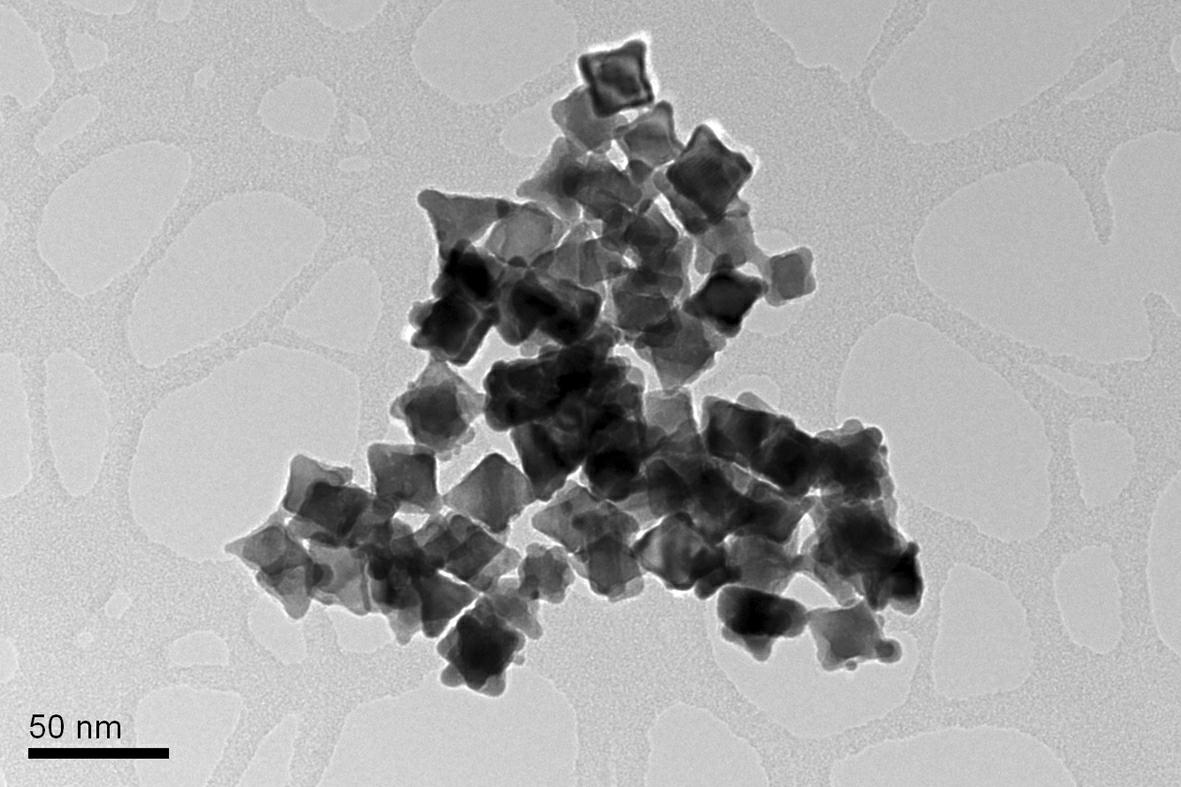

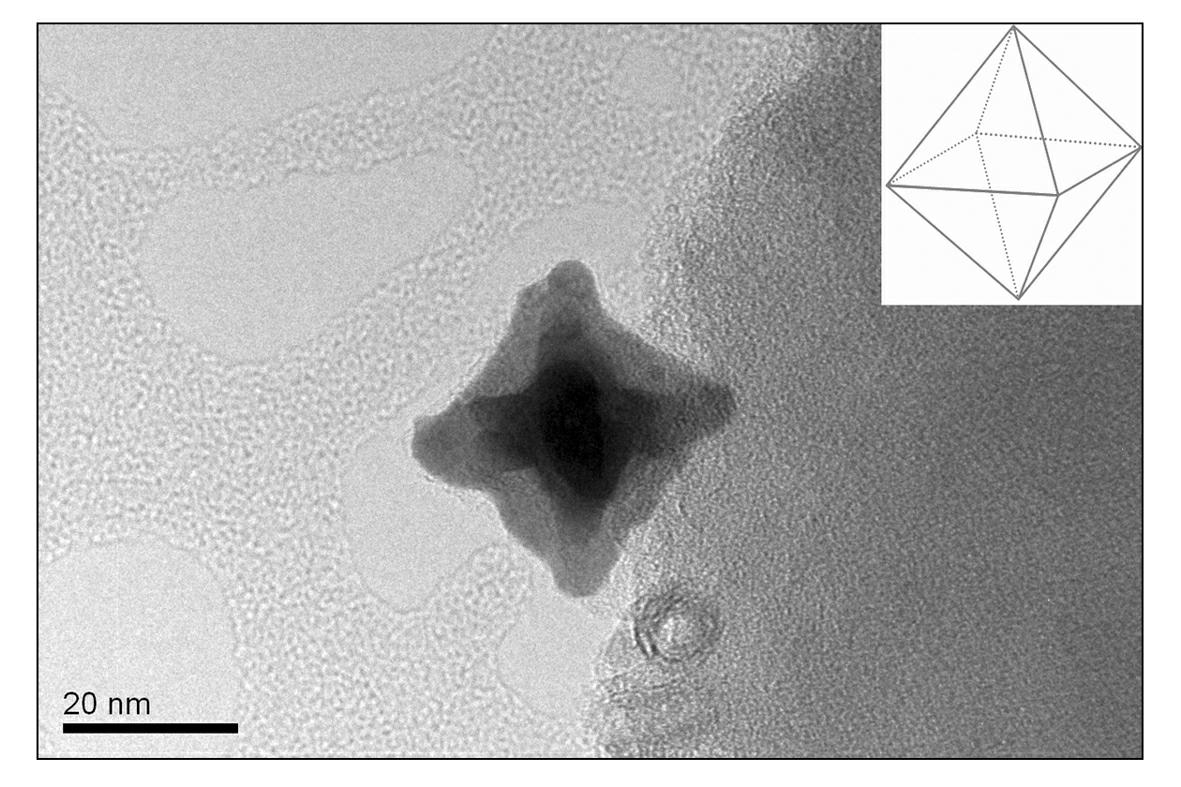

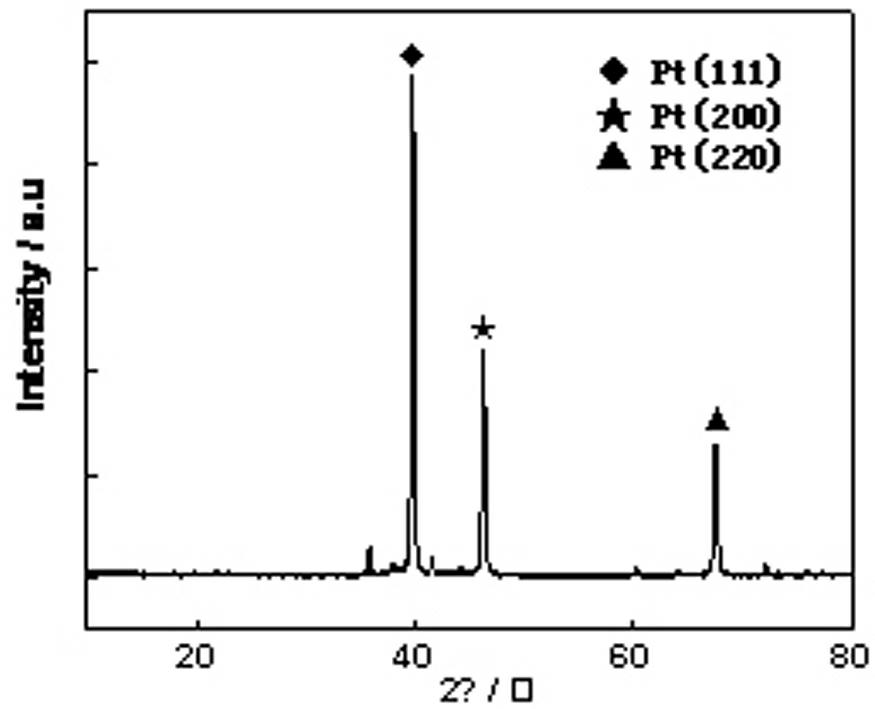

Method for preparing highly-dispersed regular octahedral platinum nano particles

A technology of regular octahedron and platinum nano-particles, which is applied in the field of preparation of highly dispersed regular octahedral platinum nanoparticles, can solve problems such as difficulties in nano-particles, and achieve the effects of high preparation success rate, simple equipment, and easy control of preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific examples: the method comprises the following steps: 1) preparation of chloroplatinic acid stock solution: 0.5g-2g of chloroplatinic acid (H 2 PtCl 6 ) was dissolved in pure water to prepare a chloroplatinic acid solution with a concentration of 50mM-400mM; 2) Preparation of organic mixed induction solution: firstly, polyethylene glycol with a molecular weight of 600-2000 was prepared into a 0.5-2M aqueous solution, labeled Solution 1; then prepare one or more of the more than 20 kinds of amino acids required by the human body, including L-lysine, L-leucine, L-serine, etc., into a 0.5-2M aqueous solution, labeled as solution 2 ;Finally, solution 1 and solution 2 were prepared into an organic mixed induction solution at a ratio of 1:1, which was marked as solution 3; 3) Hydrothermal induction method: Take 30ml-60ml of the above solution 3 and add it to a 100ml hydrothermal reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com