A three-dimensional microfluidic chip and its preparation method

A microfluidic chip and microfluidic technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of easy adsorption of organic solvents, difficulties in shaping and bonding, and easy blockage of microchannels and other problems, to achieve the effect of simple preparation method, increase the probability of successful preparation, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the microfluidic chip comprises the following steps:

[0033] (1) The prefabricated polymer (usually a mixture of polymer monomer and crosslinking agent, which can be cured at room temperature or heat to obtain a polymer) is evenly coated on a smooth substrate by spin coating or printing After curing at room temperature or heat, a polymer layer of 1 μm to 5 mm can be obtained; by controlling the preparation process, the thickness of the polymer layer can be controlled. For example, when the polymer layer is prepared by the spin coating method, spin at a speed of 1500r / min for 35 seconds A polymer layer of about 20 μm can be obtained, and the higher the rotation speed, the smaller the concentration of the prefabricated polymer, the longer the rotation time, the thinner the polymer layer, and when using the printing method, the thinner the hole network, the prepared The polymer layer is also thinner; and the choice of the substrate is related to ...

Embodiment 1

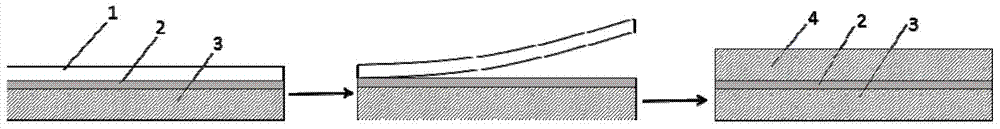

[0038] A microfluidic chip is composed of a first substrate and a second substrate, the surfaces of the first substrate and the second substrate are connected by a polymer layer of 5mm, the preparation method of the chip is as follows figure 1 Shown:

[0039] 1) Preparation of substrate chip:

[0040] Select two silicon wafers as the substrate, and process the required microfluidic structure on the silicon wafer, then rinse the chip with deionized water to remove impurities such as oil and particles on the surface of the substrate, clean it and put it in a clean working area Dry on a hot table for later use.

[0041] 2) Preparation of polymer:

[0042] The polymer described here is PDMS. Add the PDMS elastomer and PDMS curing agent into the paper cup at a ratio of 10:1, then use a clean glass rod to stir the mixture in one direction until there are uniform small bubbles in the mixture, then let the stirred mixture stand until the air bubbles are completely eliminated.

[00...

Embodiment 2

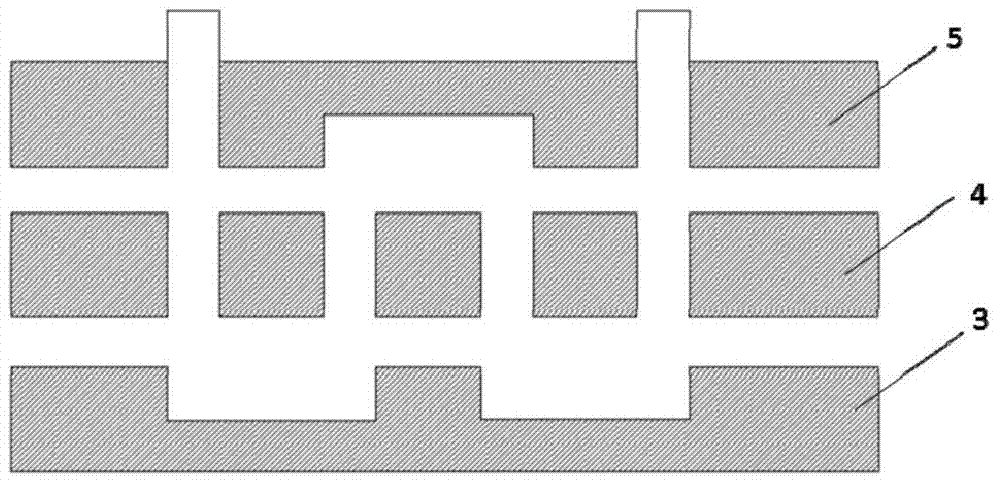

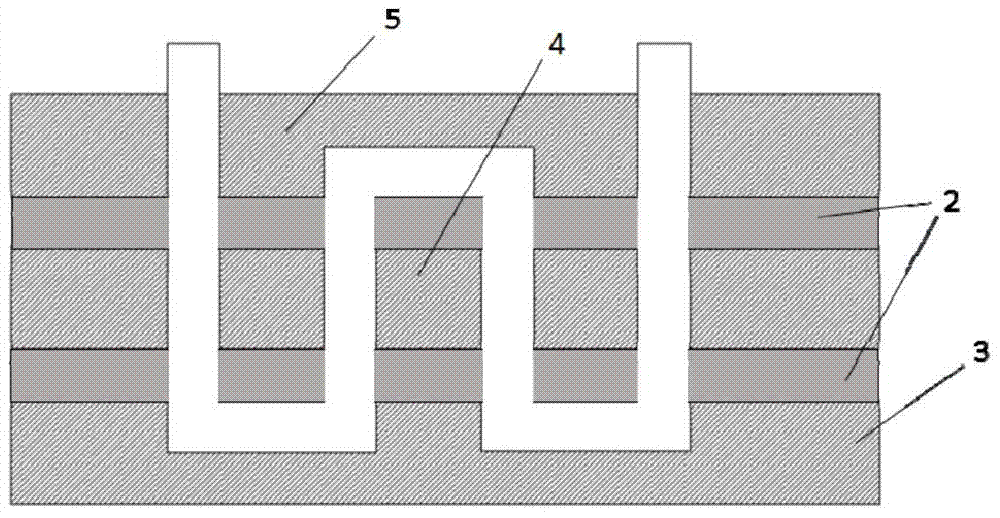

[0052] 1) Preparation of substrate chip:

[0053] Select three glass chips as the first substrate, the second substrate and the third substrate respectively, and process the microfluidic structure respectively, such as Figure 2a As shown, there are first substrate 3 , second substrate 4 and third substrate 5 from bottom to top. Then rinse the chip with deionized water to remove impurities such as oil and particles on the surface of the substrate. After cleaning, put it on the hot table in the clean work area to dry for later use.

[0054] 2) Preparation of film:

[0055] The adhesive film described here is a PET adhesive film. Cut the adhesive film according to the principle that the adhesive film is larger than the base chip size, and then clean the adhesive film with deionized water until the color pattern is not visible to the light and does not hang water, and then put the cleaned film in the clean work area Dry on the hot table, the temperature of the hot table is 65 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com