Rotary shear mark tool rest of automatic wire stripper

A technology of wire stripping machine and cutter, which is applied in the direction of line/collector parts, electrical components, equipment for dismantling/armored cables, etc., can solve the problem of wire sheath residue, etc., and achieve the effect of solving the problem of wire sheath residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

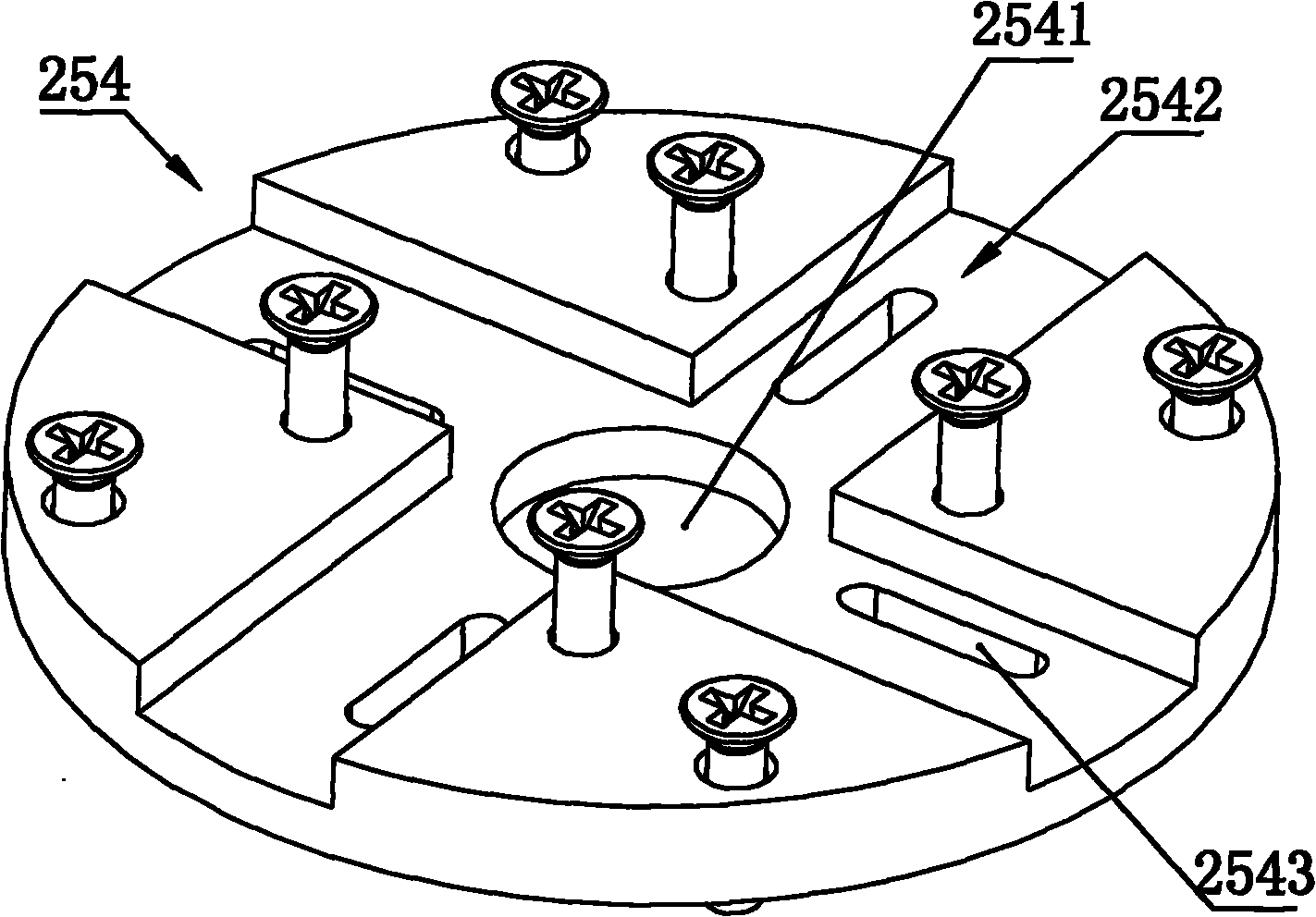

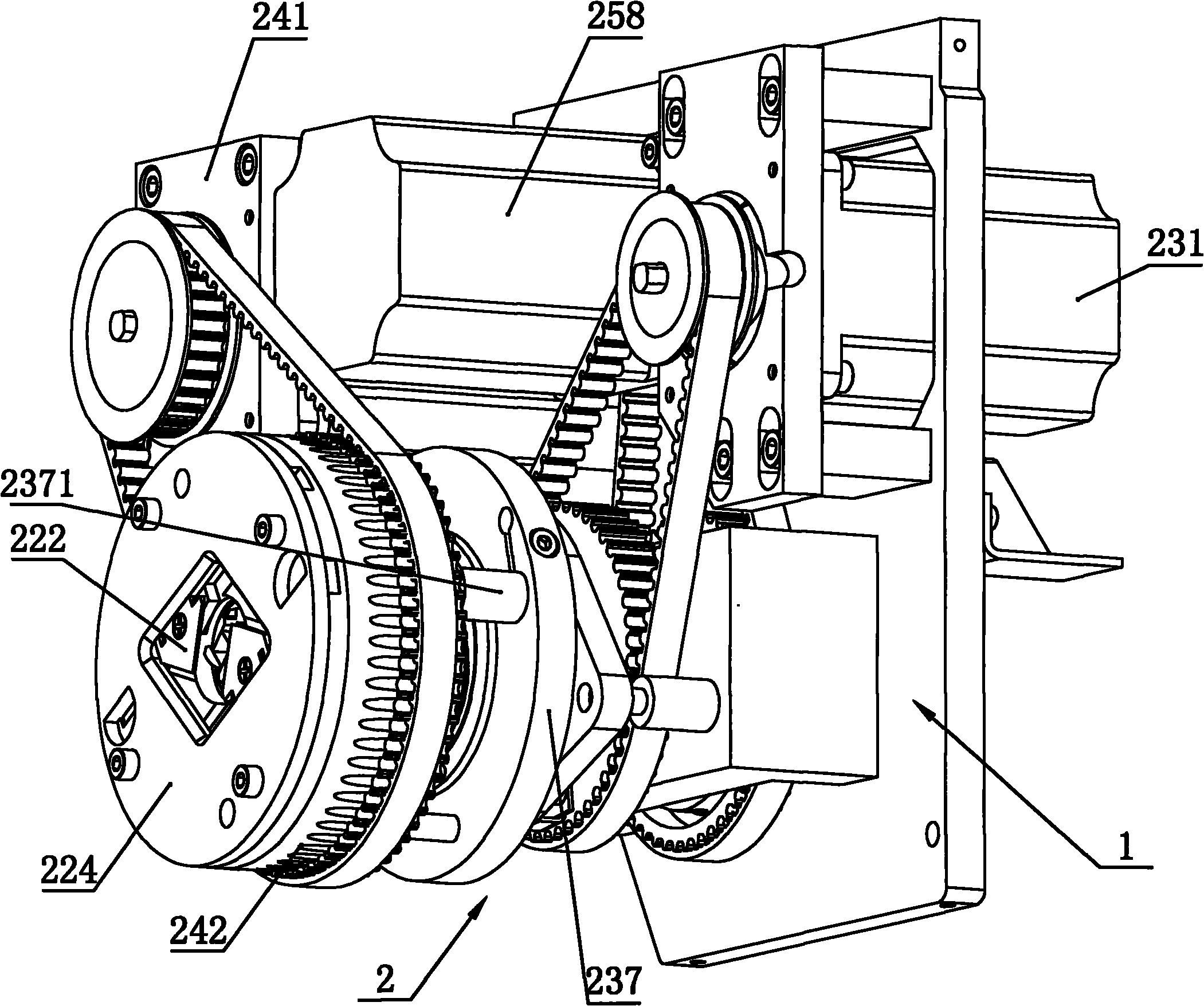

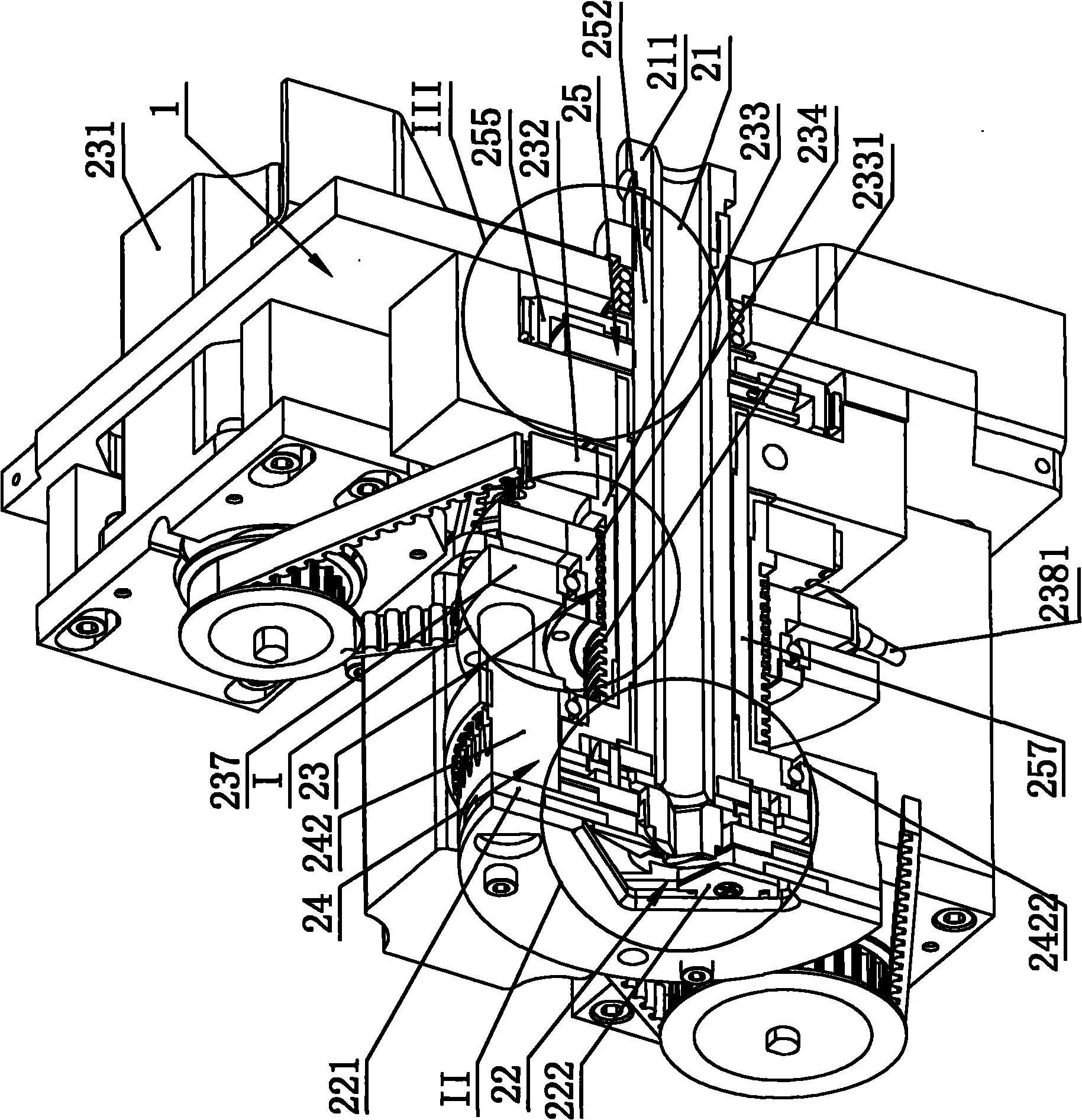

[0026] Such as Figure 1-3 The specific embodiment of the present invention shown includes a mounting frame 1, a knife rest assembly 2 installed on the mounting frame 1, and a motor assembly, and the knife rest assembly 2 includes a wire inlet pipe 21, a cutter assembly 22. The cutter combining mechanism 23 and the cutter rotating mechanism 24. The motor assembly includes a combining motor 231 adapted to drive the cutter combining mechanism 23 and a rotating motor adapted to drive the cutter rotating mechanism 24 241, the cutter rotation mechanism 24 includes a ring gear 242 that is driven and matched with the rotation motor 241, and the ring gear 242 is provided with a left and right through installation cavity 2421, and the cutter parallel mechanism 23 includes The transmission gear 232 that cooperates with the parallel knife motor 231 is provided with a threaded tube 233 that is fixedly interlocked with the transmission gear 232. The threaded tube 233 is provided with an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com