Waterproof bus

A waterproof and busbar technology, applied in conductors, climate change adaptation, insulated cables, etc., can solve problems such as difficult to guarantee waterproof and moisture-proof effect, short circuit, busbar burrs, etc., and achieve good waterproof effect, small size, dynamic and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

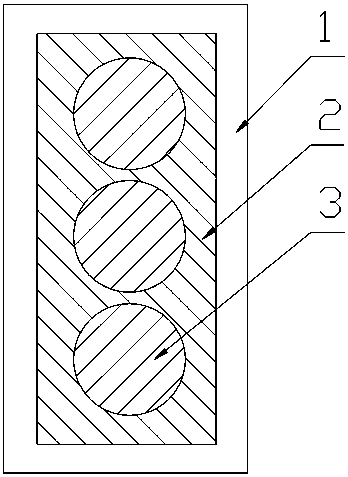

[0008] The present invention is a waterproof busbar, which has a phase line body 3 laminated up and down, and a shell 2 is cast around the phase line body. The shell is made of unsaturated polyester resin and asbestos. A light stabilizer and a flame retardant are added to the polyester resin, and a metal sheath 1 is additionally installed outside the shell.

[0009] The waterproof busbar of the present invention adopts special unsaturated polyester resin and asbestos mixed material to make high-performance insulating material, and the copper phase wire is directly poured and sealed, so there is no air gap, no chimney effect, and no burr or overload on the busbar. It will cause a short circuit, and it is small in size, more stable in dynamic and heat, and better in waterproof effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com