Method for growing tabular gallium oxide crystals through edge-defined film-fed growth process

A technology of guided mode method and gallium oxide, which is applied in the field of growing flaky gallium oxide crystals by guided mode method, which can solve the problems of reducing crystal utilization rate and restricting the development of crystal industrialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

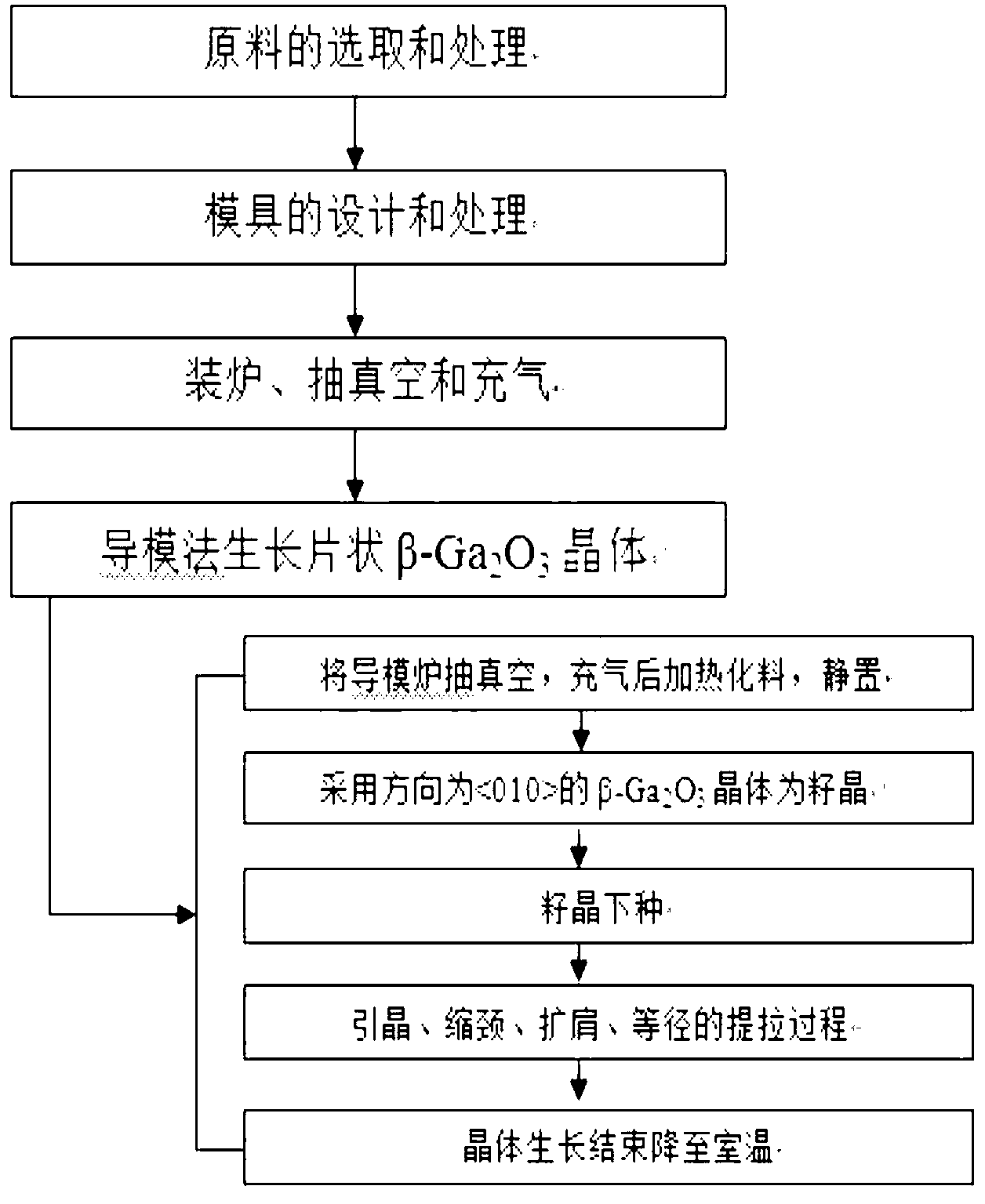

[0027] The method for growing flaky gallium oxide crystals by the guided mode method of the present invention comprises the following steps:

[0028] (1) Use gallium oxide powder with a purity of 99.999%, heat and dry at 500°C for 3 hours for later use.

[0029] (2) The iridium mold is used, the inner surface of the top of the mold is mechanically polished to achieve a mirror effect, the roughness is less than 0.8μm, the width of the mold slit is 0.5mm, and the iridium crucible is washed with deionized water for later use;

[0030] (3) Select β-Ga with the normal direction of the end face 2 o 3 The single crystal is used as the seed crystal, and the (100) plane is used as the main growth plane;

[0031] (4) Growth of flake β-Ga by guided mode method 2 o 3 the crystal

[0032] ① Vacuumize the furnace by 1×10 -4 Pa, slowly filled with high-purity CO 2After the gas reaches 7 bar, let it stand still for 20 minutes, and use a medium-frequency induction heating tungsten heat...

Embodiment 2

[0037] The method for growing flaky gallium oxide crystals by guided mode method comprises the following steps:

[0038] (1) Use gallium oxide powder with a purity of 99.999%, heat and dry at 800°C for 5 hours before use.

[0039] (2) The iridium mold is used, the inner surface of the top of the mold is mechanically polished to achieve a mirror effect, the roughness is less than 0.8μm, the width of the mold slit is 0.5mm, and the iridium crucible is washed with deionized water for later use;

[0040] (3) Select β-Ga with the normal direction of the end face 2 o 3 The single crystal is used as the seed crystal, and the (100) plane is used as the main growth plane;

[0041] (4) Growth of flake β-Ga by guided mode method 2 o 3 the crystal

[0042] ① Vacuumize the furnace by 1×10 -4 Pa, slowly filled with high-purity CO 2 After the gas reaches 7 bar, let it stand still for 30 minutes, and use a medium-frequency induction heating tungsten heating device to slowly heat until...

Embodiment 3

[0047] The method for growing flaky gallium oxide crystals by guided mode method comprises the following steps:

[0048] (1) Use gallium oxide powder with a purity of 99.999%, heat and dry at 700°C for 4 hours before use.

[0049] (2) Forging molds made of iridium are used, and the inner surface of the top of the mold is mechanically polished to achieve a mirror effect. The roughness is less than 0.8 μm, and the width of the mold slit is 0.5 mm. The iridium crucible is washed with deionized water for later use;

[0050] (3) Select β-Ga with the normal direction of the end face 2 o 3 The single crystal is used as the seed crystal, and the (100) plane is used as the main growth plane;

[0051] (4) Growth of flake β-Ga by guided mode method 2 o 3 the crystal

[0052] ① Vacuumize the furnace by 1×10 -4 Pa, slowly filled with high-purity CO 2 After the gas reaches 7 bar, let it stand still for 25 minutes, and use a medium-frequency induction heating tungsten heating device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com