Oil circulation water-cooling control system for transformer of submerged arc furnace

A control system and water-cooling system technology, applied in the field of transformers, can solve problems such as single control mode, high failure rate, and low degree of intelligent control, and achieve the effects of ensuring normal operation, increasing reliability, and efficient automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the examples, but the embodiments of the present invention are not limited to the scope indicated by the examples.

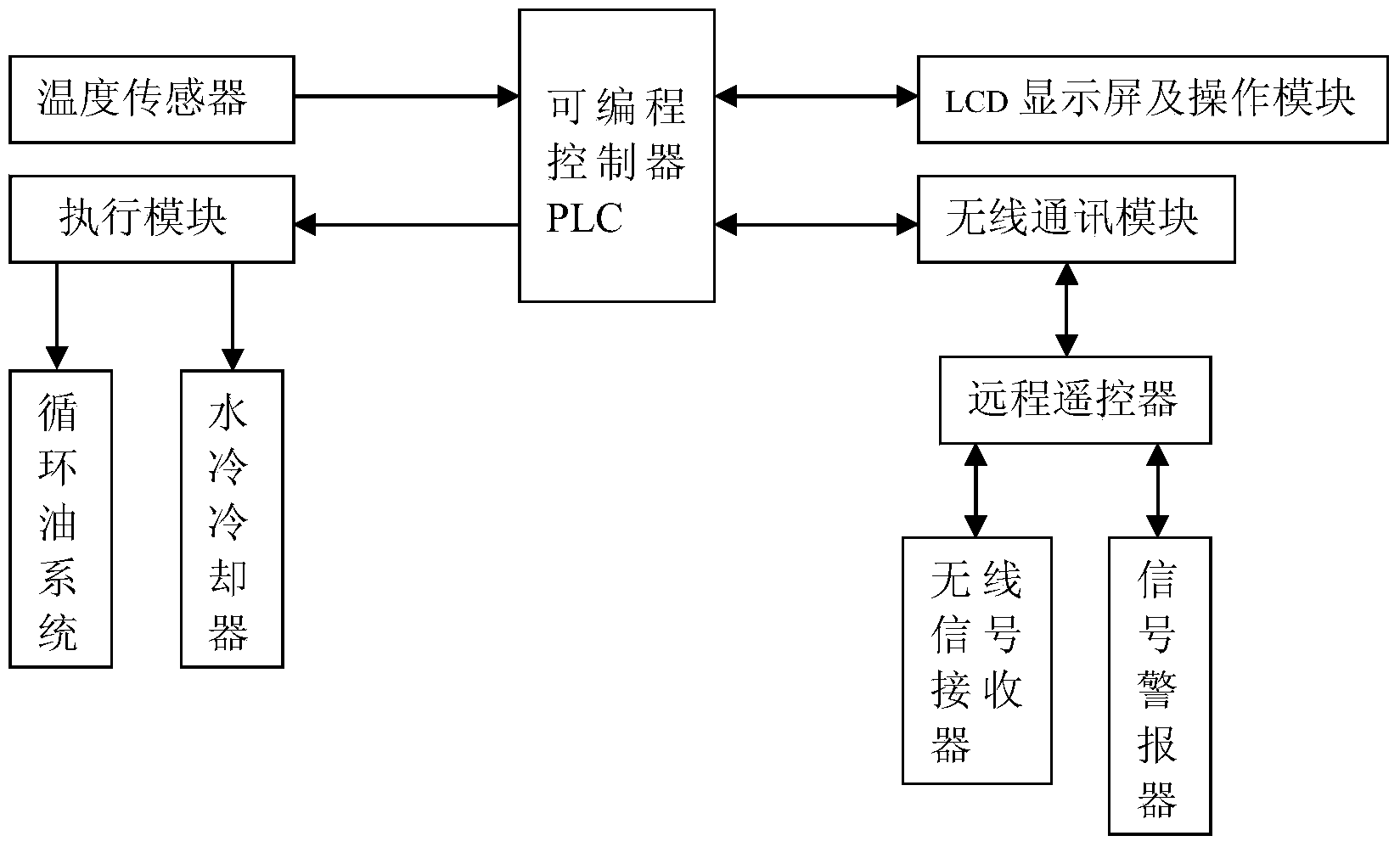

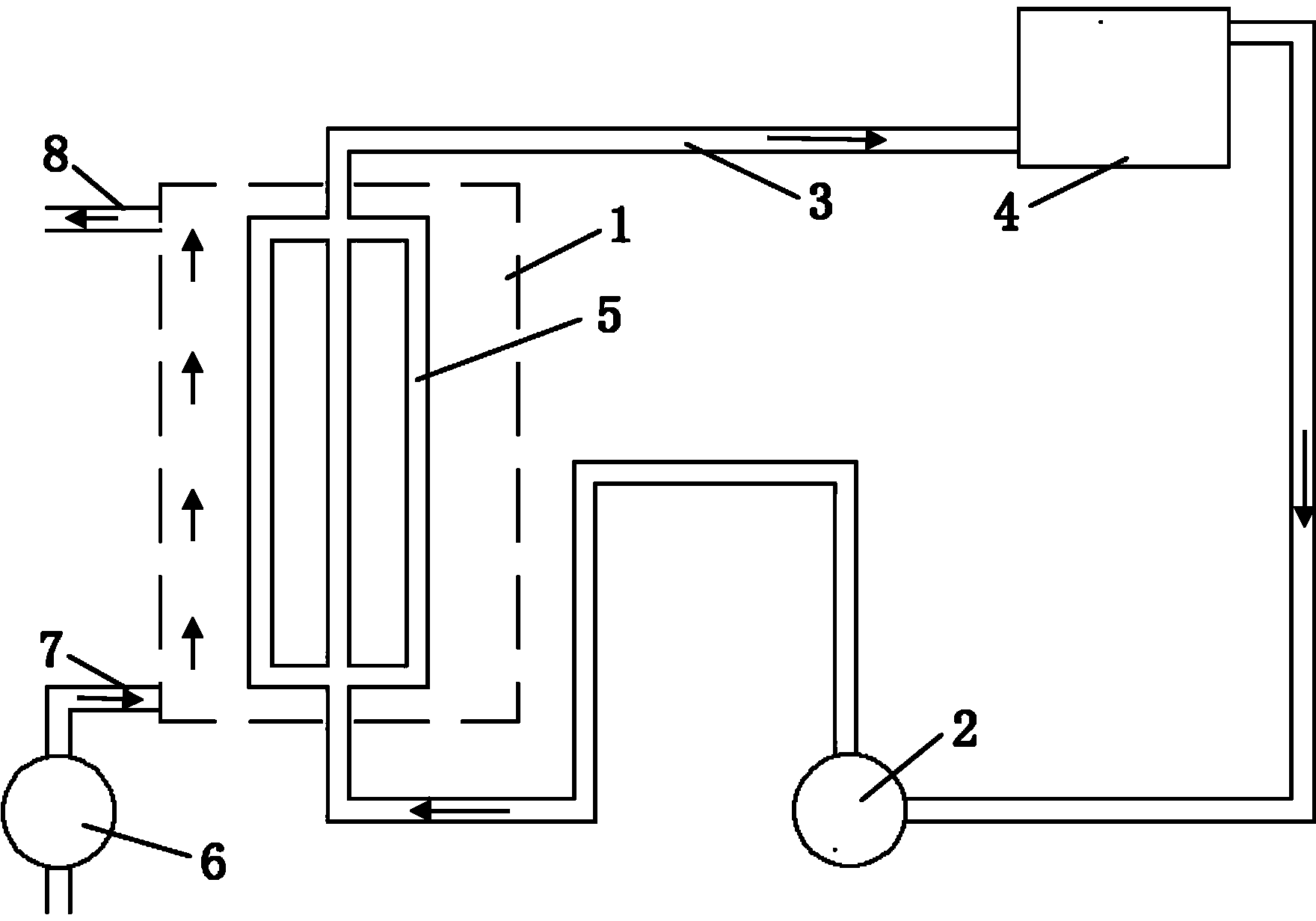

[0023] combined with figure 1 and 2 , an oil circulation water cooling control system for a submerged arc furnace transformer, including a water cooling system, a control device, a temperature sensor and an execution module. in:

[0024] The water cooling system is set to include a circulating oil system and a water cooling cooler, and is connected with the execution module. The circulating oil system is mainly composed of oil pump 2, oil pipe circuit 3, and transformer oil tank 4. During operation, the upper oil in the transformer oil tank 4 is sucked out through the oil pipe by means of the oil pump, and then returned to the lower part of the oil tank 4 after being cooled by the cooler, forming a cycle oil circuit. The water-cooled cooler is mainly composed of a radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com