Special equipment for laser micro-cladding

A technology of laser micro cladding and special equipment, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of difficult to meet industrial rapid composite manufacturing, inability to combine micro-pen micro-spray and laser, and inability to preset different materials and other problems, to achieve the effect of shortening processing time, high degree of automation, and shortening diffusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

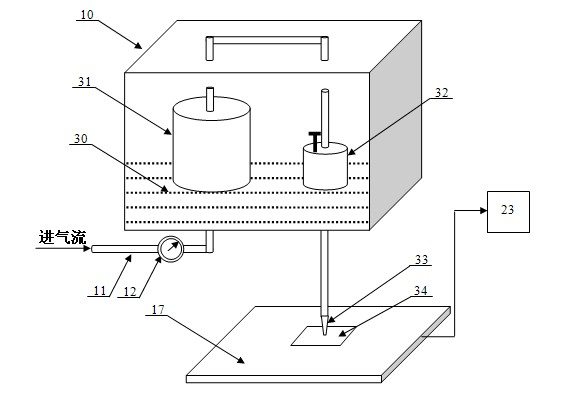

[0025] The laser used in the present invention may be a semiconductor laser, a solid laser, a fiber laser or a lamp-pumped solid laser. The above-mentioned lasers can adopt continuous or quasi-continuous output mode.

[0026] The invention is suitable for direct writing of electronic pastes of various materials and different properties, and can quickly obtain electronic components with good performance. The electronic paste includes conductive paste, resistance paste, dielectric paste or other electronic paste, and the substrate can be ceramic, glass, silicon, epoxy resin, polyimide and other materials.

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

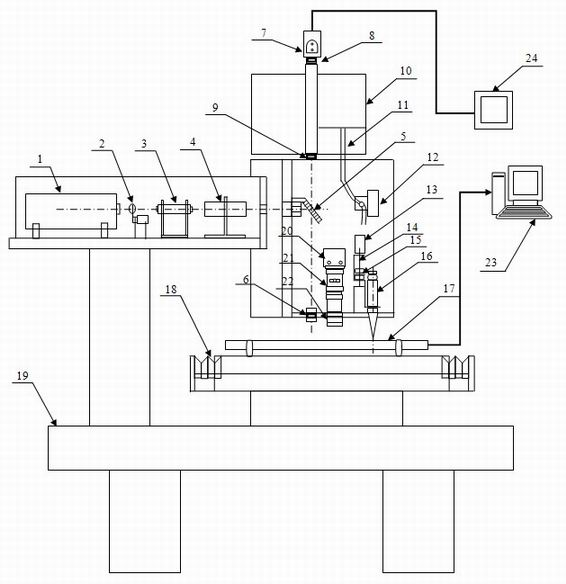

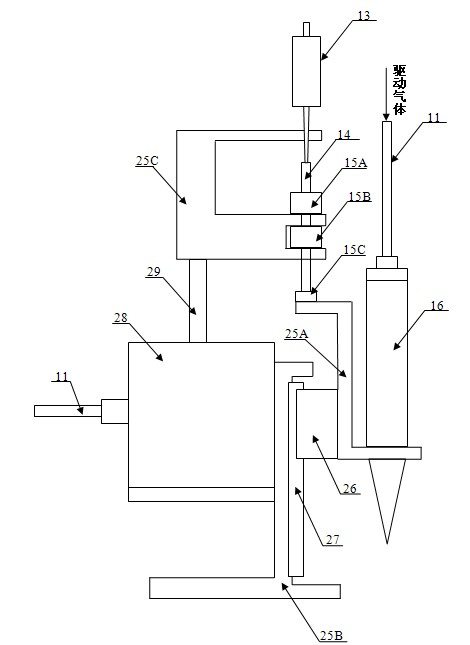

[0028] The equipment of the invention mainly includes five parts: a workbench, a laser processing system, a CCD monitoring and positioning system, a direct writing system and a control system.

[0029] like figure 1 As shown, the workbench includes an operation tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com