Patents

Literature

1034 results about "Magnesium sulfate heptahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fume desulfurizing and denitrifying device based on magnesia and method

InactiveCN102350197AEfficient recyclingSimple processDispersed particle separationMagnesium nitratesEngineeringSlurry

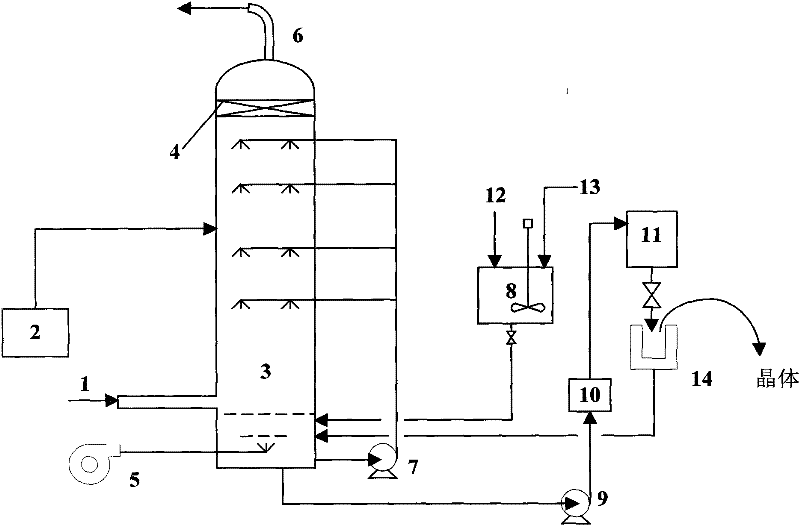

The invention relates to technology for treating fume pollutants and aims at providing a fume desulfurizing and denitrifying device based on magnesia and a method. The fume desulfurizing and denitrifying device based on the magnesia and the method are technically characterized in that SO2 is desorbed at the lower part of a desulfurizing and denitrifying tower by using magnesia slurry, a metal M2+ catalyst is added into circular absorption liquid, and air is also blown into the desulfurizing and denitrifying tower so as to quickly oxidize a desulfurized product of MgSO3 into MgSO4; ozone is introduced into the middle part of the desulfurizing and denitrifying tower so as to oxidize NO in fume into NOx; and the magnesia slurry is sprayed into the upper part of the tower, the NOx is absorbed, and magnesium nitrate is generated. Magnesium sulfate heptahydrate and magnesium nitrate hexahydrate can be respectively obtained by the conventional crystal separation of magnesium sulfate and the magnesium nitrate in the absorption liquid. According to the fume desulfurizing and denitrifying device based on the magnesia and the method, the desulfurizing and denitrifying procedures are finished in one tower by using the magnesia, and the recycle of the by-products of the SO2 and the NO is also realized. The fume desulfurizing and denitrifying device based on the magnesia and the method have simple desulfurizing and denitrifying processes, low investment, low resistance and low running cost. By adopting the fume desulfurizing and denitrifying device based on the magnesia and the method, the desulfurizing rate of more than 96 percent and the denitrifying rate of more than 92 percent can be obtained.

Owner:EAST CHINA UNIV OF SCI & TECH

Soiless culture nutrient solution

InactiveCN103172438AInhibition of reproductionIncrease resistanceFertilizer mixturesCalcium nitrate tetrahydrateManganese

The invention relates to the soiless culture field and in particular relates to a soiless culture nutrient solution; every liter of water comprises the following components by weight: major constituents consisting of 900mg-2200mg of much EM (Effective Microorganisms) probiotics liquid, 900mg-2200mg of brown sugar, 900mg-1000mg of calcium nitrate tetrahydrate, 700mg-900mg of potassium nitrate, 150mg-220mg of ammonium dihydrogen phosphate and 300mg-500mg of magnesium sulfate heptahydrate; micro constituents consisting of 20mg-25mg of EDTA (Ethylene Diamine Tetraacetic Acid) chelated iron, 2mg-3mg of boric acid, 2mg-3mg of manganese sulfate monohydrate, 0.1mg-0.5mg of zinc sulfate heptahydrate, 0.01mg-0.1mg of copper sulfate and 0.01mg-0.08mg of ammonium molybdate tetrahydrate. The soiless culture nutrient solution provided by the invention can be used for improvising the immunity of the soiless culture nutrient solution for resisting plant diseases and insect pests of the crops.

Owner:北京天食和谷农业科技有限公司

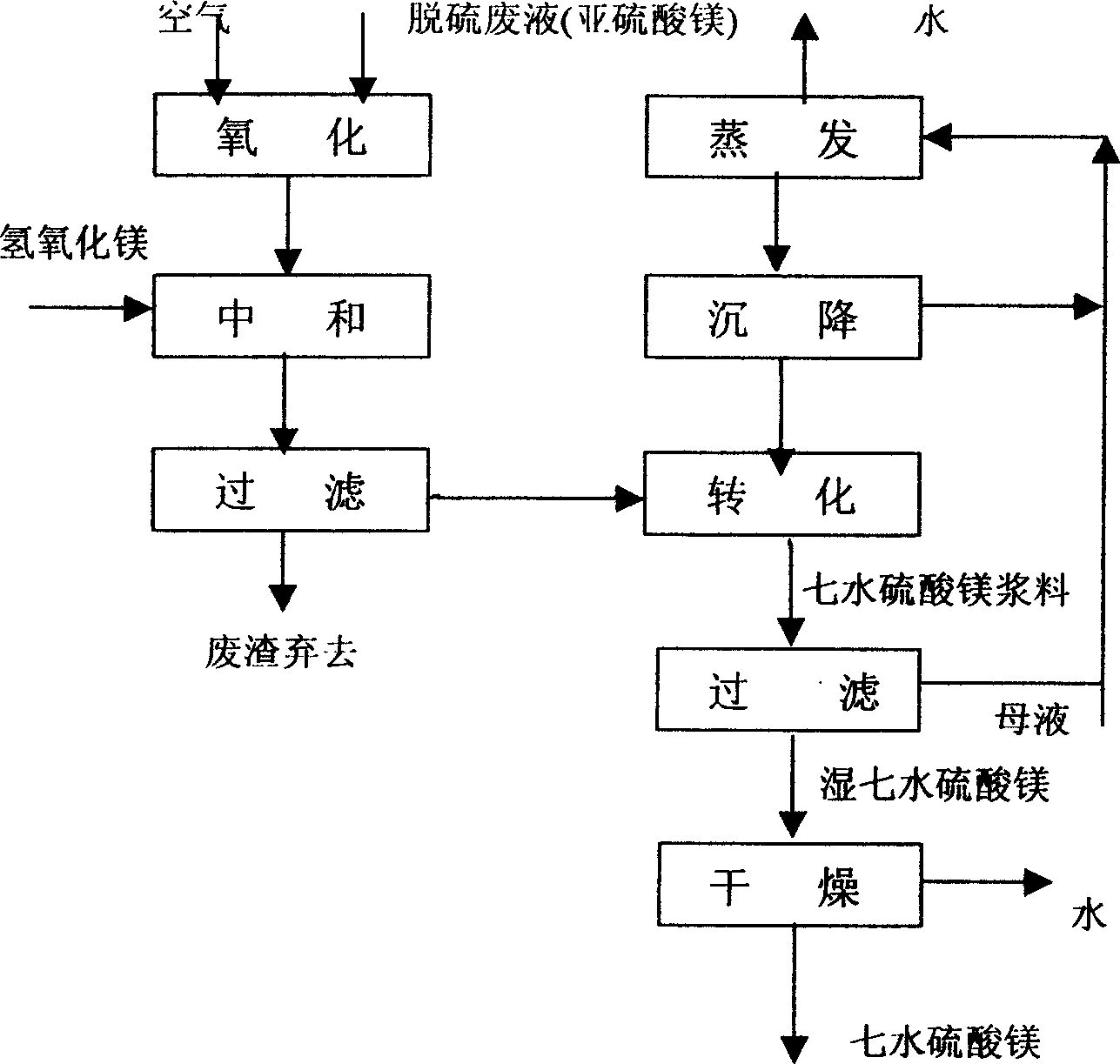

Magnesium sulfate production method using magnesium oxide and desulfurated waste fluid

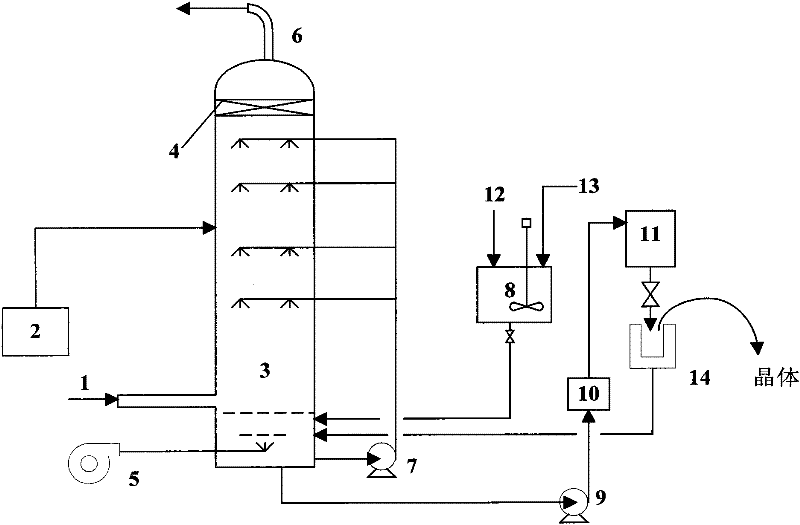

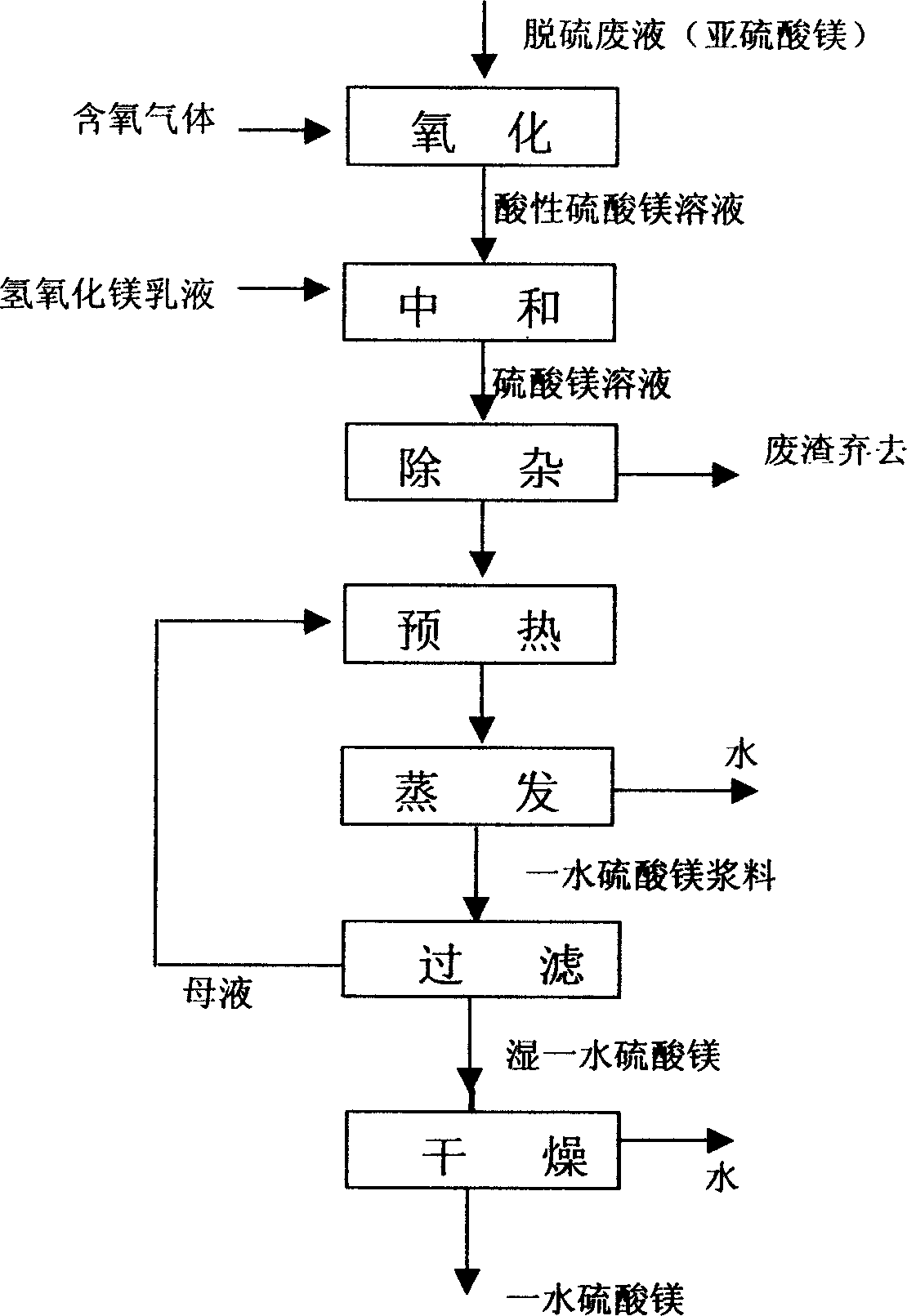

InactiveCN1544331ASolve the problem of discharge into the seaExcellent energy consumptionDispersed particle separationWater/sewage treatmentLiquid wasteSulfur

The invention provides a process for preparing magnesium sulphate by utilizing magnesium oxide desulfurized exhausted liquid comprising the steps of oxidation step, neutralization step, edulcoration step, evaporation concentration, solid-liquid separation step, drying and packing step. By controlling different evaporation temperature, discharging condition and various equipment, kieserite and magnesium sulphate can be prepared respectively.

Owner:天津市昌昊化工股份合作公司

Calcium hypochlorite blended tablets

A non-Division 5.1 Oxidizer tablet consisting essentially of a blend of hydrated calcium hypochlorite with magnesium sulfate heptahydrate, wherein the blend contains at least about 17% by weight of water based on the total weight of the blend; contains from about 0.1% to about 10% of lime based on the total weight of the hydrated calcium hypochlorate and magnesium sulfate heptahydrate and the average dissolving rate of the tablet is less than 150 grams per day.

Owner:INNOVATIVE WATER CARE LLC

Calcium hypochlorite blended tablets

A non-Division 5.1 Oxidizer tablet consisting essentially of a blend of hydrated calcium hypochlorite with magnesium sulfate heptahydrate, wherein the blend contains at least about 17% by weight of water based on the total weight of the blend and the dissolving rate of the tablet is less than 150 grams per day.

Owner:INNOVATIVE WATER CARE LLC

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

Light-weight and high-strength magnesium oxysulfate foamed plate and preparation method thereof

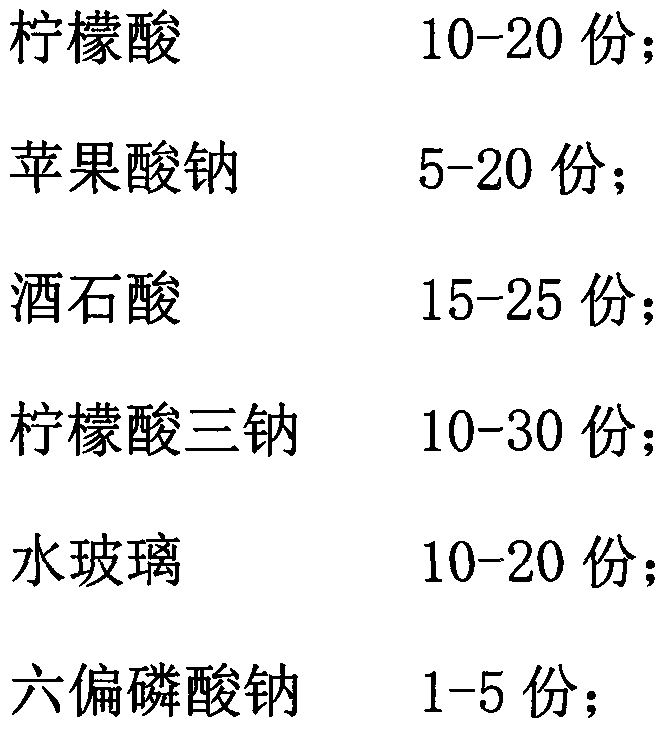

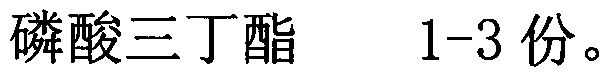

The invention provides a light-weight and high-strength magnesium oxysulfate foamed plate which is obtained with magnesium oxysulfate as a cementing material. The foamed plate is prepared from, by weight, 40-50 parts of light-calcined magnesia, 40-50 parts of a magnesium sulfate heptahydrate solution, 1.5-3 parts of a modifying agent, 5-6 parts of a foaming agent, 1.5-2.5 parts of foam stabilizer, 1-2 parts of a waterproof agent, 0.5-1 part of a water reducing agent and 2-3 parts of polypropylene fibers. The modifying agent is prepared from one or more of citric acid, boric acid, phosphoric acid and sodium citrate. The foaming agent is hydrogen peroxide with the mass concentration being 25-30%. The foam stabilizer is triethanolamine oleate aqueous emulsion with the mass concentration being 8-10%. The absolute dry bulk density of the magnesium sulfate foamed plate is lower than 200 kg / m<3>, the absolute dry comprehensive strength is 0.7 MPa or above, a heat conduction coefficient is lower than 0.045 W / (m.K), the magnesium sulfate foamed plate has the advantages of being light in weight, high in strength, good in hole structure, good in heat-preserving and sound insulating effect, free of active magnesia and good in fire resistance and having no corrosion effect on metal, and the light-weight and high-strength magnesium oxysulfate foamed plate is particularly suitable for serving as a fireproof door and internal wall heat-preserving and heat-insulating material. The invention further provides a preparation method of the magnesium oxysulfate foamed plate.

Owner:广东龙湖科技股份有限公司

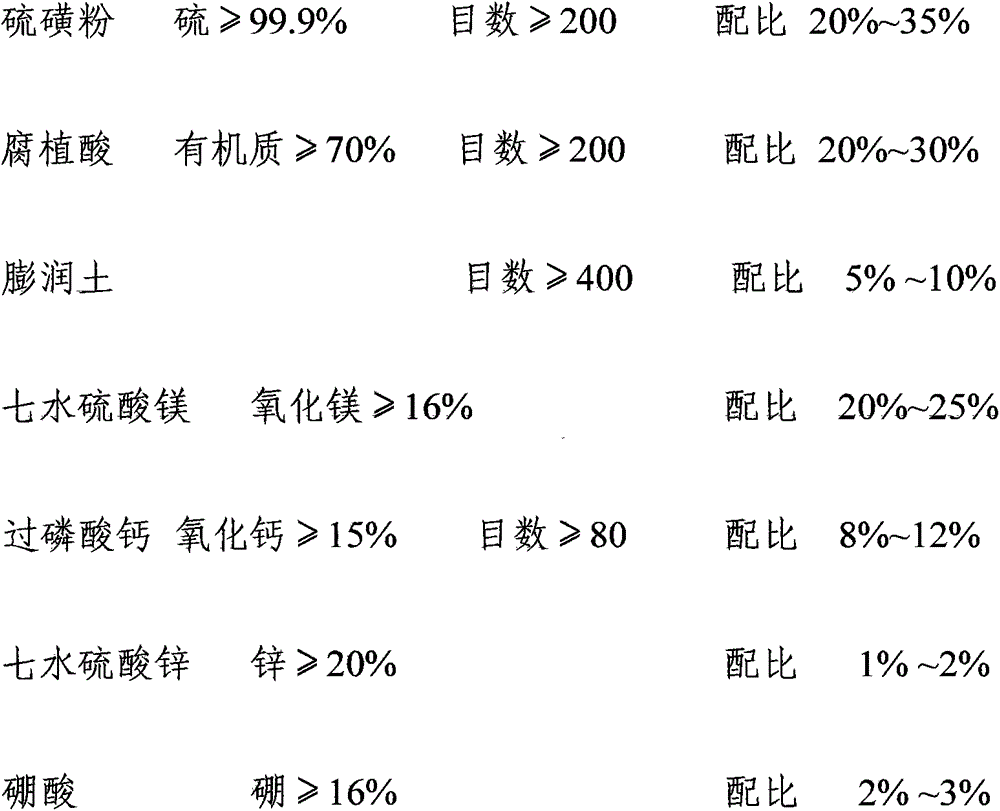

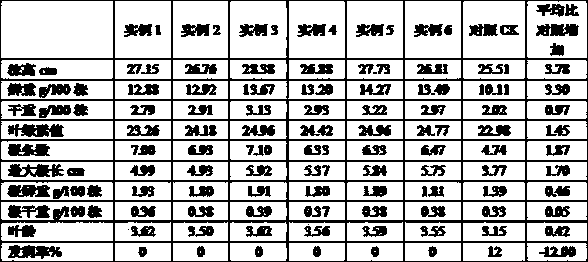

Saline-alkali soil conditioner

InactiveCN104591926AImprove deficiency symptomsEnhance salt-alkali resistanceSuperphosphatesMagnesium fertilisersPlant rootsSodium Bentonite

The invention relates to a composition for improving soil, in particular relates to a saline-alkali soil conditioner. The saline-alkali soil conditioner is prepared by mixing the following components by weight percent: 20%-35% of sulfur powder, 20%-30% of humic acid, 5%-10% of bentonite, 20%-25% of magnesium sulfate heptahydrate, 8%-12% of calcium superphosphate, 1%-2% of zinc sulfate heptahydrate and 2%-3% of boric acid. The saline-alkali soil conditioner can be used for regulating acid-base level of the soil, and effectively supplementing microelements in the soil, improving the nutritional deficiency symptom of crops, chelating harmful heavy metal elements in the soil, reducing saline and alkali degree, promoting the soil to form a granular structure, improving root growth environment of crops, enhancing saline and alkali resistance of crops, disease resistance and cultivation of resilience, reducing the harm of saline and alkali to plant roots, and releasing the effective phosphorous solidified by the soil, increasing soil fertility, holding water and saving fertilizer so as to finally and completely improve the soil, recover the soil fertility, increase both production and income and improve crop quality and utilization rate of the fertilizer.

Owner:SHANDONG JINHUANGYU BLUE SOIL MODIFIED ORGANISMS CO LTD

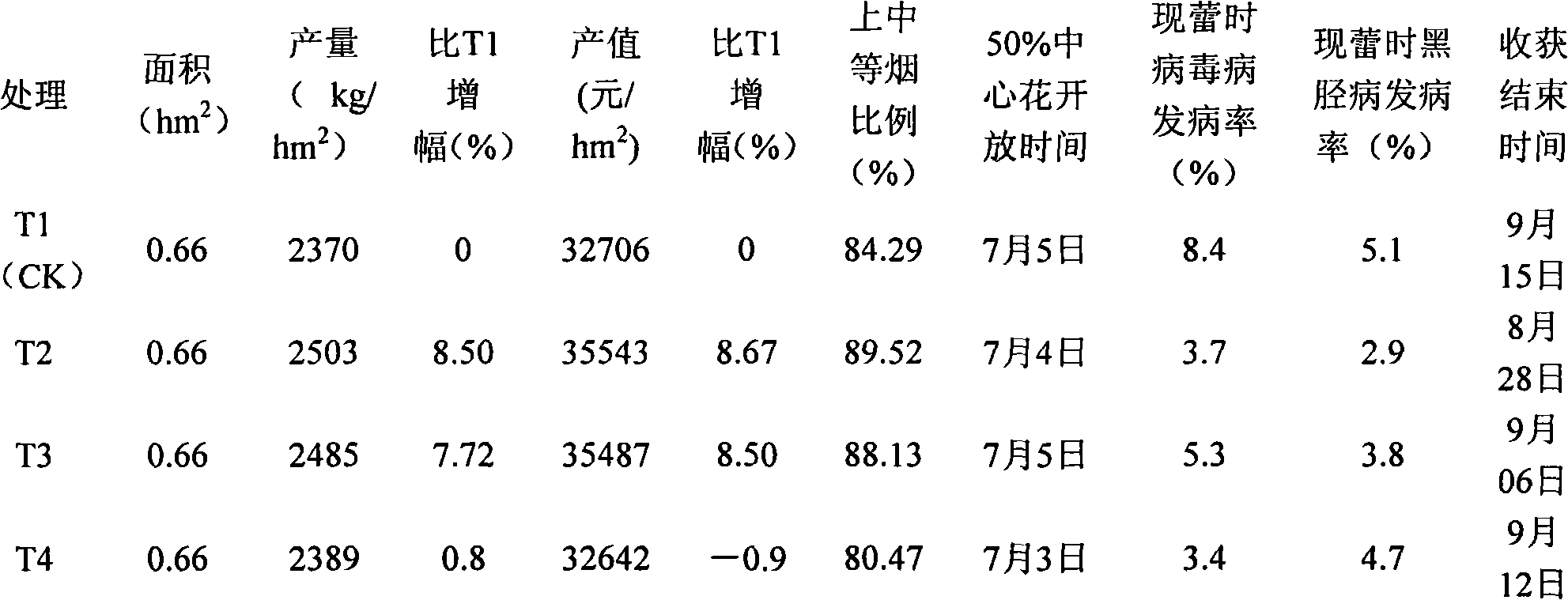

Dedicated fertilizer for tobacco and production method of dedicated fertilizer

InactiveCN103772072AReduce contentReduce accumulationFertilising methodsHorticultureChelated zincNitrohumic acid

The invention discloses a dedicated fertilizer for tobacco, and relates to a fertilizer. The dedicated fertilizer comprises the following raw materials: 100 kg of ammonium sulfate, 31 kg of urea, 200 kg of nitric phosphate, 89 kg of di-ammonium phosphate, 100 kg of calcium superphosphate, 10 kg of calcium magnesium phosphate fertilizer, 230 kg of potassium sulfate, 15 kg of borax, 21 kg of amino acid chelated zinc, manganese, copper, iron and tombarthite, 100 kg of nitrohumic acid, 40 kg of magnesium sulfate heptahydrate, 28 kg of a biological agent, 11 kg of a synergistic agent and 28 kg of a soil conditioner. Compared with the prior art, the dedicated fertilizer has the advantages that tobacco yield can be improved by 36 percent; the agronomic character and quality can be improved; the tobacco growing period can be shortened; the environment can be protected; the plant stress resistance can be improved; the prospects in improving economic benefits of tobacco growers and the like are wide; the smoking health of a human body is guaranteed.

Owner:汪庭府

Leaf vegetable nutrient solution formula

InactiveCN103012004AMeet nutritional needsReduce nitrateFertilizer mixturesCalcium nitrate tetrahydrateNutrient solution

The invention discloses a leaf vegetable nutrient solution formula. The leaf vegetable nutrient solution formula is characterized in that leaf vegetable nutrient solution comprises fertilizers and citric acid; the leaf vegetable nutrient solution comprises the following components: major elements of calcium nitrate tetrahydrate 450-500 mg / L, potassium nitrate 180-250 mg / L, monopotassium phosphate 50-80 mg / L, magnesium sulfate heptahydrate 400-620 mg / L and ammonium nitrate 20-70 mg / L; trace elements of boracic acid 1-5 mg / L, manganous sulfate 1-4 mg / L, zinc sulphate 0.1-1 mg / L, ammonium molybdate 0.005-0.05 mg / L, copper sulphate heptahydrate 0.01-1 mg / L and ethylene diamine tetraacetic acid disodium ferric salt 5-40 mg / L; citric acid 3-20 mg / L; and the balance of water. The leaf vegetable nutrient solution formula disclosed by the invention is reasonable in components, good in stability and wide in range of application.

Owner:湖南壹叶都市农业发展有限公司

Full-nutrient paddy rice seedling breeding matrix and preparation method thereof

The invention discloses a paddy rice seedling breeding matrix, and belongs to the technical field of soilless culture. The full-nutrient paddy rice seedling breeding matrix is prepared from the following raw materials: decomposed organic manure, turf, clay, zeolite powder or bentonite, vermiculite, fine river sand, rice hull powder or corn straw powder or mushroom residue powder, soybean meal, ammonium sulfate, calcium superphosphate, potassium chloride, magnesium sulfate heptahydrate, zinc sulfate heptahydrate, ferrous sulfate heptahydrate, boric acid, copper sulfate pentahydrate, manganese sulfate monohydrate and sodium metasilicate nonahydrate. The full-nutrient paddy rice seedling breeding matrix disclosed by the invention has the advantages of high fertilizer-retaining property and water-retaining property, good air permeability, high buffering, full nutrient and more persistence in fertility, achieves the pH of 5.0-5.5, and is lower in cost by utilizing agricultural wastes, namely rice hulls, corn straws, mushroom residues and the like, suitable for batch production, good in seedling breeding effect and convenient for a farmer to use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

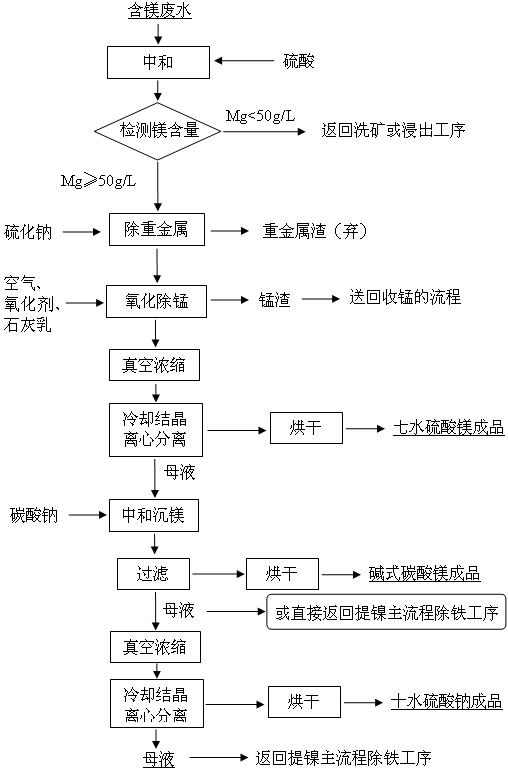

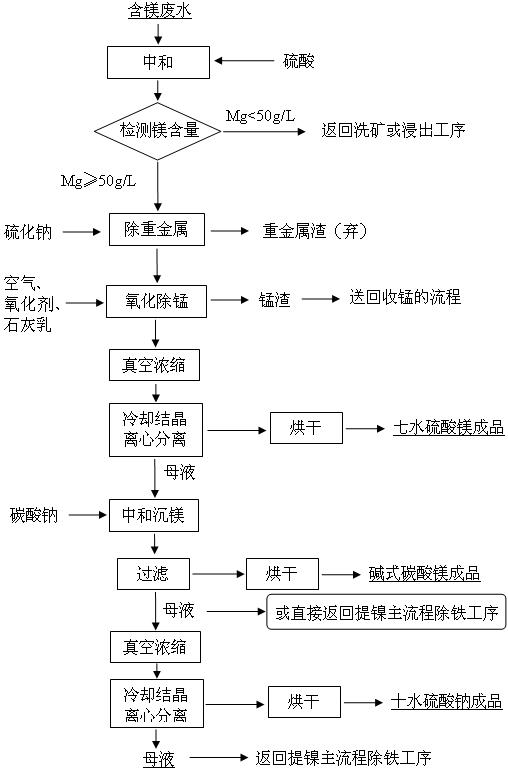

A comprehensive treatment method for laterite nickel ore hydrometallurgy wastewater

ActiveCN102276099ASolve the emission problemReduce manufacturing costMagnesium carbonatesMagnesium sulfatesManganeseEvaporation

The invention discloses a comprehensive treatment method of waste water from laterite-nickel ore wet smelting, which comprises the following steps: adjusting magnesium-containing waste water to be neutral so as to return the waste water to the ore-washing or leaching procedure for a process purpose, increasing the magnesium concentration of the waste water to above 50 g / L, performing heavy metal removal and manganese removal, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying to obtain magnesium sulfate heptahydrate, performing magnesium precipitation of the mother liquor after crystallization by sodium carbonate, separating basic magnesium carbonate, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying of the mother liquor after magnesium precipitation to obtain sodium sulfate decahydrate, or returning the mother liquor after magnesium precipitation directly to the iron-removing procedure of the nickel-extraction flow and to be used as a sodium source for iron removal by a sodium jarosite method. The method of the invention is simple and practical,has low cost, does not generate waste by-products, can both produce salable chemical products and reduce the production cost of the main flow for nickel recovery, and also prevents environment pollution.

Owner:广西银亿新材料有限公司

Accelerant facilitating growth of salt-resistive nitrifying bacteria in high-salt wastewater

InactiveCN104711213ADoes not increase COD contentSolve the problem of difficult growthBacteriaWater contaminantsSodium bicarbonateDipotassium phosphate

The invention discloses an accelerant facilitating the growth of salt-resistive nitrifying bacteria in high-salt wastewater. The accelerant comprises 30-40g sodium chloride, 0.2-0.6g ammonium sulfate, 0.01-0.05g magnesium sulfate heptahydrate, 0.8-1.5g dipotassium phosphate, 0.01-0.05g ferrous sulfate, 7-8.2g calcium chloride, 1-1.7g sodium bicarbonate, 0-0.5g sodium nitrite, 1-5ml vitamin liquid, 1-5ml trace element solution, and 5-10ml bacterium solution per 1000ml water, wherein pH (potential of hydrogen) is 7.8. The accelerant facilitating the growth of the salt-resistive nitrifying bacteria in the high-salt wastewater is free of organic matters such as sugar, contains the inoculated bacterium solution, is suitable for being directly put into the high-salt wastewater for use in an ammonia nitrogen removal technology by a biological method, and allows the high-salt wastewater to be capable of quickly having an environment appropriate for the growth of the salt-resistive nitrifying bacteria. Under the condition that other conditions are the same, after the accelerant is used, a removal rate of ammonia nitrogen can be increased by above 25%, and the accelerant meets requirements on removal of ammonia nitrogen from the high-salt wastewater by a biochemical method.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

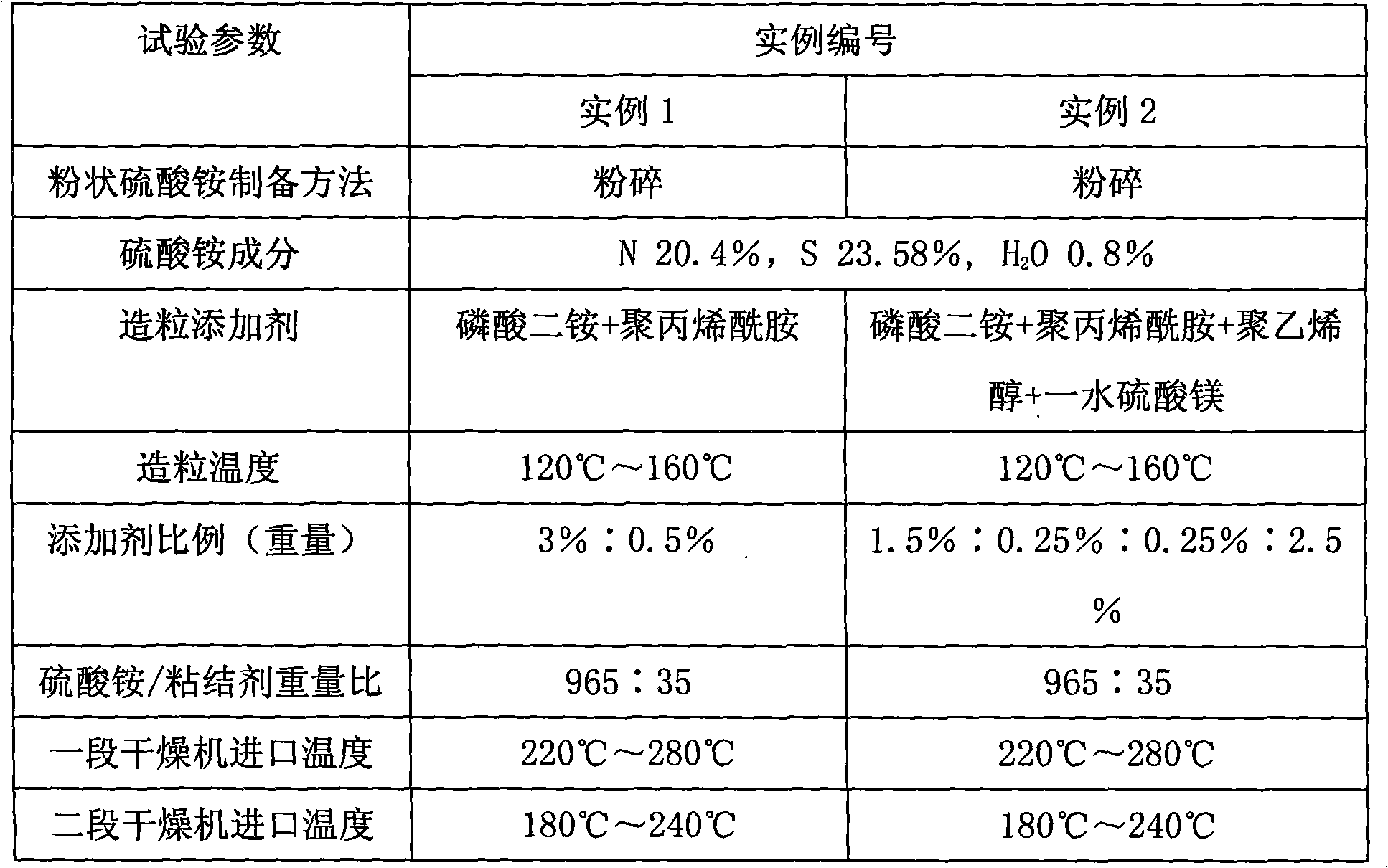

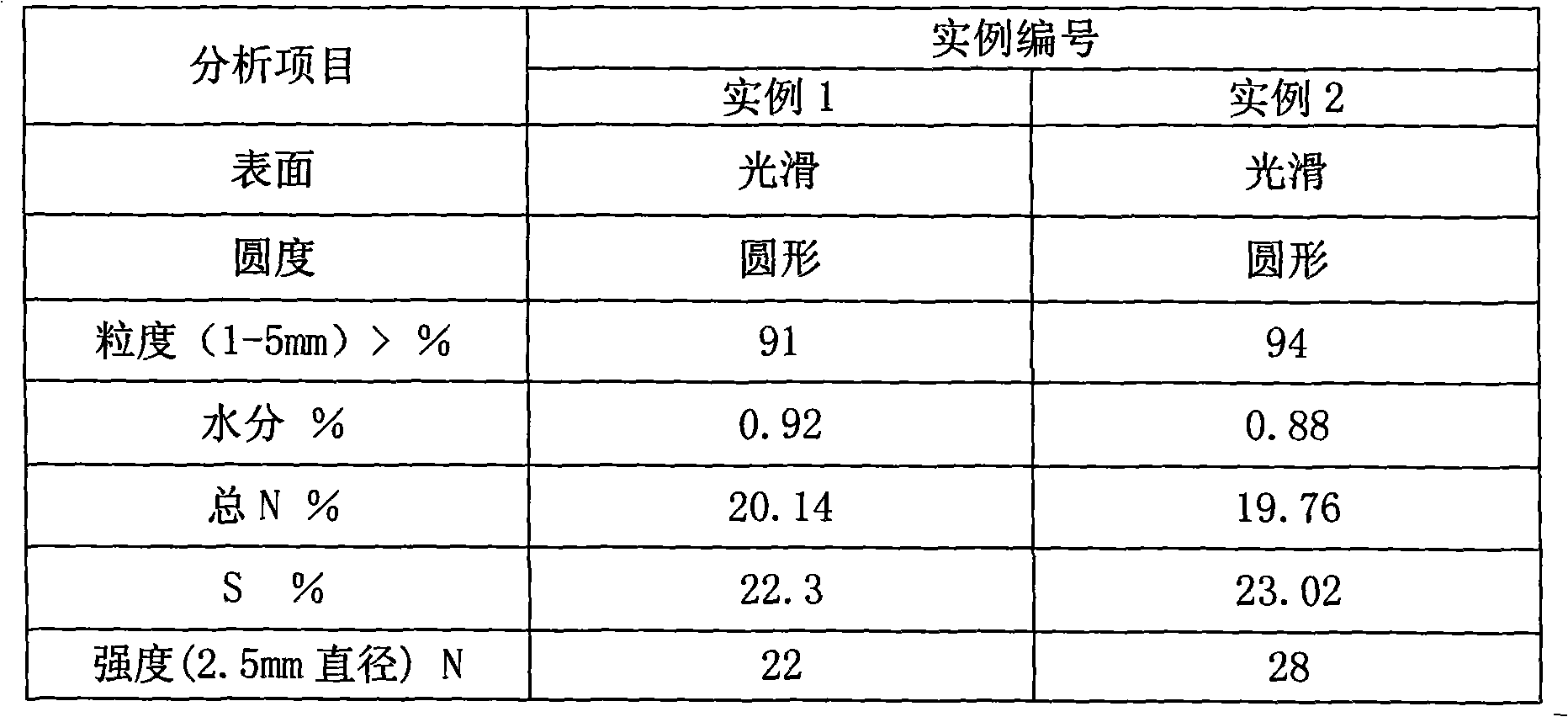

Method for preparing particle ammonium sulfate product by organic-inorganic binder

ActiveCN101570455ASimple production processEasy to operateFertiliser formsAmmonium salt fertilisersPhosphatePolyethylene glycol

A method for preparing particle ammonium sulfate product by organic-inorganic binder, comprises the following steps: (1) polyacrylamide, polyethylene glycol and polyvinyl alcohol are selected to be organic binder; monoammonium phosphate, diammonium phosphate, ammonium bicarbonate, magnesium sulfate monohydrate, magnesium sulfate hetahydrate and heptahydrate zinc sulphate are selected to be inorganic binder; (2) crystal ammonium sulfate is crashed; (3) the one or more organic binder is dissolved, mixed evenly with the one or more inorganic binder in a solution pump and a pelletizer, and is sprayed with steam or water on the surface of ammonium sulfate to carry out pelleting to obtain semi-finished product; (4) the semi-finished product is dried; (5) dried finished product is screened after inspected particles with suitable particle sizes are selected to be the product. The invention has the following advantages: (1) the process is simple, thus facilitates operation; (2) the binder is accessible, and the product has uniform particle sizes with strength being suitable for large scale mechanized operation; (3) the mixture ratio of the binder is free, thus being capable of satisfying large scale mechanized operation. The invention is suitable for popularization in compound fertilizer production.

Owner:WENGFU (GRP) CO LTD

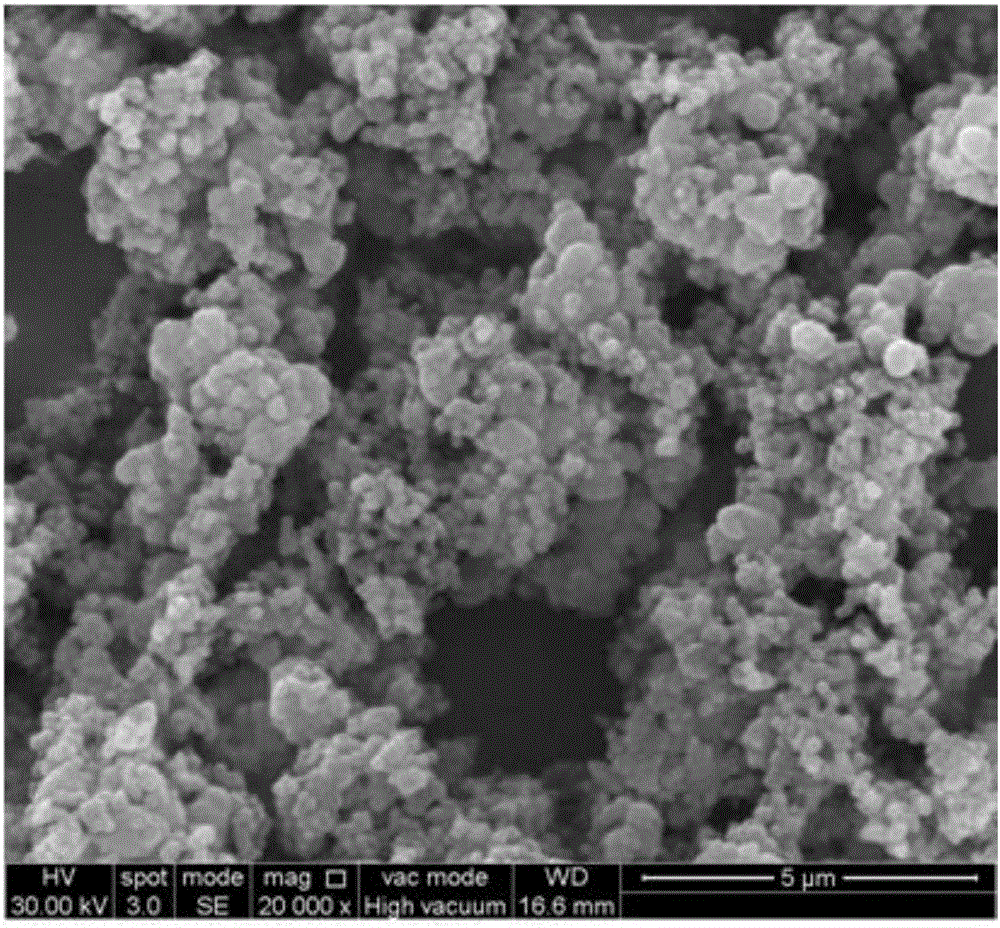

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

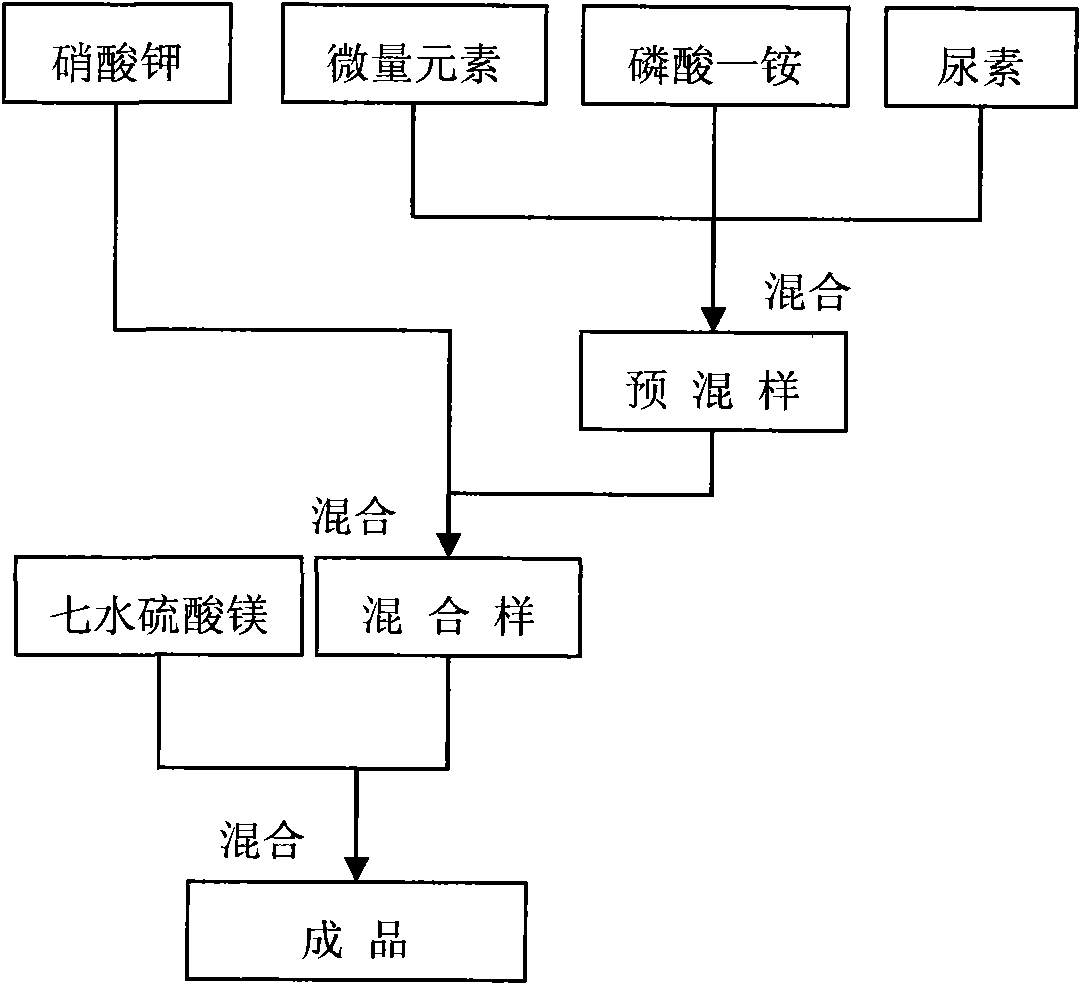

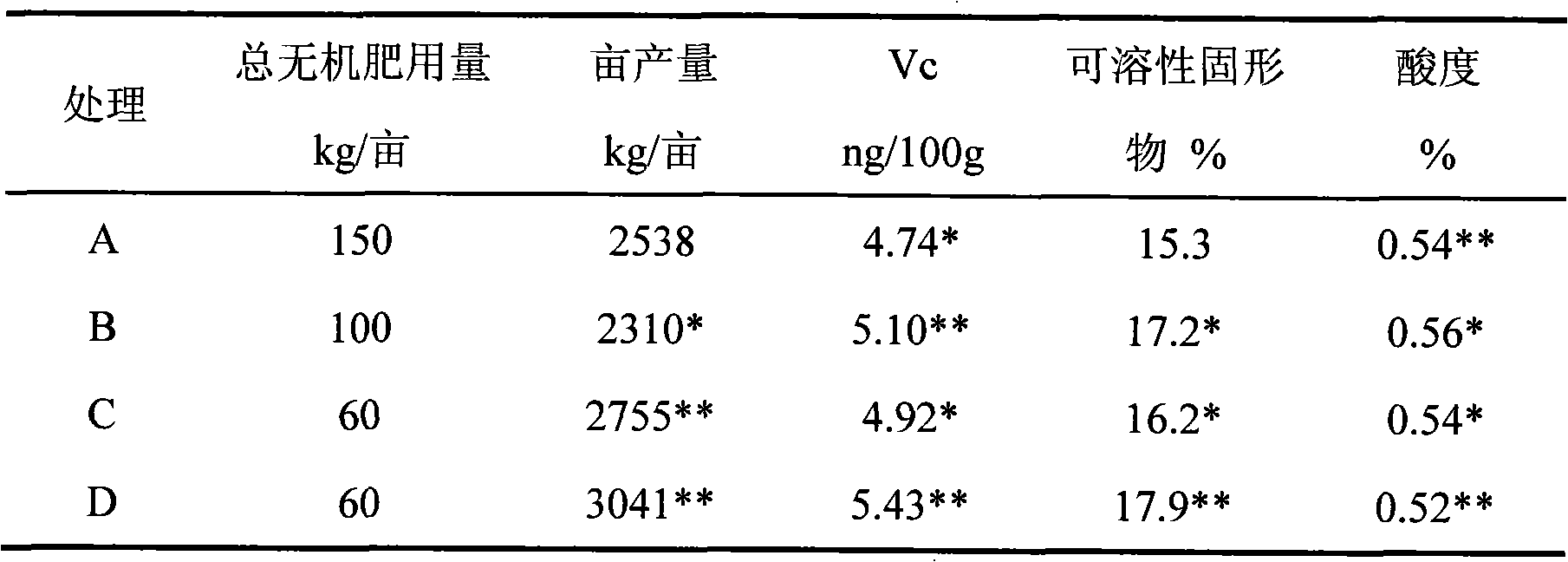

High concentration drip irrigation fertilizer exclusively used in fruit enlargement period of grapes and preparation method thereof

InactiveCN101638335AIncrease productionImprove qualityMagnesium fertilisersAlkali orthophosphate fertiliserHigh concentrationPhosphate

The invention provides high concentration drip irrigation fertilizer exclusively used in the fruit enlargement period of grapes utilized in a drip irrigation system and a preparation method thereof. The main components of the drip irrigation fertilizer exclusively used in the fruit enlargement period of grapes are as follows (according to the parts by weight): 611-723 parts of potassium nitrate, 90-108 parts of monoammonium phosphate, 33-41 parts of urea, 124-256 parts of magnesium sulfate heptahydrate, 0.3-0.6 part of boric acid, 3.6-5.8 parts of EDTA chelated iron, 0.2-0.4 part of EDTA chelated copper, 0.6-1.0 part of chelated manganese, 0.002-0.004 part of sodium molybdate and 1.0-1.6 parts of EDTA chelated zinc. The drip irrigation exclusively used fertilizer has dramatic effects, canobviously improve the yield and quality of grapes, and can save fertilizer and improve efficiency. The drip irrigation exclusively used fertilizer combines the domestic all-pervading trend of the irrigation system and the main national principle of saving fertilizer and improving efficiency and has quite wide market prospect.

Owner:KUNMING UNIV OF SCI & TECH

Water culture nutrient solution of blueberry and preparation method thereof

InactiveCN102101803APromote absorptionReturn to normal growthFertilizer mixturesBiotechnologyCalcium nitrate tetrahydrate

The invention belongs to the technical field of fruit tree culture, in particular to a water culture nutrient solution prescription of a blueberry and a preparation method thereof. In the technology, the water culture nutrient solution of a blueberry comprises the following elements: 95-110mg / L of N, 10-15mg / L of P, 125-135mg / L of K, 80-90mg / L of Ca, 20-28mg / L of Mg, 4-6mg / L of Fe, 0.3-0.6mg / L of B, 0.4-0.6mg / L of Mn, 0.04-0.06mg / L of Zn, 0.02-0.04mg / L of Cu and 0.002-0.004mg / L of Mo. A pH value of the water culture nutrient solution is 4.8 to 5.5. The preparation method of the nutrient solution comprises the following steps of: weighing EDTA (Ethylene Diamine Tetraacetic Acid) ferrisodium, boric acid, manganese sulfate tetrahydrate, zinc sulphate heptahydrate, copper sulfate pentahydrate and ammonium molybdate tetrahydrate for dissolving into water and blending into 100 times of trace element mother liquor for storage and later use; additionally weighing calcium nitrate tetrahydrate, potassium nitrate, monopotassium phosphate and magnesium sulfate heptahydrate for dissolving into water; absorbing the trace element mother liquor into the solution according to the consumption; adding water for quantifying to needed volume; uniformly stirring; and adjusting the pH value of the solution to be 4.8 to 5.5 with 0.1mg / L dilute H2SO4 or dilute NaOH. By utilizing the technology, the water culture aims of growing a plurality of aquatic roots in 20 days after a blueberry seedling is transplanted and having the plant survival rate of more than 90 percent can be achieved.

Owner:JINLING INST OF TECH

Fruit and vegetable water flush fertilizer

InactiveCN104355884AGood colorIncrease profitCalcareous fertilisersMagnesium fertilisersColor effectPhosphate

The invention provides a fruit and vegetable water flush fertilizer. The fruit and vegetable water flush fertilizer is prepared from the following raw materials: carbamide, ammonium sulfate, monoammonium phosphate, potassium chloride, calcium chloride, magnesium sulfate heptahydrate, potassium fulvate, amino acid trace element chelates and a plant growth regulator. The plant growth regulator is prepared from the following raw materials: diethyl aminoethyl hexanoate, compound sodium nitrophenolate, abscisic acid, sodium naphthylacetate, indolebutyric acid, natural brassin lactone and tea saponin. The fruit and vegetable water flush fertilizer can be used for regulating plant growth and improving the fertilizer utilization rate, and has the advantages of improving resistance, resistance to disease and resistance to pests, and accelerating solanaceous vegetables to early mature; the fruits and vegetables are high in coloring effect, resistant to storage and transportation and high in yield.

Owner:安徽沃福农业生物科技股份有限公司

Nutrient solution special or water culture of lettuce and preparing method of nutrient solution

The invention relates to a nutrient solution special for water culture of lettuce and a preparing method of the nutrient solution, and belongs to the technical field of nutrient solutions of water-cultured lettuce. A formula of the nutrient solution special for water culture of the lettuce comprises a major element solution A, a microelement solution B and a chicken manure biogas slurry solution C. The major element solution A comprises the solution A1 and the solution A2, wherein the solution A1 is composed of 236 g / T of calcium nitrate terahydrate, 133.5 g / T of potassium nitrate and 26.5 g / T of ammonium nitrate, and the solution A2 comprises 50 g / T of monopotassium phosphate, 58 g / T of potassium sulphate and 123 g / T of magnesium sulfate heptahydrate. The microelement solution B comprises 10-20 g / T of chelated iron, 1.43 g / T of boric acid, 1.065 g / T of manganese sulfate, 0.11 g / T of zinc sulfate, 0.04 g / T of copper sulfate and 0.01 g / T of ammonium molybdate. The chicken manure biogas slurry solution C is composed of 2, 000 ml of a concentrated solution of a high-concentration chicken manure fermentation solution. The concentrated solution of the high-concentration chicken manure fermentation solution is added, the using amount of nutrient elements is reduced by 30-50%, and environment friendliness is achieved. The quality of the water-cultured lettuce is improved, static cultivation is achieved, and the lettuce becomes mature earlier by around 7 days.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

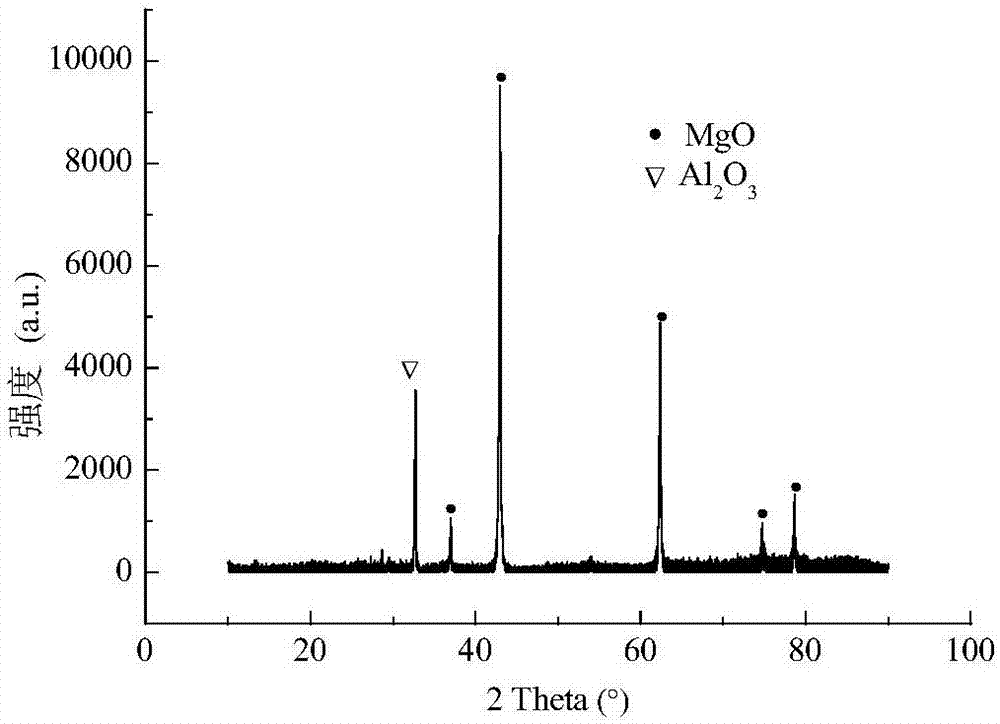

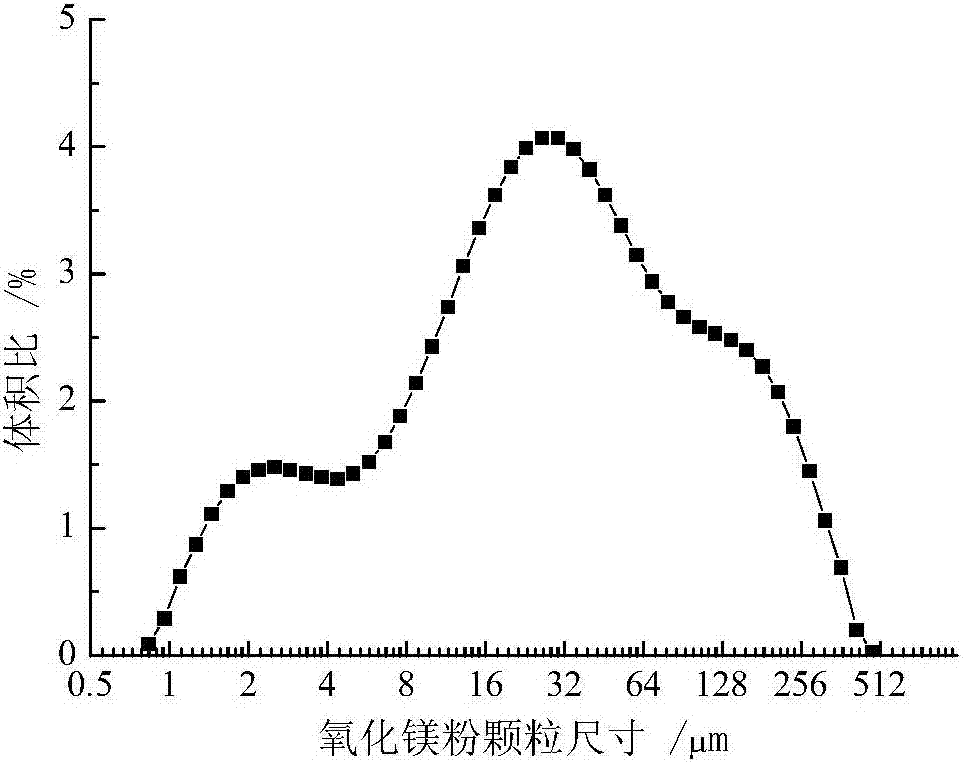

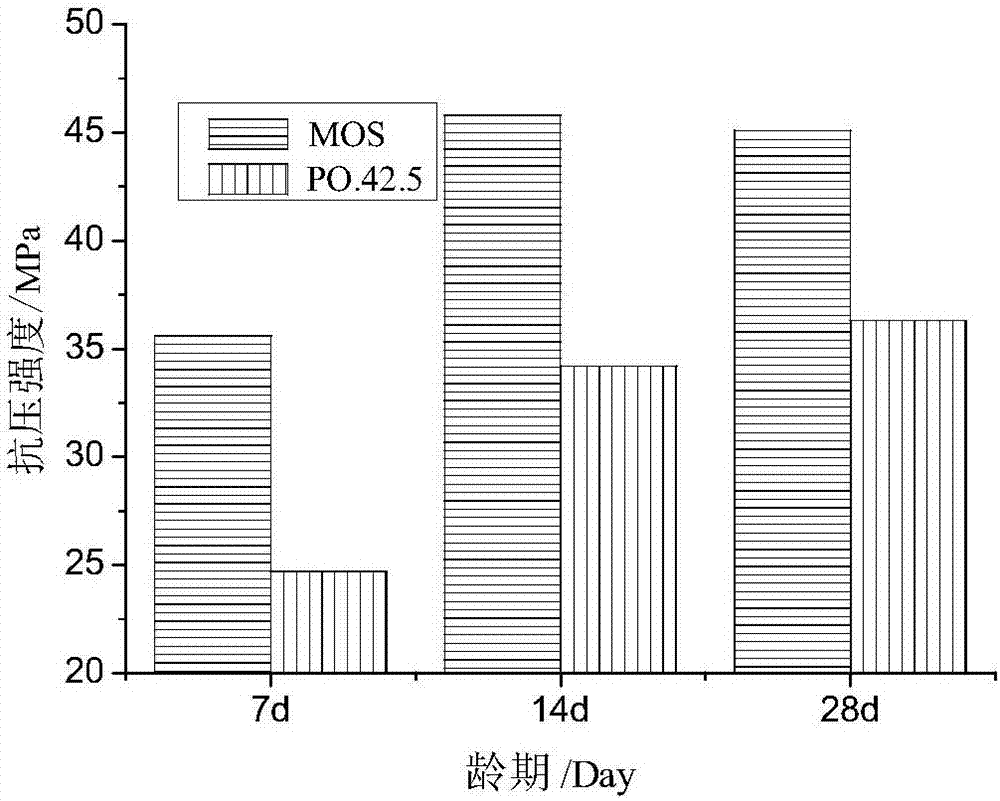

Magnesium oxysulfate-based inorganic composite gelling material with high flexural strength

ActiveCN106882933AImprove mechanical propertiesGood mechanical propertiesPortland cementFlexural strength

The invention discloses a magnesium oxysulfate-based inorganic composite gelling material with high flexural strength. The magnesium oxysulfate-based inorganic composite gelling material is prepared from the following components in parts by weight: 334 to 352 parts of light-calcined magnesium oxide powder, 146 to 154 parts of magnesium sulfate heptahydrate, 1.48 to 2.23 parts of citric acid and 19 to 37 parts of silicon ash. The magnesium oxysulfate-based inorganic composite gelling material has the advantages that by adding the citric acid, the modifying function is realized; by adding the silicon ash, the flexural strength and compressive strength are improved; in each age period, the mechanical property is excellent, and the flexural strength in the 28-day age period is 22 to 23MPa; compared with common portland cement P.0425 with the same water-cement ratio, the flexural strength is increased by 238%; the corresponding softening coefficient of a prepared standard gelling mortar specimen is about 0.85, so that the water-resistant property is higher; the magnesium oxysulfate-based inorganic composite gelling material is completely suitable for important structures soaked in water or in damp environments.

Owner:NINGBO UNIV

Compound irrigation fertilizer for solanaceous vegetables and applying method thereof

InactiveCN102180733AMeeting nutritional needsIncrease vitalityFertilising methodsHorticulturePhosphateChelated zinc

The invention discloses a compound irrigation fertilizer for solanaceous vegetables and an applying method thereof. The fertilizer is prepared from the following raw material components in percentage by weight: 30-38 percent of urea, 0-10 percent of monopotassium phosphate, 0-13 percent of potassium nitrate, 10-15 percent of potassium humate, 0-10 percent of magnesium sulfate heptahydrate, 20-40 percent of potassium sulfate, 0-15 percent of monoammonium phosphate, 0.1-0.2 percent of compound sodium nitrophenolate, 0.1-0.3 percent of boric acid, 0.05-0.15 percent of sodium naphthalene acetate and 0.5-2 percent of amino acid chelated zinc, manganese, copper and iron. The fertilizer can fully supply nutrients so as to meet the nutrition requirement on the solanaceous vegetables, and contains humic acid, amino acid, macro elements, medium elements, trace elements and the like. The irrigation fertilizer contains sodium naphthalene acetate serving as a rooting agent and compound sodium nitrophenolate serving as a synergistic agent, so that the root activity can be facilitated, soil is improved, fertilizer absorption is enhanced, and a quick and long fertilizer effect is achieved. High-quality raw materials without irritant odor are selected carefully, precipitates and irritant odor are not produced when the fertilizer is applied along with water, absorption is facilitated, and the utilization ratio of the fertilizer is increased. Prematurity and precocity fruiting of the solanaceous vegetables can be facilitated, reproductive differentiation is accelerated, the commodity value of the solanaceous vegetables is increased, and the yield of the solanaceous vegetables can be increased by 35-35 percent.

Owner:SHENYANG AGRI UNIV

Leaf fertilizer special for tobacco

The invention discloses a leaf fertilizer special for tobacco, which comprises monopotassium phosphate, magnesium sulfate heptahydrate, zinc sulfate, borax, ammonium molybdate, L-malic acid, glutamic acid, brassinolide and solvent water. Inorganic and organic nutrient substances are provided for the growth of tobacco to meet the basic growth requirement of tobacco; for example, magnesium, boron and zinc are medium trace nutrient elements deficient at the tobacco zone in Hubei; the glutamic acid and the malic acid can be directly involved in certain important metabolic activities during the growth of tobacco, in particular tricarboxylic acid cycle, and promote the growth of tobacco in the later stage to timely switch from nitrogen metabolism into carbon metabolism, so as to improve maturity and quality; and the plant growth modifier, brassinolide, can induce to strengthen the immunity of tobacco and improve the virus and fungal disease resisting capability of tobacco.

Owner:XIANGYANG COMPANY OF HUBEI TOBACCO

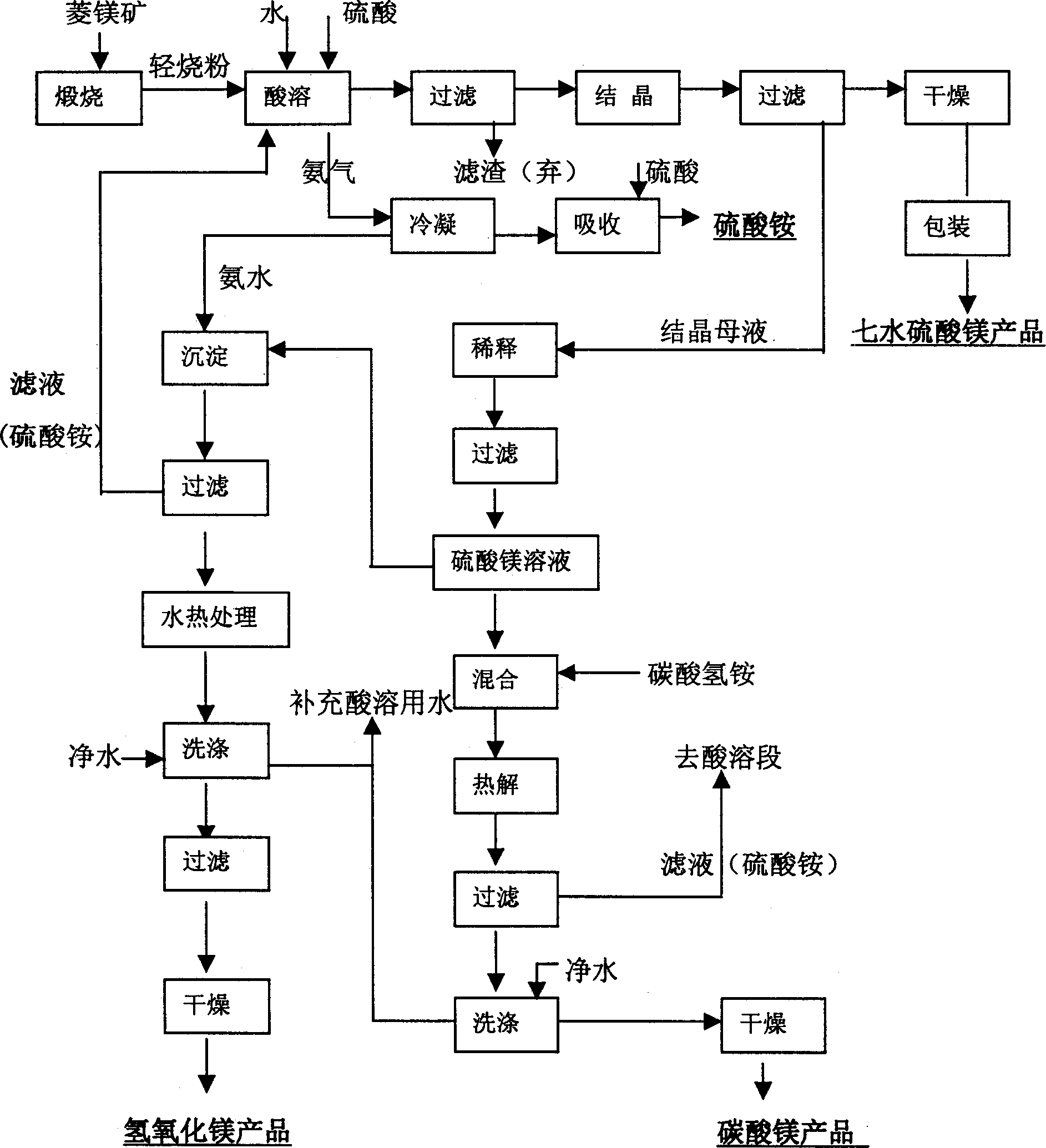

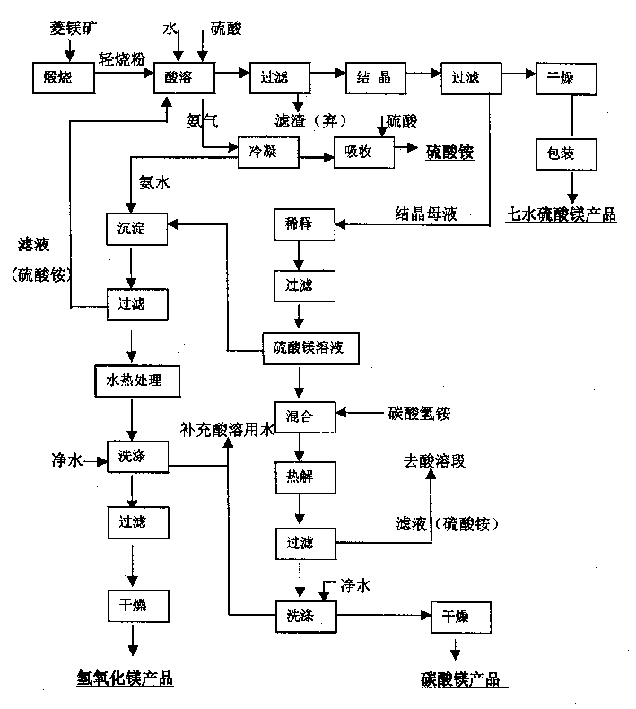

Method for integrated production of magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite

InactiveCN1401573AImprove protectionReduce manufacturing costMagnesium carbonatesMagnesium sulfatesAmmonium Hydrogen CarbonateCarbonate

A process for preparing magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite includes reaction of light-burned magnesium oxide powder obtained by calcining magnesite, the solution of ammonium sulfate as the by-product obtained by reaction with magnesium carbonate and magnesium hydroxide precipitate and industrial concentrated sulfuric acid, evaporating ammonia gas, dissolving in water, depositing to obtain magnesium hydroxide, controlling acidity and temp. filtering to remove impurities, cooling crystallizing to obtain magnesium sulfate heptahydrate, diluting the mother liquid, preparing alkaline magnetic carbonate by ammonium hydrogen carbonate method, and sulfuric acid absorption to residual ammonia water to obtain ammonium sulfate as by-product. Its advantage is no generation of gas and liquid pollutants.

Owner:TSINGHUA UNIV

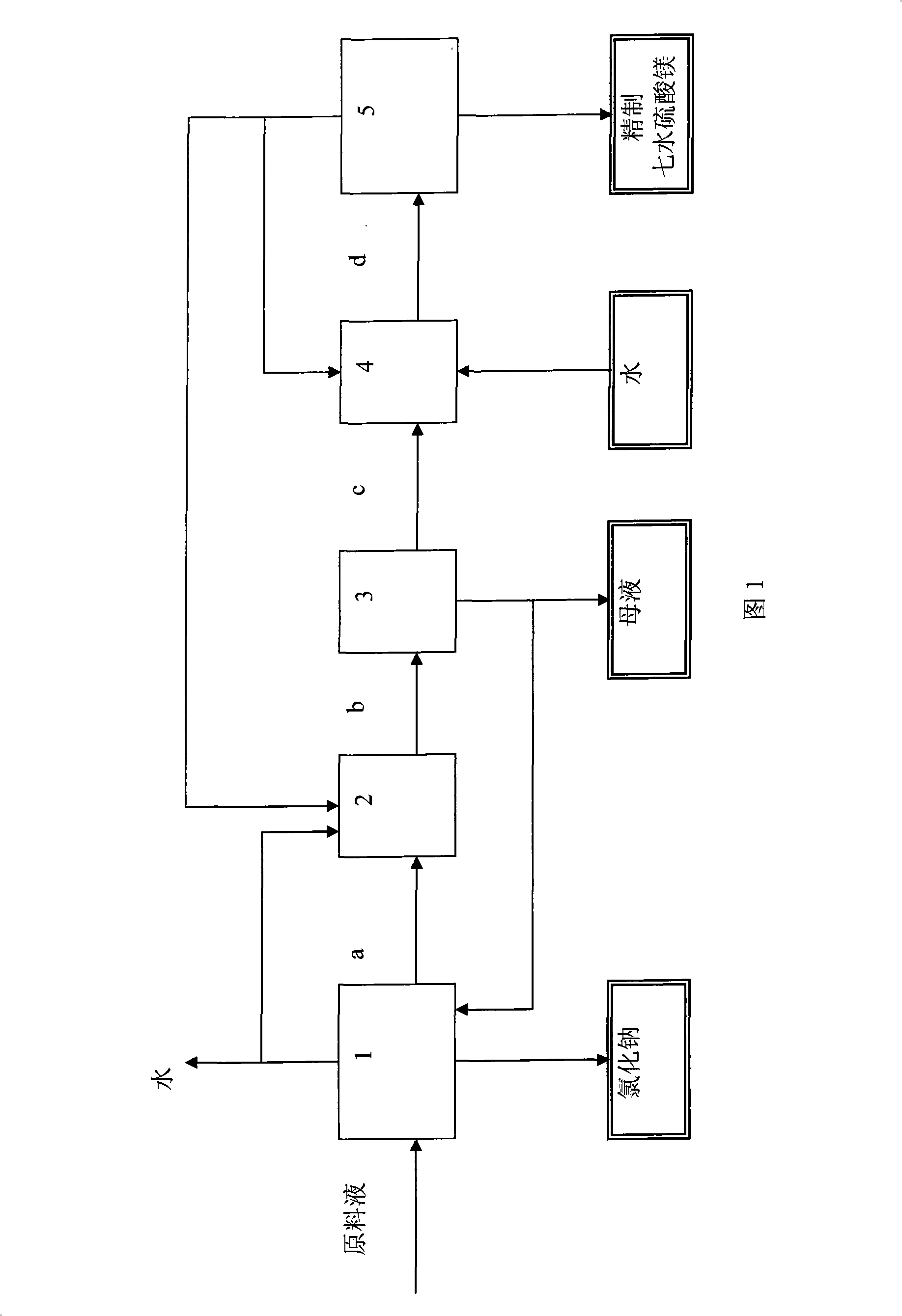

Method for preparing sodium chloride and magnesium sulphate heptahydrate with brine

InactiveCN101343071ASufficient precipitationHigh purityMagnesium sulfatesAlkali metal chloridesBoiling pointAqueous solution

The invention discloses a method for using brine to produce sodium chloride and heptahydrate magnesium sulfate, comprising the steps that: (1) brine is taken as a raw material, the molar ratio of SO4<2->:Mg<2+> in the brine is 0.1-0.8, and the molar ratio of SO4<2->:Na<+> is 0.025-1; and the pressure is decreased for boiling evaporation, the pressure is controlled to make the boiling temperature be 75 DEG C to 50 DEG C after the evaporation, and the molar ratio of SO4<2>:Na<+> in the solution is 0.4-2.5; (2) solid-liquid separation is implemented, and the solid phase is washed with saturated sodium chloride aqueous solution and is then dried for obtaining the sodium chloride; (3) a mother liquid of salt production is added with water to prepare a mixture; (4) the mixture is cooled and guided into a crystallizer, then crystals are separated out; and (5) solid-liquid separation is carried out for obtaining a crude product having a solid phase of heptahydrate magnesium sulfate. The method has advantages of simple equipment, simple process, complete separation of sodium chloride, high purity and yield of heptahydrate magnesium sulfate, having no miscellaneous salt removing link in the process, and realizable joint production of sodium chloride and heptahydrate magnesium sulfate.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

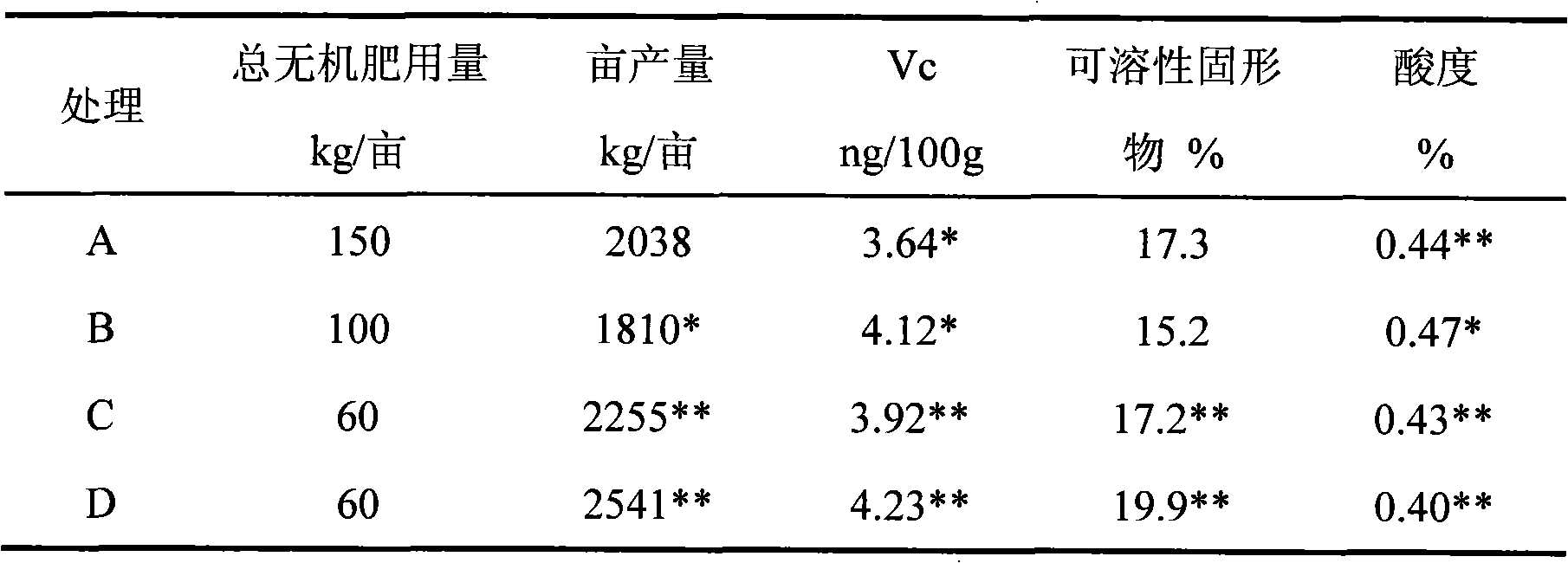

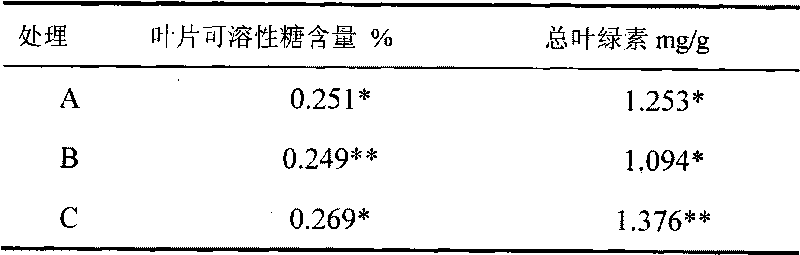

High concentration drip irrigation special fertilizer for vegetative growth phase of grapes

InactiveCN101696131AGood for healthReduce healthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGrowth phaseHigh concentration

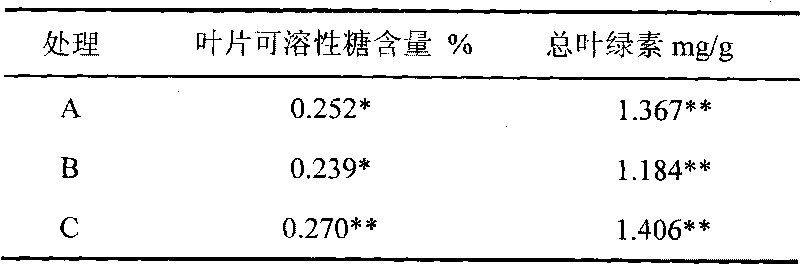

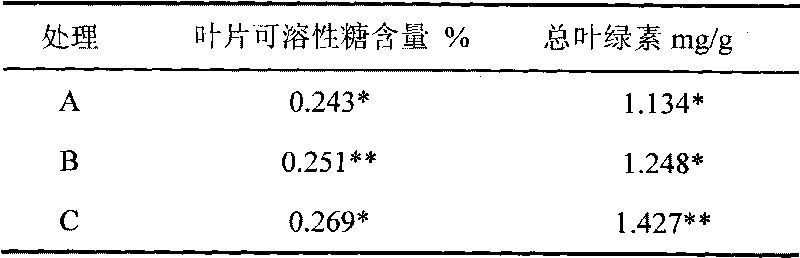

The invention provides a high concentration drip irrigation special fertilizer for the vegetative growth phase of grapes. The fertilizer comprises the following main components in part by weight: 244 to 267 parts of potassium nitrate, 181 to 198 parts of monoammonium phosphate, 357 to 390 parts of urea, 139 to 209 parts of magnesium sulfate heptahydrate, 0.3 to 0.6 part of boric acid, 3.6 to 5.8 parts of EDTA chelated iron, 0.2 to 0.4 part of EDTA chelated copper, 0.6 to 1.0 part of EDTA chelated manganese, 0.002 to 0.004 part of sodium molybdate, and 1.0 to 1.6 parts of EDTA chelated zinc. The special fertilizer is especially designed for a drip irrigation system, and is suitable for the requirement on each element at the vegetative growth phase of the grapes. The special fertilizer can obviously improve the photosynthesis of plants and the nutrient substance accumulation amount of leaves, establishes a firm substance foundation for quick inflation of fruits and fruit growth in later period, and has the effect better than that with only the application of a base fertilizer or only the application of a straight fertilizer so as to achieve the aims of reducing fertilizer and improving effect. Currently, the country widely popularizes drip irrigation technology and fertilizer reducing and effect improving technology, and the fertilizer plays a role in reducing fertilizer and improving effect in a grape drip irrigation system and has a wide market prospect.

Owner:KUNMING UNIV OF SCI & TECH

Special organic fertilizer for grapes

InactiveCN102617220AIncrease the number of knotsImprove air conditionFertilizer mixturesPhosphateMonopotassium phosphate

The invention discloses a special organic fertilizer for grapes. Organic fertilizer extract liquid is used as base liquid, and potassium sulphate, potassium dihydrogen phosphate, urea, superphosphate, magnesium sulfate heptahydrate, zinc sulfate heptahydrate, sodium borate and the like are added in the organic fertilizer extract liquid. The special organic fertilizer for grapes consists of elements including, by weight percentage, from 22.0 to 24.0% of nitrogen, from 11.0 to 12.0% of phosphorus, from 11.0 to 12.0% of potassium, from 0.6 to 1.2% of calcium, from 0.7 to 1.4% of magnesium, from 1.8 to 2.8% of sulphur, from 0.08 to 0.1% of zinc and from 0.18 to 0.2% of boron. The utilization rate of the fertilizer can be increased, the zinc in the fertilizer can increase the number of grapes in each grape bunch, the boron can improve shriveling of the grapes, the number of shriveled grapes is reduced, similar maturity of the grapes can be prompted, growth of the grapes is promoted, yield of the grapes is increased, and quality of the grapes is improved.

Owner:江苏田娘农业科技有限公司

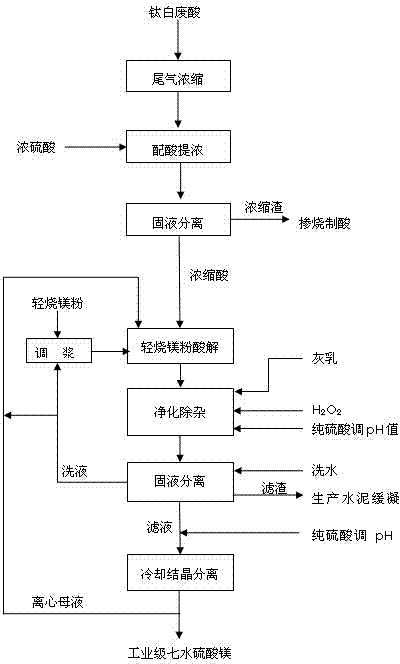

Method for producing industrial-grade magnesium sulfate by using titanium white waste acid

ActiveCN104118893AReduce processing difficultyInhibitory concentrationMagnesium sulfatesFerrous sulfate ironSulfate

The invention relates to a method for producing industrial-grade magnesium sulfate by using titanium white waste acid. According to the method, the titanium white waste acid is purified by using a manner of preparing acid and concentrating, so that the influence of salts such as ferrous sulfate in the titanium white waste acid on preparation of industrial-grade magnesium sulfate heptahydrate is reduced; purified and concentrated acid reacts with caustic-burned magnesia powder; the purification treatment is carried out by adjusting pH value by using acetylene sludge or lime milk; impurities in the magnesium sulfate can be effectively removed by using a manner of oxidizing by using hydrogen peroxide and re-adjusting the pH value by using pure sulfuric acid under alkaline conditions; the titanium white waste acid is used for preparing acid and concentrating so as to react with the caustic-burned magnesia powder, so that the concentration process for preparing magnesium sulfate by using titanium white waste acid is cancelled, the application range of the titanium white waste acid is expanded; and the method for producing industrial-grade magnesium sulfate by using titanium white waste acid is simple in production process, small in investment, low in cost, high in yield and high in product purity. The overall process is free of waste and byproduct, remarkable in social benefit and great in economic benefit.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Fertilizer

InactiveCN103420738AImprove utilization efficiencyImprove water retentionFertilizer mixturesManganeseField tests

The invention relates to a fertilizer, which comprises the following components by weight: 15-25% of carbon, phosphorus and potassium, 3-6% of humic acid, 0.5-2% of amino acid, 1-4% of boron, 1-4% of iron, 0.5-2% of manganese, 1-5% of a water-retaining agent, 1-4% of zinc and 60-70% of magnesium sulfate heptahydrate; and the carbon, phosphorus, potassium humic acid, amino acid, boron, iron, manganese, water-retaining agent, zinc and magnesium sulfate heptahydrate are all powdery and mixed. The product provided by the invention not only can increase utilization efficiency of water and fertilizer but also can increase the output of crops; in field tests widely carried out in several regions of the world, the fertilizer reduces irrigation amount and increases output; and a large amount of practice proves that the fertilizer has the most substantial effect and generates the most impressive incomes when applied to economic crops.

Owner:王勇

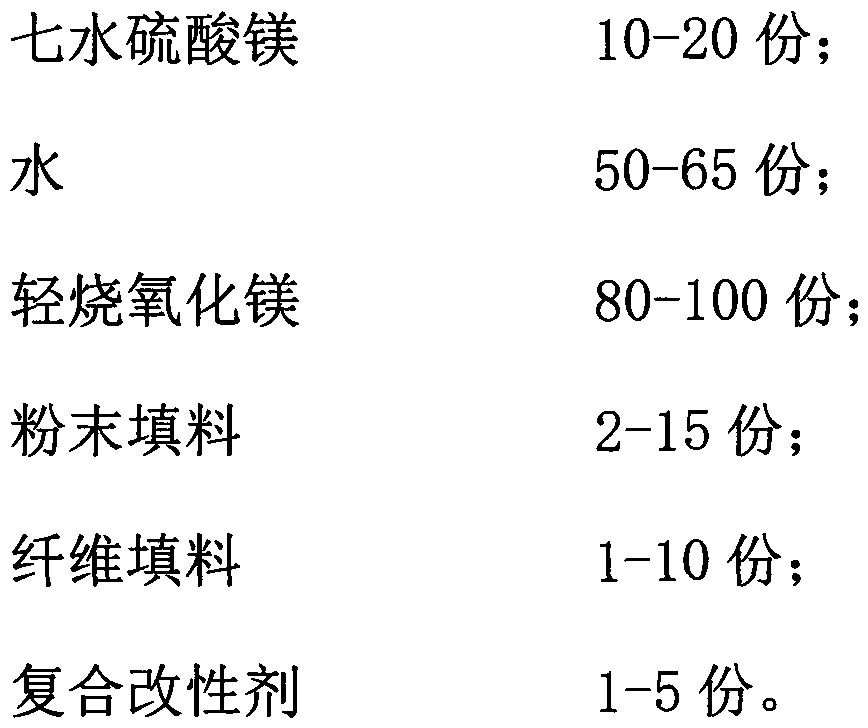

Magnesium oxysulfate cementing composite material for prefabricated thermal insulation wallboard and preparation method

The invention discloses a magnesium oxysulfate cementing composite material for a prefabricated thermal insulation wallboard and a preparation method. The magnesium oxysulfate cementing composite material is prepared from, by weight, 10-20 parts of magnesium sulfate heptahydrate, 50-65 parts of water, 80-100 parts of light calcined magnesia, 2-15 parts of powdered filler, 1-10 parts of fibrous filler and 1-5 parts of compound modifier. The preparation method of the composite material comprises the steps that magnesium sulfate heptahydrate is prepared into an aqueous solution, light calcined magnesia and the powdered filler are added, stirring is conducted for 5 min, the compound modifier and the fibrous filler are added, stirring is continuously conducted for 10 min to 30 min, an obtained magnesium oxysulfate cementing material slurry is added into a mold paved with a non-woven cloth and a fiberglass mesh cloth, and curing molding is conducted. The prefabricated thermal insulation wallboard produced through the magnesium oxysulfate cementing composite material has the advantages of being high in strength and good in water resistance, and the problems of scumming, warping deformation and the like are avoided.

Owner:杨红健

Plant infusion nutrient solution and preparation method thereof

InactiveCN101811909AImprove stress resistanceHigh activityFertilizer mixturesCalcium nitrate tetrahydrateHigh absorption

The invention discloses plant infusion nutrient solution and a preparation method thereof and aims to provide nutrient solution which can be directly infused into the plants, stimulate the tree activity, promote the plants to rapidly take root and sprout, quickly supply nutrition to the trees, and enhance the tree stress resistance, and a preparation method of the nutrient solution. The proportion of the nutrient solution is that: every 1,000ml of deionized water contains 0.05 to 0.1g of monopotassium phosphate, 0.02 to 0.045g of potassium nitrate, 0.15 to 0.3g of calcium nitrate tetrahydrate, 0.11 to 0.2g of magnesium sulfate heptahydrate, 0.03 to 0.06g of ferrous sulphate heptahydrate, 0.07 to 0.15g of disodium ethylene diamine tetraacetate, 0.015 to 0.025g of manganese sulfate tetrahydrate, 0.012 to 0.018g of zinc sulfate heptahydrate, 0.04 to 0.06g of copper sulfate pentahydrate, 0.015 to 0.022g of ammonium molybdate, 0.015 to 0.02g of indolebutyric acid, and 0.008 to 0.015g of 6-benzylaminopurine. The plant infusion nutrient solution satisfies the needed nutrient in the process of transplanting big trees, has high absorption utilization ratio, quick response, stable form, high activity, and is easily absorbed by the plants.

Owner:TIANJIN LVDONG PLANT NUTRITION TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com