Production method and equipment for co-production of bamboo charcoal and bamboo vinegar

A production method and technology for bamboo vinegar are applied in the field of bamboo charcoal and bamboo vinegar processing, can solve problems such as unsatisfactory quality of vinegar liquid and bamboo tar, and achieve the effects of high degree of automation, high production efficiency and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

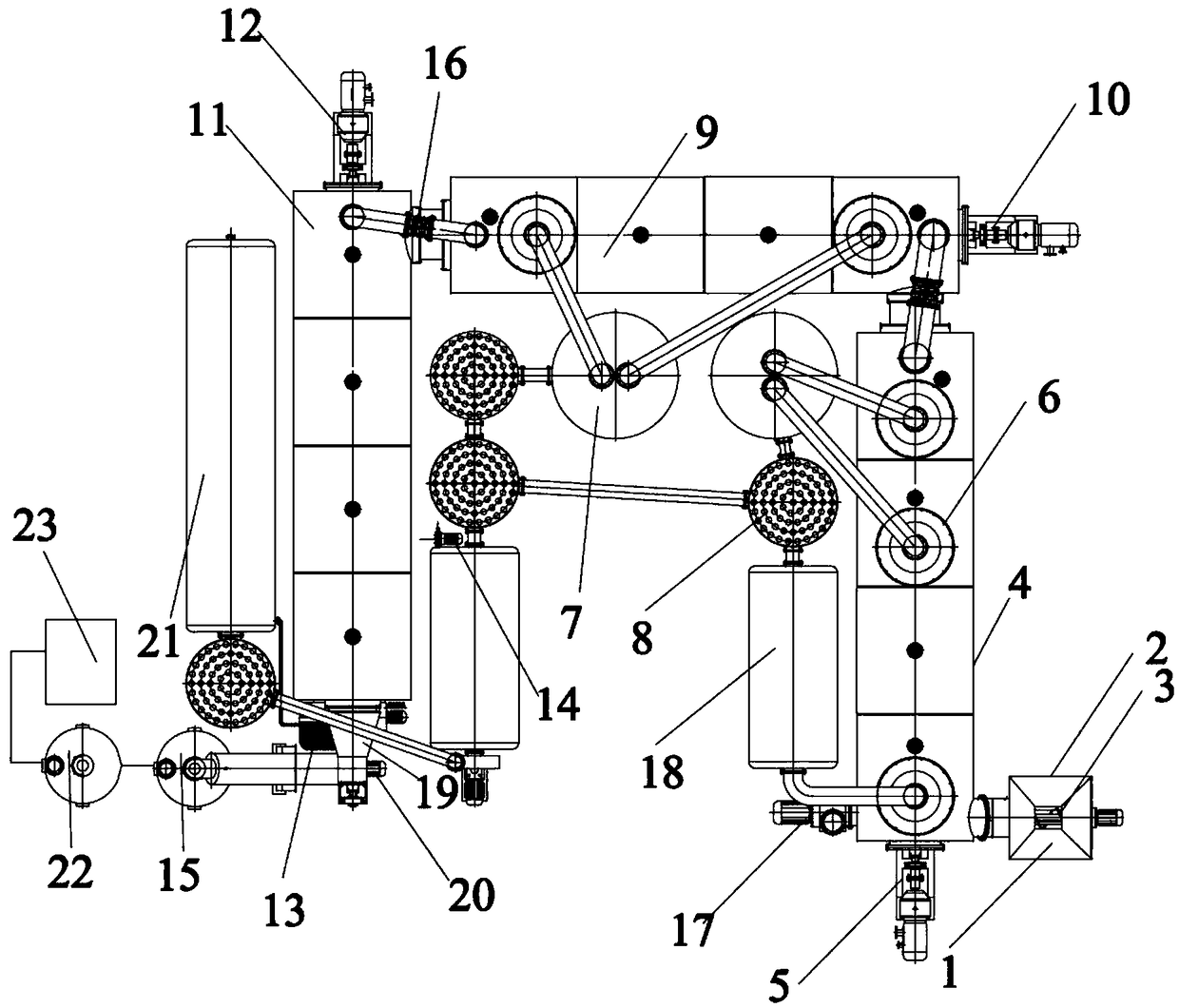

[0048] Such as figure 1 Shown, a kind of coproduction prepares the production equipment of bamboo charcoal and bamboo vinegar, and described production equipment comprises following mechanism:

[0049] The feeding mechanism 1 includes a hopper 2 and a first screw conveyor 3, and the outlet of the hopper 2 communicates with the inlet of the first screw conveyor 3;

[0050] The preheating mechanism 4 is located at the downstream of the feeding mechanism 1. The preheating mechanism 4 includes the preheating mechanism body and the second screw conveyor 5 supporting it. The top of the preheating mechanism body is provided with at least one bamboo oil and gas collection mechanism 6. The bamboo oil and gas gas collection mechanism 6 is also connected with a dust collector 7, and the air outlet of the dust collector 7 is communicated with the condenser 8;

[0051] The pyrolysis mechanism 9 is located at the downstream of the preheating mechanism 4, and the pyrolysis mechanism 9 inclu...

Embodiment 2

[0070] A kind of coproduction prepares the production method of bamboo charcoal and bamboo vinegar, described method step is as follows:

[0071] S1 raw material selection: select the discarded moso bamboo from moso bamboo products processing enterprises as production raw materials;

[0072] S2 Phyllostachys edulis broken: according to technological requirement, moso bamboo strip branches and leaves are broken into 3mm piece, adopt pretreatment liquid to soak 1h, the weight percent composition of described pretreatment liquid is as follows: water-insoluble dextran 8%, 15% sodium bicarbonate, 5% %aminophylline, the balance is deionized water; then drained, pre-dried at 60-70°C until the moisture content is 20%, and sent to the preheating mechanism through the feeding mechanism;

[0073] S3 Preheating: The preheating temperature is controlled at 100-150°C, and the preheated moso bamboo raw materials are gradually pushed into the pyrolysis mechanism. At the same time, the bamboo ...

Embodiment 3

[0078] A kind of coproduction prepares the production method of bamboo charcoal and bamboo vinegar, described method step is as follows:

[0079] S1 raw material selection: select the discarded moso bamboo from moso bamboo products processing enterprises as production raw materials;

[0080] S2 Phyllostachys edulis broken: according to technological requirement, moso bamboo strip branches and leaves are broken into 5mm piece, adopt pretreatment liquid to soak 2h, the weight percent composition of described pretreatment liquid is as follows: water-insoluble dextran 3%, 10% sodium bicarbonate, 2 % aminophylline, the balance is deionized water; then drained, pre-dried at 60-70°C until the moisture content is 20%-25%, and sent to the preheating mechanism through the feeding mechanism;

[0081] S3 Preheating: The preheating temperature is controlled at 200-250°C, and the preheated moso bamboo raw materials are gradually pushed into the pyrolysis mechanism. At the same time, the bam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com