Patents

Literature

223 results about "Inner wall zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

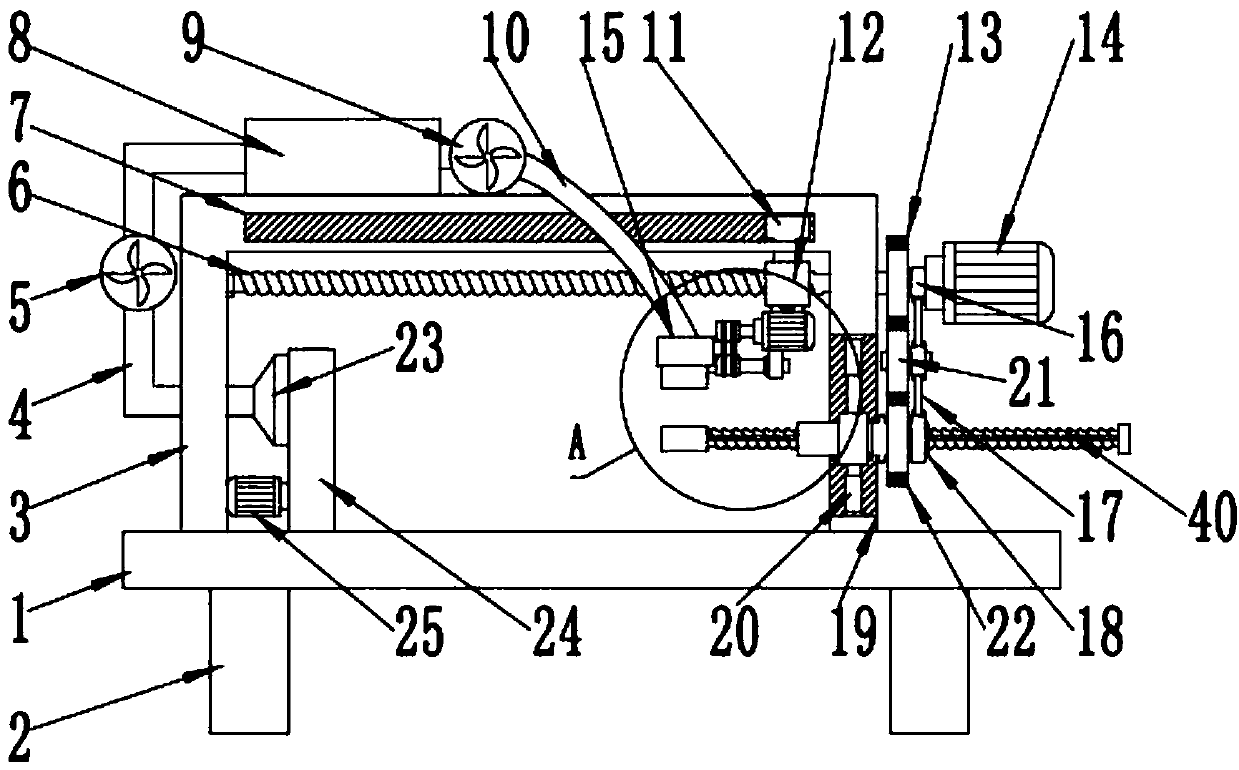

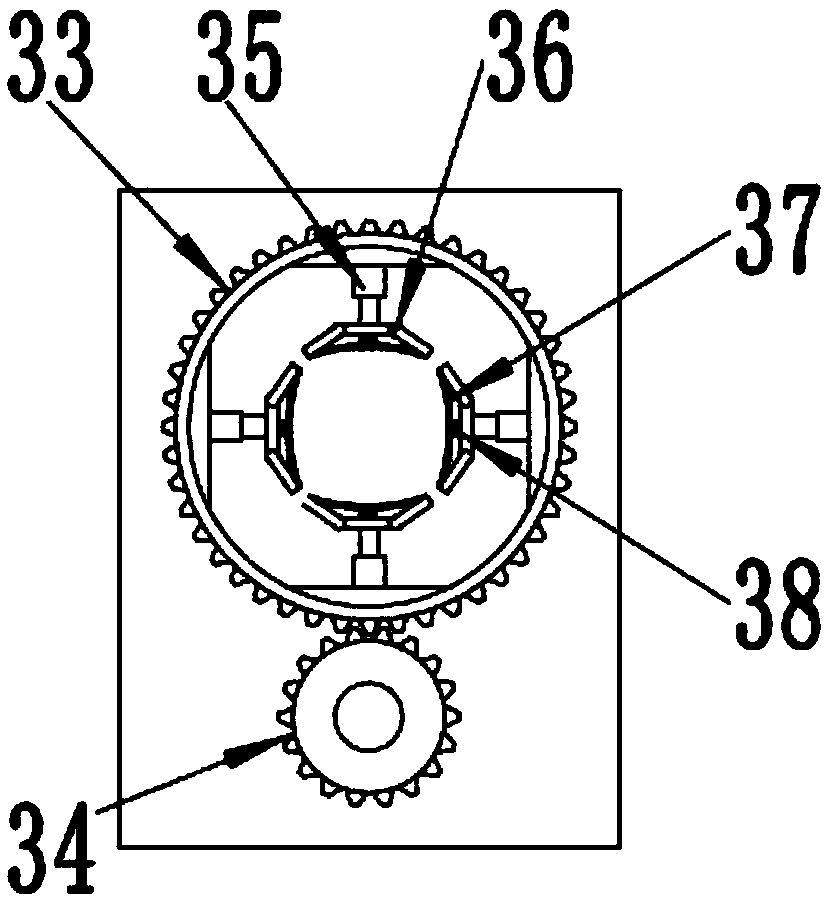

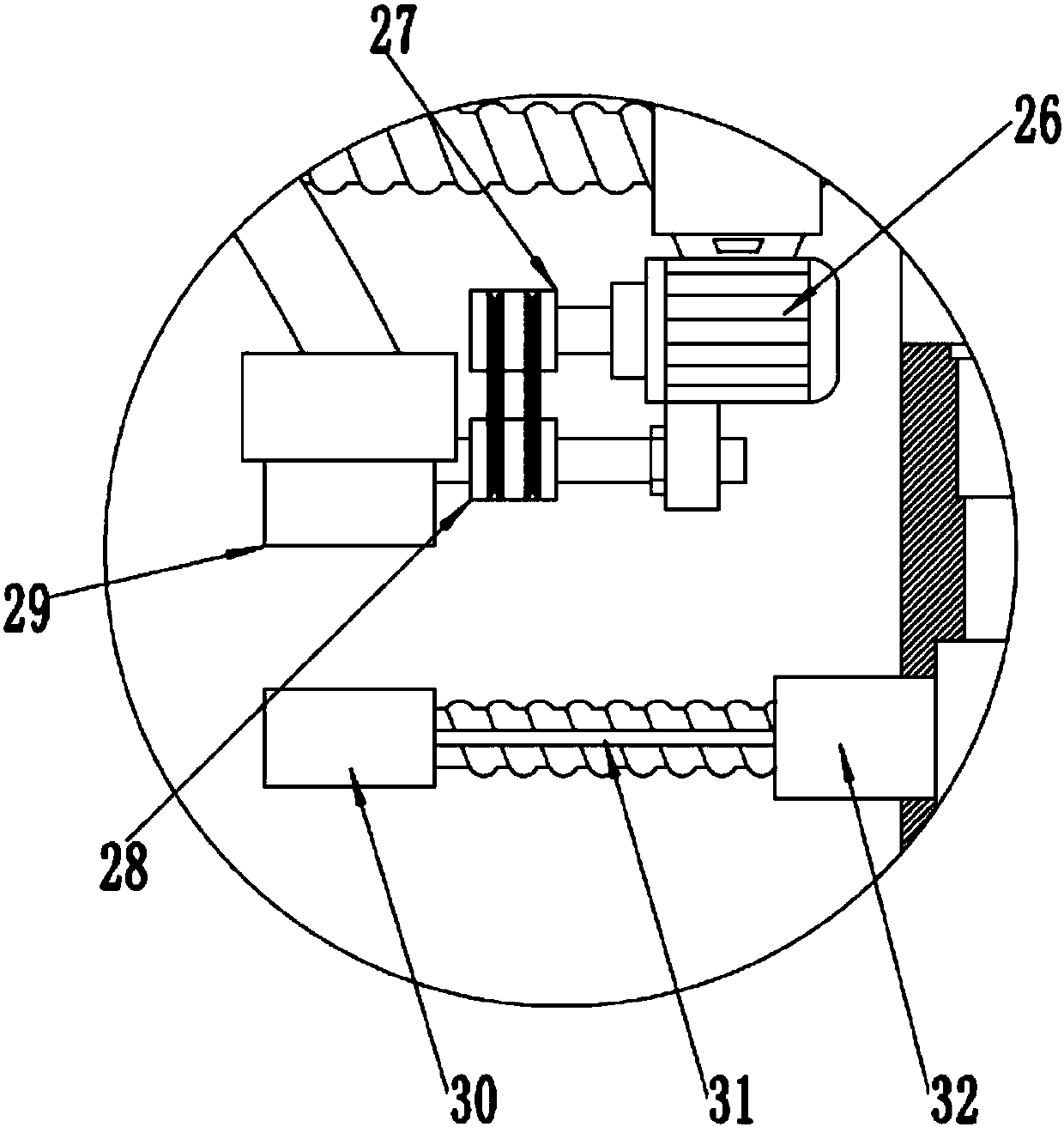

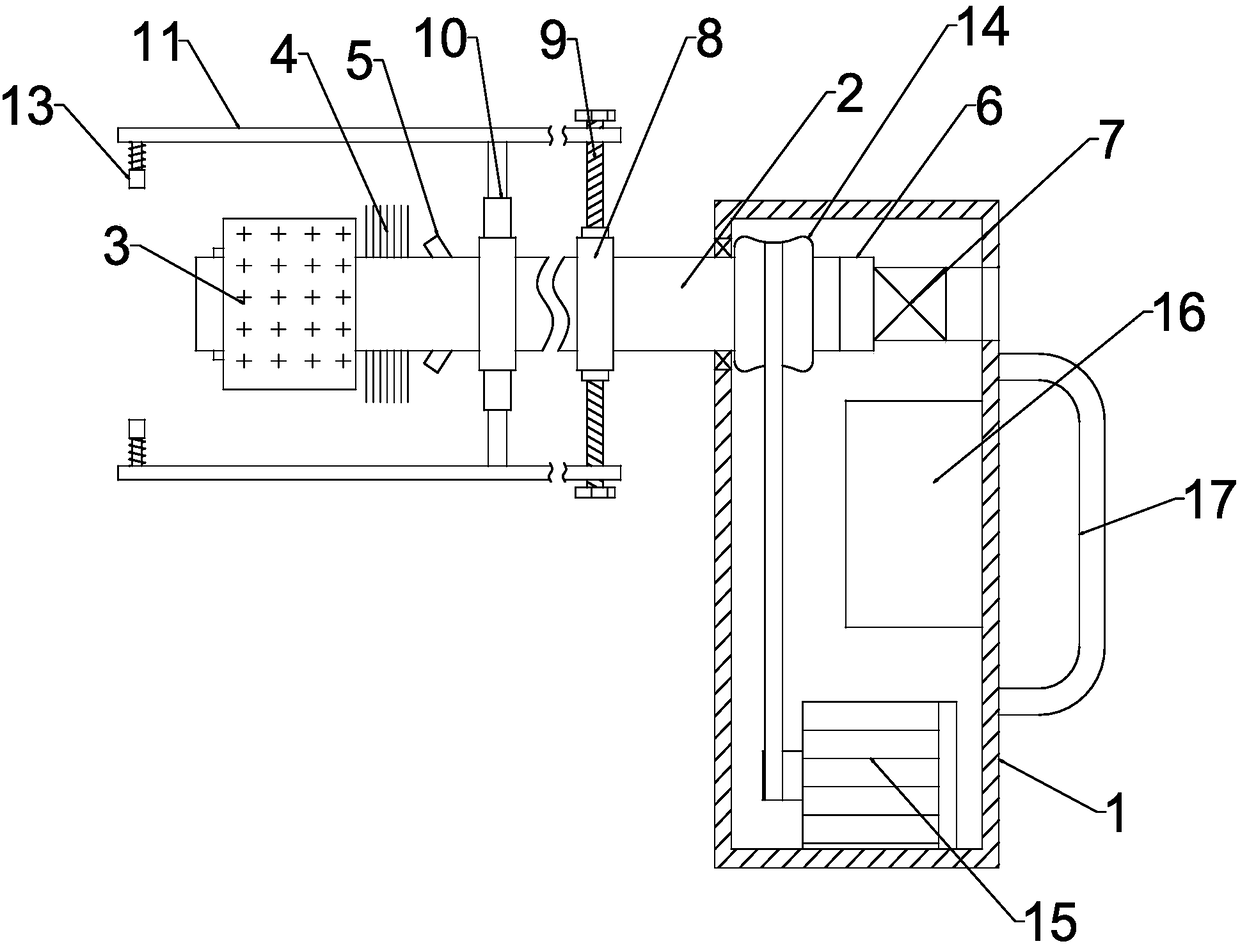

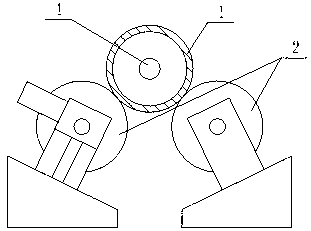

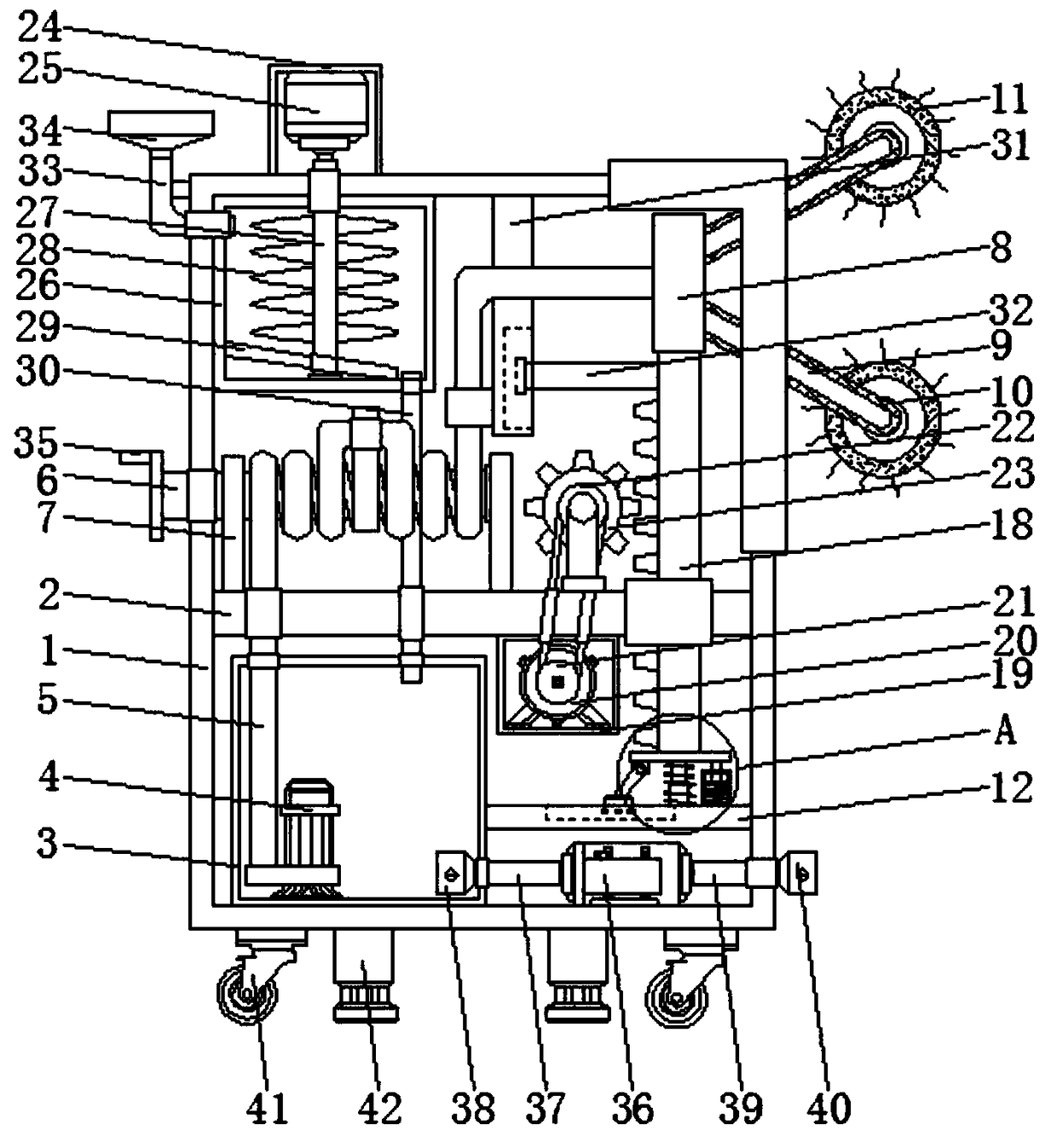

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

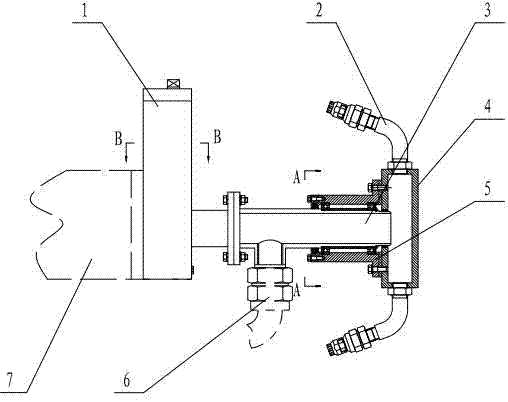

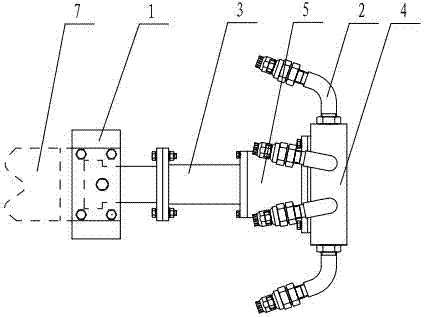

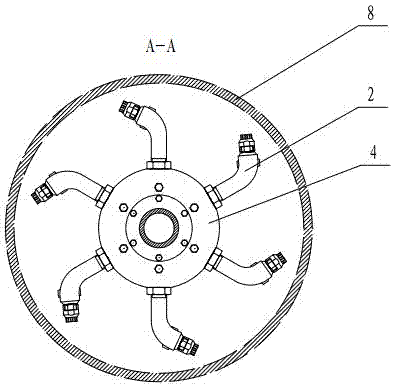

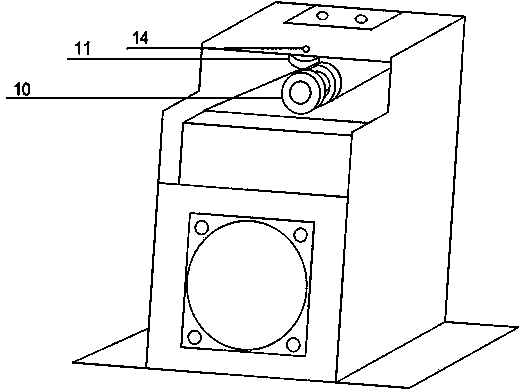

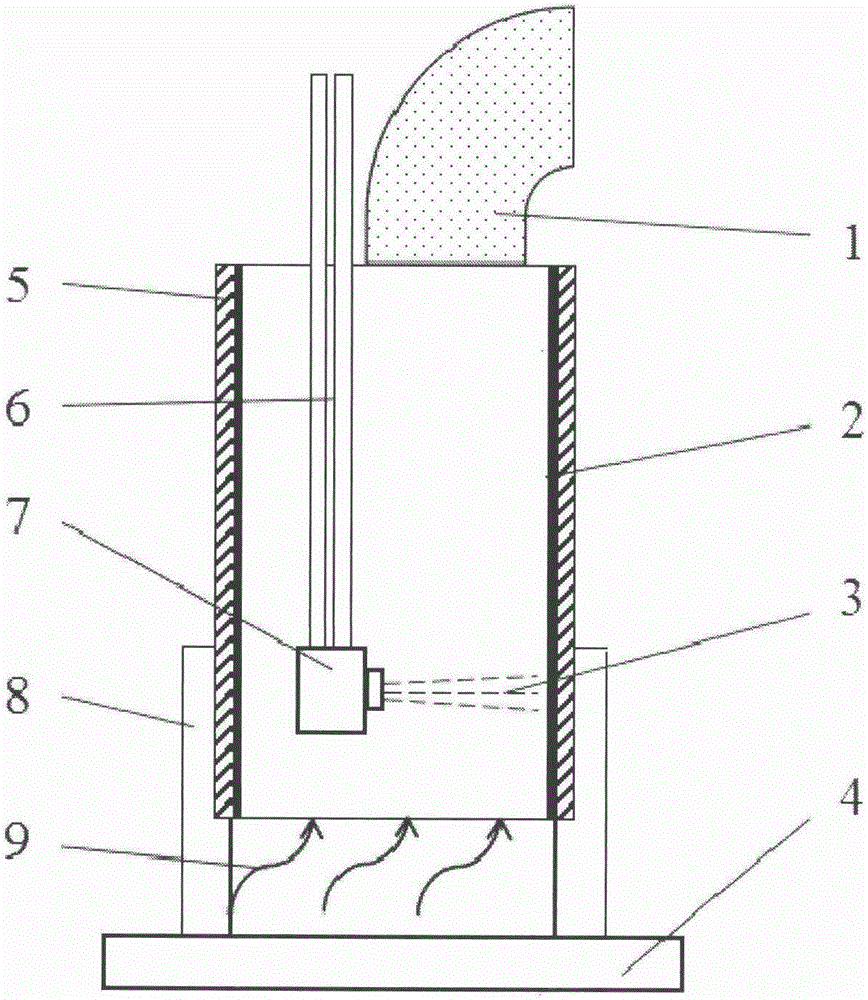

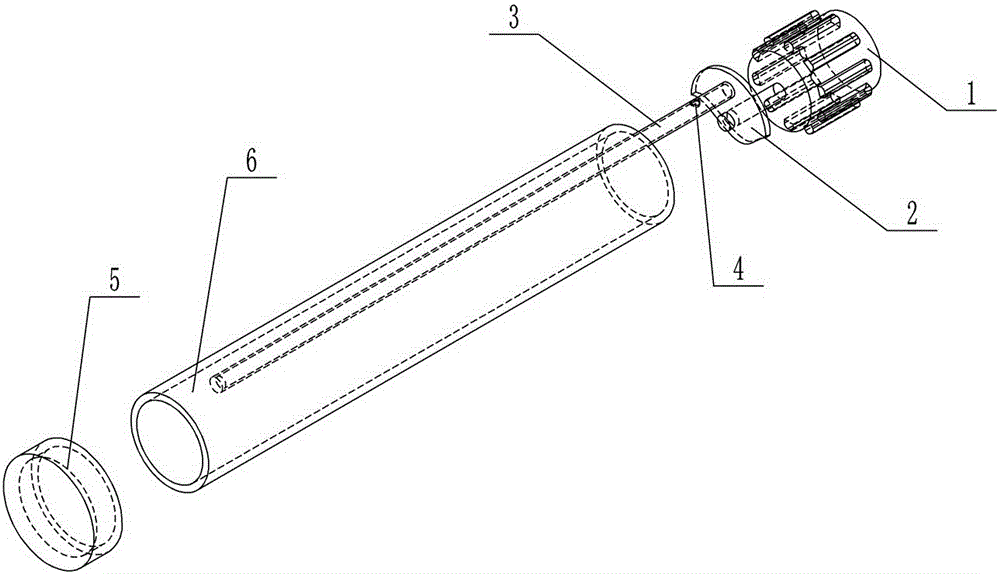

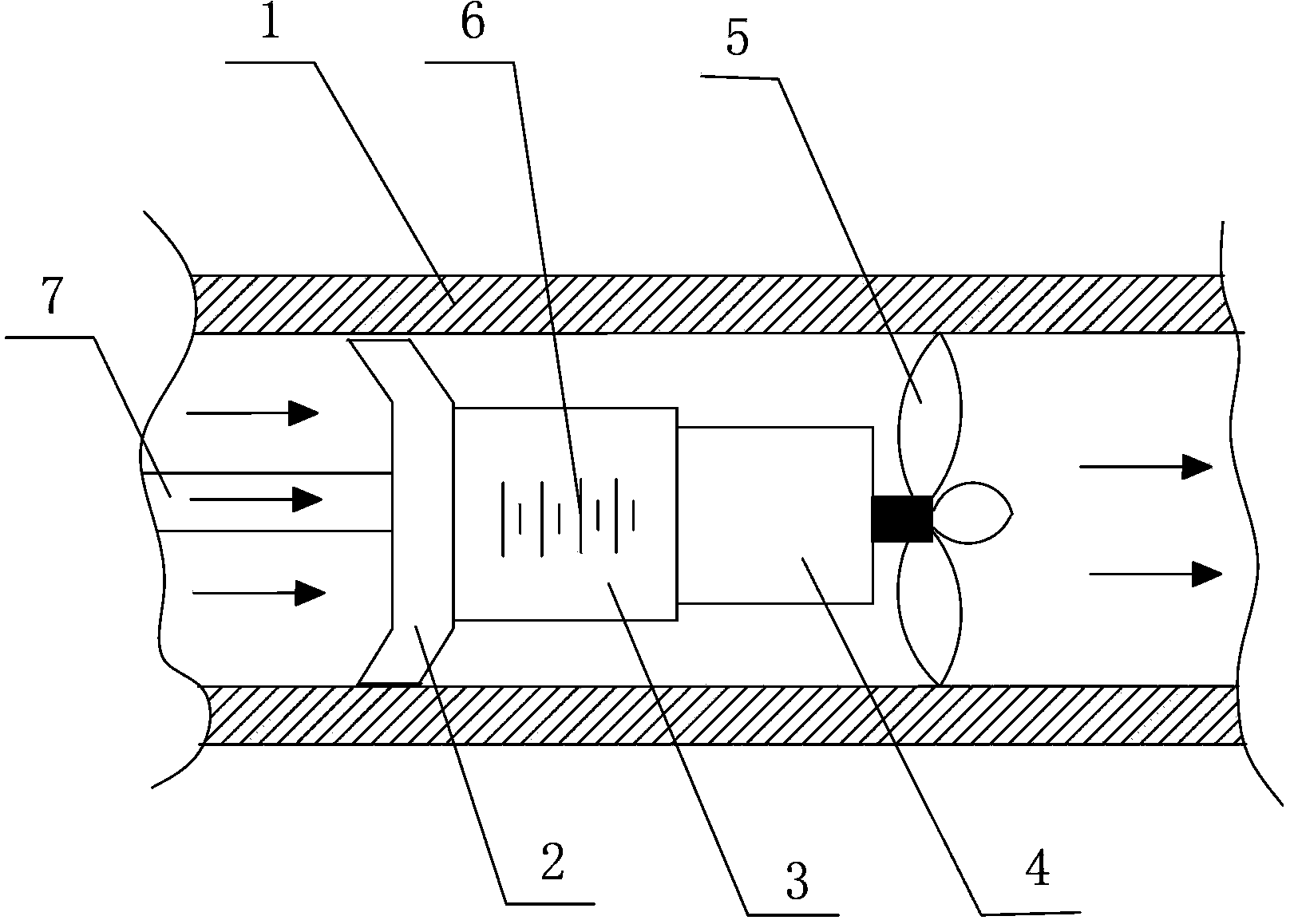

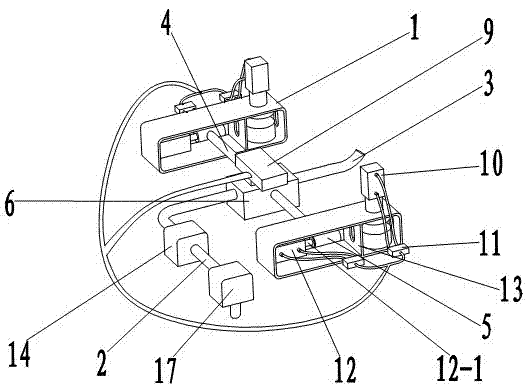

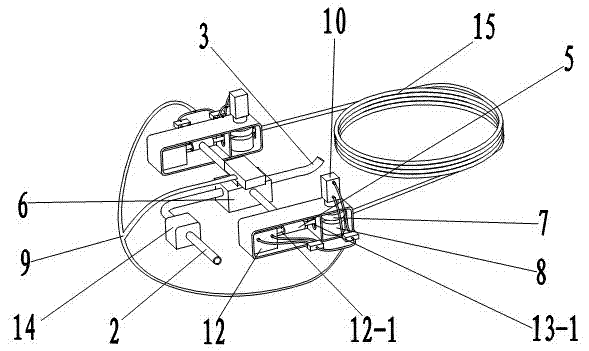

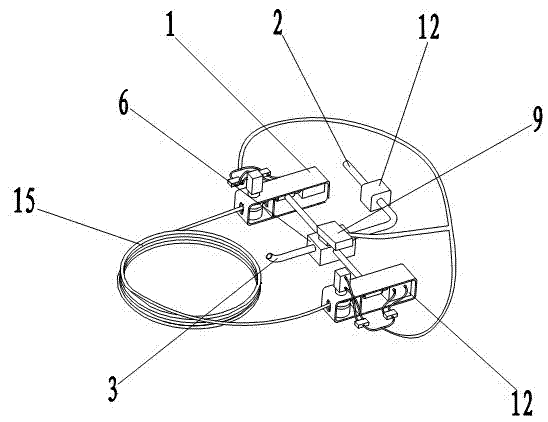

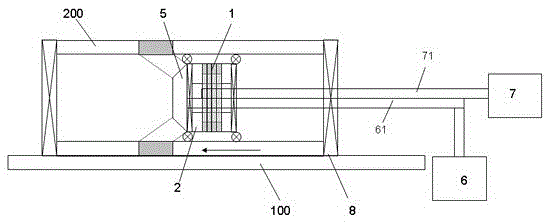

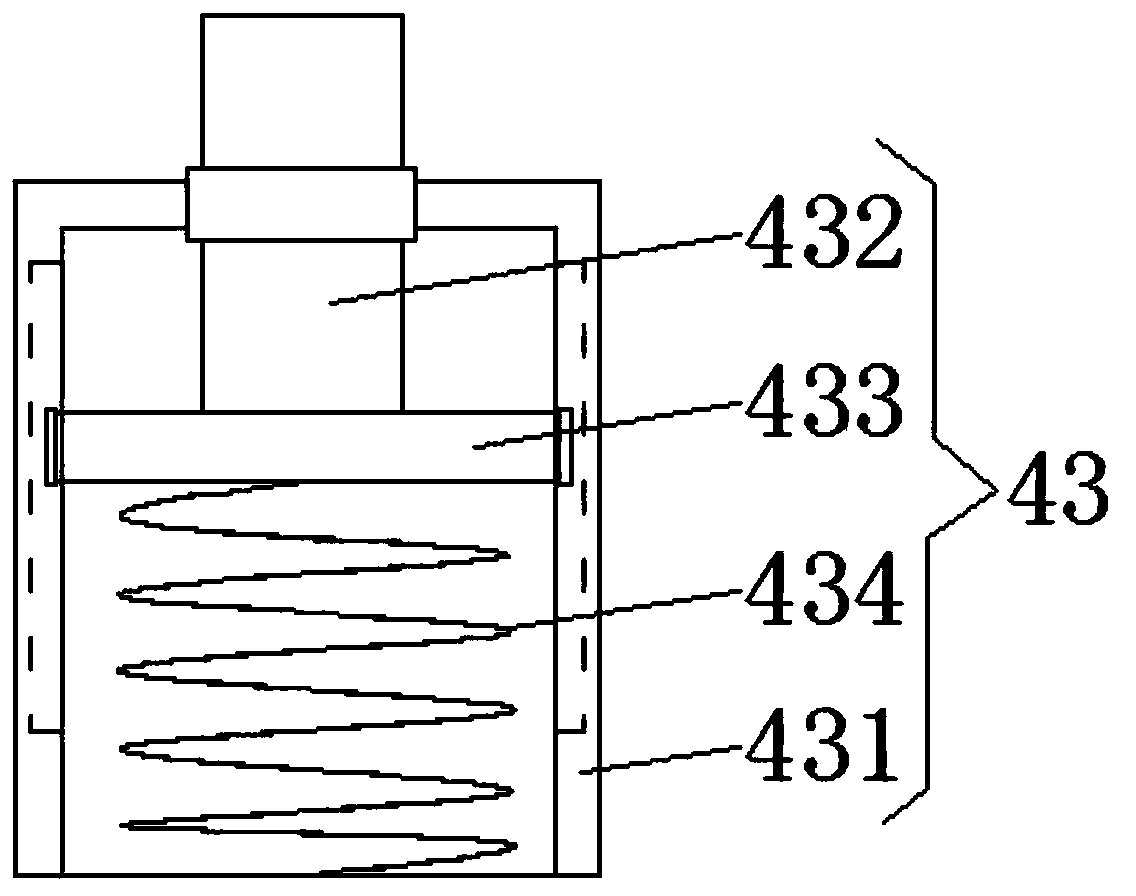

Spinning purging device for inner wall of steel pipe

ActiveCN102357492AAchieve spin effectTo achieve the purpose of purging the whole areaHollow article cleaningSpray nozzleEngineering

The invention discloses a spinning purging device for the inner wall of a steel pipe. The spinning purging device comprises a lead screw lifting device, a three-way cavity and a spinning nozzle device; the spinning nozzle device is connected with the lead screw lifting device through the three-way cavity; the spinning nozzle device comprises a rotary sleeve, a turntable and a nozzle; the nozzle comprises an air spray head, an inner screw joint and a bent pipe rod; one end of the bent pipe rod is fixedly connected with the air spray head through the inner screw joint, and the other end of the bent pipe rod is provided with a thread matched with a mounting hole of the turntable; the included angle of two end faces of the bent pipe rod is 120 degrees; and the mounting included angle between the air spray direction of the nozzle and the axis of the turntable is 0 to 90 degrees. By reasonably arranging the number and the angle of the nozzle, using the purging reacting force of compressed air and adjusting the flow rate and the pressure of the compressed air, the spinning speed is controlled, and the purpose of full-area purging of the inner wall of the steel pipe is fulfilled; a power source such as an electromotor or a motor or the like is not needed, so the energy consumption is reduced; and the spinning purging device is simple in integral structure and light in weight, and reduces the load of a cantilever.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

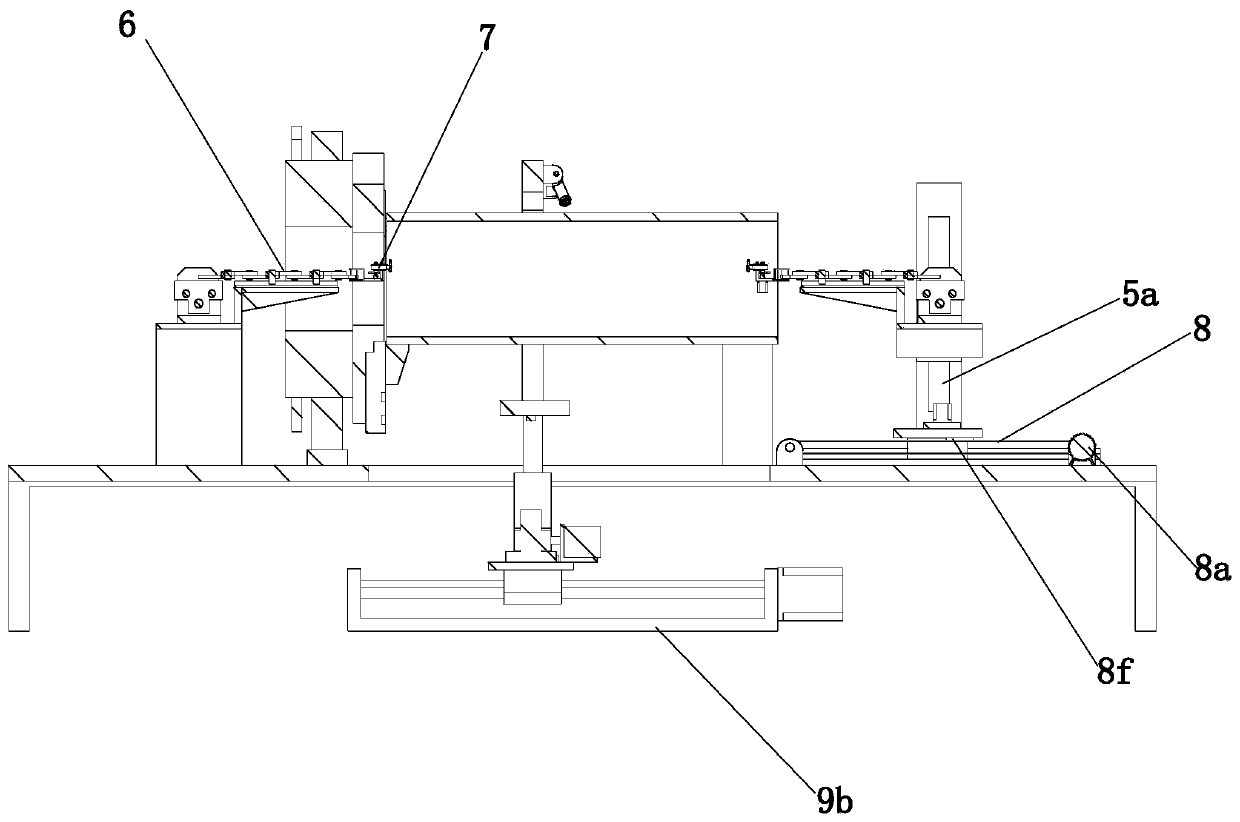

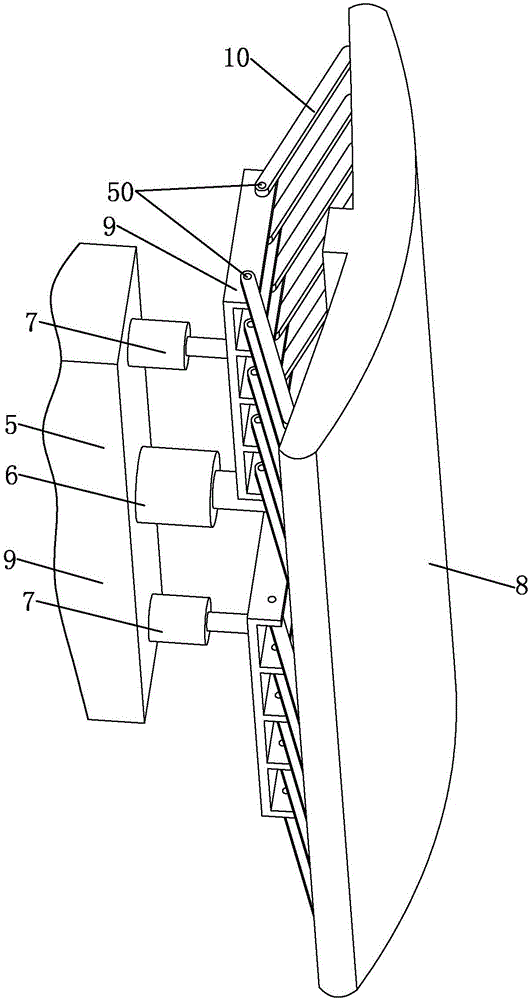

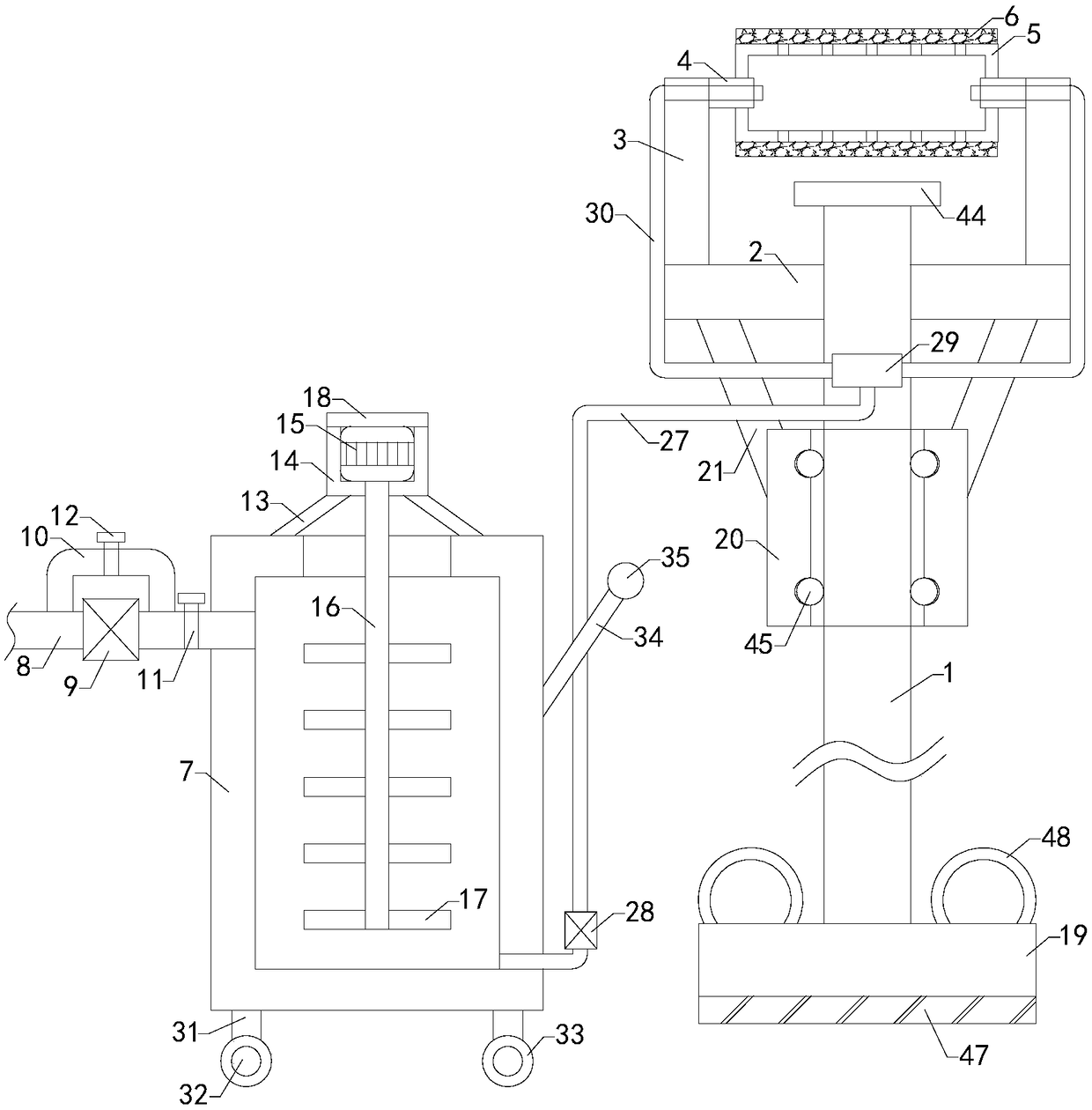

Automatic spraying machine for inner wall and outer wall of steel pipe

ActiveCN109746144AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipePretreated surfacesCoatingsEngineeringAutomation

The invention discloses an automatic spraying machine for the inner wall and the outer wall of a steel pipe, and belongs to the field of steel pipe spraying equipment. The automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, an operation table and a rotating mechanism, wherein the inner wall spraying mechanism comprises a first spraying assembly,a second spraying assembly and a material moving assembly; the first spraying assembly and the second spraying assembly comprise an extending and feeding component and a rotating and spraying component; the material moving assembly comprises a lifting component, a material moving plate and a material moving component; and the lifting component is arranged at the top of the material moving plate.According to the automatic spraying machine disclosed by the invention, the inner wall spraying mechanism can extend to the inner part of the steel pipe and automatically perform the operation of uniform spraying on the inner wall of the steel pipe, the situation that the local inner wall of the steel pipe is not sprayed is avoided; and the operation of spraying can be automatically performed on the outer wall of the steel pipe through the outer wall spraying mechanism, so that the automation degree is high, and the situation that a worker manually performs the operation of spraying on the outer wall of the steel pipe is not needed.

Owner:浙江金汇休闲制品有限公司

Method for size restoring and reinforcing of outer wall and inner wall of water-cooling cylinder sleeve of engine

InactiveCN103710660AImprove wear resistanceImprove wear reduction performanceMolten spray coatingCylinder headsWear resistantWater cooling

The invention relates to a method for size restoring and reinforcing of an outer wall and an inner wall of a water-cooling cylinder sleeve of an engine. According to the method, a nickel-based anti-attrition and wear-resistant coating is prepared on the inner wall of the cylinder sleeve by utilizing an inner hole plasma spraying technique, and a nickel-aluminum composite coating is prepared on the outer wall of the cylinder sleeve by utilizing an supersonic speed plasma spraying technique. The cylinder sleeve scrapped due to the abrasion and the corrosion can be remanufactured, and the size of the cylinder sleeve is restored according to the actual requirement; meanwhile, the abrasion performance of the inner wall as well as the corrosion resistance of the outer wall of the cylinder sleeve are improved, the service life is prolonged, the remanufacture possibility is improved, the restoring cycle is reduced, and the energy, the fund and the labor force are saved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

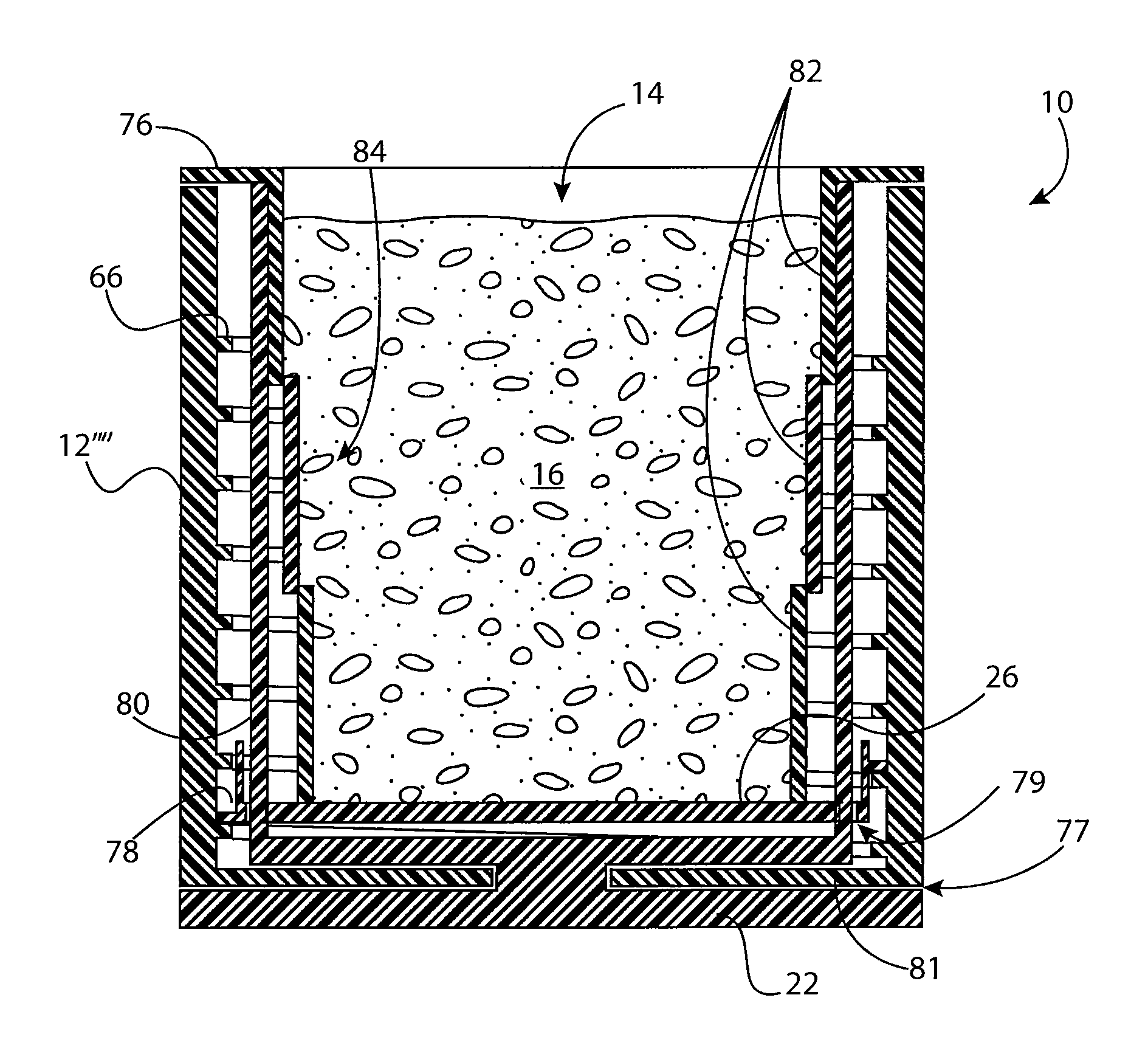

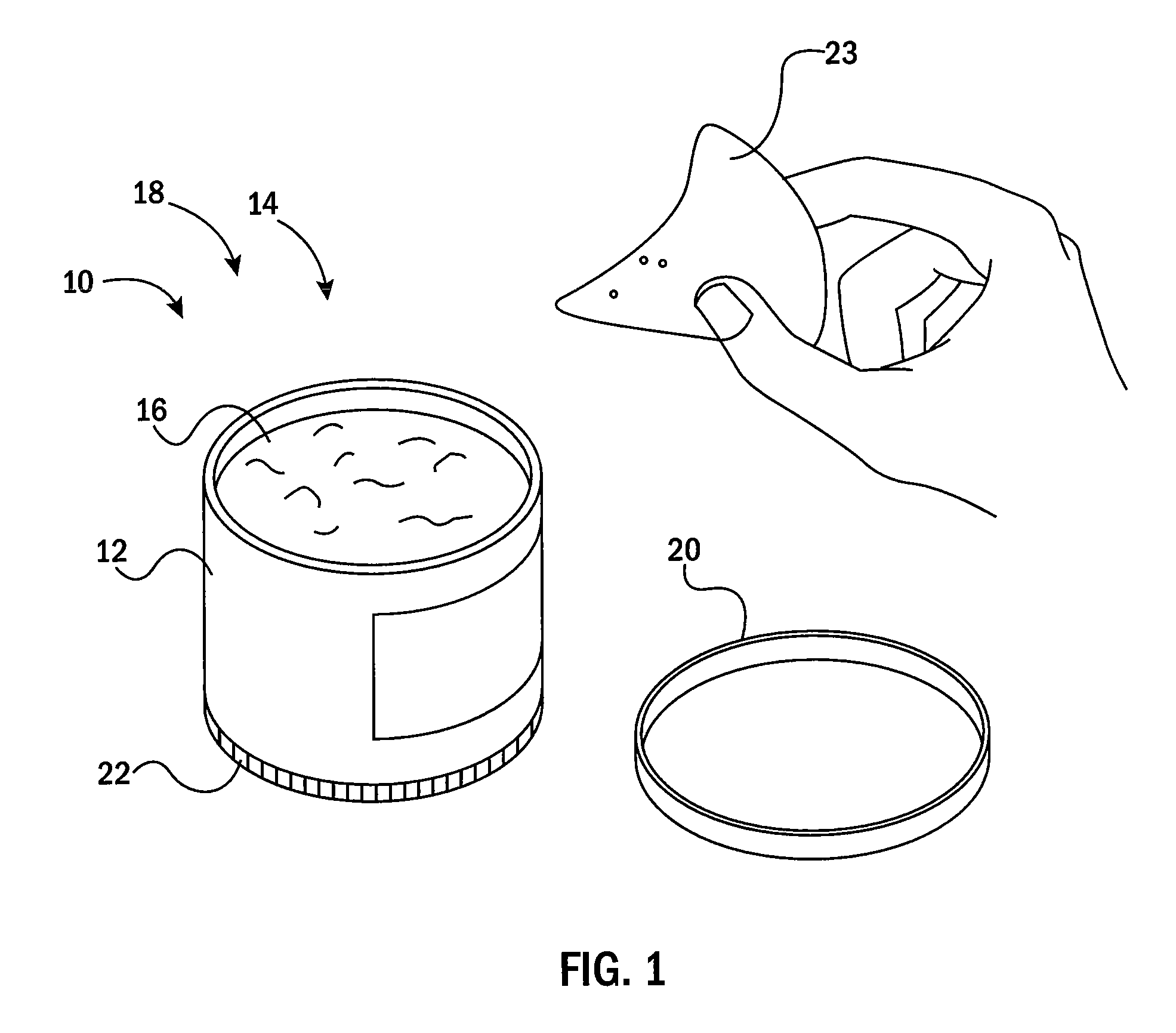

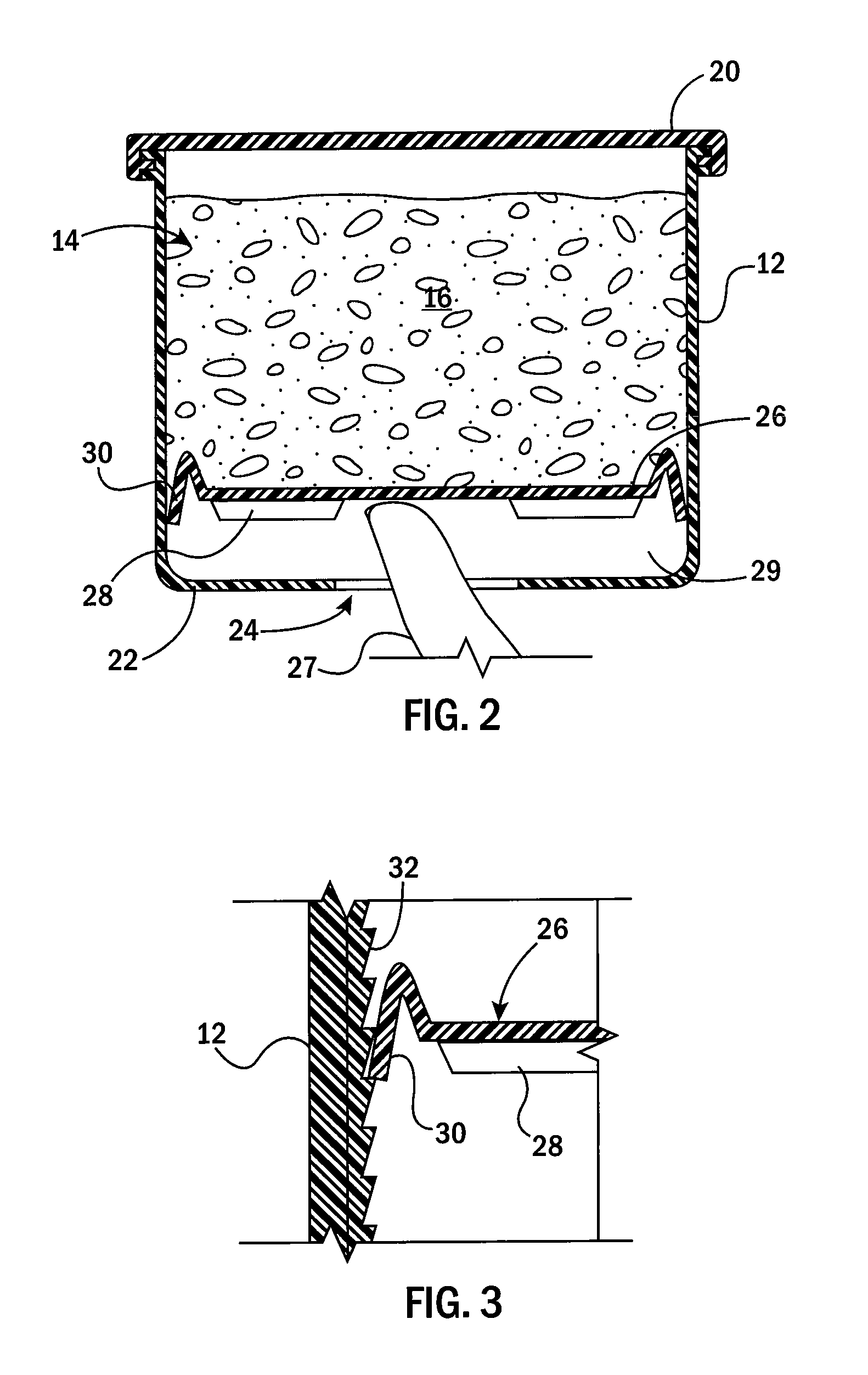

Container with elevating inner wall

InactiveUS8627987B2Reduce decreaseAvoid elevationLiquid transferring devicesInk reservoir pensEngineeringMechanical engineering

A container, for example for a food product or the like, provides an elevating lower inner surface that may sealably support a contained food product to raise the upper surface of the food product as it is consumed. Importantly, the container avoids an extension of the elevating mechanism into the product itself, reducing problems of contamination and leakage.

Owner:WISYS TECH FOUND

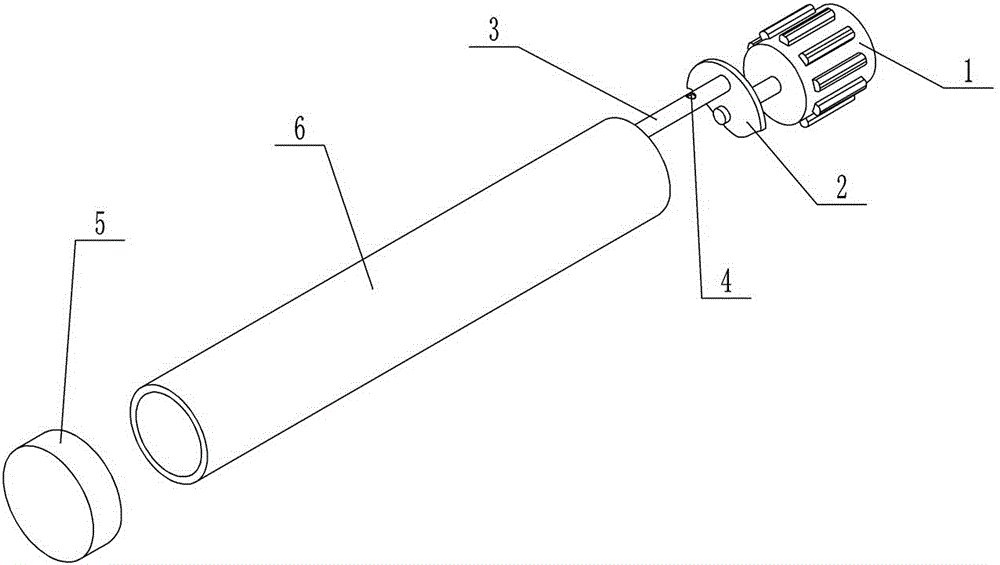

Handheld type pipeline end opening inner wall polishing device

InactiveCN108067960AEasy to collectAvoid affecting the machining accuracyGrinding drivesGrinding headsBall bearingEngineering

The invention discloses a handheld type pipeline end opening inner wall polishing device comprising a shell, a rotating pipeline, a polishing head, a rotating connector, a motor and a storage battery.The upper portion of the left wall of the shell is provided with the rotating pipeline. The periphery of the rotating pipeline is provided with a polishing head, a brush, spray nozzles, sliding ringsleeves and a belt pulley. The right end of the rotating pipeline is connected with a miniature air pump through a rotating connector. Each sliding ring sleeve is composed of a ball bearing and sliding strips. The upper side and the right side of the sliding ring sleeve on the right side are provided with threaded adjusting rods. The upper end and the right end of the sliding ring sleeve on the left side are provided with sliding loop bars. The threaded adjusting rods and the sliding loop bars are provided with holding plates in a connected manner. The opposite inner sides of the holding plates are provided with rotating rods and tightly pressing plates. A motor and a storage battery are arranged in the shell. The right side of the shell is provided with a handle rod. By the adoption of the handheld type pipeline end opening inner wall polishing device, a pipeline can be stably clamped and fixed, the machining depth is freely adjusted, chippings generated by polishing during machiningcan be synchronously cleaned and rapidly blown away, the machining precision is improved, and it is guaranteed that the pipeline is clean.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

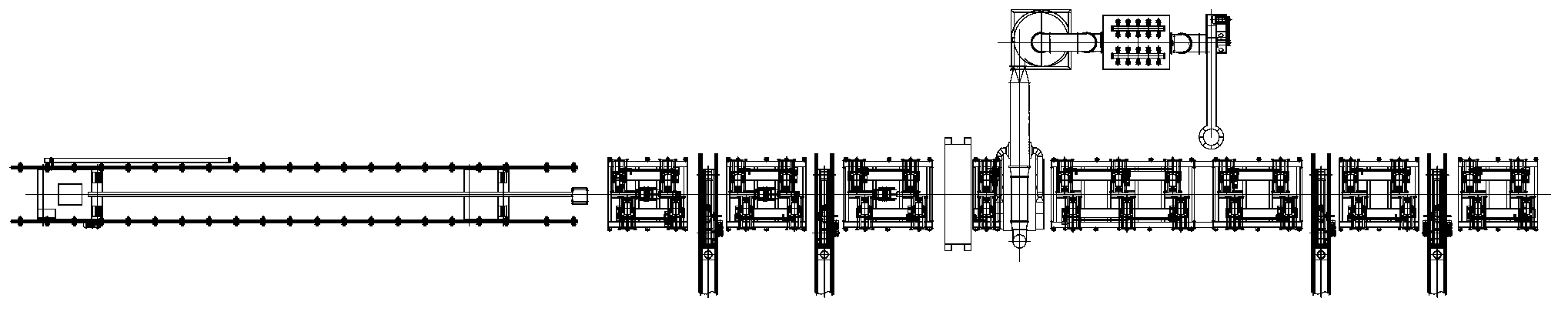

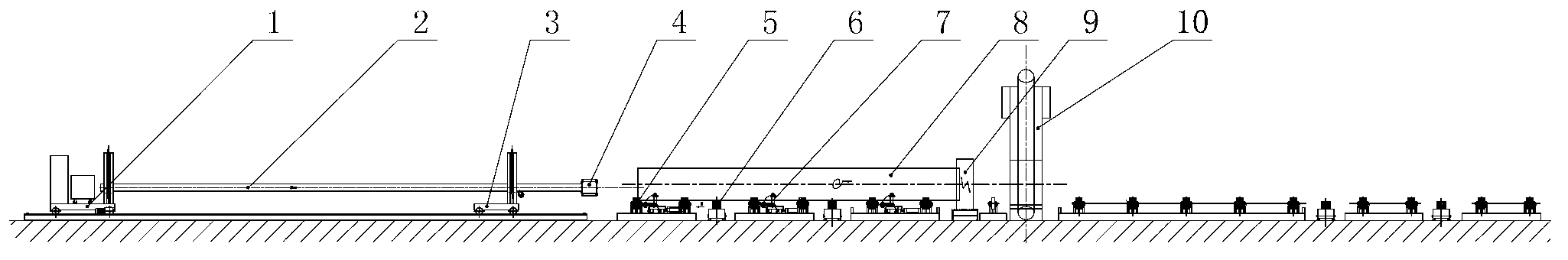

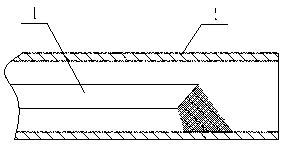

One-step shaping technology for coating epoxy powder on inner wall and outer wall of steel pipe

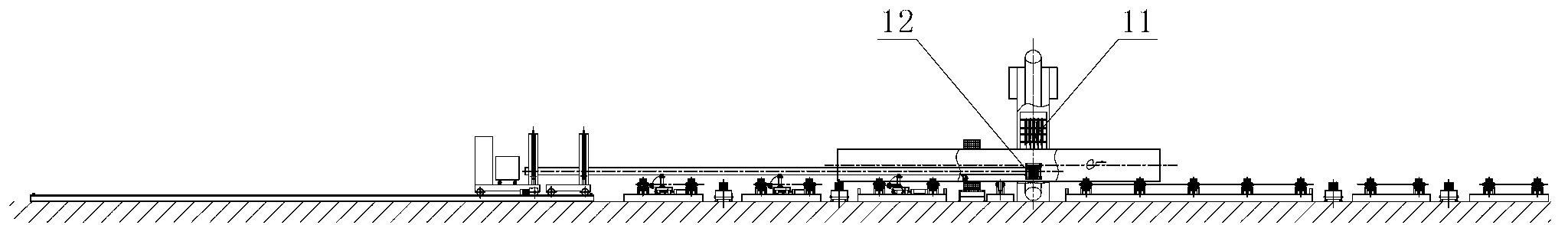

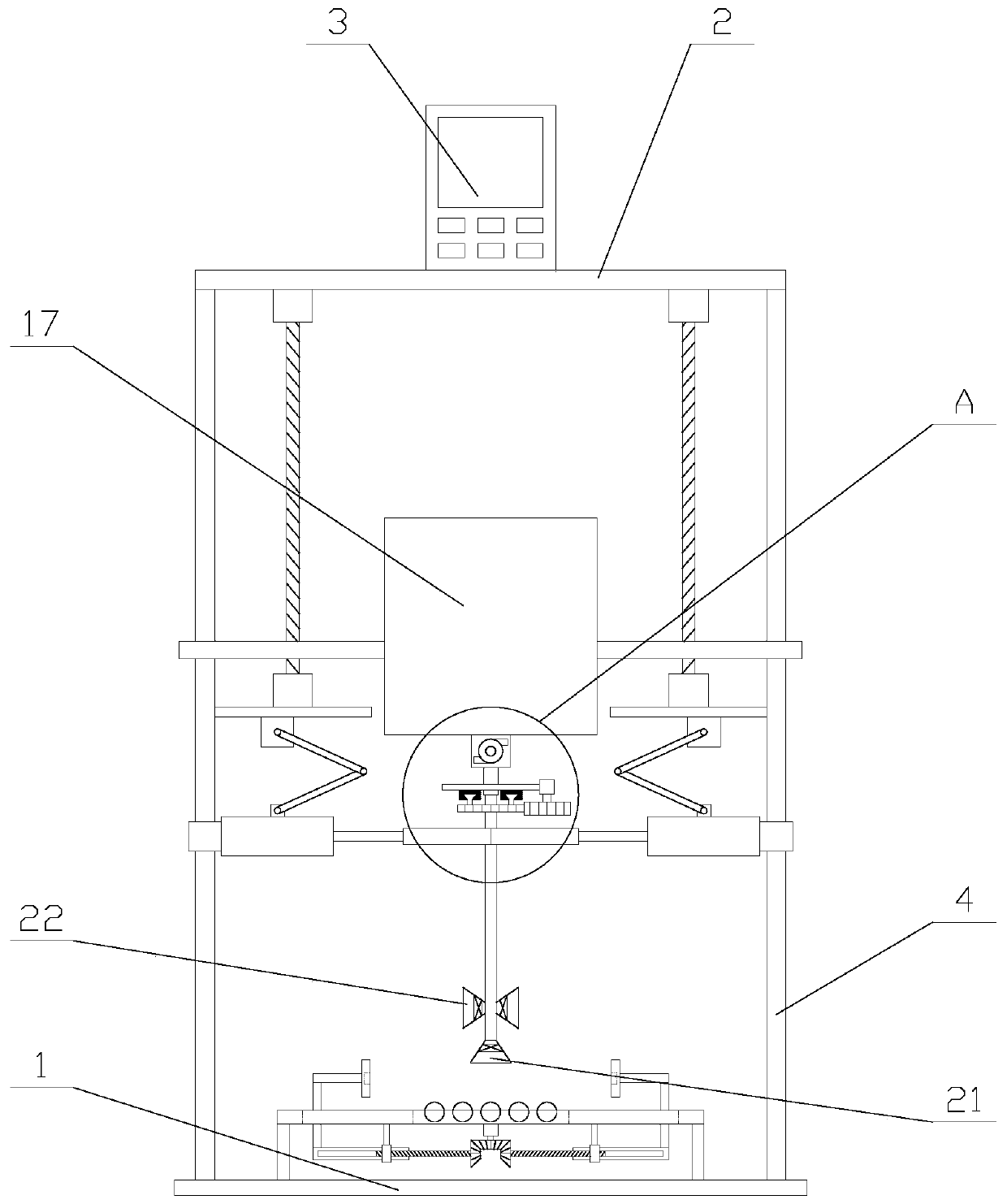

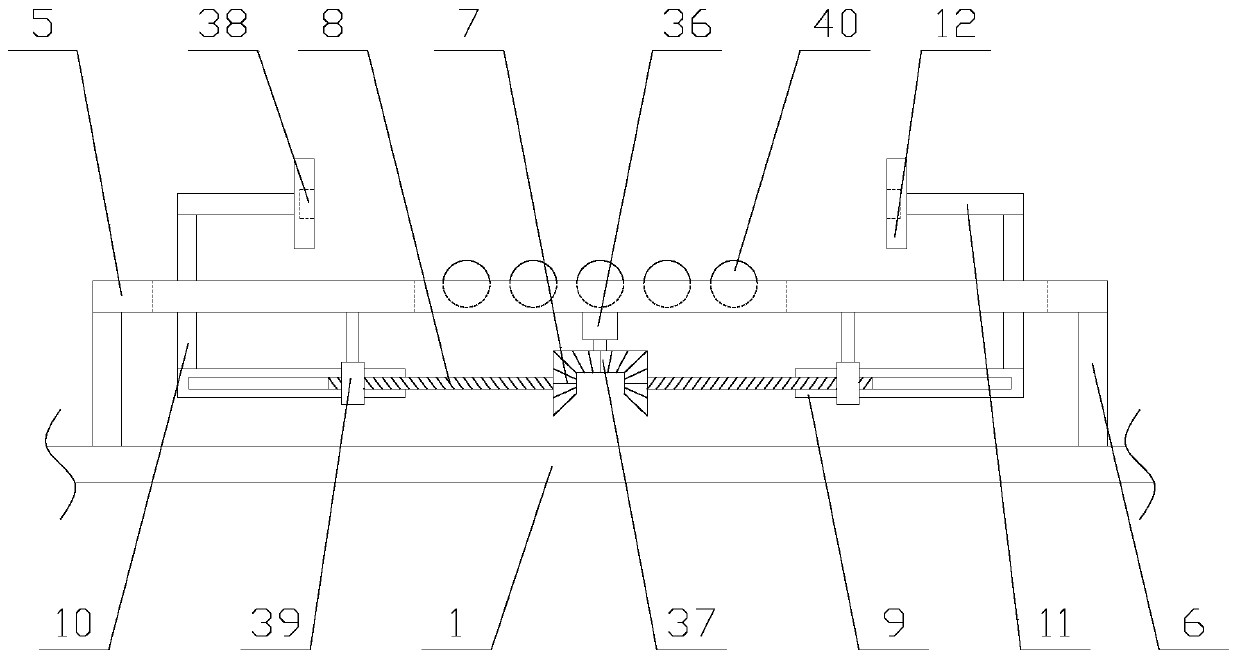

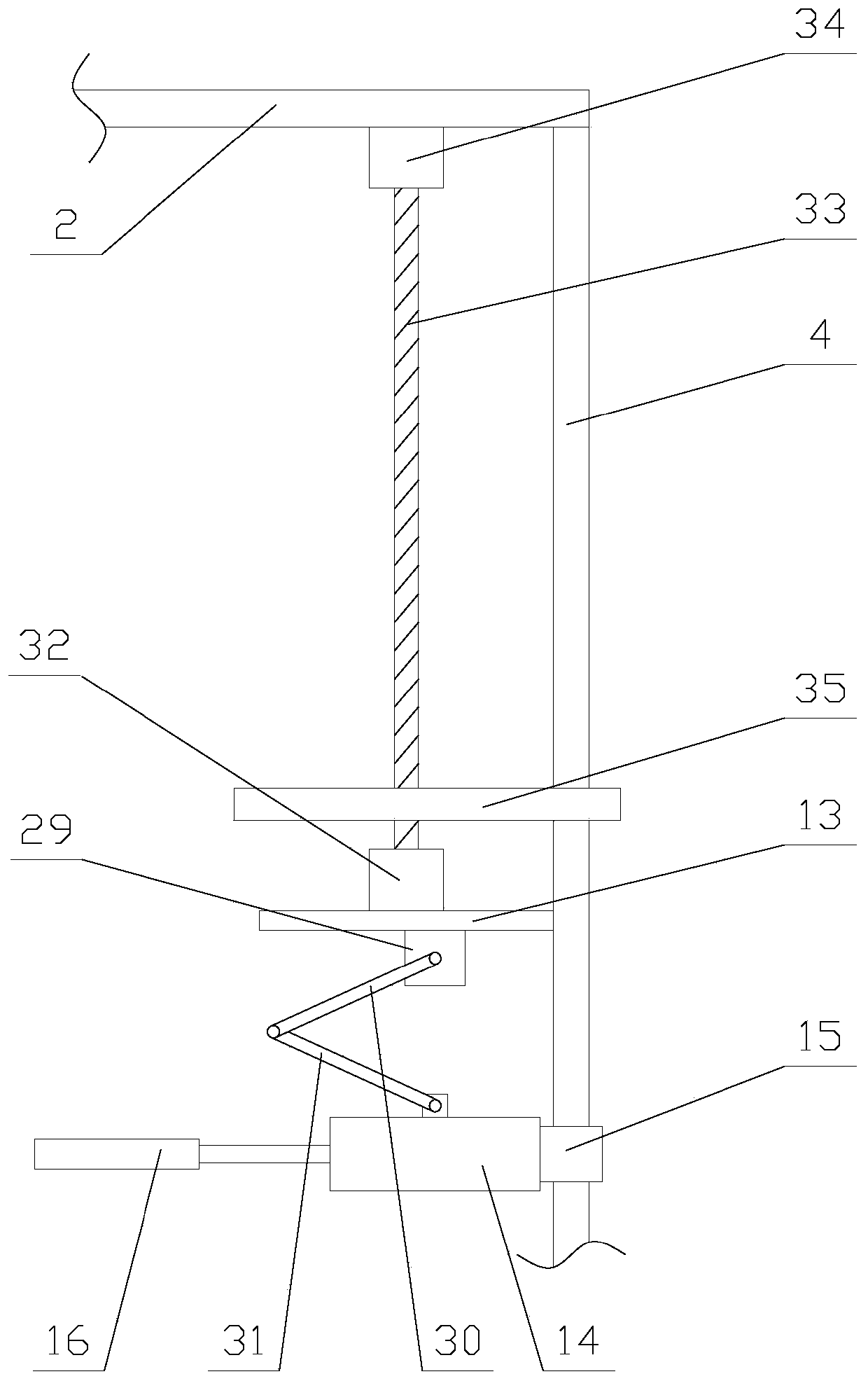

InactiveCN103170445ACompact layoutSmall footprintSpraying apparatusPretreated surfacesEpoxyProduction line

The invention relates to a one-step shaping technology for coating epoxy powder on the inner wall and the outer wall of a steel pipe. The one-step shaping technology for coating the epoxy powder on the inner wall and the outer wall of the steel pipe is characterized in that epoxy powder spraying of the inner wall of the steel pipe and epoxy powder spraying of the outer wall of the steel pipe are carried out simultaneously in one production line; the production line comprises an internal movable epoxy powder spraying trolley, an internal epoxy powder spraying rod, a support rail trolley, a spray nozzle, a spiral conveyer roller path, pipe delivering trolleys, the steel pipe, a medium frequency heating coil and an external epoxy powder spraying chamber; the external epoxy powder spraying chamber is arranged in the middle of the production line, the medium frequency heating coil is arranged on one side of the internal epoxy powder spraying rod nearby the external epoxy powder spraying chamber, and the medium frequency heating coil can be used for finishing heating of the inner wall and the outer wall of the steel pipe at the same time; and the epoxy powder spraying of the inner wall of the steel pipe and the epoxy powder spraying of the outer wall of the steel pipe are finished at the same time in the production line. The one-step shaping technology for coating the epoxy powder on the inner wall and the outer wall of the steel pipe has the advantages that the technological layout is compact, the spraying of the inner wall of the steel pipe and the spraying of the outer wall of the steel pipe can be finished at the same time, the occupied area is small, work efficiency is high, energy is saved, and the one-step shaping technology for coating the epoxy powder on the inner wall and the outer wall of the steel pipe is suitable for anti-corrosion coating treatment on inner walls and outer walls of steel pipes with various diameters.

Owner:北钢管业(营口)有限公司

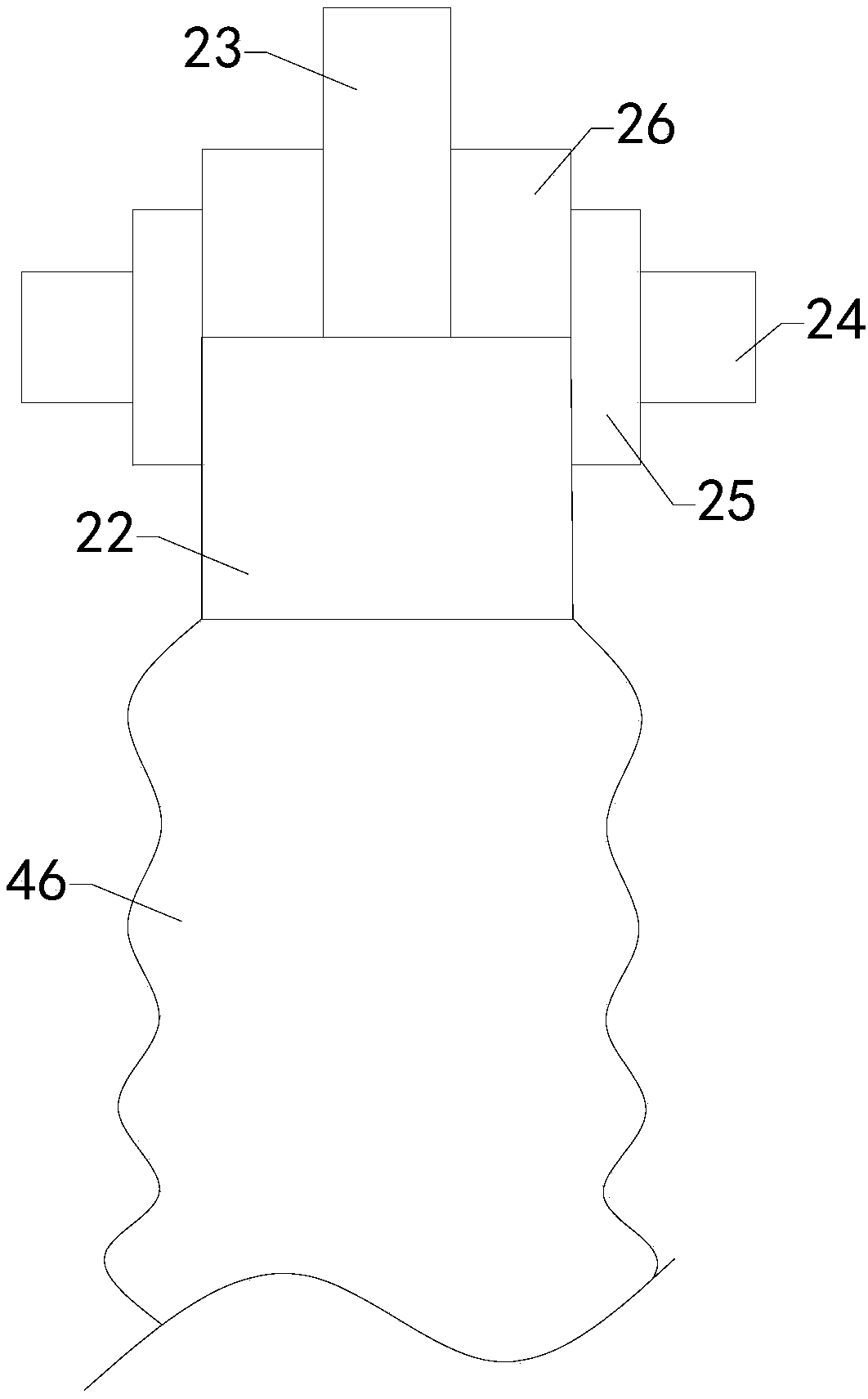

Spraying device for processing inner wall of cylindrical container

ActiveCN110394261AAffects respiratory healthSpray evenlySpraying apparatusRespiratory healthEngineering

The invention relates to a spraying device for processing the inner wall of a cylindrical container. The device comprises a base, a top plate, a controller, a placing mechanism, a spraying mechanism,two vertical rods and two sealing mechanisms, wherein the placing mechanism comprises a platform, a driving assembly, a plurality of positioning assemblies and a plurality of supporting legs, the positioning assemblies comprise strip-shaped openings, transmission bevel gears, screw rods, translation blocks, movable plates, cross rods and clamping plates, the sealing mechanisms comprise side plates, lifting assemblies, telescopic assemblies, air cylinders, sleeve rings and sealing plates. According to the spraying device for processing the inner wall of the cylindrical container, the position of the container is adjusted conveniently through the placing mechanism, so that a spray pipe in the spraying mechanism and the axis of the container are positioned on the same straight line, uniform spraying is facilitated, and the spraying quality is ensured, moreover, a bottle opening of the container can be sealed by the sealing mechanisms in a spraying process, so that the situation that paintis diffused to the outside of the container to influence the respiratory health of a user is prevented, the spraying safety is guaranteed, and the practicability of the device is improved.

Owner:临沂文衡信息技术有限公司

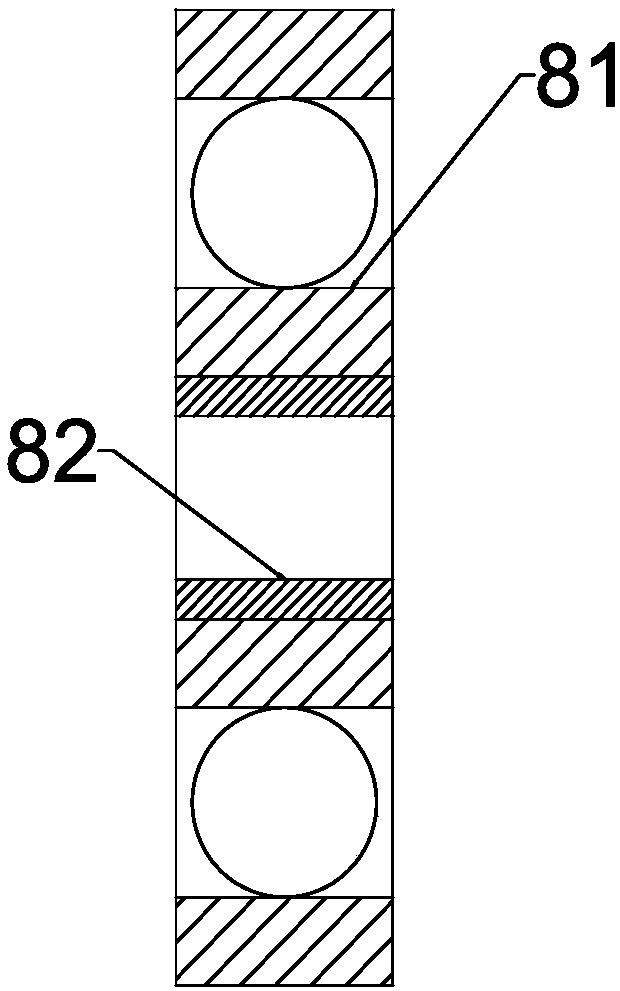

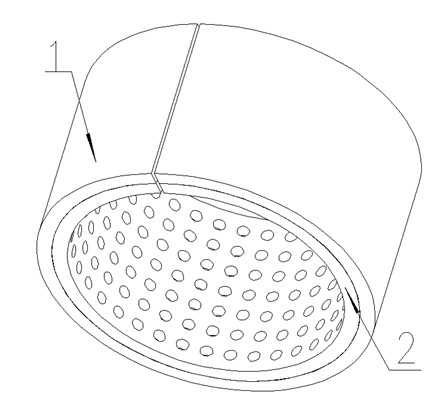

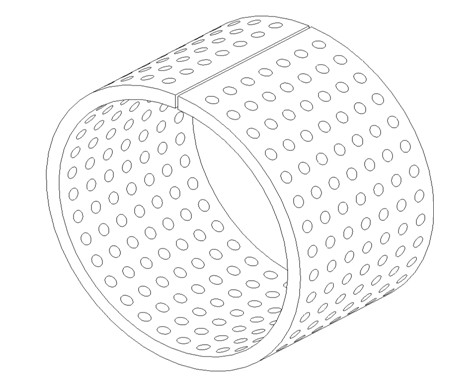

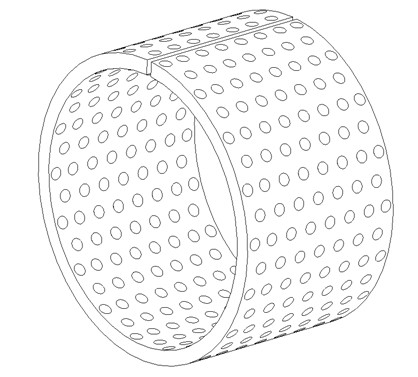

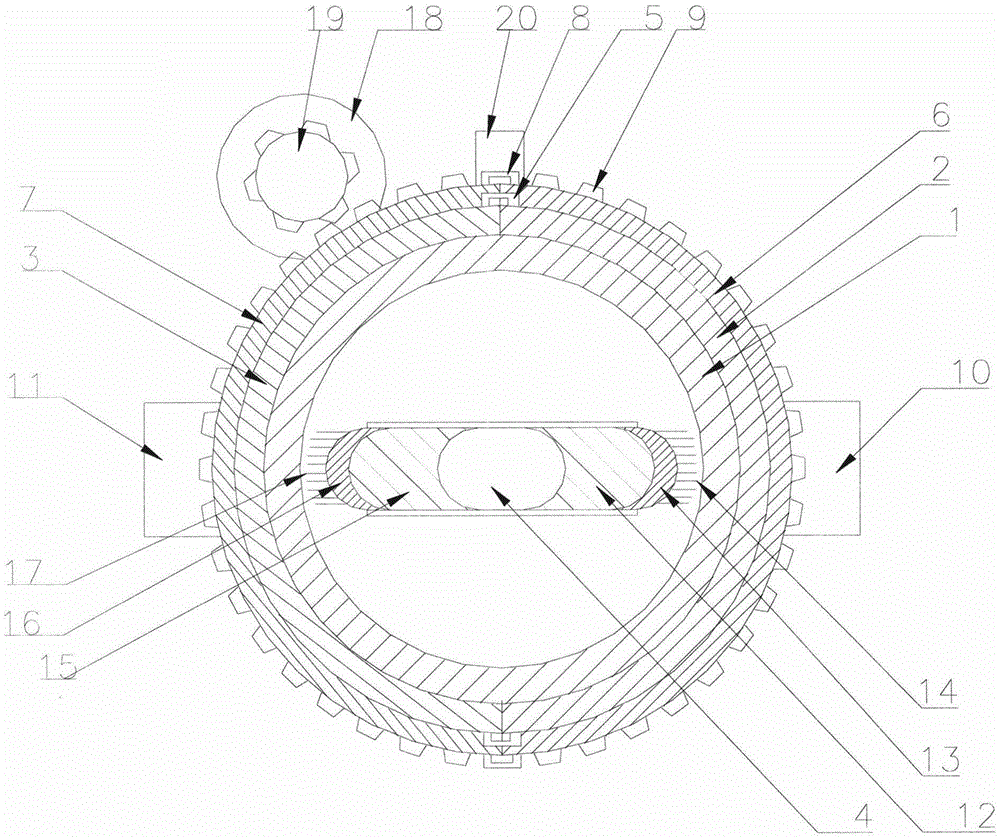

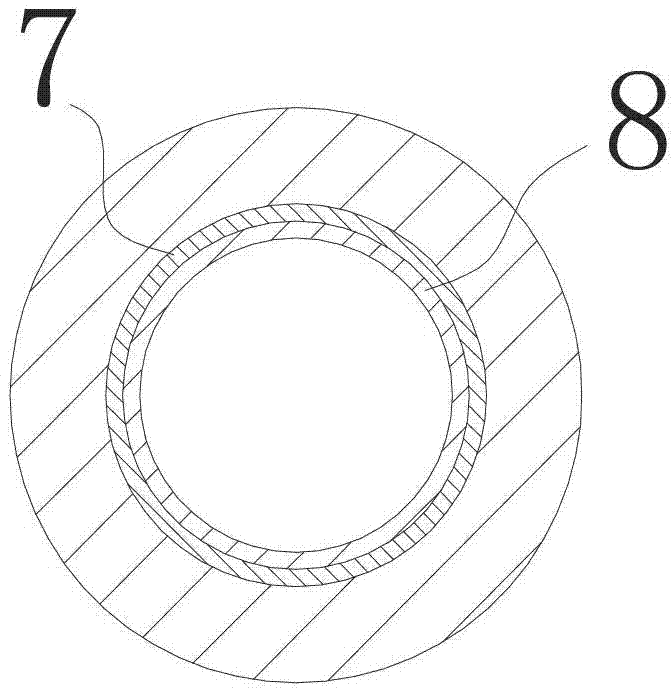

Sliding bearing with micro holes on inner wall thereof

InactiveCN102022434AGuaranteed lifeReduce friction and wearBearing componentsSliding contact bearingsEngineeringWear resistance

The invention discloses a sliding bearing with micro holes on the inner wall thereof, which is prepared through the steps of welding a bearing bush and a bearing lining the surface of which is uniformly provided with micro through holes; and then rolling, wherein the bearing lining is arranged in the bearing bush; the total area of the micro through holes on the surface of the bearing lining accounts for 10 to 20 percent of the surface area of the inner wall of the bearing lining; and the ratio of depth to diameter of the micro through holes on the surface of the bearing lining is 0.05 to 0.2. The sliding bearing disclosed by the invention has the advantages that the micro through holes on the bearing lining form micro grooves on the inner wall of the sliding bearing, and the micro grooves are used for storing the lubricating oil, and when sufficient lubricating oil is stored in the micro grooves, a dynamic pressure oil film is formed between the bearing bush of the sliding bearing and an axle journal rubbing pair, thereby reducing the rubbing wear; the elastic deformation of the bearing lining is enlarged, the rubbing pair is in an elastic hydrodynamic lubrication state, and the bearing is good in abrasion resistance and obvious in lubrication effect; and the bearing is simple in processing and easy to manufacture.

Owner:ZHEJIANG UNIV

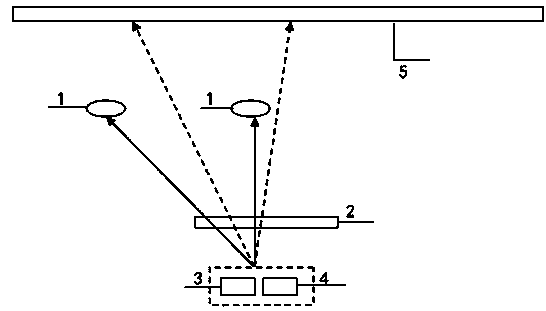

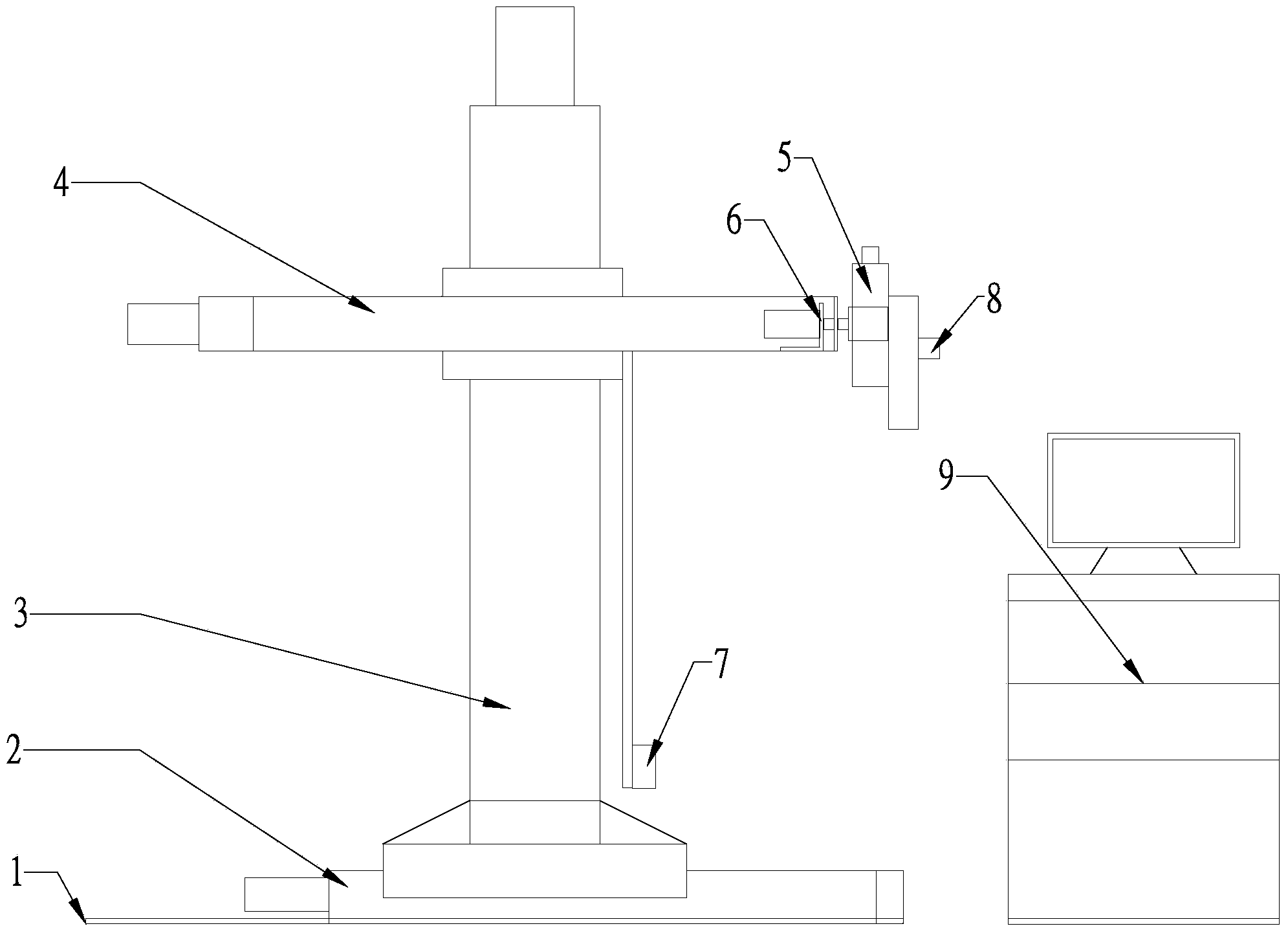

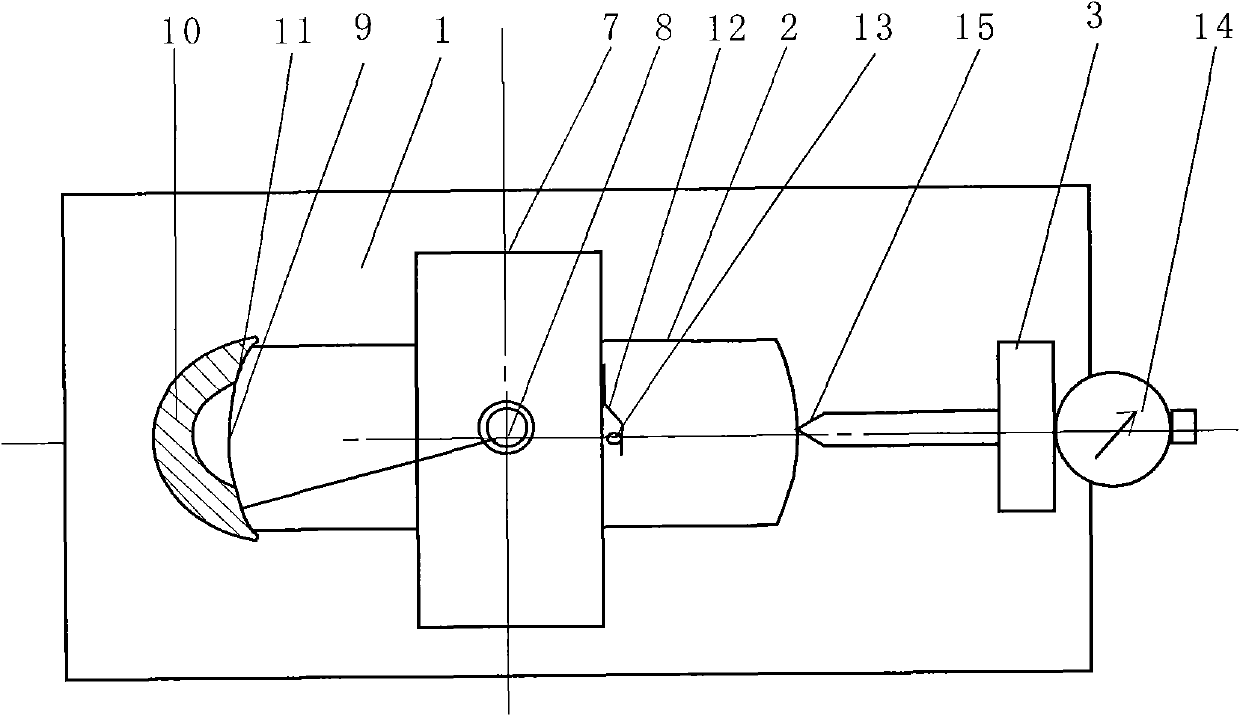

Method for distinguishing temperature of outer wall of cracking furnace tube from temperature of inner wall of hearth and measurement device

ActiveCN104374478AEasy to moveSimple and beautiful appearanceRadiation pyrometryMeasurement deviceEngineering

The invention provides a method for distinguishing the temperature of the outer wall of a cracking furnace tube from the temperature of the inner wall of a hearth and a measurement device. When the temperature of the outer wall of the cracking furnace tube is measured through a temperature measurement module, the distance of a practical temperature measurement object is synchronously measured through a distance measurement module, and either the measured temperature is the temperature of the outer wall of the cracking furnace tube or the temperature of the inner wall of the hearth is distinguished according to the measured distance. By means of the method and the measurement device, the temperature and the distance of the practical temperature measurement object can be synchronously measured in the severe production environment of a cracking furnace, the temperature of the outer wall of the cracking furnace tube and the temperature of the inner wall of the hearth are effectively and rapidly distinguished through different distance features of the temperature-measured object, and the implementation device for the method is simple in structure, easy to implement and low in manufacturing cost.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

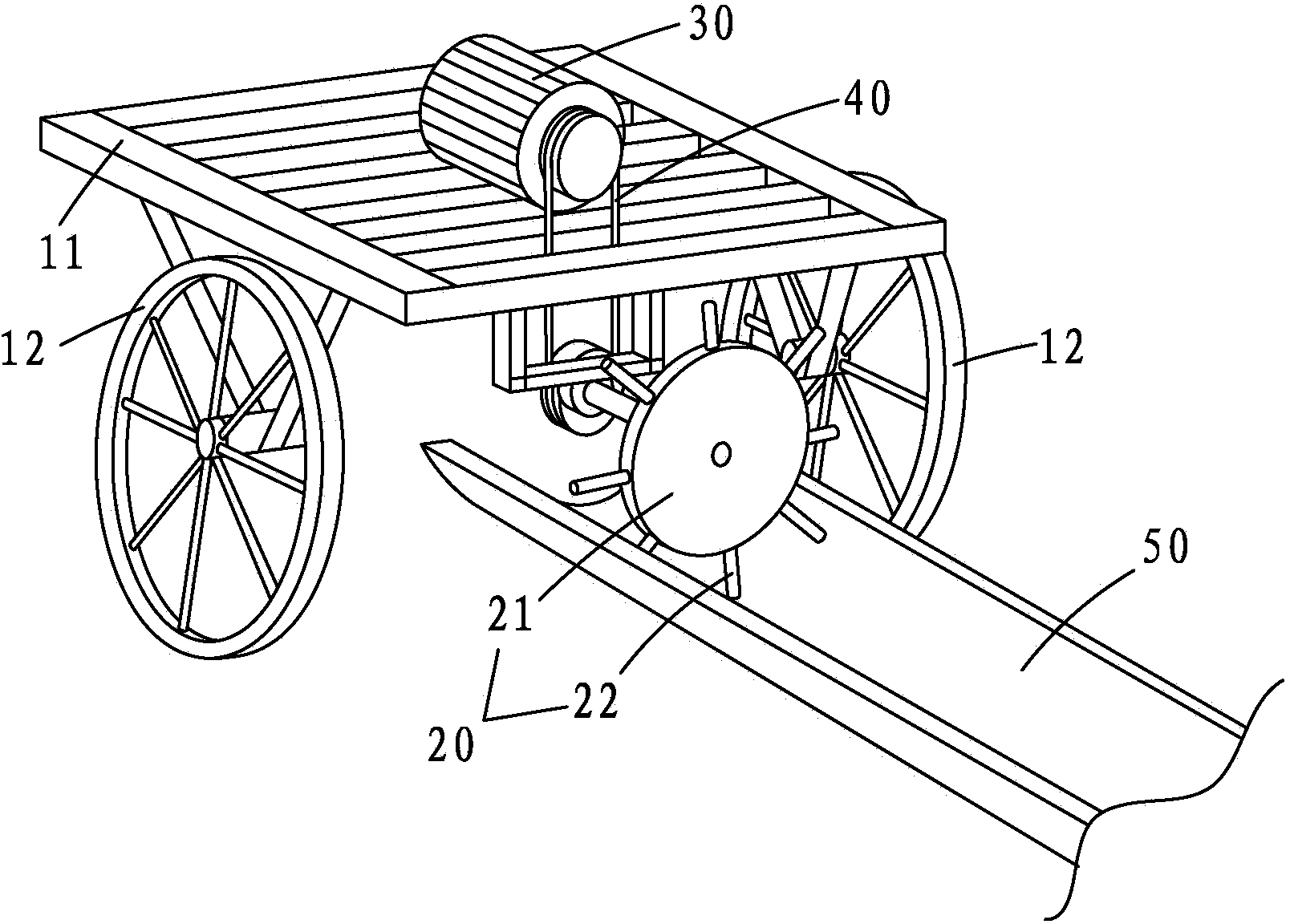

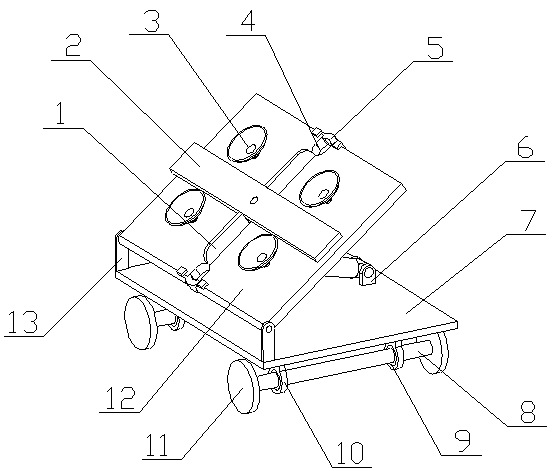

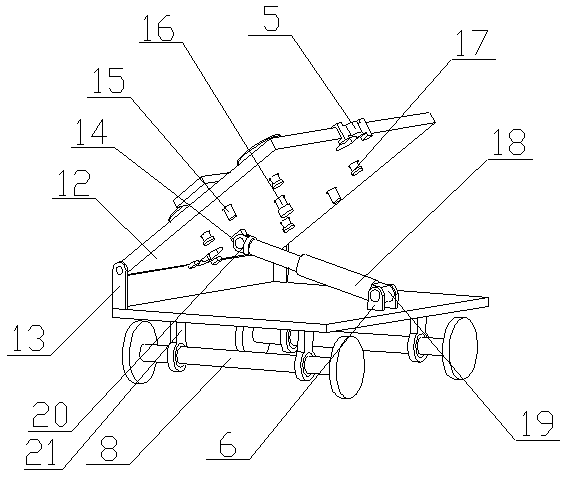

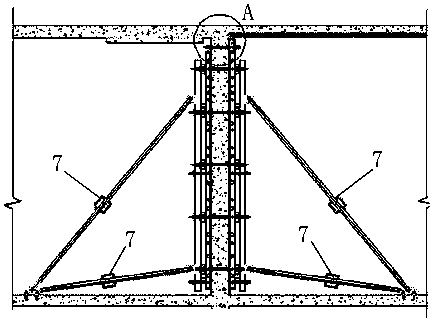

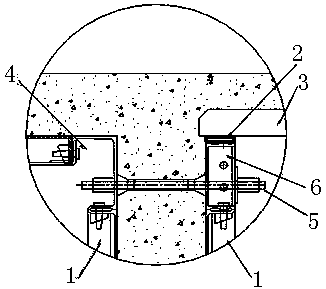

Tool for cleaning inner wall of concrete tubular pile die

ActiveCN103660020AEasy to operateFast cleaningCeramic shaping apparatusStructural engineeringEngineering

The invention discloses a tool for cleaning the inner wall of a concrete tubular pile die. The tool comprises a supporting vehicle body, a cleaner, an electromotor and a transmission mechanism. The cleaner is fixedly hung near the supporting vehicle body, the electromotor is fixedly installed on the supporting vehicle body, the cleaner comprises a rotary plate, a plurality of steel wire brushes are arranged on the outer edge of the rotary plate at intervals, the electromotor is connected with a rotary shaft through the transmission mechanism, and the rotary shaft is fixedly connected with the middle of the rotary plate of the cleaner. When the supporting vehicle body moves along the die, the cleaner is right arranged in the die, the electromotor drives the cleaner to rotate, and therefore the steel wire brushes on the cleaner brush away concrete blocks on the inner wall of the die. The tool for cleaning the inner wall of the concrete tubular pile die is simple and efficient, can clean the concrete blocks on the inner wall of the steel die easily and is ideal in cleaning effect, thereby greatly reducing labor intensity, improving labor efficiency and improving the production speed.

Owner:FUJIAN DADI CONCRETE PILE

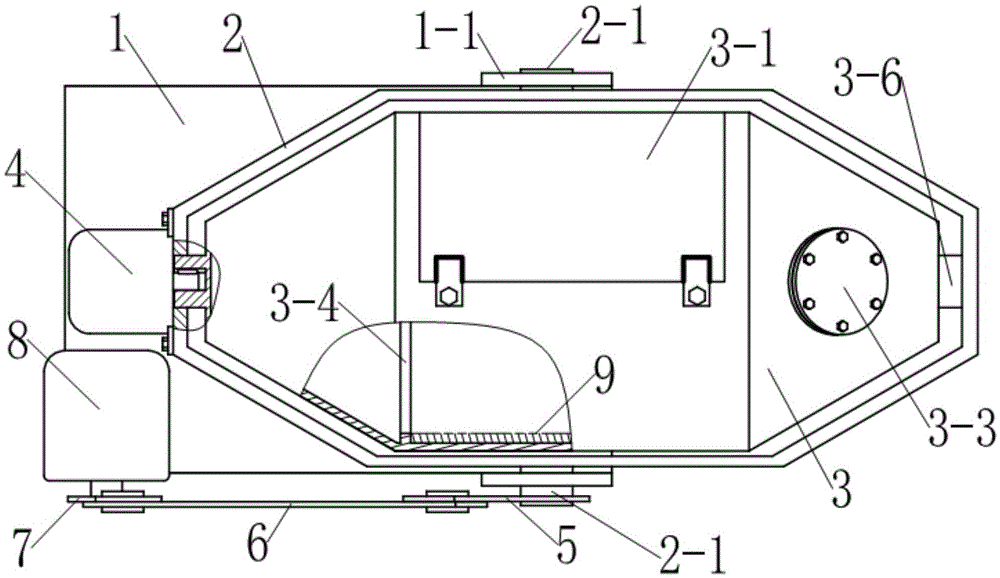

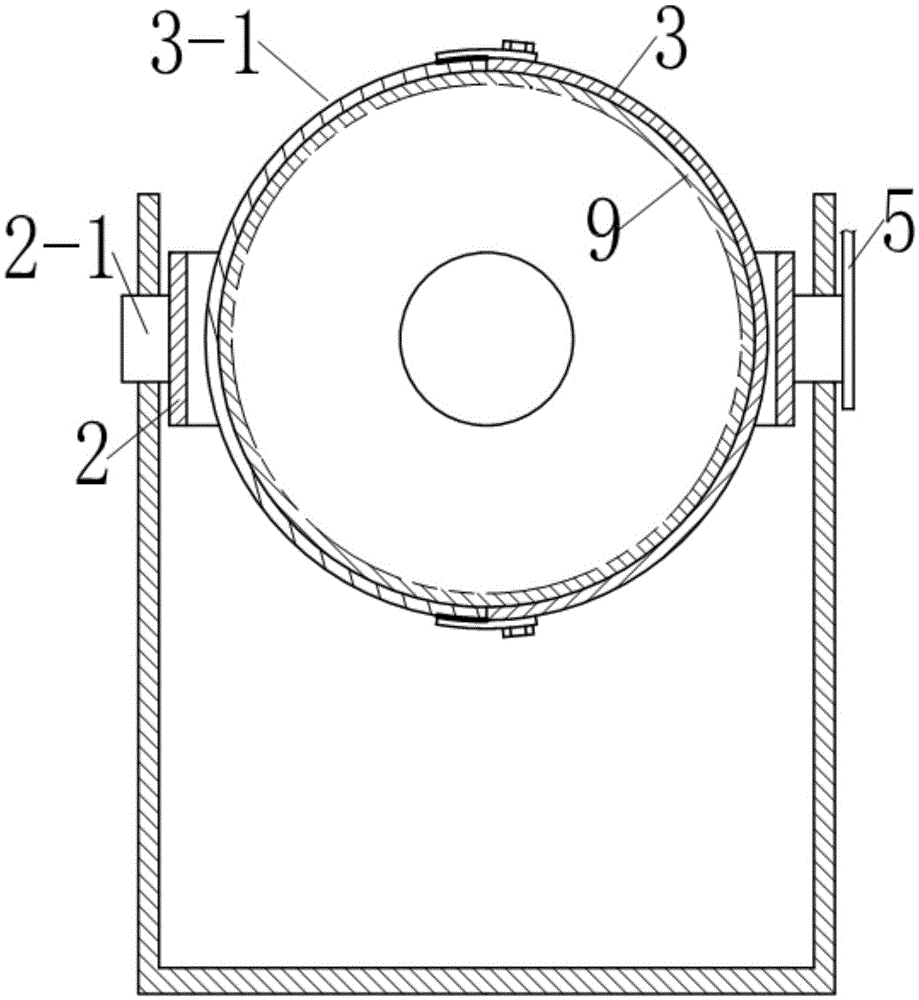

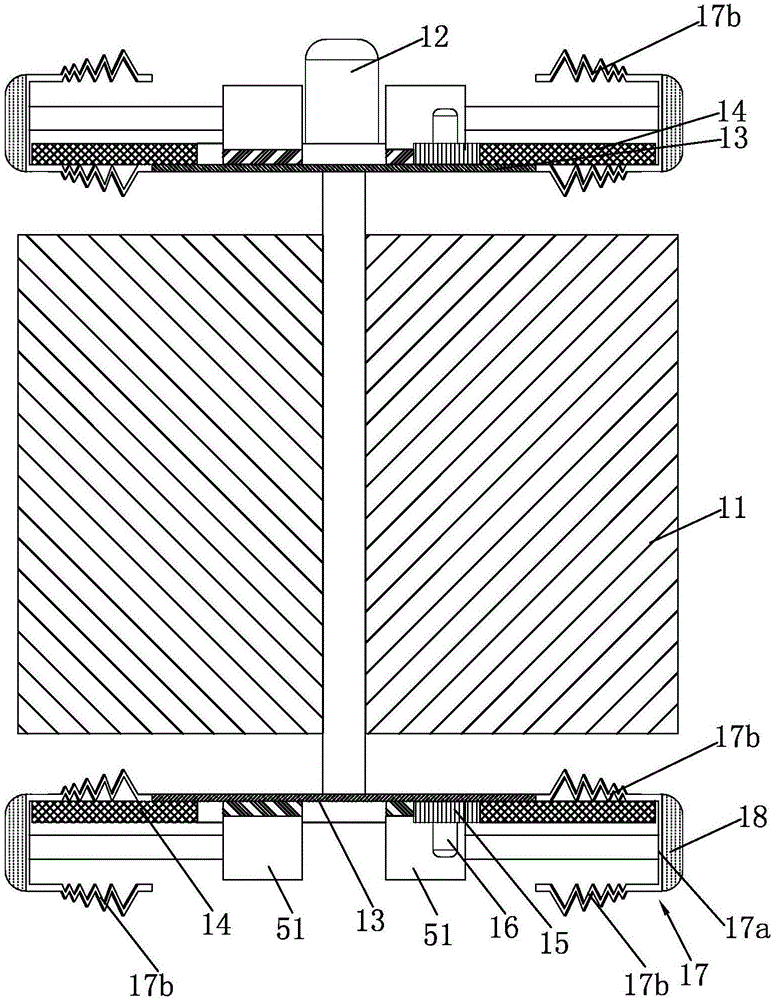

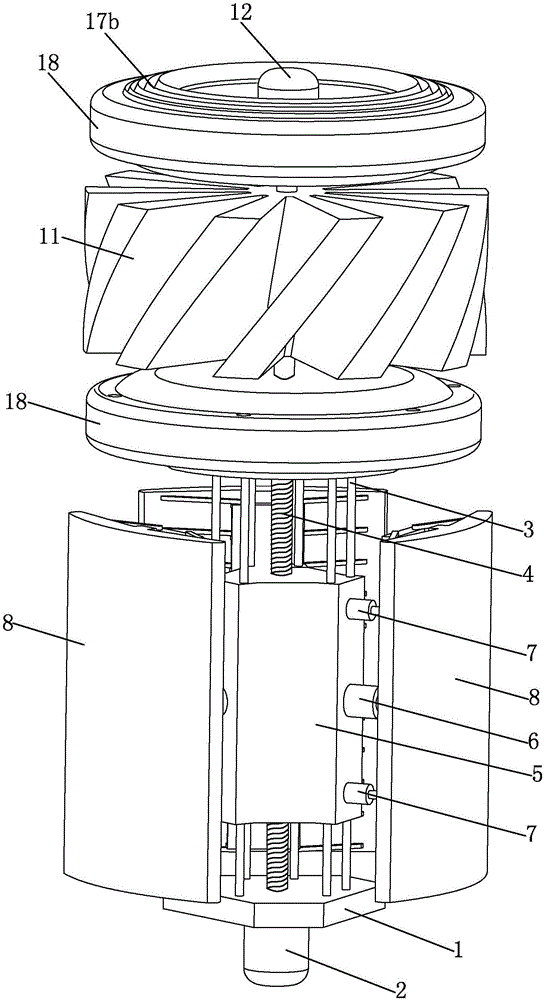

Polishing device for inner wall of tubular workpiece

ActiveCN105538121AContinuous and uniform micro-grindingUniform grinding force distributionEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention discloses a polishing device for the inner wall of a tubular workpiece. The polishing device comprises a rack, a drum and a crank and rocker mechanism, wherein the rack is composed of a base and a swinging and rotating frame arranged on the base, and the middle portions of the two sides of the swinging and rotating frame are horizontally supported by two supporting columns extending from the base through lugs; a tubular workpiece clamping opening is formed in the side wall of the drum, and the outer side of the clamping opening is provided with an arc pressing cover which covers the clamping opening; a charging opening with a sealing cap is arranged at one end of the drum; the two ends of the drum are supported by the two ends of the swinging and rotating frame through other lugs, and one end of one of the lugs is connected with an output shaft of a first motor arranged outside the swinging and rotating frame. The crank and rocker mechanism is formed by sequentially hinging a crank, a connecting rod and a rocker, wherein the free end of the crank is fixedly connected with an output shaft of a second motor arranged on the base, and the free end of the rocker is fixedly connected with the corresponding lug. The polishing device provided by the invention has the advantages that polishing is uniform, and the structure is simple.

Owner:射阳金昌鑫精密模具科技有限公司

Robot for cleaning inner wall of pipe

The invention discloses a robot for cleaning the inner wall of a pipe. A motor and guide shafts are mounted on a lower mounting plate. The lower end of each guide shaft is fixed to the lower mounting plate. A nut is in threaded connection to a screw rod and provided with three or more radially-extending-and contracting assemblies in the circumferential direction. Among the radially-extending-and contracting assemblies, the upper side and the lower side of each large linear motor are each provided with a small linear motor in a symmetrical manner; a piston rod of each large linear motor is fixed to the center of a rubber block, and a piston rod of each small linear motor is fixed to a radially-moving block; the upper side and the lower side of each roll brush are each provided with a sealing and fixing device in a symmetrical manner, and a set of liquid passing holes are uniformly formed in the rim of a fixing disc in each sealing and fixing device in the circumferential direction; the upper end of the screw rod is matched with the fixing disc of the lower sealing and fixing device in a rotary manner, and the upper ends of the guide shafts are fixed to the corresponding fixing disc; and a roll brush motor is mounted on the fixing disc of the upper sealing and fixing device. By means of the robot for cleaning the inner wall of the pipe, contaminants on the inner wall of the pipe can be removed thoroughly and efficiently.

Owner:CHONGQING UNIV OF TECH

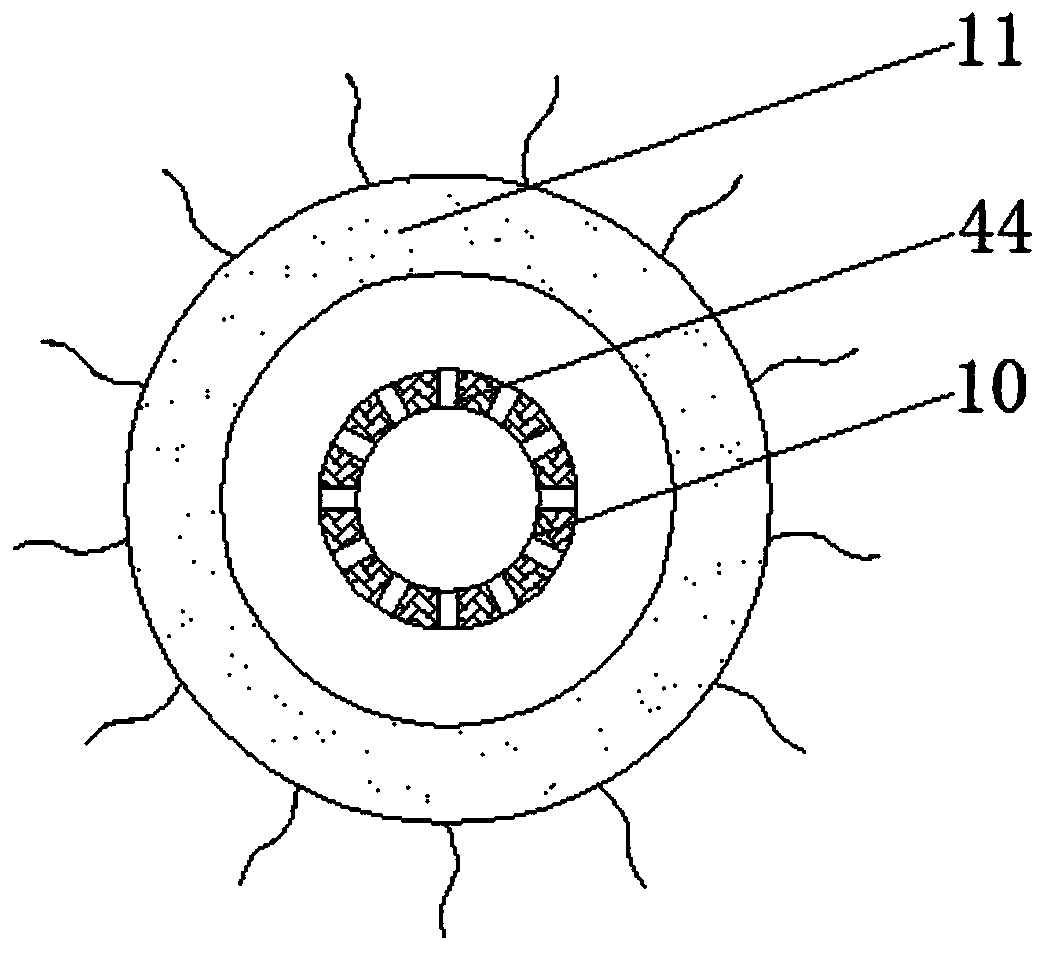

Pipeline inner-wall cleaning device

The invention relates to a pipeline inner-wall cleaning device which mainly comprises lining rings, an inner-wall cleaning rotor, outer rotating rings, a motor and a gear and is suitable for non-ferromagnetic pipeline cleaning. The lining rings hoop a pipeline, and the outer rotating rings hoop the lining rings. Under the action of magnets on the lining rings, the magnetic field of rotor magnets on the inner-wall cleaning rotor interacts with the magnetic field of magnets outside the pipeline, and the outer magnetic field acts on the attitude of the inner-wall cleaning rotor. The gear is engaged with an outer rotating ring gear to drive the outer rotating rings to rotate. The left magnet and the right magnet rotate to drive the inner-wall cleaning rotor to rotate, and a left brush and a right brush wash the inner wall of the pipeline to play a role in cleaning. The inner-wall cleaning rotor can be taken into the pipeline to any depth under the action of the magnetic fields. The pipeline inner-wall cleaning device has the advantages of being free of limitation of pipeline length, and can be widely applied to various non-ferromagnetic pipeline inner-wall cleaning. The pipeline inner-wall cleaning device has the remarkable advantages of simple structure and convenience in operation and maintenance and has a wide market prospect.

Owner:金保莱管道系统江苏有限公司

Wall-brick laying device for inner wall in building construction

The invention relates to a wall-brick laying device for an inner wall in building construction, and discloses a wall brick laying device. The wall brick laying device travels along the wall surface, two wall bricks are compressed and fixed on the wall surface through matching of a rotating plate and a pressing plate, and a gap can be reserved, the precision of wall brick laying can be improved, and the laying efficiency is improved. The wall brick laying device is characterized in that two sets of fixing rods are arranged at the bottom of a fixing plate, each set of fixing rods is composed oftwo fixing rods, a fixing ring is arranged at one end of each fixing rod, and a transverse rod penetrates through the two fixing rings in the same set; a fixing bearing is arranged between each transverse rod and the corresponding fixing ring, two idler wheels are arranged at the two ends of each transverse rod correspondingly, and two supporting plates are arranged on the front side and the rearside of the fixing plate correspondingly and get close to the left side of the fixing plate; and the two sides of the rotating plate are hinged to the two supporting plates correspondingly, two connecting lugs are arranged on the fixing plate, rotating lugs are arranged between the two connecting lugs and hinged to the two connecting lugs correspondingly, the bottom of an oil cylinder is arrangedon the rotating lugs, and a rotating block is arranged at one end of a piston rod on the oil cylinder.

Owner:广东铭锦建设有限公司

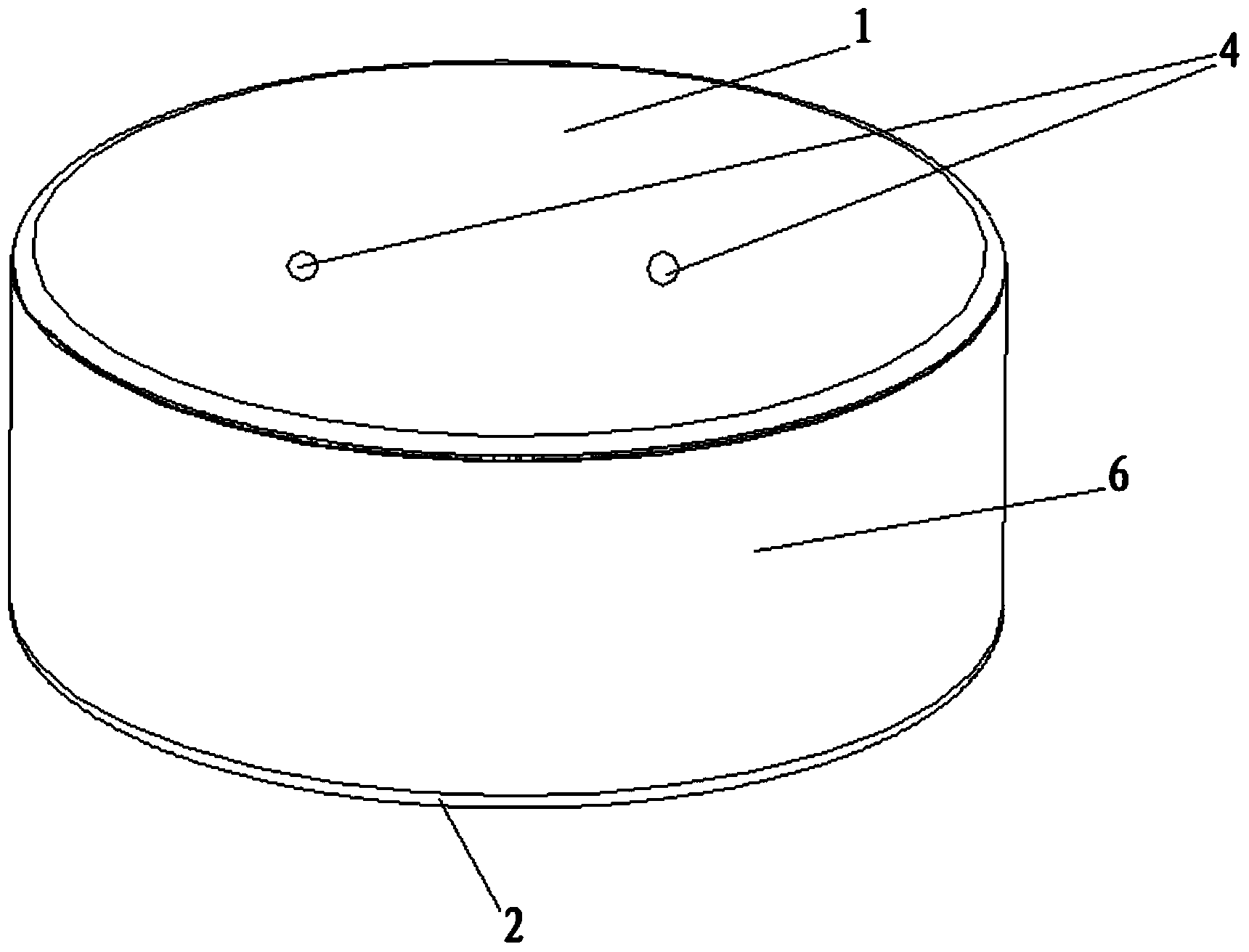

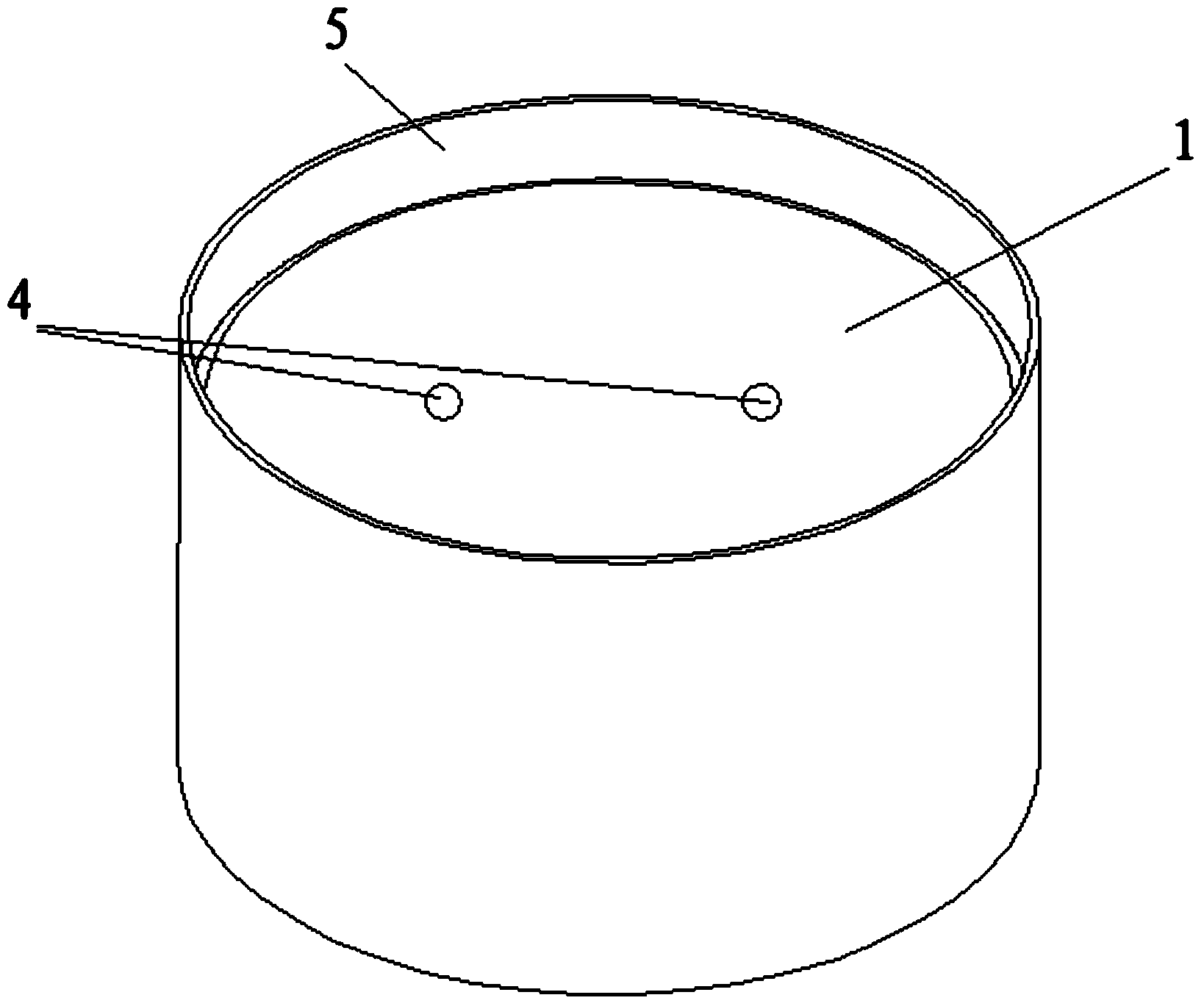

Soft airbag for loading inner pressure on inner wall of cylinder

ActiveCN104297068AReduce weightLow costMaterial strength using tensile/compressive forcesInternal pressureSpace environment

The invention particularly relates to a soft airbag for loading inner pressure on an inner wall of a cylinder, belonging to the technical field of space environment strength. The airbag is a round-cake-shaped airbag composed of an upper end face, a lower end face and a side wall, wherein cloth strips are uniformly stuck between the upper and lower end faces in the airbag and two pipe nozzles are arranged on the upper end face; and a plurality of buckles are annularly stuck on the upper end face. The airbag is machined by adopting a PVC thin film. In a testing process, when cable and hose equipment need to be arranged on the inner wall of a test piece, a cable and a hose are required to pass through the airbag; an axial hole is formed in the center of the airbag; and a hard pipe penetrates into the hole. In a testing process, when different inner pressure loads are loaded at different heights of the test piece, the plurality of airbags are sequentially mounted in the axial direction; two hoses are led out from each airbag and are used for pressurizing and measuring pressure; and in a mounting process, the two hoses of the airbag on the upper side penetrate through the hard pipe at the center of the airbag on the lower side. The soft airbag for loading the inner pressure on the inner wall of the cylinder has light weight and low cost and is convenient to mount.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

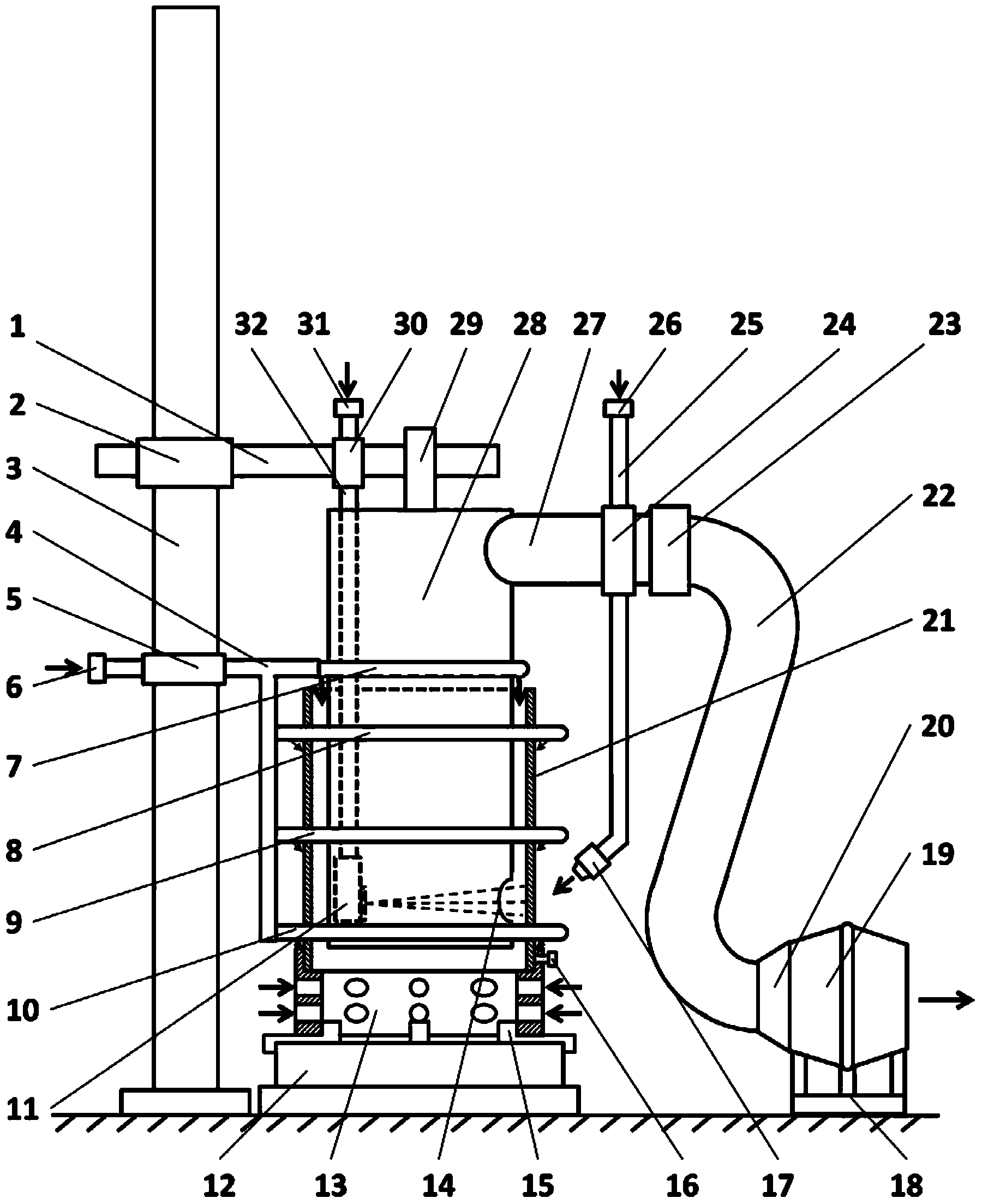

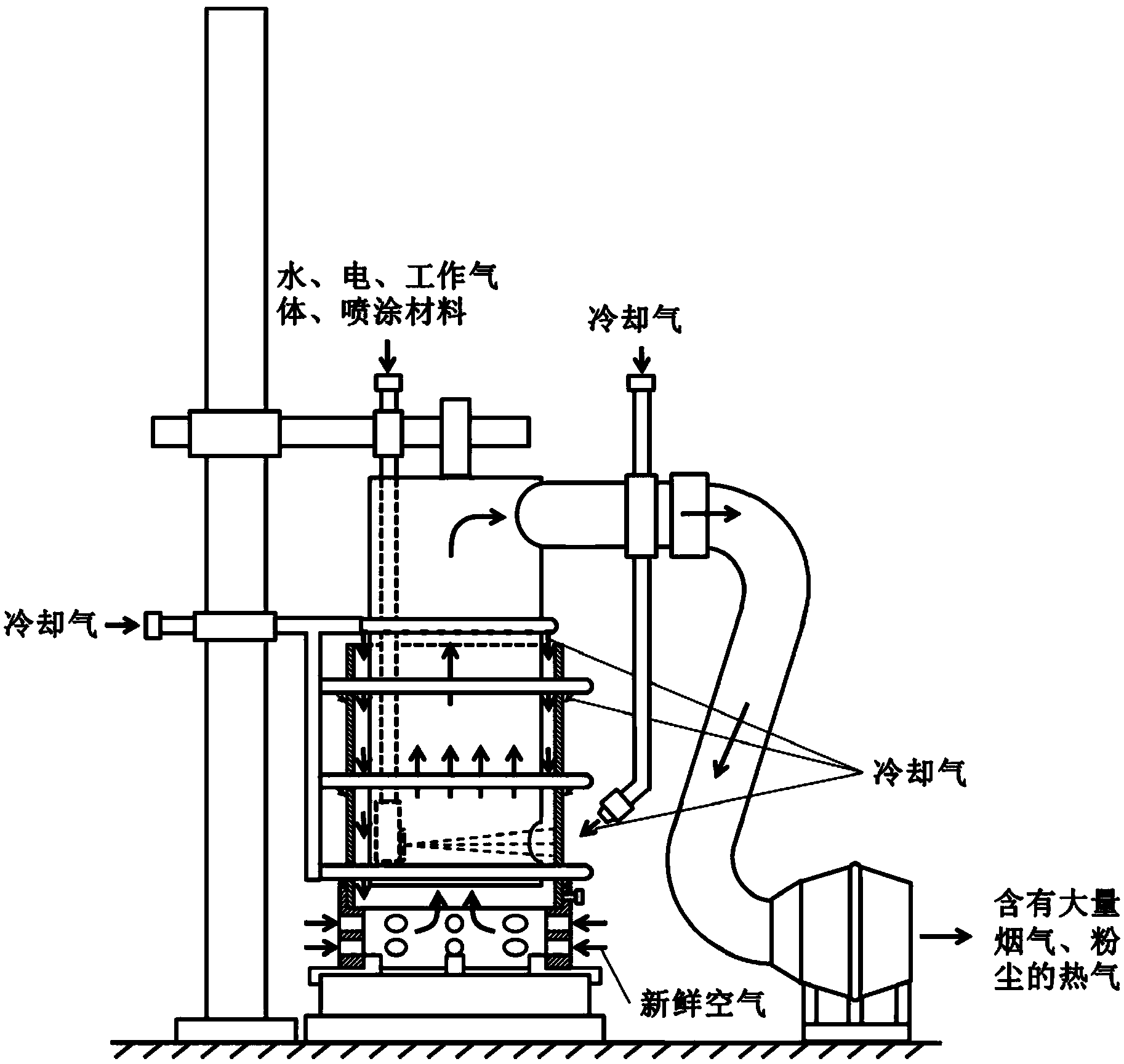

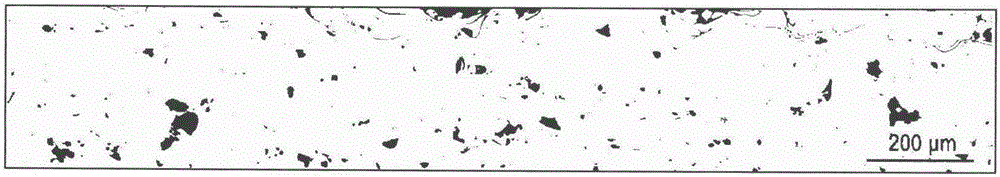

Plasma transfer arc spraying method for strengthening inner wall of cylinder sleeve of heavy truck

The invention relates to a plasma transfer arc spraying method for strengthening the inner wall of a cylinder sleeve of a heavy truck. The plasma transfer arc spraying method for strengthening the inner wall of the cylinder sleeve of the heavy truck comprises the steps that the inner wall of the cylinder sleeve is cleaned, and brown fused alumina is used for sand blasting for roughening treatment; an iron-based cored wire is sprayed to the inner wall of the cylinder sleeve of the truck through plasma transfer arc spraying, so that an abrasion-resistant and corrosion-resistant coating is obtained, wherein the iron-based cored wire is provided with stainless steel skin, and a core is formed by using FeCrBSi or FeCrBSi as a metal base material and adding other materials as compound phases; and the obtained coating is honed through a diamond honing stick. By adoption of the plasma transfer arc spraying method for strengthening the inner wall of the cylinder sleeve of the heavy truck, the defects that frictional power consumption is high, abrasion and corrosion occur easily, the fuel efficiency is low, and tail gas combustion is incomplete are overcome; and the friction coefficient between a piston ring and the inner wall of the cylinder sleeve is decreased, fuel is saved, and the service cycle of an engine is remarkably prolonged.

Owner:YANGZHOU UNIV

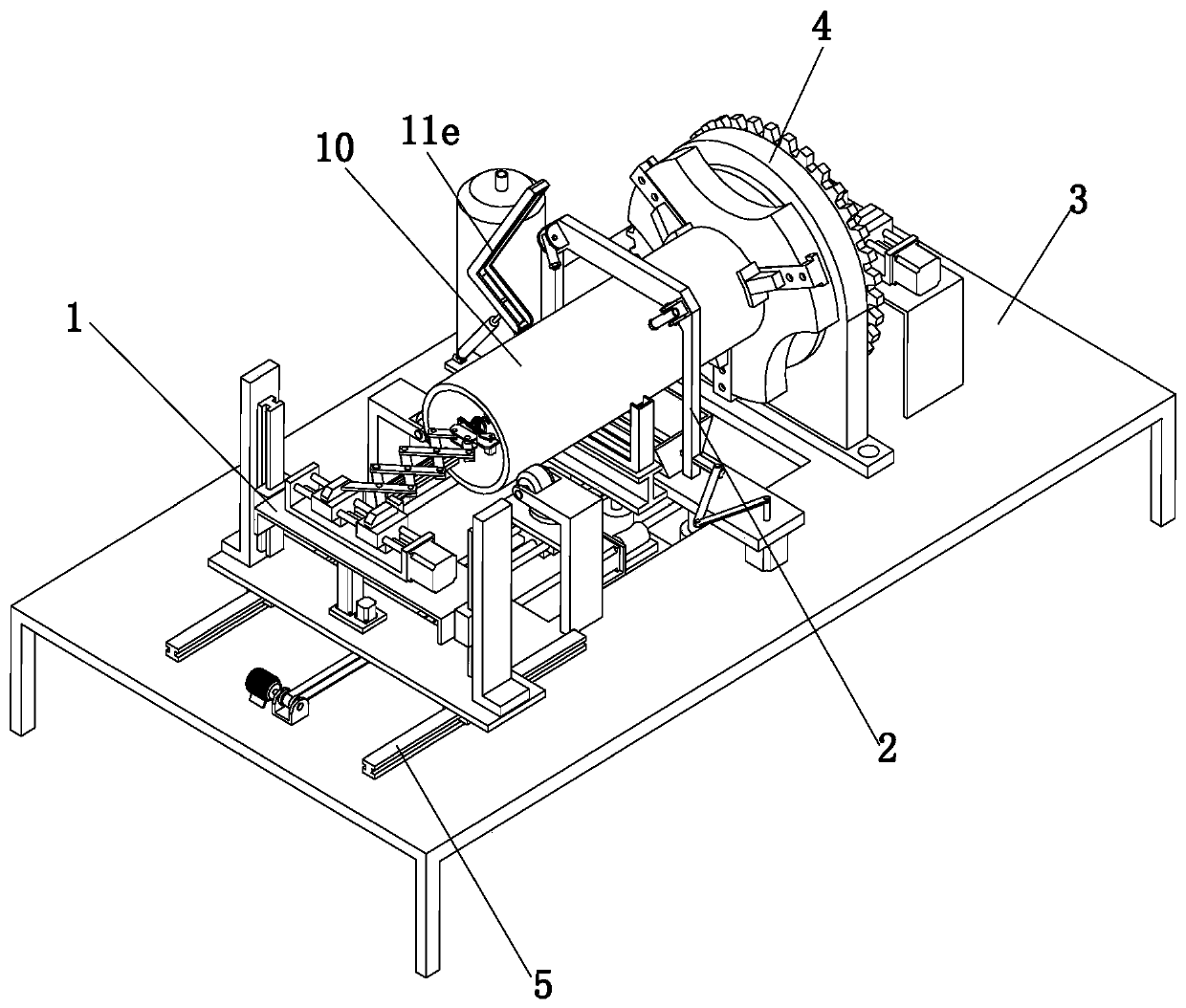

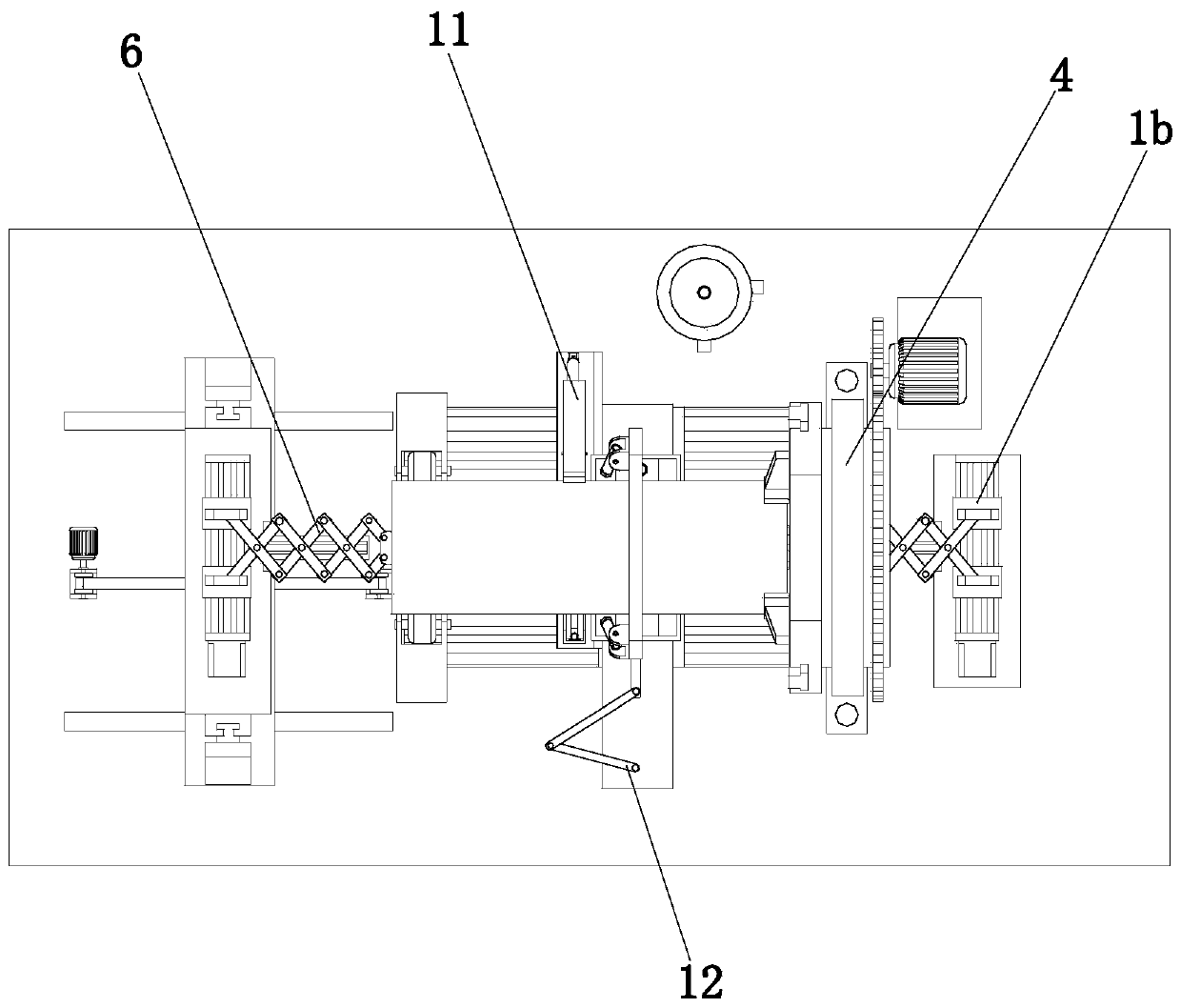

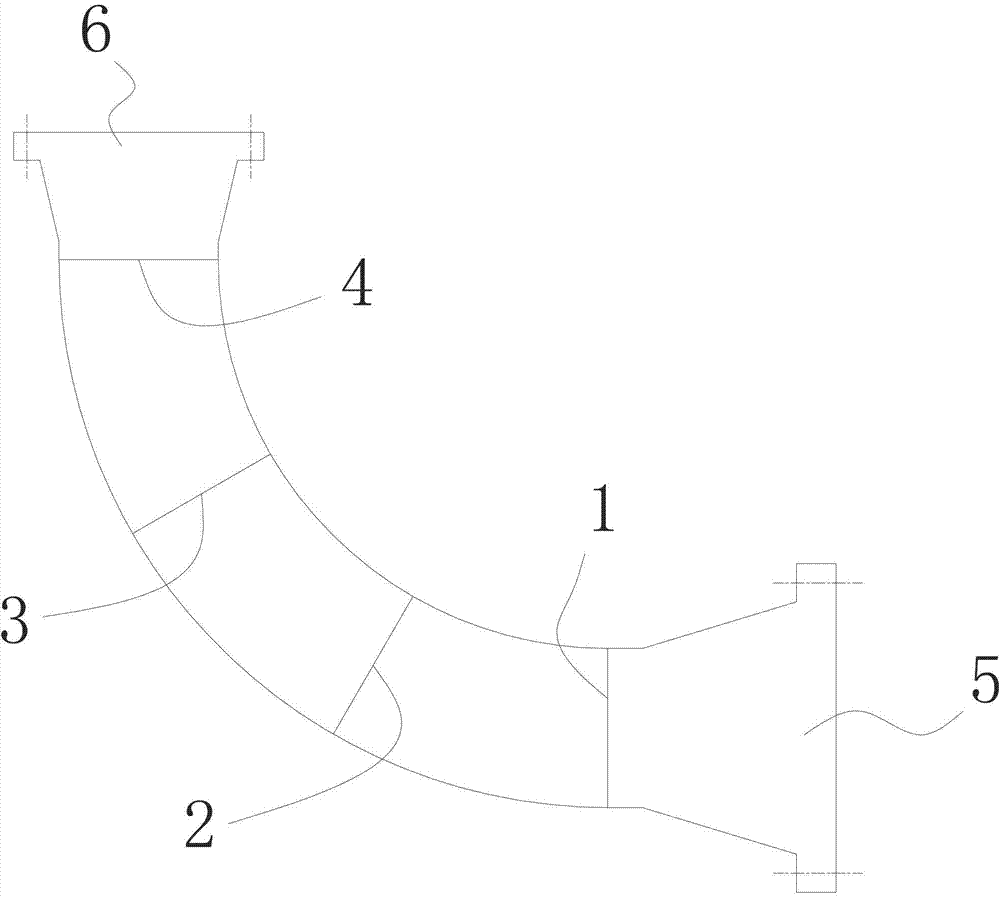

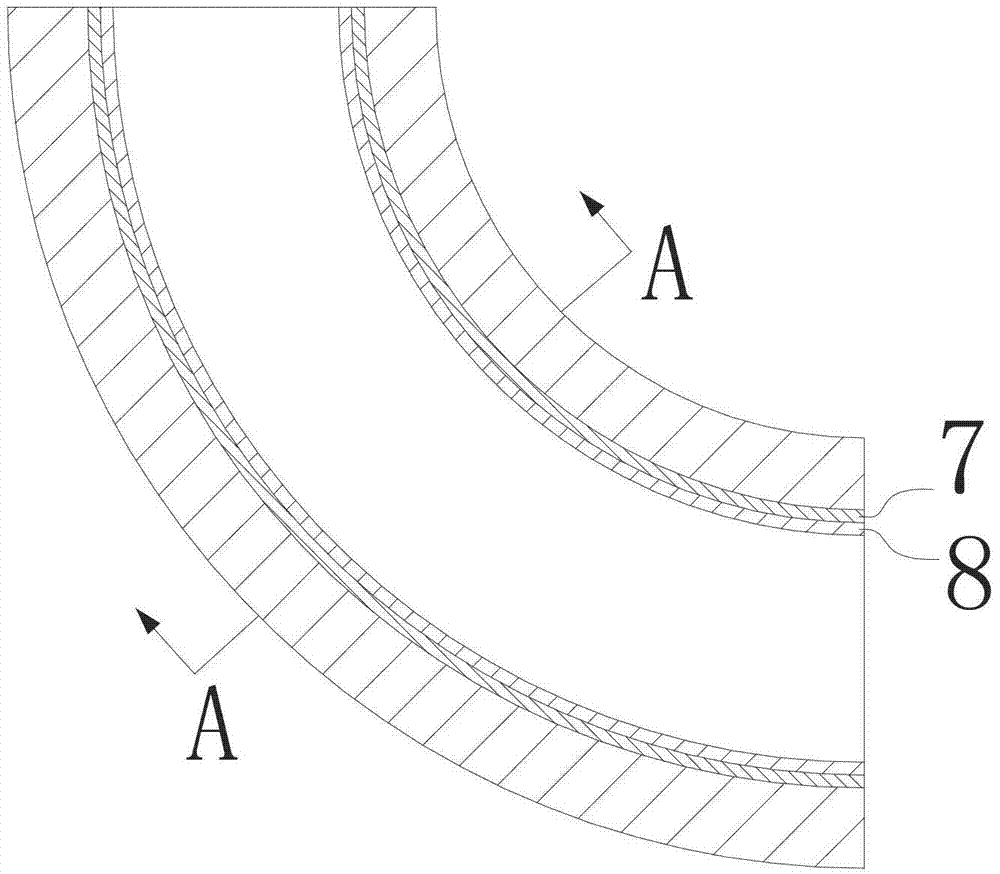

Bead-welding method of inner wall of 90-degree bent pipe

ActiveCN103170810AGuarantee product qualityReduce the amount of processArc welding apparatusEngineeringOvality

The invention discloses a bead-welding method of an inner wall of a 90-degree bent pipe for a large-scale pressure vessel, which can shorten the manufacturing cycle and effectively ensure the bead-welding quality of a transition layer and an anti-corrosion layer. The method is characterized in that the method comprises the following steps: a. selecting a pipe billet of a straight pipe; b. heating the pipe billet of the straight pipe in a furnace, taking out the heated pipe billet of the straight pipe, and performing compression moulding to the pipe billet on a pressing machine by a mould to form the 90-degree bent pipe, wherein the ovality of the formed 90-degree bent pipe is controlled to be less than or equal to 3%; c. performing bead welding to the surface of the inner wall of the formed 90-degree bent pipe by an automatic bead-welding machine for the inner wall of the bent pipe to form the transition layer; and d. performing bead welding to the surface of the transition layer to form the anti-corrosion layer by the automatic bead-welding machine for the inner wall of the bent pipe. According to the method, the pipe billet of the straight pipe is heated to be pressed into the 90-degree bent pipe, and then bead welding is directly performed in the 90-degree bent pipe to form the transition layer and the anti-corrosion layer, so that the working procedures can be greatly reduced, and the bend-welding quality of the transition layer and the anti-corrosion layer can be effectively ensured through ovality control.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Form fitting method of single laminating plate and inner wall

The invention relates to a form fitting method of a single laminating plate and an inner wall. The form fitting method comprises the following steps of 1, after binding of rebars of the inner wall andembedding of water and electricity, installing a formwork of the inner wall after the construction is qualified in acceptance; 2, building a support scaffold at the outer side of the formwork of theinner wall; 3, arranging an adjustable rubber strip at the top part of the formwork of the inner wall in the single laminating plate area, wherein the adjusting rubber strip is in an O shape and is made of rubber material; 4, lifting and mounting the laminating plate; 5, binding the rebars at the surface layer of the laminating plate; 6, embedding oblique support feet of an aluminum alloy wall formwork, checking the distance between oblique supports and the exposing length of a threaded opening of a bolt, taking reinforcing measure between the bolt and the rebar, and avoiding the displacementof the bolt in the concrete casting process; 7, pouring the concrete. The form fitting method has the advantages that the grout leakage of the concrete is prevented, and the certain economic benefit and social benefit are realized.

Owner:SHANGHAI BAOYE GRP CORP

Polishing device for inner wall of stainless steel pipe fitting

The invention belongs to the technical field of grinding for the interiors of pipes, and particularly discloses a polishing device for the inner wall of a stainless steel pipe fitting. The polishing device comprises a drive motor and a grinding bar and further comprises an eccentric wheel. The eccentric wheel is fixed to an output shaft of the drive motor. The grinding bar is fixed to the eccentric wheel. The distance between the rotating center of the eccentric wheel and the grinding bar is equal to the radius of the inner wall of the stainless steel pipe fitting. The grinding bar is hollow, grinding liquid is contained in the grinding bar, water outlet holes are formed in the grinding bar along the axis of the grinding bar, and a water inlet hole is formed in the end, close to the eccentric wheel, of the grinding bar. The grinding bar is made to stretch into the stainless steel pipe fitting, the eccentric wheel is driven by the drive motor to rotate and drives the grinding bar to rotate, the grinding bar is promoted to be in contact with the inner wall of the stainless steel pipe fitting, and therefore the inner wall of the stainless steel pipe fitting is ground. In addition, when the grinding bar rotates, grinding materials in the grinding bar are thrown out of the water outlet holes to impact the inner wall of the stainless steel pipe fitting under the action of centrifugal force.

Owner:重庆骏成机械配件有限公司

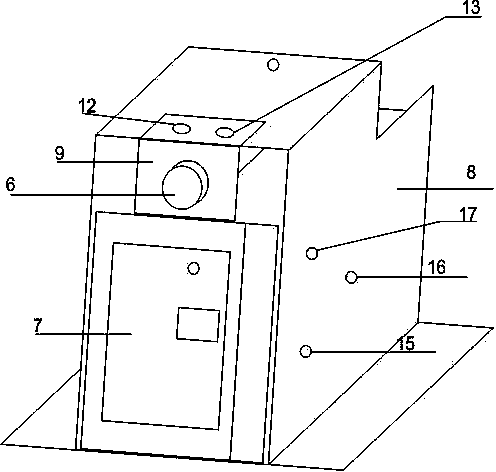

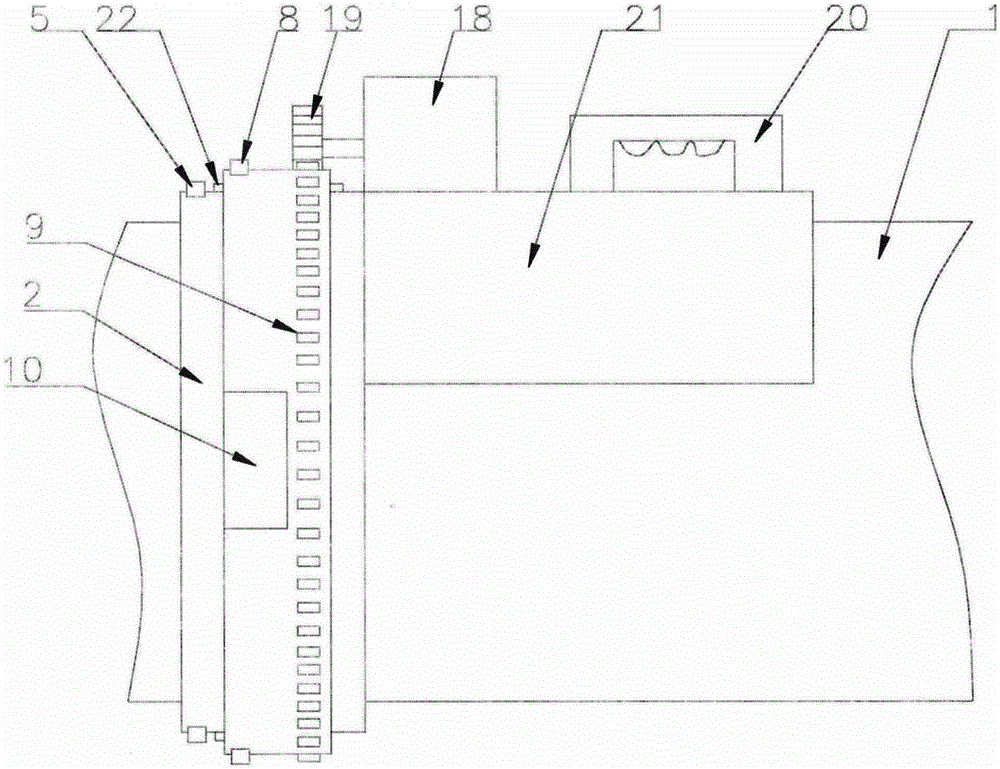

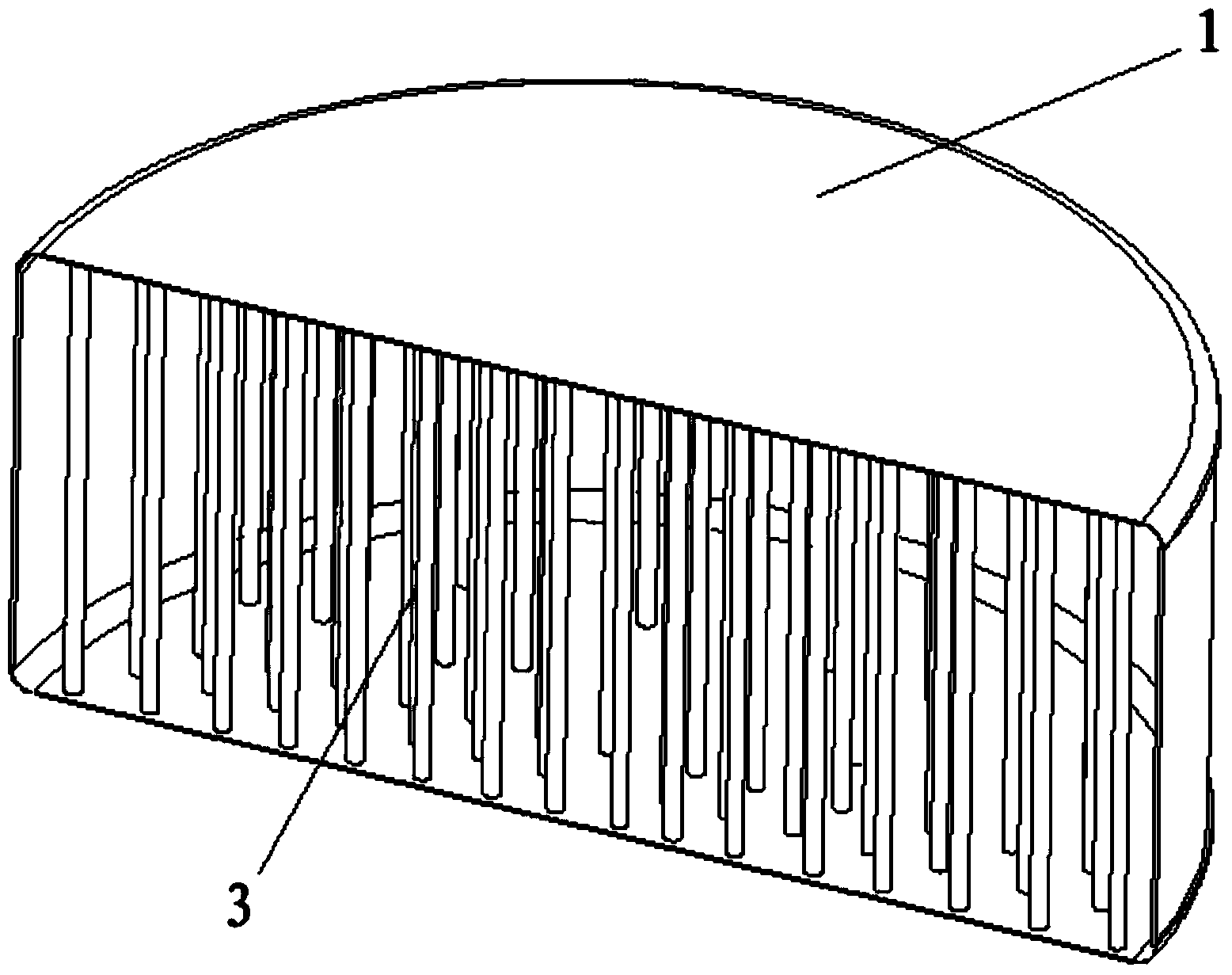

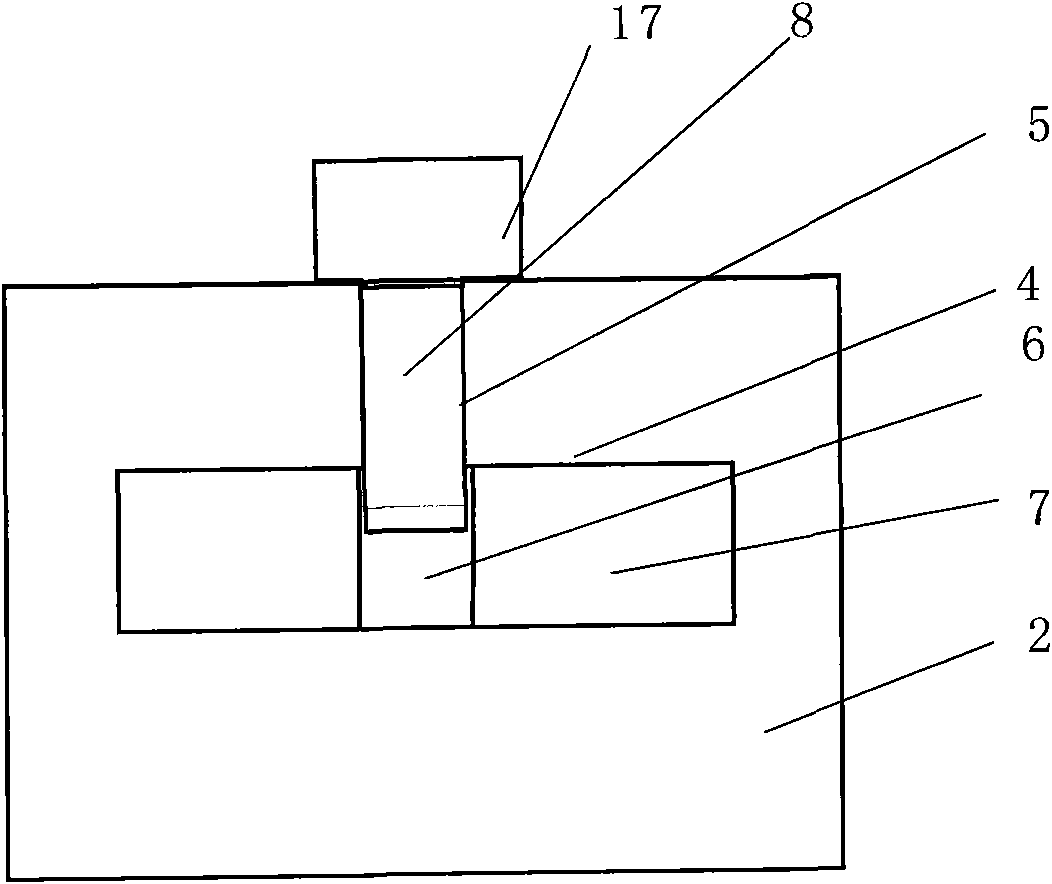

Movable execution system for on-line circumferential code spraying of inner wall of hollow cylindrical product

InactiveCN103481665AHeight adjustableGuaranteed uptimeTypewritersPower drive mechanismsThree-dimensional spaceDistance detection

The invention discloses a movable execution system for on-line circumferential code spraying of the inner wall of a hollow cylindrical product. The movable execution system comprises a base, a first transverse moving device which is arranged on the base, a first longitudinal moving device which is arranged on the first transverse moving device, a second transverse moving device which is arranged on the first longitudinal moving device, a circumferential rotating device which is arranged on the second transverse moving device, a second longitudinal moving device which is arranged on the circumferential rotating device, a product distance detection device which is arranged on the first longitudinal moving device, a jet printing distance detection device which is arranged on the circumferential rotating device, and a manipulator which is arranged on the side edge of the movable execution system. The movable execution system for on-line circumferential code spraying of the inner wall of the hollow cylindrical product is simple in structure and convenient to use, and five sets of movable devices are combined so that the purpose of moving at any position in three-dimensional space can be achieved.

Owner:合肥友高包装工程有限公司

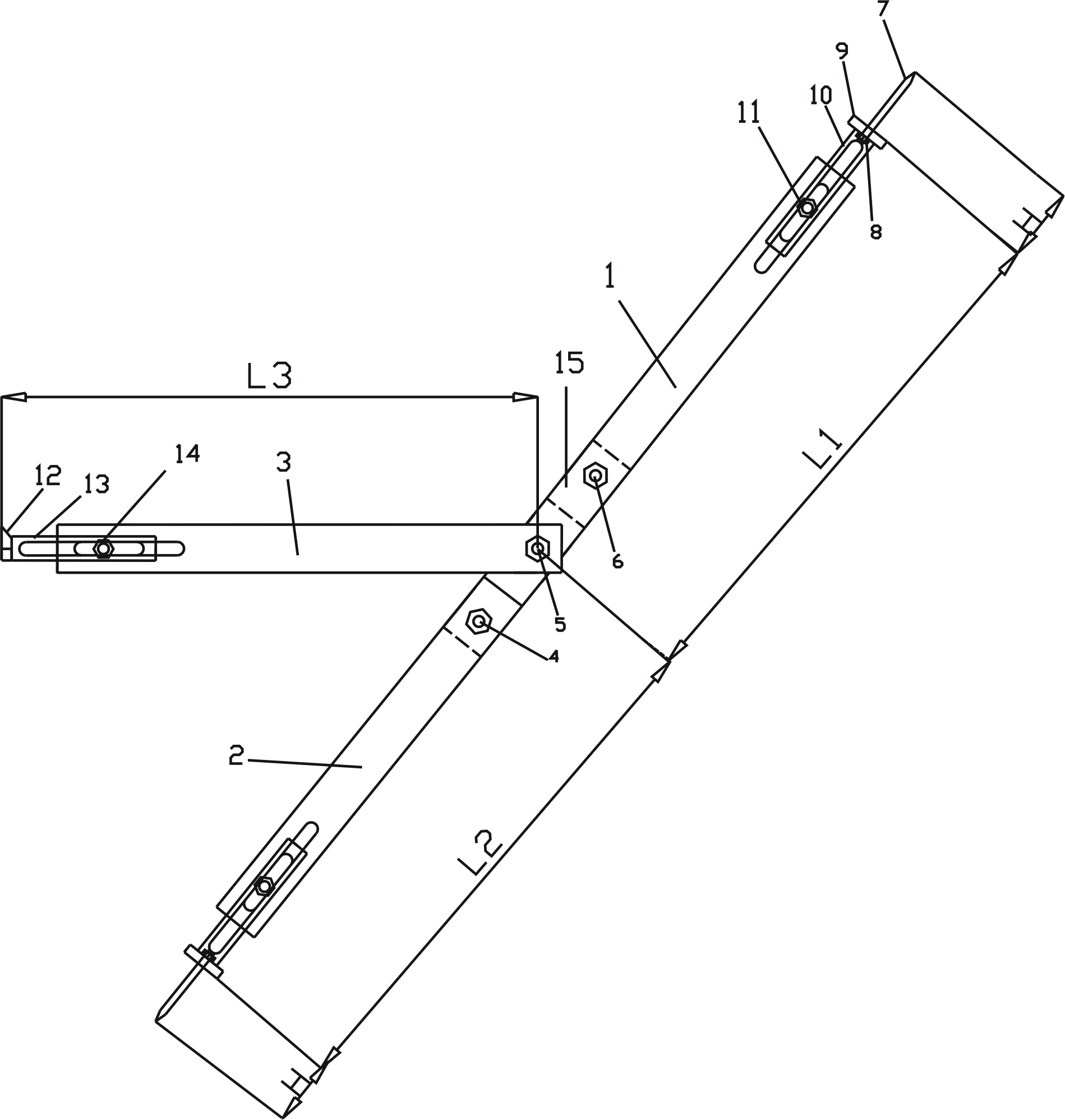

Detection control method for thickness of sprayed material on inner wall of pipeline

InactiveCN102205298AShorten detection timeShorten the timeLiquid surface applicatorsCoatingsEngineeringHinge point

The invention relates to a detection control method for the thickness of a sprayed material on the inner wall of a pipeline. The detection control method comprises the steps of: 1, regulating a detection control device for the thickness of the sprayed material on the inner wall of the pipeline so that the distance from a hinge point among a first fixing arm, a second fixing arm and a rotating armto the outer end of a fixing plate of a measuring needle is equal to a distance from the hinge point to the outer end of a scraper blade and is equal to the value obtained by dividing the difference of a diameter inside the pipeline and 2H by 2, enabling the distance from the outer end of a first fixed arm measuring needle fixing plate and the outer end of a second fixed arm measuring needle fixing plate to the front end of an adjustable measuring needle to be equal to H, wherein H is a design thickness of the sprayed material on the inner wall of the pipe; fixing the first fixed arm and the second fixed arm at a position with any diameter in the state of intersecting the first fixed arm and the second fixed arm for 180 DEG, detecting and correcting so that the thickness of the sprayed material at the diameter is equal to H; 3, rotating the rotating arm, detecting and scraping redundant sprayed material, recording a detecting result; 4, continuing spraying according to the detection result; 5, repeating the steps 3 and 4 until the thickness is qualified; and 6, taking out the detection control device. The method has the advantages of convenience for use, rapidness in detection, time and labor saving and wide application range.

Owner:CHINA FIRST METALLURGICAL GROUP

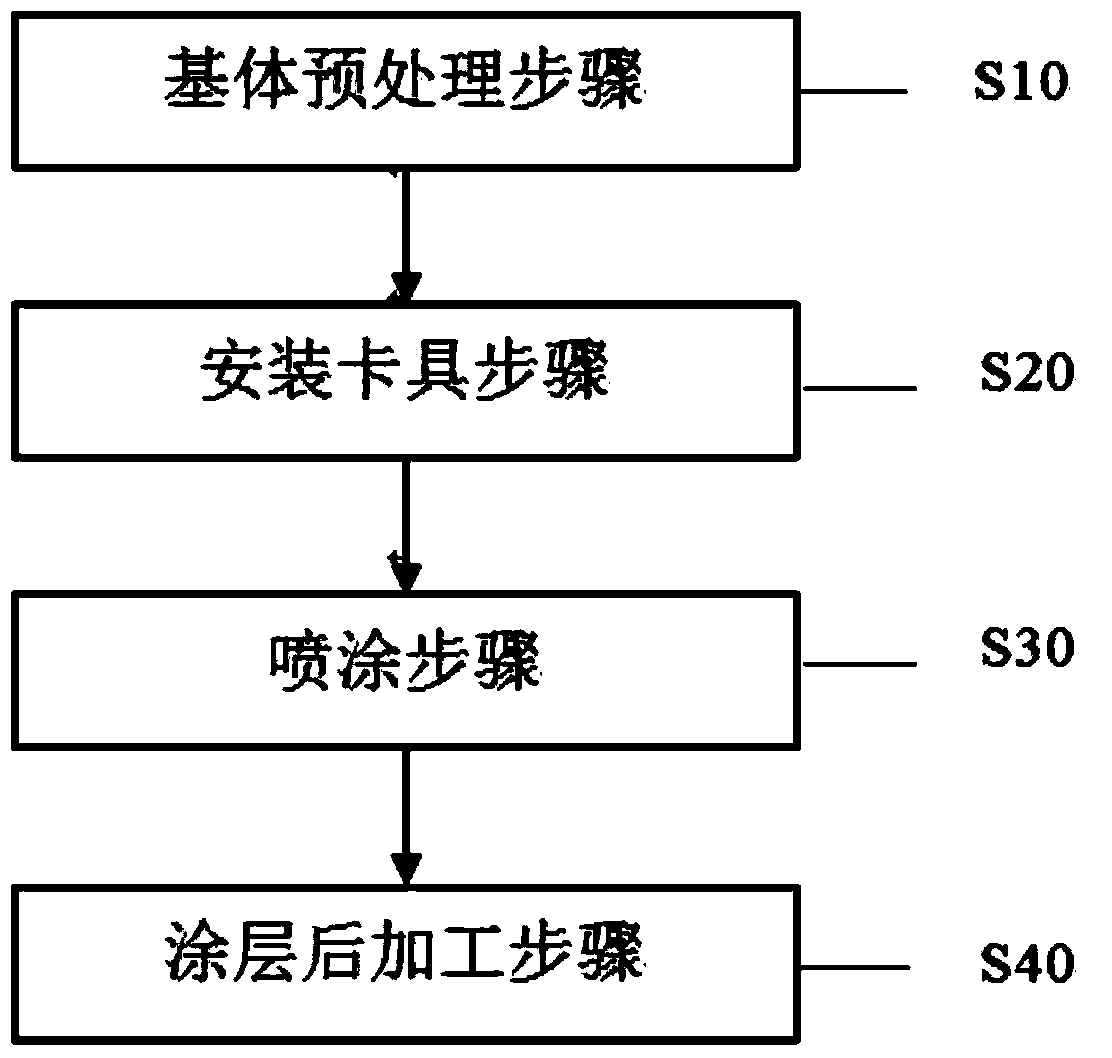

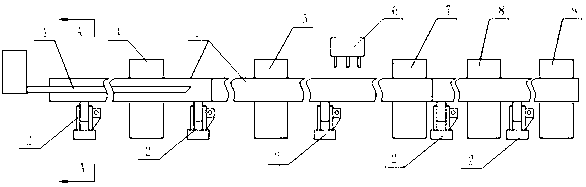

Technology for coating three-layer polyethylene structure on outer wall and fusing epoxy resin on inner wall of steel pipe

ActiveCN102837425AWon't breakGuaranteed uniformityLiquid surface applicatorsCoatingsEpoxyIntermediate frequency

The invention relates to a technology for coating a three-layer polyethylene structure on an outer wall and fusing an epoxy resin on an inner wall of a steel pipe. The technology comprises the following steps: performing shot-blasting treatment on the inner and outer walls of the steel pipe by using a shot-blasting machine, and then conveying the steel pipe by a conveying device; inserting the steel pipe into an intermediate-frequency induction furnace and heating, and then inserting a spray head at the front end of a spray gun into an inner front end of the steel pipe and spraying epoxy resin powder on the inner wall of the steel pipe; secondarily heating the advancing steel pipe; causing the steel pipe to continuously pass by an outer wall powder-spraying trolley, an adhesive winding machine and a polyethylene winding machine in turn; spraying the epoxy resin powder through the spray gun on the outer wall powder-spraying trolley; winding an adhesive film on the outer wall of the steel pipe through the adhesive winding machine; winding a polyethylene belt on the outer wall of the steel pipe through the polyethylene winding machine; conveying the steel pipe wound with the polyethylene belt by the conveying device; and utilizing the waste heat of the steel pipe to flow evenly and solidify. The inner wall of the steel pipe manufactured by utilizing the technology has excellent anti-corrosion property for resisting acid-base salts and the outer wall has characteristics of excellent corrosion resistance, acid-base resistance, ageing resistance and mechanical shock resistance.

Owner:WEIFANG EAST PIPE IND TECHNICAL CO LTD

Pipe inner wall washing device

The invention discloses a pipe inner wall washing device. The pipe inner wall washing device comprises a sealing base, a battery installing bin, a motor and washing blades which arranged in a pipe to be washed, wherein one end of the sealing base is connected with a push rod for pushing the sealing base to advance along the inner wall of the pipe to be washed, the battery installing bin is installed at the other end of the sealing base, a battery pack for supplying power for the motor is arranged inside the battery installing bin, the motor is fixedly installed on the sealing base, and the washing blades are fixedly installed on an output shaft of the motor and wash the inner pipe of the pipe to be washed. The pipe inner wall washing device adopts a mechanical washing method of the micro motor, is simple in structure, low in cost, flexible in using mode, high in flexibility and good in using effect and has good application prospect.

Owner:XIAN JINHE OPTICAL TECH

Cleaner for inner wall of steel pipe

InactiveCN101890416BReasonable structureSimple structureHollow article cleaningArchitectural engineeringSteel tube

The invention relates to a cleaner for the inner wall of a steel pipe, which comprises a water pump and a four-way reversing valve, wherein the four-way reversing valve is provided with a water inlet pipe, a drain pipe, a left connecting pipe and a right connecting pipe; the end parts of the two connecting pipes are respectively connected with a casing pipe; a cavity, which is communicated with the connecting pipes, is arranged in the casing pipe; the front end of the casing pipe forms a socket which matches with the end part of the steel pipe; and the cavity is communicated with the socket. The invention has a reasonable and simple structure, and is especially suitable for long thin stainless steel coil pipes. The actions of the water pump and the four-way reversing valve can circularly clean the inner wall of the steel pipe, thereby enhancing the efficiency; and the clamping mechanism can clamp the steel pipe, thereby greatly enhancing the production safety. The complete device is simple and convenient to operate, lowers the production cost, enhances the safety and is suitable for popularization.

Owner:ZHEJIANG JINGNING CLEAN STEEL PIPE

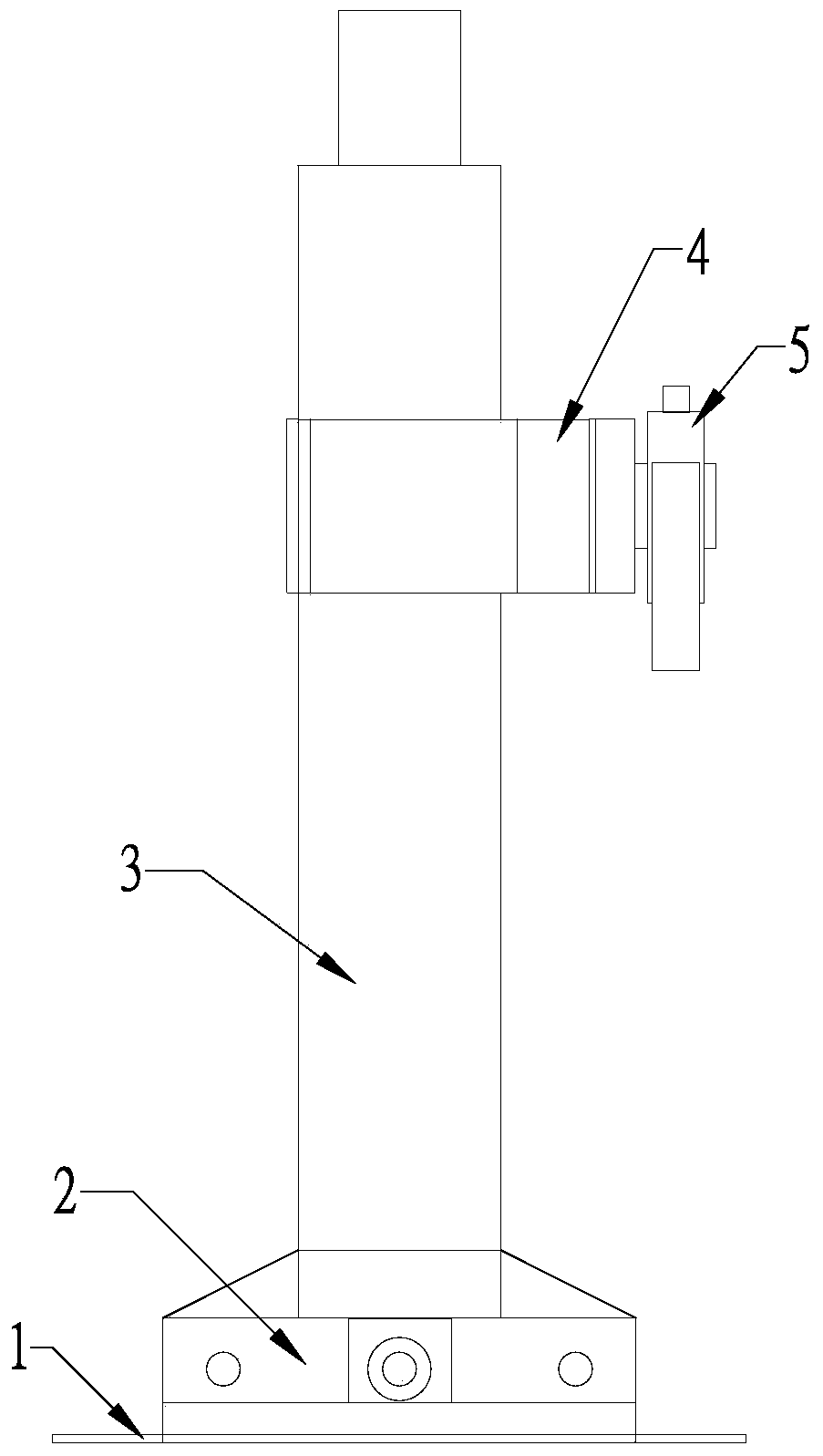

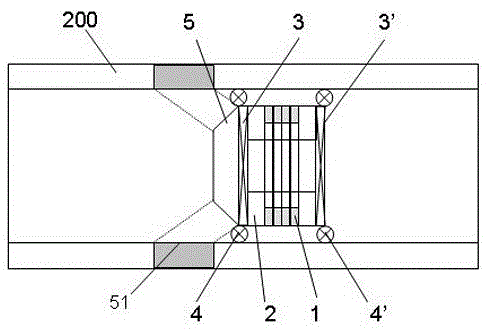

Method and device for improving hardness of inner wall of steel tube

ActiveCN105648190AExtended service lifeStay resilientFurnace typesIncreasing energy efficiencyInduction hardeningMechanical property

The invention provides a method and device for improving hardness of the inner wall of a steel tube. A scanning type induction hardening process is adopted, heat treatment is carried out on the inner wall of the whole steel tube, an induction coil is placed on the steel tube, and the steel tube rotates and relatively moves relative to the induction coil; in the process that the steel tube and the induction coil relatively move, the induction coil is powered on to heat, and the heated steel tube is instantly subject to water spraying cooling after heating; the heating frequency is selected to range from 500 Hz to 2000 Hz; and the speed of movement of the steel tube relative to the induction coil is between 3 mm / s and 6 mm / s, and the rotating speed of the steel tube ranges from 5 rpm to 20 rpm. Compared with a conventional manner that heat treatment is carried out on the steel tube or the steel tube is not treated, the skin effect of induction heating is used, in the heating process, the temperature of the inner wall of the steel tune is high, the temperature of the outer wall is low, and a temperature gradient is formed; after water spraying cooling is carried out, the aim of improving the hardness and the abrasive resistance of the inner wall is achieved; and meanwhile the outer wall basically keeps mechanical properties of toughness, strength and the like of an original matrix structure.

Owner:BAOSHAN IRON & STEEL CO LTD

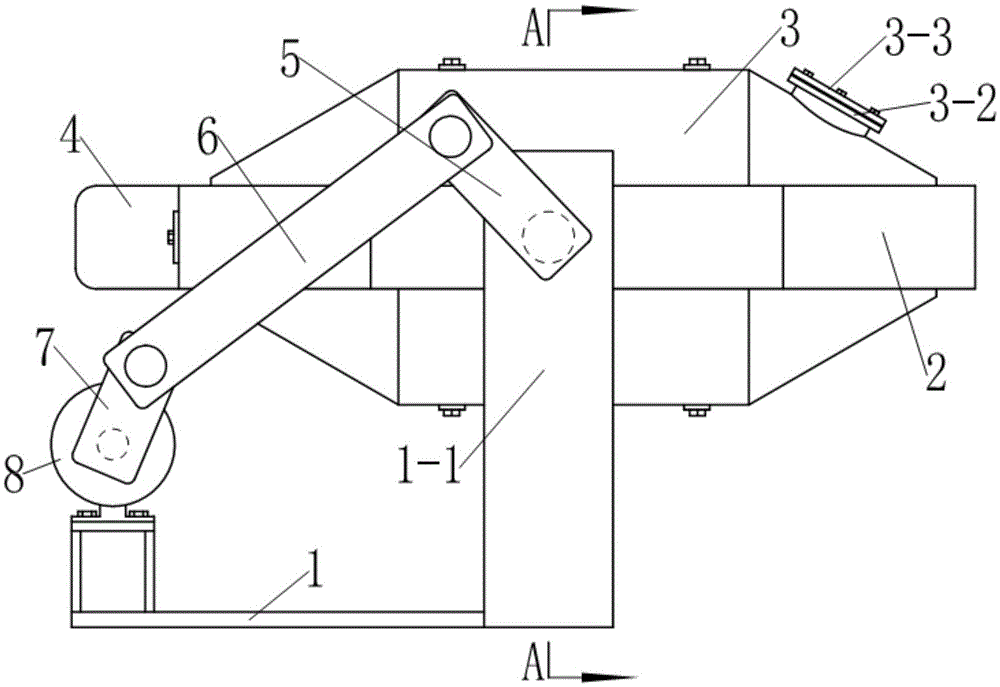

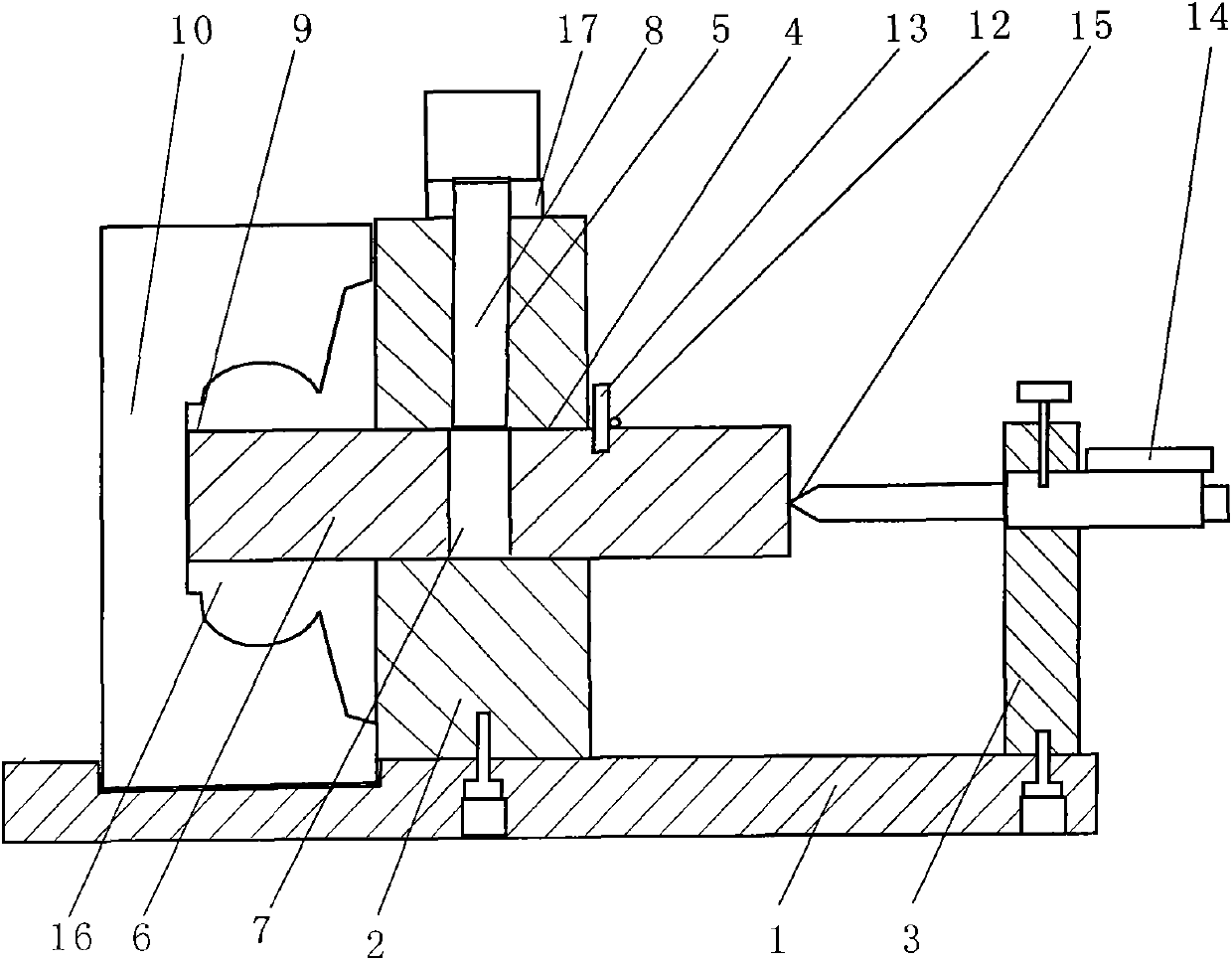

Detection device for center distance of circular arcs on two sides of inner wall of piston bridge and application method of detection device

InactiveCN102003928AEasy to operateImprove detection accuracyMechanical clearance measurementsMeasurement deviceWorkbench

The invention discloses a detection device for center distance of circular arcs on two sides of the inner wall of a piston bridge, which is provided with a workbench, wherein a locating stopper and a meter frame are arranged on the workbench; the locating stopper is provided with a notch and a shaft hole; the shaft hole penetrates through the locating stopper from the top to the notch; a detection sliding block is inserted into the notch; the detection sliding block is provided with a locating hole; the detection end of the detection sliding block is a circular arc of which the radius is equal to the standard radius of the circular arcs on the two sides of the inner wall of the piston bridge; a locating core shaft is arranged in the shaft hole; a length measuring device is fixed on the meter frame; and a spring is fixed on the locating stopper. The application method comprises the following steps: inserting the locating core shaft into the shaft hole, locating the detection sliding block, and adjusting the reading of the length measuring device to zero; and lifting the locating core shaft, and abutting the swash plate socket of the piston against the detection sliding block, thus the reading of the length measuring device is the error of the center distance between circular arcs on the two sides of the inner wall of the piston bridge. The detection device and method have the advantages of high detection precision, are convenient in operation, and can meet the requirements for industrial production.

Owner:浙江春晖空调压缩机有限公司

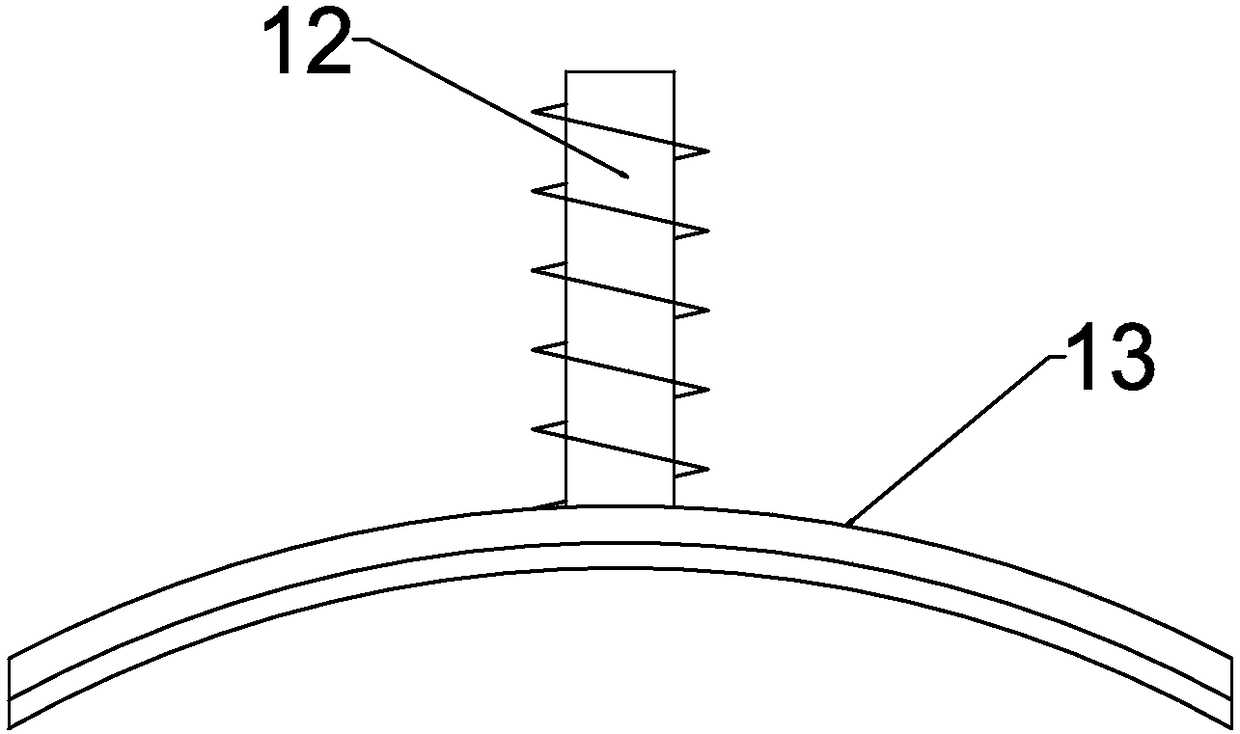

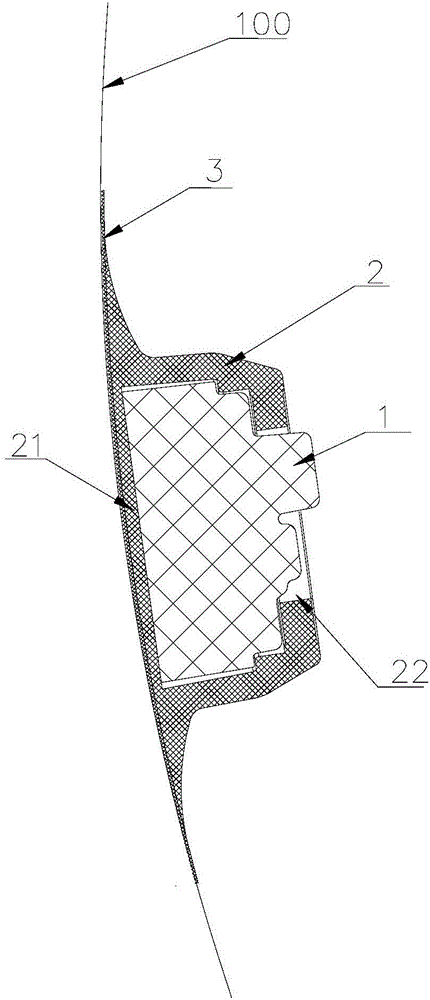

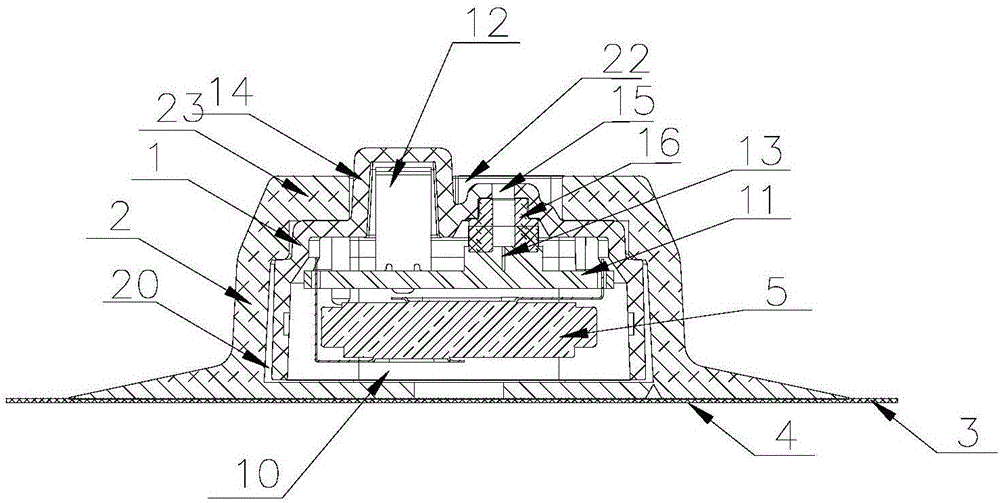

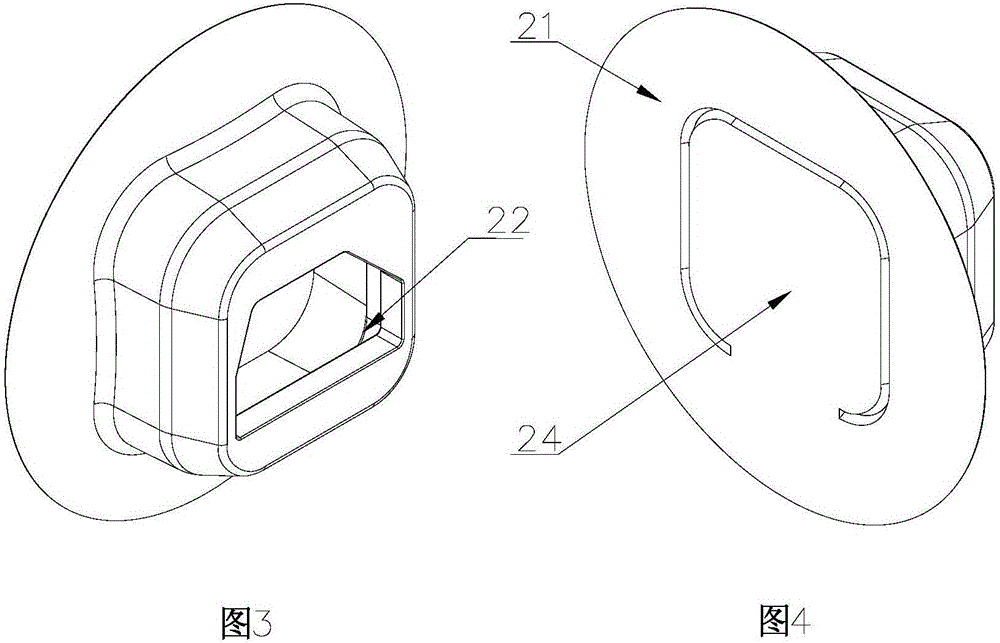

Tire pressure monitoring device bonded with inner wall of outer tube

InactiveCN106080056AEasy to fixWork reliablyTyre measurementsEngineeringTire-pressure monitoring system

The invention provides a tire pressure monitoring device bonded with the inner wall of an outer tube. The tire pressure monitoring device comprises a sensor electronic box, a rubber cover and a bonding layer, wherein the electronic box is used for installation of electronic elements of the tire pressure monitoring device; and the rubber cover is provided with an inner space for installation of the electronic box and a bottom surface larger than the cross section of the inner space in area, and the bottom surface is further provided with the bonding layer larger than the bottom surface in area. The tire pressure monitoring device can be reliably fixed to a crown of a tire, can work reliably, is long in service, coexists with the tire, and is sensitive in signal transmitting and receiving.

Owner:HAMATON AUTOMOTIVE TECH CO LTD

Wall surface painting device adapting to different wall surfaces

InactiveCN108756169AQuality improvementAvoid rapid cakingBuilding constructionsExtreme weatherArchitectural engineering

The invention discloses a wall surface painting device adapting to different wall surfaces. The wall surface painting device adapting to the different wall surfaces includes a box body. A long plate is fixedly connected between two sides of the inner wall of the box body, two sides of the top of the long plate are fixedly connected with support plates, and one sides of the support plates are connected with rotary rods in a rotating mode. One ends the rotary rods penetrate through the support plates and the box body in sequence and extends to one side of the box body. The bottom of the inner wall of the box body is fixedly connected with a painting box, and the bottom of the inner wall of the painting box is fixedly connected with a material suction pump. A discharge port of the material suction pump communicates with a first discharge pipe. The invention relates to the technical field of painting. The wall surface painting device adapting to the different wall surfaces can paint automatically through the rolling of a rolling brush, and can spray and paint at the same time, the situation that the painting is caked rapidly in extreme weather can be effectively avoided, the quality ofthe wall surface painting is improved, the speed of the painting can be greatly improved by using double rolling wheels, the work efficiency is improved, the labor time of painting is reduced, and the painting efficiency is improved.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

Inner wall finishing device for interior trim of building

InactiveCN109403602AEasy continuous coatingImprove practicalityBuilding constructionsDrive shaftEngineering

The invention relates to the technical field of decoration and finishing accessory devices for buildings, in particular to an inner wall finishing device for interior trim of a building. The inner wall finishing device for interior trim of the building can mix needed coating conveniently according to application requirements, and painting and covering of an inner room wall along a straight line can be performed conveniently, and further convenient to paint and cover continuously without dipping the coating. The inner wall finishing device for interior trim of the building comprises a connecting rod, a connecting plate, a left fixing plate, a right fixing plate, two sets of fixing shafts, roller shafts, a coating brush, a mixing box, a first feeding pipe, a second feeding pipe, a first transmission pump, a second transmission pump, a first circulation pipe, a second circulation pipe, a plurality of sets of supporting rods, a protective box, a motor, a transmission shaft, a plurality ofsets of stirring blades, a base plate, a movable pipe, two sets of connecting shafts, a movable rod, a supporting plate, a fixing rod, two sets of fixing nuts, a feed delivery pipe, a feed delivery pump, a one-to-two joint, a left flow dividing pipe and a right flow dividing pipe, wherein two sets of fixing rings are arranged at the top end of the movable rod.

Owner:史寿福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com