High-temperature-resistant honeycomb node adhesive and preparation method thereof

A technology for adhesives and high temperature resistance, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of unsatisfactory bonding compatibility, low temperature resistance level, etc., and achieve good toughening effect , good heat resistance, the effect of maintaining high temperature strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific Embodiment 1: In this embodiment, a high-temperature-resistant honeycomb node adhesive consists of 100 parts of main resin, 10-15 parts of BMT-type bismaleimide resin, and 10-15 parts of phenolic cyanic acid ester, 8 to 12 parts of copolymerization modifier, 15 to 30 parts of rubber elastomer toughening agent, 4 to 12 parts of inorganic nano filler and 220 to 280 parts of solvent, among which, BMT type bismaleimide The mass ratio of amine resin, phenolic cyanate and copolymerization modifier is 5:5:4.

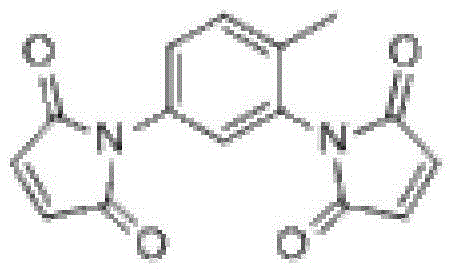

[0020] BMT type bismaleimide resin in the present embodiment, chemical structural formula is:

[0021]

[0022] The BMT-type bismaleimide resin is a commercially available product, purchased from Honghu Shuangma New Material Technology Co., Ltd. (formerly Hubei Honghu Shuangma Resin Factory), and the trade name is T-type Shuangma BMI-06 resin.

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the adhesive consists of 100 parts by mass of main resin, 35-40 parts of process-modified resin, and 20-25 parts of rubber elastic body. Toughening agent, 6-10 parts of inorganic nano filler and 240-260 parts of solvent. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the main resin is composed of an alkynyl-terminated isoimide resin. Others are the same as in the first or second embodiment.

[0025] In this embodiment, the alkynyl-terminated isoimide resin is divided into:

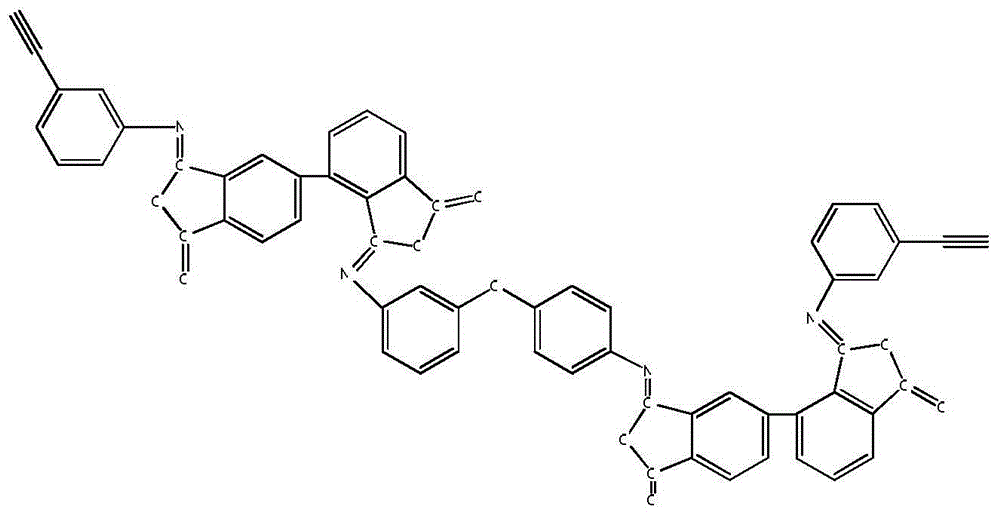

[0026] High molecular weight alkyne-terminated isoimide resin, the chemical structural formula is:

[0027]

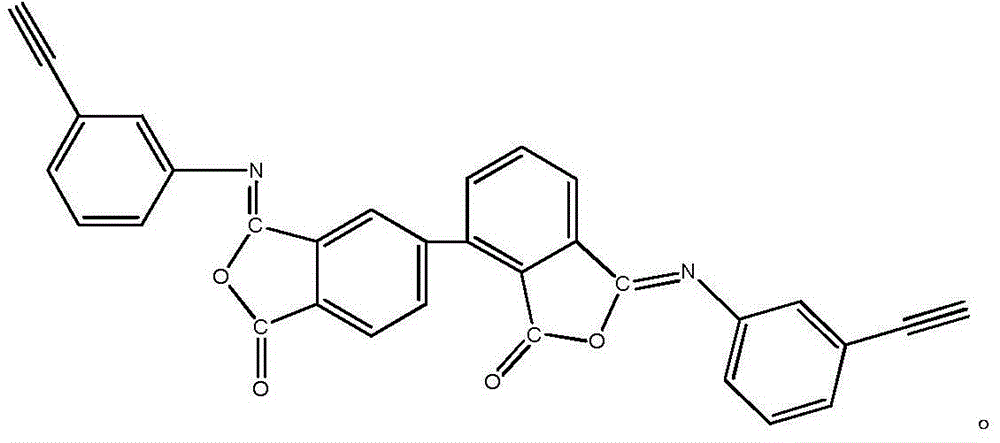

[0028] Low molecular weight alkyne-terminated isoimide resin, the chemical structural formula is:

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com