Magnetic path horizontal rotary type hoisting permanent magnet

A horizontally rotating permanent magnet technology, applied in the field of lifting permanent magnets, can solve the problems of high processing roughness, inability to process, and inability to lock the ratchet wheel, and achieve the effect of saving processing time and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

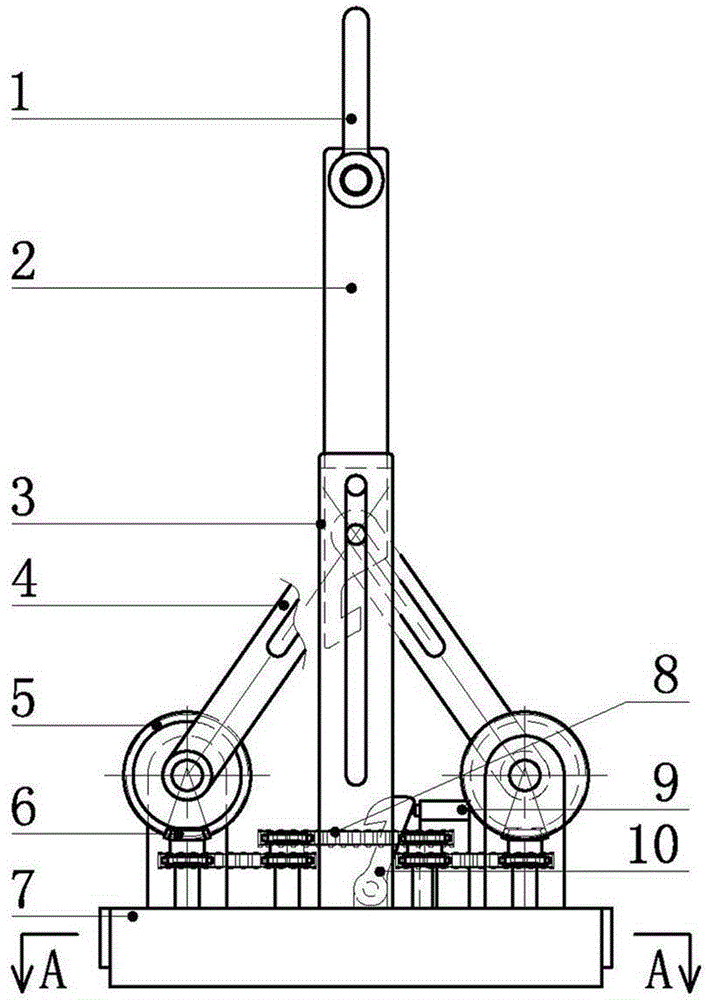

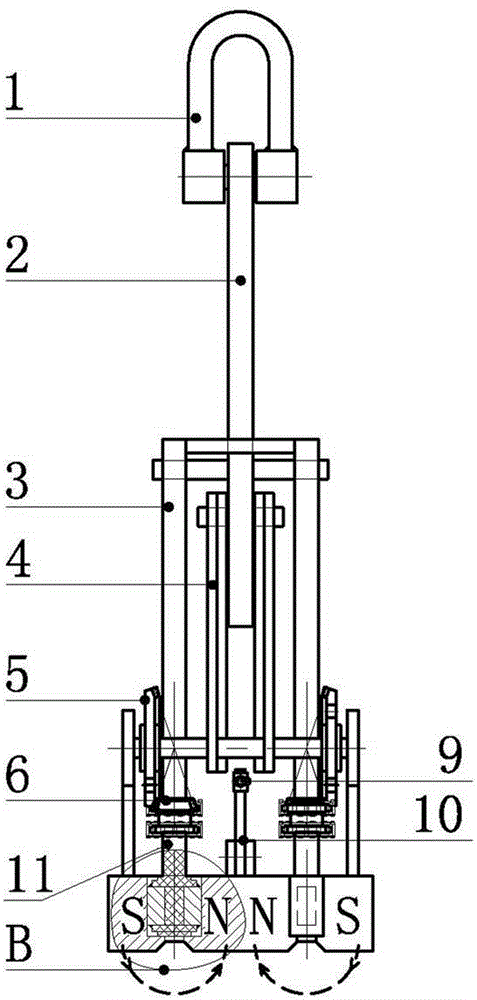

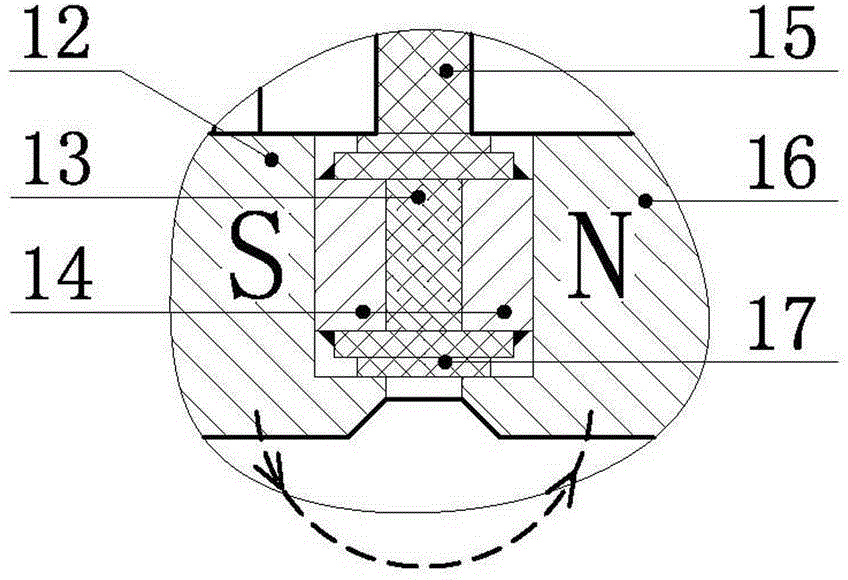

[0028] Iron-absorbing state: the lifting ring (1) and the hooked boom (2) drop to the bottom, forcing the hook (10) to unhook and the self-elastic device (9) retracts and locks, and the lifting ring (1) and the hooked boom (2) Lifting up, it drives the left and right hoists (4) and the large bevel gear (5) to rotate, and is transmitted to the small bevel gear (6) to rotate horizontally, and then is transmitted to the multiple gears in the magnetic system body (7) through the roller chain (8). A rotating magnetic shaft (11) rotates (see figure 1 and figure 2 ), when the S pole surface and the N pole surface of the permanent magnet block (13) in each rotating magnetic shaft (11) are on the same surface, a magnetic field is generated at the bottom of the lifting permanent magnet to reach the iron-absorbing state (see Figure 5 ).

[0029] Iron unloading state: the lifting ring (1) and the hooked boom (2) are lowered again, driving the left and right hanging plates (4) and the ...

example 2

[0031] As an improvement, in order to enhance the magnetic field, a group of fixed permanent magnets ( 20) (see Figure 7 ), when the permanent magnet block (13) in each rotating magnetic shaft (11) rotates to the same side as the S pole surface and N pole surface of the side fixed permanent magnet (20), the bottom of the lifting permanent magnet generates magnetism, reaching iron-absorbing state (see figure 2 ); when the permanent magnet block (13) in each rotating magnetic axis (11) rotates 180 degrees, it is not on the same side as the S pole surface and the N pole surface of the side fixed permanent magnet (20), and the S pole surface of the two sets of permanent magnets The pole and the N pole conduct each other, the magnetic circuit cancels each other, the bottom of the lifting permanent magnet does not show magnetism, and the iron unloading state is reached (see Figure 8 ).

example 3

[0033] As an improvement, the rotating magnetic shaft (11) of the main body of the magnetic system in Example 1 and Example 2 rotates, and the rotating magnetic shaft (11) is driven by a motor, hydraulic transmission, pneumatic transmission or other mechanical means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com