Flue gas desulfurization and denitration method

A technology for desulfurization and denitrification, flue gas, applied in the direction of separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of high investment and operation costs, complicated process, large reagent volume, etc., and achieve low investment and operation costs Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

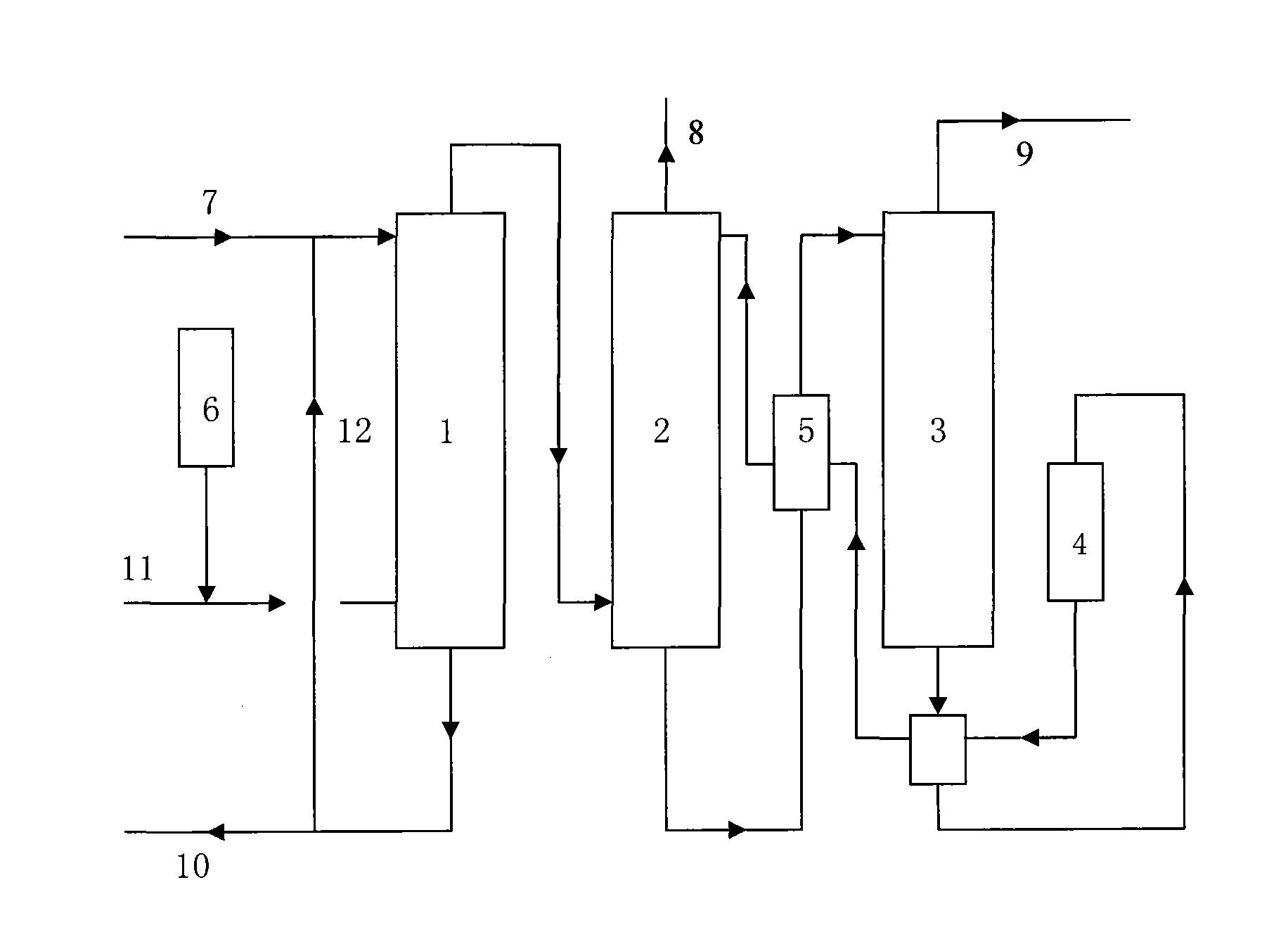

[0025] First, the generated ozone is injected into the catalytic cracking flue gas pipeline at a flue gas temperature of 100-150°C. The ozone fully contacts and reacts with nitrogen oxides in the flue gas, and the flue gas volume is 50m 3 / h, NO, SO 2 The content is 400mg / m 3 , 2000mg / m 3 , according to the flue gas per cubic meter, the ozone content is 1280mg, and the ozone is passed into the flue gas, and the contact time is 3s. The ozone and NO x The molar ratio of the substances is 2:1, the flue gas is in reverse full contact with the 45°C washing acidic water, absorbs the nitrogen oxides that have been oxidized by ozone, and absorbs the remaining while oxidizing, while removing dust and cooling down, and the spray volume in the water washing tower is 120kg / h, the NO content in the flue gas from the washing tower is 72mg / m 3 (Converted into NO), the denitrification rate is 82%. After the preliminary treatment, the flue gas enters the sulfur dioxide absorption tower and...

Embodiment 2

[0027] First, the generated ozone is injected into the catalytic cracking flue gas pipeline at a flue gas temperature of 100-150°C. The ozone fully contacts and reacts with nitrogen oxides in the flue gas, and the flue gas volume is 50m 3 / h, NO x , SO 2 The content is 550mg / m 3 , 2000mg / m 3 , according to the flue gas per cubic meter, the ozone content is 2640mg, and the ozone is passed into the flue gas, and the contact time is 5s. The ozone and NO x The molar ratio of the substances is 3:1. Under the condition of adiabatic saturation, the flue gas is fully in reverse contact with the washing acidic water at 60°C to absorb the nitrogen oxides that have been oxidized by ozone, and the residual is absorbed while being oxidized. The amount of internal spraying is 150kg / h, and the NO content in the flue gas from the washing tower is 77mg / m 3 (Converted into NO), the denitrification rate is 86%. After preliminary treatment, the flue gas enters the sulfur dioxide absorption to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com