Patents

Literature

125results about How to "Improve air condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

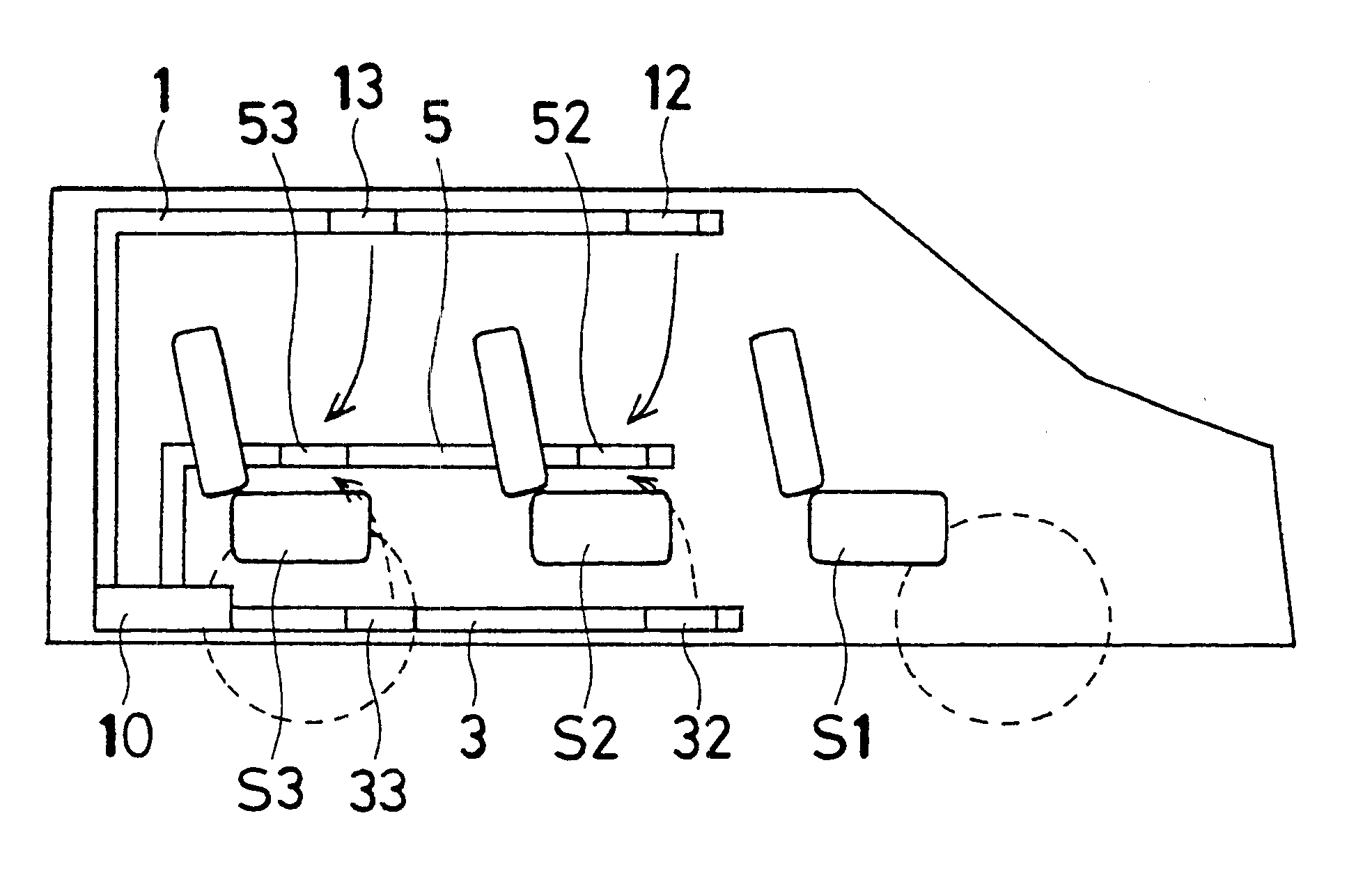

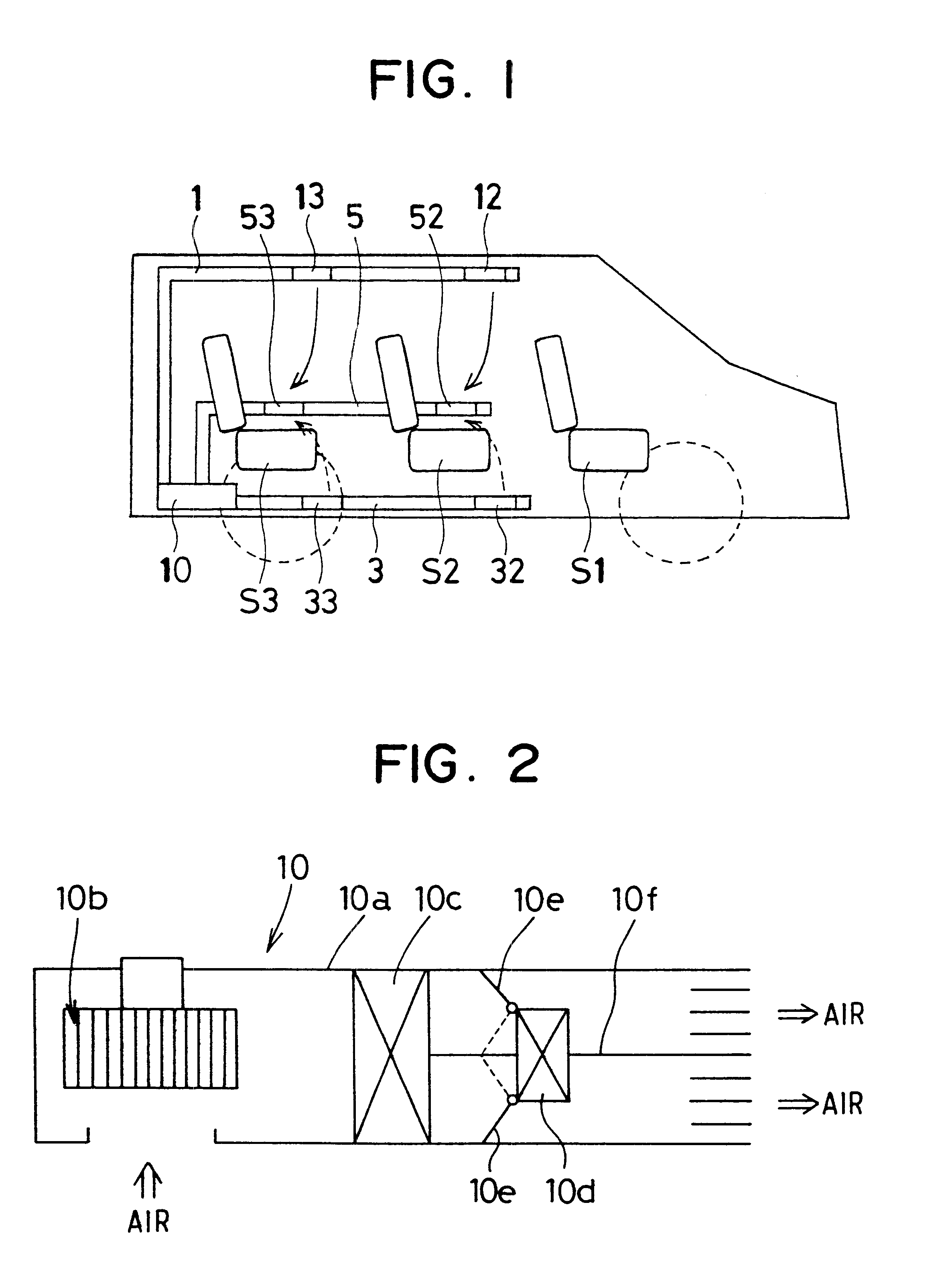

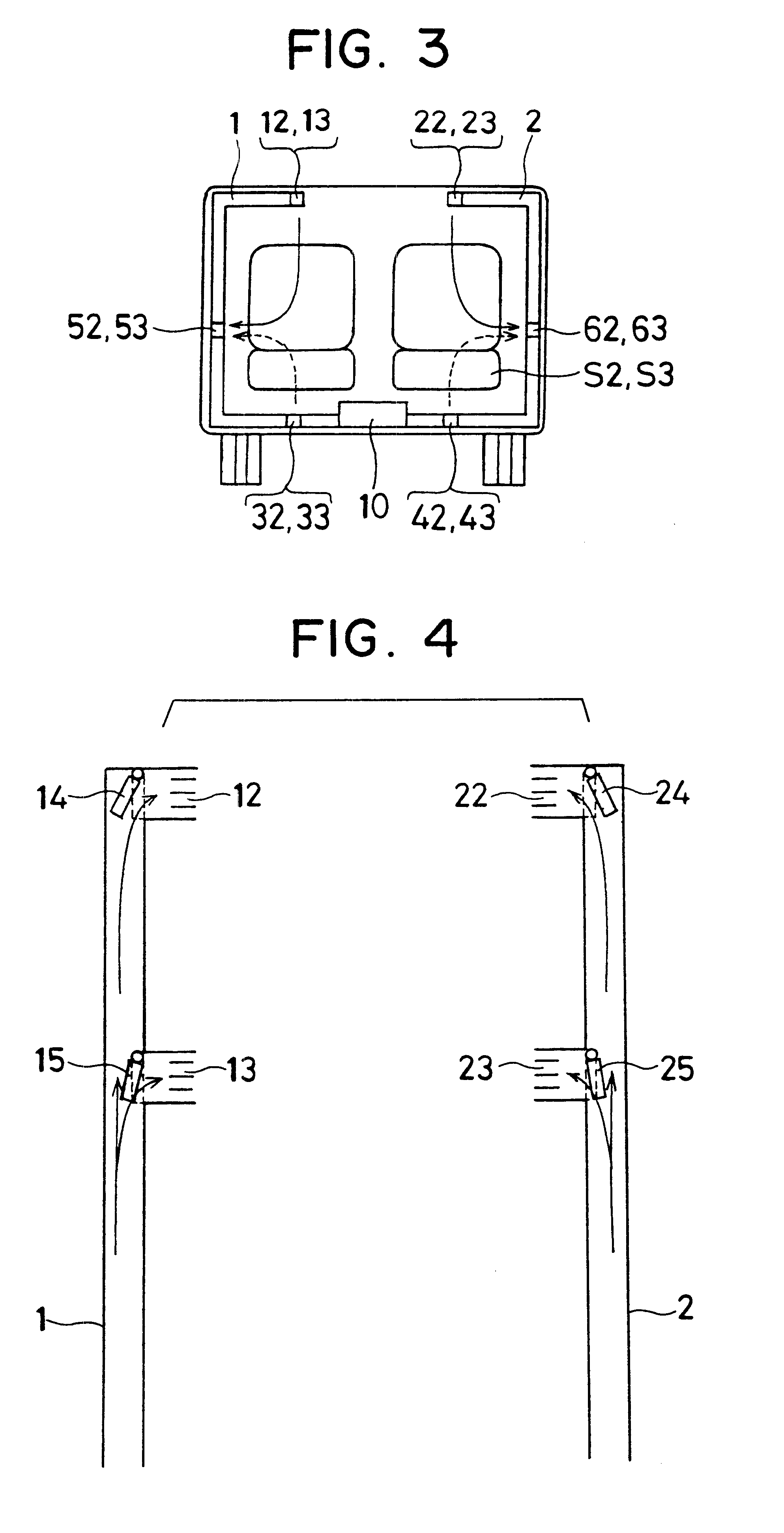

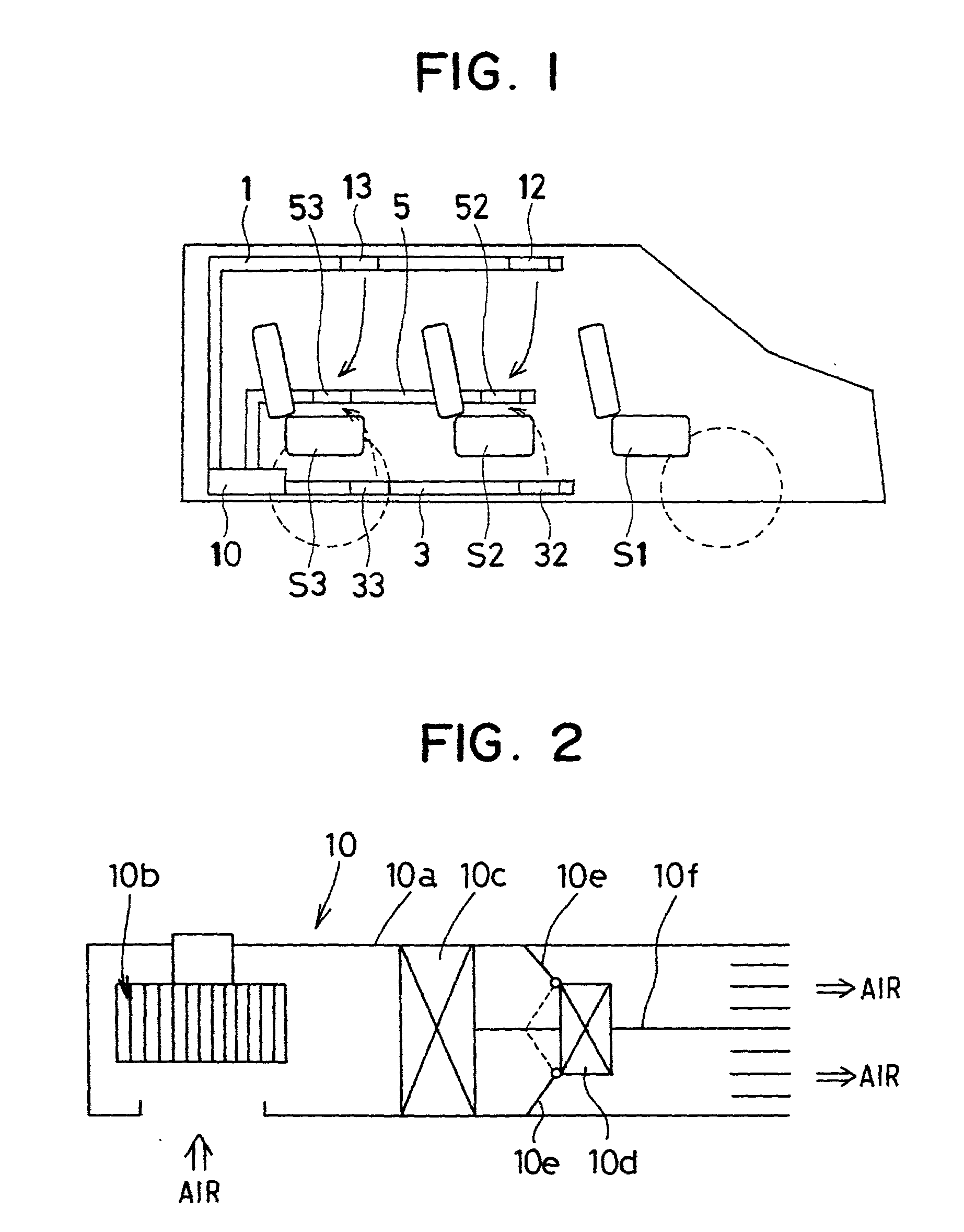

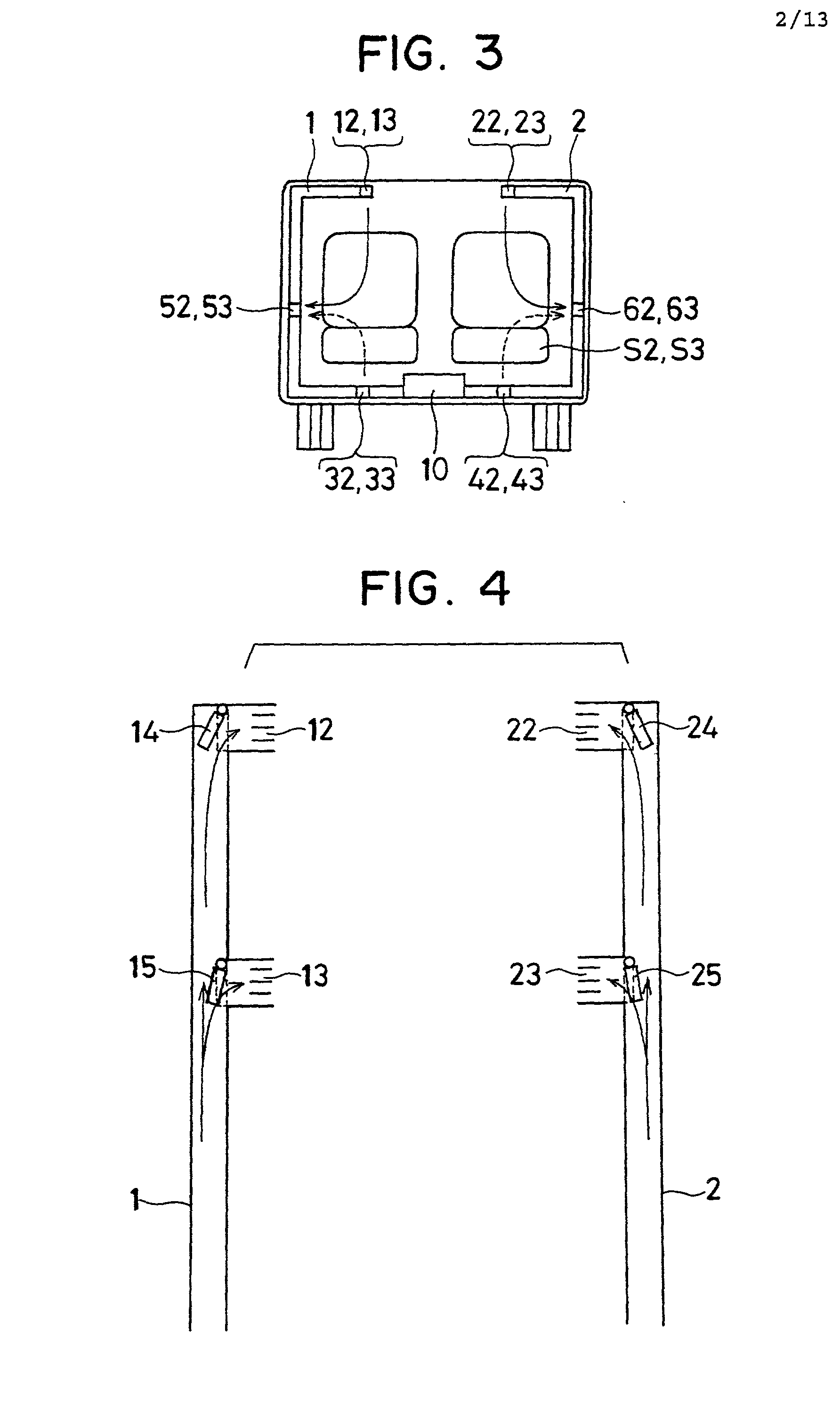

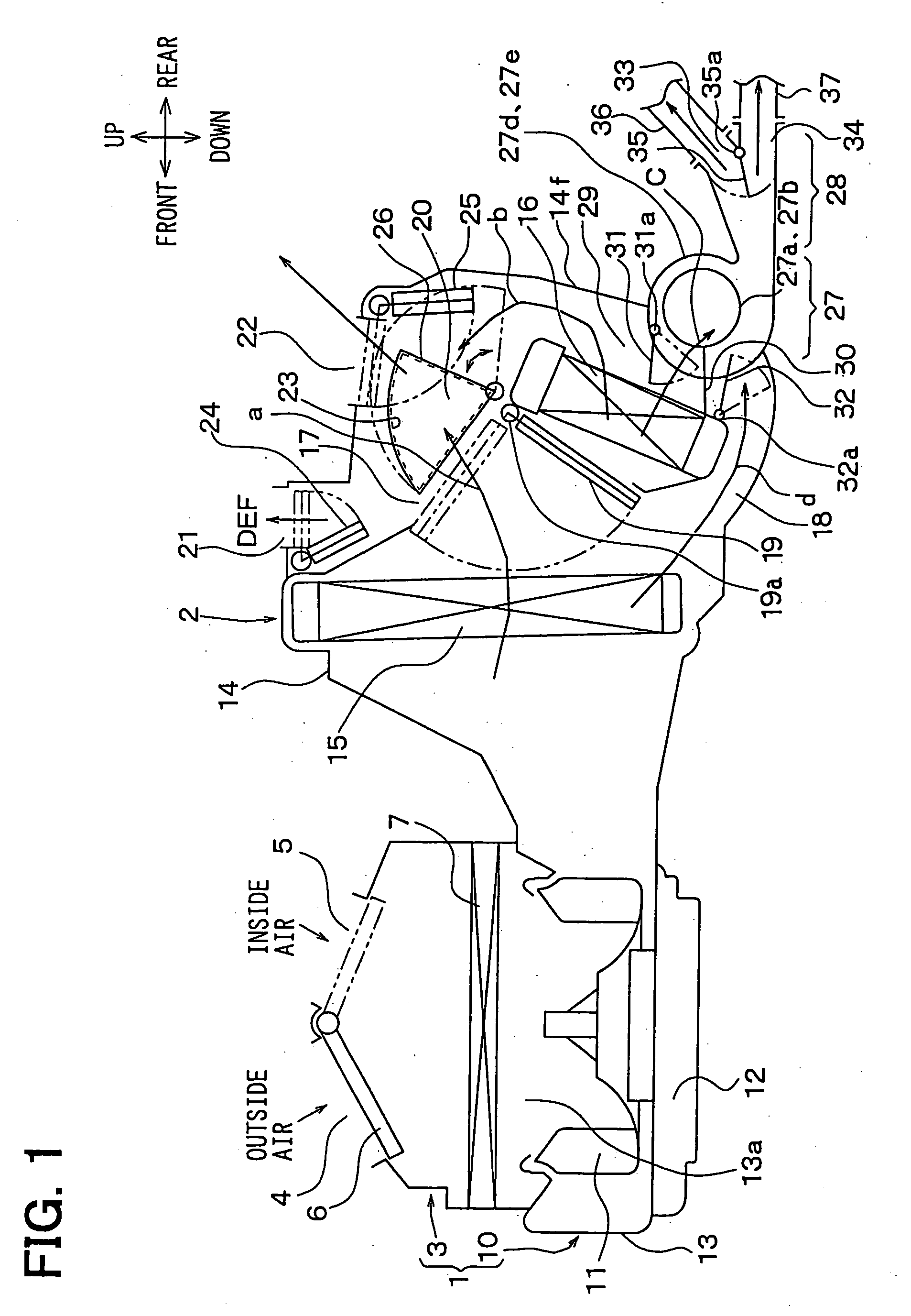

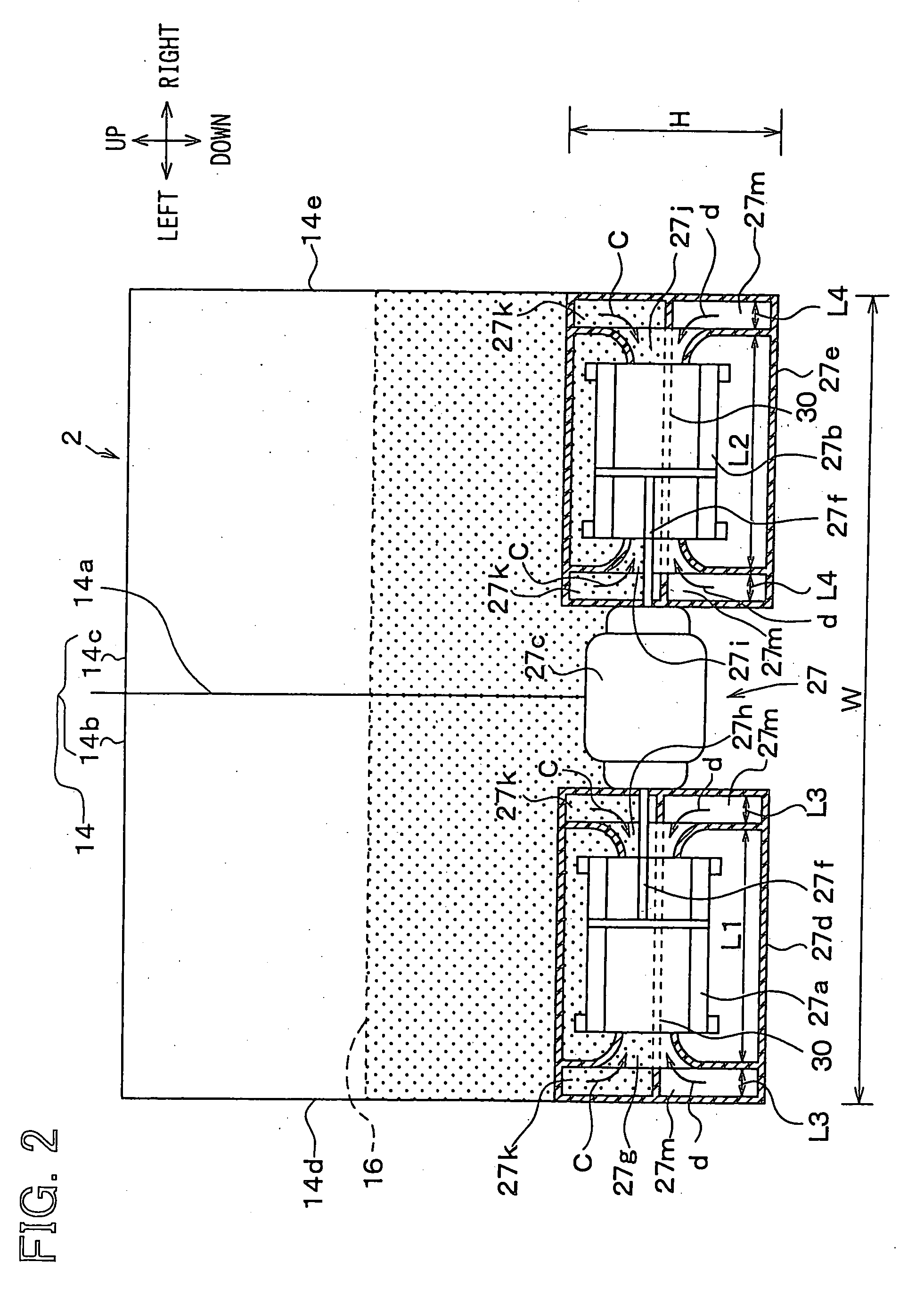

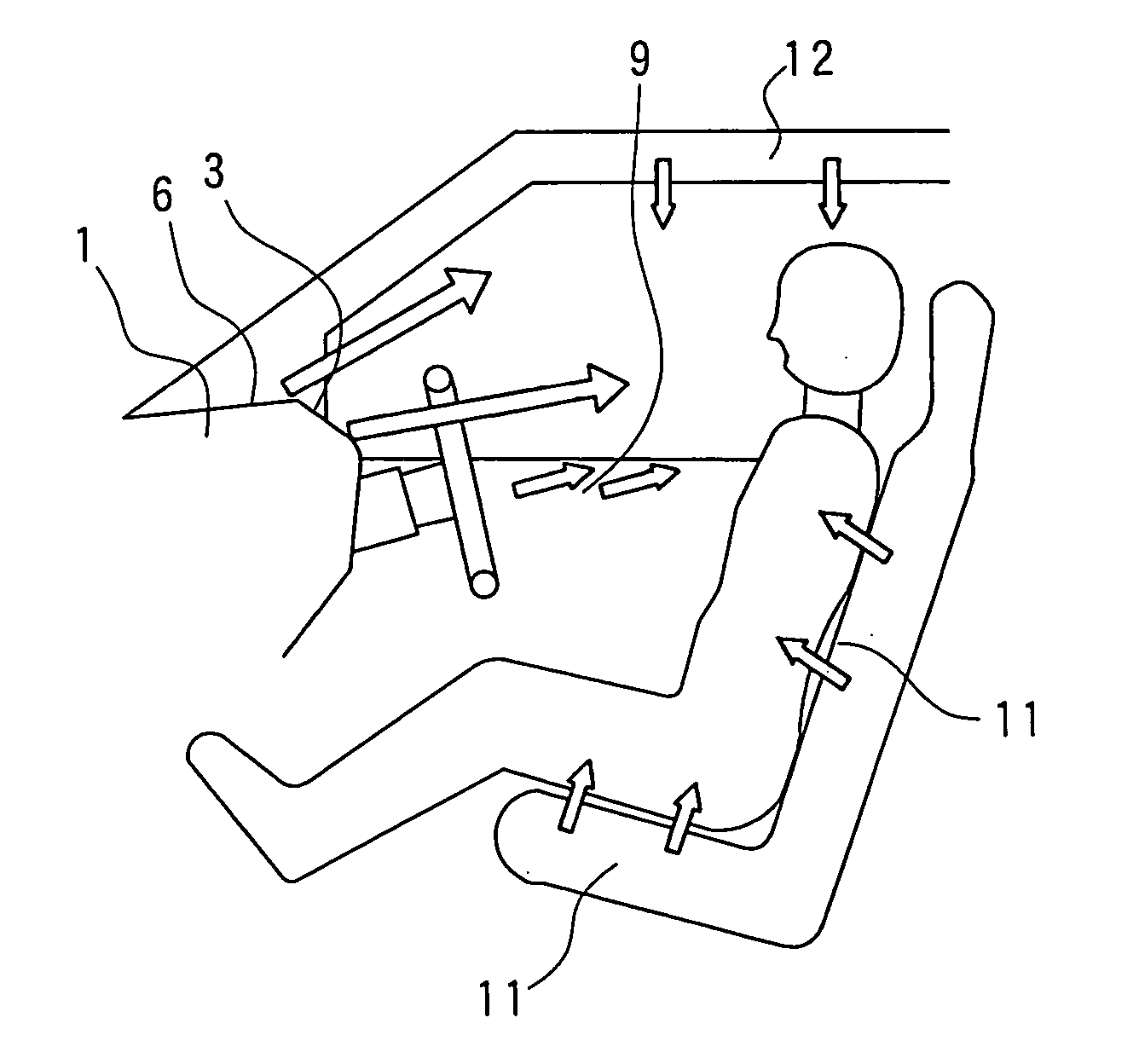

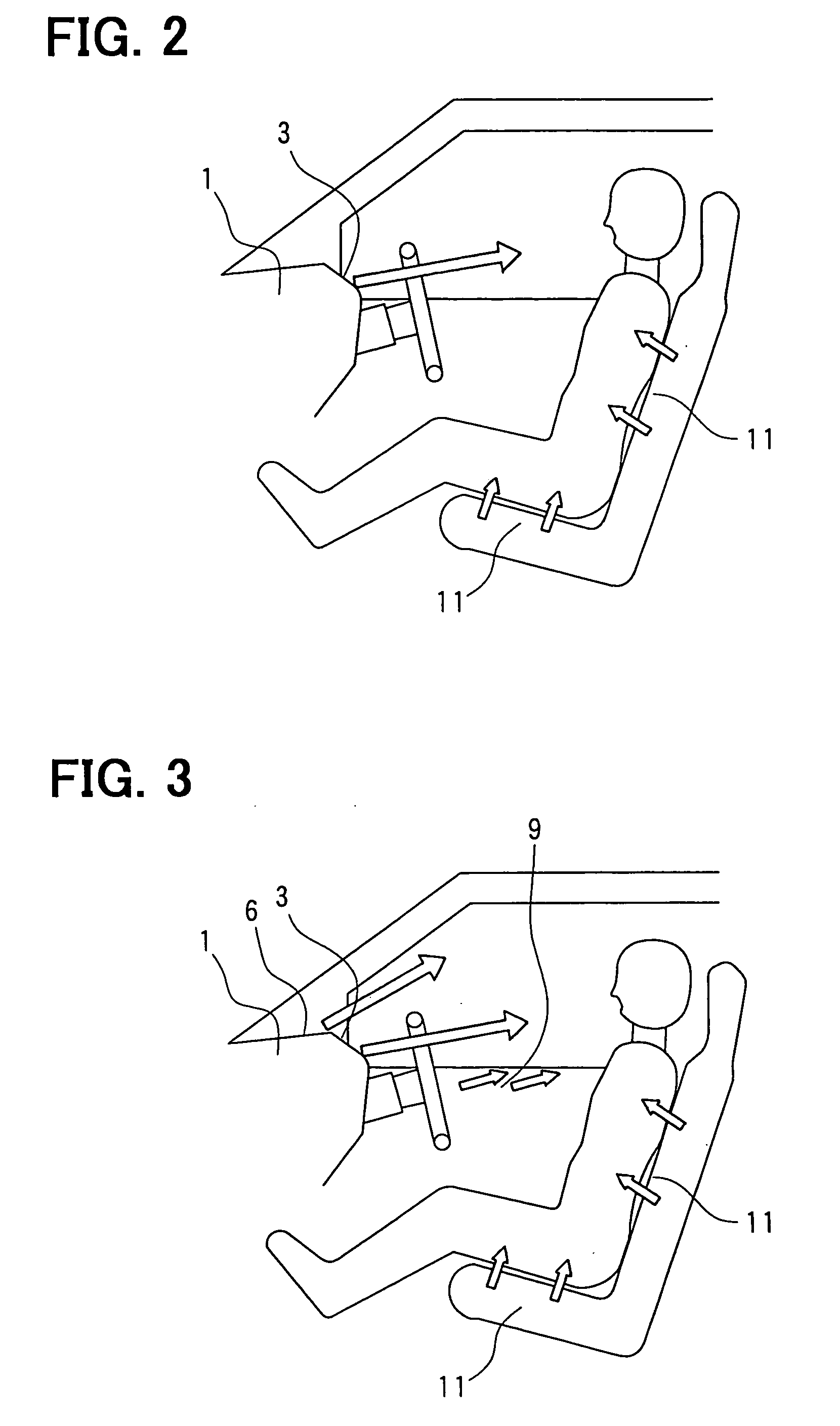

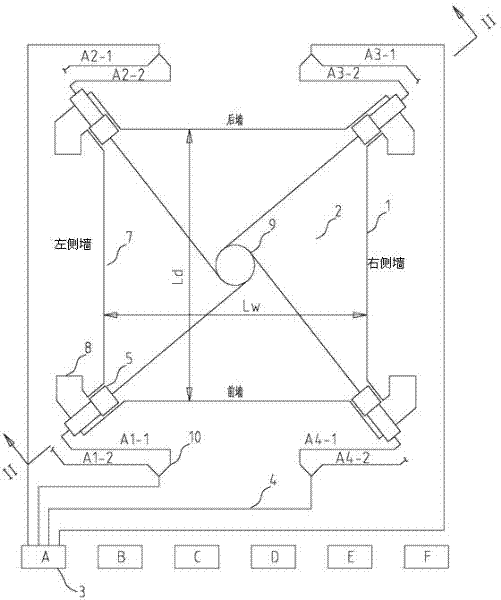

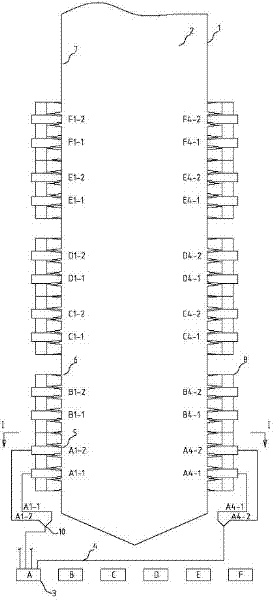

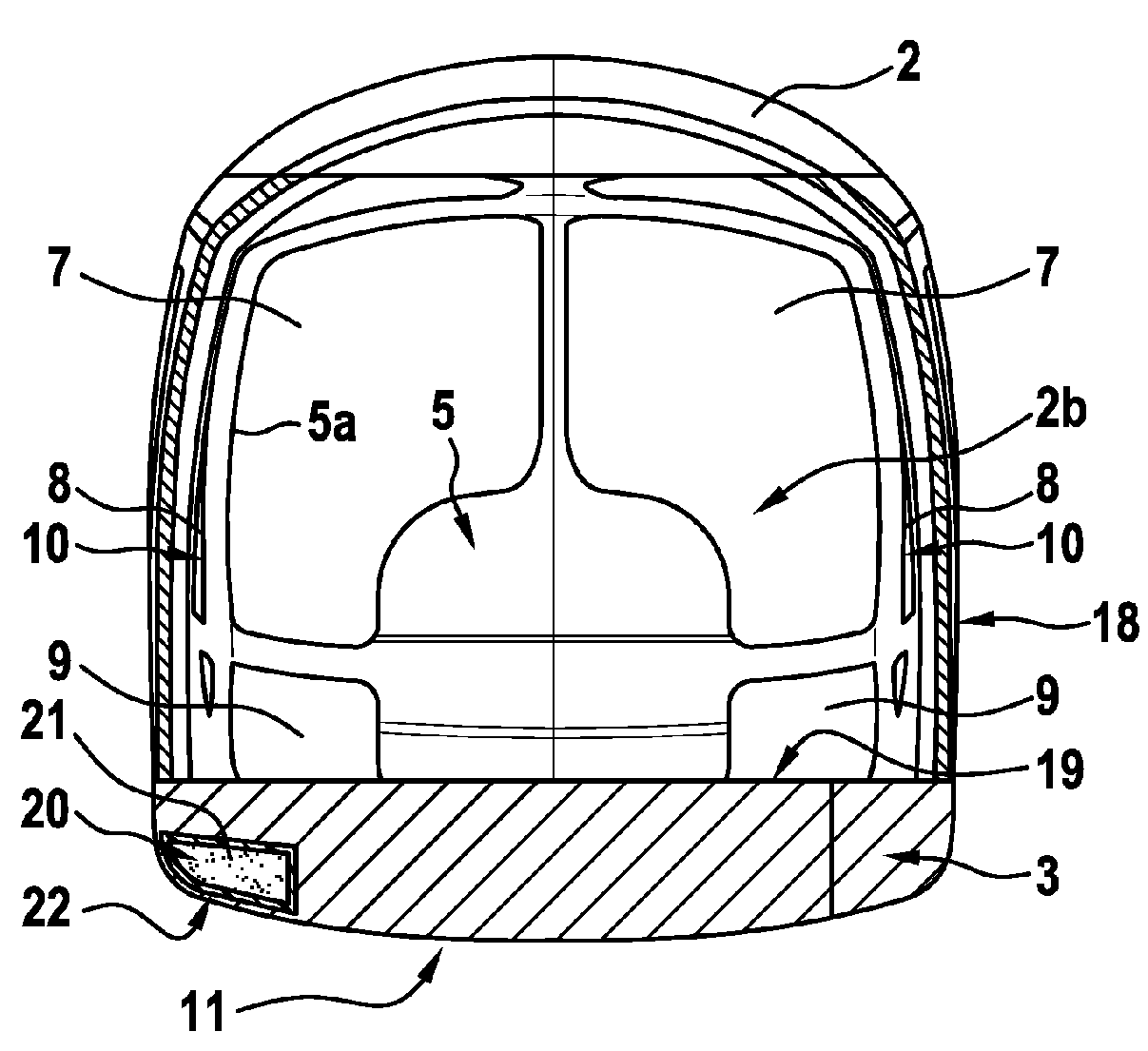

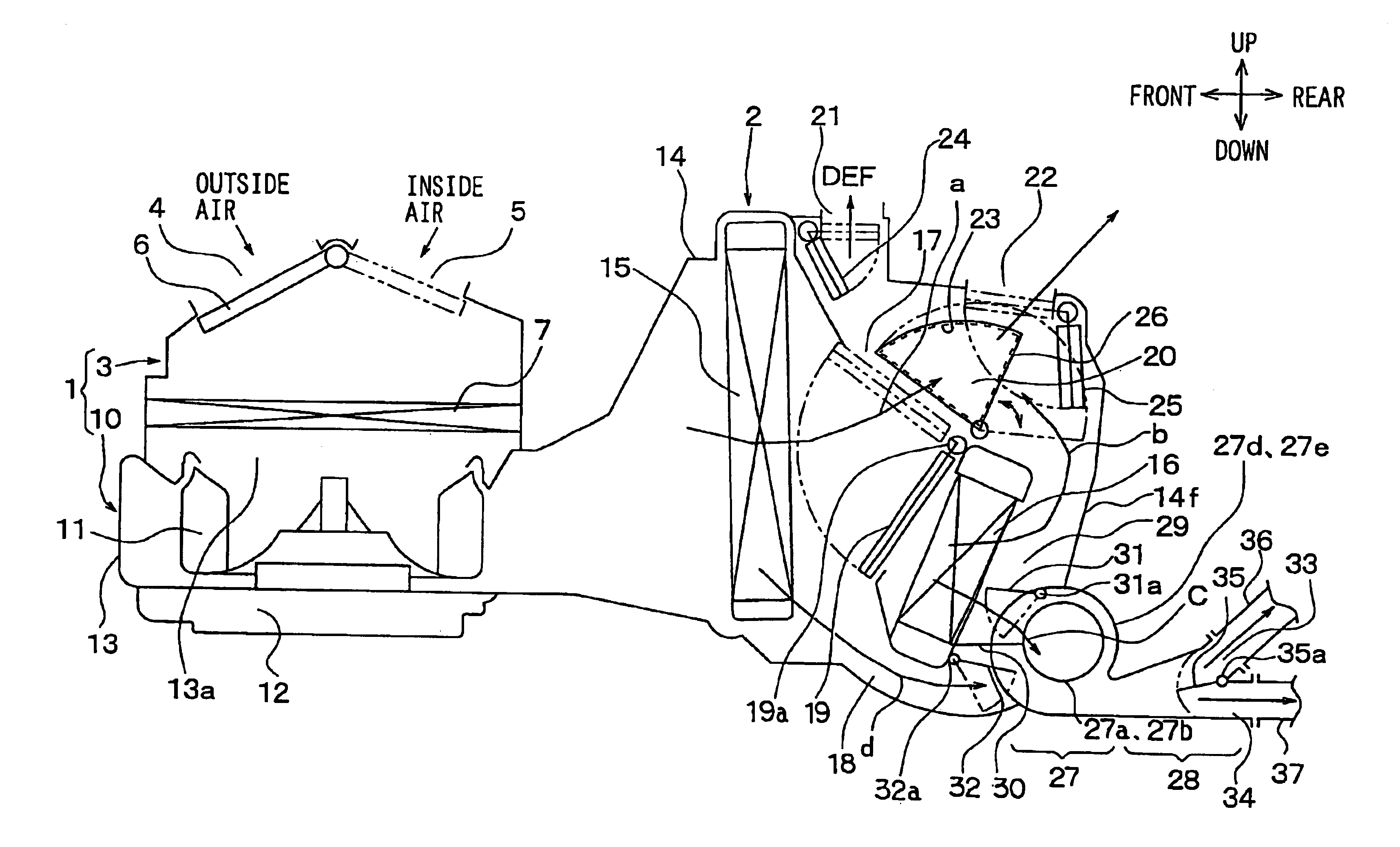

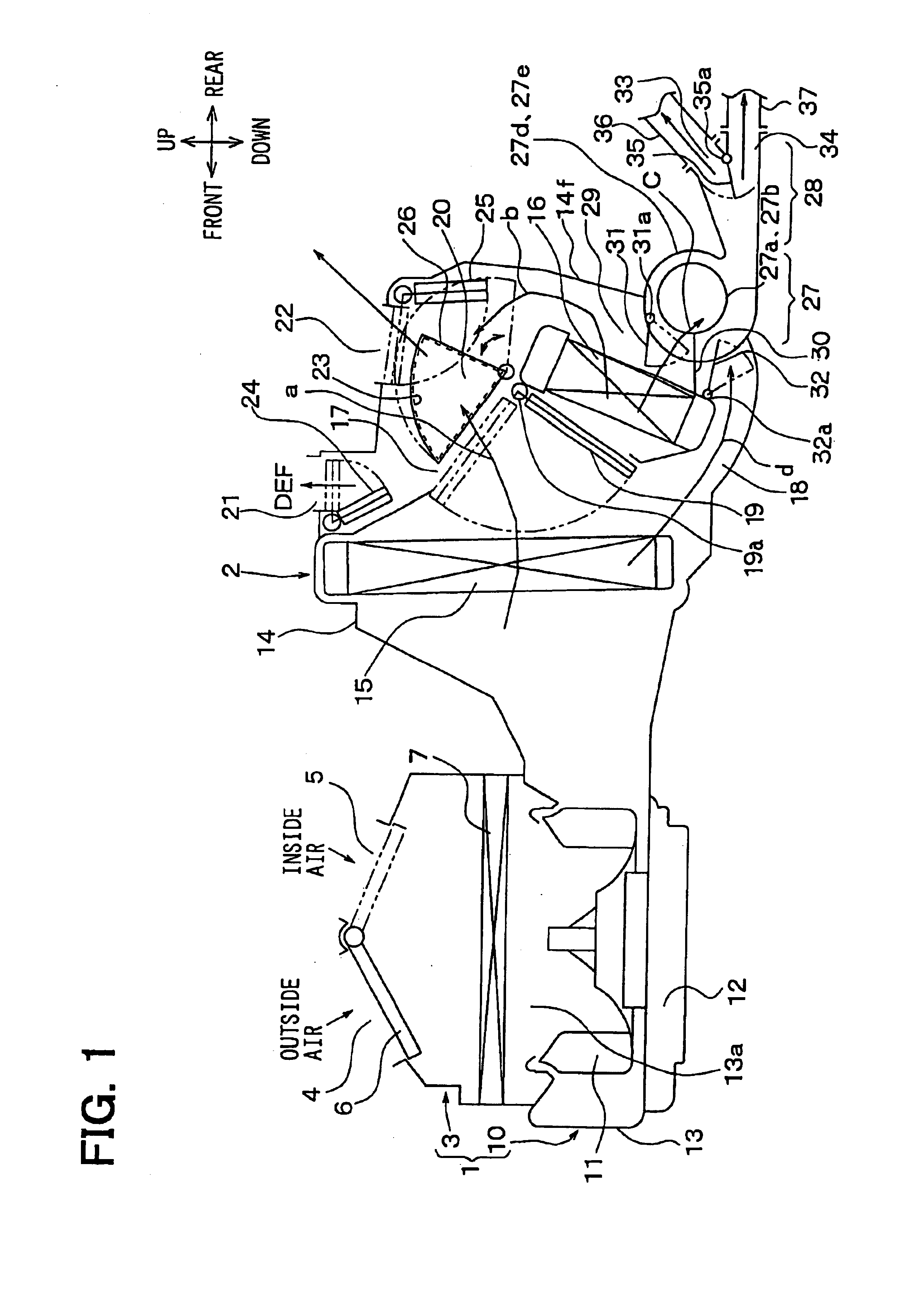

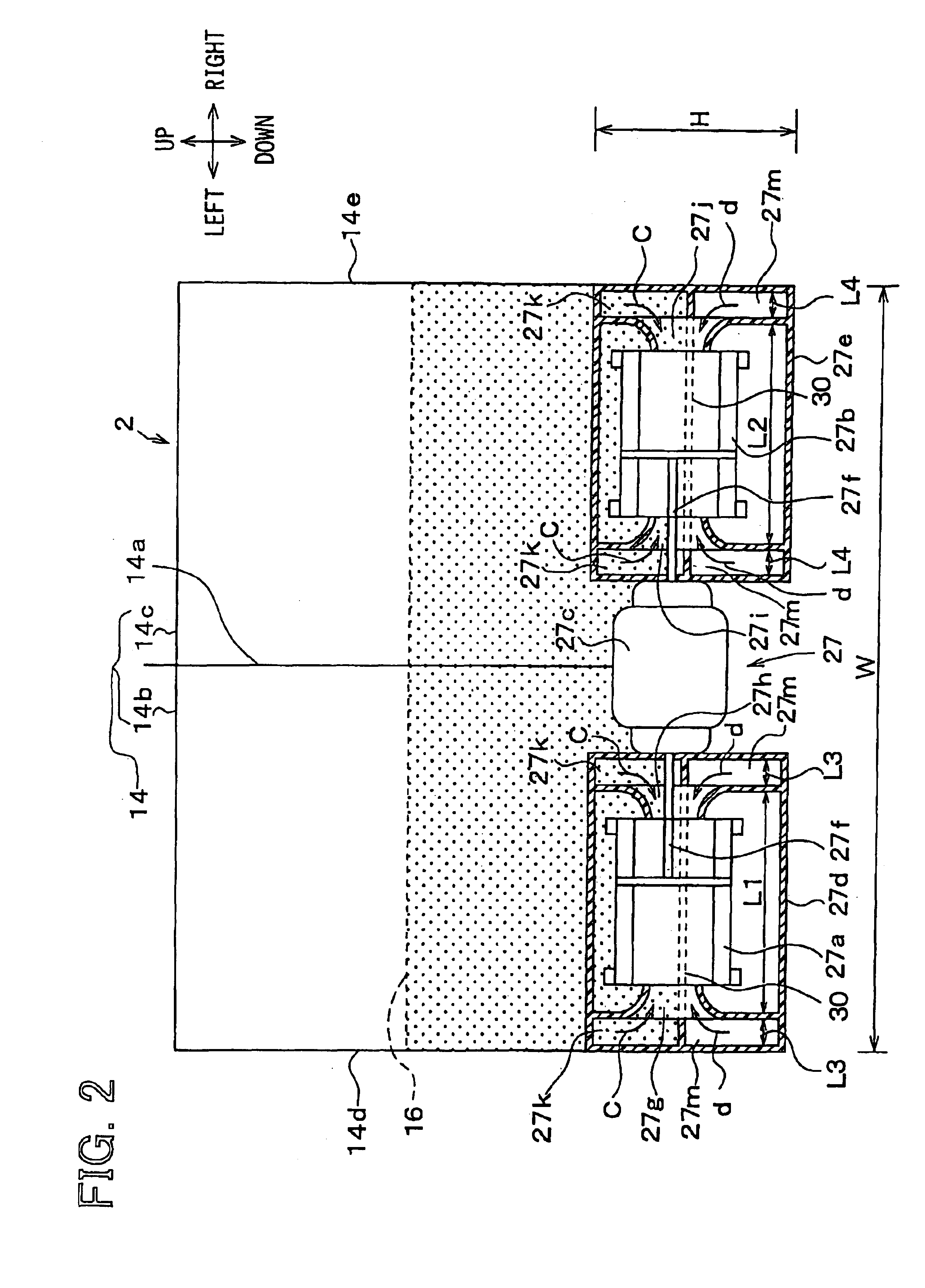

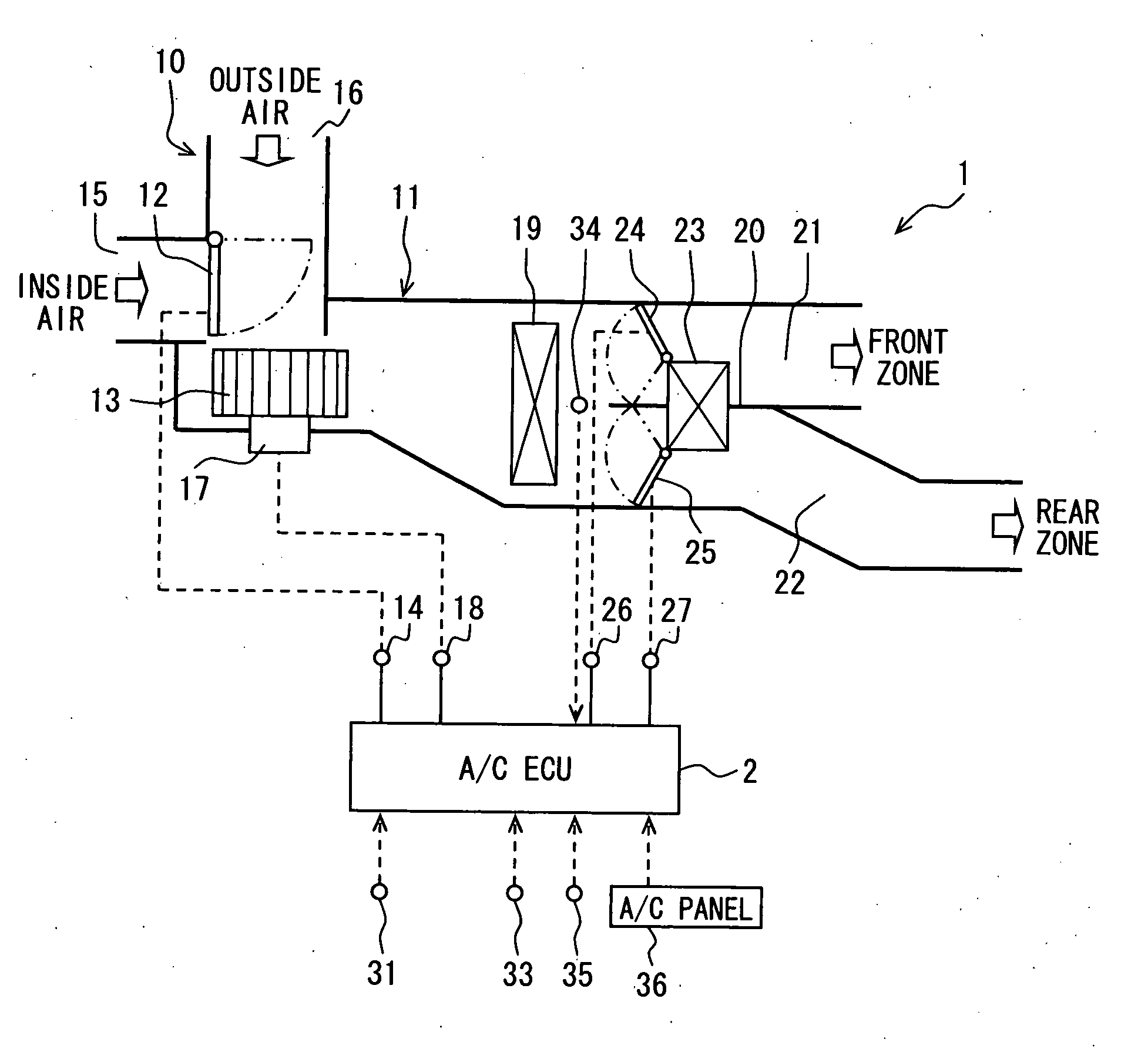

Vehicle air conditioner having air suction port for each seat

InactiveUS6491578B2Improve controlEfficient executionAir-treating devicesSeat heating/ventillating devicesCold airEngineering

In a vehicle air conditioner, each of cool air outlets is provided at an upper side of each seat at second and third seat lines from a most front seat so that cool air from an air conditioning unit is blown from the cool air outlets toward upper sides of the seats, respectively, and each of warm air outlets is provided at a lower side of each seat at the second and third seat lines so that warm air from the air conditioning unit is blown from the warm air outlets toward lower sides of the seats, respectively. In addition, each of suction ports is provided for each corresponding seat at the second and third seat lines so that air inside a passenger compartment is sucked from the suction ports to be returned to the air conditioning unit.

Owner:DENSO CORP

Vehicle air conditioner having air suction port for each seat

InactiveUS20010029162A1Improve controlEfficient executionAir-treating devicesSeat heating/ventillating devicesCold airEngineering

In a vehicle air conditioner, each of cool air outlets is provided at an upper side of each seat at second and third seat lines from a most front seat so that cool air from an air conditioning unit is blown from the cool air outlets toward upper sides of the seats, respectively, and each of warm air outlets is provided at a lower side of each seat at the second and third seat lines so that warm air from the air conditioning unit is blown from the warm air outlets toward lower sides of the seats, respectively. In addition, each of suction ports is provided for each corresponding seat at the second and third seat lines so that air inside a passenger compartment is sucked from the suction ports to be returned to the air conditioning unit.

Owner:DENSO CORP

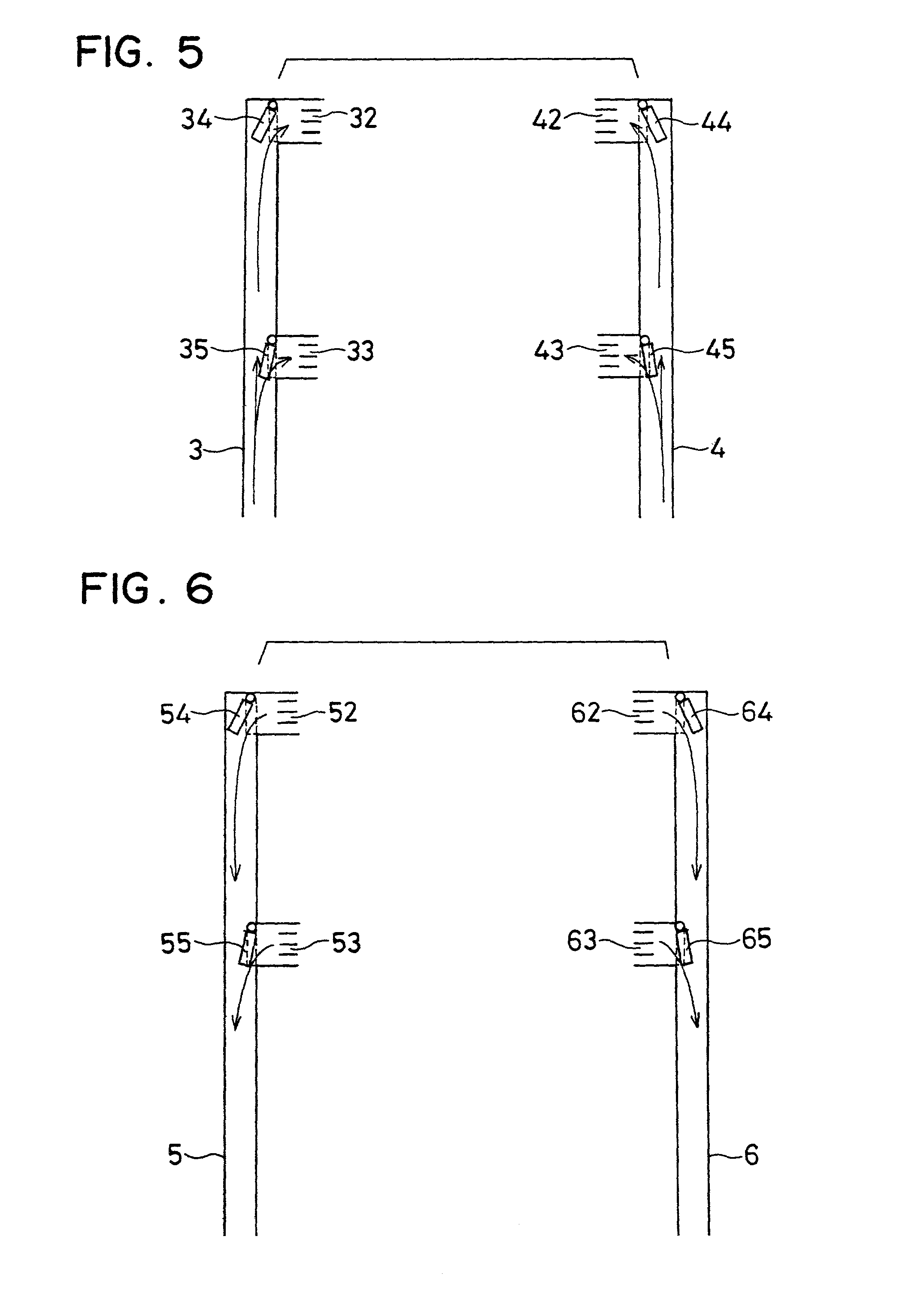

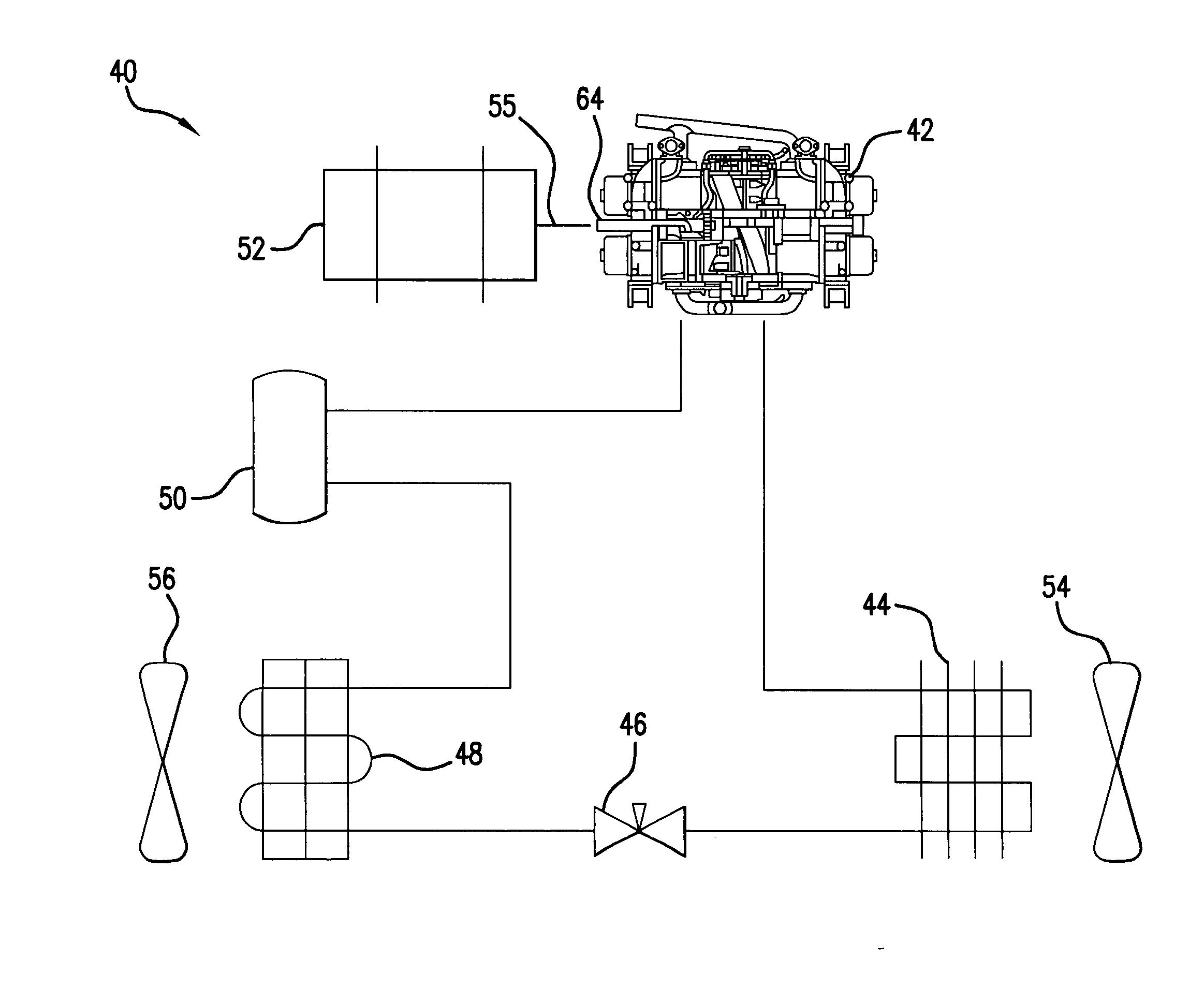

Evaporator apparatus and method for modulating cooling

InactiveUS20090277197A1Improve energy efficiencyGreat turndownCompression machines with non-reversible cycleEvaporators/condensersEngineeringAir conditioning

This invention relates to a method and an apparatus for a modulating air conditioning system having increased energy efficiency and greater turndown capabilities. A modulating air conditioning system includes modulating at least one of the following components: a compressor, a compressor driver, a condenser fan, an evaporator fan, an effective evaporator surface area, an effective condenser surface area and / or an expansion device.

Owner:VARIDIGM CORP

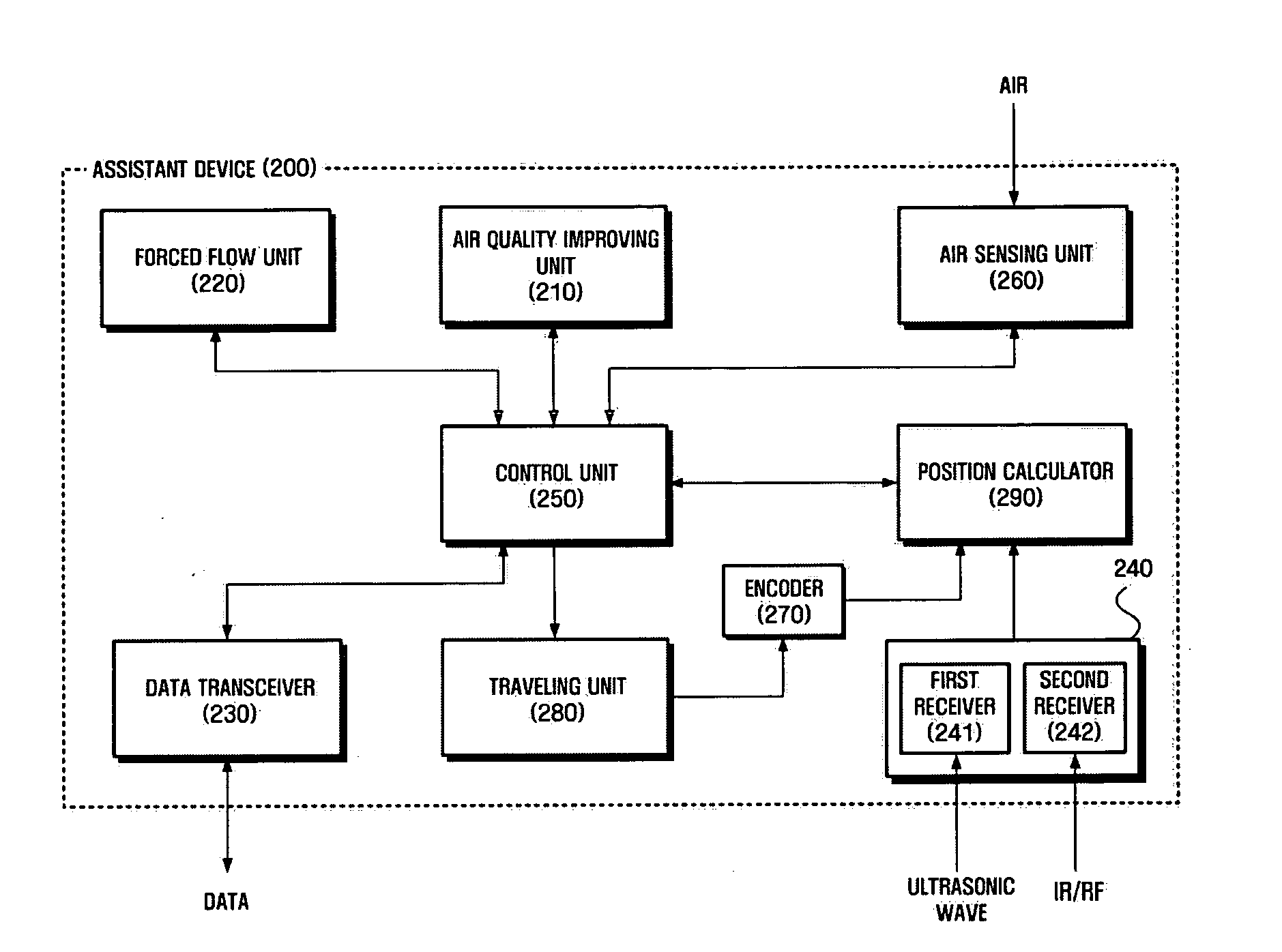

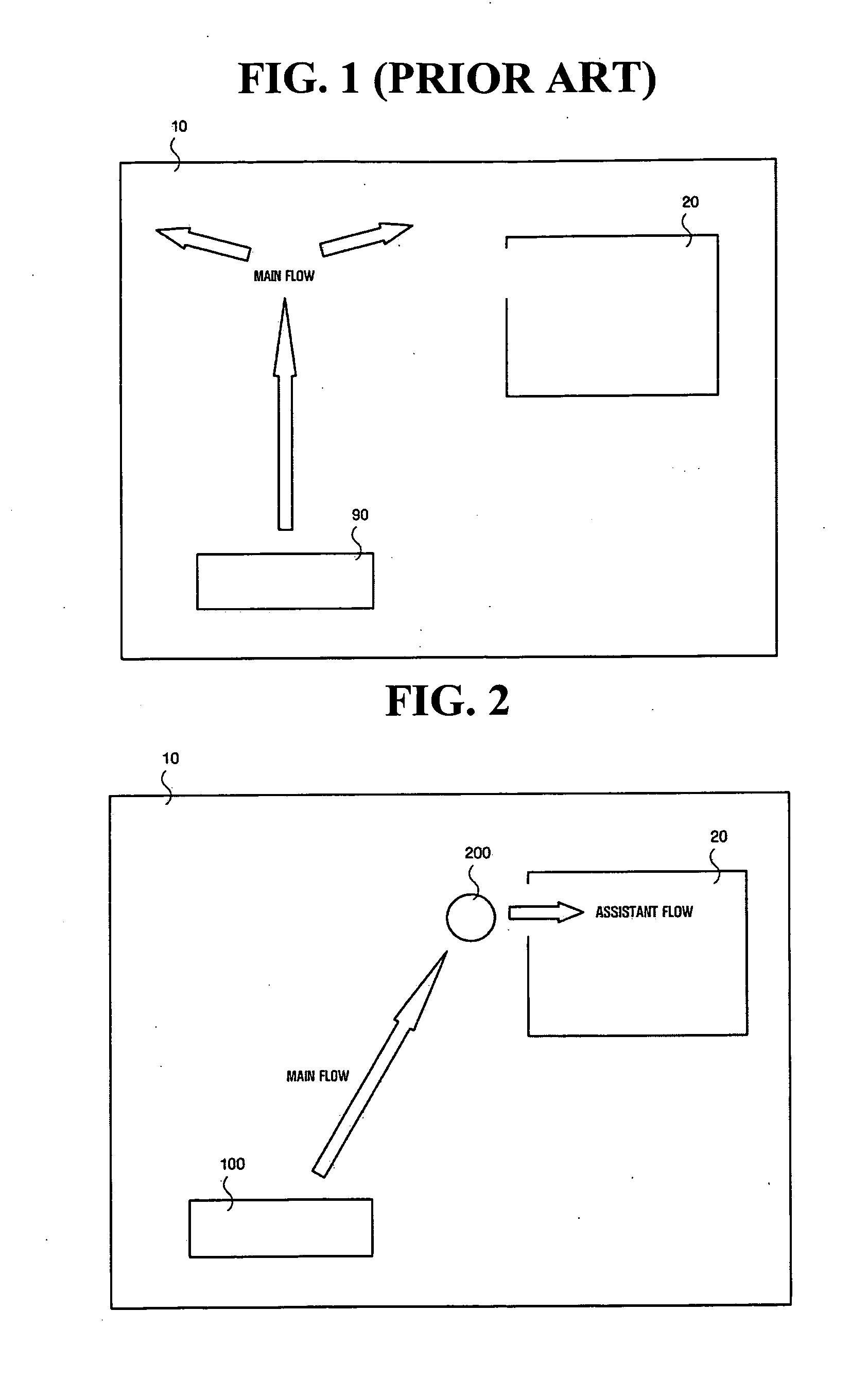

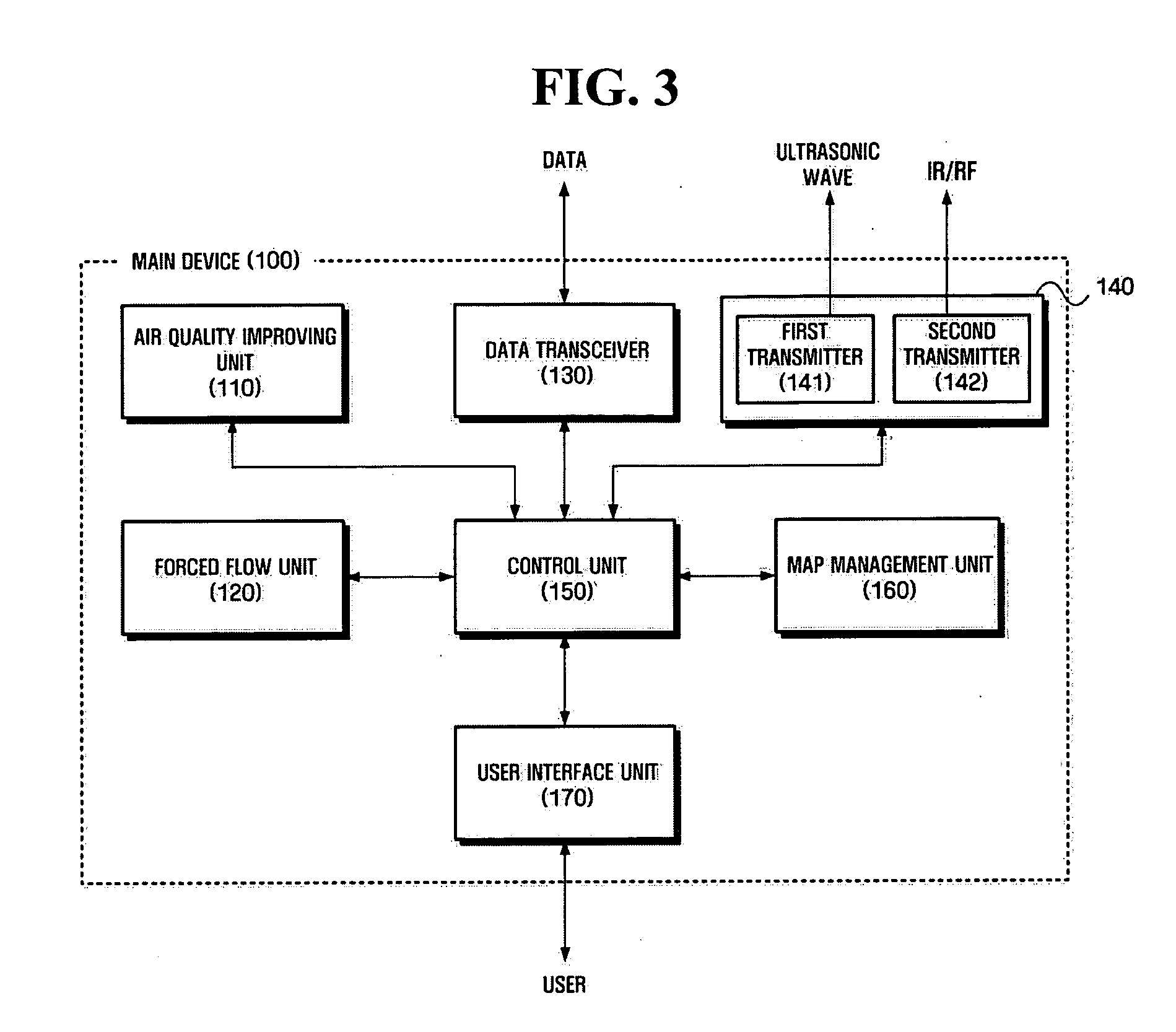

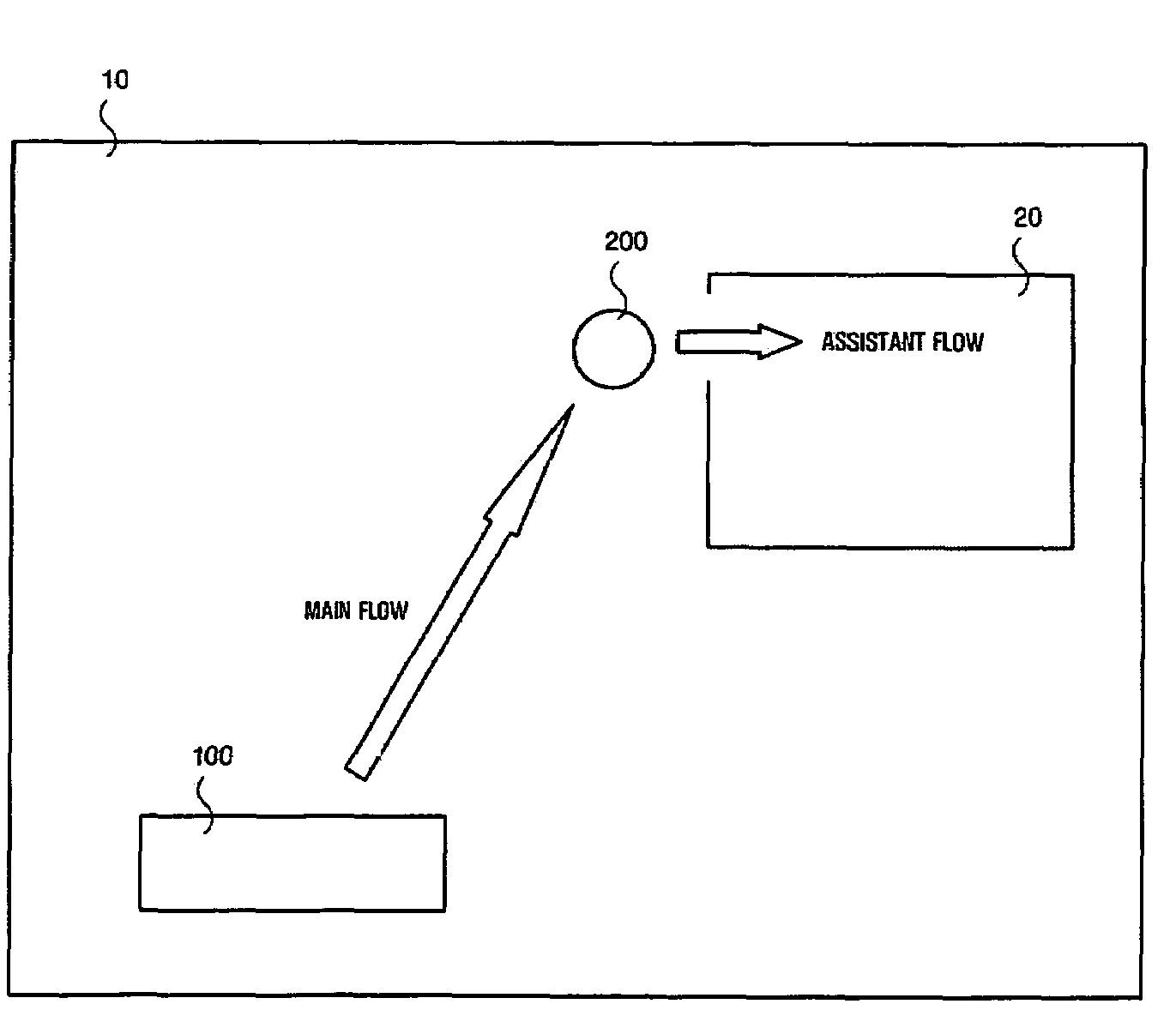

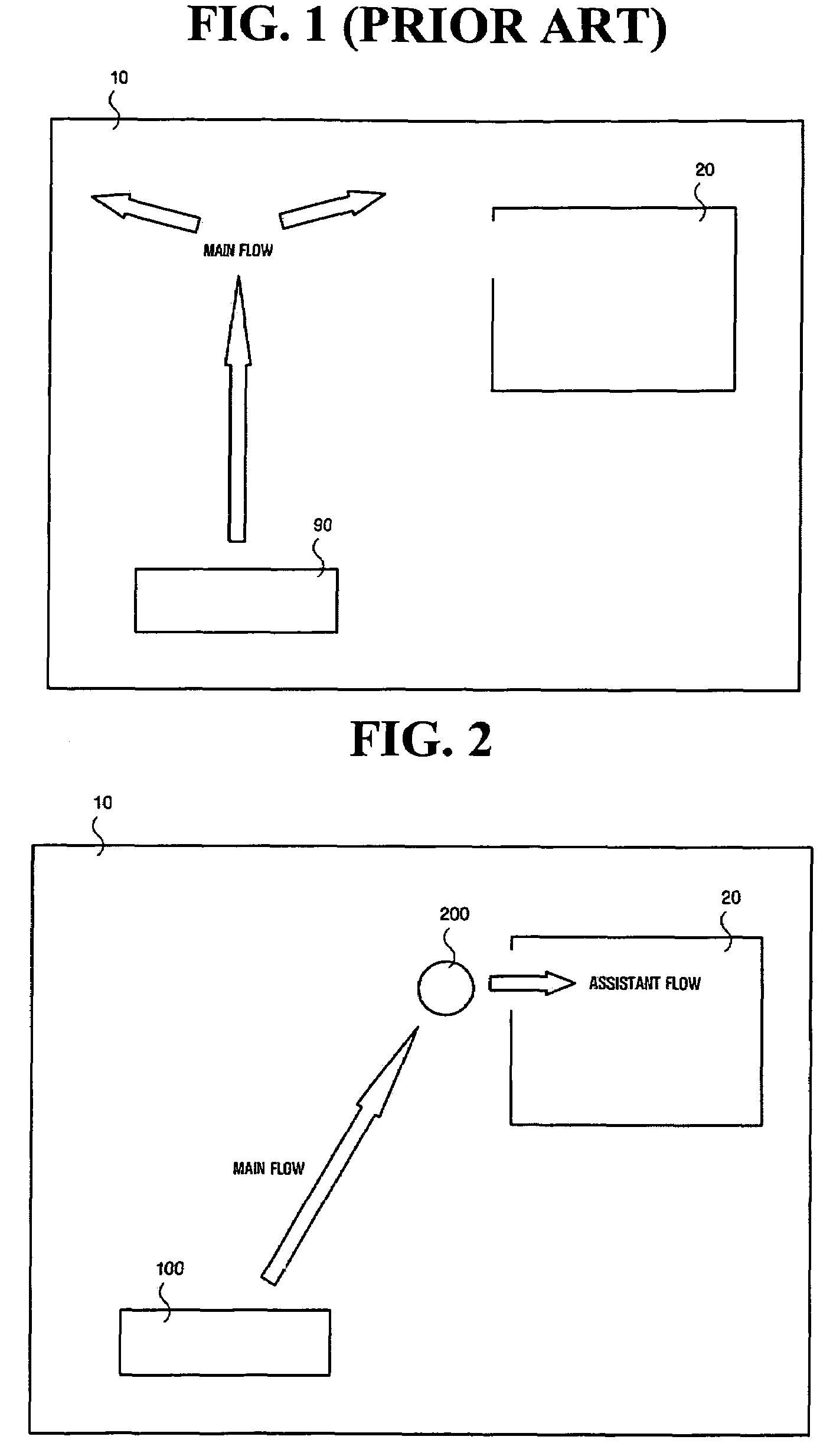

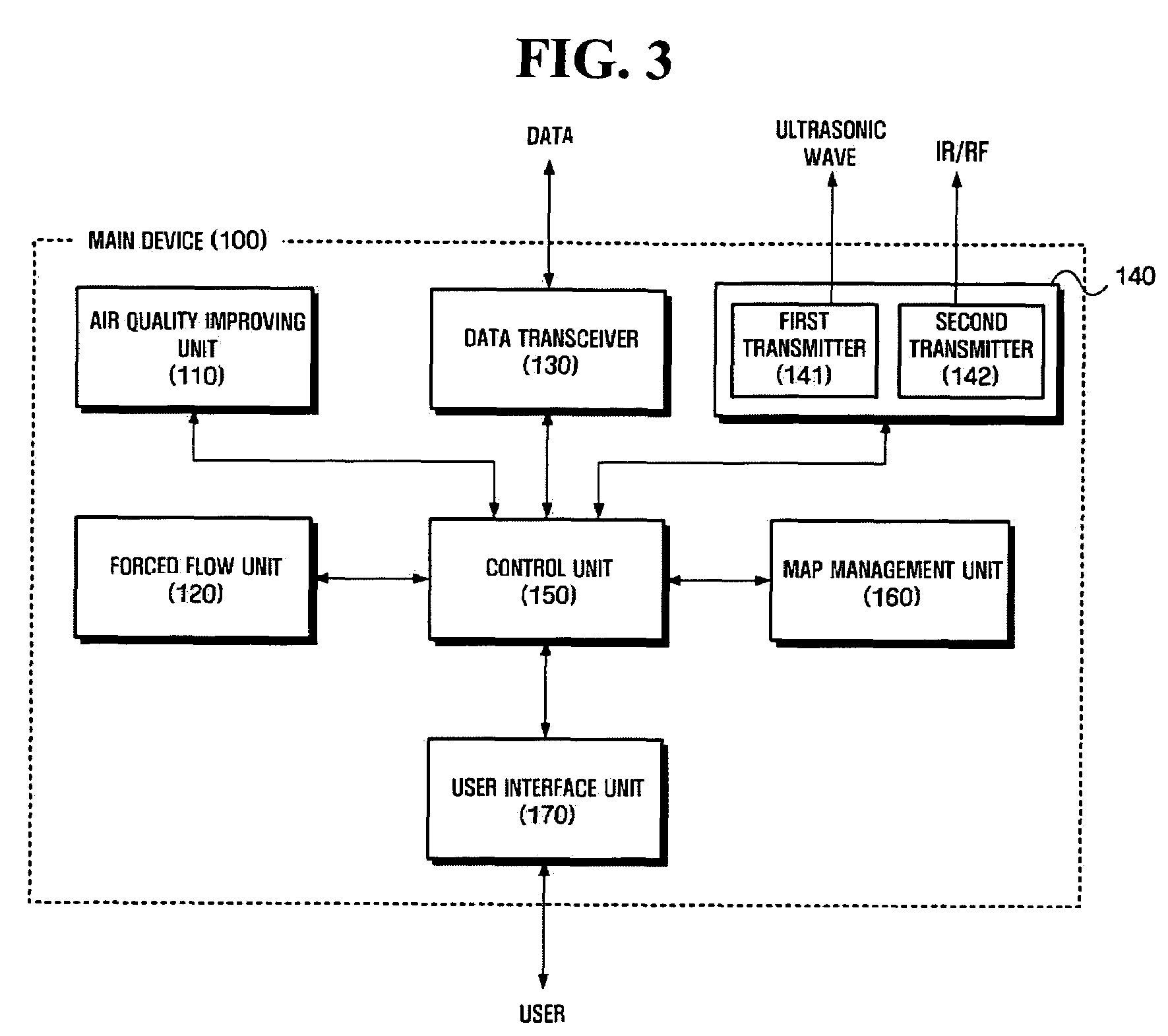

System and method for managing indoor air through cooperation between air conditioner and mobile assistant device

ActiveUS20060064204A1Improve air qualityIncrease valueMechanical apparatusLighting and heating apparatusPrimary operationAir quality index

A method and system for efficiently managing indoor air through cooperation between a mobile device and a stationary air conditioner. The system may include at least one stationary air conditioner and at least one mobile assistant device that move with a predetermined management area and cooperates with the air conditioner. The air conditioner may include an air quality improving unit improving a value of a predetermined air quality index into an appropriate range, a first forced flow unit generating a main flow to transport improved air toward the abnormal region, and a control unit controlling the air quality improving unit and the first forced flow unit to perform a main operation on the abnormal region and transmitting a command instructing the assistant device to perform an assistant operation on the abnormal region to the assistant device.

Owner:SAMSUNG ELECTRONICS CO LTD

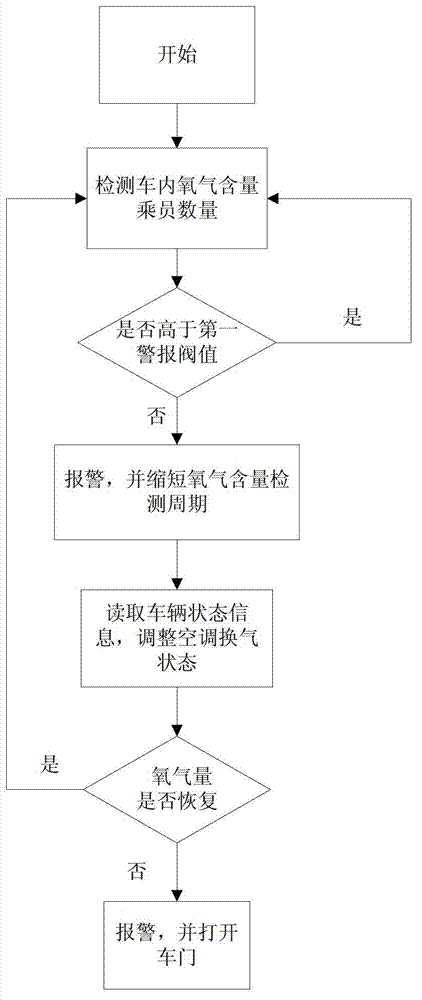

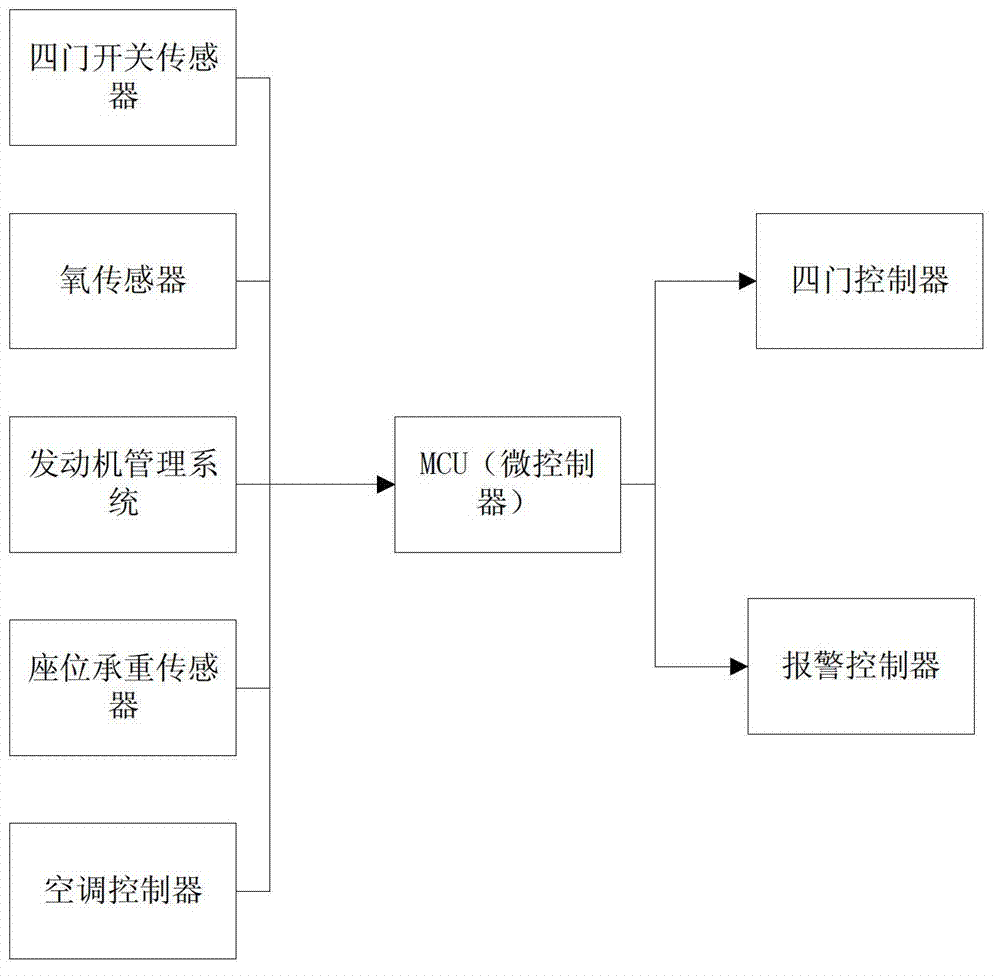

Intelligent monitoring and controlling method and device for oxygen content in car

ActiveCN102848999AImprove air conditionIntelligent monitoring of oxygen contentAir-treating devicesVehicle heating/cooling devicesSleep stateOxygen content

An intelligent monitoring and controlling method for oxygen content in a car uses cycle wakeup for operation. The method includes when operation is started, monitoring whether there are passengers in the car or not, and starting to monitor oxygen content in the car if the passengers are detected to be in the car under wakeup condition; alarming by a system to remind the passengers in the car of paying attention to space ventilation in the car when oxygen content in the car is lower than a first alarm threshold value and anoxic risk is possibly caused, and turning on an air conditioner for ventilation simultaneously to improve air condition in the car; and activating an alarm when oxygen content in the car is detected to be further reduced and is close to a second alarm threshold value and the passengers in the car are in danger of life, and unlocking locks of four doors so that people outside can come in to rescue. After operation is finished, the system enters a sleep state to save energy. The invention further discloses a device implementing the method. By the use of the intelligent monitoring and controlling method and device, lives and health of the passengers in the car can be prevented from threatening of insufficient oxygen content.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

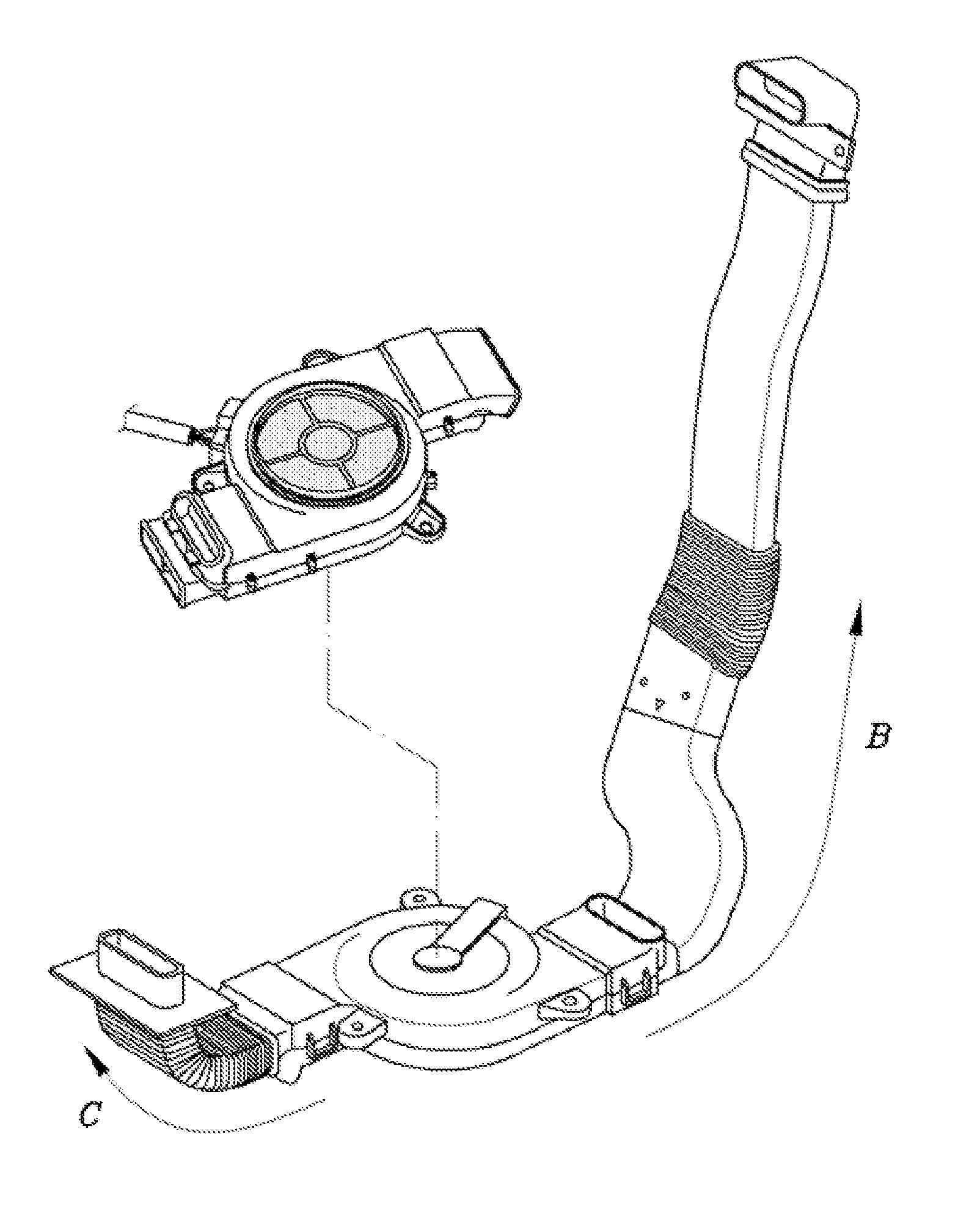

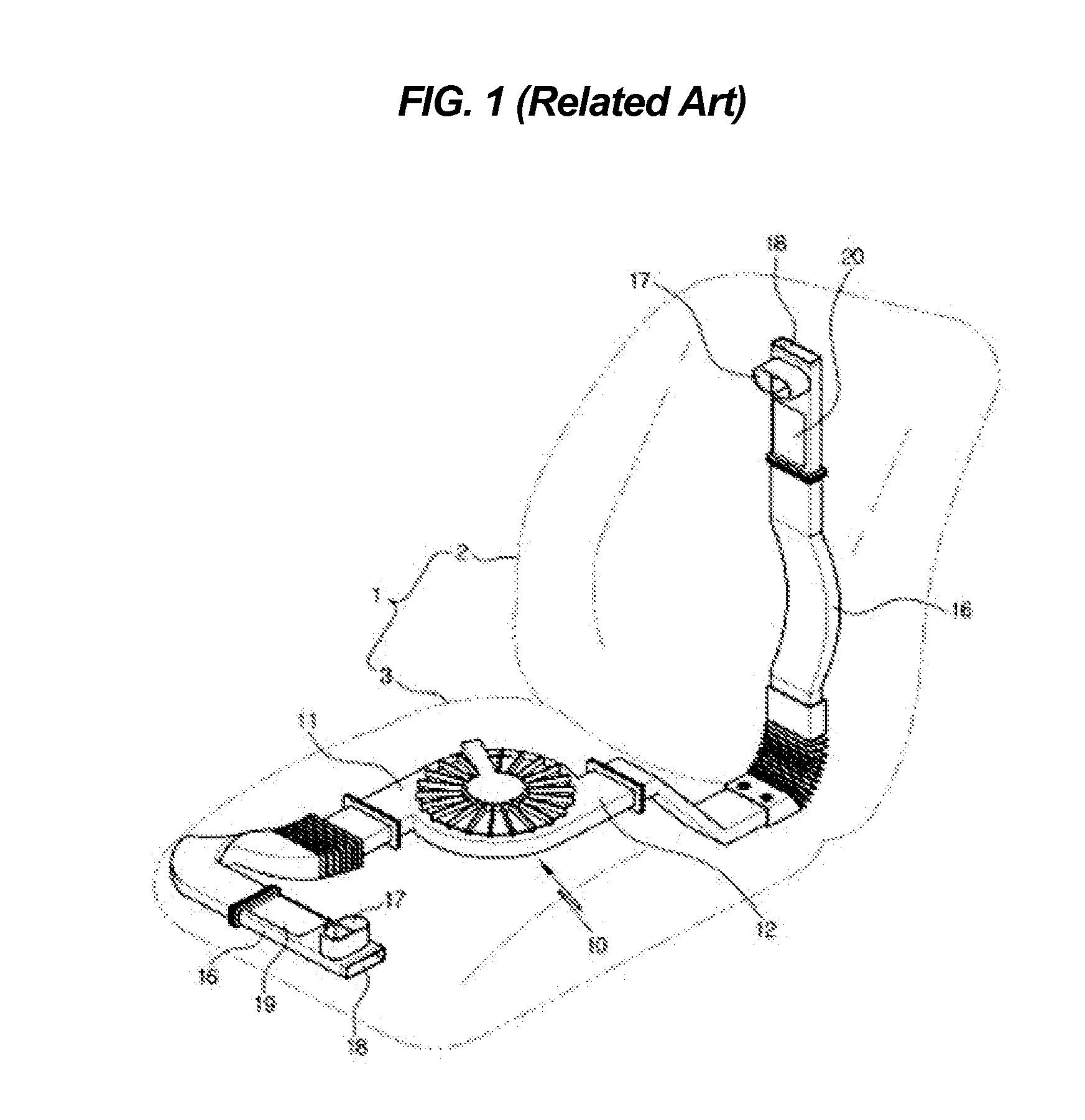

Air-conditioning ventilation seat module for vehicles

InactiveUS20120144844A1Avoid misuseImprove air conditioning efficiencyVehicle seatsMachines using electric/magnetic effectsCold airInterior space

An air-conditioning ventilation seat module for vehicles, may include a blower unit having a housing, a thermoelectric module having a casing mounted in the housing, wherein a thermoelectric device may be mounted in the casing, and wherein an internal space of the casing may be divided into a cold air path and a hot air path, a separator connected to one side of the thermoelectric module between the cold air path and the hot air path and having a curved section in order to maximize an amount of absorbing a condensate that may be created by a temperature difference between the cold air path and the hot air path when the seat module operates in cooling mode.

Owner:HYUNDAI MOTOR CO LTD +2

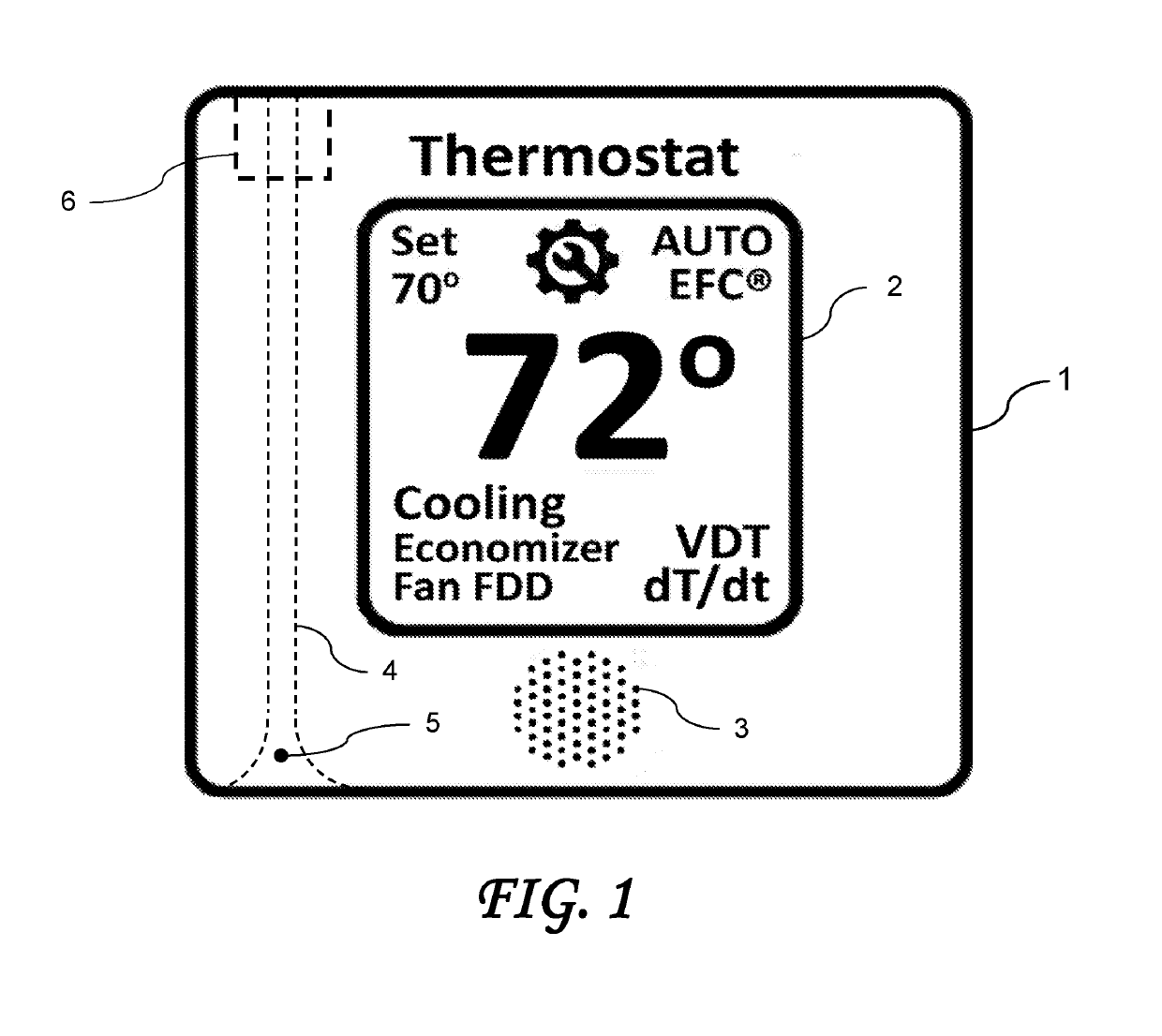

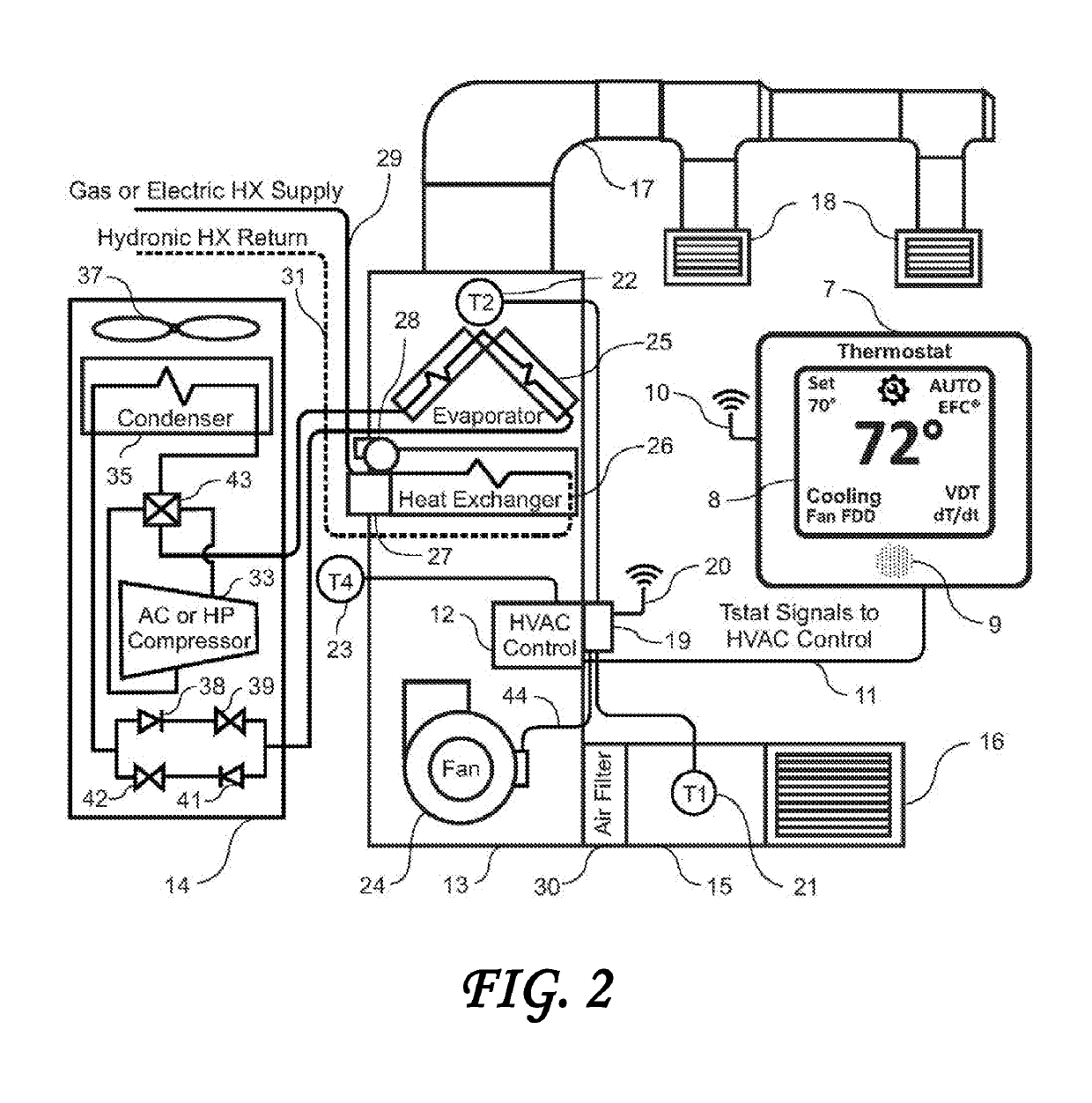

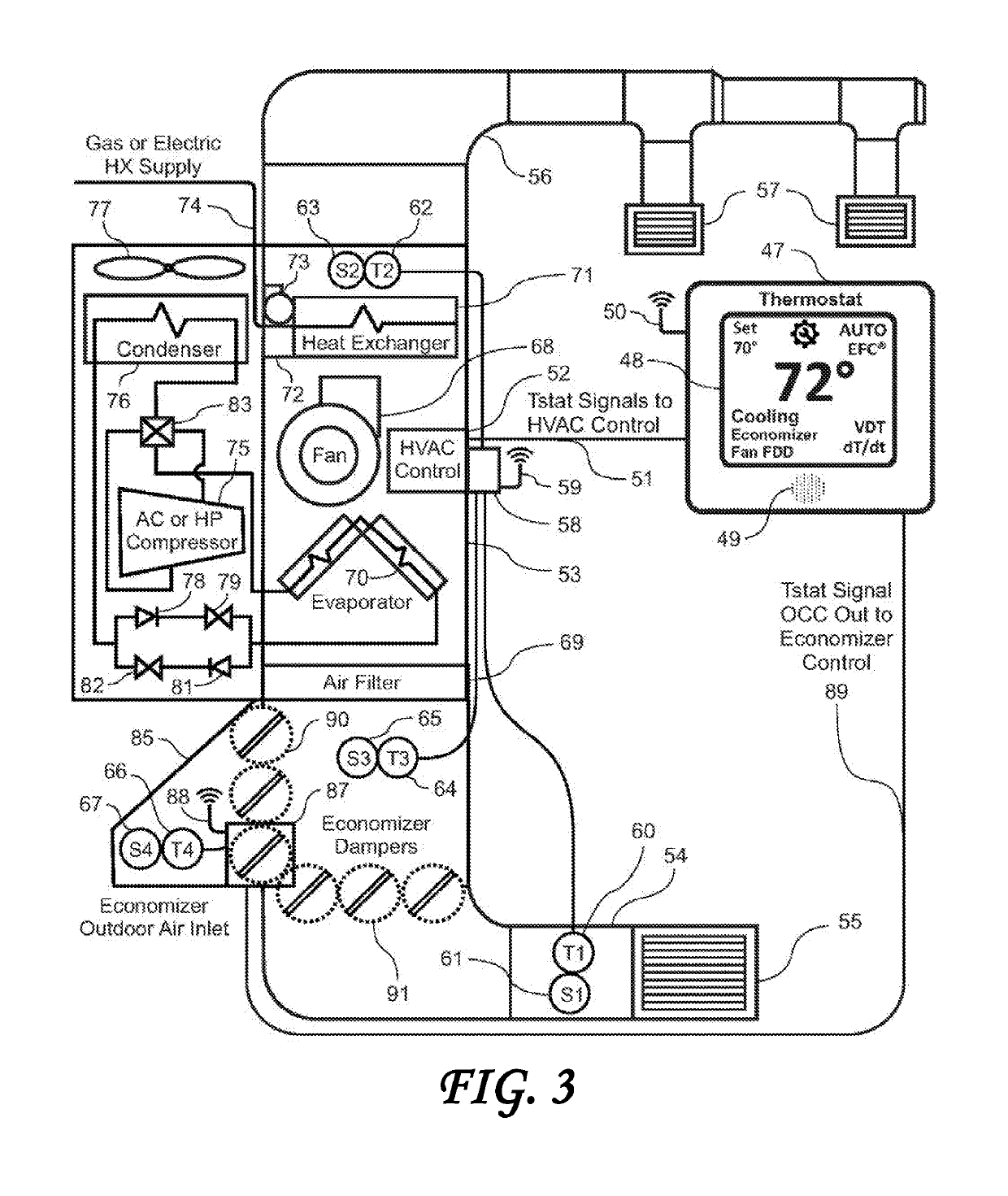

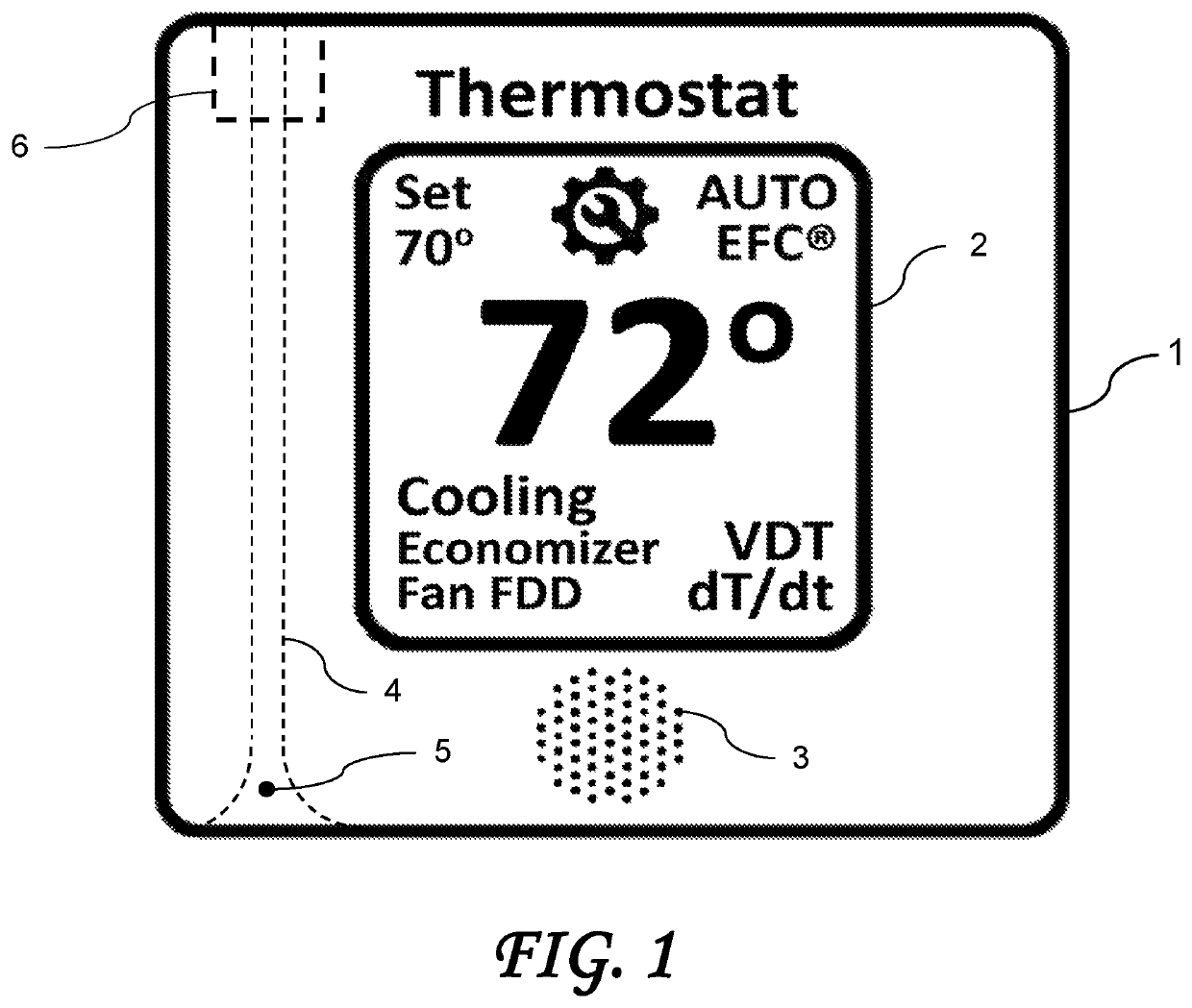

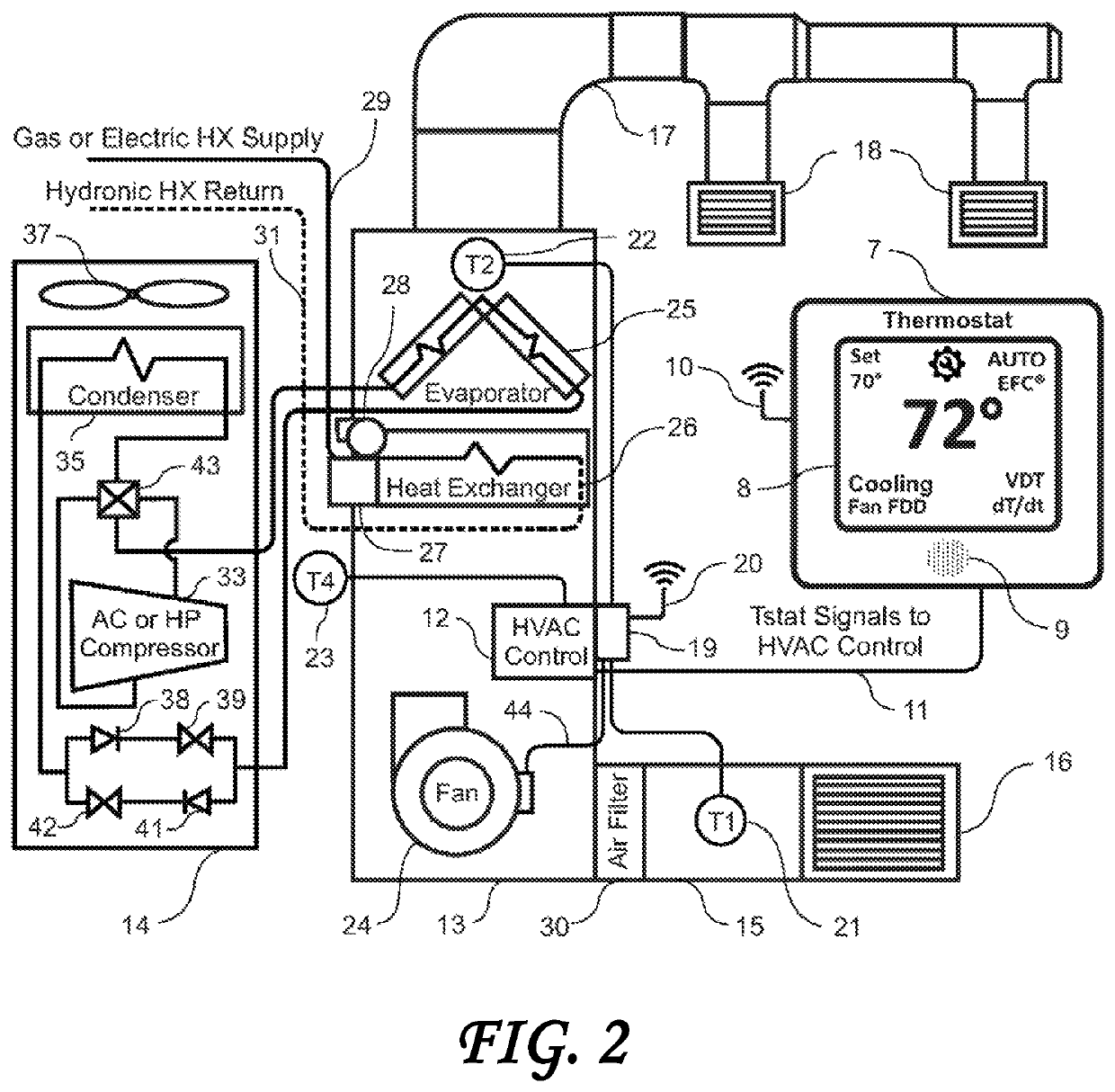

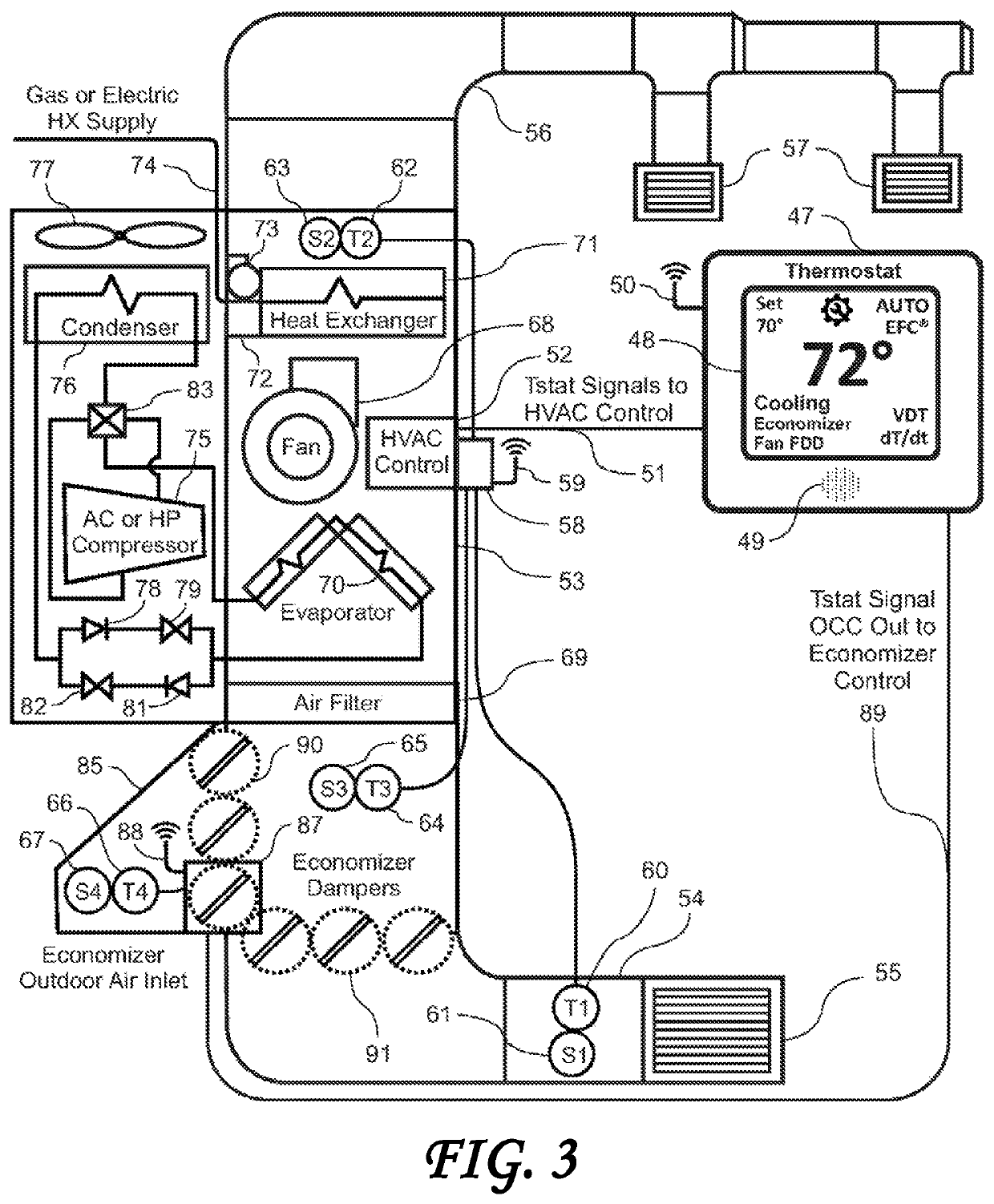

Variable Differential Variable Delay Thermostat

ActiveUS20190195523A1Improve efficiencyEnsure occupant comfortMechanical apparatusSpace heating and ventilation safety systemsCooling temperatureHeating system

A method for providing a cooling or heating variable fan-off delay based on a Conditioned Space Temperature (CST) measured during a current variable fan-off delay period compared to CST values measured during the current variable fan-off delay period. The method may also include turning off a cooling or heating system and continuing to operate an HVAC fan until the CST reaches an Inflection Point (IP) where a rate of change of the CST with respect to time (dT / dt) equals zero plus or minus a confidence interval tolerance. The method may also include providing a cooling or heating variable differential (or offset) and / or variable fan-off delay based on the duration of the thermostat call for cooling or heating, an off cycle time, a cooling temperature split, a heating temperature rise, outdoor air temperature, supply air temperature or a rate of change with respect to time of any of these HVAC parameters.

Owner:LAU JAMES

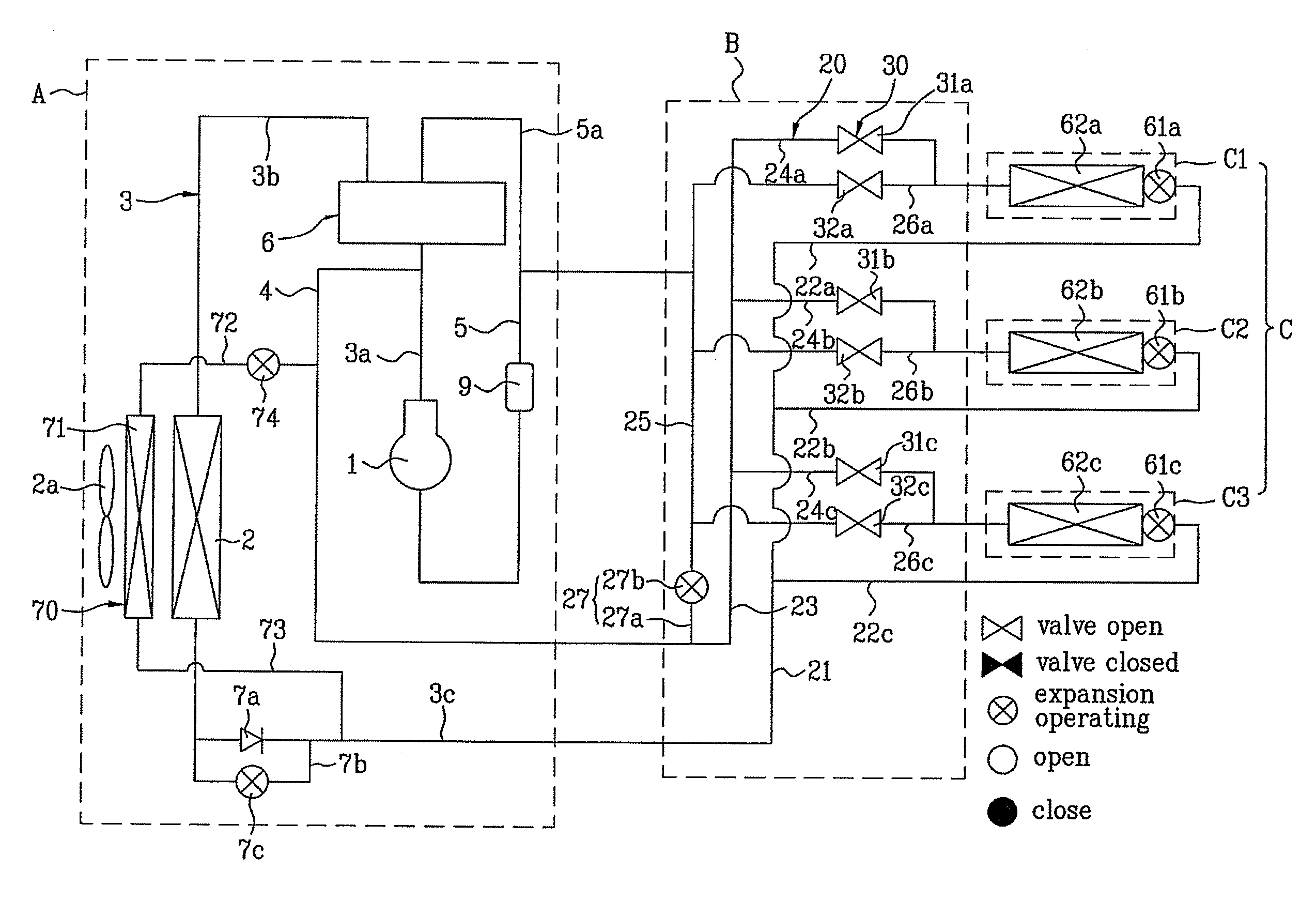

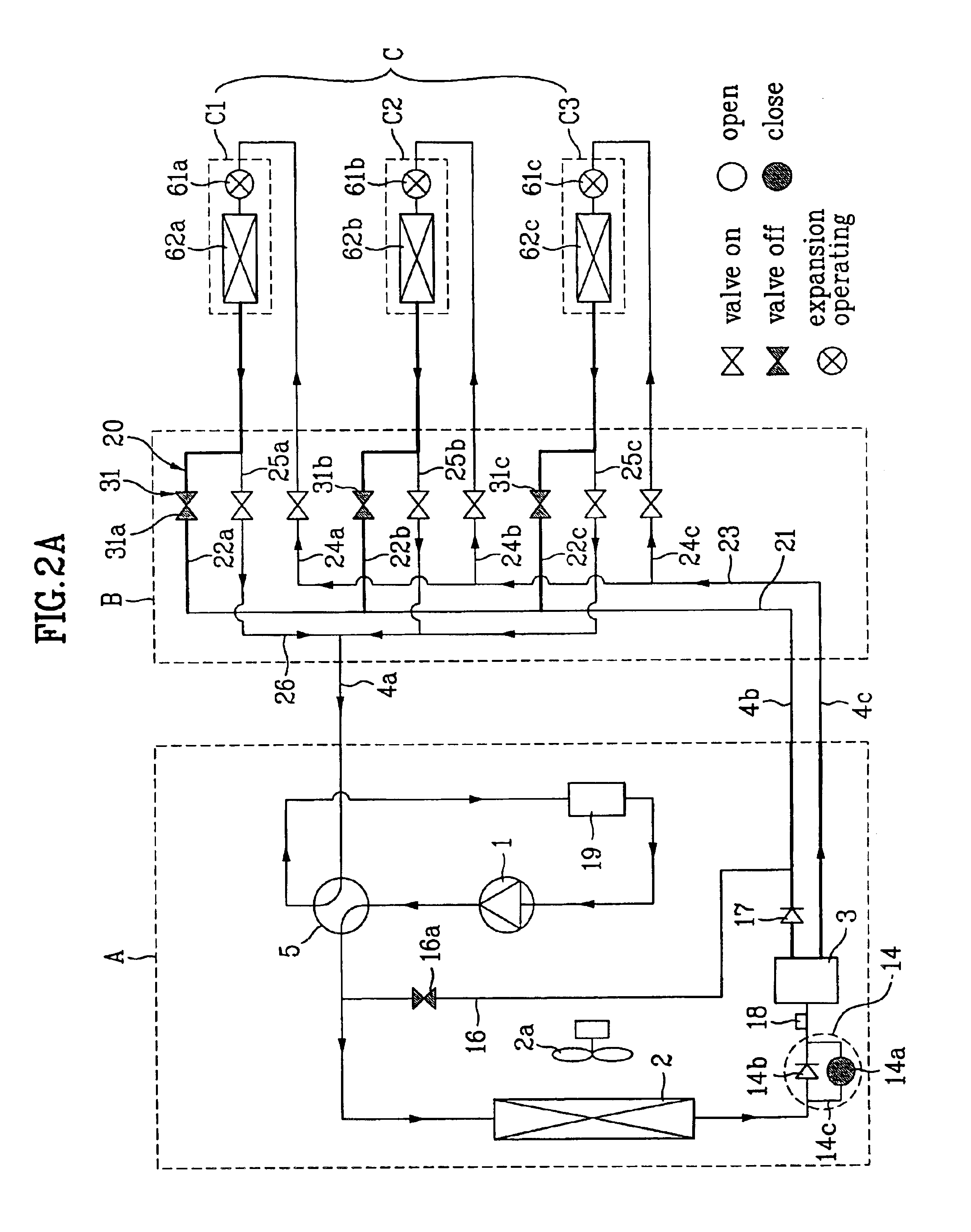

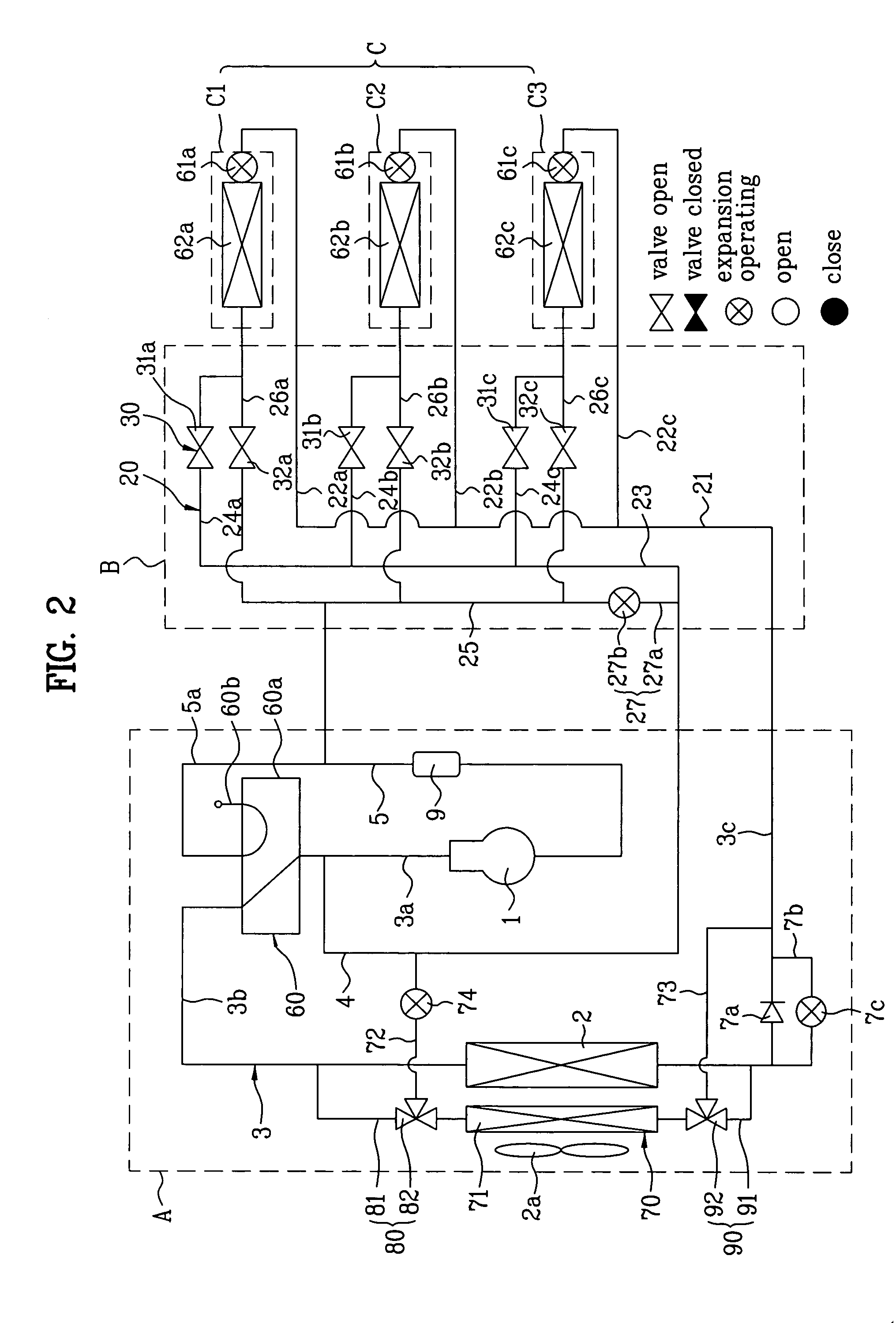

Multi-type air conditioner with defrosting device

InactiveUS20070130967A1Improve air conditionImprove defrosting effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringDistributor

Multi-type air conditioner comprising an outdoor unit installed in an outdoor, comprising a compressor, a refrigerant flow controlling part connected to a discharge end of the compressor for guiding the refrigerant proper to operation conditions selectively, an outdoor heat exchanger connected to the refrigerant flow controlling part, a defrosting device at a side of the outdoor heat exchanger, and a piping system connected between the parts, a plurality of indoor units each installed in a room and having an indoor heat exchanger and an electronic expansion valve having one end connected to one end of the indoor heat exchanger, and a distributor between the outdoor unit and the indoor units for selectively guiding refrigerant from the outdoor unit to the plurality of indoor units proper to operation conditions, and guiding the refrigerant passed through the indoor units to the outdoor unit again.

Owner:LG ELECTRONICS INC

Special organic fertilizer for grapes

InactiveCN102617220AIncrease the number of knotsImprove air conditionFertilizer mixturesPhosphateMonopotassium phosphate

The invention discloses a special organic fertilizer for grapes. Organic fertilizer extract liquid is used as base liquid, and potassium sulphate, potassium dihydrogen phosphate, urea, superphosphate, magnesium sulfate heptahydrate, zinc sulfate heptahydrate, sodium borate and the like are added in the organic fertilizer extract liquid. The special organic fertilizer for grapes consists of elements including, by weight percentage, from 22.0 to 24.0% of nitrogen, from 11.0 to 12.0% of phosphorus, from 11.0 to 12.0% of potassium, from 0.6 to 1.2% of calcium, from 0.7 to 1.4% of magnesium, from 1.8 to 2.8% of sulphur, from 0.08 to 0.1% of zinc and from 0.18 to 0.2% of boron. The utilization rate of the fertilizer can be increased, the zinc in the fertilizer can increase the number of grapes in each grape bunch, the boron can improve shriveling of the grapes, the number of shriveled grapes is reduced, similar maturity of the grapes can be prompted, growth of the grapes is promoted, yield of the grapes is increased, and quality of the grapes is improved.

Owner:江苏田娘农业科技有限公司

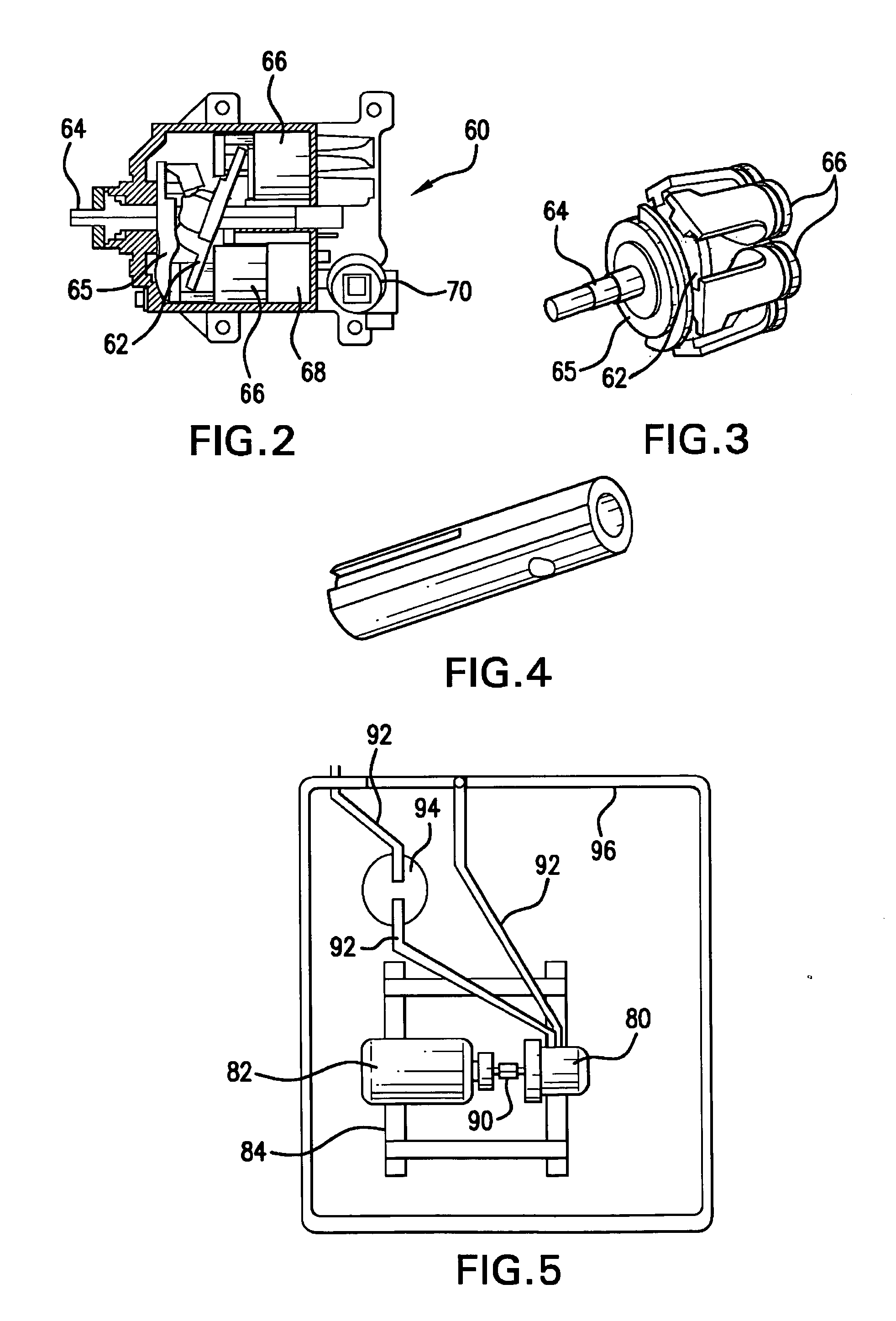

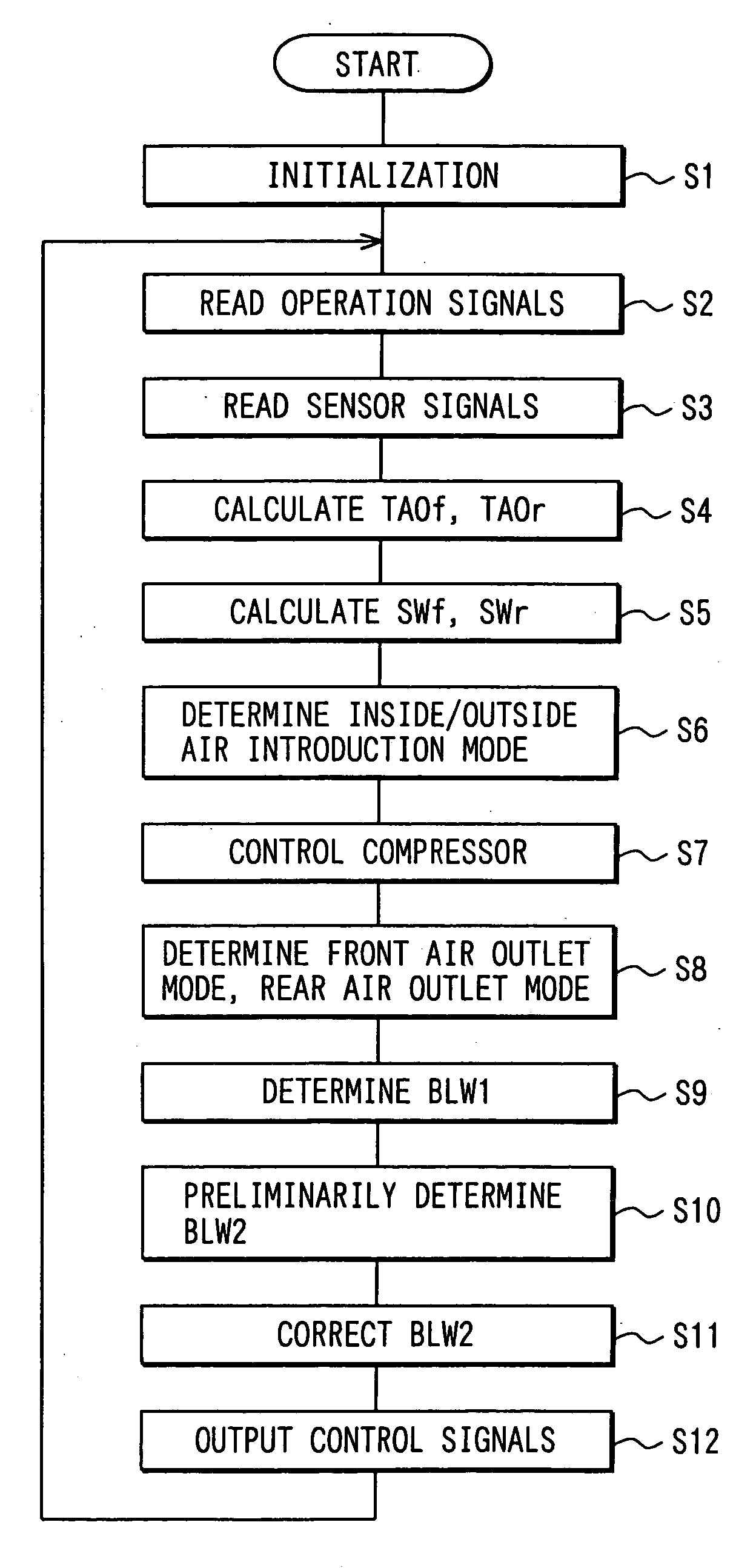

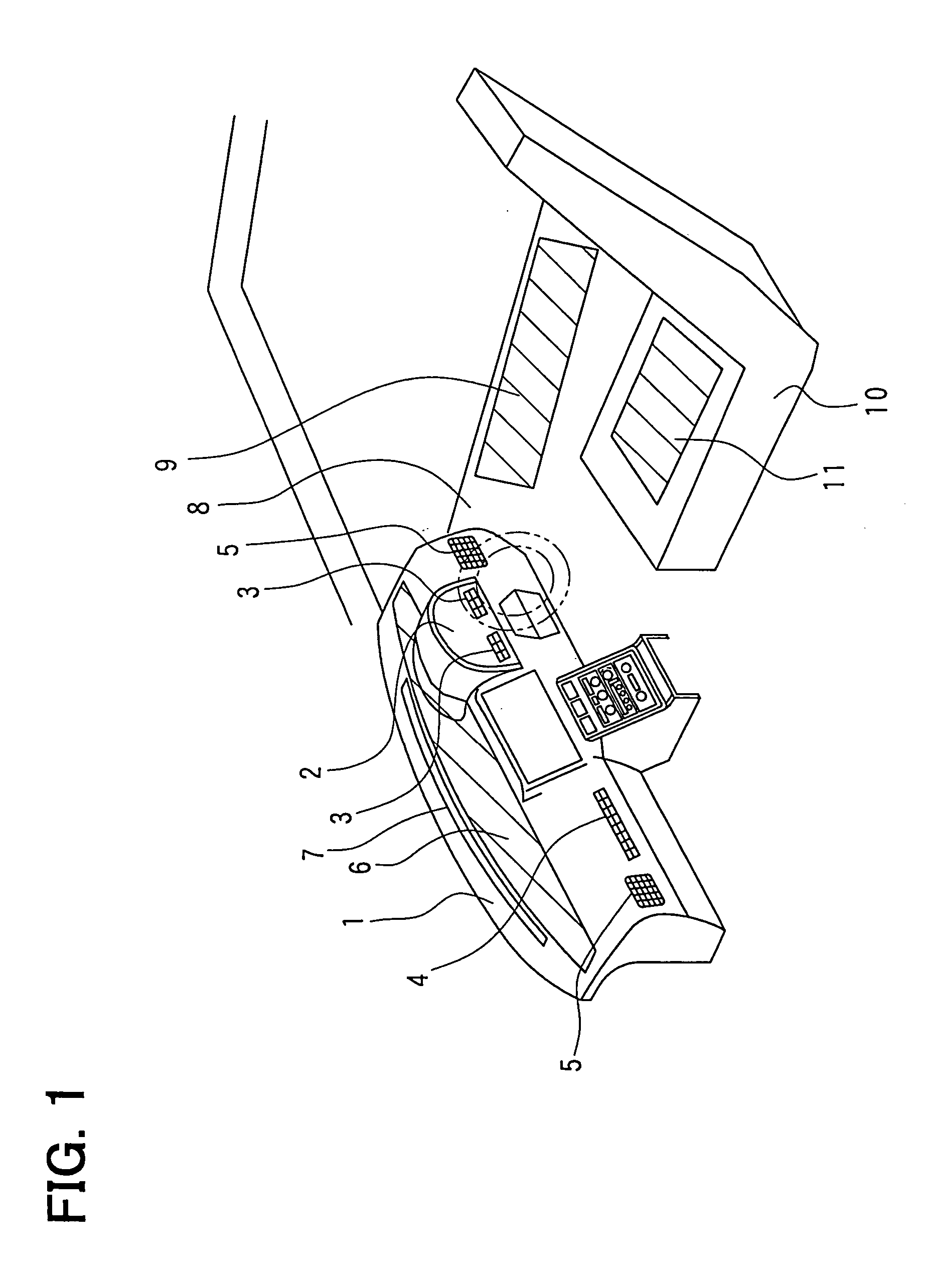

Vehicle air conditioner with automatic control of main blower and sub-blower

InactiveUS20040098995A1Ensure correct executionIncrease air volumeAir-treating devicesRailway heating/coolingAutomatic controlAutomotive engineering

A vehicle air conditioner includes a main blower and a sub-blower for blowing air into a passenger compartment. The main blower is disposed to blow conditioned air in a front air passage toward a front seat area in the passenger compartment, and the sub-blower is disposed in a rear air passage having an air flow resistance larger than that in the front air passage so that a part of air blown by the main blower is blown by the sub-blower toward a rear seat area in the passenger compartment through the rear air passage. In the air conditioner, an air amount blown by the sub-blower is controlled to be increased in accordance with a decrease of an air amount blown by the main blower. Therefore, automatic control of the air amount blown by the sub-blower can be accurately performed.

Owner:DENSO CORP

System and method for managing indoor air through cooperation between air conditioner and mobile assistant device

ActiveUS7366588B2Quick controlAccurate detectionMechanical apparatusLighting and heating apparatusPrimary operationAir quality index

A method and system for efficiently managing indoor air through cooperation between a mobile device and a stationary air conditioner. The system may include at least one stationary air conditioner and at least one mobile assistant device that move with a predetermined management area and cooperates with the air conditioner. The air conditioner may include an air quality improving unit improving a value of a predetermined air quality index into an appropriate range, a first forced flow unit generating a main flow to transport improved air toward the abnormal region, and a control unit controlling the air quality improving unit and the first forced flow unit to perform a main operation on the abnormal region and transmitting a command instructing the assistant device to perform an assistant operation on the abnormal region to the assistant device.

Owner:SAMSUNG ELECTRONICS CO LTD

Melon and fruit fresh-keeping liquid and preparation method thereof

InactiveCN101199298AImprove stabilityReduce manufacturing costFruit and vegetables preservationSucroseFiltration

The invention is a melon-fruit preservative solution which is composed of chitosan solution (2.5-5.0w percent), gelatin (2.0-5.0w percent), glycerol (0.5-1.0w percent), cane sugar (0.5-1.0w percent), tragantine (5.0-10.0w percent) and plant rosemary extract (80.0-85.0w percent). The chitosan solution is the saturated liquid of chitosan in acetic acid with concentration of one percent; the plant rosemary extract is distillate of the plant rosemary with temperature of 90-103 DEG C received by distillation after the filtration and slag removal through being soaked in water with the volume 40 times greater than that of plant rosemary. The invention has advantages of easy material getting, simple preparation method, low production cost, small energy consumption, innocuity to human bodies, non environment pollution, long preserving time for melon and fruit-in particular to high-grade fruit and good effects.

Owner:DALIAN POLYTECHNIC UNIVERSITY

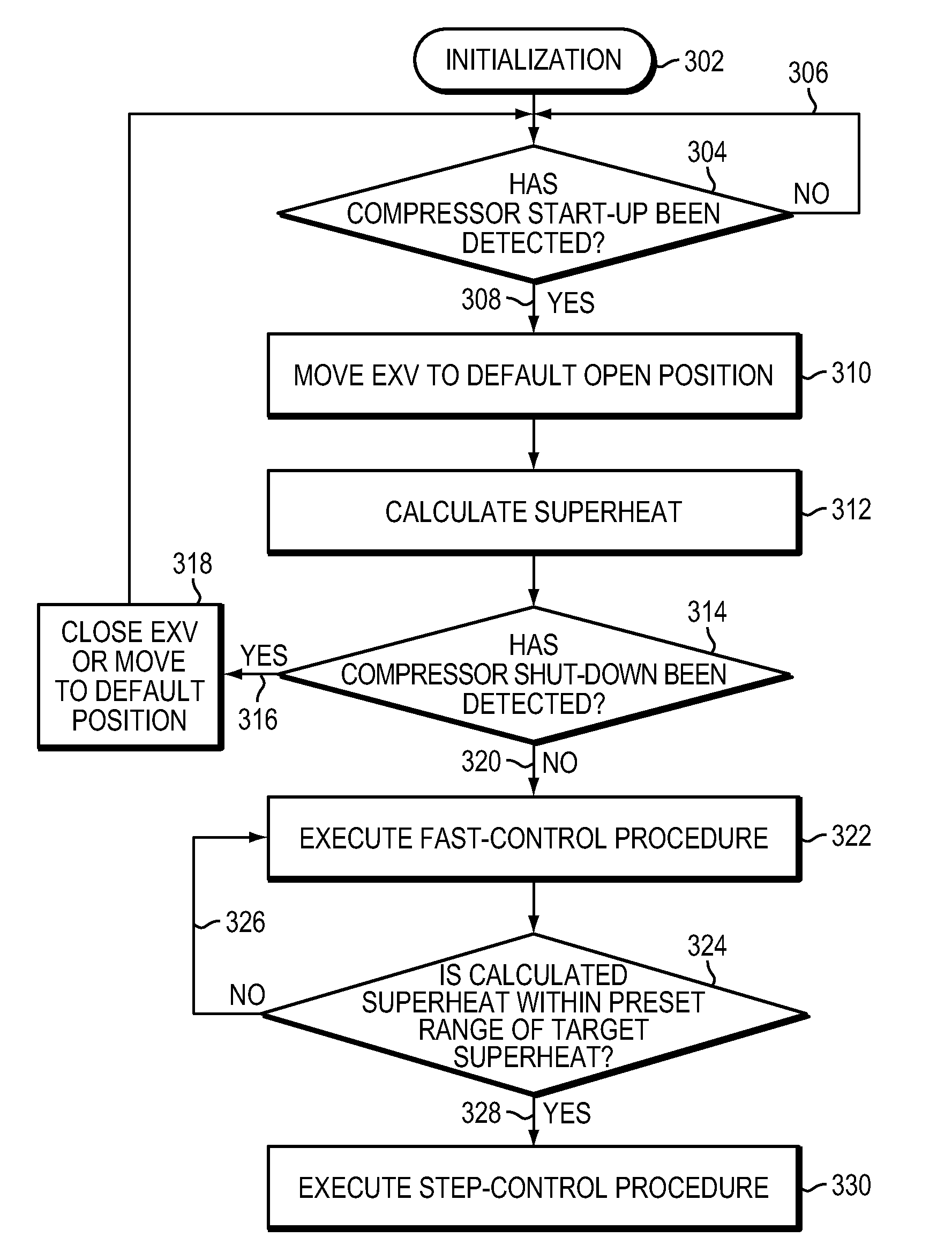

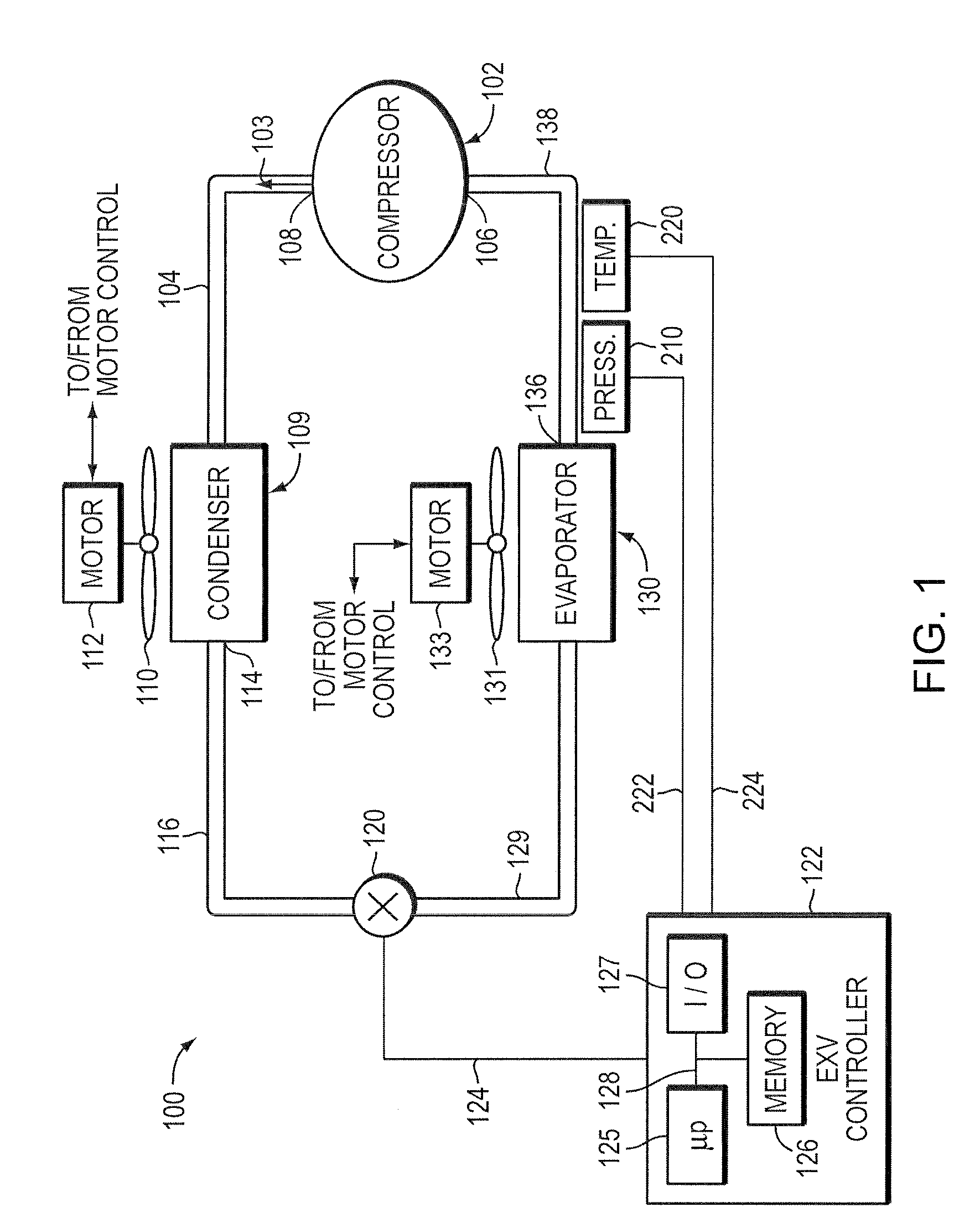

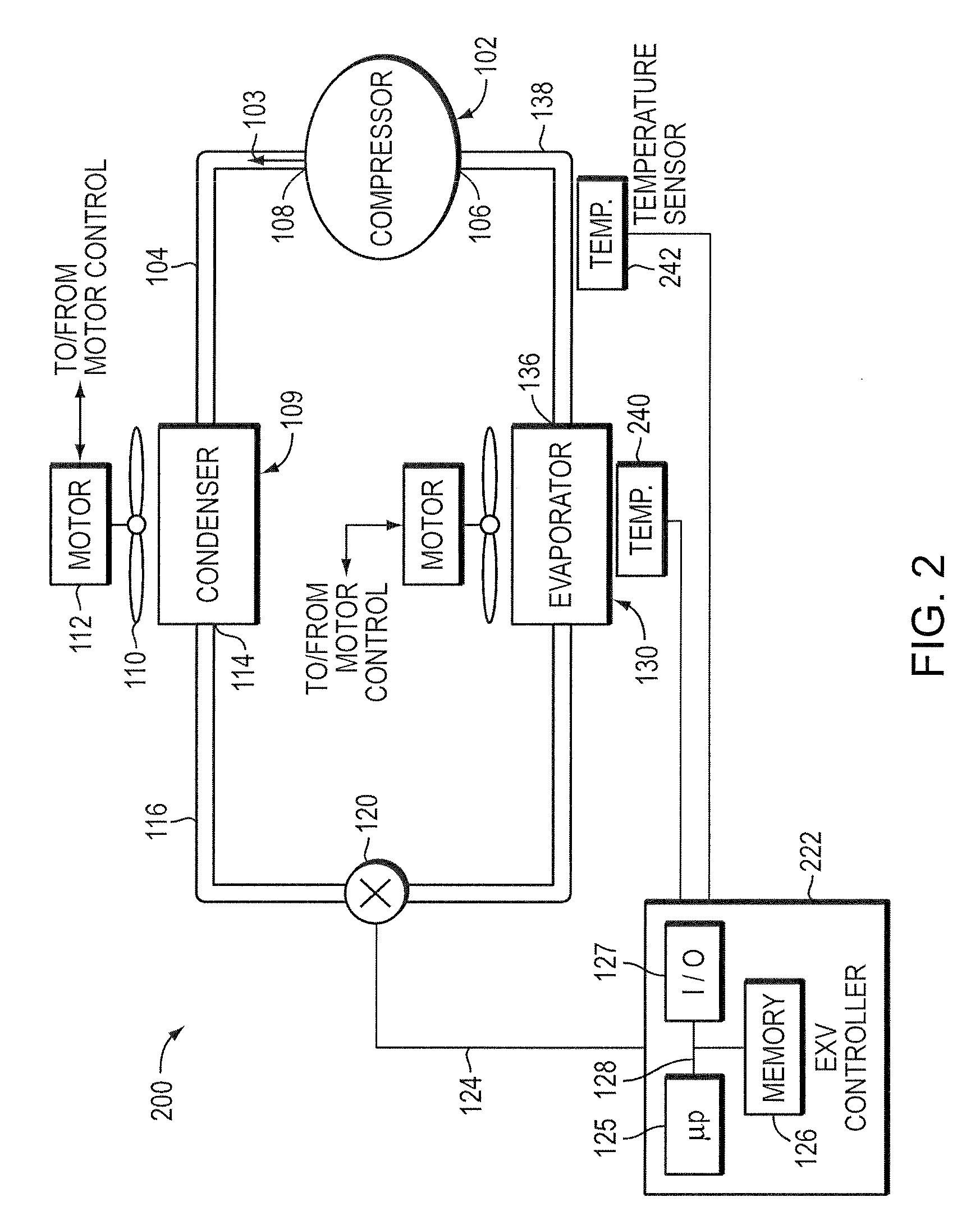

System and method for controlling an air conditioner or heat pump

ActiveUS7784296B2Minimizes degree of opening and closingAvoid damageMechanical apparatusAuxillary controllers with auxillary heating devicesEngineeringAir conditioning

A control procedure operates an expansion valve of an air conditioning system. The control procedure utilizes a first control procedure to bring a calculated superheat value within a range of a target superheat value, and a second control procedure to cause the calculated superheat value to match the target superheat value. Both the first and second control procedures preferably use Proportional, Integral, Derivative control algorithms.

Owner:NORTEK GLOBAL HVAC

Vehicle air conditioner

InactiveUS20040102151A1Uniform temperature distributionUniform distribution of wind speedAir-treating devicesRailway heating/coolingThermal radiationAir conditioning

In an initial stage of a cool down operation of a vehicle air conditioner, a rapid cooling operation is performed while cool air is directly blown to a passenger from direct air outlets. In a later stage of the cool down operation of the vehicle air conditioner, a temperature of an inner wall portion of a passenger compartment is reduced while cool air is indirectly supplied to the passenger of the passenger compartment from the indirect air outlet. Accordingly, cool air can be locally blown to the passenger in the initial stage, and cool air can be supplied to the entire passenger compartment while restricting an adverse effect due to heat radiation of the inner wall portion in the later stage. Thus, operation performance of the air conditioner can be improved while comfortable air conditioning feeling can be given to the passenger in the passenger compartment.

Owner:DENSO CORP

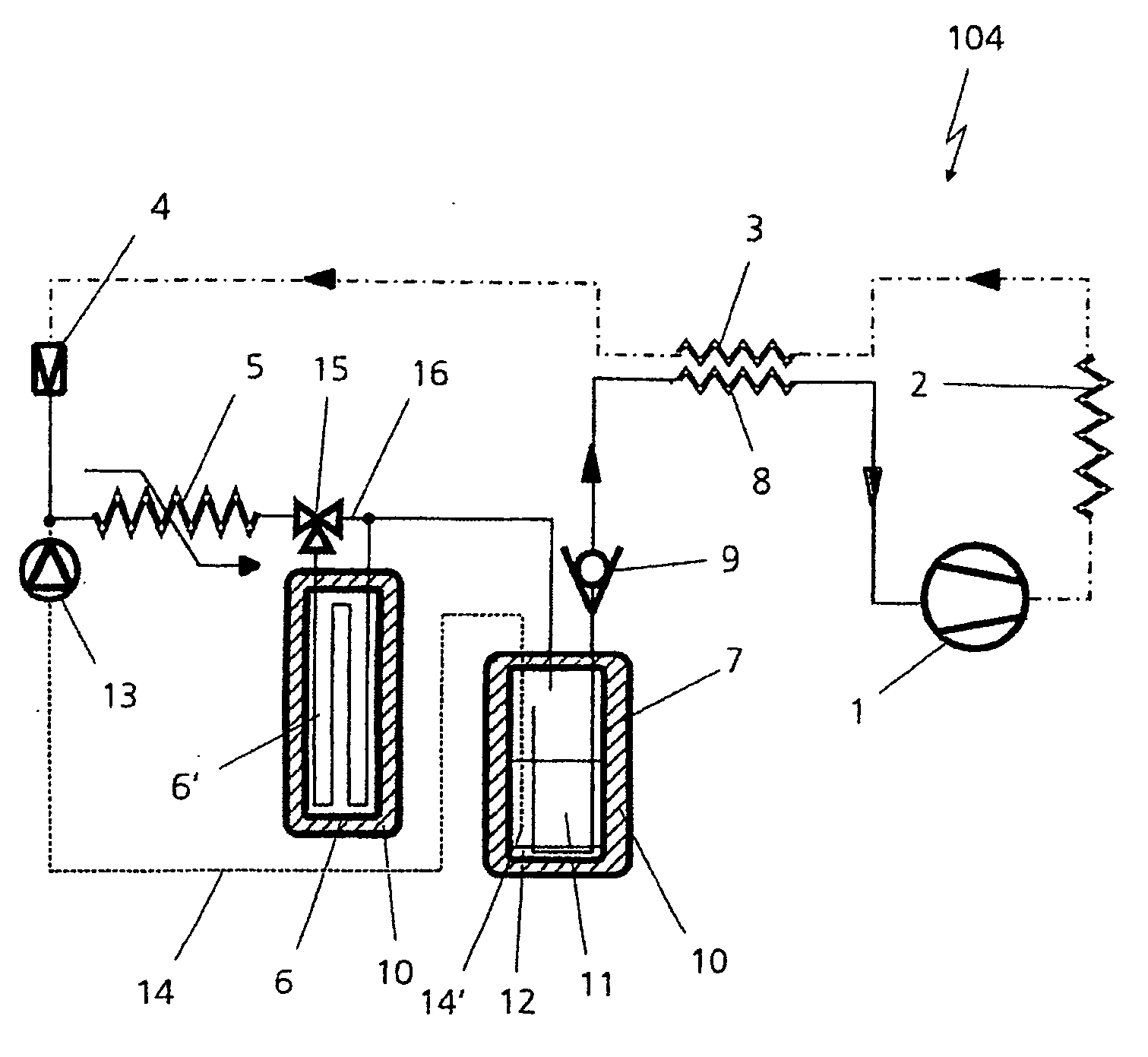

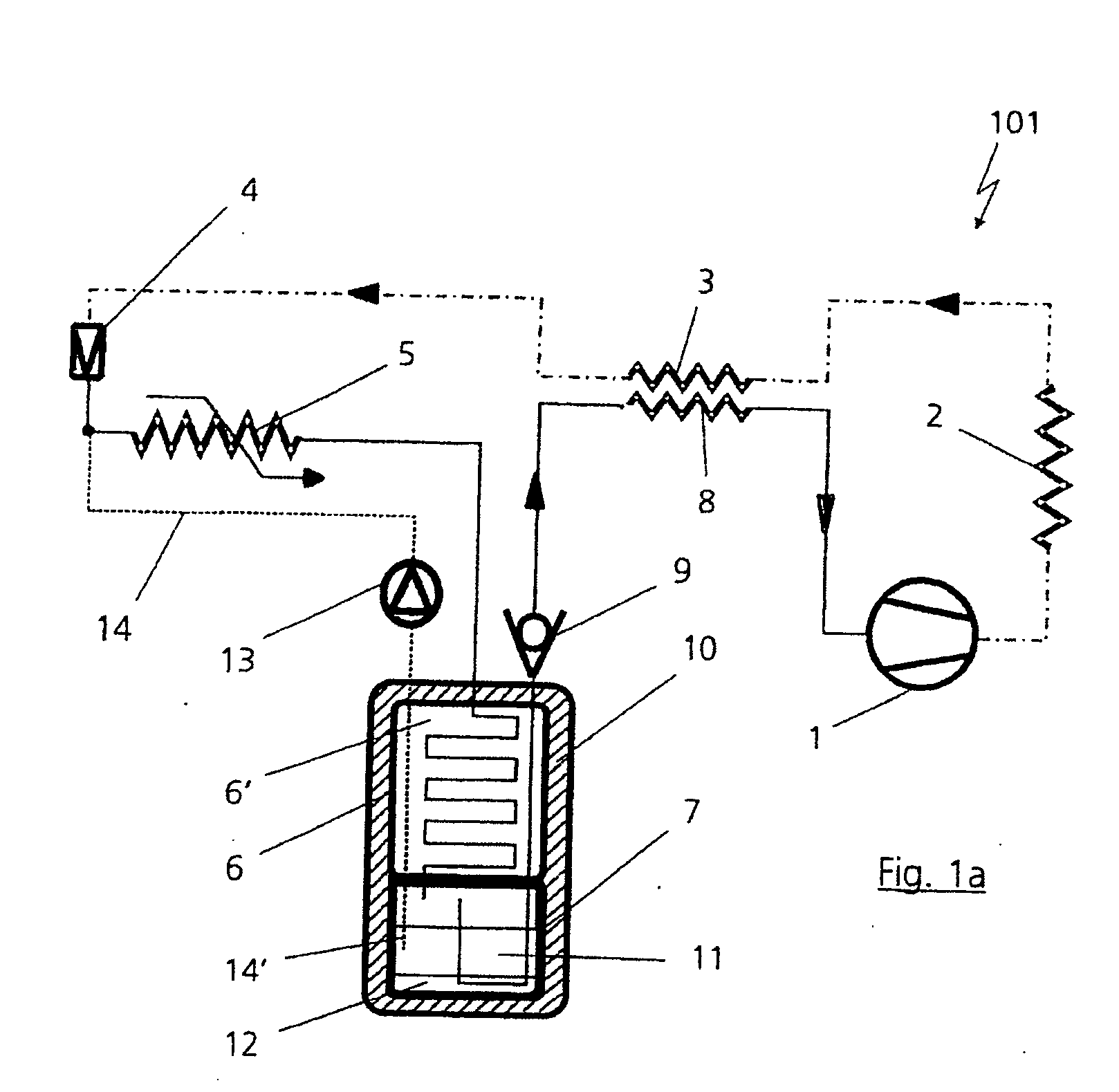

Air-conditioning installation, especially for motor vehicles

InactiveUS20060168991A1Minimizes increase in pressureIncrease pressureAir-treating devicesHeat storage plantsRefrigerantChiller

The invention relates to an air-conditioning installation, in particular for motor vehicles, having a compression refrigeration circuit of a refrigerant for A / C operation with a high-pressure region, a suction region and a connected stationary air-conditioning circuit, in particular for stationary air-conditioning operation when the compression refrigeration circuit is switched off, having a compressor, an expansion valve, an evaporator as cooler for releasing refrigeration to the environment, and a thermal accumulator comprising a heat storage medium. The thermal accumulator serves as a refrigeration accumulator and as a condenser during stationary air-conditioning operation. The refrigerant which is present serves as heat transfer medium for transferring the refrigeration from the thermal accumulator to the evaporator in the stationary air-conditioning circuit. The evaporator and the thermal accumulator are connected in series in terms of the flow of refrigerant.

Owner:DAIMLER AG

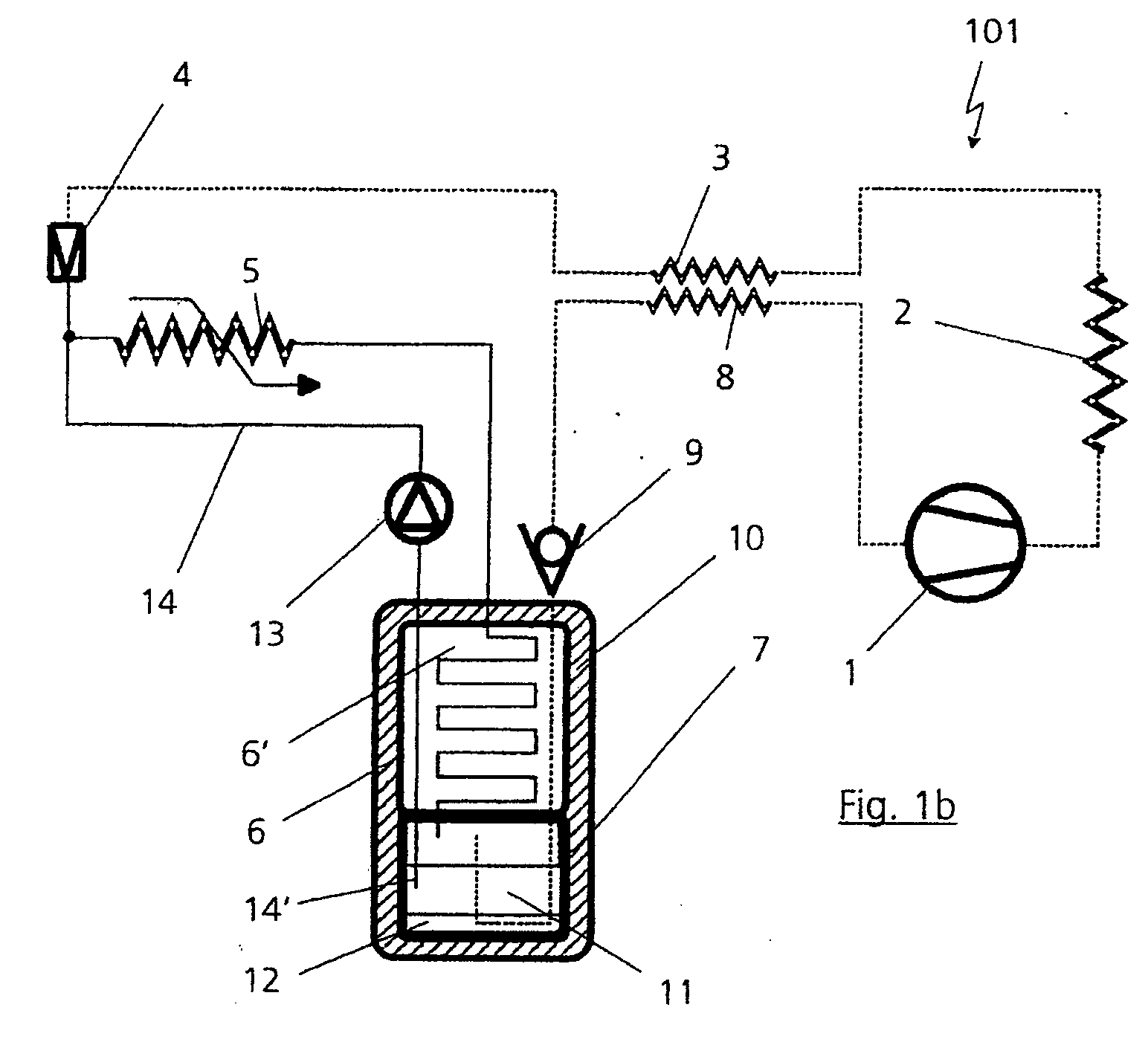

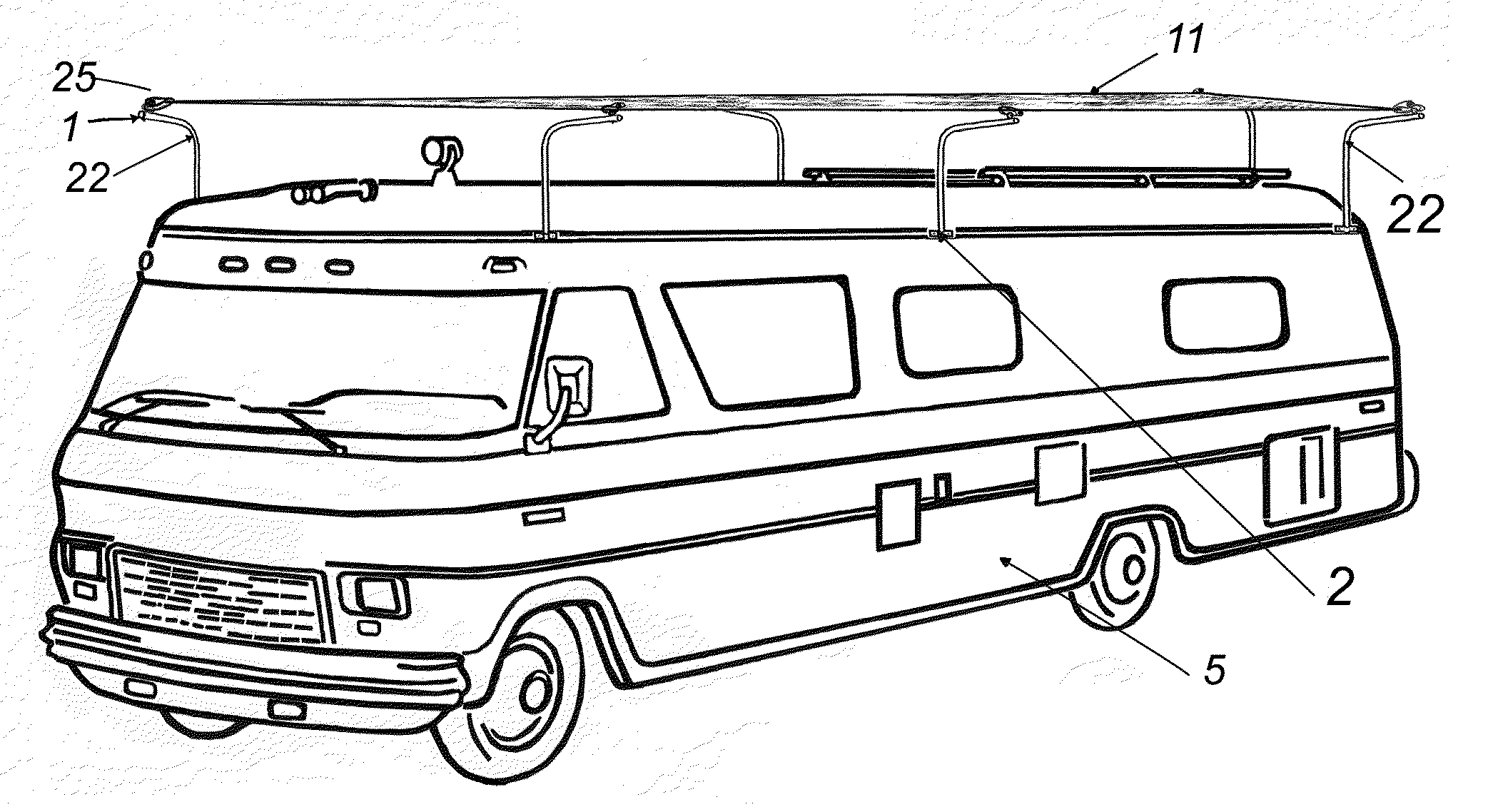

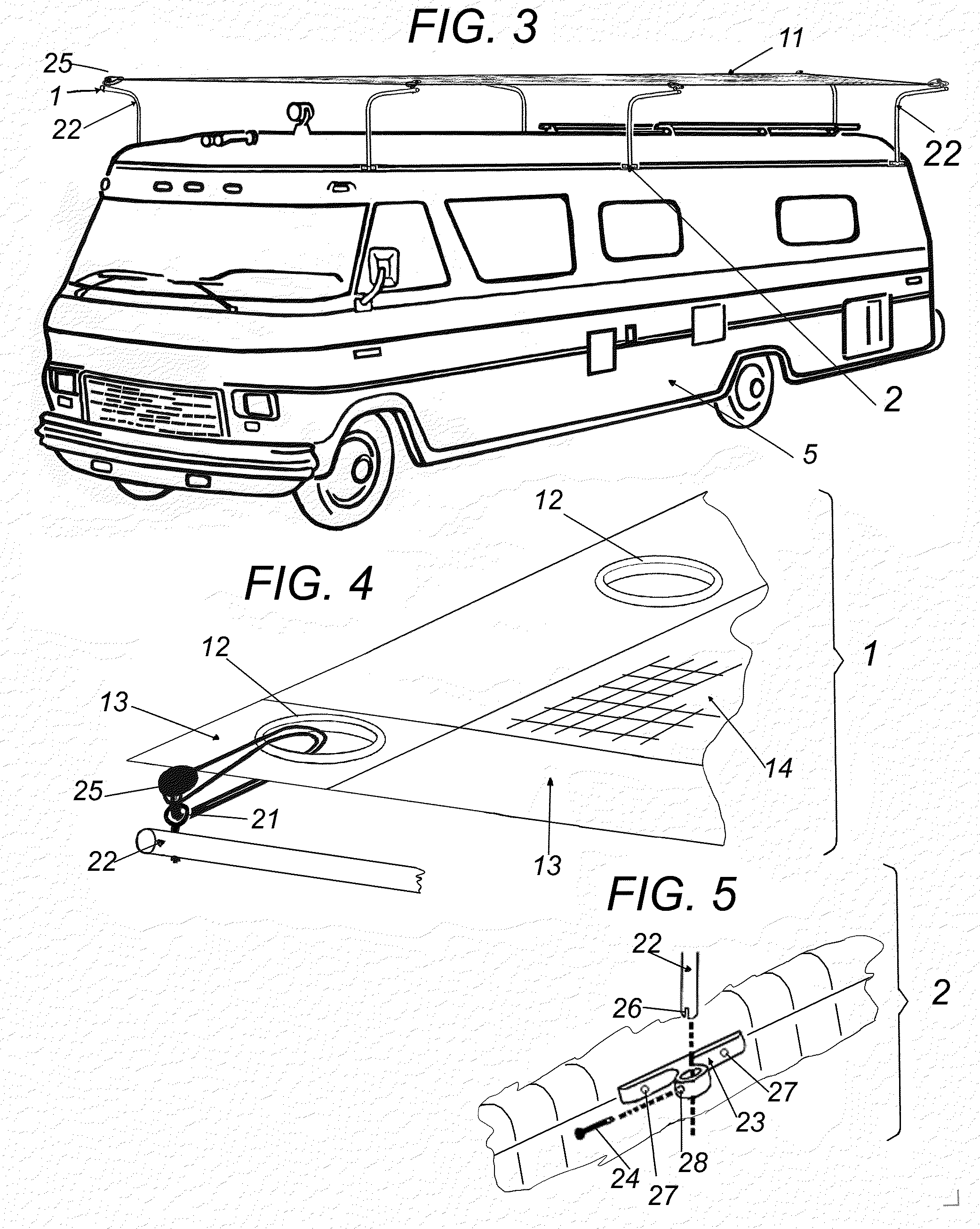

Recreational Vehicle (RV) Portable Sunscreen Canopy

InactiveUS20050011547A1Eliminate potentialImprove air conditionTents/canopiesRemovable external protective coveringsViolet rayNacelle

This invention applies a flaccid, porous, horticulture shade material as a sunscreen canopy for an RV to reduce the heat and ultra violet rays for protection of roof mounted and internal accessories from damage as well as lower internal cabin temperatures. Wind shear is greatly reduced by using porous material. Recreational vehicles are either stored or in use. Either way, the temperature internal to the vehicle can reach temperatures between 100 and 140 degrees during hot days. The challenge presented is to mechanically attach the sunscreen canopy with fasteners, tent poles and mounting extrusions to a vehicle to hold the flaccid canopy at a horizontal position above a large recreational vehicle and be simple to setup and takedown for transport. This invention successfully demonstrates how to meet the protection objectives as well as enhances the air conditioning of an RV to improve occupant comfort.

Owner:HERNDON FRED RICHARD +1

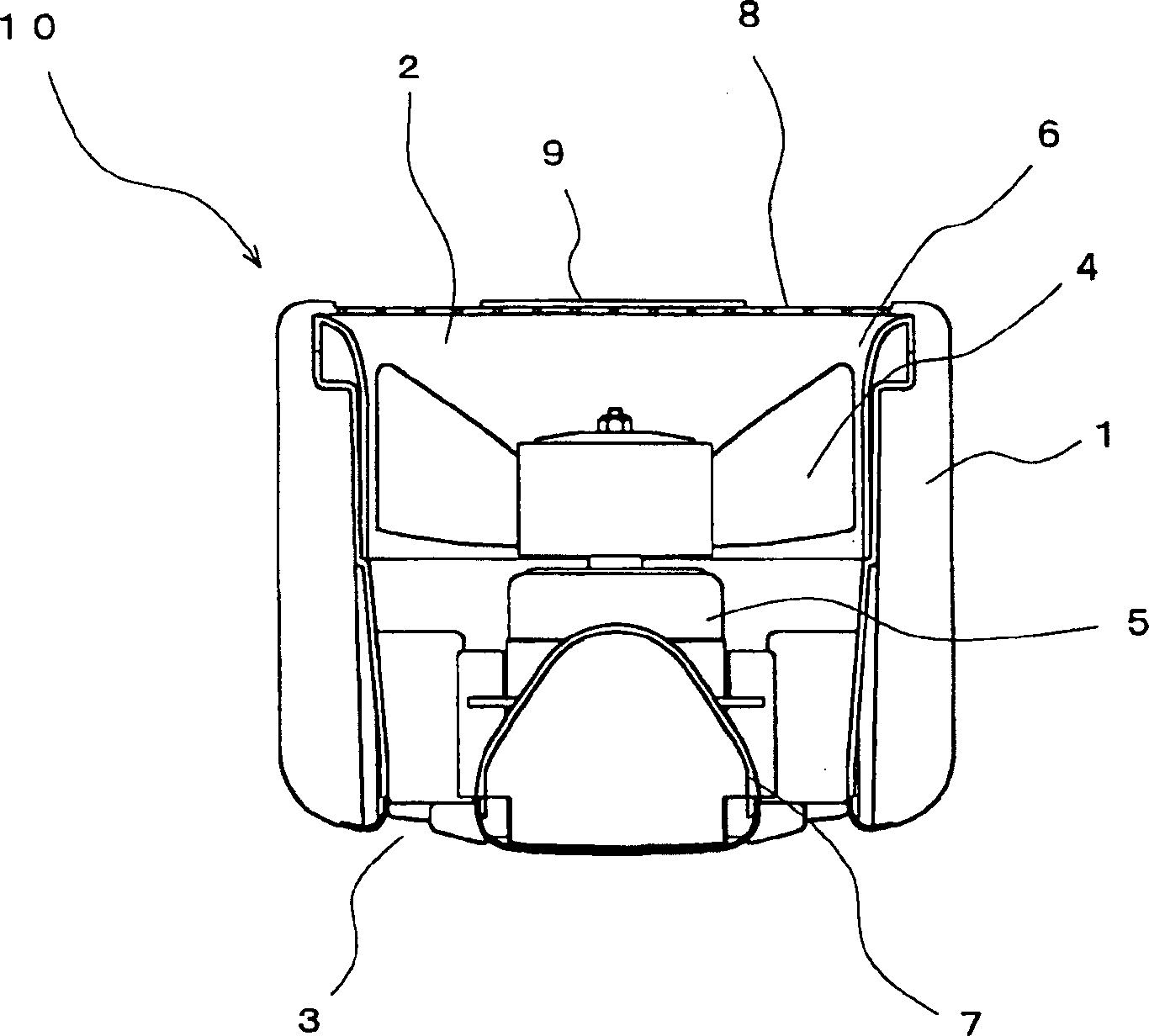

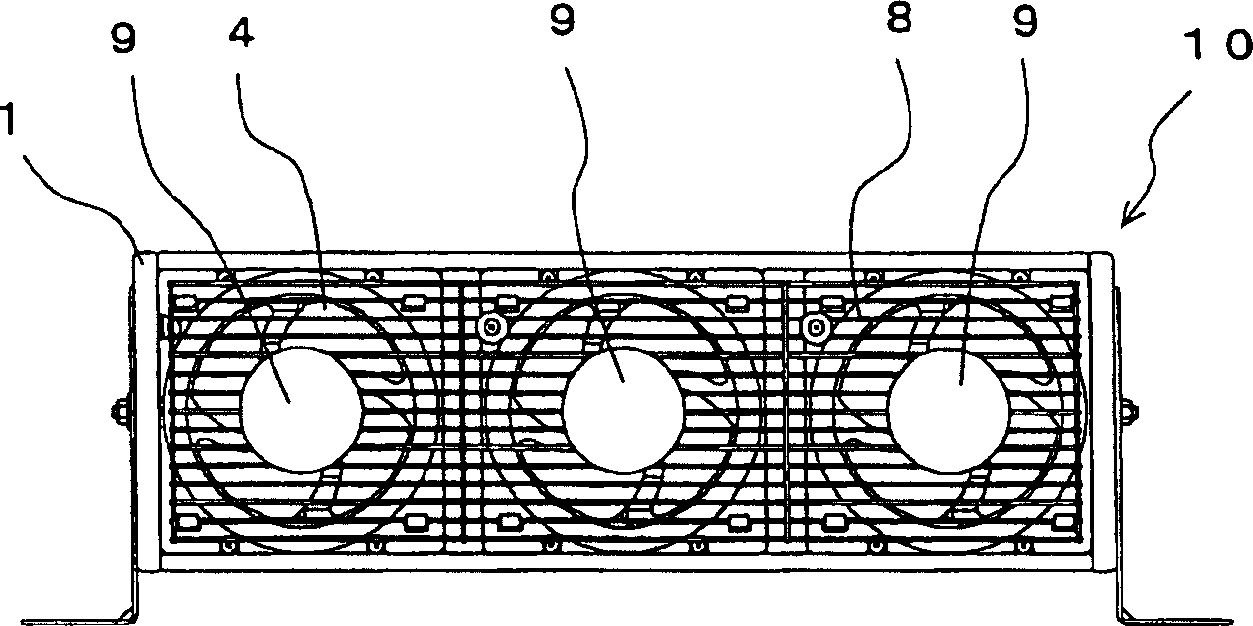

Blower

InactiveCN1683840ACause of blockage eliminatedEasy and automatic cleaningSpace heating and ventilation safety systemsPump componentsEngineeringControl circuit

The invention provides a blowing device capable of easily and automatically eliminating dust adhered to a filter or a protecting guard, in regard to a blower having a filter and a protecting guard in a suction opening thereof. This blowing device is provided with a main body box body 1 having the suction opening 2 on a back surface side and a blowing opening 3 on a front side thereof, a motor 5 provided inside the main body box body to normally and reversely rotate, an axial flow fan 4 fitted to a rotary shaft of the motor, and the filter or the protecting guard 8 fitted to the suction opening. A control circuit of the motor is provided with a switch means 11 for switching rotating direction of the motor to the opposite direction, and a time switch 12 for setting operating time of the switch means is provided. Reverse rotating operation is performed with a constant interval, and dust adhered to the filter or the protecting guard is blown off for cleaning.

Owner:MITSUBISHI ELECTRIC CORP

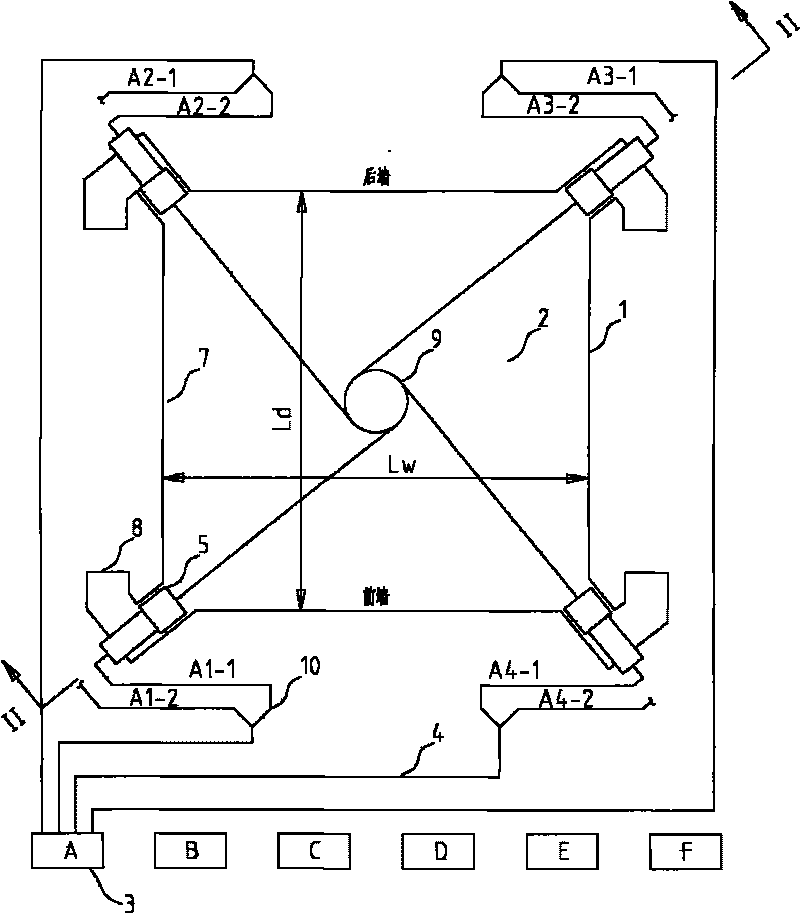

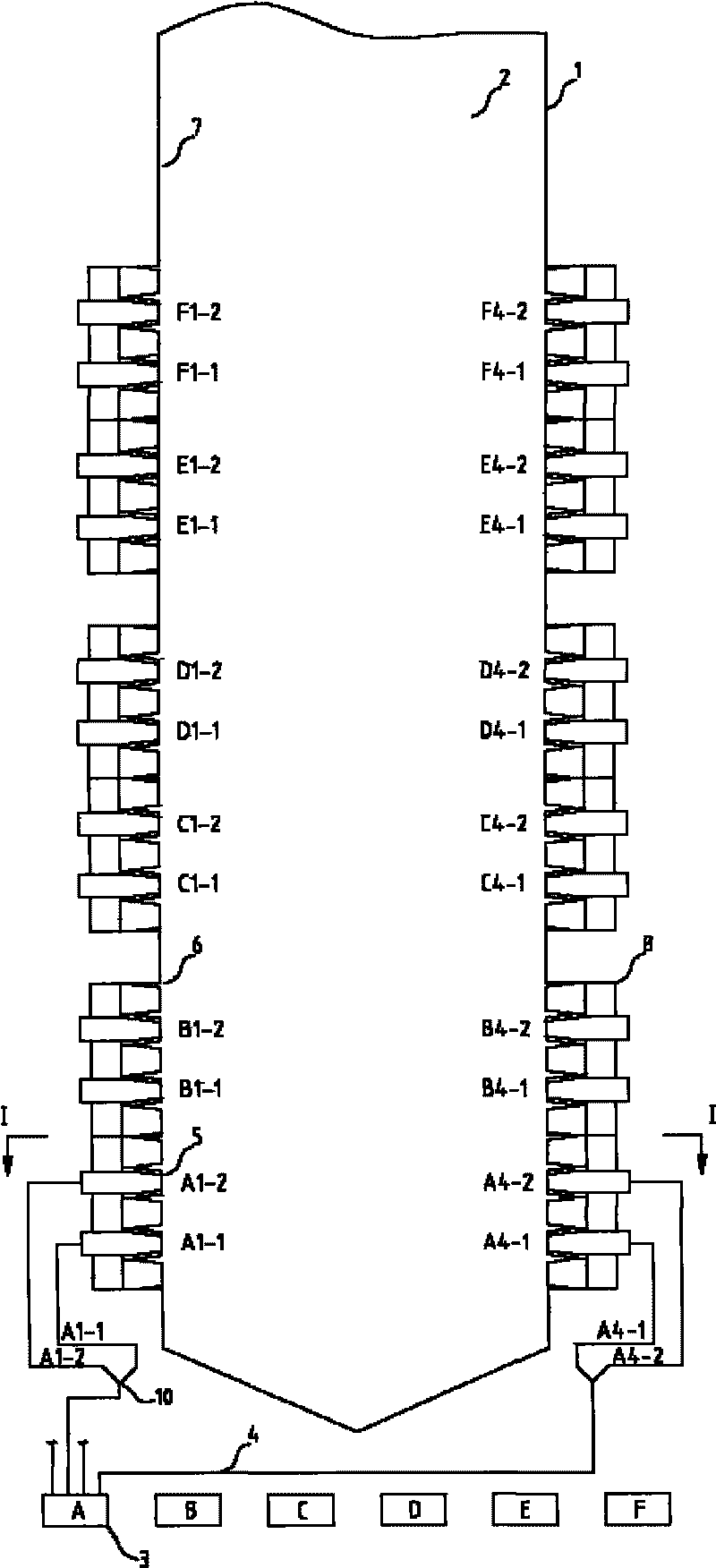

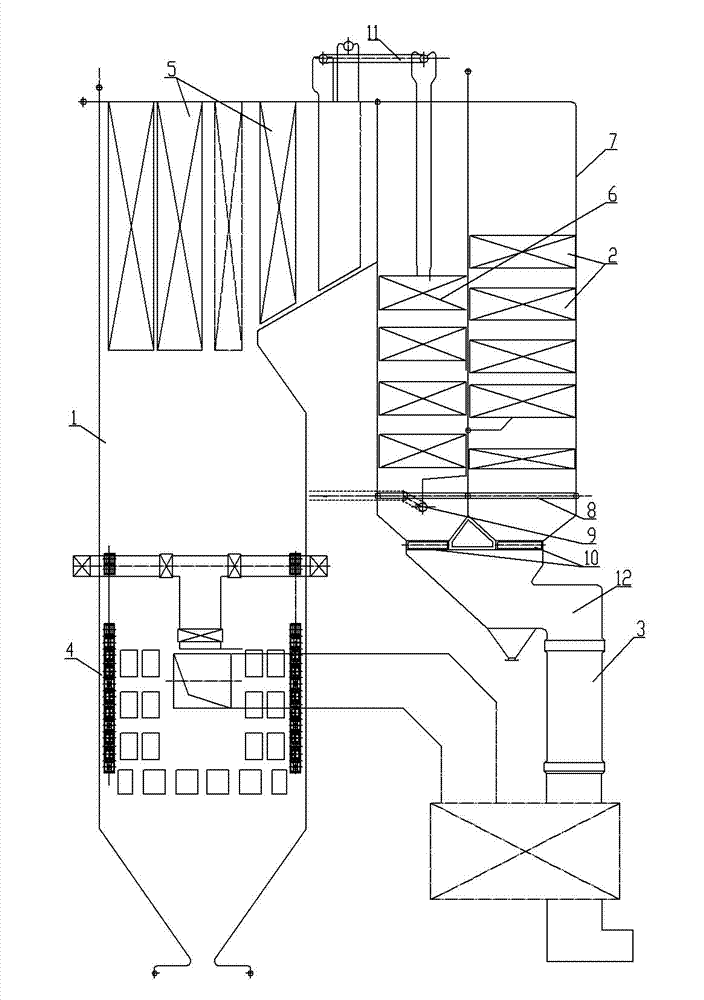

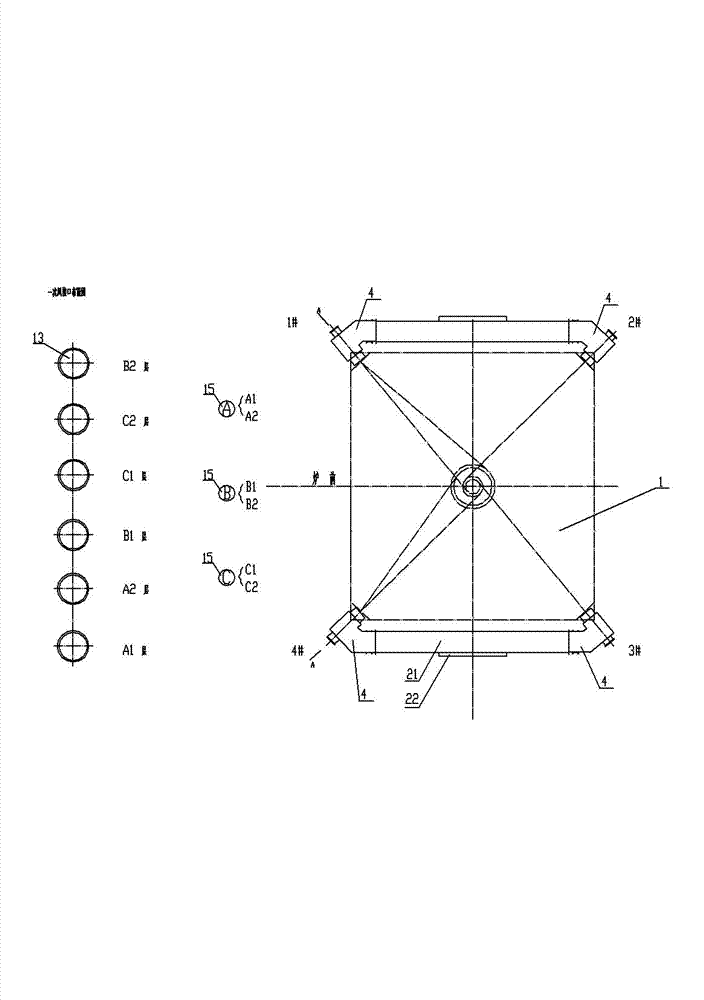

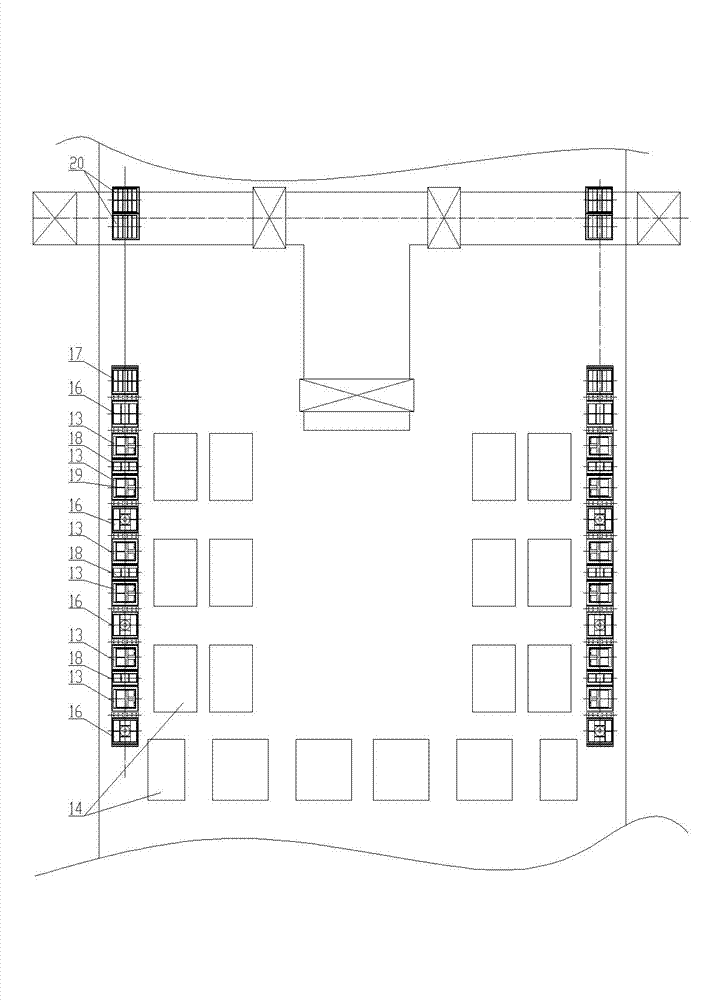

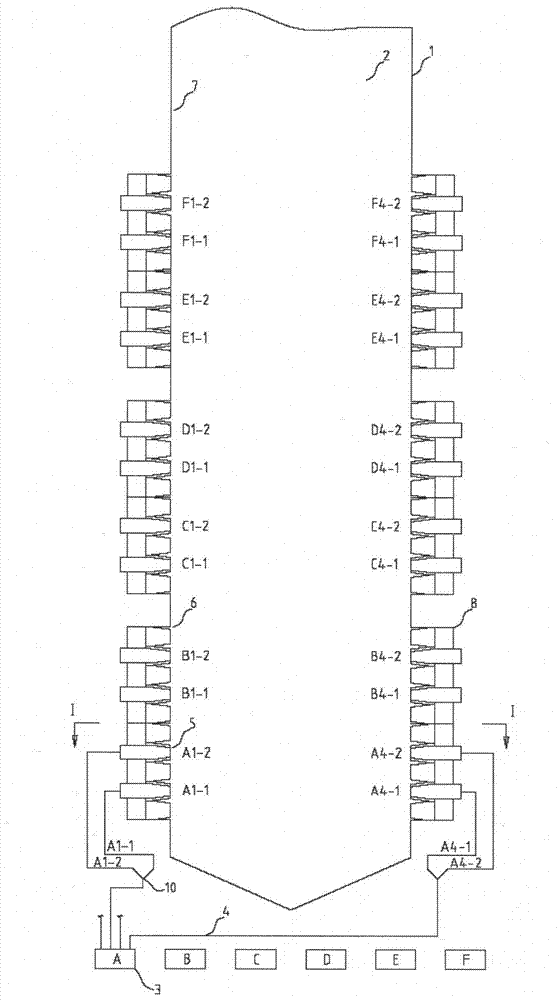

Hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors

ActiveCN101709871AGuaranteed to catch fire in timeReduce overall heightCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow loadAirflow

The invention provides hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors, which is characterized in that: two groups of combustors are arranged on each water-cooling wall or two groups of combustors are arranged on two opposite water-cooling walls of a hearth respectively and a group of combustors are arranged on the other two opposite water-cooling walls respectively, each group of combustors are at least divided into a small group; and each small group of combustors are vertically provided with at least two primary air pulverized nozzles and three secondary air pulverized nozzles at intervals. Each coal mill is connected with eight or six primary air pulverized nozzles which have the same level with that of the coal mill. The start and stop of each coal mill affect the running of the eight or six primary air pulverized nozzles which are on the same layer. The hexagonal or octagonal tangential arrangement of the anthracite burning single-fireball direct-flow combustors can decrease the number of the air pulverized nozzles in a single group of combustors on the premise of meeting the requirements of the thermal power of a single air pulverized nozzle and the number of the total air pulverized nozzles, allows the thermal load qHr of a wall in a combustor area to be relatively high, and guarantees the timely ignition of an pulverized anthracite flow and low-load combustion of a boiler without oil.

Owner:SHANGHAI BOILER WORKS

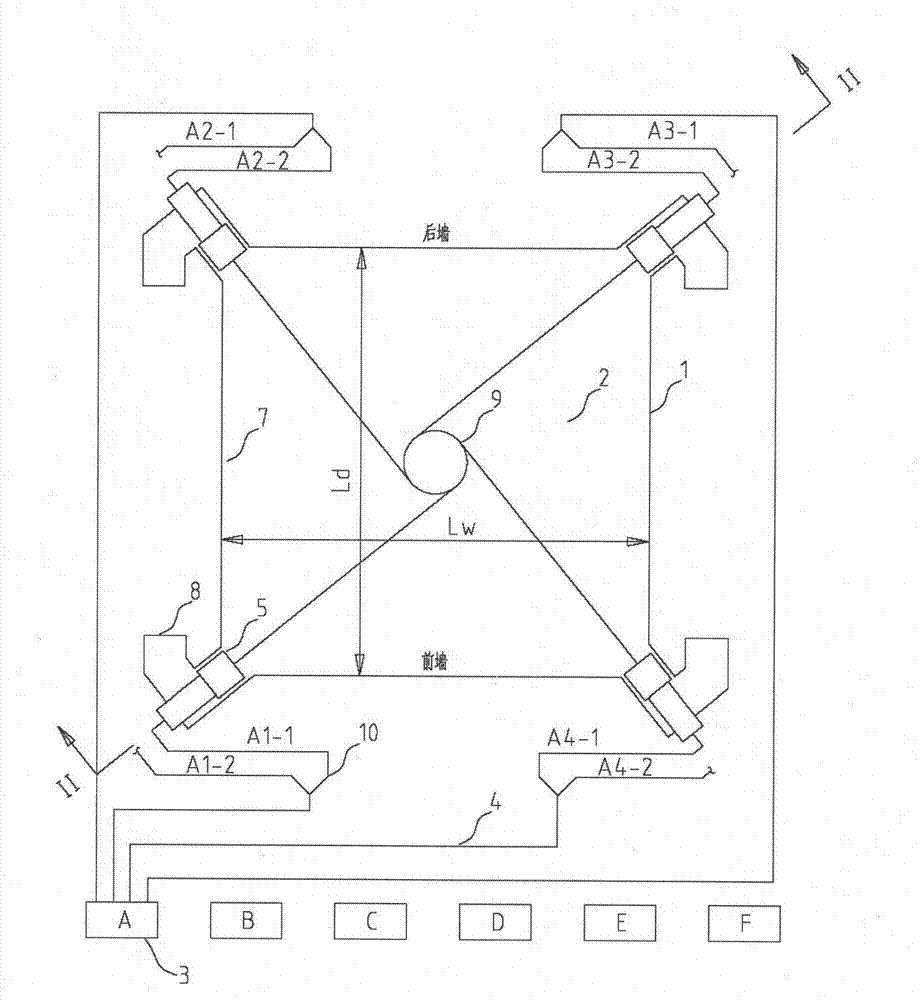

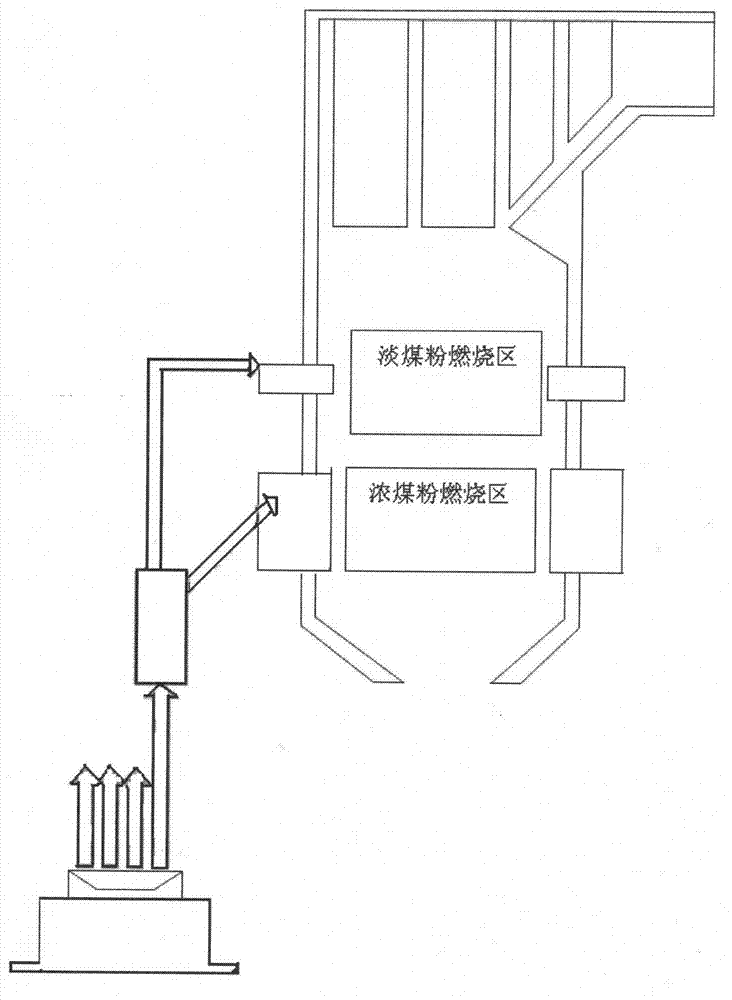

Coal dust thickness-thinness separating and distributing structure of single-fireball eight-corner direct-flow burner

ActiveCN102563634AIncrease concentrationIncrease heat loadPulverulent fuel combustion burnersWater-tube boilersDistributed structureBurns temperature

The invention discloses a coal dust thickness-thinness separating and distributing structure of a single-fireball eight-corner direct-flow burner. Eight groups of burners are arranged on a boiler body, two groups of the burners are arranged on each water cooled wall, each group of the burners comprises a plurality of the burners with nozzles facing to the same direction, and a center line of each nozzle of the eight groups of the burners forms an imaginary inscribed circle along the same tangential direction in a boiler chamber. In the coal dust thickness-thinness separating and distributing structure, the eight groups of the burners are distributed on four water cooled wall of a boiler, therefore, the coal dust concentration of a thick coal dust area is increased, the heat load qHr of the wall face of the area of the lower burners is higher, and the burning temperature in the area can achieve the requirement of stable-combustion of firing of anthracite. The distance of jet flow from outlets of the nozzles to a downstream adjacent-angle airflow is short, a lower primary air coal dust airflow speed can be adopted, the intensity of a heat flow of the outlets of the nozzles is high, and passing convection and radiation heat transfer amount are improved to ensure timely firing of the airflow of anthracite coal dust and steady burning of the boiler in low load without oil.

Owner:SHANGHAI BOILER WORKS

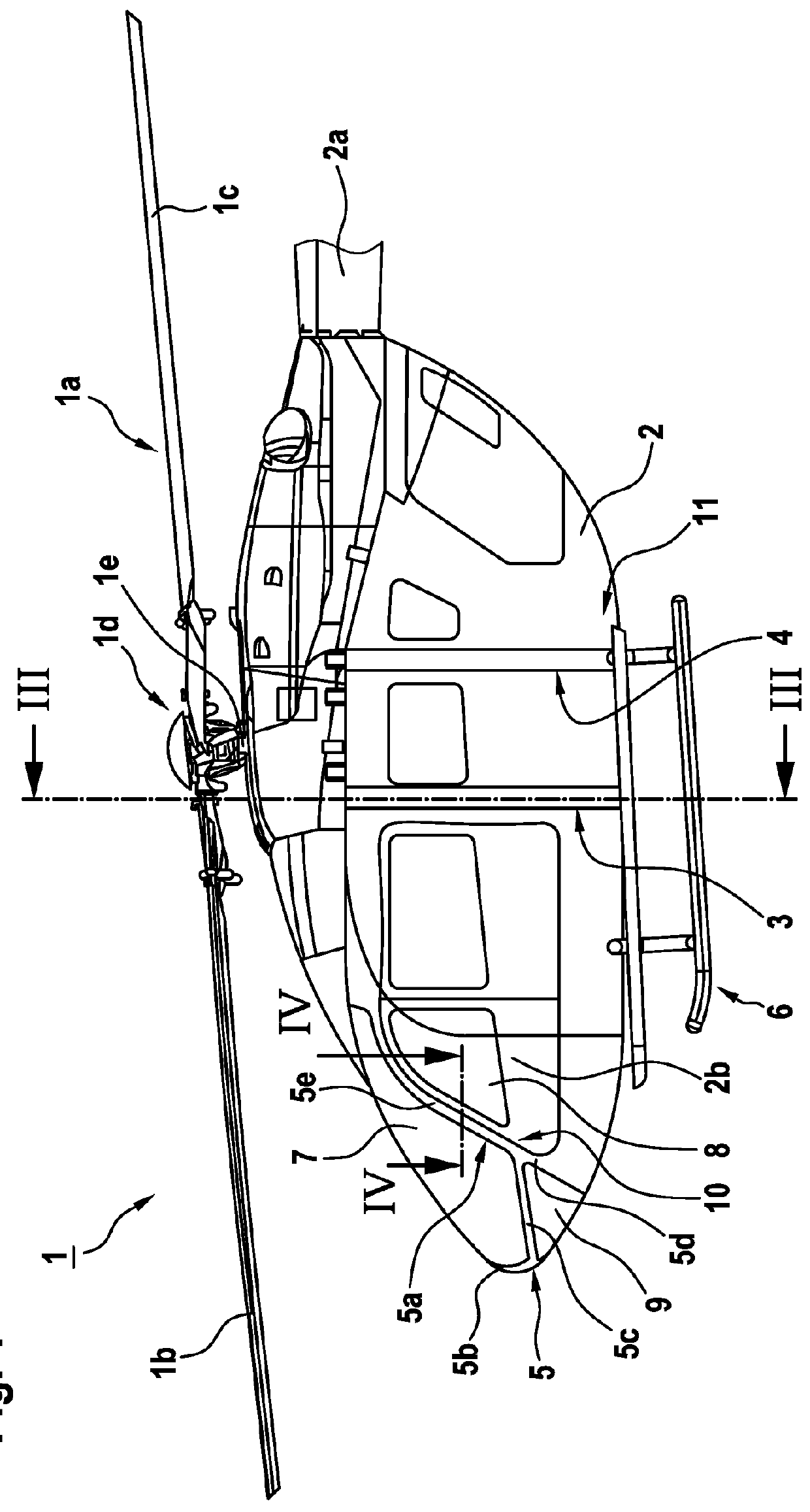

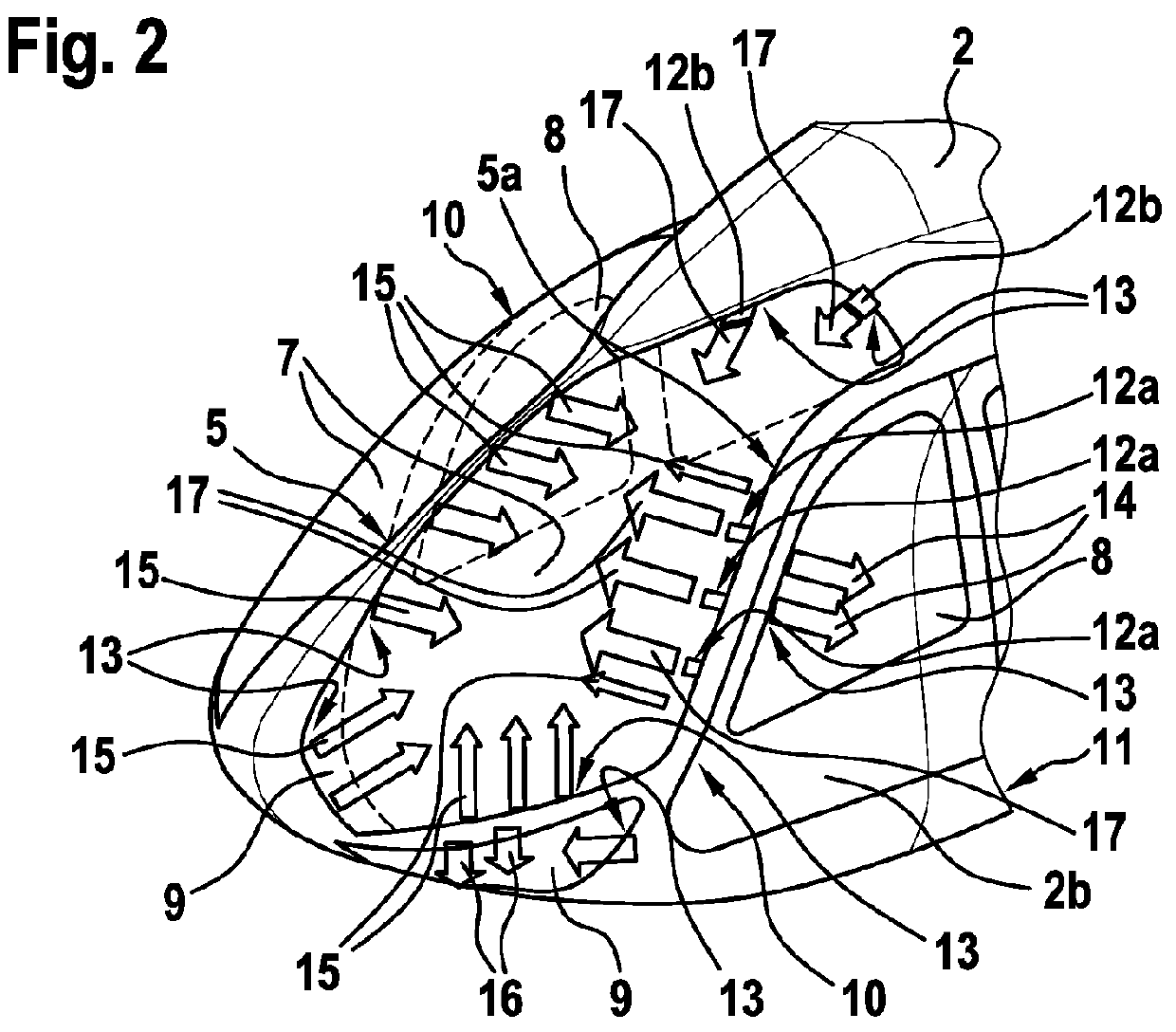

Aircraft with a framework structure that comprises at least one hollow frame

ActiveUS20160031562A1Improve air conditionImproved ventilating systemFuselage framesAir-treatment apparatus arrangementsFuselagePolymer

An aircraft with a fuselage that comprises a framework structure having at least one hollow frame that is integrally formed in one piece and comprises fiber reinforced polymers, the at least one hollow frame defining an integrated ventilation air duct that is adapted for guiding ventilation air into the aircraft.

Owner:AIRBUS HELICOPTERS DEUT GMBH

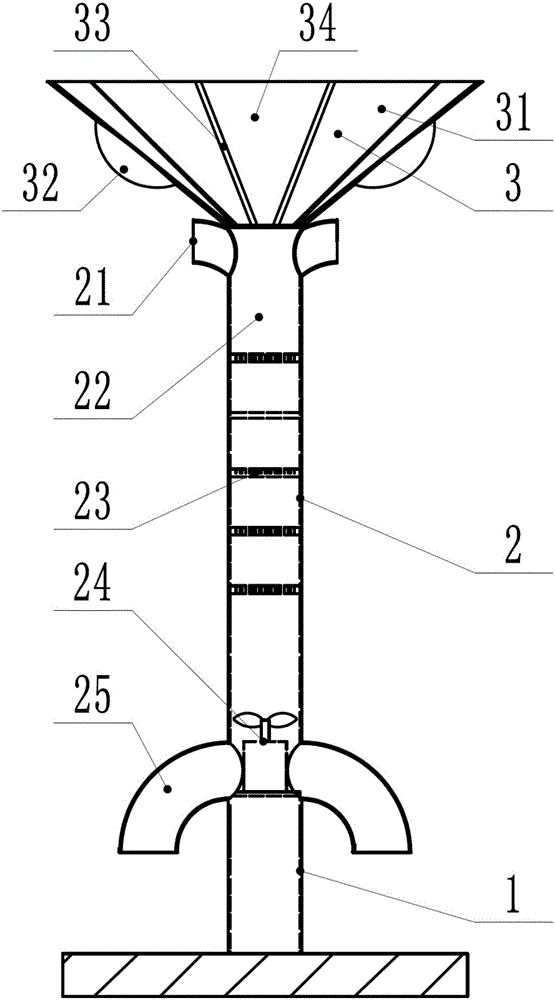

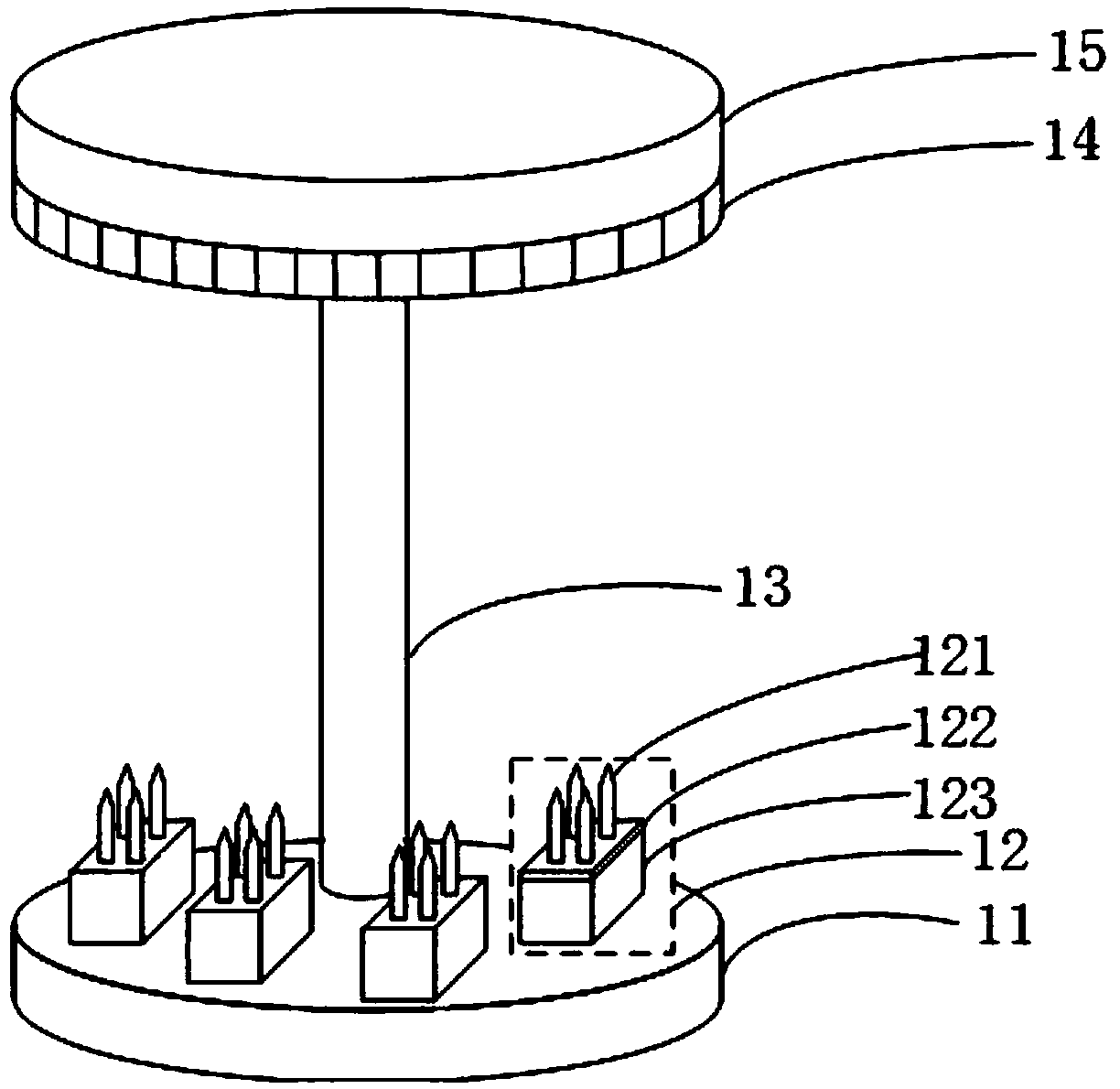

Solar street lamp type maintenance-free haze removal and purification equipment

ActiveCN105805688AReduce usageImprove air conditionMechanical apparatusDispersed particle filtrationSolar street lightAir purification

The invention provides solar street lamp type maintenance-free haze removal and purification equipment, belongs to the field of air purification and solves the problem that conventional haze removal equipment cannot realize haze removal and purification of air in main people gathering areas of the whole city. The adopted scheme is that the solar street lamp type maintenance-free haze removal and purification equipment comprises a base, a purifying device and a power supply device, wherein the base is fixedly mounted on the ground and used for supporting the purifying device and the power supply device; the purifying device is mounted above the base and used for purifying haze; and the power supply device is arranged above the purifying device and used for supplying power for the purifying device and comprises a funnel-shaped top surface formed by encircling a plurality of solar panels, a water outlet is formed in the bottom of the funnel-shaped top surface, the water outlet of the power supply device is communicated with a water inlet of the purifying device, and at least two street lamps are arranged on the outer side surface of the funnel-shaped top surface.

Owner:周聪

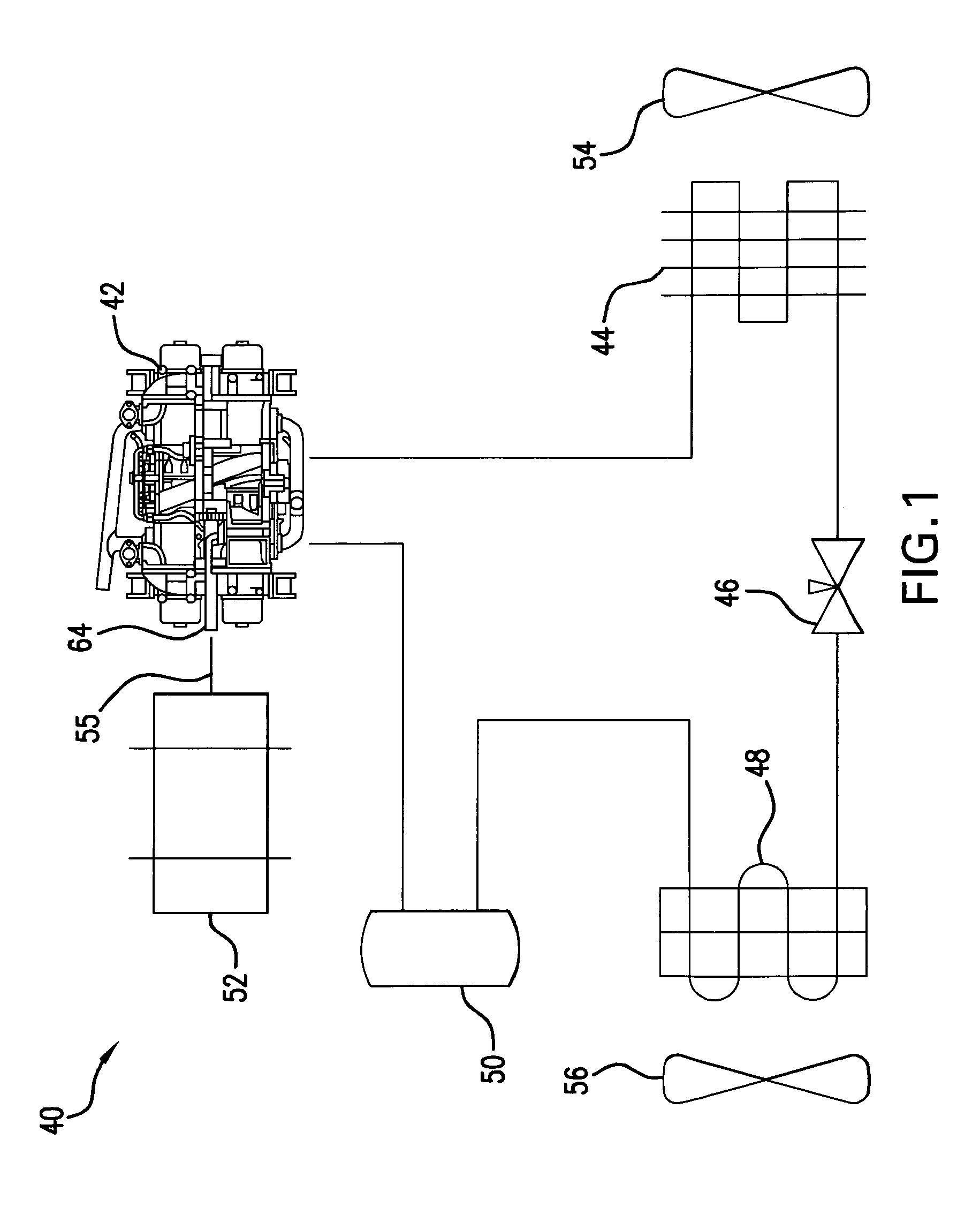

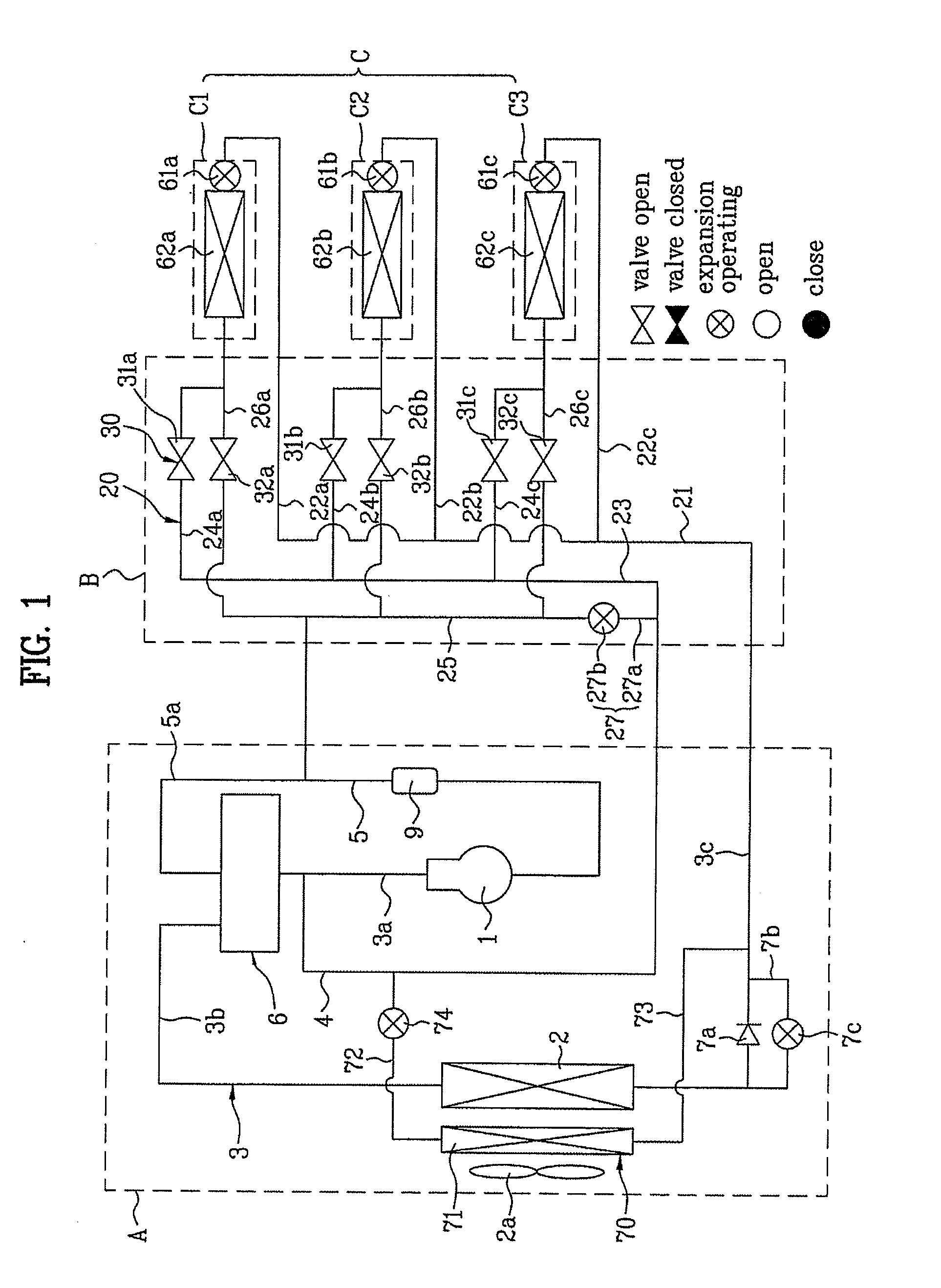

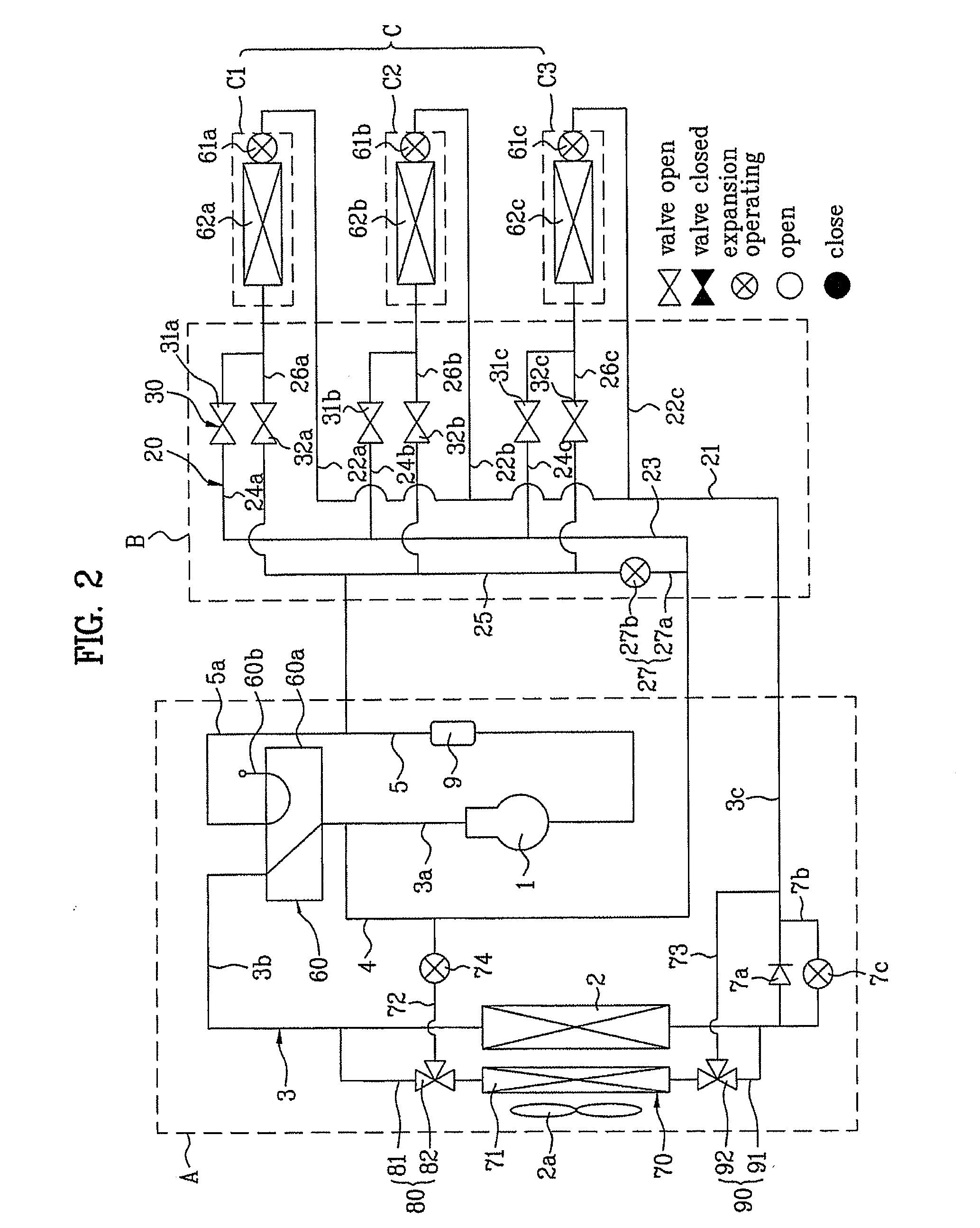

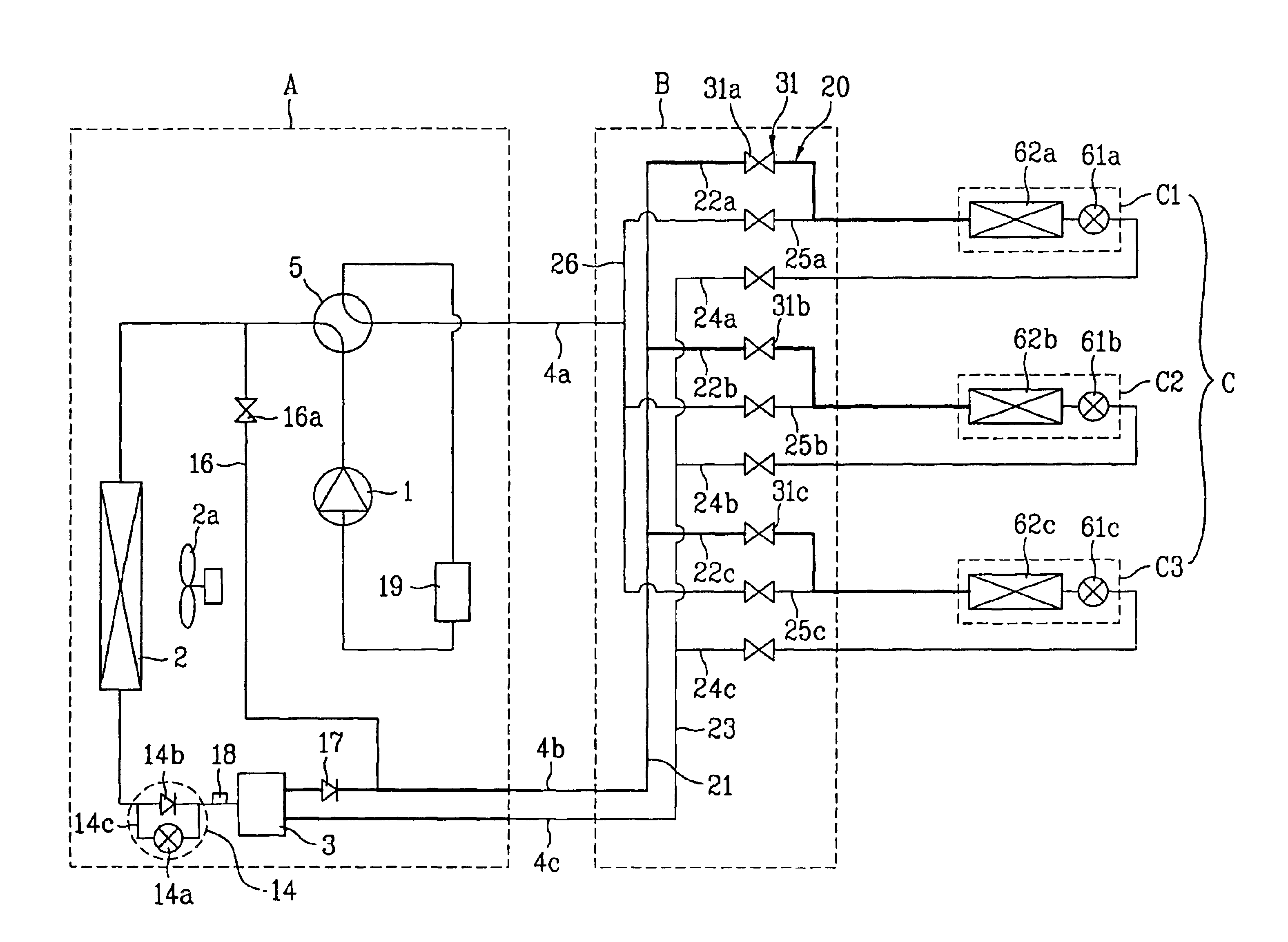

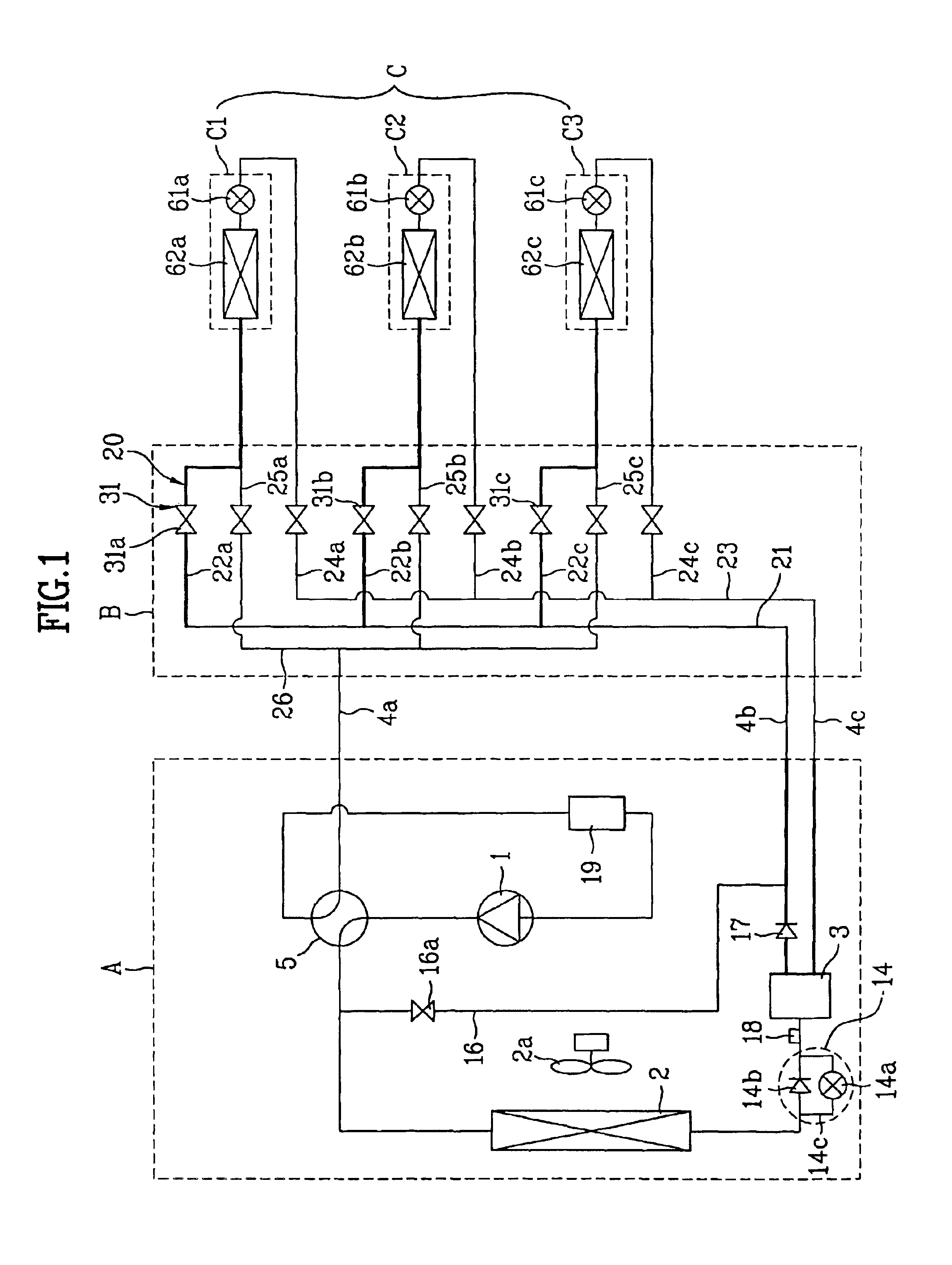

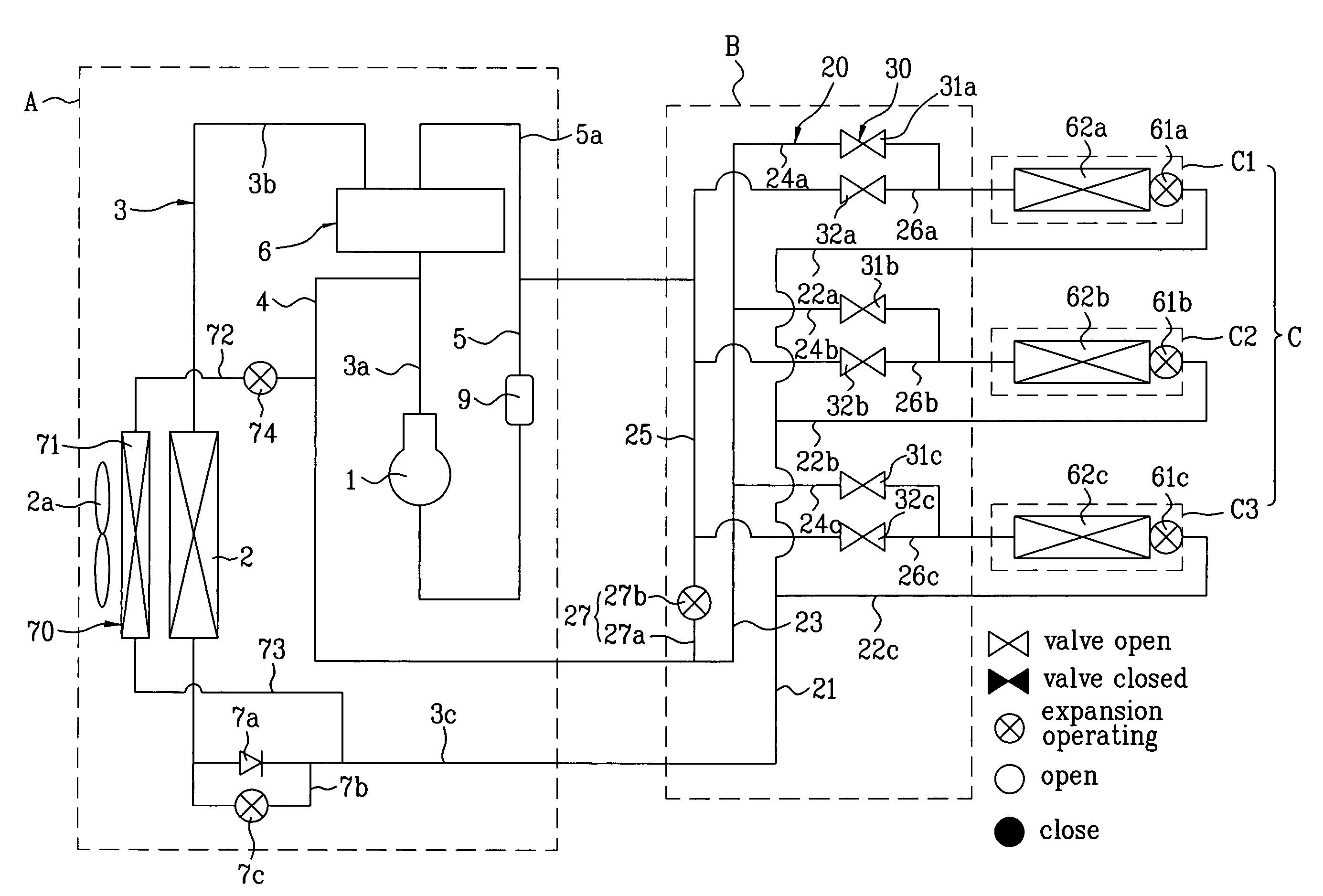

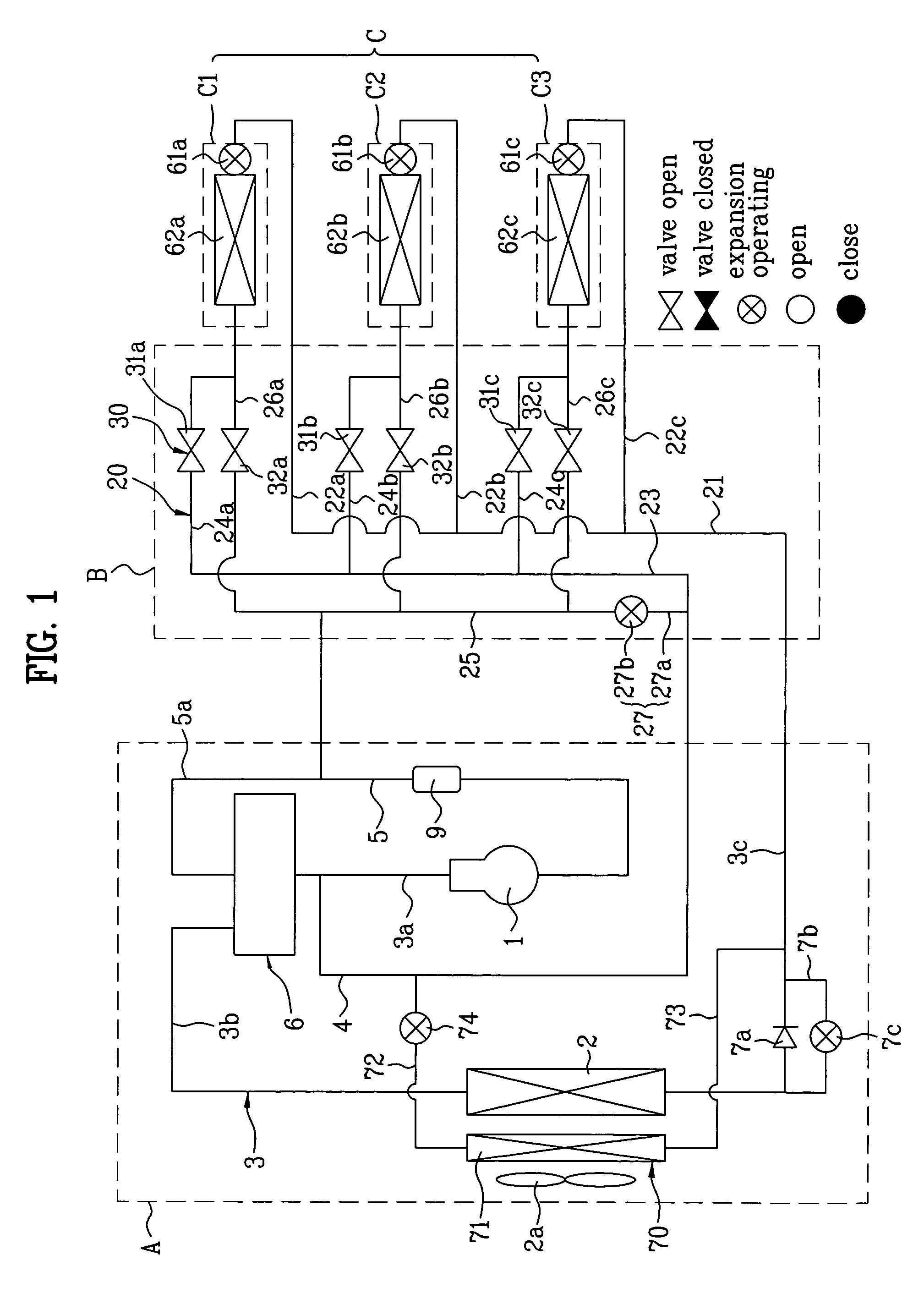

Multi-air conditioner and operation method thereof

InactiveUS6973796B2Improve air conditioning efficiencyImprove air conditionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsVapor–liquid separatorFour-way valve

Disclosed is a multi-air conditioner including: an outdoor unit having a compressor, an outdoor heat exchanger, and an outdoor fan for ventilating the outdoor heat exchanger; a plurality of indoor units each having an electronic expansion valve and an indoor heat exchanger; a distributor for selectively guiding a refrigerant of the outdoor unit into the plurality of indoor units according to an operation condition; a four-way valve for selectively switching a flow direction of the refrigerant flowing through the outdoor heat exchanger; a selective expansion unit for selectively expanding the refrigerant according to the flow direction of the refrigerant; a gas-liquid separator for separating a vapor-phase refrigerant and a liquid-phase refrigerant, from the refrigerant flowing from the outdoor heat exchanger; and a connection tube part having a first connection tube for connecting the four-way valve with a distributor, a second connection tube for connecting an upper portion of the gas-liquid separator with the distributor thereby guiding a vapor-phase refrigerant, and a third connection tube for connecting a lower portion of the gas-liquid separator with the distributor thereby guiding a liquid-phase refrigerant.

Owner:LG ELECTRONICS INC

Vehicle air conditioner with automatic control of main blower and sub-blower

InactiveUS6915650B2Precise automatic controlEnsure correct executionAir-treating devicesRailway heating/coolingAutomatic controlEngineering

A vehicle air conditioner includes a main blower and a sub-blower for blowing air into a passenger compartment. The main blower is disposed to blow conditioned air in a front air passage toward a front seat area in the passenger compartment, and the sub-blower is disposed in a rear air passage having an air flow resistance larger than that in the front air passage so that a part of air blown by the main blower is blown by the sub-blower toward a rear seat area in the passenger compartment through the rear air passage. In the air conditioner, an air amount blown by the sub-blower is controlled to be increased in accordance with a decrease of an air amount blown by the main blower. Therefore, automatic control of the air amount blown by the sub-blower can be accurately performed.

Owner:DENSO CORP

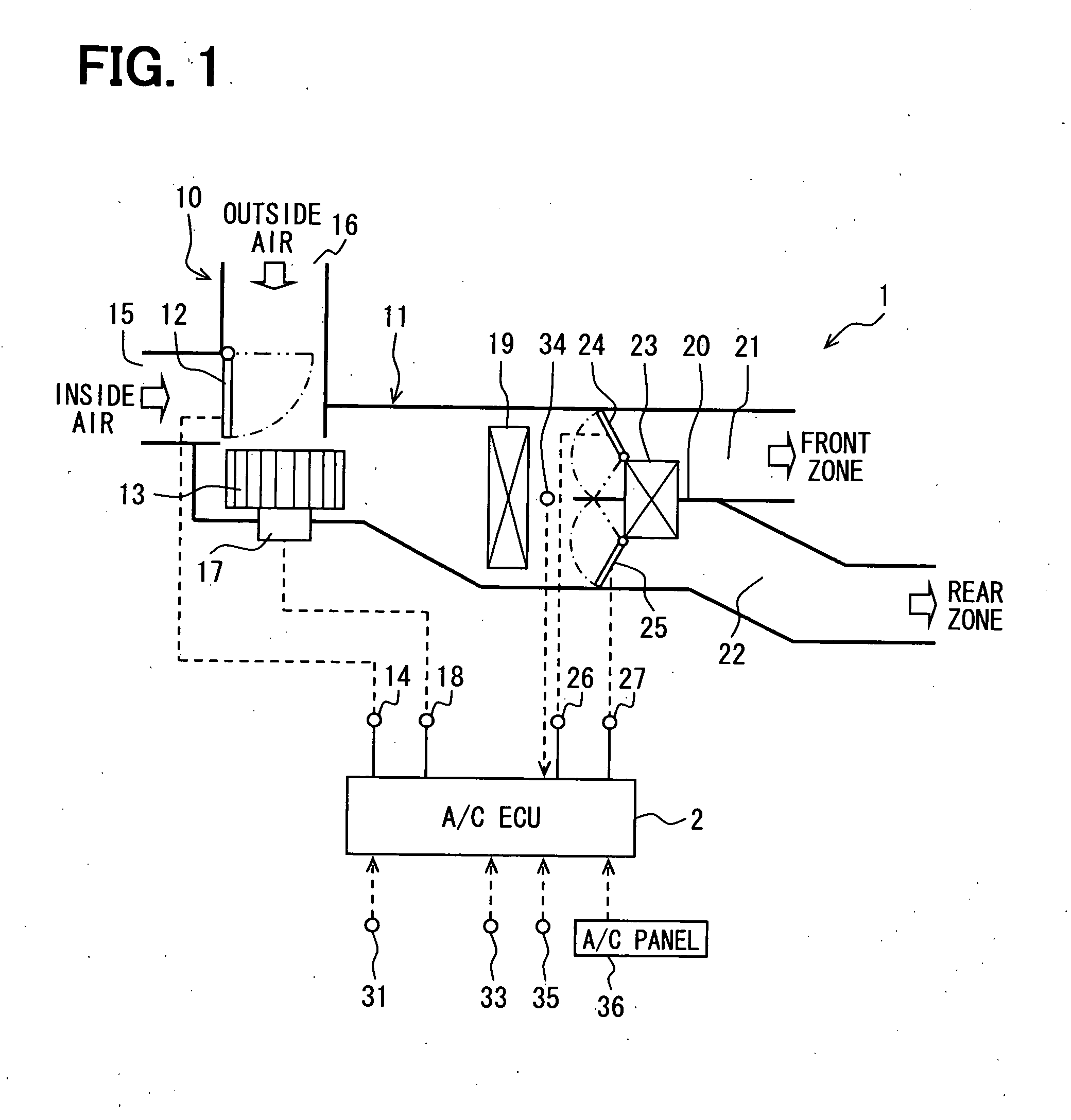

Vehicular air conditioning apparatus and air conditioning method

InactiveUS20100022178A1Air conditioningFeel goodAir-treating devicesVehicle heating/cooling devicesAir volumeEngineering

A control unit of a vehicular air conditioning apparatus calculates a front target temperature, a rear target temperature, and a reference air volume level based on a deviation between the front target temperature and the rear target temperature. The control unit further calculates a correction amount for correcting the reference air volume level based on a deviation between the front target temperature and the rear target temperature.

Owner:DENSO CORP

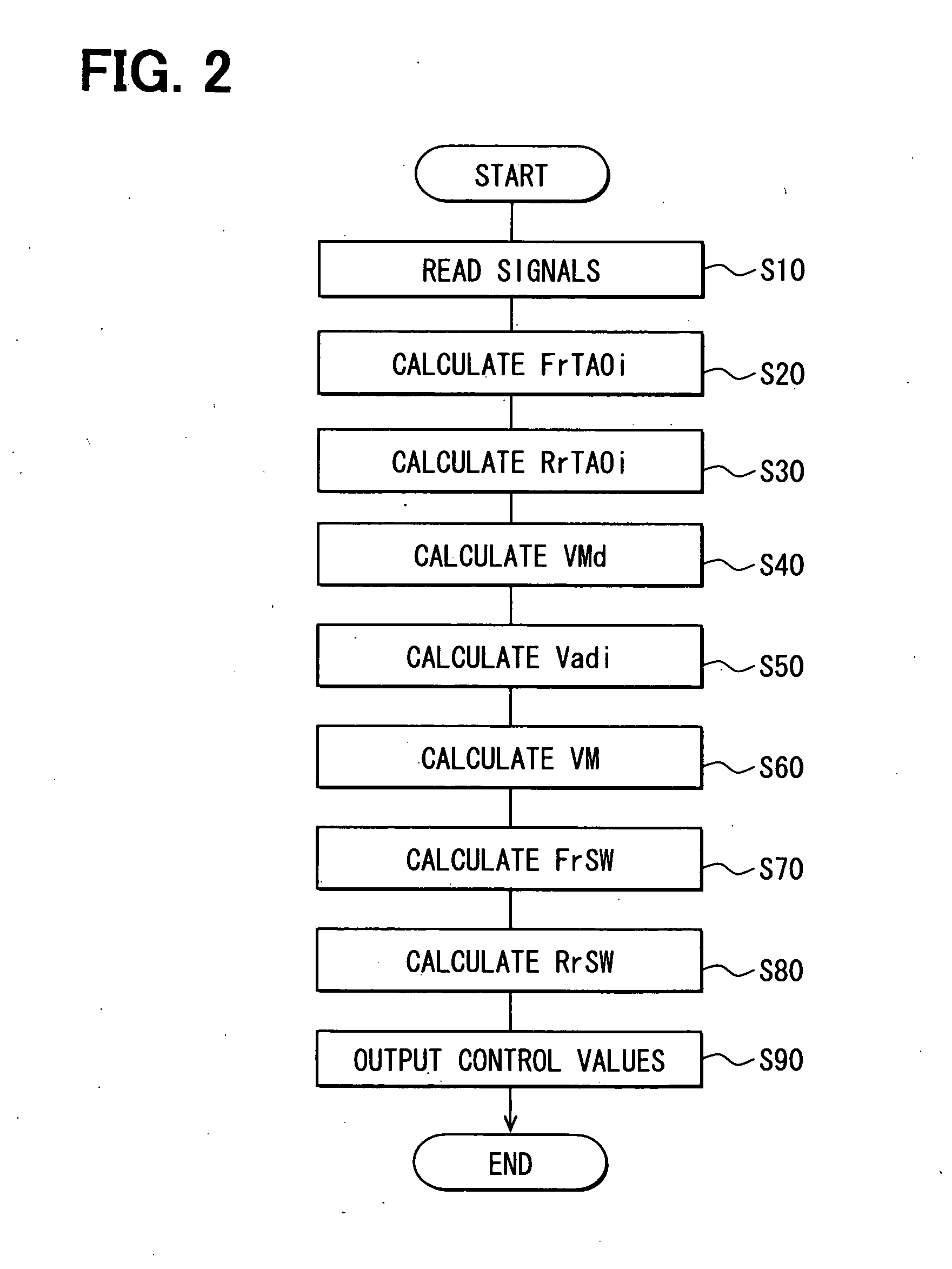

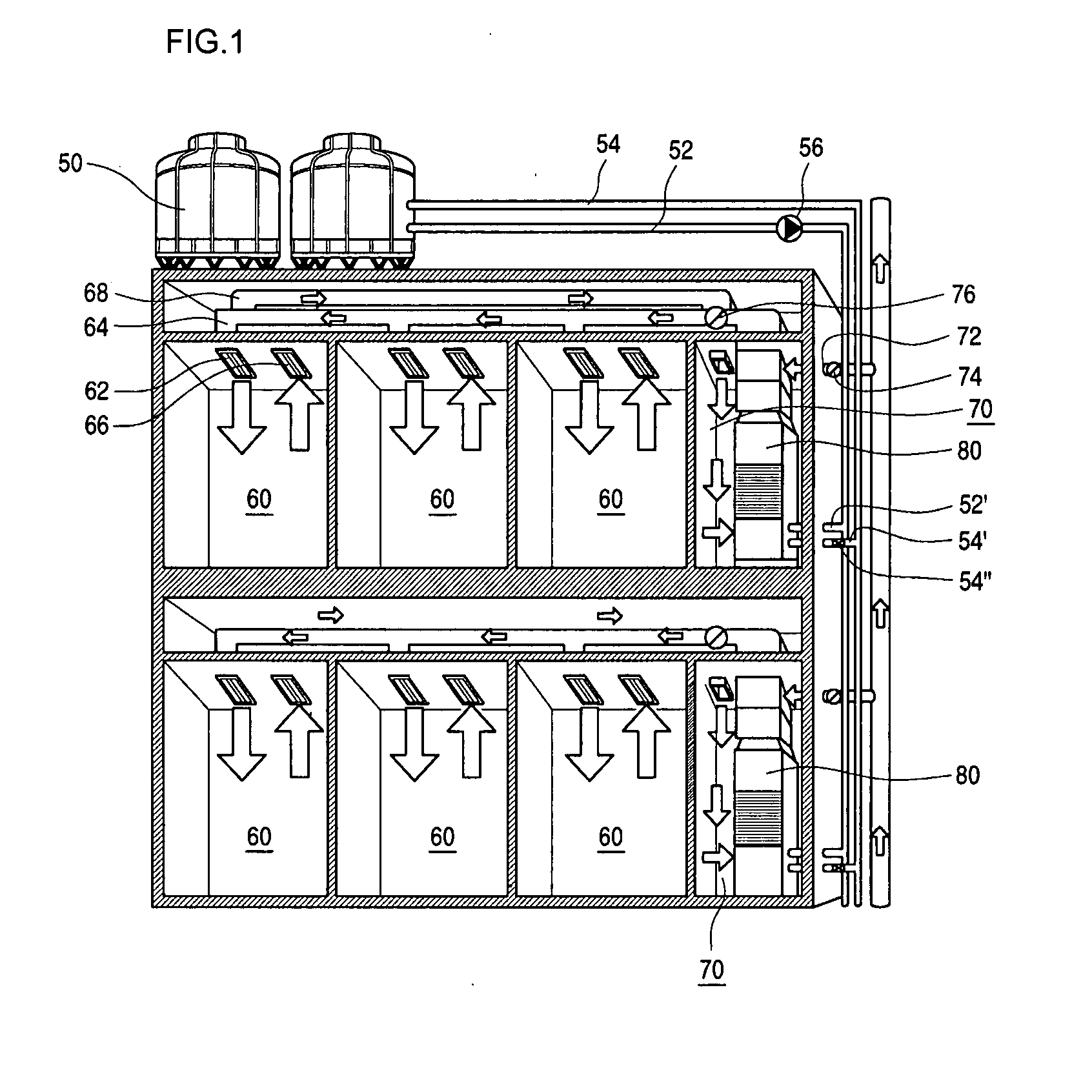

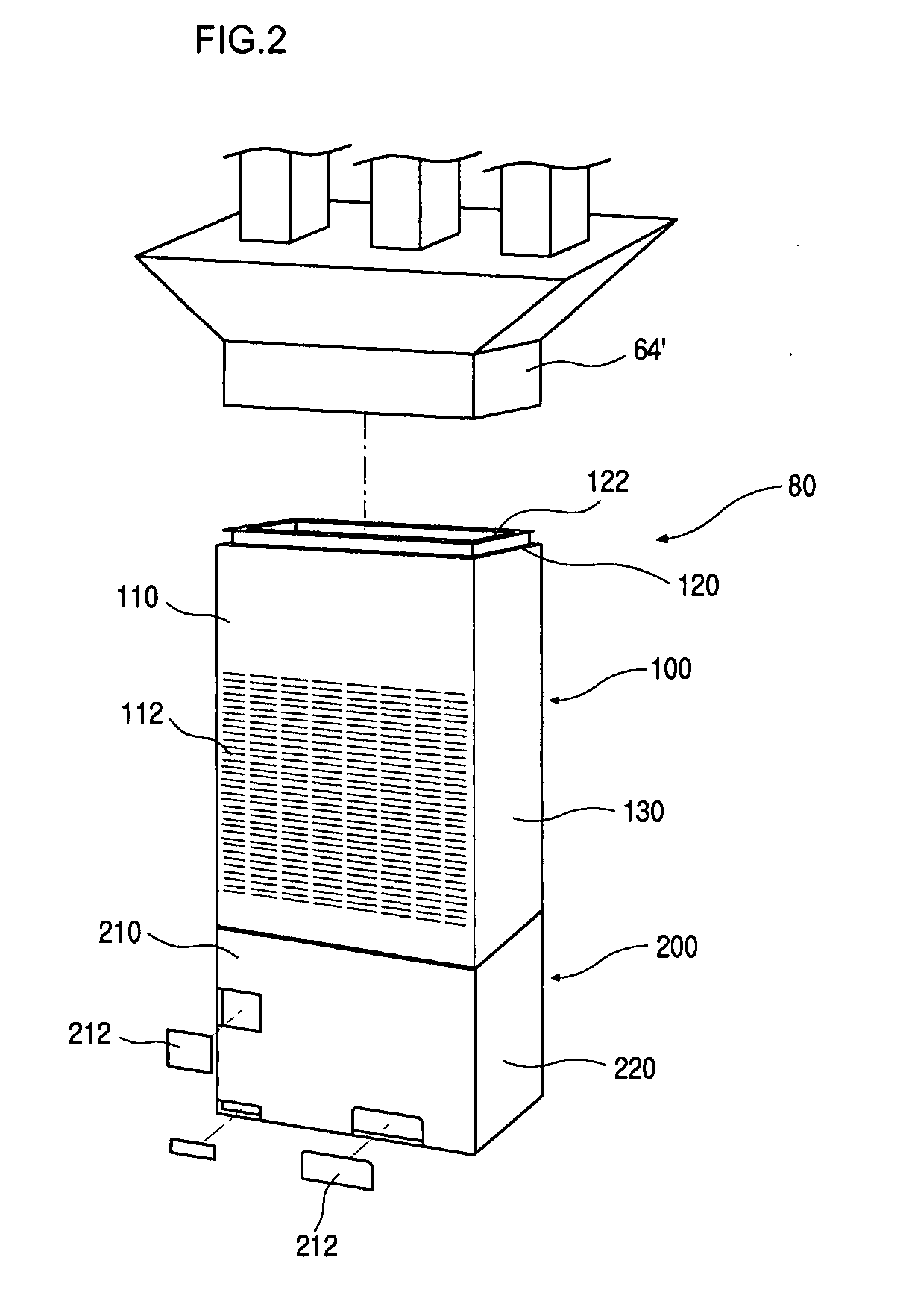

Water-cooled air conditioner

ActiveUS20080087030A1Improve convenienceEasy to useRotary/oscillating piston combinations for elastic fluidsCompressorCooling towerPlate heat exchanger

A water-cooled air conditioning system includes an indoor unit having a first heat exchanger where air and refrigerant are heat-exchanged with each other, an outdoor unit having a second heat exchanger where water and the refrigerant are heat-exchanged with each other, a cooling tower for cooling the water directed to the second heat exchanger, a discharge duct for guiding the air conditioned in the indoor unit to an indoor space for an air conditioning, and an intake duct for guiding the air in the indoor space to the indoor unit. The second heat exchanger is a plate type heat exchanger having a space that is divided into a plurality of sections along which the refrigerant and the cooling water separately flow.

Owner:LG ELECTRONICS INC

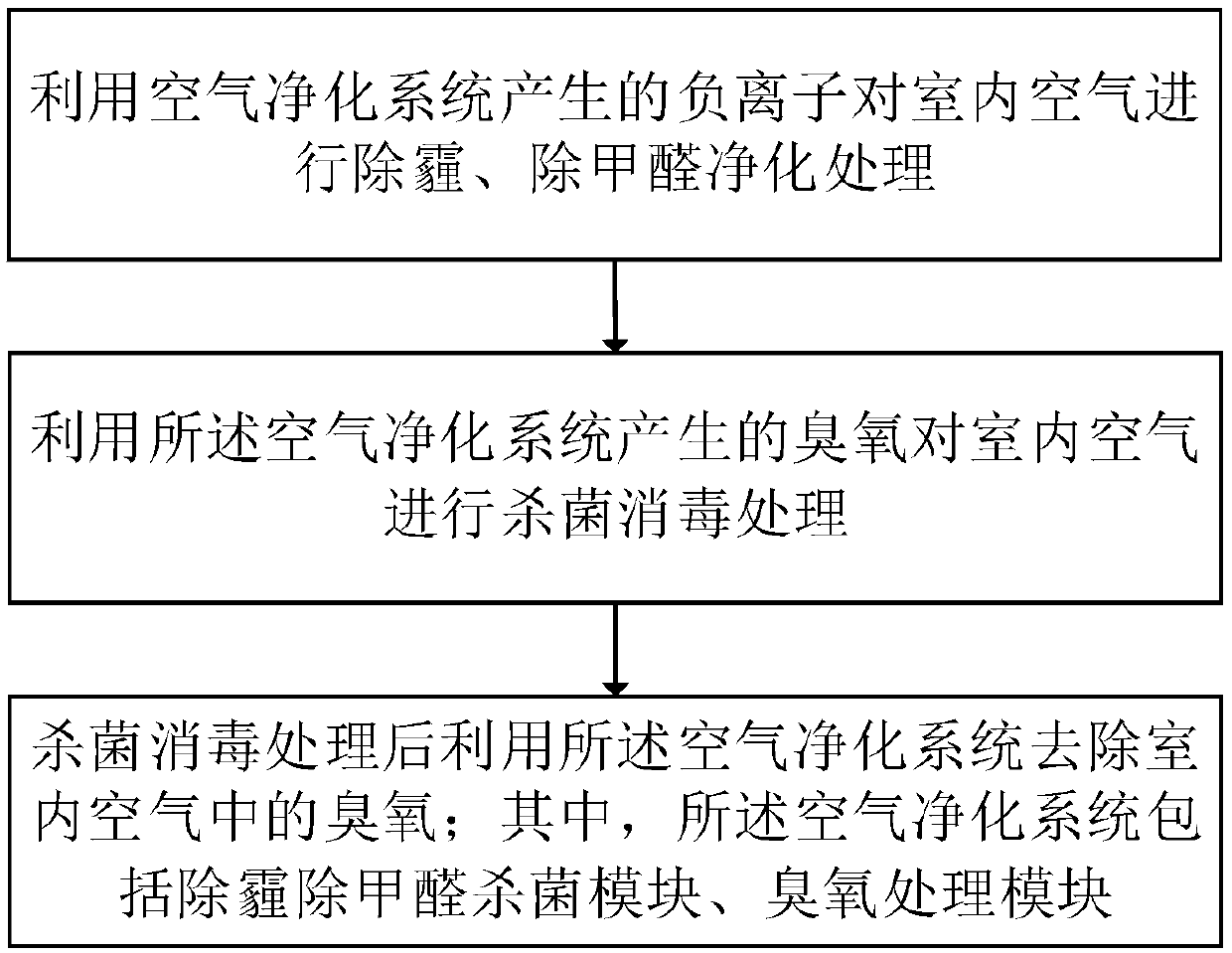

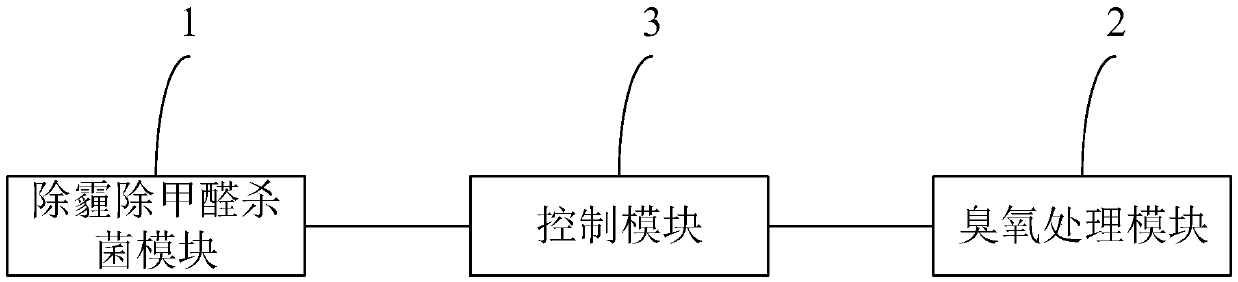

Indoor air purification method

ActiveCN110671756AImprove air conditionPrevent virus spreadMechanical apparatusSpace heating and ventilation safety systemsEnvironmental chemistryIndoor air

The invention relates to an indoor air purification method. The indoor air purification method comprises the following steps: carrying out haze removal and formaldehyde removal purification treatmenton indoor air by virtue of negative ions generated by an air purification system; carrying out sterilization and disinfection treatment on the indoor air by virtue of ozone generated by the air purification system; and removing the ozone in the indoor air by virtue of the air purification system after the sterilization and disinfection treatment, wherein the air purification system comprises a haze removal, formaldehyde removal and sterilization module, and an ozone treatment module. According to the indoor air purification method, the haze removal and formaldehyde removal purification treatment or the sterilization and disinfection treatment is carried out according to an indoor use condition and an indoor air condition, then the sterilization and disinfection treatment is carried out byvirtue of the ozone, and then the ozone removal treatment can be carried out according to an indoor ozone concentration, so that the ozone left in air is prevented from causing harm to bodies; and after the haze removal and formaldehyde removal treatment, the sterilization and disinfection treatment, and the ozone removal treatment, the indoor air condition can be improved, and indoor virus spreading due to a too high haze concentration or germ residual is avoided.

Owner:XIDIAN UNIV

Fault detection diagnostic variable differential variable delay thermostat

ActiveUS10712036B2Ensure occupant comfortAdd equipmentMechanical apparatusSpace heating and ventilation safety systemsControl engineeringThermostat

A Fault Detection Diagnostic (FDD) variable differential and variable fan-off delay Heating Ventilating Air Conditioning (HVAC) thermostat control method. The FDD method detects a fan-on setting, reports a FDD fan-on alarm, overrides a fan-on setting, and turns off an HVAC fan. The FDD method detects, reports, and corrects a short-cycle by providing a variable differential based on: a cooling or heating cycle duration, or an off-cycle time. The variable fan-off delay is based on: a Conditioned Space Temperature (CST), comparing a current CST to the CST measured during the fan-off delay, a rate of change of CST with respect to time (dT / dt), dT / dt reaches an inflection point, the CST crosses a fan-off-delay differential, a cooling cycle duration, a heating cycle duration, a cooling temperature split, a heating temperature rise, an outdoor air temperature, a supply air temperature, or the rate of change with respect to time of these HVAC parameters.

Owner:LAU JAMES

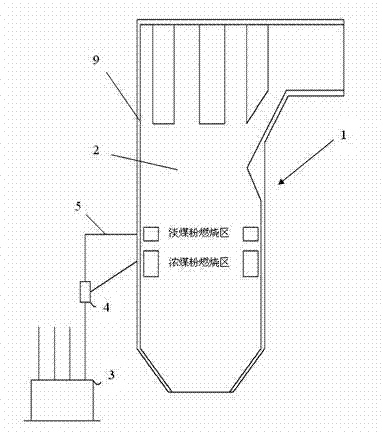

Pulverized coal boiler capable of subcritically combusting lean coal

ActiveCN103206699AImprove fullnessNot easy to deflectIndirect carbon-dioxide mitigationSteam boilersAir preheaterCombustor

The invention provides a pulverized coal boiler capable of subcritically combusting lean coal. The pulverized coal boiler comprises a hearth, superheaters, coal economizers and an air preheater. Combustors are arranged in the hearth. The pulverized coal boiler is characterized in that the superheaters include high-temperature superheaters and low-temperature superheaters, the high-temperature superheaters are arranged on the upper side of the hearth, a flue with a vertical shaft is communicated with the upper side of the hearth, two sides of the flue with the vertical shaft are separated from each other, the low-temperature superheaters and the coal economizers are respectively arranged on the two sides of the flue with the vertical shaft, a superheated steam inlet pipeline is arranged below the low-temperature superheaters, an emergency spray attemperator is mounted on the overheated steam inlet pipeline, the flue with the vertical shaft is provided with flue gas temperature regulating barriers which are respectively arranged below the low-temperature superheaters and the coal economizers, and the high-temperature superheaters and the low-temperature superheaters are respectively connected with trim spray attemperators. The pulverized coal boiler has the advantages that the lean coal with the Vdaf (volatile) equal to 14% can be sufficiently combusted in the boiler, so that energy is sufficiently utilized, and the pulverized coal boiler is energy-saving.

Owner:WUXI HUAGUANG BOILER

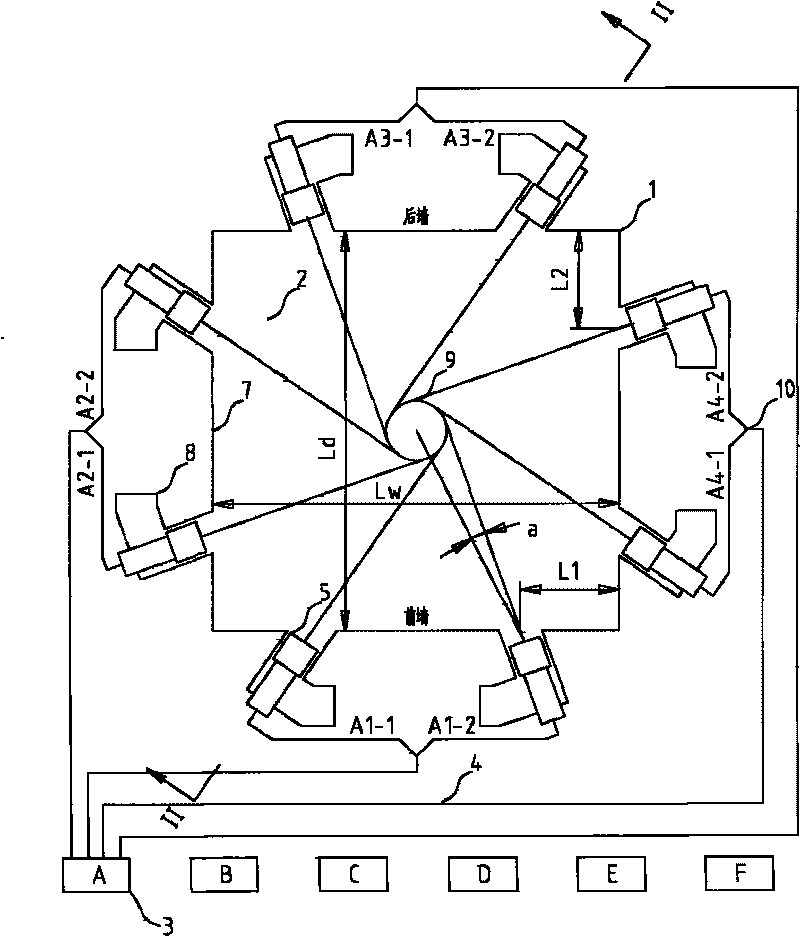

Pulverized coal shade separate arrangement mode of direct-current burner with double fireballs

ActiveCN103090368AIncrease concentrationGuaranteed not to oilCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

The invention provides a pulverized coal shade separate arrangement mode of a direct-current burner with double fireballs for burning anthracite coal. The pulverized coal shade separate arrangement mode is characterized in that each boiler is provided with eight groups of burners; the eight groups of burners are at the same level; four groups of burners form an imaginary circle inside a hearth; the other four groups of burners form another imaginary circle inside the hearth; each group of burners are divided into two small groups in the vertical direction; the first small group of burners are named as 'primary air / thick pulverized coal' burners; and the second small group of burners are named as 'primary air / thin pulverized coal' burners. The thermal load qHr of the wall surface of a burner zone is high under the premise of ensuring the power of the entire boiler; and timely inflaming of anthracite pulverized coal air flow and low-load stable combustion of the boiler without oil can be ensured.

Owner:SHANGHAI BOILER WORKS

Multi-type air conditioner with defrosting device

ActiveUS7308800B2Improve air conditionImprove defrosting effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringDistributor

Multi-type air conditioner comprising an outdoor unit installed in an outdoor, comprising a compressor, a refrigerant flow controlling part connected to a discharge end of the compressor for guiding the refrigerant proper to operation conditions selectively, an outdoor heat exchanger connected to the refrigerant flow controlling part, a defrosting device at a side of the outdoor heat exchanger, and a piping system connected between the parts, a plurality of indoor units each installed in a room and having an indoor heat exchanger and an electronic expansion valve having one end connected to one end of the indoor heat exchanger, and a distributor between the outdoor unit and the indoor units for selectively guiding refrigerant from the outdoor unit to the plurality of indoor units proper to operation conditions, and guiding the refrigerant passed through the indoor units to the outdoor unit again.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com