PECVD-based enhanced graphene film coating device and method

A technology of graphene film and coating equipment, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as easy deviation or displacement, unfavorable coating process, insufficient plasma density, etc., to achieve Flexible and easy to use, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

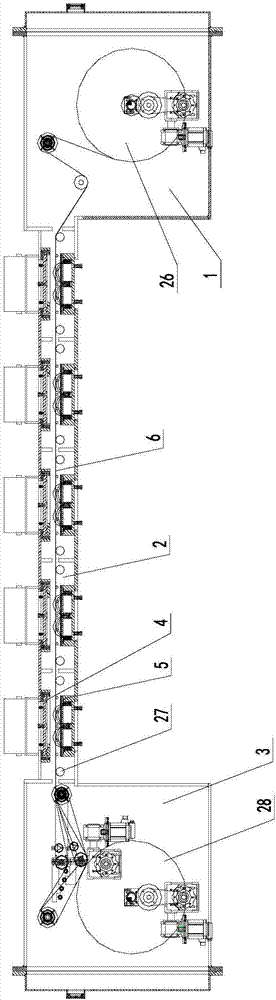

[0043] A kind of enhanced graphene film coating equipment based on PECVD in this embodiment, such as figure 1 As shown, it includes a plurality of vacuum chambers and a substrate conveying mechanism, and the substrate conveying mechanism runs through a plurality of vacuum chambers; along the conveying direction of the nickel foam substrate, a plurality of vacuum chambers include successively connected unwinding chambers 1, a plurality of Coating chamber 2 (five in the present embodiment) and winding chamber 3; In each coating chamber, the upper and lower sides of nickel foam substrate 6 are respectively provided with radio frequency discharge plate 4 and plasma magnetron enhancing device 5.

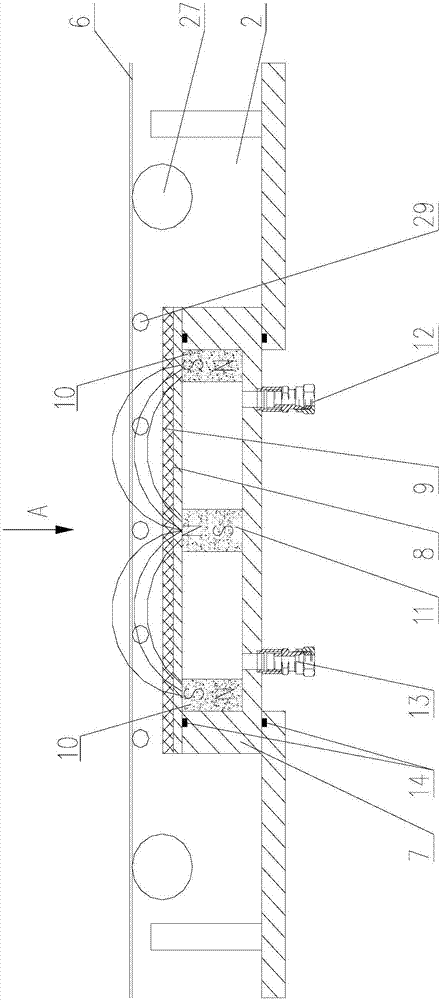

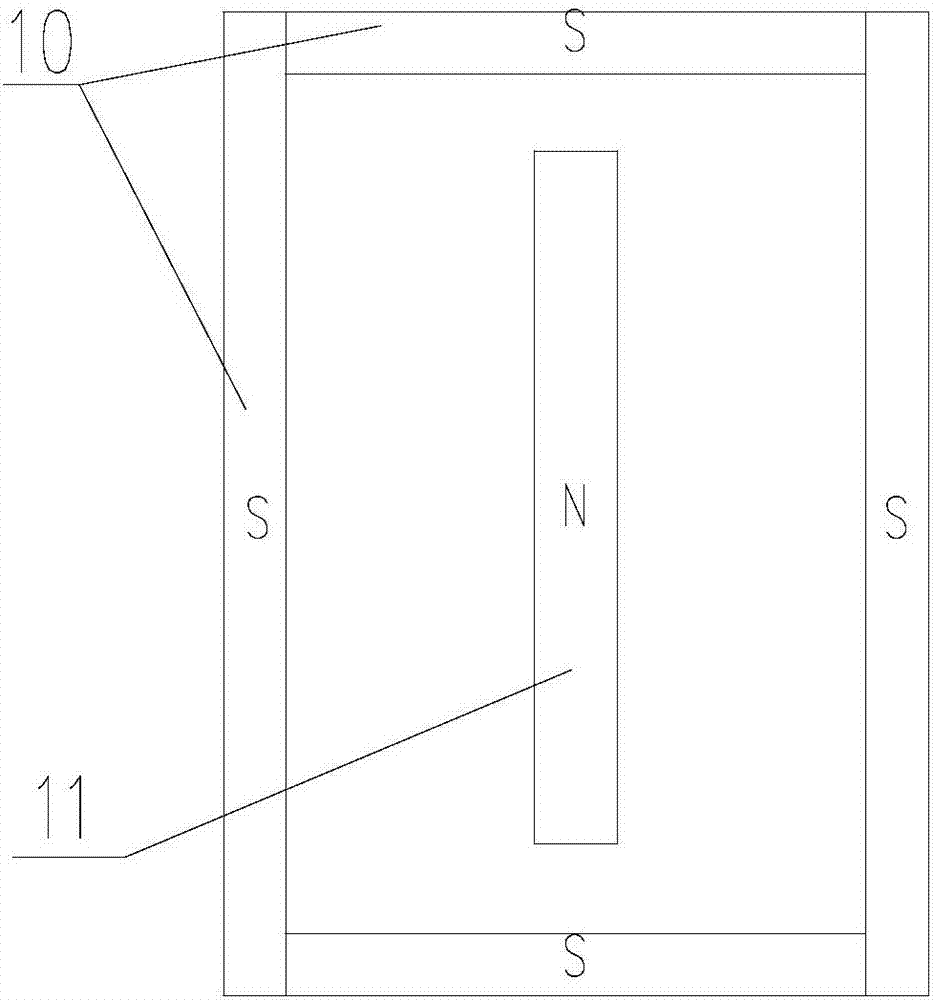

[0044] Such as figure 2 or image 3 As shown, the plasma magnetron enhancement device includes a magnetic base body 7, a magnetic field body 8, a graphite plate 9, an outer ring magnet 10, and an intermediate magnet 11. The magnetic base body is a box-shaped structure with an open top, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com