Patents

Literature

149results about How to "Stay resilient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

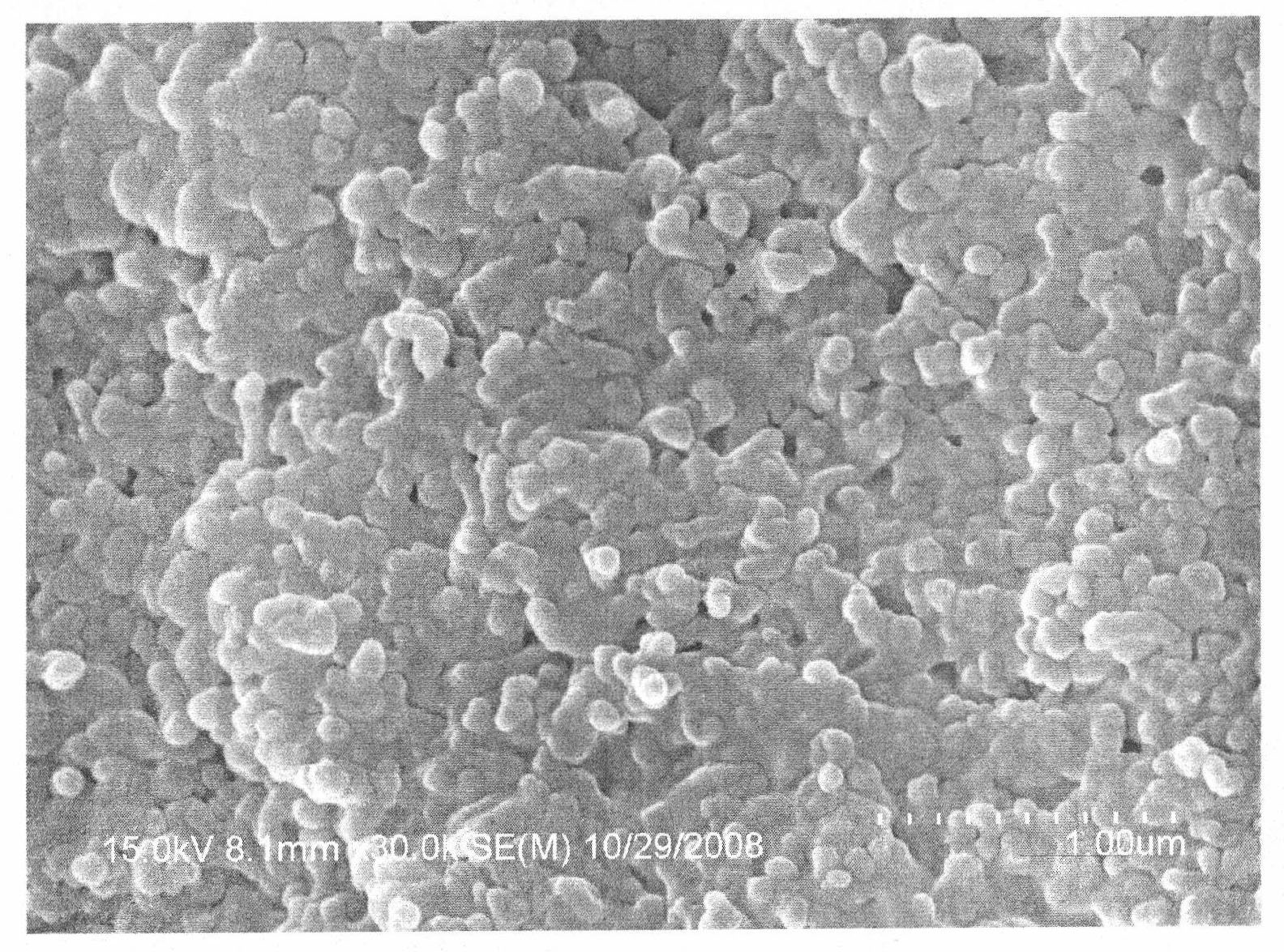

A kind of fine-grained WC-based cemented carbide material and preparation method thereof

A fine-grained WC-based cemented carbide material and a preparation method thereof. The fine-grained WC-based cemented carbide material uses fine-grained WC as a matrix, Mo or Ni as a binder, and TaC, VC, One or more types of TiC are grain inhibitors, Cr3C2 is used as a hardener, and C, SiC or rare earth metals are used as a toughener. The size of fine-grained WC is 0.8-1μm. WC of this size can It brings about an increase in hardness and flexural strength. This cemented carbide material provides an alternative to Co and has high hardness, good toughness, and excellent comprehensive wear resistance.

Owner:四川欧曼机械有限公司

Novel WC-based hard alloy material and preparation method thereof

The invention relates to a novel high-performance WC-based hard alloy material and a preparation method thereof, and belongs to high-technology structural ceramics and the application field thereof. The high-performance WC-based hard alloy material in the invention takes 20 to 80 mass percent of submicron / nanometer WC powder as a matrix, 2 to 20 mass percent of metal Mo and metal Ni which have high chemical stability at a high temperature and rare earth as a binder, is added with 0.1 to 5.0 mass percent of crystal particle inhibitor, 10 to 80 mass percent of high-hardness material diamond or cubic boron nitride micro-powder as a hardening agent, and 0.5 to 15 mass percent of SiC nanostructure and the like as a toughing agent, and is prepared by fast sintering technology, in particular by discharge plasma sintering or medium frequency induction heating sintering. A sintered body has the characteristics of fine crystal particles, high hardness, strength and flexibility and high comprehensive abrasive resistance, is particularly suitable for preparing geological drilling machines and tools used under heavy load conditions, and also can be used for preparing high-performance machined cutting tools, moulds and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

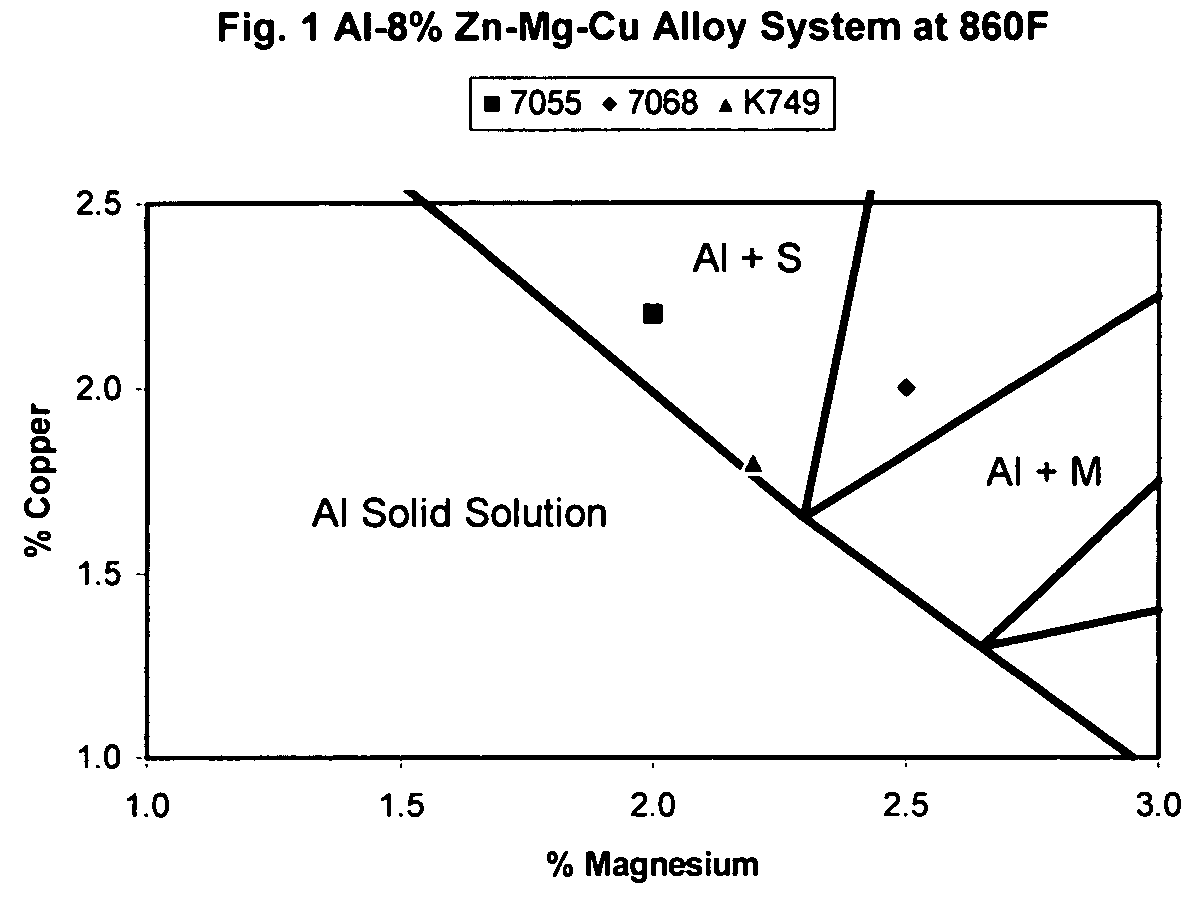

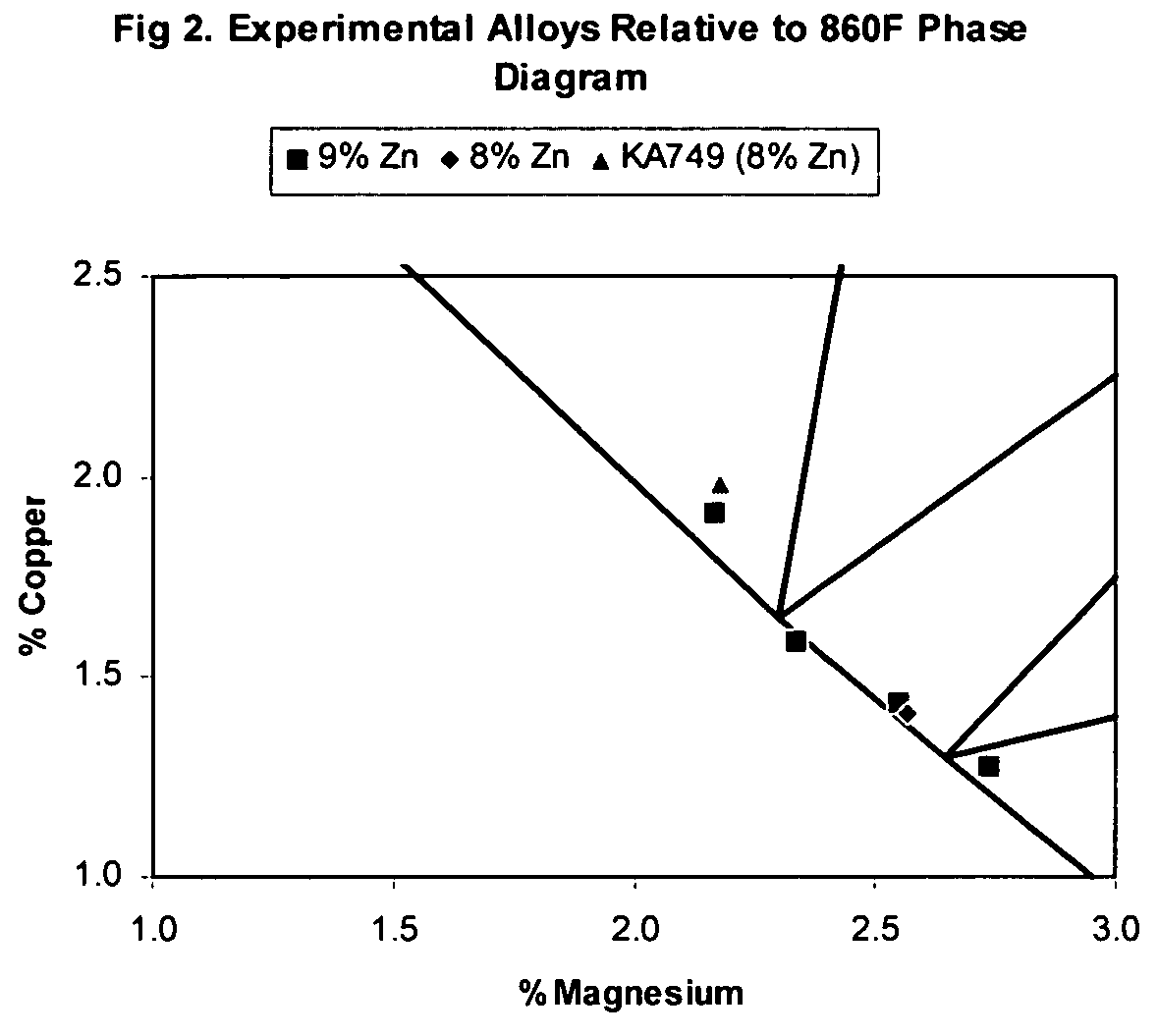

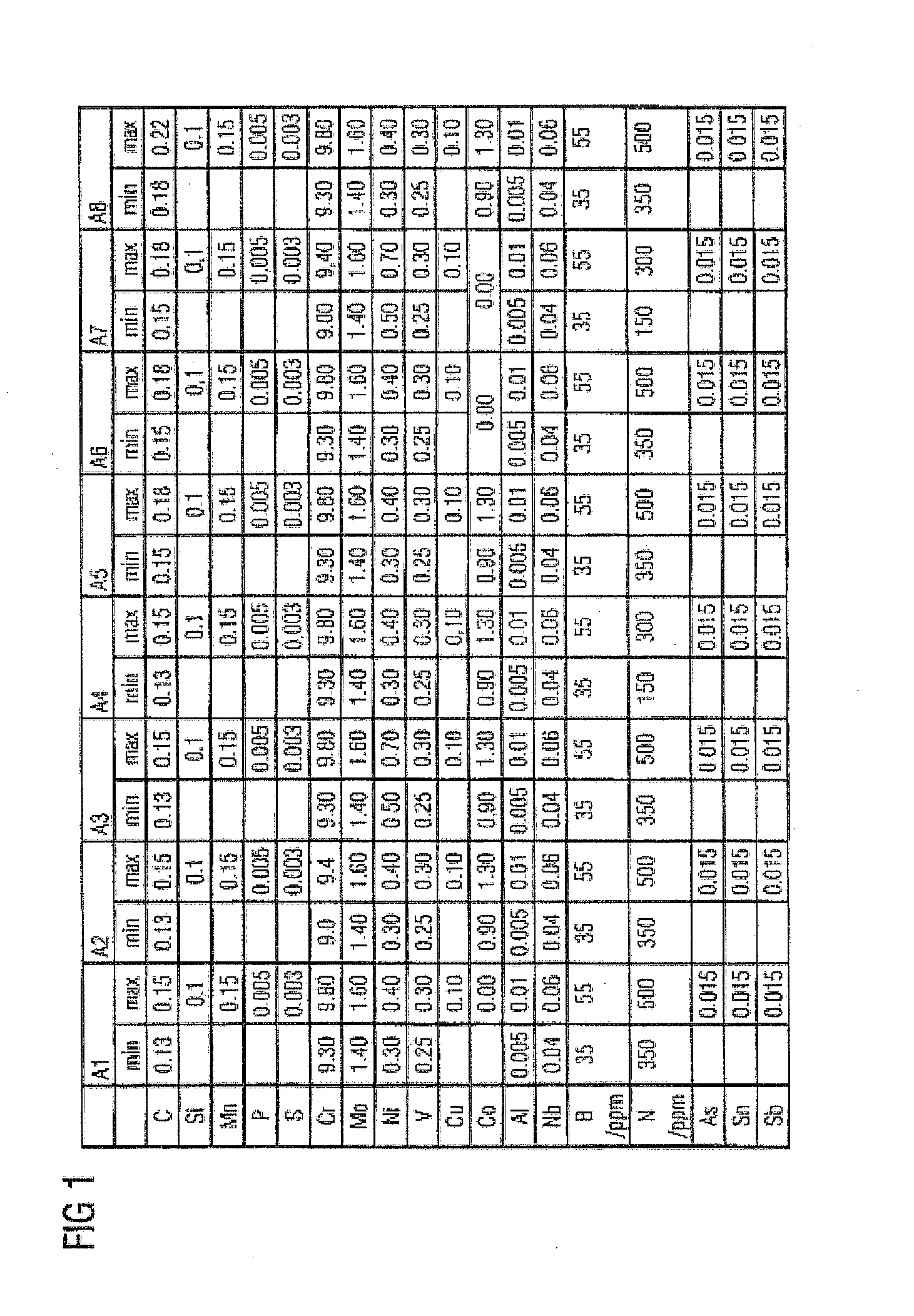

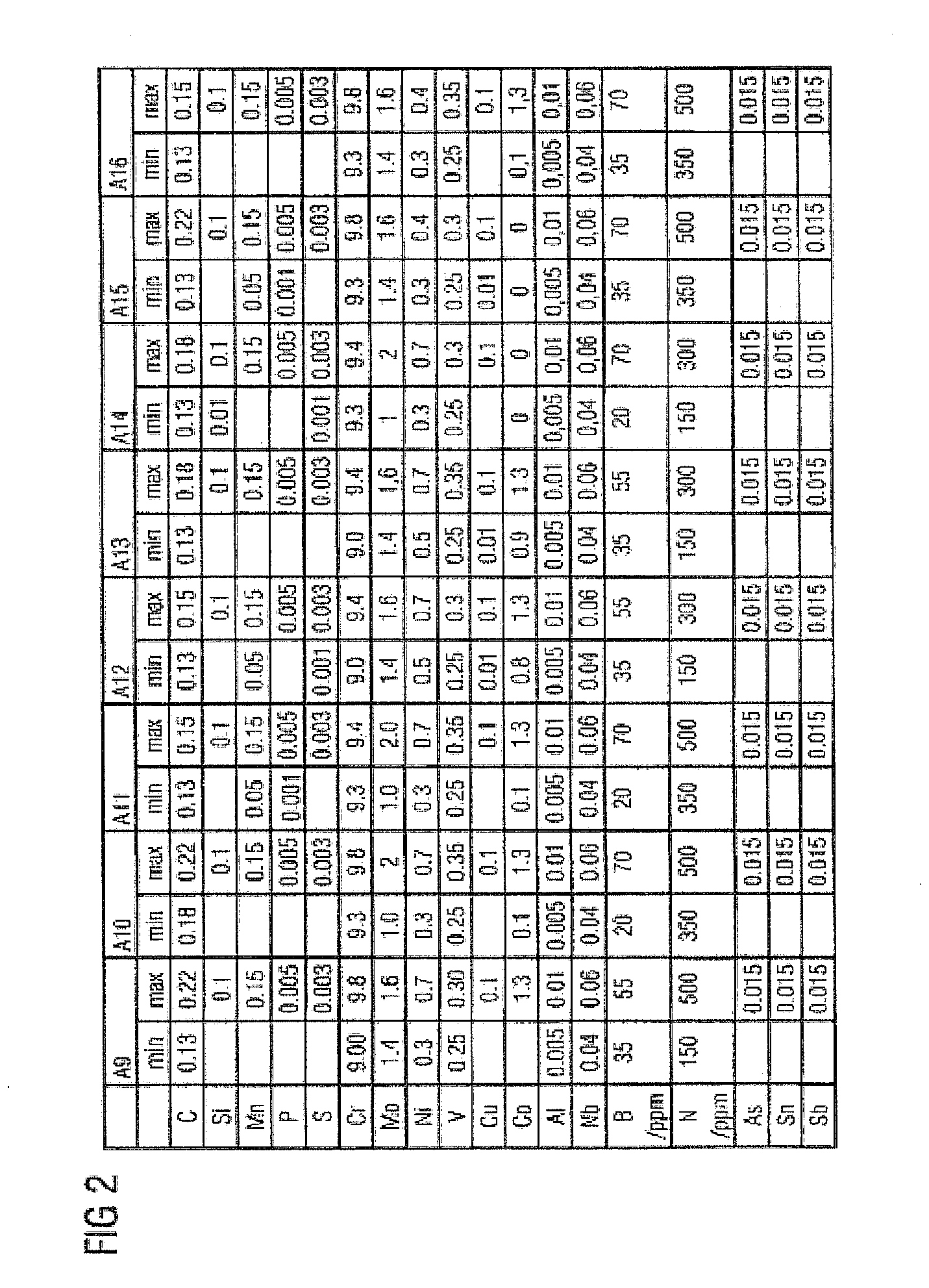

High strength aluminum alloys and process for making the same

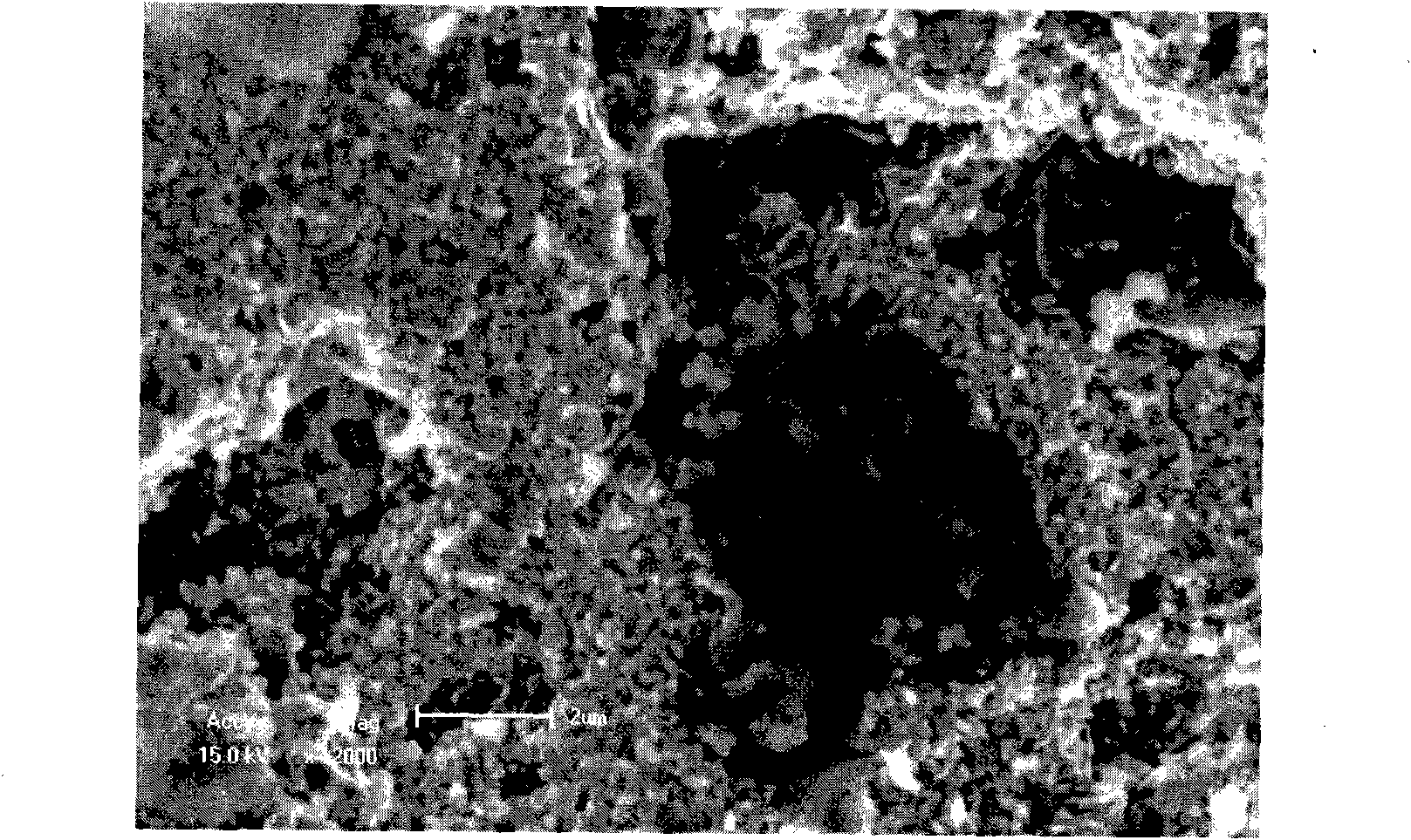

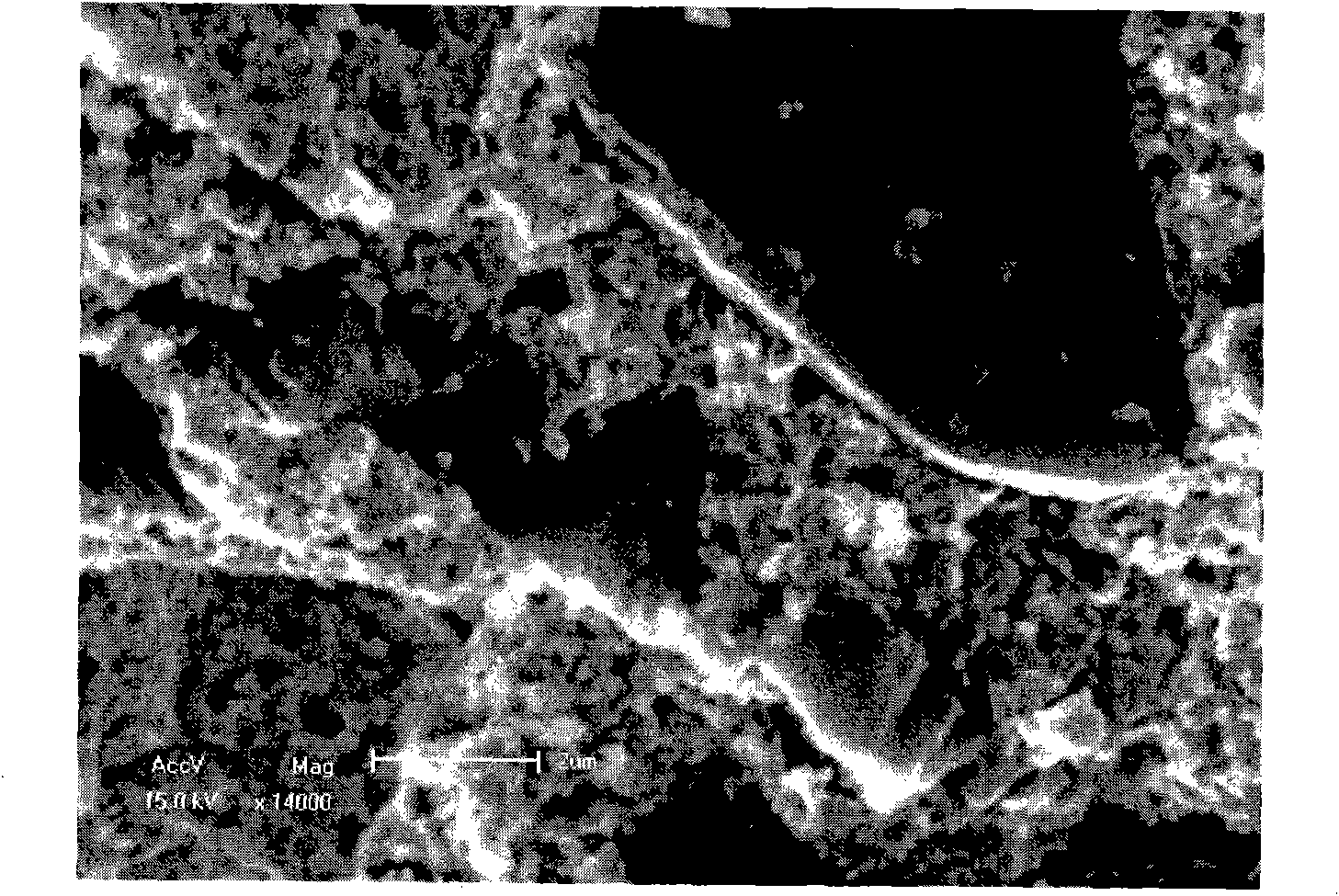

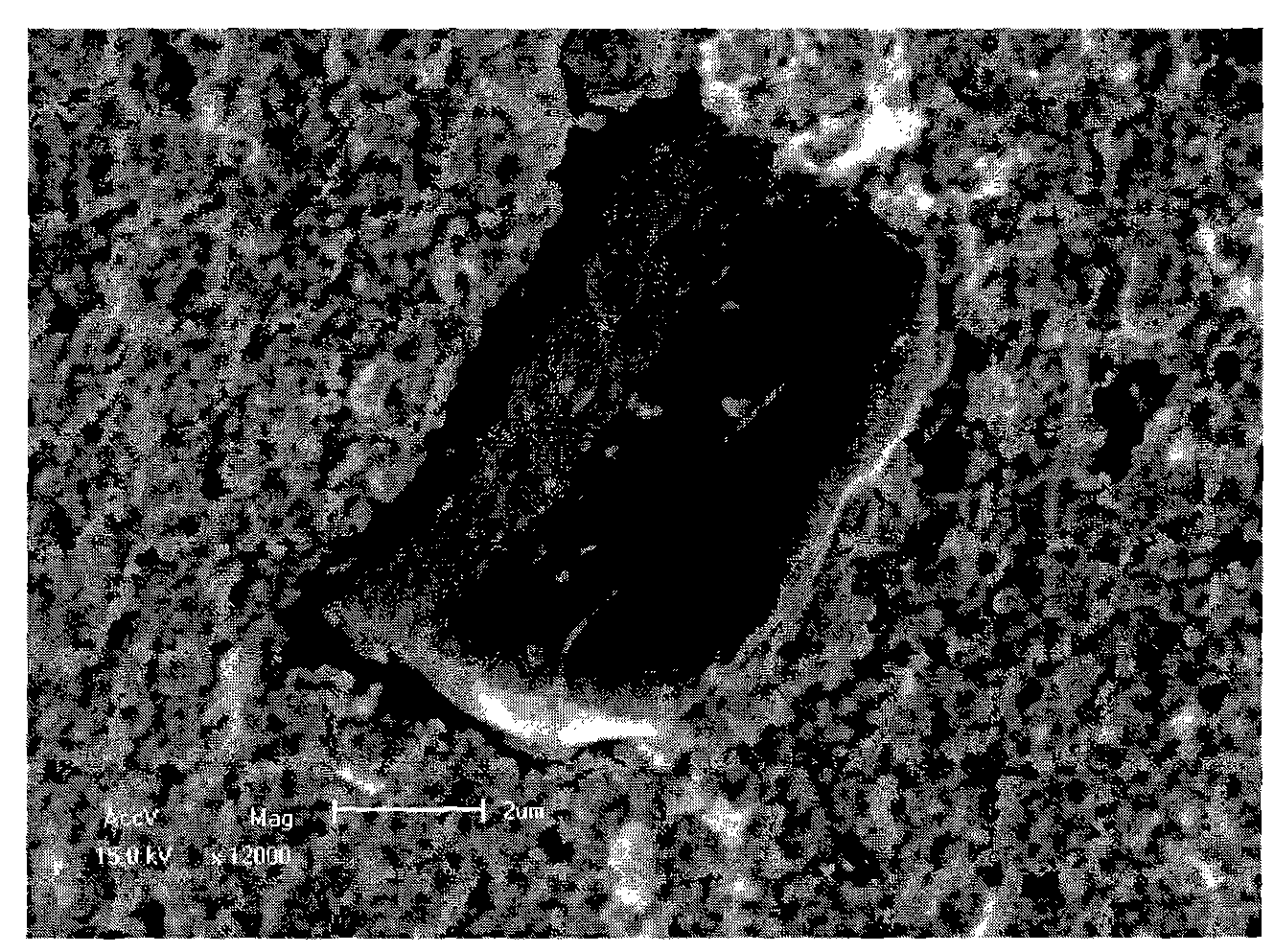

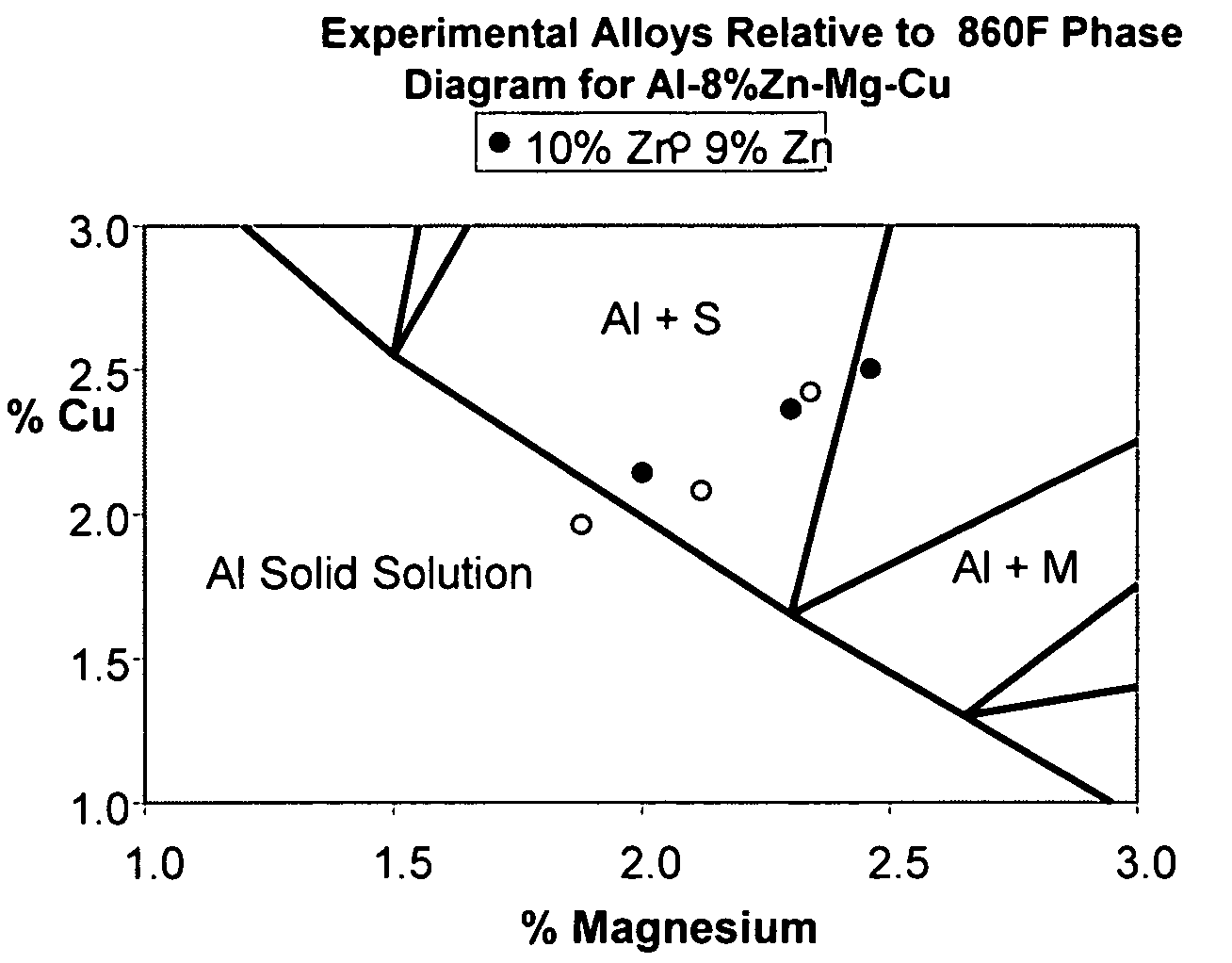

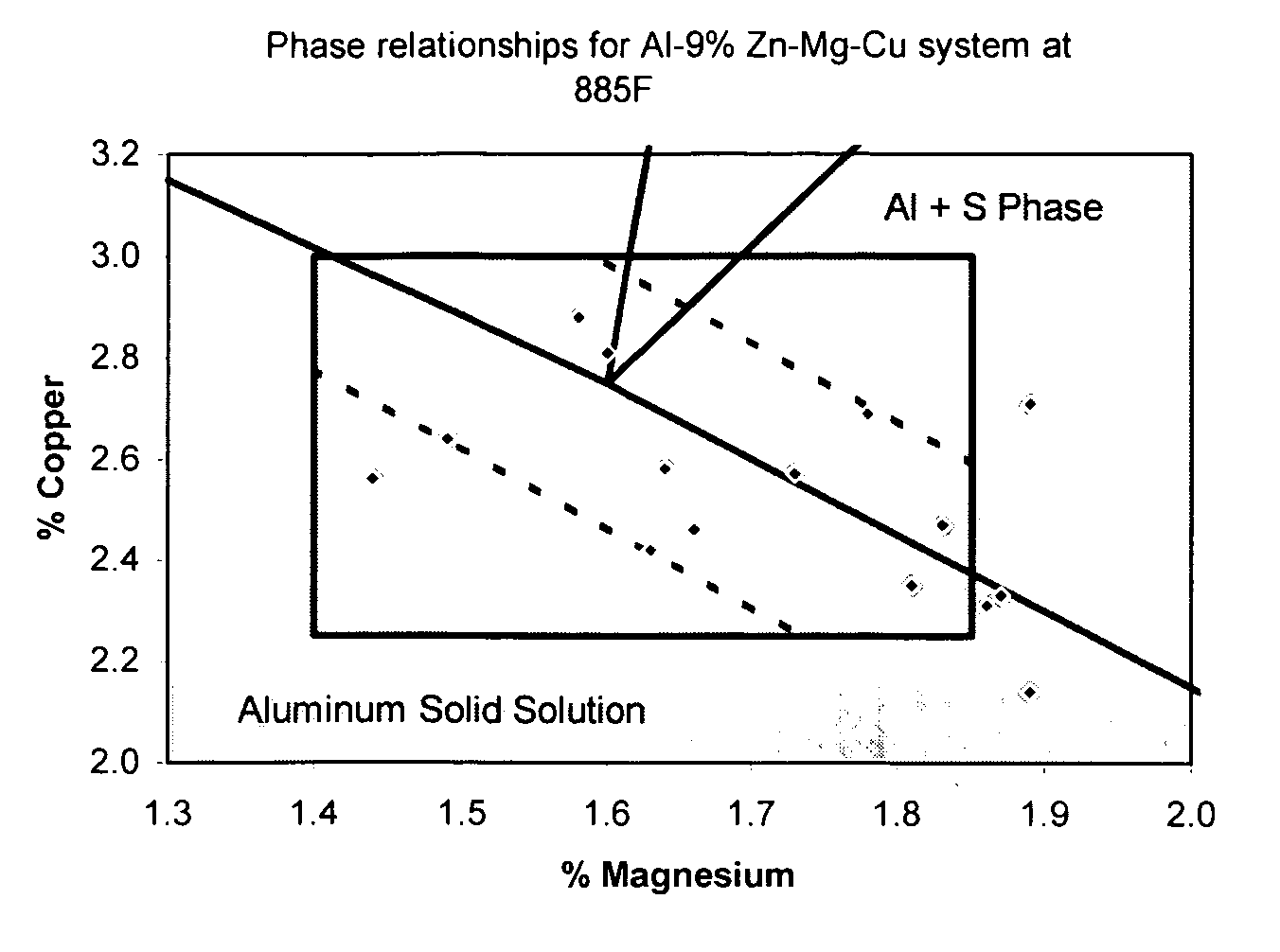

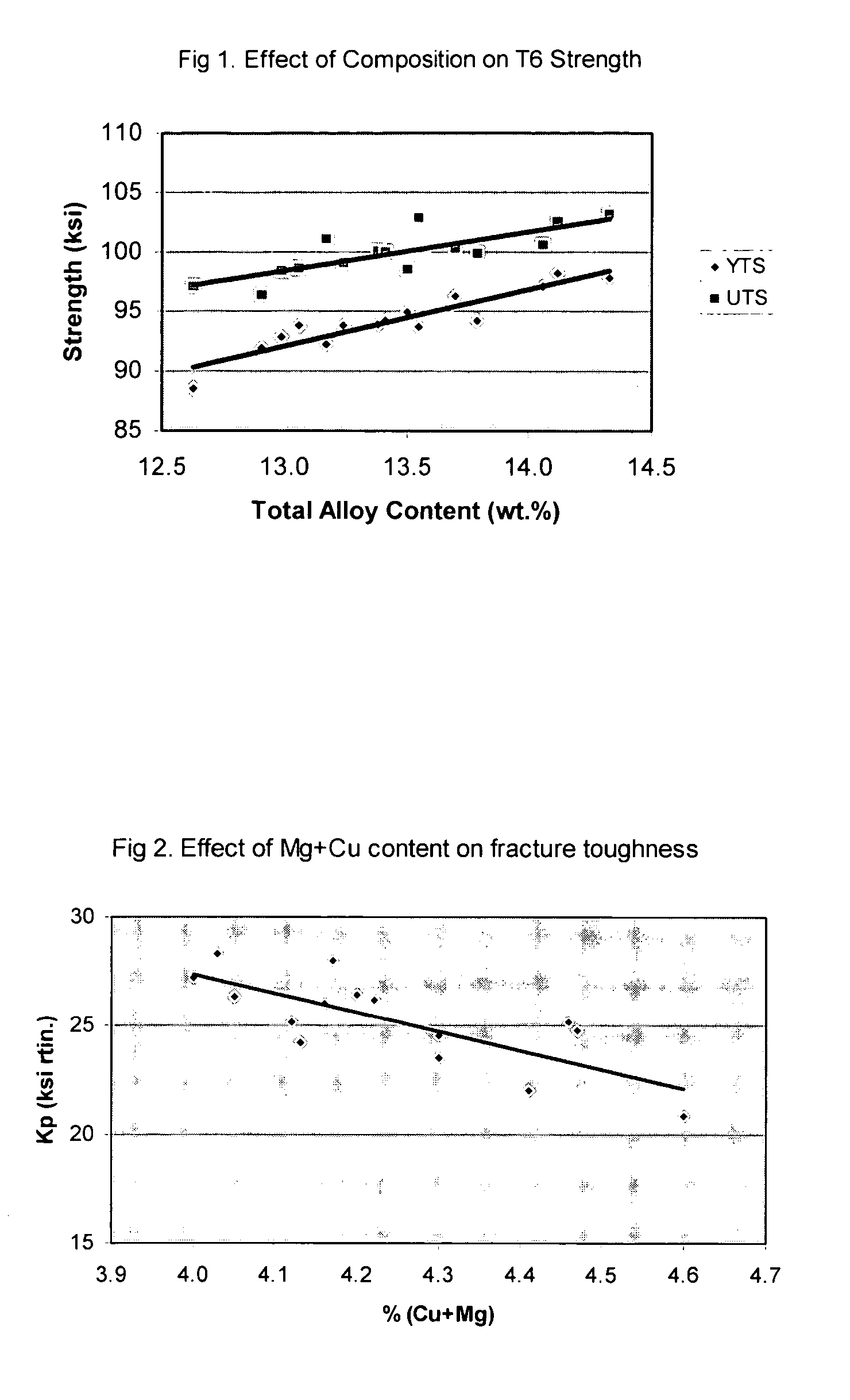

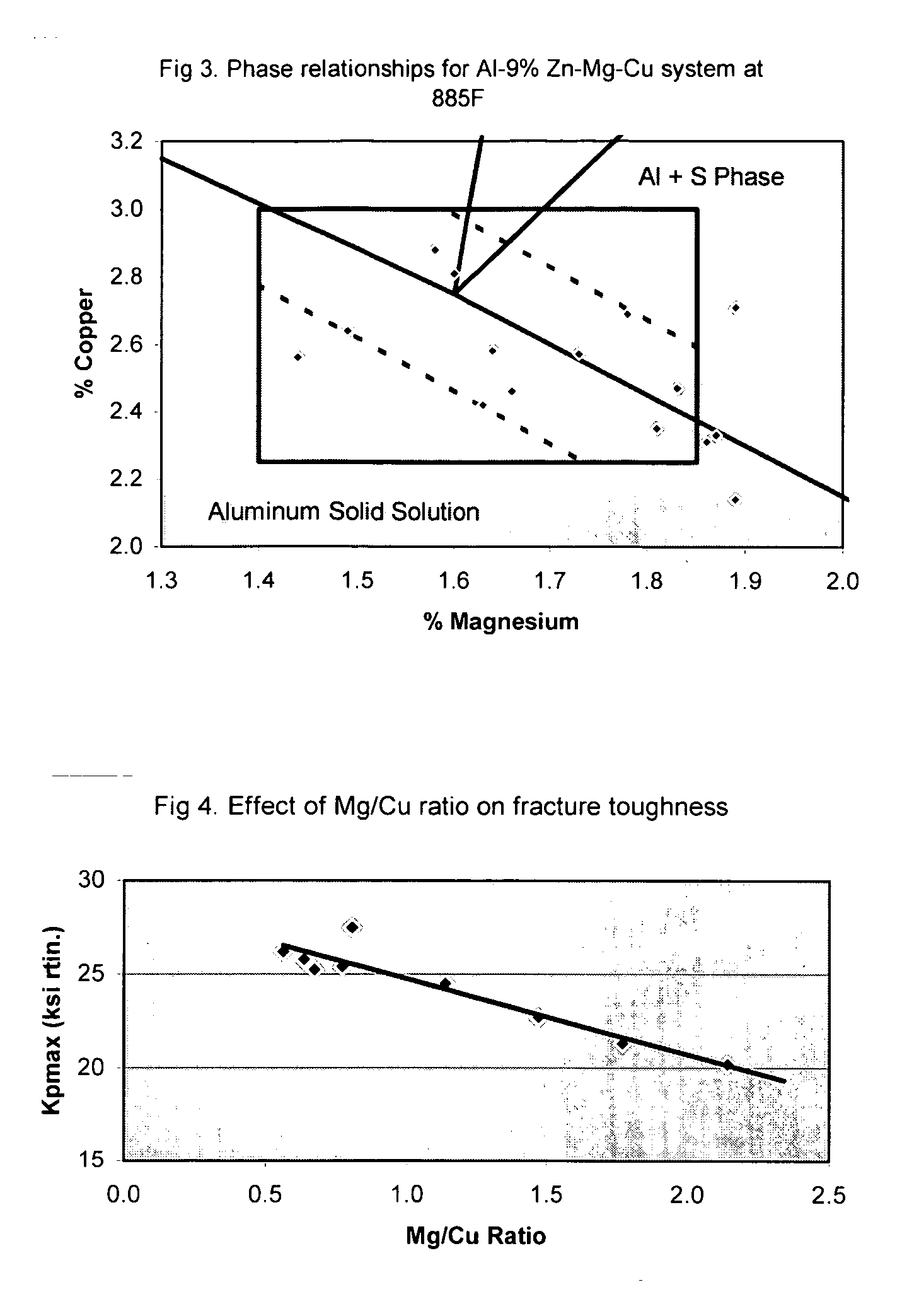

High strength aluminum alloys based on the Al—Zn—Mg—Cu alloy system preferably include high levels of zinc and copper to provide increased tensile strength without sacrificing toughness. In addition, small amounts of scandium are also preferably employed to prevent recrystalization. Preferred ranges of the elements include by weight, 8.5-11.0% Zn, 1.8-2.4% Mg, 1.8-2.6% Cu, 0.05-0.30% Sc and at least one element from the group Zr, V, or Hf not exceeding about 0.5%, the balance substantially aluminum and incidental impurities. During formation of the alloys, a homogenization process is preferably employed after alloy ingot casting in which a slow rate of temperature increase is employed as the alloy is heated as near as possible to its melting temperature. For the last 20-30 F below the melting temperature, the rate of increase is limited to 20 F / hr. or less to minimize the amount of low melting point eutectic phases and thereby further enhance fracture toughness of the alloy.

Owner:KAISER ALUMINUM FABTED PRODS

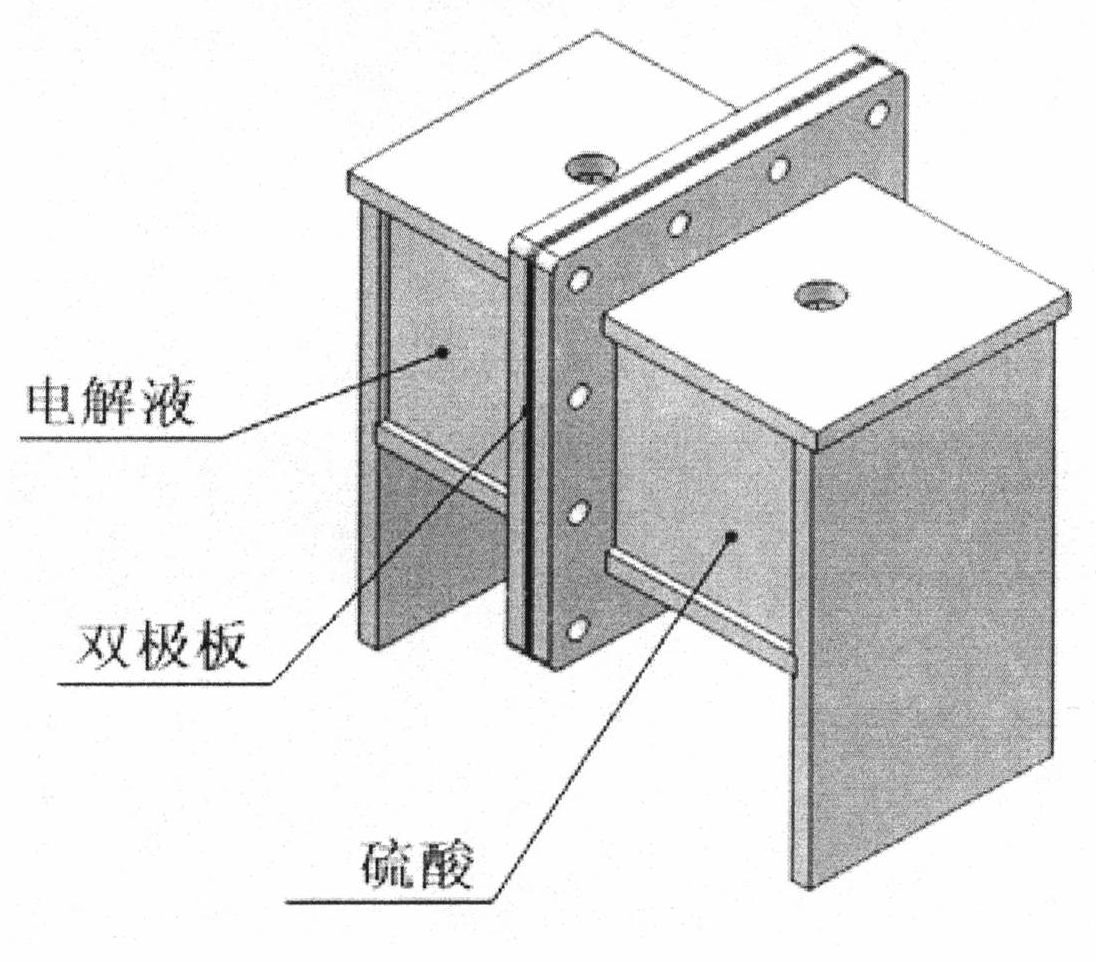

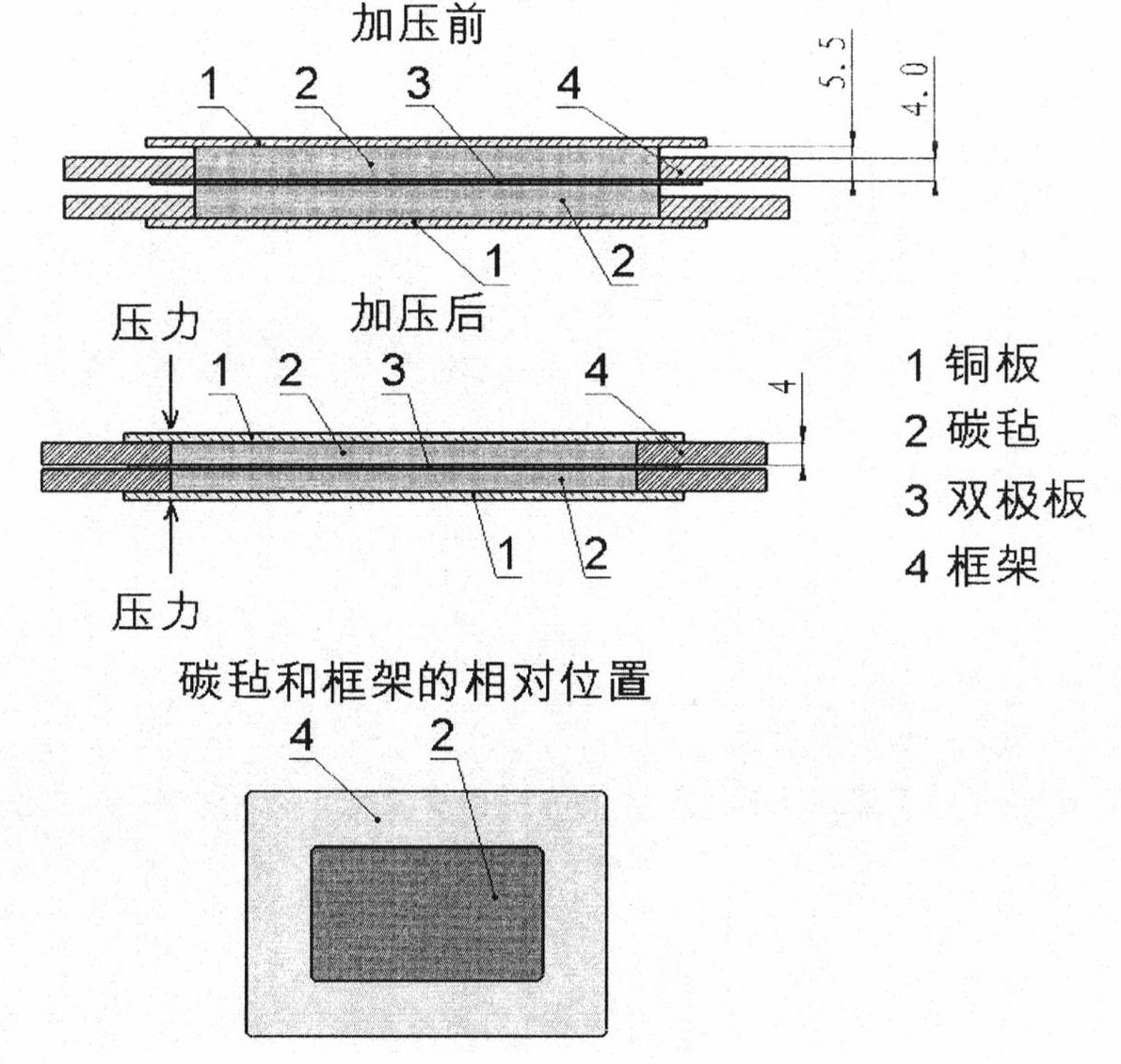

Elastomer plastic, conductive plastic, conductive plastic bipolar plate and preparation methods thereof

InactiveCN102120836AImprove mechanical propertiesExtended service lifeFinal product manufactureCell electrodesElastomerEngineering

The invention relates to an elastomer plastic which is characterized by being blended from single thermoplastic resins with at least two different specifications. The invention also relates to a conductive plastic containing the elastomer plastic and a conductive plastic bipolar plate. The invention also relates to preparation methods of the elastomer plastic, the conductive plastic containing the elastomer plastic, and the conductive plastic bipolar plate.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

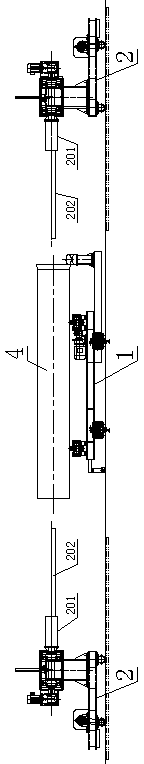

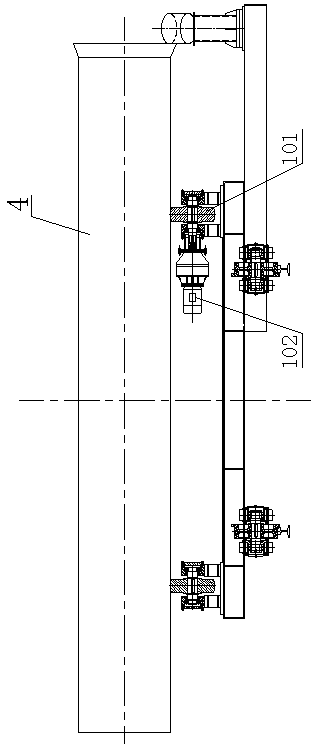

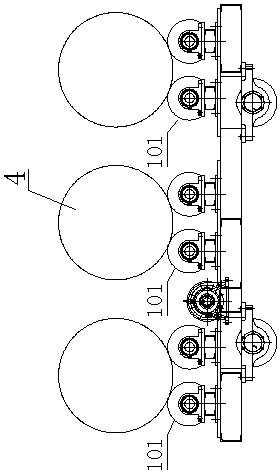

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

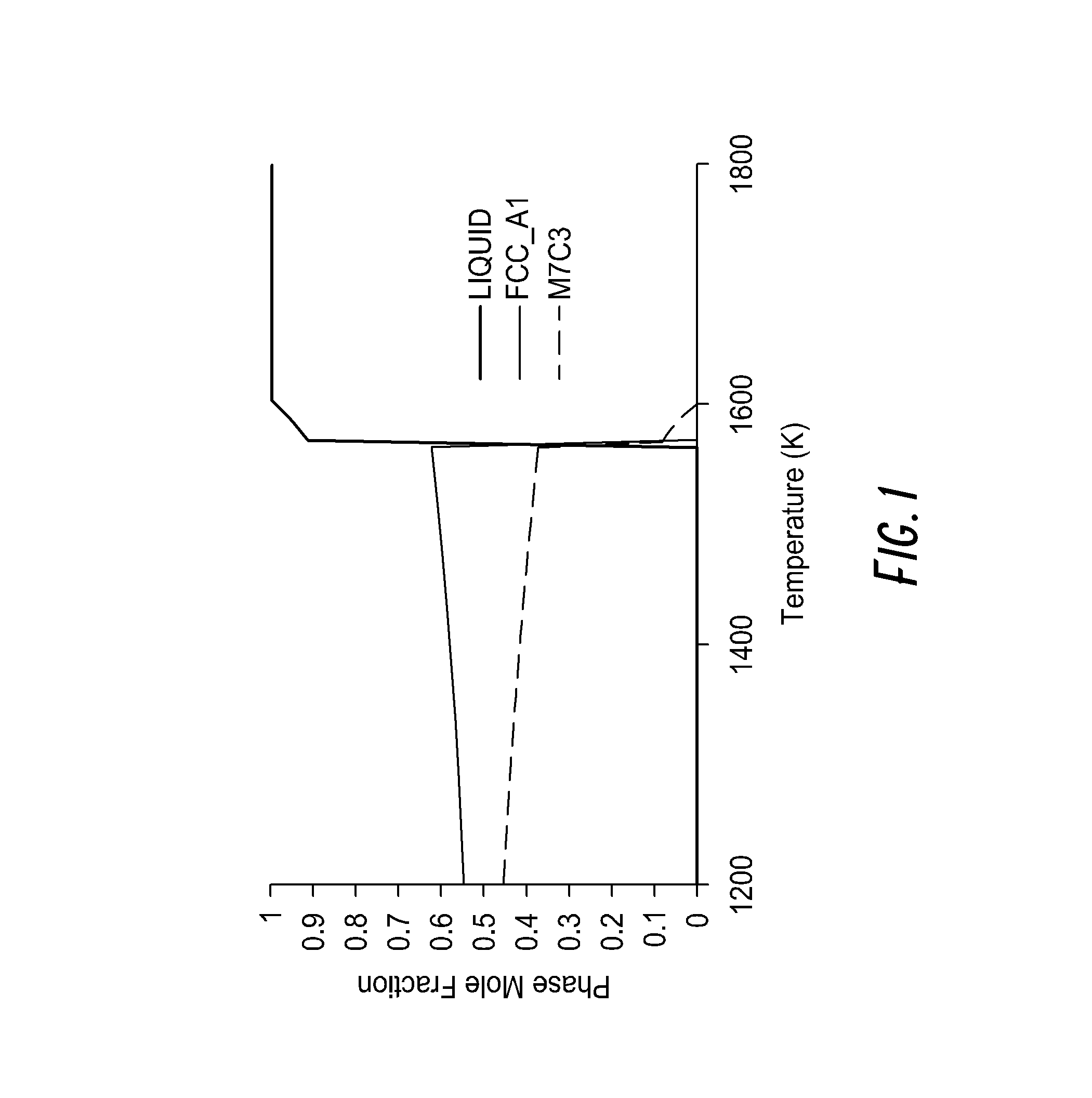

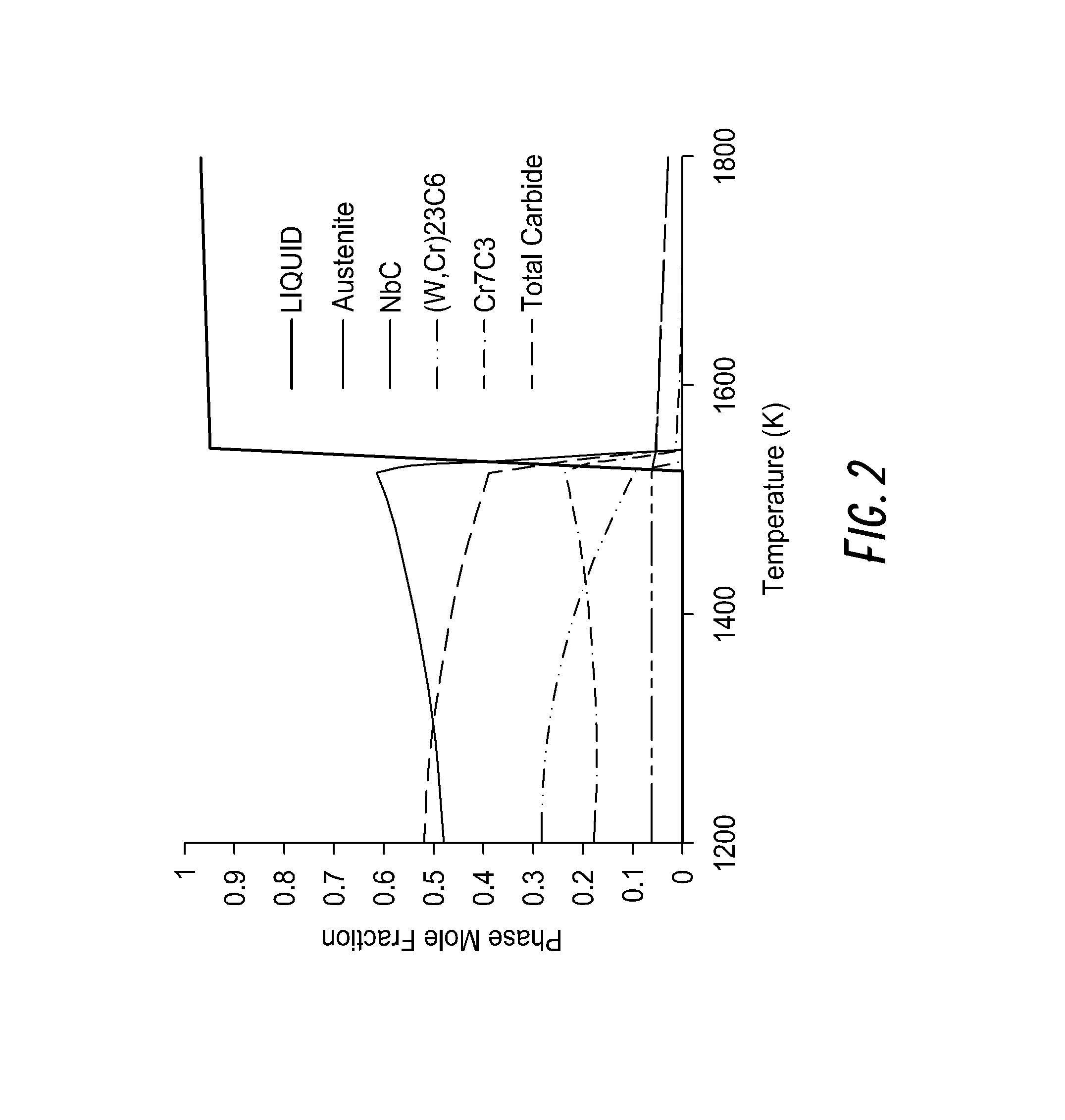

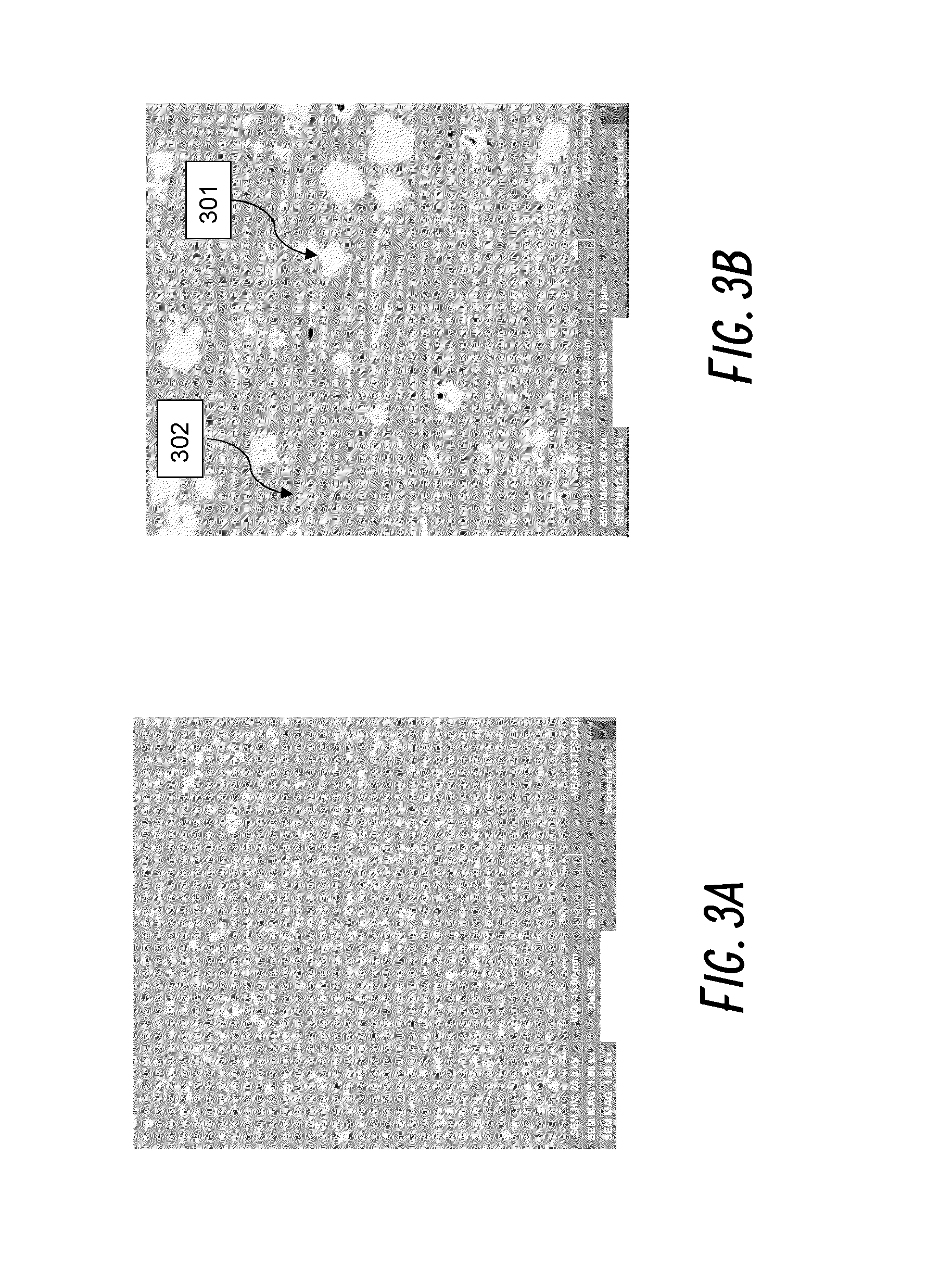

Fine-grained high carbide cast iron alloys

Embodiments of alloys having high, fine-grained carbide content, and methods of manufacturing such alloys. The alloys can be determined through the use of thermodynamic, microstructural, and compositional criterial in order to create a high strength and high toughness alloy. In some embodiments, the alloys can be used as a wear resistant component.

Owner:SCOPERTA INC

Preparation method for fish balls

InactiveCN105394620AKeep umamiStay resilientFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentBiotechnologyVegetable oil

The invention relates to the technical field of food processing, in particular to fish balls and a preparation method thereof. The fish balls are prepared from, by weight, 70-120 parts of fresh fish flesh, 1-12 parts of vegetable oil, 0.2-3 parts of salt, 0.5-6 parts of minced garlic and 0.2-5 parts of fruit peels, and cheese or lean meat or mustard can be selected as stuffing. The preparation method of the fish balls comprises the steps that 1, the raw materials are weighed according to the formula of the fish balls, the fresh fish flesh is made into muddy flesh, the fruit peels are mashed, and the fresh muddy fish flesh, the vegetable oil, the salt, the minced garlic and the fruit peels are mixed evenly to obtain a raw material mixture; 2, the raw material mixture is repeatedly flapped until glue is generated; 3, the glue-generated raw material mixture is kneaded into balls, and then the fish balls are obtained. The fish balls have the advantages that the mouthfeel is fresh and smooth, the toughness is excellent, the delicious flavor and faint scent are achieved, the taste is unique and diversified, and the fresh mouthfeel and toughness of the fresh fish flesh are kept through the preparation method; in addition, operation is easy, and therefore the fish balls are easy to popularize and have the good market prospect.

Owner:黄淦林

Heat treatment process of high-carbon chromium bearing steel

The invention provides a heat treatment process of high-carbon chromium bearing steel and belongs to the technical field of steel materials and heat treatment. The heat treatment process comprises the steps of smelting, forging, incomplete annealing, normalizing, quenching and tempering, double-refining processing, carbonitriding and surface chromizing. According to the invention, repeated quenching, tempering and other heat treatment, surface carbonitriding and surface chromizing processes are mainly adopted to reinforce the hardness and strength and prolong the service life of a bearing, so that the finally produced bearing is higher in strength, stronger in hardness and longer in service life.

Owner:ANQING YINTAI BEARING

Multifunctional composite electrochemical deposition liquid and method of use thereof

The invention relates to multifunctional compound electrochemical deposition fluid, the composition of the deposition fluid is that the deposition fluid each liter comprises nickel sulfate 100-380g, nickel amino-sulfonate 30-50g, nickel chloride 30-50g, cobalt sulfate 5-25g, lanthanum chloride 0.1-0.6g, ammonium bifluoride 15-25g, sodium fluoride 2-4g, dodecyl polyoxyethylene ether or dodecyl polyoxypropylene nonylphenolether 0.1-1.0g, naphthalenesulfonic acid or p-toluene sulfonamide 1-3g and other is water. Compared with a background technique, the deposition fluid of the invention has the following advantages: the deposition fluid of the invention improves the internal stress condition between a basal body and a nickel layer and intensifies the adhesive force of a primary plating layer, the passivation of a nickel anode is avoided in a nickel plating process, the quality of a plating layer is greatly increased, the corrosion resistance of a nickel electroplating layer is improved, the plating layer becomes even and compact without defects such as stomatas, pockmarks and the like, the deposition fluid has the luster of semi-bright nickel, simultaneously, the hardness and the anti wear property can be improved, and the service life is prolonged.

Owner:常熟紫金知识产权服务有限公司

Anti-ultraviolet plastic woven-bag filament

InactiveCN103710787AEnhanced Anti-PurpleStay resilientConjugated synthetic polymer artificial filamentsArtifical filament manufactureWaxChemistry

The invention discloses an anti-ultraviolet plastic woven-bag filament. Through blending, melting, filtration, extrusion film-formation, water cooling, filament dividing, filament drawing and rolling, the anti-ultraviolet plastic woven-bag filament is prepared from 100 parts by weight of polypropylene, 10-12 parts by weight of polyoxymethylene, 20-24 parts by weight of linear low density polyethylene, 1.2-1.5 parts by weight of polyethylene wax, 3-3.5 parts by weight of an ethylene-methyl acrylate copolymer (EMA1125AC), 1.4-1.8 parts by weight of tributyl citrate, 0.4-0.8 parts by weight of turpentine, 0.4-0.6 parts by weight of a ultraviolet ray absorber (UV-531) and 3-3.5 parts by weight of an assistant. Through use of the ultraviolet ray absorber, ultraviolet resistance and oxidation resistance of the plastic woven product are improved, toughness of the existing plastic ribbon-like filament is kept and a cost is low. The plastic woven-bag prepared from the anti-ultraviolet plastic woven-bag filaments can effectively prevent an ultraviolet ray illumination-caused oxidation reaction so that the problem that the packaging bag prepared from the existing plastic ribbon-like filaments has a short service life.

Owner:ANHUI ANYUAN PLASTIC

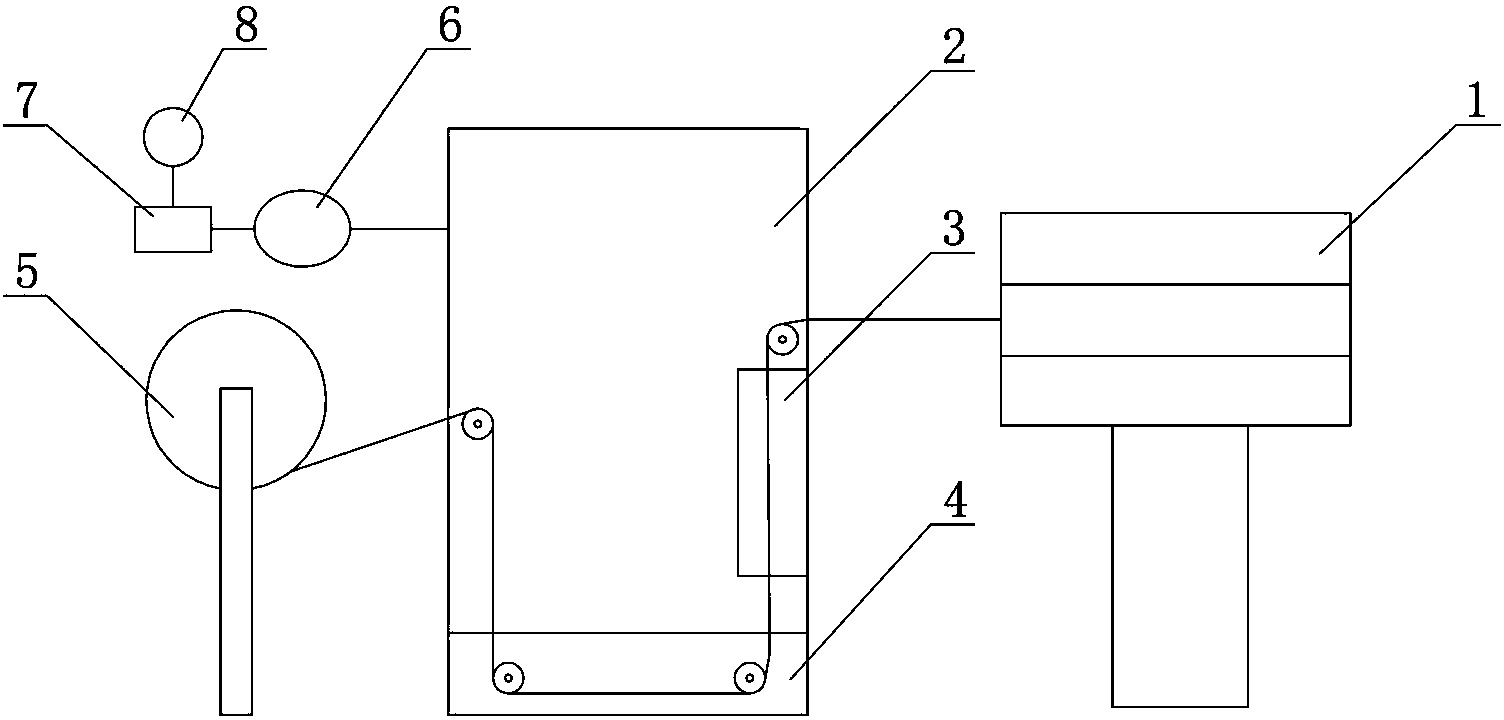

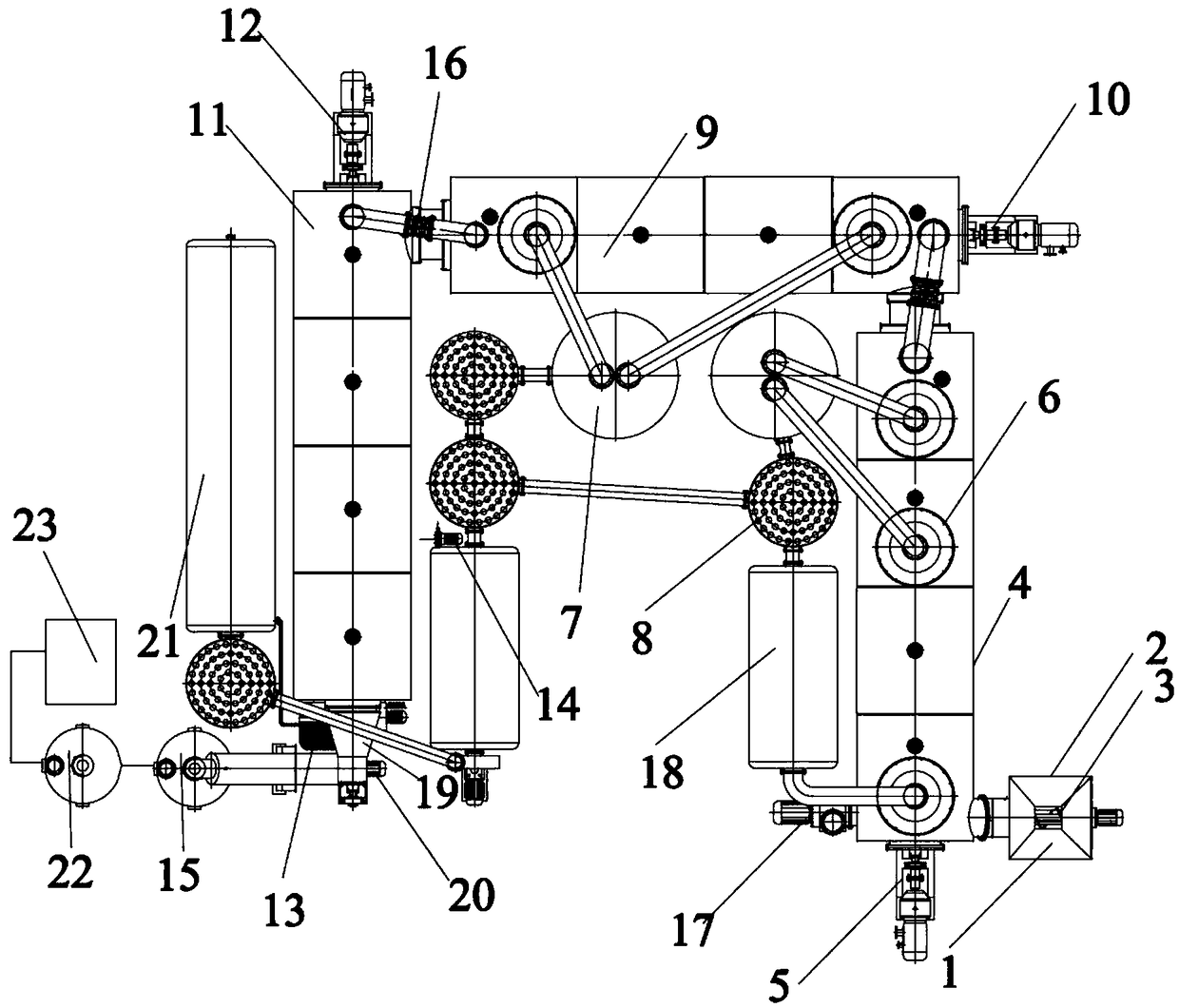

Cupreous metal wire-drawing on-line heat treatment method and on-line heat treatment device

InactiveCN104073616AStable annealing processGood effectFurnace typesHeat treatment furnacesCopper wireEngineering

The invention provides a cupreous metal wire-drawing on-line heat treatment device which comprises a wire drawing machine, wherein a wire outlet end of the wire drawing machine is connected with the inlet of an electromagnetic heating coil inlet of an electromagnetic induction heating facility, and the outlet of the electromagnetic heating coil is connected with the inlet of a cooling water tank; and the outlet of the cooling water tank is connected with a take-up pulley. The device is scientific in design, implements on-line annealing, and enhances the toughness and electric conductivity of the drawn copper wire. The invention also provides an on-line heat treatment method of the cupreous metal wire-drawing on-line heat treatment device, which comprises the following steps: 1. wire drawing; 2. on-line heat treatment; 3. water cooling; and 4. taking up. By carrying out heat treatment on the drawn cupreous metal wire, the method is scientific in design and enhances the toughness and electric conductivity of the drawn copper wire.

Owner:HENAN KAIQI POWER IND

High strength aluminum alloys and process for making the same

High strength aluminum alloys based on the Al—Zn—Mg—Cu alloy system preferably include high levels of zinc and copper, but modest levels of magnesium, to provide increased tensile strength without sacrificing toughness. Preferred ranges of the elements include by weight, 8.5-10.5% Zn, 1.4-1.85 % Mg, 2.25-3.0% Cu and at least one element from the group Zr, V, or Hf not exceeding about 0.5%, the balance substantially aluminum and incidental impurities. In addition, small amounts of scandium (0.05-0.30%) are also preferably employed to prevent recrystalization. During formation of the alloys, homogenization, solution heat treating and artificial aging processes are preferably employed.

Owner:BROOKS CHARLES E +4

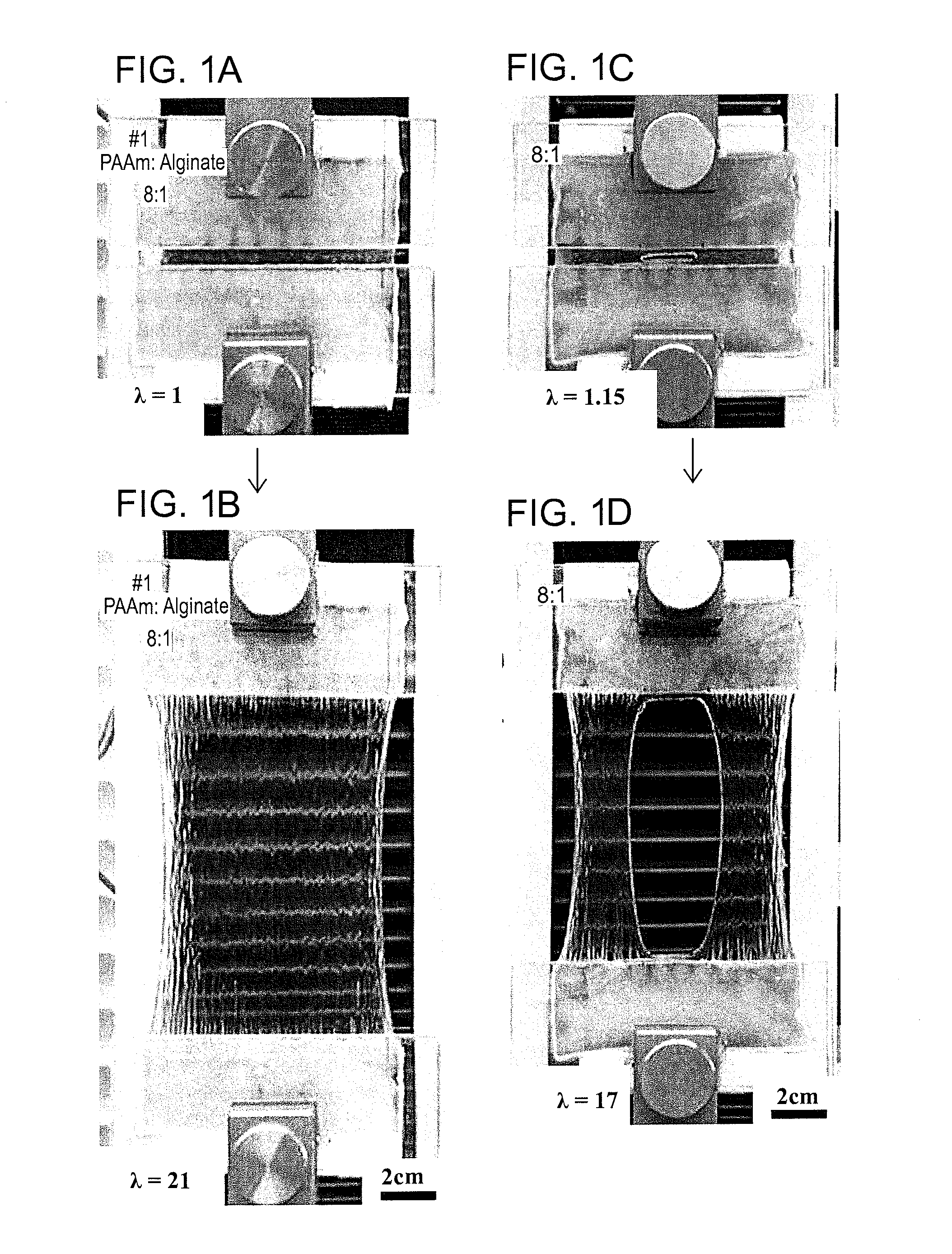

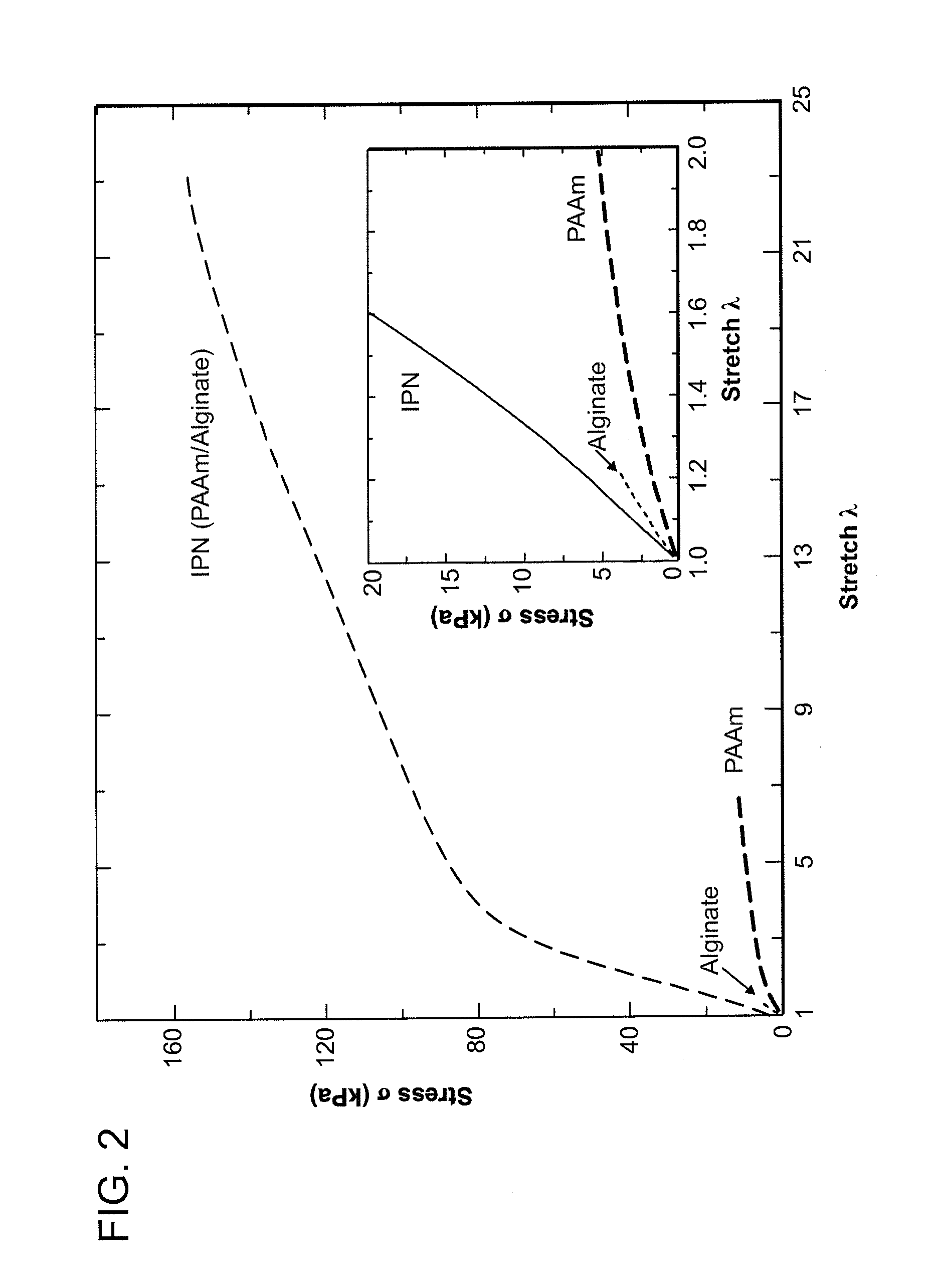

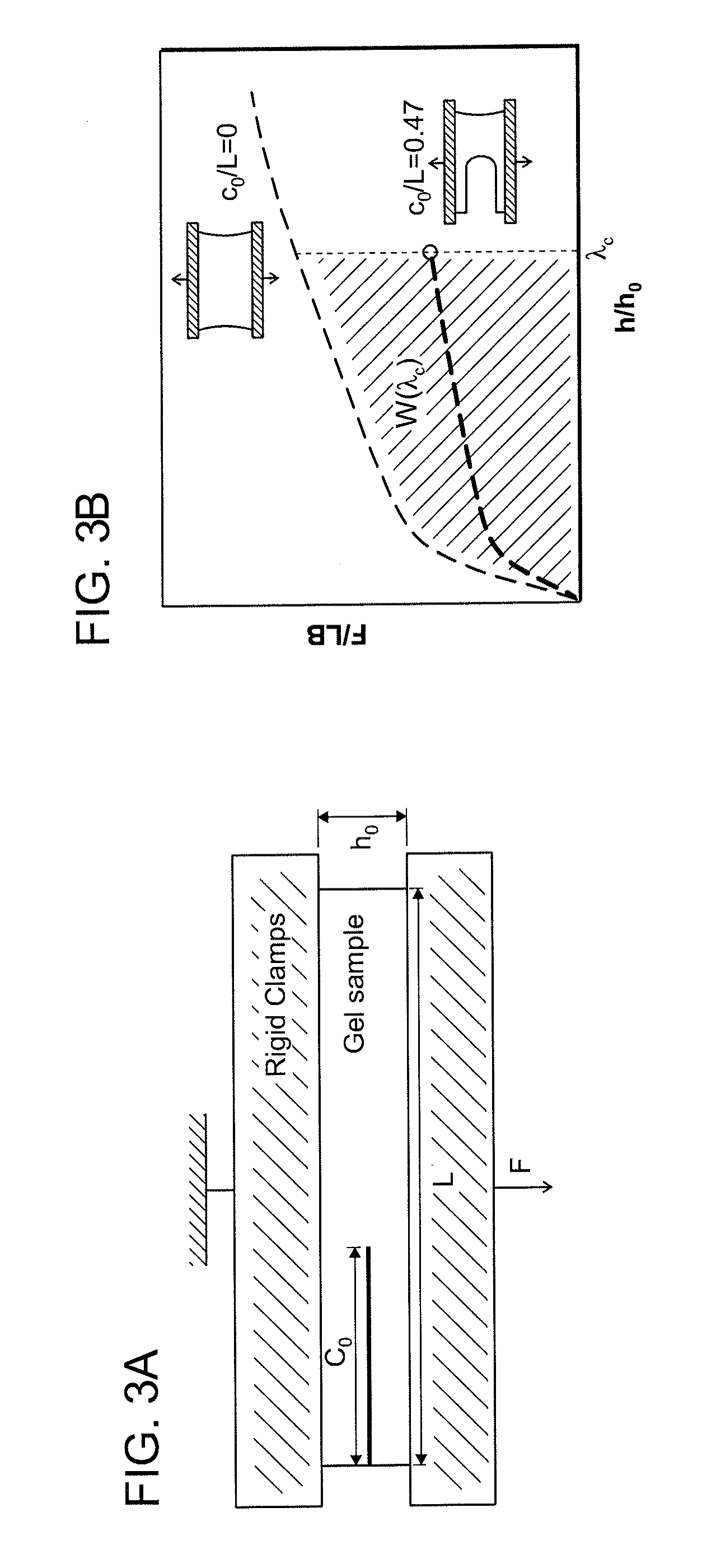

Interpenetrating networks with covalent and ionic crosslinks

ActiveUS20160354520A1Improve mechanical propertiesImprove fracture toughnessProsthesisSelf-healingEngineering

The invention features a composition comprising a self-healing interpenetrating network hydrogel comprising a first network and a second network. The first network comprises covalent crosslinks and the second network comprises ionic or physical crosslinks. For example, the first network comprises a polyacrylamide polymer and second network comprises an alginate polymer.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

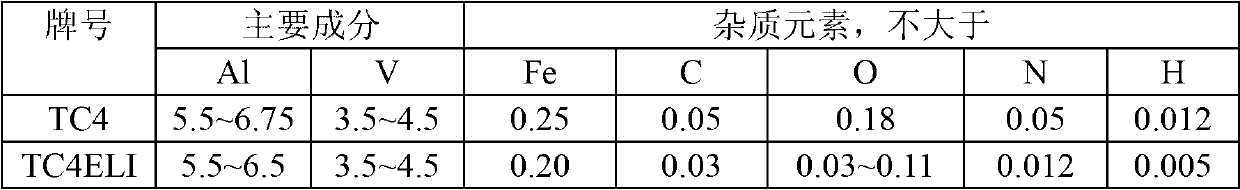

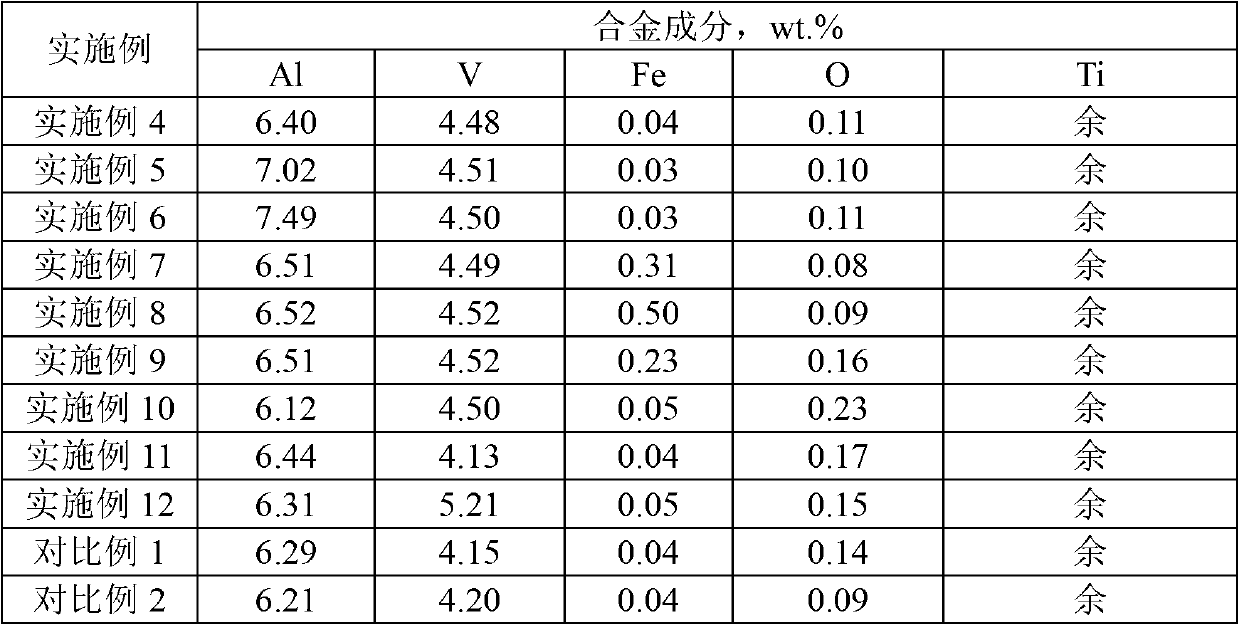

Alpha and beta combined titanium alloy wire for electron beam fused deposition rapid formed structural member with strength level of 920 MPa

The invention discloses an alpha and beta combined titanium alloy wire for an electron beam fused deposition rapid formed structural member with the strength level of 920 MPa. The alpha and beta combined titanium alloy wire is characterized in that an alpha phase is strengthened by an alloy element Al and an interstitial element O, and a beta phase is strengthened by an alloy element V and Fe, wherein the wire comprises the following components of: 6.2 to 7.5 weight percent of Al, 4.0 to 5.5 weight percent of V, 0.10 to 0.50 weight percent of Fe, 0.12 to 0.25 weight percent of O, the balance of Ti and inevitable impurity elements. The invention also provides the corresponding melting process, a thermal machining process and a thermal treatment process for the electron beam fused deposition rapid formed structural member. By the alloy wire, a requirement on the process for quickly forming by stacking the fuse wires of the electronic beams is met, and the titanium alloy structural member has relatively high mechanical performance. Great social benefits and economic benefits are created after the alloy wire is popularized and applied.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Preservative agent and preservative method of fresh flower and application

InactiveCN102870767AGood air permeabilityMaintain surface flexibility and toughnessDead plant preservationPervaporationFibroin

The invention provides a preservative agent for a fresh flower. The preservative agent is mainly prepared by adding glycerol and calcium chloride solution at certain concentrations to a 0.5% fibroin solution. The invention also provides a preservative method for the fresh flower and an application of the preservative agent in the course of red rose preservation. With the adoption of the preservative agent and the preservative method, air holes on the surfaces of petals can be closed appropriately, and a pervaporation flux of a membrane can be controlled, so that the effect of preserving the fresh flower is achieved.

Owner:ZHEJIANG ECONOMIC & TRADE POLYTECHNIC

Working liquid for fabricating preserved flowers of peony and Chinese herbaceous peony, and method for fabricating preserved flowers and preserved leaves of peony and Chinese herbaceous peony by using same

InactiveCN103843760ANot affectedStay resilientDead plant preservationEnvironment effectPolypropylene glycol

The invention relates to a working liquid for fabricating preserved flowers of peony and Chinese herbaceous peony, and a method for fabricating preserved flowers and preserved leaves of peony and Chinese herbaceous peony by using the same. The working liquid comprises one or a mixture of more than two of 50-80% methanol, ethanol, normal propyl alcohol, n-butyl alcohol and isopropanol, 20-50% polyethylene glycol 200-1000 and polypropylene glycol 200-1000; and the polyethylene glycol accounts for 60-80%, and the polypropylene glycol accounts for 20-40%. The preserved flowers and preservative liquid of the peony and the Chinese herbaceous peony fabricated by the working liquid can be stored for a long period of time in a state of being close to fresh flowers / fresh leaves, the natural gesture, the flexibility and the texture can be kept, the external environment effect is avoided, and the ornamental value is greatly enhanced.

Owner:洛阳甲天下牡丹园艺有限公司

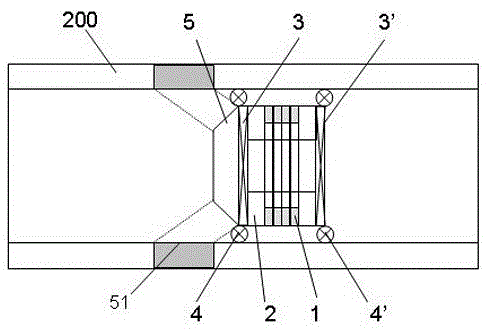

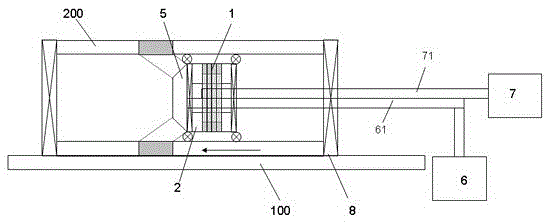

Method and device for improving hardness of inner wall of steel tube

ActiveCN105648190AExtended service lifeStay resilientFurnace typesIncreasing energy efficiencyInduction hardeningMechanical property

The invention provides a method and device for improving hardness of the inner wall of a steel tube. A scanning type induction hardening process is adopted, heat treatment is carried out on the inner wall of the whole steel tube, an induction coil is placed on the steel tube, and the steel tube rotates and relatively moves relative to the induction coil; in the process that the steel tube and the induction coil relatively move, the induction coil is powered on to heat, and the heated steel tube is instantly subject to water spraying cooling after heating; the heating frequency is selected to range from 500 Hz to 2000 Hz; and the speed of movement of the steel tube relative to the induction coil is between 3 mm / s and 6 mm / s, and the rotating speed of the steel tube ranges from 5 rpm to 20 rpm. Compared with a conventional manner that heat treatment is carried out on the steel tube or the steel tube is not treated, the skin effect of induction heating is used, in the heating process, the temperature of the inner wall of the steel tune is high, the temperature of the outer wall is low, and a temperature gradient is formed; after water spraying cooling is carried out, the aim of improving the hardness and the abrasive resistance of the inner wall is achieved; and meanwhile the outer wall basically keeps mechanical properties of toughness, strength and the like of an original matrix structure.

Owner:BAOSHAN IRON & STEEL CO LTD

Epoxy resin adhesive containing graphene oxide

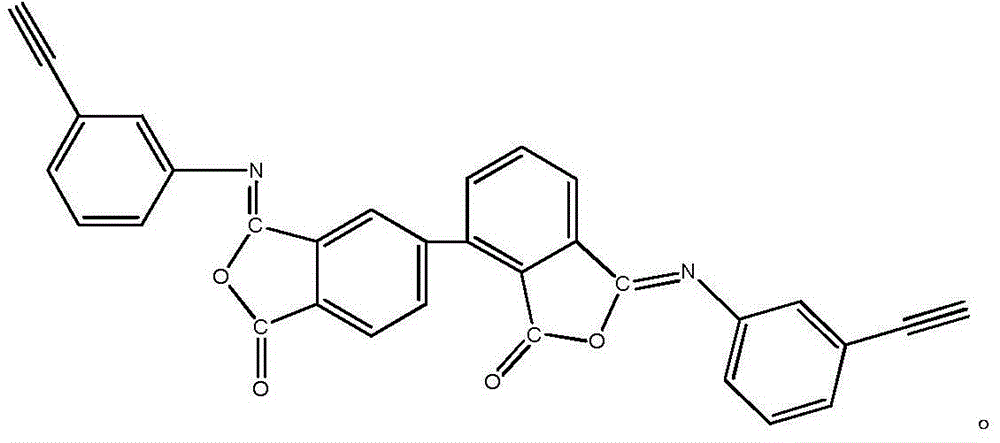

InactiveCN107418490AImprove heat resistanceImprove antibacterial propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesFlax fiberPyromellitic dianhydride

The invention discloses an epoxy resin adhesive containing graphene oxide. The epoxy resin adhesive comprises, by weight, 50-75 parts of allyl bisphenol A type epoxy resin, 5-20 parts of carboxyl-terminated polybutadiene, 5-12 parts of organic silicon resin, 5-18 parts of diaminodiphenyl-methane, 1-7 parts of pyromellitic dianhydride, 2-8 parts of 2-ethylhexyl glycidyl ether, 1-8 parts of phenyl glycidyl ether, 15-22 parts of toughening agent, 2-3.8 parts of promoter, 3-12 parts of graphene oxide, 1-4 parts of active silicon micro-powder, 2-8 parts of nano zinc oxide, 0.4-2 parts of multiwalled carbon nanotube, 1-2 parts of sulfur, 1-3 parts of flax fibers and 0.3-1.2 parts of amino-containing silane coupling agent. The epoxy resin adhesive containing the graphene oxide is excellent in antibacterial performance and good in heat resistance and cohesiveness.

Owner:安徽大松树脂有限公司

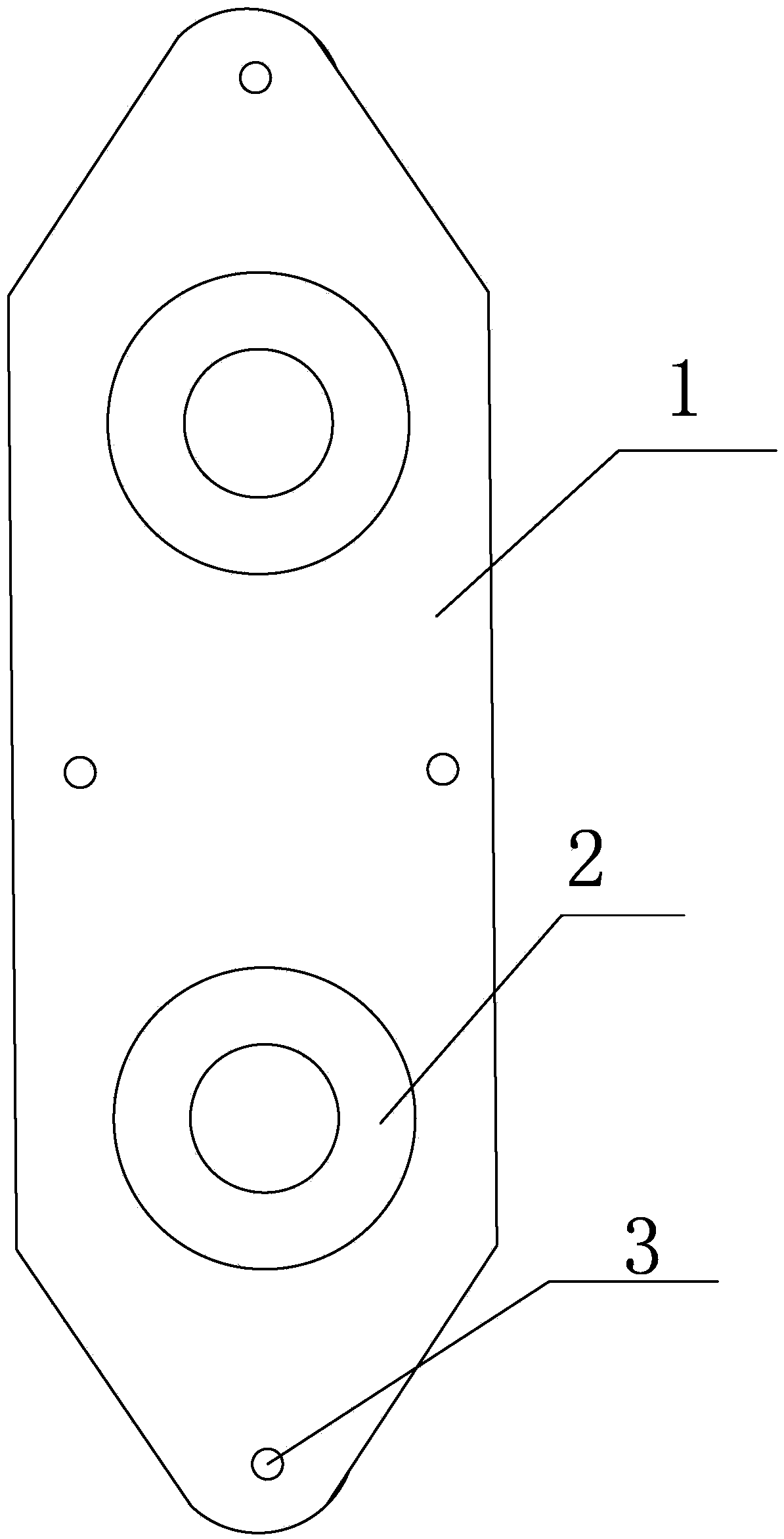

Machining method for nut plate

InactiveCN105369259AHigh tensile strengthImprove plasticityFurnace typesMetallic material coating processesRoom temperatureHardness

The invention relates to a machining method for a nut plate and belongs to the field of machining of alloy materials. The machining method includes the following steps that pretreatment is carried out, and quenching and tempering are carried out on high-strength alloy steel; heat treatment is carried out, the quenched and tempered high-strength alloy steel is forged and formed at the temperature of 1150-1220 DEG C, heat preservation is conducted for 0.3-0.6 h, quenching treatment is carried out by means of forging waste heat, the high-strength alloy steel is immediately water-cooled to the room temperature when cooled to 900 DEG C, the high-strength alloy steel is heated to 450-520 DEG C to be subjected to tempering for 2-3 h, finally the high-strength alloy steel is oil-cooled to the room temperature, and a semi-finished nut plate is obtained; and surface treatment is carried out, the semi-finished nut plate is sequentially subjected to oil and rust removal, activating treatment, blackening and passivation, and the nut plate is obtained. According to the nut plate, the high-strength alloy steel with components combined reasonably is selected to be subjected to quenching and tempering, forging, quenching, tempering and surface blackening, so that the machining cycle is greatly shortened, and the strength, hardness, toughness, corrosion resistance and abrasion resistance of the nut plate are greatly improved; meanwhile, the machining performance of the nut plate is improved, and the nut plate is easy to weld.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

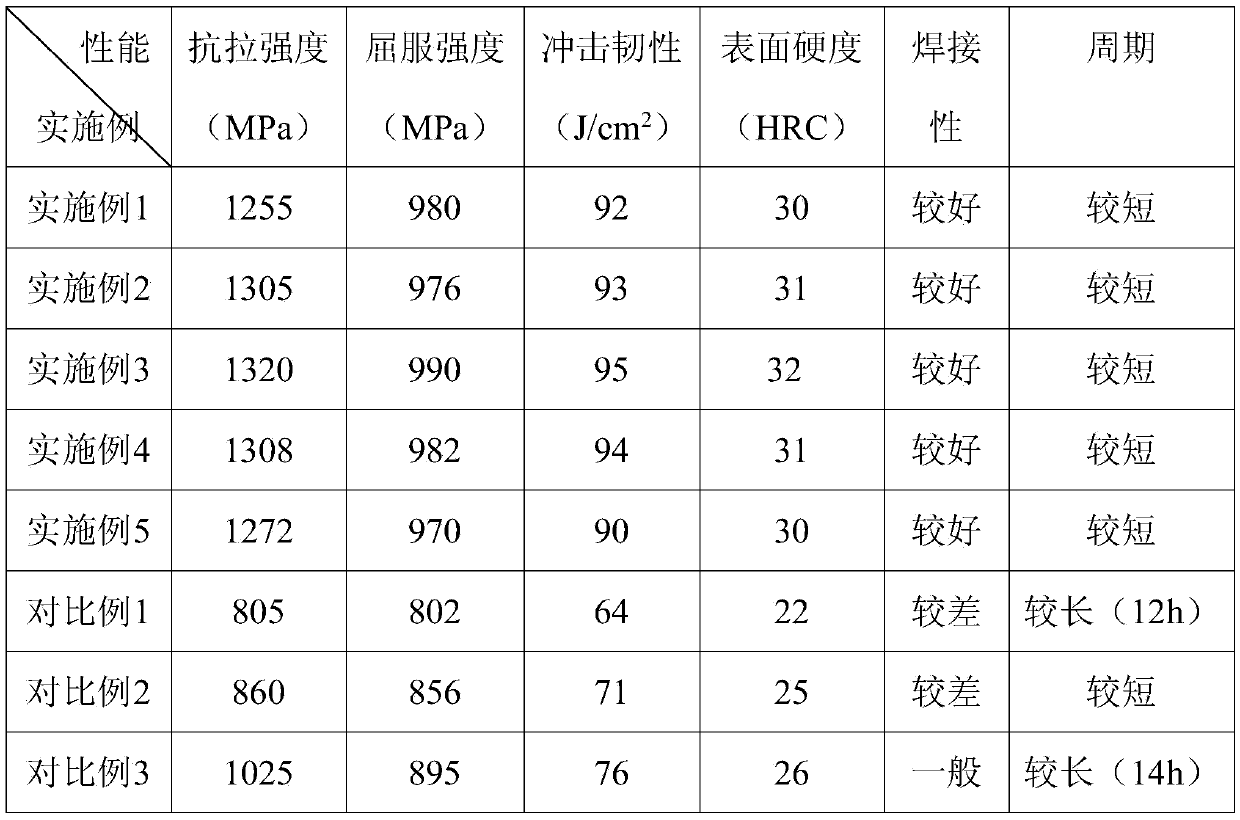

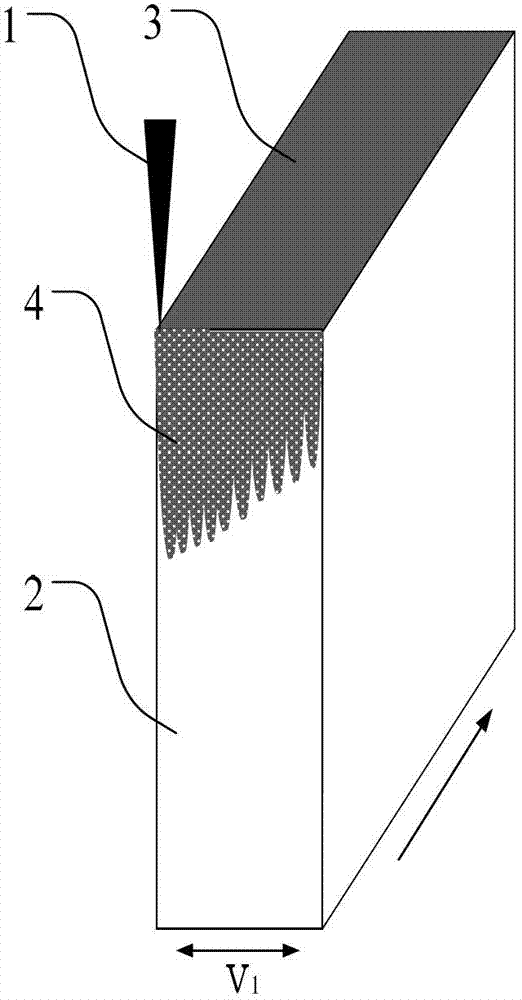

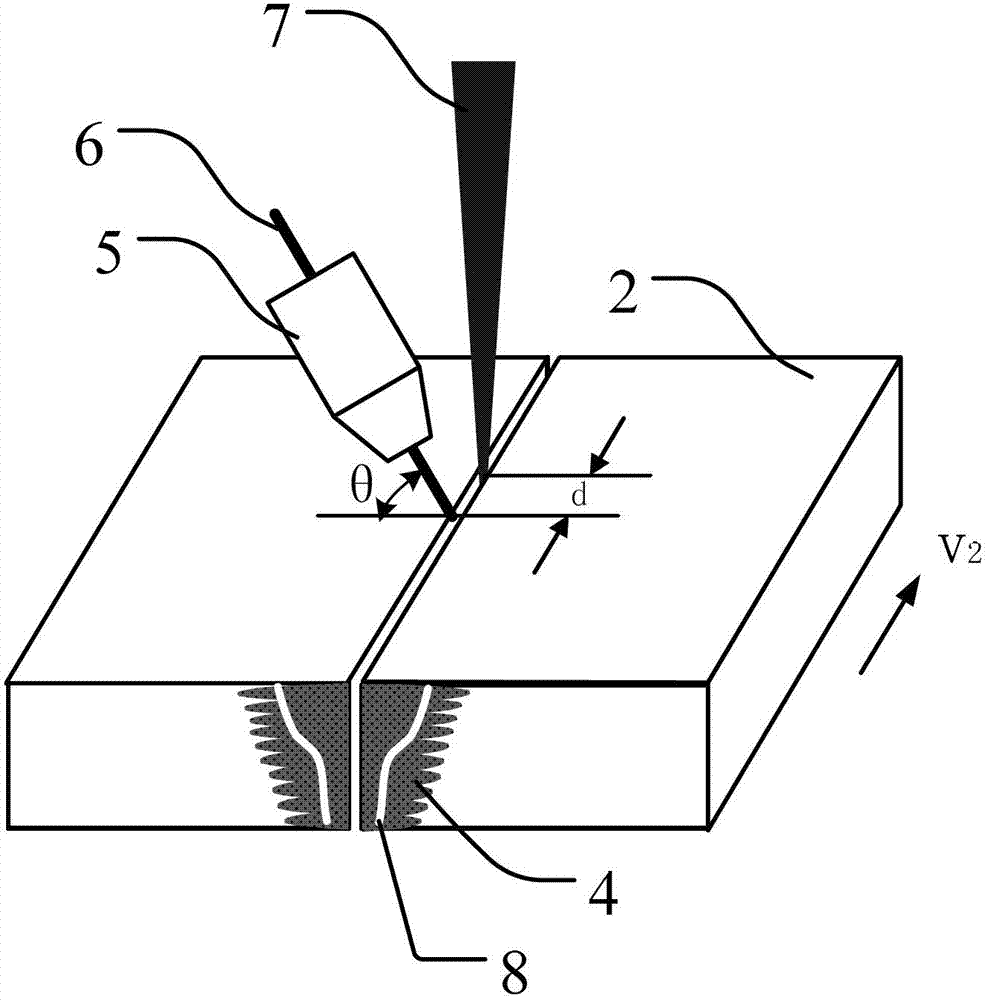

Method for improving strength and flexibility of super strength steel laser-arc hybrid welded joint

InactiveCN102848086ARefine the grain sizeReduce lossesLaser beam welding apparatusButt weldingUltimate tensile strength

The invention discloses a method for improving strength and flexibility of a super strength steel laser-arc hybrid welded joint, belonging to the technical field of super strength steel welding. The welded joint in the conventional welding technology is low in strength and poor in flexibility. The method for improving strength and flexibility of super strength steel laser-arc hybrid welded joint provided by the invention is characterized by comprising the following steps of: firstly, fusing the to-be-connected surfaces of two to-be-welded work pieces in advance by adopting a preprocessing laser to form a laser fusion preprocessing region, wherein the preprocessing laser power is 2-3kW, the scanning speed v1 is 1.5-2.5m / min, and the scanning overlap rate is 25-35%; and then, butting the fused to-be-connected surfaces of the two to-be-welded work pieces, and welding the to-be-connected surfaces by laser-arc hybrid welding. The method provided by the invention is used for butting welding of high-thickness super strength steel plates, and can improve the strength of the welded joint and improve the flexibility of the welded joint.

Owner:CHANGCHUN UNIV OF SCI & TECH

Halogen-free anti-flaming polypropylene material

InactiveCN101550253AAvoid pollutionExcellent film-forming processing performanceAmmonium polyphosphatePolypropylene

The invention relates to a halogen-free anti-flaming polypropylene material, which is characterized by comprising the following raw materials: 10 to 20 percent of first polypropylene copolymer, 27.5 to 47.5 percent of second polypropylene copolymer, 0.1 to 0.5 percent of thermal stabilizer of hindered phenol, 0.1 to 0.5 percent of thermal stabilizer monothioester, 0.1 to 0.5 percent of metal deactivator, 0.1 to 0.5 percent of processing stabilizer of phosphate ester, 2 to 10 percent of 1, 3-benzenediol bi(diphenyl phosphate ester), 0.1 to 0.5 percent of antacid agent of houghite and 30 to 50 percent of ammonium polyphosphate. The halogen-free anti-flaming polypropylene material is obtained by adopting polypropylene copolymer with the melt index of 0.2g / 10min to 0.5g / 10min and polypropylene copolymer with the melt index of 1g / 10min to 3g / 10min to carry out mixing combination, has excellent film-forming processability and can be made into films with different thickness between 0.2mm to 0.6mm.

Owner:POLYONE POLYMER SUZHOU

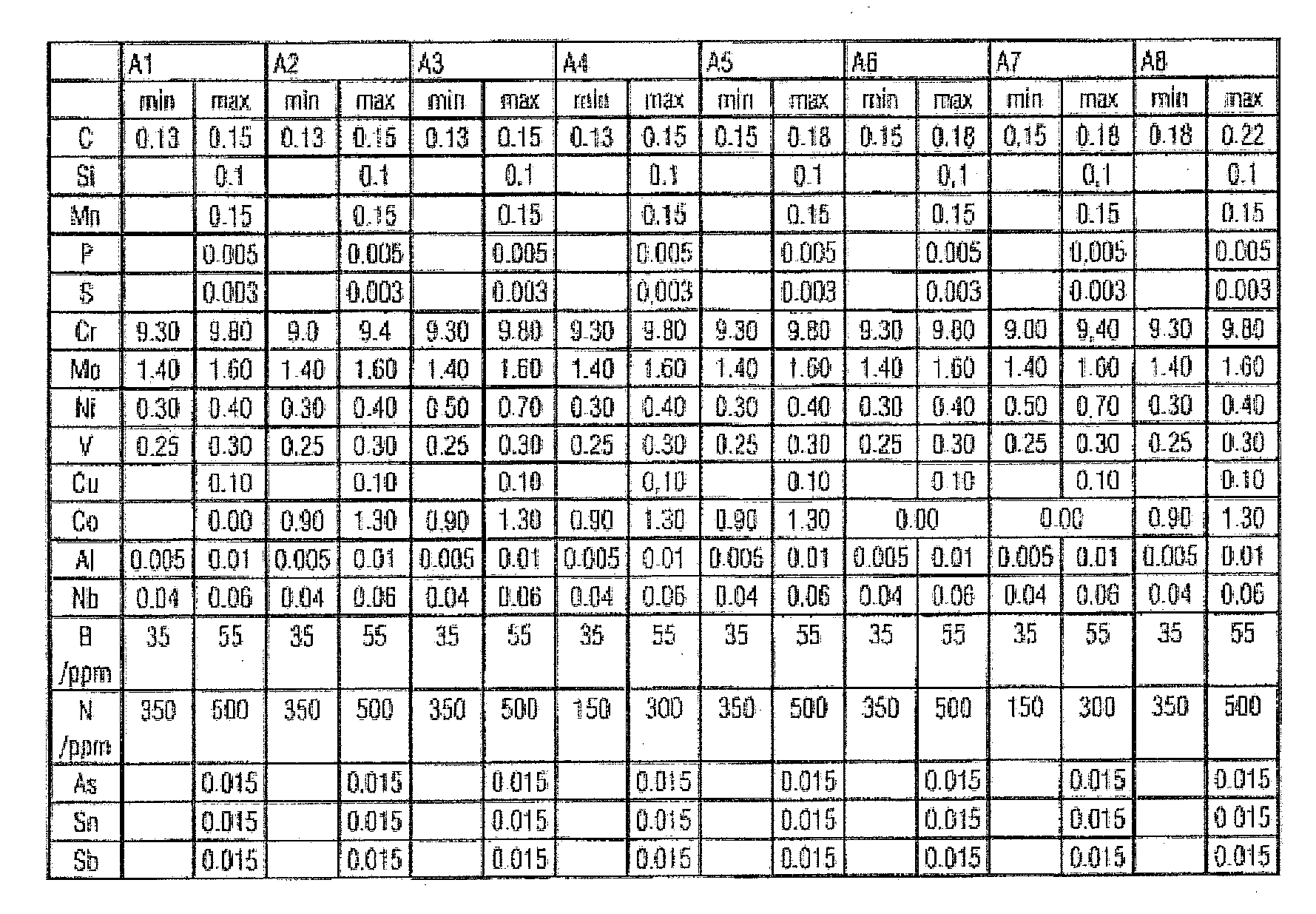

Ferritic martensitic iron based alloy, a component and a process

InactiveUS20120070329A1Improve the use temperatureMaximized strengthUltimate tensile strengthToughness

A novel ferritic martensitic alloy is provided. The ferritic martensitic alloy enables the use temperature to be increased from 500° C. to 550° C., where the strength is maintained or is even maximized and the toughness, especially for low temperatures, is maintained compared to the known iron-based alloys. Tunsten is preferably not used.

Owner:SIEMENS AG

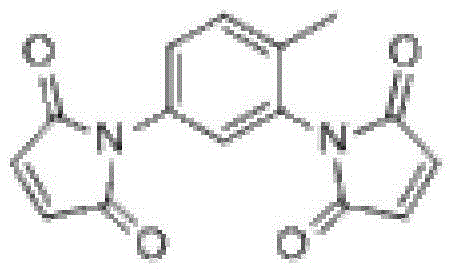

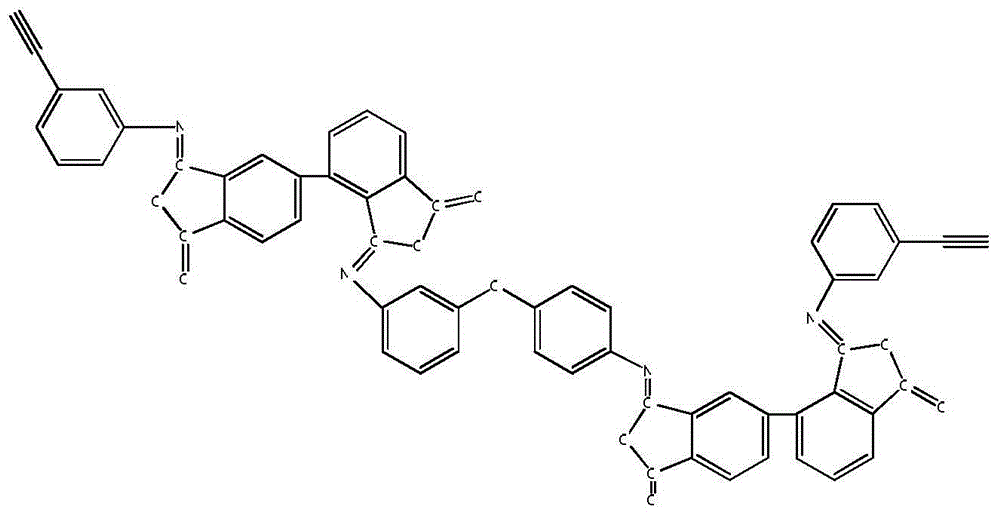

High-temperature-resistant honeycomb node adhesive and preparation method thereof

InactiveCN104479620AGood solubilityGood heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventCyanate ester

The invention discloses a high-temperature-resistant honeycomb node adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof. The high-temperature-resistant honeycomb node adhesive is used for solving the problem that the existing honeycomb node adhesive cannot meet the requirements on the manufacturing of polyimide paper honeycomb due to low temperature-resistant level and poor bonding compatibility. The adhesive is prepared from matrix resin, BMT type bismaleimide resin, phenolic cyanate ester, a co-polymerization modifier, a rubber elastomer toughening agent, inorganic nanometer filler and a solvent. The preparation method comprises the following steps: firstly, weighing; secondly, preparing toughening modified resin; thirdly, mechanically blending to obtain mixed rubber sheets; and fourthly, preparing uniform rubber liquid under stirring. The high-temperature-resistant honeycomb node adhesive is mainly applied in manufacturing aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance. The high-temperature-resistant honeycomb node adhesive prepared by the preparation method is used for the manufacturing of aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Antibacterial dish-washing detergent containing argy wormwood leaf extract

ActiveCN105255596AStrong detergencyGood foaming performanceNon-ionic surface-active compoundsDetergent compounding agentsNaCl - Sodium chlorideEther

The invention belongs to the field of chemicals for daily use, and particularly relates to an antibacterial dish-washing detergent containing argy wormwood leaf extract. The antibacterial dish-washing detergent containing the argy wormwood leaf extract mainly comprises sodium alcohol ether sulphate, sodium alkylbenzene sulfonate, fatty acid amide polyoxyethylene ether, plant extract, allantoin, humectant, ethylene diamine tetraacetic acid tetrasodium, sodium chloride, citric acid and water. The antibacterial dish-washing detergent containing the argy wormwood leaf extract which is provided by the invention has the advantages of mild cleaning, delicate foam, no irritation, no hand injury, cleansing capability and outstanding antibacterial effect, and can achieve a quick and effective cleaning effect without traces left, moreover, since the dish-washing detergent is also added with the allantoin and the compound amino acid, the dish-washing detergent can effectively prevent the phenomena of dryness, peeling and roughness from occurring on skin, keeping skin healthy, moisturized and elastic, and therefore the antibacterial dish-washing detergent containing the argy wormwood leaf extract is an antibacterial dish-washing detergent which meets the requirement of modern people.

Owner:GUANGZHOU SALIAI BIOLOGICAL GENETIC ENG CO LTD

Production method and equipment for co-production of bamboo charcoal and bamboo vinegar

PendingCN108893129AIncrease productivityHigh yieldIon-exchange process apparatusIon-exchanger regenerationSodium bicarbonateWater insoluble

The invention relates to a production method for co-production of bamboo charcoal and bamboo vinegar. The production method includes the following steps that S1, raw materials are selected; S2, moso bamboos are crushed, wherein the moso bamboos with the branches and leaves are crushed into 3-5 mm blocks according to the technological requirement, soaking with a pretreatment solution is conducted for 1-2 h, drainage is conducted, and then the objects are pre-dried at 60-70 DEG C until the water content is 20-25 % and sent to a pre-heating mechanism through a feeding mechanism, the pretreatmentsolution is prepared from, by weight, 3-8 % of water insoluble dextran, 10-15% of sodium hydrogen carbonate, 2-5% of aminophylline and the balance deionized water; S3, pre-heating is conduced; S4, pyrolysis is conducted; S5, carbonization is conducted; S6, bamboo vinegar purification is conducted, wherein bamboo vinegar obtained in the step 3 and bamboo vinegar obtained in the step 4 are mixed, anadsorption treatment agent is added in the mixture, then the mixture is stirred evenly, treated for 0.5-1 h and fully filtered, and the finished product of bamboo vinegar is obtained, the adsorptiontreatment agent refers to modified sepiolite powder. The production efficiency is high, the product yield is high, the degree of automation is high, and through organic coordination of the various mechanisms, the requirement of industrialized co-production of bamboo charcoal and high-quality bamboo vinegar can be met.

Owner:宁波甬文新能源装备研发有限公司

Low-carbon steel and preparing method thereof

The invention relates to the technical field of material preparation, in particular to low-carbon steel and a preparing method thereof. The low-carbon steel includes a matrix, and the matrix is composed of the following chemical components including, by mass, 0.17%-0.22% of carbon, 0.19%-0.25% of silicon, 0.34%-0.45% of manganese, 0.03%-0.05% of phosphorus, 0.034%-0.045% of sulfur and the balanceiron; and the low-carbon steel is ferrite grains obtained from the matrix. The method includes the following steps of conducting preservation on a low-carbon steel rod-shaped sample at 650-750 DEG C for 1.5-2 h to obtain coarse-grain structure low-carbon steel with uniform compositions; using a torsion tester to conduct torsional deformation treatment on the obtained coarse-grain structure low-carbon steel; and placing the low-carbon steel obtained by indoor temperature torsional deformation into a vacuum thermal annealing furnace for annealing treatment. By means of the low-carbon steel and the preparing method, the strength of the obtained low-carbon steel is improved by 200 MPa, and meanwhile, the considerable failure elongation and static toughness are maintained.

Owner:TANGSHAN GANGLU IRON & STEEL

Sterilization paint for artificial leather

The invention discloses sterilization paint for artificial leather. The sterilization paint for artificial leather is prepared from 78 to 89 parts by weight of vinyl acetate, 90 to 98 parts by weight of butyl acrylate, 20 to 30 parts by weight of vinyl chloride-vinylidene chloride copolymer emulsion, 10 to 12 parts by weight of a mildew inhibitor, 12 parts by weight of sodium hexametaphosphate, 10 parts by weight of ethylene glycol monobutyl ether, 50 to 60 parts by weight of water and 10 parts by weight of dimethylbenzene. A result of an industrial test shows that through coating treatment on an artificial leather surface, the sterilization paint for artificial leather can effectively retain a gloss and flexibility, can improve a service life and has excellent antibacterial properties.

Owner:WUJIANG TIANYUAN PLASTIC

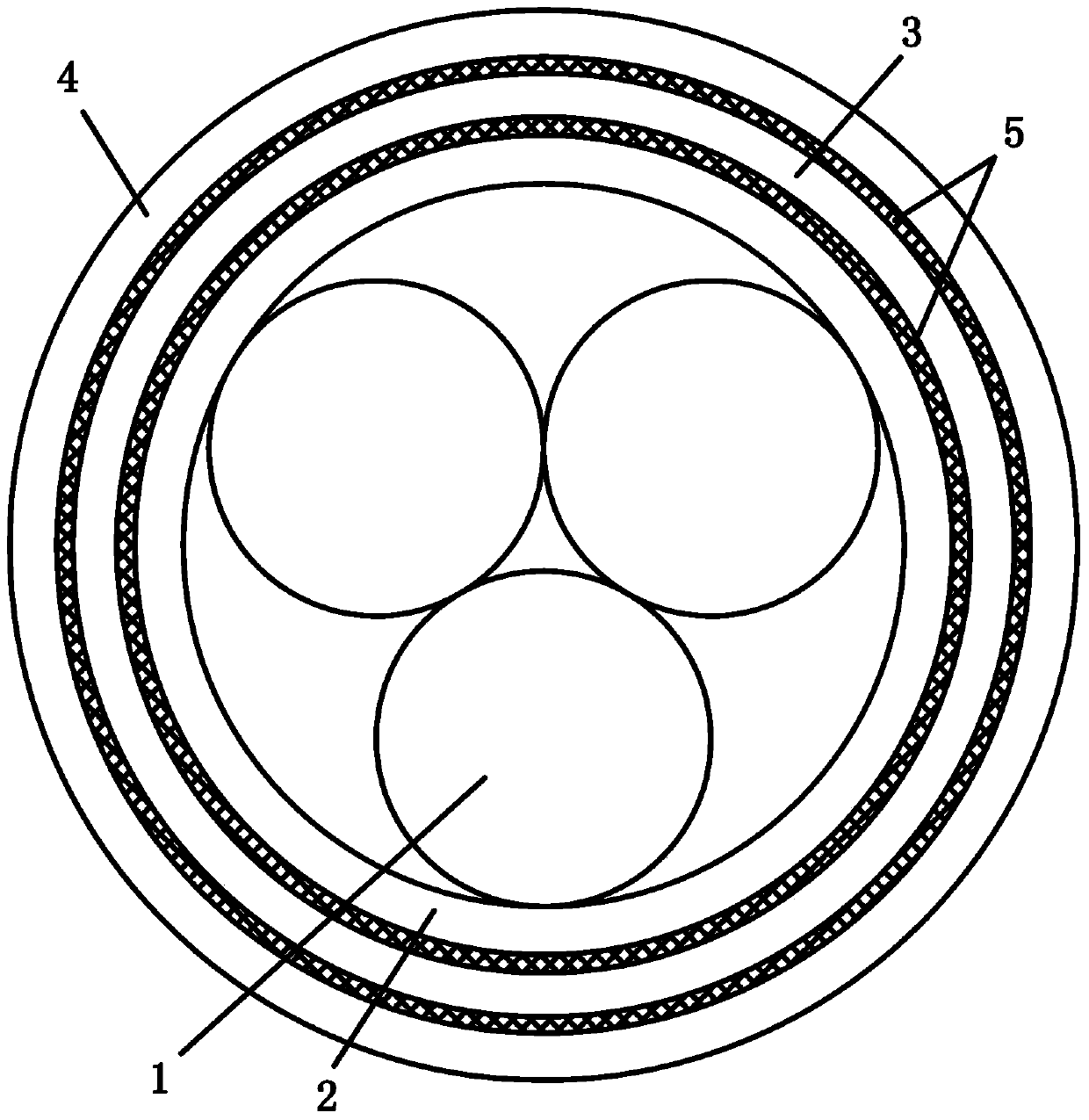

Low-smoke-zero-halogen high-flame-retardance power cable

ActiveCN103440921AStay resilientMaintain wear resistanceInsulated cablesPower cablesLow smoke zero halogenFiber

The invention discloses a low-smoke-zero-halogen high-flame-retardance power cable which structurally comprises a guiding wire. A flame retardant insulation layer is arranged on the outer side of the guiding wire. A carbon fiber flame retardant layer is arranged on the outer side of the flame retardant insulation layer. A foam flame retardant layer is arranged on the outer side of the carbon fiber flame retardant layer. The carbon fiber flame retardant layer is connected with the flame retardant insulation layer through a cross-linking layer, and the carbon fiber flame retardant layer is connected with the foam flame retardant layer through a cross-linking layer. According to the low-smoke-zero-halogen high-flame-retardance power cable, power cable flame retardant capacity is improved, and meanwhile release of toxic smoke is lowered during burning.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

Composite joint-improving oral liquid

InactiveCN1709502AStay flexibleStay resilientPeptide/protein ingredientsCarboxymethyl celluloseMedicine

The present invention relates to a compound joint-improving oral liquor made up by using (by wt%) 1.5-6% of pseudo-black multispinous ant, 0.5-5% of collagen, 0.5-4% of glycosamine hydrochlorate, 0.2-3% of chondroitin sulfate, 1-20% of honey, 0.01-0.03% of Ansaimi and 0.01-0.8% of sodium carboxymethyl cellulose as main raw material. Said oral liquor can provide nutrients for joint, can improve joint lubrication, accelerate joint repair, raise immunity of human body and promote articular metabolism normalization, etc.

Owner:北京东方兴企食品工业技术有限公司

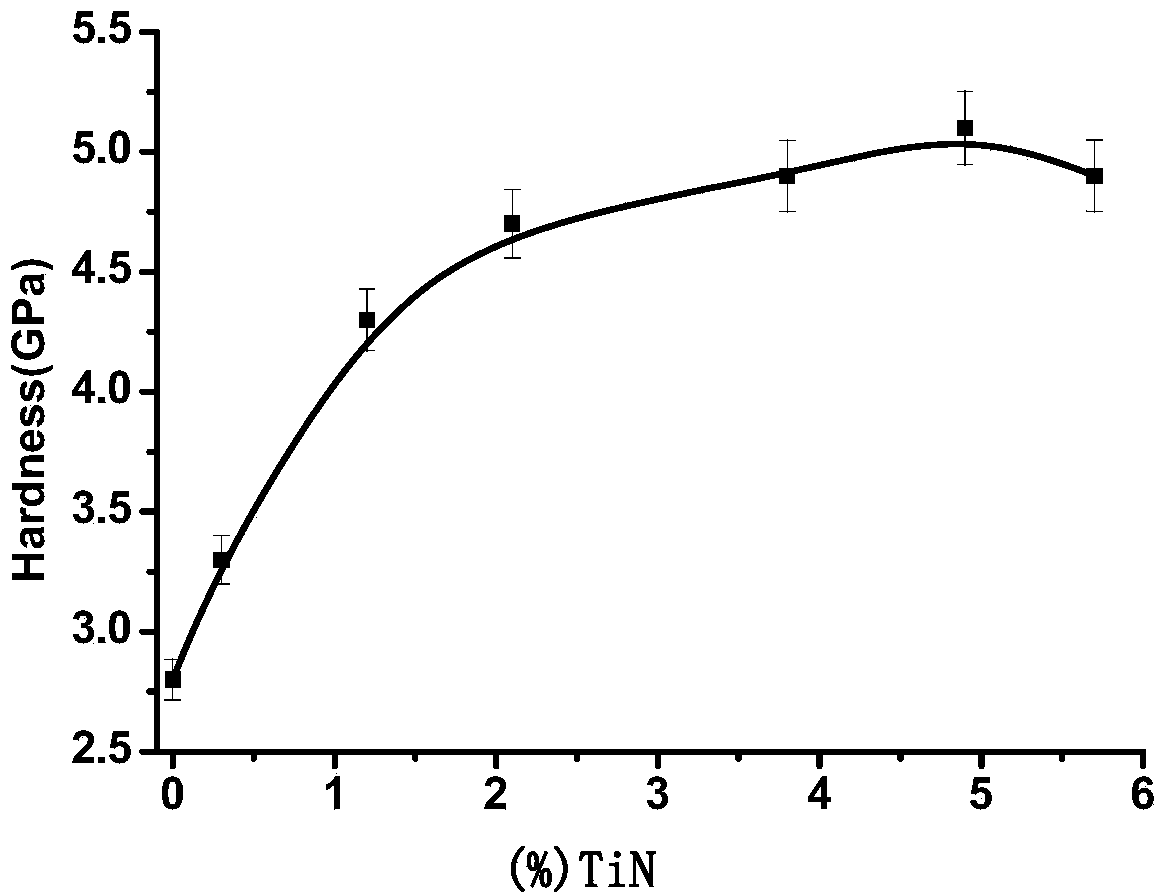

Cu-TiN nano composite film based on magnetron sputtering codeposition technology

InactiveCN104313543AStay plasticStay resilientVacuum evaporation coatingSputtering coatingComposite filmHardness

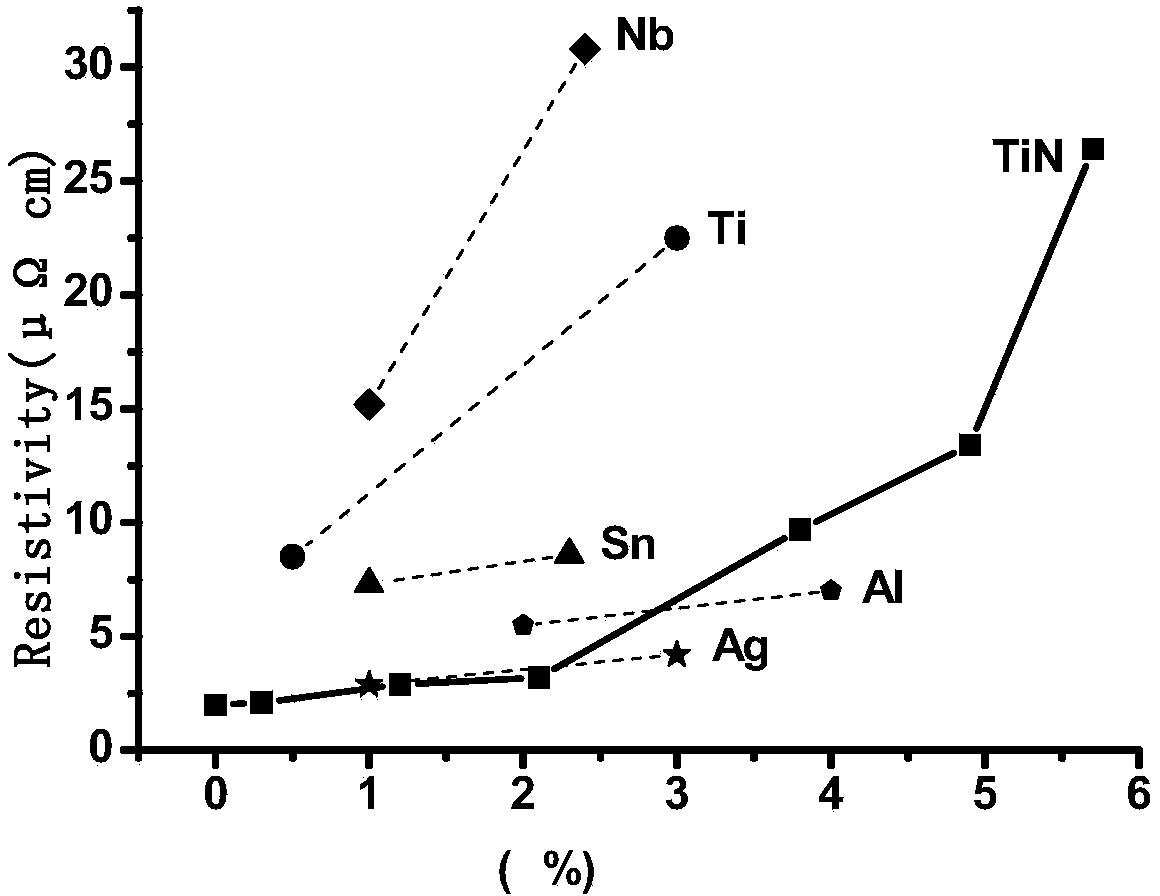

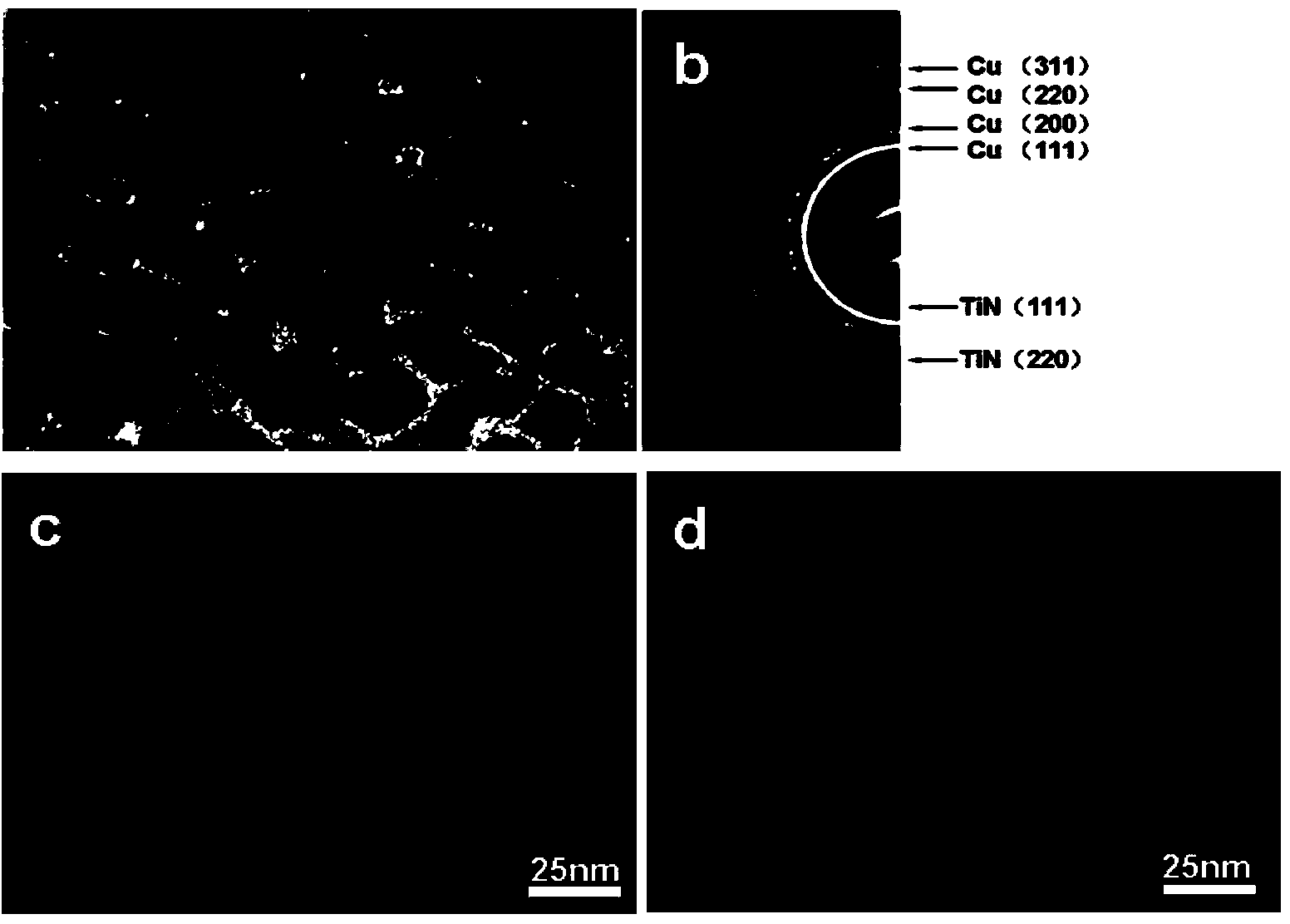

A Cu-TiN nano composite film based on a magnetron sputtering codeposition technology relates to the technical fields of micro-electrons and micromechanics, has a nanometer size, and has TiN additive particles and Cu crystal grains, which are uniformly mixed. The content of the TiN additive particles is 1.0-6.0 at.%. The composite film prepared by the invention is 4.1-5.1GPa in thickness and 3-25 micro-omega cm at electrical resistivity. When the additive contents (referred to alloy element content as for a Cu-based alloy film and referred to the content of added compounds as for a Cu-based composite film) are equal, the hardness of the composite film is obviously higher than that of the Cu-based alloy film adopted in industrial production at present, and the electrical conductivity is not lower than but much higher than that of the alloy film in most cases. The film can meet the high-hardness requirements of modern industry, in particular the technical fields of micro-electrons and micromechanics, on the conductive film.

Owner:上海工具厂有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com