Patents

Literature

265results about How to "High success rate of preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

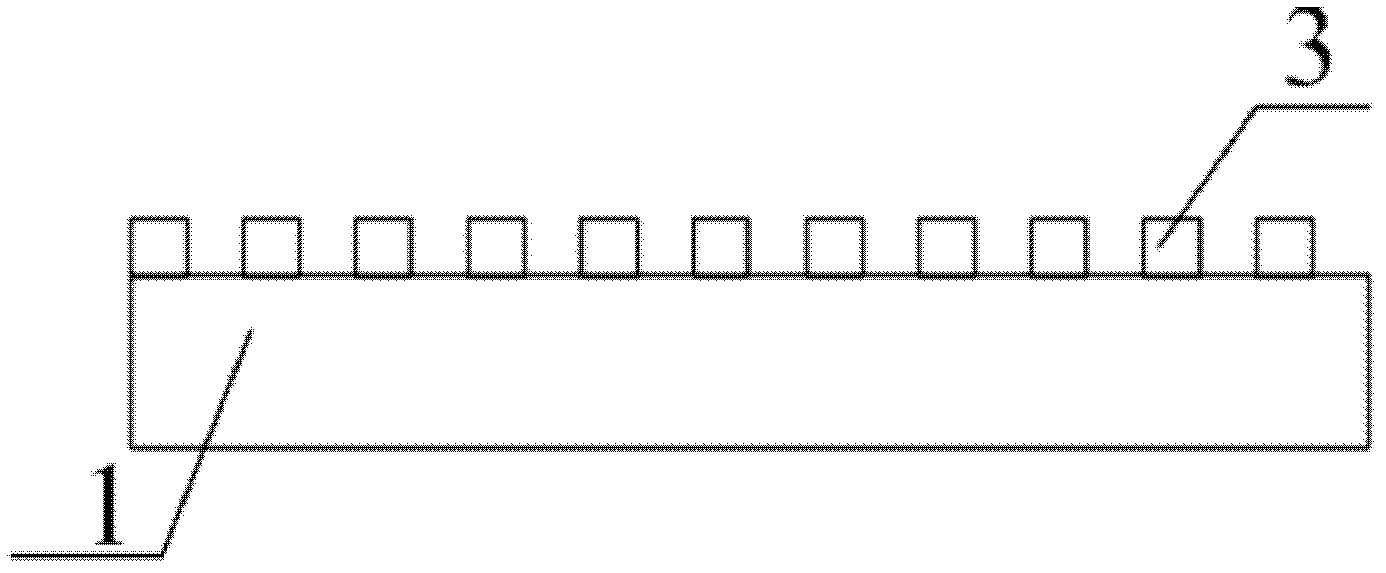

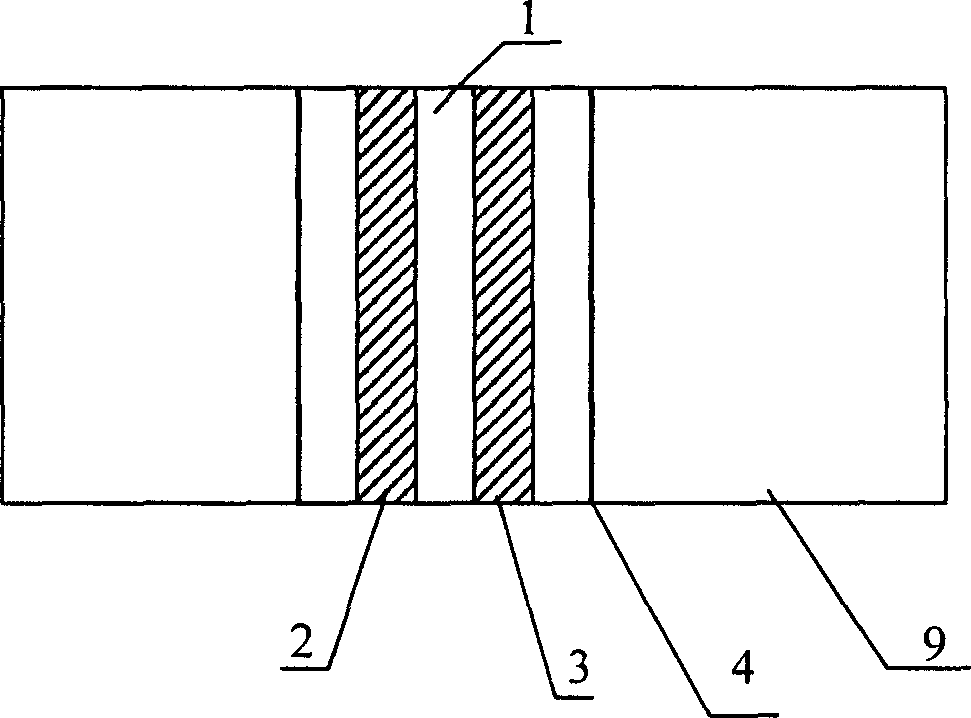

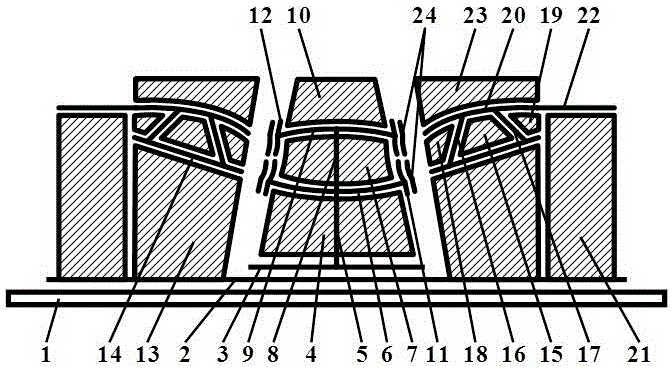

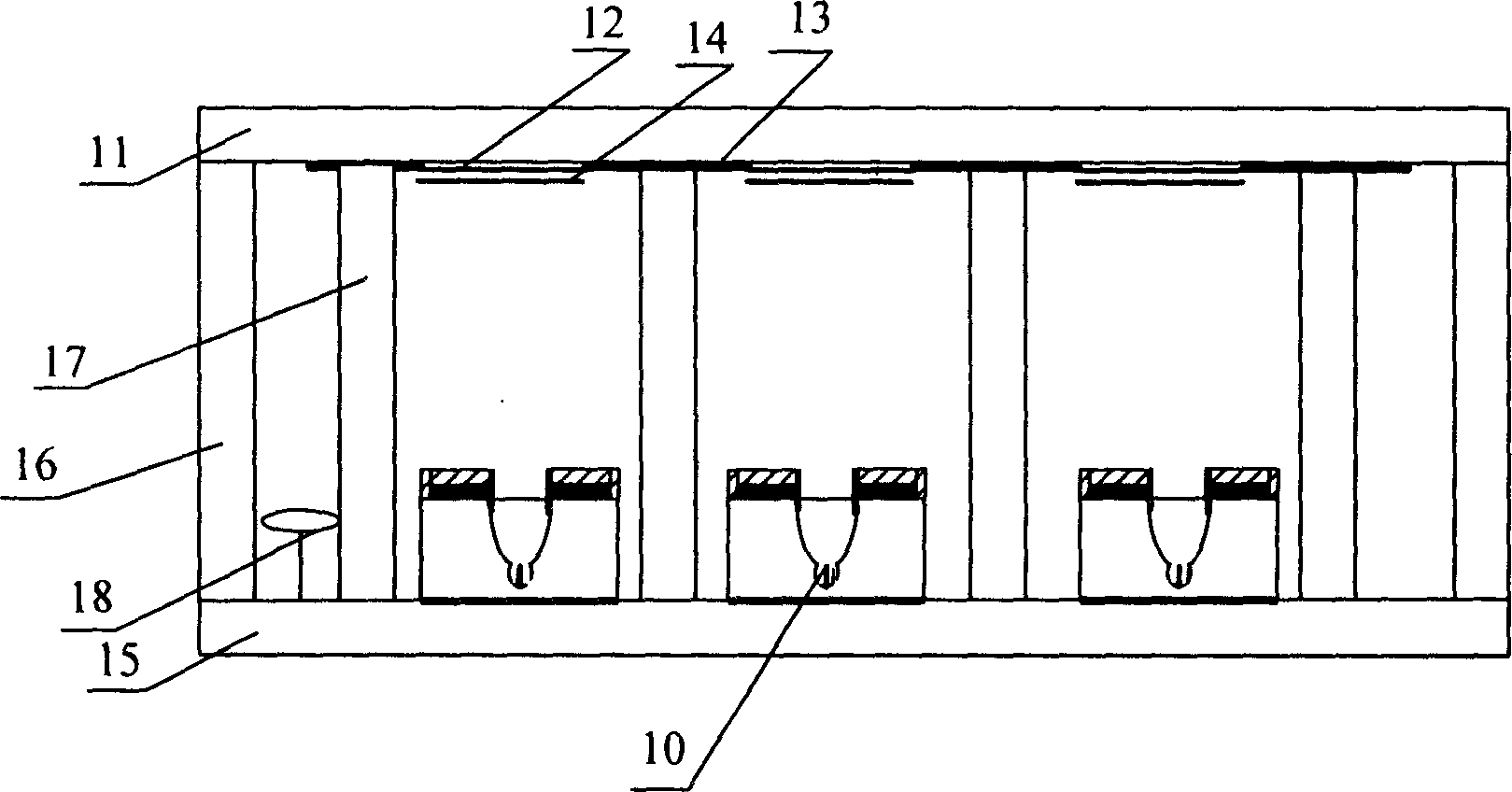

Array substrate, display panel and display device

ActiveCN106684101AHigh success rate of preparationIncrease exposureSolid-state devicesNon-linear opticsDisplay deviceActive layer

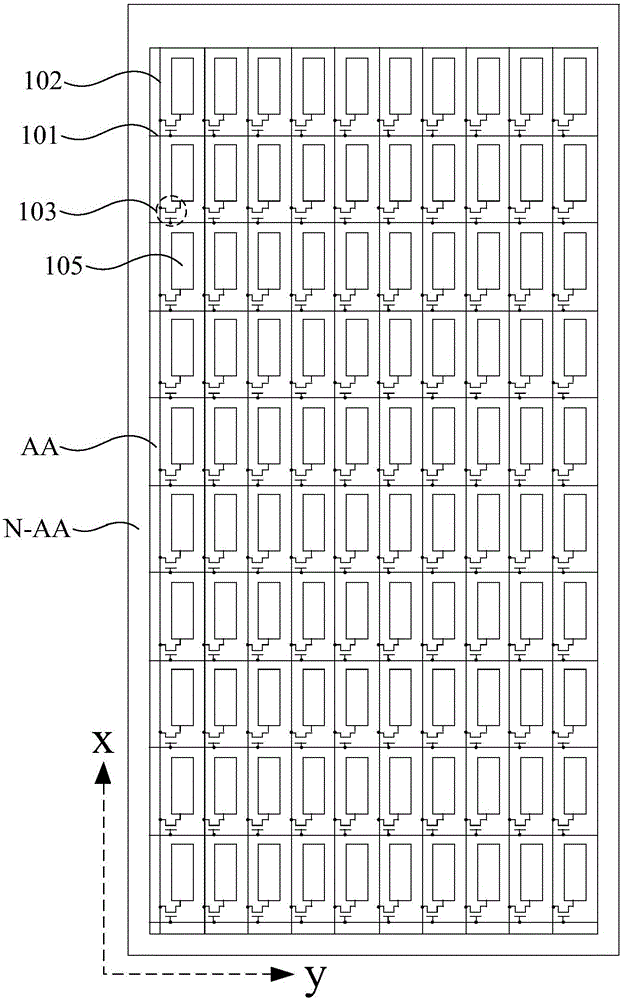

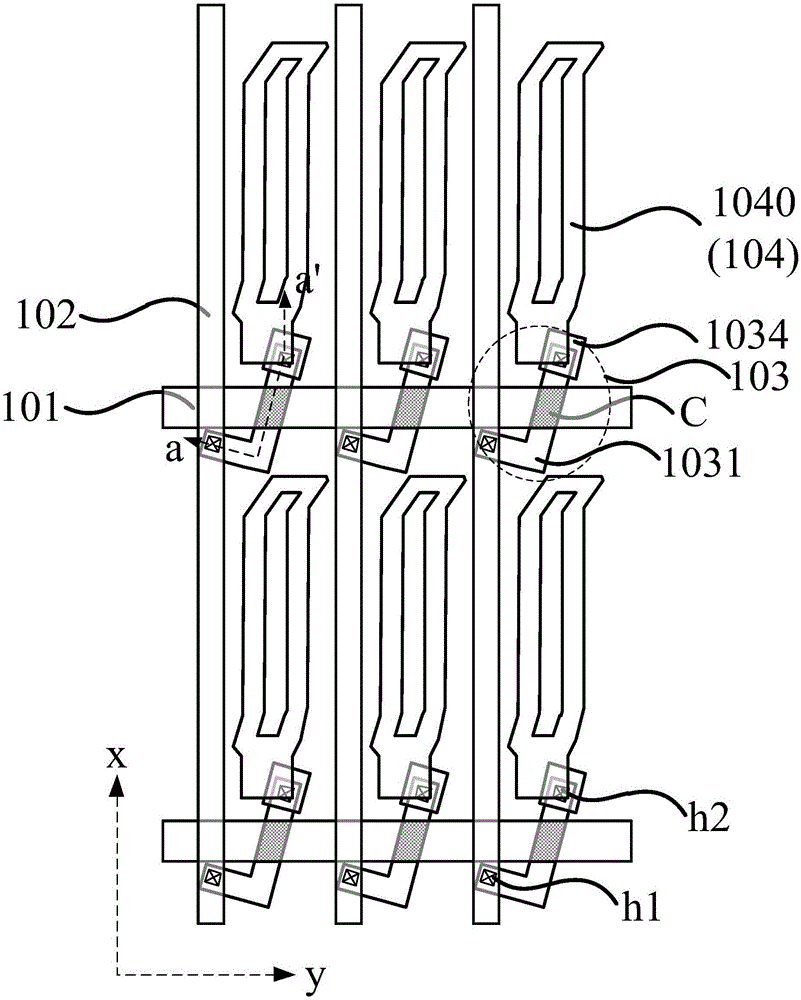

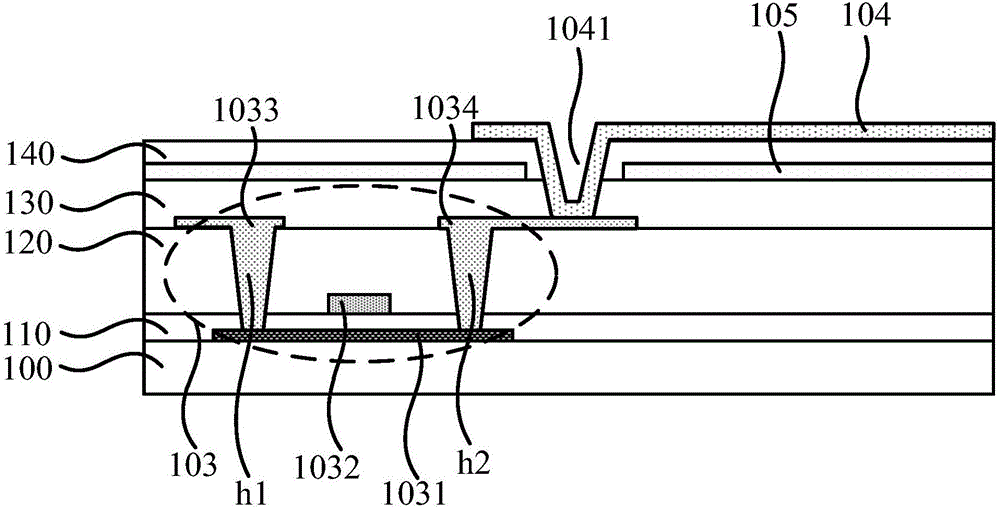

The invention discloses an array substrate, a display panel and a display device. The array substrate comprises an underlayer substrate, multiple scanning lines and multiple data lines. The scanning lines and the data lines are located on one side of the underlayer substrate. The scanning lines are arranged side by side in the first direction, the data lines are arranged side by side in the second direction, and multiple sub-pixels are defined by the scanning lines and the data lines in an insulating cross mode. The sub-pixels comprise thin film transistors, and each thin film transistor comprises an active layer, a grid, a source electrode and a drain electrode which are located on one side of the underlayer substrate. The active layers comprise channel regions, and the regions where the active layers and the grids are overlapped are the channel regions in the direction vertical to the array substrate. Each channel region comprises two opposite edges in the second direction, first included angles are formed between the stretching directions of the edges and the first direction, and the first included angles are larger than 0 degree and smaller than or equal to 40 degrees. The exposure stability of graphs in the thin film transistors can be improved, and the aperture ratio is increased to a certain degree.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Ordered porous alumina template capable of being directly used in electrochemical deposition and production method

InactiveCN101851771AHigh success rate of preparationNot easy to damageSurface reaction electrolytic coatingNanowireAlumina composite

The invention discloses an ordered porous alumina template capable of being directly used in electrochemical deposition and a production method. The ordered porous alumina template is characterized in that the thickness of a barrier layer of the ordered porous alumina template is 100-300nm; non-oxidized aluminum matrix can be directly used as an electrode for the electrochemical deposition without removing the barrier layer and plating electrodes. The production method comprises the following steps: annealing an aluminum foil to eliminate stress generated in the process of cutting the aluminum foil; washing the annealed aluminum foil to remove blot on the surface of the aluminum foil; removing a natural oxidization layer on the aluminum foil; electropolishing the aluminum foil; carrying out primary anodization on the polished aluminum foil; removing the primary oxidization film on the primary oxidized aluminum foil; and carrying out secondary anodization on the aluminum foil on which the primary oxidization film is removed. The template produced by using the method of the invention has high success rate of production, is difficult to damage, simplifies the production process flow of nanowire / ordered porous alumina composite materials, and is beneficial to research on properties of the composite materia.

Owner:TONGJI UNIV

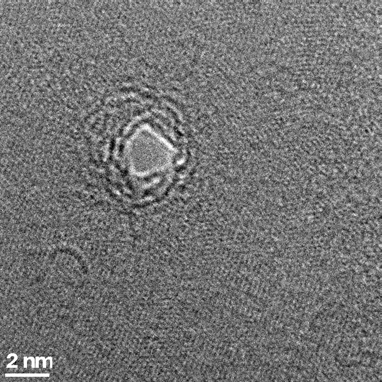

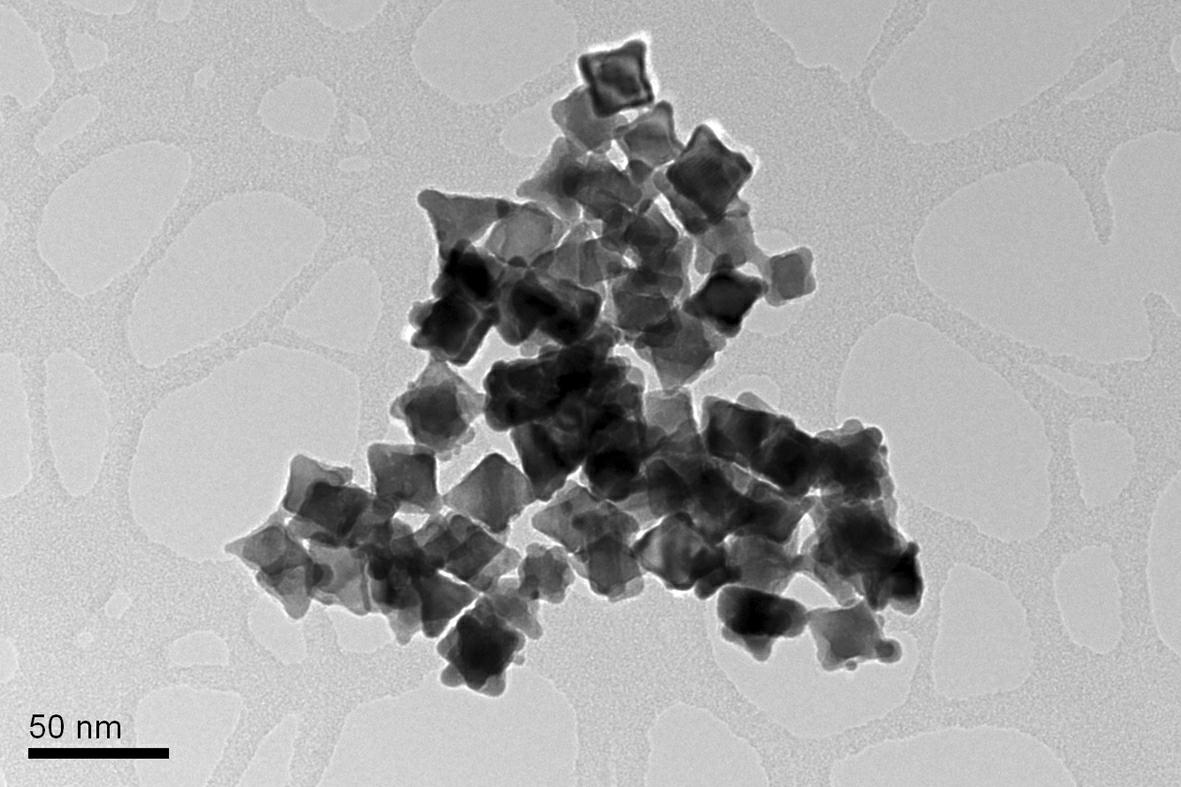

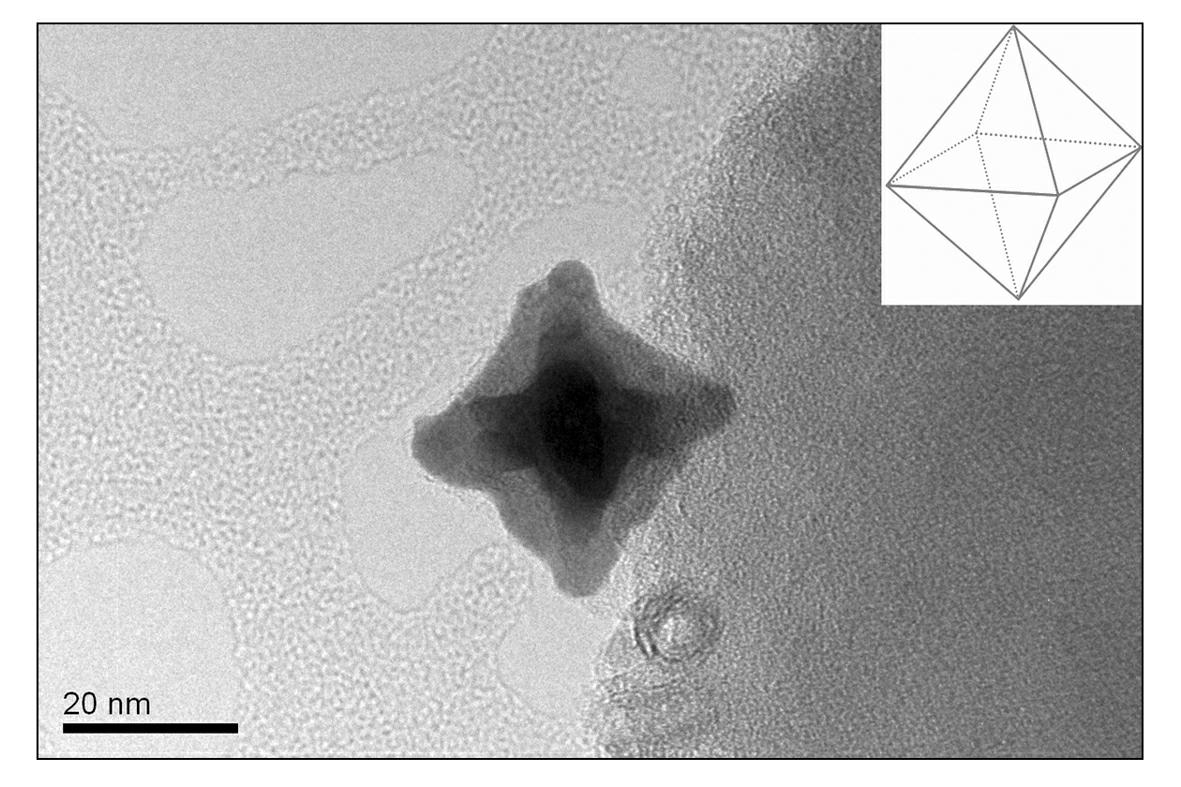

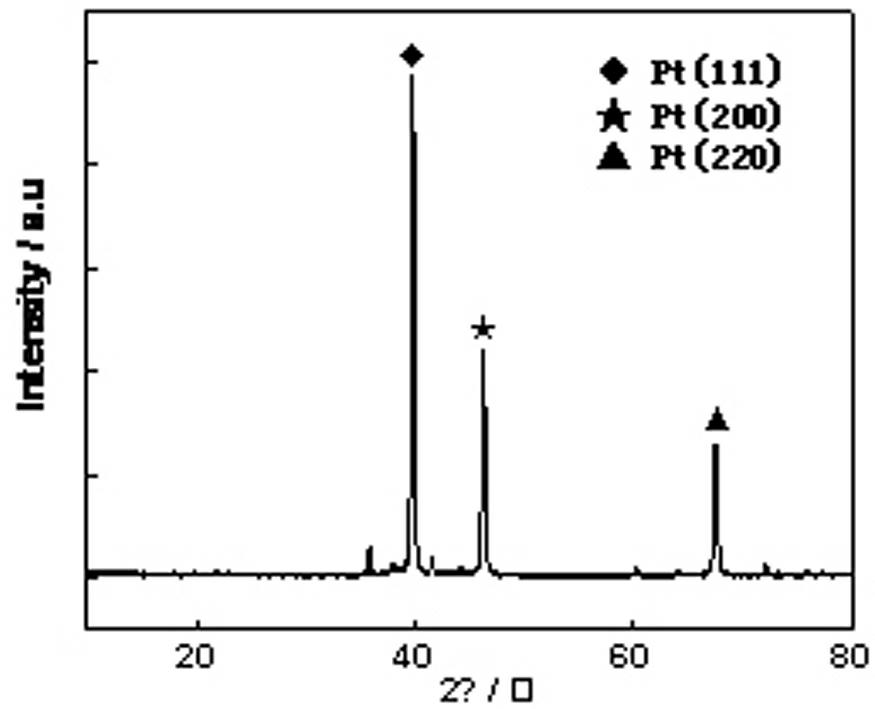

Method for preparing highly-dispersed regular octahedral platinum nano particles

The invention discloses a method for preparing highly-dispersed regular octahedral platinum nano particles. The method comprises the following steps of: 1, preparing chloroplatinic acid stock solution, namely dissolving 0.5 to 2g of chloroplatinic acid (H2PtCl6) in pure water to prepare chloroplatinic acid solution with the concentration of 50 to 400mM; 2, mixing organic matter mixed inducing solution, namely treating polyethylene glycol with the molecular weight of 600 to 2,000 to prepare aqueous solution with the concentration of 0.5 to 2M, and marking the aqueous solution as solution 1; treating one or more of more than 20 kinds of amino acid which is required by a human body to prepare the aqueous solution with the concentration of 0.5 to 2M, and marking the aqueous solution as solution 2; mixing the solution 1 and the solution 2 in a ratio of 1 to 1 to prepare the organic matter mixed inducing solution and marking the solution as solution 3; and 3, performing hydrothermal inducing, namely adding 30 to 60ml of the solution 3 into 100ml of a hydro-thermal reaction kettle, simultaneously adding 1 to 5ml of chloroplatinic acid solution with the concentration of 50 to 400Mm; and stirring the solution for half an hour, performing hydrothermal treatment at the temperature of between 150 and 200 DEG C for 3 to 8 hours, wherein after the hydrothermal treatment, the particle ripening placement time is 4 to 8 hours.

Owner:ZHEJIANG SCI-TECH UNIV

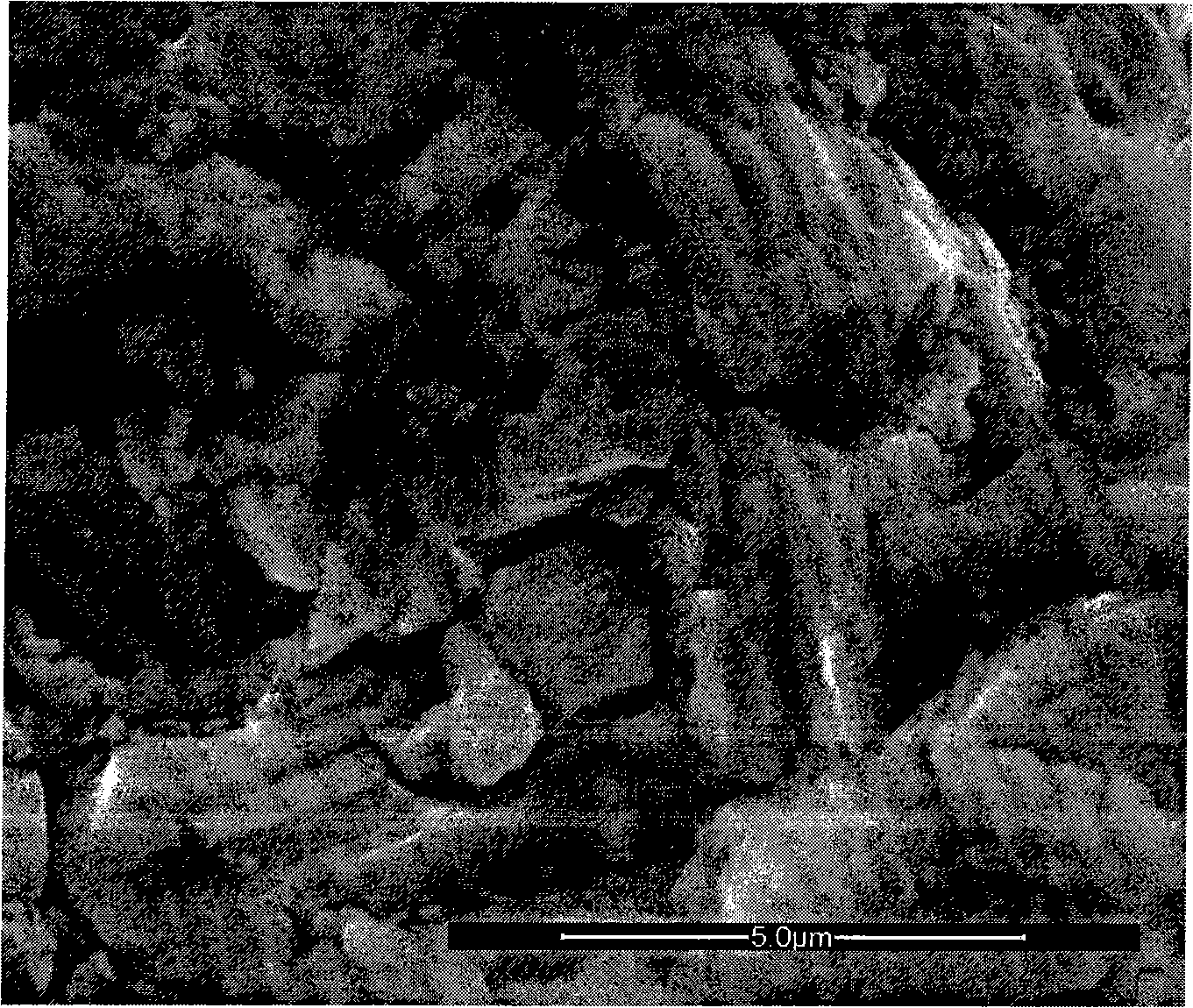

Method for preparing rare earth barium copper oxide superconducting block material

InactiveCN101717256AGuaranteed efficient growthHigh success rate of preparationRare earthHigh temperature superconducting

A method for preparing rare earth barium copper oxide superconducting block material comprises the steps of executing calcining and grinding processes in turn after mixing the RE123 and RE211 in the mole ratio of 100: (20-35); pressing the ground powder into precursor bottom piece and precursor top piece respectively; putting the precursor top piece on top of the precursor bottom piece; putting seed crystal on the precursor top piece, then putting the precursor bottom piece on a zirconium oxide bead substrate; rising temperature for heating in a sealing container, and then cooling to prepare the rare earth barium copper oxide superconducting block material. The method can prepare the high temperature superconducting block material with high performance, large single domain structure and good growth orientation under the conditions that no impurity exists and crystal lattices match completely, thereby solving the key problems of the growth and application of the superconducting block material.

Owner:SHANGHAI JIAO TONG UNIV

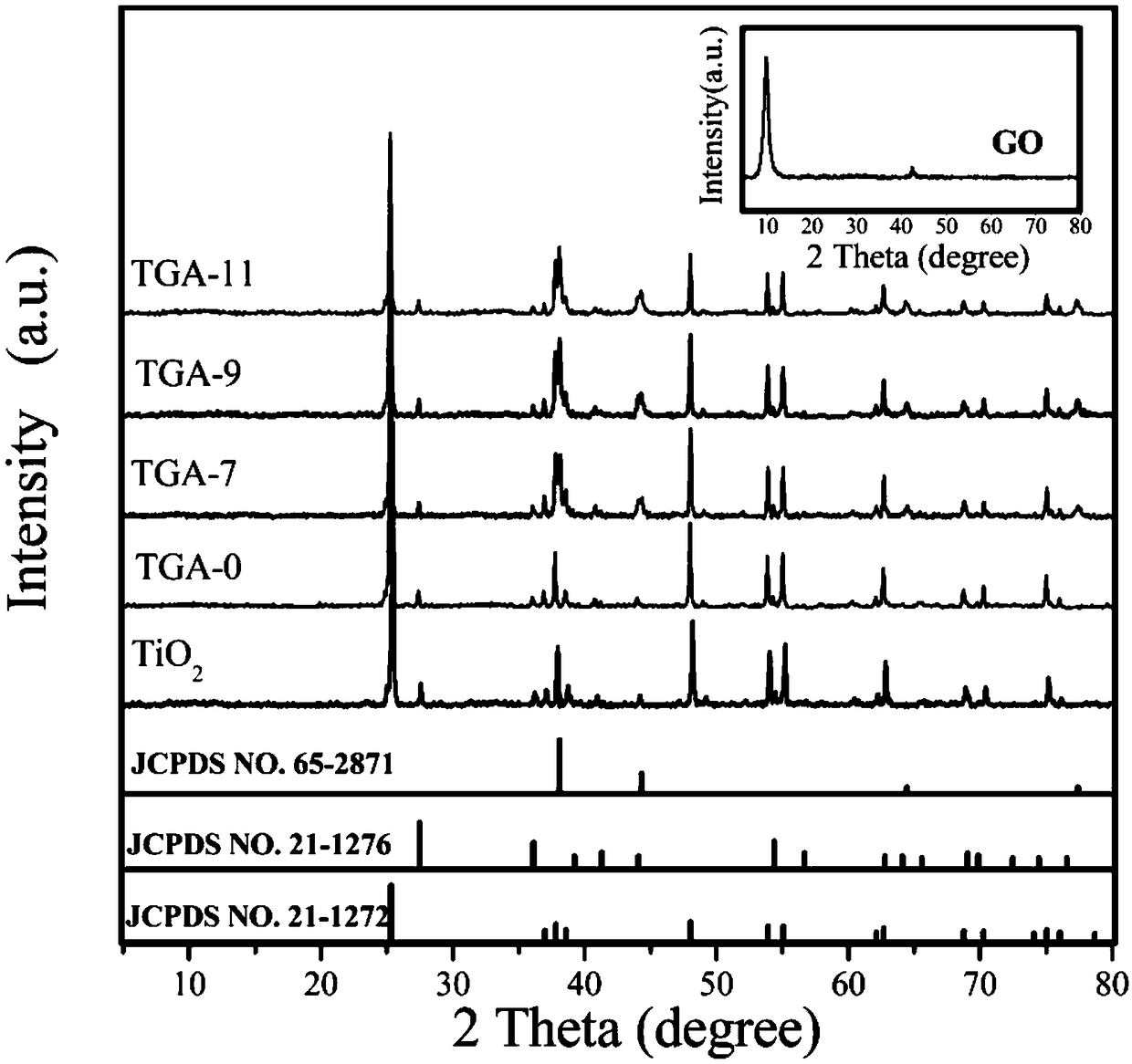

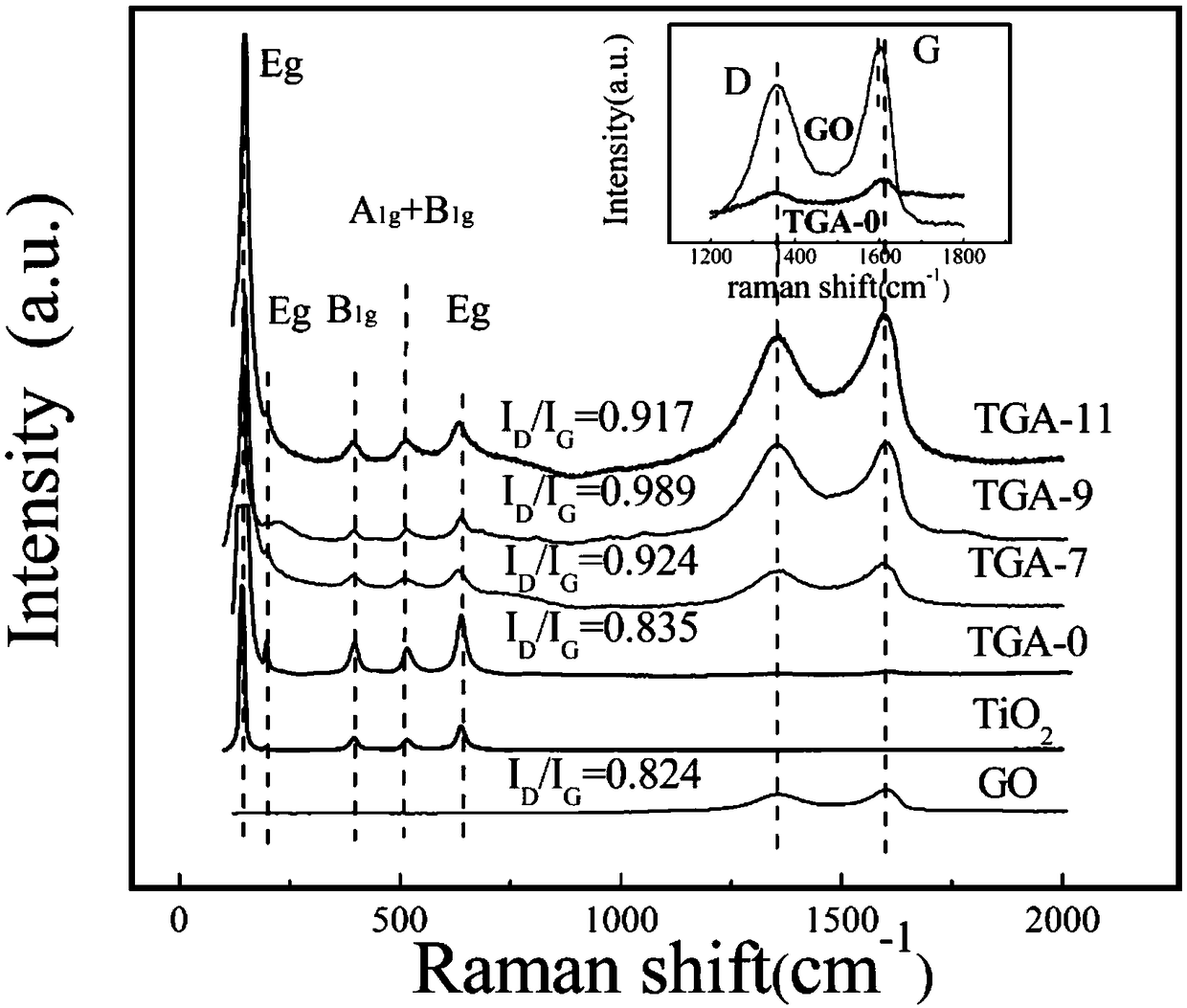

Preparation of TiO2/graphene/nano silver compound photocatalyst and degradation of formaldehyde thereby

PendingCN109482179AOvercoming the disadvantage of low photocatalytic activityGood photodegradation effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSodium citrate

The invention discloses a compound photocatalyst formed by co-modifying TiO2 by silver and graphene. The compound photocatalyst is prepared from the following steps: (1) dispersing graphene oxide in water to obtain a graphene oxide dispersion solution; (2) dissolving AgNO3 in water to obtain an AgNO3 solution; (3) mixing the graphene oxide dispersion solution, the AgNO3 solution, TiO2 powder and sodium citrate and uniformly dispersing the mixture; (4) transferring the mixture obtained in the step (3) to a hydrothermal kettle, and raising the temperature for a hydrothermal reaction; and (5) after the reaction, cooling the mixture to room temperature and washing and drying the same. The preparation method of the compound photocatalyst is simple and feasible and economic in raw material, doesnot generate toxic and harmful substances, can degrade formaldehyde in air under irradiation of visible light, and can be used repeatedly.

Owner:EAST CHINA UNIV OF SCI & TECH +1

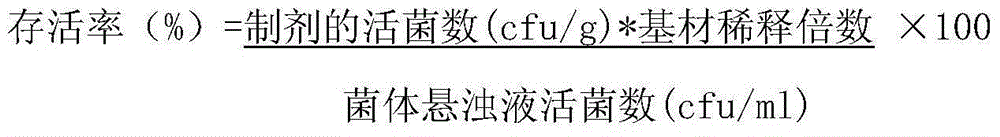

Method for preparing special microbial preparations for homemade 'fruit and vegetable enzymes', products of method and application of products

The invention provides a method for preparing special microbial preparations for homemade 'vegetable and fruit enzymes', products manufactured according to the method and application of the products. The microbial preparations include solid microbial preparations and liquid microbial preparations. A process for preparing the solid microbial preparations includes steps of preparing strains; domesticating and cultivating the strains; preparing materials for inoculants; preparing the microbial preparations. A process for preparing the liquid microbial preparations includes steps of preparing strains; domesticating and cultivating the strains; directly manufacturing the liquid microbial preparations. The method, the products and the application have the advantages that the diversified probiotics strains are domesticated and cultivated to obtain the special microbial preparations for the homemade 'fruit and vegetable enzymes', accordingly, the 'fruit and vegetable enzymes' can be conveniently manufactured at home, the manufacturing success rate can be increased, opportunity of breeding of harmful germs can be reduced as compared with natural fermentation, the sugar contents can be reduced, the fermentation time can be greatly shortened, and the special microbial preparations and the products contain large quantities of effective bioactive components.

Owner:SHANGHAI PROBIOTIK HEALTH TECH

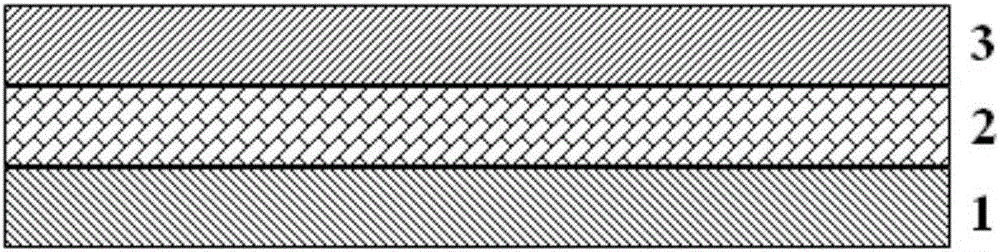

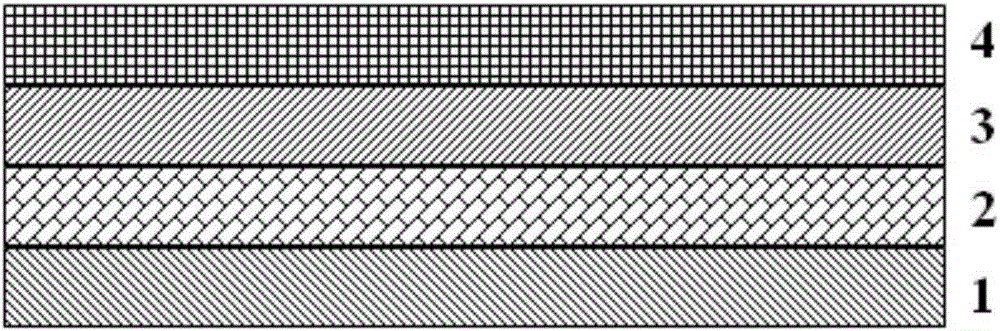

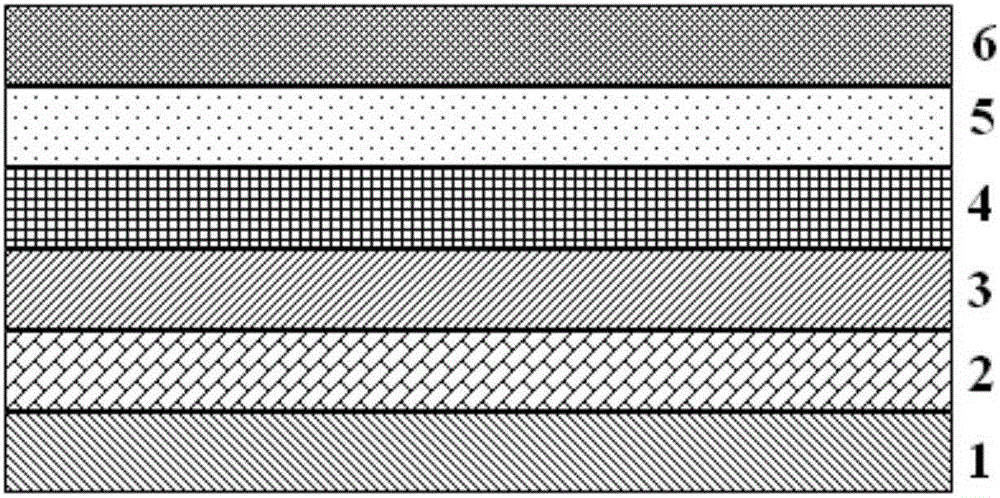

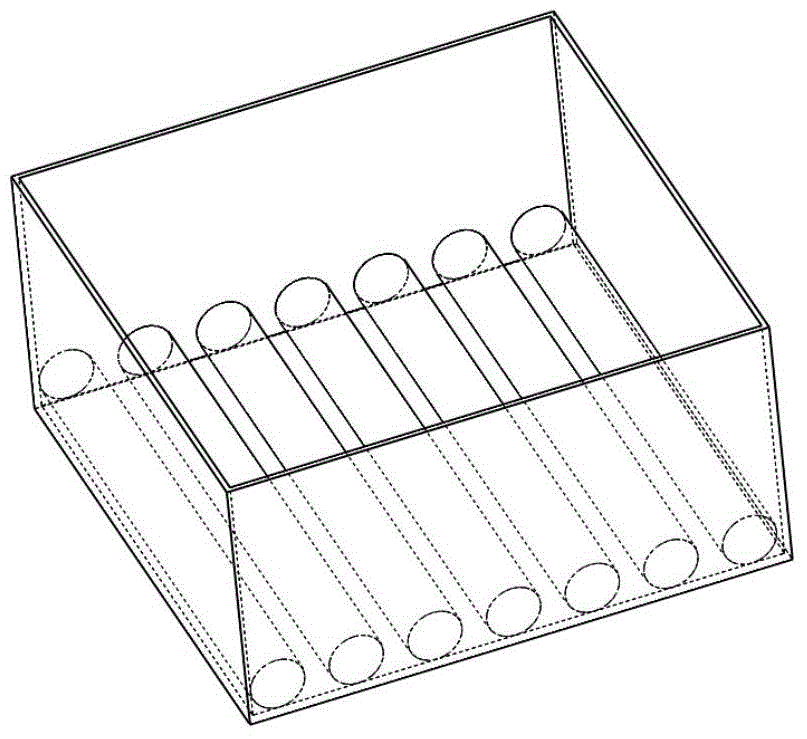

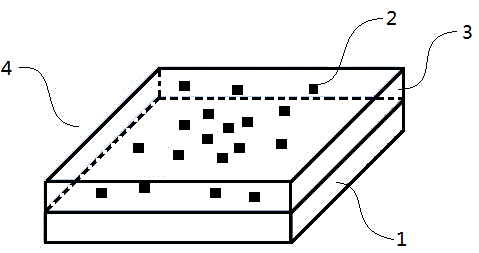

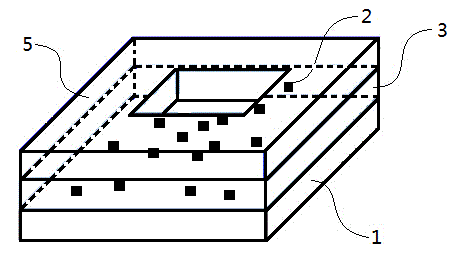

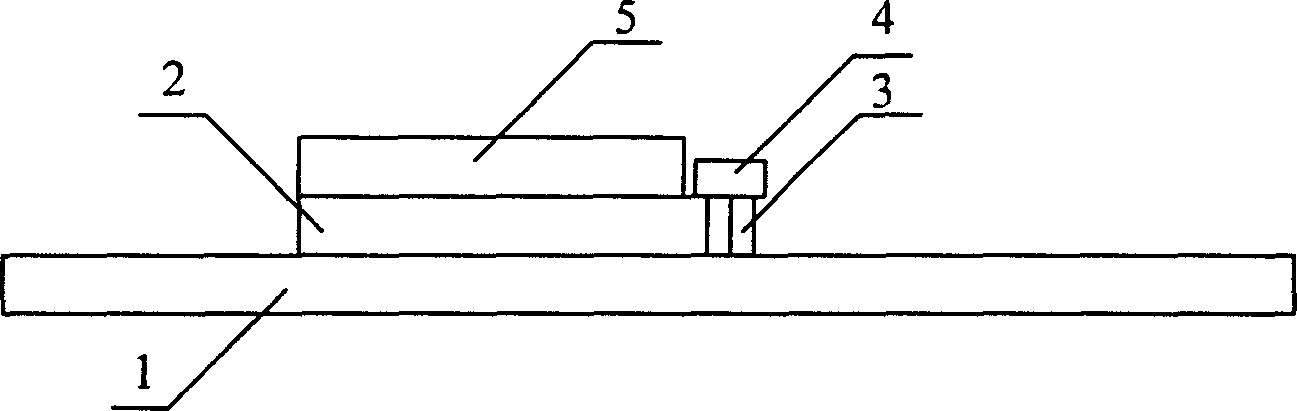

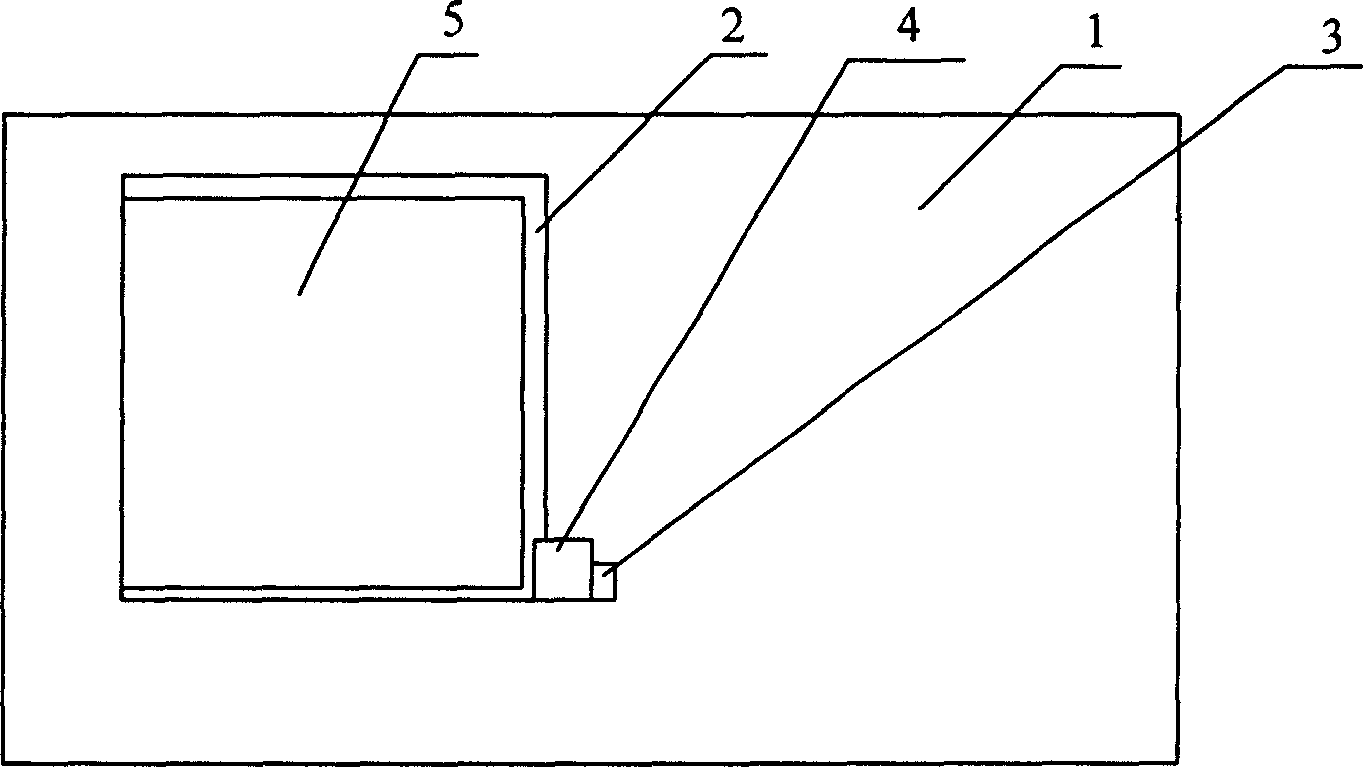

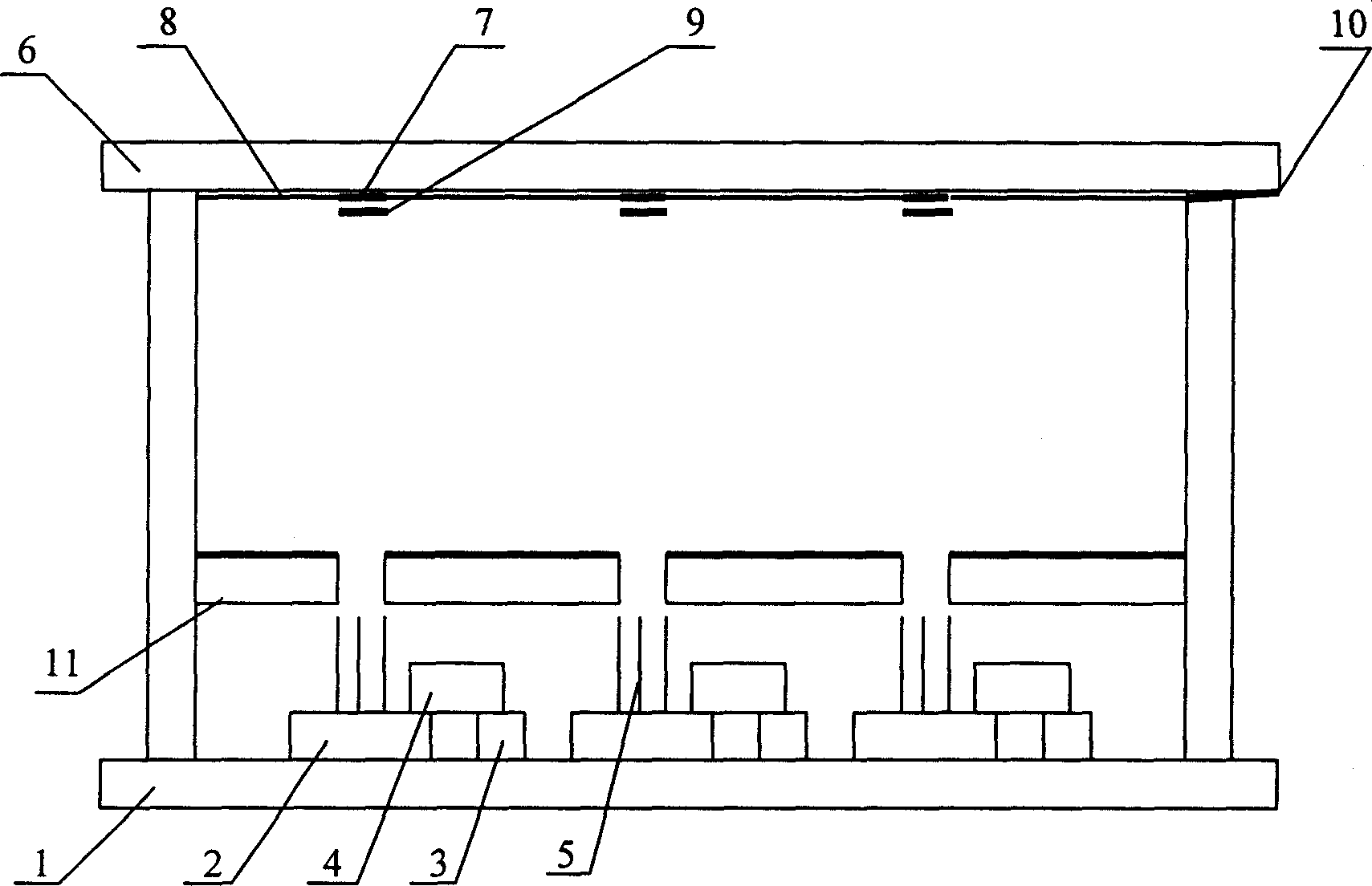

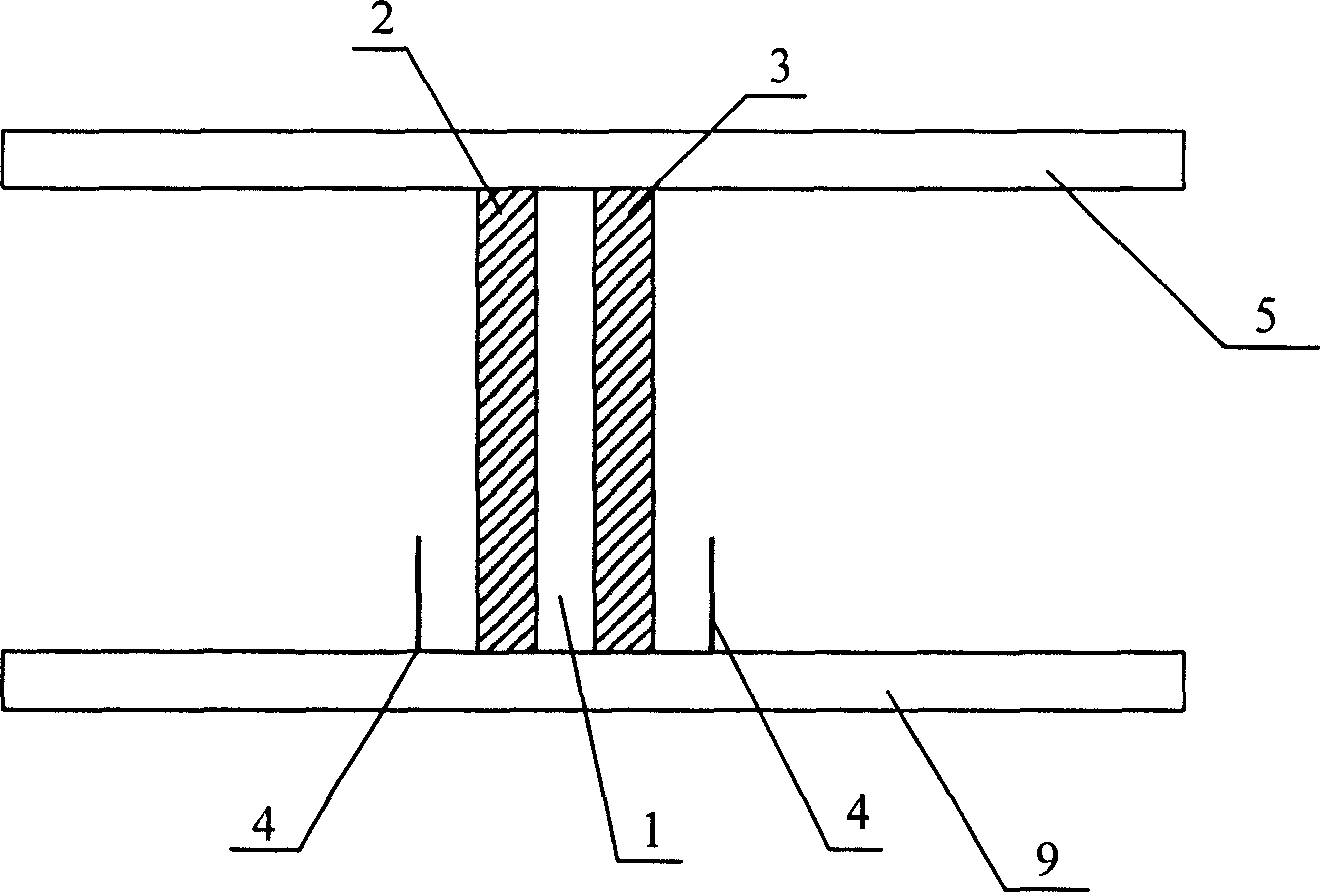

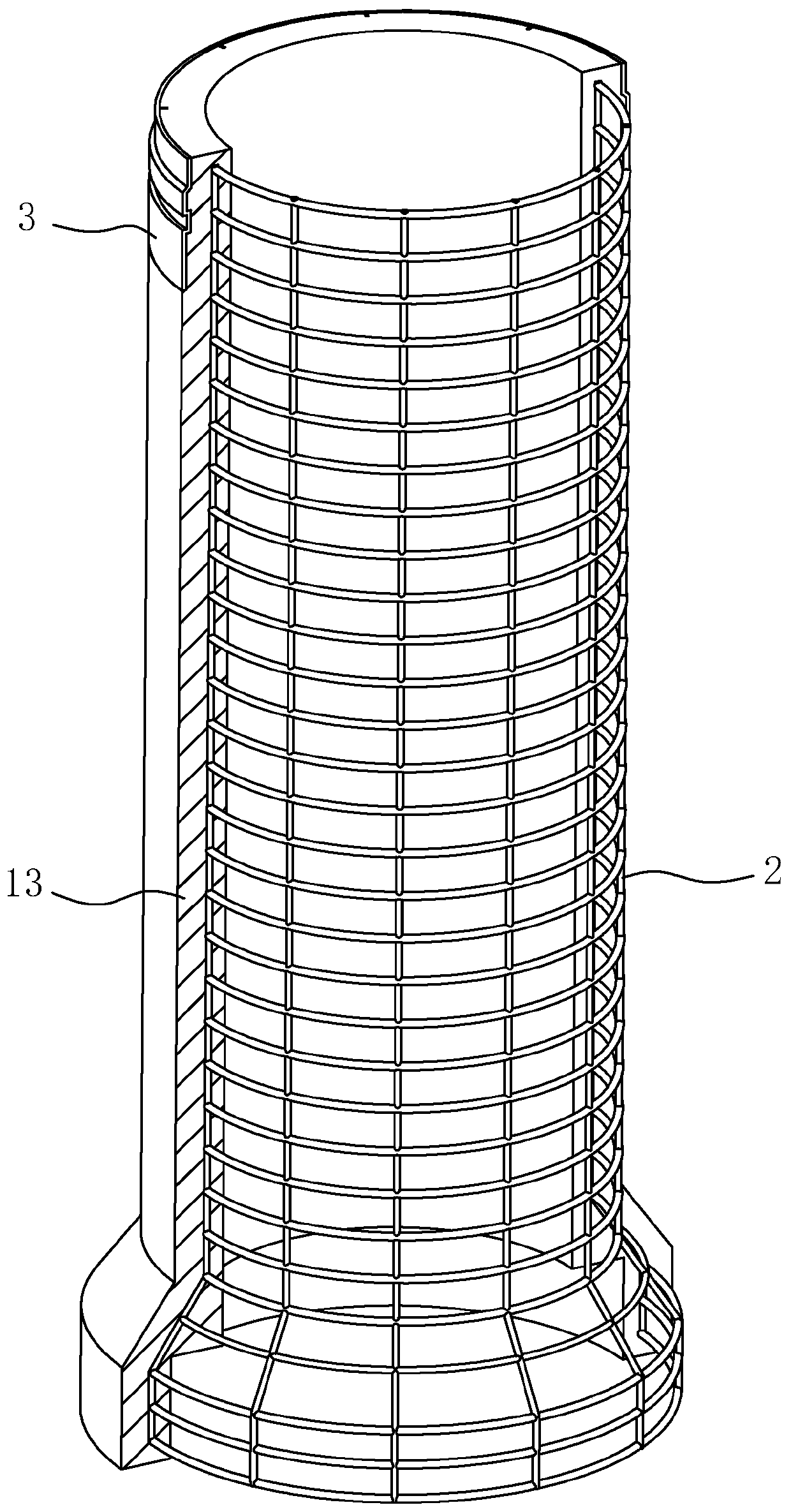

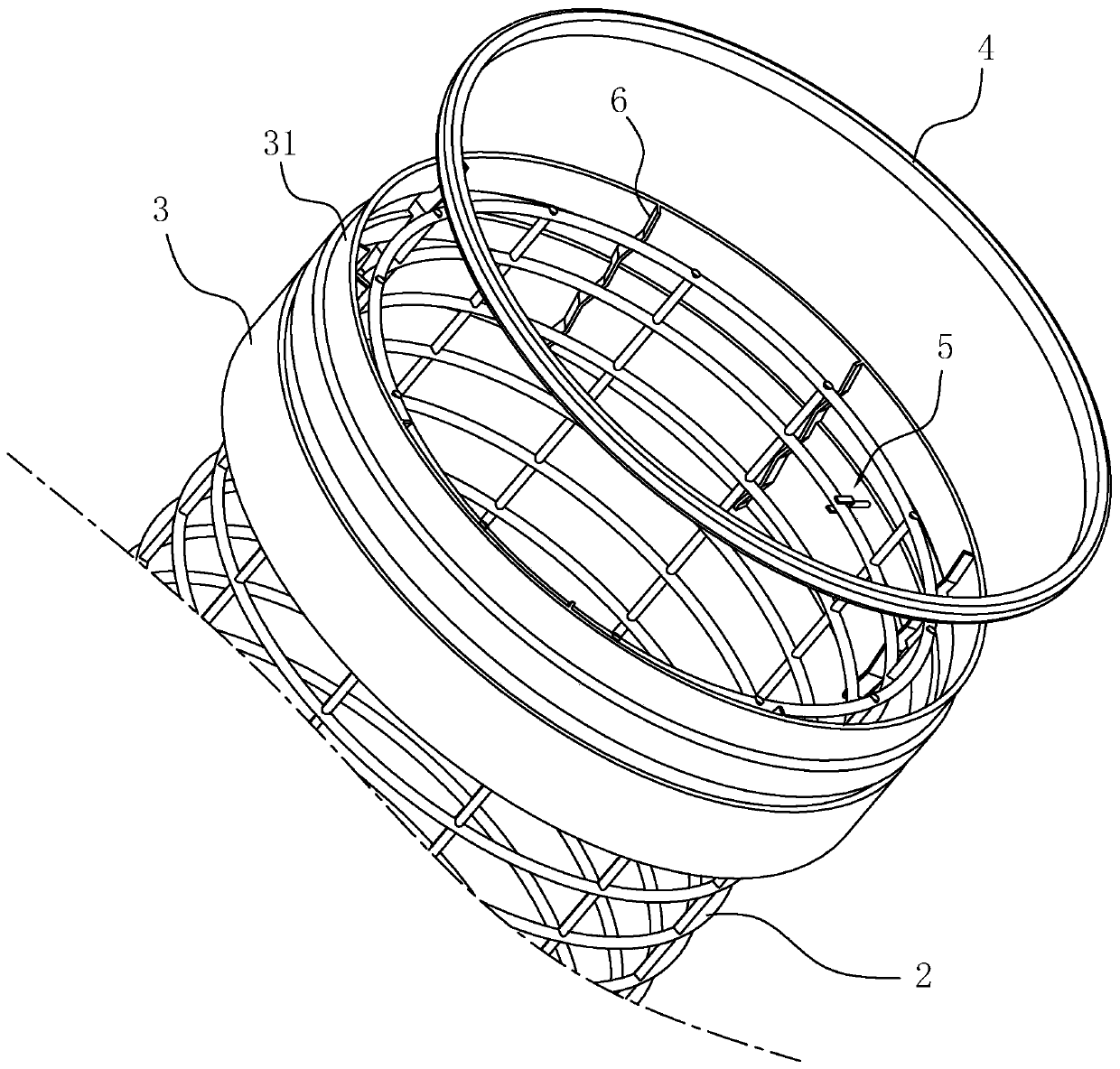

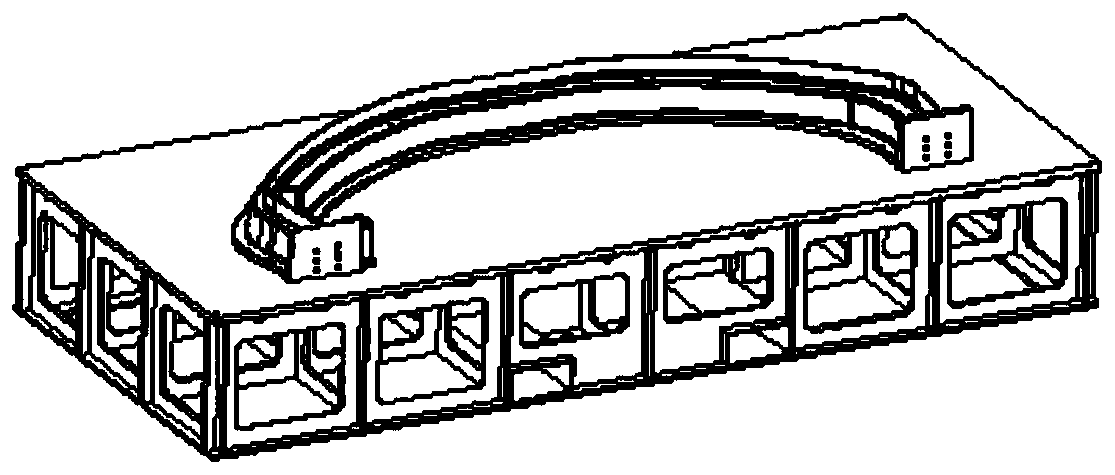

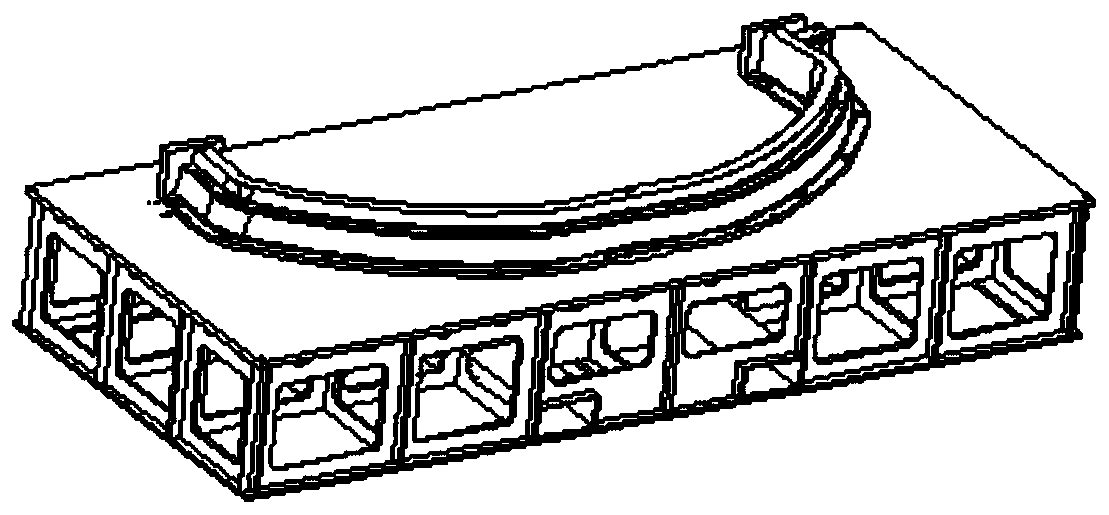

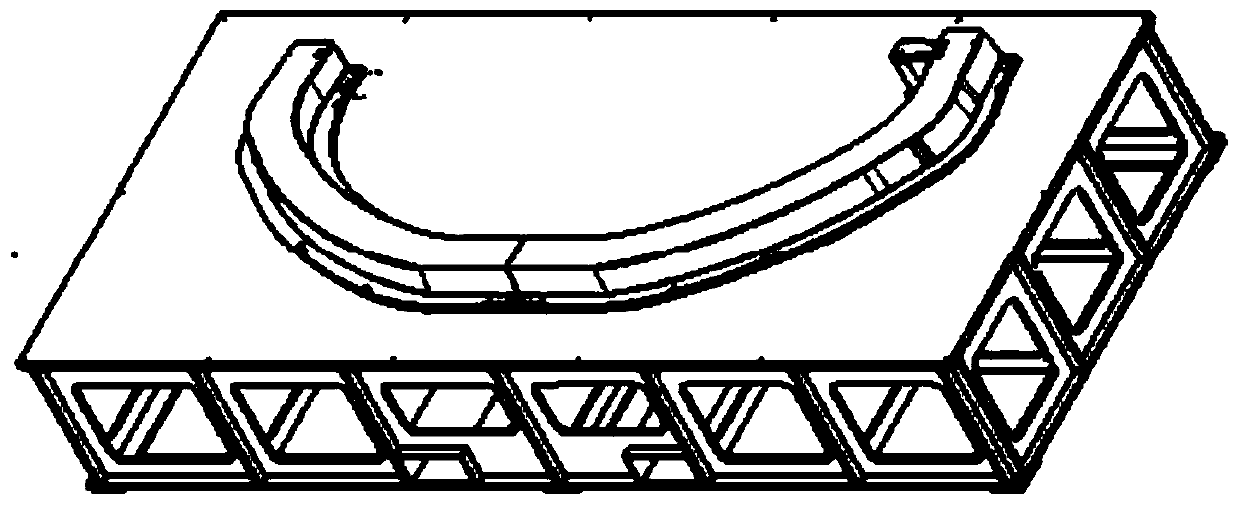

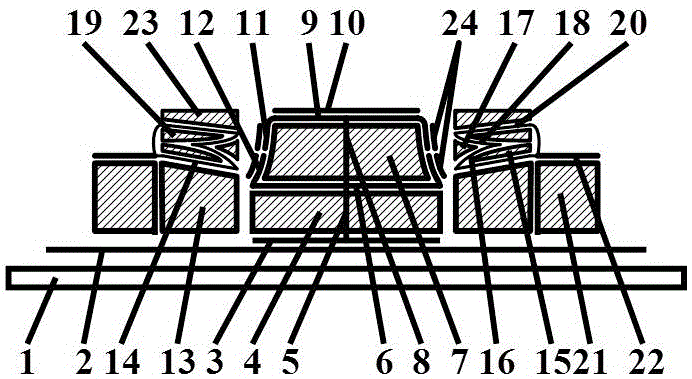

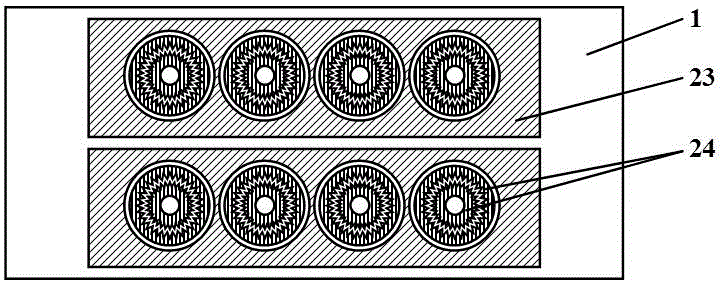

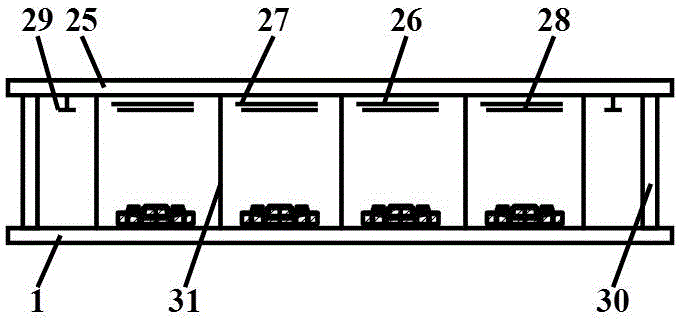

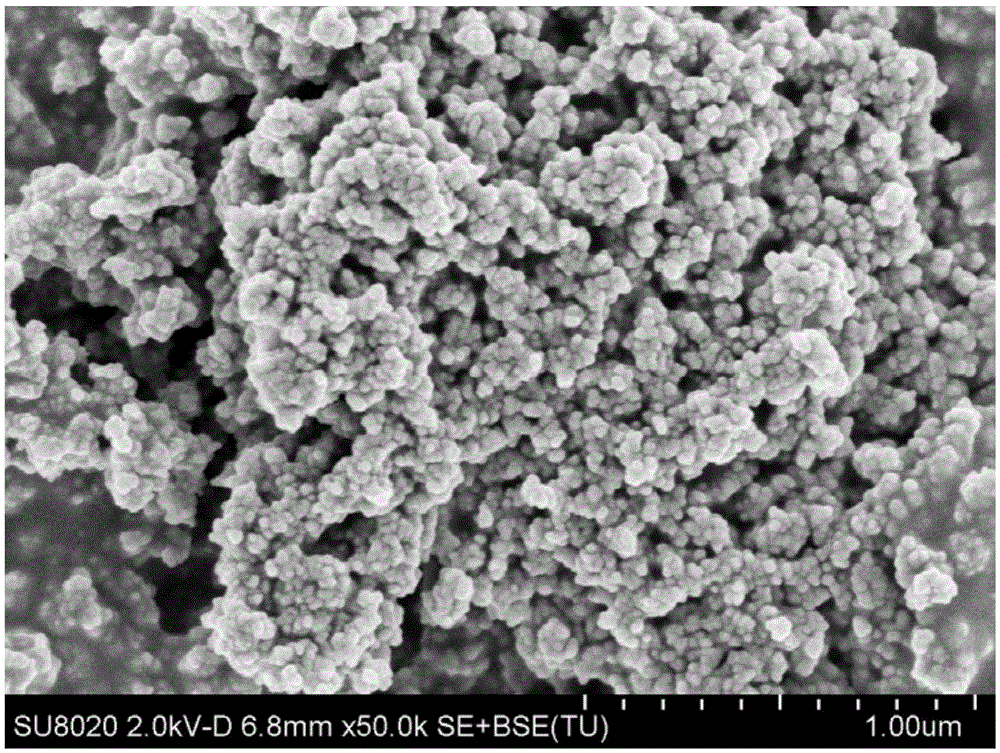

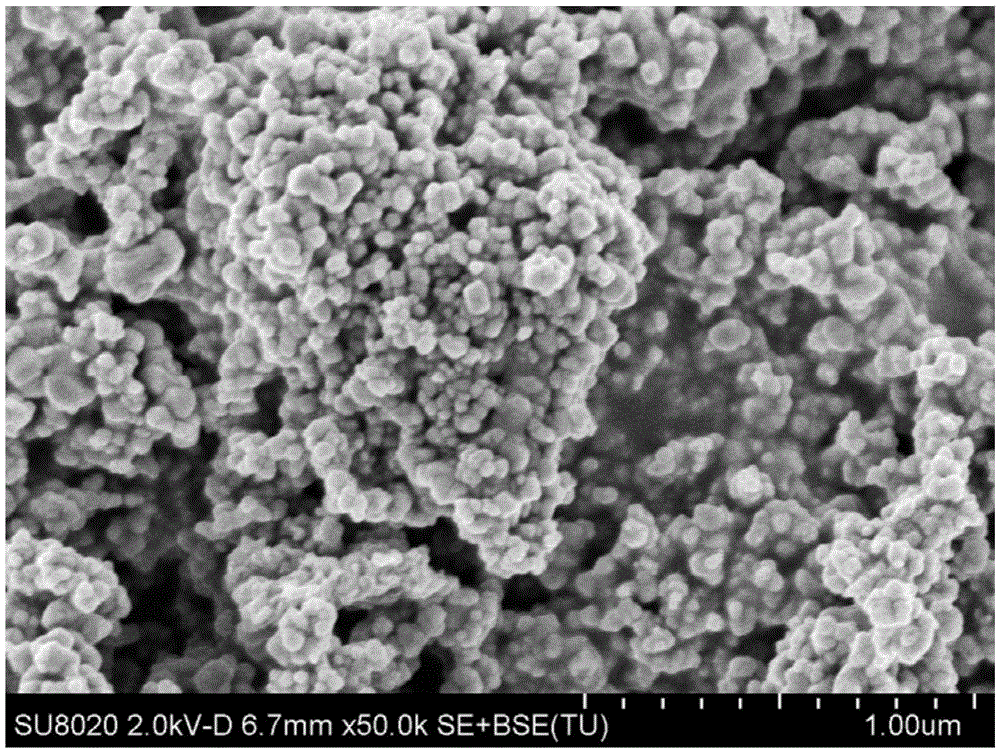

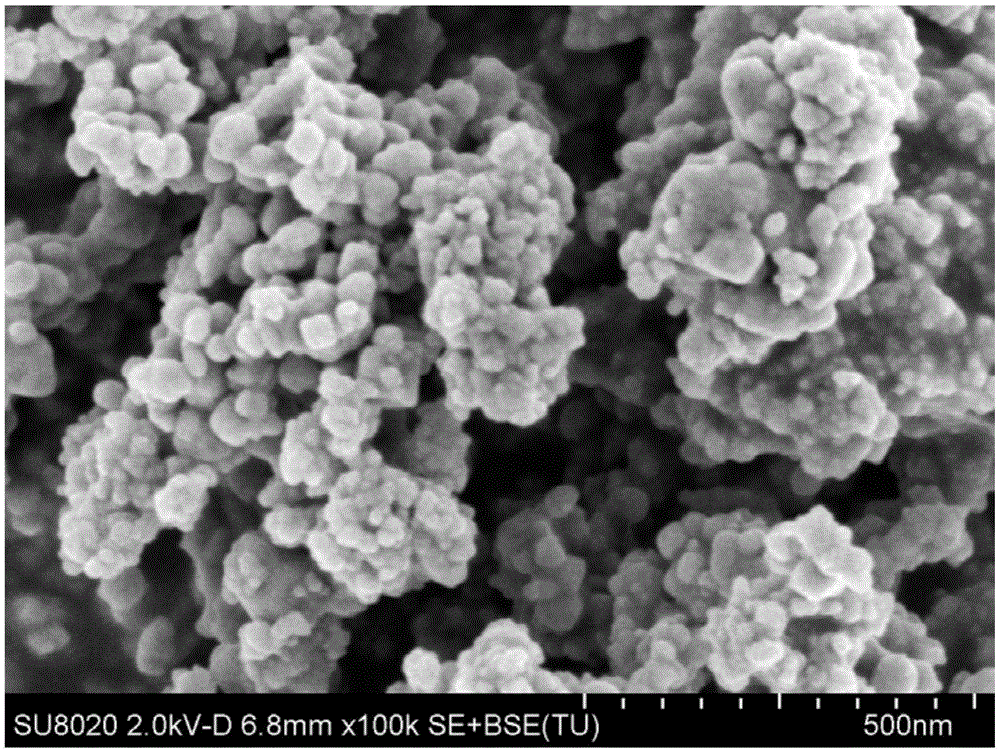

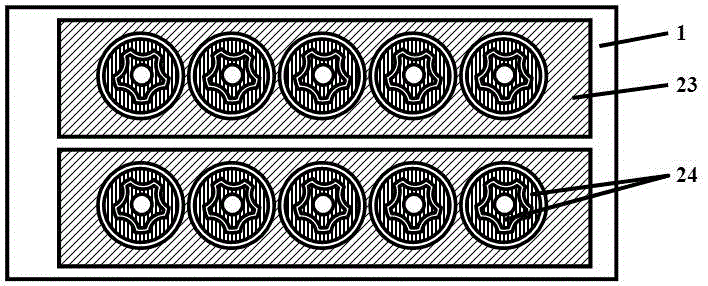

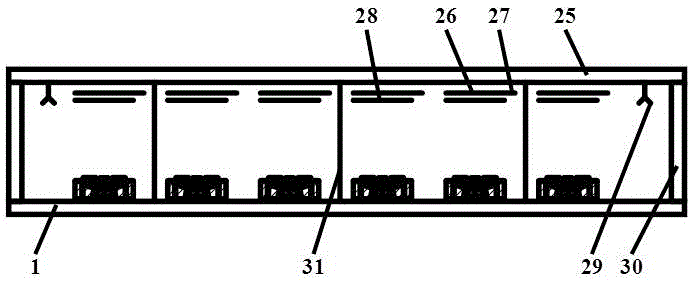

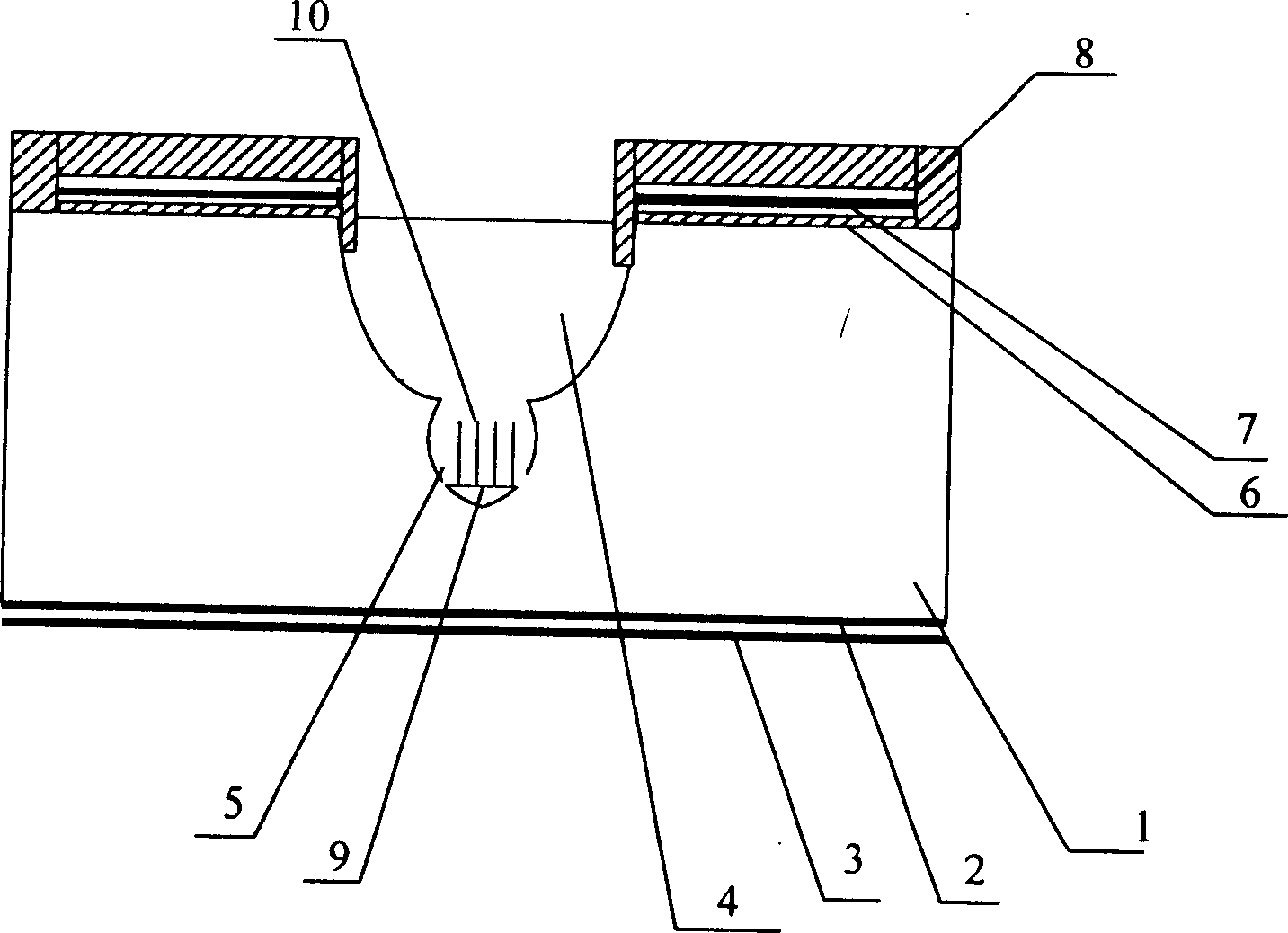

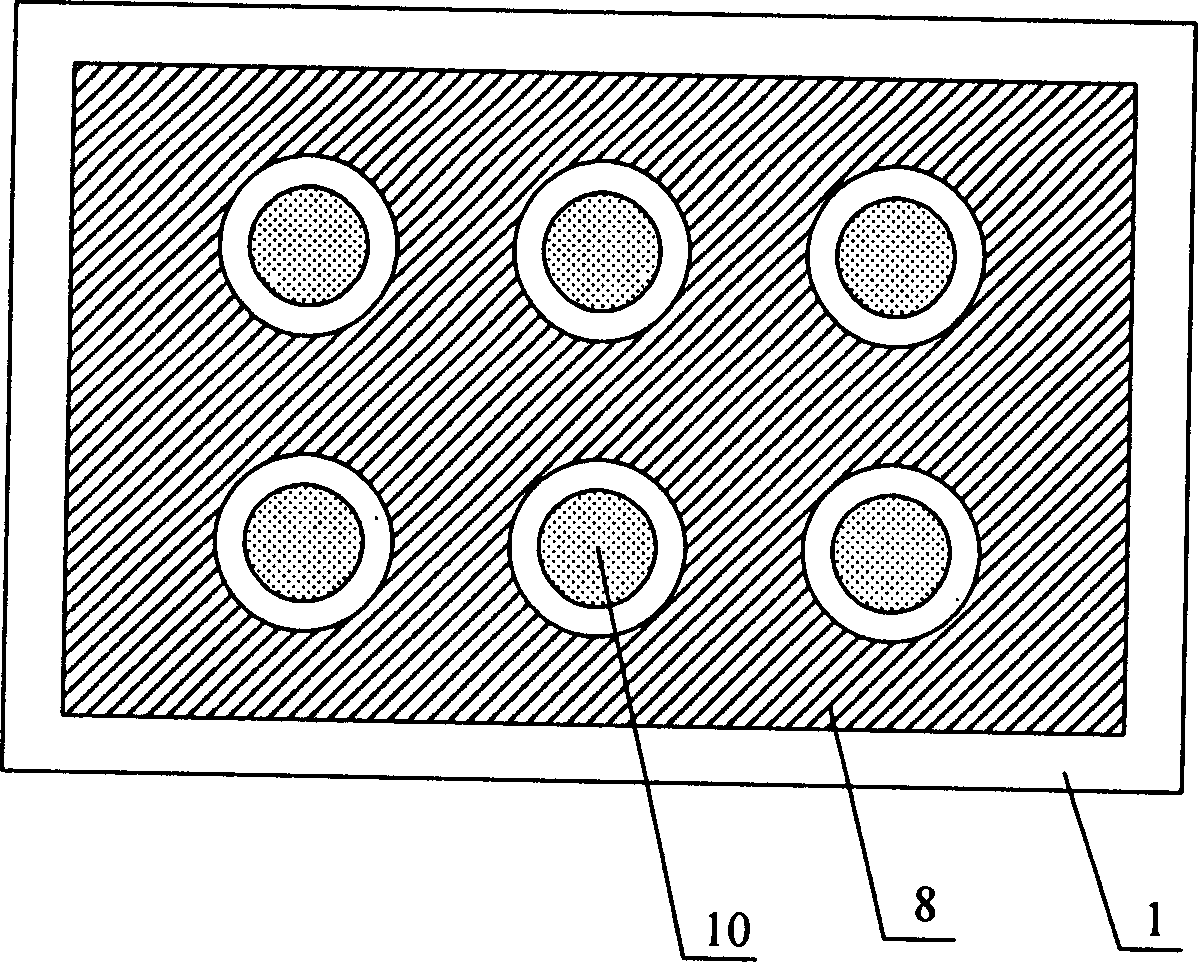

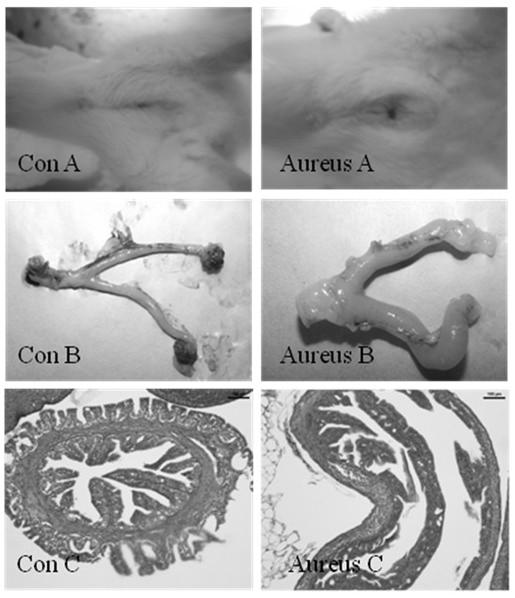

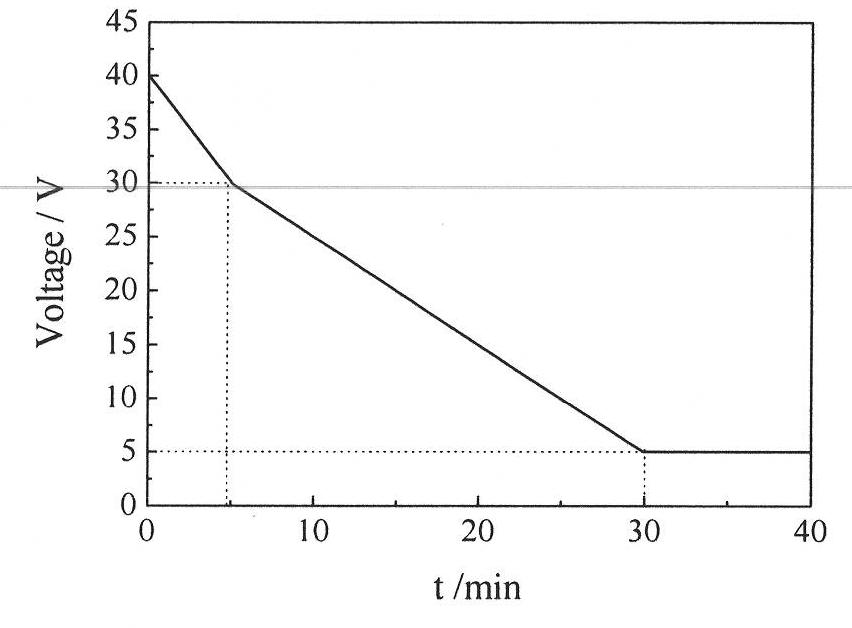

Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face

InactiveCN105032406AExpand the scope of absorptionInhibitory complexWater/sewage treatment by irradiationEnergy based wastewater treatmentWastewaterPhotocatalytic degradation

The invention discloses a preparation method and an application for palladium-modified titanium dioxide with a three-dimensional flower-like structure exposure [001] crystal face. The preparation method is characterized by comprising: a step I, preparing titanium dioxide with a three-dimensional flower-like structure exposure [001] crystal face; and a step II, preparing palladium-modified titanium dioxide with a three-dimensional flower-like structure exposure [001] crystal face. According to the preparation method and the application for the palladium-modified titanium dioxide with the three-dimensional flower-like structure exposure [001] crystal face provided by the invention, the method is simple and easy to implement; conditions are gentle; operation is simple; the preparation period is short; the preparation success rate is high; photocatalytic activity under a visible light condition is high; raw materials are economical and available; and the palladium-modified titanium dioxide can realize mass production, is easy to recycle and reuse, and can be applied to photocatalytic degradation on wastewater pollutants.

Owner:HOHAI UNIV

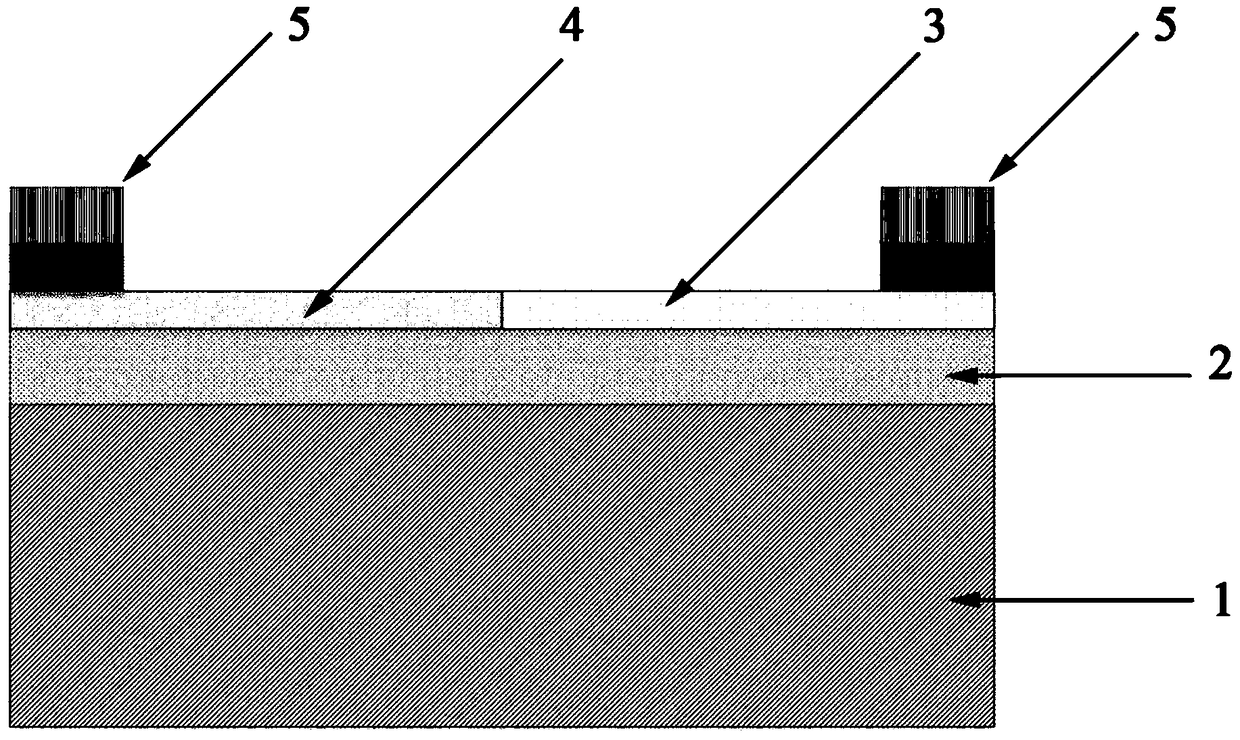

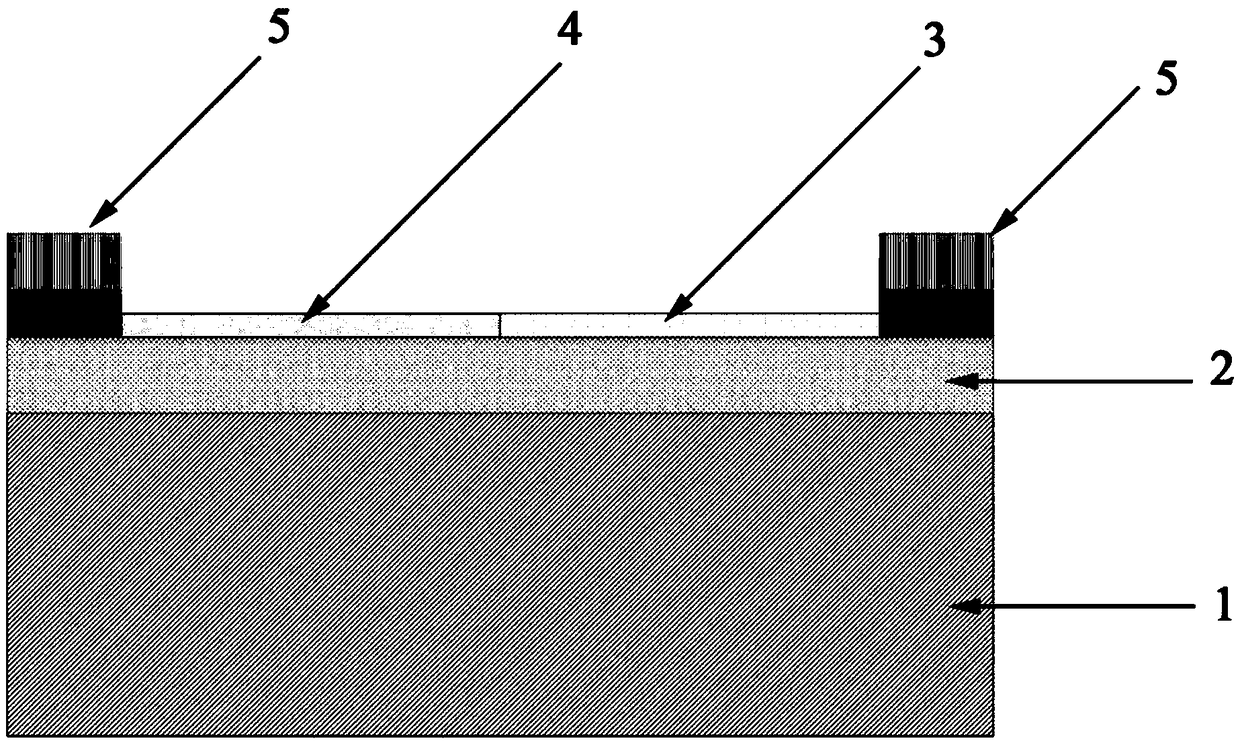

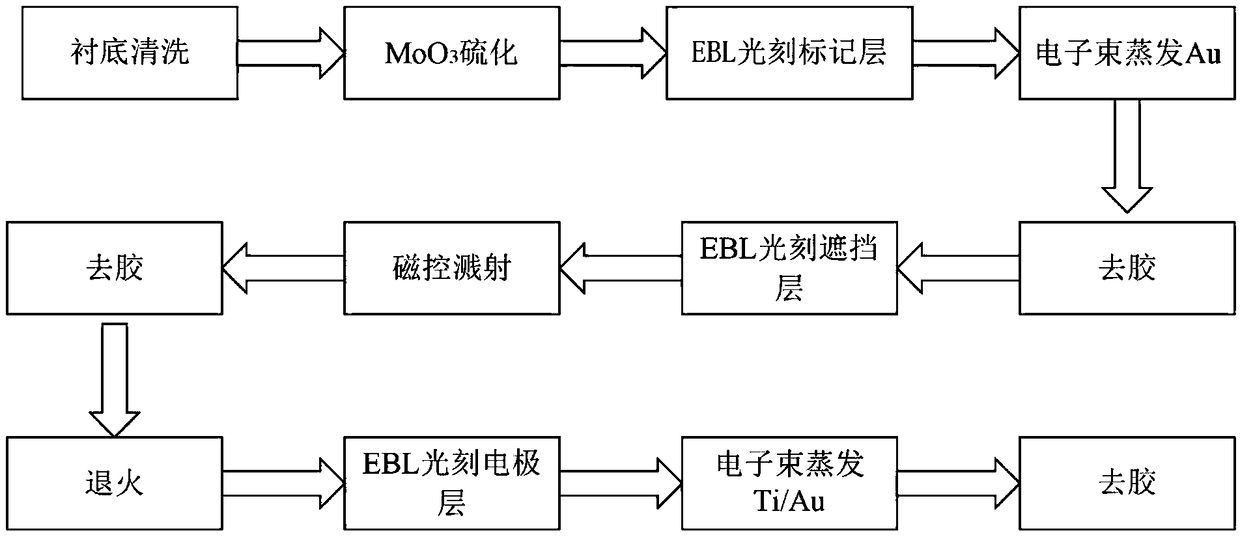

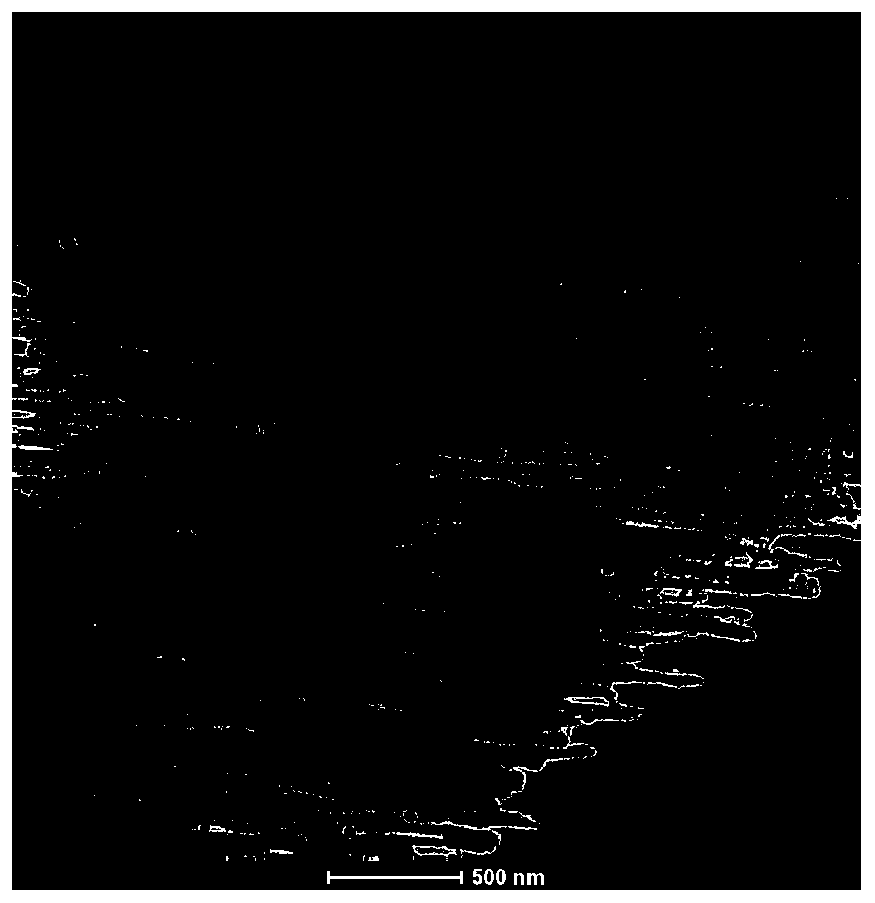

Nanometer layered horizontal homogeneous PN diode and fabrication method and application thereof

InactiveCN108666375AClose contactReduce contact resistanceFinal product manufactureNanotechnologyPhotovoltaic detectorsOxygen plasma

The invention discloses a nanometer layered horizontal homogeneous PN diode and fabrication method and application thereof. A p-type transition metal chalcogenide film and an n-type transition metal chalcogenide film both are arranged on an upper surface of a dielectric layer and are transversely connected, an electrode layer is longitudinally connected or transversely connected with the p-type transition metal chalcogenide film and the n-type transition metal chalcogenide film, and the p-type transition metal chalcogenide film and the n-type transition metal chalcogenide film comprises the same transition metal chalcogenide. The fabrication method is simple, high-efficiency and low-damage p-type doping of the transition metal chalcogenide is achieved through oxygen plasma by magnetron sputtering, effective and controllable doping is achieved, and the obtained diode is used for a photoelectric detector and has more rapid optical response and higher detection rate.

Owner:HUAZHONG UNIV OF SCI & TECH

High-performance copper alloy prepared by casting method

The invention relates to a high-performance copper alloy prepared by a casting method, and belongs to the field of copper alloys. The copper alloy comprises Cu, Cr, Zr and M, wherein the mass percentof the Cr is 0.1-5.0%, and the mass percent of the Zr is 0.1-5.0%; the M is composed of RE and at least two of Mg, Ag, B, Ga, Si, Li, Ti, Fe and Mn; the RE is selected from at least three of Ce, La, Yb, Pr, Nd and Sm; and the mass ratio of the M in the high-performance copper alloy is 0.05-0.5%. The high-performance copper alloy is subjected to casting to obtain an as-cast alloy ingot, and the as-cast alloy ingot is subjected to heat treatment and deformation treatment to obtain a finished product with excellent mechanical properties and electrical conductivity.

Owner:CENT SOUTH UNIV

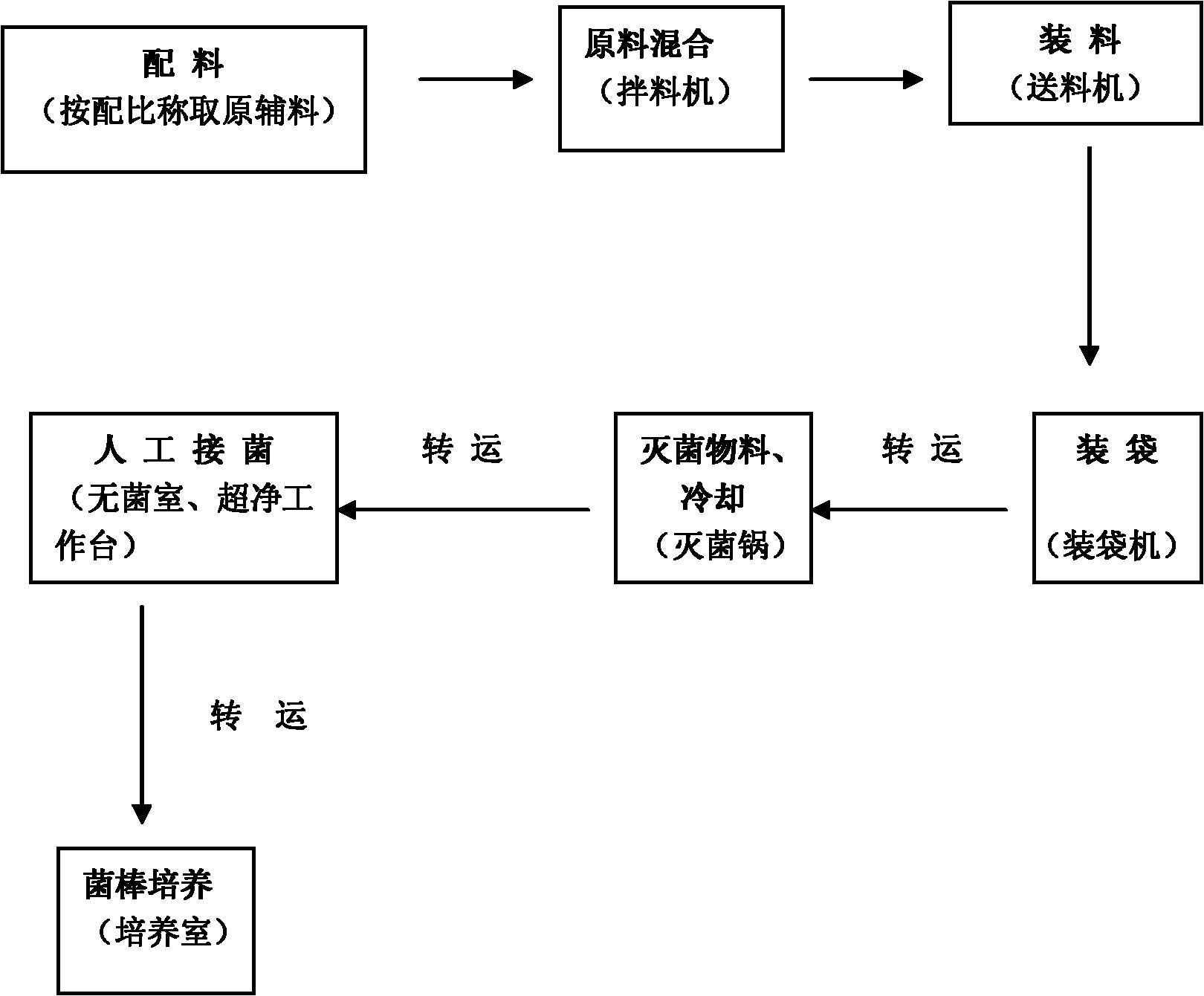

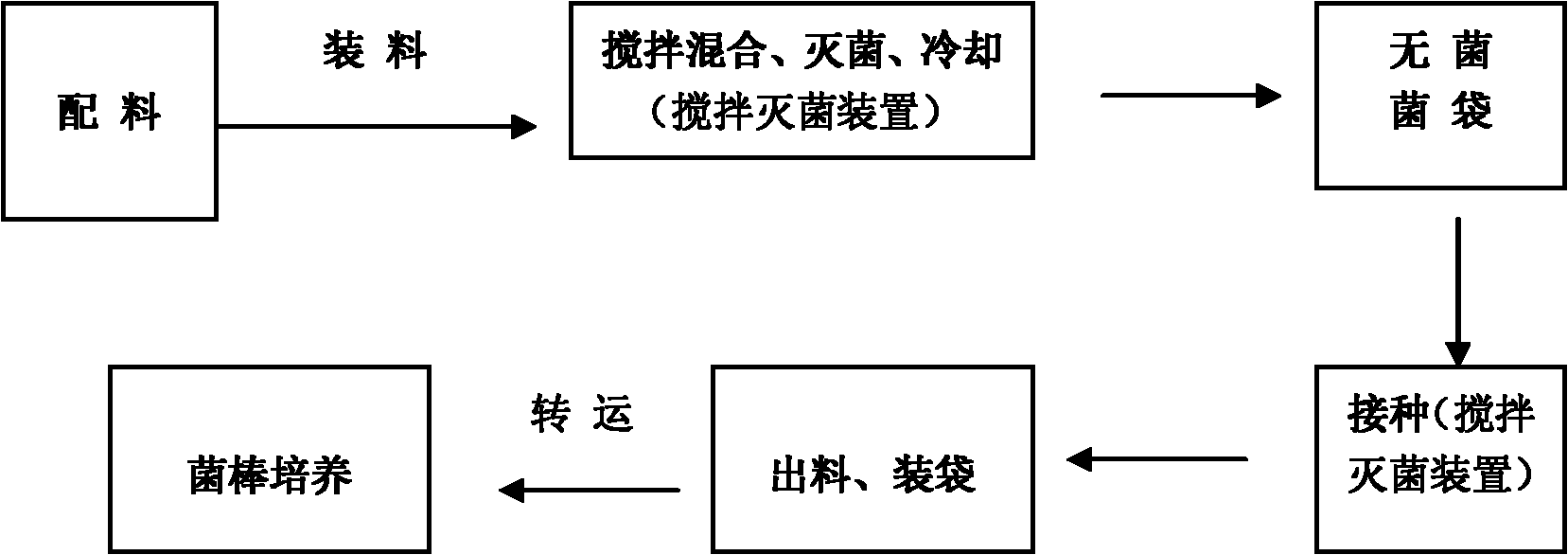

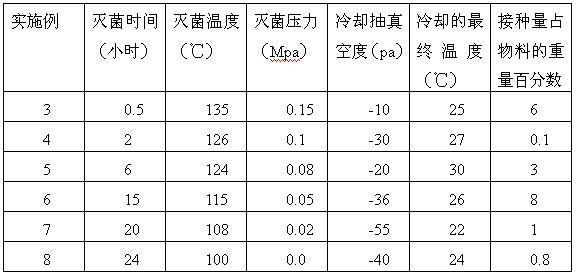

Microorganism production process

The invention relates to a production process of edible fungus sticks, and the production process comprises the following steps: mixing and stirring materials, sterilizing, cooling, inoculating and bagging, wherein the sterilizing, cooling, inoculating and bagging steps are sequentially carried out after materials are mixed and stirred; the steps of mixing and stirring materials, sterilizing, cooling and inoculating are carried out in the same stirring and sterilizing device; and the sterilization processing is carried out on the fungus bags for bagging before the bagging step. In the process provided by the invention, the manpower, equipment, facilities, power and pollution changes in the transportation course of the materials are greatly reduced; the manufacturing success rate of the fungus sticks is high; the manpower labor intensity is greatly reduced at the same time; and the production cycle of the edible fungus sticks can be effectively shortened. In general, the production process of the edible fungus sticks provided by the invention has the advantages of easy operation, high production efficiency and high manufacturing success rate of the fungus stick, has good application prospects and is difficult to pollute.

Owner:重庆良酩科技发展有限公司

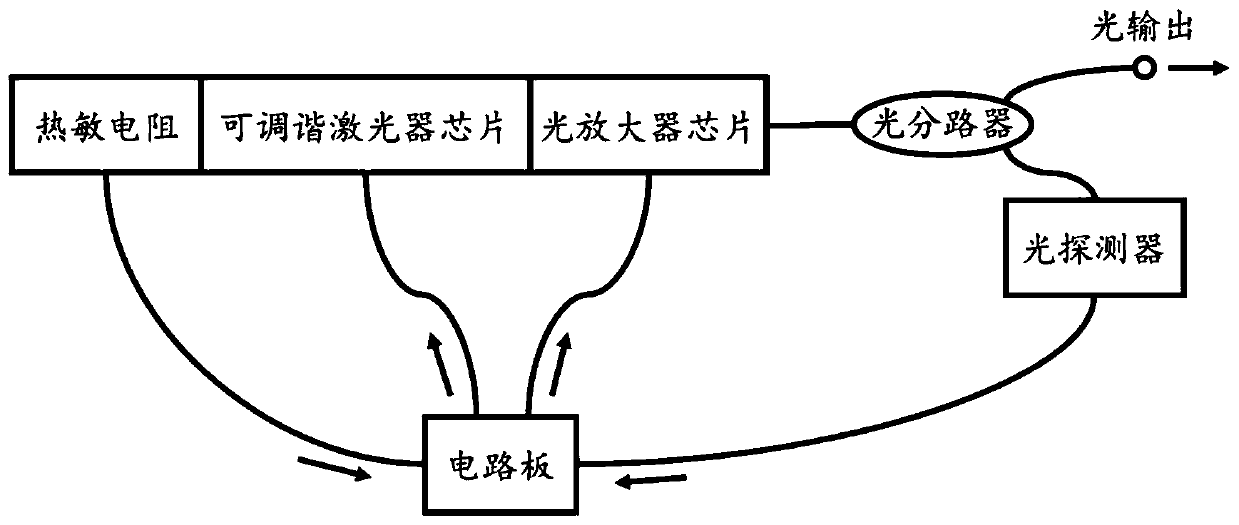

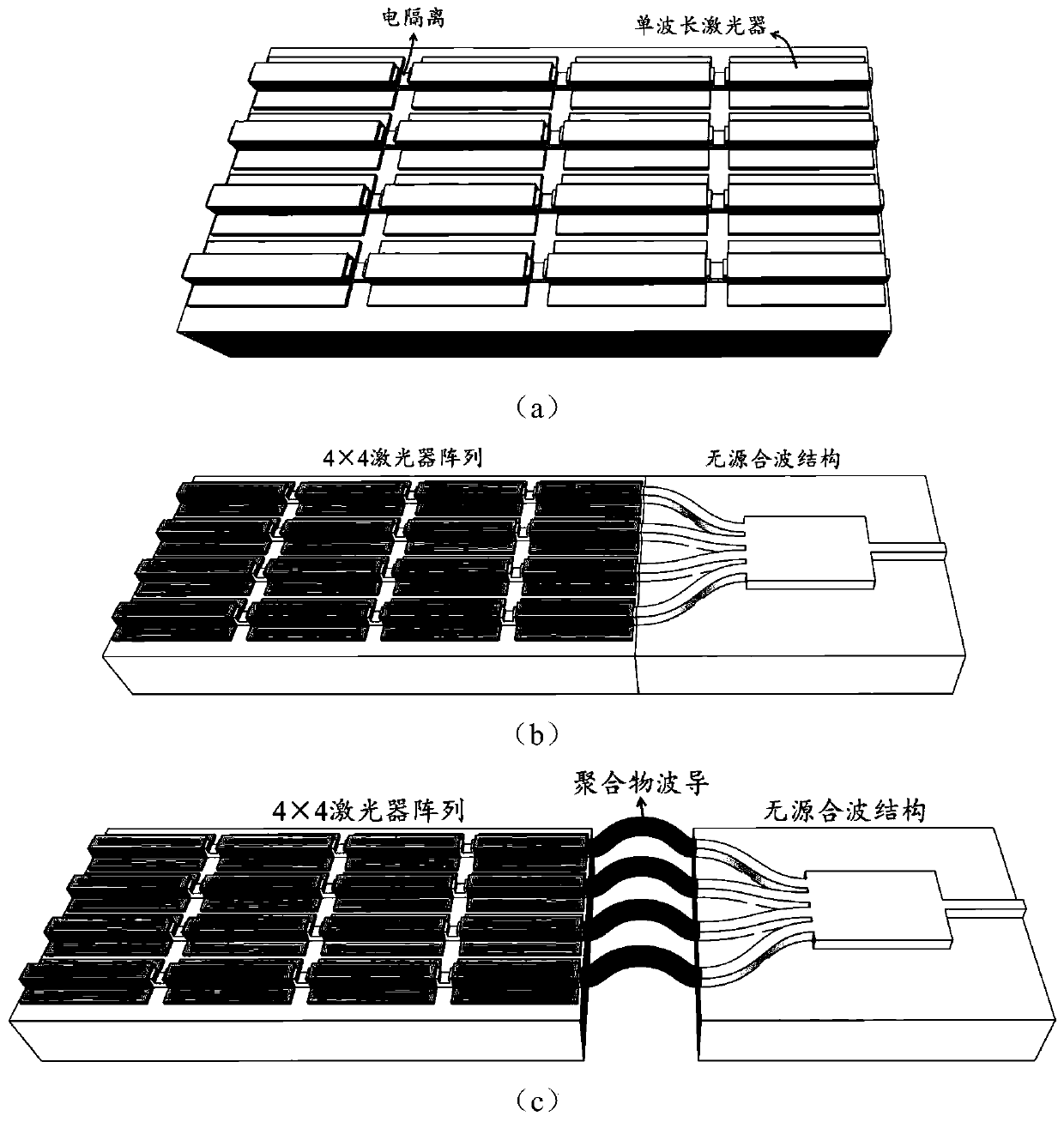

Refrigeration-free tunable semiconductor laser based on multi-wavelength array and preparation method

InactiveCN111490457ASmall overall structureSimple preparation processOptical wave guidanceLaser optical resonator constructionTunable laserOptical detectors

The invention discloses a refrigeration-free tunable semiconductor laser based on a multi-wavelength array. The refrigeration-free tunable semiconductor laser comprises a thermistor, a tunable laser array, a wave combining structure, an optical amplifier, an optical branching device, an optical detector and a main controller. According to the invention, when the laser is influenced by the externalenvironment temperature, the influence value caused by the external environment temperature is calculated, and the driving currents of the tunable laser array and the optical amplifier are respectively regulated and controlled according to the calculation result such that the purpose that the final output light is consistent with a theoretical light parameter is achieved. As no refrigeration equipment is adopted, the overall structure of the laser is greatly reduced, the preparation process is further simplified, and even a sealed packaging structure is not adopted such that the cost of a laser device is greatly reduced.

Owner:南京华飞光电科技有限公司

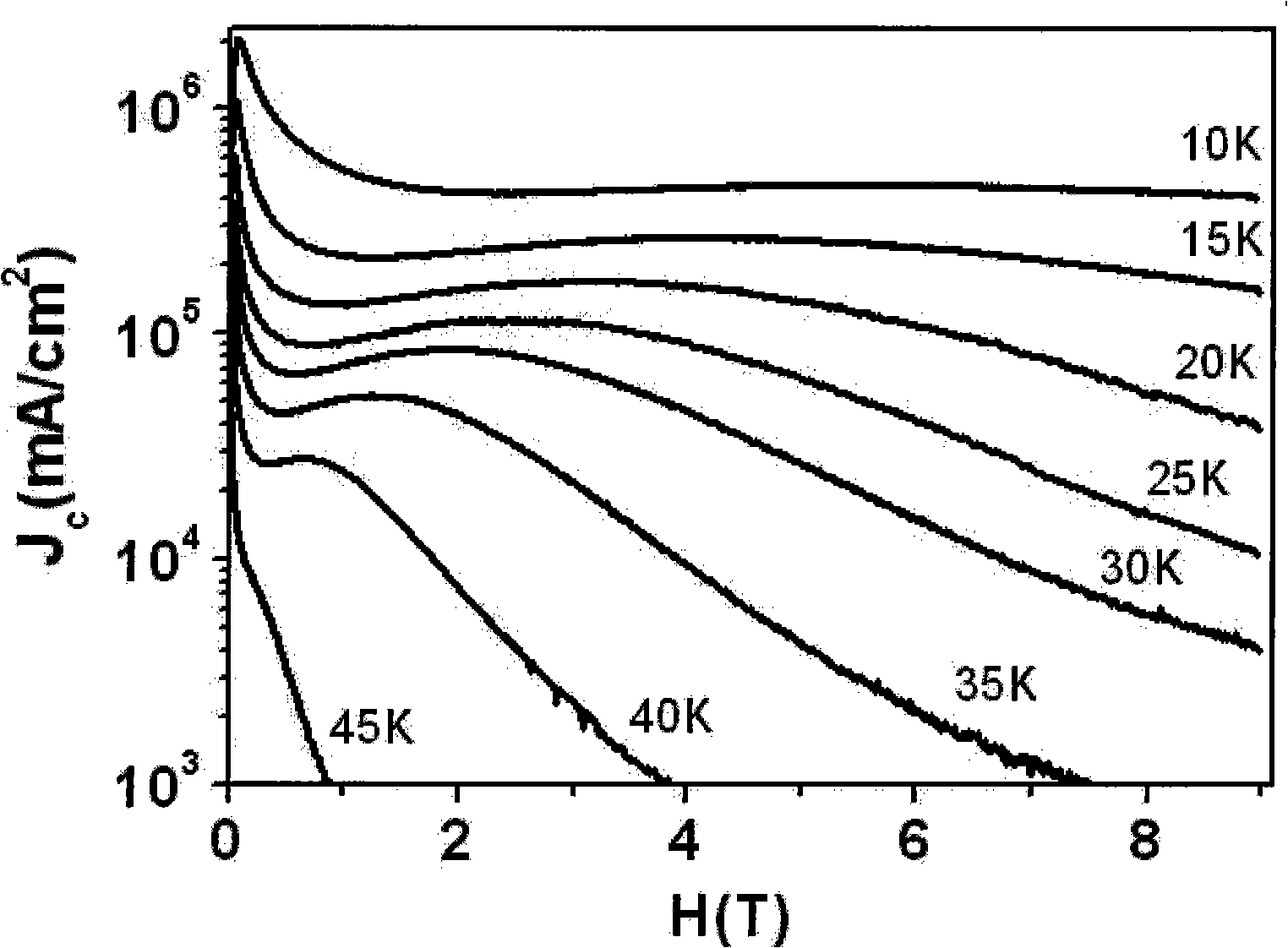

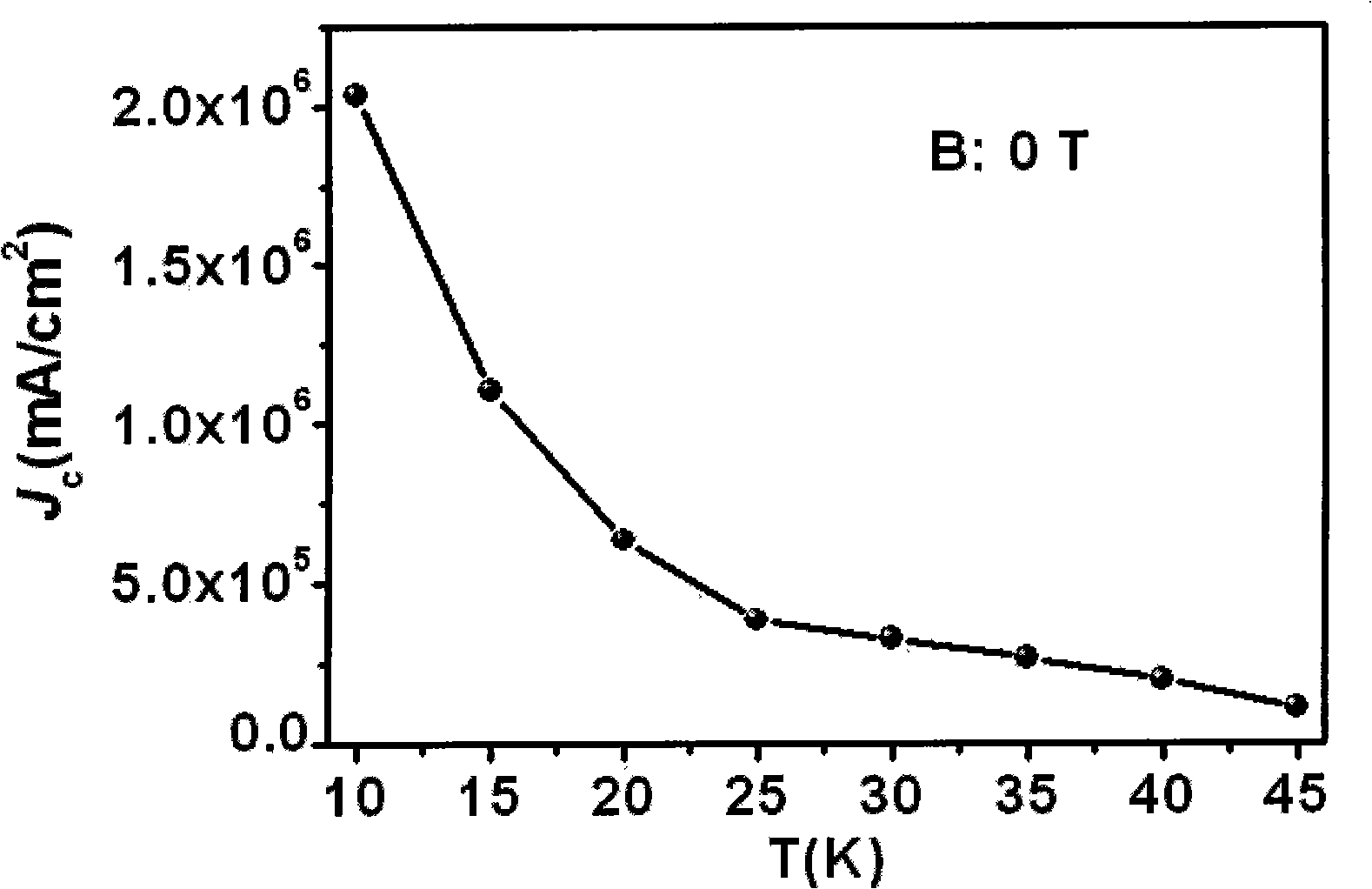

Preparation method iron based SmFeAsO1-xFx superconducting wire

InactiveCN101345103AEvenly distributedIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesCritical magnetic fieldSuperconducting transition temperature

The invention provides a preparation method of an iron-based SmFeAsO<1-x>Fx superconducting wire, comprising the steps as follows: a: material preparation: the material is prepared according to the stoichiometry of the iron-based superconducting material SmFeAsO<1-x>Fx (wherein, x is not more than 0.35 and not less than 0.15, the raw materials such as SmAs, Fe, Fe2O3 and FeF3 are weighed, grinded, uniformly mixed, arranged into a Tantalum pipe, fully fixed and compacted; the two ends of the Tantalum pipe are sealed; b: wire preparation: the Tantalum pipe is sheathed into a copper pipe and rotatablely forged; subsequently, the wire with the diameter of 1.8-2.2mm is formed by pulling and drawing; c: burning: the wire is arranged in a quartz pipe and sealed in vacuum and then put into a sintering furnace; under the protection of inert gas, the temperature of the wire is increased to 1150-1170 DEG C at the speed of 100-150 DEG C / hour, the temperature is kept for 36-50 hours and the wire is cooled with the furnace. The method of the invention has the advantages of simple technology and facilitating industrial production, and the compactness, high purification, stable superconducting performance, high superconducting conversion temperature and high critical magnetic field of the prepared iron-based SmFeAsO<1-x>Fx superconducting wire.

Owner:SOUTHWEST JIAOTONG UNIV

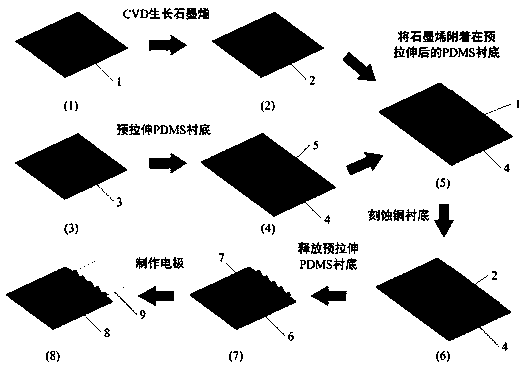

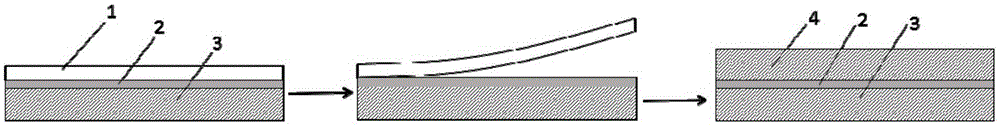

Prestretching-based graphene flexible strain sensor and preparation method thereof

ActiveCN109520411AImprove stabilityGood repeatabilityElectrical/magnetic solid deformation measurementAdhesiveRepeatability

The invention discloses a prestretching-based graphene flexible strain sensor and a preparation method thereof. The prestretching-based graphene flexible strain sensor comprises a released substrate;a graphene sensitive layer is arranged on the released substrate; conductive silver adhesives are arranged at the joints of the two ends of the graphene sensitive layer and the released substrate, andelectrodes are arranged on the upper surfaces of the conductive silver adhesives. The preparation method of the prestretching-based graphene flexible strain sensor comprises the following steps: prestretching a substrate before transferring a graphene film, and completing the transferring of the graphene film through a dry transfer method, thereby preparing the graphene flexible strain sensor based on prestretching. Larger strain measurement is achieved by the sensor provided in the invention through pre-stretching, and good stability and repeatability are achieved; the manufacturing successrate is increased through a dry transfer method, the preparation method is simplified, and large-scale manufacturing is achieved.

Owner:XIDIAN UNIV

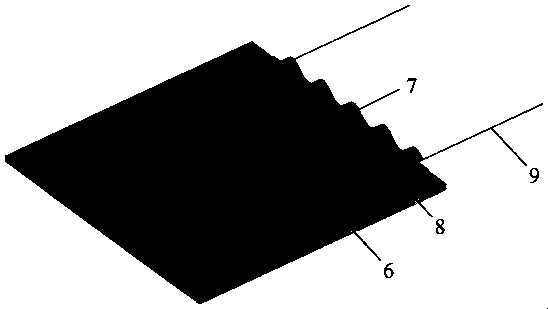

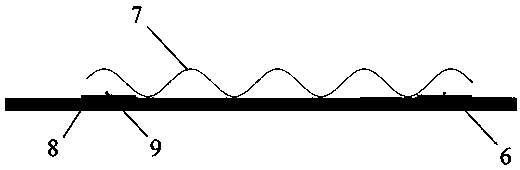

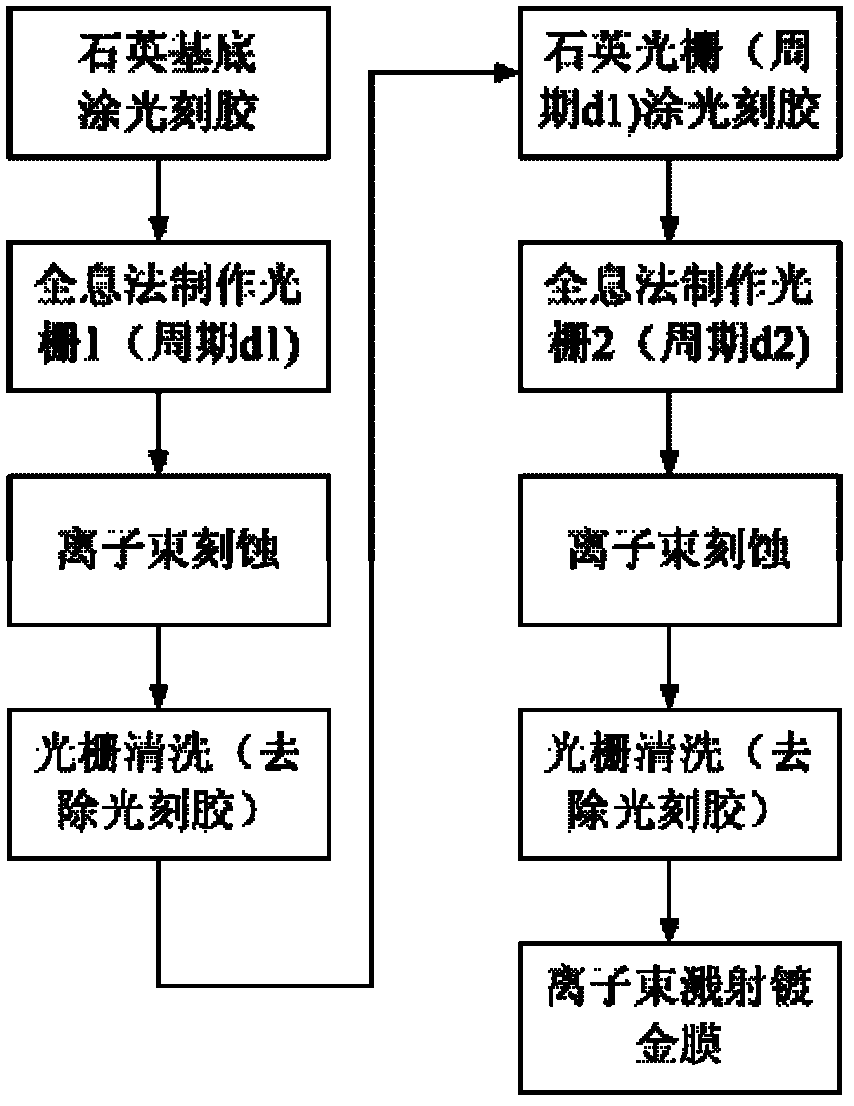

Soft X-ray double-frequency gratings and manufacture method thereof

InactiveCN102540298AFix not workingIt has the performance of resisting short-wave radiationHandling using diffraction/refraction/reflectionPhotomechanical apparatusSoft x rayGrating

The invention provides double-frequency gratings capable of working on a soft X-ray wave band and a manufacture method thereof, which belong to the technical field of grating manufacture. Rectangular-groove gratings with two different frequencies are manufactured on the same substrate to form a double-frequency grating structure. The manufacture method of the structure adopts holographic exposure-ion-beametching technology for two times, and manufactures two groups of double-frequency gratings with similar frequencies. By means of the double-frequency grating structure and the manufacture method of the double-frequency grating structure, groove-shaped structures of each group of gratings can be accurately controlled so that the requirements of the soft X-ray wave band for accuracy of the grating groove shapes are met. The gratings can provide two light beams with a small included angle and identical light strength to perform self-shearing interference. The double-frequency grating structure and the manufacture method of the double-frequency grating structure solve the problem of manufacture of shearing elements in a soft X-ray wave band shearing interference system, and provide a key technology for utilizing a shearing method to diagnose plasma electronic density.

Owner:UNIV OF SCI & TECH OF CHINA

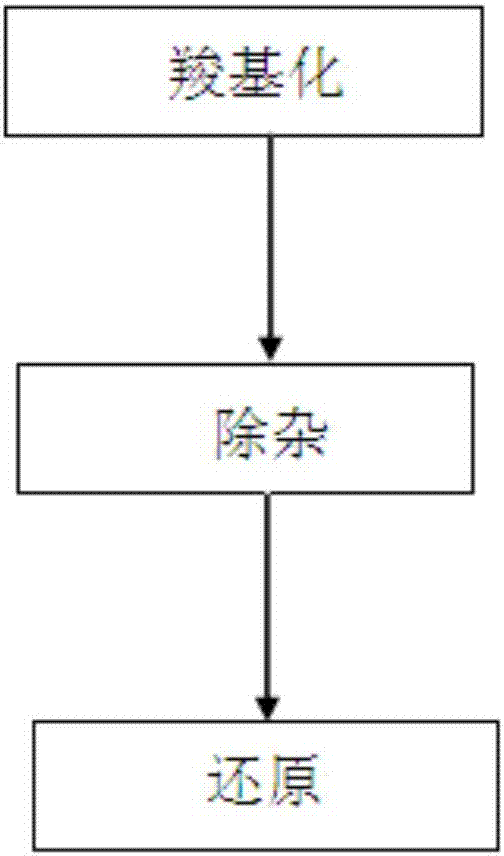

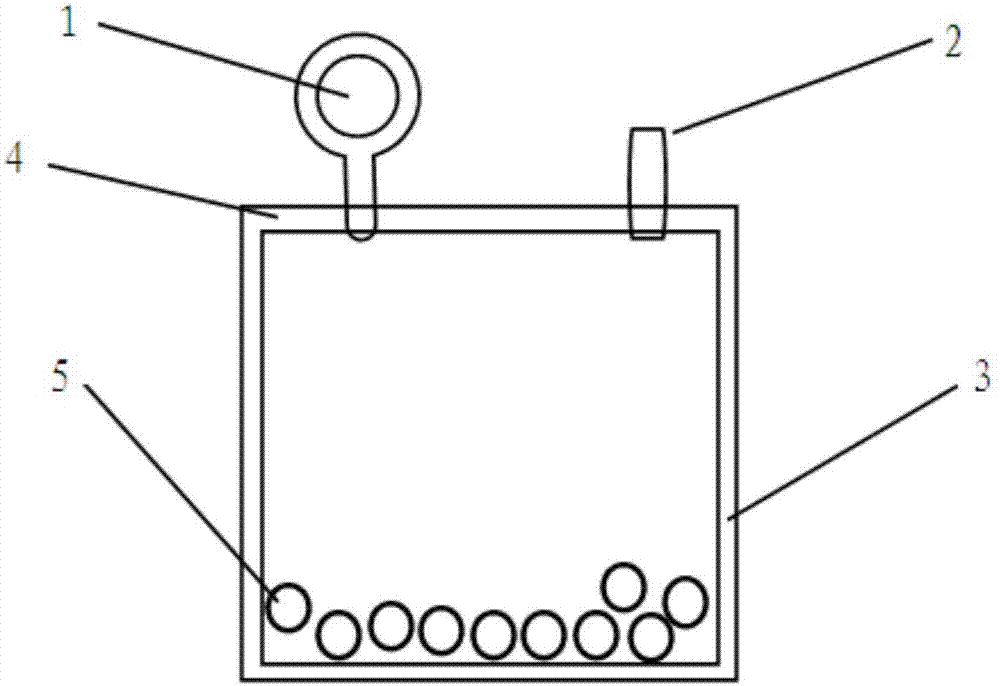

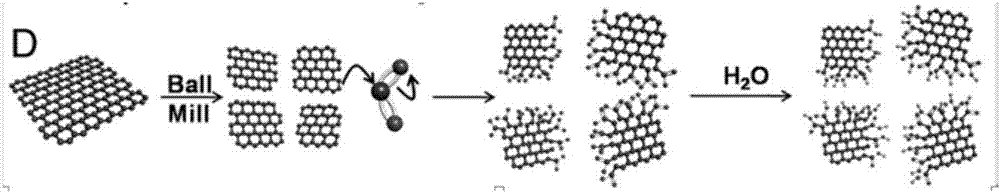

Method for preparing single-layer graphene through mechanical method

InactiveCN107089655AHigh degree of carboxylationIncrease success rateSingle layer grapheneExhaust valveSteel ball

The invention belongs to the technical field of graphene preparation and relates to a method for preparing single-layer graphene through a mechanical method. A specific technological process of the method comprises three steps of a hydroxylation process, a decontaminating process and a reduction process. The edge of natural flake graphite is processed in a carboxylation mode through a ball milling method to obtain initial carboxylation graphene powder, then pure carboxylation graphene powder with small iron content is obtained through the decontaminating process, and high-quality single-layer graphene is obtained through the thermal reduction process. The method avoids any strong oxidant and has high carboxylation degree, short ball milling time and high success rate; the decontaminating process is simple and effective; the reduction process avoids using reducing agents and is environmentally friendly; a main structure of a ball milling tank related to the hydroxylation process comprises a pressure meter, a gas exhaust valve, a tank body, a sealing cover and a stainless steel ball. The method has high preparation success rate, large yield, no pollution and low energy consumption and can achieve large-scale mechanical production through amplifying ball milling equipment.

Owner:QINGDAO UNIV

InGaN/GaN multi-quantum-well single-nano-pole LED device and manufacturing method thereof

The invention discloses an InGaN / GaN multi-quantum-well single-nano-pole LED device. The distance between an n-type GaN layer and a p-type GaN layer at the two ends of an InGaN / GaN multi-quantum-well nano-pole and the corresponding portions of a metal electrode film is smaller than or equal to 100 nm or the n-type GaN layer and the p-type GaN layer at the two ends of the InGaN / GaN multi-quantum-well nano-pole are in direct contact with the metal electrode film, a middle InxGa1-x / GaN quantum well active layer is isolated from the metal electrode film, and metal electrodes are secondarily deposited at the portions where the two ends of the InGaN / GaN multi-quantum-well nano-pole are in contact with the metal electrode film through a focused ion beam system to form ohmic contact. A method of the InGaN / GaN multi-quantum-well single-nano-pole LED device is mainly characterized in that ohmic contact of the nano-pole is formed through ultraviolet photoetching and focusing ion beam secondary depositing. By means of the method, the alignment accuracy between the electrodes and the nano-pole can be remarkably improved, the preparing success rate can be remarkably increased, multiple InGaN / GaN quantum wells are not damaged while the electrodes are prepared, good metal semiconductor contact is achieved accordingly, the electric injection current density is improved, and therefore luminance is improved. The method is suitable for preparing a single-nano-pole InGaN / GaN light emitting diode, and is particularly suitable for nanometer devices with the sizes smaller than the limitation of ultraviolet photoetching.

Owner:NANJING UNIV

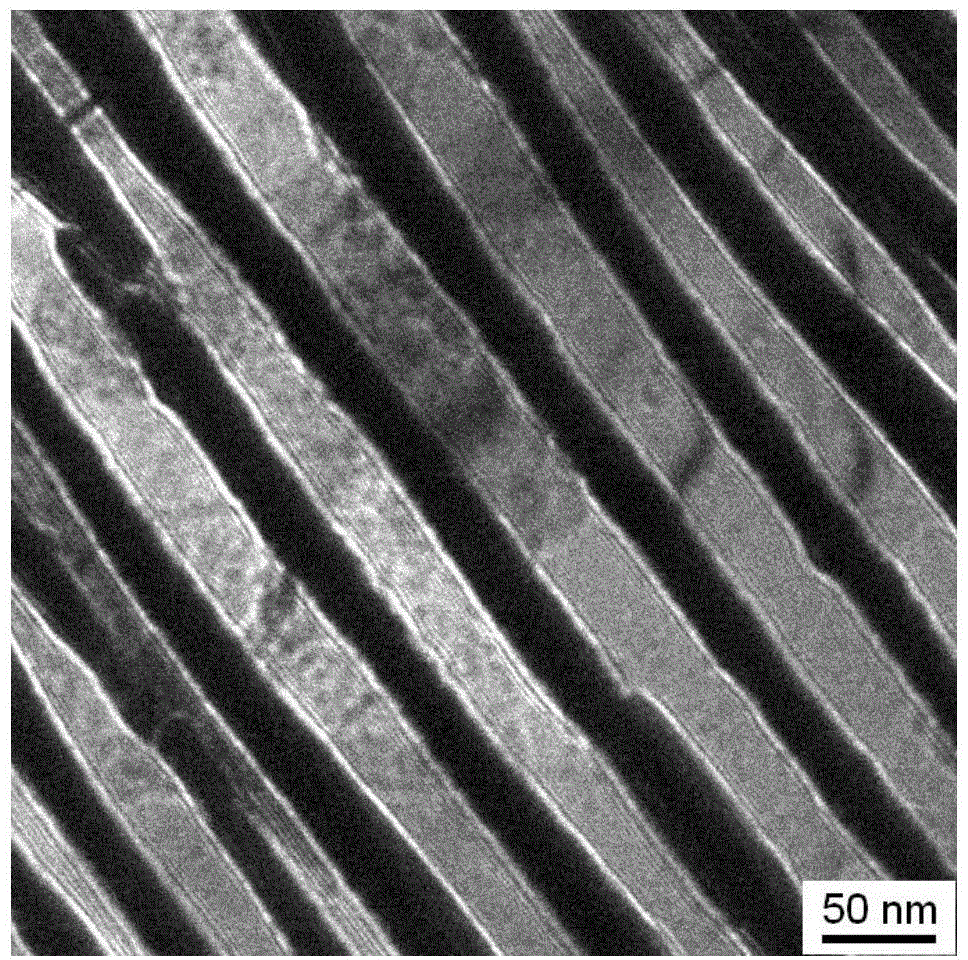

Preparation method of thin steel wire longitudinal sectional electronic microscopic sample

ActiveCN104792595ASolve hard-to-prepare puzzlesIncrease surface areaPreparing sample for investigationMetallurgyElectron microscope

The invention relates to a preparation method of a thin steel wire longitudinal sectional electronic microscopic sample. The method comprises the following processing steps: (1) cutting the sample into an initial sample with the length of 5-10 mm; (2) injecting curing glue into a mold, laying the initial sample horizontally at the bottom of the mold, and heating to enable the initial sample to be cured; (3) separating the cured sample from the mold, grinding the sample till the sample is 1 / 2 of the diameter of the steel wire, grinding the sample when the sample is turned until the thickness is 85-100 microns, using a puncher to punch a disc with the diameter of 3 mm, and ensuring that only one thin steel wire is positioned in the center of the disc; (4) uniformly coating the curing glue position of the disc surface with black grease, and utilizing a twin-jet to thin the disc, so as to obtain the sample suitable for observation under the transmission electron microscope. The preparation method can be used for the thin steel wire with the diameter from 0.1 mm to 3 mm, particularly for the thin steel wire with the diameter less than 1 mm, is simple in process, low in cost, high in operability and high in success rate of sample preparation, and successfully solves the problem that the thin steel wire longitudinal sectional electronic microscopic sample is difficult to prepare.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for preparing saturable absorber device based on black phosphorus

The invention discloses a method for preparing a saturable absorber device based on black phosphorus. According to the method, two-dimensional layered black phosphorus, which is obtained through a mechanical stripping method or which is distributed in alcoholic solution and obtained through ultrasonic concussion, is deposited on a fiber head through a directional transfer method to be used as the saturable absorbing layer of the device. The directional transfer method may effectively and high-efficiently transfer the black phosphorus to the fiber head, prevents damage to material in a manual transferring process, may accurately locate nanoscale material, prevents blind transfer, and improves a success rate of saturable absorber preparation. The black phosphorus saturable absorber prepared through the method provided by the invention employs a transmission mode, may achieve ultrashort pulse output of lasers in near-infrared and mid-infrared wavebands, has characteristics of good performance and compatibility, and is suitable for Q regulation and mode locking of lasers and optical signal processing.

Owner:南京科耐激光技术有限公司

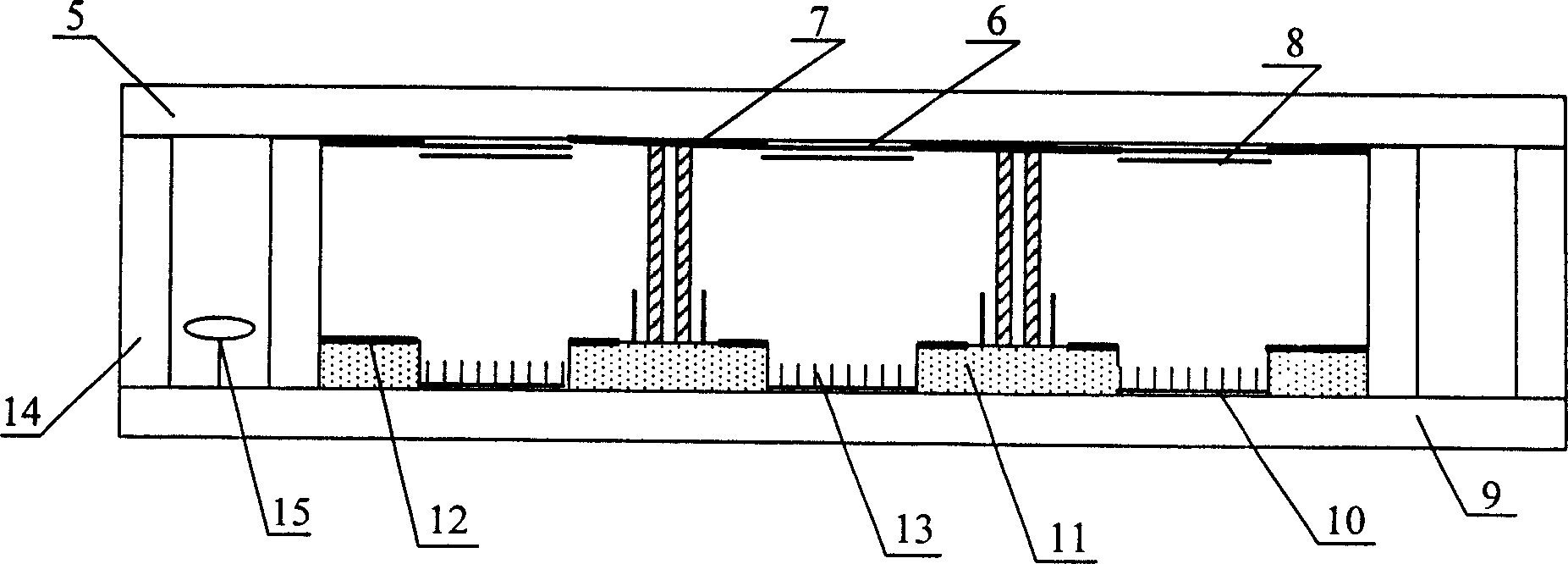

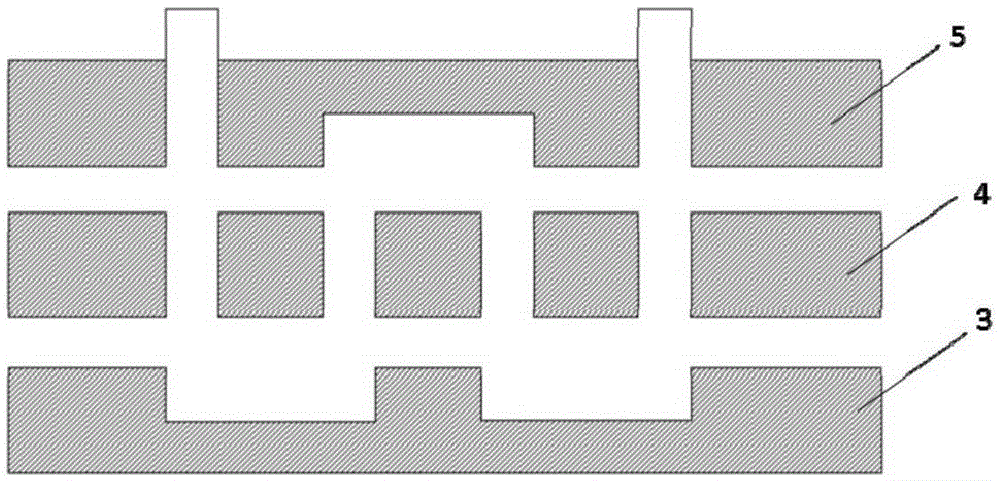

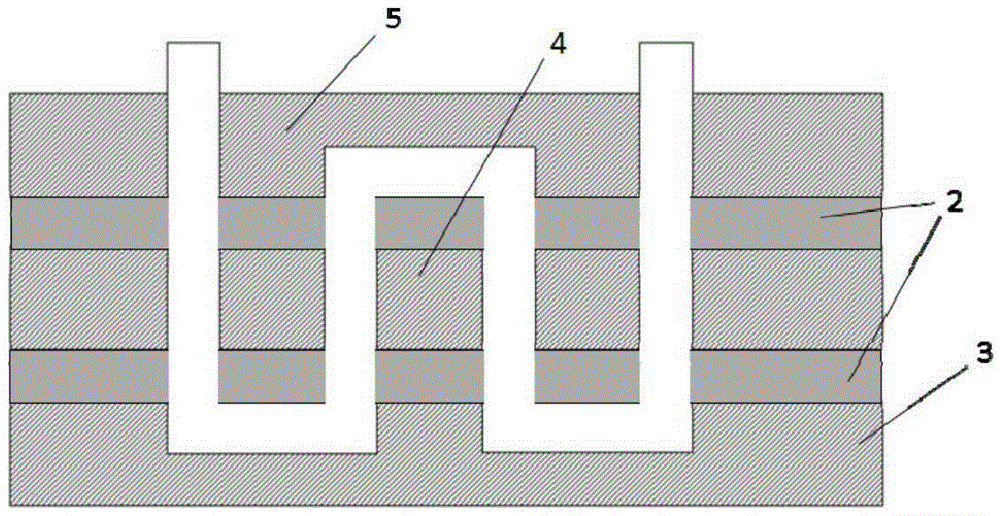

Three-pole carbon nano tube field emission flat display with ballast resistor structure and fabrication process thereof

InactiveCN1622272AHigh success rate of preparationSimple manufacturing processImage/pattern display tubesCold cathode manufactureBallast resistorPhosphor

The present invention relates to field emission display with carbon nanotube cathode, and is especially field emission plate display with ballast resistor structure and its manufacture. The field emission plate display includes sealed vacuum cavity comprising cathode panel, anode panel and glass frame, conductive In-Sn oxide film layer and phosphor layer on the anode panel, control grid, conductive cathode carbon nanotube layer on the cathode panel, ballast resistor layer and carbon nanotube cathode. The ballast resistor structure includes ballast resistors for the carbon nanotube cathode under each pixel to regulate the electron emitting capacity of the carbon nanotube, to raise the electron emitting homogeneity and stability of the whole cathode, to strengthen the adhesion carbon nanotube and cathode panel and to improve the quality of the displayed image. The present invention has the advantages of simple structure, low cost, etc.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Panel display with anti secondary electron emission supporting wall structure and its making process

InactiveCN1767136AHigh hardnessHigh strengthCathode-ray/electron-beam tube vessels/containersImage/pattern display tubesFluorescenceDisplay device

The invention relates to carbon nanometer tube cathode filed-emissive plane luminous display and its making craft, which comprises a sealed vacuum chamber formed by an anode glass plane, a cathode glass plane and around glass frame, wherein the anode glass plane arranges an anode conducing bar and a luminescent powder layer which is printed on the anode conducing bar; the cathode glass plane arranges an cathode conducing bar, an insulating isolate layer and a printed carbon nanometer tube cathode, a control grid bar used to control the electron ejection and a belong gettering unit; it arranges the supporting wall structure which can provide the supporting function to the glass plane and avert the secondary electron ejection of the supporting wall structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for preparing graphene nano holes

InactiveCN102502606AHigh success rate of preparationMeet the requirements of high-precision DNA sequencingCarbon compoundsNanoholeGraphite

The invention discloses a method for preparing graphene nano holes. The method comprises the following steps of: bombarding the surface of graphene by adopting high-energy convergent electron beams to obtain nano holes with large size, heating the graphene nano holes to the temperature of between 200 and 1,300 DEG C in a certain atmosphere under certain pressure, preserving the heat for 10 to 500 minutes, and thus reducing the aperture of the nano holes to be below 5 nanometers. By the method, the graphene holes of below 5 nanometers can be conveniently prepared, the preparation success rate can be greatly improved, and the preparation cost is reduced.

Owner:SOUTHEAST UNIV

Stereo micro-fluidic chip and preparation method thereof

ActiveCN105396631AReduce deformationHigh success rate of preparationLaboratory glasswaresPolymer sciencePolymer

The invention discloses a stereo micro-fluidic chip, comprising a first substrate, a second substrate, ..., and an N substrate, wherein the first to N substrates are provided with micro-fluidic channels or micro-fluidic chambers and successively and mutually connected via polymer layers, which enables the micro-fluidic channels or micro-fluidic chambers of the first to N substrates to be communicated, so a stereo micro-fluidic structure is formed. The invention also discloses a preparation method for the micro-fluidic chip. The preparation method comprises the following steps: uniformly coating the substrates with a prefabricated polymer and carrying out drying so as to obtain the polymer layers with sizes of 1 [mu]m to 100 [mu]m; and separately bonding the first substrate and the second substrate with one of the polymer layers and carrying out repeated lamination so as to obtain the micro-fluidic chip. Thus, bonding of the micro-fluidic chip is realized without application of pressure; and the method is simple and can be extensively used for preparation of the micro-fluidic chip.

Owner:WUHAN TEXTILE UNIV

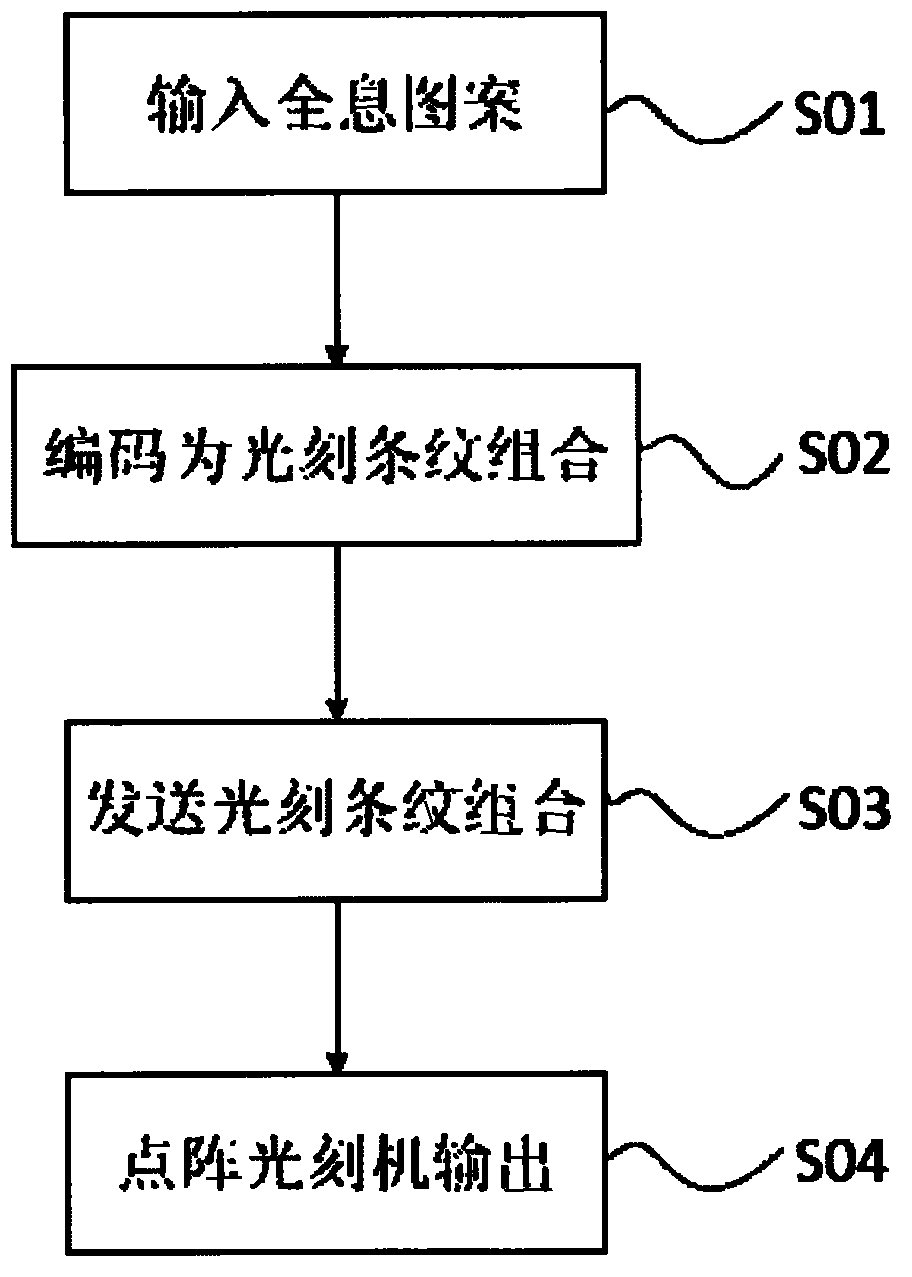

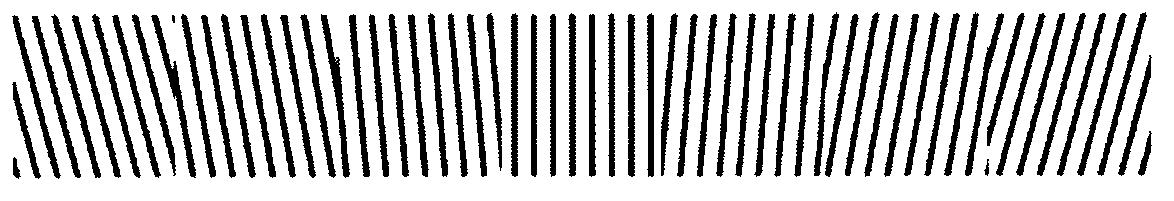

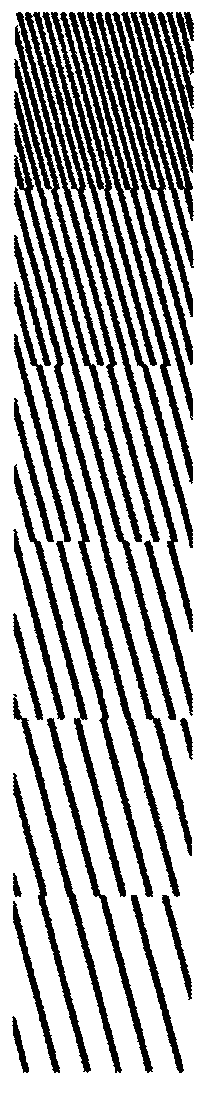

Laser holographic digital lens die and manufacturing method thereof

InactiveCN104252017ASolve complexitySolve the technical problem of more diffraction elementsOptical elementsDot matrixComputer science

The invention provides a manufacturing method of a laser holographic digital lens die. The manufacturing method is used for solving the technical problems of complicated light paths and many diffraction components of the prior art. The manufacturing method includes steps of firstly, inputting holographic patterns to a computer; secondly, encoding the holographic patterns into combination of photoetching stripes by the computer according to simulation optical encoding rules; thirdly, transmitting the combination of photoetching stripes to a dot matrix photoetching machine by the computer; fourthly, outputting the combination of photoetching stripes by the dot matrix photoetching machine to form a laser holographic digital lens die, wherein the photoetching stripes are combined modulated microstructure stripes of different frequencies and angles. The laser holographic digital lens die in the embodiment has the advantages that the process is simplified, and die manufacturing success rate is increased.

Owner:SUZHOU IMAGE LASER TECH

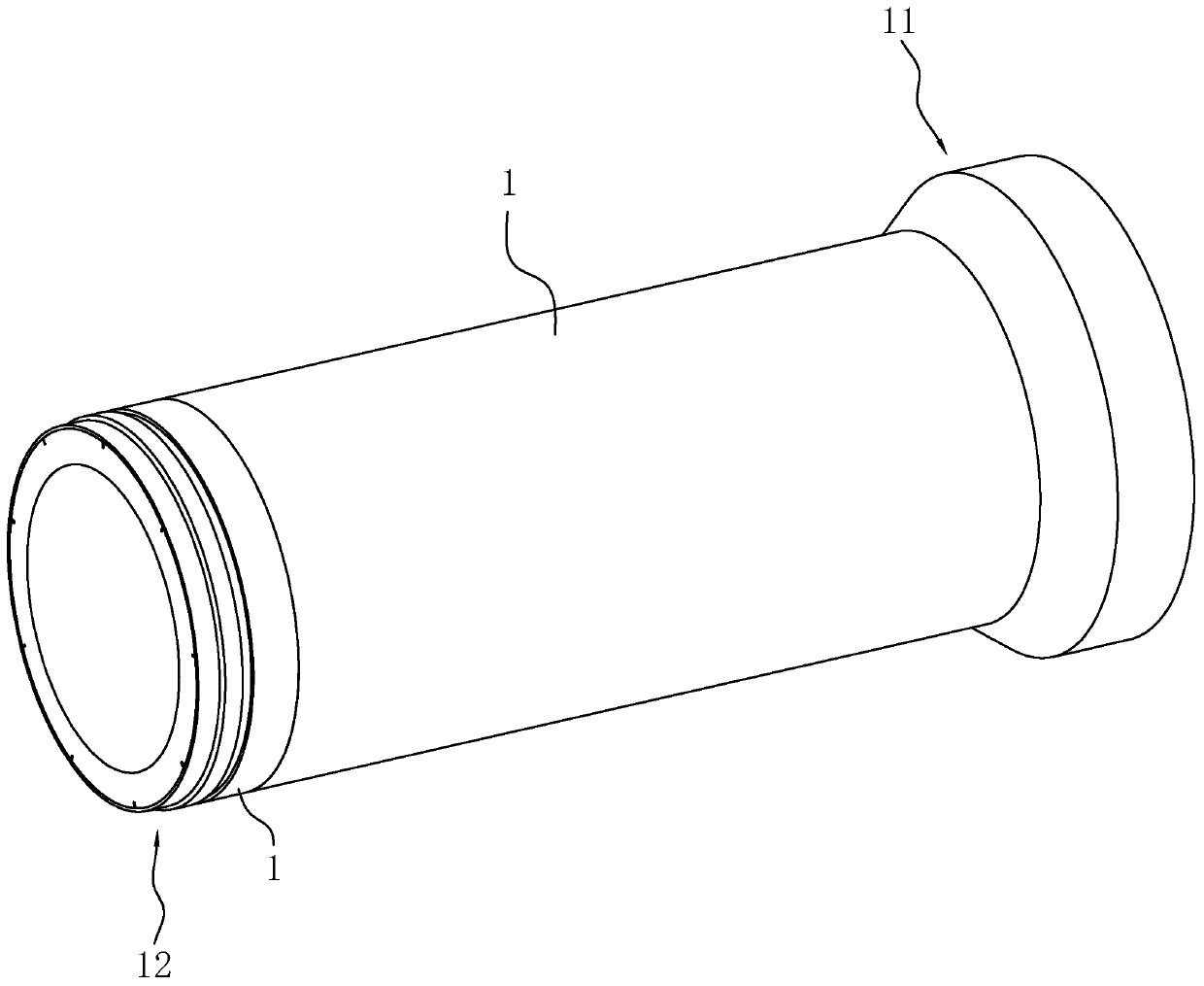

Concrete pipe and manufacturing process thereof

InactiveCN110671545AHigh success rate of preparationHigh strengthShaping reinforcementsRigid pipesManufacturing technologyConstruction engineering

The invention discloses a concrete pipe and a manufacturing process thereof. According to the technical scheme, the concrete pipe comprises a pipe body, and a socket end and a spigot end are arrangedon the pipe body. The pipe body is composed of a reinforcing steel bar keel and a concrete layer covering the reinforcing steel bar keel. The peripheral face of the spigot end of the pipe body is fixedly connected with a water stopping pipe. The concrete pipe and the manufacturing process thereof have the advantage of improving the waterproof performance of an inserting opening of the concrete pipe.

Owner:北京密云水泥制品有限责任公司

Method for realizing co-curing of L-shaped reinforcing rib and C-shaped frame-structure composite part through high-strength soft tool

ActiveCN110370676AAvoid problems such as agingShorten the manufacturing cycleNon destructiveAviation

The invention provides a method for realizing co-curing of an L-shaped reinforcing rib and a C-shaped frame-structure composite part through a high-strength soft tool. The method has the beneficial technical effects that first, co-curing of the L-shaped reinforcing rib and the C-shaped frame-structure composite part is achieved through the cooperation of a soft mold and a metal forming tool, it isguaranteed that the key parameters, such as the profile tolerance, thickness and the L-shaped axis, of the part all meet the high civil aviation manufacturing standard, and the problem of aging caused by repeated curing of materials is solved; second, in the forming process, pressure is uniformly and accurately applied to all positions of the L-shaped vertical rib and a C-shaped frame, and the temperature rise rates of all the portions of the part are kept consistent, so that the problem that the thickness of an R-angle area of the part is out of tolerance is solved; and third, non-cured preforms of the L-shaped vertical rib and a C-shaped web are combined through the soft tool, so that internal stress caused by combination after curing of an assembly is avoided, and the problems of out-of-tolerance profiles and internal non-destructive defects caused by forced assembly in the prior art are solved.

Light emitting display with high-low flat-arc polymerization independent door control tilted and closed hook face ring edge negative electrode structure

ActiveCN106683956AHigh success rate of preparationReduce manufacturing costTube/lamp screens manufactureElectrode and associated part arrangementsDisplay deviceVacuum chamber

The invention relates to a light emitting display with a high-low flat-arc polymerization independent door control tilted and closed hook face ring edge negative electrode structure. The light emitting display comprises a vacuum chamber, and a degasifier and separated insulating column auxiliary elements arranged in the vacuum chamber, wherein the vacuum chamber consists of an upper transparent hard compression resistant plate, a lower transparent hard compression resistant plate and a glass frame in the periphery; a positive electrode low-resistance film electrode layer, a positive electrode silver transfer wire layer connected with the positive electrode low-resistance film electrode layer and a fluorescent powder layer prepared on the positive electrode low-resistance film electrode layer are arranged on the upper transparent hard compression resistant plate; and the high-low flat-arc polymerization independent door control tilted and closed hook face ring edge negative electrode structure is arranged on the lower transparent hard compression resistant plate. The light emitting display has the advantages of simple manufacturing structure, stable and reliable manufacturing process, easy realization of the manufacturing process and high light emitting luminance.

Owner:山东临港智能制造产业园有限公司

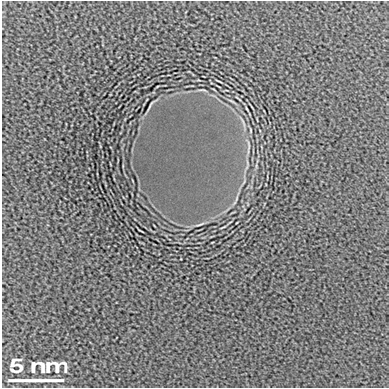

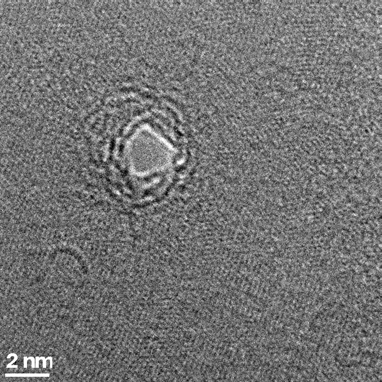

Gamma-Fe2O3-TiO2 magnetic nanocomposite material, and preparation method and applications thereof

ActiveCN106608651AImprove photocatalytic performanceReduce photocatalysisMaterial nanotechnologyWater contaminantsWastewaterPhotocatalytic degradation

The invention provides a gamma-Fe2O3-TiO2 magnetic nanocomposite material, and a preparation method and applications thereof. The gamma-Fe2O3-TiO2 magnetic nanocomposite material comprises a gamma-Fe2O3 nano material and a TiO2 nano material; the gamma-Fe2O3 nano material is loaded with theTiO2 nano material so as to form a core-shell structure. The preparation method comprises following steps: preparation of a gamma-Fe2O3 mixed solution, loading of TiO2, and calcination treatment. The preparation method is simple in operation; preparation success rate is high; the prepared material is stable; the obtained gamma-Fe2O3-TiO2 magnetic nanocomposite material possesses nanoscale size, is wide in photoresponse range, and high in photocatalytic degradation efficiency, is convenient to recycle, can be widely used for removing bisphenol A and hexavalent chromium in waste water at the same time, realizing synergistic degradation of the two pollutants, and removing bisphenol A and hexavalent chromium in water with high efficiency.

Owner:HUNAN UNIV

Light emitting display of multi-angle straight arc combination silver gate control different skew surface segmentation large skirt cathode structure

ActiveCN106847645AIncrease the number ofIncrease the anode working currentElectrode and associated part arrangementsImage/pattern display tubesDisplay deviceVacuum chamber

The invention relates to a light emitting display of a multi-angle straight arc combination silver gate control different skew surface segmentation large skirt cathode structure. The light emitting display comprises a vacuum chamber composed of an upper stiff encapsulated anti-pressure plate, a lower stiff encapsulated anti-pressure plate and a transparent glass frame, an anode low resistance film transfer layer, an anode extension thick film layer connected with the anode low resistance film transfer layer and a phosphor powder layer prepared on the anode low resistance film transfer layer are arranged on the upper stiff encapsulated anti-pressure plate, the multi-angle straight arc combination silver gate control different skew surface segmentation large skirt cathode structure is arranged on the lower stiff encapsulated anti-pressure plate, and a getter and insulation cylinder ancillary components are arranged in the vacuum chamber. The light emitting display of the multi-angle straight arc combination silver gate control different skew surface segmentation large skirt cathode structure has the advantages of high glow brightness, stable production process, excellent adjustment performance of luminous gray scales, and short response time.

Owner:阜阳市战千里知识产权运营有限公司

Panel display having precise location trap anode array strcture and its manufacturing technology

InactiveCN1794404AReduce manufacturing costIncrease display resolutionImage/pattern display tubesCold cathode manufactureManufacturing technologyFluorescence

This invention relates to a panel display with an accurate location trap cathode array structure and its process method, in which, said display includes a sealed vacuum cavity composed of a cathode panel, an anode panel and surrounding glasses, a photoetched anode conduction layer on the anode panel and a fluorescence powder layer on the anode conduction layer, a supporting wall structure and getters, an accurate location trap cathode array structure prepared on the cathode panel capable of determining the growing position of the carbon nm tube cathode and controlling its location, length and number and integrating with the control grating to reduce distances between them and avoid short circuit.

Owner:ZHONGYUAN ENGINEERING COLLEGE

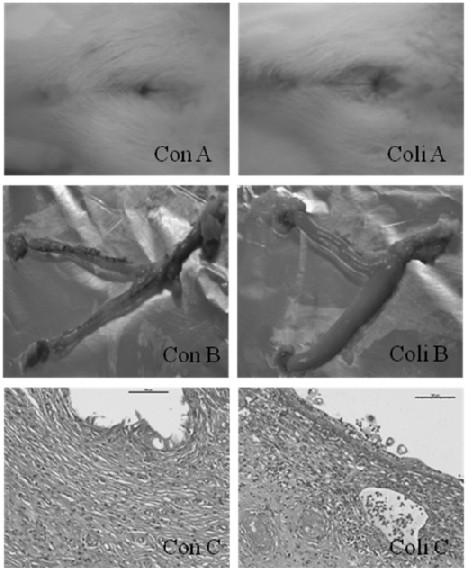

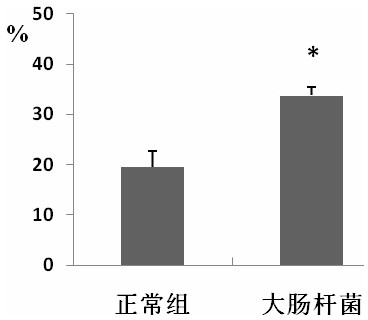

Method for making human pelvic inflammation simulating animal model

InactiveCN102205125AIncrease success rateEasy to operateOrganic active ingredientsIn-vivo testing preparationsInflammatory cellOstium uteri

The invention relates to a method for making a human pelvic inflammation simulating animal model. The method comprises the following steps of: selecting a muridae animal with no genital tract disease; and inoculating enterobacteria, staphylococcus or mycotoruloides into an animal vagina under a sterile condition for 1-8 weeks, 1-7 times every week. The method has the advantages of: high model making success rate up to 100 percent, independence of an immune-depressant, remarkable increase in secreta at a vaginal orifice, observation of bacteria through vaginal smear microscopy, observation of vacuole at an ostium uteri, metremia abscess and a large quantity of inflammatory cells in a fallopian tube through section examination of tissues and organs and remarkable increase in neutrophilic granulocytes as proved by blood examination. The method is easy to operate and grasp, has readily-available materials, has no special technical requirement for a user, is accordant with the clinical natural abiogenesis process of pelvic inflammation, and is suitable for researching the occurrence and the development of pelvic inflammation and the mechanism thereof and screening relevant medicaments.

Owner:唐和斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face](https://images-eureka.patsnap.com/patent_img/b51e76fc-e8b7-4064-8e34-1796a08328ed/HDA0000756349890000011.PNG)

![Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face](https://images-eureka.patsnap.com/patent_img/b51e76fc-e8b7-4064-8e34-1796a08328ed/HDA0000756349890000012.PNG)

![Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face Preparation method and application for palladium-modified titanium dioxide with three-dimensional flower-like structure exposure [001] crystal face](https://images-eureka.patsnap.com/patent_img/b51e76fc-e8b7-4064-8e34-1796a08328ed/HDA0000756349890000021.PNG)