Box-type annealing furnace

A box-type annealing furnace and annealing furnace technology, applied in the field of box-type annealing furnace, can solve the problems of incomplete annealing, excessive moisture in the furnace, etc., and achieve the effects of preventing heat loss, shortening the annealing cycle, and high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

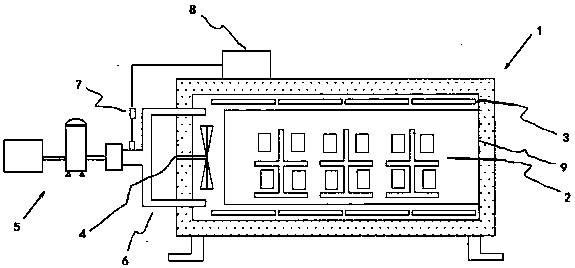

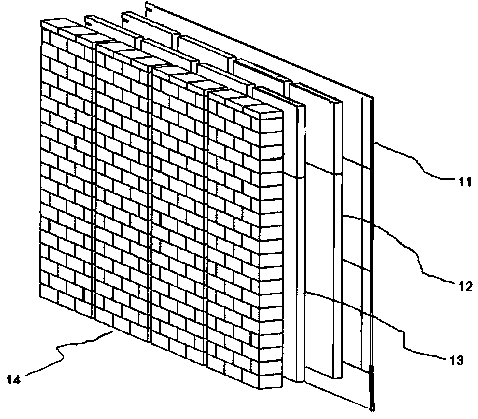

[0014] see Figure 1 to Figure 4 , these four figures provide the specific structure of an embodiment of the box-type annealing furnace proposed by the present invention. This annealing furnace comprises a hollow insulation layer 1, a bracket 2 and a heating wire 3 installed in the hollow of the insulation layer 1, and a circulating fan 4 installed on one side of the insulation layer 1, and a As for the air delivery assembly 5, the number of the brackets 2 can be set to 2-5, and the number can be adjusted according to the number of workpieces to be processed. In this embodiment, there are 3.

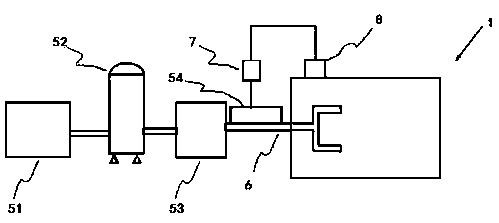

[0015] The air delivery assembly 5 includes an air compressor 51 and an air storage tank 52 respectively connected, and a precision filter 54 provided at the connection end of the air intake pipeline 6 in the air dryer 53 . Through the air delivery assembly, the compressed and filtered dry cold air can be transported to the annealing furnace through the intake pipeline 6, so as to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com