Method for advanced treatment and reuse of printing and dyeing wastewater pre-processed by macroporous resin

A macroporous resin, printing and dyeing wastewater technology, applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve problems such as resin blockage, resin work exchange capacity reduction, etc. The effect of saving investment and operating costs, prolonging the service life and regeneration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

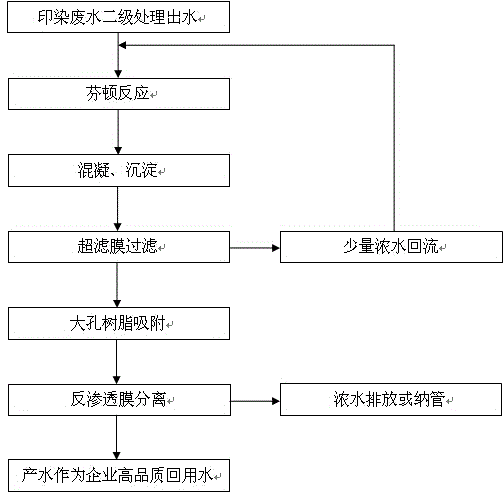

[0027] Such as figure 1 Shown is the flow chart of the present invention,

[0028] A method for advanced treatment and reuse of printing and dyeing wastewater using macroporous resin pretreatment, including the following steps:

[0029] Step 1. Fenton reaction: Take the secondary treatment effluent of printing and dyeing wastewater and add acid to adjust the PH value to 3 to 6, then perform Fenton reaction. After the Fenton reaction is completed, add alkali to adjust the pH to 7 to 8, and then add polyacrylamide. Perform coagulation and precipitation; the solubility of polyacrylamide is 1ppm to 10ppm. The Fenton reaction uses ferrous sulfate and hydrogen peroxide as the Fenton reaction agent, and the time of the Fenton reaction is controlled within 1 to 3 hours.

[0030] The above-mentioned printing and dyeing wastewater secondary treatment effluent refers to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com