Halogen-free anti-flaming polypropylene material

A flame-retardant polypropylene and copolymerized polypropylene technology is applied in the field of high-voltage breakdown-proof insulating films, which can solve problems such as not meeting environmental protection requirements, achieve good high-voltage breakdown resistance, overcome poor electrical properties, and excellent film-forming processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: A halogen-free flame-retardant polypropylene material

[0041] The material formula is as follows:

[0042] Material

Mass percentage (%)

The first copolymerized polypropylene

15

The second copolymer polypropylene

45.5

Hindered phenol heat stabilizer

0.3

Thioester heat stabilizer

0.1

metal deactivator

0.2

Phosphate ester processing stabilizer

0.4

1,3 Hydroquinone bis(diphenyl phosphate)

2

Hydrotalcite anti-acid agent

0.5

36

[0043] The melt index of the first copolymerized polypropylene is 0.2g / 10min~0.5g / 10min; the melt index of the second copolymerized polypropylene is 1g / 10min~3g / 10min; the hindered phenol heat stabilizer is 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)-1-3-5-triazine-2,4,6(1H,3H,5H)-trione; Described thioester heat stabilizer is octactadecyl thiodipropionate; Described metal deac...

Embodiment 2

[0048] Example 2: A halogen-free flame-retardant polypropylene material

[0049] The material formula is as follows:

[0050] Material

Mass percentage (%)

The first copolymerized polypropylene

10

The second copolymer polypropylene

31

Hindered phenol heat stabilizer

0.2

Thioester heat stabilizer

0.3

0.1

Phosphate ester processing stabilizer

0.3

1,3 Hydroquinone bis(diphenyl phosphate)

9

Hydrotalcite anti-acid agent

0.1

49

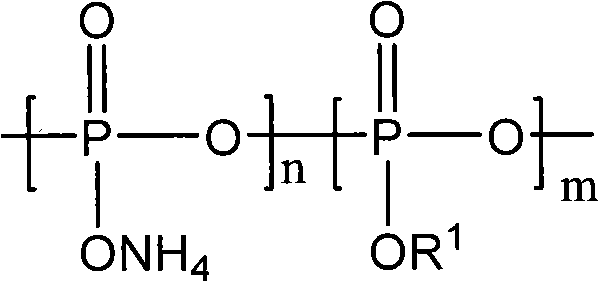

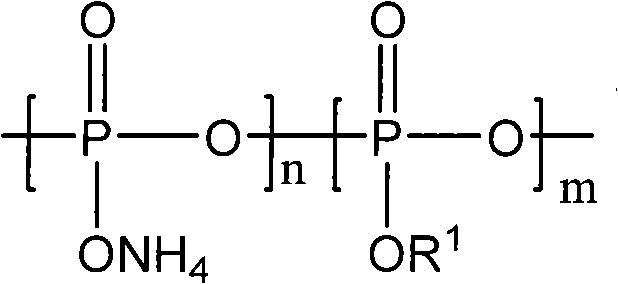

[0051] Described ammonium polyphosphate meets following general formula:

[0052]

[0053] In the formula, the sum of n and m is 1000; R 1Represents the residue of the amine group of morpholine with one hydrogen atom removed.

[0054] Other parts of the technical solution in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0055] Example 3: A halogen-free flame-retardant polypropylene material

[0056] The material formula is as follows:

[0057] Material

Mass percentage (%)

The first copolymerized polypropylene

20

The second copolymer polypropylene

27.5

Hindered phenol heat stabilizer

0.1

Thioester heat stabilizer

0.3

0.4

Phosphate ester processing stabilizer

0.2

1,3 Hydroquinone bis(diphenyl phosphate)

10

Hydrotalcite anti-acid agent

0.5

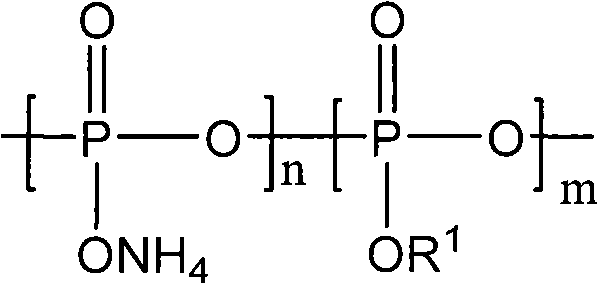

Ammonium polyphosphate

41

[0058] The sum of n and m is 2000; R 1 Represents the residue of the amine group of piperidine with one hydrogen atom removed.

[0059] Other parts of the technical solution in this embodiment are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com