Slow-release magnetized composite fertilizer for planting rapeseed and its preparation method

A compound fertilizer and slow-release technology, which is applied in the preparation of organic fertilizers, urea compound fertilizers, organic fertilizers, etc., can solve the problems of farmland soil nutrient destruction, unhealthy groundwater, fertilizer loss environment, etc., and improve the soil micro-aggregate structure , It is conducive to the reproduction of soil biological bacteria and the effect of improving soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

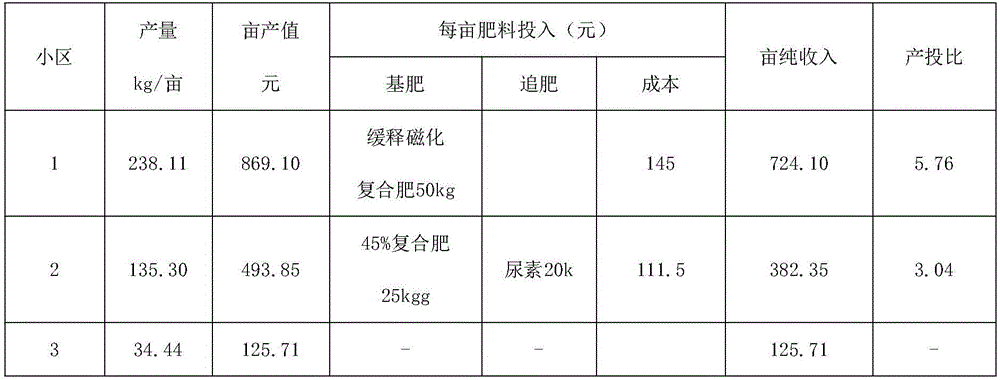

Embodiment 1

[0042] A slow-release magnetized composite fertilizer for rape planting, comprising the following raw materials in parts by weight: 26 kg of urea, 20 kg of potassium dihydrogen phosphate, 4 kg of light calcium carbonate powder, 13 kg of potassium chloride, 2.2 kg of humus fertilizer, and 0.3 kg of selenium-enriched fertilizer kg, magnesium sulfate heptahydrate 0.8kg, starch ether 1.5kg, fertilizer additive 6kg, magnetic carrier 37kg.

[0043] The humic fertilizer is made of the following raw materials in parts by weight: 14kg of pond sludge, 14kg of sewer sludge, 7kg of bean curd, 1.5kg of distiller's grains, and 4kg of talcum powder; There is a mixed gas, the mixed gas is nitrogen, argon, carbon dioxide, and oxygen mixed in a ratio of 1:1:1:2, and then the fermentation is carried out in a closed fermentation tank. The fermentation temperature is 45°C. After 3 days of fermentation, the fermentation tank is opened, and the fermented product is humus fertilizer.

[0044] The st...

Embodiment 2

[0059] A slow-release magnetized compound fertilizer for rape planting, comprising the following raw materials in parts by weight: 24 kg of urea, 18 kg of potassium dihydrogen phosphate, 3 kg of light calcium carbonate powder, 10 kg of potassium chloride, 2 kg of humus fertilizer, and 0.2 kg of selenium-enriched fertilizer , Magnesium sulfate heptahydrate 0.5kg, starch ether 1kg, fertilizer additive 4kg, magnetic carrier 34kg.

[0060] The humic fertilizer is made from the following raw materials in parts by weight: 12kg of pond sludge, 12kg of sewer sludge, 6kg of bean curd, 1kg of distiller's grains, and 3kg of talcum powder; Mixed gas, the mixed gas is nitrogen, argon, carbon dioxide, and oxygen mixed in a ratio of 1:1:1:2, and then fermented in a closed fermentation tank at a fermentation temperature of 45°C. After 3 days of fermentation, the fermentation tank is opened, and the fermented product is putrefaction Fertilizer.

[0061] The starch ether is guar ether.

[006...

Embodiment 3

[0076] A slow-release magnetized compound fertilizer for rape planting, comprising the following raw materials in parts by weight: 28 kg of urea, 22 kg of potassium dihydrogen phosphate, 5 kg of light calcium carbonate powder, 16 kg of potassium chloride, 2.5 kg of humus fertilizer, and 0.5 kg of selenium-enriched fertilizer kg, magnesium sulfate heptahydrate 1kg, starch ether 2kg, fertilizer additive 8kg, magnetic carrier 40kg.

[0077] The humic fertilizer is made from the following raw materials in parts by weight: 16 kg of pond sludge, 16 kg of sewer sludge, 8 kg of bean curd, 2 kg of distiller's grains, and 5 kg of talcum powder; Mixed gas, the mixed gas is nitrogen, argon, carbon dioxide, and oxygen mixed in a ratio of 1:1:1:2, and then fermented in a closed fermentation tank at a fermentation temperature of 45°C. After 3 days of fermentation, the fermentation tank is opened, and the fermented product is putrefaction Fertilizer.

[0078] The starch ether is guar ether. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com