Automatic fabric tension control system suitable for knitting open-width wet processing unit

An automatic control system and control system technology, which is applied in the processing of textile materials, processing textile material drums, processing textile material carriers, etc. The effect of stretching deformation, expanding the scope of adaptation, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

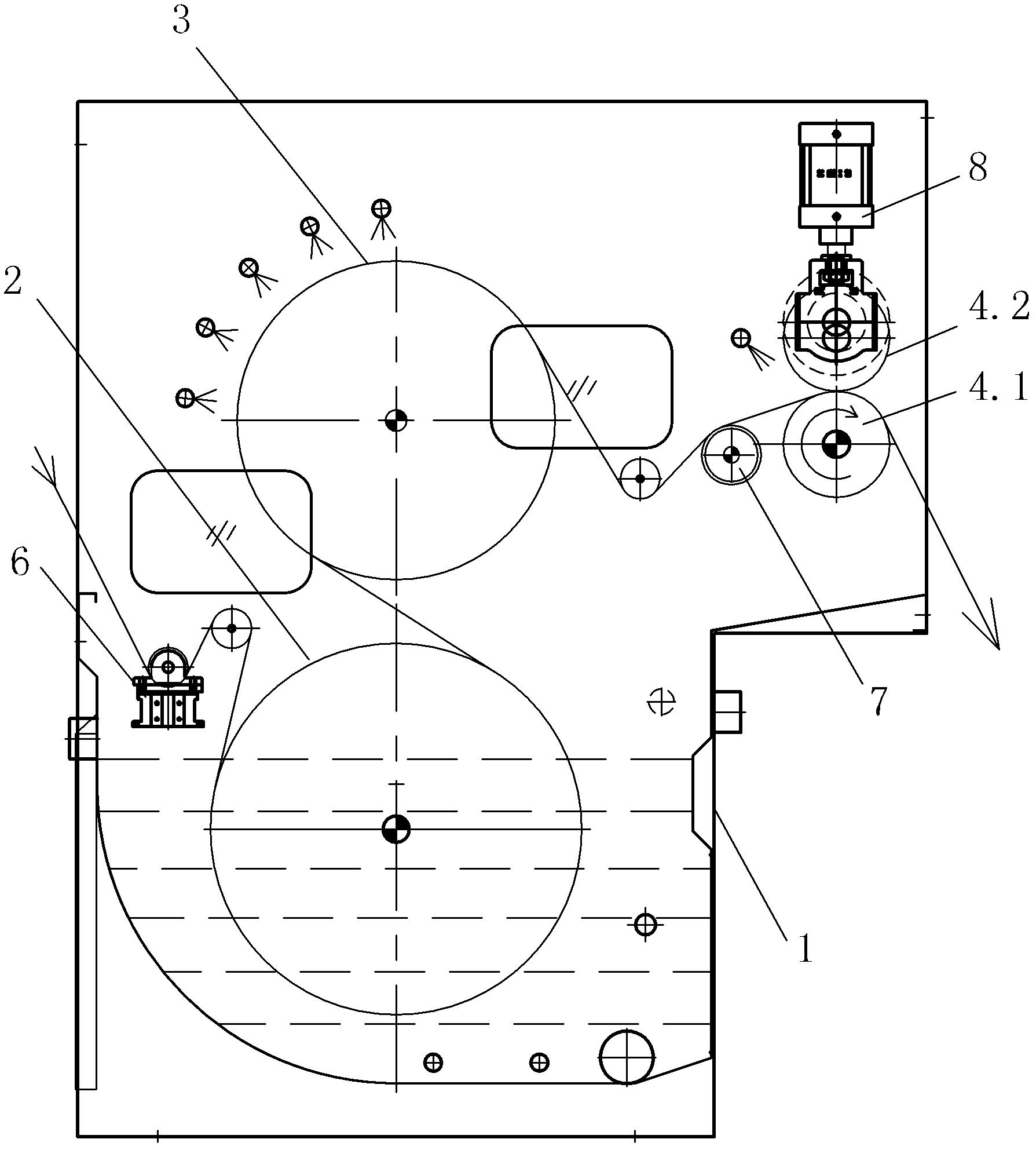

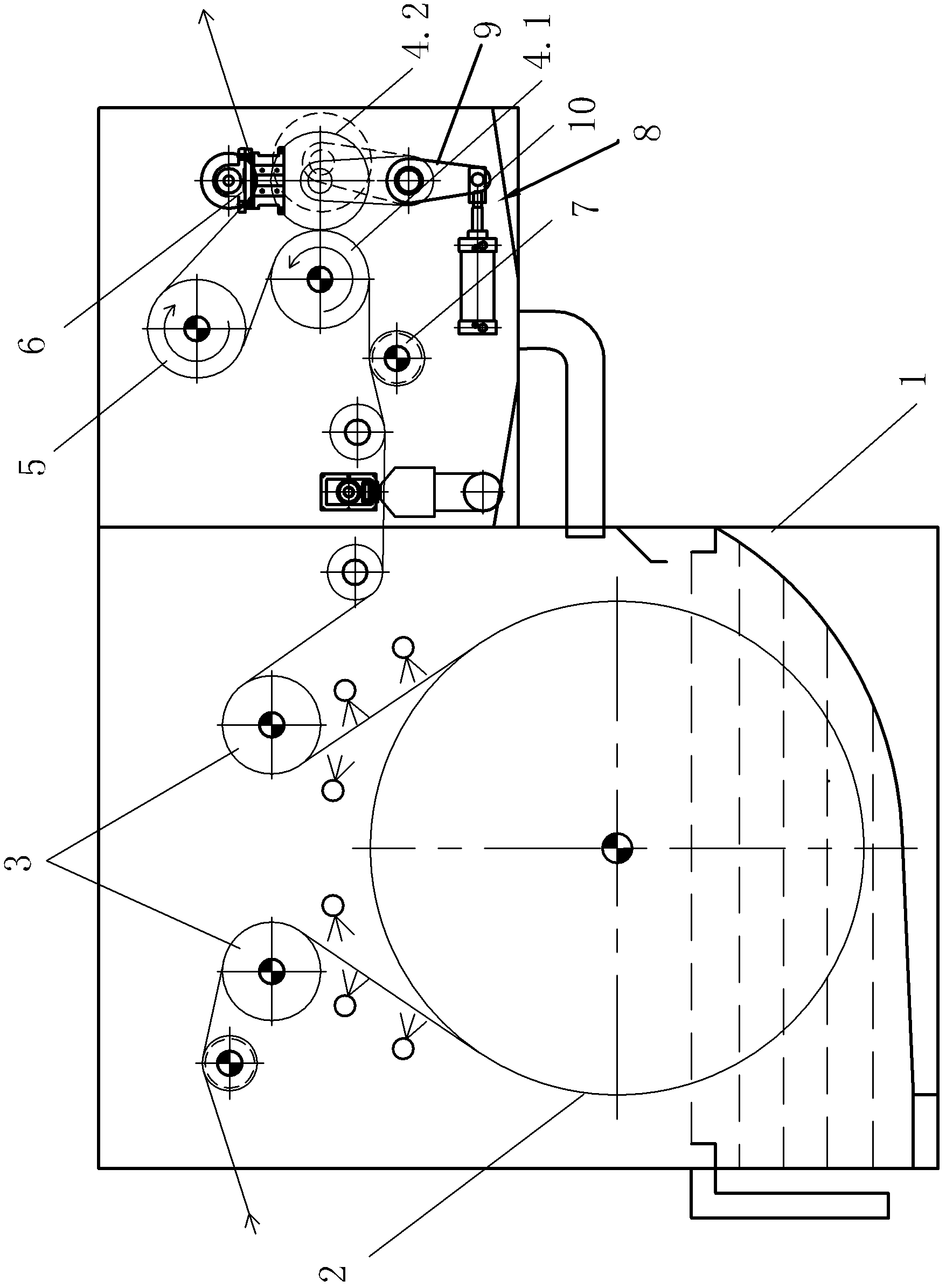

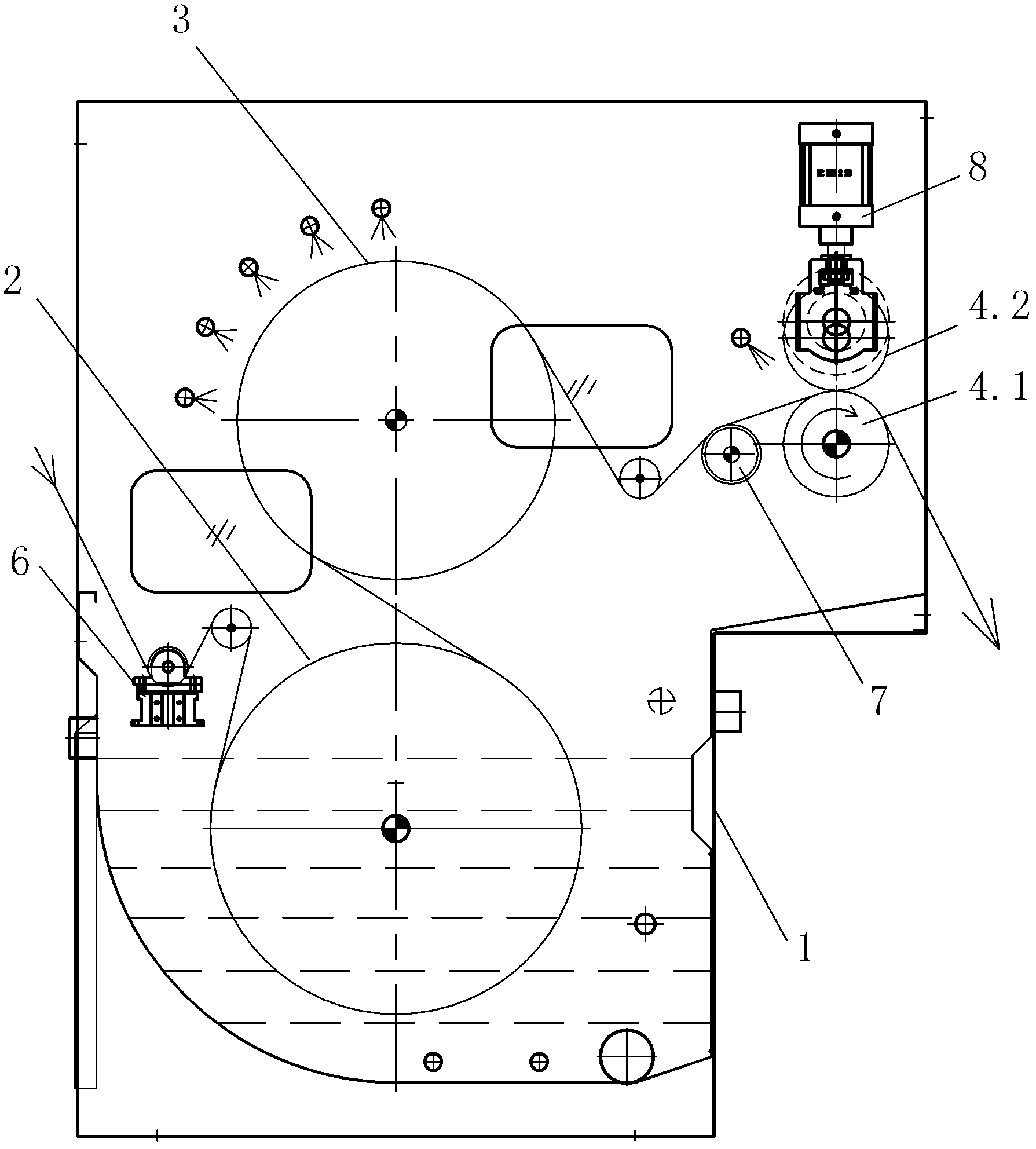

[0018] Example: Automatic fabric tension control system suitable for knitting open-width wet processing units, such as figure 1 As shown, it includes at least two groups of wet processing units, the adjacent wet processing units are connected by stations, and a plurality of wet processing units are combined to form an assembly line unit, and a drum is arranged in the cabinet 1 of the wet processing unit / roll group and roll group, the roll group is arranged in the front and / or rear of the drum / roll group station. It may also include a traction roller 5 matched with the above-mentioned roll group, and the traction roller 5 is a main driving roller, which is connected with a corresponding driving mechanism. The drum / roller set includes a lower drum 2 and an upper drum / roller 3 . Roll set includes active roll 4.1 and passive roll 4.2. Wherein, the drum 2 cooperates with the liquid in the box body 1 .

[0019] The fabric tension automatic control system suitable for knitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com