Method and device for improving hardness of inner wall of steel tube

A technology for the inner wall and hardness of steel pipes, which is applied in the field of electromagnetic induction heating, can solve the problems of different coil installation positions and water spraying methods, and does not involve process control parameters, so as to reduce production costs, improve heating efficiency, and improve inner wall hardness and wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

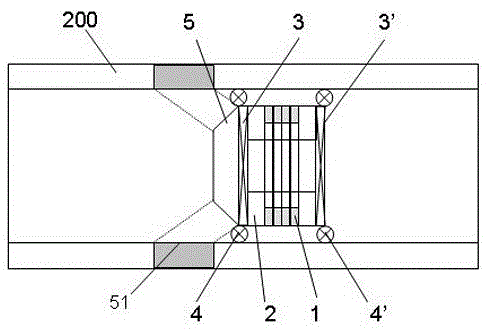

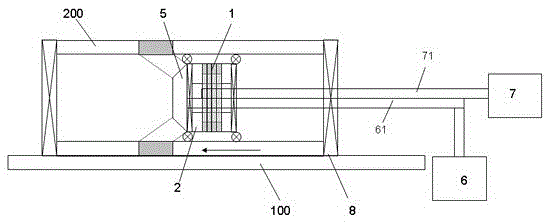

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention mainly performs induction heating and water spray quenching treatment on the inner wall of the steel pipe to improve the structure, improve the wear resistance and the service life. In the process of processing, if the heating efficiency of the heating system can be further improved while obtaining a deeper hardened layer depth, the cost performance of the steel pipe product can be improved, and its product competitiveness can be improved. Precise control of the parameters is crucial. In this embodiment, heat treatment is required for a steel pipe with a specification of φ800 mm, a wall thickness of 16 mm, and a length of 6000 mm, and the material of the steel pipe is Q345. It is required to quickly heat the inner wall of the steel pipe from room temperature to 950 degrees, and the temperature at 10 mm below the inner wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com