Patents

Literature

176results about How to "Precise automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Timed passive air sampler

ActiveCN103033398AGuaranteed tensionAvoid contactWithdrawing sample devicesAutomatic controlEngineering

The invention discloses a timed passive air sampler, which comprises an air sampler main body, wherein the air sampler main body comprises a packaging barrel with an opening at the top, an adsorbent cage which is sheathed in the packaging barrel, a blocking pillar, an electromagnet and a timing driving circuit; a timing beginning sensor and a mounting bracket are arranged on the side wall of the packaging barrel; a rubber plug matched with the top of the packaging barrel is arranged at the top end of the adsorbent cage; a return spring is arranged between the bottom of the adsorbent cage and the bottom of the packaging barrel; a bayonet which can be pulled out to expose the packaging barrel and a sensing body corresponding to the timing beginning sensor are arranged on the adsorbent barrel; the blocking pillar is arranged on the mounting bracket and can move in the radial direction of the packaging barrel and be matched with the bayonet; the electromagnet is arranged on the outer wall of the bracket of the packaging barrel and can control the blocking pillar to be departed from the bayonet; and the timing driving circuit is connected with the timing beginning sensor and the electromagnet. The timed passive air sampler can implement the accurate automatic control of the sampling time, automatic packaging, and effectively improve the sampling accuracy of the passive air sampler.

Owner:SHENZHEN INST OF BUILDING RES

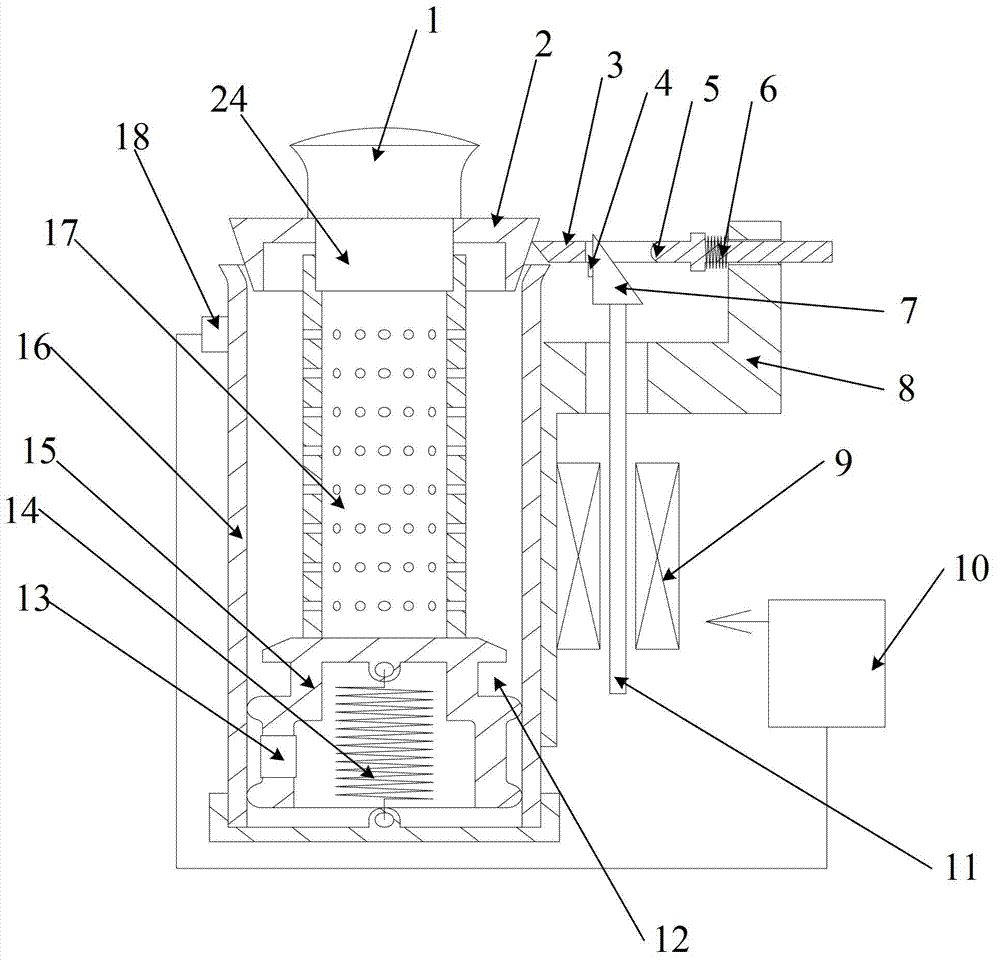

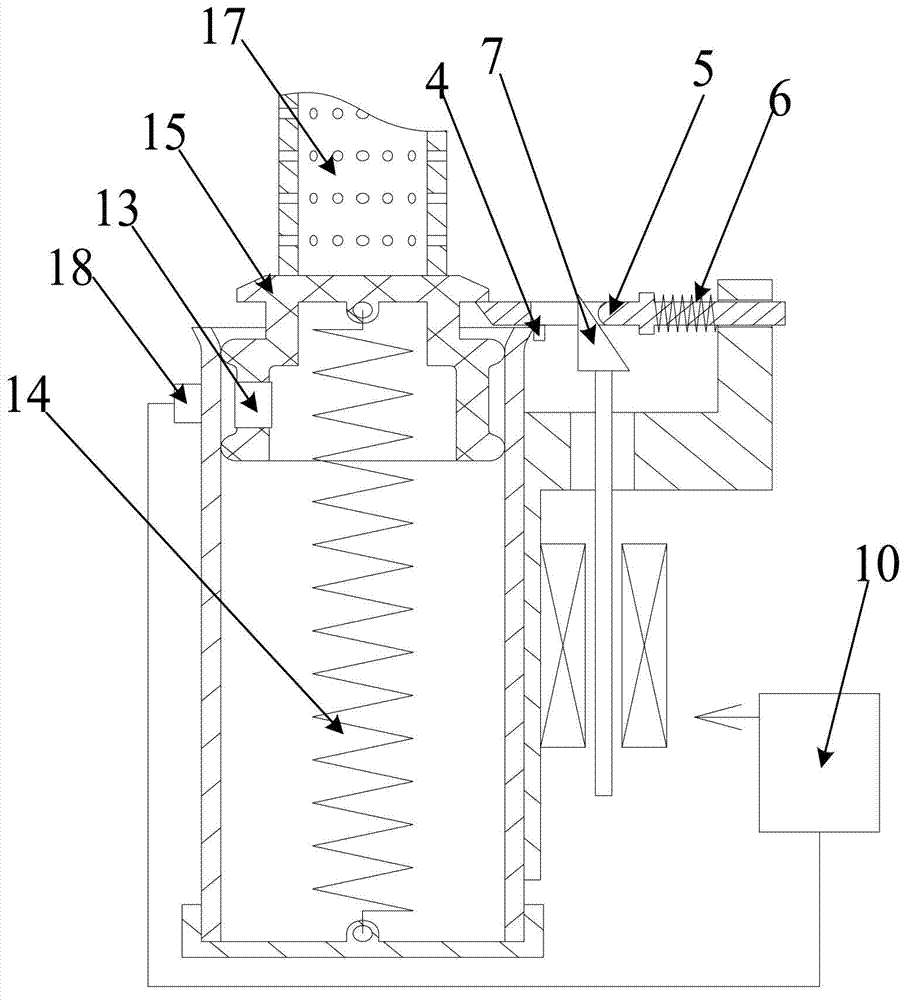

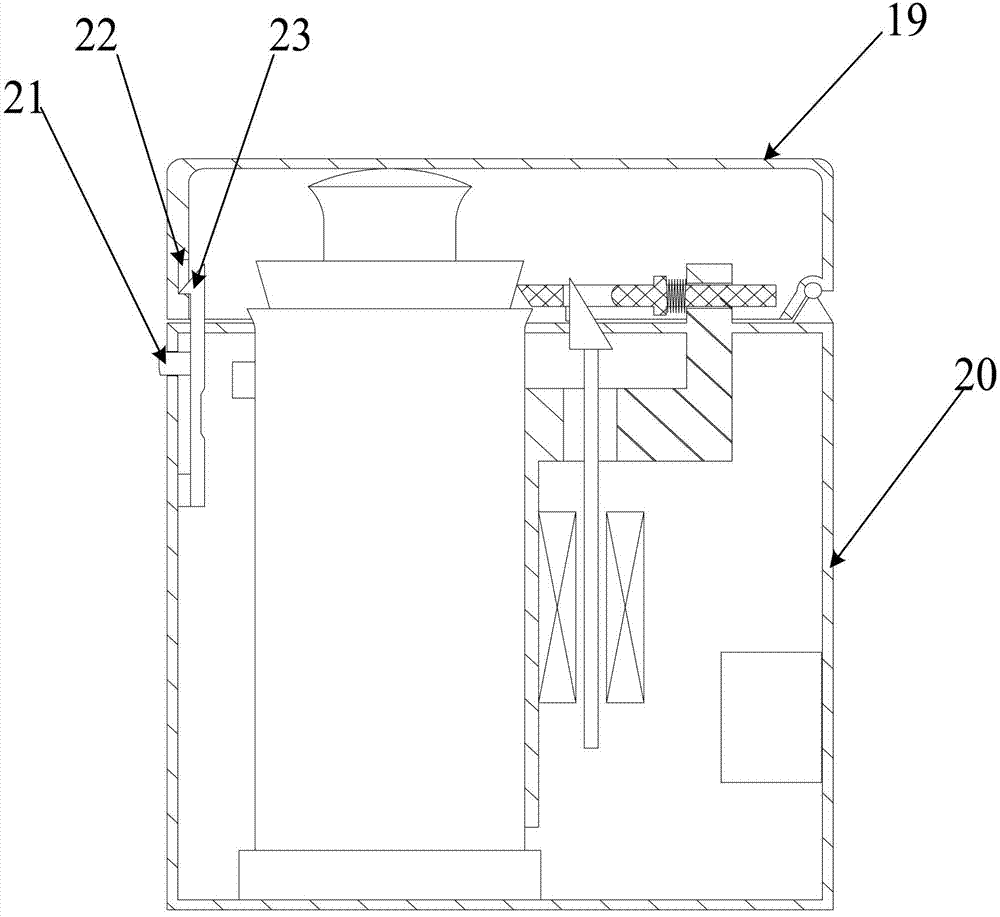

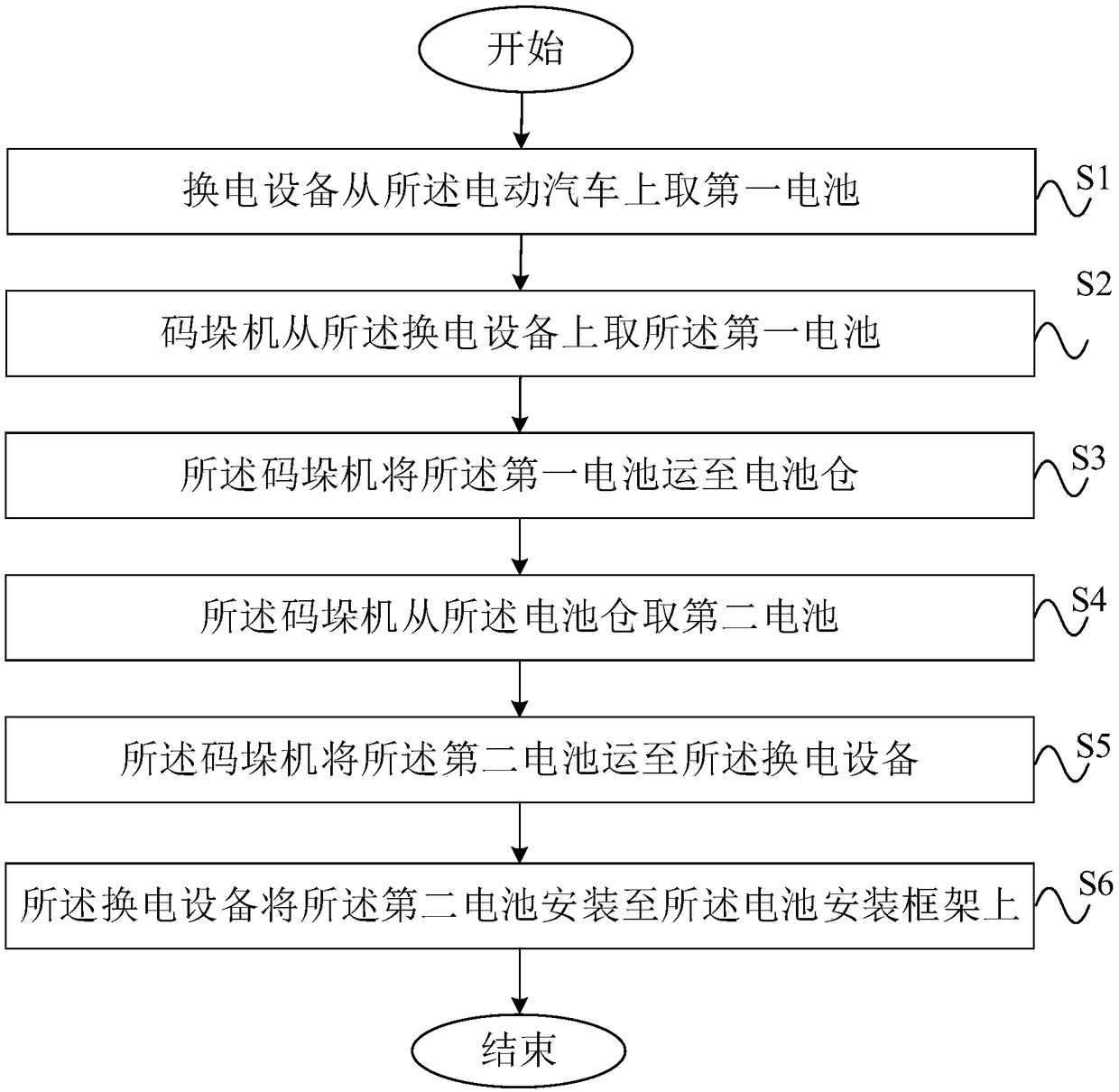

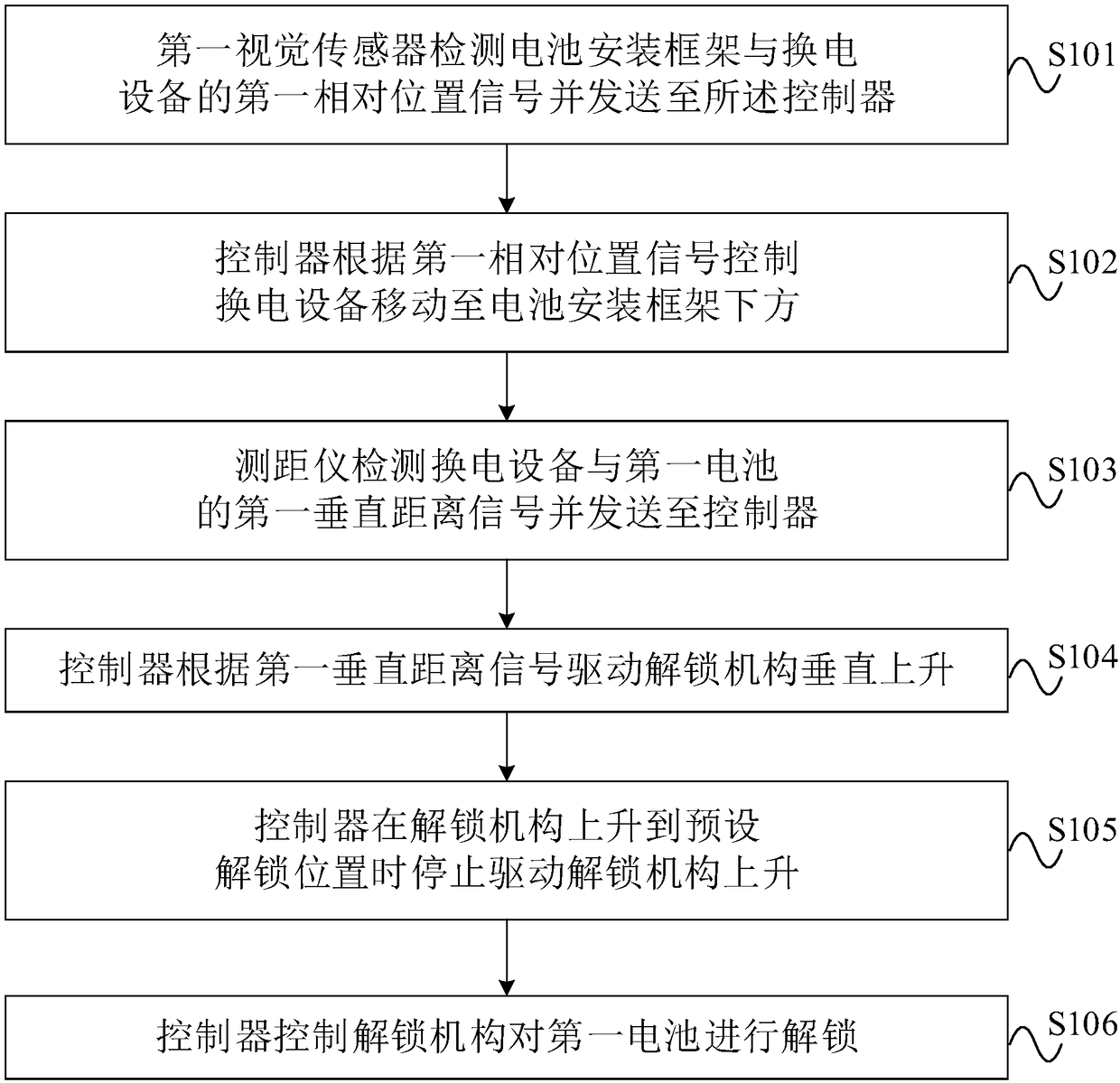

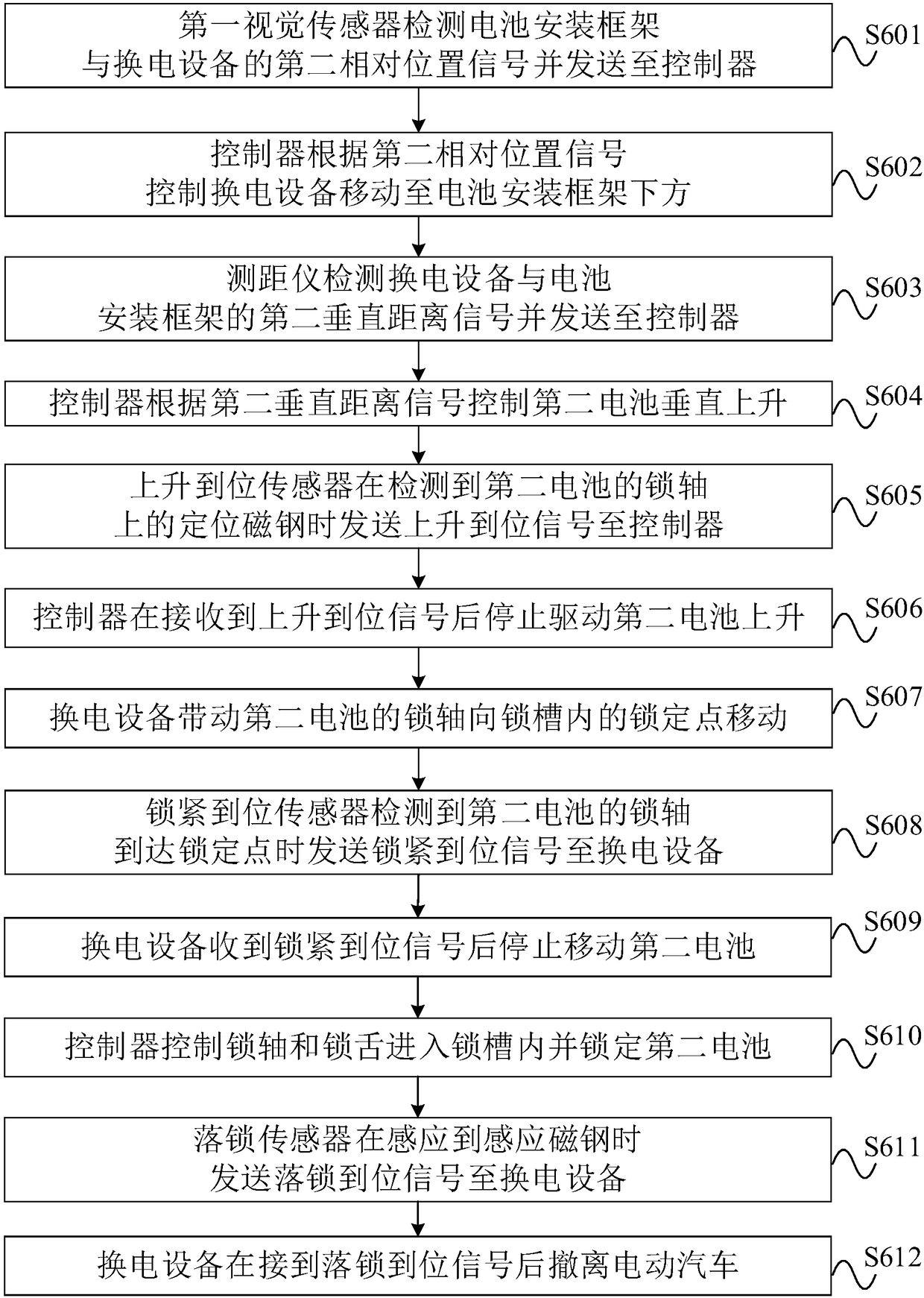

Battery replacing control method and system for electric vehicle

PendingCN108189681AImprove safety and reliability performanceImprove power exchange efficiencyCharging stationsElectric propulsion mountingElectricityAutomatic control

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH +1

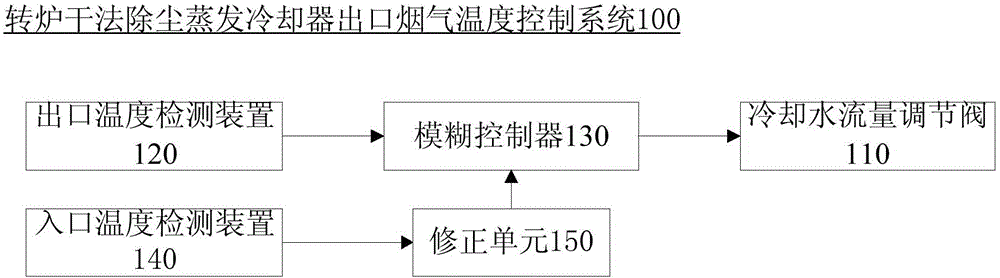

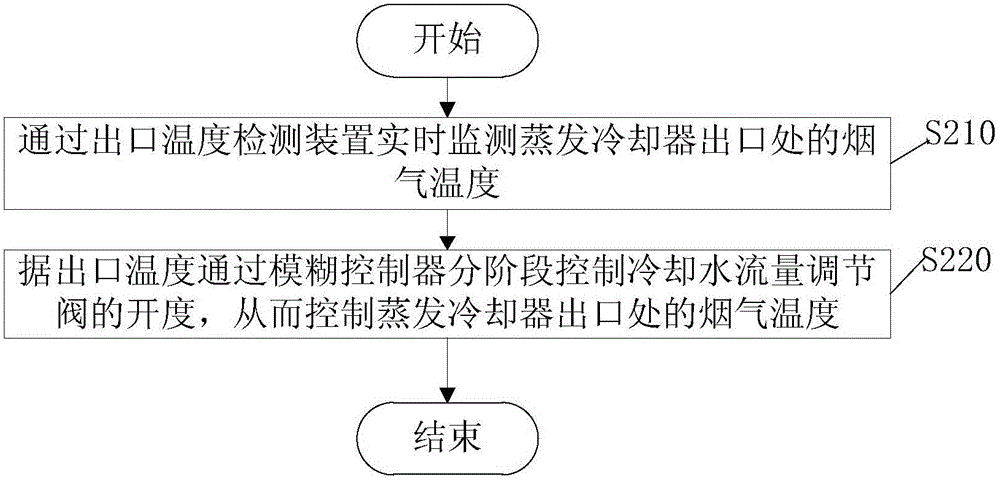

Outlet smoke temperature control system and method for converter dry method dust removing evaporative cooler

ActiveCN106048130APrecise automatic controlWide adaptabilityTemperatue controlManufacturing convertersEvaporative coolerOxygen

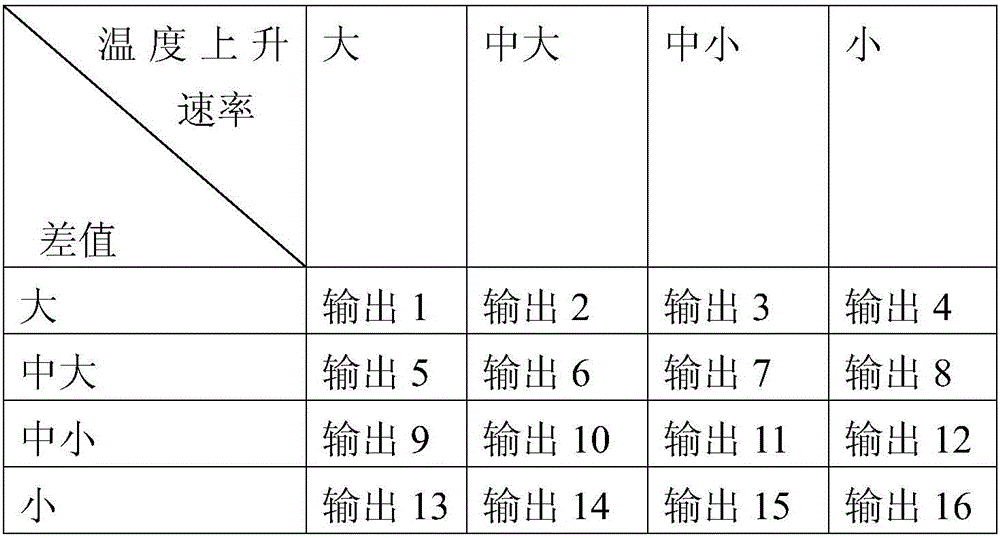

The invention provides an outlet smoke temperature control system for a converter dry method dust removing evaporative cooler. The system comprises a cooling water flow adjusting valve, an outlet temperature detecting device detecting the outlet smoke temperature of the evaporative cooler, and a fuzzy controller. The fuzzy controller divides the converter dry method dust removing process into a first stage and a second stage, the one-dimension fuzzy control rule is used for controlling the aperture of the cooling water flow adjusting valve at the first stage, and the at least two-dimension fuzzy control rule is used for controlling the aperture of the cooling water flow adjusting valve at the second stage. In the first stage starting from oxygen blowing of a converter to rising of outlet temperature to the stable state, the one-dimension fuzzy control rule is used for controlling the aperture of the cooling water flow adjusting valve according to the difference value between the outlet temperature and the set outlet temperature. At the second stage from the stable state to lowering of the outlet temperature to the specified temperature of a dust remover, the at least two-dimension fuzzy control rule is used for controlling the aperture of the cooling water flow adjusting valve according to multiple parameters, wherein the multiple parameters at least include the difference value and the outlet temperature rising rate. The system is easy to control, high in precision and capable of saving cost.

Owner:MCC HUATIAN NANJING AUTOMATION ENG

Intelligent control system for automatic irrigation of garden based on cloud computing

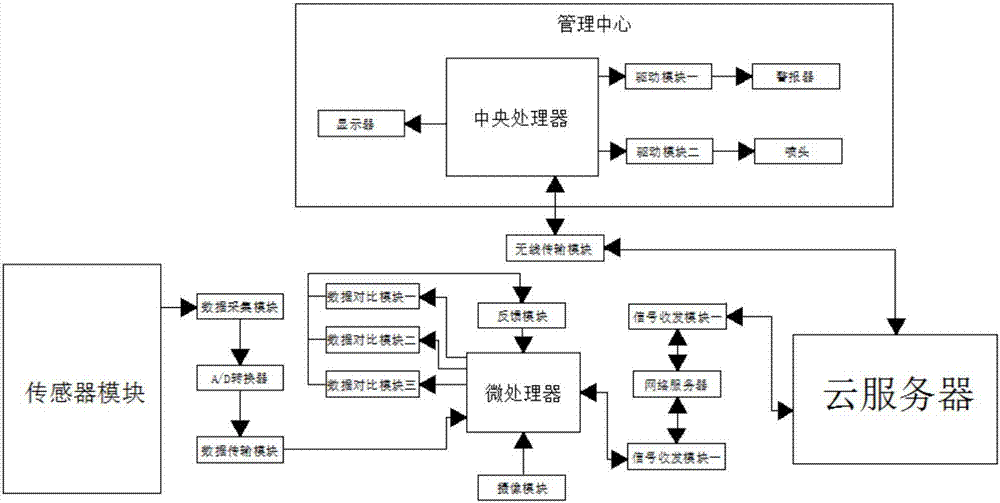

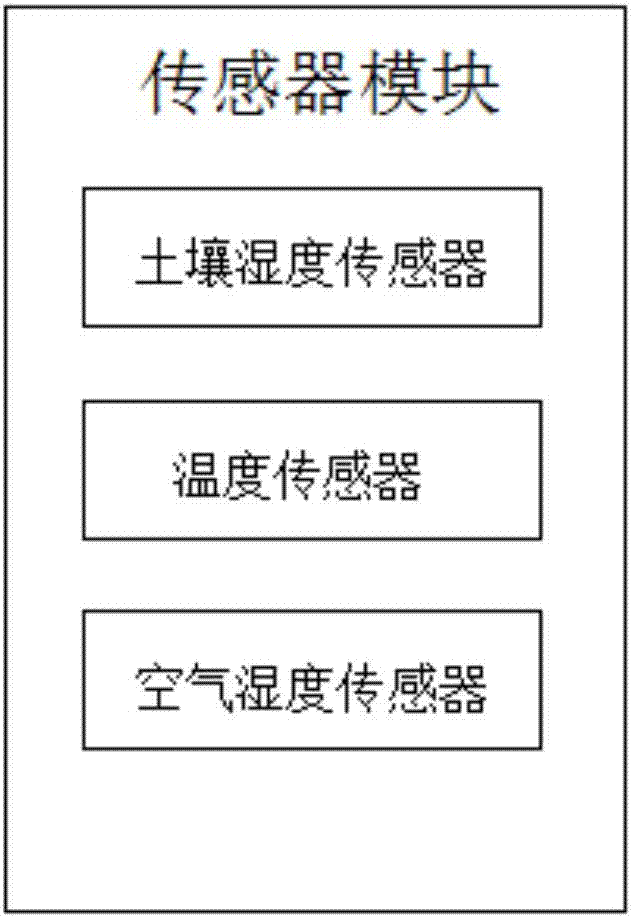

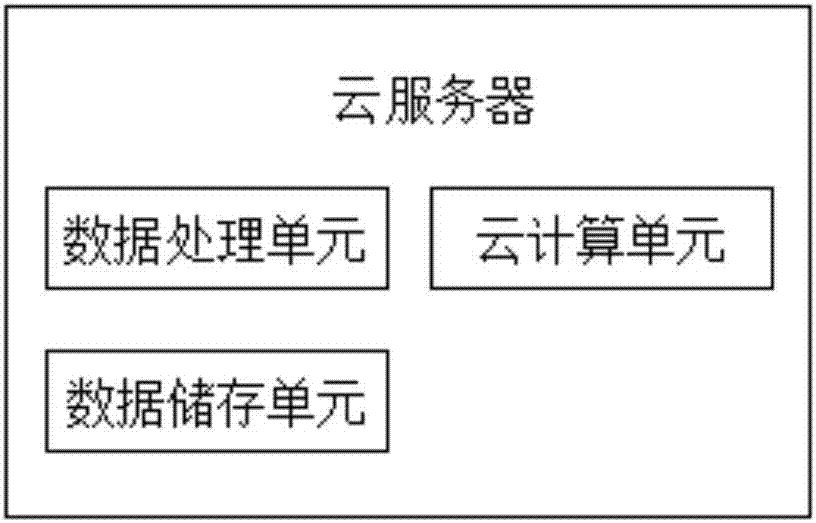

InactiveCN106962151ATimely irrigationPrecise automatic controlClimate change adaptationWatering devicesComputer moduleData transmission

The invention relates to the technical field of cloud computing, and discloses an intelligent control system for automatic irrigation of a garden based on cloud computing. The system comprises a sensor module, the output end of the sensor module is electrically connected with the input end of a data collection module, the output end of the data collection module is electrically connected with the input end of an A / D converter, the output end of the A / D converter is electrically connected with the input end of a data transmission module, and the output end of the data transmission module is electrically connected with the input end of a microprocessor. According to the intelligent control system for automatic irrigation of the garden based on the cloud computing, by arranging a cloud server, precise automation control can be achieved when the garden is irrigated, the problem that irrigation is carried out through artificial machines when the garden is irrigated is solved, and randomness of artificial mechanical irrigation is avoided, so that the garden is irrigated in time, and the problems of irrigation delay and early irrigation are solved.

Owner:SHENZHEN WING TECH CO LTD

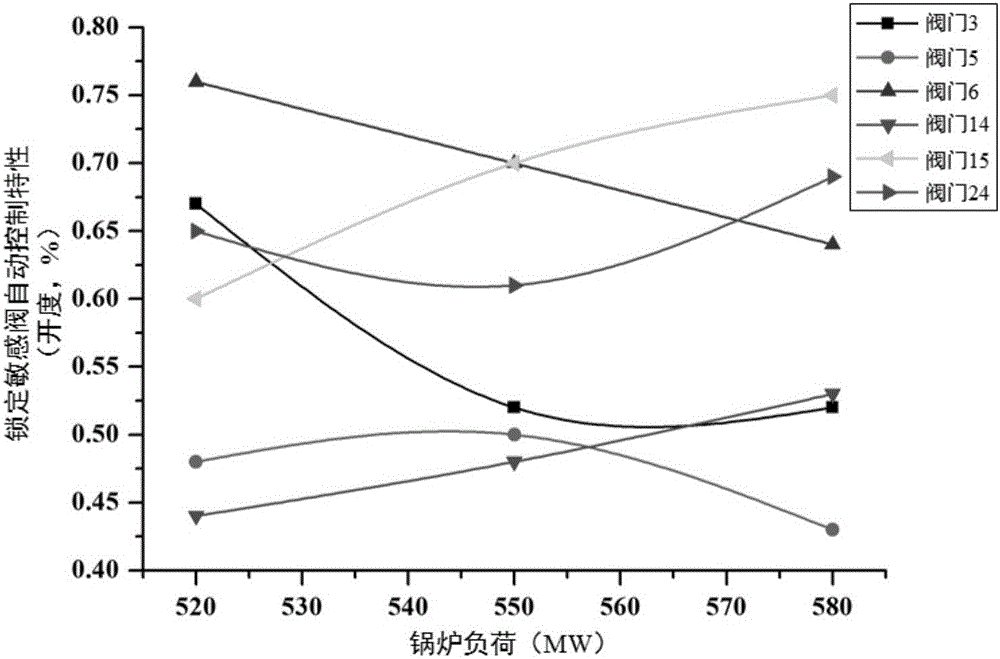

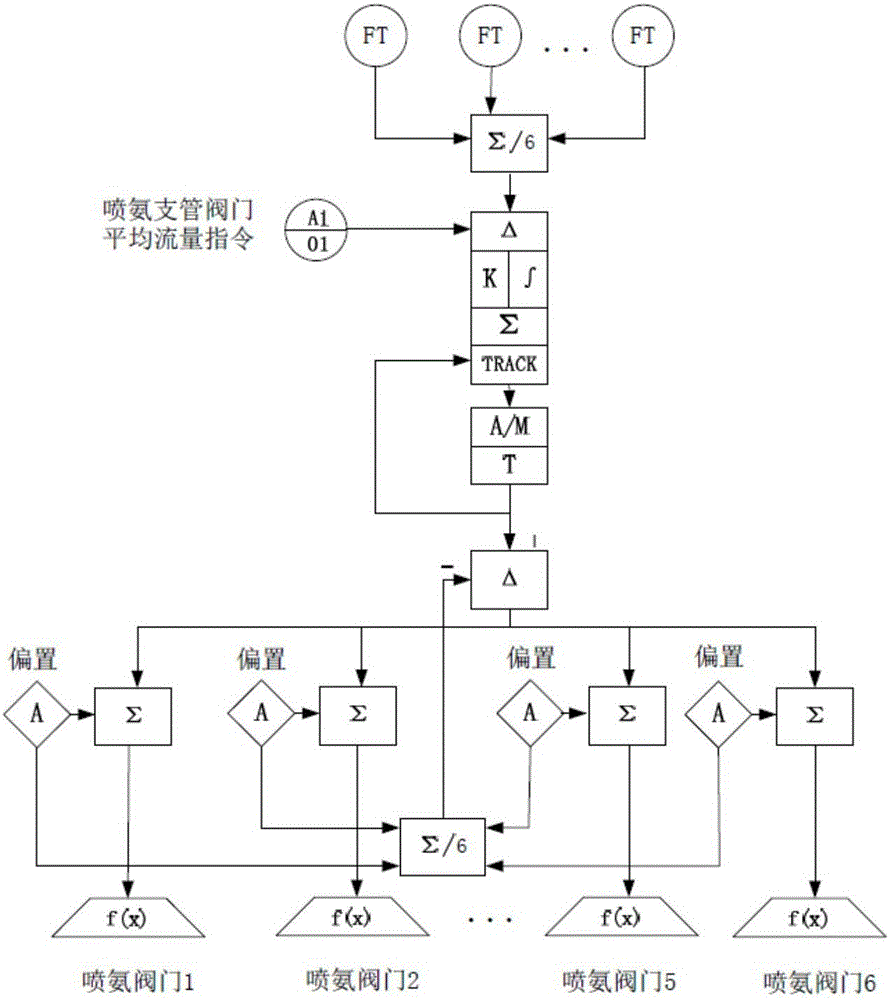

SCR system automatic control method based on ammonia spraying sensitive valve locking

ActiveCN105700504AImprove reaction efficiencySave ammonia consumptionGas treatmentDispersed particle separationAutomatic controlField tests

The present invention discloses a SCR system automatic control method based on ammonia spraying sensitive valve locking. The method comprises three steps: firstly, performing comprehensive analysis of varying load condition operation characteristics of the SCR system based on a field test and a CFD numerical simulation technology to obtain flue gas 'NOx flow' regional continuous distribution characteristics matching an AIG type; then determining the weight of each ammonia spraying branch pipe valve, locking a certain number of sensitive valves according to a preset sensitive valve locking principle, and installing an automatic regulating valve at a corresponding ammonia spraying region; finally, developing an ammonia spraying logic controller and corresponding main control and sub-control logics, realizing multistage optimization setting of parameters of the control system, and realizing the accurate automatic control of the main ammonia spraying regulating valve of the SCR system and the locking sensitive valves. The SCR system automatic control method based on ammonia spraying sensitive valve locking is able to overcome the problems of characteristics of the SCR system such as nonlinearity, large delay and the like so as to realize the accurate automatic control of the ammonia spraying of the SCR system, substantially enhance the SCR denitration reaction efficiency, save the dosage of ammonia, reduce the ammonia escape and effectively inhibit the generation of ABS.

Owner:SOUTHEAST UNIV +1

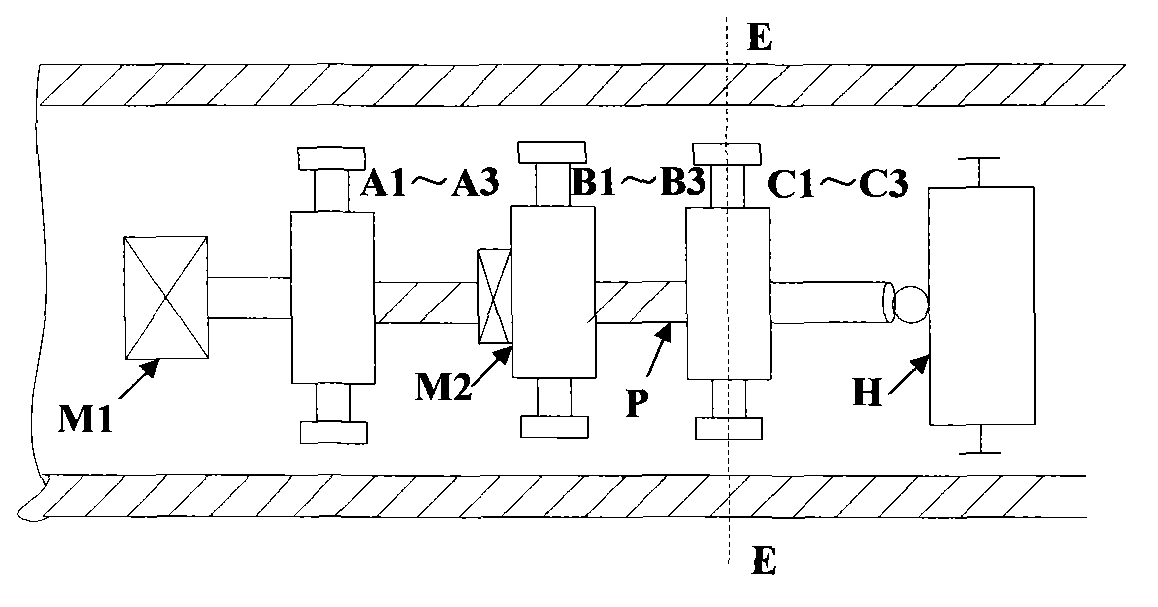

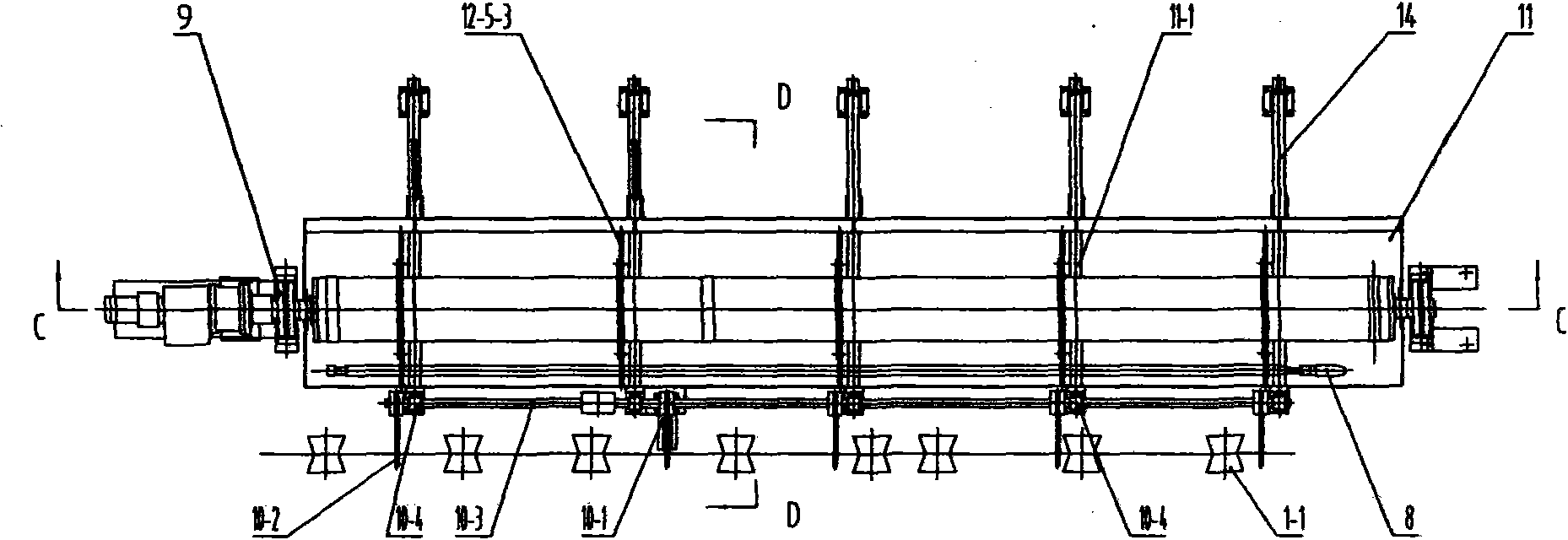

High-precision peristaltic pipeline crawl device and control method thereof

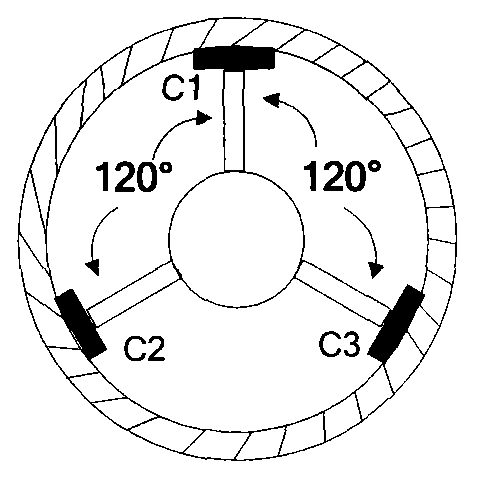

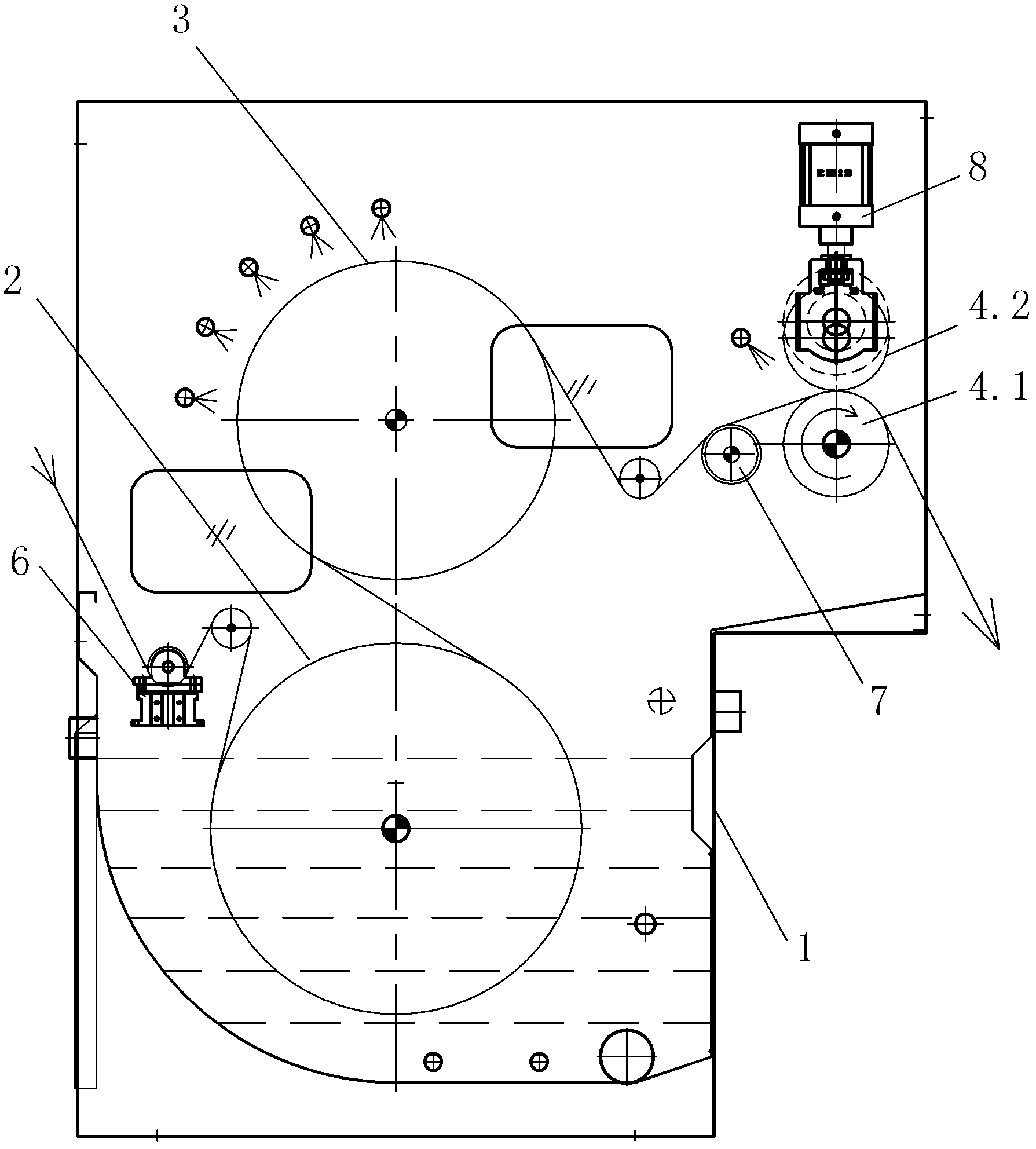

The invention discloses a high-precision peristaltic pipeline crawl device which comprises three three-claw mechanisms, a screw rod (P) and a pipeline parameter measuring head (H). The screw rod (P) is in universal rigid connection with the pipeline parameter measuring head (H). A three-claw mechanism formed by a claw (B1) to a claw (B3) is in threaded connection with the screw rod (P). A three-claw mechanism formed by a claw (A1) to a claw (A3) and a three-claw mechanism formed by a claw (C1) to a claw (C3) are connected with the screw rod (P) in a rolling shaft mode. the three-claw mechanism formed by the claw (A1) to the claw (A3) and the three-claw mechanism formed by the claw (C1) to the claw (C3) can not oppositely shift in an axial direction of the screw rod (P). The three three-claw mechanisms support the screw rod (P) and move coordinately. In a crawl process, slip can not occur, and the craw precision is high and error is less than 0.1 millimeter. Dynamic range of a stretch process is large and crawl in various pipelines with different calibers is achieved. Movement states and changes of step length speed and movement direction of the crawl device when the crawl device crawls can be precisely set and automatically controlled. Driving force or traction force in the axial direction of the crawl device is large, and the crawl device is suitable for pushing or pulling heavy load. The crawl device has an automatically locating center function.

Owner:XIDIAN UNIV

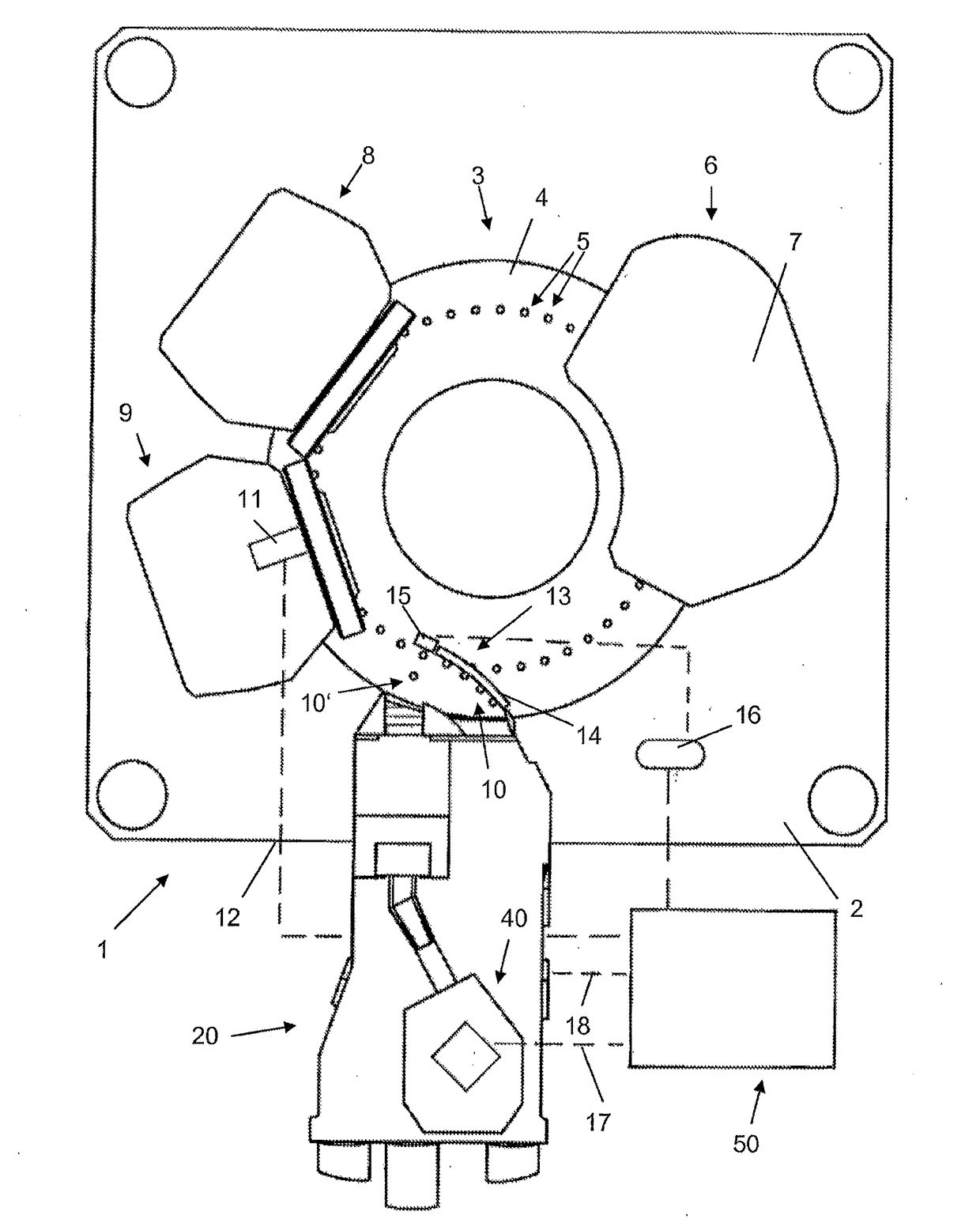

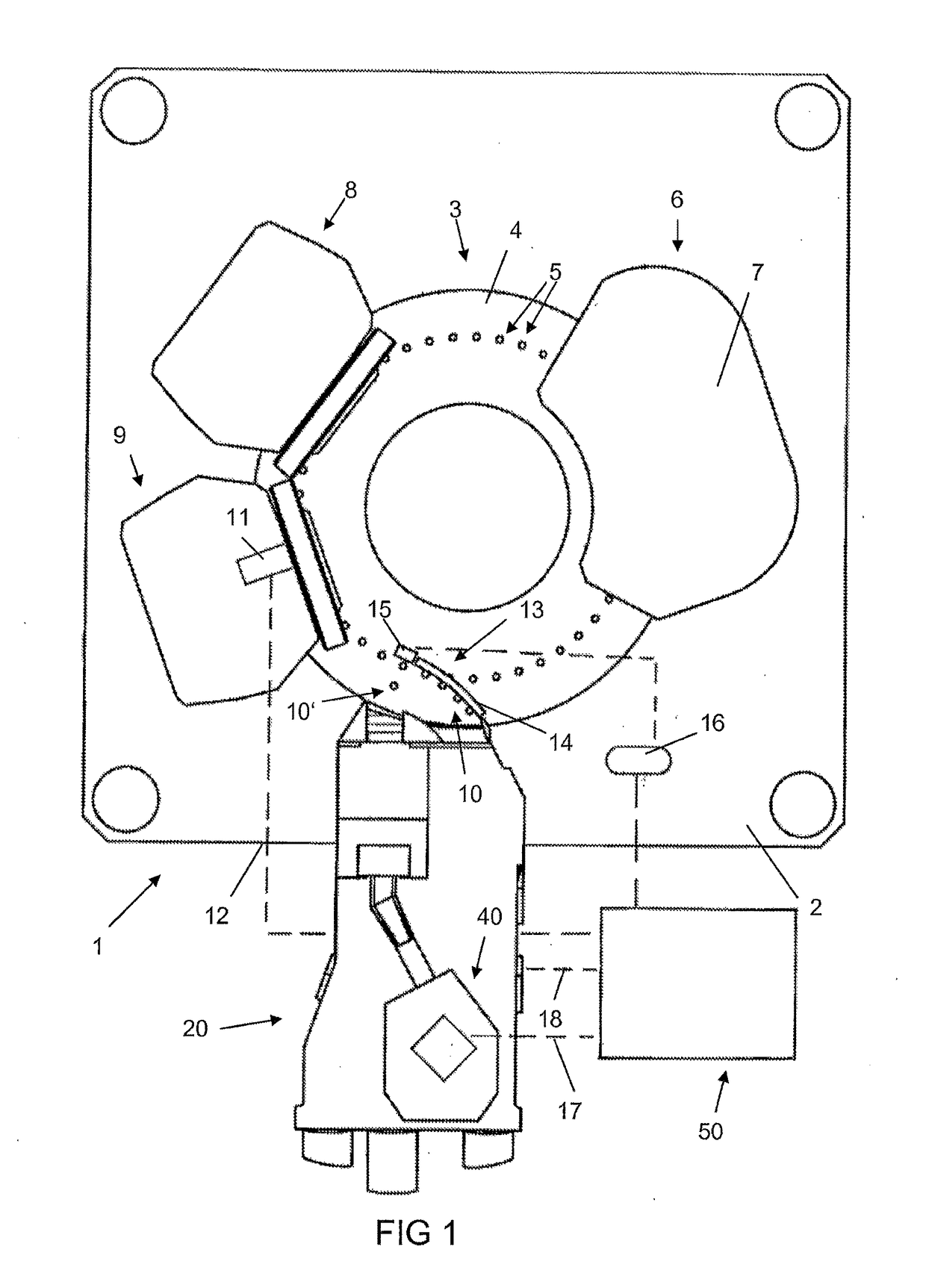

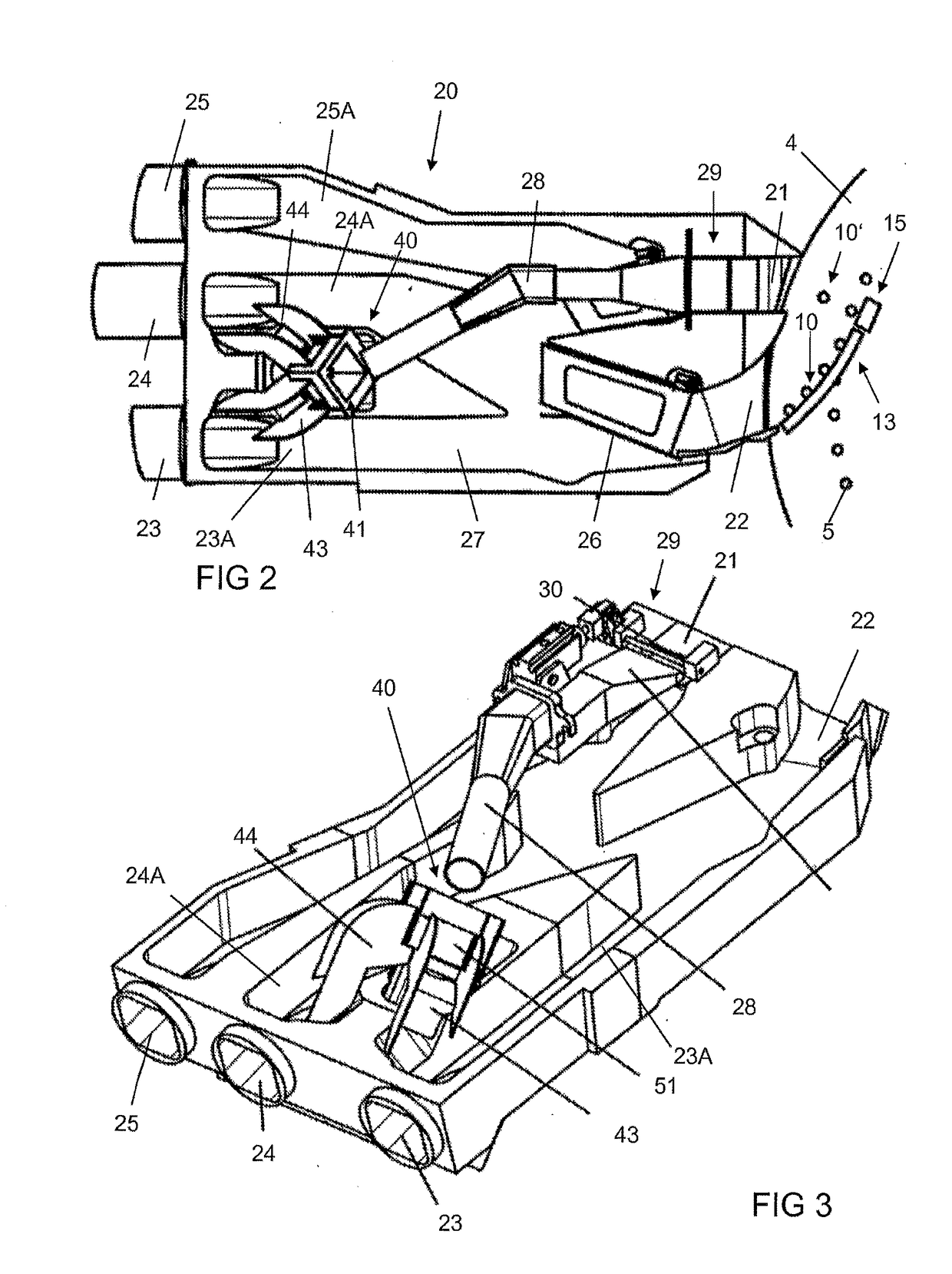

Rotary tablet press with tablet outlet, tablet outlet for said rotary tablet press and method for producing tablets on a tablet press

ActiveUS20170080662A1Increase production outputImprove adhesionSortingShaping pressControl signalTABLET CUTTER

A rotary tablet press, having a rotor, which is driveable about a vertical axis of rotation and has a die plate with die bores for producing tablets inside the die bores by means of punch pairs, having at least one filling station, having at least one pressing station, and having at least one tablet outlet for removing the produced tablets out of the rotary tablet press, with which is associated a discharging device, by way of which tablets, in dependence on a control signal, can be supplied as single tablets to a first channel or as a tablet stream to a second channel in the tablet outlet. In order to enable increased production output with improved adherence to the demands on the tablets, a weighing device with a weighing cell is incorporated into the tablet outlet, tablets from the first channel being suppliable to the weighing device by means of a supply channel.

Owner:ROMACO KILIAN GMBH

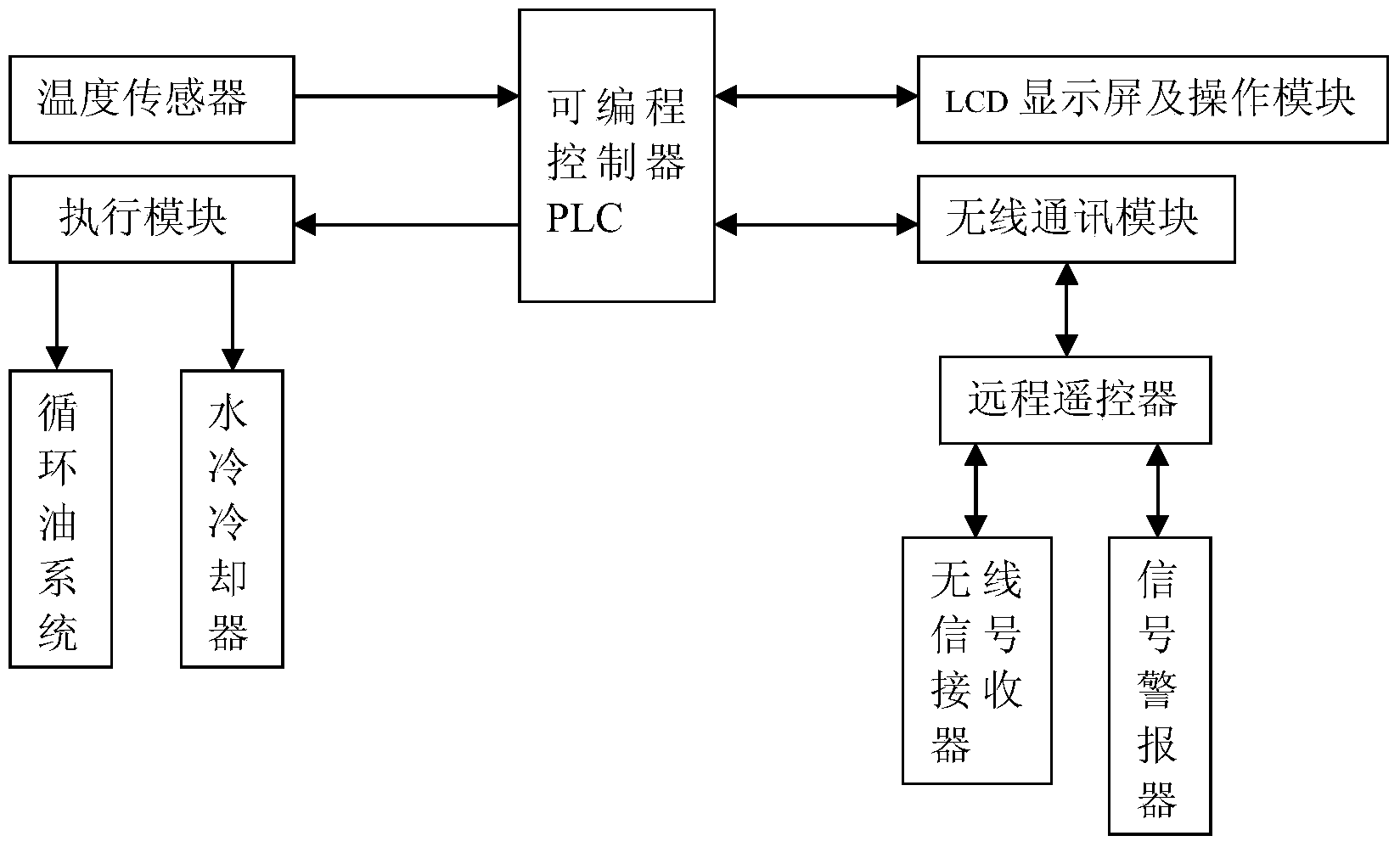

Oil circulation water-cooling control system for transformer of submerged arc furnace

InactiveCN103677007AWith remote control functionTimely controlTransformers/inductances coolingTemperatue controlEngineeringWireless

The invention discloses an oil circulation water-cooling control system for a transformer of a submerged arc furnace. The oil circulation water-cooling control system for the transformer of the submerged arc furnace comprises a water-cooling system, a control device, a temperature sensor, an actuating module, an LCD (liquid crystal display) and an operating module, wherein the water-cooling system comprises a circulating oil system and a water cooler, and is connected with the actuating module; the control device comprises a programmable logic controller (PLC), a wireless communication module and a remote controller; the remote controller is wirelessly communicated with the programmable logic controller (PLC) through the wireless communication module remotely; the temperature sensor detects the temperature of oil on the top of an oil tank of the transformer in real time, and transmits acquired oil temperature signals to the programmable logic controller (PLC); and the LCD and the operating module are connected with the programmable logic controller (PLC). The water-cooling control system has a remote control function, an intelligent monitoring function and a manual monitoring function, and can accurately and efficiently control an air-cooling system of the transformer from multiple directions; and long-term normal running of equipment is guaranteed.

Owner:柳州市五环水暖器材经营部(微型企业)

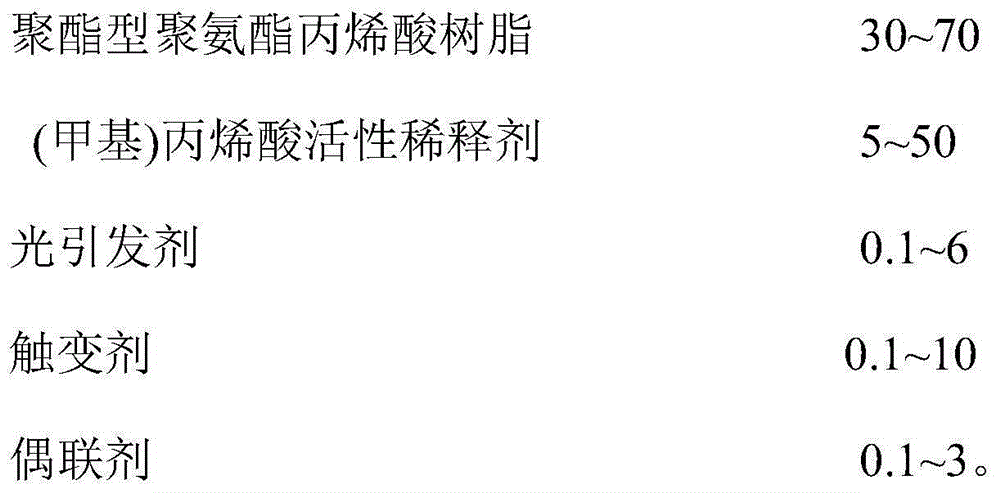

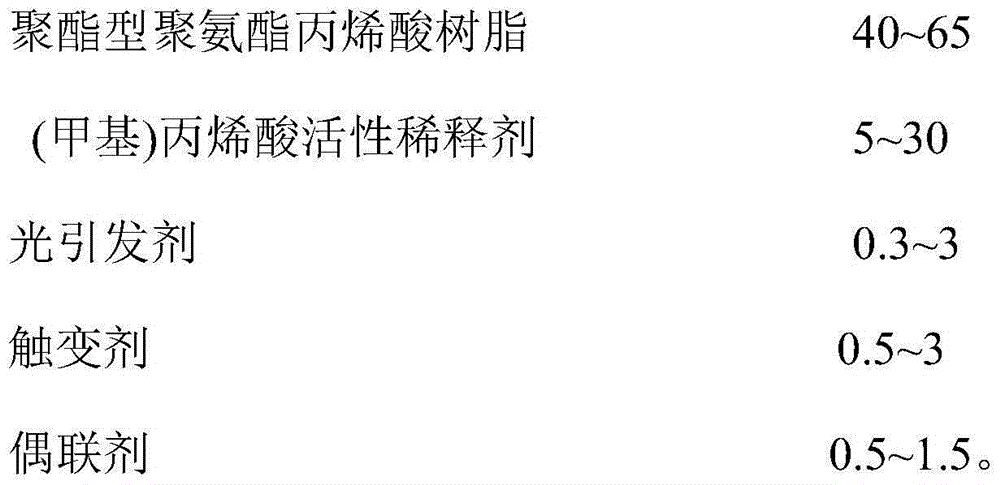

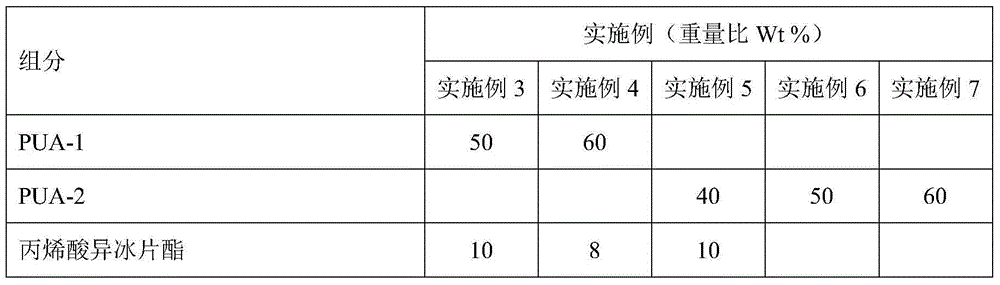

Ultraviolet curing adhesive for temporary protection in aluminum surface anodizing process and preparation method thereof

ActiveCN105176477AMeet the requirements of production and usePrecise automatic controlNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAnodizingPolyester

The invention relates to an ultraviolet curing adhesive for temporary protection in the aluminum surface anodizing process. The ultraviolet curing adhesive comprises, by weight, 30-70 parts of polyester type polyurethane acrylic resin, 5-50 parts of a (methyl)acrylic acid reactive diluent, 0.1-6 parts of a photoinitiator, 0.1-10 parts of a thixotropic agent and 0.1-3 parts of a coupling agent. The ultraviolet curing adhesive can achieve machine adhesive dispensing, and is more precise in automatic control, higher in efficiency and lower in cost; meanwhile, after anodizing is performed, the ultraviolet curing adhesive is removed more easily and is not likely to be broken, and higher in efficiency and yield, and the ultraviolet curing adhesive can completely meet the requirement for production and using of full-lamination modules.

Owner:TONSAN ADHESIVES INC

High-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method

InactiveCN102745825AEasy to realize online automatic dosingImprove controllabilityScale removal and water softeningTungstateTurbidity

The invention discloses a high-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method. The high-efficiency low-phosphorus corrosion and scale inhibiting dispersant comprises: 2%-12% of sodium benzoate, 1%-5% of molybdate (or tungstate), 1%-2% of thiazole, 3%-6% of anhydrous zinc chloride, 8%-18% of polyphosphonocarboxylate, 5%-15% of acrylic acid-2-methyl-2-acrylamido propane sulfonic acid copolymer, 3%-6% of a stabilizer, 3%-6% of a tracer, and the balance deionized water. The dispersant of the invention can be widely applicable to water quality treatment of circulating water with a sum of hardness and alkalinity of less than 1100mg / L, a chloride ion concentration of less than 1000mg / L, pH of 6.8-9.5, and turbidity of less than 20NTYU. The dispersant provided in the invention has scale and corrosion inhibiting performances able to meet the requirements of industrial circulating water design specifications and a wide source water quality application range, and has the advantages of low phosphorus, environmental protection, strong chlorine resistance, applicability for auto-medicating control, as well as convenient use, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

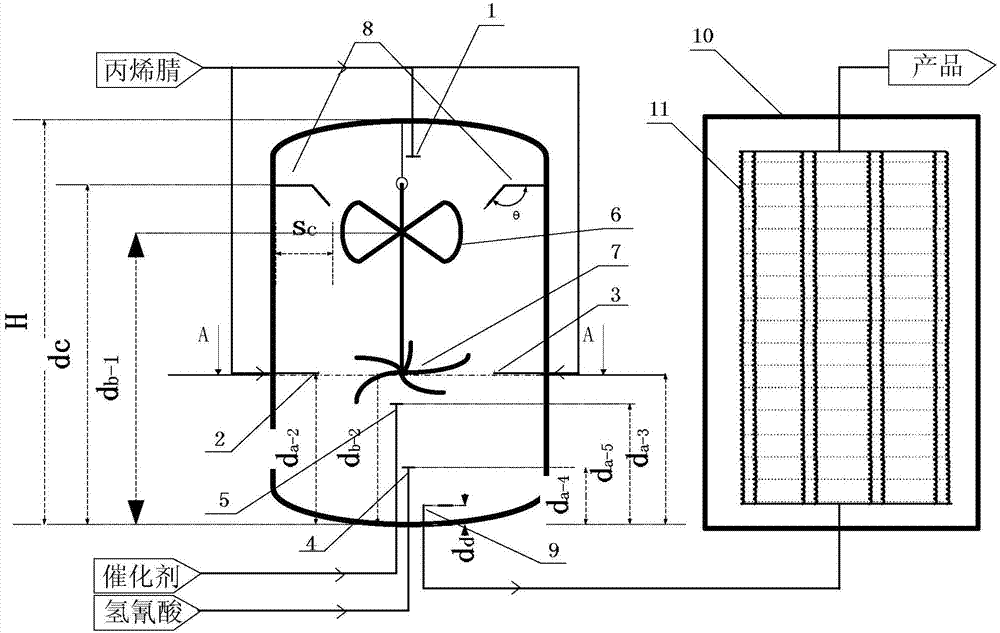

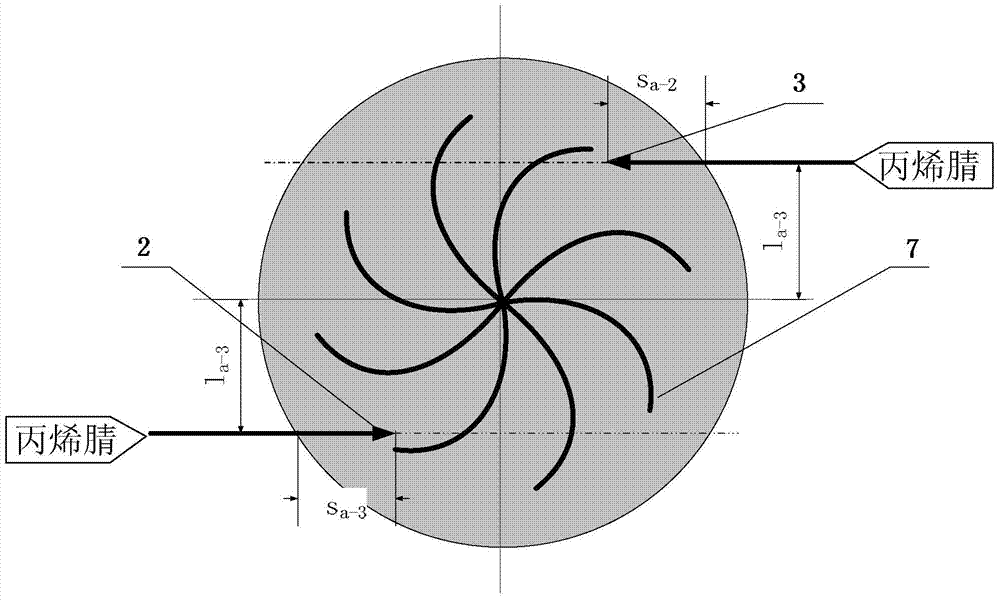

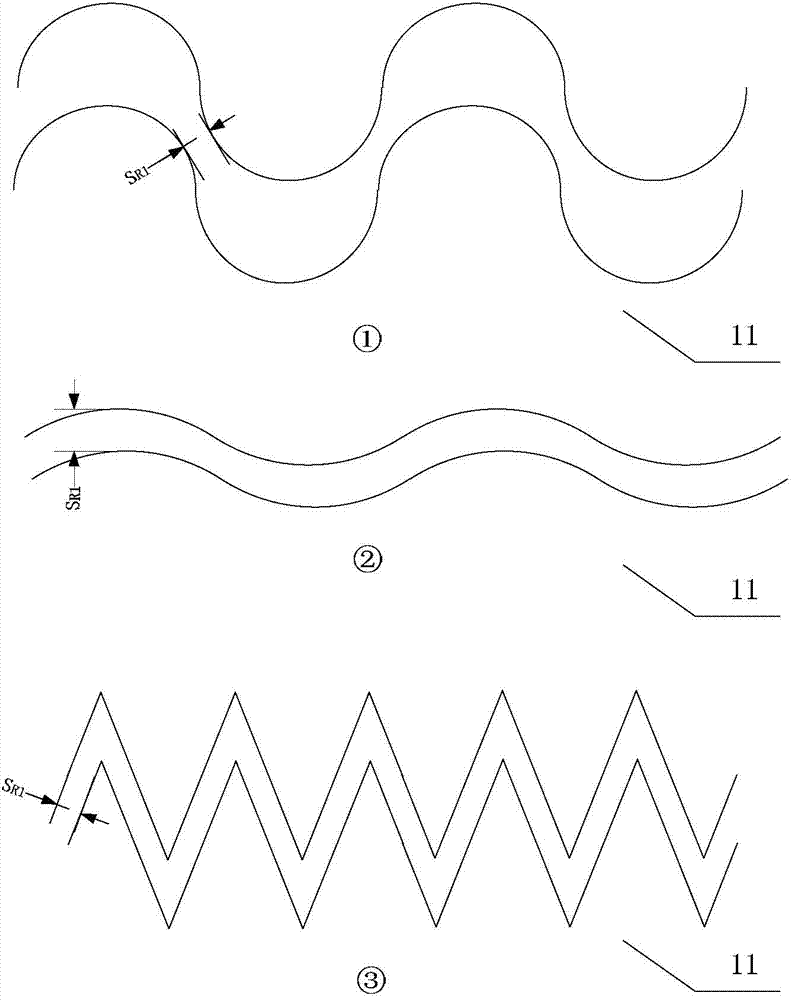

Method for continuously preparing butanedinitrile

The invention provides a butanedinitrile preparation reactor and a method for continuously preparing butanedinitrile by using the reactor. According to the invention, reaction raw materials hydrocyanic acid, acrylonitrile, and a catalyst are continuously delivered through a small mixing kettle with a special structure and a plurality of subsequent millimeter-grade to micrometer-grade regular reaction channels which have special internal structures and which are connected in parallel, such that butanedinitrile can be continuously and stably prepared with high yield. The reactor has excellent mixing effect and a heat change capacity. Compared with a traditional reactor, mass transfer and heat transfer problems during the butanedinitrile reaction process can be well solved, such that problems such as low reaction yield, large amount of by product, and the like caused by poor mass transfer and heat transfer are effectively solved. More precise automatic control of the reaction process can be easily realized. Equipment space occupation is low, energy consumption is greatly reduced, and intrinsic safety is greatly improved.

Owner:WANHUA CHEM GRP CO LTD +1

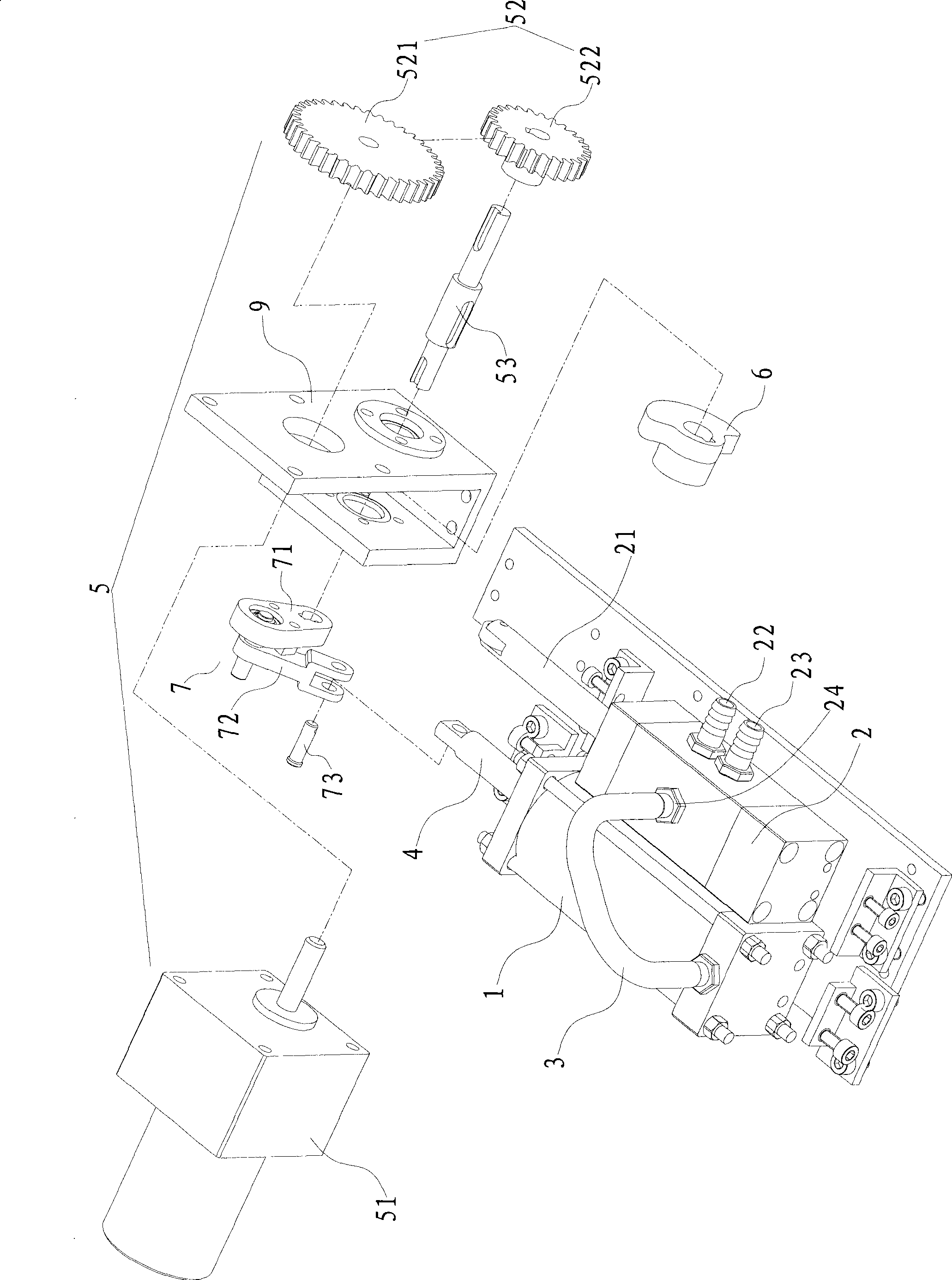

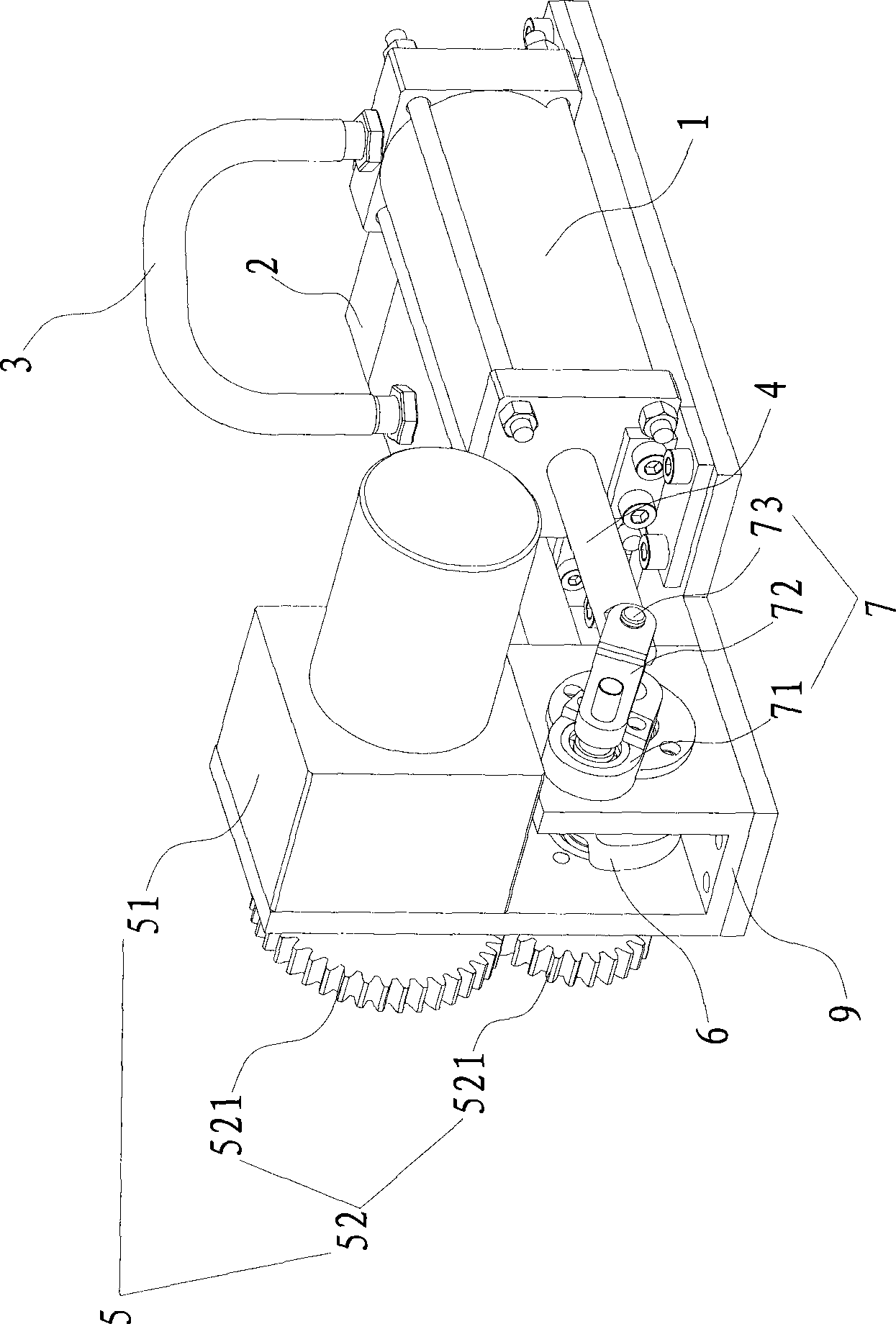

Rotary shear mark tool rest of automatic wire stripper

InactiveCN102013619ARealize fully automatic wire stripping processingPrecise automatic controlLine/current collector detailsApparatus for removing/armouring cablesCoaxial cableEngineering

The invention discloses a rotary shear mark tool rest of an automatic wire stripper, which comprises a mounting rack, a tool rest assembly arranged on the mounting rack and a motor assembly, wherein the tool rest assembly comprises a wire inlet pipe, a cutter assembly, a cutter closing mechanism and a cutter rotating mechanism. The rotary shear mark tool rest has the advantages that: the rotary shear mark tool rest is used as an accessory of the automatic wire stripper; when special cables such as coaxial cables need processing, cutters are closed through the cutter closing mechanism, and meanwhile the cutters rotate on the circumference by using the cutter rotating mechanism, so that a complete circular shear mark matched with the outline of a cable is realized on the cable, and the traditional wire skin problem is solved; and after the shear mark process is finished, the automatic wire stripper finishes an automatic wire stripping process so as to realize full-automatic wire stripping of the special cables such as the coaxial cables.

Owner:浙江君权自动化设备有限公司

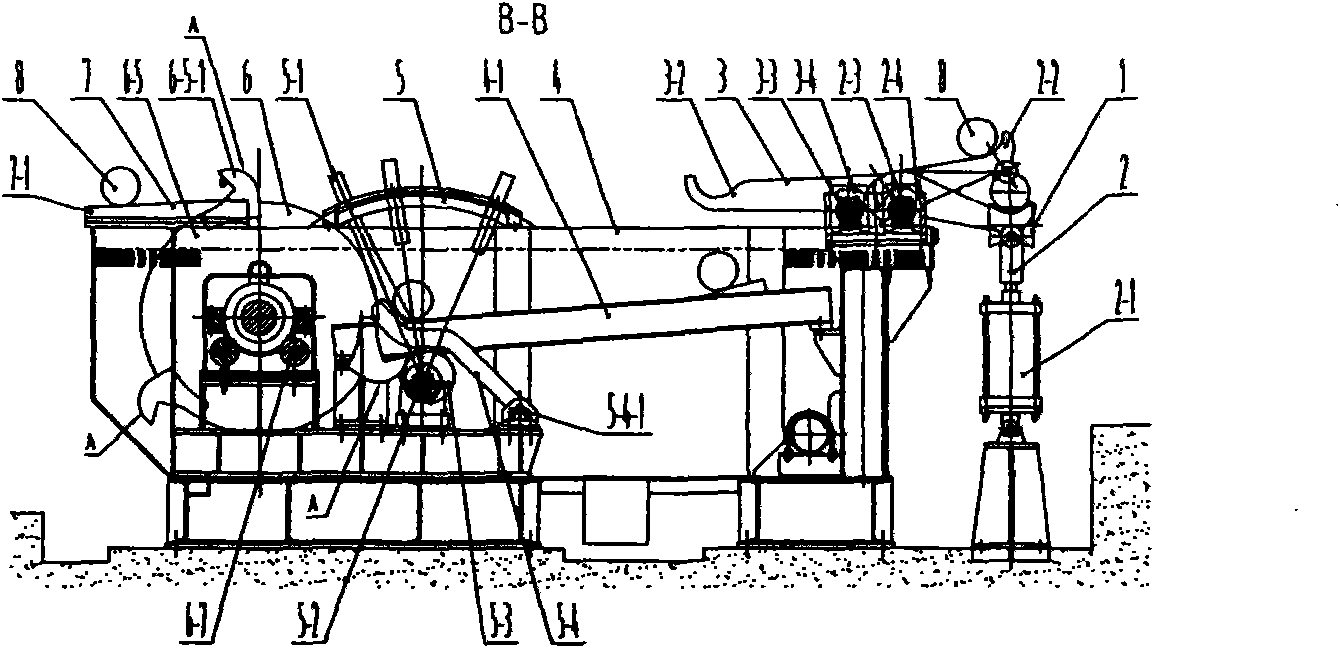

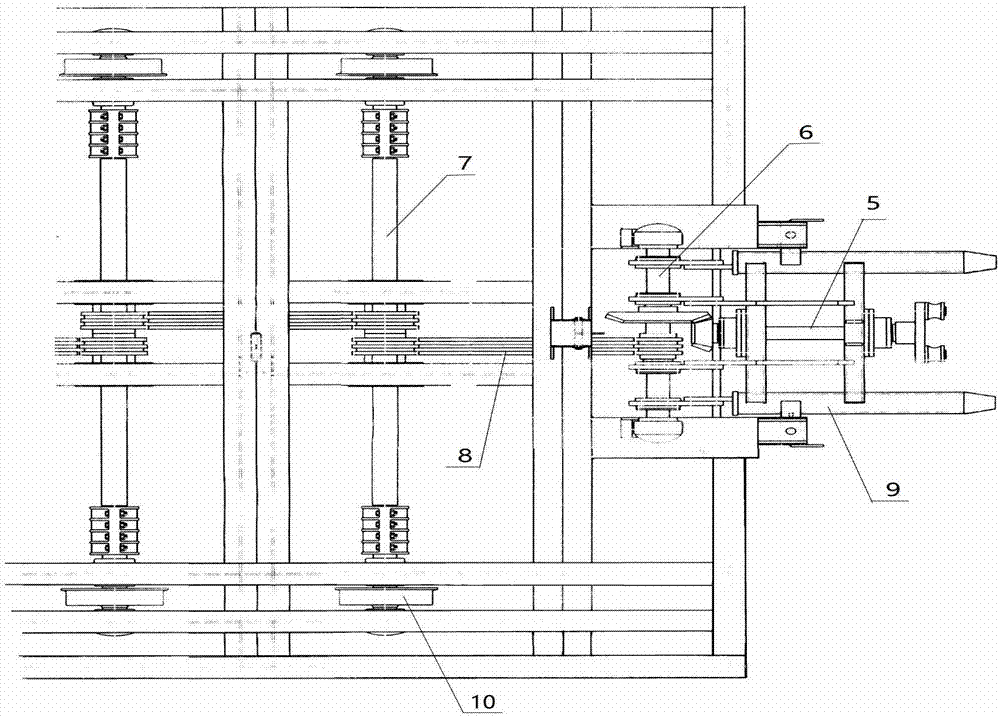

Cooling tank device of hot-rolling perforation machine set

InactiveCN101791628AGuaranteed uptimeReduce widthMandrelsMetal rolling arrangementsHydraulic cylinderCooling effect

The invention discloses a cooling tank device of a hot-rolling perforation machine set, relating to hot-rolling perforation machine set equipment. The invention solves the problems that the existing cooling tank device has large occupied area, large cooling water requirement amount, poor cooling effect and inaccurate mandril control so as to affect normal production operation. The invention is characterized in that in-bound equipment is an in-bound device 10 which is composed of a hydraulic cylinder 10-1, five material toggling grooves 10-2, a rotary shaft 10-3 and five bearing pedestals 10-4; the bottom of a cooling trough 4 is welded with five semicircular mandril slideways 4-2; a rotary device utilizes a support frame arranged outside the cooling trough and a rotary drum device 9 arranged right above the cooling trough 4; and a control mechanism is a controller 11 consisting of a profile modelling disk 11-1 and an approach switch 11-2.

Owner:TAIYUAN HEAVY IND

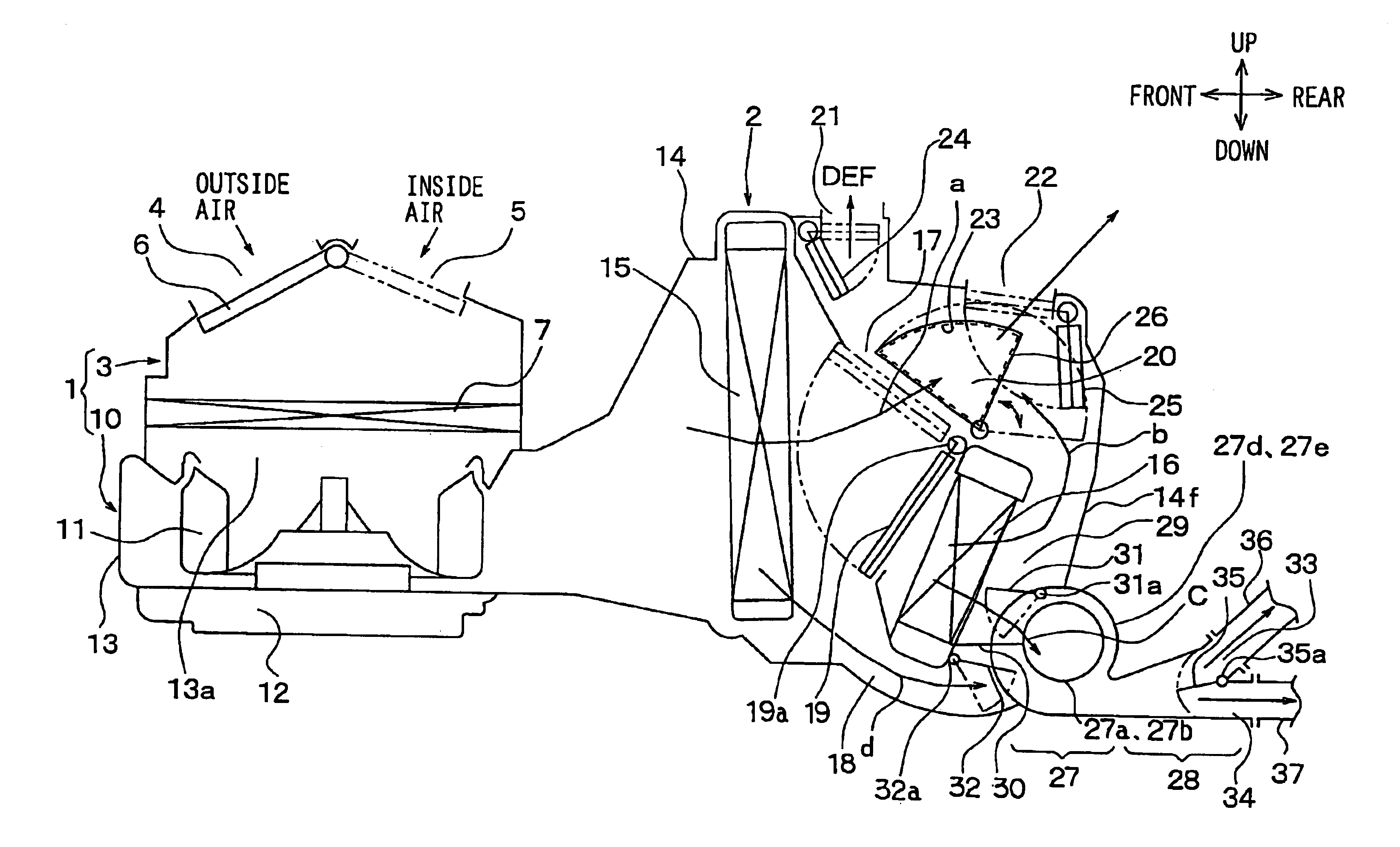

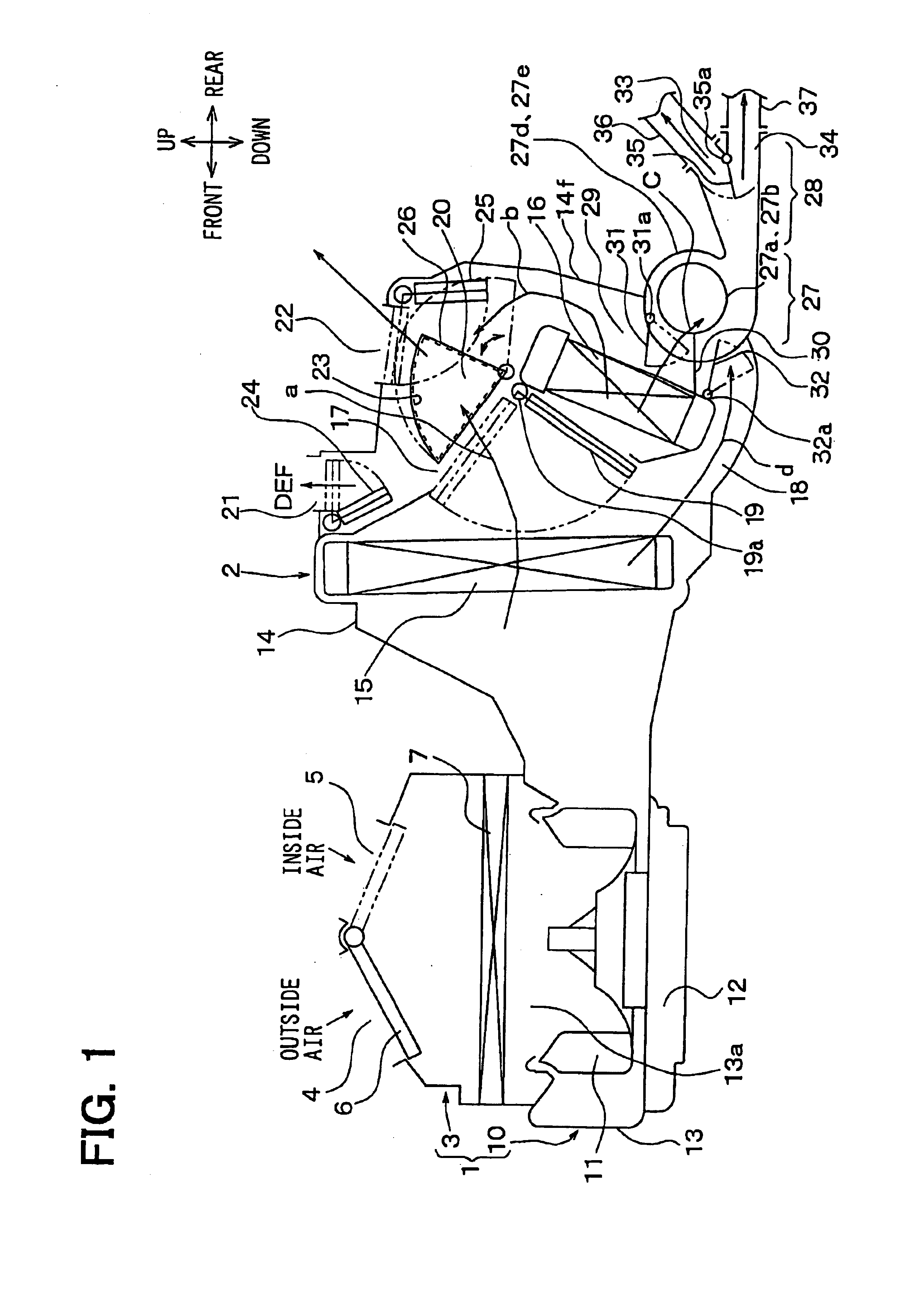

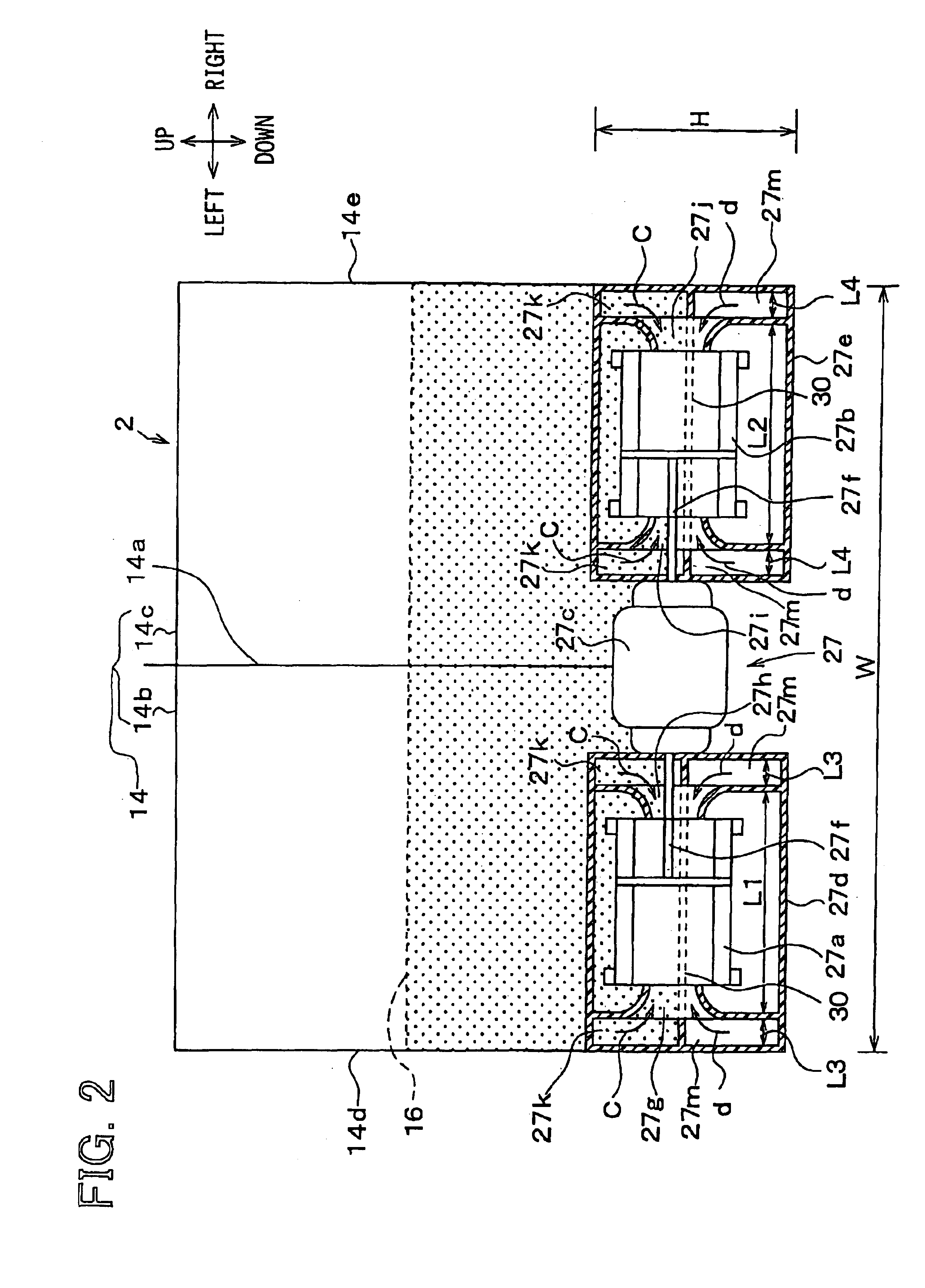

Vehicle air conditioner with automatic control of main blower and sub-blower

InactiveUS6915650B2Precise automatic controlEnsure correct executionAir-treating devicesRailway heating/coolingAutomatic controlEngineering

A vehicle air conditioner includes a main blower and a sub-blower for blowing air into a passenger compartment. The main blower is disposed to blow conditioned air in a front air passage toward a front seat area in the passenger compartment, and the sub-blower is disposed in a rear air passage having an air flow resistance larger than that in the front air passage so that a part of air blown by the main blower is blown by the sub-blower toward a rear seat area in the passenger compartment through the rear air passage. In the air conditioner, an air amount blown by the sub-blower is controlled to be increased in accordance with a decrease of an air amount blown by the main blower. Therefore, automatic control of the air amount blown by the sub-blower can be accurately performed.

Owner:DENSO CORP

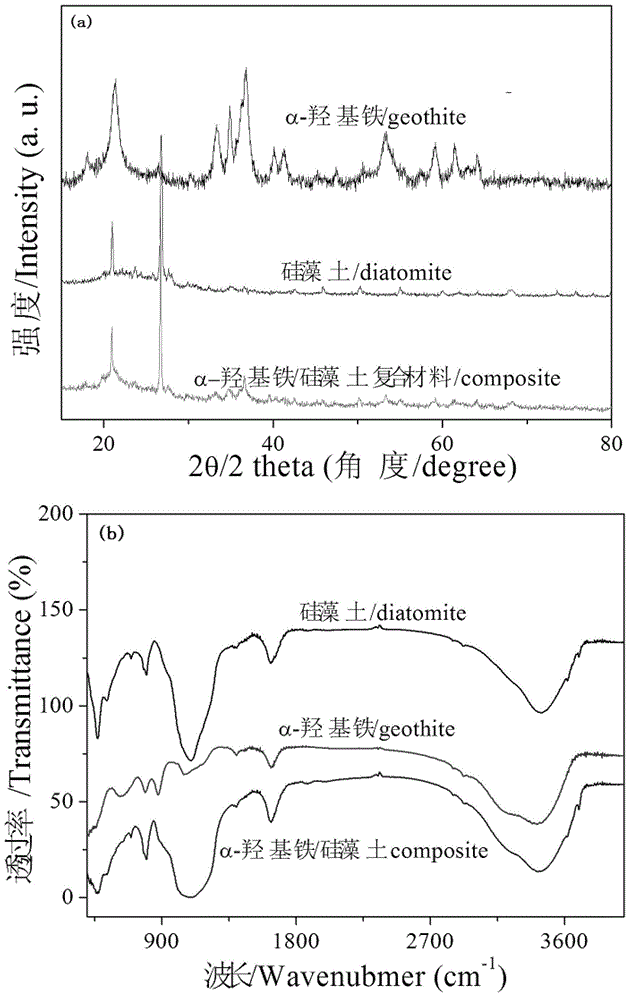

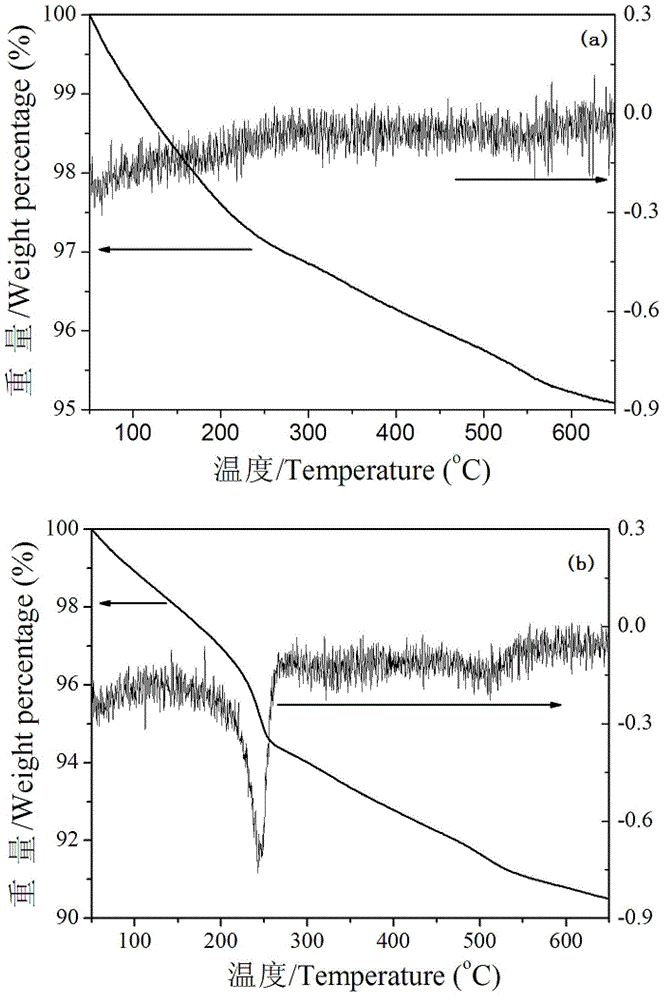

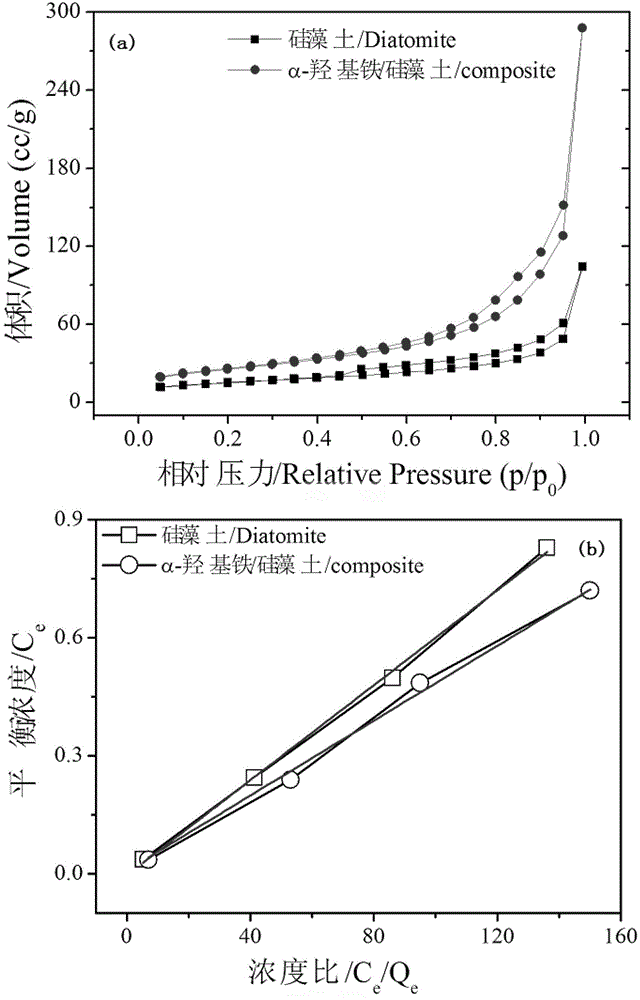

Preparation method for siliceous earth/FeOOH composite materials in micro-nano structure

The invention discloses a preparation method for siliceous earth / FeOOH composite materials in a micro-nano structure. The preparation method comprises the steps of evenly attaching FeOOH obtained by a water-bath method to the surface of siliceous earth, respectively characterizing prepared products by a field emission scanning electronic microscope and an X-ray diffraction instrument, and knowing that alpha-FeOOH is of an orthorhombic system structure, evenly distributed on the surface of the siliceous earth and even in morphological structure. The alpha-FeOOH of the composite materials is of a nano structure and has higher crystallinity and purity. During a preparation process, due to the fact that substances like templates are not added, follow-up processing is convenient to achieve, reaction temperature is low, reaction time is short, processes are simple, cost is low, and the preparation method is potentially applied to the field of environment.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Cooking equipment and device for transferring liquid materials thereof

InactiveCN101543374AReliable actionQuantitatively accurateCooking vesselsAutomatic controlReciprocating motion

The invention relates to a device for transferring liquid materials of cooking equipment, which comprises a cylinder body for storing the liquid materials, a valve body, a pipeline connecting the valve body and the cylinder body, and a power device, wherein the inside of the cylinder body is provided with a piston mechanism; the valve body is a multichannel reversing valve; the power device simultaneously drives a valve core of the valve body and the piston mechanism to allow the valve core to switch among the different channels of the valve body; simultaneously, the piston mechanism reciprocates in the cylinder body to change the size of the cylinder body; the device for transferring the liquid materials adopts coaxial transmission of a crank and a cam, has reliable action and accurate ration, and can realize accurate autocontrol; the device for transferring the liquid materials has a simple structure and small power consumption; a basic material of stainless steel is adopted to manufacture the device, can endure high temperature for a long time and is suitable to be used in automatic / semiautomatic cooking equipment; and the device for transferring the liquid materials of the cooking equipment can quantificationally provide the liquid materials needed in cooking and improve the cooking quality and efficiency.

Owner:PANSUM TECH

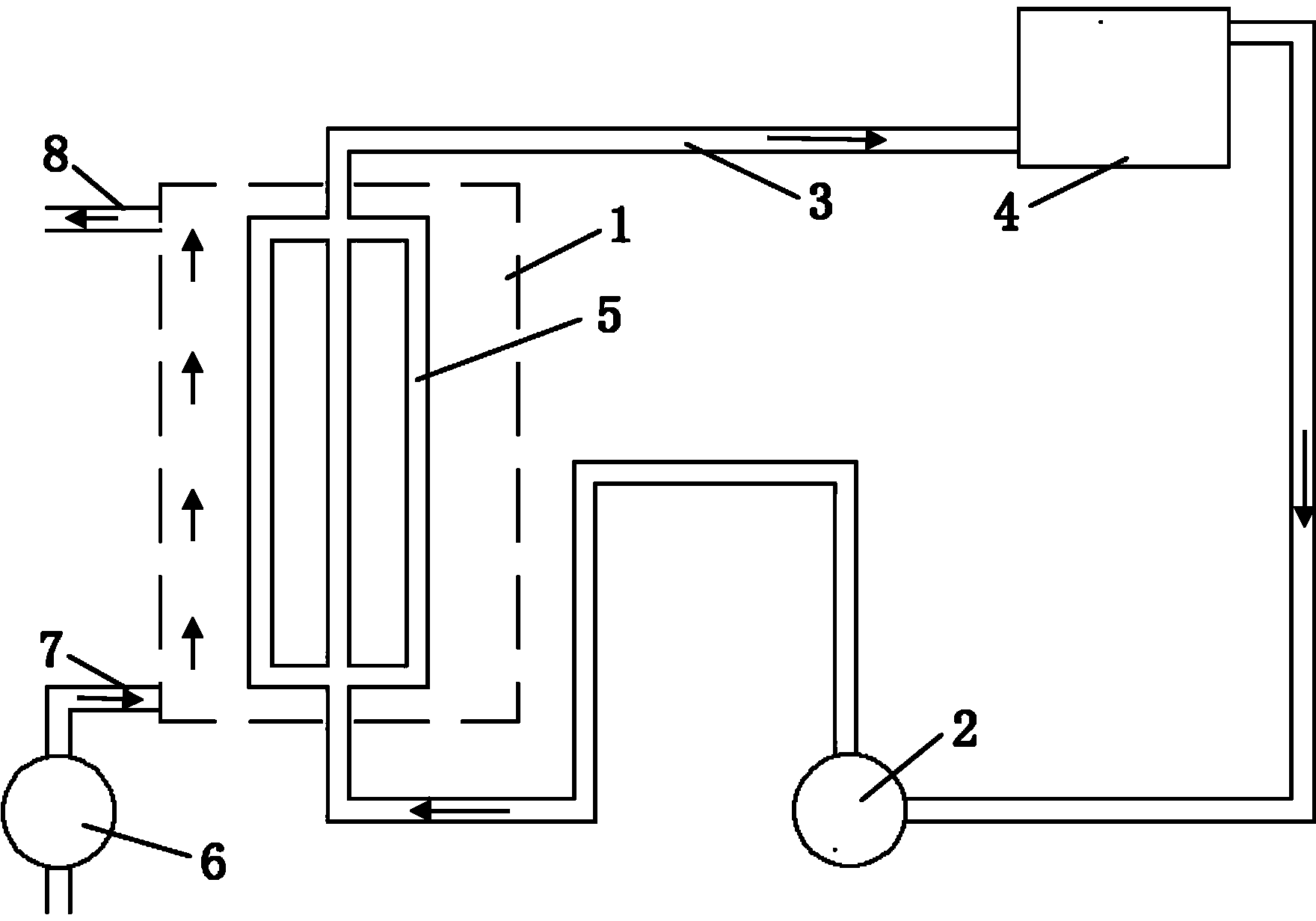

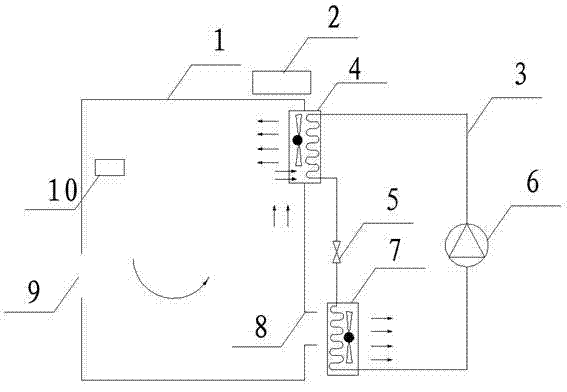

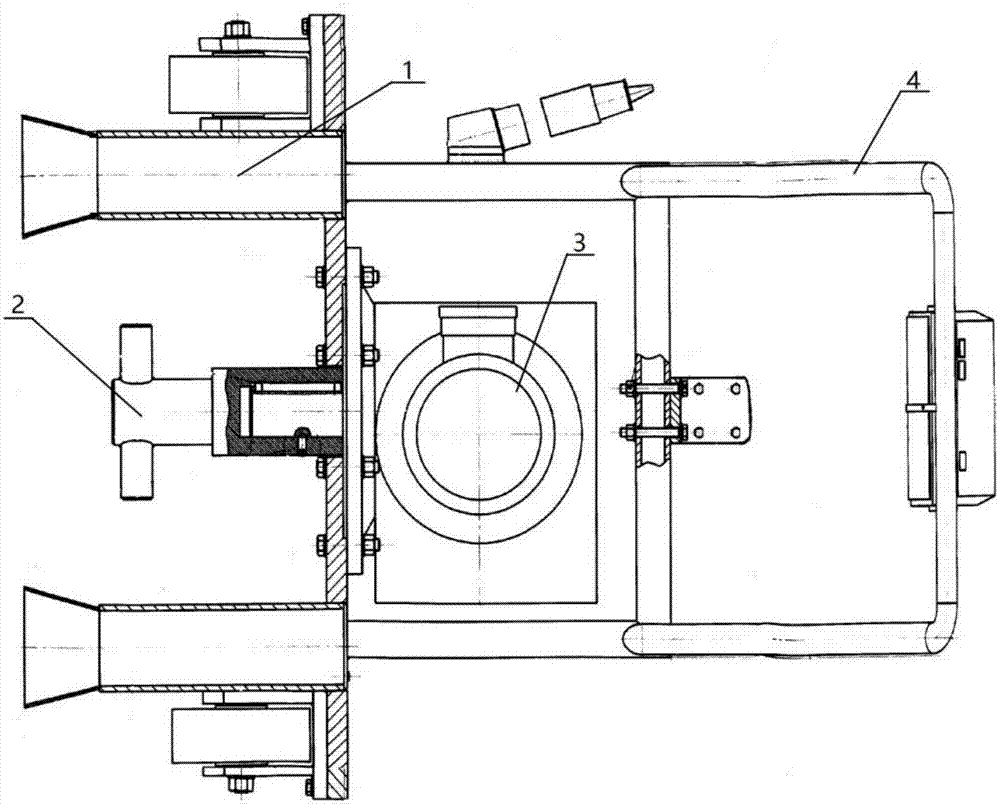

Multifunctional intelligent heat pump baking device

InactiveCN102809277AEmission reductionImprove baking qualityHeat pumpsHeating arrangementThermodynamicsFresh air

The invention discloses a multifunctional intelligent heat pump baking device which mainly comprises a baking room (1), a heat-transfer medium delivery pipeline (3), a condenser (4), an expansion valve (5), a compressor (6), an evaporator (7), a dehumidifying heat recovery port (8), a fresh air supply port (9) and a temperature and humidity sensor (10). A mounting port of the condenser (4), the dehumidifying heat recovery port and the fresh air supply port are arranged on the baking room, the evaporator is arranged at the dehumidifying heat recovery port, an outlet end of the condenser is communicated with an inlet end of the evaporator through the expansion valve, an outlet end of the evaporator is communicated with an inlet end of the condenser through the heat-transfer medium delivery pipeline, and the compressor is connected to the heat-transfer medium delivery pipeline. Energy stored in environmental media and dehumidifying heat energy in the baking room can be utilized by the aid of a heat pump, air is heated by a heat-transfer medium circulating system to dry materials, so that emission of waste gas can be reduced effectively, environmental protection can be achieved, complicated manual operation is simplified, material baking quality is improved, and baking can be controlled automatically and precisely.

Owner:LUOYANG ZHONGMAO ENVIRONMENTAL PROTECTION EQUIP

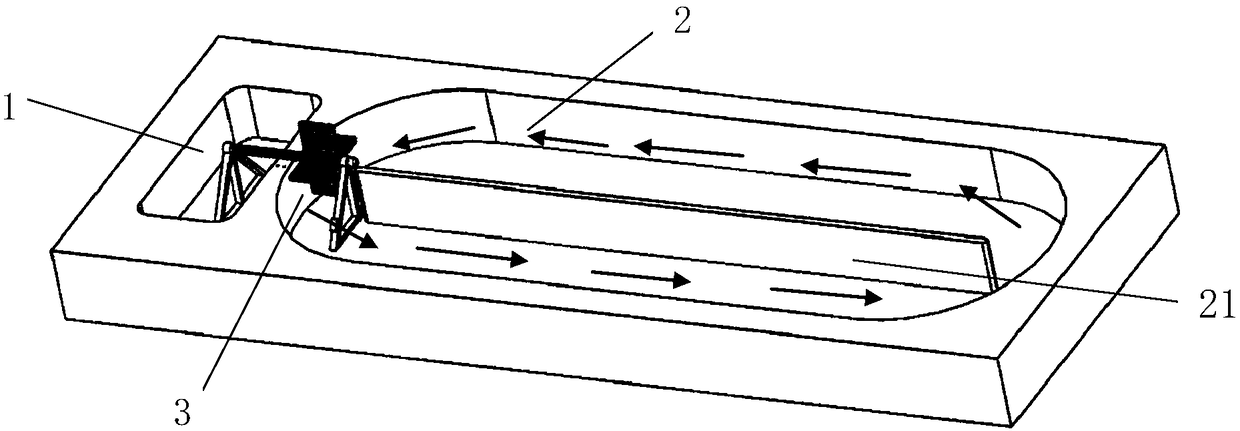

Biological filter device of circulation shallow water aquaculture system, and control method thereof

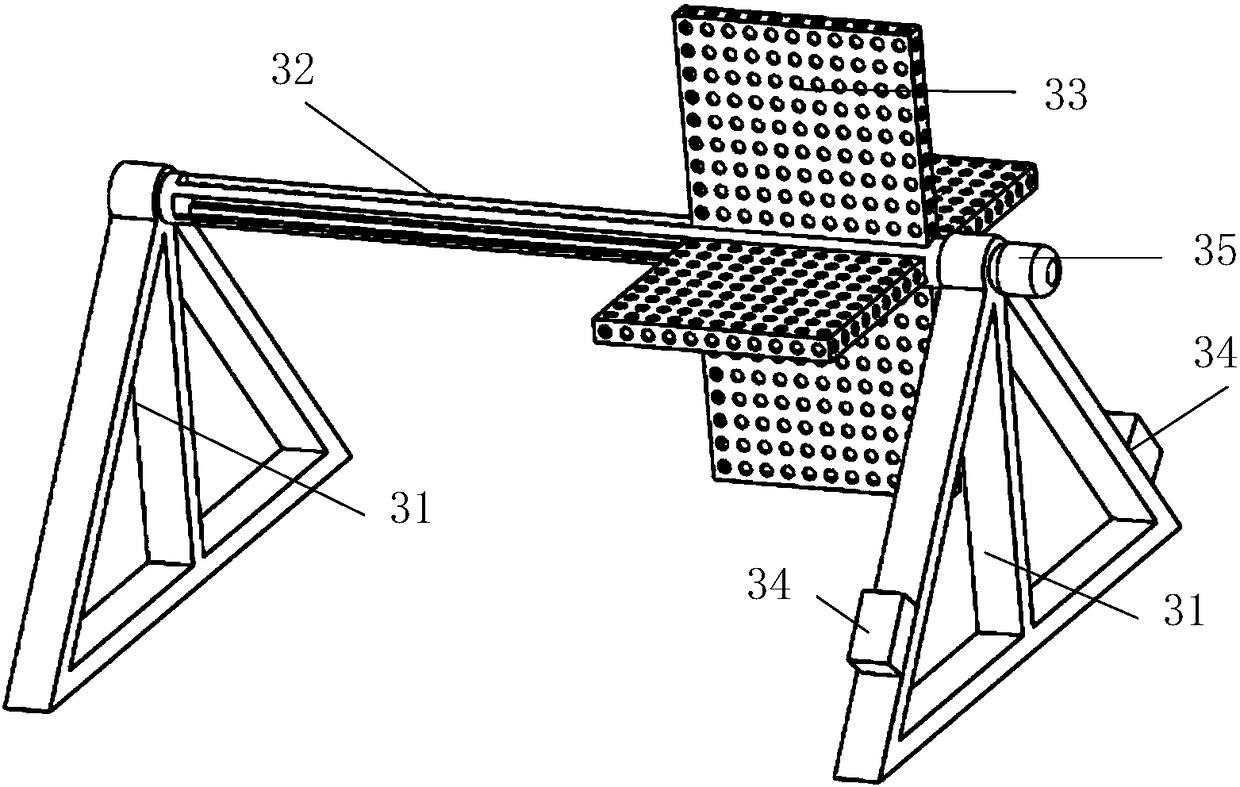

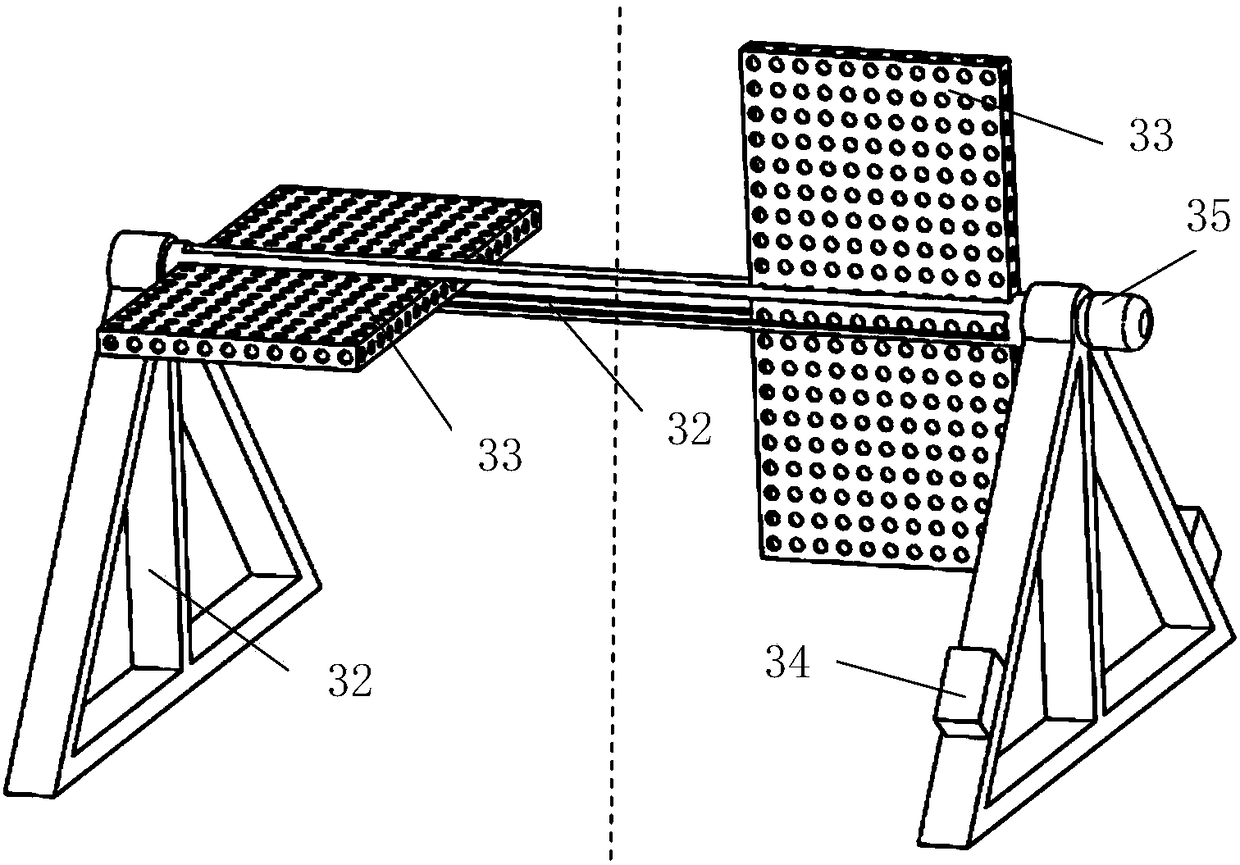

ActiveCN108394999AIncrease oxygen contentPromote growthWater treatment parameter controlSpecific water treatment objectivesBio filtrationBiological filter

The invention discloses a biological filter device of a circulation shallow water aquaculture system. The biological filter device of the circulation shallow water aquaculture system comprises a scourtrough, a filter mechanism and an aquaculture pond, wherein the scour trough and the aquaculture pond are arranged adjacently; the filter mechanism comprises a support frame, a rolling shaft and fourwing-shaped net cages; two ends of the rolling shaft is straddle mounted on the scour trough and the aquaculture pond through the support frame; the wing-shaped net cages are crosswise connected ontothe rolling shaft and can slide in an axial direction; water in the aquaculture pond has a certain flow speed and passes through the wing-shaped net cages with aquatic plants capable of absorbing ammonia nitrogen. A control method of the biological filter device is carried out in the biological filter device. According to the biological filter device of the circulation shallow water aquaculture system, and the control method thereof provided by the invention, through the wing-shaped net cages with the built-in aquatic plants, ammonia nitrogen can be absorbed continuously, and impurities are filtered, so that the oxygen content is improved; through an ammonia nitrogen detection sensor, the ammonia nitrogen content in water can be continuously obtained to control the rolling shaft to rotate, the ammonia nitrogen content is controlled accurately, and the device is suitable for cleaning different ammonia nitrogen pollution degrees of various shallow water aquaculture.

Owner:SHANGHAI OCEAN UNIV

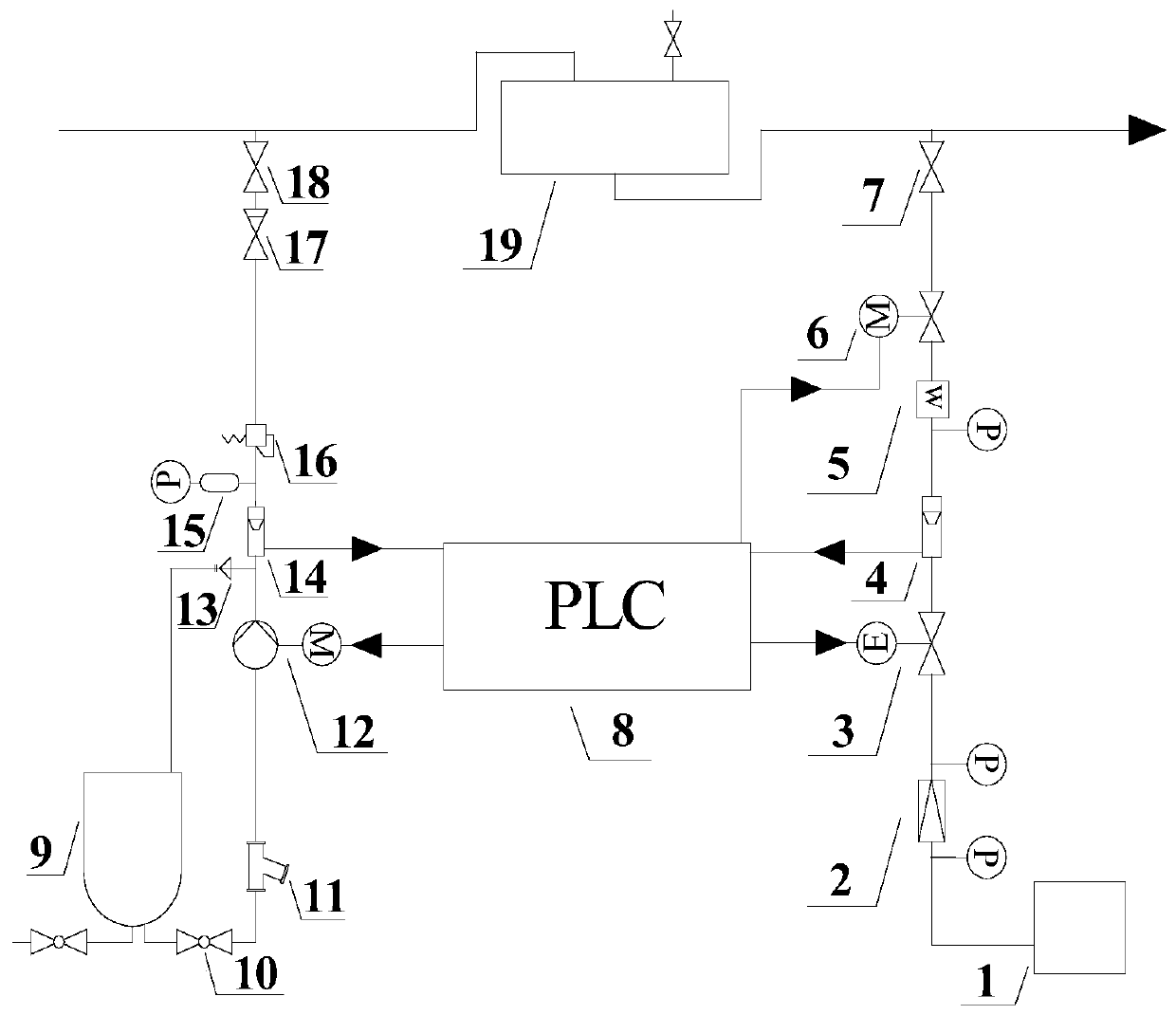

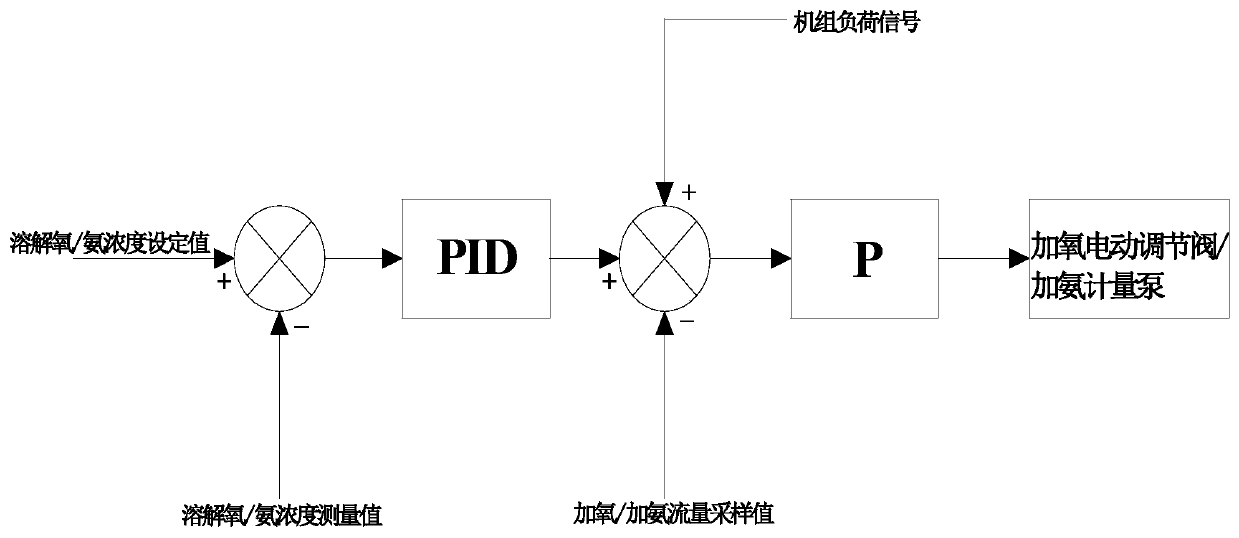

Synergistic precise control device and method for automatic oxygen addition and ammonia addition for water supply in power plant

ActiveCN110217900AGuaranteed safe operationAvoid corrosionWater treatment parameter controlTreatment using complexing/solubilising chemicalsPower stationHydrogen

A synergistic precise control device and method for automatic oxygen addition and ammonia addition for water supply in a power plant are disclosed. The device includes an automatic oxygen addition andammonia addition synergistic controller, a fed water oxygen addition system and a condensed water ammonia addition system, and mainly includes a PLC automatic oxygen addition and ammonia addition synergistic controller, an oxygen addition pressure reducing valve, an oxygen addition electromagnetic regulating valve, an oxygen addition pressure stabilizer, an ammonia addition metering pump, and other components. A fed water hydrogen conductivity signal is inputted to the PLC automatic oxygen addition and ammonia addition synergistic controller; when the fed water hydrogen conductivity is less than 0.15 [mu]S / cm, the appropriate oxygen amount and ammonia amount are controlled; when the fed water hydrogen conductivity is higher than 0.15 [mu]S / cm, an oxygen addition electric turn-off valve isturned off to stop oxygen addition and the ammonia amount is properly increased. Feedforward PID regulation is performed on oxygen addition according to a result of comparing a measured value of thedissolved oxygen content in fed water with a set value of the dissolved oxygen content by adopting a unit load as feedforward, thus achieving precise oxygen addition control. Feedforward PID regulation is performed on ammonia addition according to a result of comparing a measured value of conductivity of a deaerator inlet with a set value of the conductivity by adopting a unit load as feedforward,thus achieving precise ammonia addition control.

Owner:XIAN THERMAL POWER RES INST CO LTD

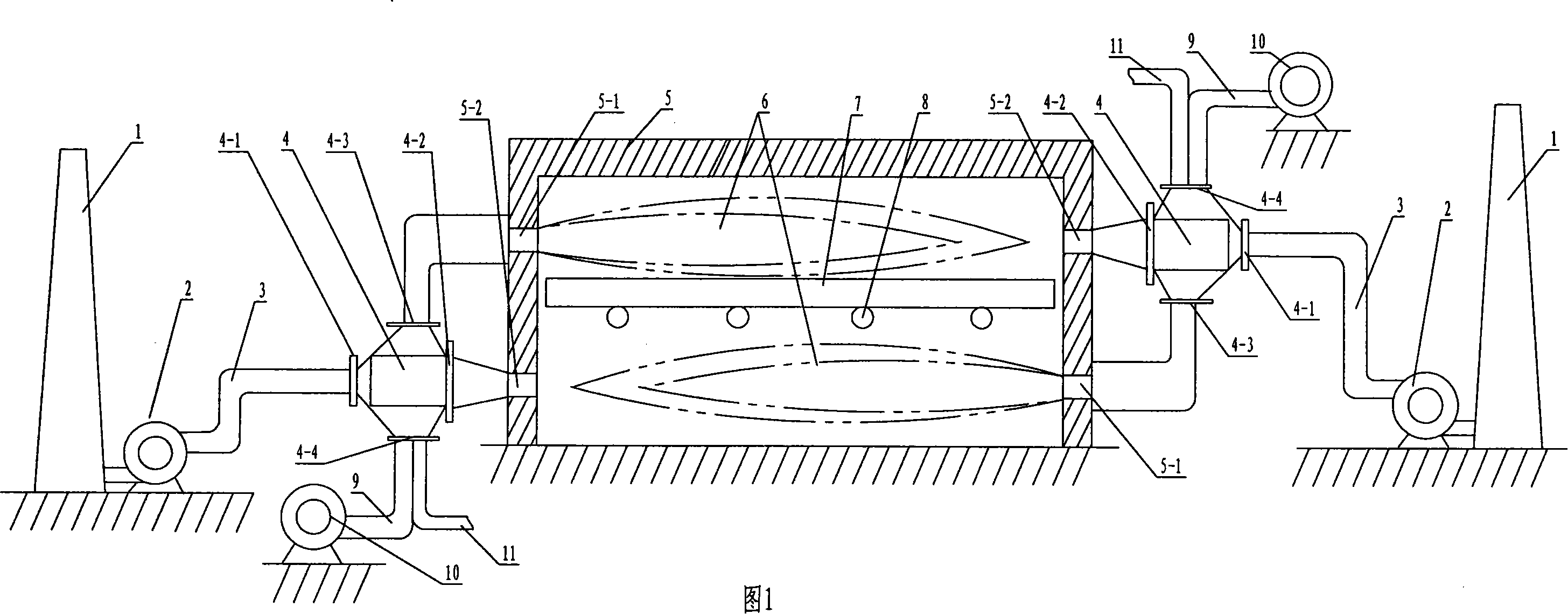

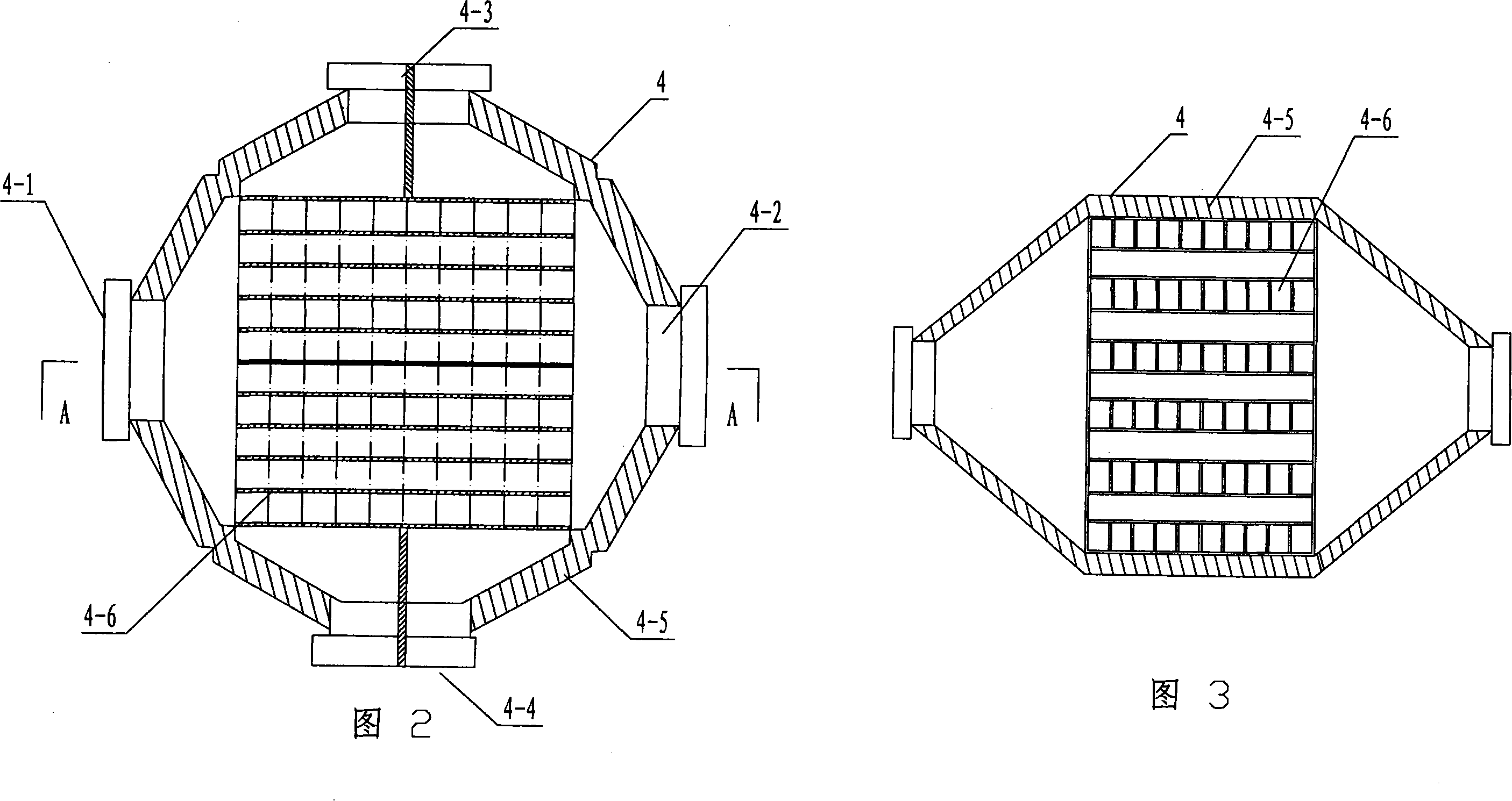

Direct backheating burned flame type heating stove and working method

InactiveCN101113872AReduce accident rateImprove work rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFurnace temperatureProcess engineering

A flame-typed heating furnace by directly regenerative combustion and a working method pertain to the heating furnace technical field, and are used for solving the problem of constant switch in working state of the existing regenerative type heating furnaces. The invention comprises a furnace body, a heat-exchange device, an air-supply device and a smoke-exhaust device. The invention is characterized in that an air fuel inlet and a high-temperature smoke outlet are separately positioned at the two sides of the furnace body, and the air fuel inlet of one side is positioned correspondingly with the high-temperature smoke outlet on the other side. The working state of each opening of the furnace body in the invention needs not switch, thereby, the working state is stable. The invention still uses a high-temperature smoke exhausting method, but the heat-exchange process adopts a method of direct regeneration, thereby needing no commutation, and furnace temperature and furnace pressure are no longer frequently fluctuated, the combustion process in the furnace is very stable, therefore, the problems of easy cracking and pre-heater smelting, softening, deforming, breaking, blocking of the furnace body are solved. The furnace failure rate is greatly decreased, and the working rate is improved, both of which provide strong and powerful technical support for stable and continuous production of the heating furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

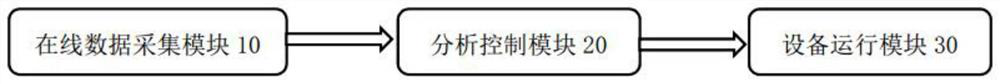

Automatic slurry amount control system for slurry circulating pumps for wet flue gas desulphurization

ActiveCN113062874APrecise automatic controlEasy to controlGas treatmentDispersed particle separationControl systemFlue gas

The invention relates to an automatic slurry amount control system for slurry circulating pumps for wet flue gas desulphurization. The system is characterized in that an online data acquisition module is used for acquiring online data parameters, and a control module is used for receiving the online data parameters, automatically calculating the required slurry circulation amount, obtaining a start-stop and variable-frequency optimal configuration scheme of the plurality of power-frequency and variable-frequency combined slurry pumps according to the required slurry circulation amount, and generating a control instruction according to the obtained optimal configuration scheme; after the instruction is executed, a fine adjustment scheme of the slurry circulation amount is obtained according to the change of the SO2 concentration of flue gas at a desulfurization outlet, and a control instruction is generated according to the obtained fine adjustment scheme; and an equipment operation module is used for receiving the control instructions, changing equipment operation parameters and executing the optimal configuration scheme and the fine adjustment scheme. According to the automatic slurry amount control system for the slurry circulating pumps for wet flue gas desulphurization, the slurry circulation amount can be accurately and automatically controlled, energy is saved to the greatest extent while the SO2 concentration at the desulfurization outlet is controlled to be in a reasonable range, and the workload of operators is reduced.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST +1

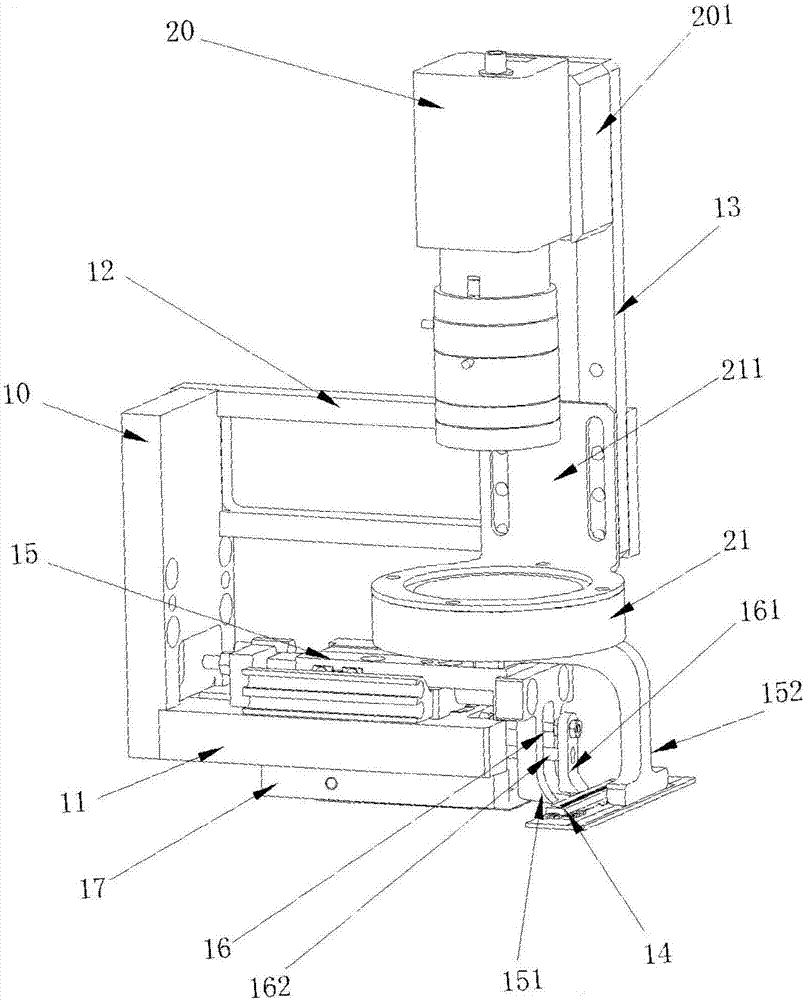

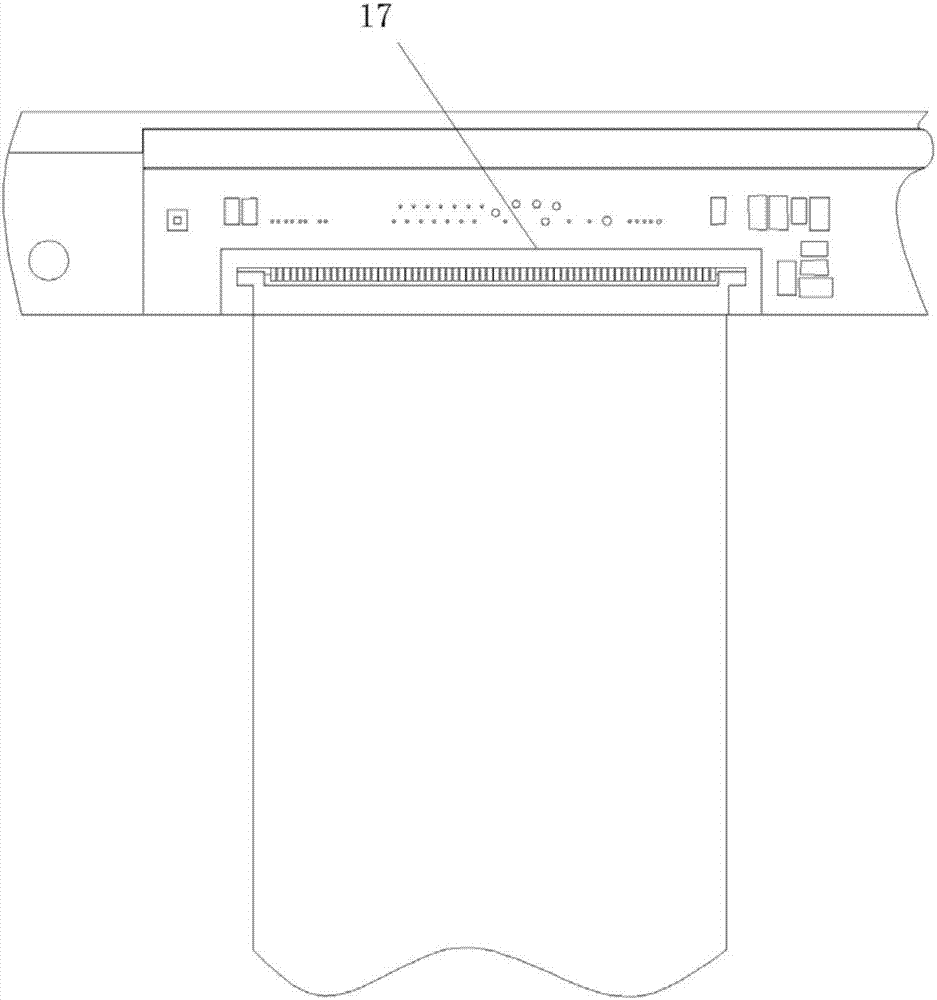

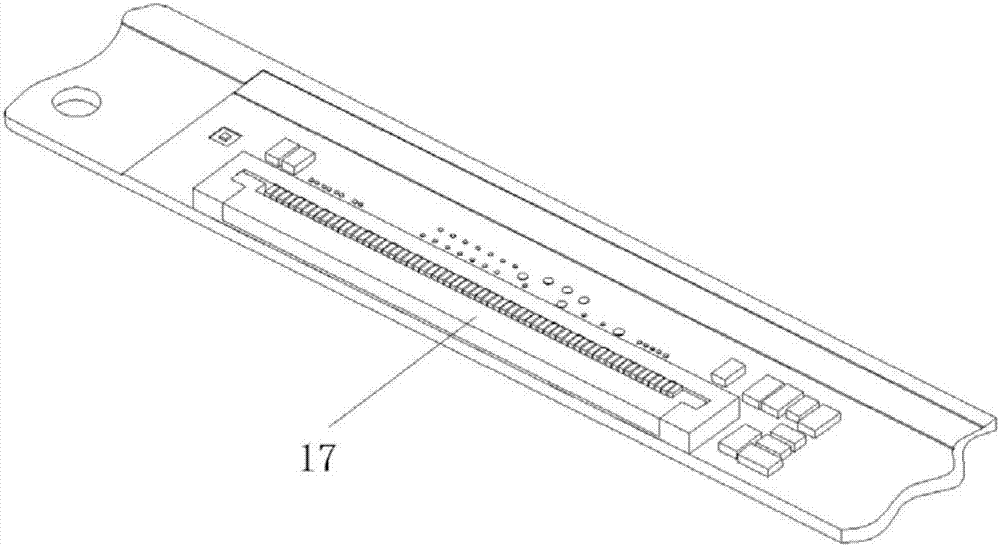

Accurate automatic insert-pull mechanism for flexible flat cable

ActiveCN107317213AImprove stabilityGuaranteed stabilityCoupling device engaging/disengagingMechanical engineering

The invention relates to an accurate automatic insert-pull mechanism for a flexible flat cable in assembly and test equipment of electronic products. The accurate automatic insert-pull mechanism for the flexible flat cable comprises a fixing plate, a first connecting plate and a second connecting plate which are connected with the fixing plate; the second connecting plate is connected with a third connecting plate; the first connecting plate is connected with an end operating mechanism and an adsorption mechanism; and the third connecting plate is connected with a camera photographing system. The automatic insert-pull mechanism for the flexible flat cable provided by the invention realizes accurate automatic insertion and pulling between the flexible flat cable and a connector, and compared with manual insertion and pulling, the efficiency is high, the plug is stable and accurate and there is no damage to the flexible flat cable and the connector.

Owner:深圳市明信测试设备股份有限公司

Vacuum oil injection system for transformer or capacitor

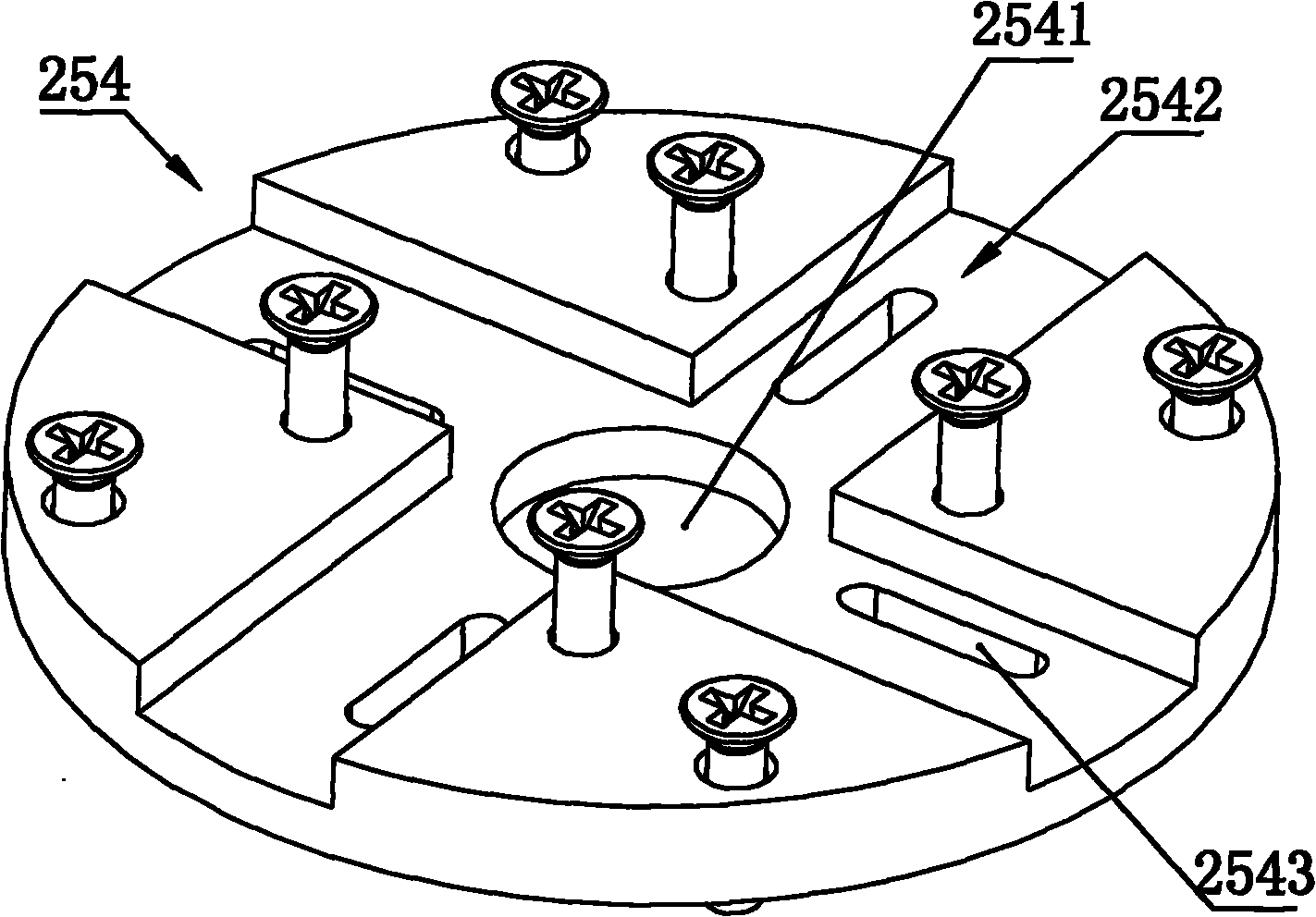

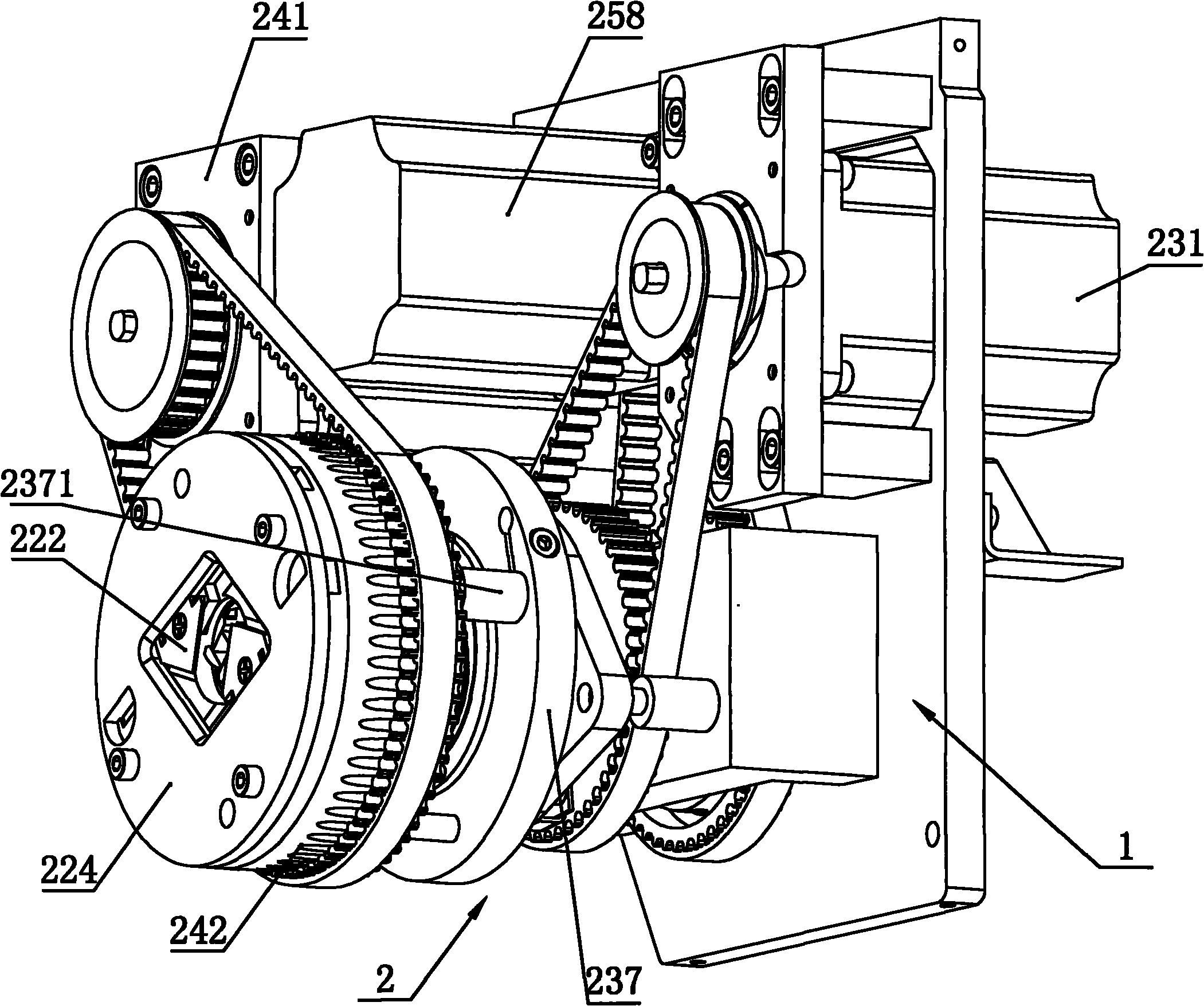

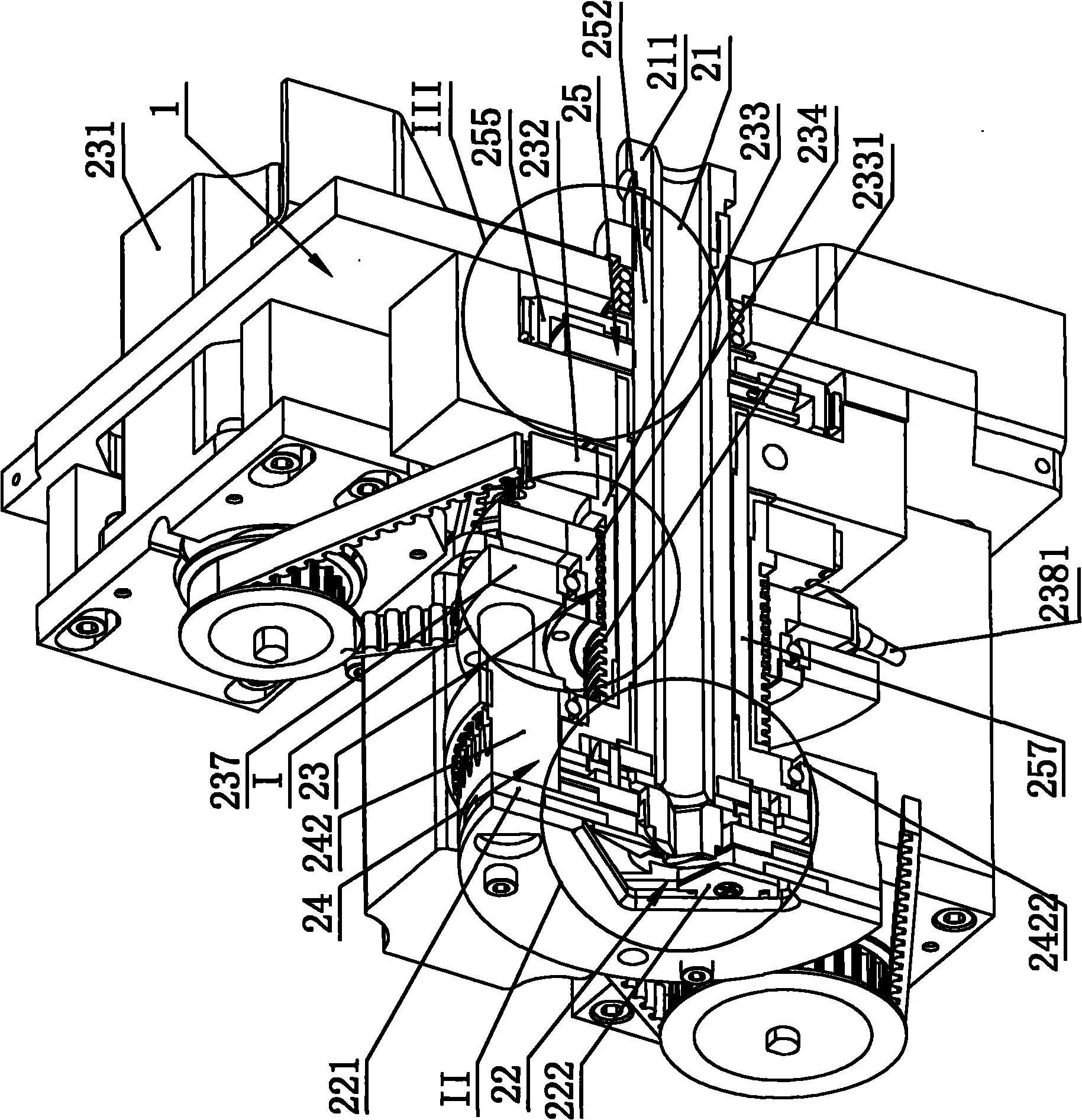

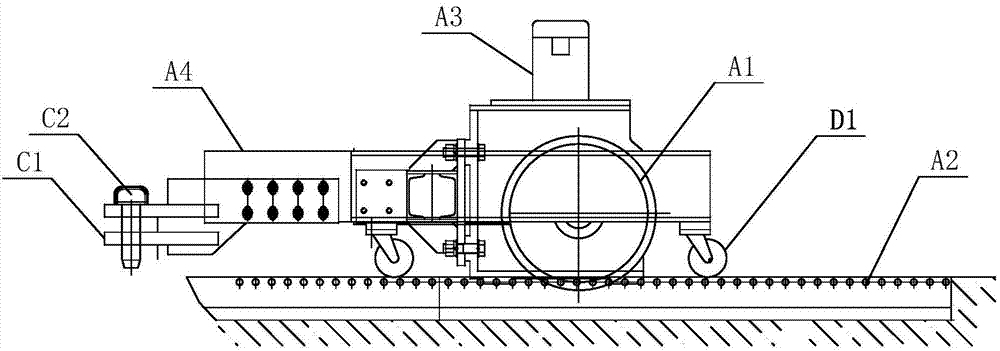

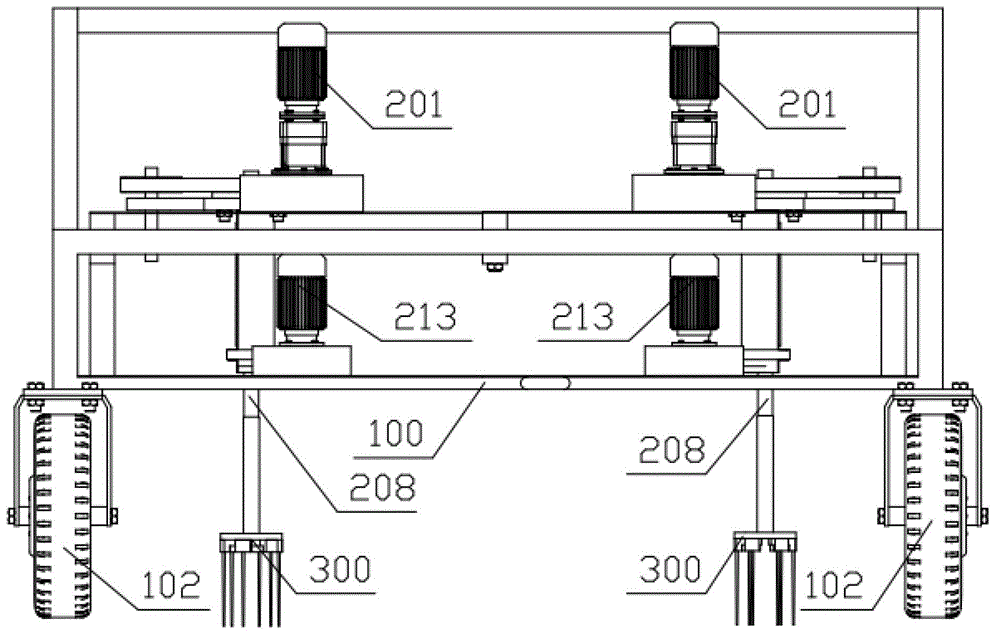

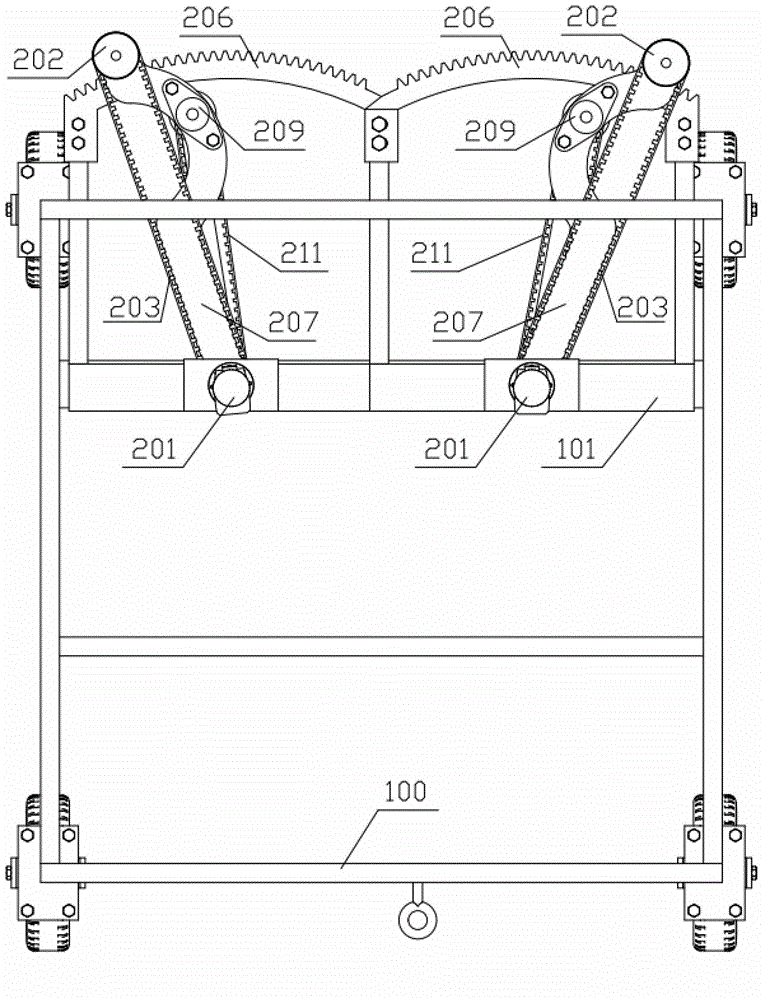

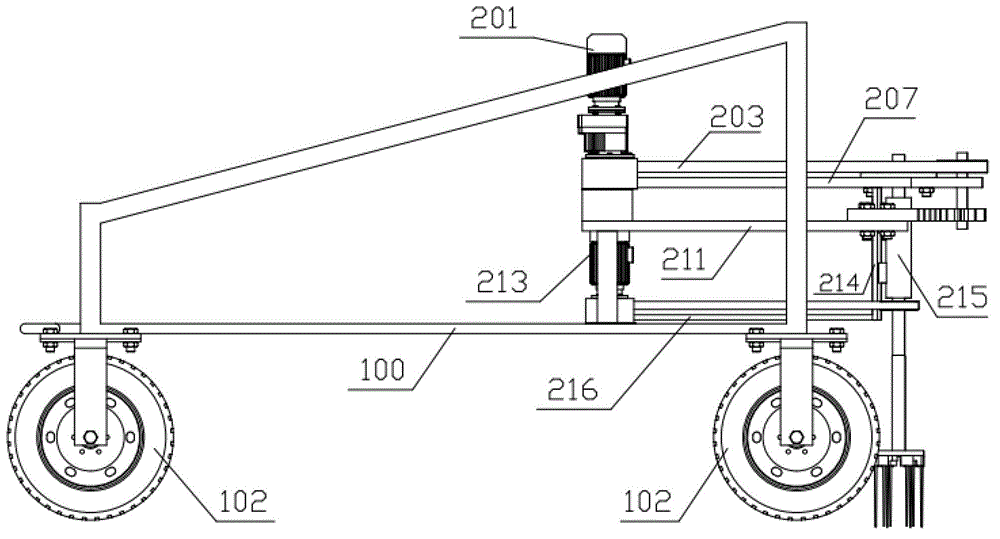

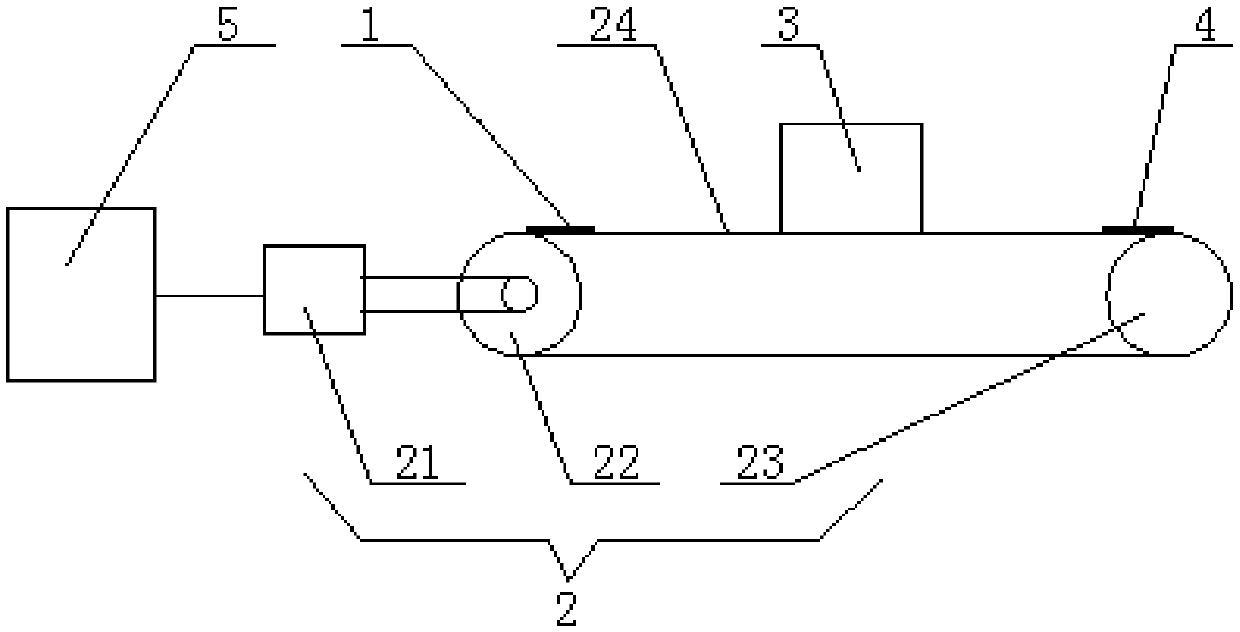

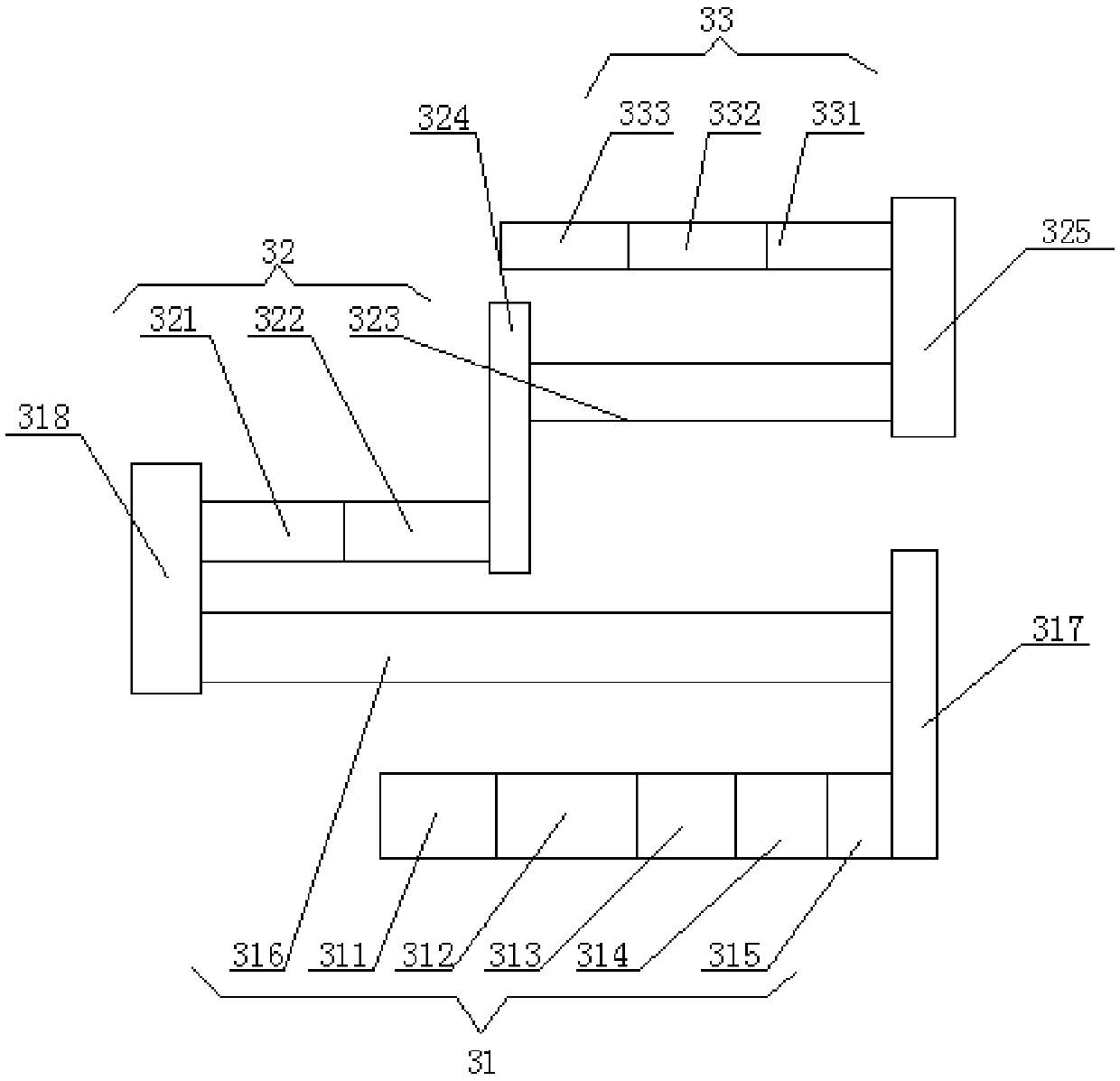

ActiveCN106992060ALarge towing weightExtended service lifeTransformers/inductances coolingLiquid transferring devicesThrough transmissionSprocket

The invention relates to a vacuum oil injection system for a transformer or a capacitor. The vacuum oil injection system comprises a towing vehicle and a vacuum oil injection device. The vacuum oil injection device comprises an oil-level controller, an oil storage tank, a buffering tank and a vacuum tank; the oil storage tank supplements oil into the buffering tank, and relying on the liquid level difference, the buffering tank automatically injects oil into the transformer or the capacitor; the oil-level controller controls the oil storage tank to stop to supplement oil when the oil level in the buffering tank is located on the upper set liquid level, and controls the oil storage tank to start to supplement oil when the oil level in the buffering tank is located on the lower set liquid level, an oil injection soaking pipe communicated with the vacuum tank is installed on an oil injection opening of the transformer or the capacitor, and the maximum liquid level permitted in the oil injection soaking pipe is slightly higher than the upper set liquid level; the towing vehicle comprises a vehicle head and a vehicle body detachably connected with the vehicle head, and the vehicle head is engaged with chain rails installed outside the vacuum tank through transmission chain wheels for achieving reciprocating motion of the towing vehicle. By means of the vacuum oil injection system for the transformer or the capacitor, automatic oil supplementing and automatic oil injection of the transformer or the capacitor are achieved, and the towing vehicle is high in transmission efficiency and long in service life.

Owner:HEFEI GENERAL MACHINERY RES INST

Weeding device capable of weeding among seedlings

InactiveCN102972111AEfficient removalFlexible operationSoil-working equipmentsVehicle frameGear wheel

The invention relates to a weeding device capable of weeding among seedlings, which comprises a frame, a weeding actuating and transmission mechanism arranged on the frame, and a weeding mechanism and wheels which are arranged at the lower part of the frame. The weeding actuating and transmission mechanism is formed in a way that an upper motor on an upper beam of the frame is connected with a planet gear through an upper rear synchronous pulley, an upper synchronous belt and an upper front synchronous pulley in sequence, the planet gear is out-meshed with a sun gear which is fixed at the rear part of the frame; a planet gear shaft and a hole in the front end of a swing arm are concentric in a matching way; a hole in the rear end of the swing arm and the upper rear synchronous pulley are concentric in the matching way; the upper end of a vertical shaft is arranged on a bearing seat at the middle front part of the swing arm through a bearing; the middle lower part of the vertical shaft is connected with a lower front synchronous pulley, and the lower front synchronous pulley is connected with a lower motor through a lower synchronous belt and a lower rear synchronous pulley in sequence; and the lower end of the vertical shaft is connected with an input shaft of the weeding mechanism. The weeding device can effectively weed among the seedlings of crops, and has the advantages of simple structure, flexible operation, convenience in operation and easiness in control.

Owner:汤烈

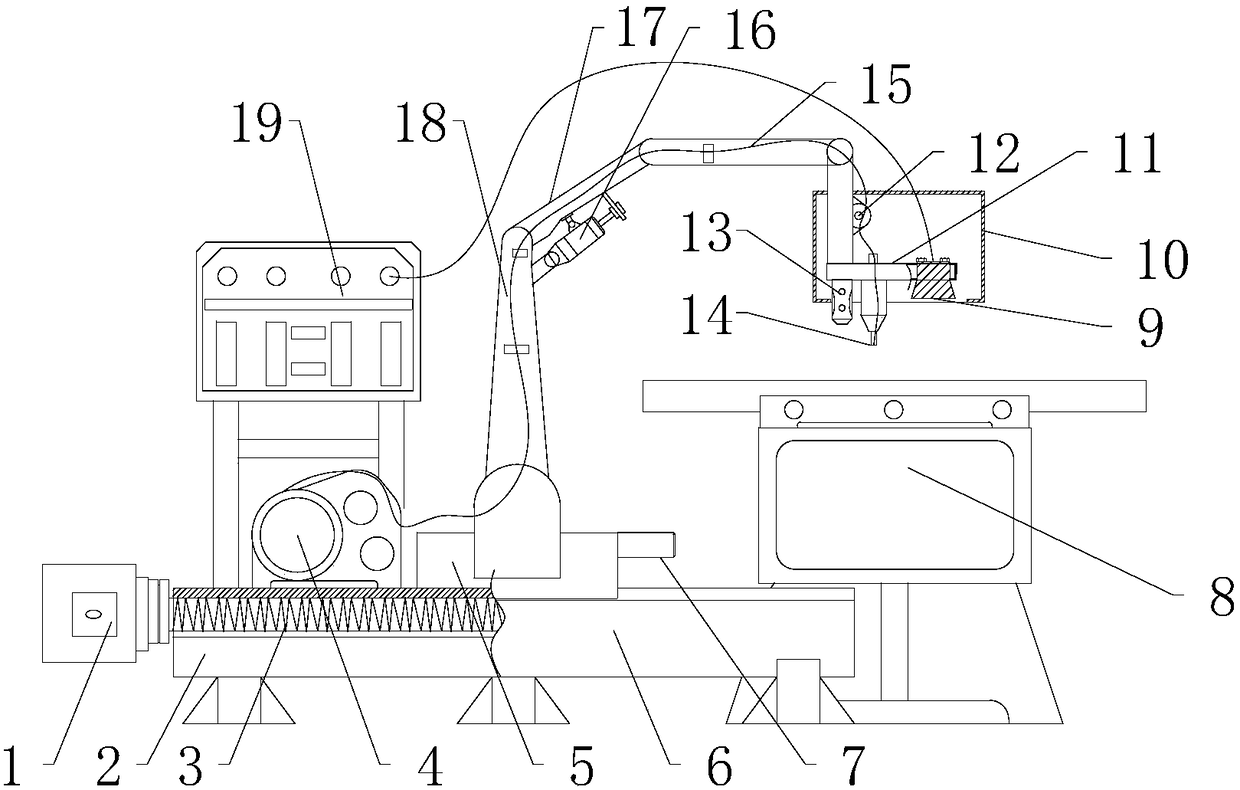

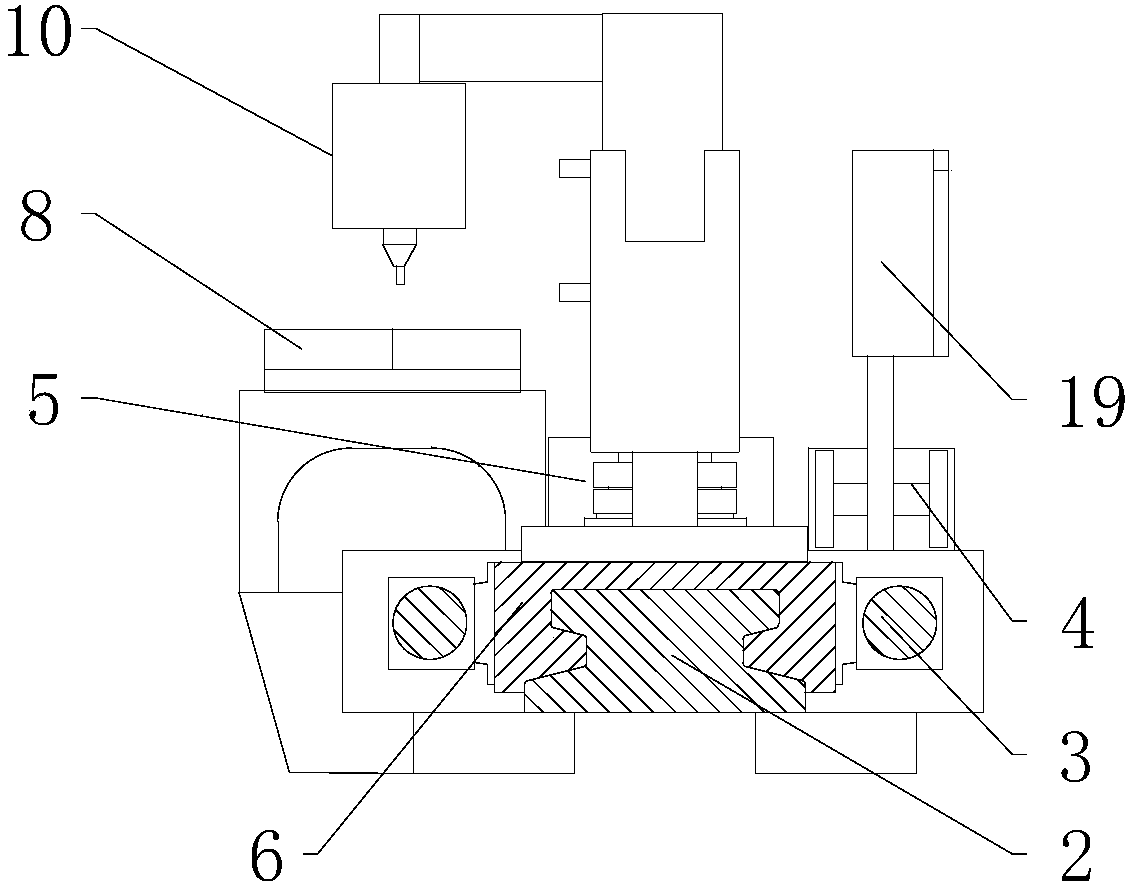

Argon arc welding robot

PendingCN108515257AGuarantee the welding quality of the weld seamHigh precisionElectrode holder supportersWelding accessoriesWeld lineIndustrial engineering

The invention provides an argon arc welding robot. The argon arc welding robot comprises an adjusting welding mechanism, a detecting positioning mechanism and a controller. The adjusting welding mechanism comprises a servo motor, a guiding sliding rail, a ball screw, a welding wire disc, a rotation base plate, a sliding block, a workbench, a front stretching arm, an air cylinder, a rocker and an upper arm. The detecting positioning mechanism comprises an arc length tracker, a laser welding line recognizer, a dustproof cover, a welding gun arm, a welding wire controller, a detection photoelectric instrument and a welding gun. Compared with the prior art, the argon arc welding robot has the following beneficial effects that accurate welding gun positioning can be guaranteed, welding line welding quality and the welding line attractiveness degree are guaranteed, the labor intensity of welding workers and influences of human factors are greatly reduced, the welding quality is guaranteed, and the welding efficiency is improved.

Owner:济南细川环保设备有限公司

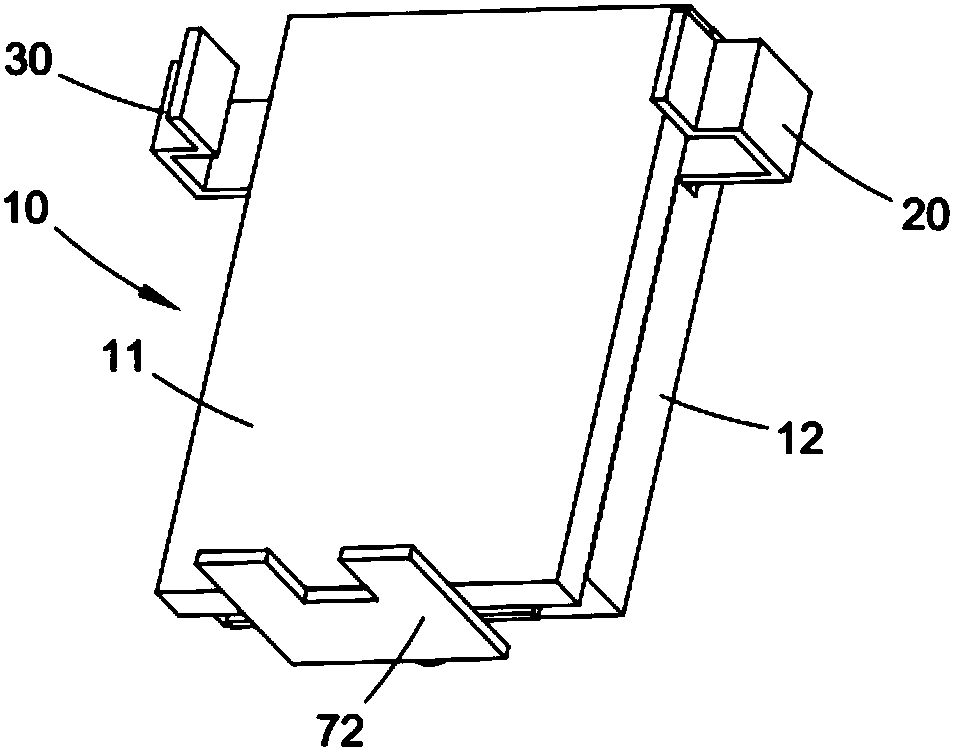

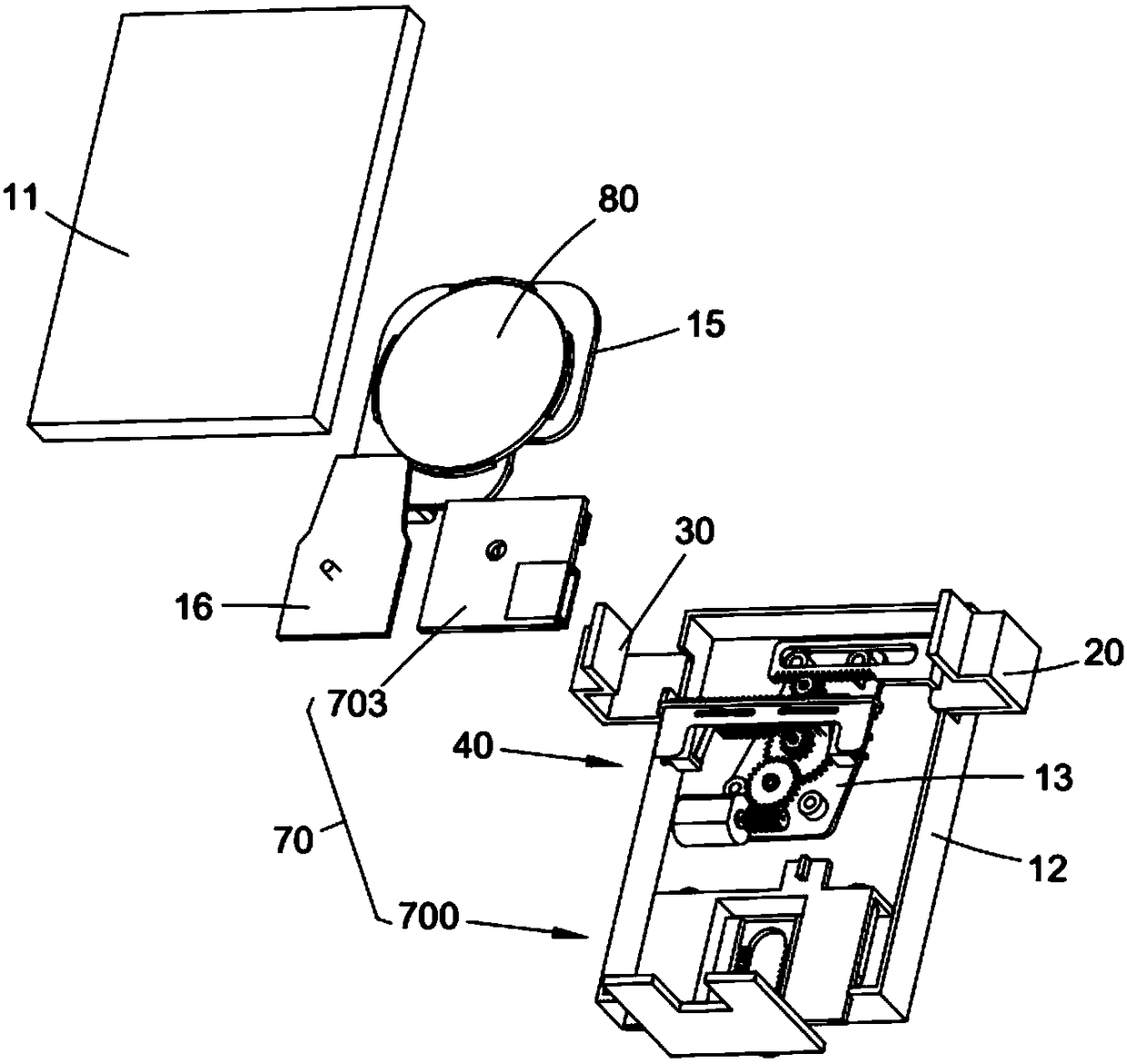

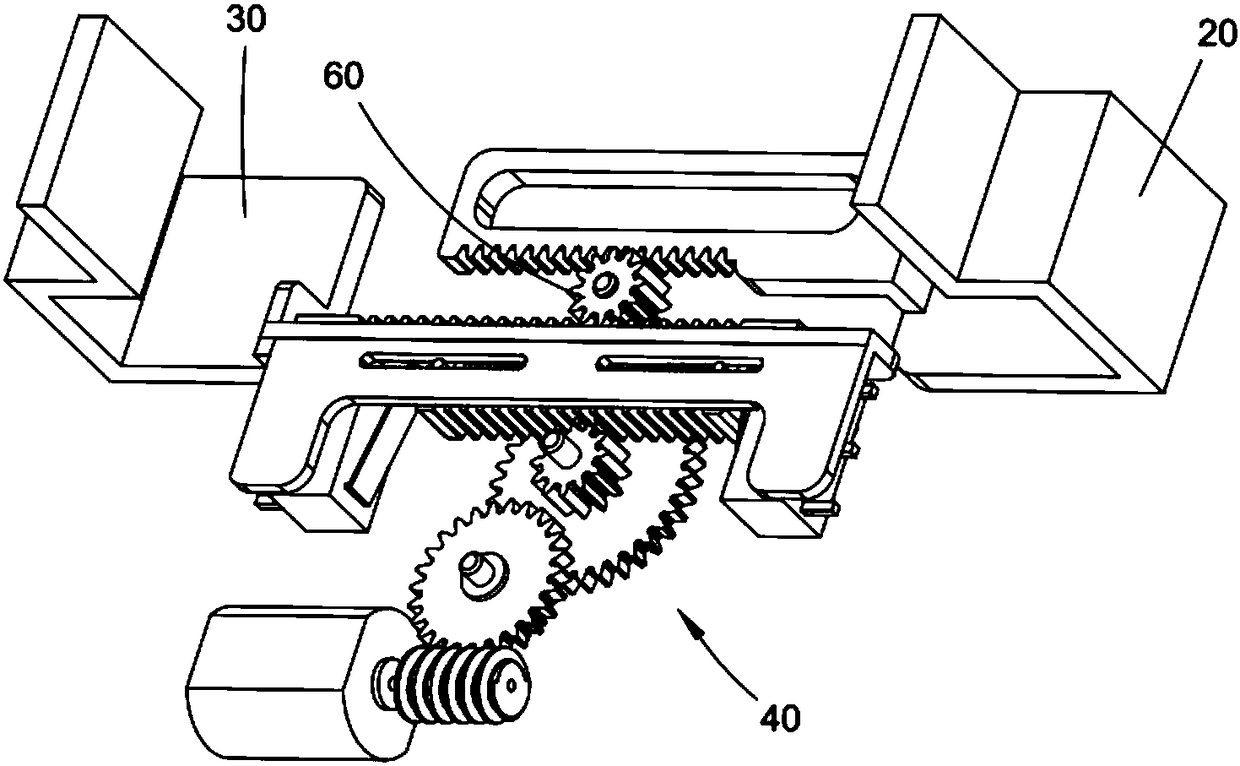

Full-automatic clamping type mobile phone holder

InactiveCN108600473APrecise automatic controlExtended service lifeTelephone set constructionsAutomatic controlEngineering

The invention discloses a full-automatic clamping type mobile phone holder, comprising a pair of clamping blocks arranged on a holder body, a driving system for driving the pair of clamping blocks toapproach or move away, and an adjusting system for controlling the operation of the driving system, wherein the adjusting system comprises a bearing tray and a PCB board, the bearing tray is elastically connected with the holder body and is provided with an induction main component, the PCB board is provided with an induction auxiliary component matched with the induction main component, and the induction auxiliary component is electrically connected with the driving system. According to the scheme of the invention, a non-contact induction device and the bearing tray are comprehensively used,the non-contact induction device is built in, and the non-contact induction device is controlled by the lifting of the bearing tray to send out-of-phase signals to the driving system, the pair of clamping blocks can be further controlled to clamp and release a mobile phone, and the purpose of ensuring the accurate automatic control of the mobile phone holder and prolonging the service life can beachieved.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

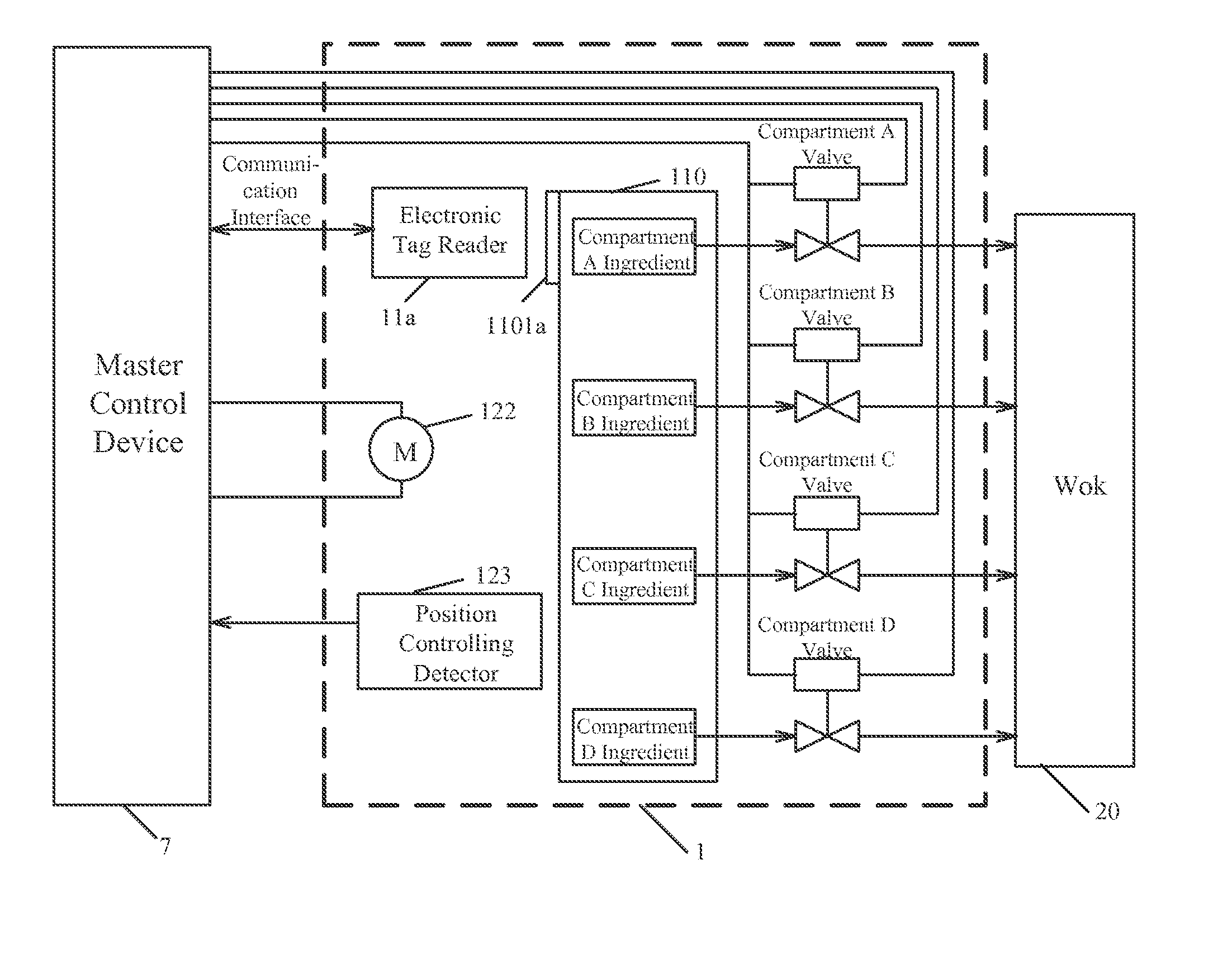

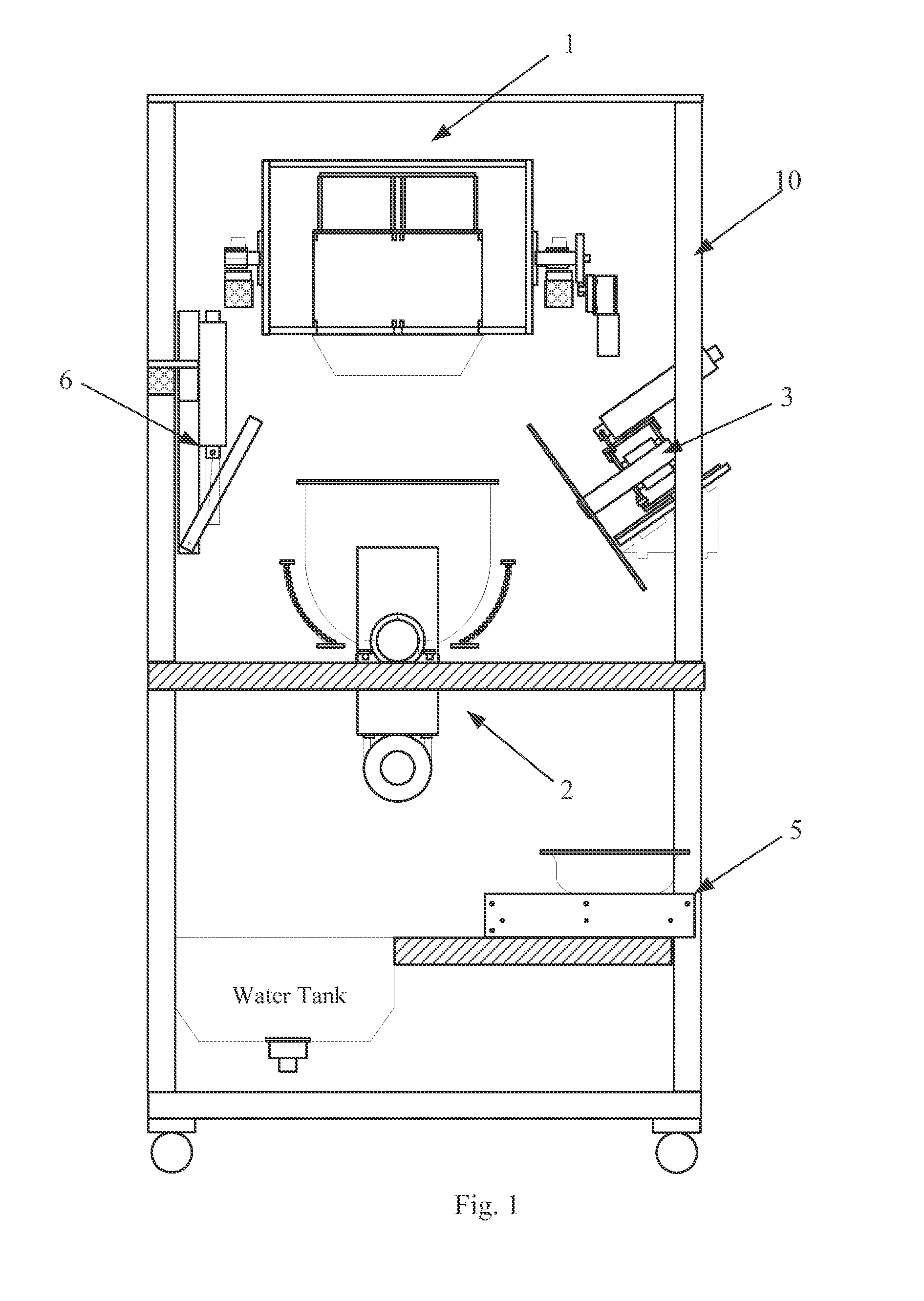

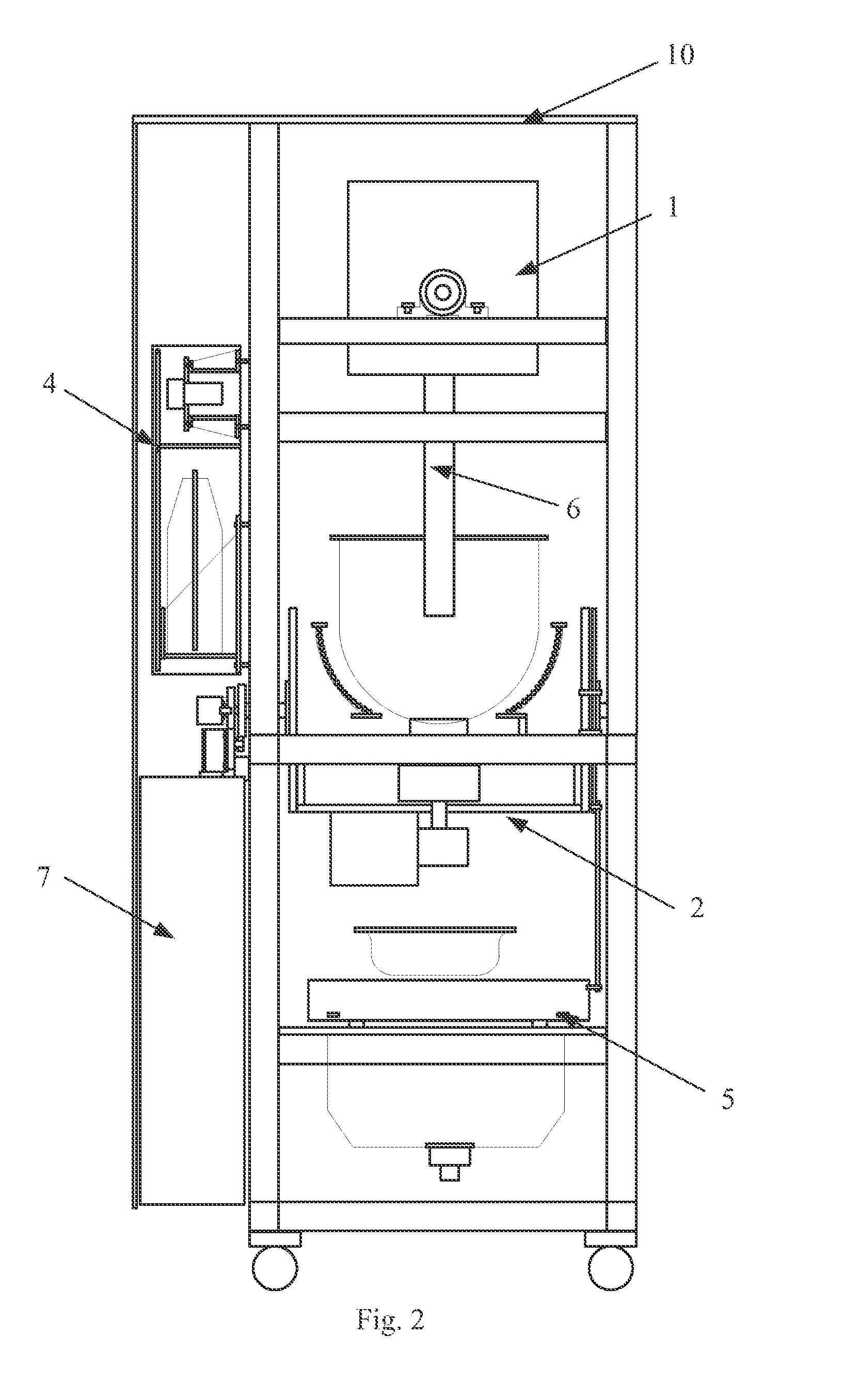

Automatic ingredient feeding apparatus applicable in a fully automated cooking machine

ActiveUS20150238046A1Improve standardizationImprove the level ofCooking vesselsBread-toastersAdditive ingredientEngineering

Owner:XU JINBIAO +1

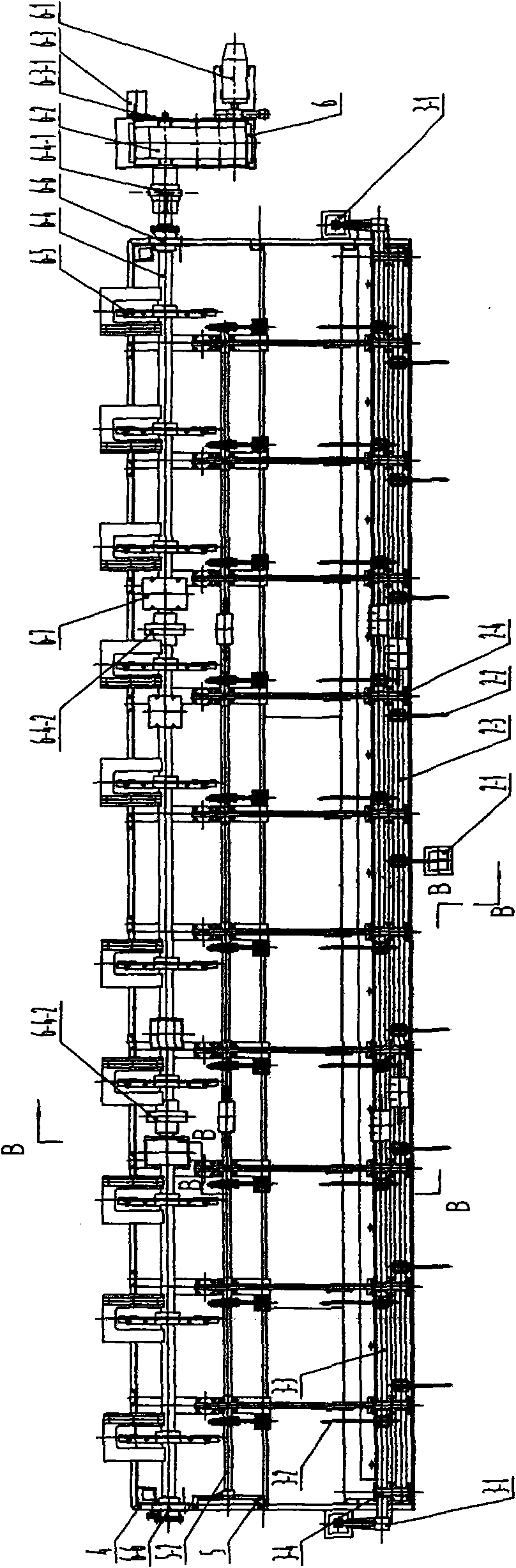

Automatic electroplating production line for circuit boards

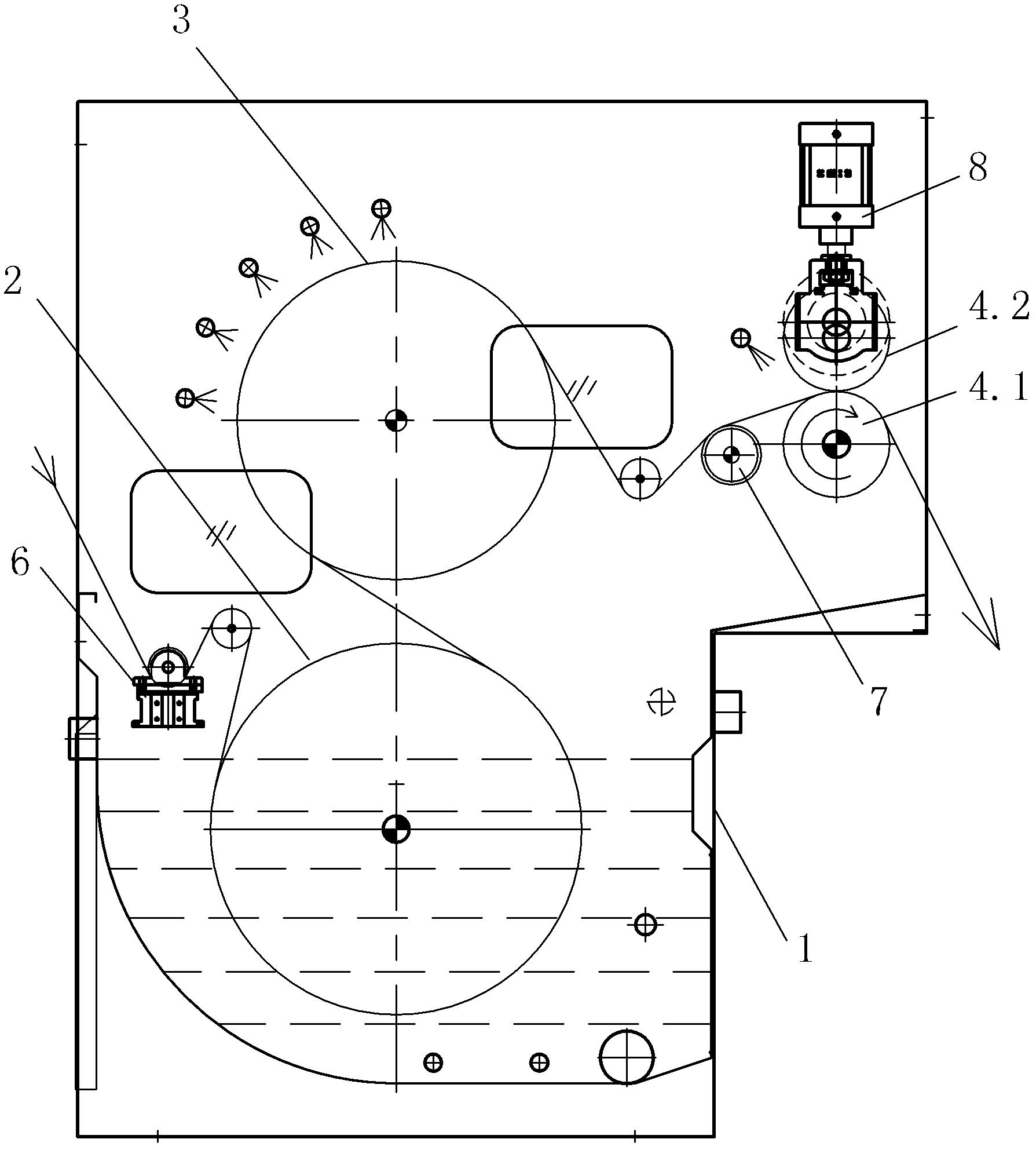

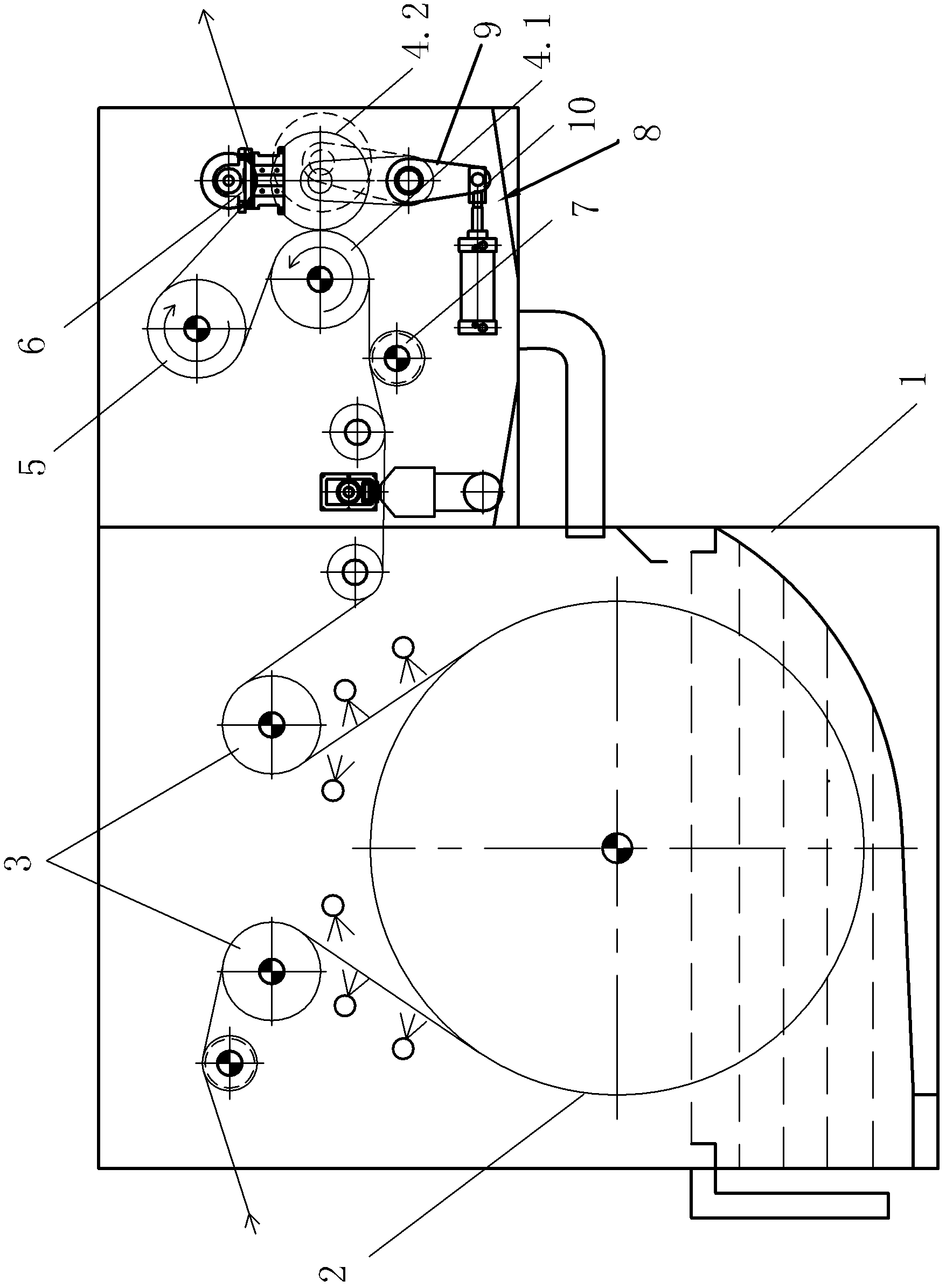

InactiveCN109628984AAchieve continuous platingRealize automatic electroplatingElectrolysis componentsProduction lineDrive wheel

The invention discloses an automatic electroplating production line for circuit boards, and relates to the field of circuit board production. The automatic electroplating production line for the circuit boards comprises a feeding area, a conveying mechanism, an electroplating mechanism, a discharging area and an electrical control system. The feeding area and the discharging area are separately located on the two sides of the conveying mechanism. The conveying mechanism comprises a driving motor, a driving wheel and a driven wheel. The driving motor drives the driving wheel to rotate. A conveying belt surrounding the driving wheel and the driven wheel is arranged outside the driving wheel and the driven wheel. An Omron PLC is used as the electrical control system. Automatic control software based on a Windows operation system platform is adopted. The circuit boards enter the automatic electroplating production line via the feeding area, then are conveyed to the electroplating mechanism, and are discharged through the discharging area after being electroplated, so that continuous electroplating of the circuit boards is achieved; and meanwhile, the PLC and the automatic control software are used for controlling the conveying speed of the conveying mechanism and realizing automatic accurate control over the electroplating process, and thus, automatic electroplating of the circuitboards is realized.

Owner:JINGDEZHEN HONGYI ELECTRONICS TECH CO LTD

Automatic fabric tension control system suitable for knitting open-width wet processing unit

ActiveCN102517827AAvoid Stretch DeformationGuaranteed qualityTextile treatment carriersTextile treatment rollersControl systemStructural engineering

The invention relates to an automatic fabric tension control system suitable for a knitting open-width wet processing unit. The system comprises at least more than two groups of wet processing units, wherein adjacent wet processing units are in station connection to form the open-width wet processing unit; drum / roller group stations and roller groups which are matched with the drum / roller groups are arranged in box bodies of the wet processing units; and the system is characterized in that: the drum / roller groups are main driving components; and the roller groups comprise driving rollers and driven rollers which are matched with each other. The invention has outstanding characteristics that: the drums / rollers, rollers and traction rollers in each wet processing unit are main driving components; numerical values of various driving mechanisms can be directly set according to differences of fabric composition and technical requirements of fabrics machined by the unit, so that the fabrics do not have tension, the fabrics are prevented from being subjected to tensile deformation in each wet processing unit, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

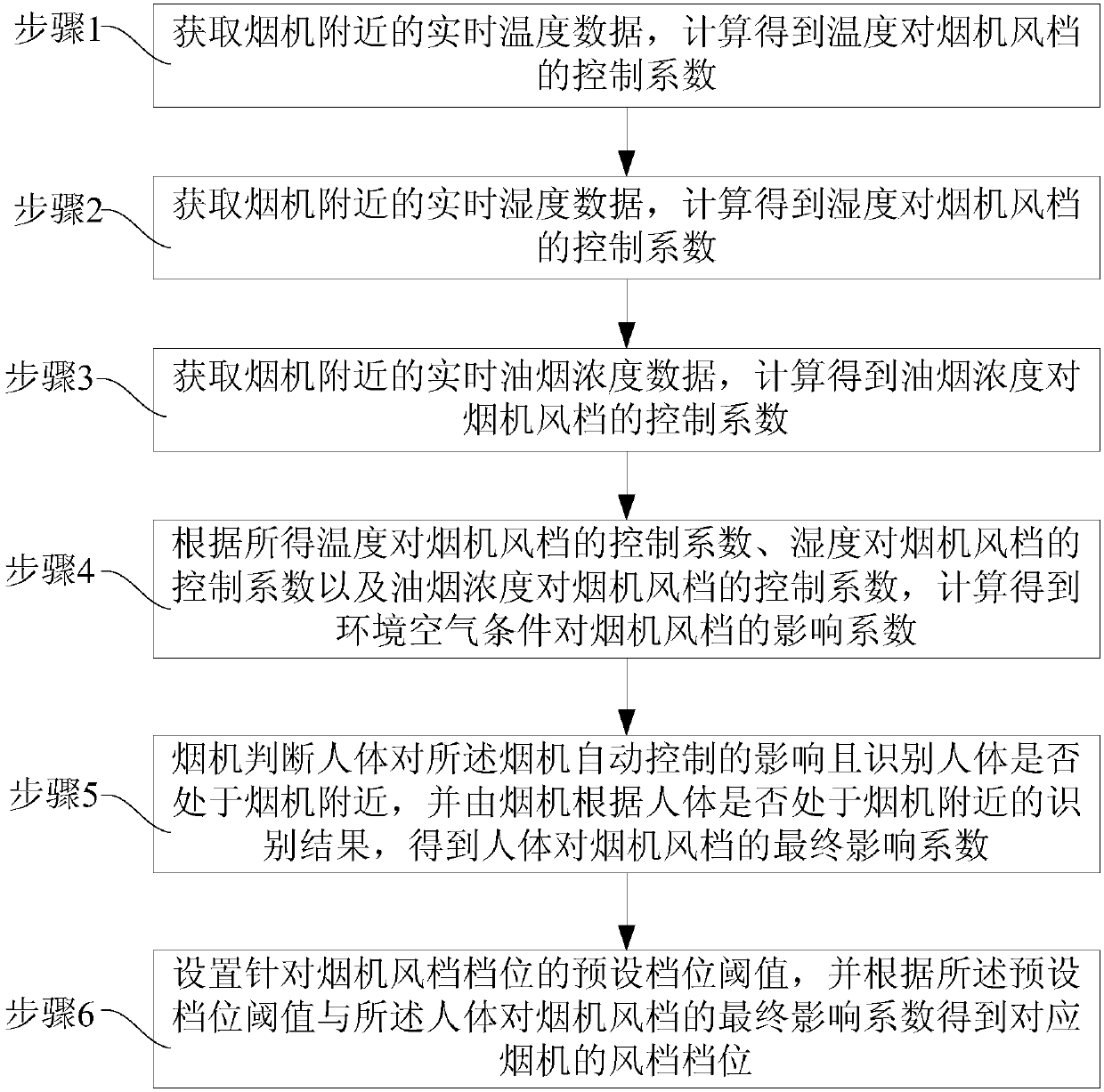

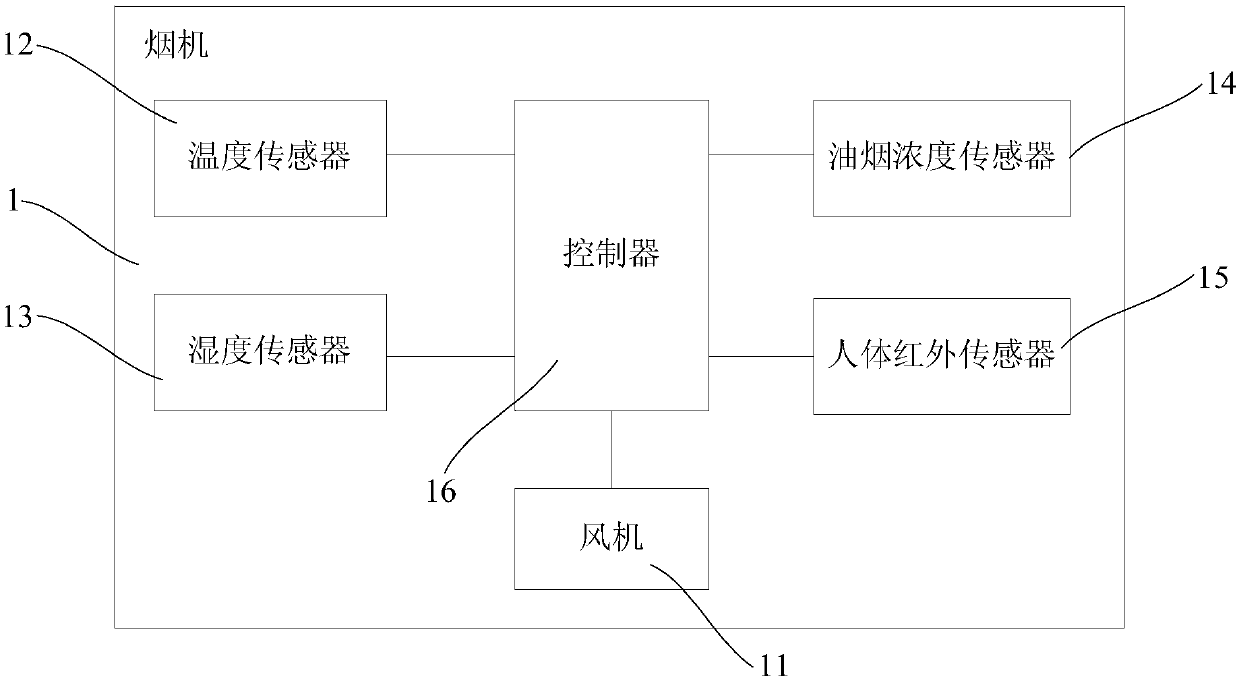

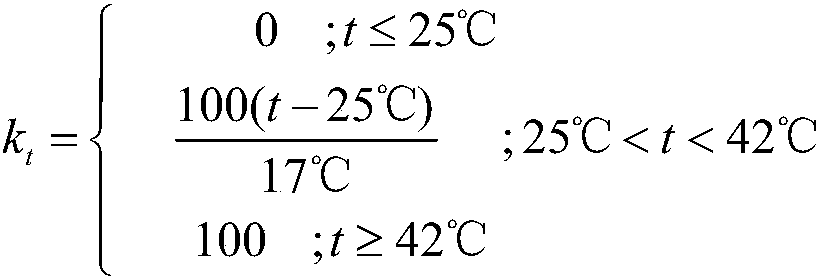

Range hood automatic control method and system based on multi-sensor fusion

ActiveCN109539342AAutomatic control real-timePrecise automatic controlDomestic stoves or rangesLighting and heating apparatusAutomatic controlEngineering

The invention relates to a range hood automatic control method and system based on multi-sensor fusion. The range hood automatic control method comprises the steps: real-time temperature data, real-time humidity data and real-time oil smoke concentration data nearby a range hood are obtained, and control coefficients, for a range hood air damper, of the temperature, the humidity and the oil smokeconcentration are calculated; according to all the obtained control coefficients, for the range hood air damper, of the temperature, the humidity and the oil smoke concentration, the influence coefficient, for the range hood air damper, of the environment air condition is obtained, and according to the identification result of whether a human body is located nearby the range hood or not, the finalinfluence coefficient, for the range hood air damper, of the human body is obtained; and a preset gear threshold value aiming at the gear of the range hood air damper is set according to the final influence coefficient, for the range hood air damper, of the human body, and according to the preset gear threshold value, the air damper gear corresponding to the range hood is obtained. According to the range hood automatic control method and system, influences of the temperature, the humidity, the oil smoke concentration and the human body factor on gear control of the range hood are sufficientlyconsidered, and through fusion processing of the various environment factor influences, the gear of the range hood air damper is real-timely and accurately controlled.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com