Method and device for underpinning antifriction separator for shallow underground space construction

An underground space and partition technology, which is applied in underground chambers, shaft equipment, earthwork drilling, etc. to achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

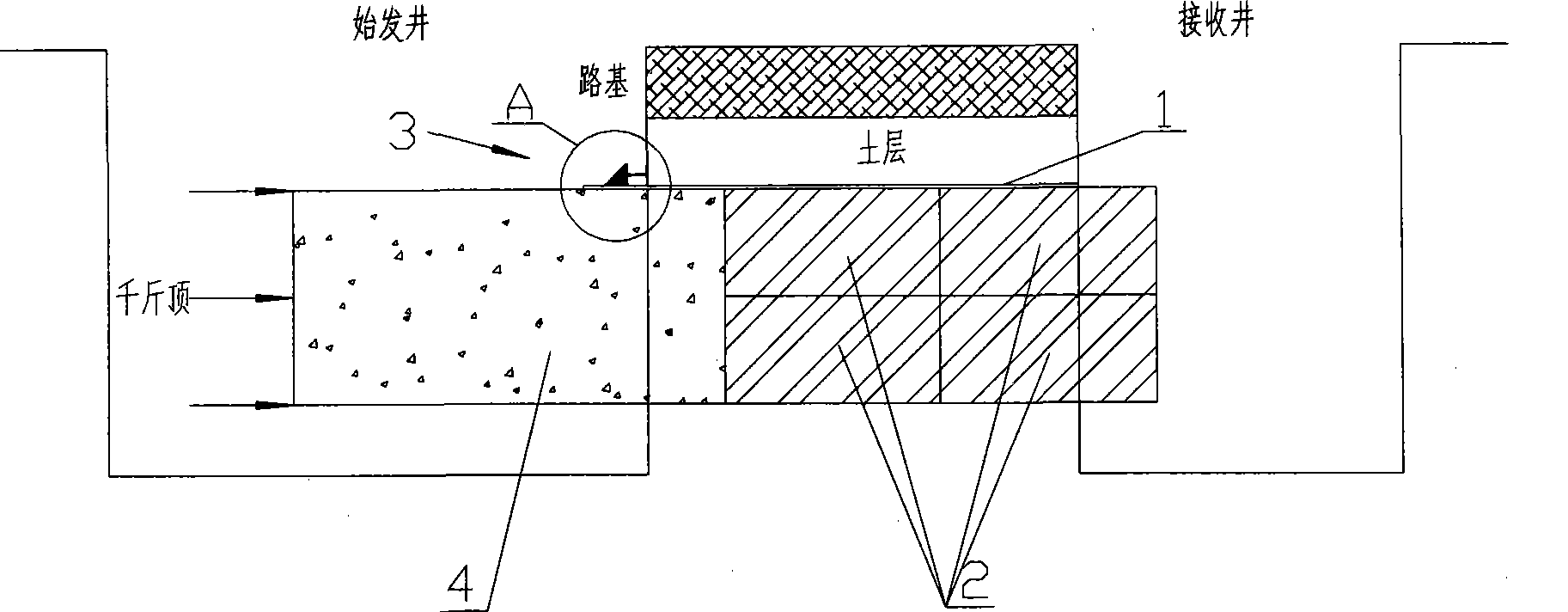

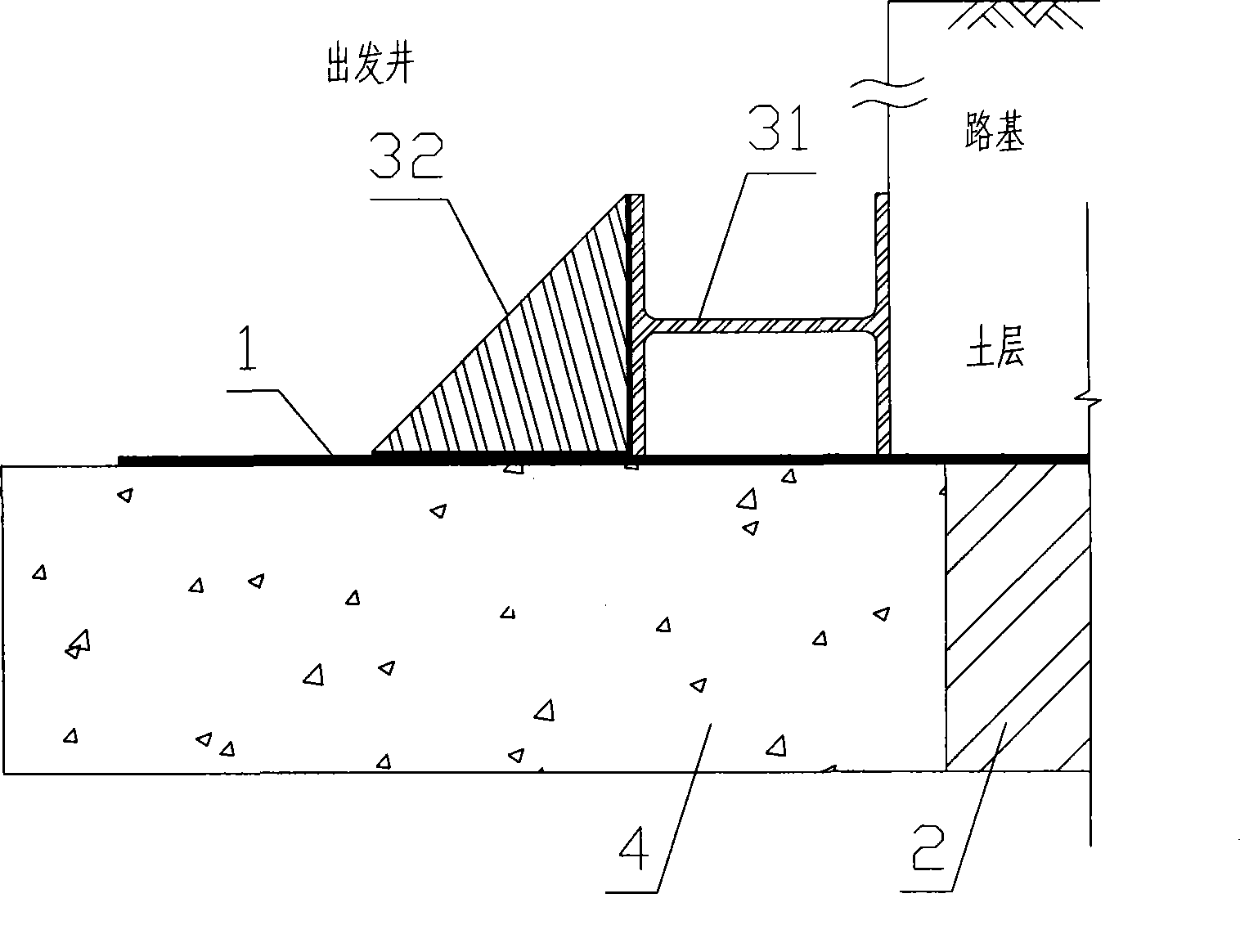

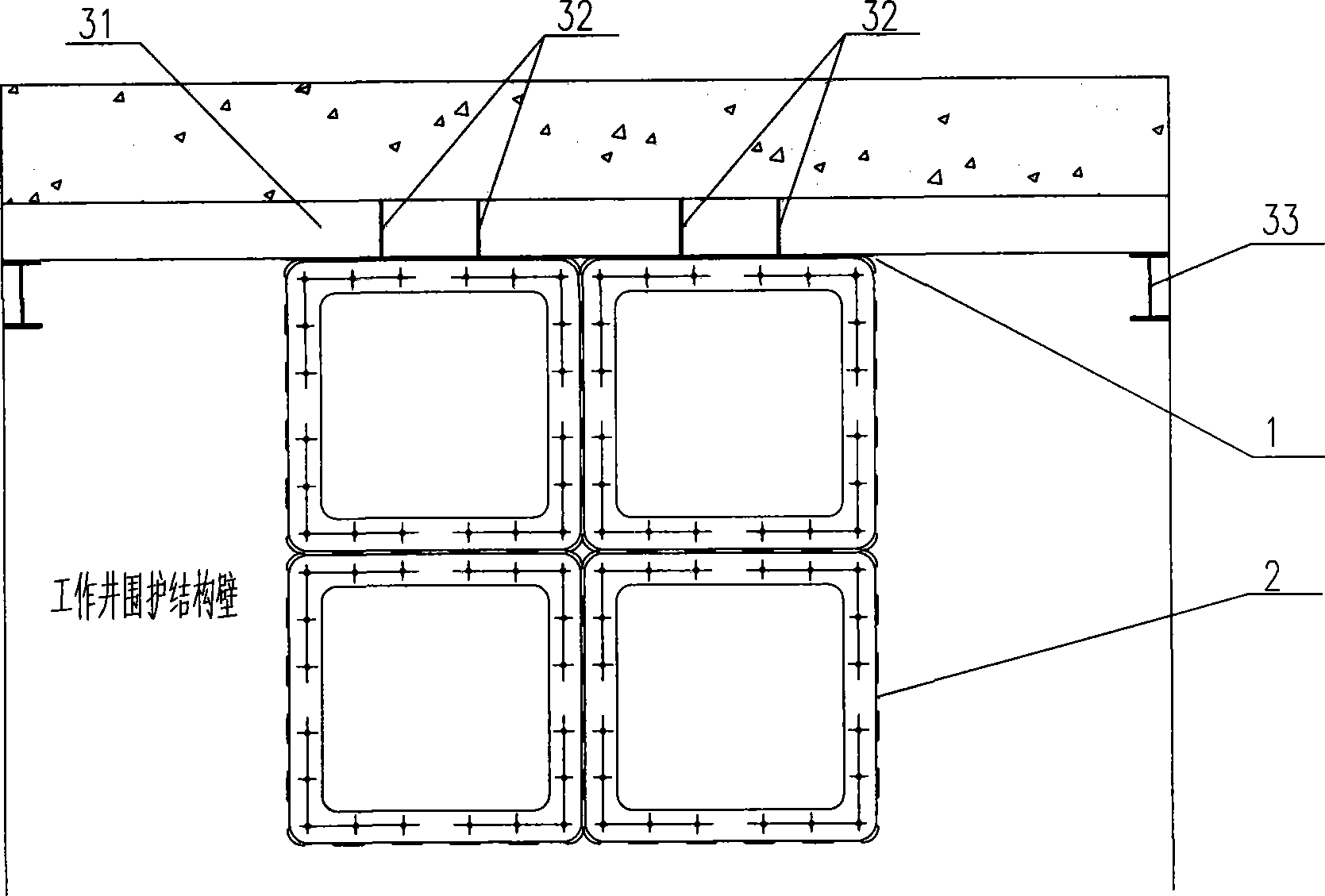

[0028] Below in conjunction with accompanying drawing, the present invention is described clearly and completely:

[0029] see Figure 1-3 , which shows a schematic cross-sectional view of the underpinning process of the anti-friction diaphragm underpinning method used in shallow underground space construction according to the present invention. This anti-friction diaphragm underpinning method for shallow underground space construction is used in conjunction with rectangular pipe jacking and box culvert jacking method construction, which includes the following steps:

[0030] The first step is to install the anti-friction partition 1 and the support pipe 2. The anti-friction partition 1 is installed on the forward end of the jacking method construction equipment by welding or bolting, and covers the upper part of the construction equipment. The support pipe 2 is connected to the rear of the jacking method construction equipment through a flange. The length and thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com