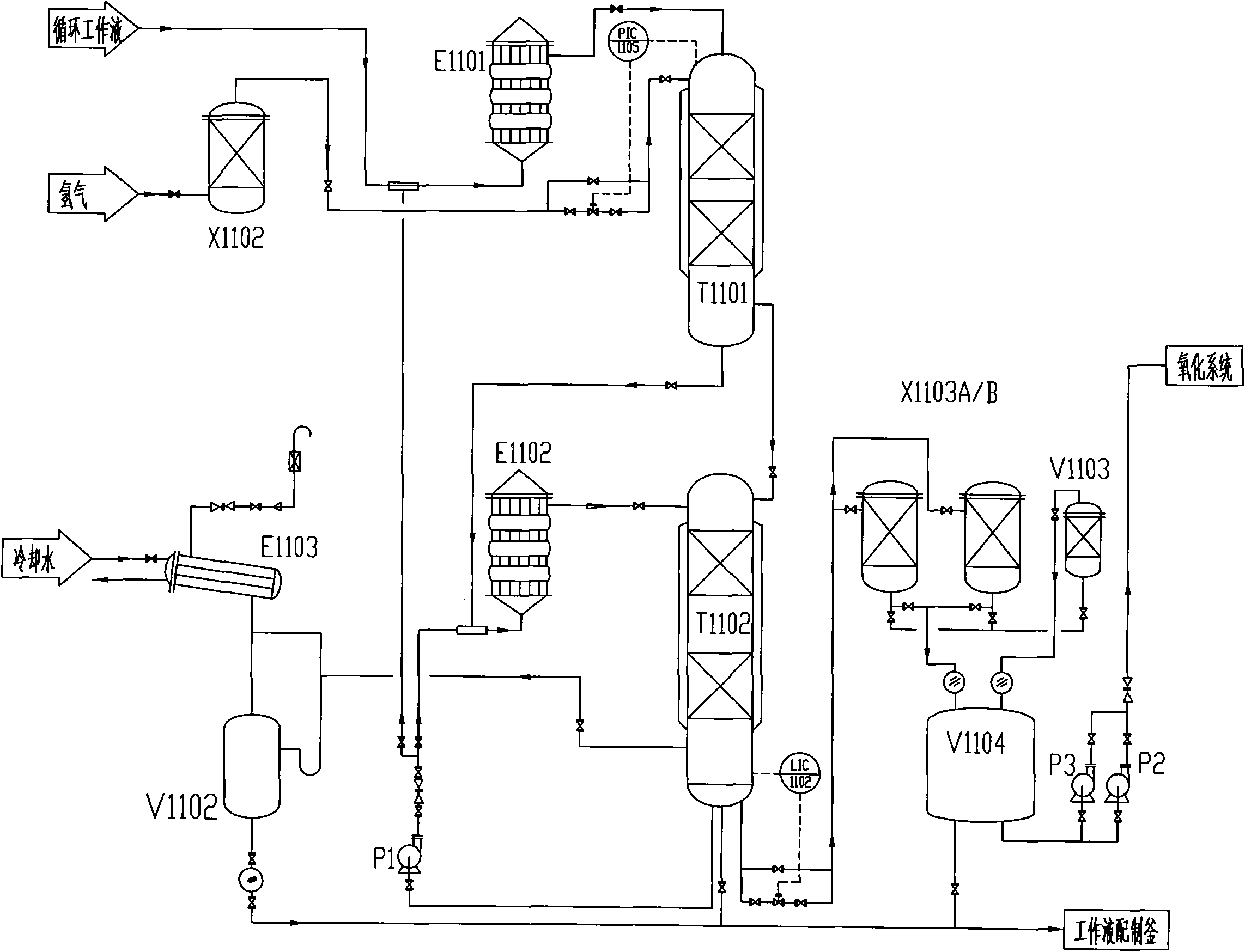

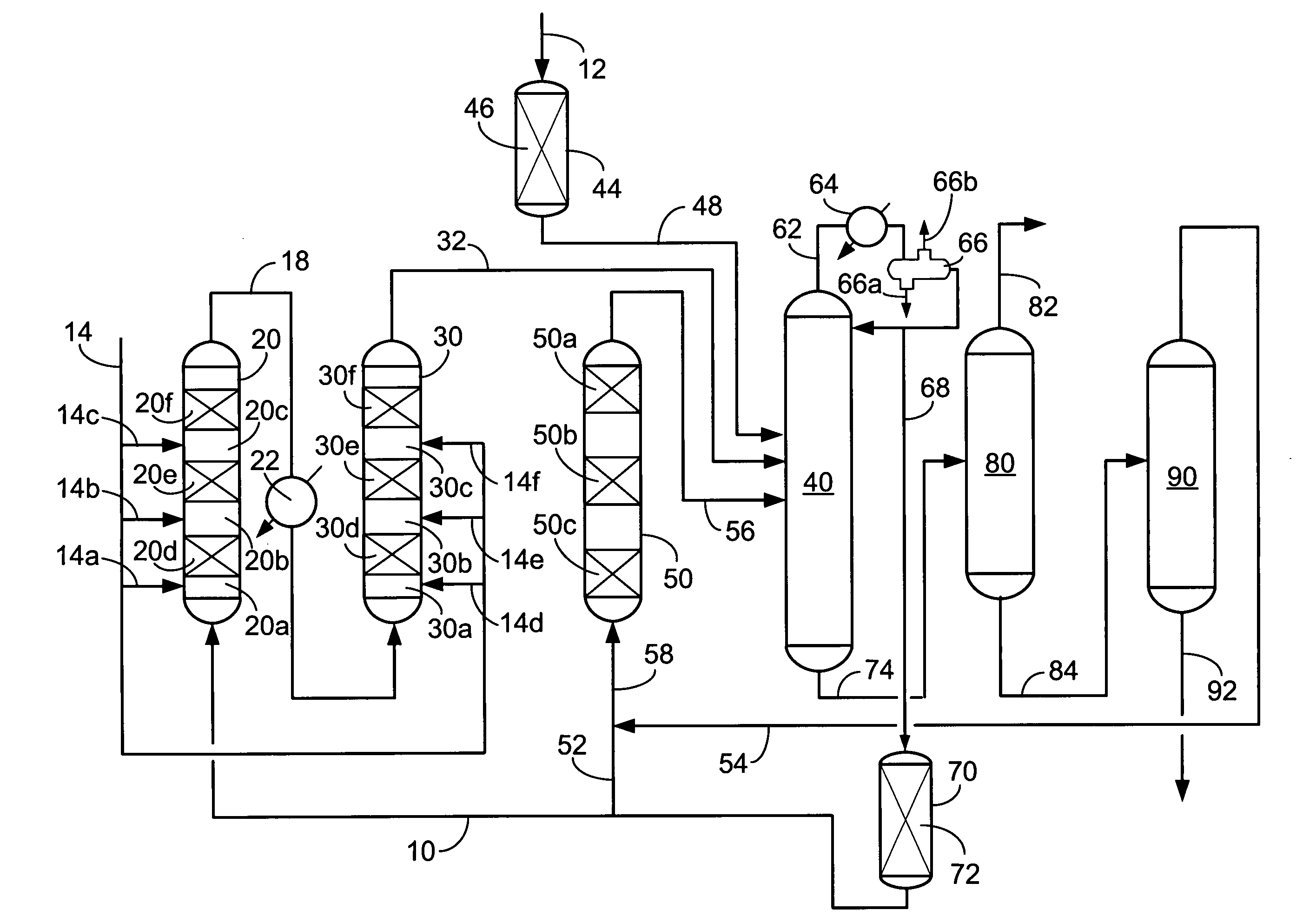

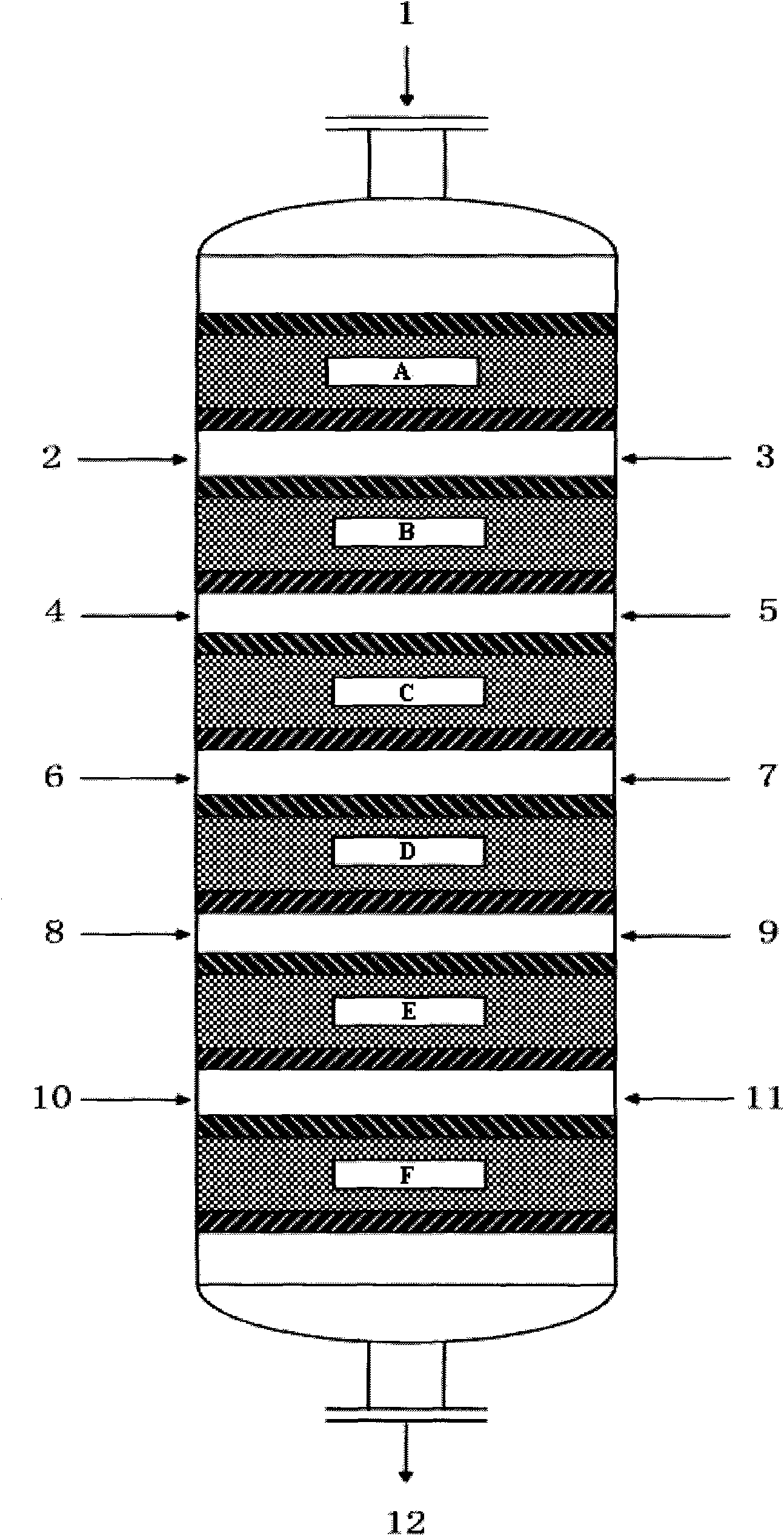

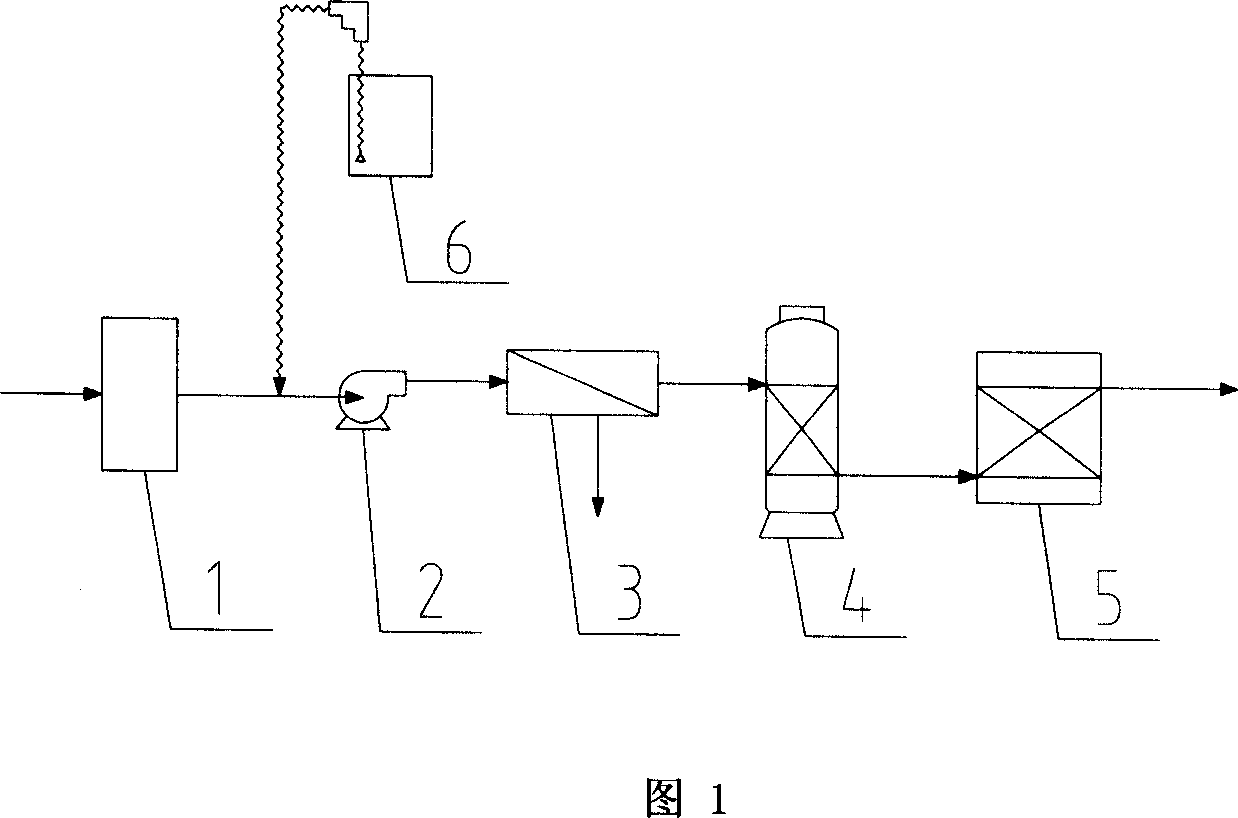

Hydrogenation system for producing hydrogen peroxide

ActiveCN101837957AHigh temperature controllabilityExtended regeneration cyclePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesVapor–liquid separatorHydrogenation reaction

The invention discloses a hydrogenation system for producing hydrogen peroxide in the field of chemical equipment. The hydrogenation system comprises a hydrogen filter, a working solution pre-heater, a hydrogenating tower, a hydride gas-liquid separator, a hydride filter, a hydride regenerative bed and a hydride storage tank, wherein the hydrogenating tower is divided into an upper tower and a lower tower; the outlet of the upper tower is connected with the inlet at the top of the lower tower; a hydride cooler is also arranged between the upper tower and the lower tower; and the inlet of the hydride cooler is connected with the outlet at the bottom of the upper tower, and the outlet of the hydride cooler is connected with the inlet at the top of the lower tower. When the system works, working solution and raw material hydrogen enter the upper tower for hydrogenation reaction; one part of the product can enter the lower tower and the other part of the product can enter the hydride cooler for cooling; the cooled product enter the lower tower to continue to undergo hydrogenation reaction; and a palladium catalyst can work in a state of high activity for a long time and the components of the working solution in the system can be ensured stable by adjusting the hydrogenation temperature in the lower tower. The hydrogenation system is particularly used for producing the hydrogen peroxide.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

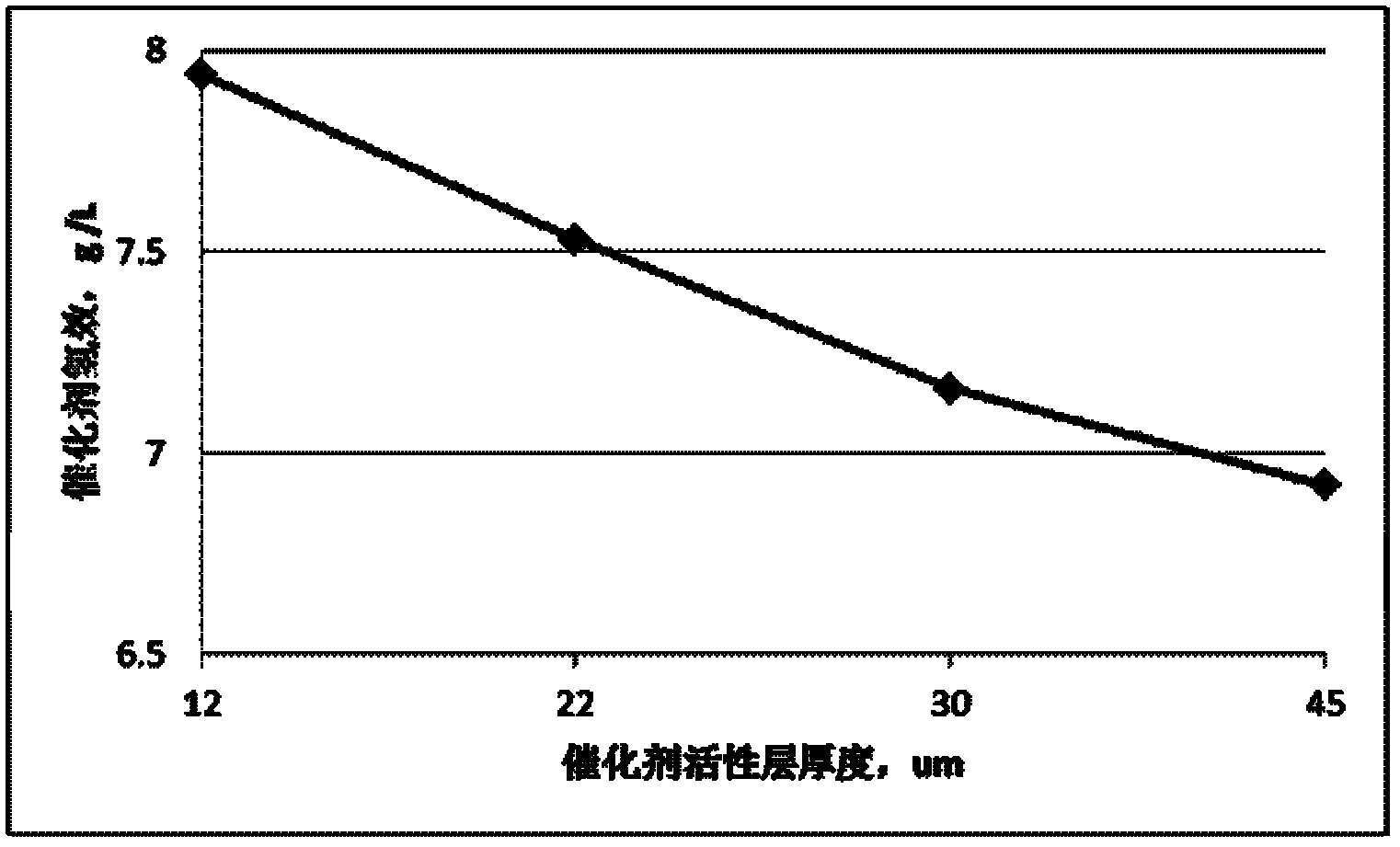

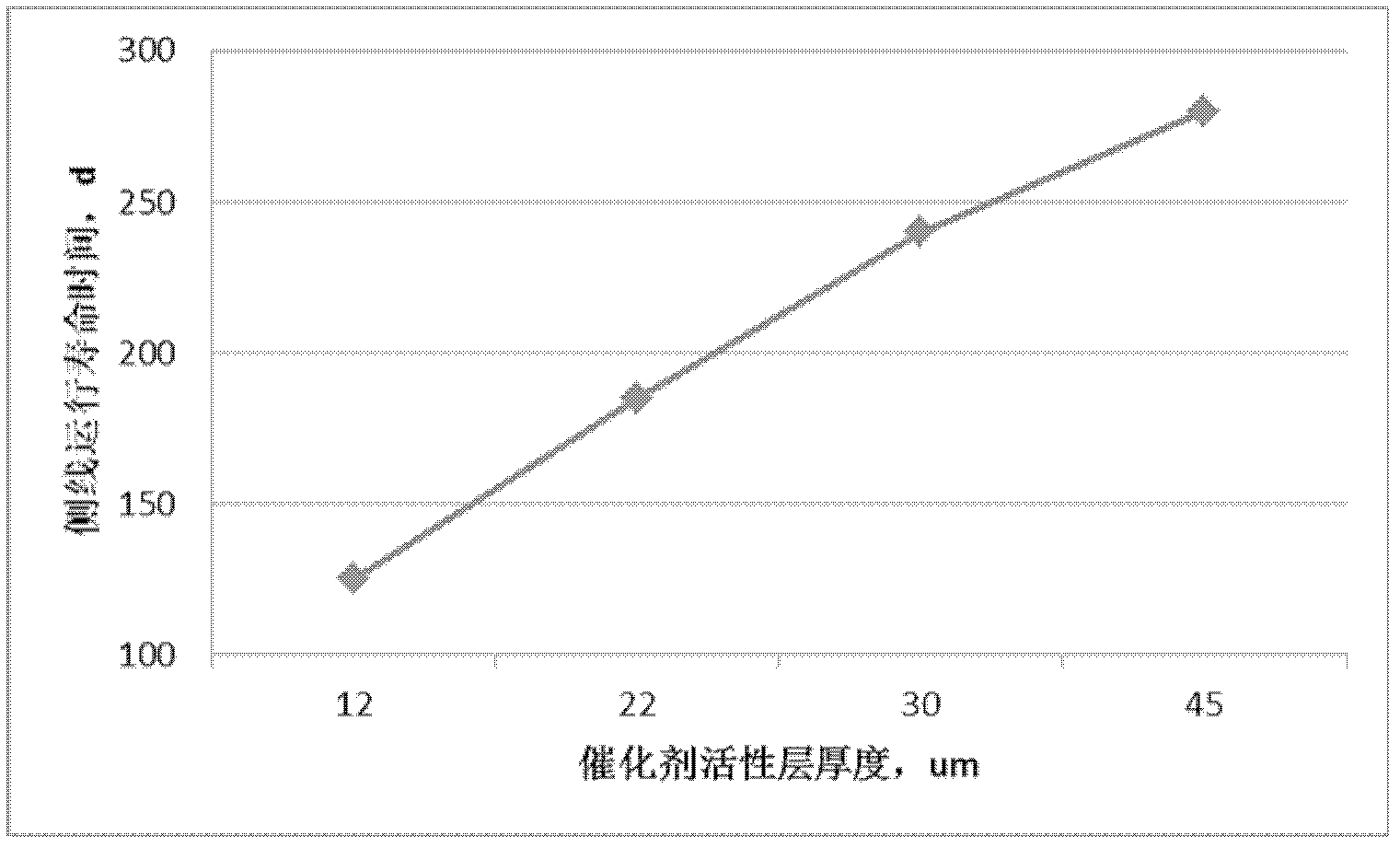

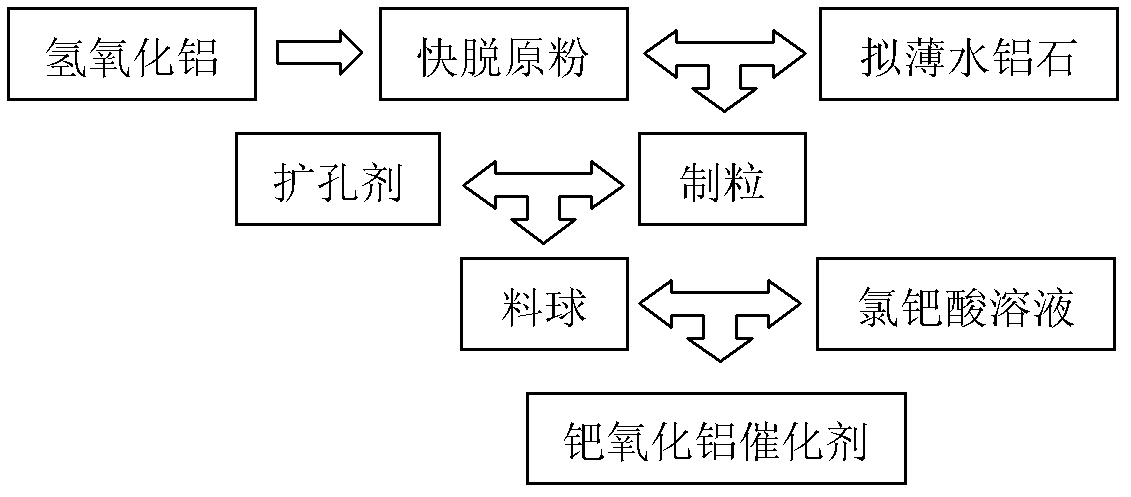

Palladium alumina catalyst for production of hydrogen peroxide by anthraquinone process and its preparation method

ActiveCN102626618AHigh activityHigh compressive strengthPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingPseudoboehmiteAluminium hydroxide

The invention discloses a palladium alumina for production of hydrogen peroxide by an anthraquinone process. The catalyst comprises gamma-Al2O3 as the carrier, the content of which is over 97wt%; and metal palladium as the main active component, the loading of which is 0.1wt%-0.5wt% and the dipping thickness of which is from 10 micrometers to 100 micrometers. The invention also discloses a preparation method of the catalyst, and the method consists of: roasting aluminum hydroxide, mixing the roasted aluminum hydroxide with pseudoboehmite, then adding a pore-expanding agent for molding, conducting surface treatment so as to obtain a catalyst carrier, then performing pre-spraying on the carrier with a locating agent, carrying out drying, and then putting the carrier into a chloropalladate solution for dipping. With appropriate specific surface area, pore volume and pore size distribution, the palladium catalyst provided in the invention is difficult to shed and fragment. In actual production of hydrogen peroxide by an anthraquinone process, the catalyst shows excellent balance between activity and selectivity, as well as good service life and regeneration cycle.

Owner:陕西开达化工有限责任公司

Process and apparatus for the removal of nitrogen compounds from a fluid stream

ActiveUS20050152819A1Increase capacityImprove adsorption capacityPhysical/chemical process catalystsHydrocarbonsAlkyl transferMolecular sieve

Disclosed is a process and apparatus for removing nitrogen compounds from an alkylation substrate such as benzene. A conventional adsorbent bed can be used to adsorb basic organic nitrogen compounds and a hot adsorbent bed of acidic molecular sieve can adsorb the weakly basic nitrogen compounds such as nitrites. Water facilitates the adsorption of the weakly basic nitrogen compounds. Running an alkylation substrate stream from a fractionation column of elevated temperature and suitable water concentration to the hot adsorbent bed may be advantageous.

Owner:UOP LLC

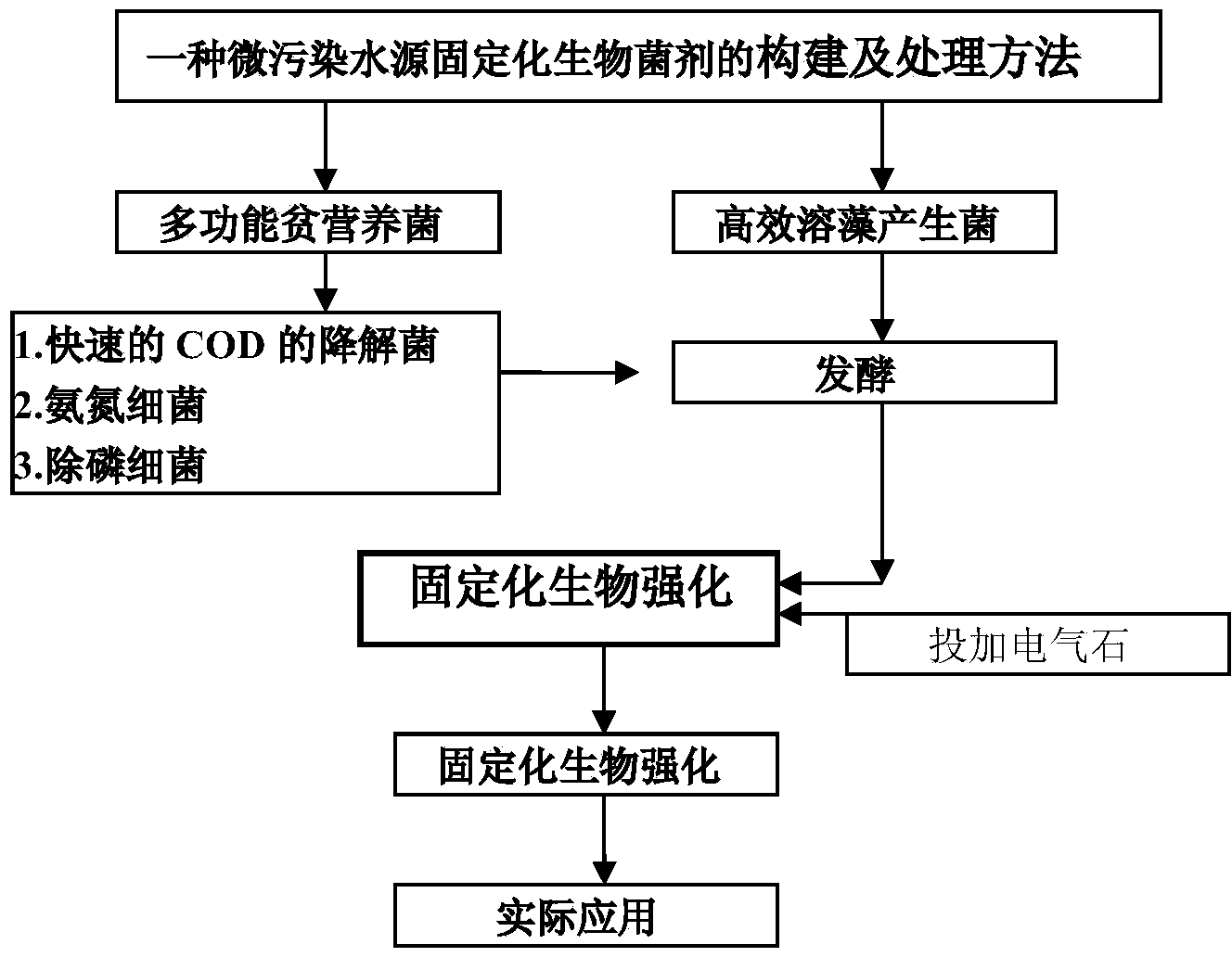

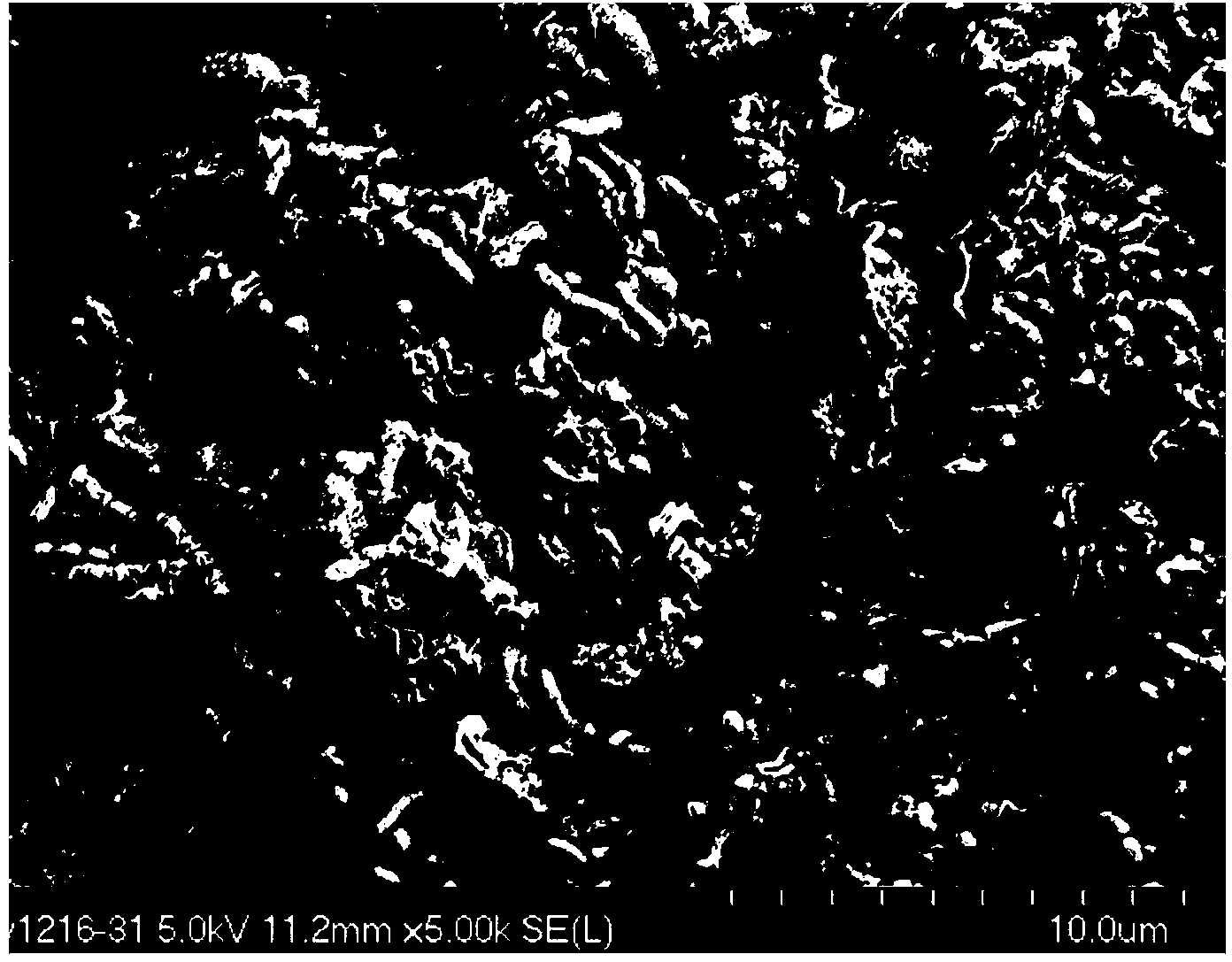

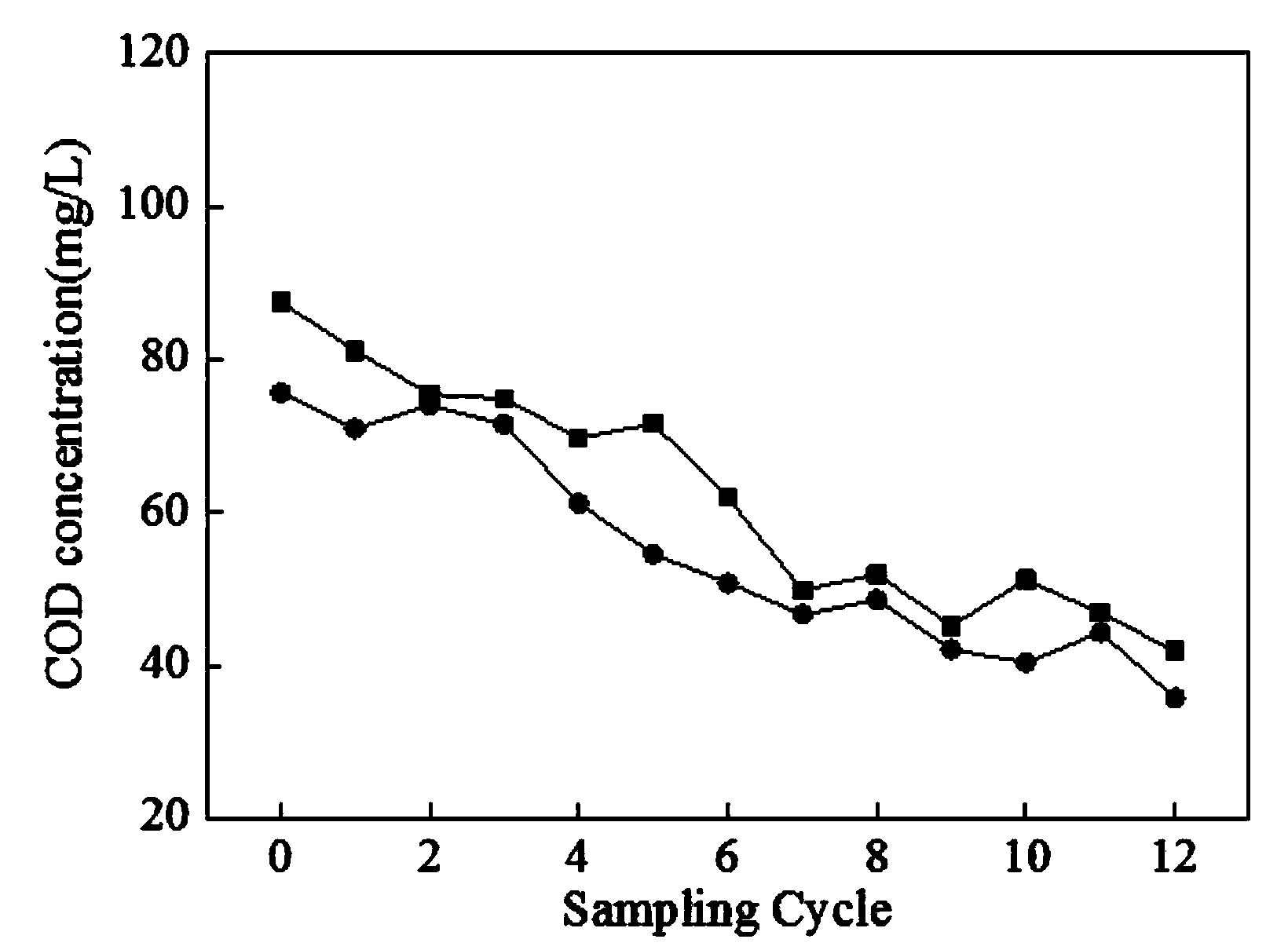

Construction method and application of immobilized biological bacterium agent for micro-polluted water source

InactiveCN104232546AImprove removal efficiencyExtended regeneration cycleBacteriaMicroorganism based processesWater sourceManganese

The invention discloses a construction method and an application of an immobilized biological bacterium agent for a micro-polluted water source and belongs to the field of ecological remediation of water environments. The method is a treating process for purifying a water body through construction of the biological bacterium agent, and ammonia nitrogen, iron, manganese, microcystis, algal toxins and the like in the water body can be removed effectively. The method comprises steps as follows: (1) rescreening and compounding of multifunctional oligotrophic ammonia nitrogen bacteria; (2) screening of efficient algicidal bacteria; (3) fermentation and construction of the bacterium agent; (4) bacterium agent immobilization and biological enhancement; (5) research on dosing methods of the bacterium agent, and treatment and biological enhancement of the micro-polluted drinking water source. The biological bacterium agent is constructed with an immobilization technology, after a system runs stably, the removal rate of the ammonia nitrogen is higher than 80%, removal rates of the microcystis and the algal toxins are higher than 40%, the removal rate of the iron in water is 50%, and the removal rate of manganese is 51%. The method can be combined with actual projects and is wider in application prospect.

Owner:松辽流域水资源保护局松辽流域水环境监测中心 +1

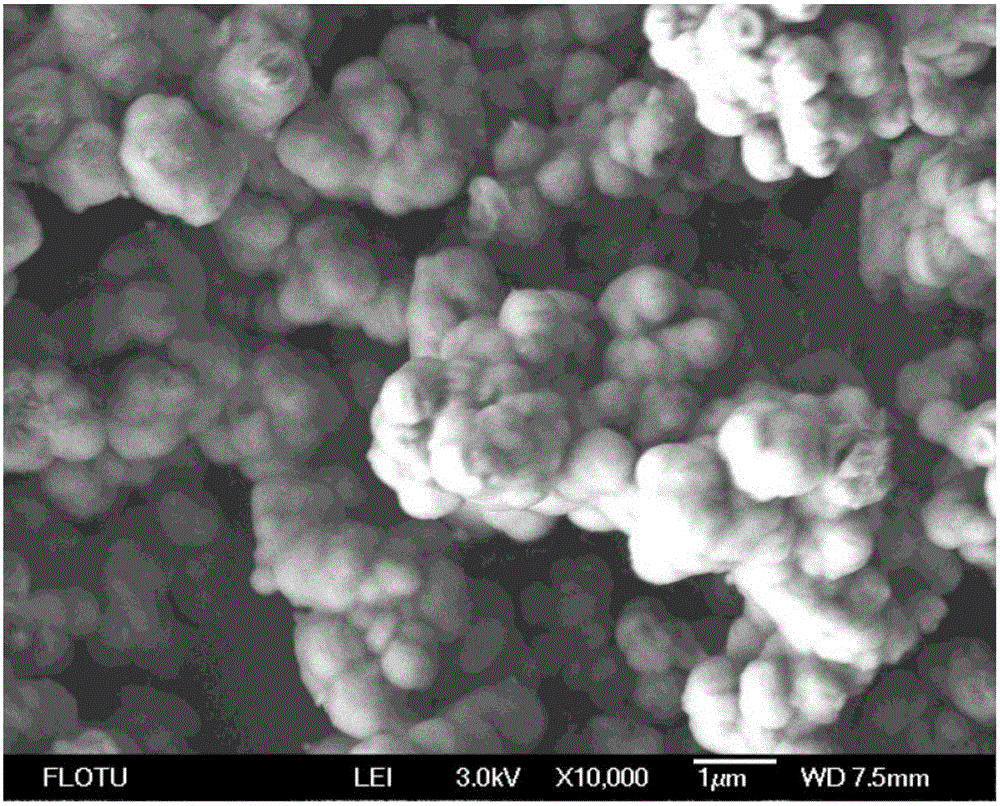

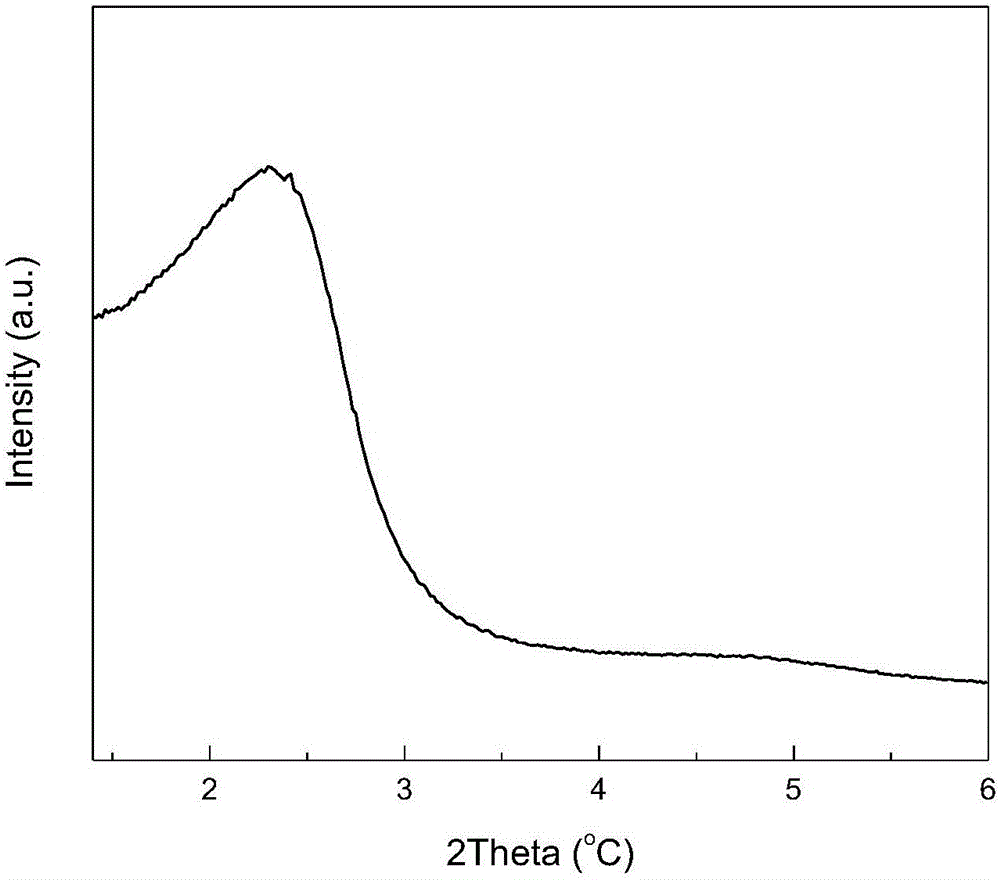

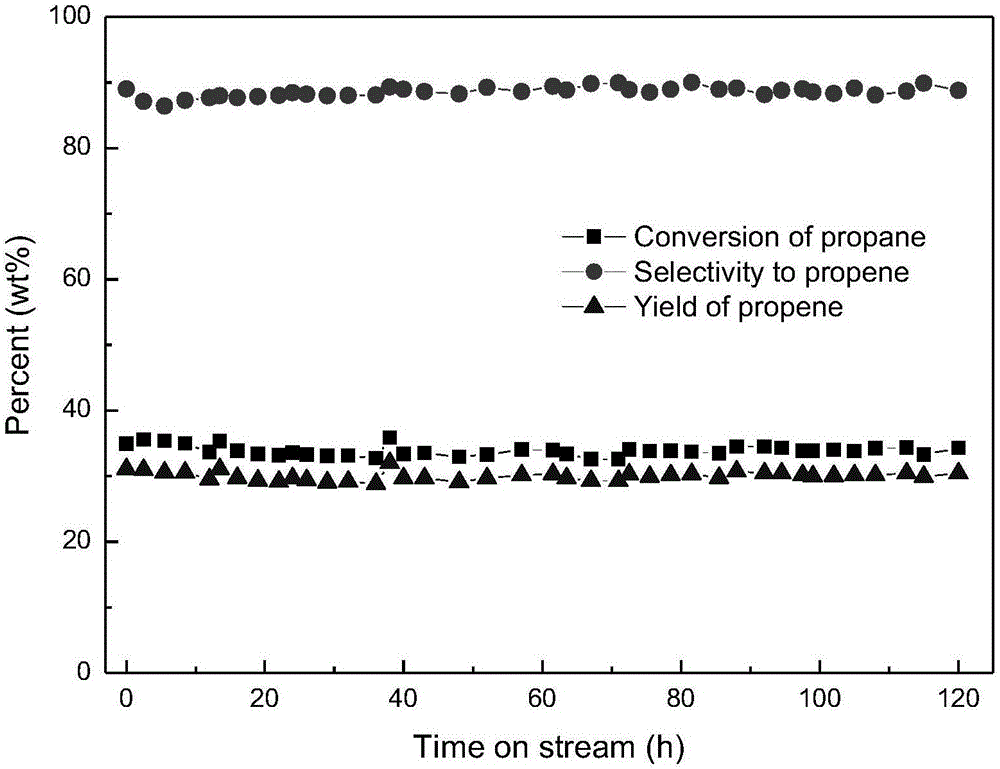

Mesoporous molecular sieve catalyst for alkane catalytic dehydrogenation and preparing method and application thereof

ActiveCN105921166AImprove conversion rateGood choiceMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkane

The invention relates to a mesoporous molecular sieve catalyst for alkane catalytic dehydrogenation and a preparing method and application thereof. The mesoporous molecular sieve catalyst is characterized in that a metal active component M is introduced in situ in the process of synthesizing a mesoporous molecular sieve HMS, and the active component M is one or a mixture of metal or metallic oxide of Pt, Pd, Ru, Rh, Ni, Co, Fe, Sn and Zn. According to the mesoporous molecular sieve catalyst for alkane catalytic dehydrogenation and the preparing method thereof, the adopted active component is low in price and environmentally friendly, is anchored to a molecular sieve skeleton and highly dispersed, and is not prone to aggregation sintering in the reaction process, the alkane conversion per pass is high, and target product olefins are high in selectivity, stable in performance and long in regeneration period.

Owner:QINGDAO SHENFEI CHEM TECH CO LTD +1

Fine desulfurization process by dry process for natural gas

ActiveCN101691512AEliminate adsorption and removal interferenceExtended regeneration cycleGaseous fuelsMolecular sieveSorbent

The invention relates to a fine desulfurization process by a dry process for natural gas. The process is three-stage normal-temperature fine desulfurization by the dry process for the natural gas: the first-stage desulfurization is crude removal of hydrogen sulfide, and uses a normal-temperature ferric oxide desulfurizer; the second-stage hydrogen sulfide fine removal reactors use a normal-temperature zinc oxide desulfurizer; and the third-stage organic sulfur fine removal reactors use a normal-temperature molecular sieve desulfurizer, wherein the normal-temperature ferric oxide desulfurizer and the normal-temperature molecular sieve desulfurizer can be regenerated for repeated use. The first-stage reactors, the second-stage reactors and the third-stage reactors must be one running reactor and one standby reactor which are mutually switched for use. The process prolongs the regeneration period of organic sulfur adsorbents, avoids the interference of inorganic sulfur on the absorption removal of the organic sulfur, reduces energy consumption and cost, and improves desulfurization accuracy.

Owner:长春惠工净化工业有限公司

Method of preparing propylene and ethylene by catalytic cracking olefin

ActiveCN1927785AHigh activityConducive to gatheringBulk chemical productionHydrocarbon by hydrocarbon crackingRare earthReaction temperature

The present invention relates to process of catalytically cracking olefin to produce propylene and ethylene, and the process is superior to available technology, which has the problems of poor high temperature hydrothermal stability of catalyst with scaling, deactivation, etc. The technological scheme of the present invention is that C4 and C4+ olefin material is catalytically cracked to produce propylene at the reaction temperature of 450-650 deg.c, reaction pressure of -0.08 to 0.5 MPa and liquid space velocity of 0.5-15 / hr under the action of ZSM-5 molecular sieve catalyst containing RE metal and phosphorus oxide. The process may be used in industrial production of propylene through cracking olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

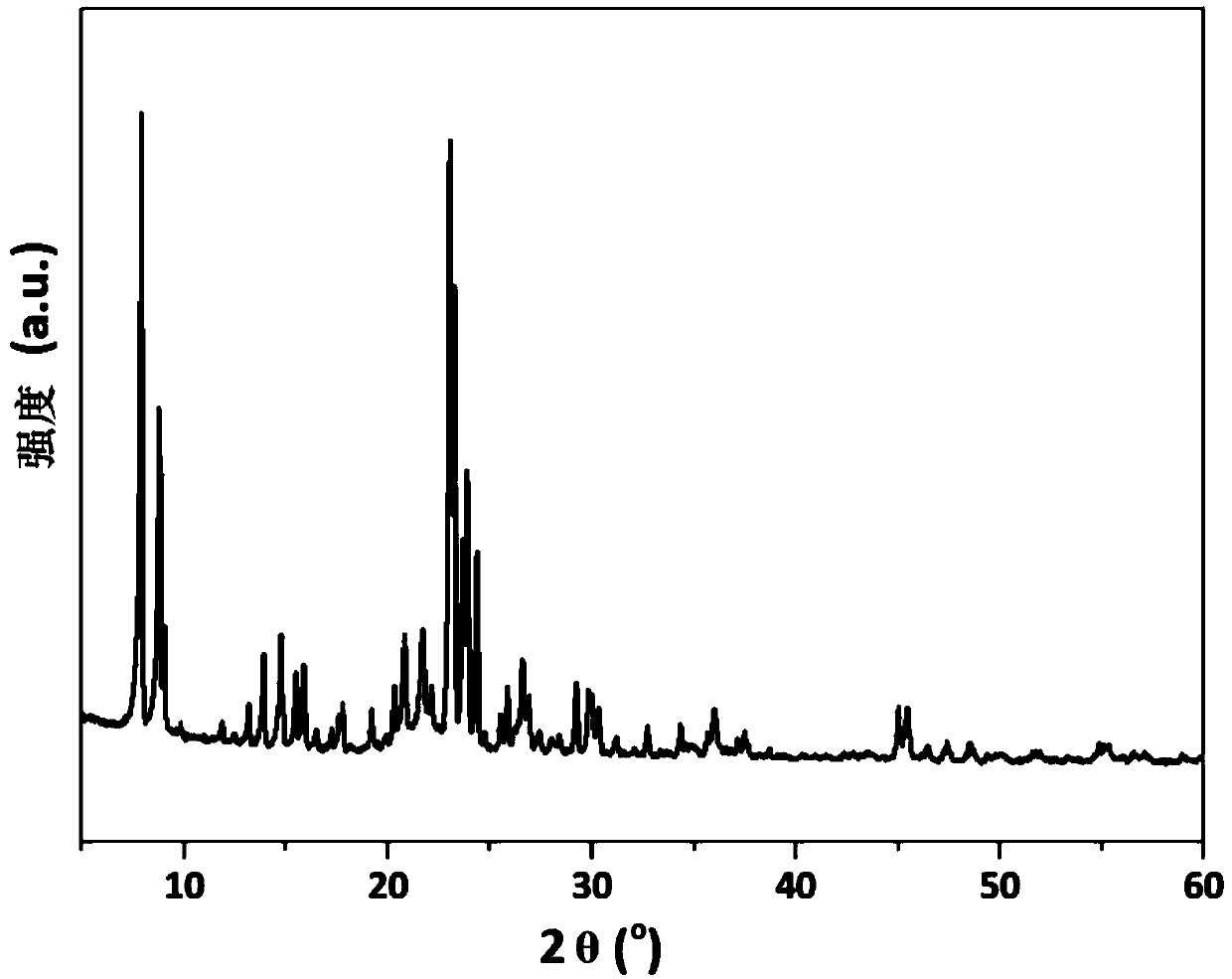

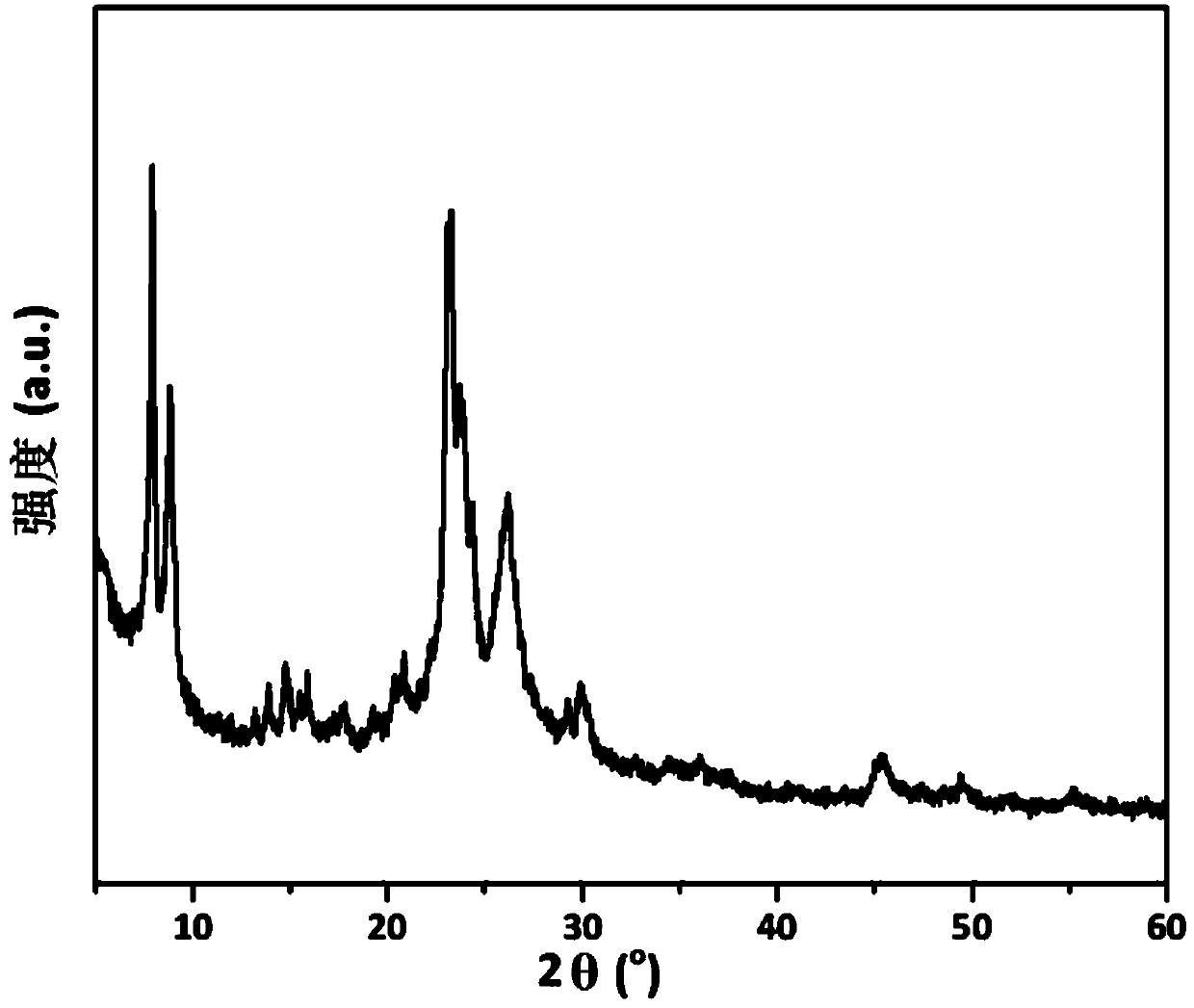

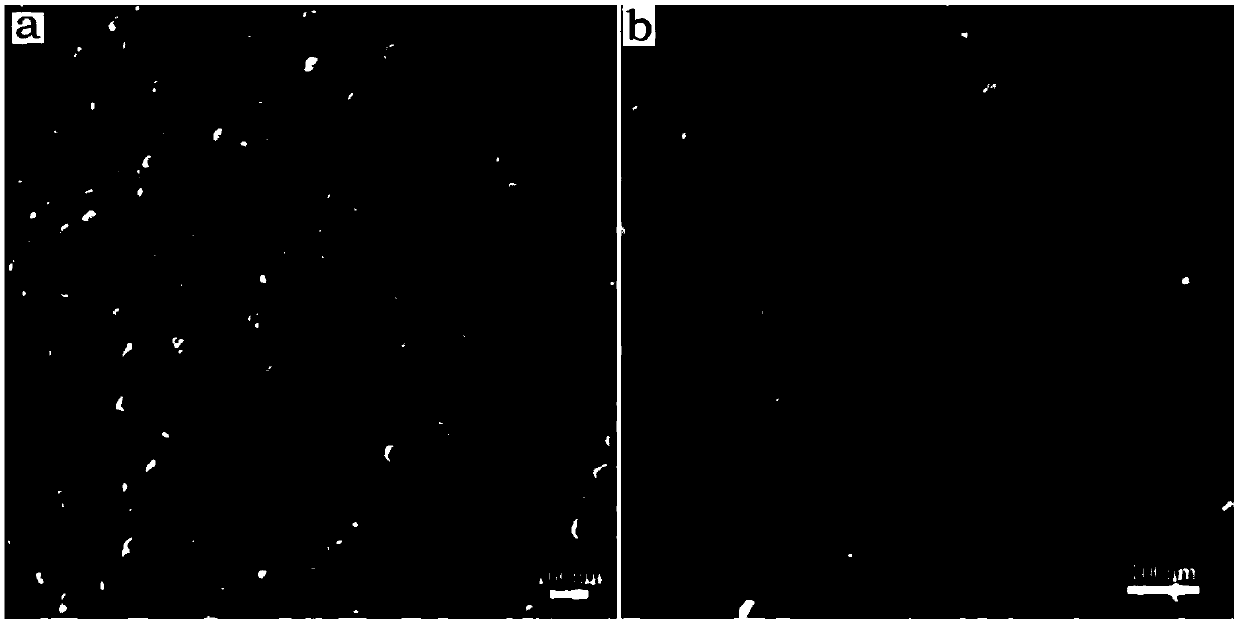

Preparation method and application of molecular sieve catalyst

ActiveCN110882715AHigh ethyl selectivityLow xylene contentMolecular sieve catalystsCatalyst activation/preparationXylyleneMolecular sieve

The invention discloses a preparation method of a molecular sieve catalyst. The preparation method comprises the following steps: obtaining a ZSM-5 seed crystal gel solution; adding a mixture I containing a silicon source, an aluminum source, an alkali and water into the ZSM-5 seed crystal gel solution to obtain a mixture, and aging the mixture to obtain a solid gel; carrying out water steam-assisted crystallization, calcination, ammonium ion exchange and calcination on the solid gel under a sealed condition to obtain a nano-ZSM-5 molecular sieve; and carrying out water steam treatment and phosphorus modification on the obtained nano-ZSM-5 molecular sieve, and performing calcination to obtain the molecular sieve catalyst. The catalyst has the characteristics of uniform distribution of acid sites, and high crystallinity, and the preparation method has the advantages of less generated wastewater, and convenience in large-scale production; and the catalyst has the advantages of good hydrothermal stability in an alkylation reaction of ethanol and benzene, keeping high ethyl selectivity under a low benzene-alcohol ratio feeding condition, low content of xylene impurities in the product, and good industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing ethylbenzene by reacting pure ethylene or dry gas with benzene

ActiveCN102040458AReduced service lifeReduce generationHydrocarbonsChemical recyclingAlkyl transferFixed bed

The invention relates to a method for producing ethylbenzene by reacting pure ethylene or dry gas with benzene, mainly solving the problems of high dimethylbenzene impurity content in the product ethylbenzene, low ethylbenzene purity, poor catalyst stability and short regeneration period and service life in the process of producing ethylbenzene by reacting pure ethylene or dry gas with benzene in the prior art. In the invention, at least a section of ZSM-5 molecular sieve catalyst I the SiO2 / Al2O3 mol ratio of which is 50-150, and at least a section of ZSM-5 molecular sieve catalyst II the SiO2 / Al2O3 mol ratio of which is 160-300 are loaded in an alkylation fixed bed type reactor; 30-70wt% of pure ethylene or dry gas enters the bed loaded with the catalyst I, and the residual pure ethylene or dry gas enters the bed loaded with the catalyst II; 80-100wt% of benzene enters the first section of the bed loaded with the catalyst I from the top of the reactor, and the residual benzene enters each catalyst bed below section by section; and the difference between the inlet temperature of each section of catalyst bed and the material inlet temperature at the top of the reactor is controlled not to exceed + / -5 DEG C. The technical scheme better solves the problems and can be used in the industrial production of ethylbenzene by reacting the pure ethylene or the dry gas with the benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal compound-type arsenic removal agent, preparation method and application thereof

InactiveCN103877931ASimple production processLarge specific surface areaOther chemical processesRefining with metal oxidesSyngasCopper

The invention discloses a metal compound-type arsenic removal agent, a preparation method and an application thereof, the metal compound-type arsenic removal agent is composed of a carrier and a metal active ingredient loaded on the carrier; the carrier is active carbon, and the metal active ingredient is more than one selected from copper, iron, nickel or silver. The arsenic removal agent has the advantages of simple production technology, large specific surface area, and good active metal dispersibility, deep arsenic removal of the oil product can be realized, surface acidity is low, the colloid generation is reduced, so that the arsenic removal agent is benefit for prolonging the regeneration period of a catalyst, the arsenic removal agent has the advantages of high arsenic removal rate and low energy consumption, and is suitable for large-scale industrial production, and can be used for removing arsenic from the light dydrocarbon materials such as propylene, ethene and deeply purifying arsenic in synthetic gas prepared by taking coal, coke, heavy oil, oil residue or natural gas as raw materials.

Owner:SHANGHAI UNIV OF ENG SCI

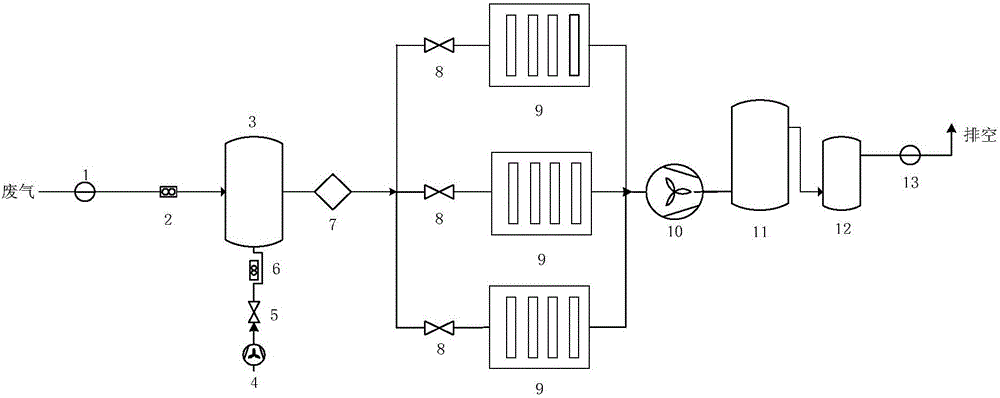

Method and equipment for treating volatile organic compounds by low-temperature plasma coupling adsorption

InactiveCN105833677AReduce fill volumeExtended regeneration cycleAuxillary pretreatmentBenzenePlasmonic coupling

The invention provides equipment and a method for treating volatile organic compounds by low-temperature plasma coupling adsorption, wherein a low-temperature plasma process and an adsorbing process are adopted, and volatile organic waste gas and odor gas are firstly treated by a low-temperature plasma device, and then enter an adsorbing device to be treated. When a low-temperature plasma coupling adsorption method is applied to treat organic waste gas and odor waste gas with non-methane hydrocarbon lower than 6000 ppm and sulfuretted hydrogen lower than 100 ppm, benzene in exhaust is lower than 4mg / m<3> and various odorous substances completely reach the standards in comparison with a mode of purely using an adsorbing method or purely using low-temperature plasmas; and the filling amount of an ozone disintegrant can be reduced by more than 50% and the regeneration period is prolonged by one time and more in comparison with a mode of independently using low-temperature plasmas.

Owner:CHINA PETROLEUM & CHEM CORP +1

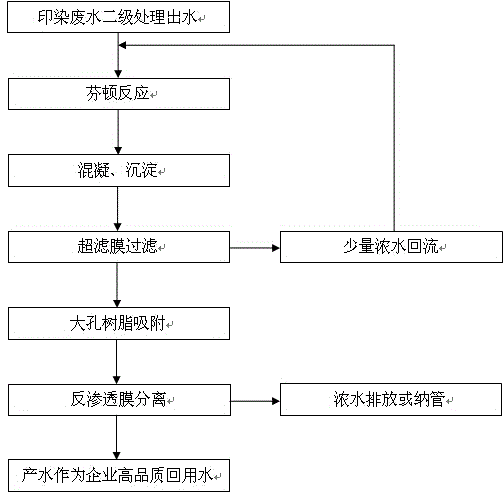

Method for advanced treatment and reuse of printing and dyeing wastewater pre-processed by macroporous resin

InactiveCN104098206ALow investment and operating costsImprove water qualityMultistage water/sewage treatmentWaste water treatment from textile industryUltrafiltrationChemistry

The invention discloses a method for advanced treatment and reuse of printing and dyeing wastewater pre-processed by macroporous resin. The method comprises the following steps: taking the printing and dyeing wastewater for the secondary treatment; performing conducting Fenton reaction precipitation, ultra-filtrate membrane filtration, macroporous resin absorption and reverse osmosis membrane separation on discharged wastewater subjected to the treatment, wherein the output water of the reverse osmosis membrane is adopted as the high-quality water for recycling for enterprises, and the concentrated water of the reverse osmosis membrane is emitted on standard, or is emitted to a sewage plant through nano tubes for centralized processing. The method has the advantages that (1) the regular pre-processing technology and multi-media filtration procedure before the macroporous resin is eliminated, and the investment and operation cost is reduced; (2) the ultra-filtrate membrane filtration is adopted as the pre-processing of the macroporous resin, the input water quality is improved, pollutants, such as suspended solids, in water are greatly reduced, the service life and the regeneration period are prolonged, and the operation cost is lowered; (3) the macroporous resin absorption is added as the pre-processing of the reverse osmosis membrane on the basis of the ultra-filtration, the input water quality of the reverse osmosis membrane is improved, pollution is relieved, the service life and the cleaning period are prolonged, and the water output of the reverse osmosis membrane is improved.

Owner:NINGBO QINGSHUIYUAN WATER TECH

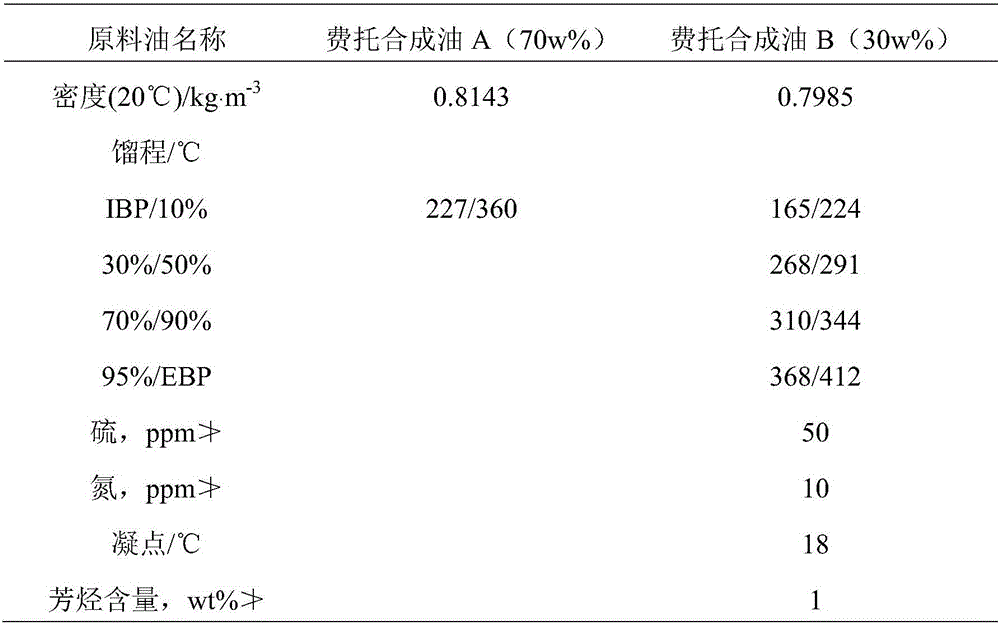

Selective hydrogenation catalyst for producing aviation kerosene and preparation method and application thereof

InactiveCN105944752AReduce reunionAchieve high efficiencyMolecular sieve catalystsHydrocarbon oils refiningReaction temperatureCoal

The invention discloses a selective hydrogenation catalyst for producing biological aviation kerosene and a preparation method and an application thereof. The catalyst comprises a carrier and a main metal active component; the main metal active component is loaded on the carrier; the main active metal component accounts for 0.05-1.15 wt% of the catalyst finished product and is Pt or / and Pd; the carrier comprises the raw materials by the weight percentage: 2-10% of molecular sieve, 25-65% of amorphous silicon aluminum, 30-65% of alumina and 2-10% of a graphene auxiliary agent. The method comprises the steps: placing the carrier in a solution containing Pt and / or Pd metal salts, and immersing for 4-20 h, to obtain a carrier after impregnation; and drying the carrier obtained after impregnation, and then treating the dried carrier in a reducing atmosphere, to obtain the selective hydrogenation catalyst. Under the same loading capacity, the selective hydrogenation catalyst has larger representative active surface area and more active sites, reduces the reaction temperature, and improves the hydrogenation performance.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

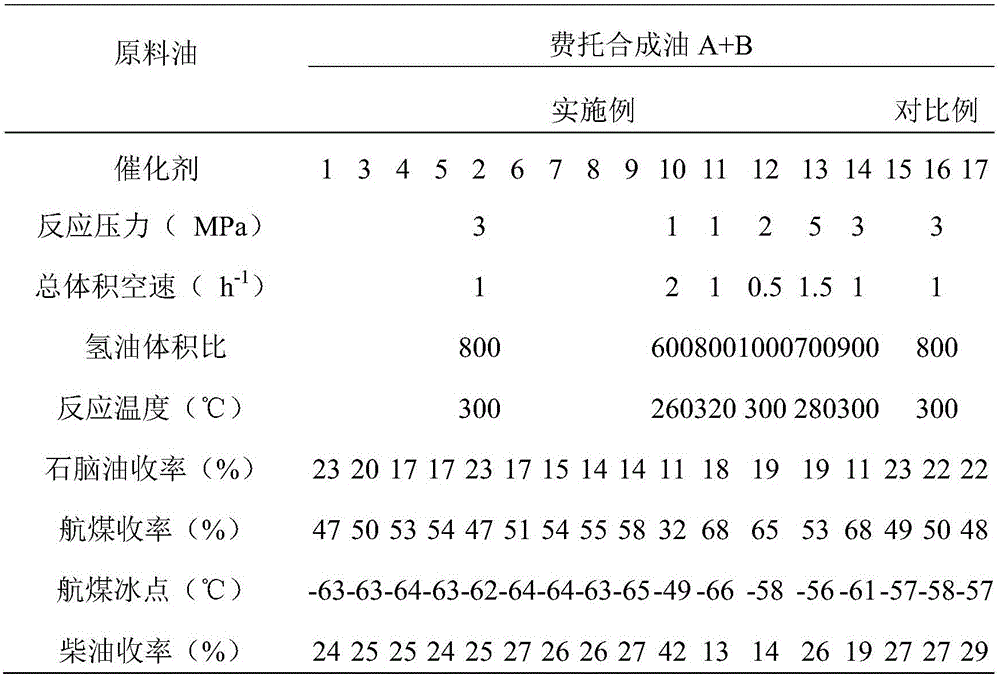

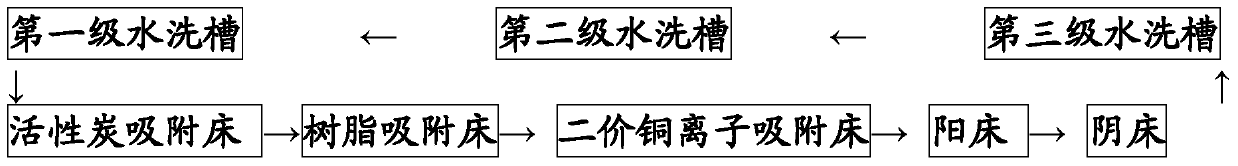

Zero-discharge on-line treatment process for preparing deionized water from copper sulphate electroplating waste water

InactiveCN105565533ARealize zero-emission recyclingExtended regeneration cycleCellsWaste water treatment from metallurgical processWater useIon exchange

The invention relates to a zero-discharge on-line treatment process for preparing deionized water from copper sulphate electroplating waste water. The treatment process comprises 1, adsorbing organic matters in the copper sulphate electroplating waste water through combination of active carbon and ion exchange resin, 2, adsorbing heavy metal ions in the waste water treated through the step 1 through ion exchange resin and 3, purifying the electroplating waste water without the organic matters and heavy metal ions through a purified water ion exchange preparation method to obtain deionized water. The organic matters in the copper sulphate electroplating waste water are removed through the combination of active carbon and ion exchange resin so that the organic matters in the copper sulphate electroplating waste water are completely removed and a regeneration period and a service life of the later resin are prolonged. Through the zero-discharge on-line treatment process, the copper sulphate electroplating waste water is completely purified to form deionized water satisfying electroplating water quality requirements and the prepared deionized water is returned to a copper sulphate electroplating unit so that water use and waste water treatment processes in the copper sulphate electroplating unit form a closed cycle and thus 100% recycle is realized.

Owner:深圳市汇利龙科技有限公司

A manganese deoxidizer adopting a cerium-based oxide as a carrier, a preparing method thereof and applications of the deoxidizer

ActiveCN106378144ALow priceExtended regeneration cycleHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsChemical industryPolyolefin

The invention relates to deoxidization techniques in the chemical industry and particularly provides a manganese deoxidizer adopting a cerium-based oxide as a carrier, a preparing method thereof and applications of the deoxidizer. A catalyst comprises active components, a carrier and an adhesive, wherein the active components include Cu and MnO and account for 35-75% by weight of the catalyst, the carrier is CeO2 or a CeO<2>-MOx composite oxide and accounts for 20-50% by weight of the catalyst, and the adhesive is one or more selected from a group consisting of kaolin, high-alumina cement, pseudo-boehmite and titanate and accounts for 1-20% by weight of the catalyst. A product of the manganese deoxidizer is suitable for activation and regeneration conditions of polyolefin apparatuses at present, and is high in deoxidization capacity and long in service lifetime, and therefore the product is suitable for large-scale industrial application.

Owner:DALIAN CATALYTIC ENG TECH

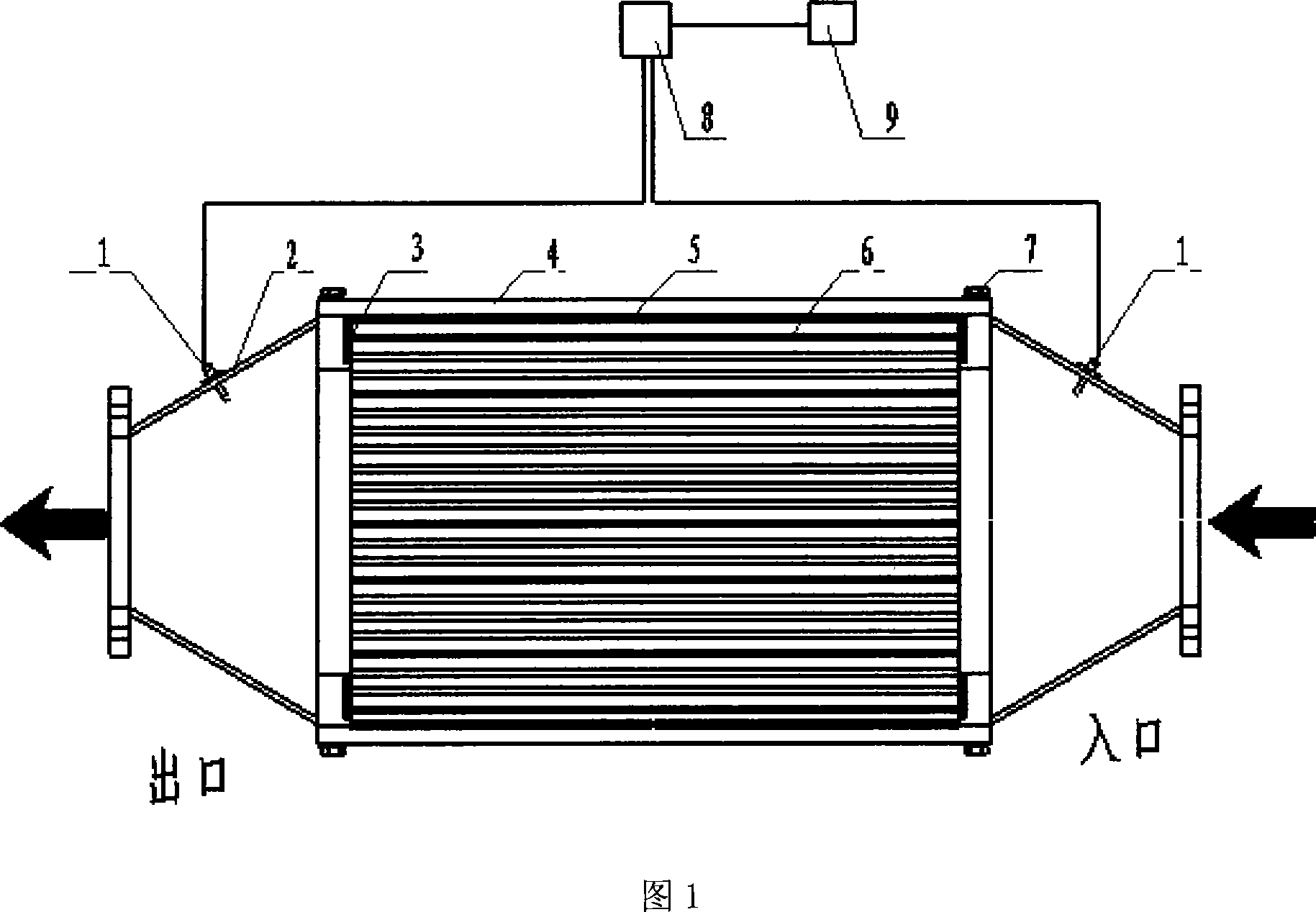

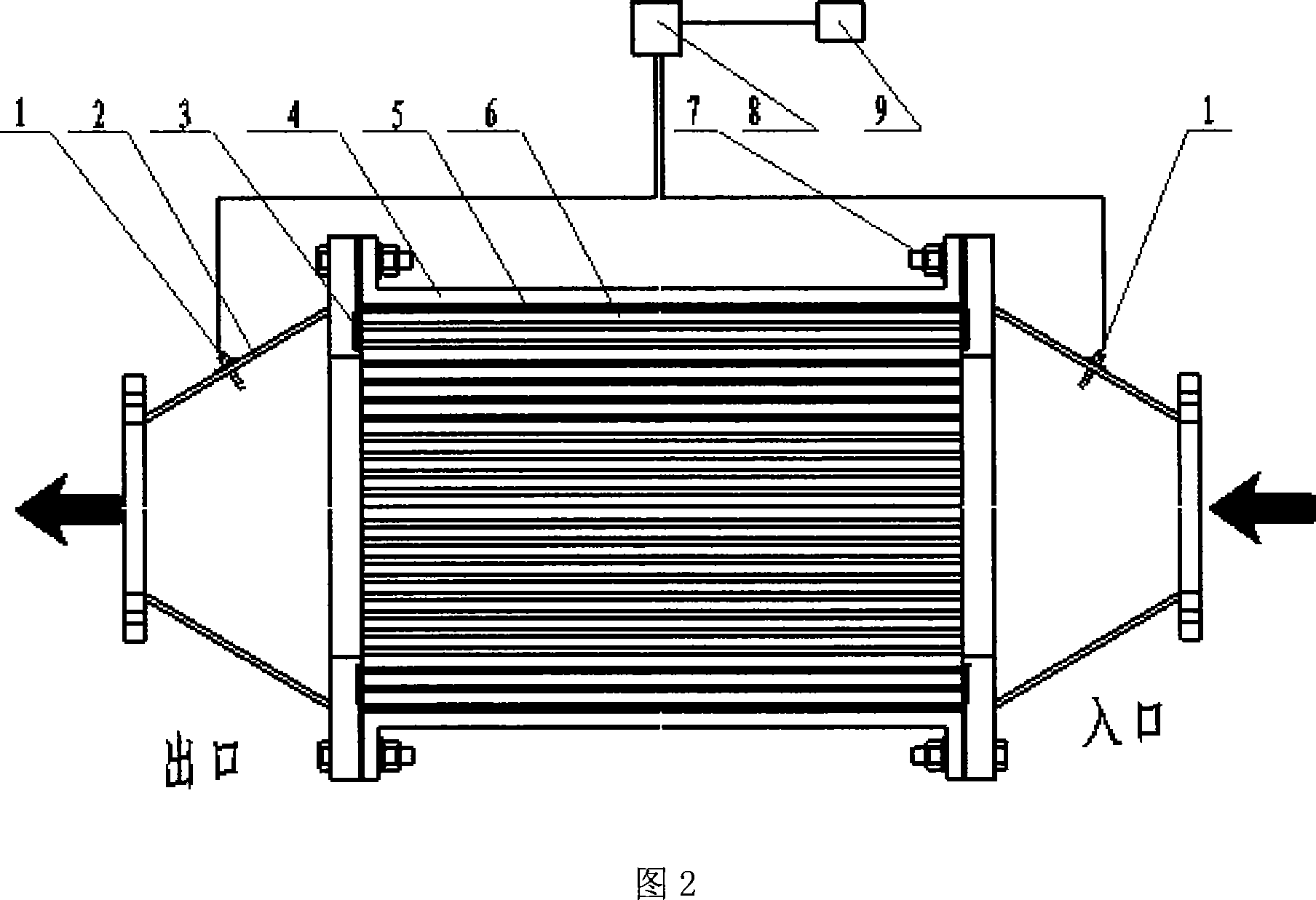

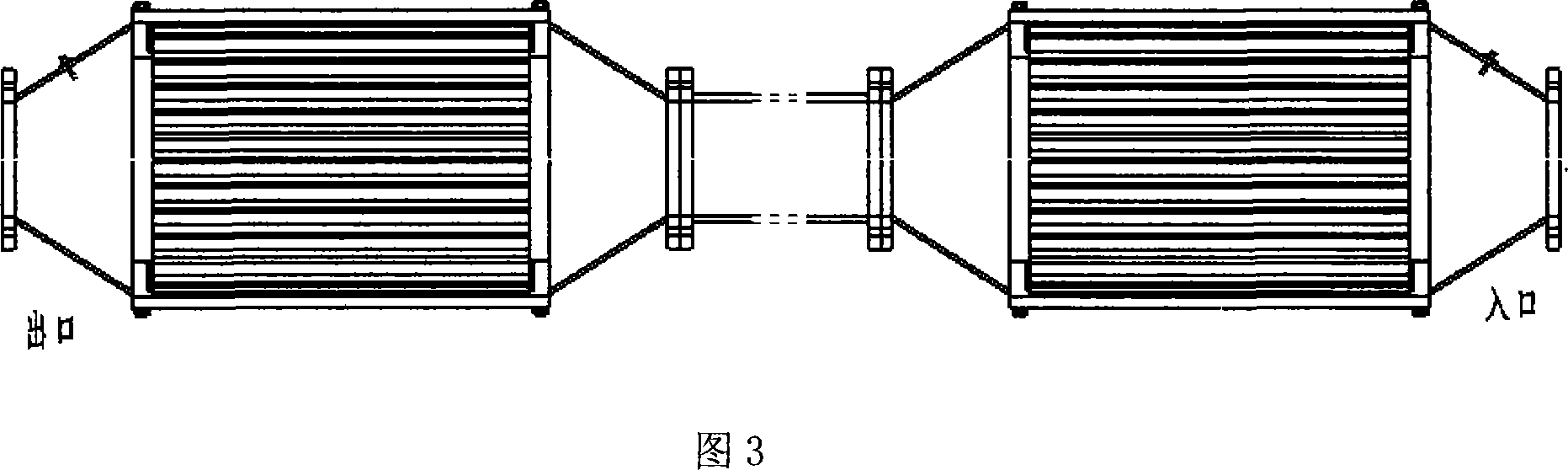

Diesel engine particle catcher

InactiveCN101059094AReduce cloggingExtended regeneration cycleInternal combustion piston enginesExhaust apparatusParticulatesFilling materials

The present invention involves the post-processor technology of diesel engine, particularly relates to a detachable diesel engine particle drip catcher. It consists of shell, filter element, pressure sensor, control unit and display device. Said shell uses separated shell and bolts (7) precompact connection, the filter element (6) is removable, filling materials are filled between the middle press plate (4)of shell and filter element (6), the partitioned particle drip catcher shell is divided into shell (2) and filter element (6) which are filled with filling materials between them, the two ends (2) of shell are tail gas input and output mouth, pressure sensor (1) is installed on the two ends of shell and connected with control unit (8), display device (9) is connected on the control unit (8). The invention aims at particle in different diameters in diesel engine, staged-filters and traps in order to improve the filtering effect, reduce trap device blocking up, prolong its regeneration cycle and retarding aging speed of filter elements, it improves the use life of particulate trap device.

Owner:JILIN UNIV

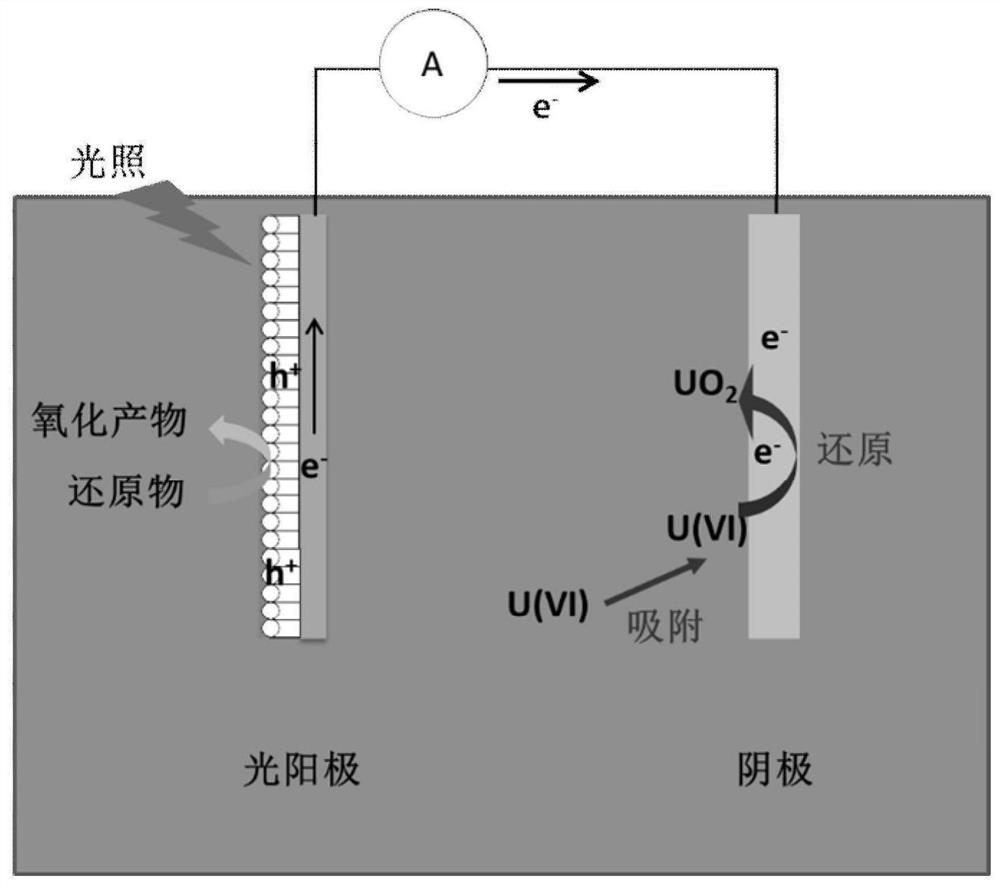

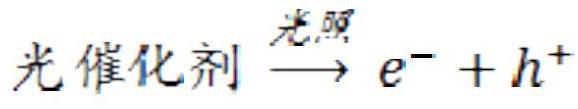

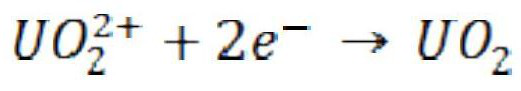

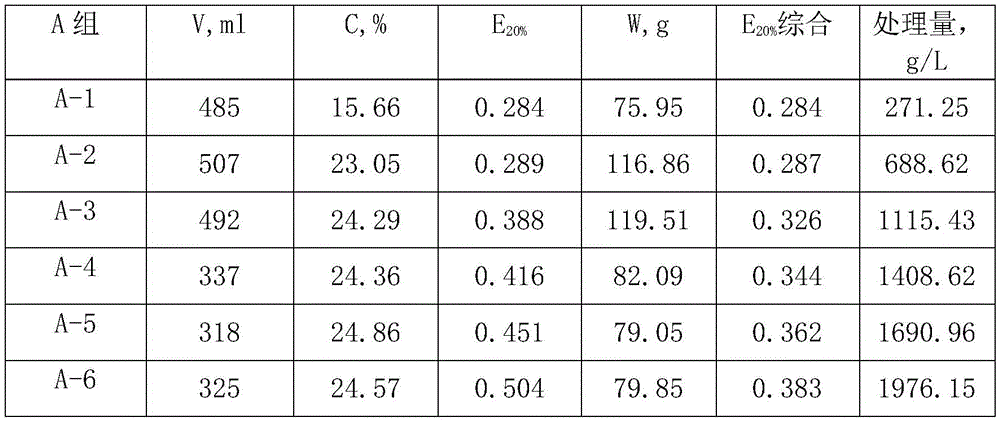

Device and method for extracting uranium from uranium-containing wastewater or seawater and application thereof

ActiveCN112342385AExtended regeneration cycleReduce extraction costsProcess efficiency improvementPhotoelectrochemical storage cellsAir atmosphereCathodic reaction

The invention discloses a device, method and application for extracting uranium from uranium-containing wastewater or seawater, and the device for extracting the uranium comprises a photo-anode, a cathode reaction piece and a photocatalytic light source. The photo-anode comprises an anode reaction piece and a photocatalyst layer arranged on the surface of the anode reaction piece. The cathode reaction piece is connected with the anode reaction piece through a wire. The photocatalytic light source adopts ultraviolet light, visible light or infrared light. When a photocatalytic fuel cell is usedfor extracting the uranium from the uranium-containing wastewater and seawater, an external power source is not needed, a proton exchange membrane and an oxide inhibitor do not need to be added, meanwhile, inert gas atmosphere protection is not needed, and operation can be conducted in the air atmosphere. Hexavalent uranyl ions in the wastewater and seawater can be efficiently reduced into tetravalent uranium which is low in toxicity and almost insoluble in water, the tetravalent uranium is gathered onto a cathode, uranium is desorbed from the surface of a photocatalyst without acid picklingor air purging reoxidation, uranium can be efficiently recycled by regularly replacing a cathode material, uranium reduction products are easy and convenient to collect, and continuous operation of asystem is not influenced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for regenerating anion exchange resin

InactiveCN105562126AIncreased regenerative exchange capacityExtended regeneration cycleSugar derivativesIon-exchanger regenerationAlcoholChromatographic column

The invention relates to the field of ion exchange resin regeneration and provides a method for regenerating anion exchange resin. The method comprises the steps of putting the anion exchange resin to be regenerated into a glass chromatographic column at the temperature of 5-50 DEG C through a wet-process column packing method, wherein the diameter-height ratio is 1: 2-1: 8, making 0.5-8 BV of an alcohol-alkaline solution pass through an anion exchange column, conducting washing till PH is not higher than 9, then making 0.5-6 BV of a hydrochloric acid solution pass through the anion exchange column, conducting washing till PH is not lower than 5, finally, making 0.5-6 BV of a sodium hydroxide solution pass through the anion exchange column, and conducting washing till PH is not higher than 9, so that regeneration of the anion exchange resin is completed. By means of the method, defects of existing anion exchange resin regeneration methods in stevioside production are overcome, the regeneration exchange capacity of the anion exchange resin is greatly improved, the handling capacity is remarkably increased, and the regeneration cycle is longer.

Owner:PURECIRCLE JIANGXI BIOTECH CO LTD

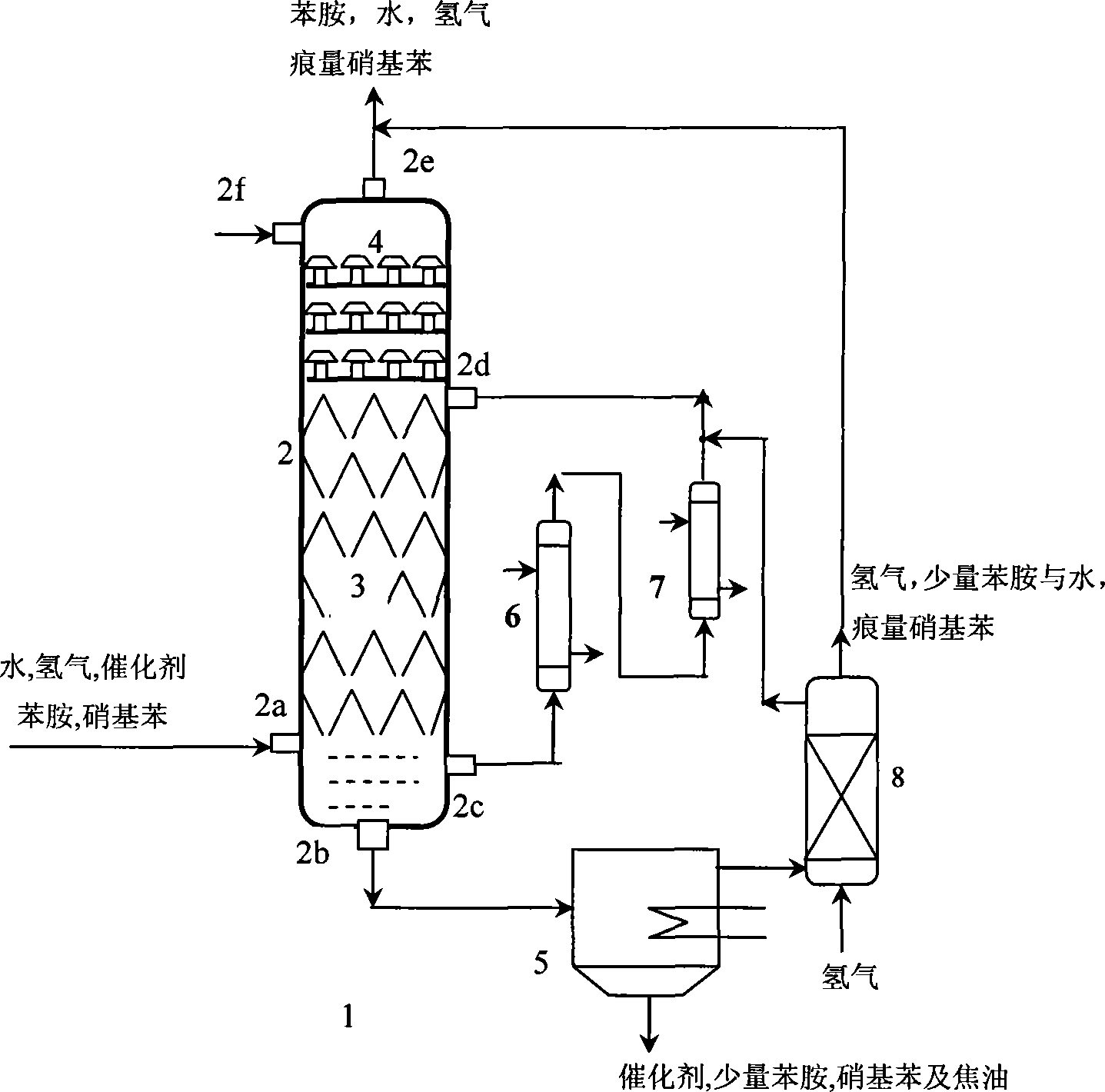

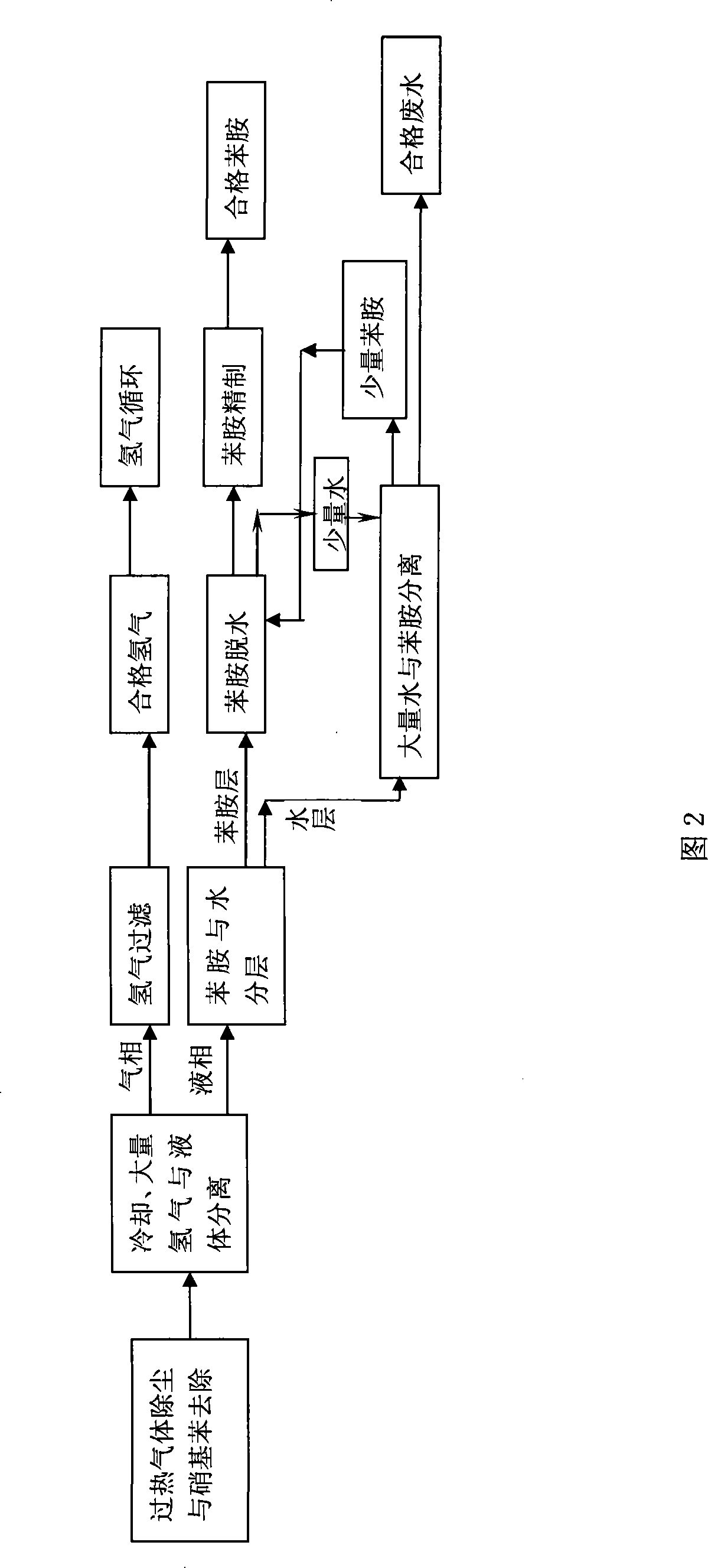

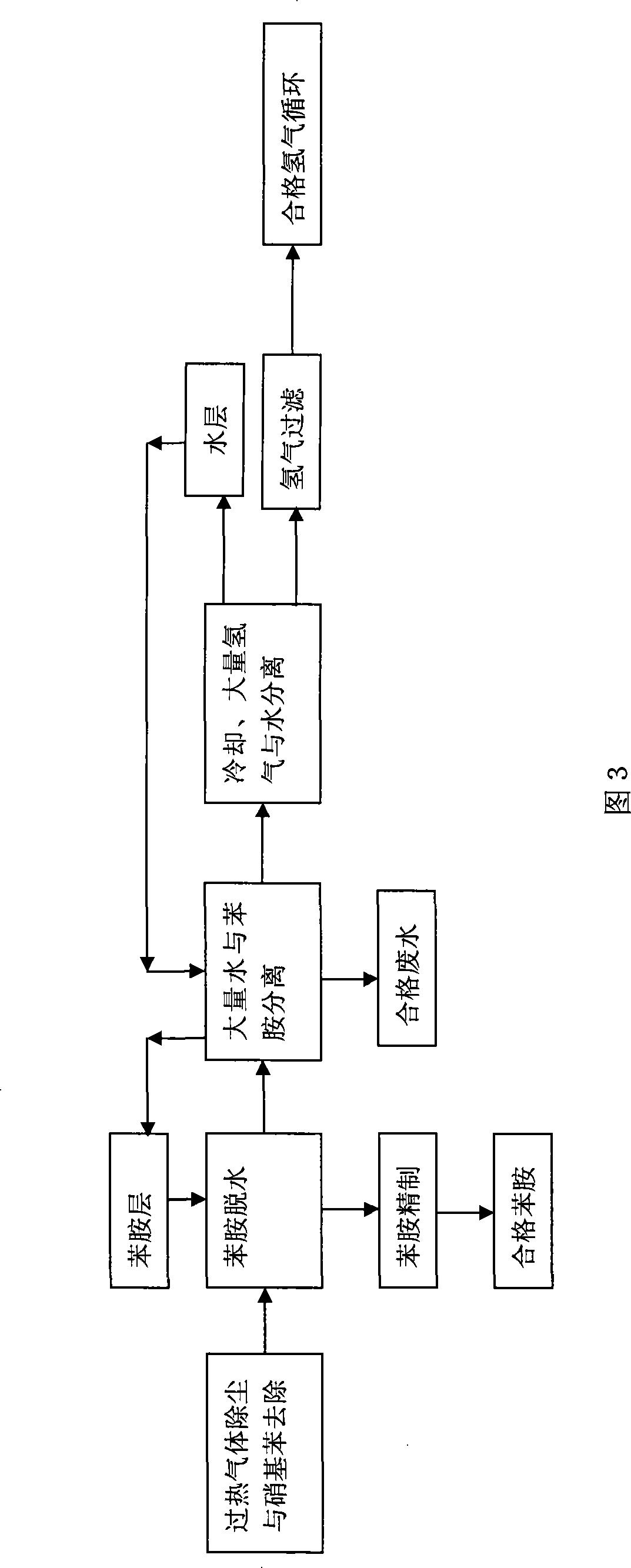

Aniline post processing system and method

InactiveCN101239916AWon't clogExtension of timeAmino compound purification/separationOrganic compound preparationHydrogenProcess integration

Disclosed is a post-processing system and method of aniline, which relates to a device and method for processing catalyst powder after fluidized bed for hydrogenation preparing aniline from nitrobenzene, and reducing nitrobenzene content in aniline. In the invention, over-hot gas containing catalyst powder is directly fed into a device provided with an inclined barrier and a valve tray structure. Rising of catalyst powder is prevented by the inclined barrier, the valve tray structure and liquid spraying, the sparaying liquid at the bottome is discharged timely. The invention also proposes three methods for processing the gas induced from the device to respectively obtain eligible aniline (wherein nitrobenzene content is less than 0.5 mg / kg), eligible wastewater (wherein aniline content is less than 50 mg / kg) and eligible hydrogen (aniline is less than 0.1% and used for circulation). The device of the invention can effectively solve the default that, the catalyst powder is deposited in the cooled liquid thereby jamming a heat changer and increasing the process resistance), and realize long-period continuous operation.

Owner:TSINGHUA UNIV

Method for producing propylene

ActiveCN101092326AHigh selectivityImprove stabilityChemical recyclingBulk chemical productionSpace velocityAlkene

This invention relates to a method for producing propylene. The previous methods cannot satisfy high reaction space velocity, high hydrocarbon conversion rate, high propylene selectivity and long catalyst regeneration cycle at the same time. The method in this invention utilizes C4 or higher olefins as the raw materials, and contacts olefin raw materials and MFI zeolite catalyst (SiO2 / Al2O3 mol. ratio lower than 360) to produce propylene-containing effluent. The yield of propylene is 30-50 wt.% of olefin raw materials. The method can be used in industrial production of propylene from C4 or higher olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing industrial ultra-pure water by reverse osmosis postposition softener

InactiveCN101085682ASmall footprintLess investmentGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisOperational costsTreated water

The invention relates to a process of preparing industrial ultra-pure water with softening apparatus rear- mounted hyperfiltration apparatus. It comprises processes of hyper- filteration and softening pre- treated water, and preparation of high- purity water in continuous electric deion and desalt apparatus. The invention is characterized by reduced softening apparatus size, small occupation area, low investment, long regenerative period for softening apparatus, low energy consumption, small operational cost, simple operation and convenient maintenance.

Owner:上海三邦水处理技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com