Patents

Literature

69results about How to "No air gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

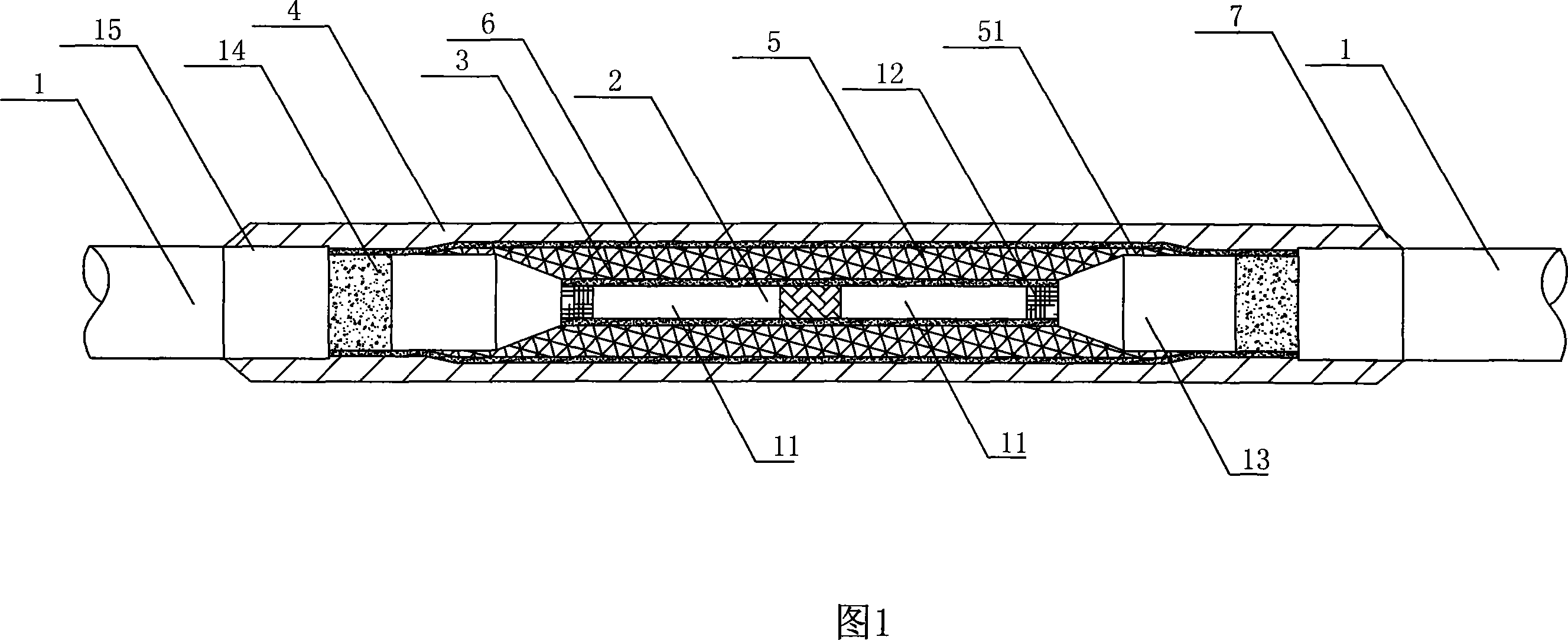

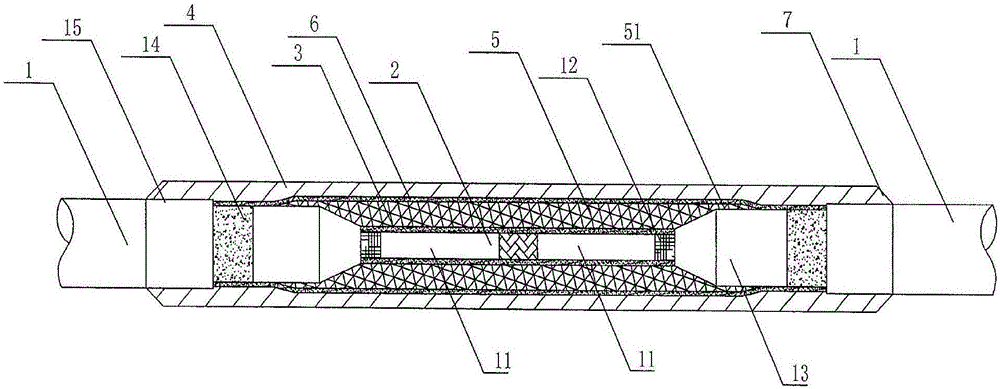

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

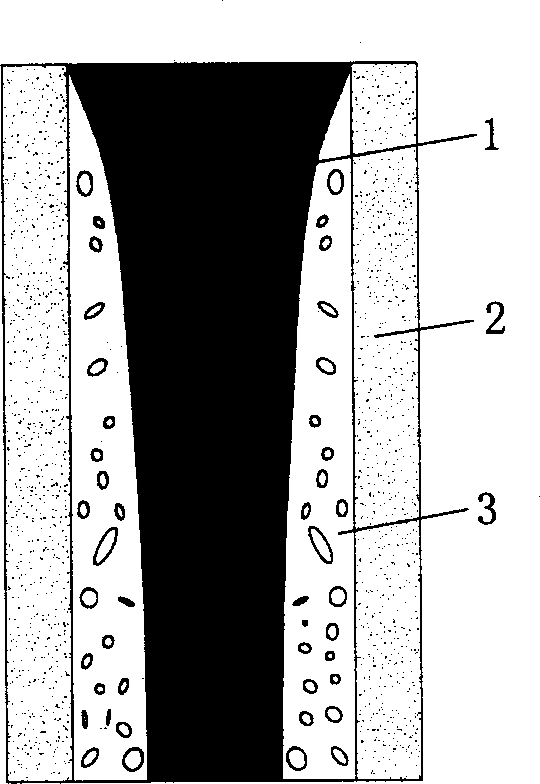

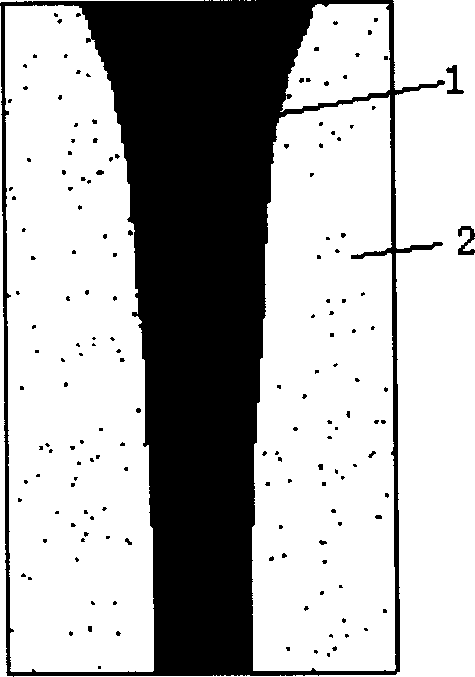

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

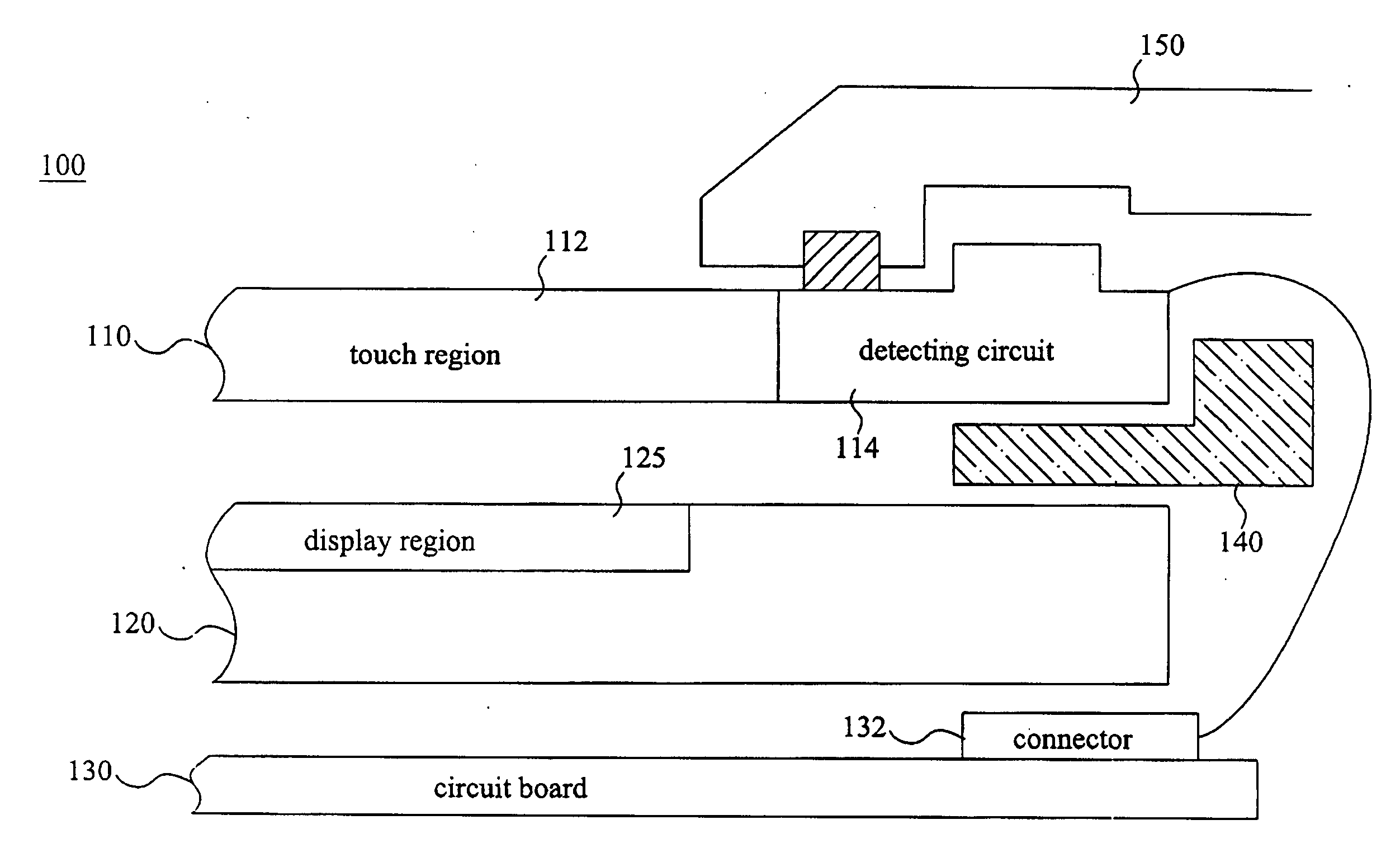

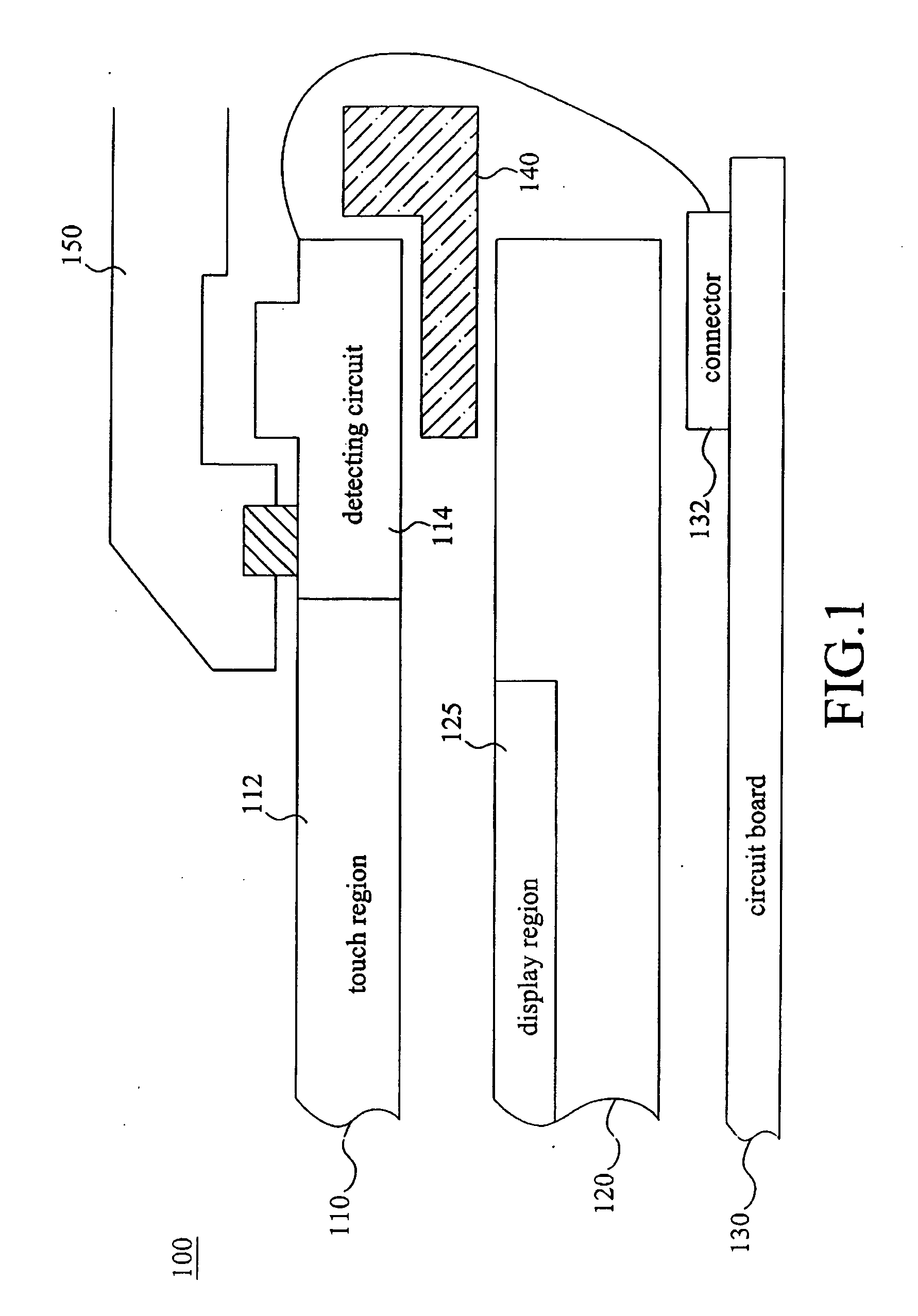

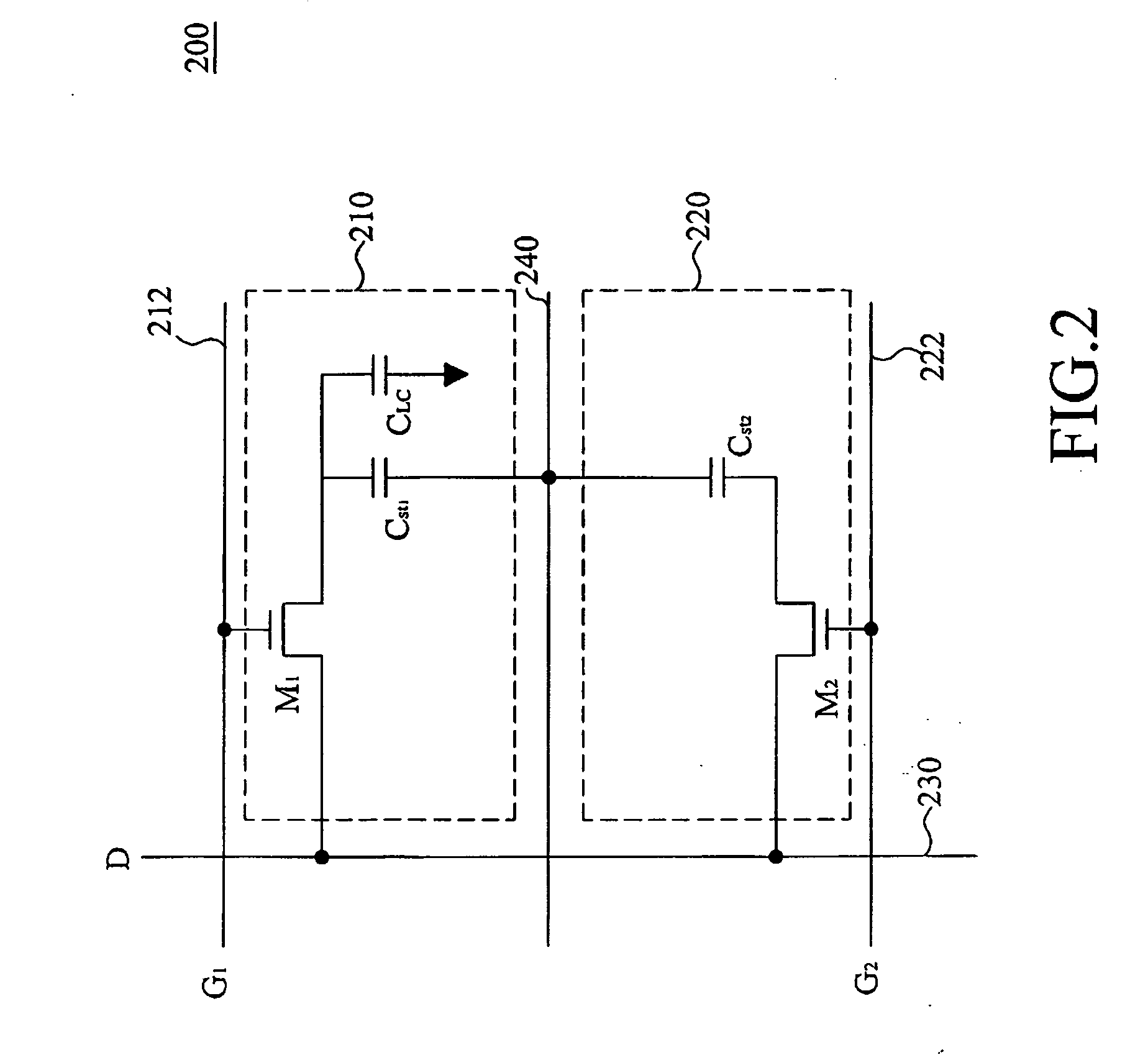

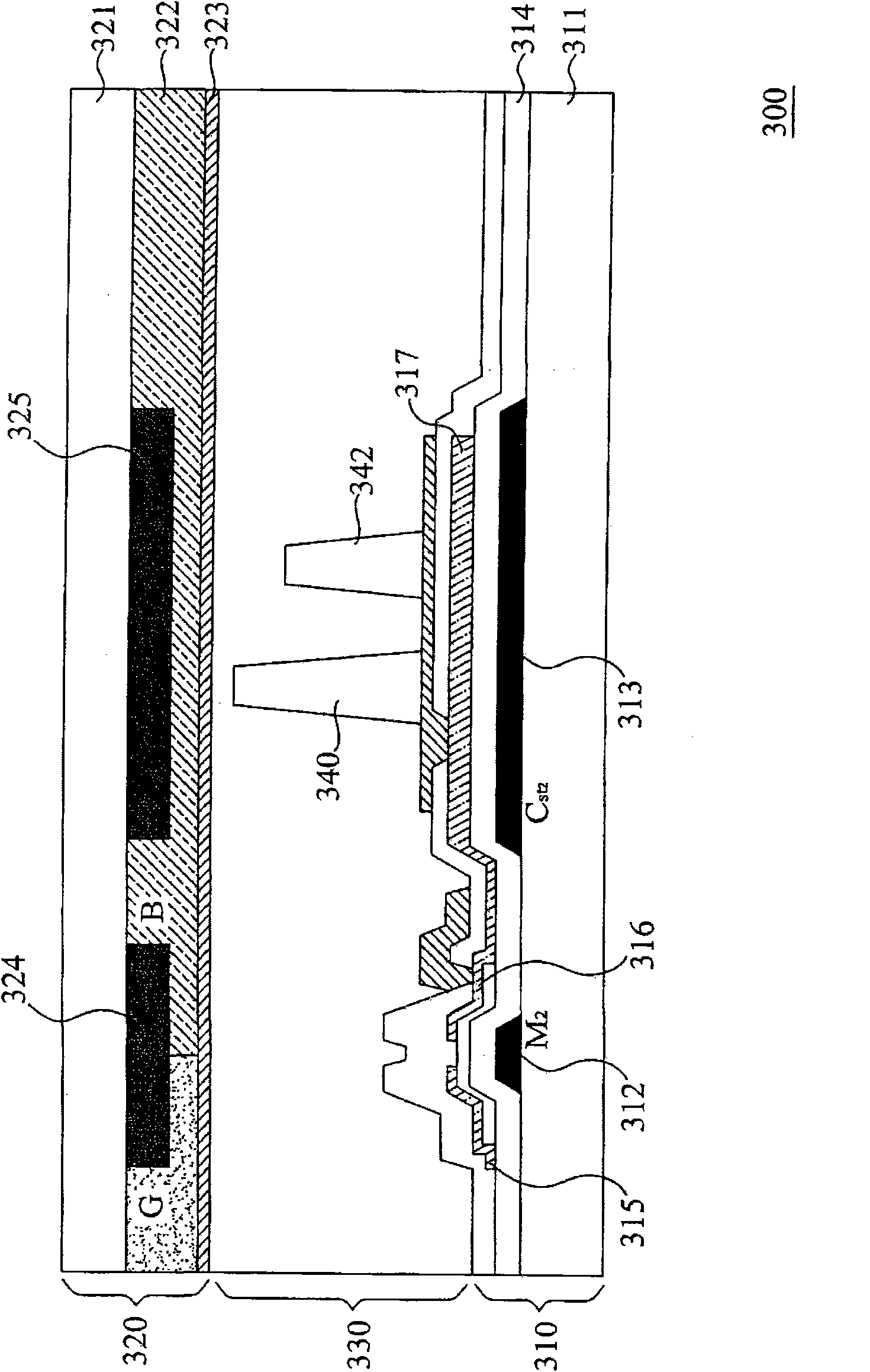

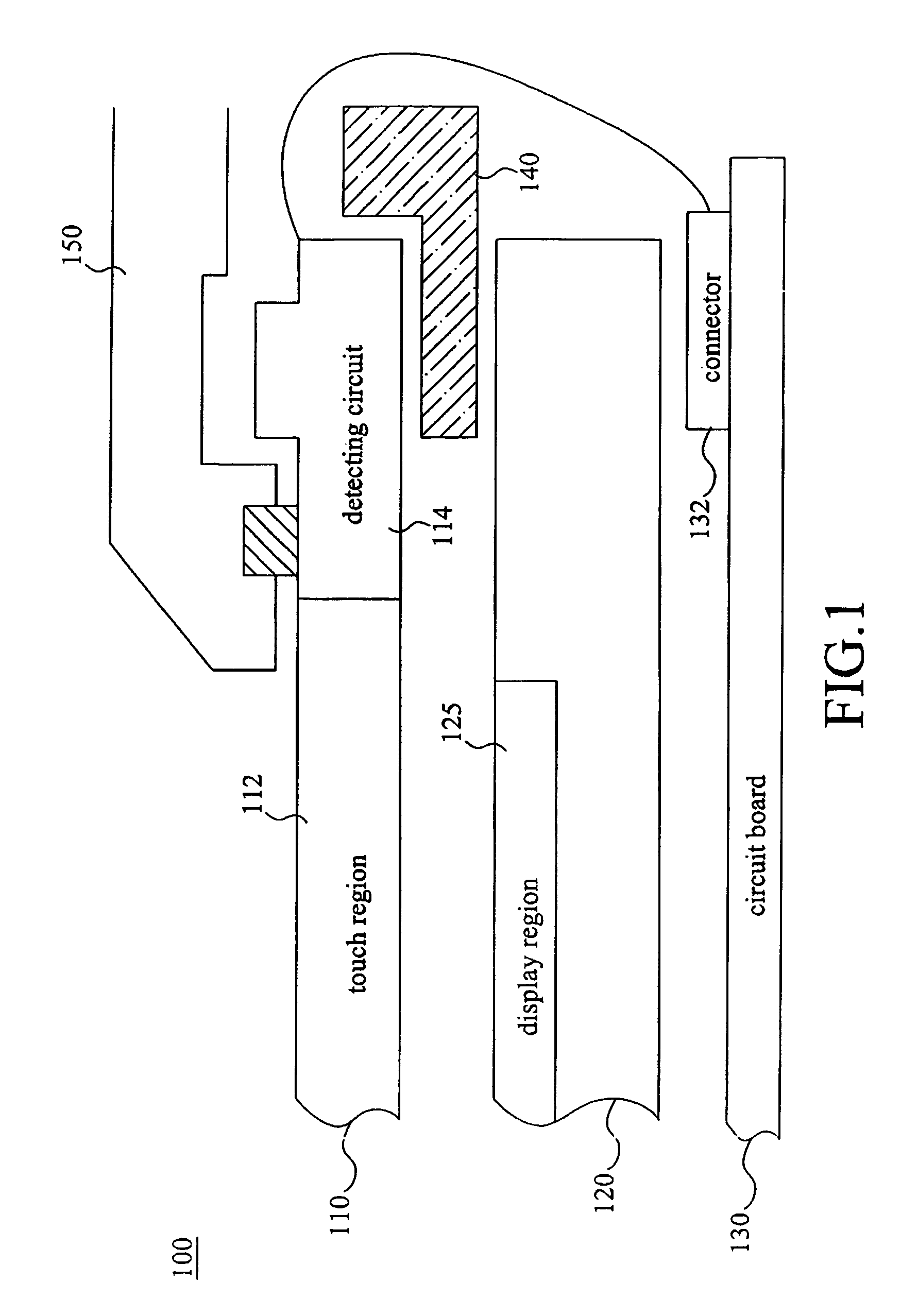

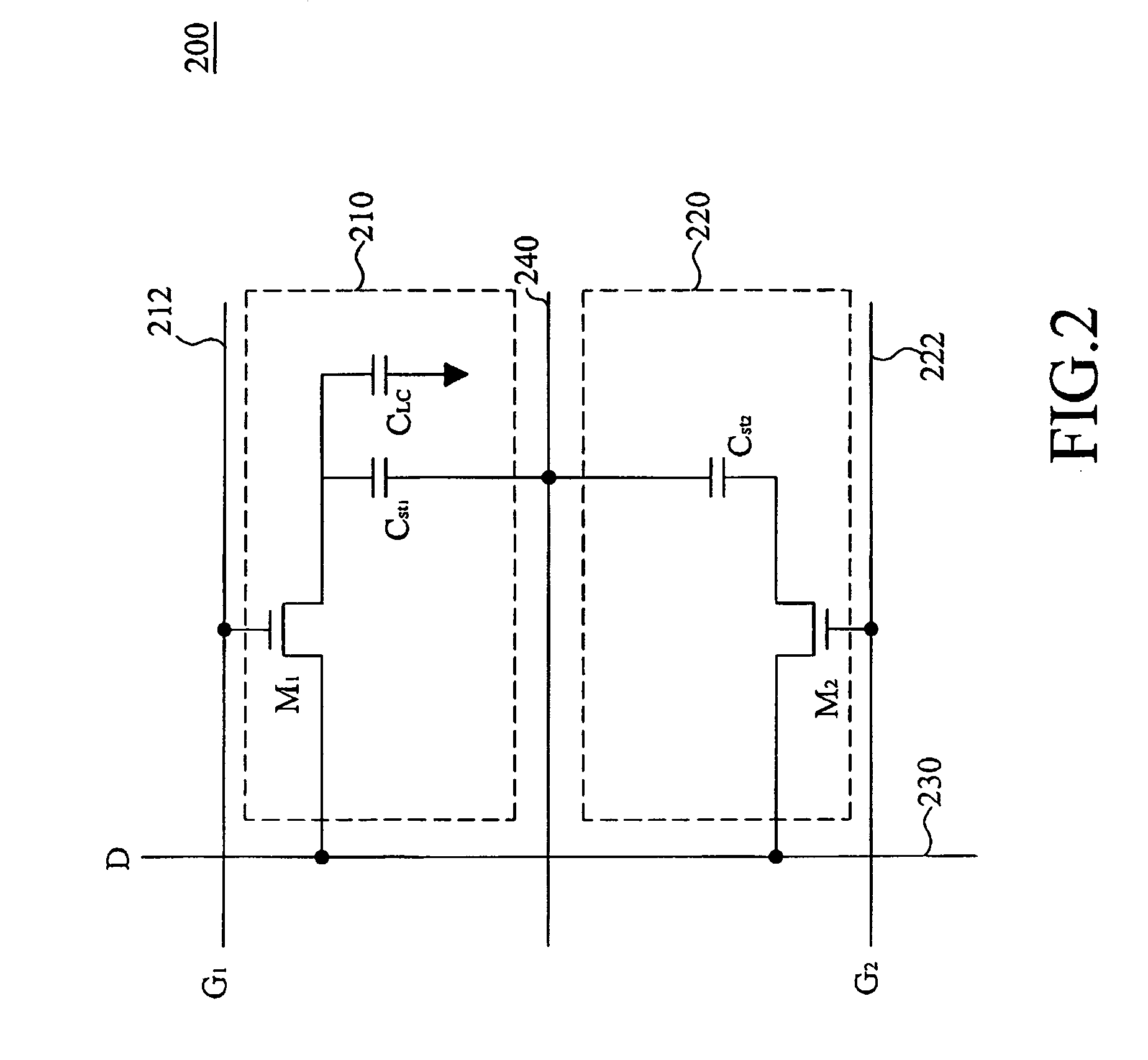

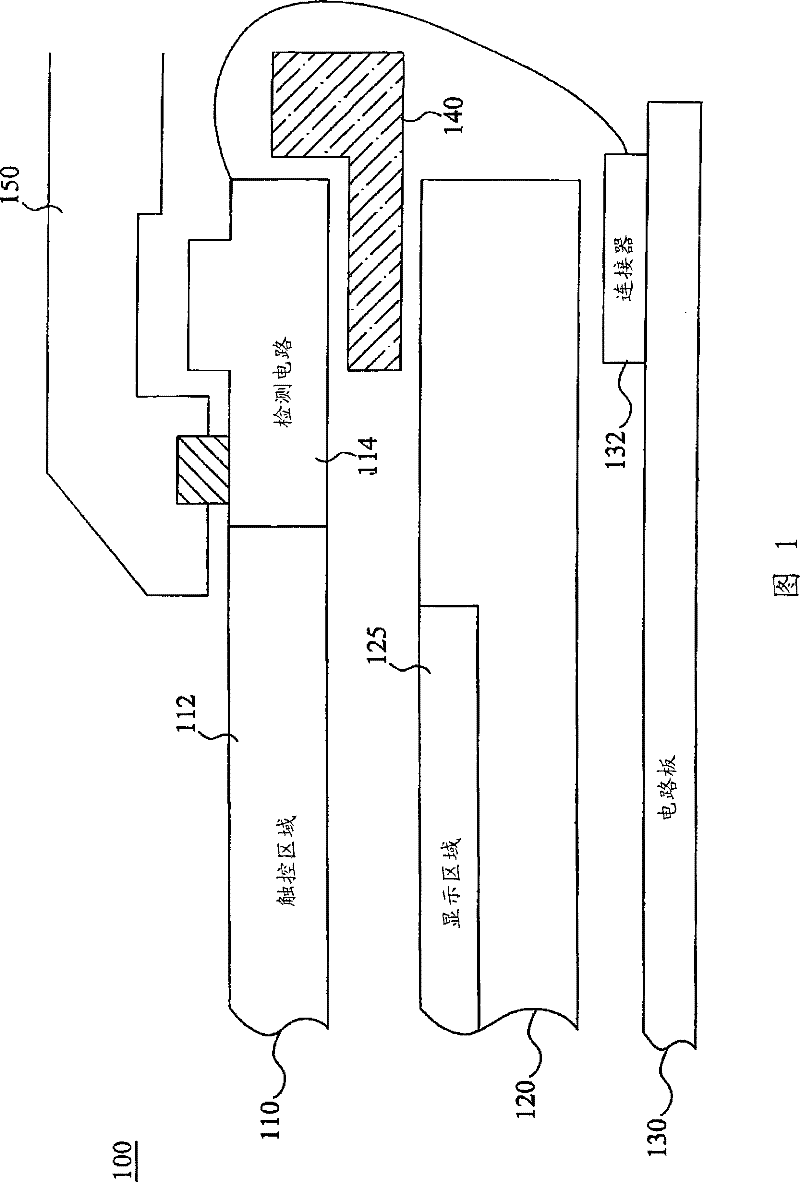

Integrated pixel structure, integrated touch panel LCD device and method of controlling the same

An integrated pixel structure, an integrated touch panel LCD device and a method of controlling the same are provided. The integrated pixel structure includes a transistor matrix substrate, a color filter substrate being parallel with the transistor matrix substrate, and a liquid crystal layer placed between the transistor matrix substrate and the color filter substrate. The transistor matrix substrate includes a first transistor, a first storage capacitor connected to the first transistor, a second transistor, a second storage capacitor connected to the second transistor, and a conductive protrusion. The conductive protrusion is disposed corresponding to the second storage capacitor and configured to electrically connect the second storage capacitor and the color filter substrate.

Owner:ACER INC

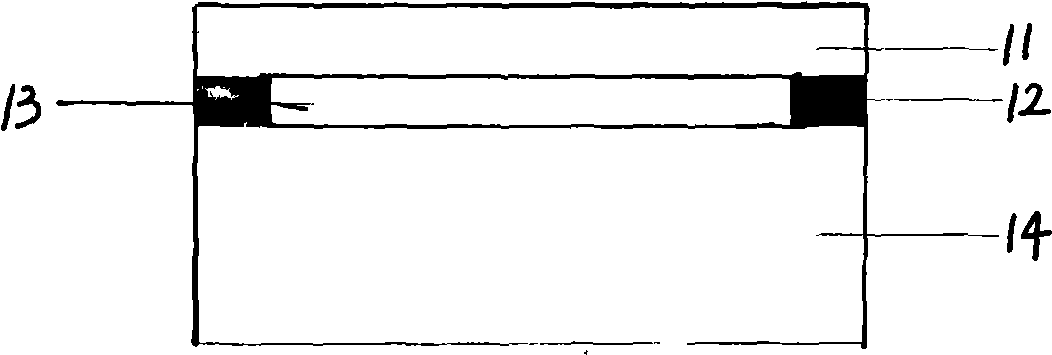

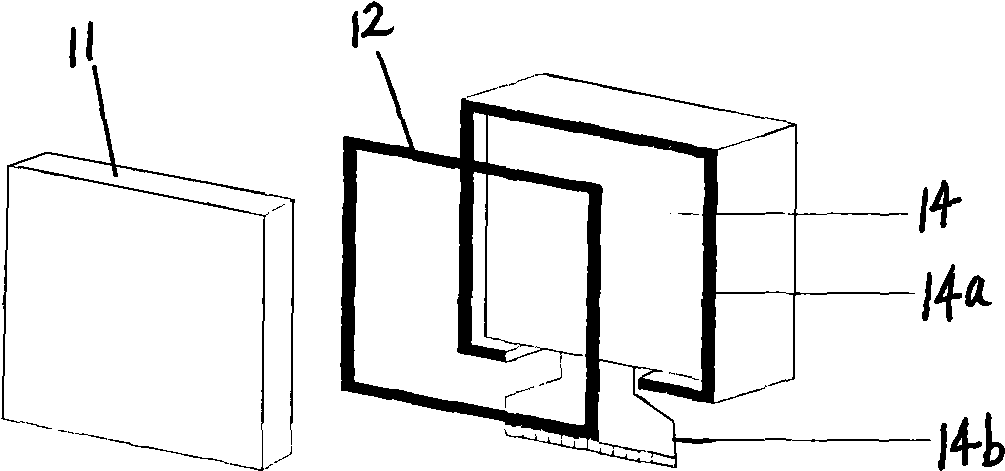

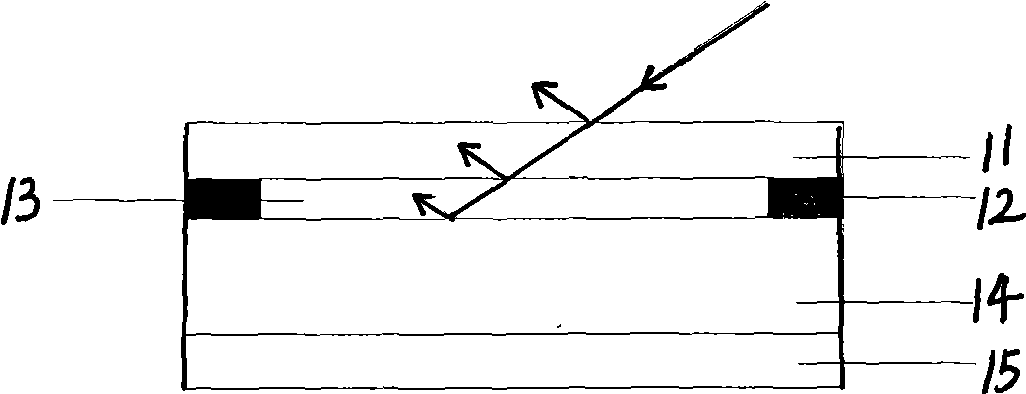

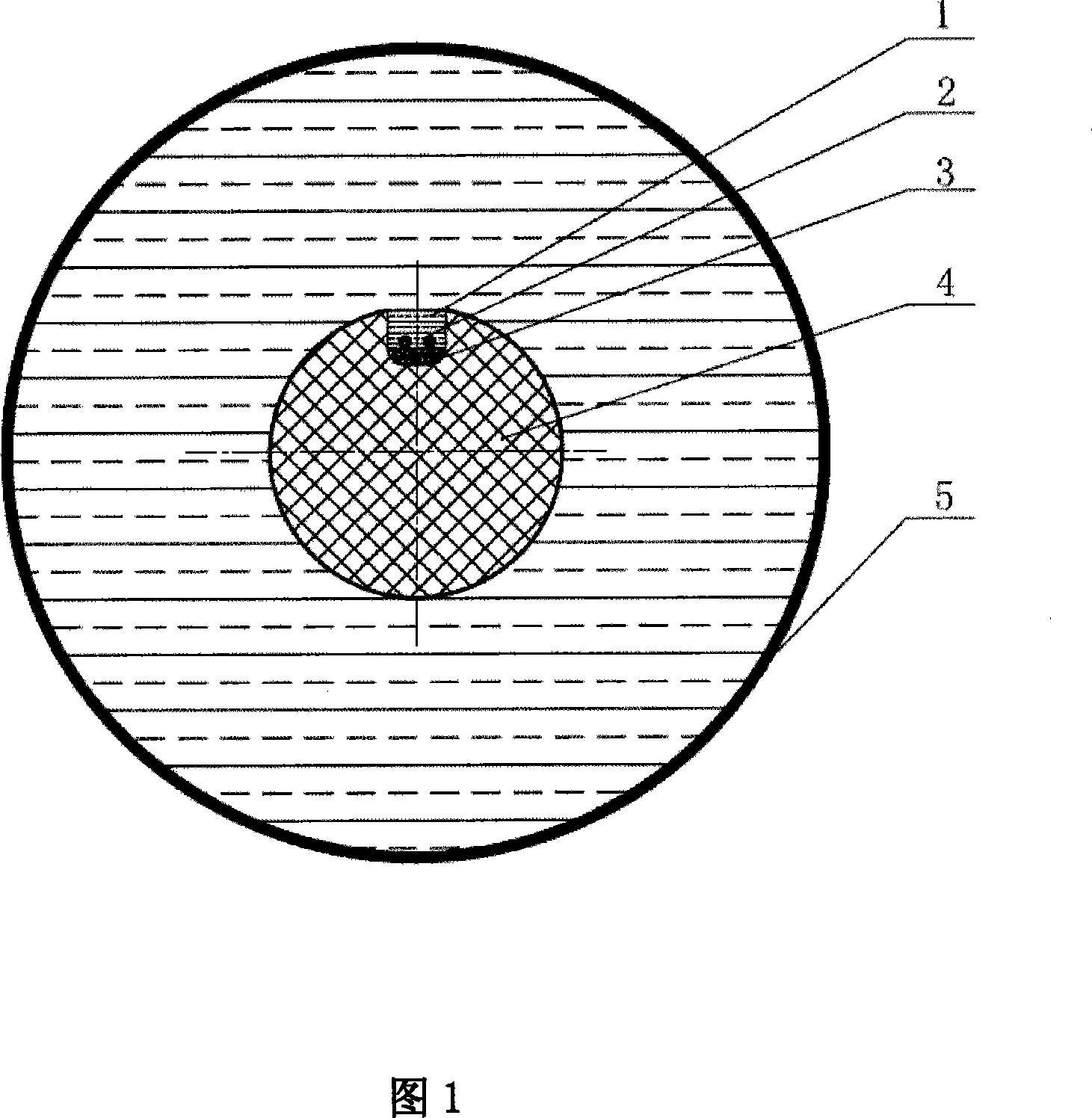

Touch screen and panel display module integrated combination module and method for producing the same

InactiveCN101504496AReduce light lossHigh light transmittanceStatic indicating devicesSolid-state devicesTransmittanceReflectivity

The invention discloses an integrative composite module of a touch screen and a flat panel display module and a method for manufacturing the same. The composite module comprises the touch screen, the flat panel display module, and a middle adhesive layer for adhering the touch screen and the flat panel display module, wherein the adhesive layer is an optical adhesive layer which fully covers the visual area of the touch screen, and the refractive index of the optical adhesive layer is same as or similar to that of the interface of the touch screen and the flat panel display module. The composite module is provided with the optical adhesive layer between the touch screen and the flat panel display module, and the refractive index of the optical adhesive layer is same as or similar to that of the interface of the touch screen and the flat panel display module, thus the reflectivity of the composite module can be reduced effectively, the light loss of the composite module can also be reduced simultaneously, and the light transmittance of the combined module is improved. The composite module adopts a simple manufacturing method and is easy to operate.

Owner:TRULY SEMICON

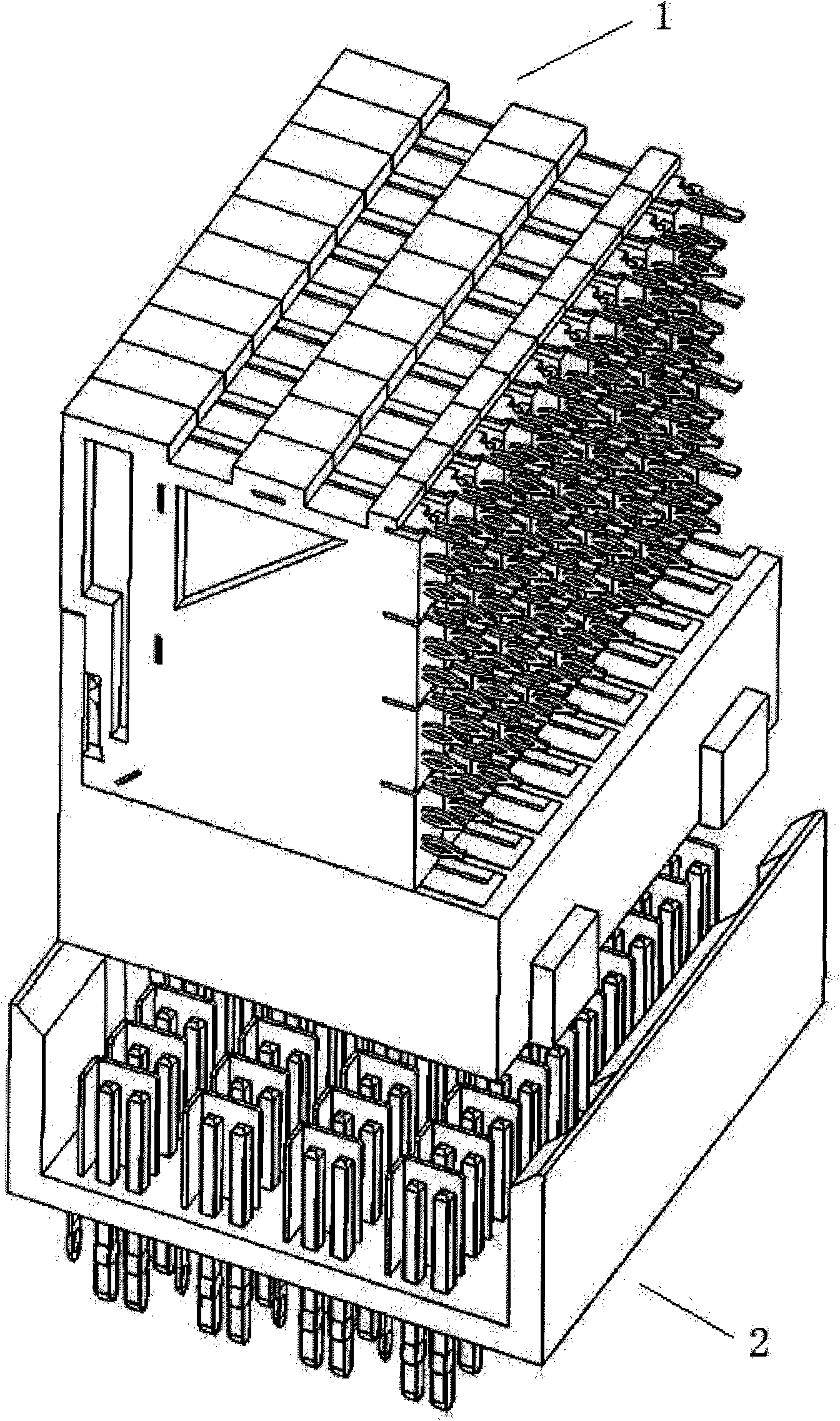

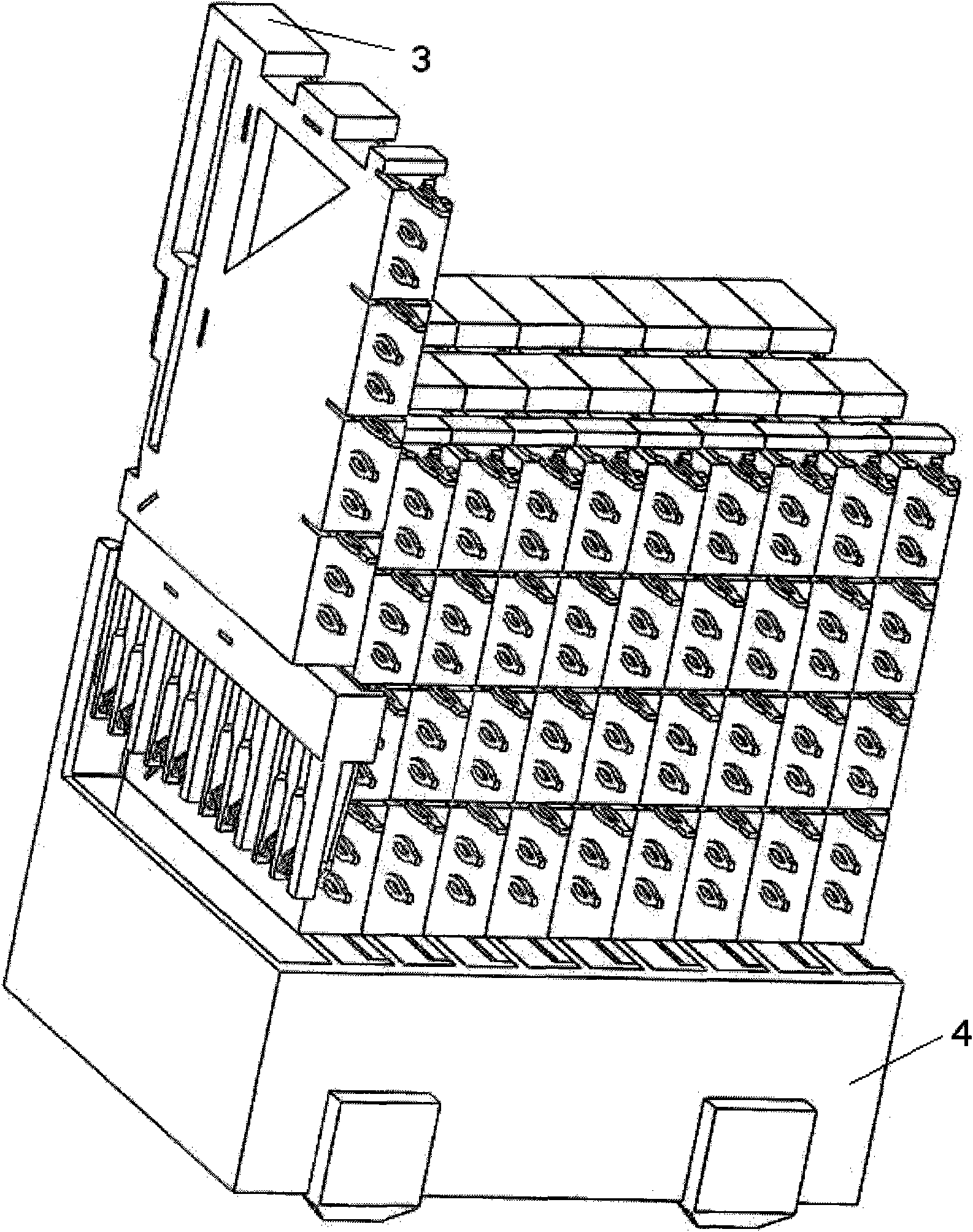

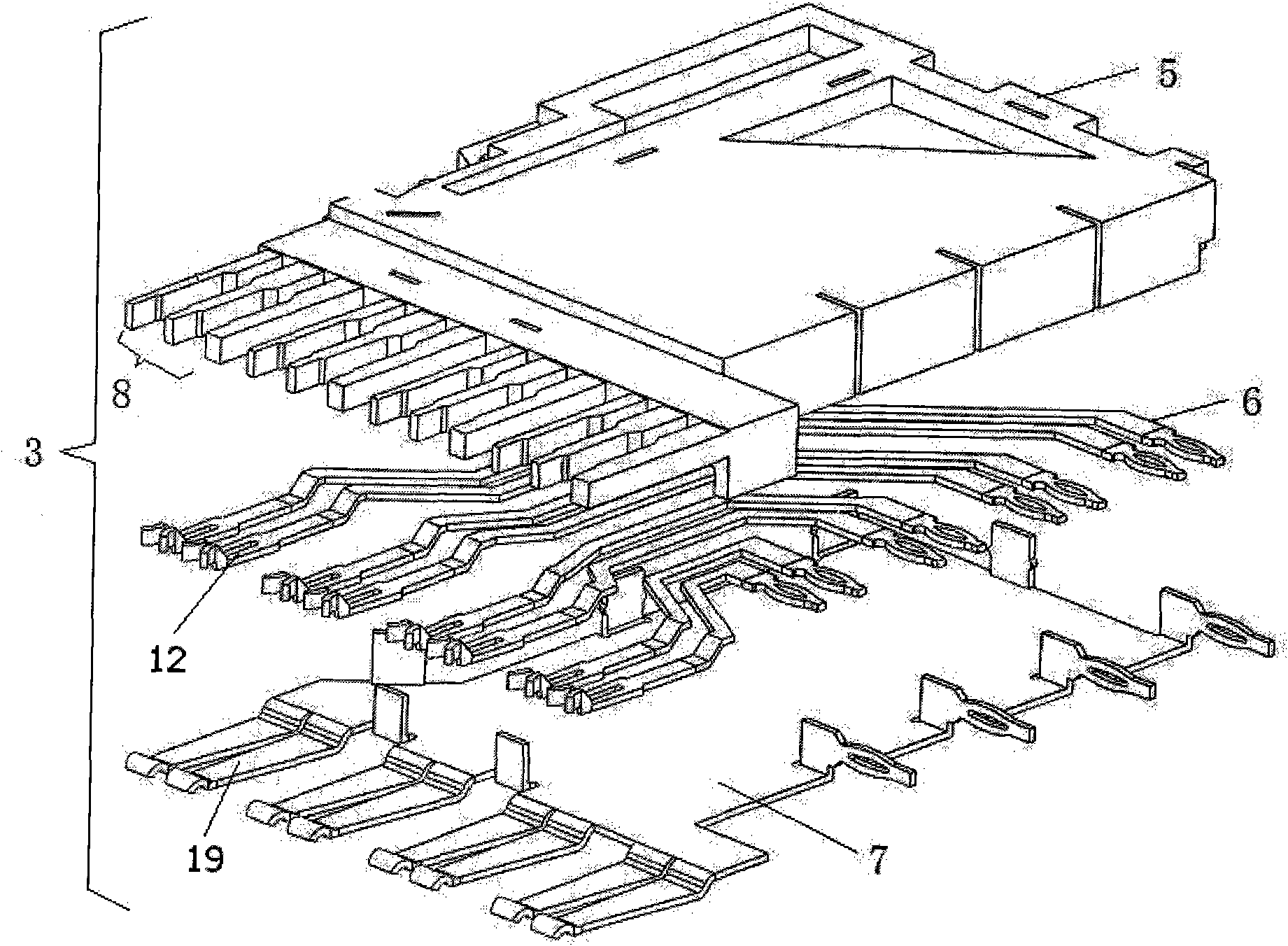

Connector socket capable of protecting jack terminal

InactiveCN102088148ASo as not to damageHigh strengthCoupling device detailsEngineeringMechanical engineering

The invention relates to a connector socket capable of protecting a jack terminal, wherein the socket comprises a module base and m jack modules, wherein the jack modules are composed of jack bases, jacks and jack shielding plates; one end of the jack base is provided with n plugs which are arranged in order; each plug is composed of two side columns and a central column disposed between the two side columns; the gaps formed among the two side columns and the central column are used for containing the jack terminal on the jack; and the outlines of the two side columns, the central column and the jack terminal within the plug are linear; the module base comprises n*m plug cavities which are used for installing n*m plugs and jack terminals contained in the plugs, wherein each plug cavity isinternally provided with a side wall and a central wall, and the plug and the jack terminal are arranged in the cavity between the side wall and the central wall. The connector socket capable of protecting a jack terminal provided by the invention has the advantages that the jack modules can be prevented from damaging while assembling by providing the plugs which are used for protecting the jacks, the jack bases and the jacks are integrated by means of injection molding, and the production and assembly efficiencies are improved.

Owner:CHINA AEROSPACE TIMES ELECTRONICS

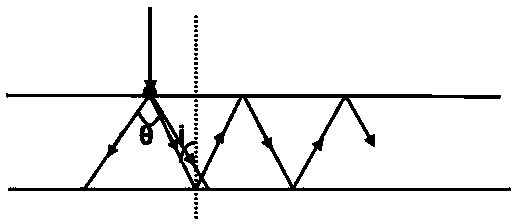

Design method and system for no air gap stable filling casting

InactiveCN1552542AReduce design sizePrevent splashFoundry mouldsFoundry coresSystems designNonferrous metal

A method for designing the non-air-gap smooth-filling casting features controlling the filling smoothness, lowering the filling speed, preventing air and oxidized film from coming in molten metal, reducing the size of pouring channel, and increasing the technological output rate. Its casting system has a pouring cup, a plug rod system connected with said pouring cup and opened when filled molten metal in the pouring cup reaches its 1 / 2-1 / 3 height, and the arc corner between vertical and horizontal pouring channels. Its pouring speed is 0.5-1.0 m / s.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

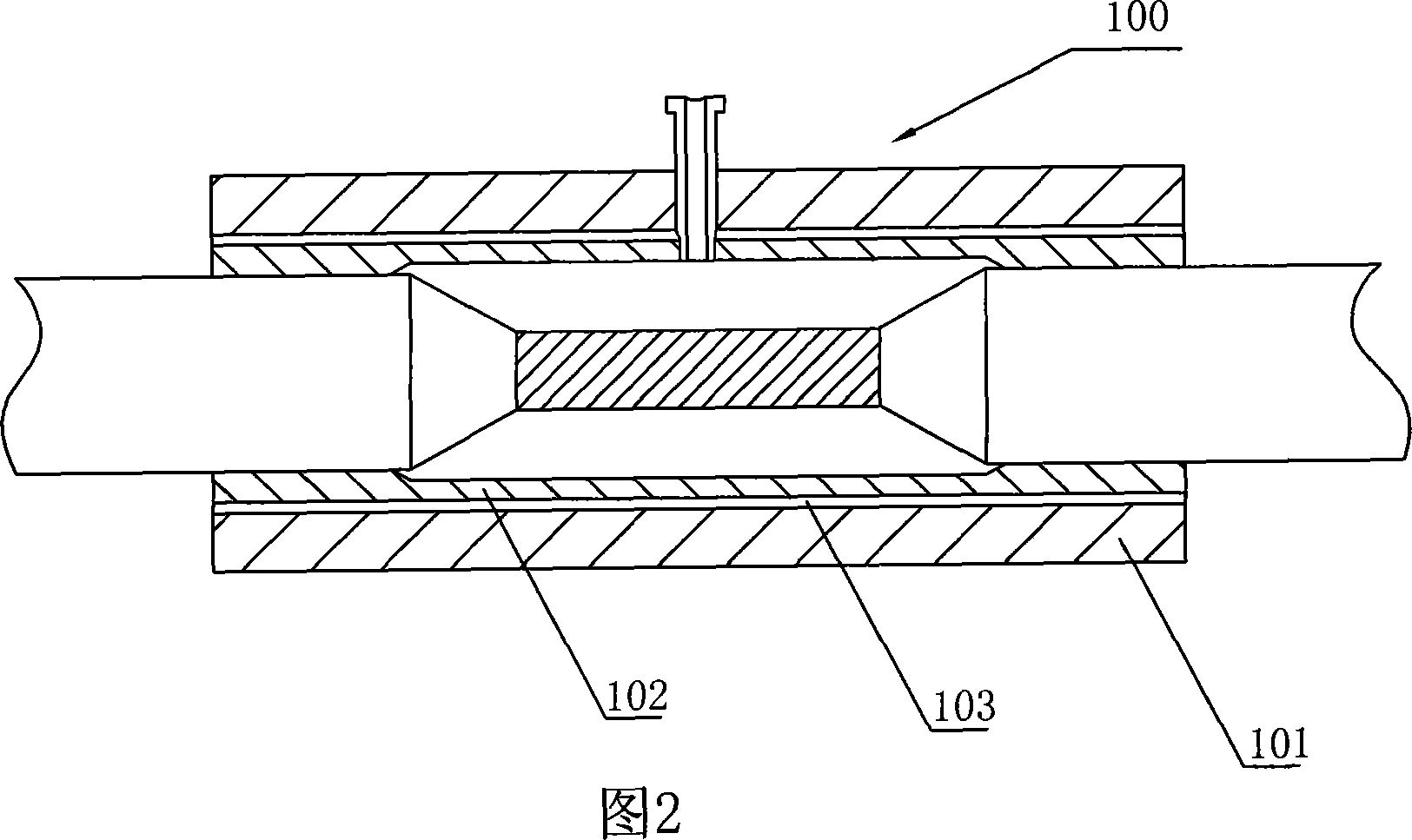

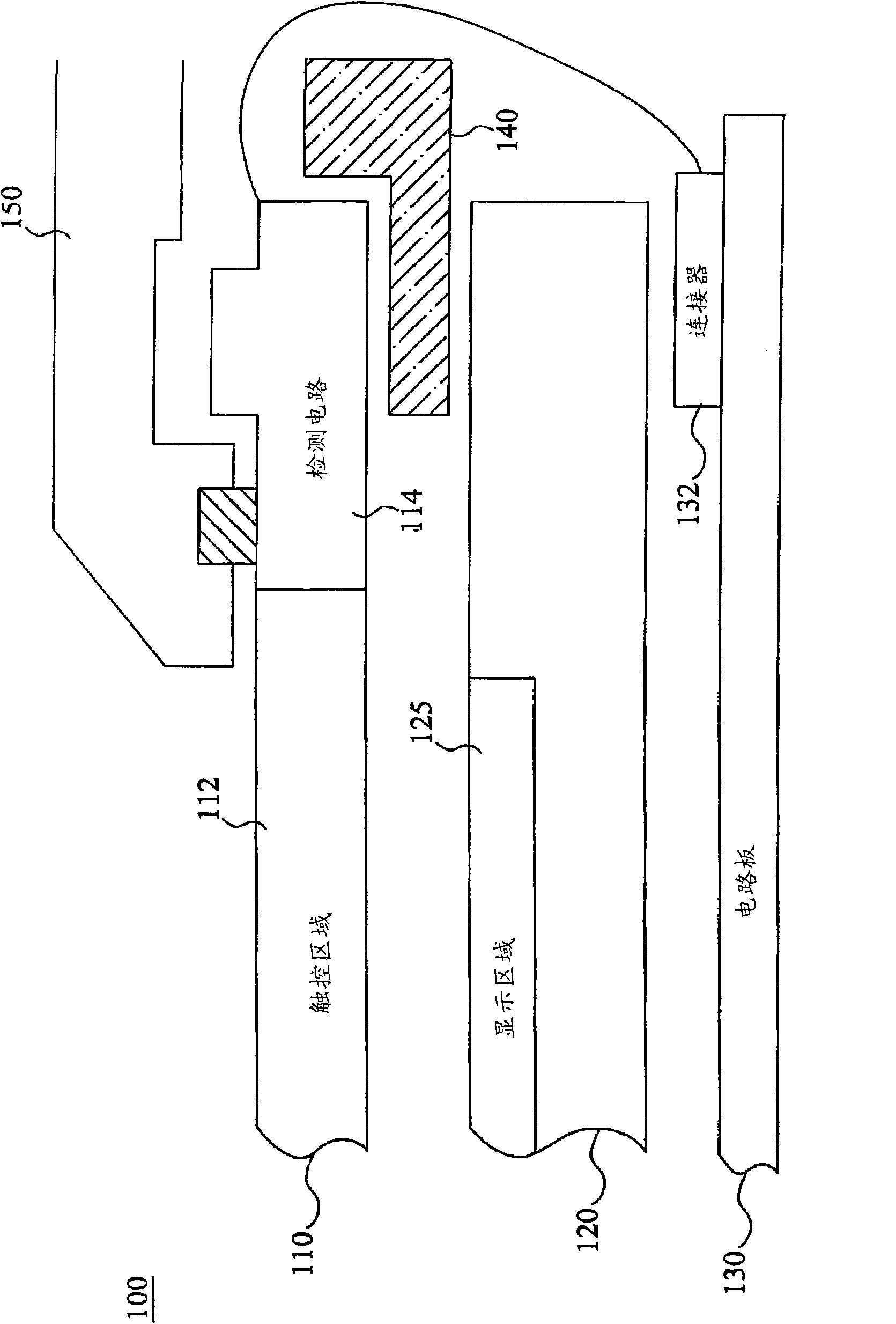

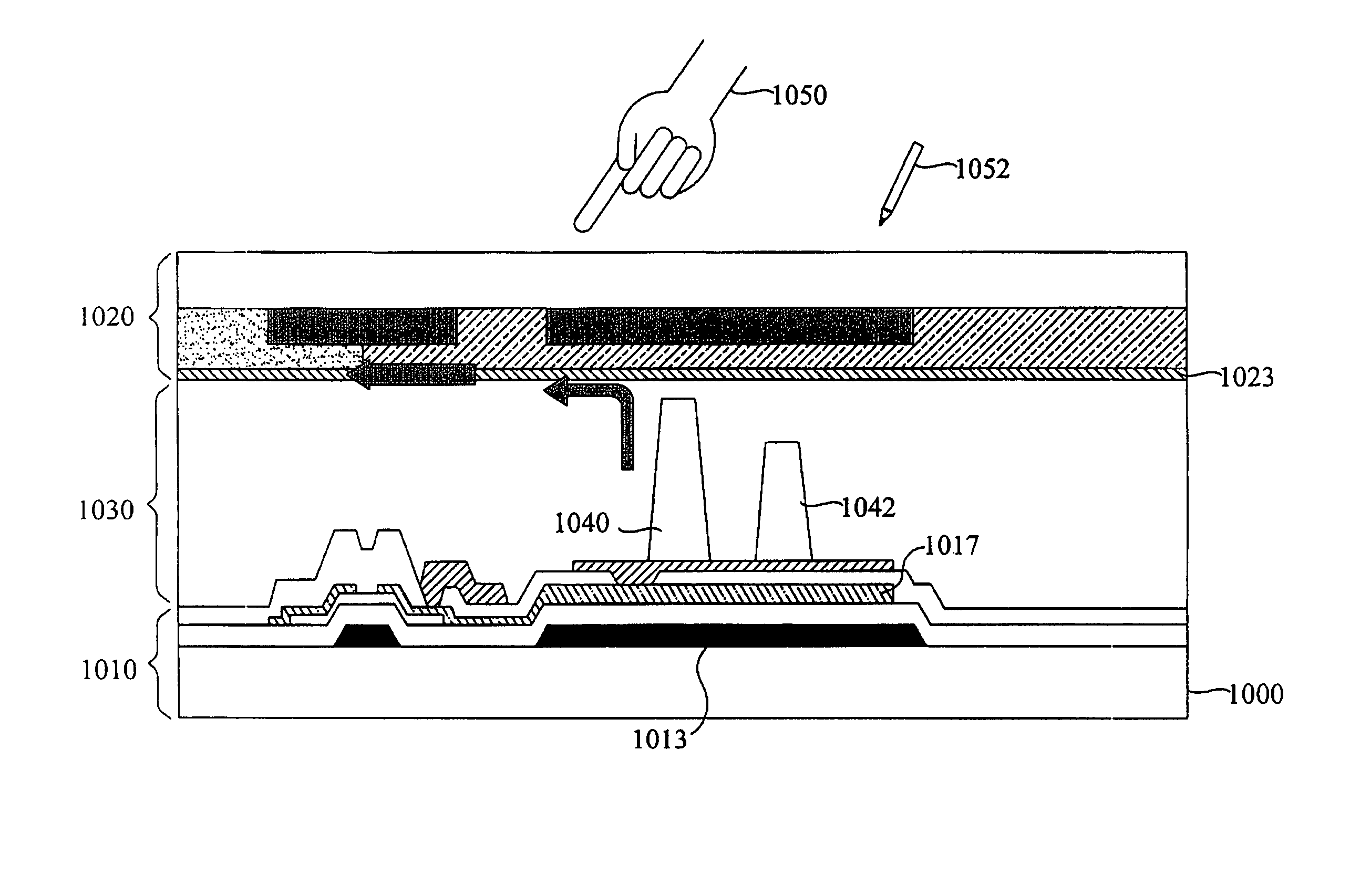

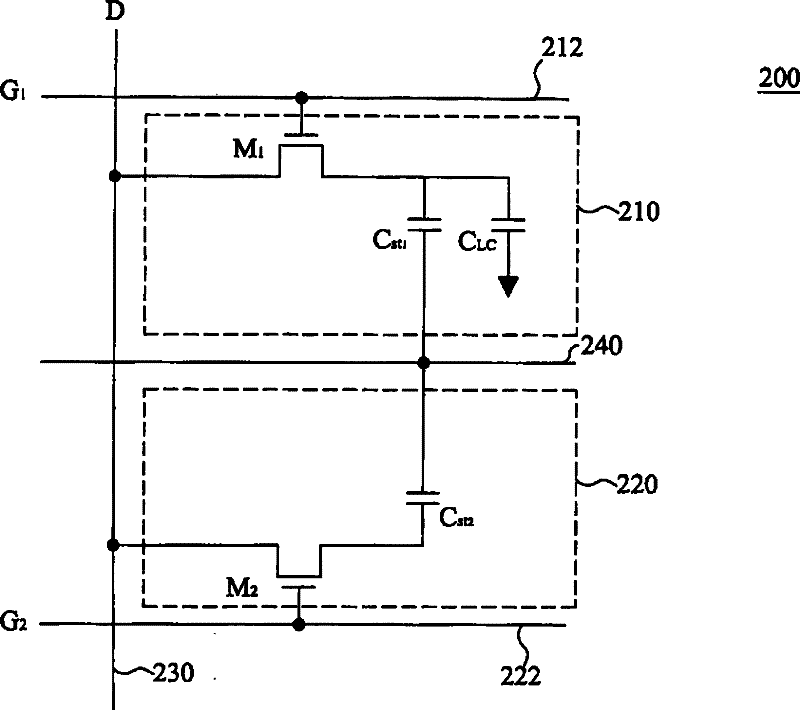

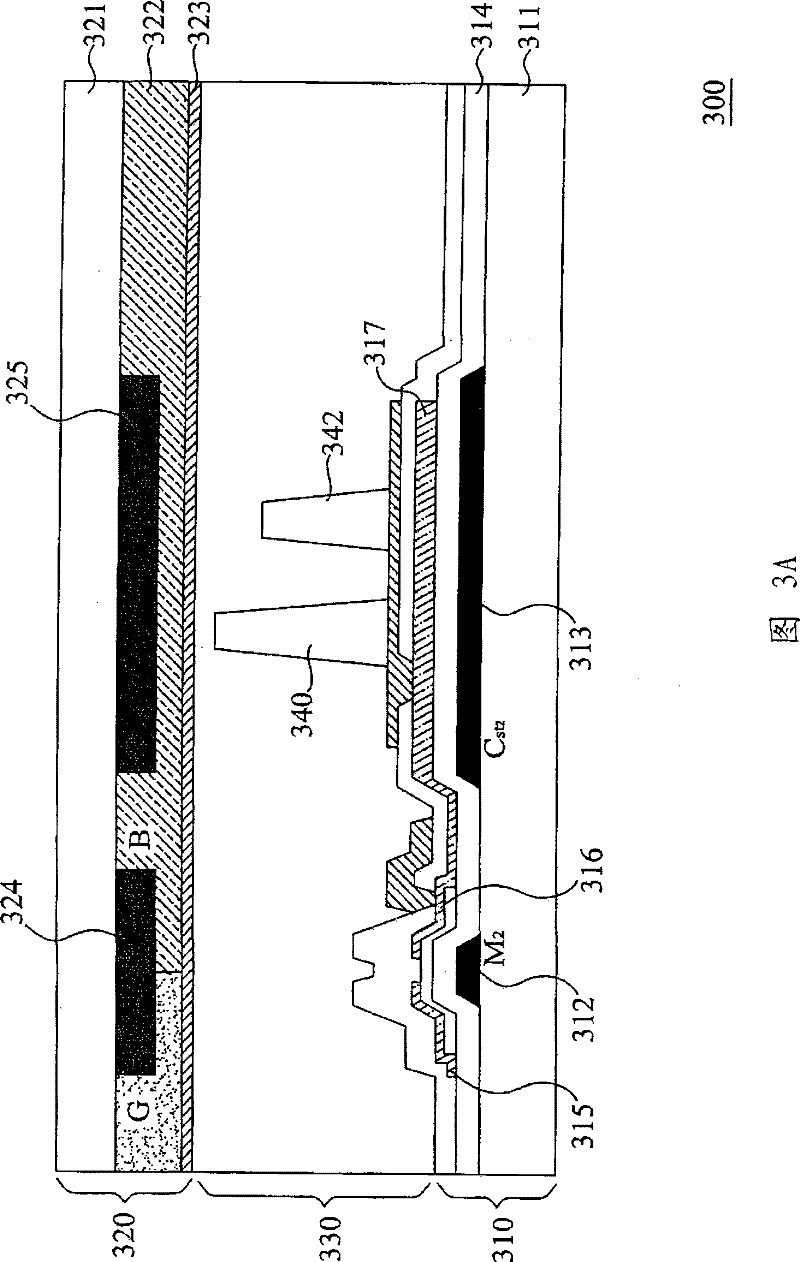

Integrated pixel structure, integrated touch control liquid crystal display device and touch control method thereof

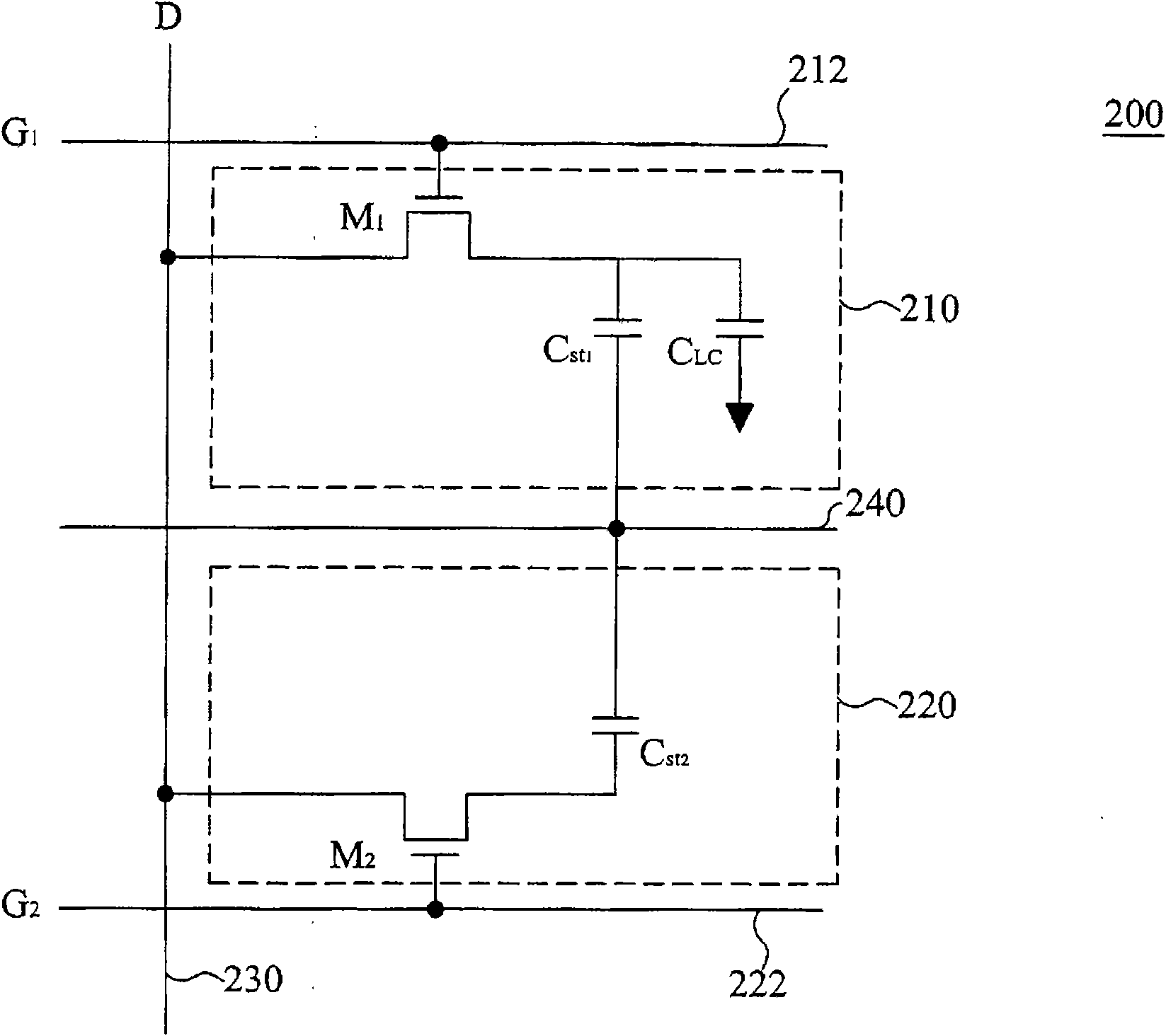

ActiveCN101661201ANo air gapWith multi-touch functionStatic indicating devicesNon-linear opticsTransistor arrayCapacitance

The invention provides an integrated pixel structure, an integrated touch control liquid crystal display device and a touch control method thereof. The integrated pixel structure comprises a transistor array base plate, a color light filter base plate parallel to the transistor array base plate, and a liquid crystal layer clamped between the transistor array base plate and the color light filter base plate, wherein the transistor array base plate comprises a first transistor, a first storage capacitor connected with the first transistor, a second transistor, a second storage capacitor connected with the second transistor, and a conducting convex body which corresponds to the second storage capacitor in order to electrically connect the second storage capacitor and the color light filter base plate when the color light filter base plate is extruded.

Owner:ACER INC

Integrated pixel structure, integrated touch panel LCD device and method of controlling the same

An integrated pixel structure, an integrated touch panel LCD device and a method of controlling the same are provided. The integrated pixel structure includes a transistor matrix substrate, a color filter substrate being parallel with the transistor matrix substrate, and a liquid crystal layer placed between the transistor matrix substrate and the color filter substrate. The transistor matrix substrate includes a first transistor, a first storage capacitor connected to the first transistor, a second transistor, a second storage capacitor connected to the second transistor, and a conductive protrusion. The conductive protrusion is disposed corresponding to the second storage capacitor and configured to electrically connect the second storage capacitor and the color filter substrate.

Owner:ACER INC

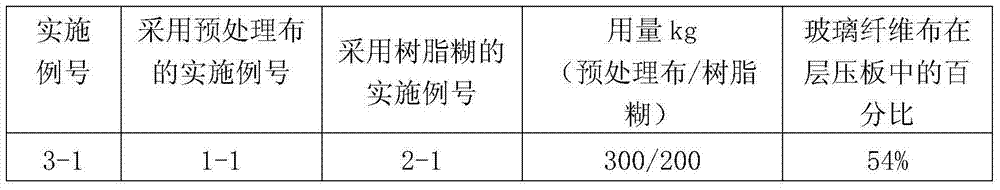

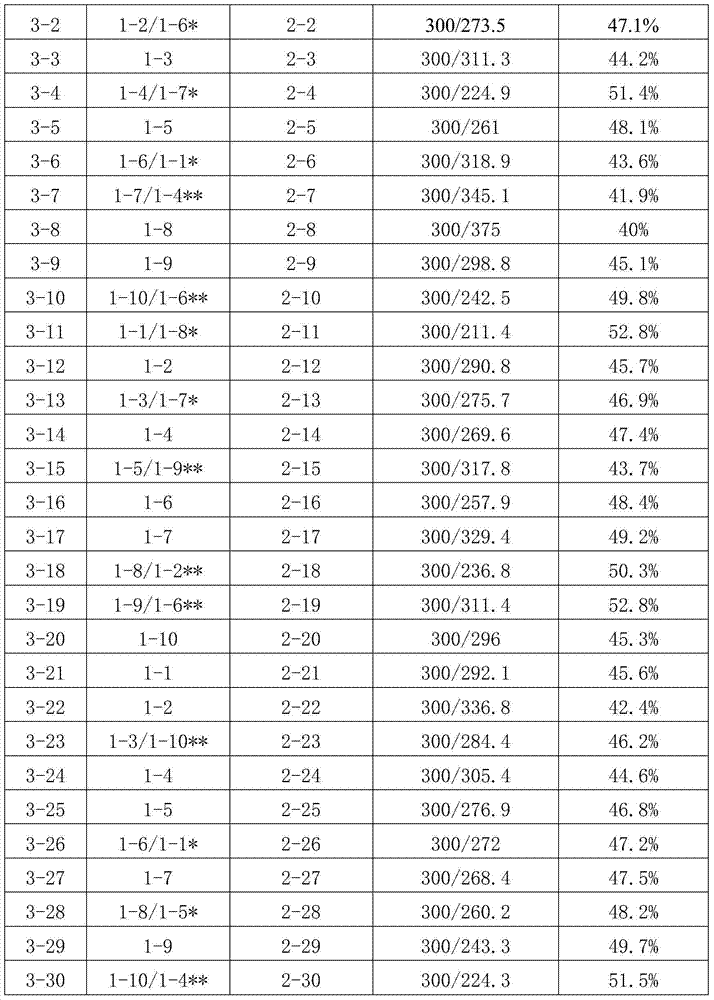

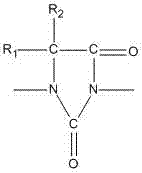

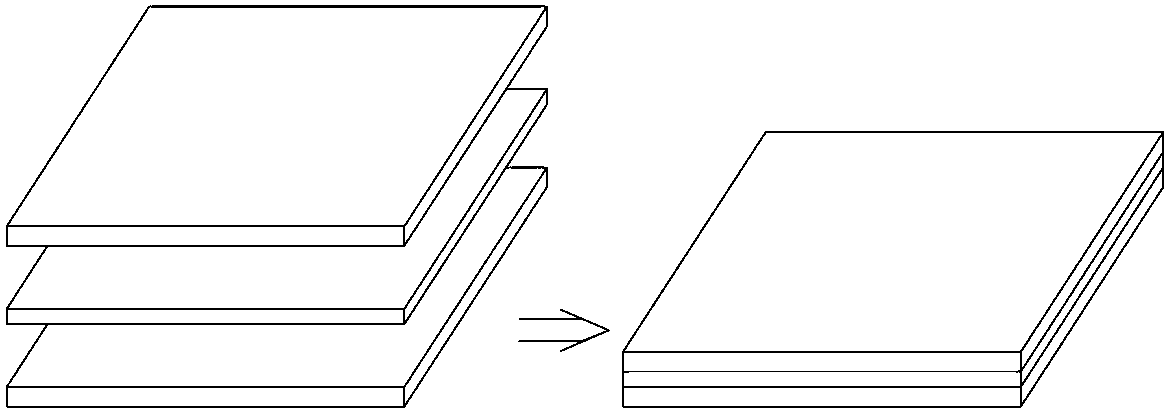

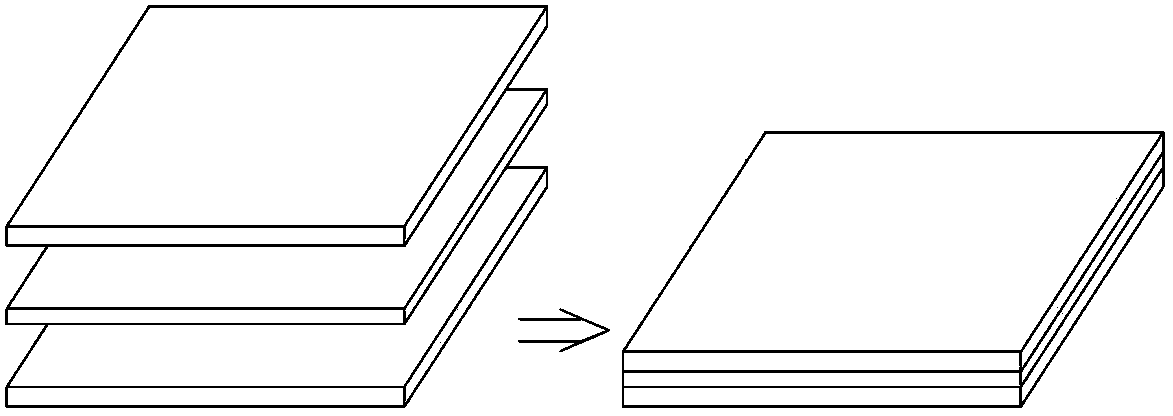

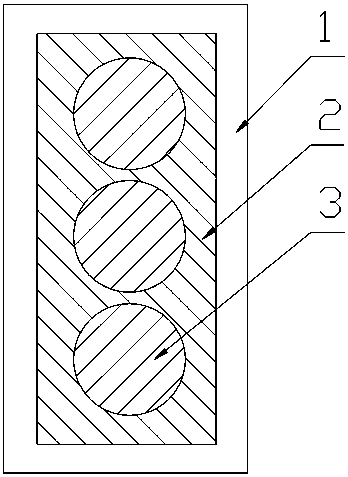

Unsaturated polyester glass fibre cloth laminated board and preparation method thereof

ActiveCN103496236AHigh mechanical strengthIncrease crosslink densitySynthetic resin layered productsLaminationGlass fiberFiber

The invention discloses an unsaturated polyester glass fibre cloth laminated board. The unsaturated polyester glass fibre cloth laminated board is characterized by being formed by more than one layer of overlapped unsaturated polyester glass fibre cloth prepreg through hot pressing, wherein each layer of unsaturated polyester glass fibre cloth prepreg is formed by one layer of glass fibre cloth to be pretreated and resin paste coating two sides of the glass fibre cloth to be pretreated. A preparation method of the unsaturated polyester glass fibre cloth laminated board comprises the following steps: preparing the glass fibre cloth to be pretreated, preparing the resin paste, and preparing the unsaturated polyester glass fibre cloth laminated board through hot pressing. According to the invention, the unsaturated polyester glass fibre cloth laminated board has the characteristics of high mechanical strength, halogen-free flame retardance, low shrinking percentage and the like, and is particularly applicable to components with high-strength insulation structures of motors, electrical appliances, high-tension power transmission and transformation equipment and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

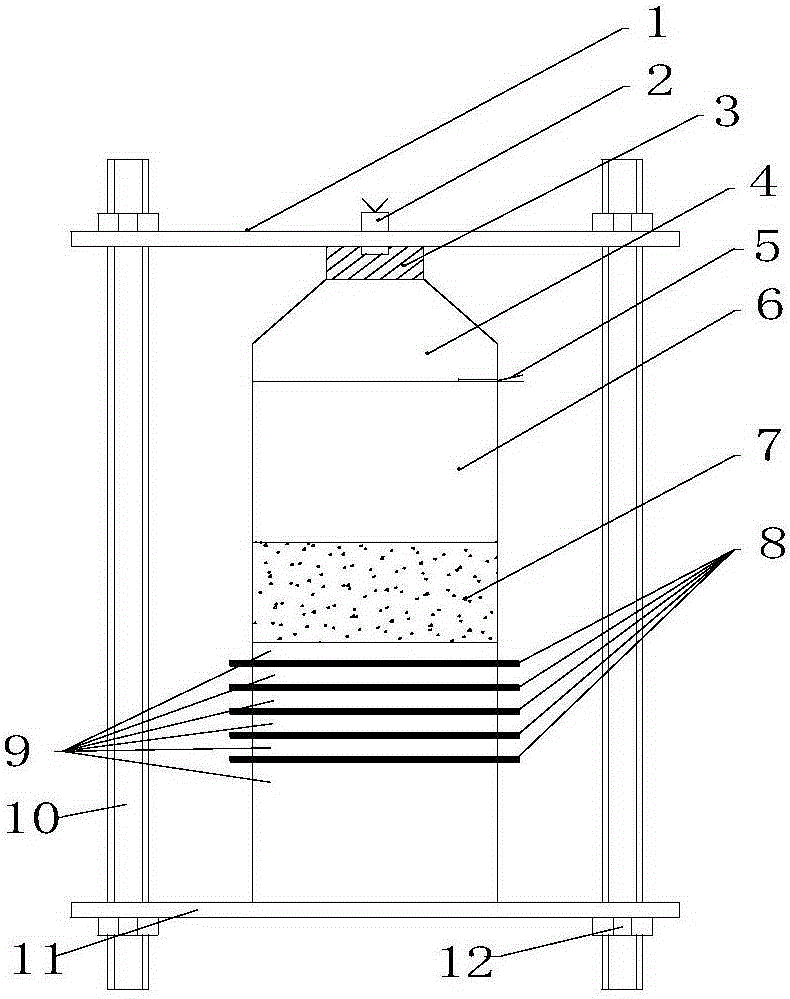

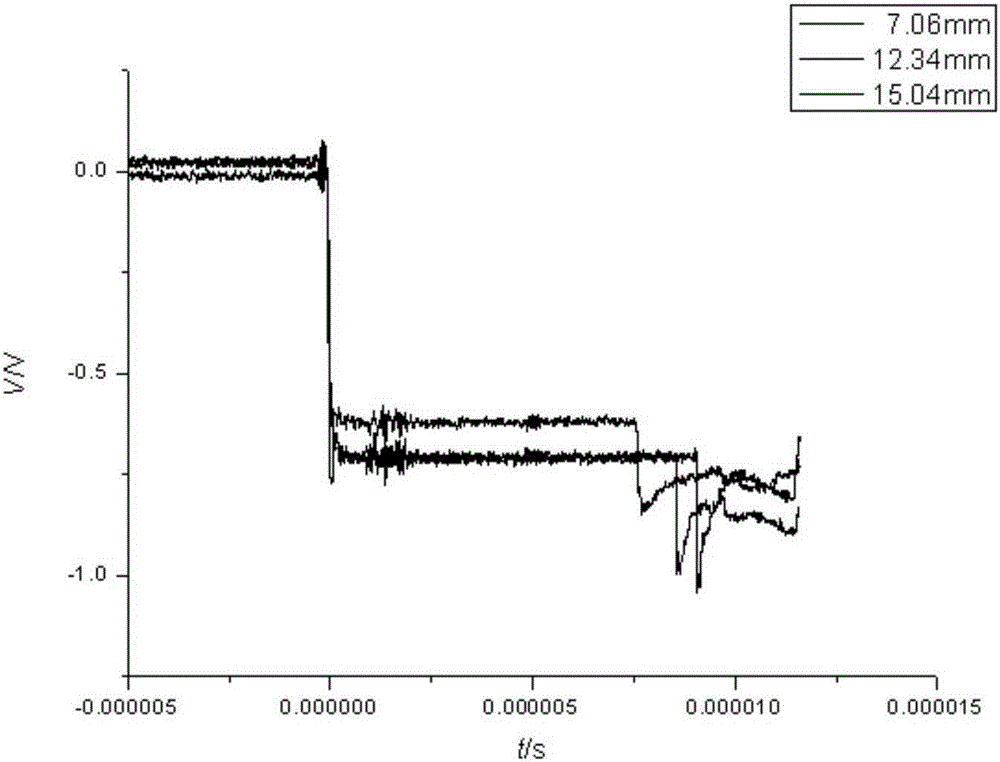

Mounting method of device for testing pressure at different depths under impact of explosives and powders

ActiveCN105203245AEasy to fixNo displacementFuel testingMeasurement of explosion forceSoftware engineeringPlane wave

The invention discloses a mounting method of a device for testing pressure at different depths under the impact of explosives and powders. According to the method, all testing components are fixed through a testing support, and reliable positioning of all the components is guaranteed; a powder column to be tested, manganin piezoresistive sensors, a partition plate, a loaded powder column, a plane wave generator and a booster explosive are placed between a lower fixing plate and an upper fixing plate from bottom to top, screws and nuts are used for squeezing and fixing, and no air gaps exist between all the components. The method is applied to mounting the device for testing the pressure at different depths under the impact of the various explosives and powders, all the components are reliably fixed and positioned, and the accuracy of test measuring results is guaranteed.

Owner:XIAN MODERN CHEM RES INST

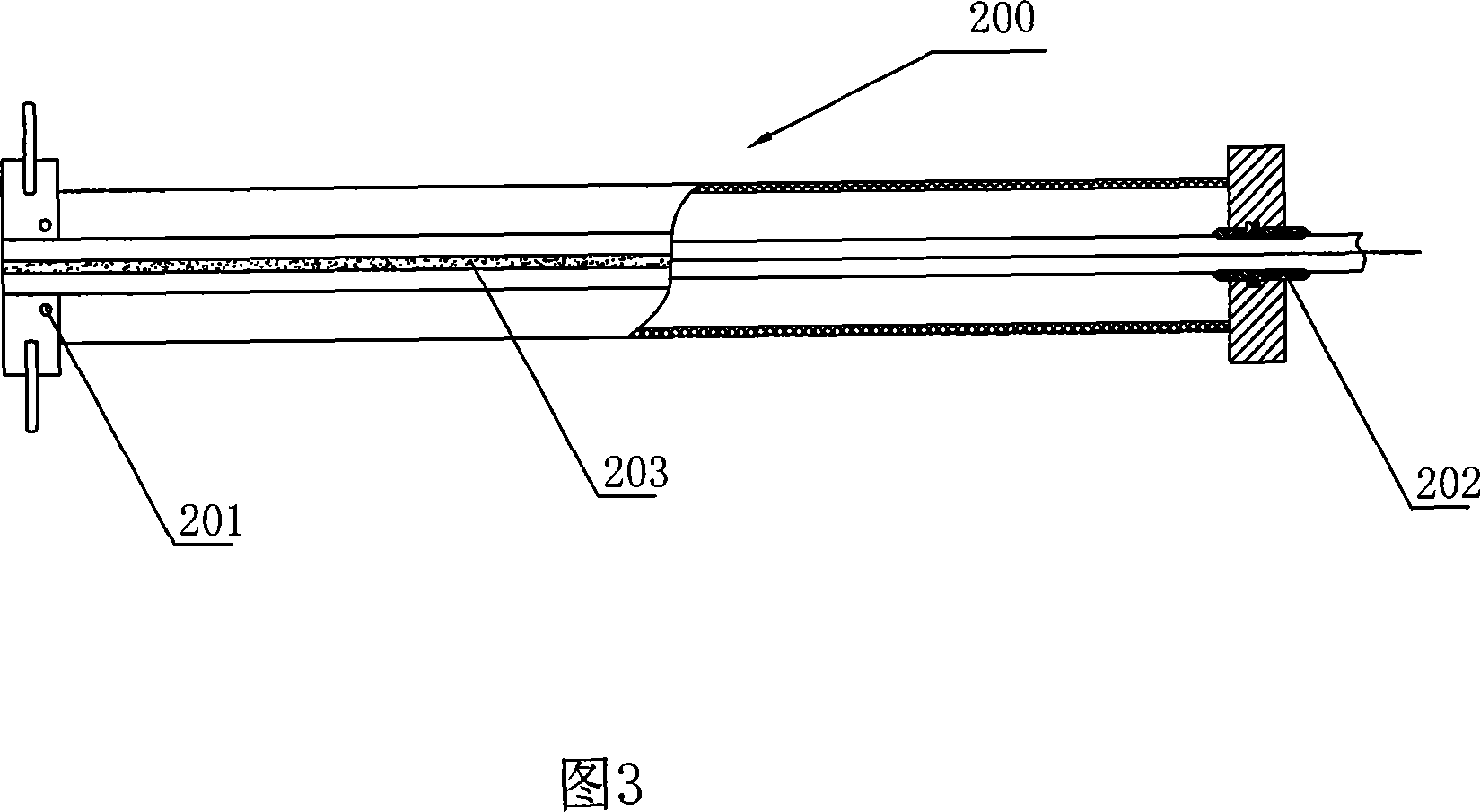

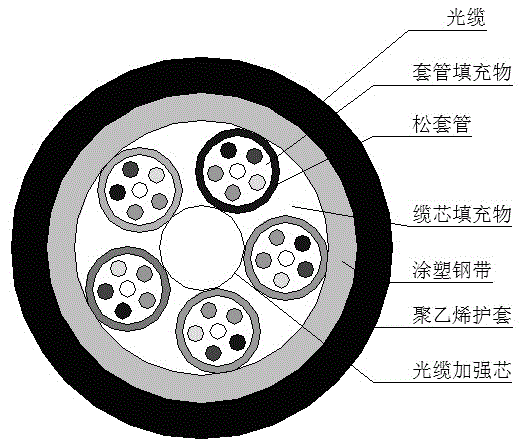

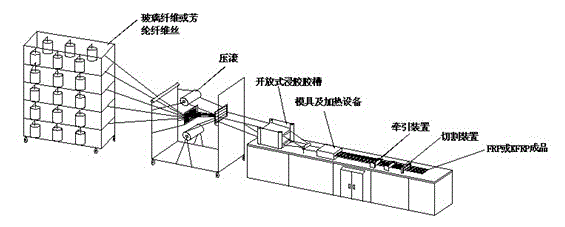

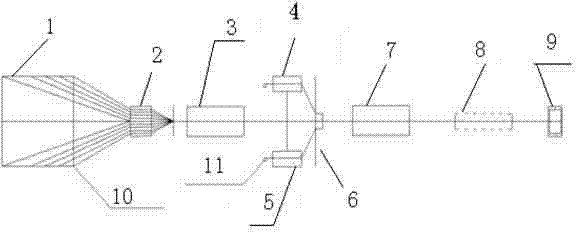

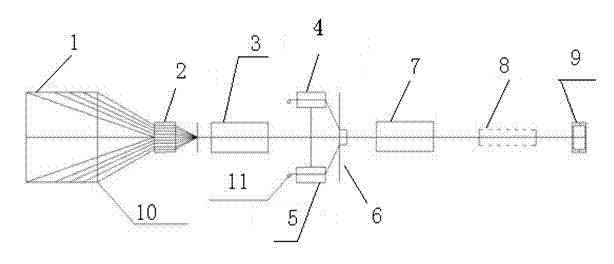

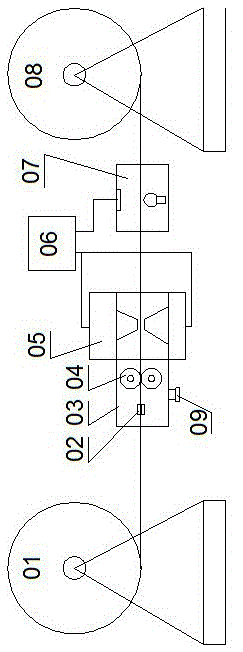

Sealing dipping pultrusion system device for producing optical fiber reinforced core and preparation method

The invention discloses a sealing dipping pultrusion system device for producing an optical fiber reinforced core and a preparation method. The device is characterized in that a heat moisture removing device, a seal pressure dipping device, a heat molding mold, a mechanical traction device and a rolling reel device are arranged at the right side of a guide creel in sequence, the upper end of a transparent sealing glue storage tank is connected with a glue inlet through a 1# valve and a pipeline; the lower end of the transparent seal glue storage tank is connected with the seal pressure dipping device through a 2# valve and a pipeline; the bottom of the seal pressure dipping device is connected with a glue outlet through a 3# valve and a pipeline; and the tail end of the seal pressure dipping device is connected with a vacuum pump through a 4# valve and a pipeline. The device provided by the invention is simple in structure, pollution-free for atmosphere, harmless for bodies of workers, and the harmful gases in glue material cannot be volatized; the product is strong in corrosion resistance, resistant to rust, free from nitrogen damage, does not affect the signal propagation performance of optical fiber, is insensitive to electric shock and long in service life. The product has no air gap, is large in density, high in strength and excellent in performance, thus, the device can be widely used for the manufacturing industry of optical fiber communication.

Owner:西安永兴科技发展有限公司

Mine cable rubber sheath conductor shielding material

InactiveCN103819820AImprove conductivityHigh purityInsulated cablesInsulated conductorsElectrical conductorPlasticizer

The invention discloses a mine cable rubber sheath conductor shielding material, which is prepared from the following raw materials in parts by weight: 100 parts of ethylene propylene diene monomer, 70 to 90 parts of imported conductive carbon black, 2 to 5 parts of cross-linking agent, 2 to 6 parts of assistant cross-linking agent, 10 to 40 parts of plasticizer, 1 to 5 parts of anti-aging agent, 1 to 5 parts of flowing dispersing aid and 5 to 30 parts of colloidal graphite powder. A high-voltage mine cable prepared from the mine cable rubber sheath conductor shielding material has the advantages of uniform conductor surface electric field, non-strippability of a conductor shielding layer and an insulating layer, high ozone resistance and high thermal aging resistance.

Owner:上海蓝昊电气江苏有限公司

Preparation method of crosslinked polyethylene cable connector

InactiveCN106374397AElectrical performance improvements and enhancementsEliminate void defectsApparatus for joining/termination cablesAnti stressEngineering

The invention relates to a cable connector, in particular to a preparation method of a crosslinked polyethylene cable connector. The preparation method comprises the following steps: firstly, peeling and cutting insulating layers at two ends of a cable so that a core of the cable is exposed; secondly, cutting the crosslinked insulating layers on two sides of the connector to be conical; thirdly, setting an anti-stress cone at the end of the cable, and fixing the treated cable to two ends of an insulating forming die, wherein the insulating forming die comprises a metal outer die and an elastic lining die, an elastic die expansion gap is formed between the metal outer die and the elastic lining die, and the temperature of an inner cavity of the insulating forming die is raised to be 120 DEG C; fourthly, after performing cleaning drying treatment on the surface of the insulating layer, setting an outer semi-conducting layer in combination with an outer shielding layer reserved section of the cable; and fifthly, wrapping a metal belt on the surface of the outer semi-conducting layer in a gap manner, using an oxyhydrogen flame to firmly weld two ends of the metal belt and the outer surface of a lead protective tube so as to form a metal projective sleeve tube, and then using the oxyhydrogen flame to trim welding surfaces at two ends of the metal protective sleeve tube so as to form a slope connecting section.

Owner:重庆三峡电线电缆科技股份有限公司

Method for manufacturing solar double-glass assembly

InactiveCN104183669AUniform temperature transferMelted completelySemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringSurface layer

The invention discloses a method for manufacturing a solar double-glass assembly. The method includes the following steps that (1) a PVB adhesive film, a solar battery string, a PVB adhesive film and surface layer tempered glass are sequentially laid on bottom layer tempered glass, so that the solar double-glass assembly is formed; (2) whether hidden cracking pieces exist in solar battery pieces of the double-glass assembly in the first step is checked, and the hidden cracking pieces are removed; (3) the double-glass assembly is placed in a laminating machine under the -1 barometric pressure, the process is kept for 30-40 minutes, then an upper chamber of the laminating machine is placed at the pressure of -0.5 MPA, a lower chamber is placed at the pressure of -1 MPA, the process is kept for 20-30 minutes, afterwards, the temperature rises to be 140+ / -5 DEG C, and at the pressure of -0.5 MPA to -0.6 MPA, the process is kept for 20-30 minutes; (4) whether hidden cracking pieces exist in the solar battery pieces of the laminated double-glass assembly is checked, and the hidden cracking pieces are removed; (5) the double-glass assembly is fixed, the double-glass assembly is placed in an autoclave, and after a dehumidifier is used for dehumidifying, under the conditions of 20-150 DEG C and 0-1.3 MPA, the process is kept for 2-4 hours.

Owner:JIANGSU CHENDIAN SOLAR PHOTOELECTRIC TECH

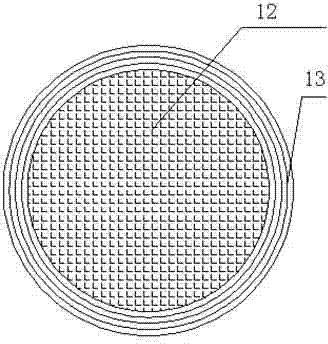

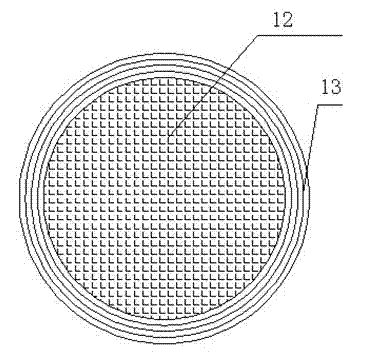

Cable core of carbon fiber composites

ActiveCN103093888AImprove mechanical propertiesExtend working lifeInsulated cablesInsulated conductorsGlass fiberEpoxy

The invention relates to a cable core of carbon fiber composites. The cable core of the carbon fiber composites comprises a bearing core (12) and a protective layer (13), and the protective layer (13) covers the outer portion of the bearing core (12) through a winding process. The cable core is characterized in that the bearing core (12) is the composite of epoxy resin and carbon fibers, wherein the epoxy resin is heat resisting and high in mechanical property, and the protective layer (13) is the composite of epoxy resin and glass fibers, wherein the epoxy resin is high temperature resisting and weather resisting. Due to the fact that the bearing core and the protective layer are chosen to be different epoxy resin systems, the high mechanical property of the epoxy resin system of the bearing core cannot be influenced by the epoxy resin system of the outer protective layer, the good weather resisting property of the outer protective layer protects the bearing core from being damaged by outer environment, and the combination property of the cable core is greatly improved.

Owner:CHANGJI POWER SUPPLY COMPANY STATE GRID XINJIANGELECTRIC POWER +1

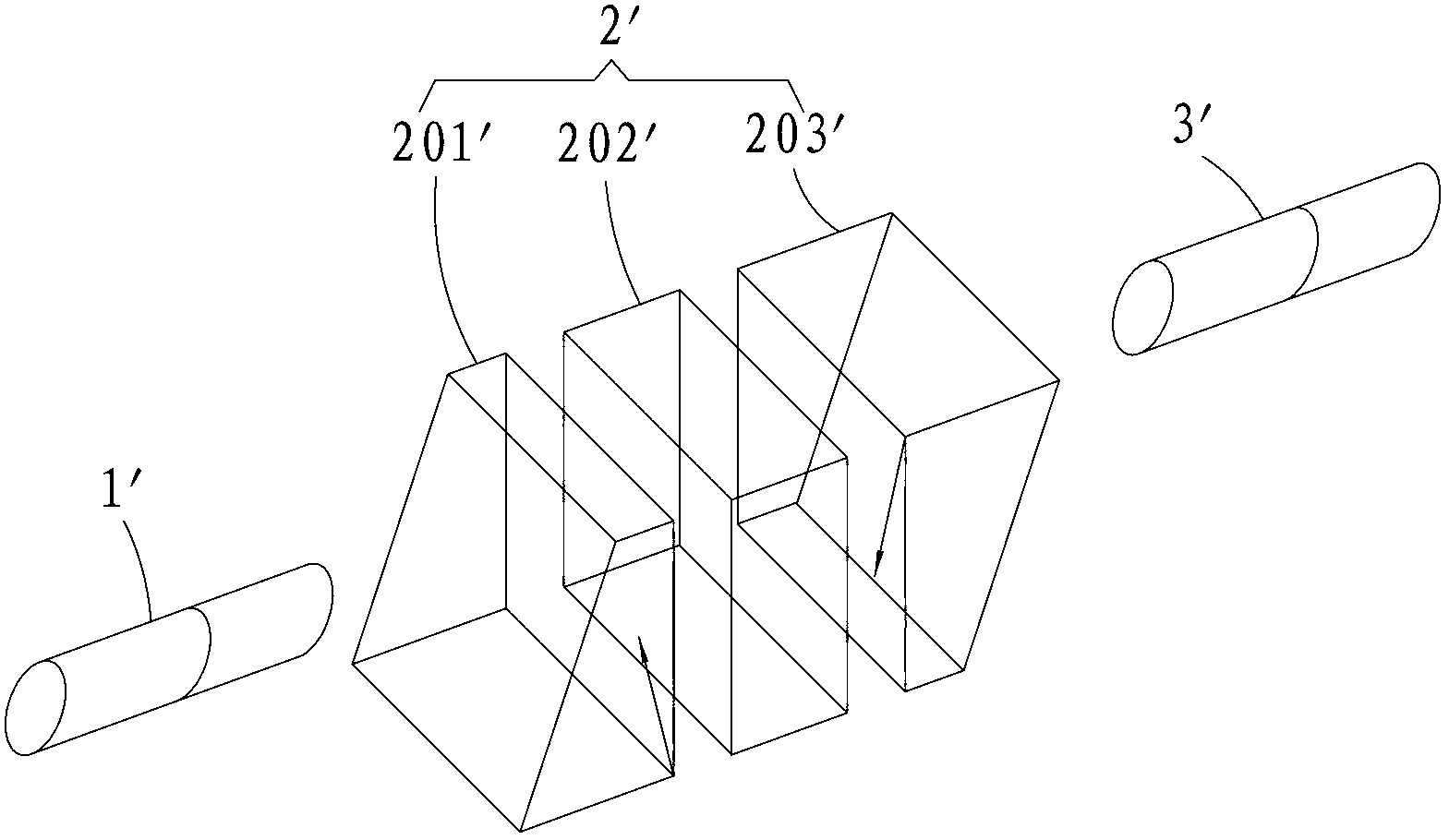

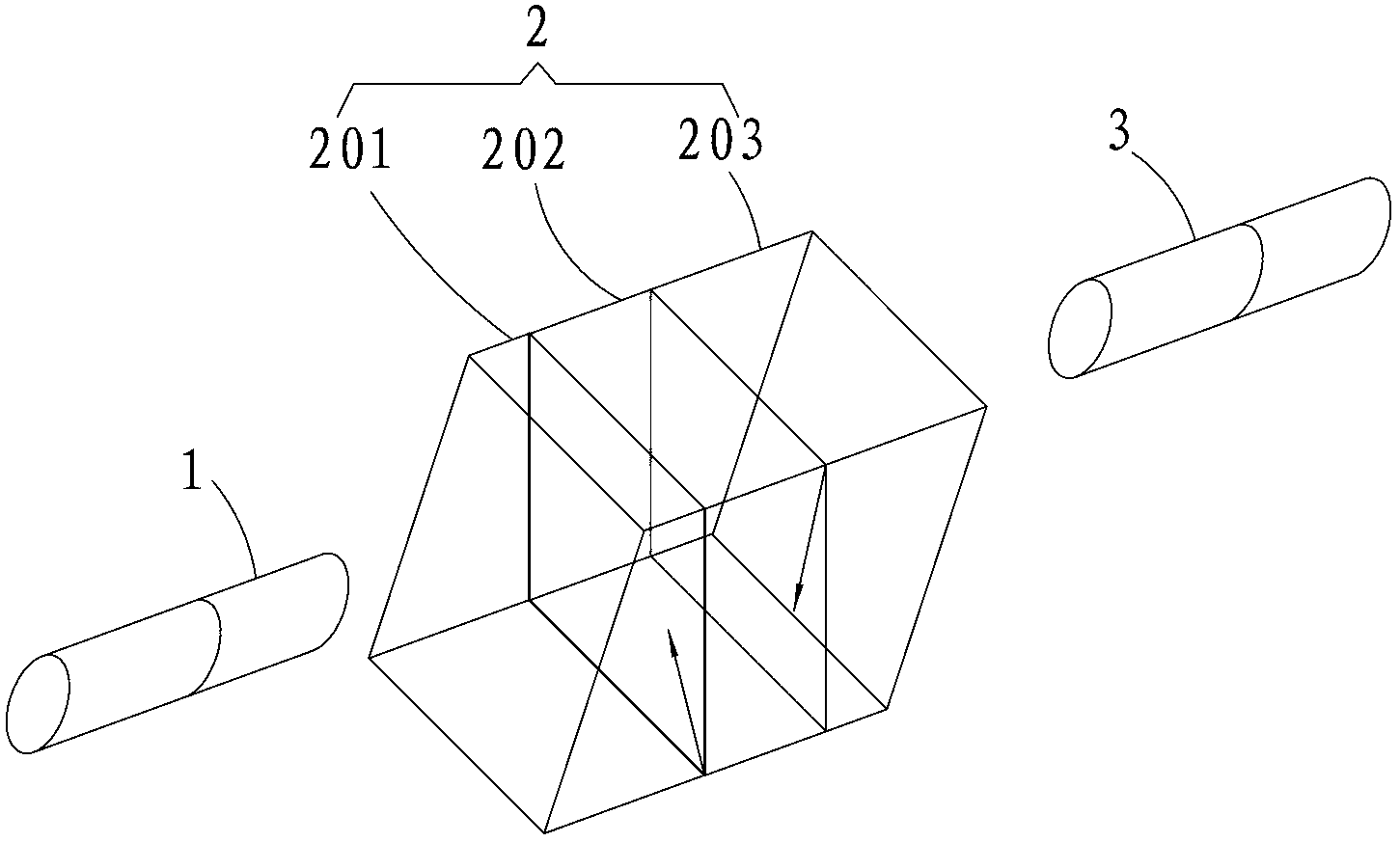

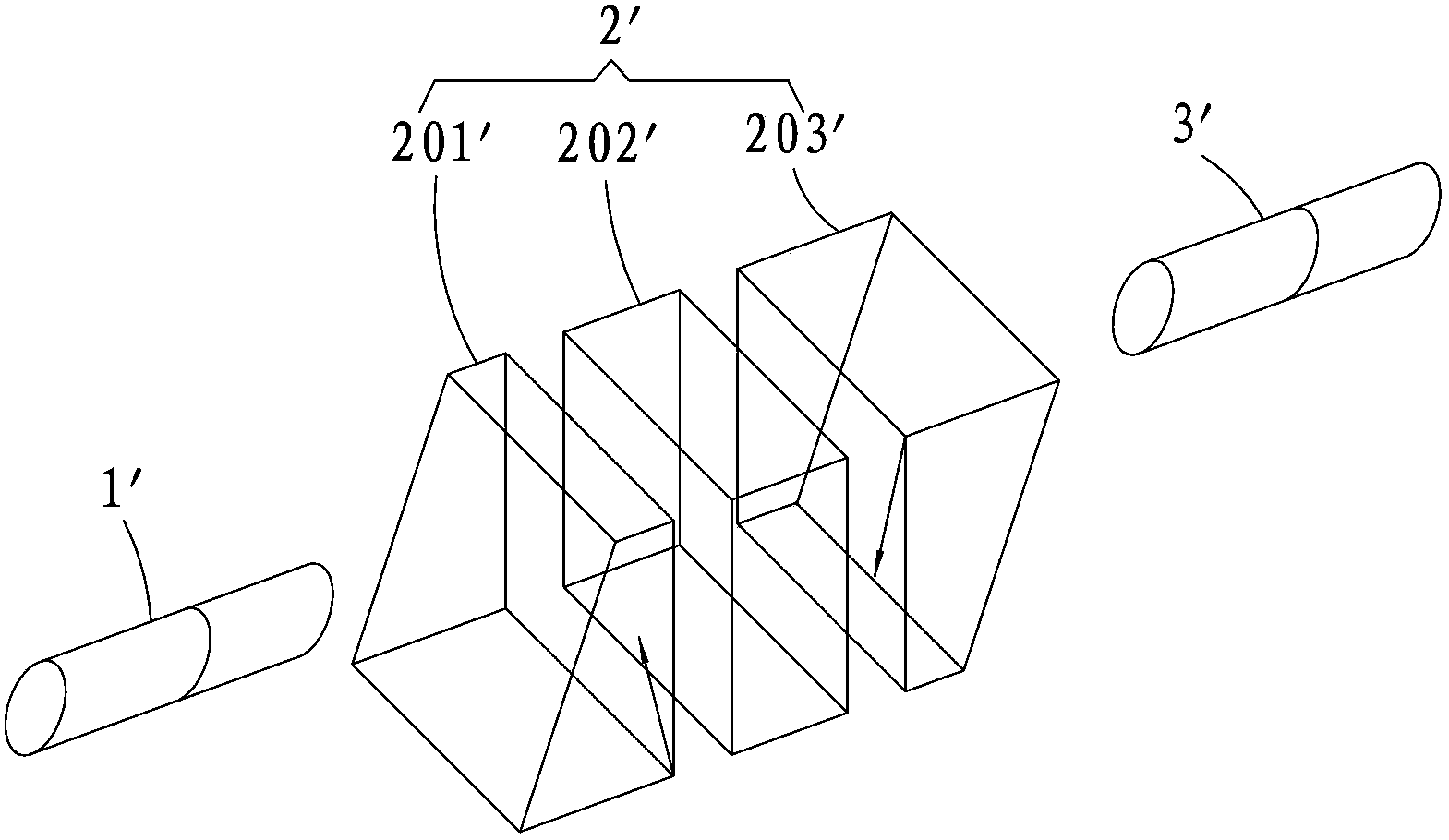

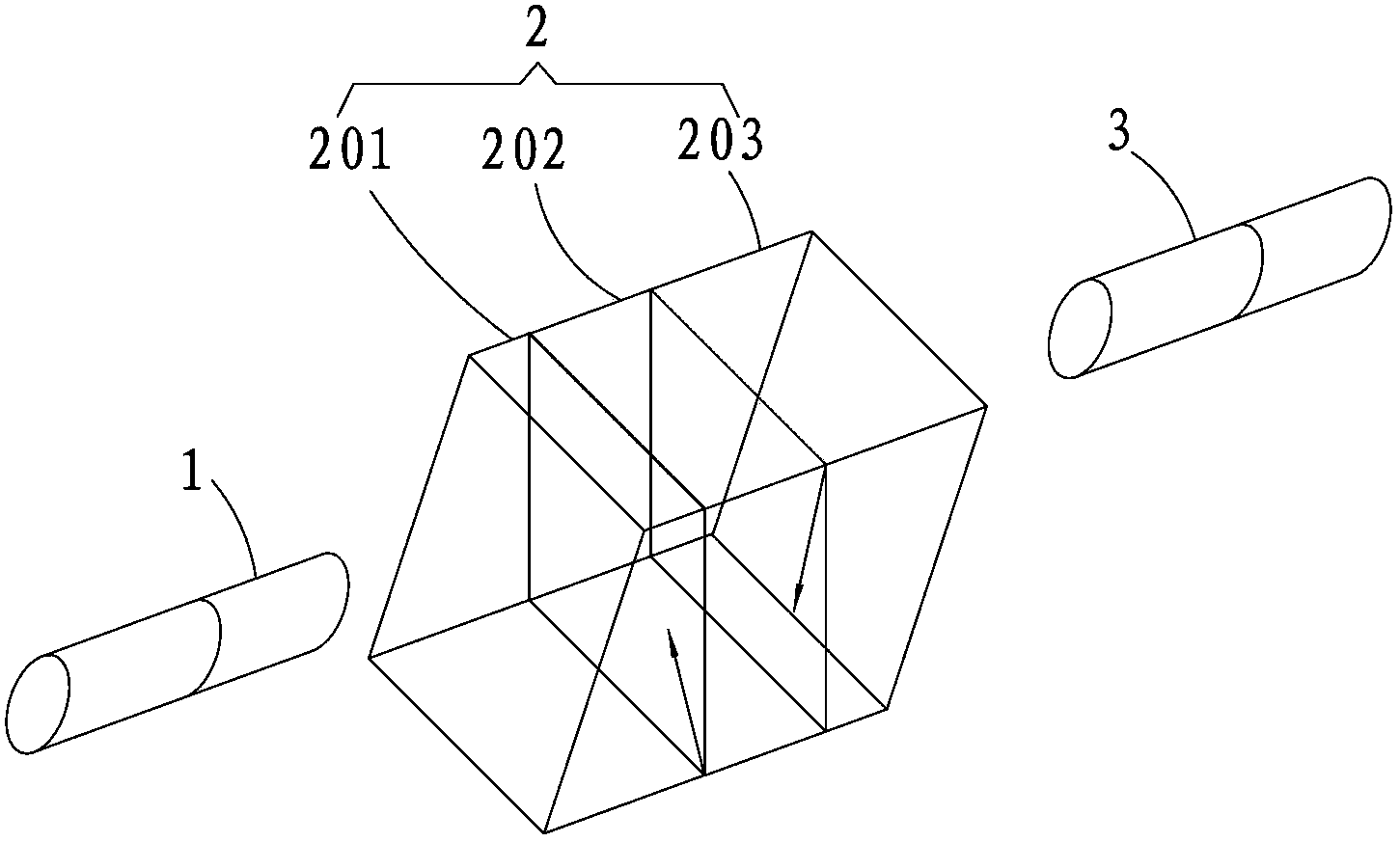

Manufacturing method of polarization-independent optical isolator, bonding technology and solution of optical components

ActiveCN102707461AReduce manufacturing costIncrease productivityNon-linear opticsOptical pathEngineering

The invention provides a manufacturing method of a polarization-independent optical isolator. The manufacturing method comprises the following steps of: cutting a first birefringent crystal flat plate, a polarization rotating crystal flat plate and a second birefringent crystal flat plate into the plates with the same light-penetration size; bonding the plates into a composite crystal flat plate with the large light-penetration size in an oxy-hydrogen catalytic bonding technology and then cutting the composite crystal flat plate into long strips; grinding and polishing wedge-angle planes; plating an anti-reflection film for increasing air permeability; cutting into an integrated bonded isolator core according to the actual usage size; and finally, assembling into a complete polarization-independent optical fiber online isolator. According to the manufacturing method of polarization-independent optical isolator, a bonding technology and a solution of optical components provided by the invention, various discrete optical components of the isolator core do not need to be manufactured independently, an optical path without glue is guaranteed, no air gap exists among the optical components, and a problem of difficultly treating parallelism in assembling of the discrete optical components is solved; the relative loss of the polarization is reduced, the application range and the service life of the isolator core are improved, the production cost is reduced by a large margin and the production efficiency is improved.

Owner:CASIX

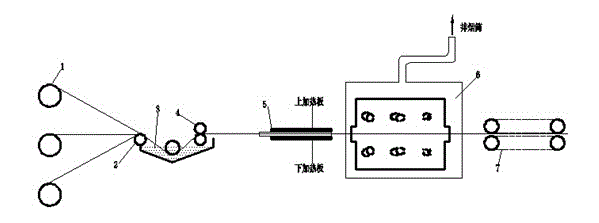

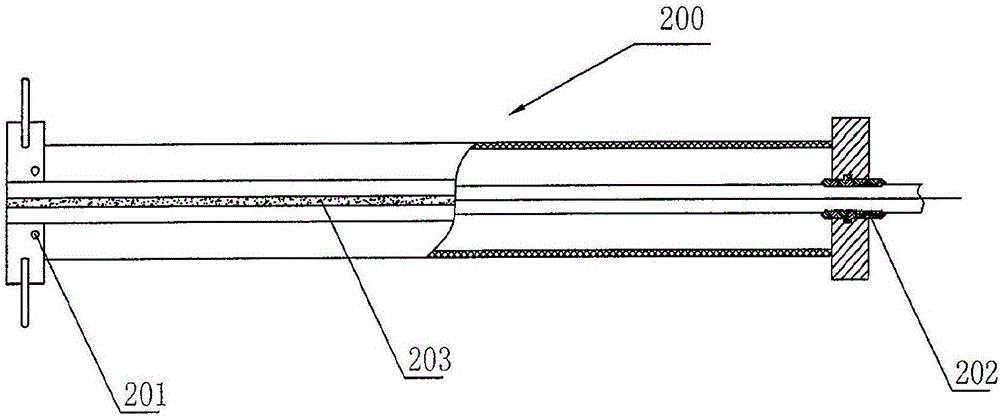

Manufacture method of cable core

InactiveCN103093897AImprove mechanical propertiesExtend working lifeCable/conductor manufactureGlass fiberEpoxy

The invention relates to a manufacture method of a cable core. The manufacture cost of the cable core comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is epoxy resin with heat-resisting high mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite core are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree reaches more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resistant and weather resistant; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through the second curing oven after being compounded, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:STATE GRID CORP OF CHINA +1

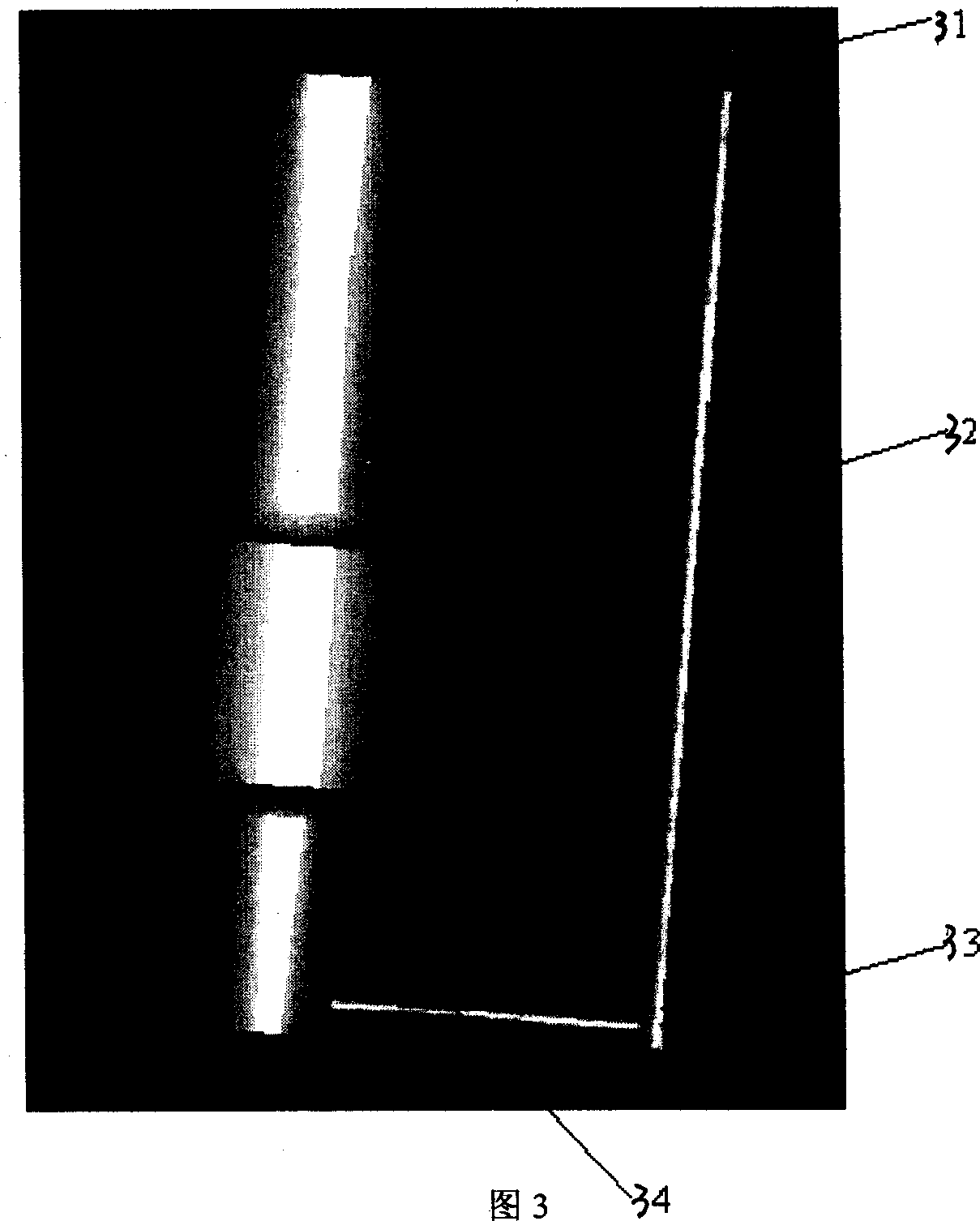

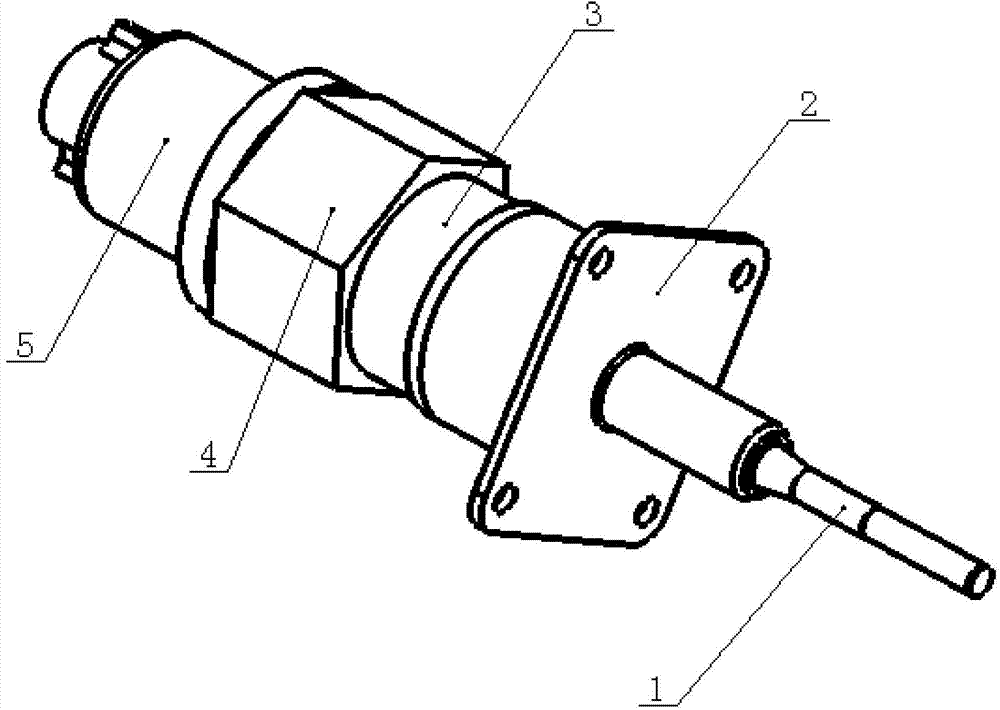

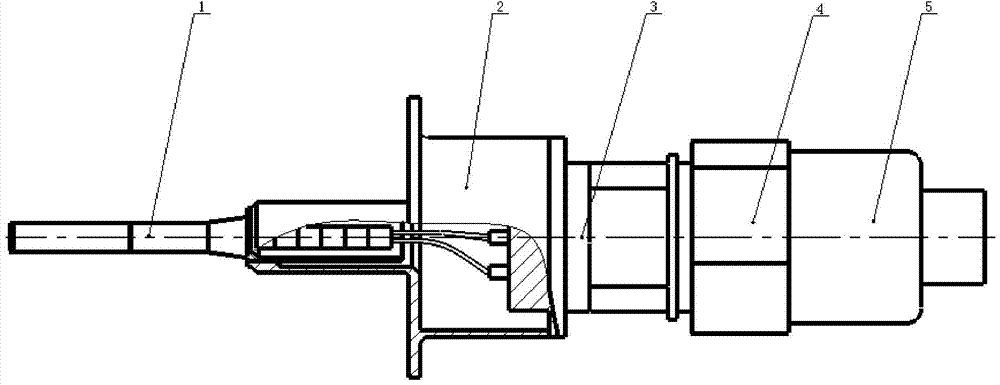

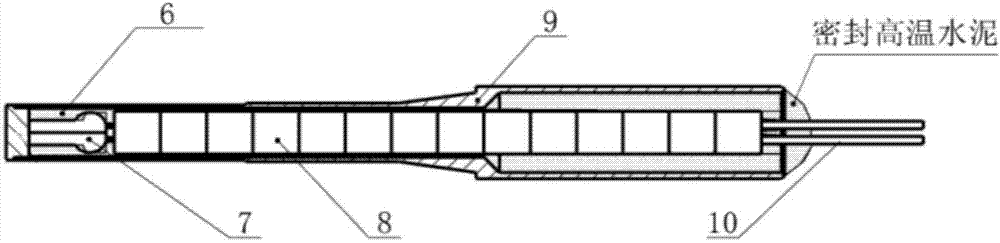

High-temperature temperature sensor

ActiveCN103698042AExtended service lifeHigh temperature resistanceThermometers using electric/magnetic elementsUsing electrical meansAviationChemical industry

The invention provides a high-temperature temperature sensor. The high-temperature temperature sensor comprises a temperature sensing element assembly, a mounting sleeve, a socket, a plug and a tail accessory which are sequentially arranged, wherein the temperature sensing element assembly comprises a protective sleeve, and a temperature sensing element and an insulating bushing which are arranged in the protective sleeve; a leading wire of the temperature sensing element penetrates into the insulating bushing after being welded with an inner conducting wire; the tail part of the temperature sensing element assembly is sealed by using high-temperature cement; a positioning bayonet which is welded with the protective sleeve is arranged at the front end of the mounting sleeve; temperature signals detected by the temperature sensing element are transmitted to a controller through the socket, the plug and the tail accessory. Compared with the prior art, the high-temperature temperature sensor has the advantages that the temperature sensing element for high-temperature temperature measurement adopts a platinum thermistor; the measurement accuracy is high; the signals are not required to be compensated or amplified; an internal structure adopts segmented design and package; the time constant is small; the reliability is high. Meanwhile, the product is simple in structure, light in weight and convenient to assemble and disassemble, and is suitable for the high temperature measurement of pipeline temperature in the field of aviation, aerospace, chemical industry and metallurgy.

Owner:天津航空机电有限公司

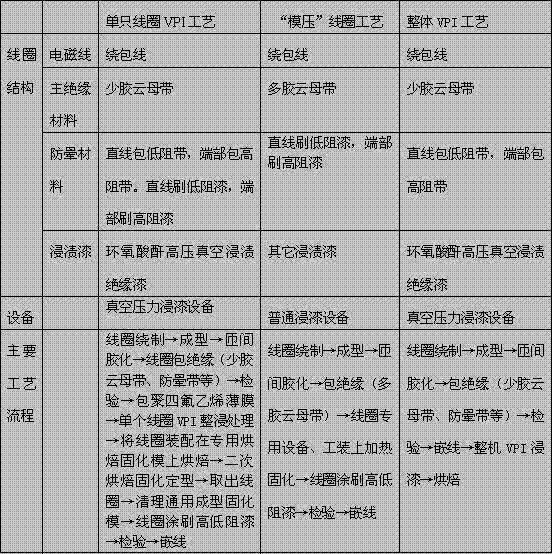

Single coil VPI process

InactiveCN103840612AReduce insulation thicknessReduce product costManufacturing dynamo-electric machinesSingle coilElectrical and Electronics engineering

The invention discloses a single coil VPI process so as to solve the problem that a large water power generator carries out the VPI process difficultly in the prior art. The single coil VPI process sequentially comprises the following steps that VPI and baking are carried out on a single coil, and the coil is embedded. According to the scheme, the single coil VPI process has the advantages that the whole machine coil embedding is carried out after the single coil is manufactured in a VPI mode, the size of an iron core is large, operation is not easy, the insulation thickness can be decreased, the product cost is lowered, and the insulation quality of a motor is promoted to be a high level, the service life of the motor is prolonged, and the difficult problem of manufacturing of a stator coil in a medium-type water power generator is solved.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

Manufacturing method of polarization-independent optical isolator, bonding technology and solution of optical components

ActiveCN102707461BReduce manufacturing costIncrease productivityNon-linear opticsWedge angleHydrogen

Owner:CASIX

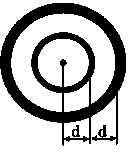

Method for measuring medium refractive index

InactiveCN104316495AEasy to get materialsSimplePhase-affecting property measurementsLaser lightPowder suspension

A method for measuring a medium refractive index comprises the following steps that firstly, fluorescent powder is selected according to wavelengths, and the fluorescent powder and organic solvent are mixed and vibrated; secondly, the surface of a measured sample with the thickness ranging from 1 mm to 10 mm is coated with the fluorescent powder suspension liquid; thirdly, the coated sample is placed at the focus of a lens, the face coated with a thin film is made to right face the lens, a laser is turned on, laser light is focused on the to-be-measured sample coated with the thin film through the lens, and a series of concentric circle light rings can be observed on the thin film; fourthly, the internal radius of a first inner side light ring or the difference of internal radii of the adjacent light rings is recorded as d; fifthly, d is substituted into the formula seen in the specification, and then the refractive index is calculated. The refractive index of a slab medium can be measured in the near ultraviolet band, visible light band and near-infrared band through the method.

Owner:CENT SOUTH UNIV

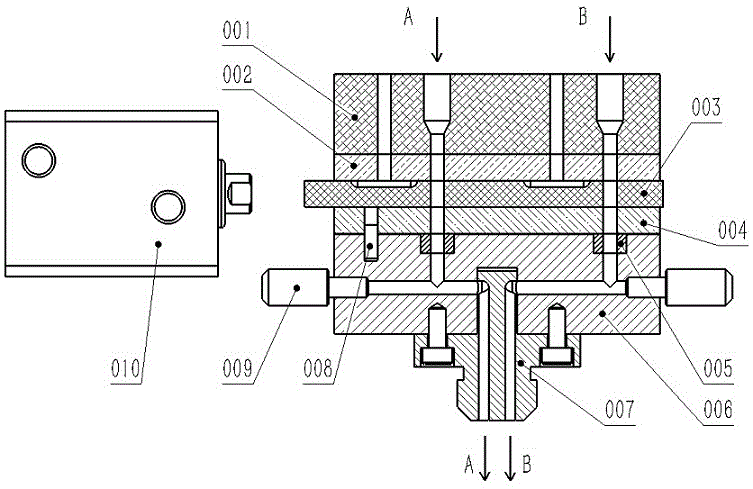

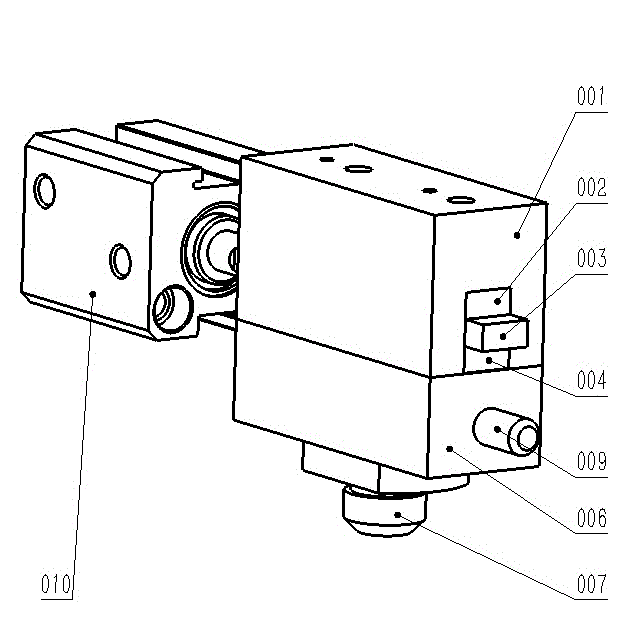

Sliding vane switch valve for AB glue volume metering type dispensing

InactiveCN104889029AHigh precisionImprove sealingLiquid surface applicatorsMultiple way valvesEngineeringMechanical engineering

The best way at present for AB glue super-small glue volume high precision dispensing consists of two screw rod valves, however domestic screw rod valve technologies are not mature, and how to replace becomes a problem. The invention provides a volume metering type AB glue sliding vane valve, and is used for switching glue replenishment and glue discharge.

Owner:于飞

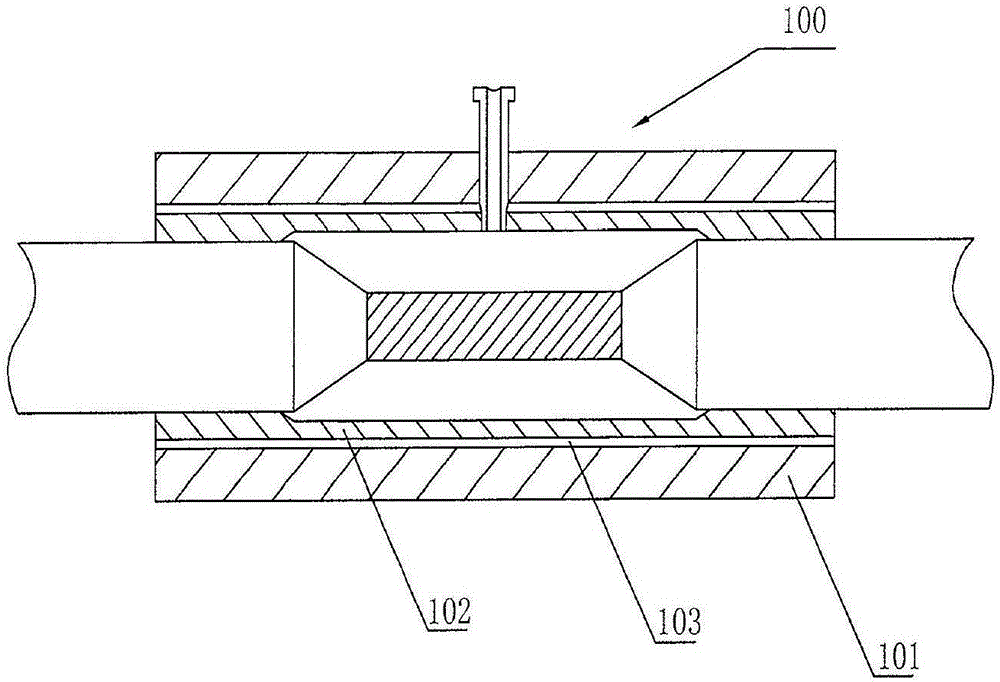

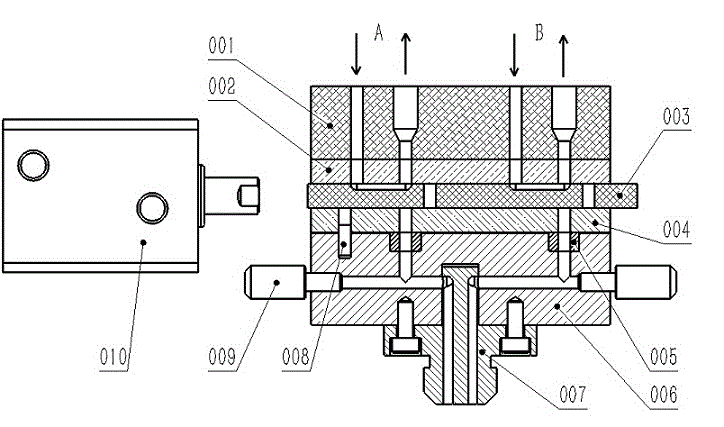

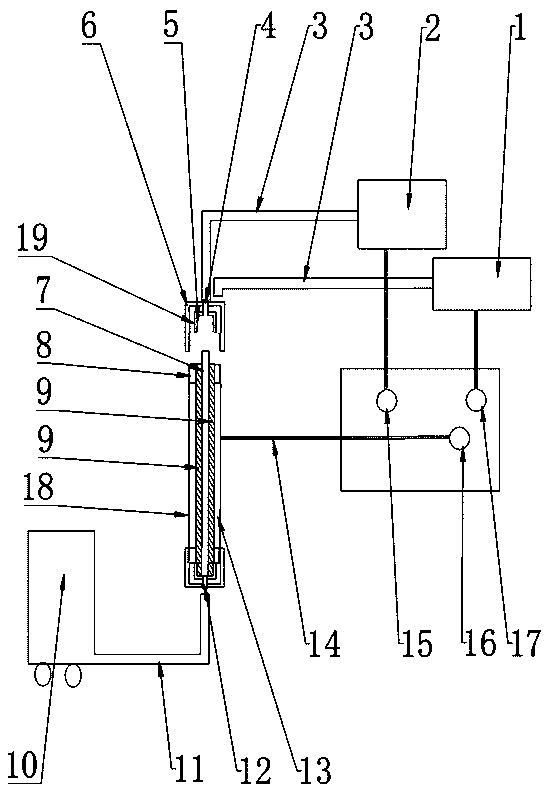

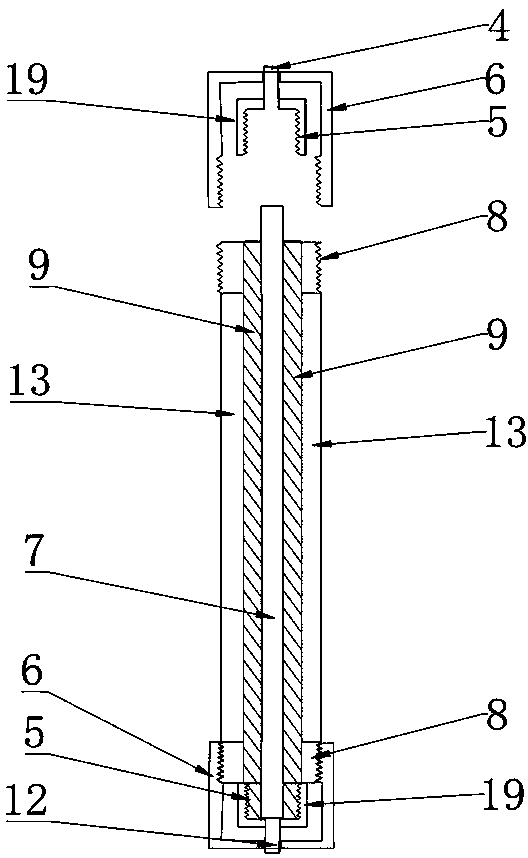

Preparation apparatus and preparation method for insulated pull rod used for circuit breaker

The invention discloses a preparation apparatus and a preparation method for an insulated pull rod used for a circuit breaker. Specifically, the invention provides a preparation apparatus for an insulated pull rod used for a circuit breaker, and also provides a method of preparing the insulated pull rod by the apparatus. By combing the apparatus and the method, the insulated pull rod with homogeneous texture, no air gap and moisture can be prepared, thus ensuring the electromechanical properties of the insulated pull rod. Also, no organic solvent is involved in the raw materials, and repeated heating is not needed, thus being conducive to environmental protection and energy saving. Also, vacuum pressure is adopted for one-step molding, threads can be formed at the end of the insulated pull rod, and the influence of machining on the strength of the insulated pull rod can be avoided. Therefore, compared with insulated pull rods prepared by traditional processes, the insulated pull rod prepared by the apparatus and method provided by the invention has excellent electromechanical properties and insulating properties.

Owner:GOODE EIS SUZHOU CORP LTD

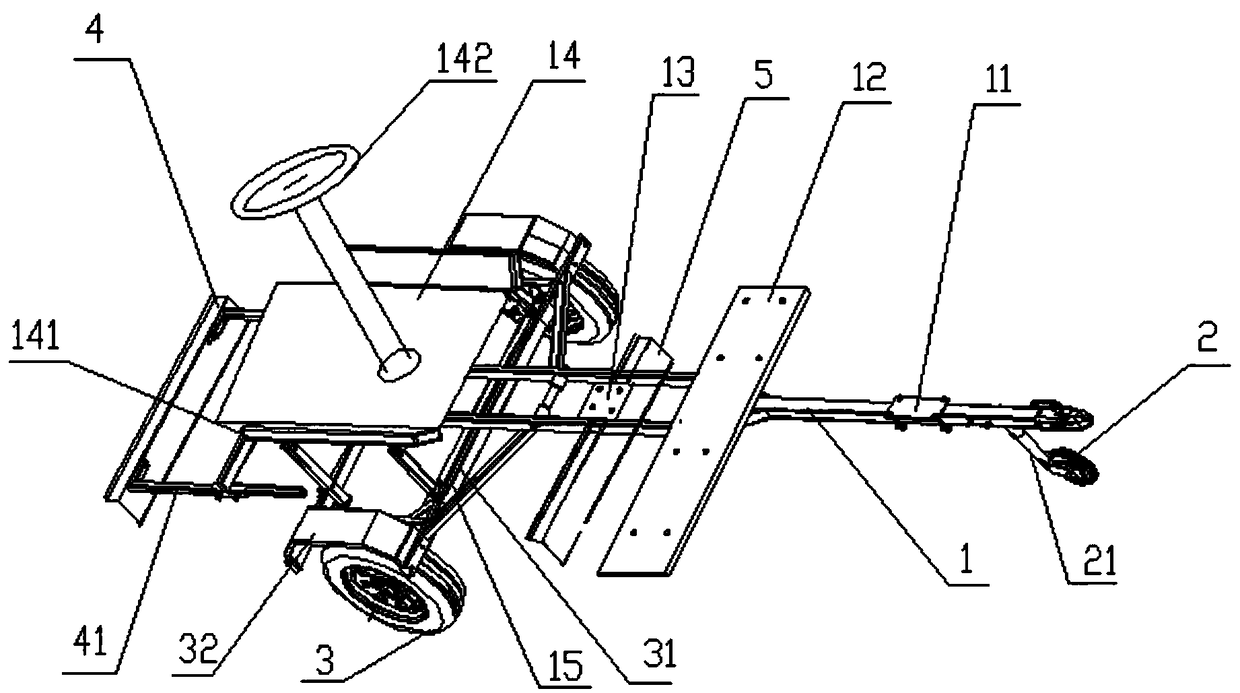

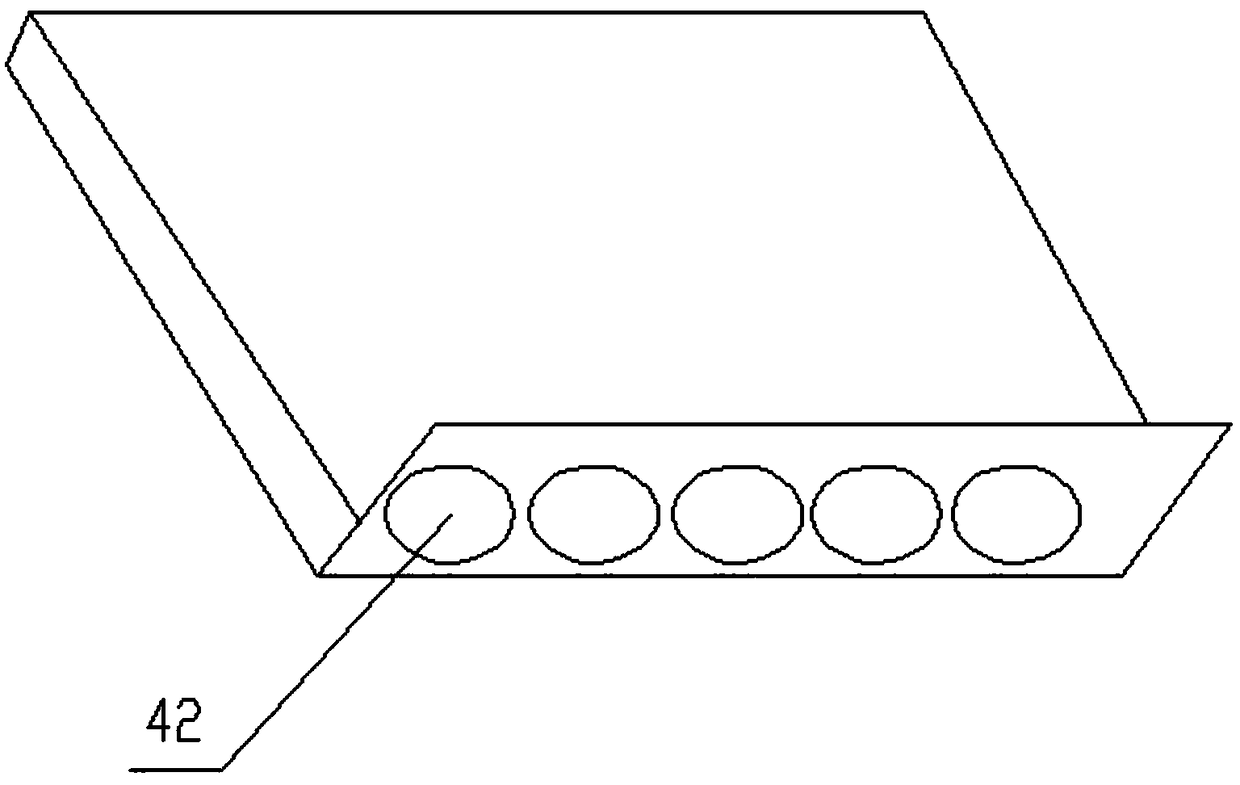

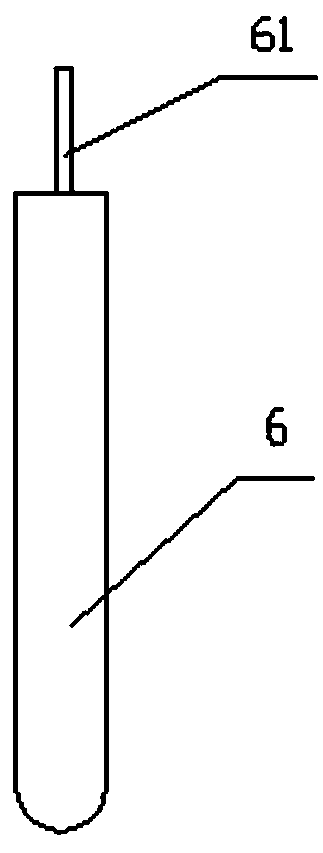

Integrated machine for pouring park cement roadbeds

The invention discloses an integrated machine for pouring park cement roadbeds. The integrated machine comprises an integrated machine chassis, a steering wheel, support wheels, a vibrating screen, abulldozing baffle, a vibrating rod and a concrete funnel, wherein the steering wheel, the support wheels, the vibrating screen and the bulldozing baffle are mounted under the integrated machine chassis; the concrete funnel is mounted above the integrated machine chassis; the steering wheel is arranged in the position at the front-most end of the integrated machine chassis; the vibrating screen ismounted at the rearmost end of the integrated machine chassis; the support wheels are arranged in adjacent positions of the vibrating screen; the two support wheels are respectively arranged on two sides of the integrated machine chassis; and the two support wheels and the steering wheel form a triangular structure. Through the integrated machine, the concrete is mounted under the integrated machine through the processes of pouring, bulldozing, vibrating for removing gaps and leveling; the cement roadbeds needed to be respectively constructed can be completed by one worker through one machine;the manpower investment is greatly reduced; the working efficiency is improved.

Owner:尤婷婷

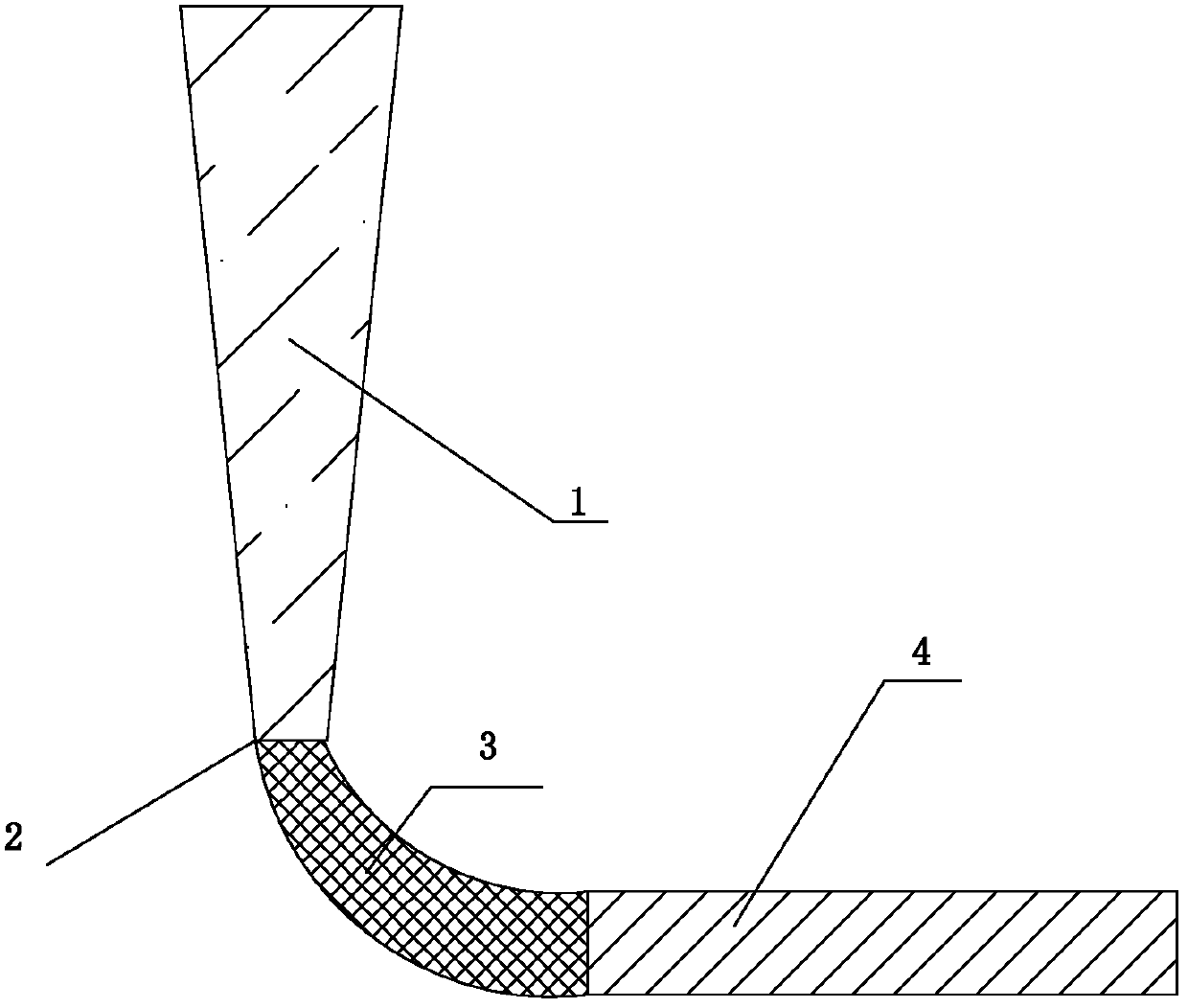

Gating system capable of effectively controlling air entrainment and slag entrainment and design method thereof

ActiveCN102319891BAvoid it happening againGuaranteed purityMolten metal pouring equipmentsFoundry mouldsSystems designSlag

The invention relates to a gating system capable of effectively controlling air entrainment and slag entrainment and a design method thereof. The gating system comprises a sprue, a runner and a plurality of ingates; the sprue is of a big-end-up conical structure, and the maximum cross-sectional area of the upper end is 1.5 to 3 times larger than the minimum cross-sectional area of the lower end; the runner is connected with the lower end of the sprue through a smooth curve, the radius of the curve is 1 to 5 times larger than the equivalent diameter of the runner, the cross-sectional radius ofthe curve is reduced, and the radius-reducing change is between 1 and 5 times larger than the cross-sectional equivalent radius of the runner; the ingates are connected with the runner, and the sum of the cross-sectional areas of the ingates is 2 to 10 times larger than the cross-sectional area of the runner. The invention solves the problem that the conventional gating system is not reasonable and can hardly guarantee the smooth filling and purity of molten metal, the phenomena of secondary oxidation, air entrainment and slag entrainment are prevented in the process of pouring molten metal, so that the quality of castings can be guaranteed, and the invention is suitable for the design of gating systems for the sand mold casting, metal mold casting, casting blank casting and precision casting of non-ferrous metal, ferrous metal, high-temperature alloy and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

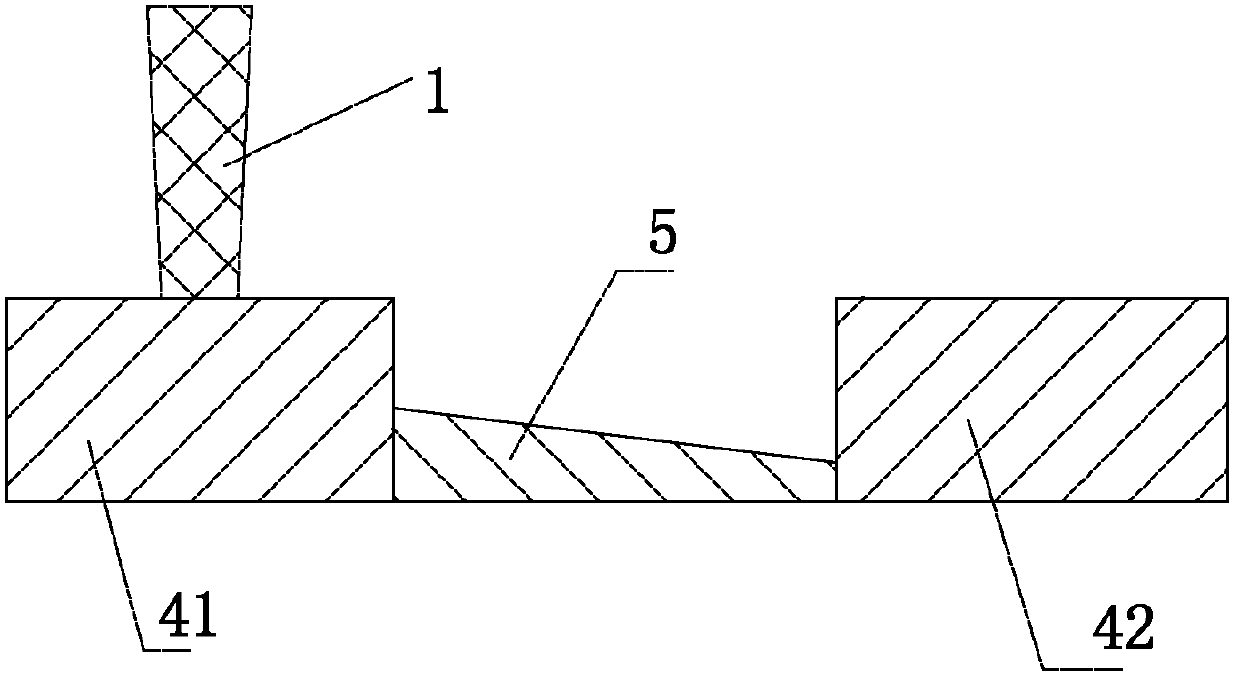

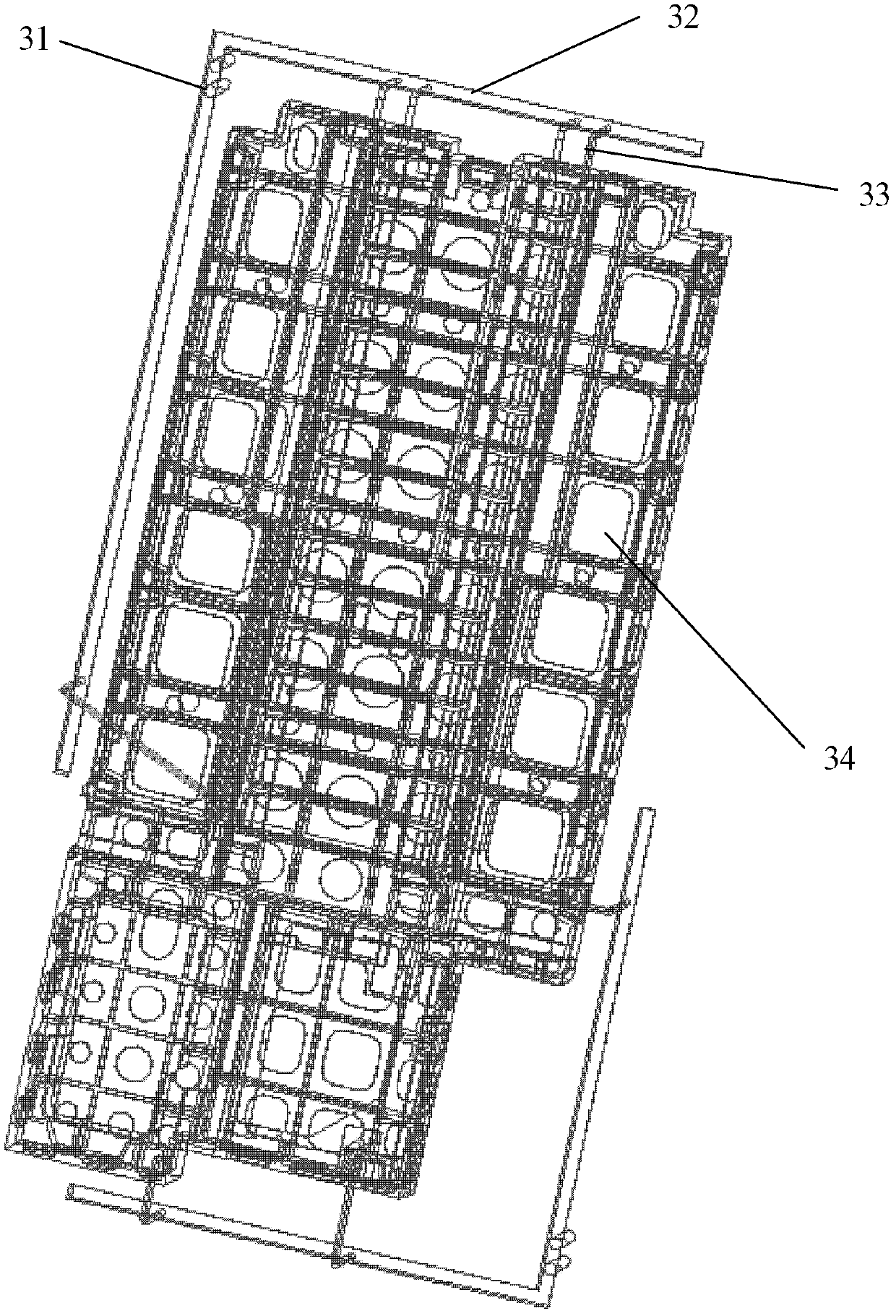

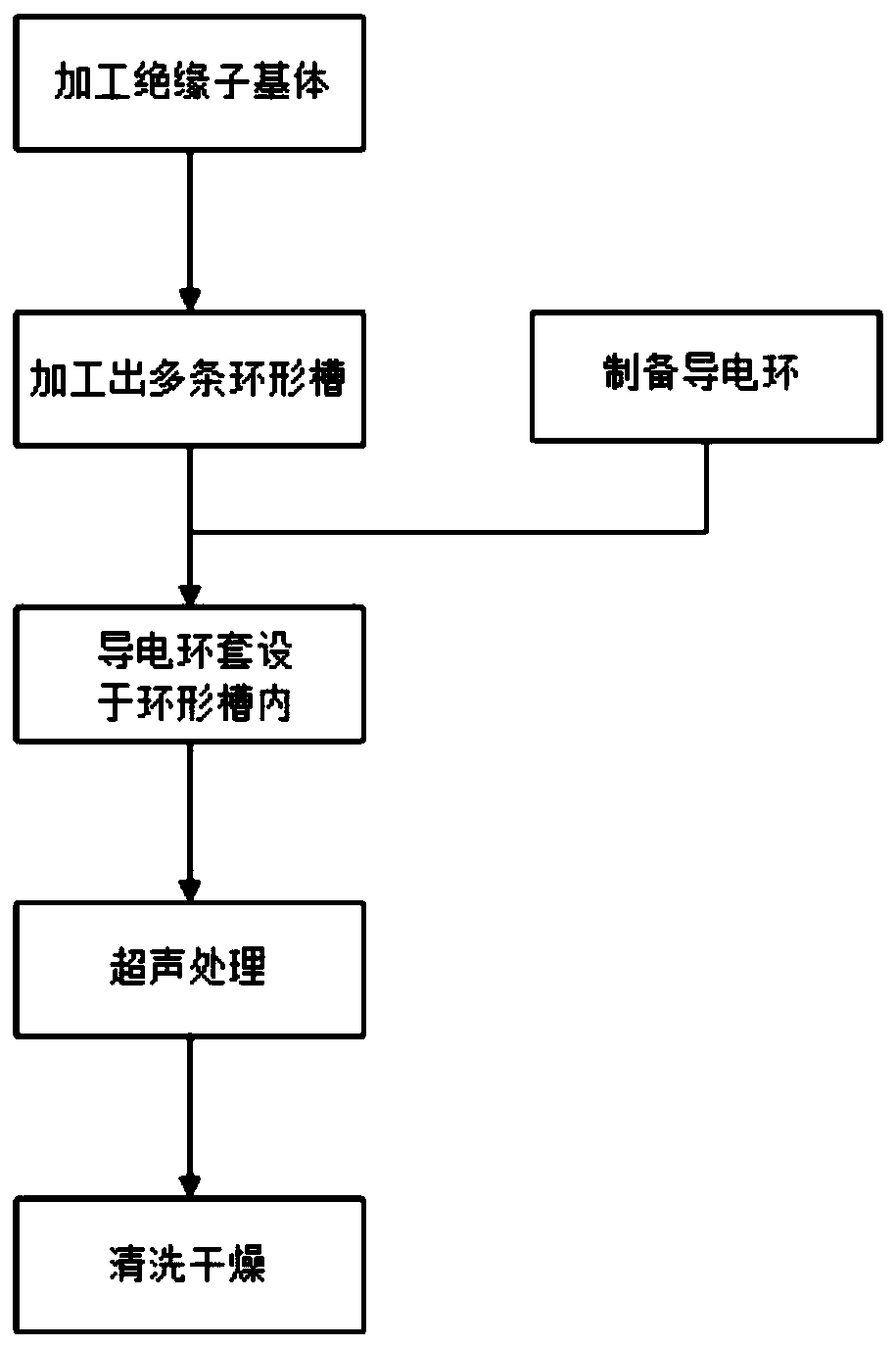

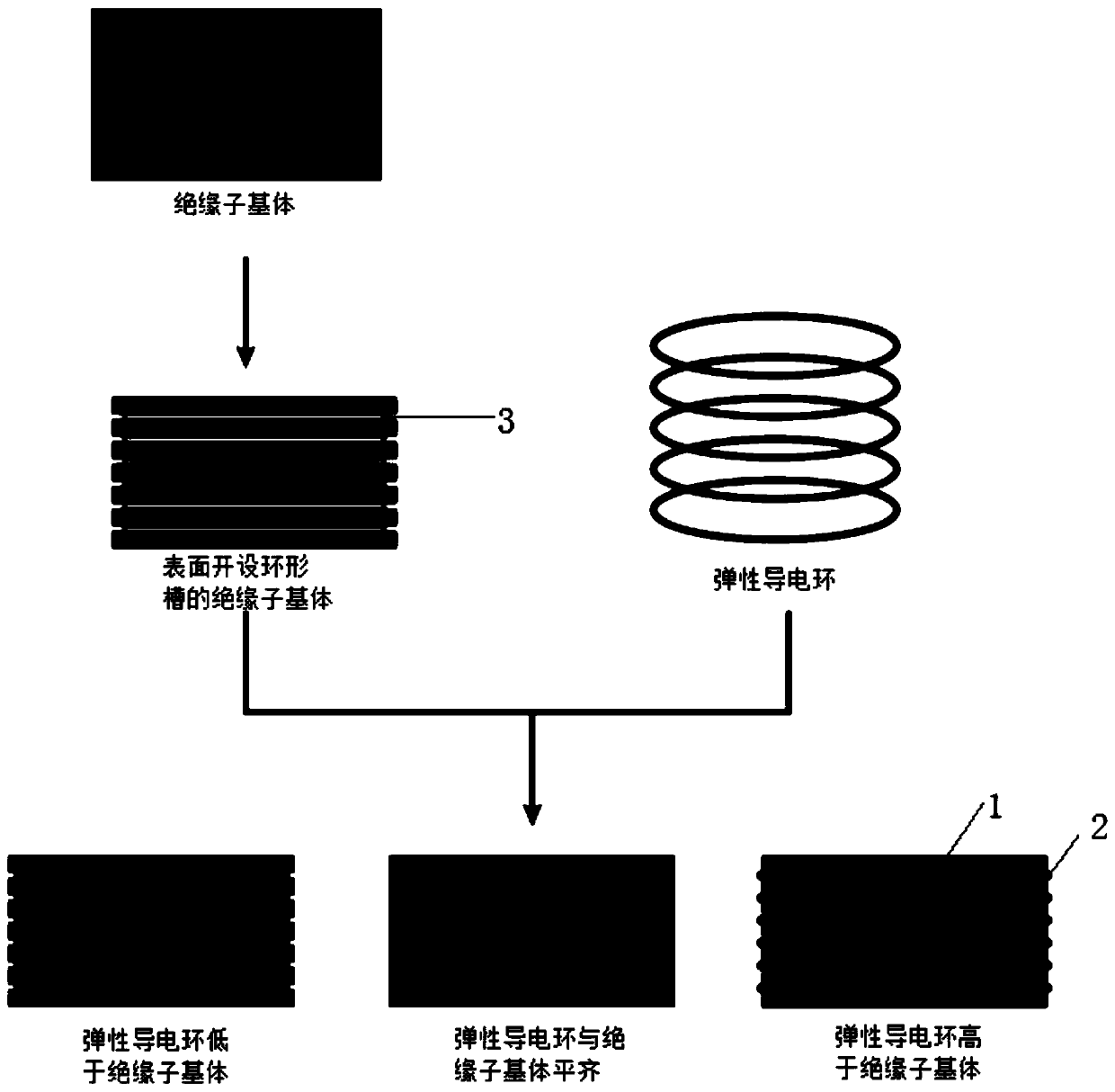

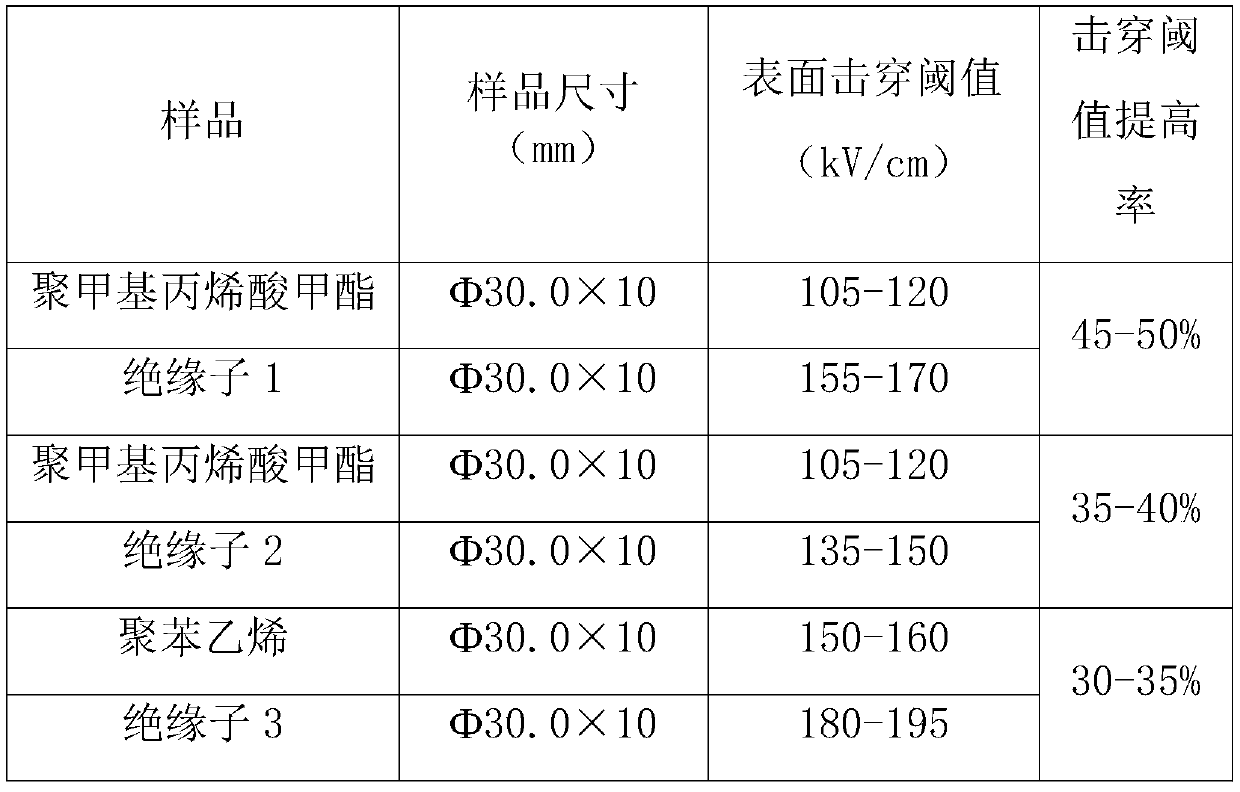

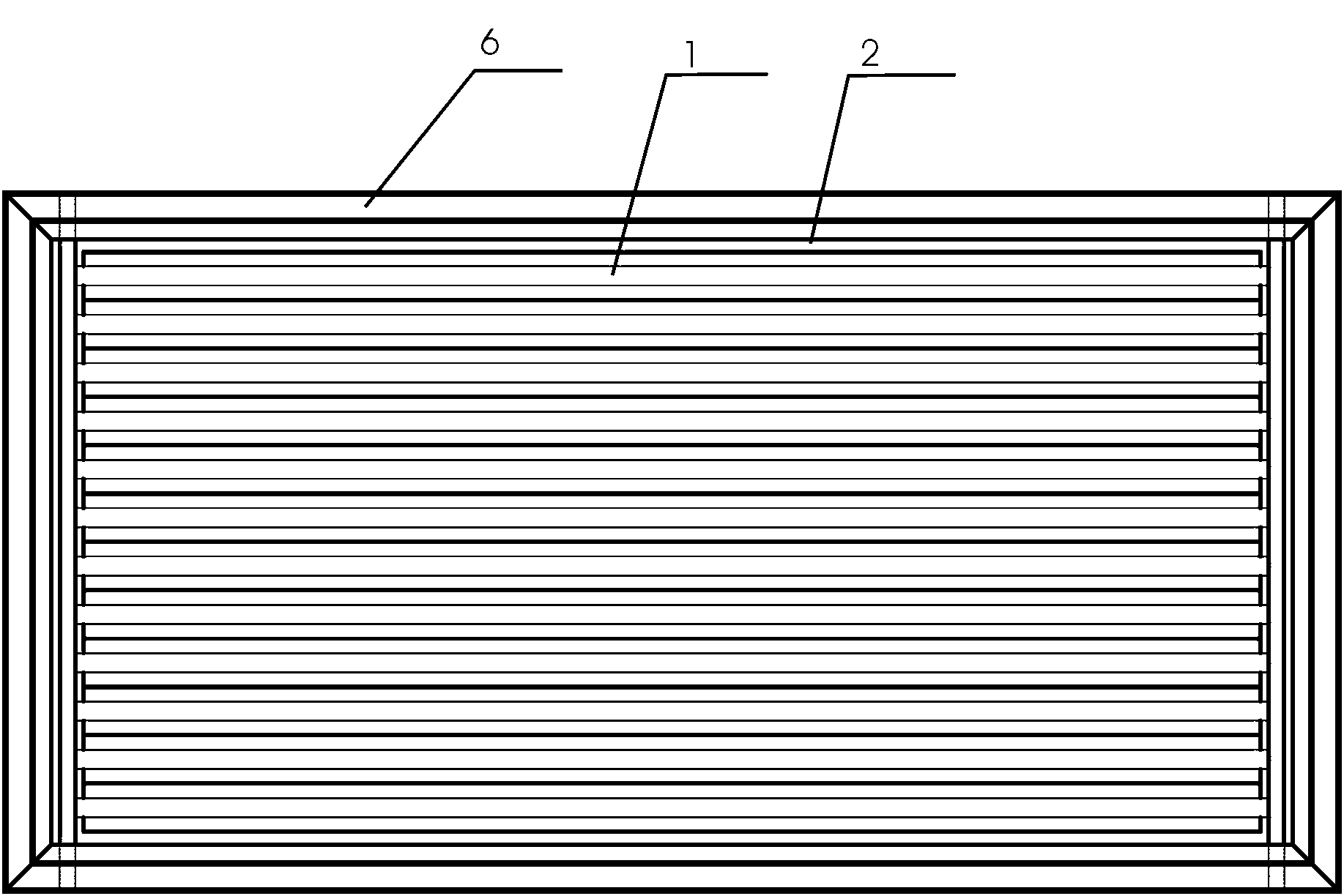

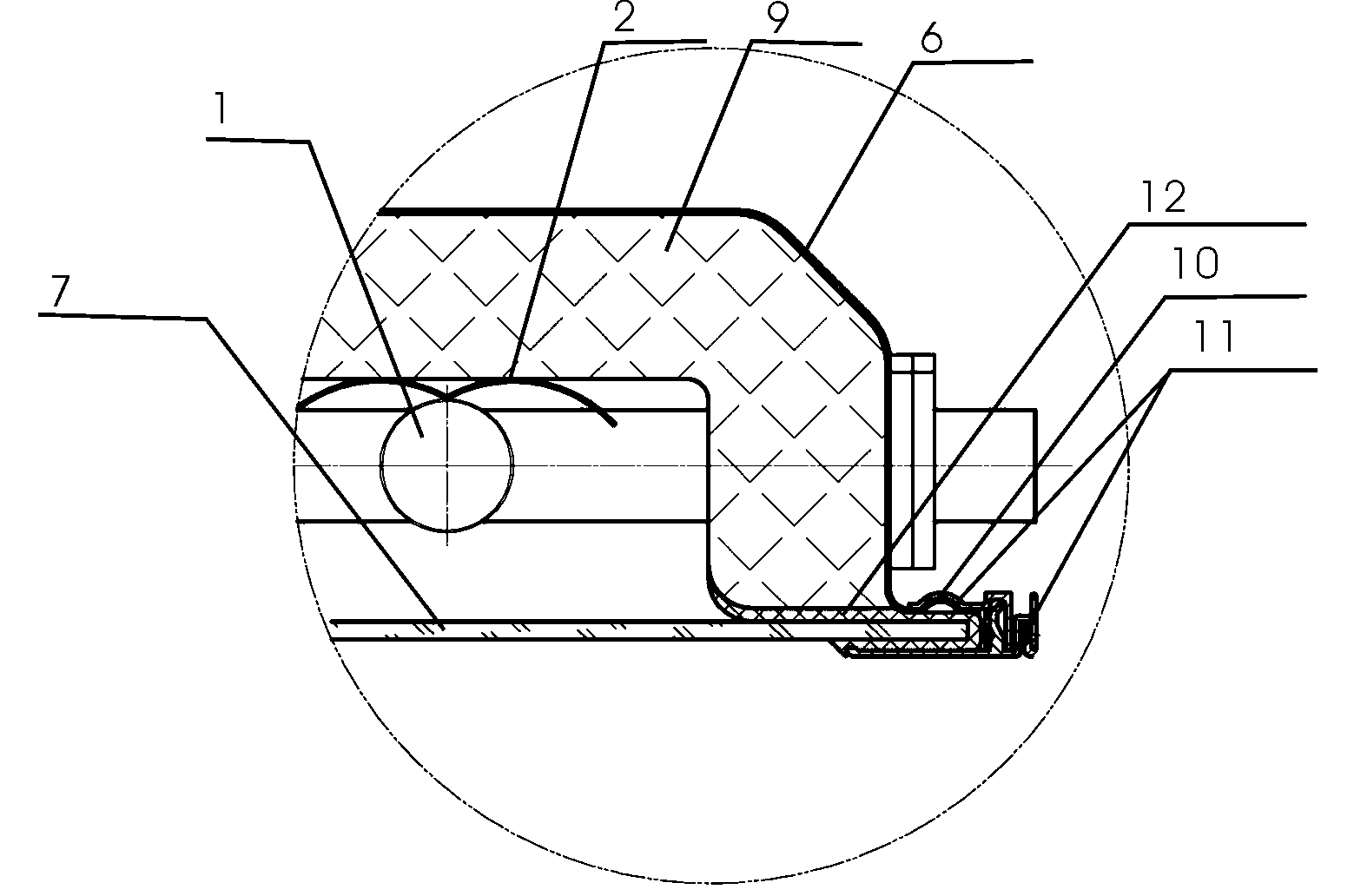

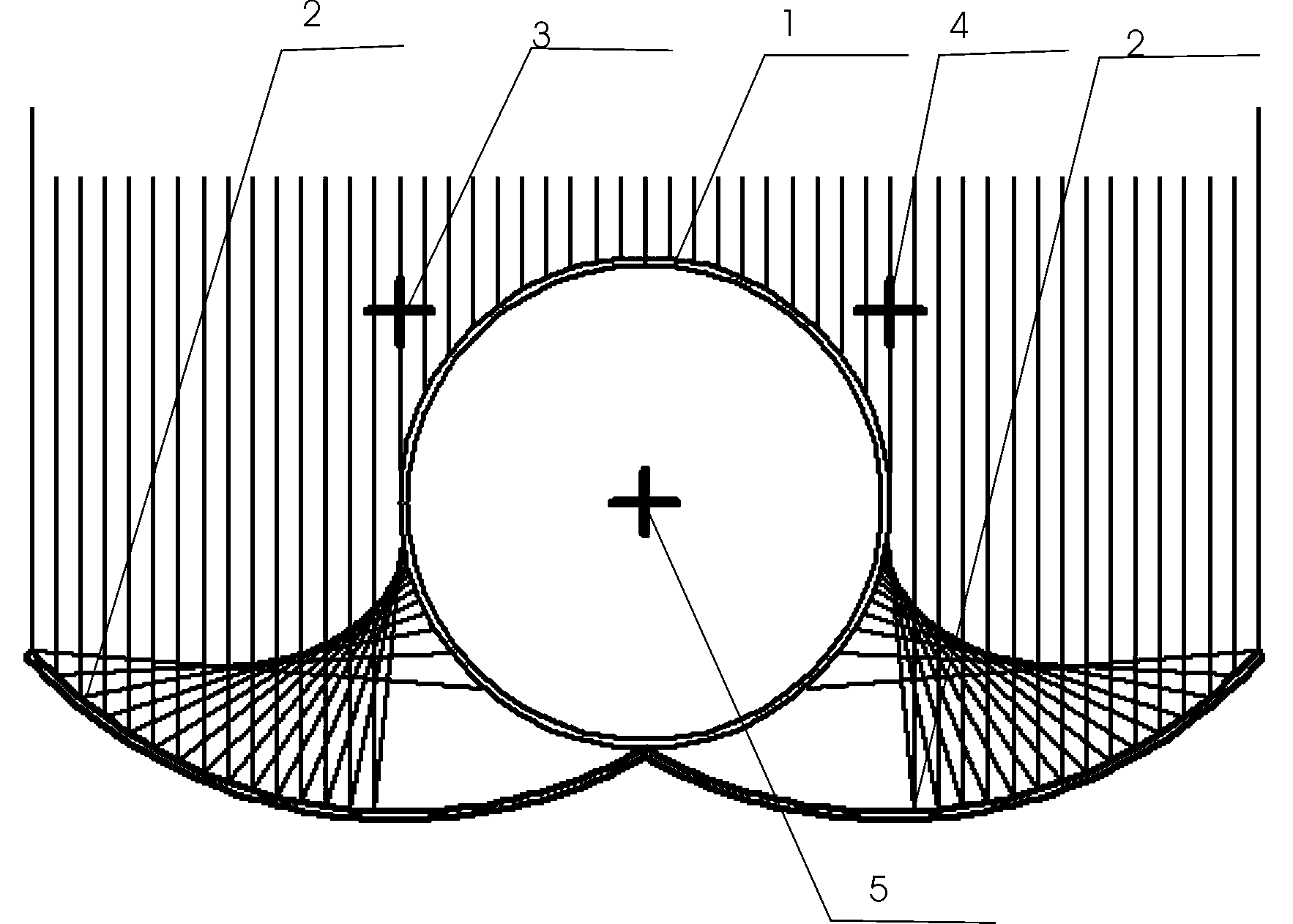

Insulator and preparation method thereof

ActiveCN110136899AMaintain strengthStay resilientInsulatorsInsulation layerElectric field distortion

The invention belongs to an insulating device and a preparation method thereof and particularly relates to an insulator and a preparation method thereof. The problem that an existing insulator has lowsurface breakdown voltage, poor reliability and difficulty in meeting the vacuum insulation requirements of a high-voltage device is solved. The insulator includes an insulator base and elastic conductive rings. The outer surface of the insulator base is provided with a plurality of mutually parallel annular grooves. The adjacent annular grooves have the same slot pitch, and the elastic conductive rings are sleeved in the annular grooves. By sleeving the elastic conductive rings in the annular grooves, while the difficulty and cost of the preparation process of a high-gradient insulator are significantly reduced, the stability and reliability are improved. Since the invention does not involve the processing process of post-machining and grinding, unstable factors such as metal chips and burrs in an insulation layer after the processing of a traditional high-gradient insulator are avoided, the electric field distortion caused by the metal chips is avoided, and the consistency of the performance of the insulator is ensured while the breakdown voltage is raised.

Owner:NORTHWEST INST OF NUCLEAR TECH

Totally closed internal light condensation medium temperature solar flat plate heat collector

InactiveCN103234280AIncrease operating temperatureClear business prospectsSolar heating energySolar heat devicesThermodynamicsGlass cover

The invention belongs to the technical field of solar heat collectors and particularly provides a totally closed plate type solar heat collector. The heat collector is a medium temperature heat collector capable of providing hot water or steam higher than 100 DEG C. The totally closed internal light condensation medium temperature solar flat plate heat collector consists of a casing, a glass cover plate, a solar heat collecting plate and a heat collecting pipeline. A heat preserving material is filled in a cavity portion, a solar heat collecting plate core consists of a light condensing plate with a circular arc shaped cross section and a heat absorbing pipe, wherein the arc-shaped circle center of the light condensing plate is located on the outer circumference of the heat absorbing pipe, the heat absorbing pipe is located above a circular arc in the light condensing plate, and a heat absorbing coating is plated on the surface of the heat absorbing pipe. The casing is basin-shaped, the glass cover plate is arranged on the casing, the glass cover plate, the lower portion of the light condensing plate of a frame and a heat collector frame are sealed through sealing strips, the heat preserving material is filled under the light condensing plate and in a cavity of the heat collector, and the heat absorbing pipe is communicated with a hot water circulating pipeline. The flat plate heat collector has the high-heat-collection area but reduces the heat radiating area, simultaneously adopts a totally closed tank body structure and thoroughly avoids a breathing phenomenon.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

High pressure resistant insulation supporting post containing tightly packaged fiber as well as manufacture and application thereof

InactiveCN101251553AImprove insulation performanceHigh insulation performance indexTransformersTransformers/inductances detailsFiberEpoxy

The present invention discloses a high-voltage resistant insulation strut comprising tight coated fibers, and a manufacture and an application thereof, belonging to the technical field of the high-voltage resistant insulation strut in electrical power transmission and the manufacture and application thereof. The insulation strut comprises an epoxy core rod, sealing fasteners, tight coated fibers, epoxy resin, an insulation sleeve and cushioning liquid cement. The two ends of the epoxy core rod are provided with a sealing fastener respectively, and the epoxy core rod is provided with a groove which runs through the two ends. Two tight coated fibers are parallelly arranged in the groove. The two ends of each tight coated fiber traverse through end surfaces of the two sealing fasteners respectively. The groove is filled with the cushioning liquid cement. The epoxy core rod is arranged in the insulation sleeve in such a manner that the central axis is overlapped with the central axis of the insulation sleeve. A space among the top of the cushioning liquid cement, the epoxy core rod and the insulation sleeve is filled with the epoxy resin. The strut has the advantages of high insulation performance index, high mechanical strength, good local discharge and voltage resistance performance and the performance of the tight coated fiber being not affected by outside stress. Particularly, the strut is suitable for being used as a data transmission channel for a high-voltage current transformer.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Integrated pixel structure, integrated touch control liquid crystal display device and touch control method thereof

ActiveCN101661201BNo air gapWith multi-touch functionStatic indicating devicesNon-linear opticsCapacitanceTransistor array

The invention provides an integrated pixel structure, an integrated touch control liquid crystal display device and a touch control method thereof. The integrated pixel structure comprises a transistor array base plate, a color light filter base plate parallel to the transistor array base plate, and a liquid crystal layer clamped between the transistor array base plate and the color light filter base plate, wherein the transistor array base plate comprises a first transistor, a first storage capacitor connected with the first transistor, a second transistor, a second storage capacitor connected with the second transistor, and a conducting convex body which corresponds to the second storage capacitor in order to electrically connect the second storage capacitor and the color light filter base plate when the color light filter base plate is extruded.

Owner:ACER INC

Macro-molecular leakage-free self-adhering aluminum foil and manufacturing method

ActiveCN105479853ANo air gapImprove compactnessLaminationLamination apparatusAluminum foilUltimate tensile strength

The invention relates to macro-molecular leakage-free self-adhering aluminum foil which is good in folding resistance and fatigue resistance, high in strength, good in shielding performance and free of return loss and meanwhile has high reliability and self-adhering strength, and a manufacturing method. A PET film and one side of the aluminum foil are composited through an adhering agent, and the other side of the aluminum foil is coated with a modified PE glue layer. The macro-molecular leakage-free self-adhering aluminum foil has the advantages that the aluminum foil is resistant to folding and fatigue and high in strength which is several times that of the prior art; the wrapping self-adhering performance is good, and stripping strength formed after adhesion is several times that of the prior art; air gaps on the surface of the aluminum foil are filled with same-attribute nano aluminum, the compactness of the aluminum foil is greatly improved, the purpose of manufacturing the macro-molecular leakage-free self-adhering aluminum foil through low-grade aluminum foil is achieved, and therefore the requirement for the rolling precision of the aluminum foil is greatly lowered, and the manufacturing cost of the aluminum foil is reduced; insulating strength is high, the shielding effect is good, the return loss phenomenon is avoided, and the tensile strength is good.

Owner:HANGZHOU JULI INSULATION

Waterproof bus

InactiveCN109659075ANo air gapWill not cause a short circuitClimate change adaptationInsulated cablesMixed materialsPolyester resin

The invention relates to a waterproof bus. The waterproof bus has a up-and-down laminated type phase line body, a housing is casted around the phse line body, the housing is made of unsaturated polyester resin and asbestos through pouring, a light stabilizer and a flame retardant are added to the polyester resin, and a metal sleeve is arranged at the outer portion of the housing. The waterproof bus employs the special unsaturated polyester resin mixed with an asbestos mixed material to form a high-performance insulating material. The copper-made phase line is directly casted and sealed withoutan air gap and chimney effect so that the bus bar burr or overload will not cause short circuit, the volume is small, the dynamic heat is more stable, and the waterproof effect is better.

Owner:湖北莲花电力母线制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com