Cupreous metal wire-drawing on-line heat treatment method and on-line heat treatment device

A heat treatment device and heat treatment method technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of reduced toughness, reduced thermal conductivity, increased resistance, etc., to achieve improved toughness and electrical conductivity, stable annealing process, and scientific design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

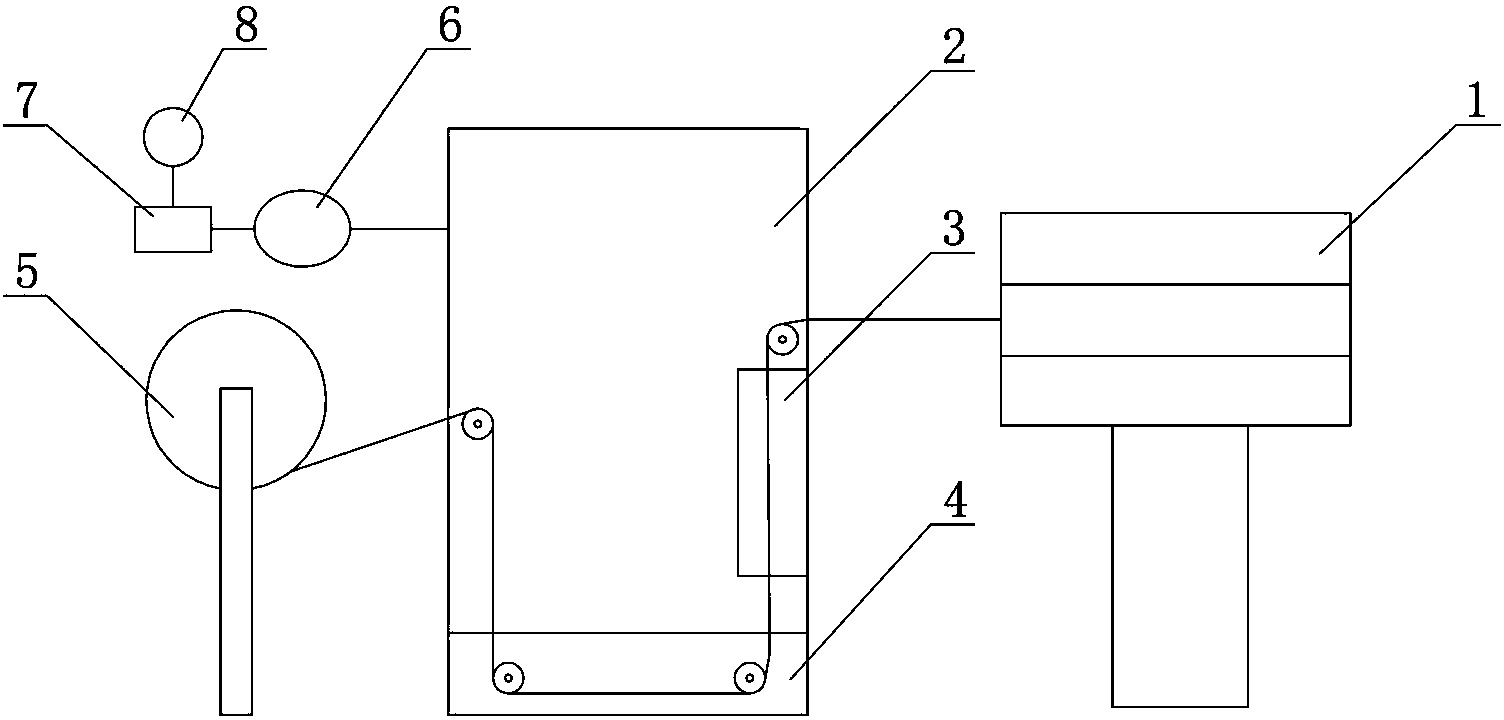

[0025] Such as figure 1 As shown, a copper metal wire drawing online heat treatment device includes a wire drawing machine 1, the outlet end of the wire drawing machine 1 is connected to the entrance of the electromagnetic heating coil 3 of the electromagnetic induction heating device 2, and the electromagnetic heating coil 3 is arranged from top to bottom, which can ensure that the copper The line keeps a straight line under the action of its own weight and will not touch the electromagnetic heating coil 3. The outlet of the electromagnetic heating coil 3 is connected to the inlet of the cooling water tank 4. The cooling water tank 4 is arranged under the electromagnetic induction heating device 2, and the outlet of the cooling water tank 4 is connected to the The take-up wheel 5, when working, the copper metal is drawn by the wire drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com