High pressure resistant insulation supporting post containing tightly packaged fiber as well as manufacture and application thereof

A technology of tight-packed optical fibers and insulating pillars, applied in insulators, transformers, voltage/current isolation, etc., can solve the problems of uneven thickness, decreased polarization transmission performance stability of tight-packed optical fibers, and no longer suitable for data transmission channels, etc. Achieve the effect of high insulation performance index, stable polarized light transmission performance, excellent partial discharge and withstand voltage performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

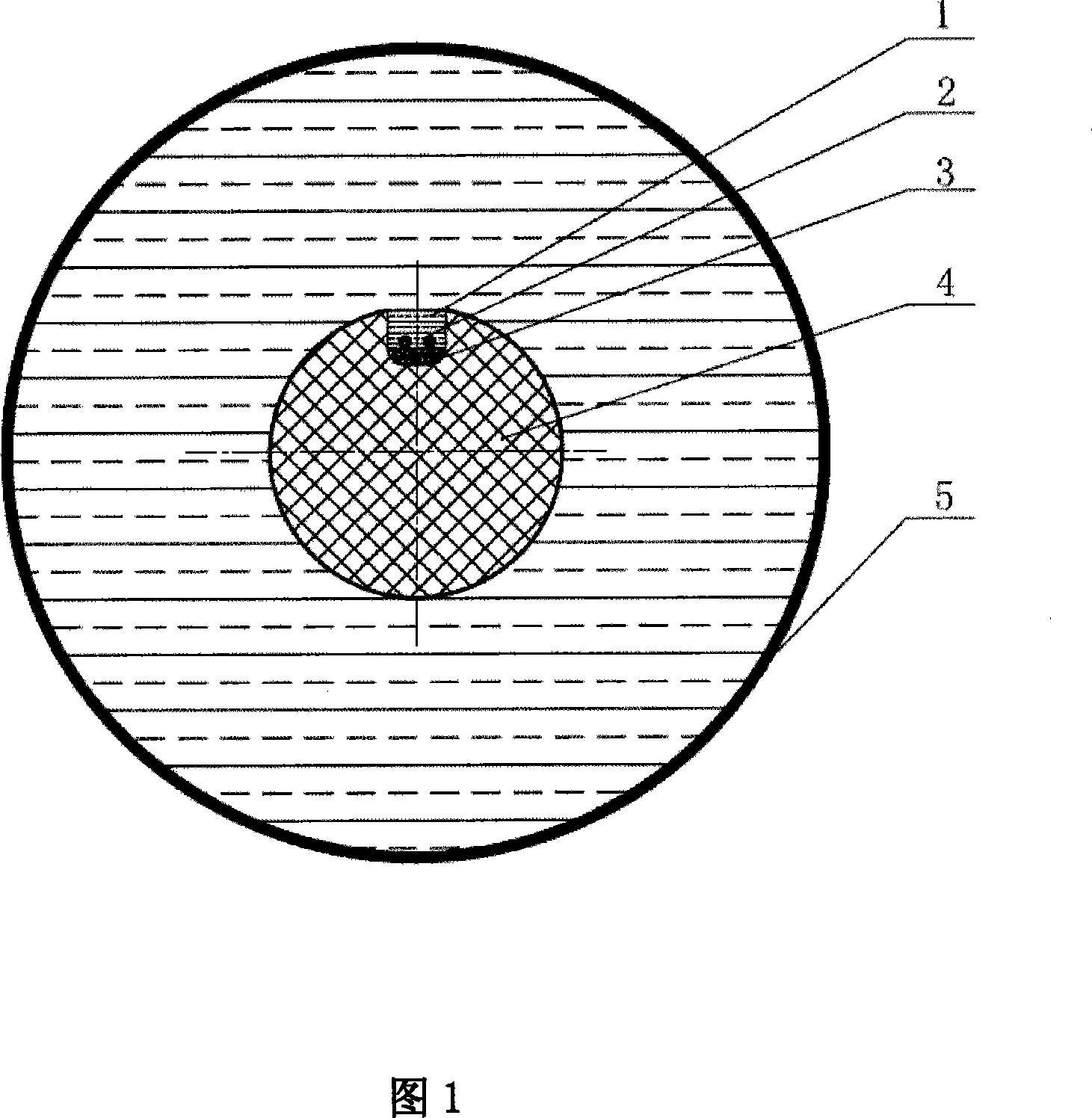

[0035] Embodiment 1: One of the high-voltage-resistant insulating pillars containing tightly-packed optical fibers. This embodiment has the structure shown in FIG. 1 .

[0036]A high-voltage insulating support with tight-packed optical fibers, including epoxy core rod 4, sealing fasteners, tight-packed optical fiber 2, epoxy resin 1 and insulating sleeve 5, epoxy core rod 4 is an insulating cylinder, and is placed in the ring The cylindrical surface of the oxygen mandrel 4 is provided with a groove parallel to the central axis of the epoxy mandrel 4, and runs through the two ends of the epoxy mandrel 4. There are sealing fasteners at both ends of the epoxy mandrel 4, and in the groove Two tight-packed optical fibers 2 are placed side by side on the bottom of the groove, and the two ends of each tightly-packed optical fiber 2 respectively pass through the corresponding small holes on the end surface of the sealed fastener and pass through the end surface of the sealed fastener....

Embodiment 2

[0037] Embodiment 2: The second high-voltage-resistant insulating pillar containing tightly-packed optical fibers. This embodiment has the structure shown in FIG. 1 . This embodiment is identical to Embodiment 1 except for the following differences: the width and depth of the groove are 10 mm and 10 mm, respectively.

Embodiment 3

[0038] Embodiment 3: The third high-voltage-resistant insulating pillar containing tightly-packed optical fibers. This embodiment has the structure shown in FIG. 1 . This embodiment is identical to Embodiment 1 except for the following differences: buffer glue 3 is D04(L)RTV silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com