Tire pressure monitoring device bonded with inner wall of outer tube

A tire pressure monitoring and bonding layer technology, applied in tire measurement, tire parts, transportation and packaging, etc., to achieve long service life, reliable operation, and sensitive signal transmission and reception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

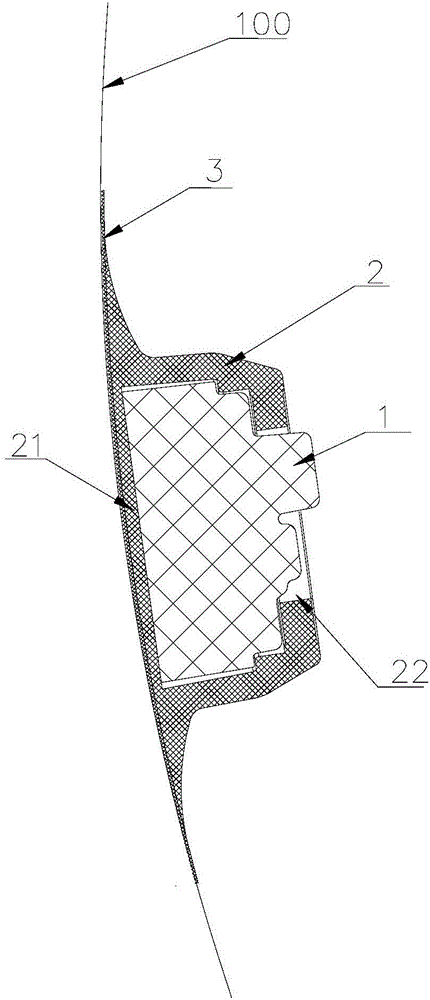

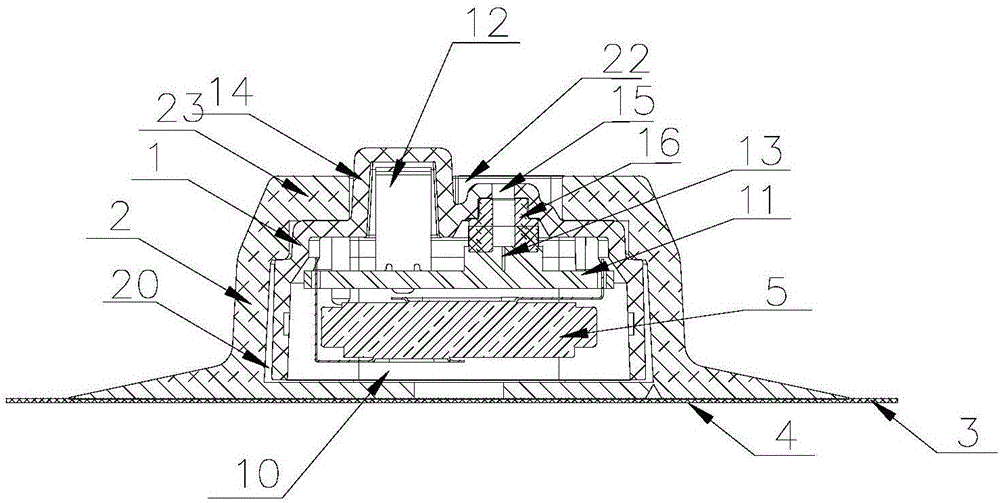

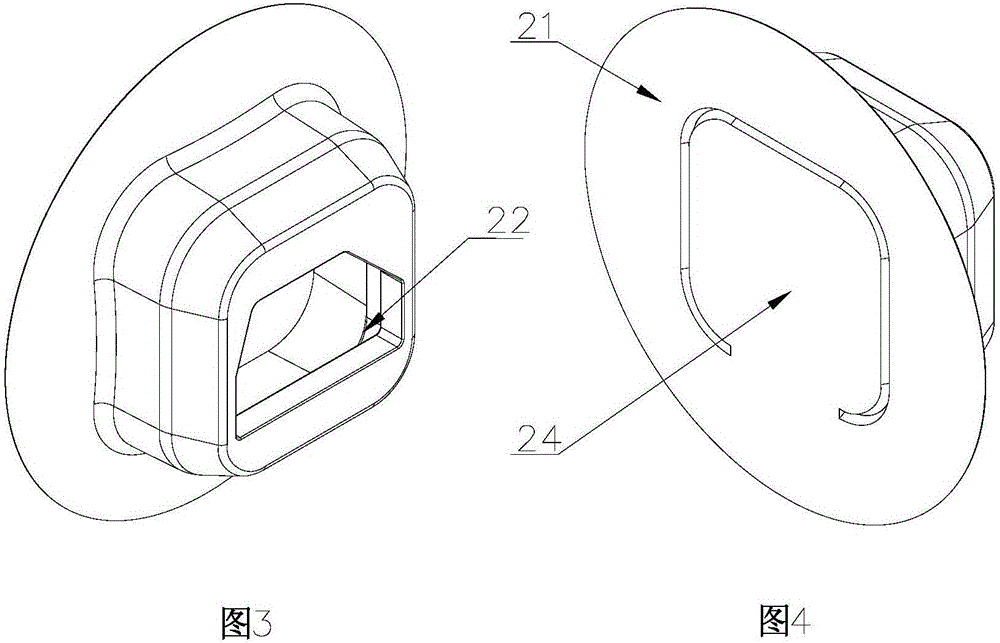

[0017] Refer to attached picture. A tire pressure monitoring device adhered to the inner wall of the tire provided by the present invention includes a sensor electronic box 1, a rubber cover 2, and an adhesive layer 3. The electronic box 1 is used for installing electronic components of the tire pressure monitoring device. The rubber cover 2 is provided with an inner space 20 for installing the electronic box 1 and a bottom surface 21 with an area larger than the cross section of the inner space, and an adhesive layer 3 with an area larger than the bottom surface on the bottom surface 21 . The size of the inner space is slightly smaller than that of the electronic box, and the electronic box is clamped tightly in the inner space by using the deformation ability of the rubber.

[0018] The cross-sectional shape of the inner space 20 is roughly rectangular, and the contour of the bottom surface 21 is circular or elliptical.

[0019] The bottom surface 21 is a grinding surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com