New production formula and use method of exquisite glaze

A technology for producing formula and exquisite glaze, applied in the field of ceramics, can solve problems such as concave holes, cracks, bubbles, etc., and achieve the effect of overcoming easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

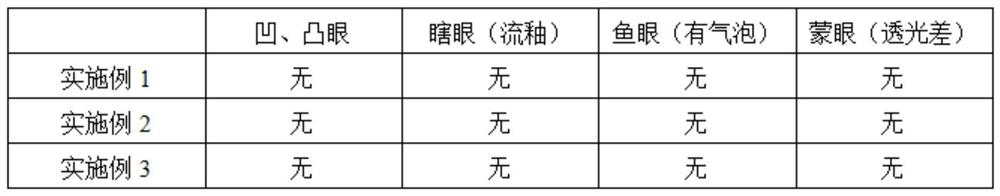

Examples

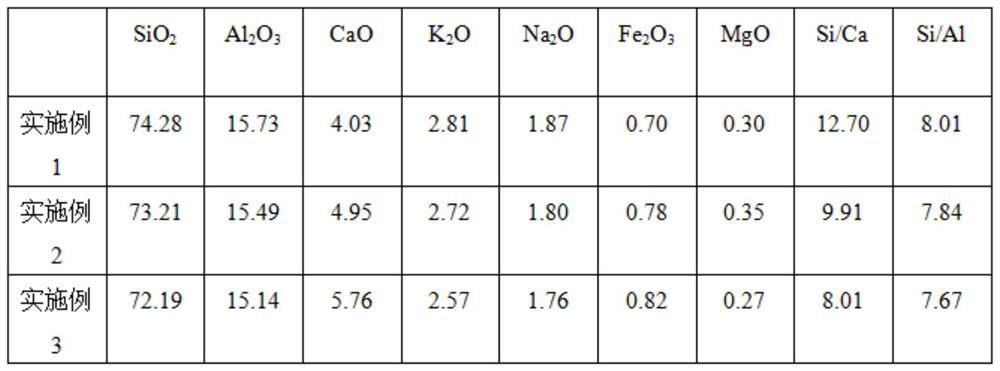

Embodiment 1

[0026] The raw materials include the following molar mass percentages: Yunnan kaolin 15%, quartz 10%, Japan Kamado feldspar 15%, volcanic rock sodium titanate composite material 11%, Hunan Pingjiang feldspar 3%, forsterite powder 2%, boron fusion Block 25%.

[0027] As a preferred technical solution of the present invention, the preparation method is as follows:

[0028] Mix 15% Yunnan kaolin, 10% quartz, 15% Kamado feldspar, 11% volcanic sodium titanate composite material, 3% Hunan Pingjiang feldspar, 2% forsterite powder, and 25% boron frit with water. Put into a ball mill, then add ball stones, and ball mill for 22 hours at a speed of 2000 / h to get the new Linglong glaze slurry.

[0029] As a preferred technical solution of the present invention, the manufacturing method of the volcanic rock sodium titanate composite material is as follows:

[0030] Step 1: Dissolve sodium titanate and volcanic stone powder in water according to the molar mass ratio of 1:5.3, and stir wel...

Embodiment 2

[0041] Raw materials including the following molar mass percentages: Yunnan kaolin 25%, quartz 25%, Japan Kamado feldspar 26%, volcanic rock sodium titanate composite material 17%, Hunan Pingjiang feldspar 6%, forsterite powder 7%, boron fusion Block 50%.

[0042] As a preferred technical solution of the present invention, the preparation method is as follows:

[0043] Mix 25% Yunnan kaolin, 25% quartz, 26% Kamado feldspar, 17% volcanic sodium titanate composite material, 6% Hunan Pingjiang feldspar, 7% forsterite powder, and 50% boron frit. Put into a ball mill, then add ball stones, and ball mill for 22 hours at a speed of 2400 / h to get the new Linglong glaze slurry.

[0044] As a preferred technical solution of the present invention, the manufacturing method of the volcanic rock sodium titanate composite material is as follows:

[0045] Step 1: Dissolve sodium titanate and volcanic stone powder in water according to the molar mass ratio of 1:5.8, and stir them evenly, pla...

Embodiment 3

[0056] Raw materials including the following molar mass percentages: Yunnan kaolin 20%, quartz 17%, Japanese Kamado feldspar 21%, volcanic sodium titanate composite material 14%, Hunan Pingjiang feldspar 4%, forsterite powder 57%, boron fusion Block 38%.

[0057] As a preferred technical solution of the present invention, the preparation method is as follows:

[0058] Yunnan kaolin 20%, quartz 17%, Japanese Kamado feldspar 21%, volcanic rock sodium titanate composite material 14%, Hunan Pingjiang feldspar 4%, forsterite powder 57%, boron frit 38%, add water and mix evenly Ball mill, then add ball stones, and ball mill for 22 hours at the speed of 2000-2400 / h to get the new Linglong glaze slurry.

[0059] As a preferred technical solution of the present invention, the manufacturing method of the volcanic rock sodium titanate composite material is as follows:

[0060] Step 1: Dissolve sodium titanate and volcanic stone powder in water according to the molar mass ratio of 1:5.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com