Remote intelligent active drilling pressure control system and method

A pressure control and intelligent technology, which is applied in the direction of comprehensive factory control, earthwork drilling and flushing, etc., can solve the problems of back pressure compensation device not satisfying long-term grouting, high cost of hydraulic control system, large fluctuation of pressure control, etc. , to achieve the effects of easy and precise control of wellhead back pressure, simple structure and stable outlet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

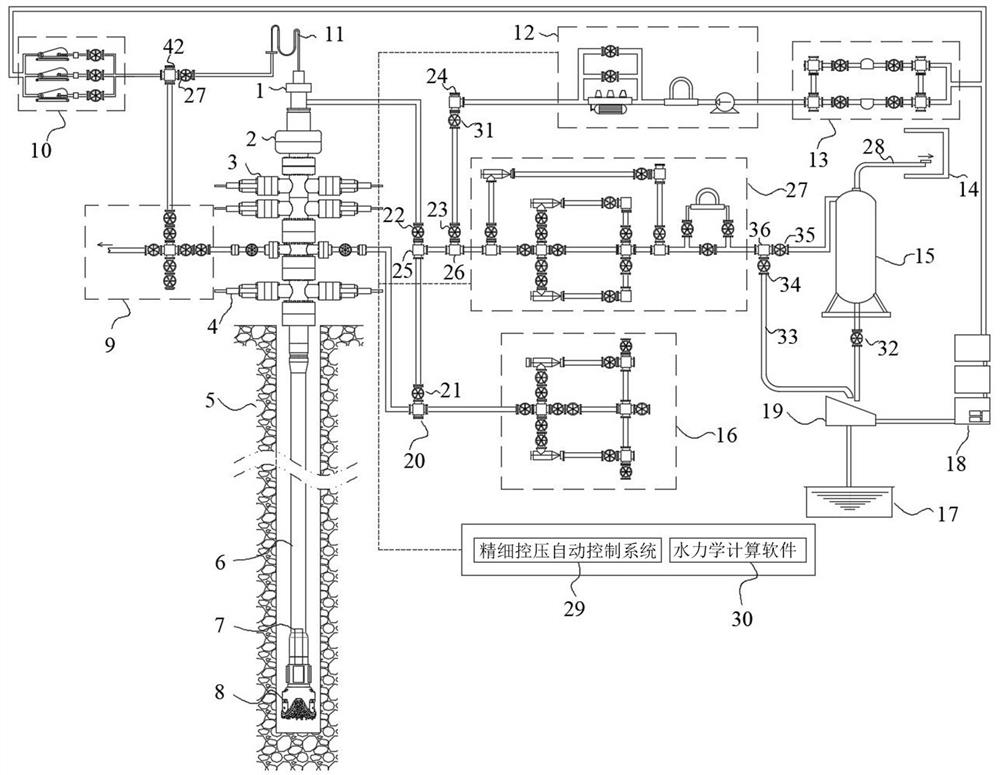

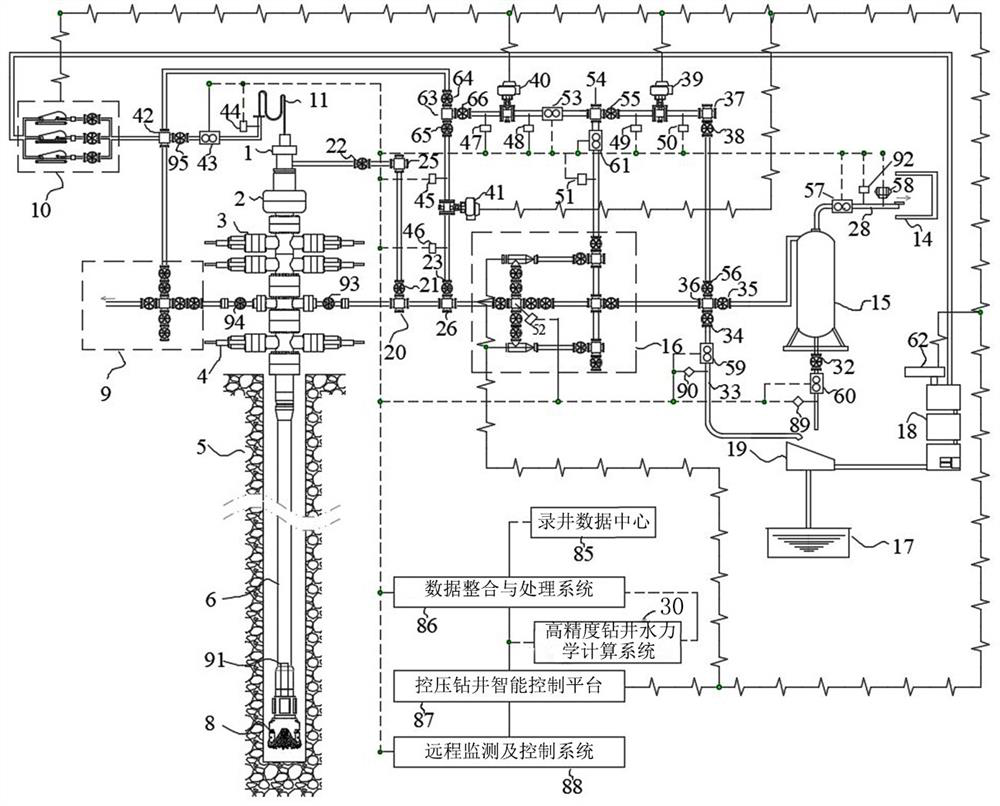

[0080] figure 2 A remote intelligent active drilling pressure control system according to an embodiment of the present invention is schematically shown.

[0081] like figure 2 As shown, a remote intelligent active drilling pressure control system described in this embodiment includes a ground multi-parameter online monitoring system, a rotary blowout preventer 1, a ground simple throttling control manifold, a wellhead back pressure compensation manifold, a graded The injection device 62 , the downhole storage pressure measurement device 91 , the drilling hydraulics calculation system 30 , the managed pressure drilling intelligent control platform 87 , and the remote monitoring and control system 88 .

[0082] The described remote intelligent active drilling pressure control system is not equipped with a gas-liquid separator alone, but uses the gas-liquid separator 15 that is standard for the well team.

[0083] The ground multi-parameter online monitoring system includes: ...

Embodiment 2

[0138] An embodiment of the present invention is a remote intelligent active drilling pressure control method. The described drilling pressure control method uses the aforementioned remote intelligent active drilling pressure control system, and the specific steps are as follows:

[0139] S1: Pre-input drilling parameters and engineering calculation data to the MPD intelligent control terminal before drilling.

[0140] The drilling parameters include well type, well type, well depth, well body structure, wellbore trajectory, displacement, WOB, rotational speed, formation lithology, drilling fluid density and viscosity, and reservoir parameters, etc. The data source is input in advance. in drilling engineering design. The engineering calculation data includes formation three pressure profiles (pore pressure, collapse pressure, leakage pressure), fracture parameters (development degree, fracture density, fracture width, etc.), plugging parameters, etc. The pre-input data comes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com