Macro-molecular leakage-free self-adhering aluminum foil and manufacturing method

A polymer, aluminum foil technology, applied in chemical instruments and methods, layered products, lamination and other directions, can solve the problems of cable communication signal attenuation, insufficient purity of aluminum ingots, increase in return loss, etc., to improve the density, Excellent tensile strength, the effect of reducing the requirement of rolling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

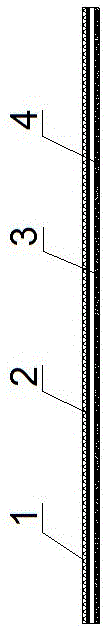

[0010] Embodiment 1: with reference to attached figure 1 and figure 2 . A polymer non-leakage self-adhesive aluminum foil, the PET film 1 is compounded with an adhesive 2 and an aluminum foil 3 on one side, and a modified PE adhesive layer 4 is coated on the other side of the aluminum foil 3. The surface of the aluminum foil 3 is a surface without air gaps. The air gaps on one or both sides of the aluminum foil 3 are filled with nano-aluminum. The air gap refers to the tiny holes and gaps, that is, the tiny through holes and gaps caused by impurities and the roll itself during the aluminum foil rolling process are filled with nano-aluminum, so that the compactness of the aluminum foil has been further improved.

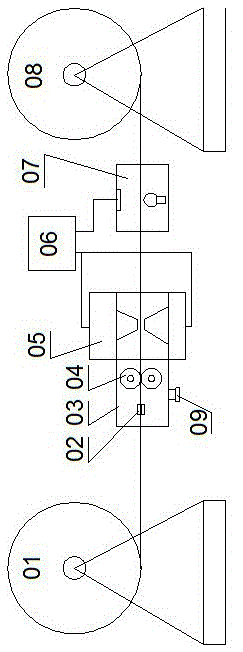

[0011] Its aluminum foil surface air gap filling production line includes PLC controller 06, aluminum foil air gap detection device 07, nano-aluminum spraying device 05 and nano-aluminum rolling forming device 03; The photoelectric signal output terminal of the g...

Embodiment 2

[0013] Example 2: On the basis of Example 1, a method for preparing a polymer non-leaking self-adhesive aluminum foil, 1) One side or two sides of the aluminum foil 3 are respectively filled with nano-aluminum of the same property, so that there is no air gap on the aluminum foil surface; 2) Then the PET film 1 is compounded on one side of the aluminum foil 3 with an adhesive 2; 3) Apply the modified PE glue on the non-composite surface of the aluminum foil 3 and dry it to obtain a modified PE film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com