Patents

Literature

208results about How to "Avoid affecting the machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

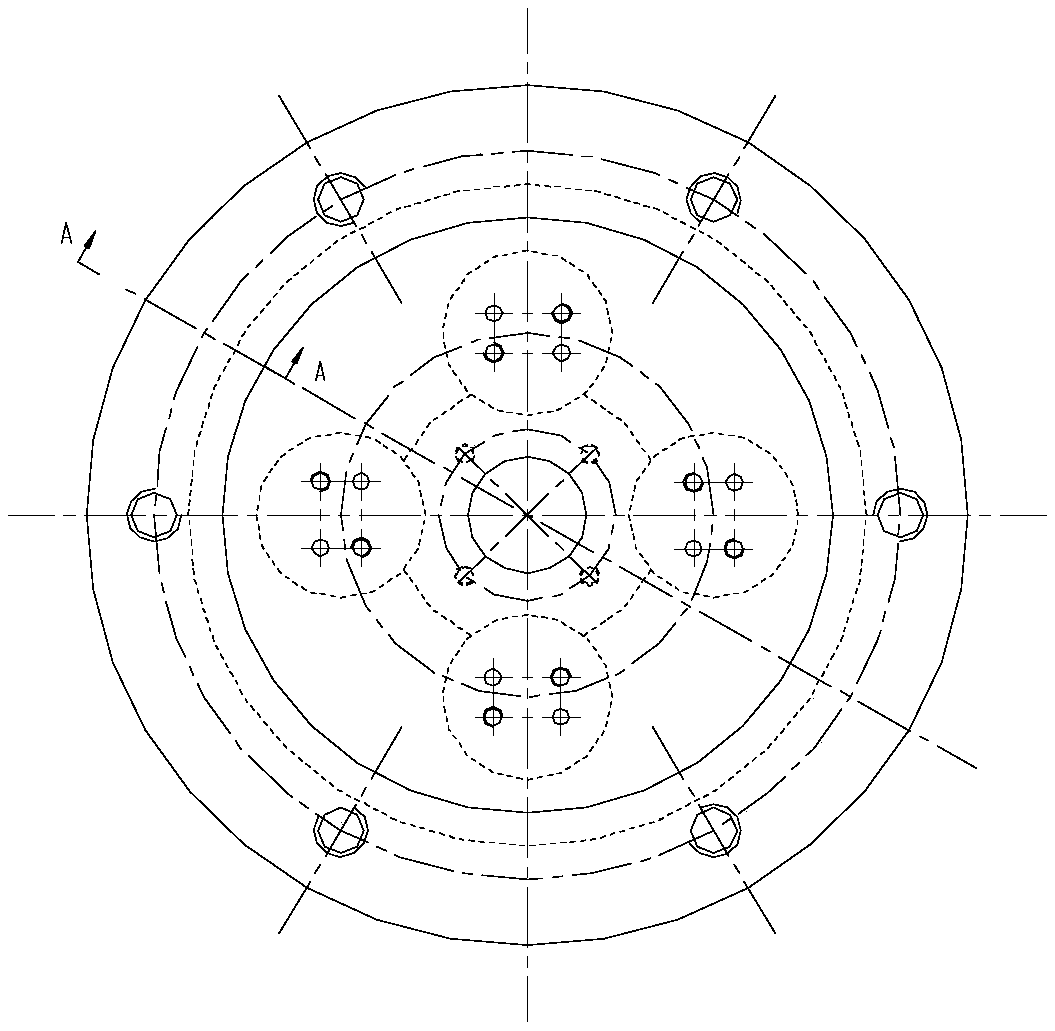

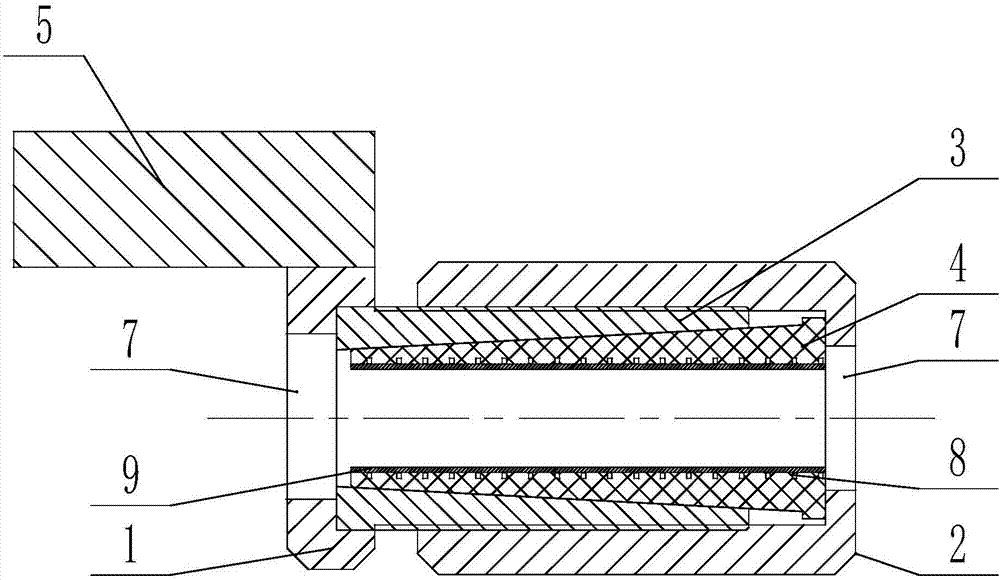

Hub lathe jig

InactiveCN102211209AQuick positioning clampingGuaranteed machining accuracyPositioning apparatusTurning machinesHydraulic cylinderEngineering

The invention provides a hub lathe jig, relating to a jig for the field of machining. The hub lathe jig comprises a positioning disc, a clamping pull head, a supporting sleeve, a tensioning spacer and a pull tube, wherein the positioning disc comprises a main body part and a positioning part, wherein the main body part is connected to a lathe principal shaft, and the positioning part protrudes out of one end of the main body part to position a hub bearing hole; the clamping pull head comprises a connecting shaft and a positioning shaft, wherein the connecting shaft is arranged in a through hole of the positioning disc, the positioning shaft is connected to one end of the connecting shaft, which is far away from the positioning disc, the end part of the connecting shaft is inwards concavely provided with a connecting hole, the positioning shaft is inwards concavely provided with an annular groove near the tail position of a free end, and a protruded clamping part is formed at the outer side of the groove; the supporting sleeve is sleeved on the surface of an excircle positioned at the inner side of the annular groove of the positioning shaft, the outer surface of the supporting sleeve is matched with the inner surface of one of inner holes of a hub, and the end surface of the inner side of the supporting sleeve is clamped on the end surface of the inner side of the inner hole of the hub; the tensioning spacer is arranged in the annular groove and clamped with the end surface of the outer side of the supporting sleeve; one end of the pull tube is connected with the connecting hole of the connecting shaft of the clamping pull head, and the other end of the pull tube is connected with a hydraulic cylinder.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

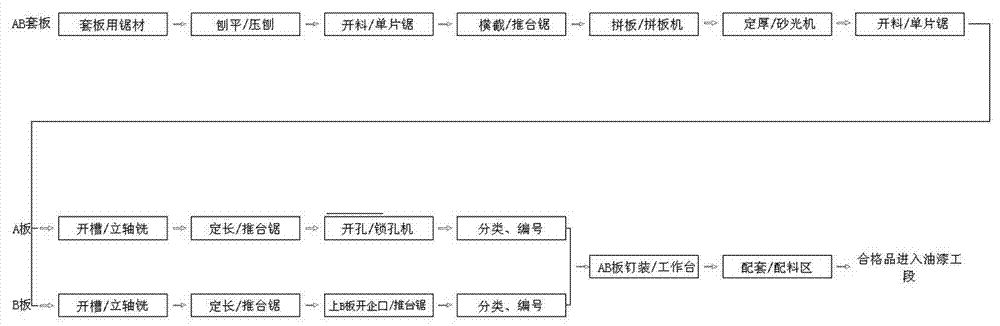

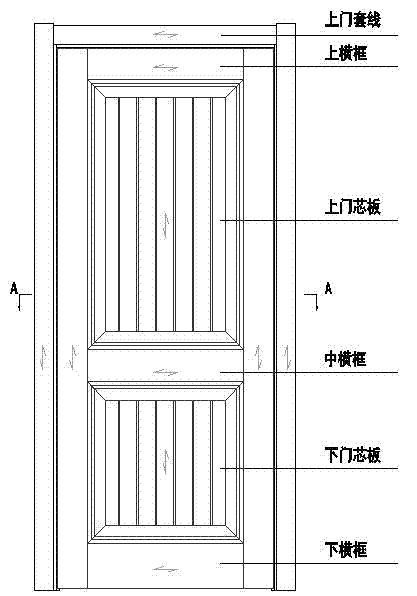

Manufacturing process of raw wood door

ActiveCN104760108AReduce the probability of shrinkage seamsAvoid late cracking defectsWood working apparatusParticulatesPollution

The invention provides a manufacturing process of a raw wood door. The manufacturing process comprises the steps of (1) synchronously preparing a door leaf, a plate A, a plate B and a door cover line; (3) painting through a paint room after preparing the parts above; maintaining; matching; warehousing a packing box. The raw wood door manufactured by the process has the advantages that the probability of contraction joints of the wood door in later use can be greatly reduced, and moreover, the defect of cracking of the raw wood door in later period can be avoided the pollution of air, in particular particles can be minimized according to the manufacturing process; 100% of high gloss paint can be achieved; 30% of energy charge can be saved; the environment is improved by 40%; operators can be protected well.

Owner:JIANGSU KENTIER SENGONG TECH

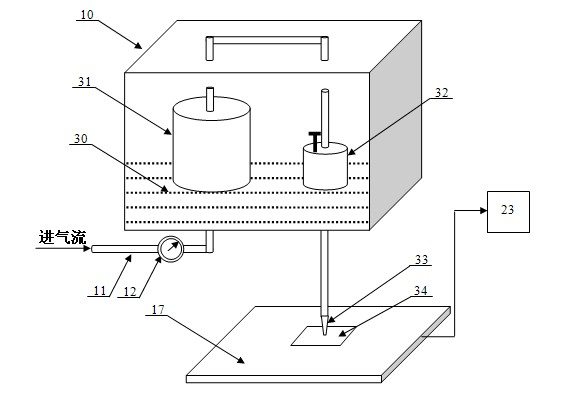

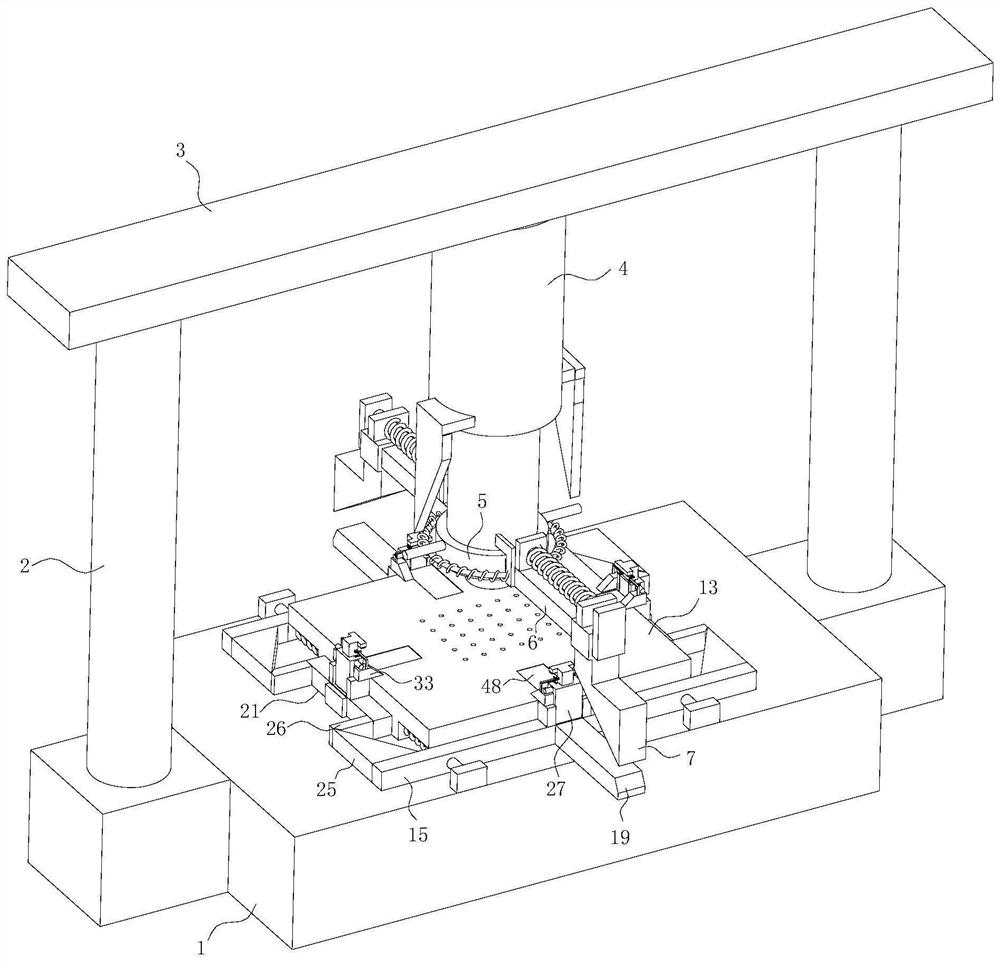

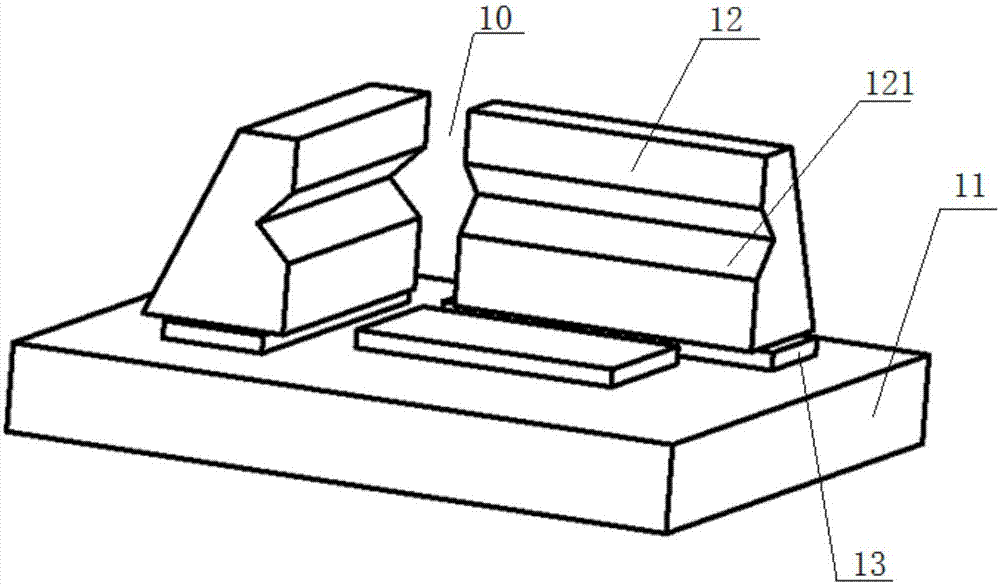

Special equipment for laser micro-cladding

ActiveCN102011123AShorten processing timeGuaranteed accuracyMetallic material coating processesLaser beam welding apparatusOptical pathPhysics

The invention discloses special equipment for laser mirco-cladding. The equipment comprises a workbench, a laser processing system and a control system, and is characterized by also comprising a charge coupled device (CCD) monitoring and positioning system and a direct writing system, wherein the CCD monitoring and positioning system comprises a coaxial CCD sensor, a paraxial CCD sensor, a zoom lens, an imaging eye lens, a zoom optical system, a paraxial imaging object lens and an external monitor; the direct writing system comprises a micro-pen direct writing device and a micro-jet direct writing device; the micro-pen direct writing device comprises a support, a guide rail, a cylinder, a slider, a piston rod, a dial gauge, a micro adjustment nut and a micropen; and the micro-jet direct writing device comprises a water bath kettle, a gas-guide tube, a micro-pressure gauge and a micro-jet tool. In respect of the equipment, a laser optical path and the installation stations and working modes of the micro-jet direct writing device and the micropen are reasonably designed, and laser processing, the micropen and the micro-jet direct writing system are integrated on the same working platform, thereby realizing advantage complementation of various processing methods.

Owner:HUAZHONG UNIV OF SCI & TECH

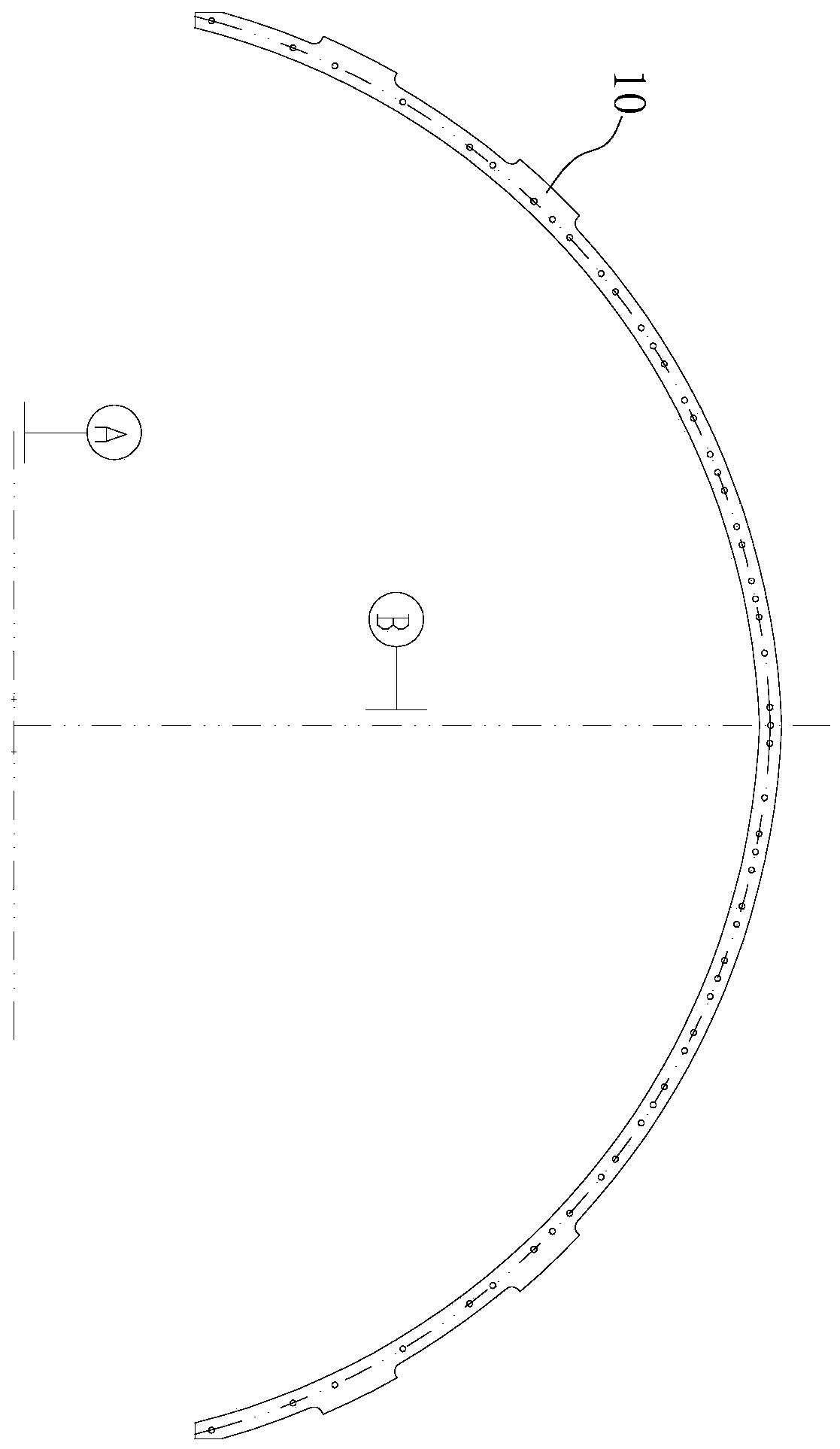

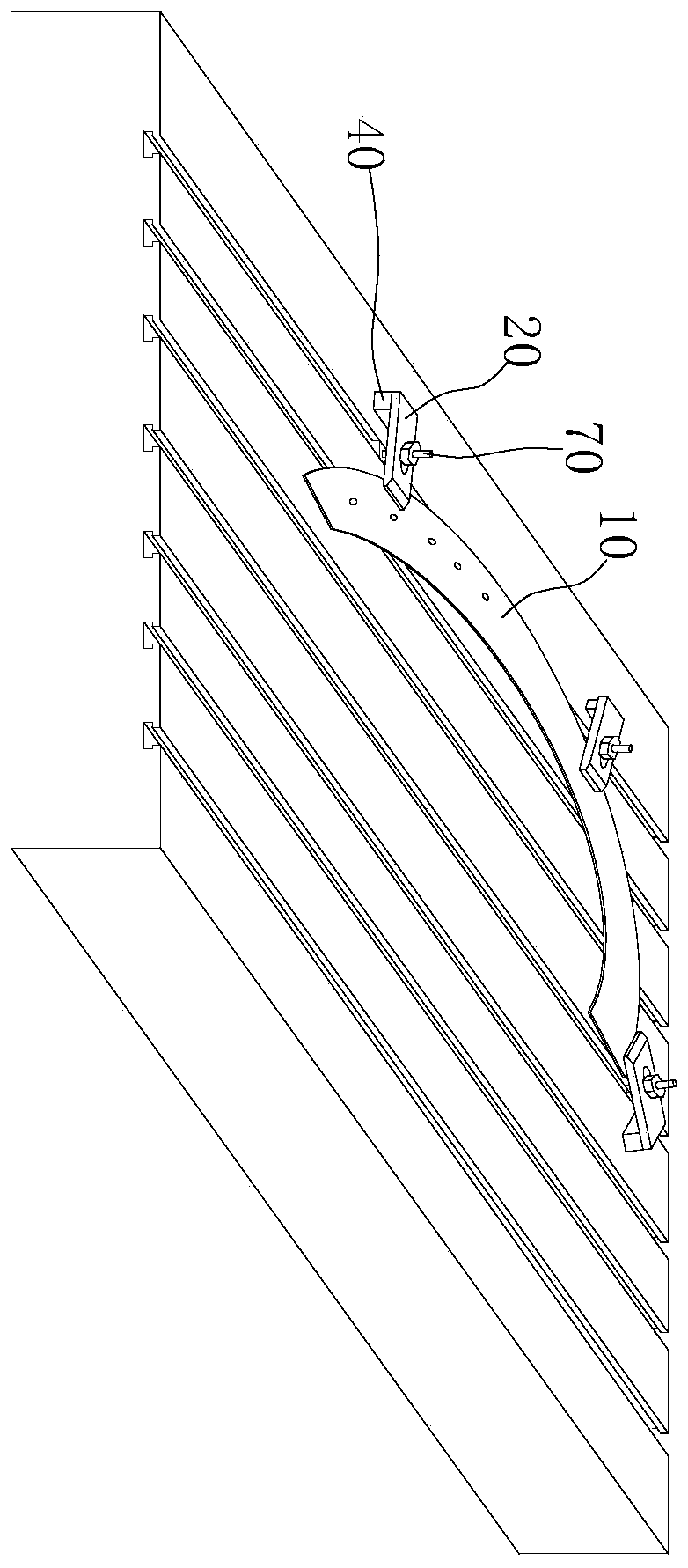

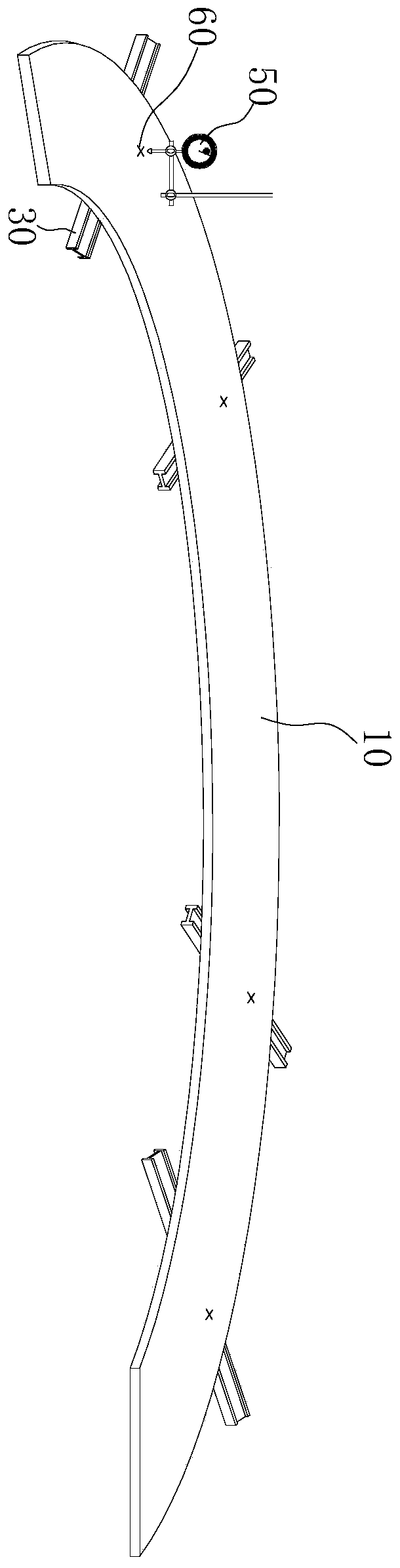

Machining method for series holes of large-size thin-walled bow-shaped part

InactiveCN110977330AAvoid affecting the machining accuracyReduce distortionMeasurement/indication equipmentsPositioning apparatusNatural agingMachining

The invention discloses a machining method for series holes of a large-size thin-walled bow-shaped part. The machining method comprises the following steps: blanking, shape rough-milling, natural aging, shape semi-finish-milling, natural aging, finish-milling of the upper surface and finish-boring. According to the machining method of the series holes of the large-size thin-walled bow-shaped part,natural aging is increased between rough-milling and semi-finish-milling as well as between semi-finish-milling and finish-milling machining so as to release cutting stress, reduce deformation of a workpiece and avoid affecting the machining precision of subsequent boring, and hole milling is replaced with boring to reduce the cutting stress; and during finish-boring, the workpiece is clamped, before the workpiece is compressed, all compressing points are detected by a dial indicator, the same position is detected by the dial indicator when the workpiece is compressed, and data detected in the previously time and in the later time of all the positions are kept the same so as to avoid the situation that the position accuracy of serial hole machining is out of tolerance due to deformation of the workpiece before and after clamping, in this way, the position precision of serial hole machining is improved, the design requirements of a drawing are met, and the machining method is used forthe technical field of hole machining.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

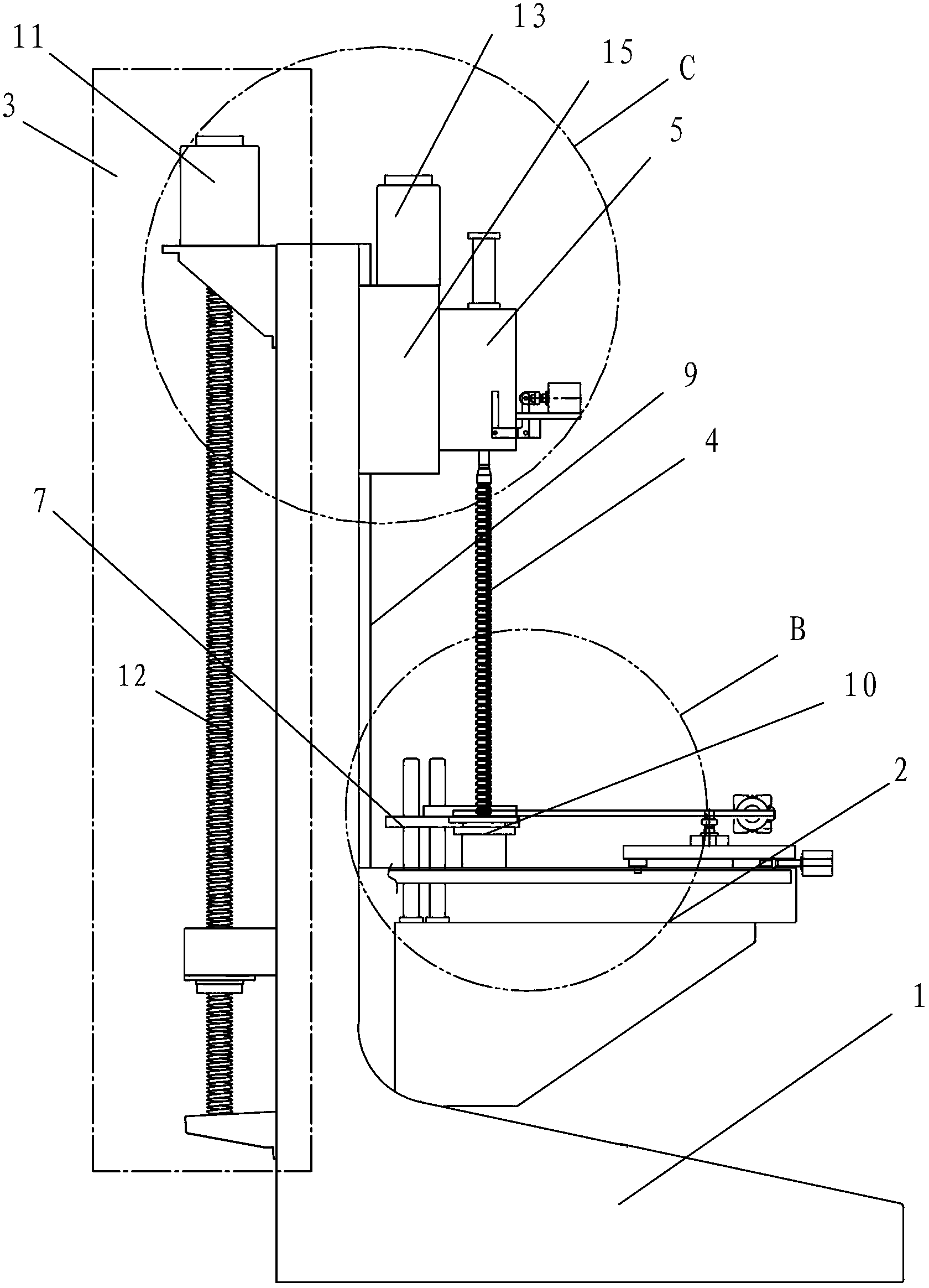

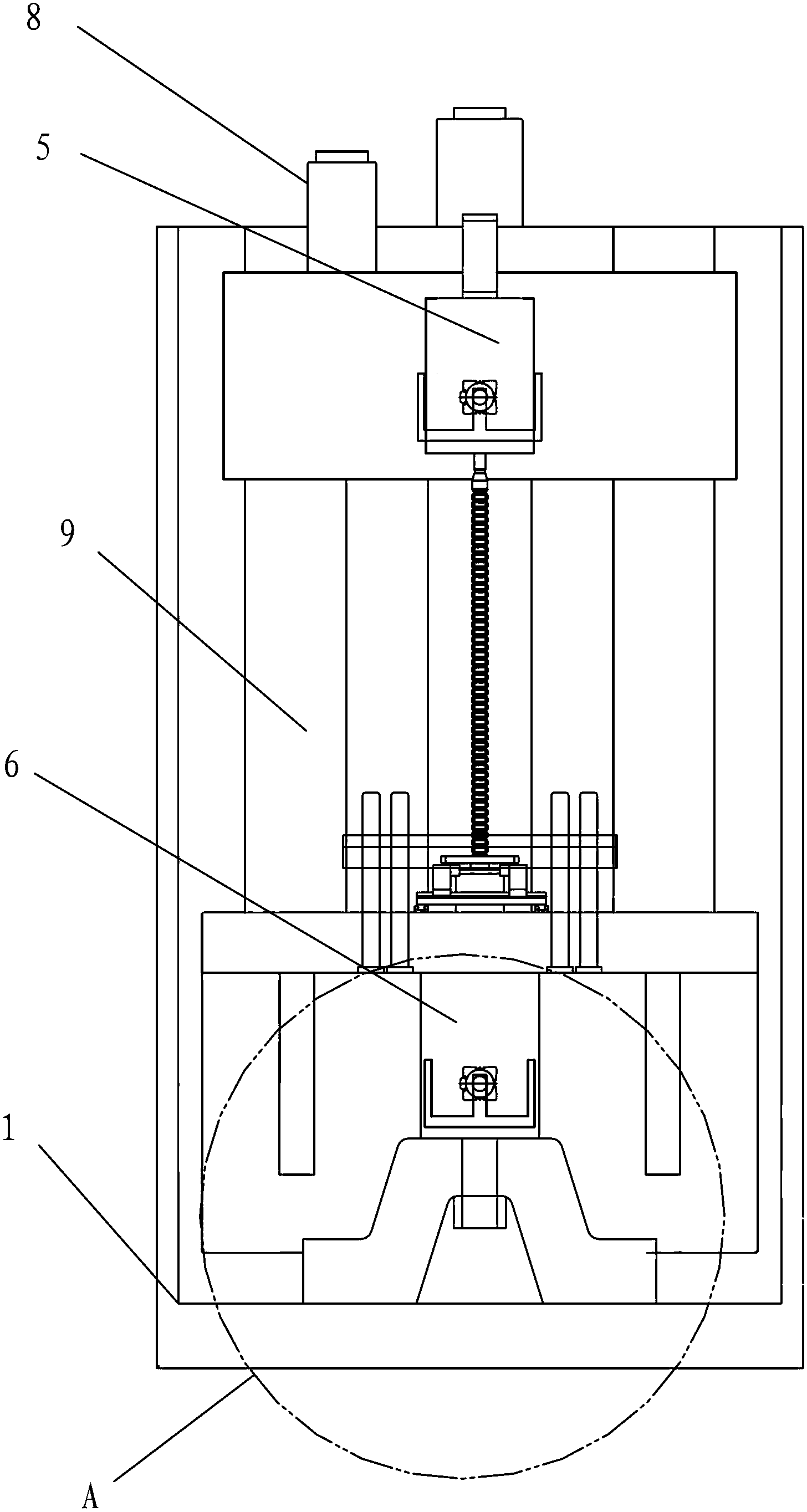

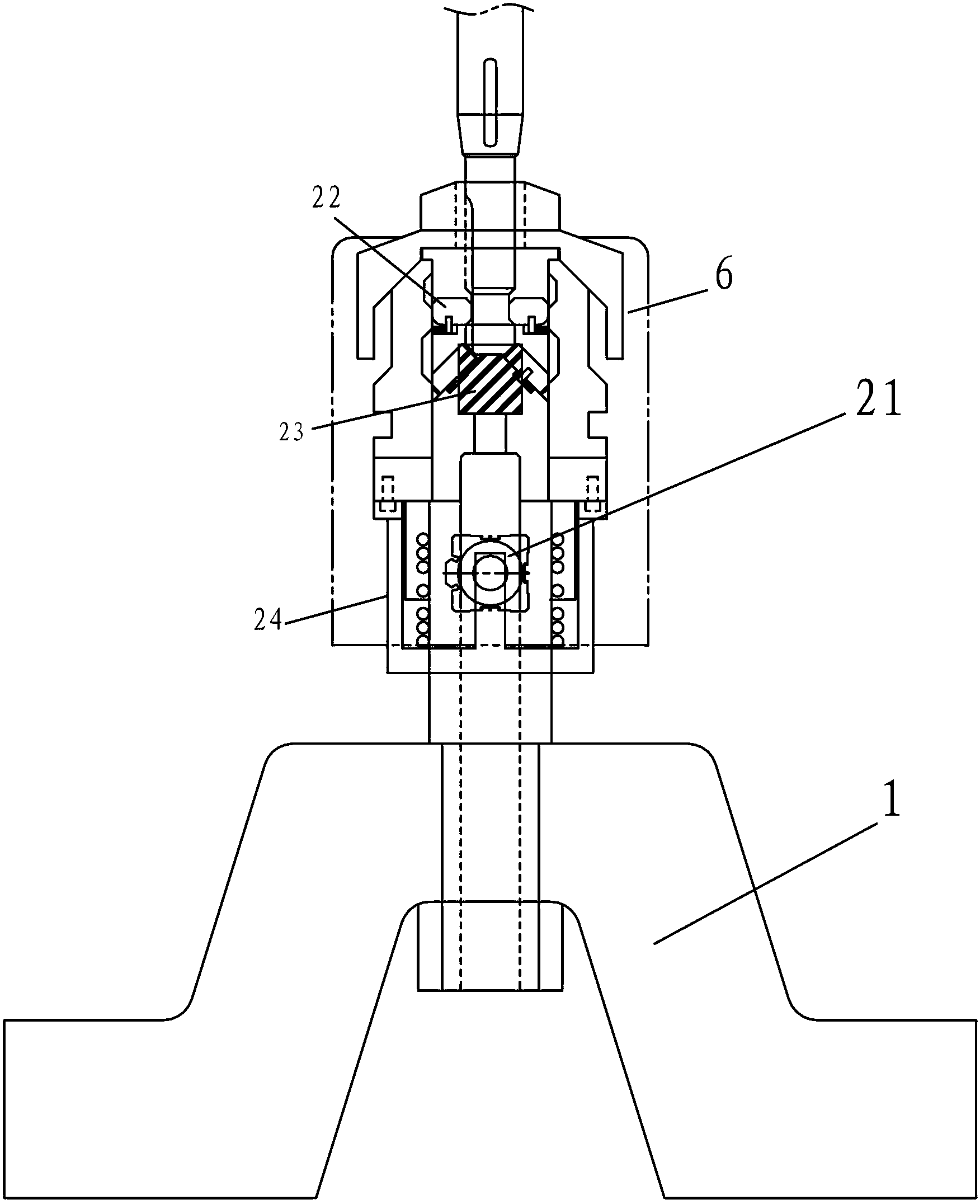

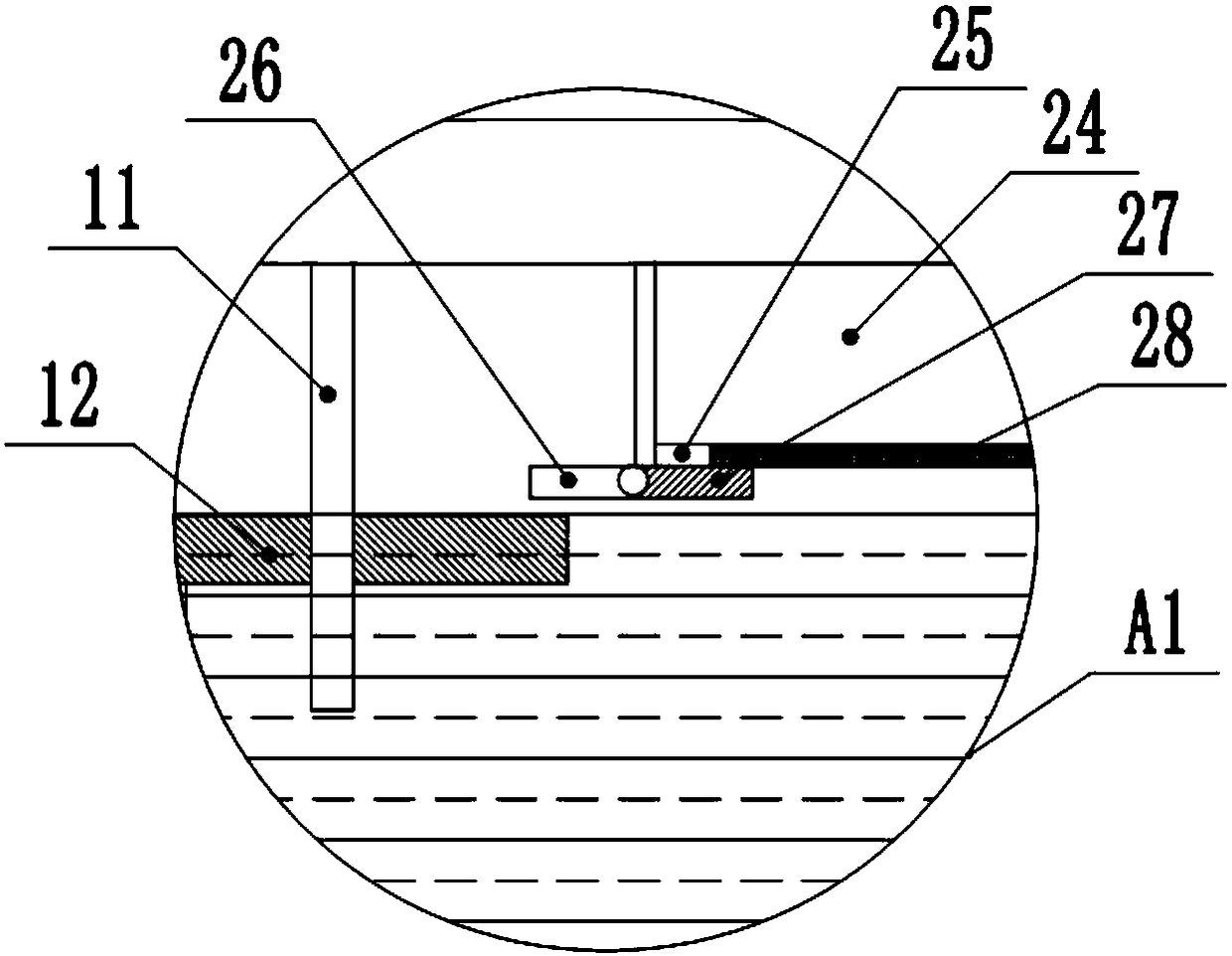

Hard broaching finish machining process for surface of internal keyway and device

InactiveCN102699419AGuaranteed stabilityOvercoming the challenges of broachingBroaching toolsBroaching machinesMachining processMachine tool

The invention relates to a hard broaching finish machining process for a surface of an internal keyway. The internal keyway of a part is sleeved at one end of a cutter which is same with the internal keyway in shape to fix both ends of the cutter so that the part moves along the cutter axially at a speed of 4-10m / s. During movement, deviation of the center of the internal keyway in the part and the axis of the cutter is maintained smaller than or equal to 0.01mm. The cutter is of a sectionally differential stepped structure. The blade hardness is greater than or equal to HRC67. The invention further provides a hard broaching finish machining device for the surface of the internal keyway. Both ends of the cutter are respectively fixed on an upper tool apron and a lower tool apron which are located above and below a work table and installed coaxially. A work table drive device drives the work table to move along a guide rail on a machine tool body to realize high speed machining of an internal spline of a workpiece to be machined. The hard broaching finish machining process for the surface of the internal keyway and the device provided by the invention are simple in process method and reasonable in structure of the device, and has high machining precision and efficiency for internal keyways, and low cost and energy consumption, and industrialized production can be realized in a large scale.

Owner:尹时中

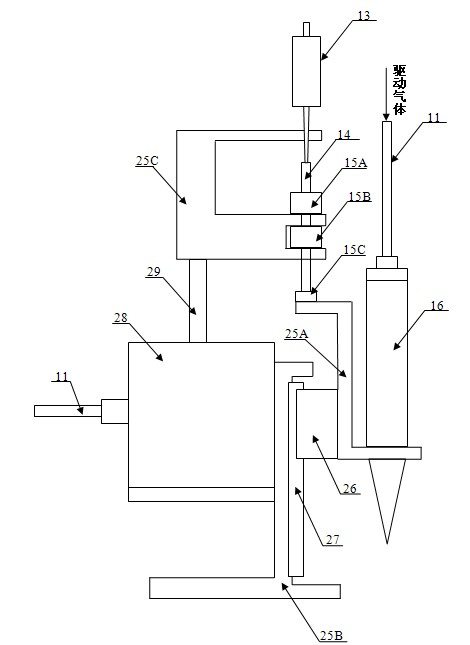

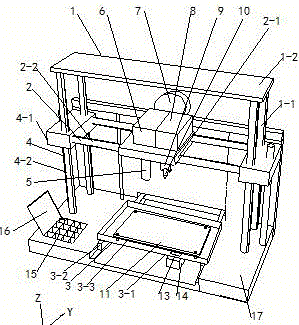

3D printing and milling combined machine tool

InactiveCN105773970AImprove printing efficiencyImprove surface qualityAdditive manufacturing apparatusMilling equipment detailsHigh surfaceDrive motor

The invention discloses a 3D printing and milling combined machine tool, and belongs to the technical field of 3D printing. The 3D printing and milling combined machine tool is high in printing efficiency and machining precision. A drive motor is fixed to the upper surface of a motion sliding table X of an X-axis motion assembly. The output end of the drive motor penetrates the motion sliding table X of the X-axis motion assembly to be fixedly connected with the upper end of a rotary shaft. An opening is formed in the lower end of the rotary shaft. One of multiple milling tools is clamped in the opening of the rotary shaft, and the corresponding milling tool is connected with the opening of the rotary shaft through a bolt. A chip bearing groove is formed in a motion sliding table Y of a Y-axis motion assembly, and a machining platform is fixedly connected with the motion sliding table Y of the Y-axis motion assembly through a bolt. A discharging opening is formed in the motion sliding table Y of the Y-axis motion assembly, and a recycling box is arranged at the lower end of the discharging opening. According to the 3D printing and milling combined machine tool, a model is subjected to precision machining while 3D printing is achieved, printing efficiency is improved, and high-surface-quality machining precision can be achieved.

Owner:HARBIN DINGZHI RUIGUANG TECH CO LTD

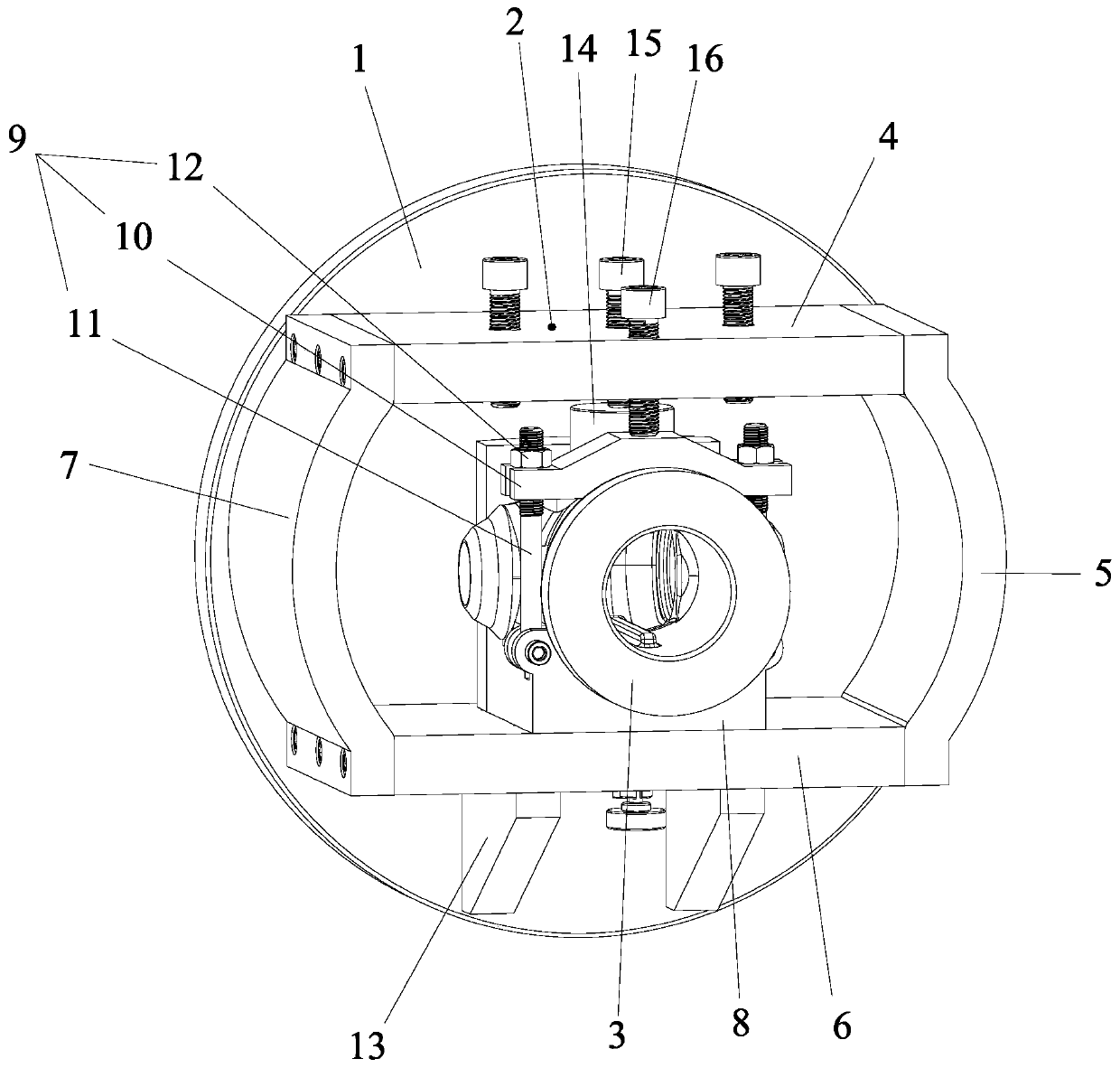

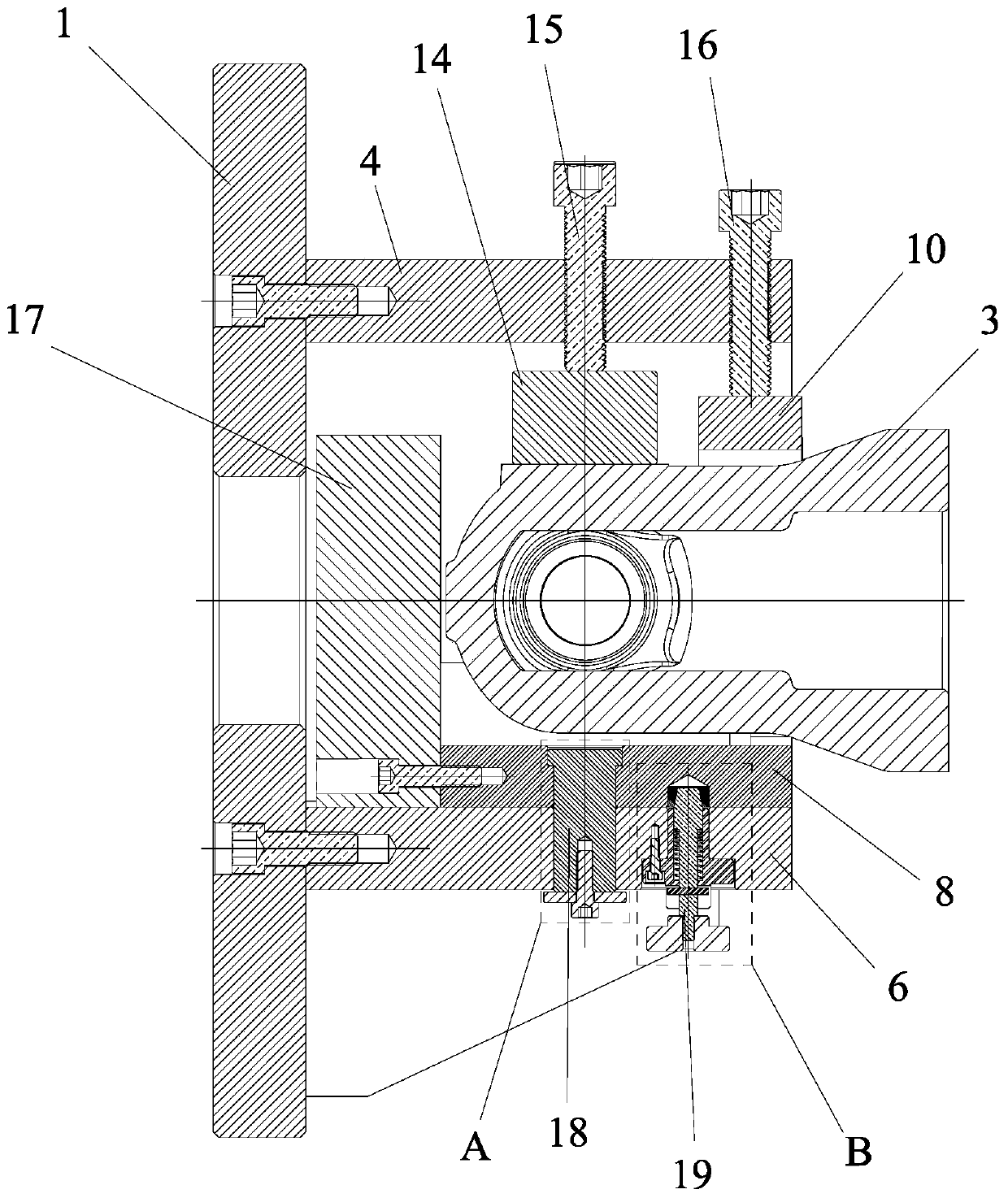

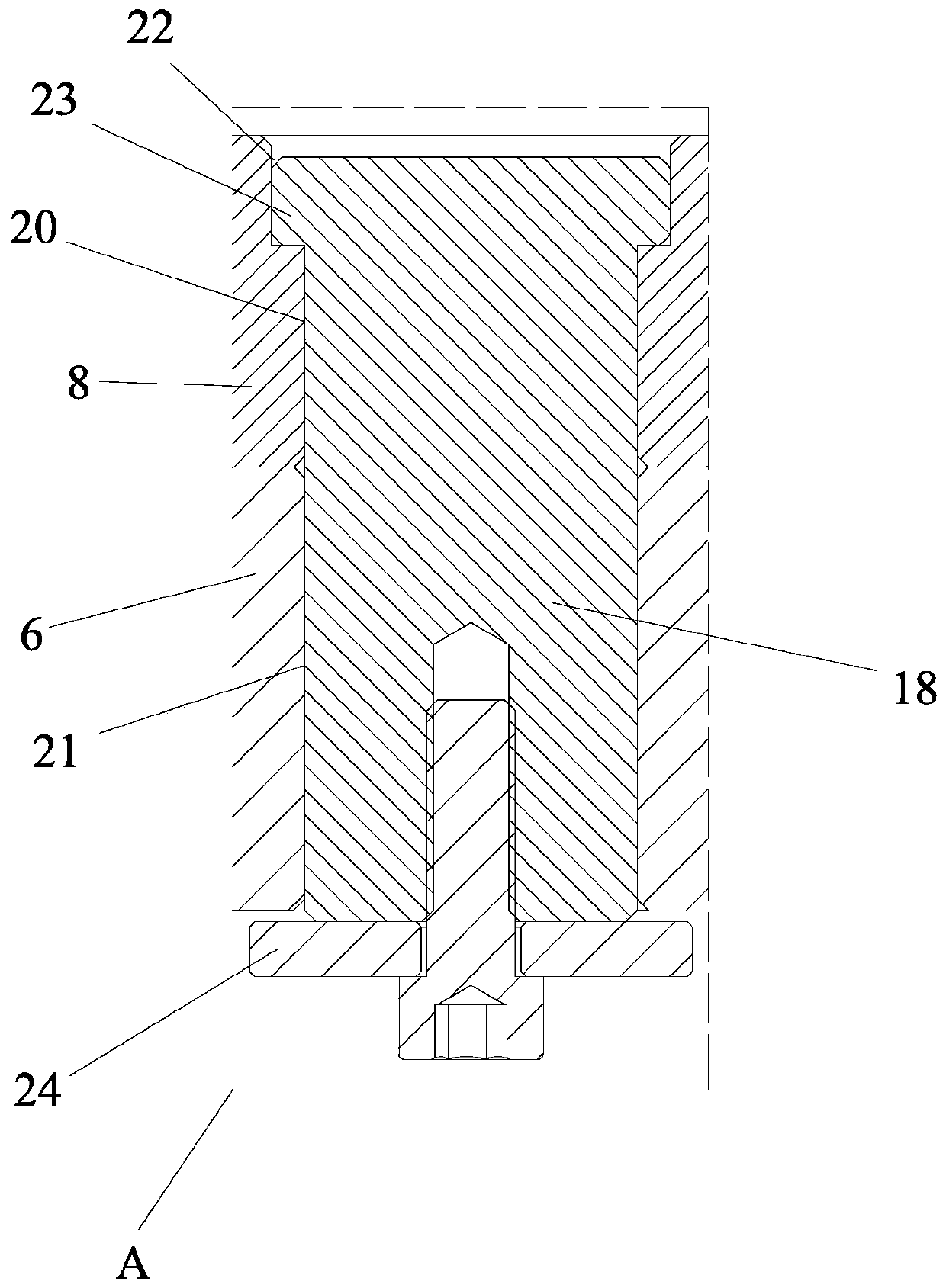

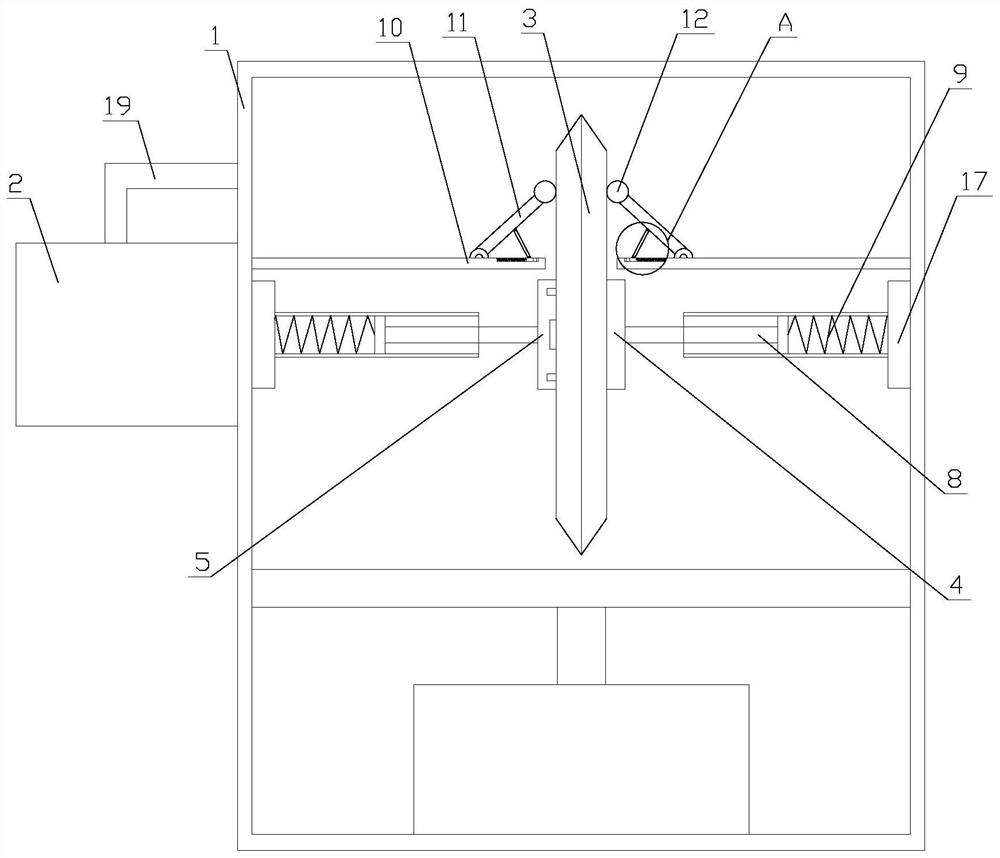

Valve body machining tool clamp for butt welding connection of high-pressure valve

ActiveCN110936196AAccurate clamping and positioningGuaranteed machining accuracyPrecision positioning equipmentPositioning apparatusButt weldingEngineering

The invention discloses a valve body machining tool clamp for butt welding connection of a high-pressure valve. The clamp comprises a clamping rotary disc, a positioning frame is arranged on the clamping rotary disc in a linked mode, the positioning frame comprises an upper positioning plate, a right positioning plate, a lower positioning plate and a left positioning plate which are sequentially connected to form a closed loop, a base used for containing a valve body is arranged on the lower positioning plate in a rotating mode, and a clamping mechanism used for clamping the valve body is arranged on the base; a plurality of positioning holes are formed in the base in the rotating direction of the base, and a positioning mechanism arranged in one positioning hole in a penetrating mode andpositioning the base is arranged on the lower positioning plate. The clamp is firm in clamping, safe, reliable, high in machining efficiency and accurate in clamping and positioning, and the machiningprecision of the valve body is guaranteed.

Owner:CHAODA VALVE GRP

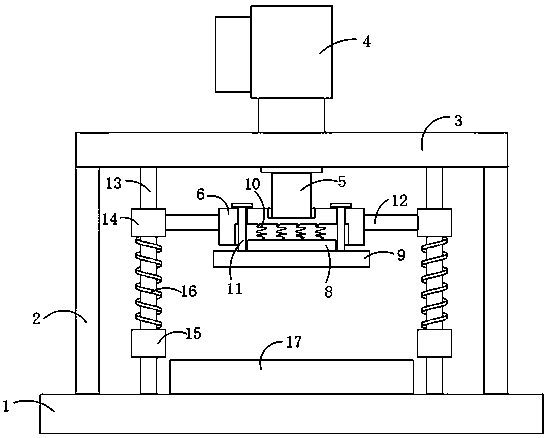

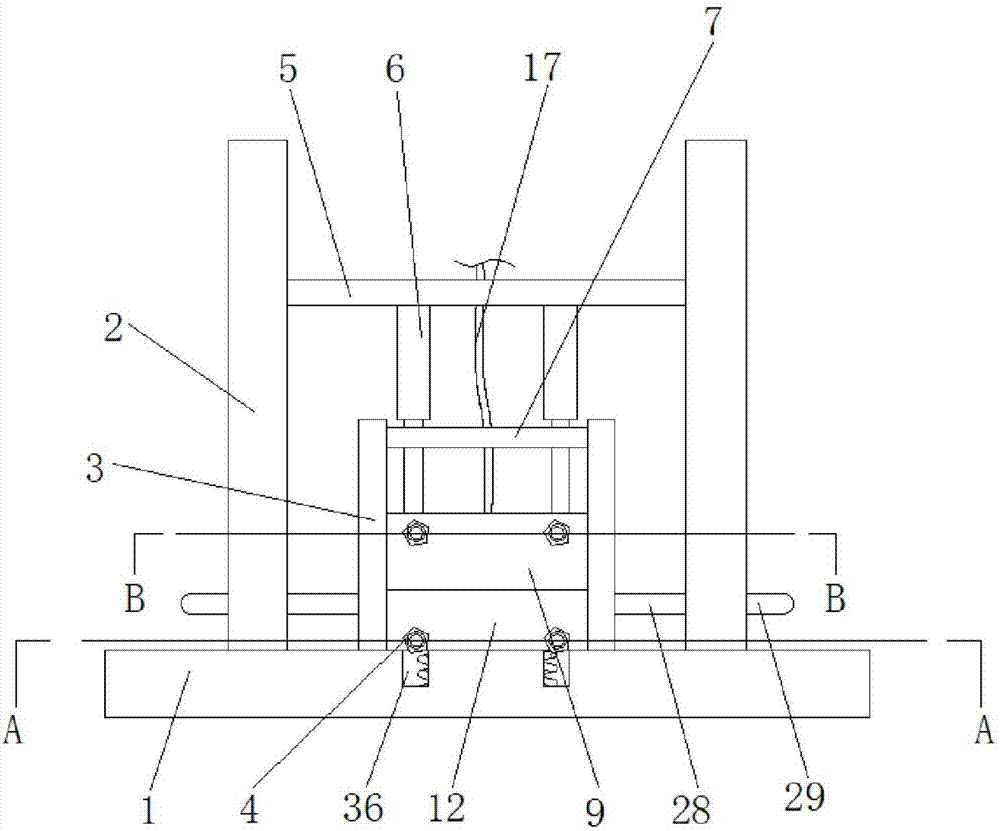

Press machine high in machining precision

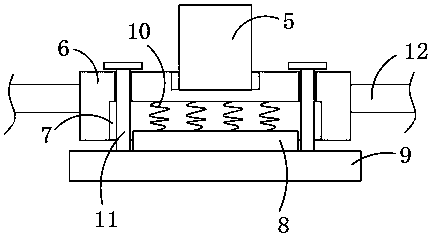

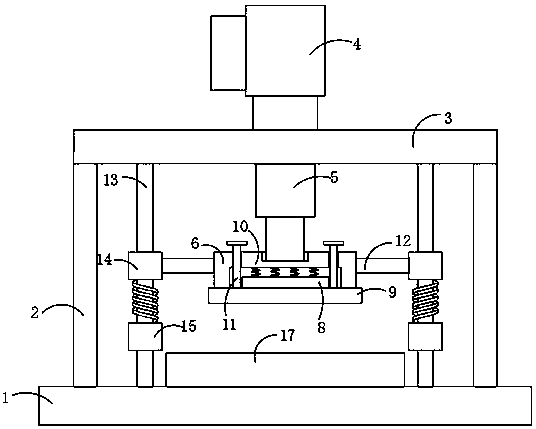

InactiveCN109332495AHigh precisionImprove stamping precisionShaping toolsShaping safety devicesHydraulic cylinderPunching

The invention discloses a press machine high in machining precision. A base is included. The upper end of the base is fixedly connected with an upper cover plate through two supporting plates. A hydraulic cylinder is fixedly connected to the upper end of the upper cover plate. The two supporting plates are symmetrically arranged on the two sides of the lower end of the hydraulic cylinder. The telescopic end of the hydraulic cylinder penetrates through the upper cover plate and is fixedly connected with a punching head. The lower end of the punching head is fixedly connected with a punching buffering device. The two sides of the punching head are symmetrically provided with guiding columns corresponding to the punching buffering device in position. The upper ends and the lower ends of the two guiding columns are fixed to the opposite side walls of the upper cover plate and the base correspondingly. The press machine is compact in structure, the punching buffering device is arranged at the lower end of the punching head and matched with a damping mechanism, damping buffering and protection functions are achieved for to-be-punched accessories and other mechanical structures on the press machine in the punching process, and meanwhile the punching precision is improved under the guiding action of the guiding columns.

Owner:江苏纽克光谱科技有限公司

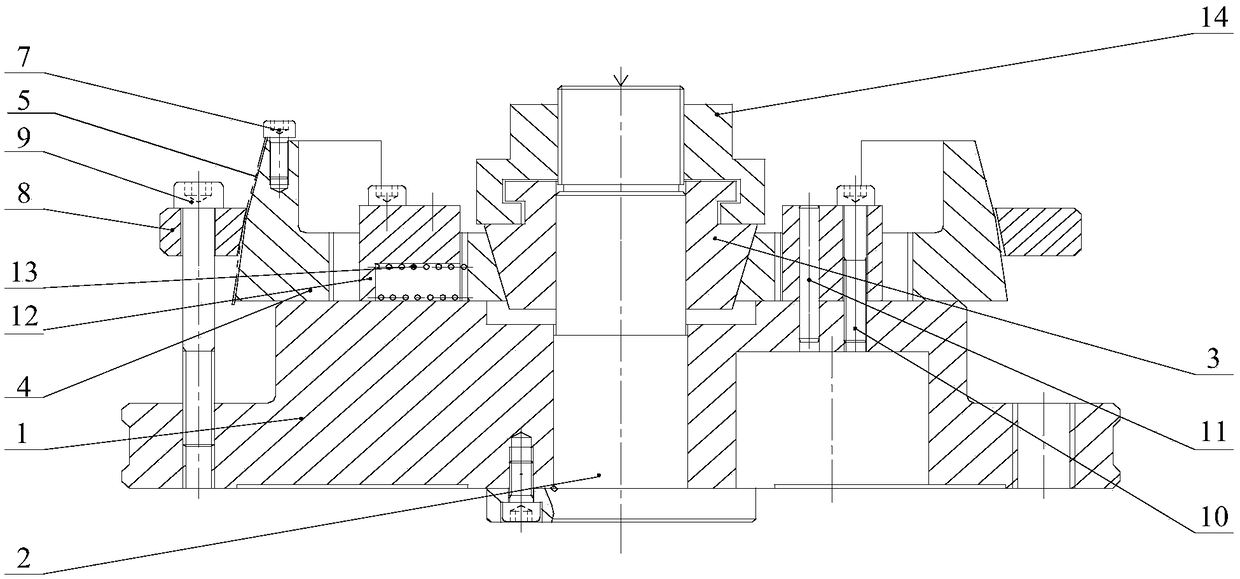

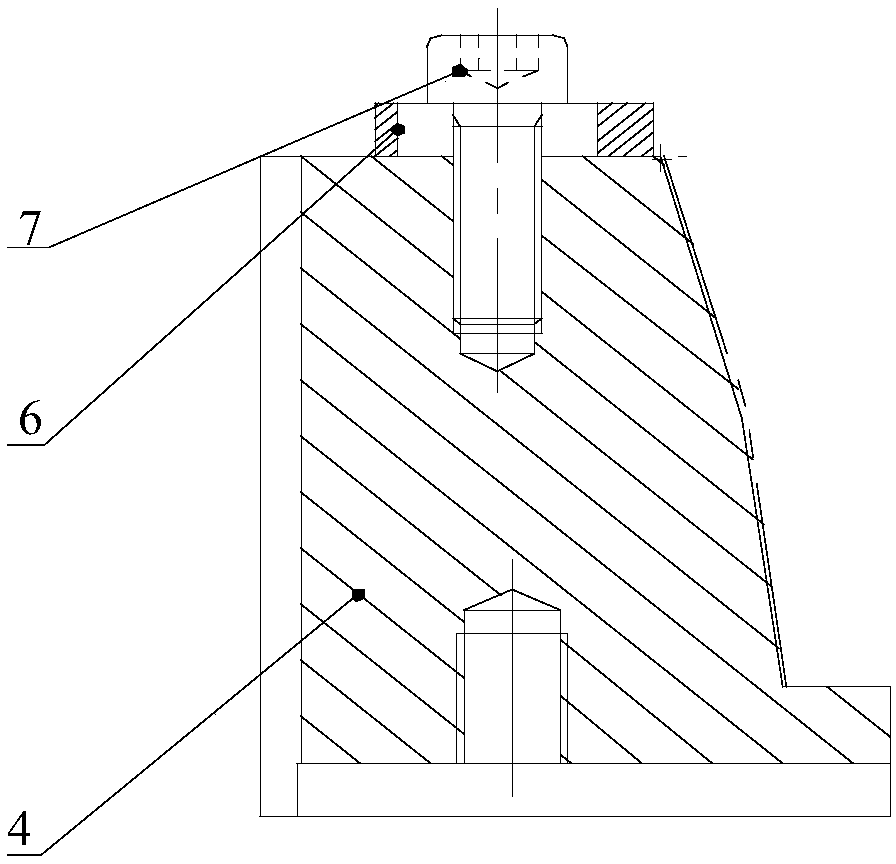

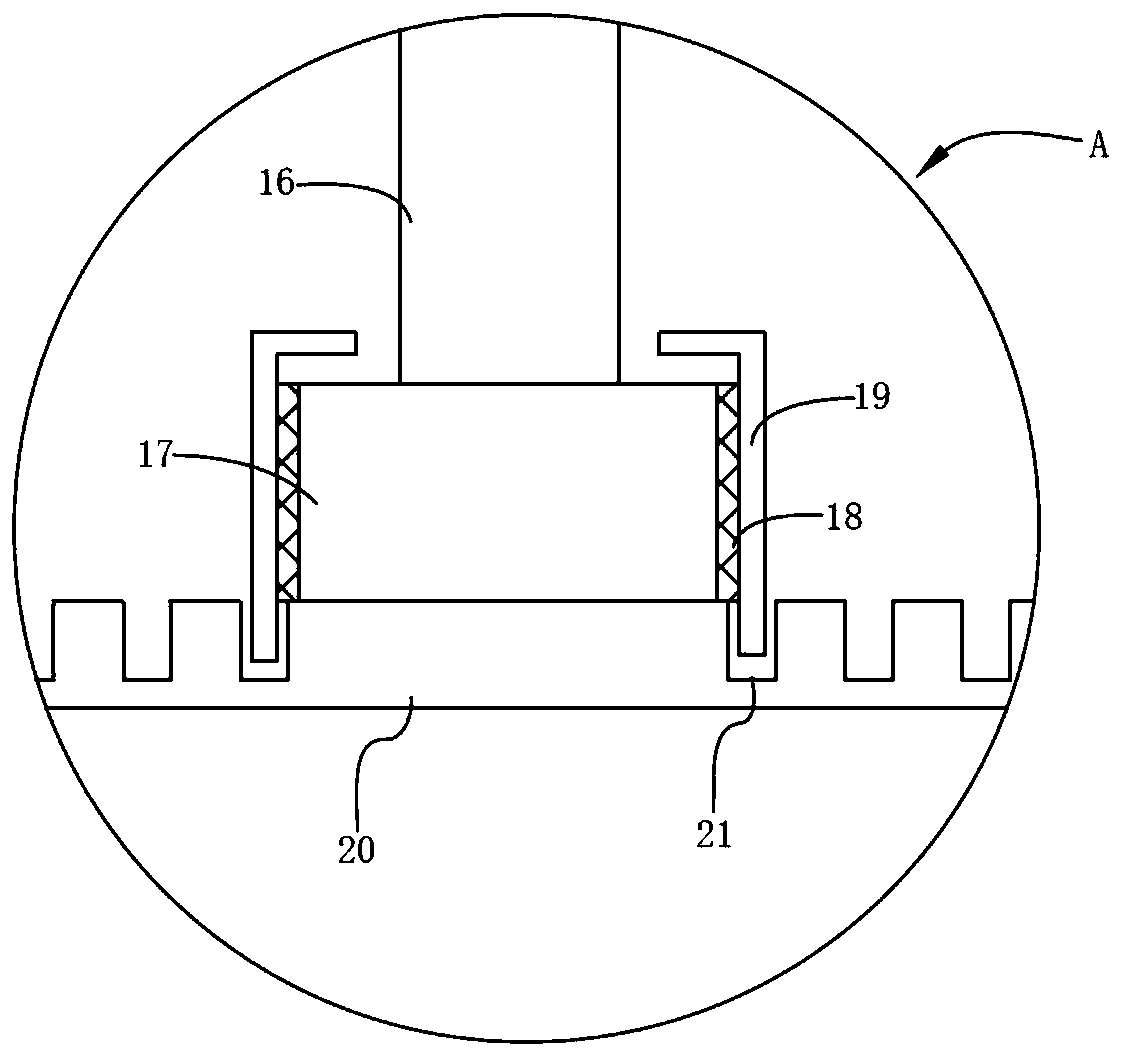

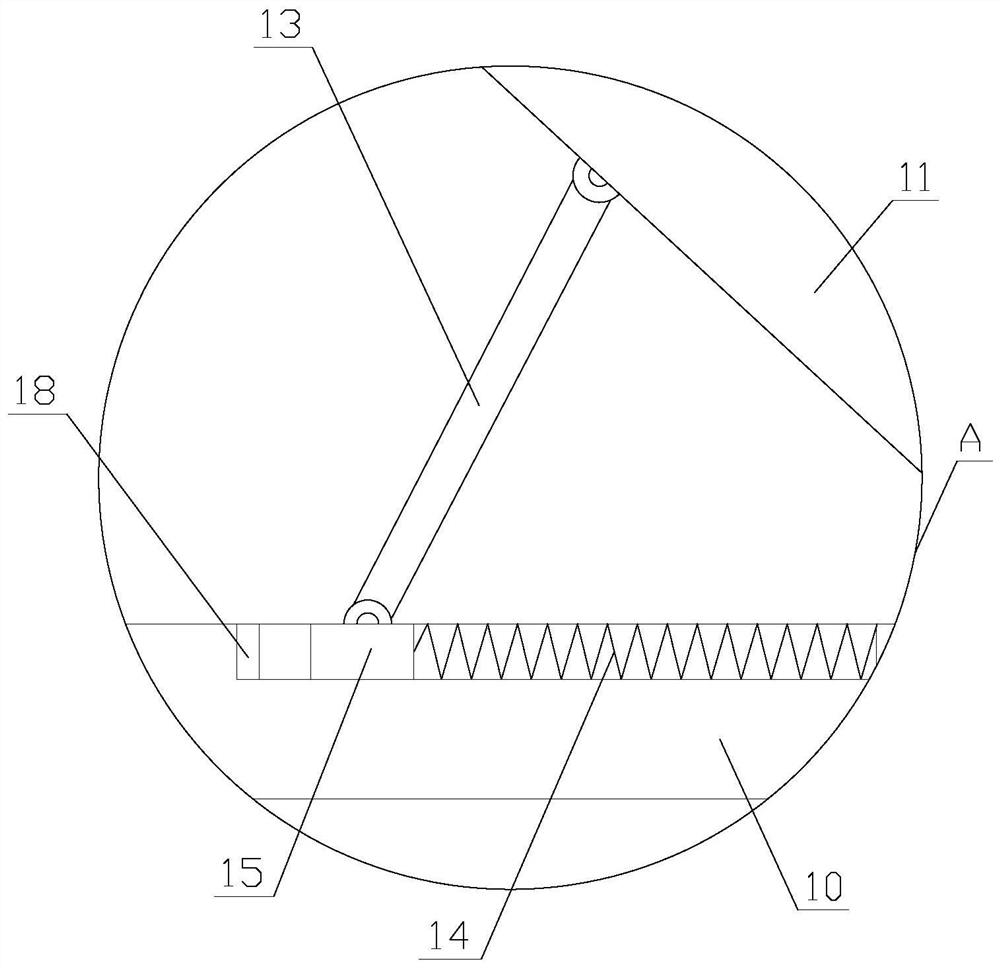

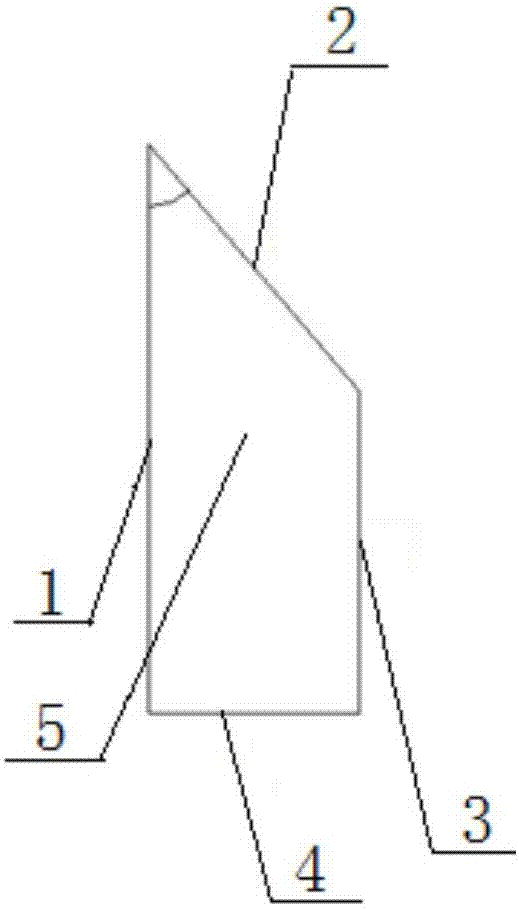

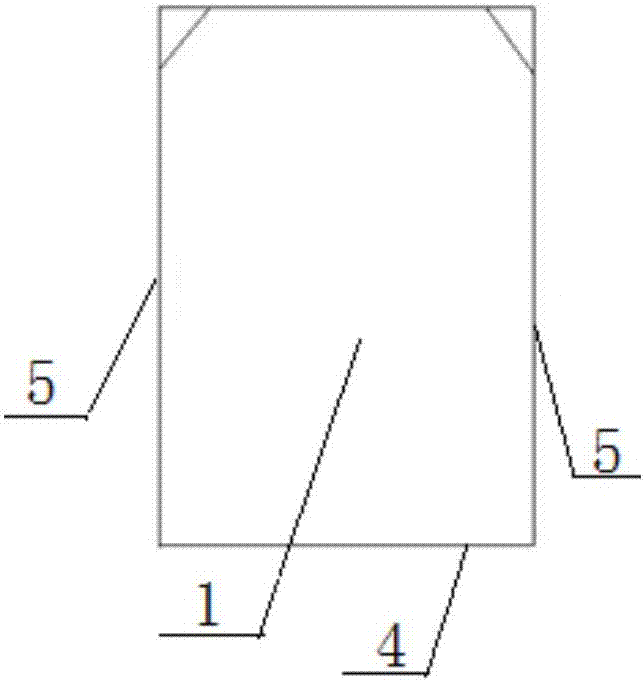

Fixture for end face turning of rotary part and process method

InactiveCN108637273AAvoid affecting the machining accuracyReduce security risksPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a fixture for end face turning of a rotary part. The fixture is used for clamping the rotary part with the diameter gradually decreasing from one end to the other end. The fixture specifically comprises a tightening mechanism and a compression ring mechanism, wherein the tightening mechanism can limit circumferential rotation of the rotary part and axial movement of the rotary part from the big end to the small end, while the compression ring mechanism compresses the rotary surface of the rotary part and limit axial movement of the rotary part from the small end to thebig end, and thus complete limiting of axial and circumferential directions of the rotary part is realized, the situation that the rotary part deviates during turning and affects the processing precision is prevented, and meanwhile the potential safety hazards are reduced. The invention further discloses a process method using the fixture for end face turning of the rotary part.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

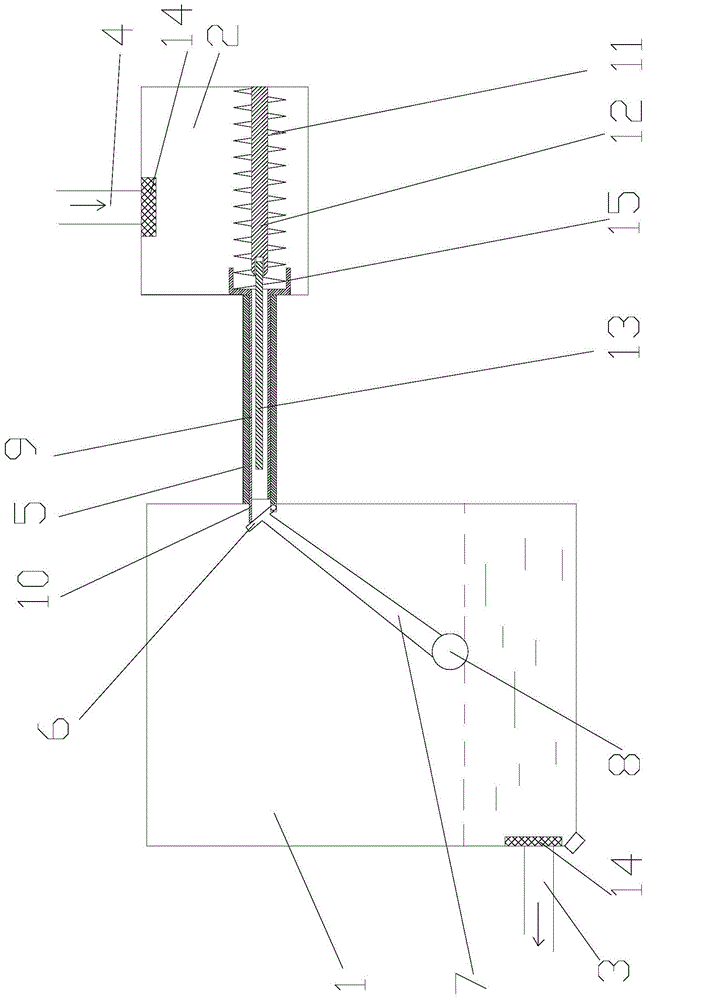

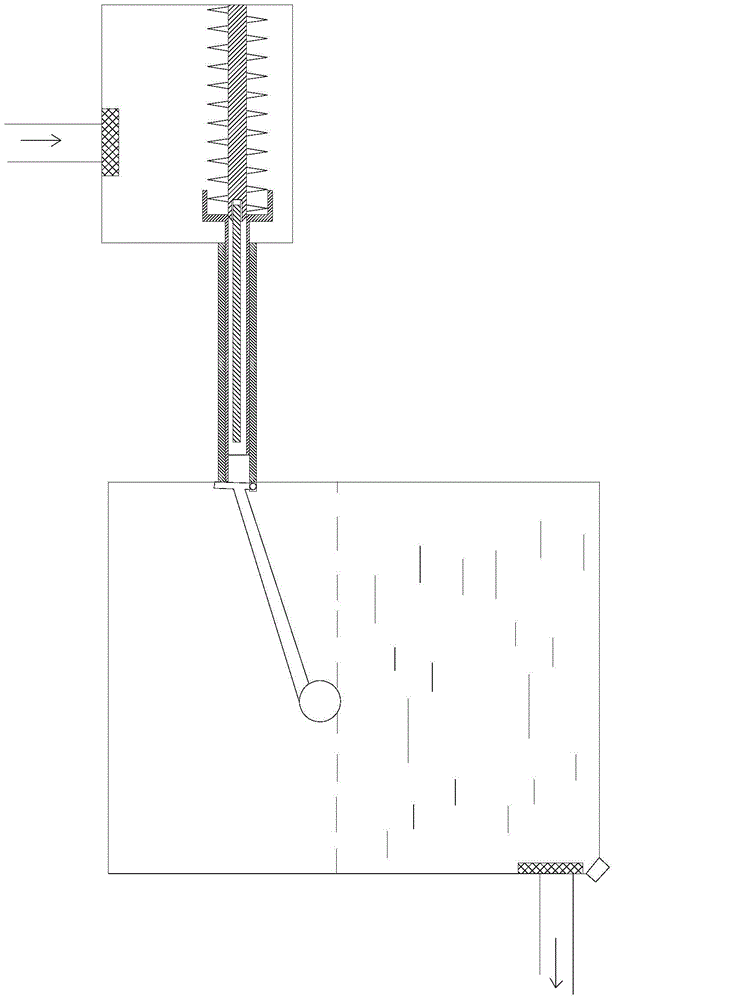

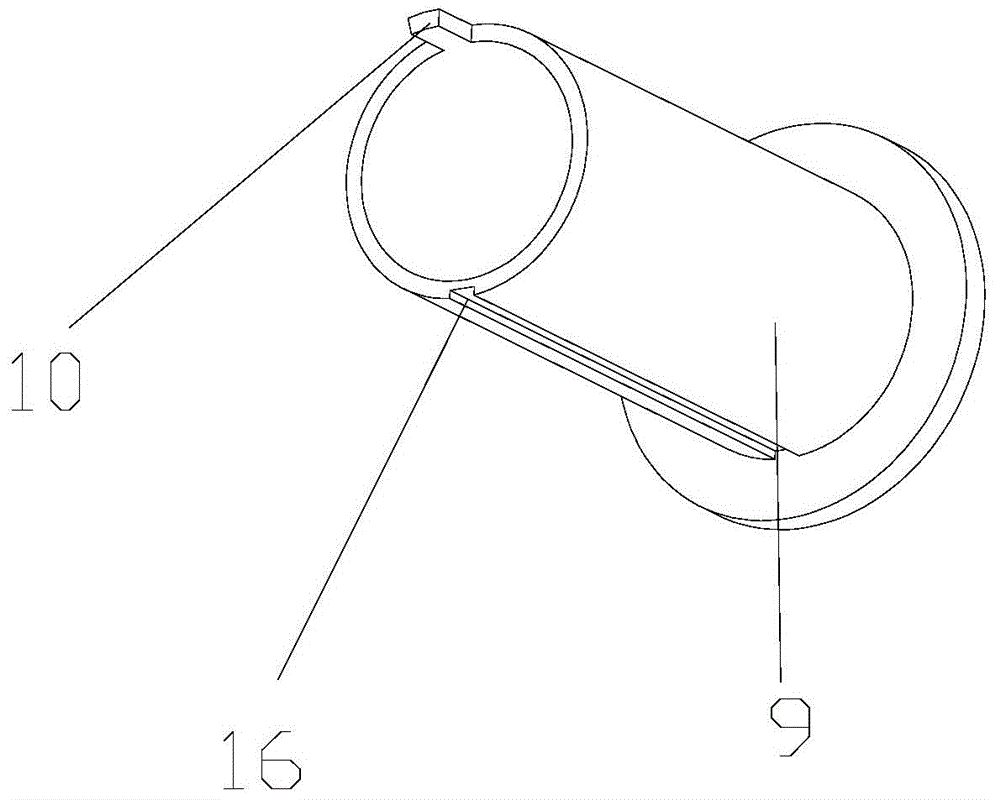

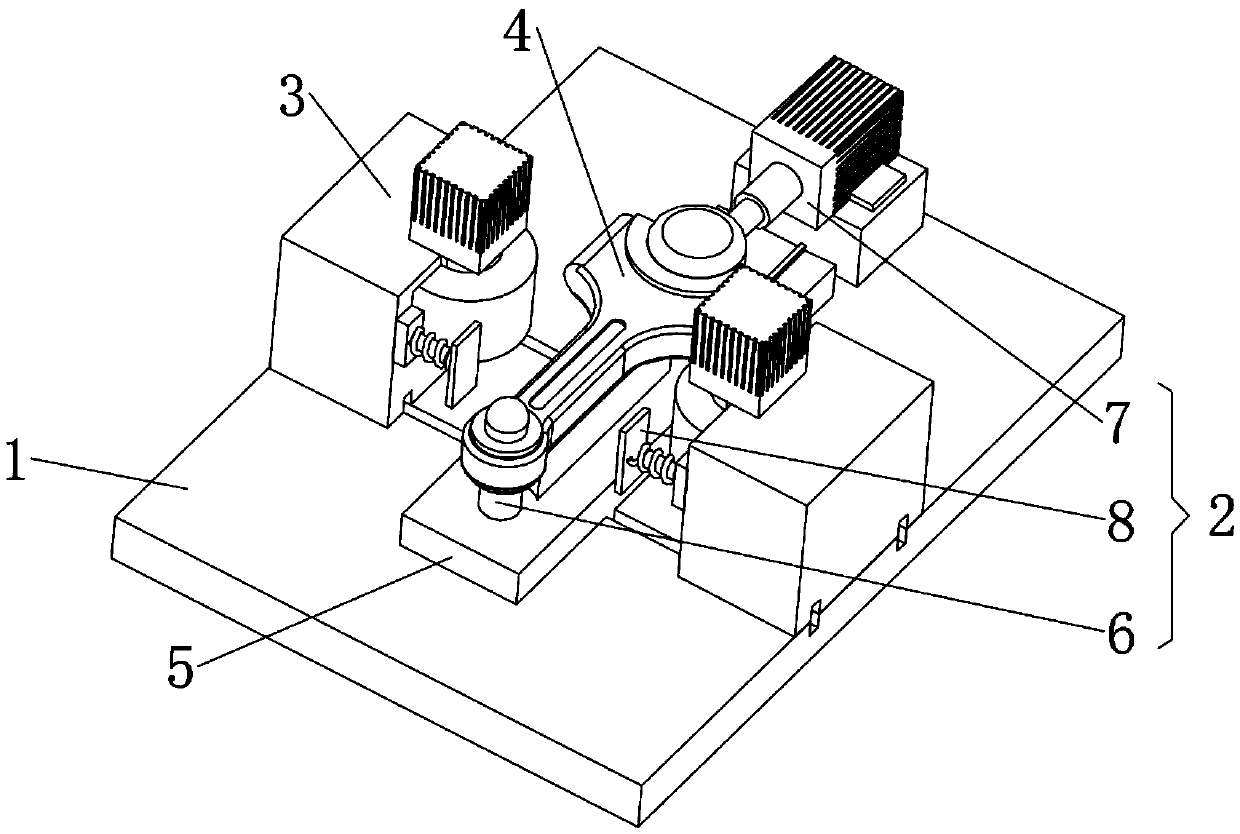

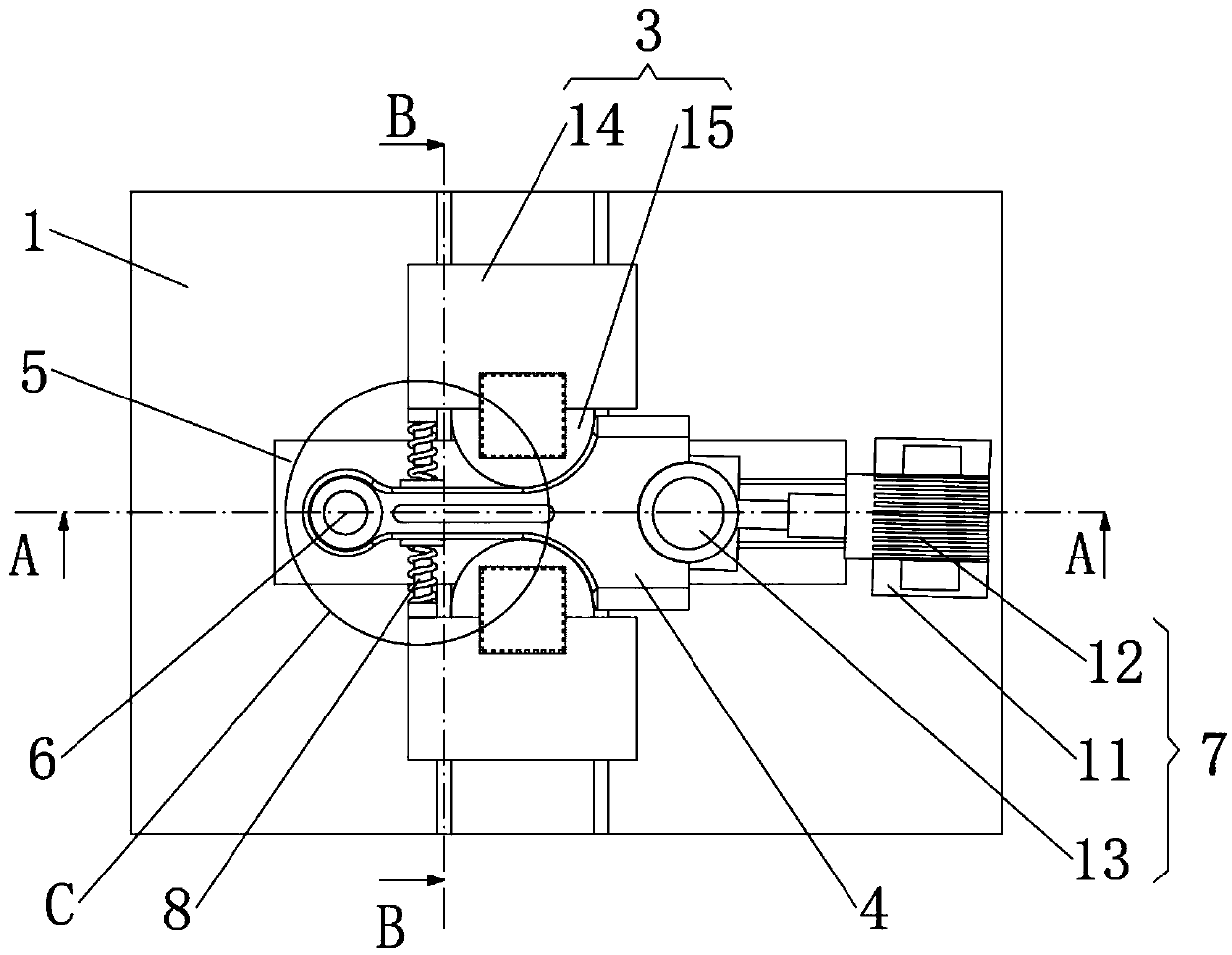

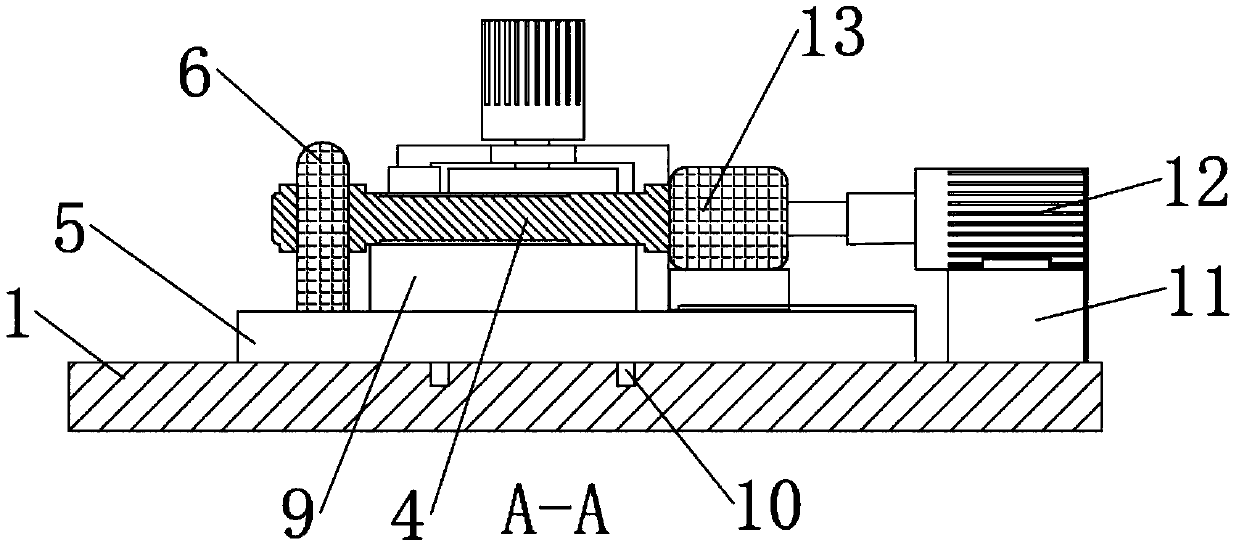

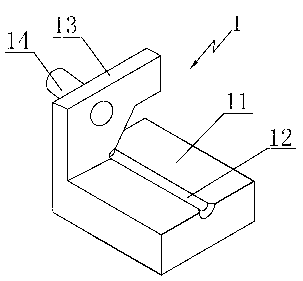

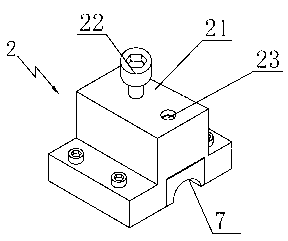

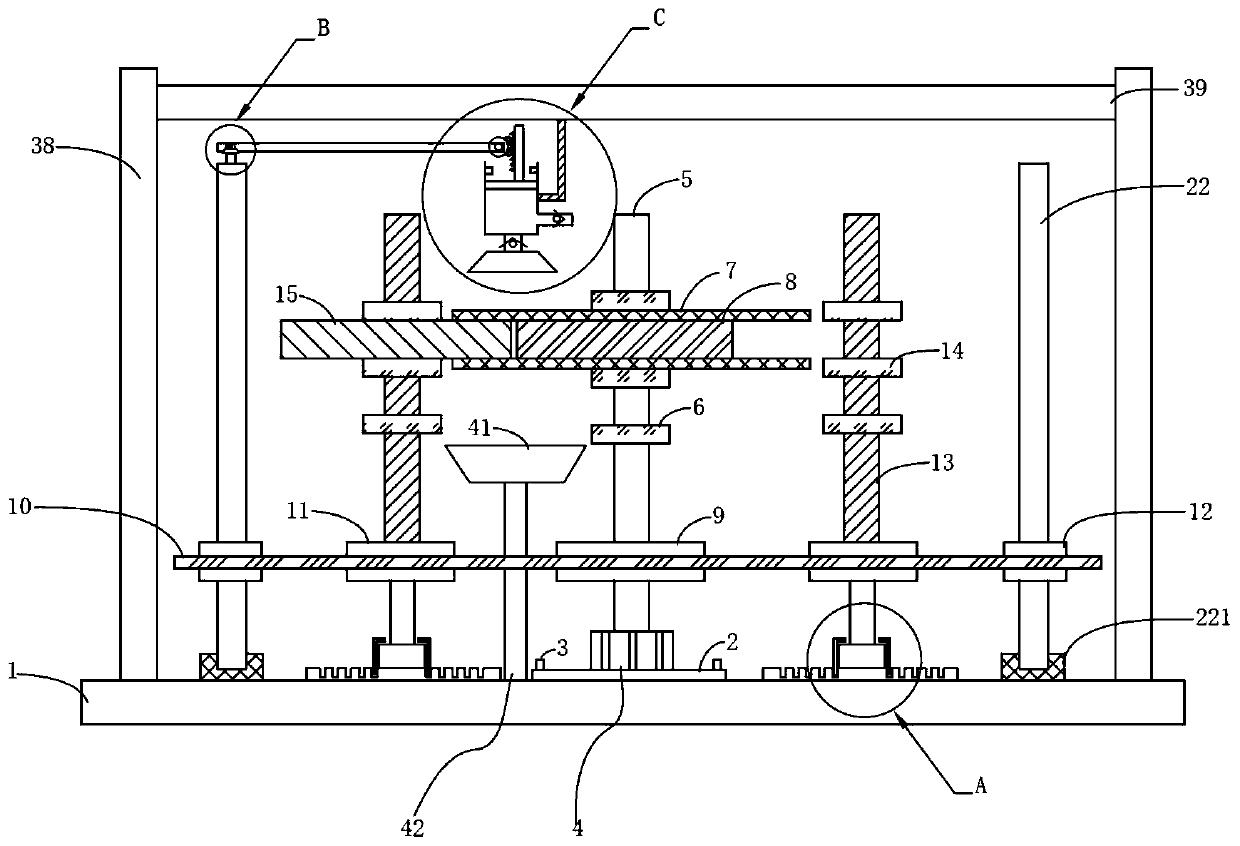

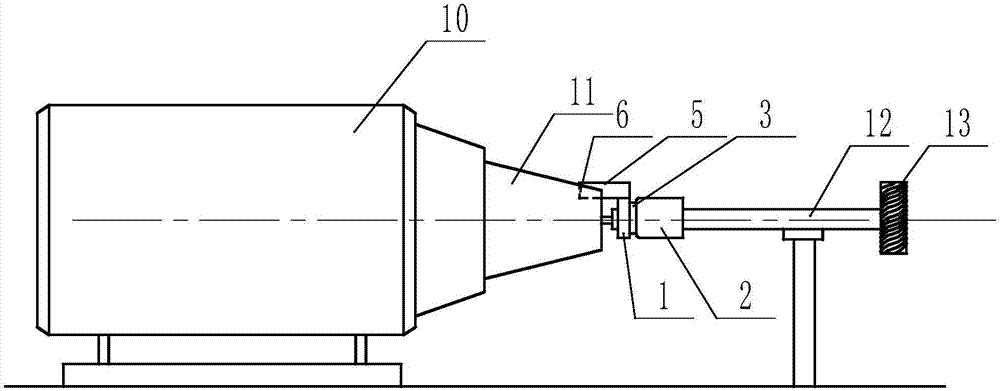

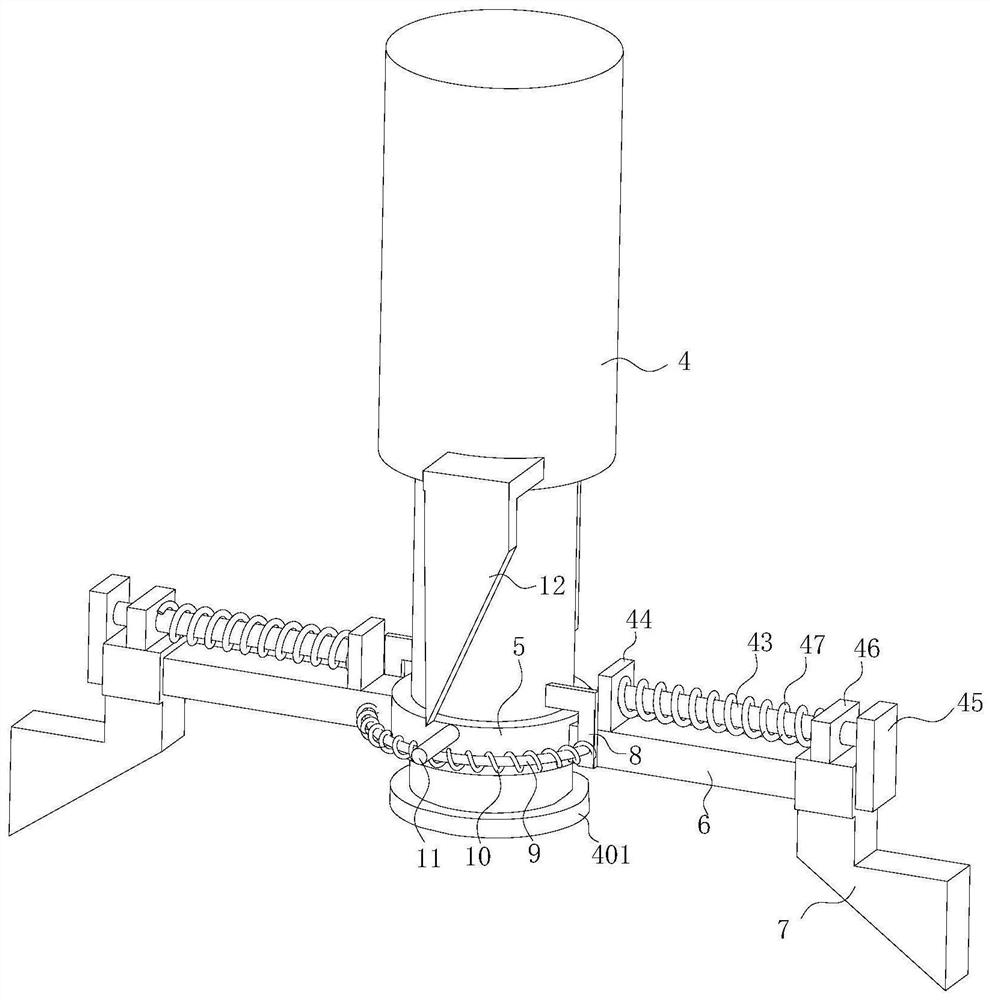

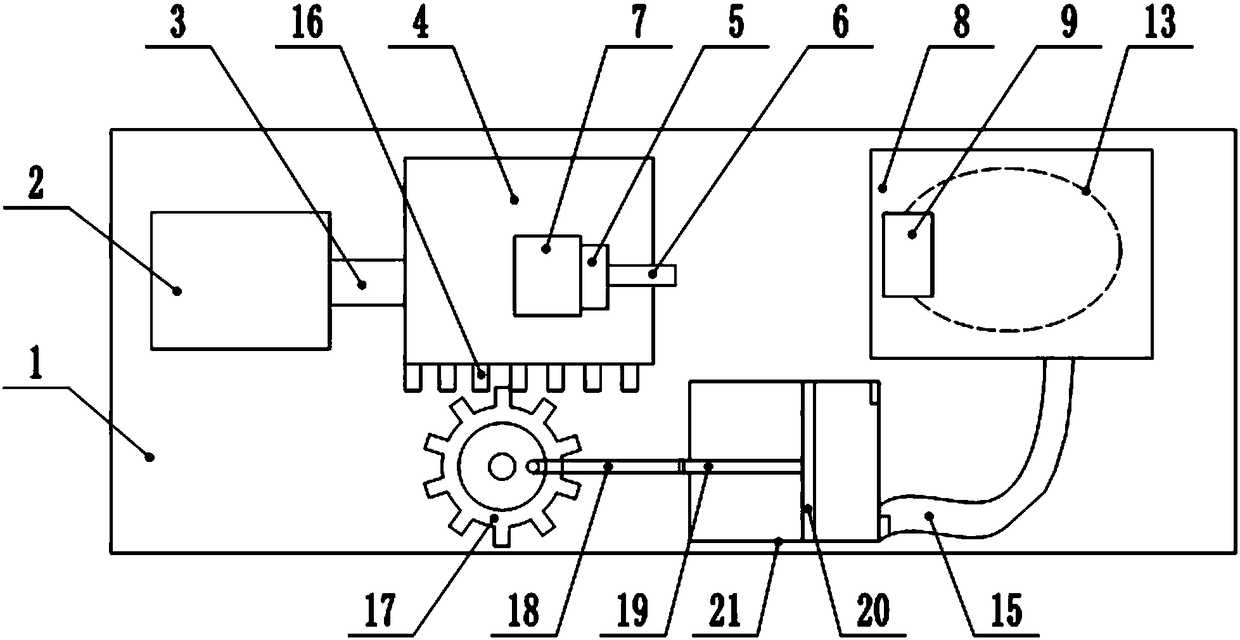

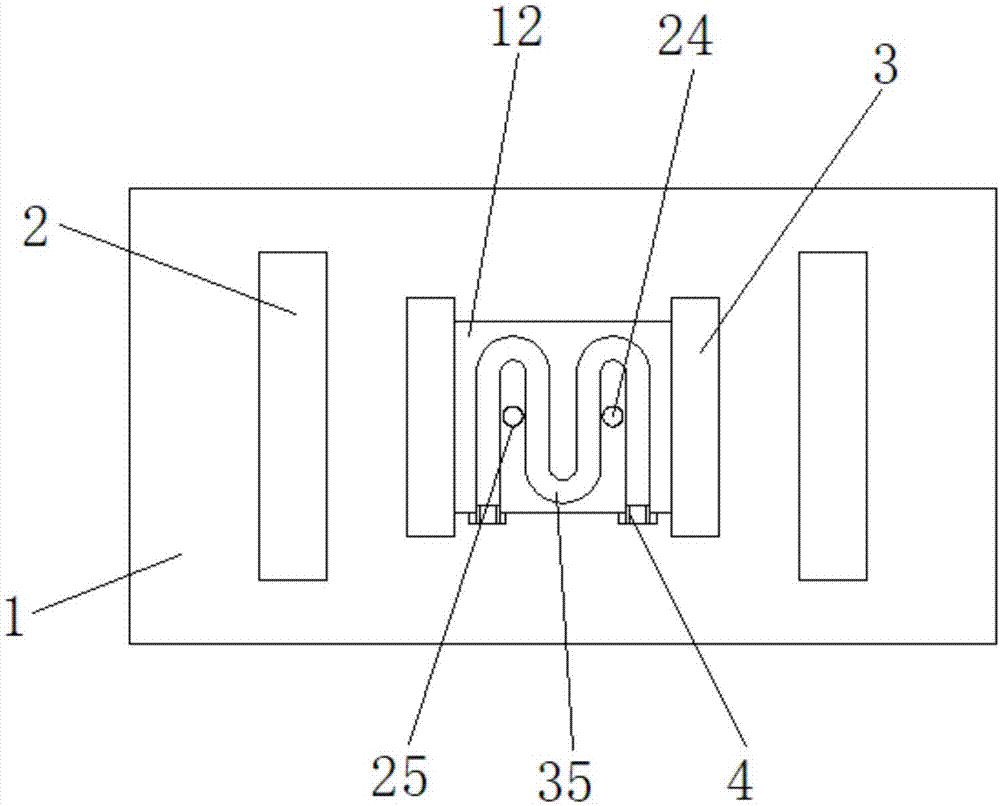

Cutting fluid circulating device

ActiveCN104589152AImprove recycling efficiencyImprove efficiencyMagnetic separationMaintainance and safety accessoriesEngineeringService efficiency

The invention discloses a cutting fluid circulating device which comprises a first box body (1) and a second box body (2), wherein the first box body (1) is connected to the second box body (2) through a connecting pipe (5); one end, connected to the first box body (1), of the connecting pipe (5) is articulated with a baffle plate (6); the baffle plate (6) is connected with a floating ball (8) through a rocking bar (7); the inner wall of the connecting pipe (5) is matched with a slip pipe (9) in a sliding manner; one end of the slip pipe (9) is provided with an extension end (10); the other end of the slip pipe (9) is connected with the second box body (2) through an on-off device; the on-off device comprises a pressure spring (11) and a core rod (12); one end of the core rod (12) is fixedly arranged on the inner wall of the second box body (2); the pressure spring (11) sleeves on the core rod (12); one end of the pressure spring (11) is connected with the inner wall of the second box body (2), and the other end of the pressure spring (11) is connected with the end face of the slip pipe (9); the core rod (12) is provided with a magnet (13). According to the cutting fluid circulating device, the cutting fluid circulating service efficiency is high.

Owner:湖北润达新材料有限公司

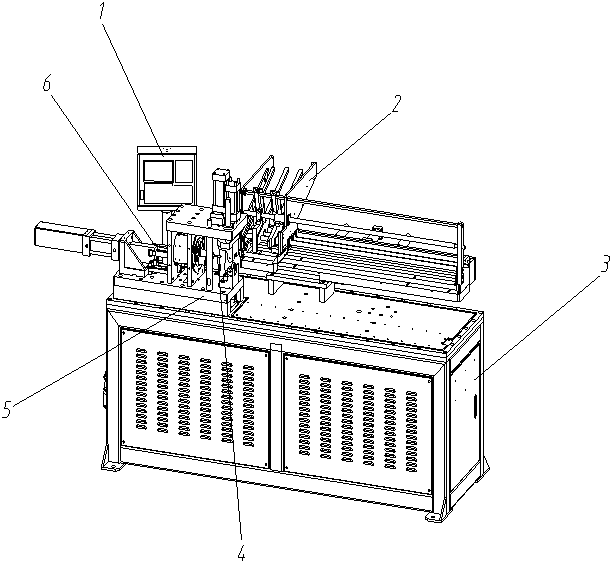

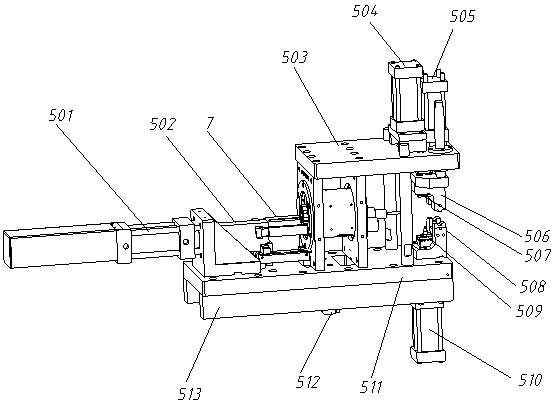

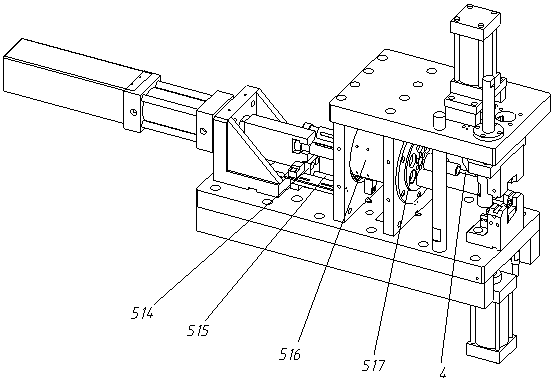

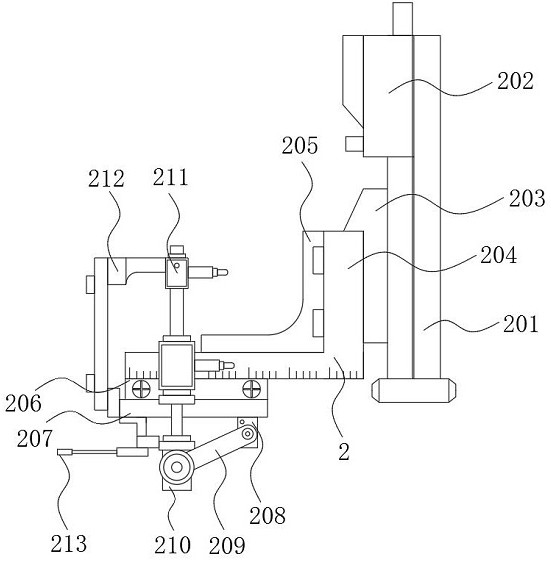

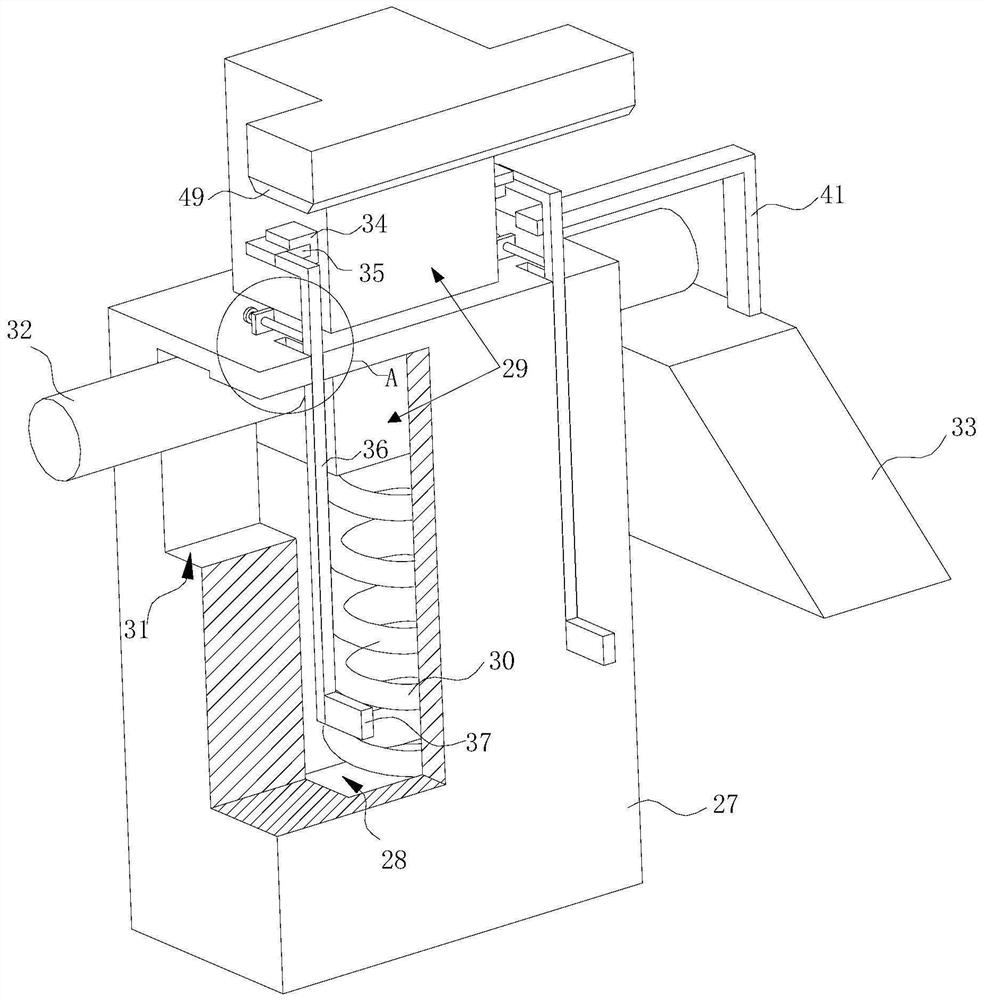

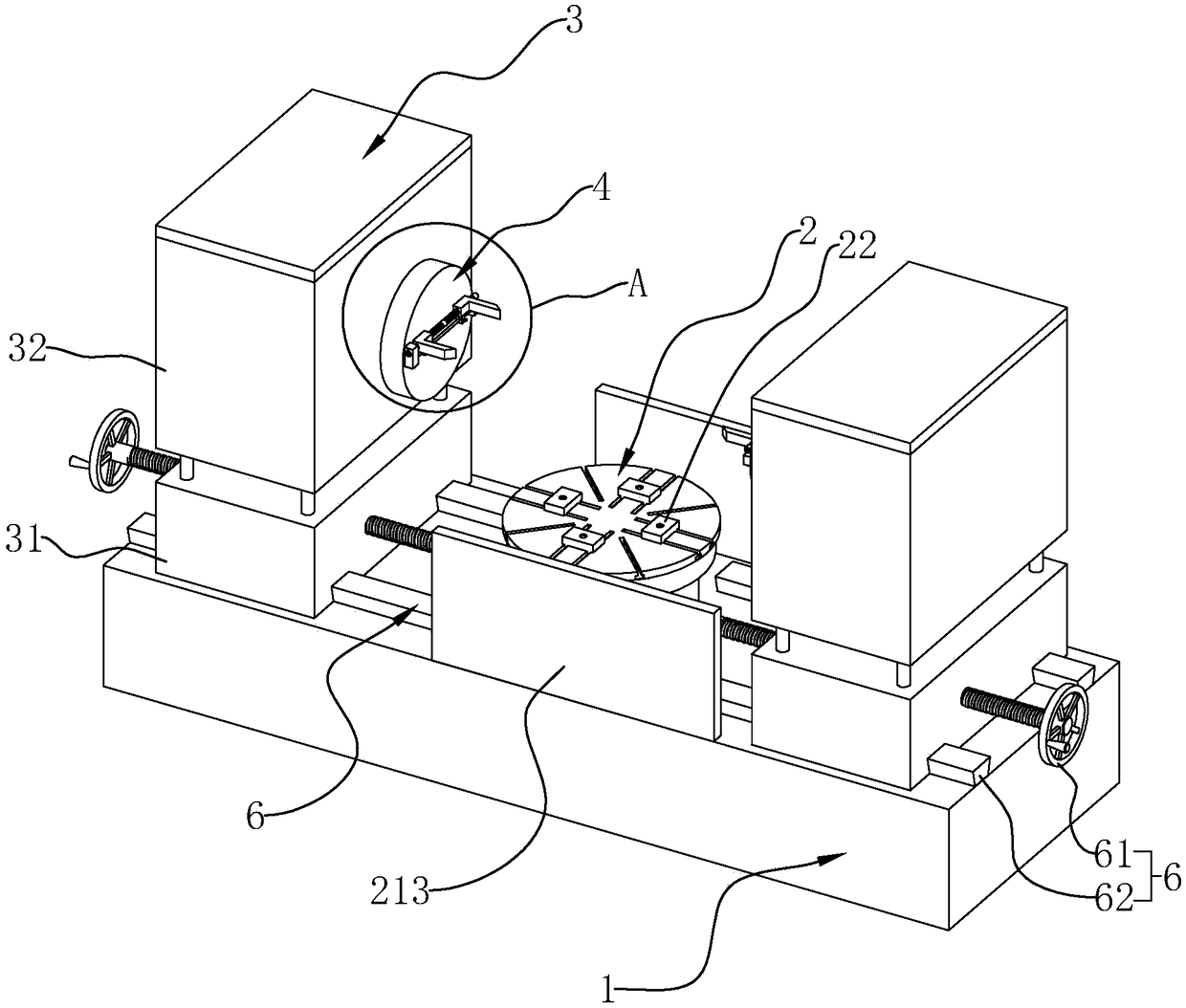

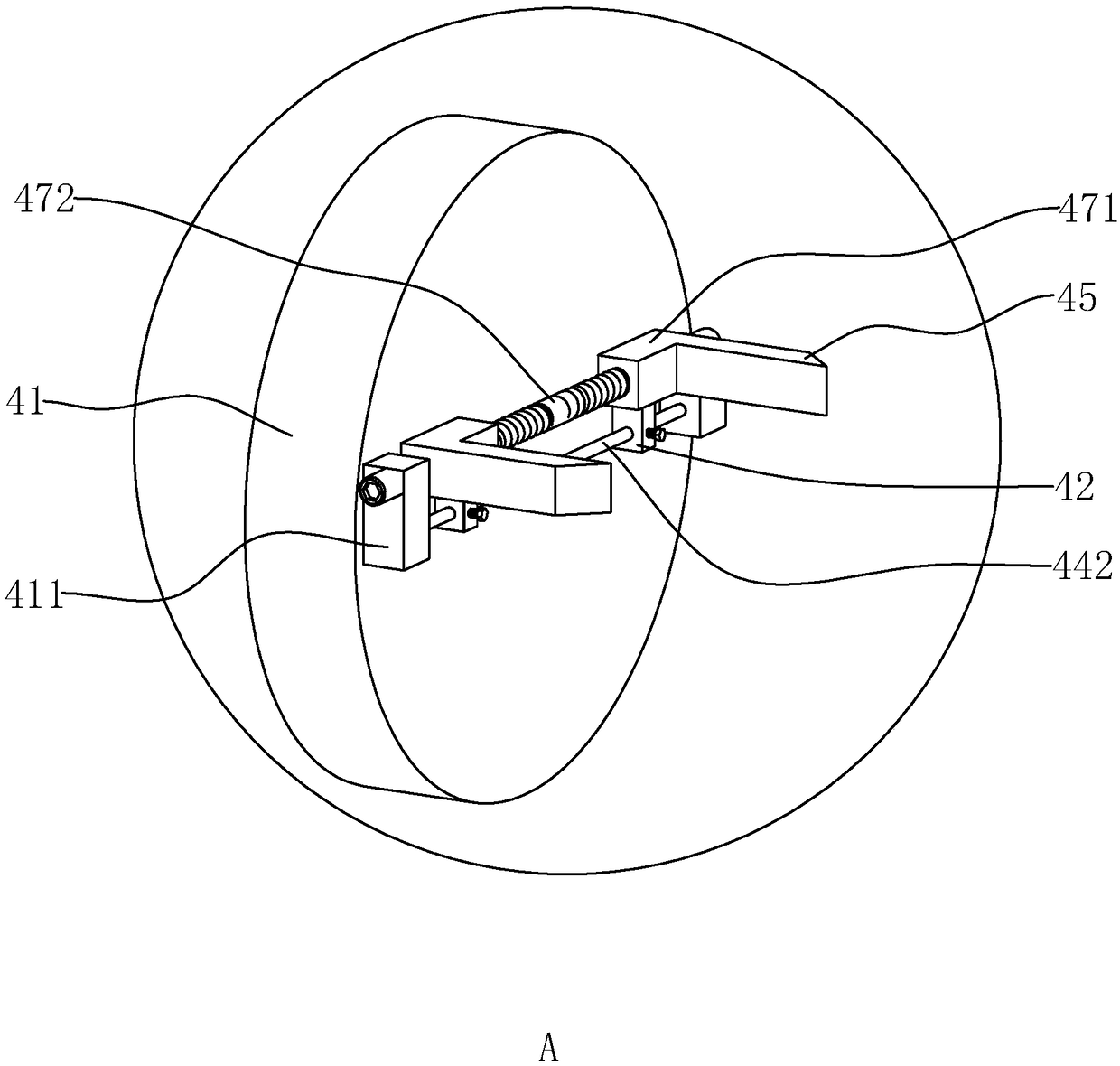

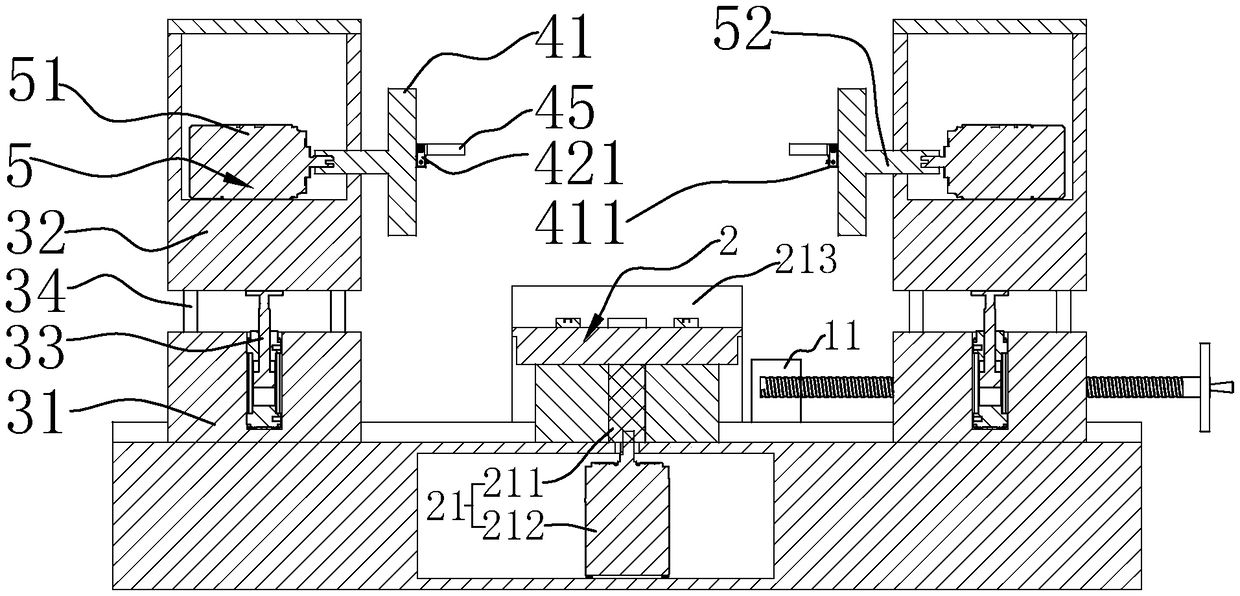

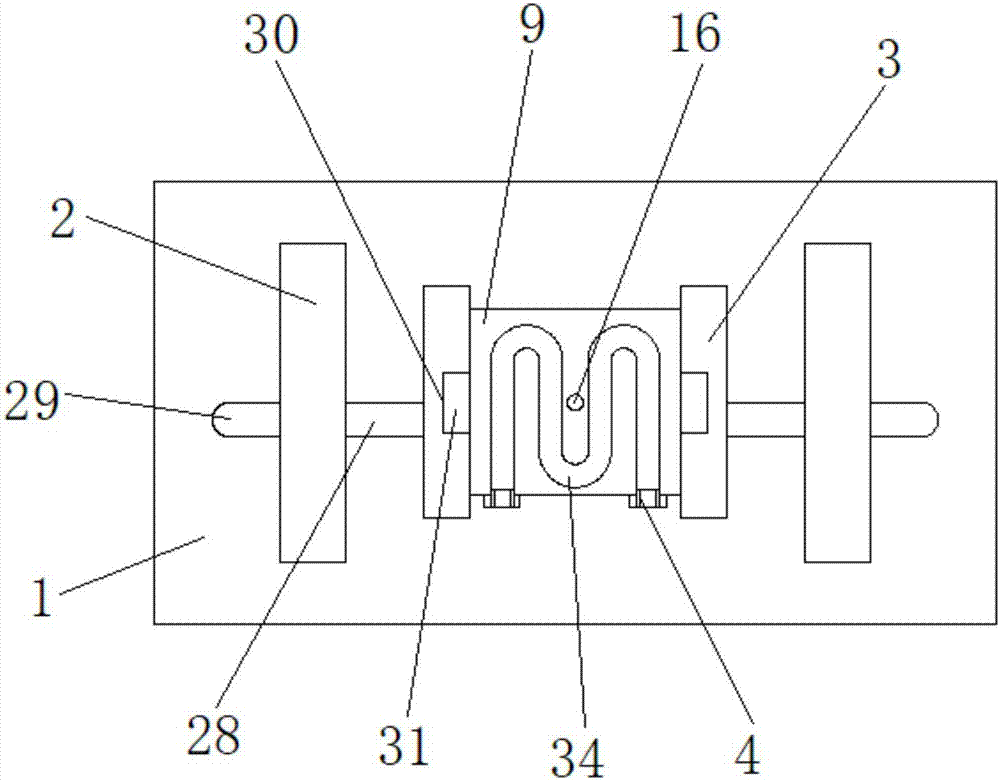

Pipe end forming machine

PendingCN108435858AAchieve replacementAvoid affecting the machining accuracyMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention discloses a pipe end forming machine comprising a rack and a control device. The rack is provided with a first forming device. The first forming device comprises a first bracket, a pushmechanism, a transposition mechanism and a clamping and pressing mechanism. The first bracket is fixed to the rack, the push mechanism is arranged at one end of the first bracket, and the clamping andpressing mechanism is arranged on the side face of the push mechanism and is connected with the first bracket. The transposition mechanism is arranged between the push mechanism and the clamping andpressing mechanism, and the transposition mechanism is internally provided with a punch shaft. One end of the punch shaft is connected with the push mechanism, the other end of the punch shaft is connected with a punch, and a feeding device is arranged behind the clamping and pressing mechanism and is fixed to the rack. The control device is connected with the push mechanism, the transposition mechanism and the clamping and pressing mechanism, and the control device is arranged on the rack. The pipe end forming machine is high in automated degree and high in machining efficiency, dies can be replaced automatically, and pipe ends of various shapes can be machined.

Owner:广州捷晟自动化控制设备有限公司

Automobile engine connecting rod locating and machining equipment

ActiveCN109531328AReasonable structureFunctionalEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses automobile engine connecting rod locating and machining equipment. The automobile engine connecting rod locating and machining equipment comprises a machining table, a locatingmechanism and a machining mechanism. A locating support seat is arranged on the upper surface of the machining table. A connecting rod support seat is arranged on the upper surface of the locating support seat. The locating mechanism comprises a small-end fixing pillar, a large-end fixing device and a rod body fixing device. The large-end fixing device comprises a hydraulic machine support seat,a hydraulic machine and a large-end fixing pillar. A connecting rod is arranged on the upper surface of the connecting rod support seat. The machining mechanism comprises a grinding wheel seat and a grinding wheel. According to the automobile engine connecting rod locating and machining equipment, a small end of the connecting rod is arranged outside the small-end fixing pillar in a sleeving manner, and the large-end fixing pillar is controlled to be in close contact with a large end of the connecting rod through the hydraulic machine, so that the connecting rod is fixed preliminarily; the rodbody fixing device is arranged at the left side of the grinding wheel seat; when the grinding wheel seat moves toward the inner side, two pressing plates are in contact with the two sides of a rod body of the connecting rod and gradually clamp, and the rod body of the connecting rod is prevented from shifting in the machining process; and locating and clamping are conducted fast and effectively.

Owner:阜南县申通机械制造有限公司

Cylindrical workpiece processing multipurpose tool

InactiveCN103100869AIncrease profitFlexible operationPositioning apparatusMetal-working holdersEngineeringDrill hole

The invention relates to a cylindrical workpiece processing multipurpose tool. The cylindrical workpiece processing multipurpose tool comprises a base, a clamping block and a jig, wherein a semicircular groove is formed in a fixing plate on the base, a locating plate is arranged at one end, arranged at the semicircular groove, of the fixing plate, and a locating column is vertically arranged on the locating plate. A big boss is arranged at the top of a clamping block, a bolt and an upper drill hole are formed in the big boss, an insert is arranged at the bottom of the clamping block, a semicircular groove is formed in the insert, and a lower drill hole is formed in the top of the insert. A small boss is arranged at the top of the jig, a drill hole is formed in the small boss, and a U-shaped square groove is formed in the bottom of the jig. The insert at the bottom of the clamping block, the U-shaped square groove at the bottom of the jig and the semicircular groove on the fixing plate form a round hole in a matching mode. An installation plate is fixed on a side, arranged on the locating plate, of the fixing plate, a locating bolt is arranged on the installation plate, a limiting block is arranged at the other end of the fixing plate, and the limiting block is over against an end of the semicircular groove of the fixing plate. The cylindrical workpiece processing multipurpose tool is simple in structure, flexible to operate, high in the utilization rate of a tool device and high in locating accuracy.

Owner:WUXI HANGHU TECH

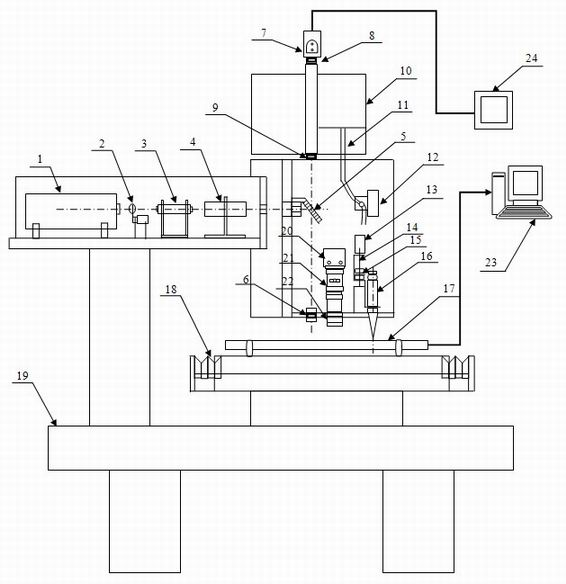

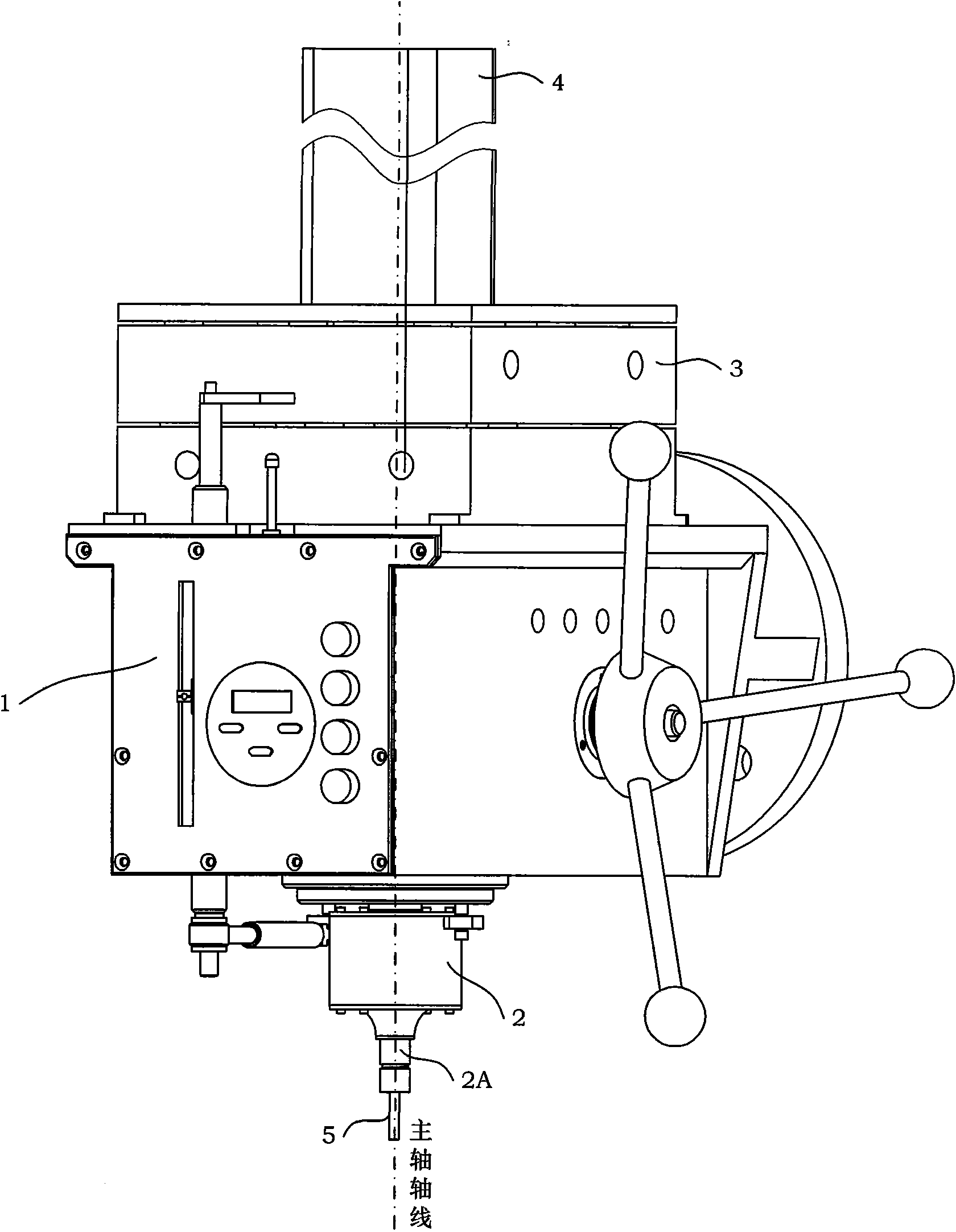

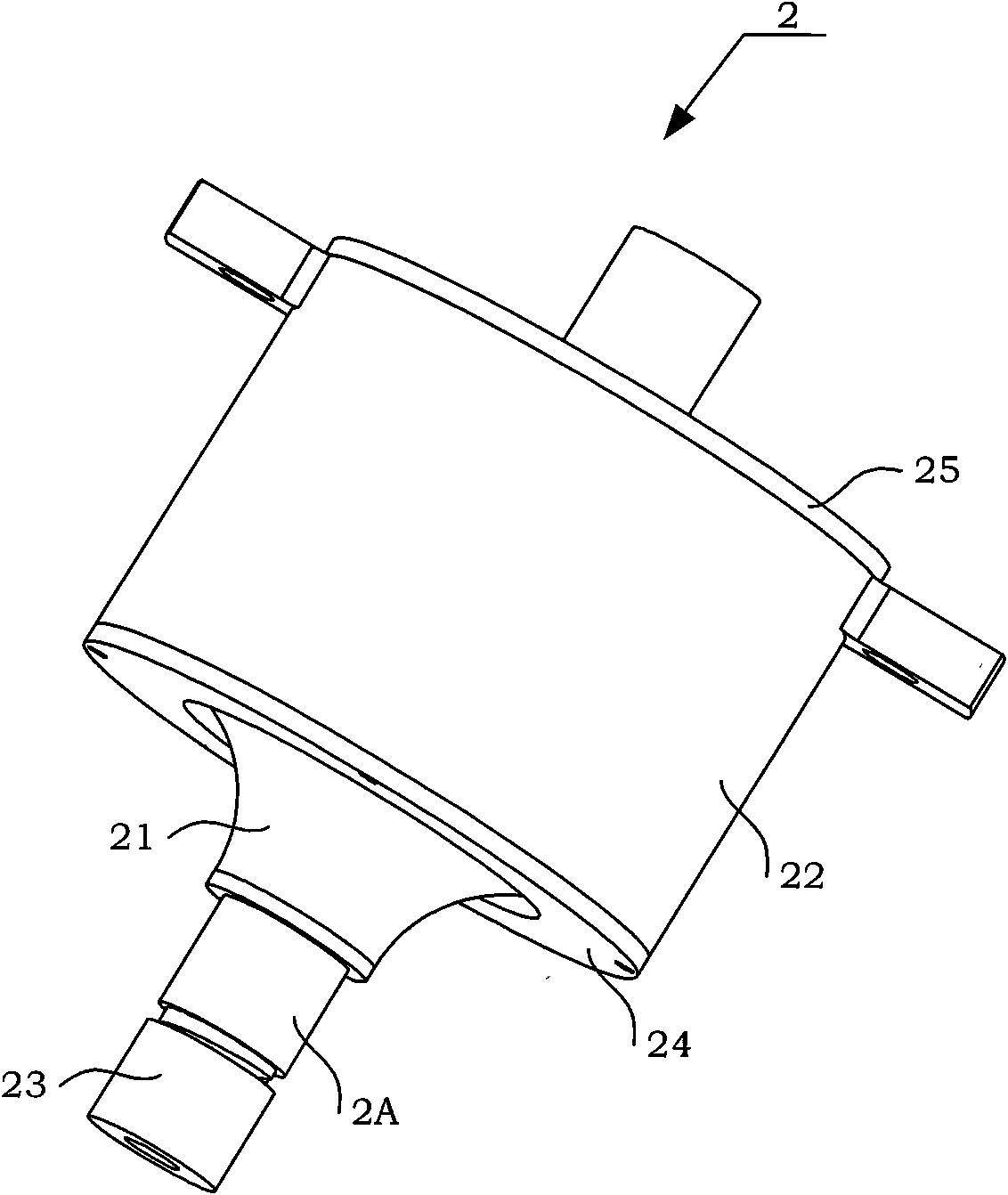

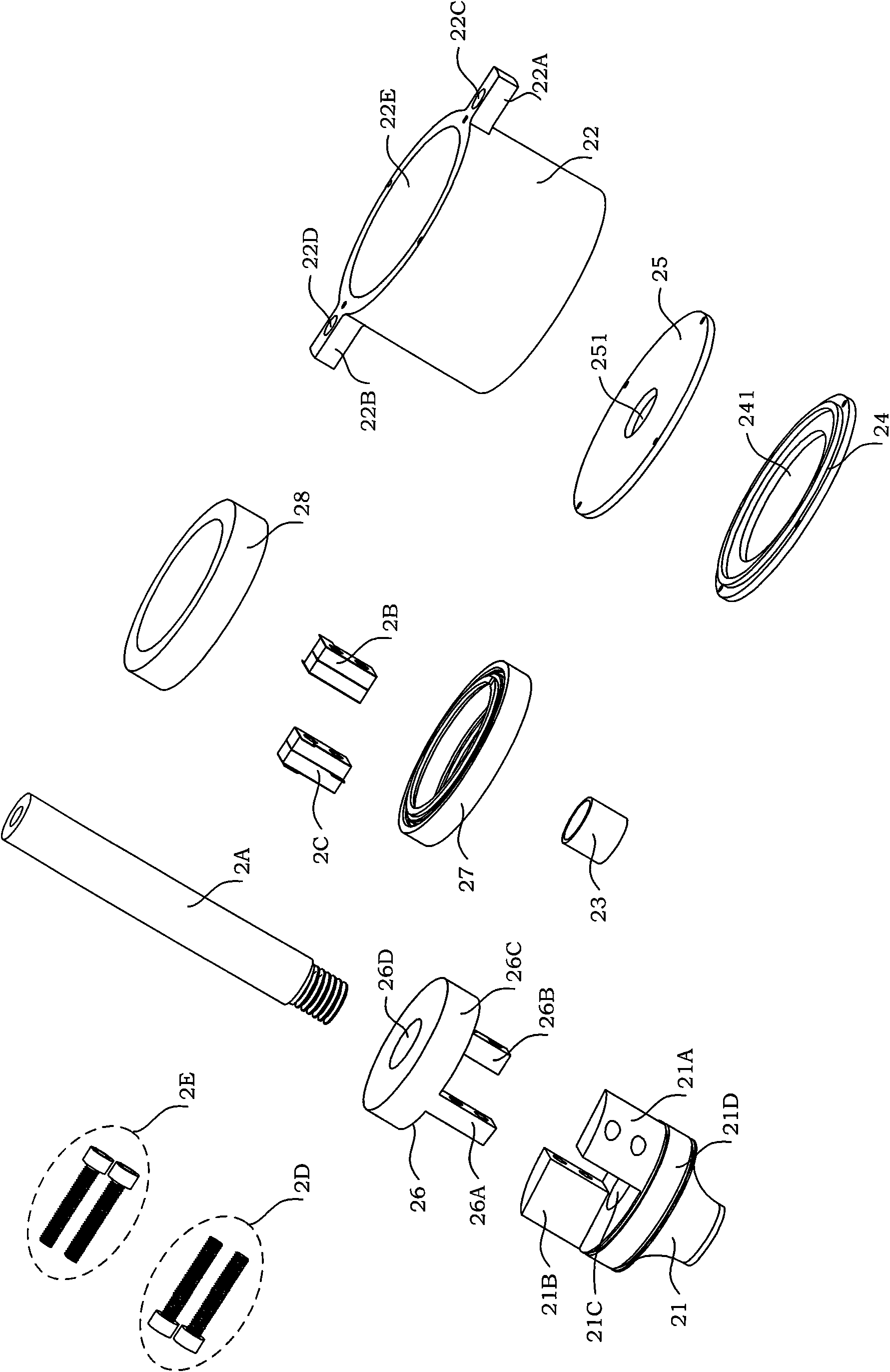

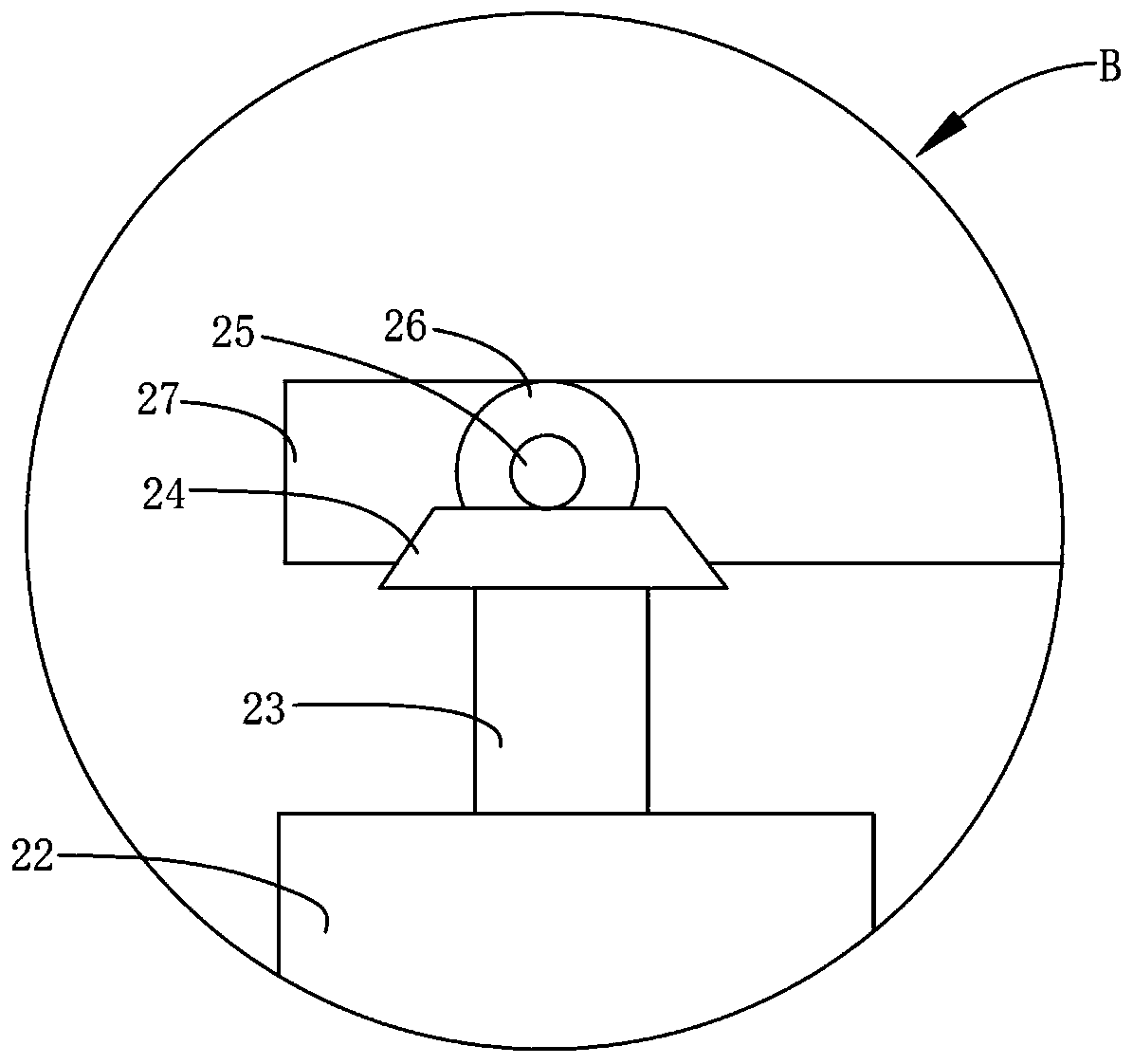

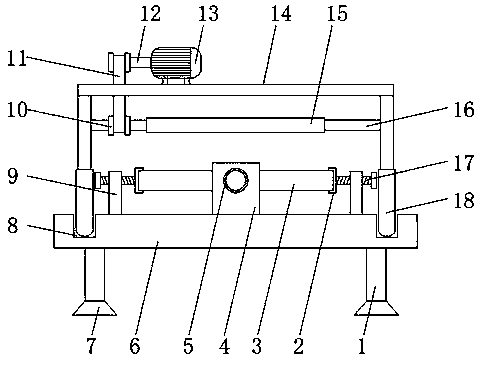

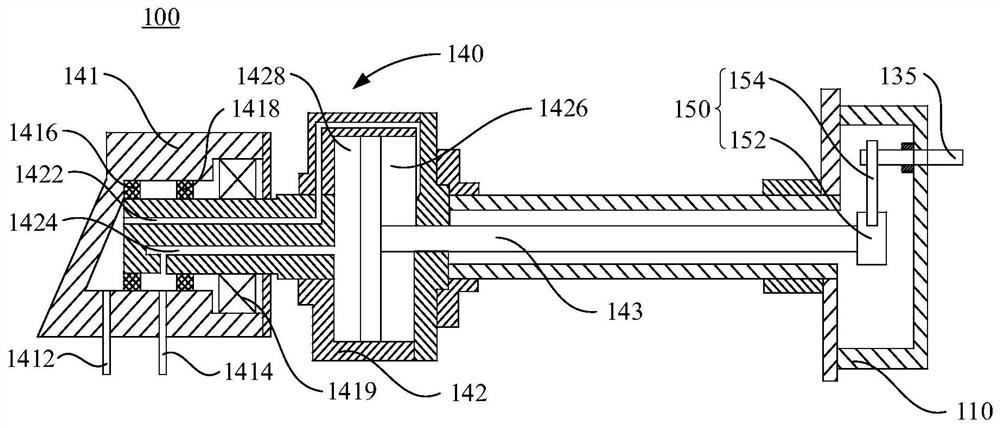

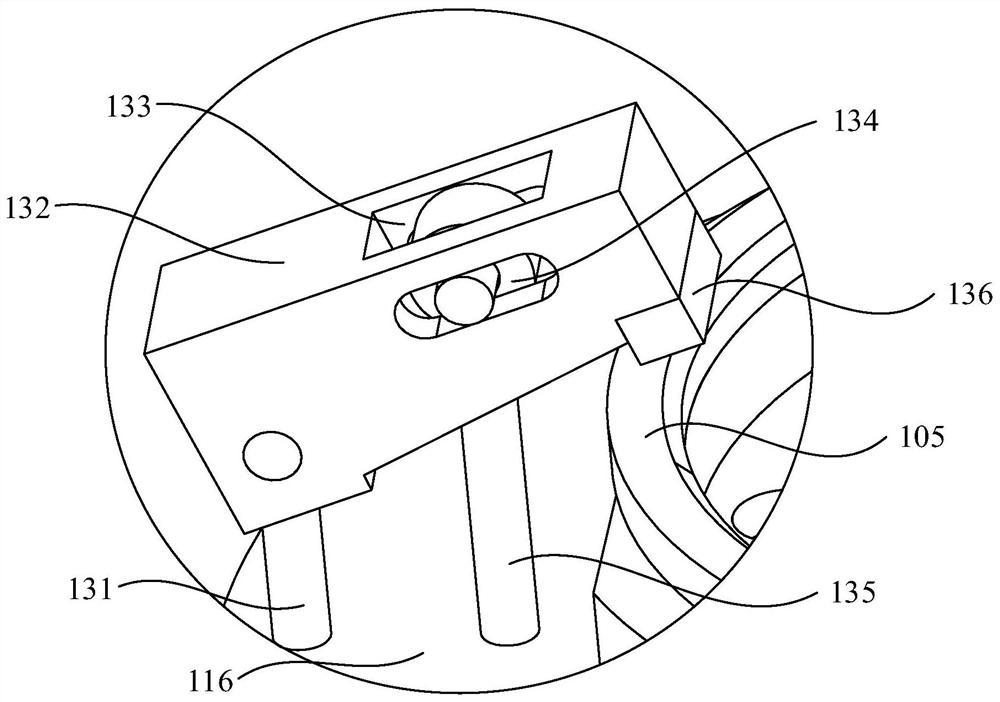

High-low frequency compound torsional vibration tapping device

InactiveCN101633064AExtended service lifeIncrease flexibilityThread cutting machinesEngineeringTorsional vibration

The invention discloses a high-low frequency compound torsional vibration tapping device comprising a main shaft mechanism, an ultraphonic transduction vibration assembly, a floating assembly and a servo motor, wherein the ultraphonic transduction vibration assembly is arranged in the main shaft mechanism; the servo motor is arranged on a supporting plate of the floating assembly; and the floating assembly is arranged on the surface of a mounting plate of a main shaft box of the main shaft mechanism. The torsional vibration tapping device can be suitable for high-low frequency compound torsional vibration tapping with low frequency less than 60 Hz and high frequency more than 16 kHz and combines low frequency torsional vibration provided by the servo motor and high frequency torsional vibration provided by the ultraphonic transduction vibration assembly, thereby realizing the high-low frequency compound torsional vibration tapping of a cutter, simplifying the structure of the device and enhancing the precision of equipment; in addition, the invention realizes the radial floating of the cutter by installing an X-directional floating assembly and a Y-directional floating assembly, prevents larger radial force from being generated during processing and realizes the flexible processing of the torsional vibration tapping device in such a way that the axial floating of a main shaft of the cutter is provided by a spline part assembly.

Owner:BEIHANG UNIV

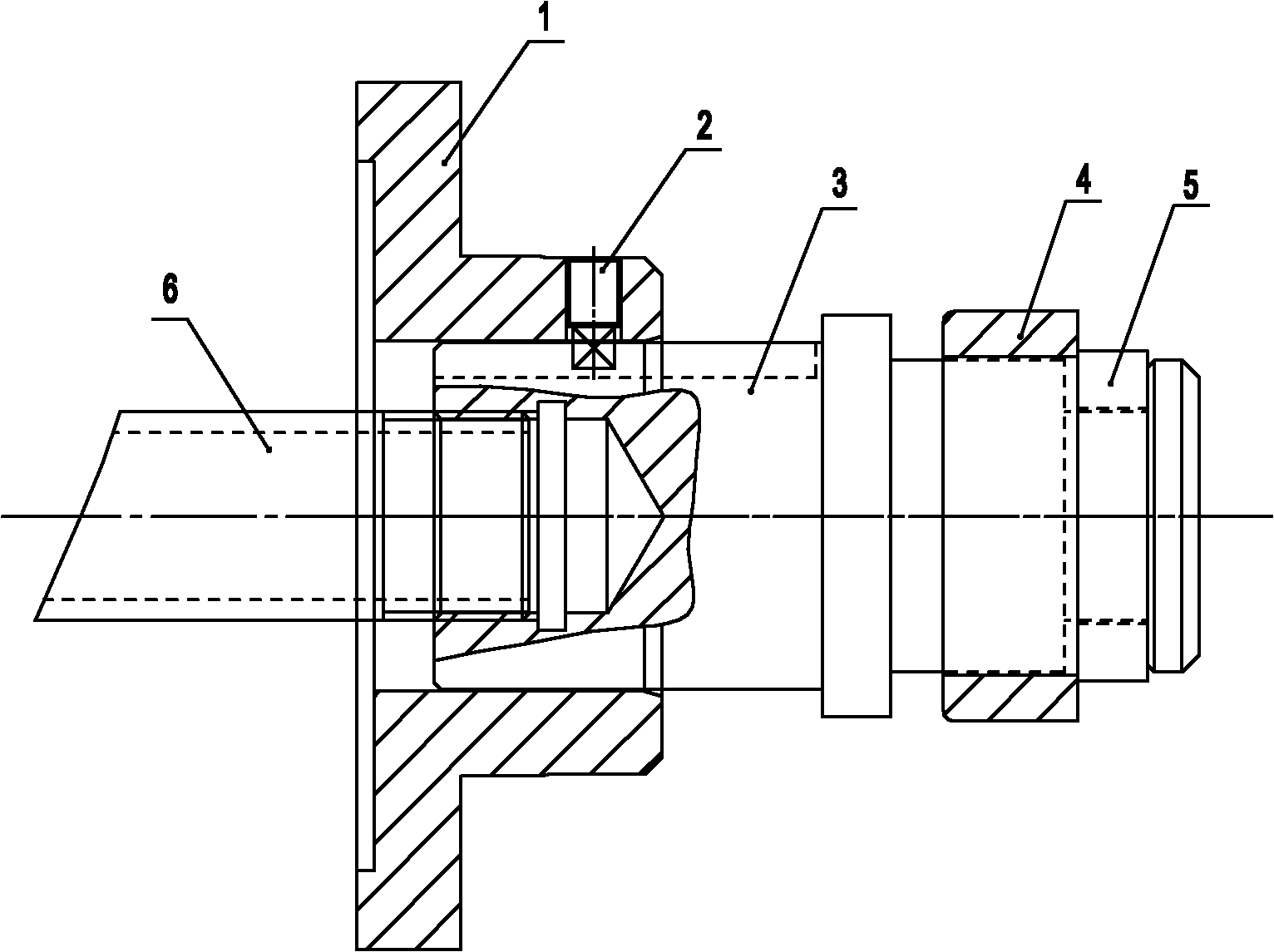

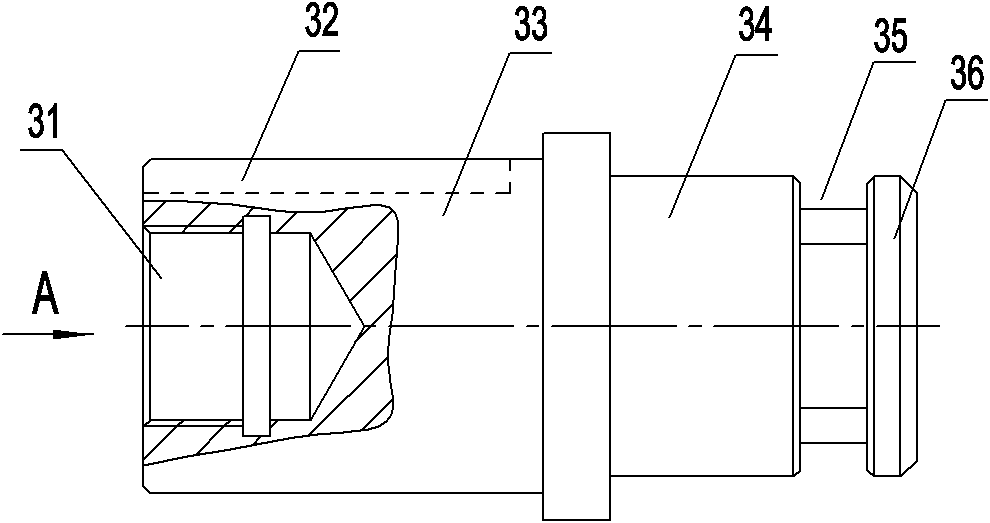

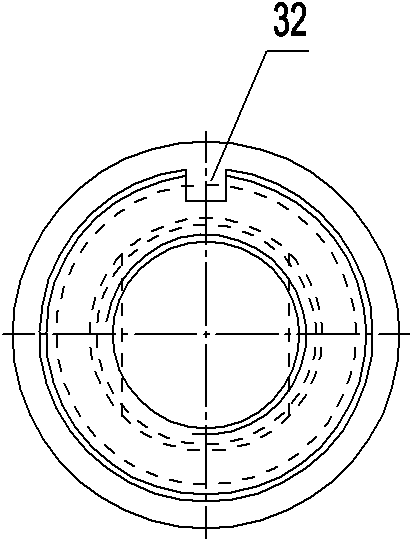

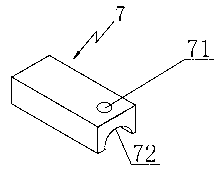

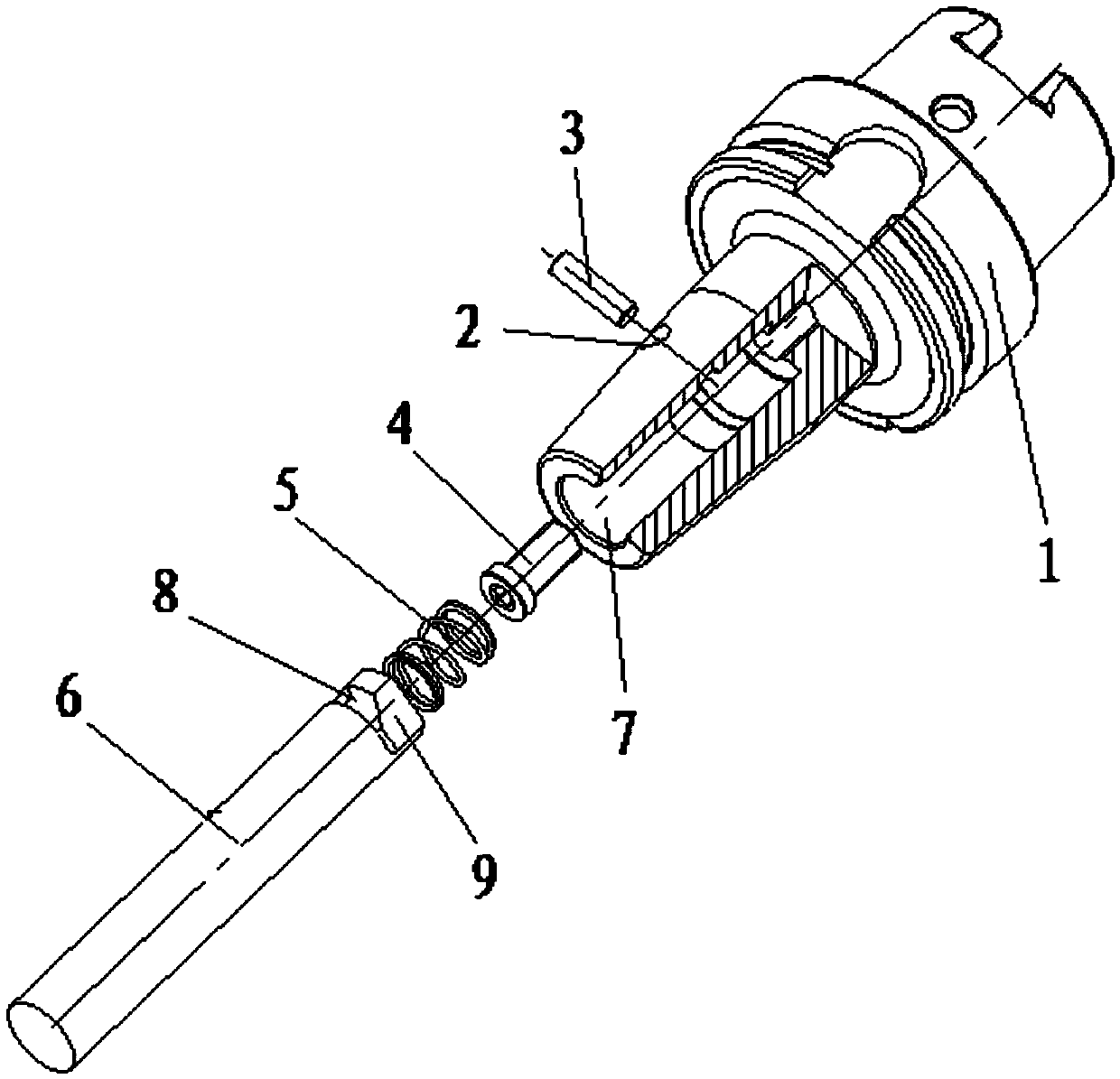

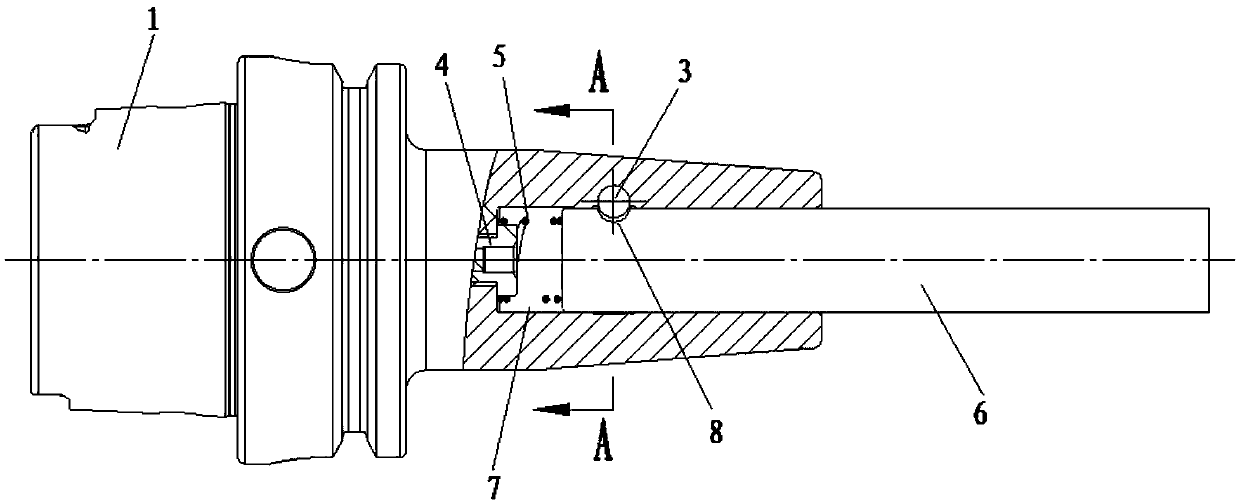

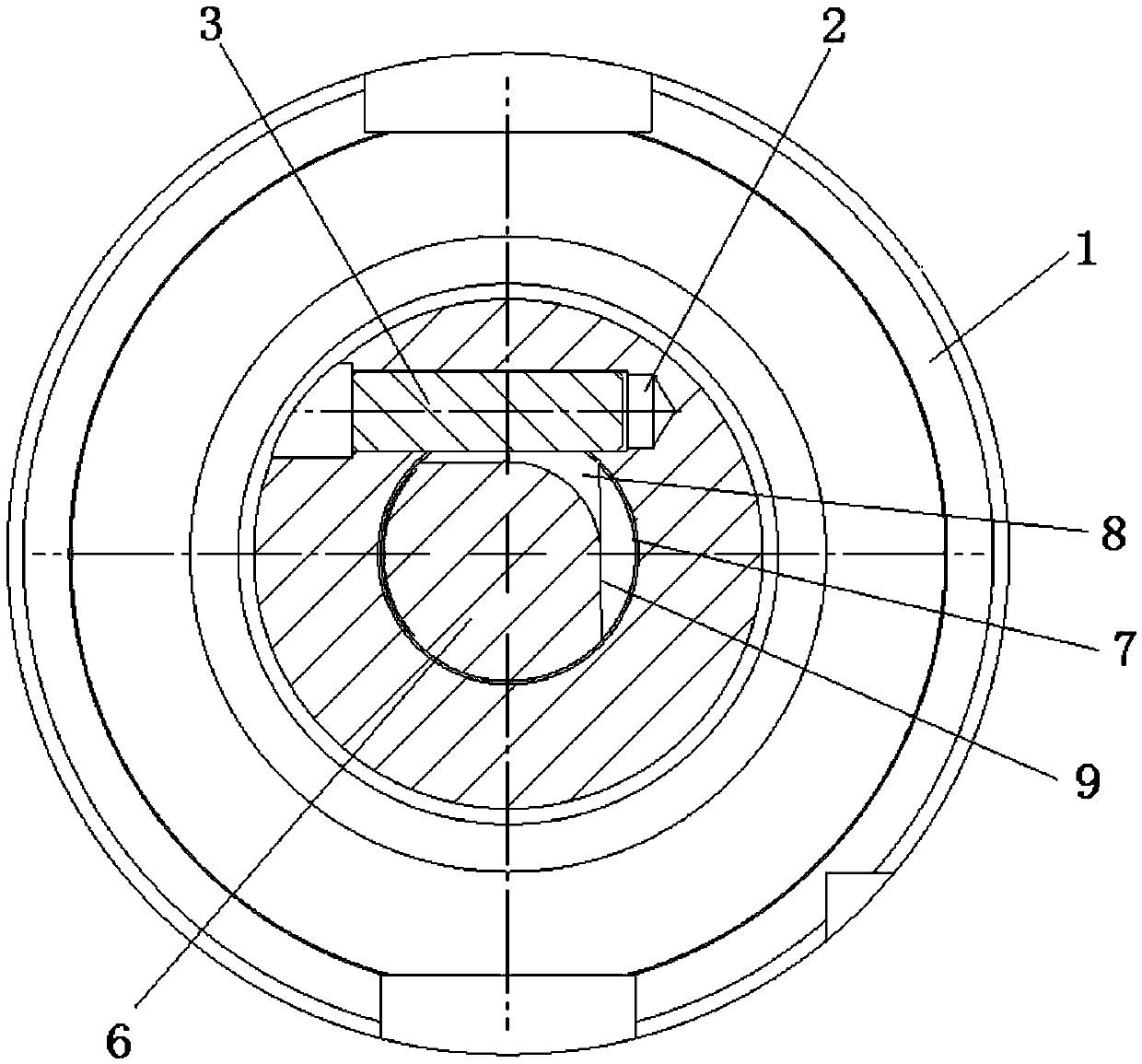

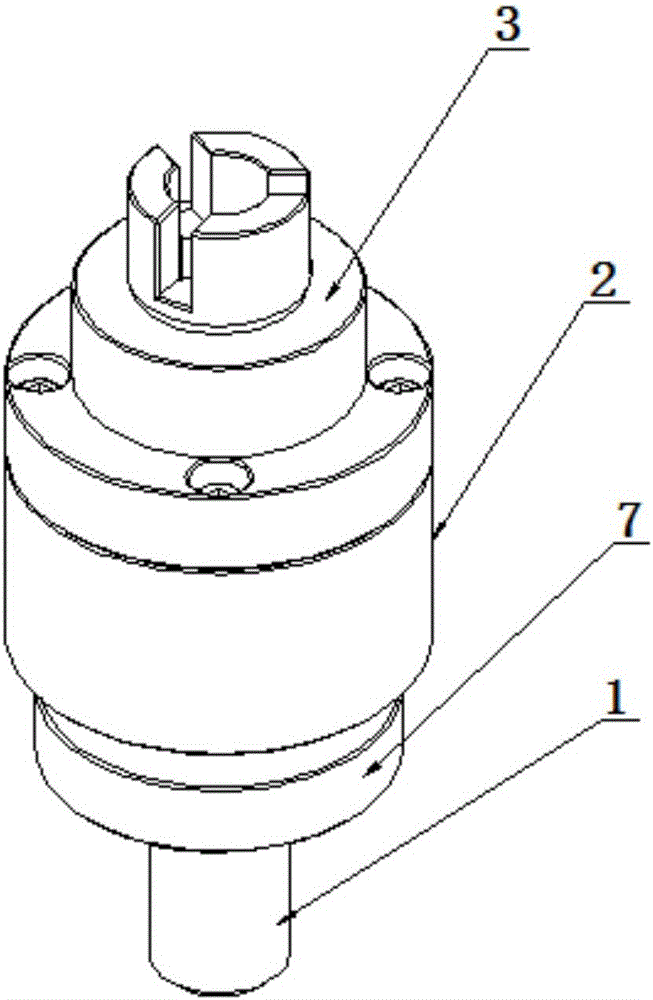

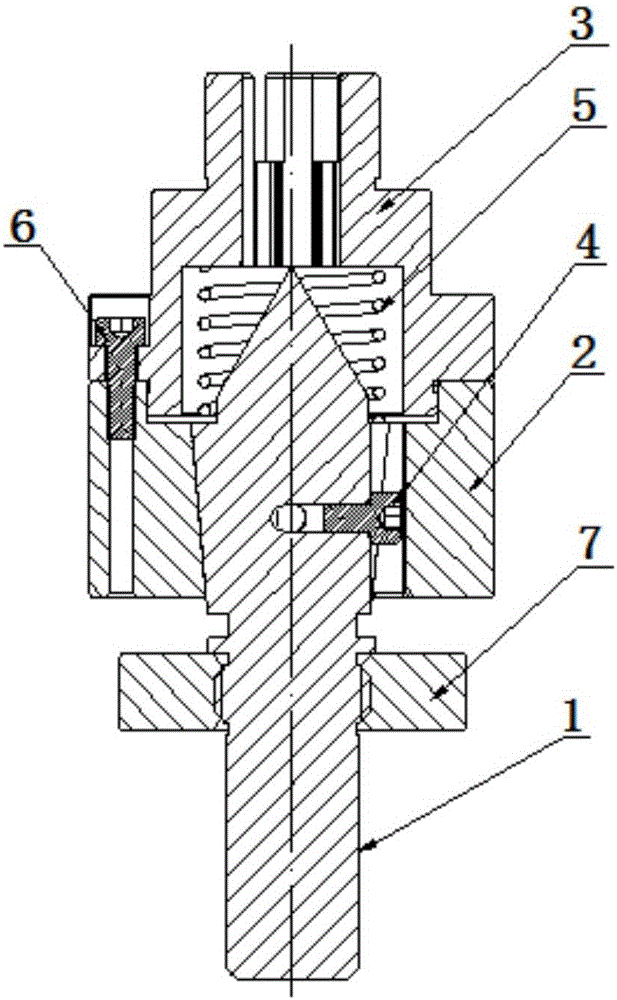

Cutter fixing structure and cutter and cutter handle suitable for same

ActiveCN105500083AEasy to assemble and disassembleAvoid affecting the machining accuracyPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a cutter fixing structure and a cutter and a cutter handle suitable for the same, relates to the field of machining tools, and provides a cutter fixing structure capable of preventing the cutter from moving. The cutter fixing structure comprises the cutter handle and the cutter, a cutter hole extending from the end of the cutter handle to the inside is formed in the cutter handle, and the cutter is inserted into the cutter hole and clamped by the cutter handle. The cutter fixing structure further comprises a safety locking pin, a locking pin hole extending from the side of the cutter handle to the inside is formed in the cutter handle, the cutter is provided with a locking pin passing groove and a retracting concave platform, the retracting concave platform extends from the end face of the cutter to the locking pin passing groove, and the safety locking pin is installed in the locking pin hole and inserted into the locking pin passing groove and is used for limiting axial movement of the cutter; when clamping on the cutter is released by the cutter handle, and the cutter is rotated till the retracting concave platform is over against the safety locking pin, the cutter moves out of the cutter handle without limitation of the safety locking pin. The cutter fixing structure is mainly suitable for shrinkage fit of the cutter handle.

Owner:CENTRIX EG

Running-in device of gear

InactiveCN110125761ASave time at workSimplify the machining processSeat surface grinding machinesPistonEngineering

The invention discloses a running-in device of a gear. The device comprises a base, a sliding plate is fixedly arranged on the base, multiple adjusting nuts are arranged on a center thread rod in a threaded manner, a running-in wheel is arranged between adjacent running-in plates in a threaded manner, a gear to be subjected to running in is arranged between adjacent positioning nuts in a threadedmanner, a second transmission wheel is fixedly connected to the center of an incomplete gear through a connecting shaft, the incomplete gear and a rack are movably engaged, a pushing plate is movablyarranged in a piston, the piston is provided with an air outlet pipe and an air inlet pipe in a communication manner, and one-way valves are arranged in the air outlet pipe and the air inlet pipe. According to the running-in device of the gear, the device can adapt to multiple specifications of gears, the multiple gears can be subjected to running-in at the same time, the gear face and two planesof the gears can be subjected to running in at the same time, the efficiency is higher, a device capable of blowing off and collecting abrasive dust is internally arranged, and the machining of the running-in gear can be effectively improved.

Owner:BENGBU COLLEGE

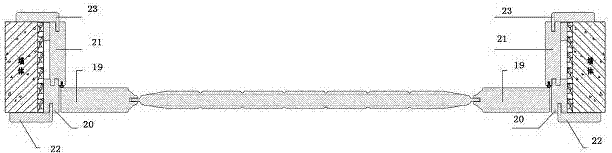

Shaft coupling used between motor rotating shaft and spline connecting shaft

InactiveCN107202074ASo as not to damageAvoid corrosionCouplings for rigid shaftsMechanical energy handlingMaximum diameterCoupling

The invention provides a shaft coupling used between a motor rotating shaft and a spline connecting shaft. The shaft coupling used between the motor rotating shaft and the spline connecting shaft comprises a left sleeve chuck, a right sleeve chuck, a shaft sleeve and a conical sleeve; a positioning key which is fixed in the axis direction is welded on the outer surface of the left sleeve chuck; the positioning key is clamped in a positioning groove in the motor rotating shaft; the shaft sleeve is connected with the left sleeve chuck; internal threads are formed on the inner side of the right sleeve chuck and are matched with external threads on the shaft sleeve; the two ends of the shaft sleeve are open; the inside diameter of the opening in one end, which is in contact with the left sleeve chuck, of the shaft sleeve is smaller than that of the opening in the other end of the shaft sleeve, so that a conical through hole is formed; the conical sleeve which is matched with the conical through hole of the shaft sleeve is arranged in the shaft sleeve; a shaft hole is formed in the conical sleeve; tightening openings are formed in the end surfaces of the left sleeve chuck and the right sleeve chuck; the inside diameters of the tightening openings are greater than the inside diameter of the shaft hole and smaller than the maximum diameter of the conical sleeve; and the conical sleeve is extruded to the shaft sleeve through the tightening openings by rotating the right sleeve chuck. The shaft coupling provided by the invention is simple in structure; force is applied to the spline connecting shaft uniformly; a fixing effect is good.

Owner:HUBEI WEINENGDA TRANSMISSION CO LTD

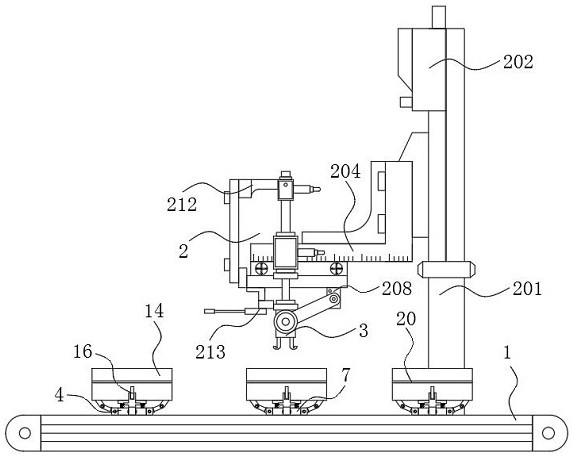

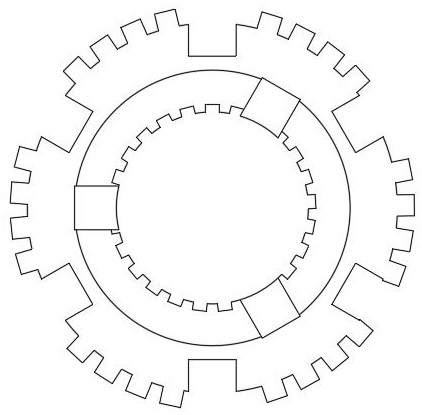

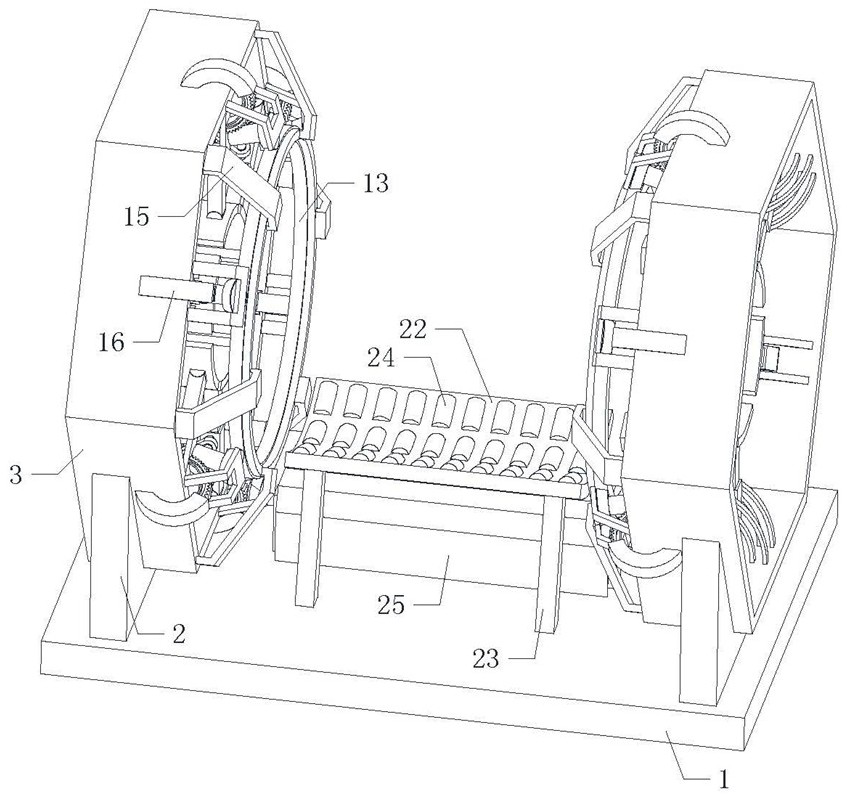

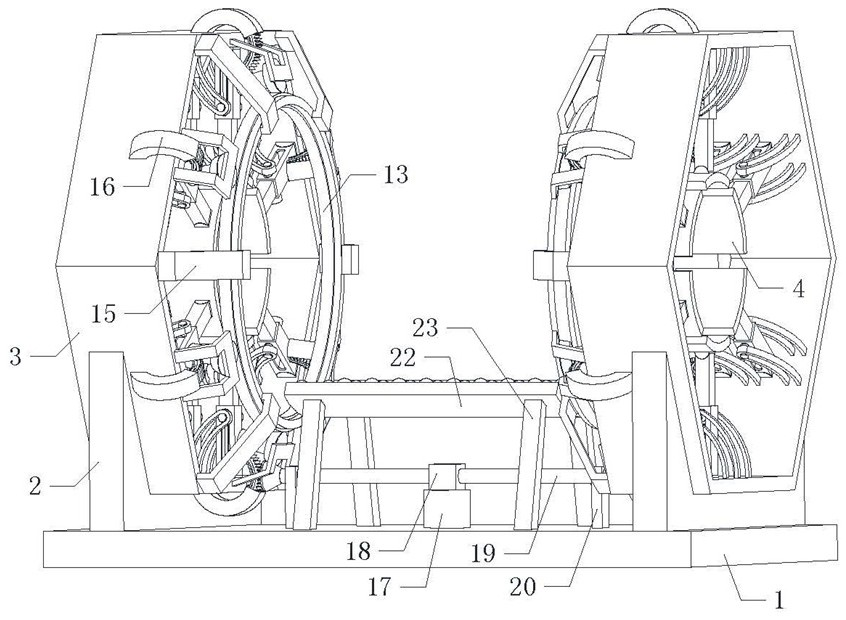

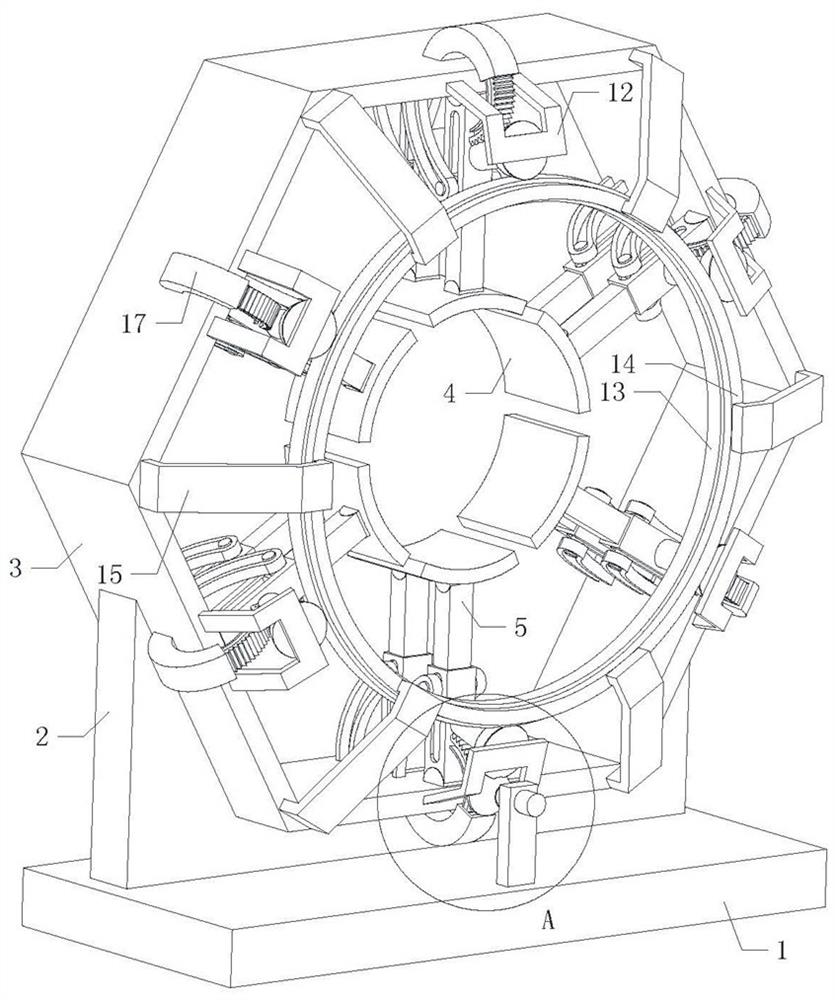

Automatic splined hub machining equipment with function of integrally forming tooth profile

InactiveCN112222339AIt has the function of tooth shape integral formingEasy to adjustMetal-working feeding devicesGear wheelsMotor vehicle partStructural engineering

The invention discloses an automatic splined hub machining equipment with the function of integrally forming a tooth profile, and relates to the technical field of automobile part production. The equipment specifically comprises a conveying belt, a quantitative conveying mechanism, an inner hole end face axial linkage clamp, a movable clamping mechanism and a tooth profile forming composite die, wherein the quantitative conveying mechanism is arranged at the top end of the conveying belt, and the movable clamping mechanism is arranged on one side of the top end of the conveying belt. Accordingto the automatic splined hub machining equipment with the function of integrally forming the tooth profile, the tooth profile forming composite die is arranged, so that the problems that in the background art, the efficiency is low and the production cost is high due to common sequential single-tooth machining of existing splined hub material outer tooth spline machining equipment are perfectly solved; due to the design of the die, integral forming and final shaping of tooth bottoms, tooth tops and tooth sides of outer teeth of a splined hub are achieved, it is guaranteed that the dimensionalprecision of a workpiece meets the requirement after extrusion forming through uniform distribution of rolling components and release frames located in inner cavities of two layers of annular supports, and the applicability is higher.

Owner:东莞市帕特慕可科技有限公司

Stamping device capable of automatically correcting and stamping workpieces

InactiveCN112246996AHigh precisionImprove pass rateMetal-working feeding devicesPositioning devicesHydraulic cylinderStructural engineering

The invention discloses a stamping device capable of automatically correcting and stamping workpieces in the technical field of stamping devices. The stamping device comprises a stamping mechanism andan automatic calibration mechanism, the automatic calibration mechanism is arranged at the middle position of the stamping mechanism, the stamping mechanism comprises a base, supporting stand columnsare fixedly connected to the left and right sides of the top of the base, the tops of the two supporting stand columns are jointly and fixedly connected with a supporting plate, and a hydraulic cylinder is fixedly connected to the middle position of the bottom of the supporting plate. When the hydraulic cylinder descends and before stamping is carried out, push blocks on the periphery are automatically driven to to accurately position a plate at the stamping position, then the hydraulic cylinder continues to descend to stamp the plate again, and therefore accurate positioning of the stampingcenter position of the plate is achieved, the plate machining precision is greatly improved, and the plate stamping percent of pass is greatly increased.

Owner:吉安持凡电子科技有限公司

Cutting device with high precision

InactiveCN112454507APrevent slippingImprove stabilityMetal working apparatusElectric machineryProcessing accuracy

The invention relates to a cutting device with high precision. The cutting device comprises a fixing box, a motor, a lifting mechanism, a clamping mechanism and detecting mechanisms, the clamping mechanism comprises a blade, a connecting assembly and clamping assemblies, and each detecting mechanism comprises a connecting plate, an abutting rod, a ball, a supporting rod, a second spring and a sliding block. According to the cutting device with high precision, elastic clamping of the blade is achieved through the clamping mechanism, positioning of the blade is achieved through positioning pins,the blade can rotate better, slipping of the blade is prevented, limiting of the center of the blade is achieved through positioning rods, the axis of the blade coincides with the axis of a motor rotating shaft all the time, the stability of the blade is improved, installation is convenient, the blade is detected through the detection mechanisms, the situation that the blade deforms after being used for a long time, and consequently the machining precision is affected is prevented, and the use practicability is improved.

Owner:陆明祘

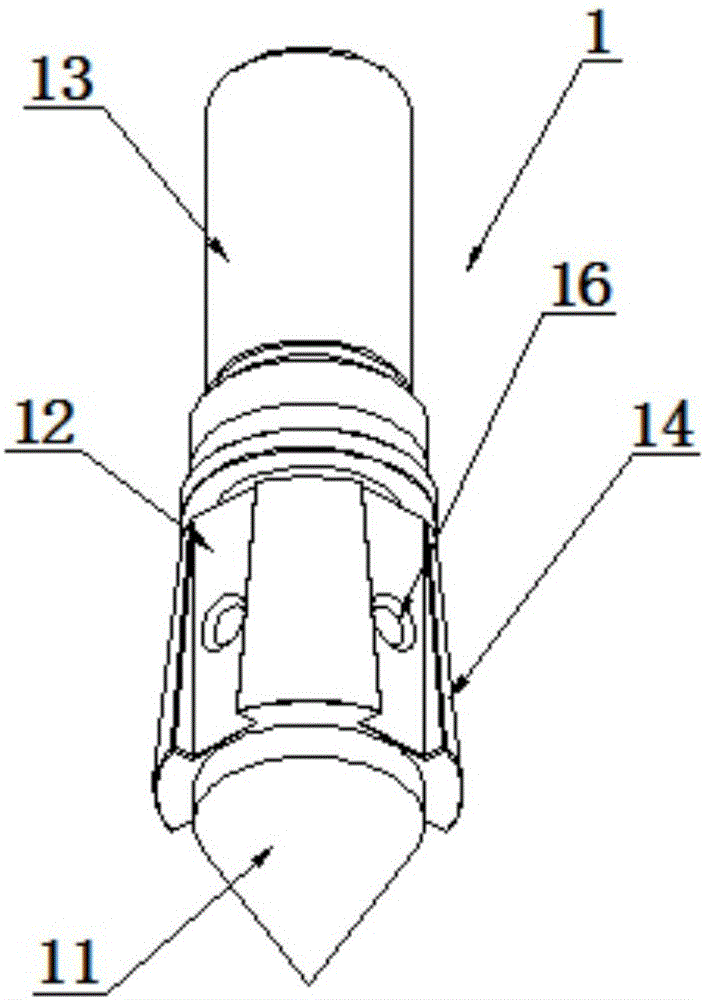

Fixture for performing excircle finish turning on starter armature

ActiveCN105798681AIncrease contact areaPrevent looseningTailstocks/centresPositioning apparatusRelative displacementLocking mechanism

The invention discloses a fixture for performing excircle finish turning on a starter armature. The fixture comprises a centre which sequentially comprises a tip part, an adjustment part and a rod part. The fixture further comprises a center hole adjustment sleeve and a rough positioning sleeve which is of a hollow structure, wherein the center hole adjustment sleeve is arranged on the adjustment part in a sleeving manner, the rough positioning sleeve and the center hole adjustment sleeve are coaxially installed, the rough positioning sleeve is arranged on the tip part in a sleeving manner, and an inner cavity of the rough positioning sleeve is provided with a clamping tooth matched with the starter armature. The fixture further comprises a spring adjustment mechanism and a radial locking mechanism, wherein the spring adjustment mechanism is arranged between the center hole adjustment sleeve and the rough positioning sleeve and used for adjusting relative displacement between the centre and the clamping tooth, and the radial locking mechanism is arranged in the center hole adjustment sleeve and used for limiting rotation of the centre. The fixture for performing excircle finish turning on the starter armature is stable in structure and convenient to operate, the coaxial precision of clamping and machining precision of the starter armature are effectively improved, and the production efficiency is greatly improved.

Owner:GUANGXI YUCHAI BONAITE ELECTRIC APPLIANCE

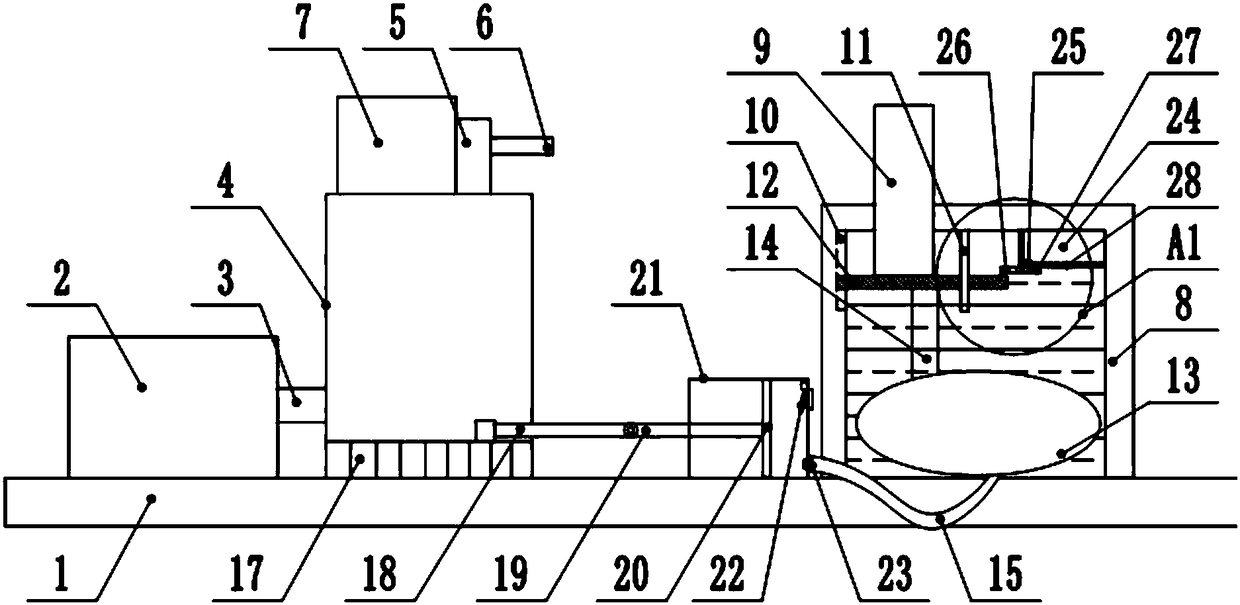

Metal processing device with generating method

InactiveCN108907752AAvoid affecting the machining accuracyReduce shakingFeeding apparatusLarge fixed membersEngineeringMechanical engineering

The invention discloses a metal processing device with a generating method. The metal processing device is technically characterized by comprising a base, a working table mounted on the base and rotating horizontally, a cutting device rotating vertically, a cutting driving device for driving the cutting device to rotate, and a moving device driving the cutting device to move horizontally along thebase toward a workpiece to be processed, wherein the working table is provided with a fixing clip for fixing the workpiece to be processed; the cutting device is used for cutting the workpiece; and after the workpiece is fixed by the fixing clip, the working table drives the workpiece to rotate horizontally, then the moving device drives the cutting device to horizontally approach the workpiece to be processed along the base, and then the cutting driving device drives the cutting device to perform vertical rotation, thereby performing spherical cutting on the workpiece on the working table.

Owner:BEIJING SHAHE METALLURGICAL MACHINE MFGCO

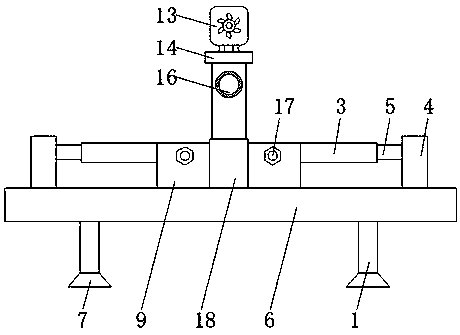

Key slot machining device

InactiveCN108161483ASlow contactAvoid damageFeeding apparatusLarge fixed membersIodine solutionsEngineering

The invention relates to a key slot machining device. The key slot machining device comprises a rack, a cylinder and a supporting table; the supporting table and the cylinder are connected and slidably connected to the rack; the supporting table is provided with a machining cutter; the rack is further provided with a machining tank, and an iodine solution is stored in the machining tank; the machining tank is provided with a first sliding chute and a second sliding chute, and a supporting plate is slidably connected between the first sliding chute and the second sliding chute; the bottom of astorage box is fixedly connected with an air bag, the upper portion of the air bag is fixedly connected with a moving rod, and the bottom of the air bag is connected with an air guide pipe; a rack isarranged at the bottom of the supporting table and engaged with a gear, a first connection rod is rotationally connected to the eccentric position of the gear, the other end of the first connection rod is rotationally connected with a second connection rod, and the other end of the second connection rod is fixedly connected with a sliding plate; and the rack is further fixedly connected with a collecting tank, the sliding plate is slidably connected in the collecting tank, the collecting tank is provided with an air inlet and an air outlet, and the air outlet communicates with the air guide pipe. By means of the key slot machining device, the problem that scraps generated in the machining process of key slots affect the machining precision of the key slots is solved.

Owner:宁波德深机械设备有限公司

Efficient polishing device for wood board used for furniture processing

InactiveCN109986452AReduce processing timeImprove processing efficiencyPolishing machinesGrinding drivesDrive shaftArchitectural engineering

The invention discloses an efficient polishing device for a wood board used for furniture processing. The efficient polishing device comprises a placement frame, a hollow base, clamping plates and a cover plate, wherein fixed blocks are welded on the two sides of the upper end of the hollow base, two telescopic rods are symmetrically and movably mounted on the two sides, away from the fixed blocks, of the upper end of the hollow base through chutes, second rotating rods are rotationally mounted on the telescopic rods, a polishing shaft is welded between the two symmetrically distributed secondrotating rods, the cover plate is welded at the top ends of the two symmetrically distributed telescopic rods, a motor is mounted at the upper end of the cover plate, a driving shaft is mounted on one side of the motor, the two sides of the placement frame are rotationally mounted on the fixed blocks through first rotating rods, the clamping plates are mounted on the hollow base, first threaded rods are mounted on the clamping plates through threads, and a clamping blocks is mounted at one end of each first threaded rod. According to the efficient polishing device for the wood board used forthe furniture processing, the placement frame rotates through the first rotating rods after one surface of the wood board is polished, so that the unpolished surface of the wood board is turned over and is subjected to polishing work.

Owner:常鑫

Clamping device for metal machining

ActiveCN113245877AImprove clamping strengthImprove stabilityPositioning apparatusMetal-working holdersMetal machiningEngineering

The invention relates to the technical field of clamping tools, in particular to a clamping device for metal machining. The clamping device comprises a base, two installing plates are symmetrically arranged on the base, polygonal outer frames are arranged on the installing plates, a plurality of arc-shaped clamping plates are annularly and uniformly distributed inside the polygonal outer frame, and the number of the arc-shaped clamping plates corresponds to that of the edges of the polygonal outer frame. According to the structure, the clamping strength of a metal part can be effectively improved, the stability of the metal part during machining is improved, the situation that the part moves and influences the machining precision is avoided, meanwhile, the equipment can automatically clamp the part, manpower during manual operation is simplified, and practicability is improved.

Owner:WEIFANG BUSINESS VOCATIONAL COLLEGE

Fixture for roof prism gluing part production

The invention discloses a fixture for roof prism gluing part production, and belongs to the technical field of optical component production. The fixture for roof prism gluing part production comprises a base, two limit blocks, three square flat plates, a 45-degree rest and a square brick. Glue grooves are formed in the middles of the limit blocks, a glue groove is formed in the middle of a large surface of the 45-degree rest, the square brick has a 90-degree angle, angular accuracy is within 1', the two limit blocks are vertically used, the three square flat plates are placed among the two limit blocks and the base and between a semi-finished product and the base, the surface evenness of the base is lambda / 4, the finish degree of the base is second level, accuracy of the 90-degree angle of the limit blocks is within 30', and the tolerance of the square flat plates is + / -0.01mm. Processing accuracy of a roof ridge surface is ensured, processing cycle is shortened, working efficiency and angular accuracy are improved, dimensional errors are decreased, and product qualification ratio is increased.

Owner:JIANGNAN OPTICS CO LTD

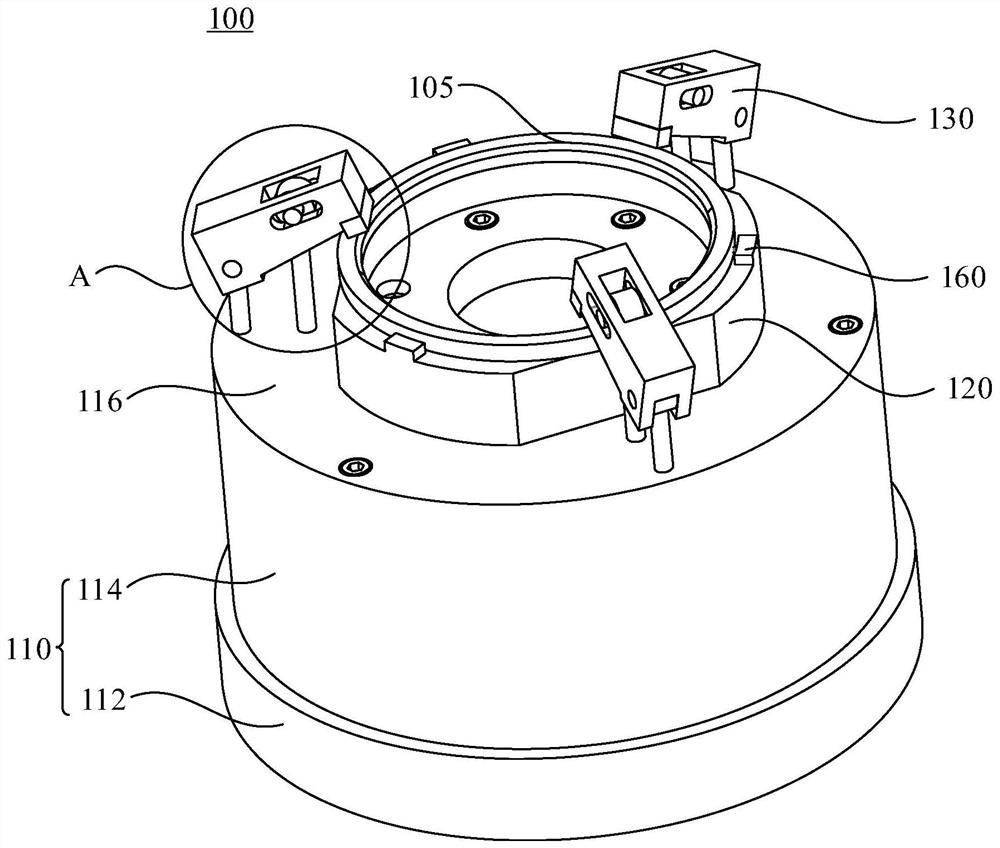

Automatic workpiece fixing clamp and machining equipment

PendingCN112692315AAvoid deformationImprove the efficiency of clamping and fixingChucksMachine buildingStructural engineering

The invention discloses an automatic workpiece fixing clamp and machining equipment, and relates to the technical field of machine manufacturing. The automatic workpiece fixing clamp comprises a fixing base and a positioning chuck arranged on the fixing base. A plurality of clamping assemblies are further arranged on the mounting face, provided with the positioning chuck, of the fixing base in a circumferential array mode, the positioning chuck is used for containing a workpiece, and the automatic workpiece fixing clamp further comprises a driving assembly. The driving assembly is in transmission connection with the clamping assemblies through transmission assemblies arranged in the fixing base, and the clamping assemblies are driven to axially clamp or loosen the workpiece. The consistency of clamping force can be improved, deformation of the workpiece is avoided, and the workpiece clamping and fixing efficiency is improved.

Owner:南京一顺汽车零部件有限公司

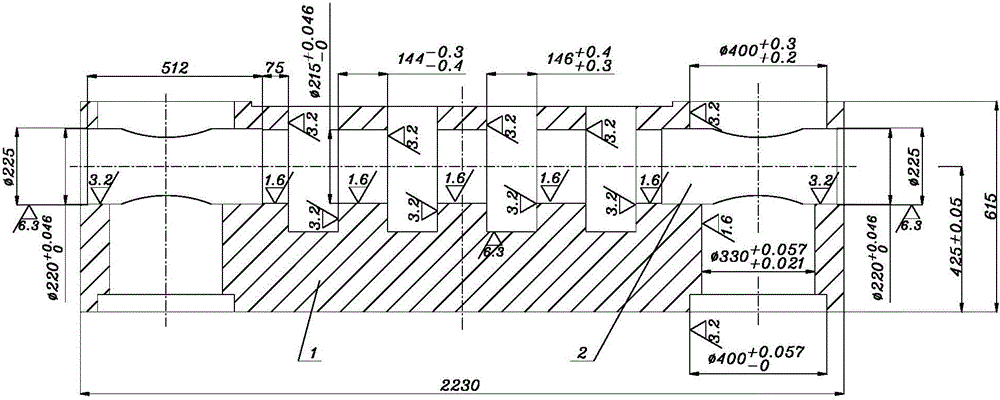

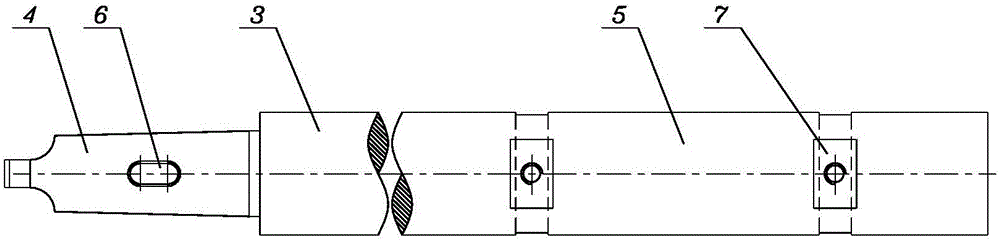

Method for machining overlong concentric ladder through hole on ordinary boring machine through lengthening boring cutter rod

ActiveCN105834481AGuaranteed sizeGuaranteed geometric toleranceBoring barsBoring/drilling machinesPosition toleranceSurface roughness

The invention relates to a method for machining an overlong concentric ladder through hole on an ordinary boring machine through a lengthening boring cutter rod. The method comprises the steps that 1, all parts of a workpiece are subjected to rough machining, and the periphery of the workpiece is subjected to finish machining; 2, the workpiece is subjected to alignment and clamping; 3, the lengthening boring cutter rod is composed of a taper shank section and a bare shaft section, the bare shaft section is provided with a plurality of boring cutter grooves in the longitudinal direction, and the shaft end of the bare shaft section is sleeved with a sliding sleeve; 4, a tailstock bracket is installed on the ordinary boring machine; 5, the lengthening boring cutter rod penetrates through the concentric ladder through hole, one end of the taper shank section is connected with a spindle of a machine tool, one end of the bare shaft section is installed on the tailstock bracket through the sliding sleeve, and the sliding sleeve and the tailstock bracket are tightly locked; a boring cutter body is installed, and try cutting is conducted; and 7, after try cutting is qualified, all the parts of the concentric ladder through hole are subjected to finish machining to reach the requirement of a drawing. According to the method for machining the overlong concentric ladder through hole on the ordinary boring machine through the lengthening boring cutter rod, existing machine tool auxiliaries are fully utilized, and the situation that the bore hole machining precision is influenced due to sinking of the lengthening boring cutter rod is avoided; and the effect that the size, the form and position tolerance and the surface roughness of the overlong concentric ladder through hole machined on the ordinary boring machine meet the requirements is ensured, so that the machining cost is reduced, and the production efficiency is improved.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

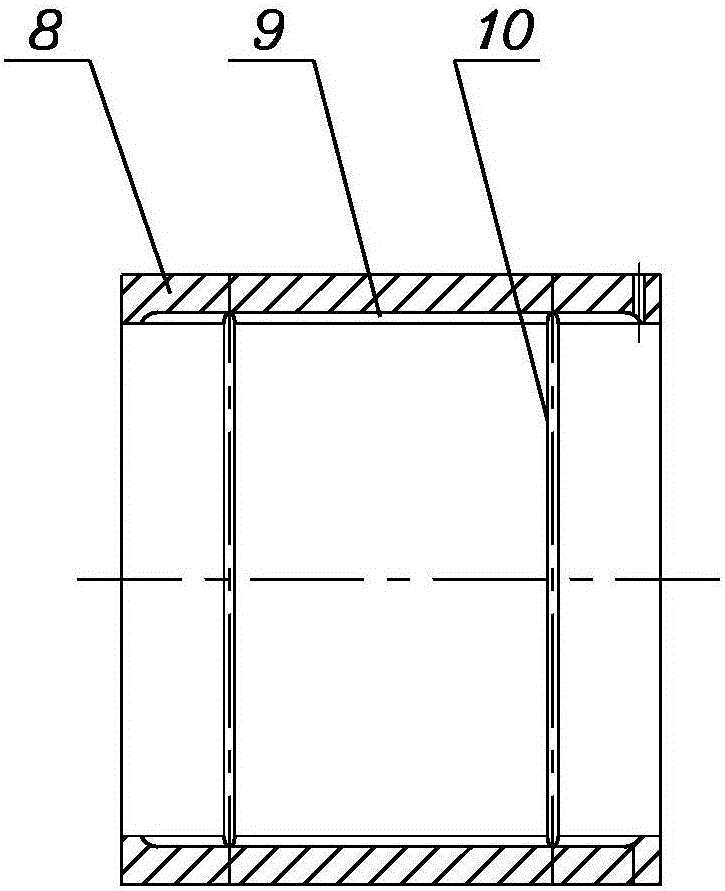

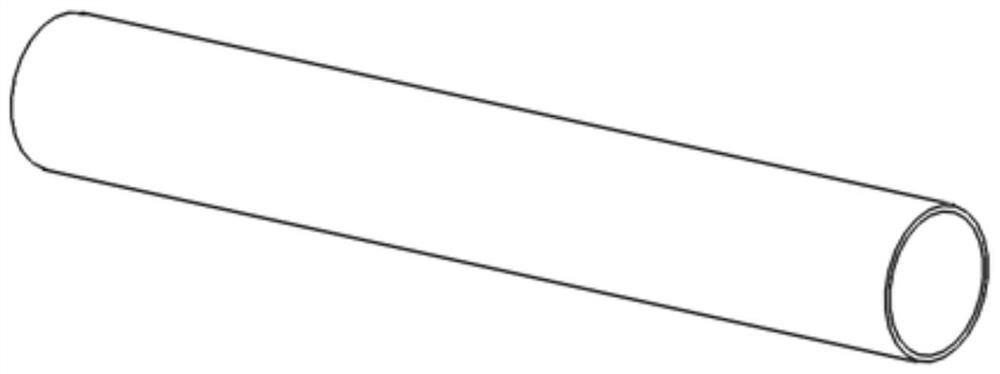

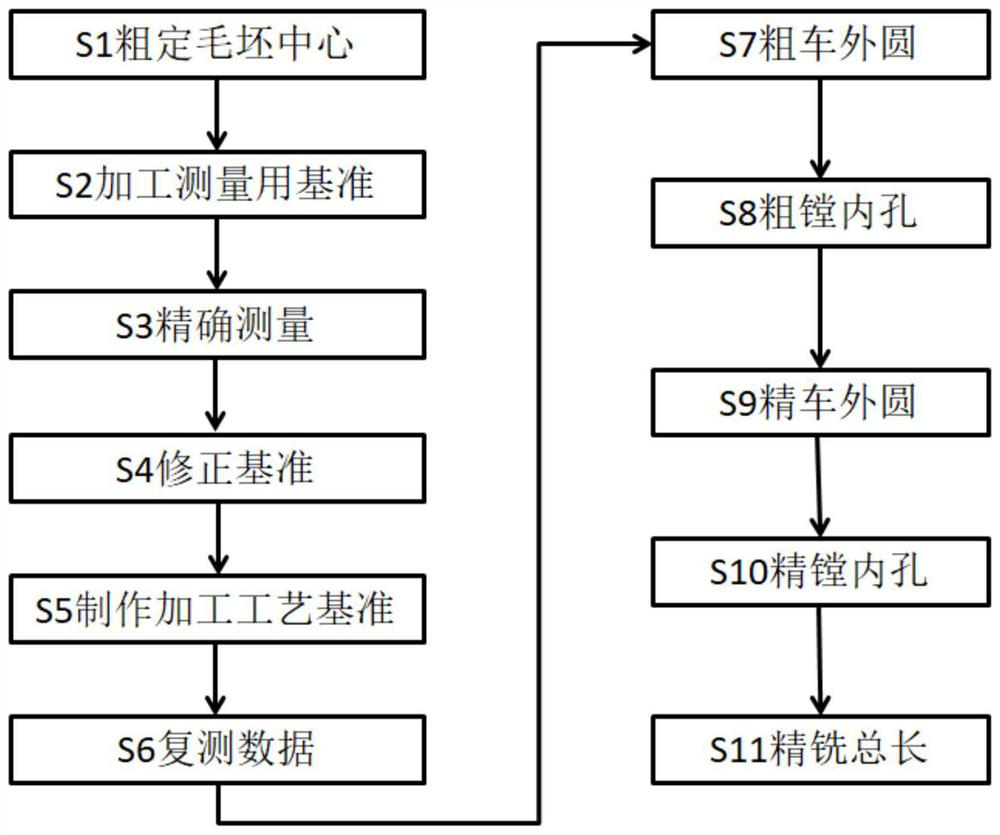

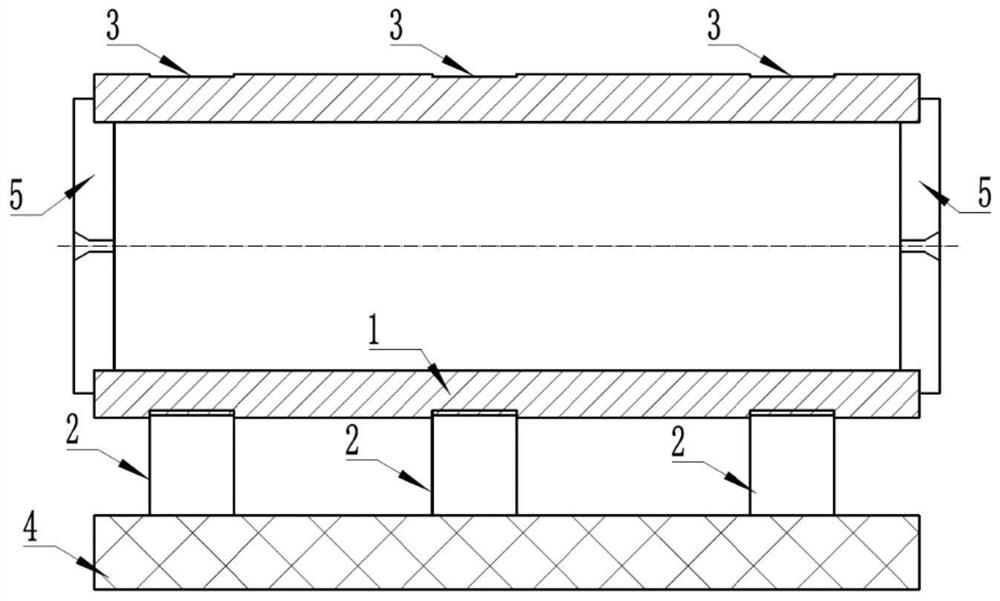

Machining technology for ultra-long large-diameter thin-wall steel pipe

The invention discloses a machining technology of an ultra-long large-diameter thin-wall steel pipe. The technology comprises a steel pipe blank outer circle machining step and an inner hole machining step, and further comprises the previous steps that S1, the center of a blank is roughly determined; S2, a reference for measurement is machined; S3, accurate measurement is performed; S4, the reference is corrected; S5, a machining technology reference is manufactured; and S6, data are retested to ensure that the reference is correct. According to the technology, three-dimensional scanning and a traditional technology are combined, a blank model is constructed through three-dimensional scanning to be matched with a target model, the center of the blank and the machining reference are accurately positioned at a time, the steel pipe blank is further supported by arranging a tool clamp at the machining reference, the strength of the ultra-long steel pipe is improved, the problem that the machining precision is affected due to deflection generated by gravity in the length direction of the steel pipe is solved, and the machining technology reference is effectively transferred when different machine tools alternately work.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

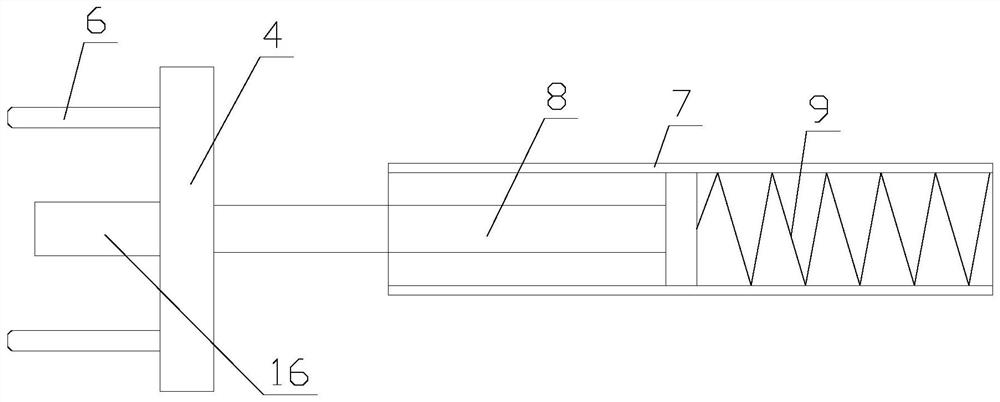

Injection molding machine with locating function

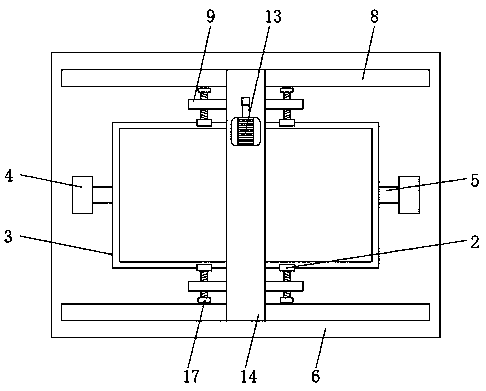

ActiveCN107443676AWith positioning functionAvoid affecting the machining accuracyTransverse planeEngineering

The invention discloses an injection molding machine with a locating function. The injection molding machine comprises a bottom plate. Two vertical plates are fixedly connected to the upper surface of the bottom plate and are symmetrical with the central axis of the bottom plate as the reference. Supporting plates are further fixedly connected to the position, located between the two vertical plates, of the upper surface of the bottom plate, and the two supporting plates are symmetrical with the central axis of the bottom plate as the reference. The position, located above the supporting plates, between the inner side faces of the two vertical plates is fixedly connected with a transverse plate. Two electric push rods are fixedly mounted at the position, corresponding to the position between the two supporting plates, of the lower surface of the transverse plate. According to the injection molding machine with the locating function, limiting grooves are formed in the inner side faces of the supporting plates, limiting blocks are in sliding connection in the limiting grooves, the output ends of the electric push rods penetrate inserting holes and extend to the positions below a reinforcement plate, motion of a first mounting block can be guided, the situation that when moving up and down along with the output ends of the electric push rods, the first mounting block inclines to influence the product processing precision is avoided, and the problems provided in the background technology are solved.

Owner:无锡安森源通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com