Patents

Literature

100results about How to "Reduce occupational diseases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building artificial stone block integrated machining equipment with reciprocating grinding function

InactiveCN107414625AImprove sanding effectImprove grinding efficiencyGrinding wheel securing apparatusGrinding carriagesProcess efficiencyEngineering

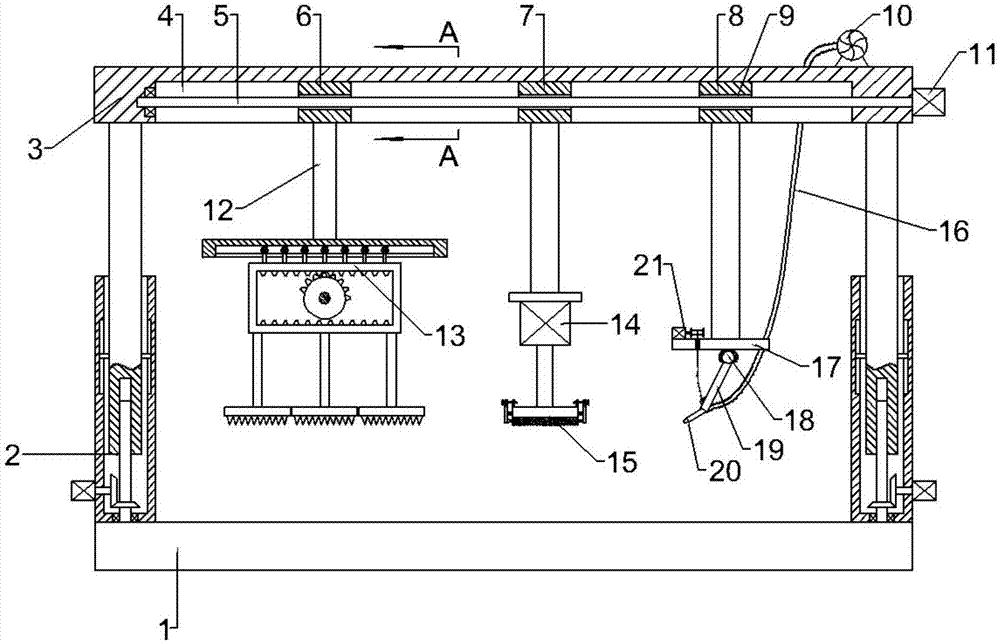

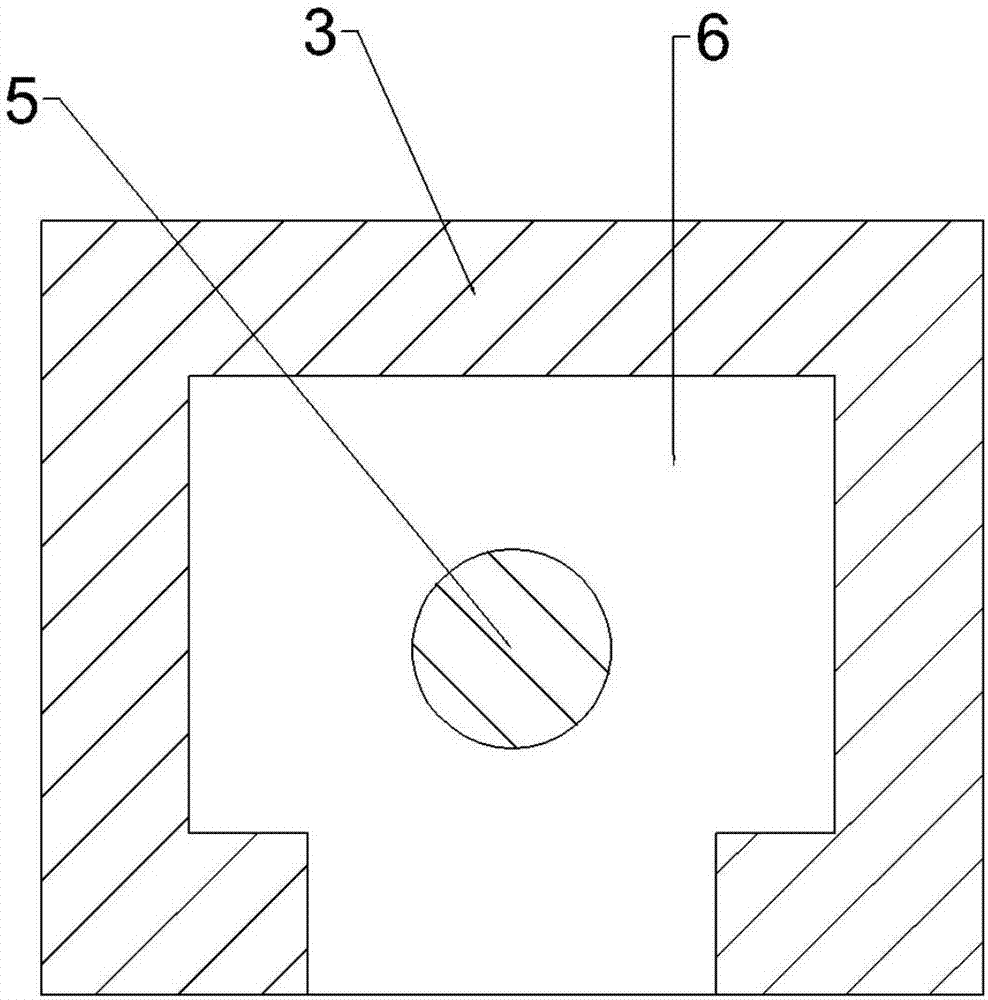

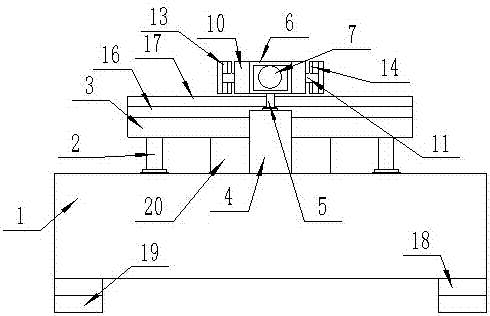

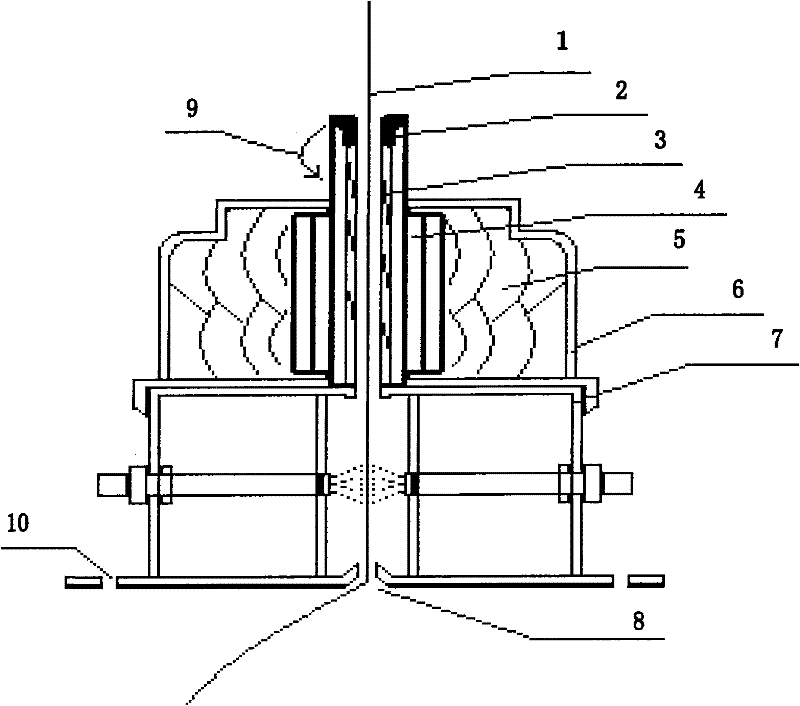

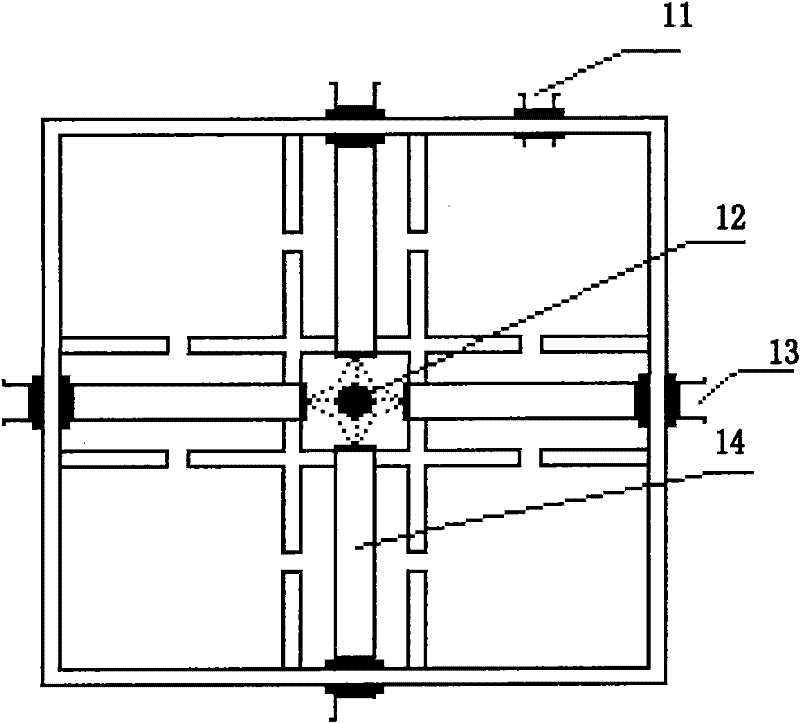

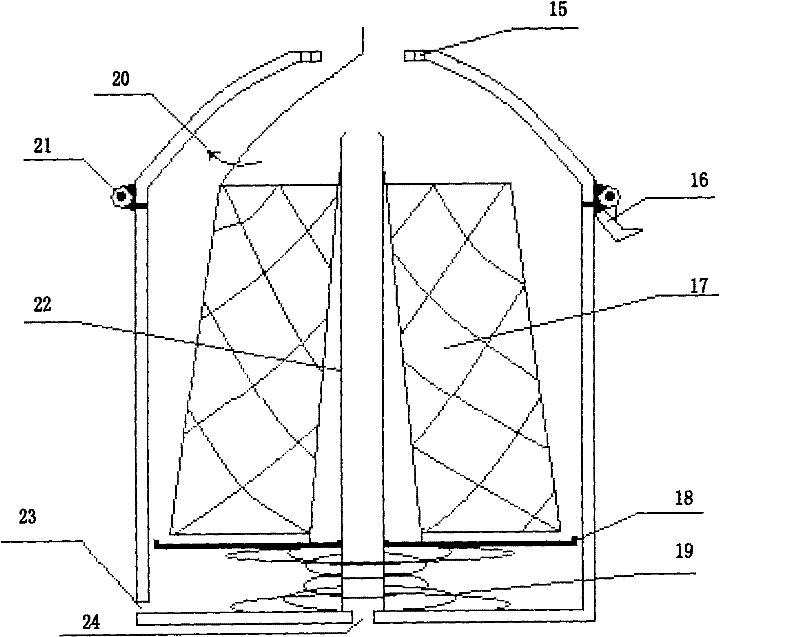

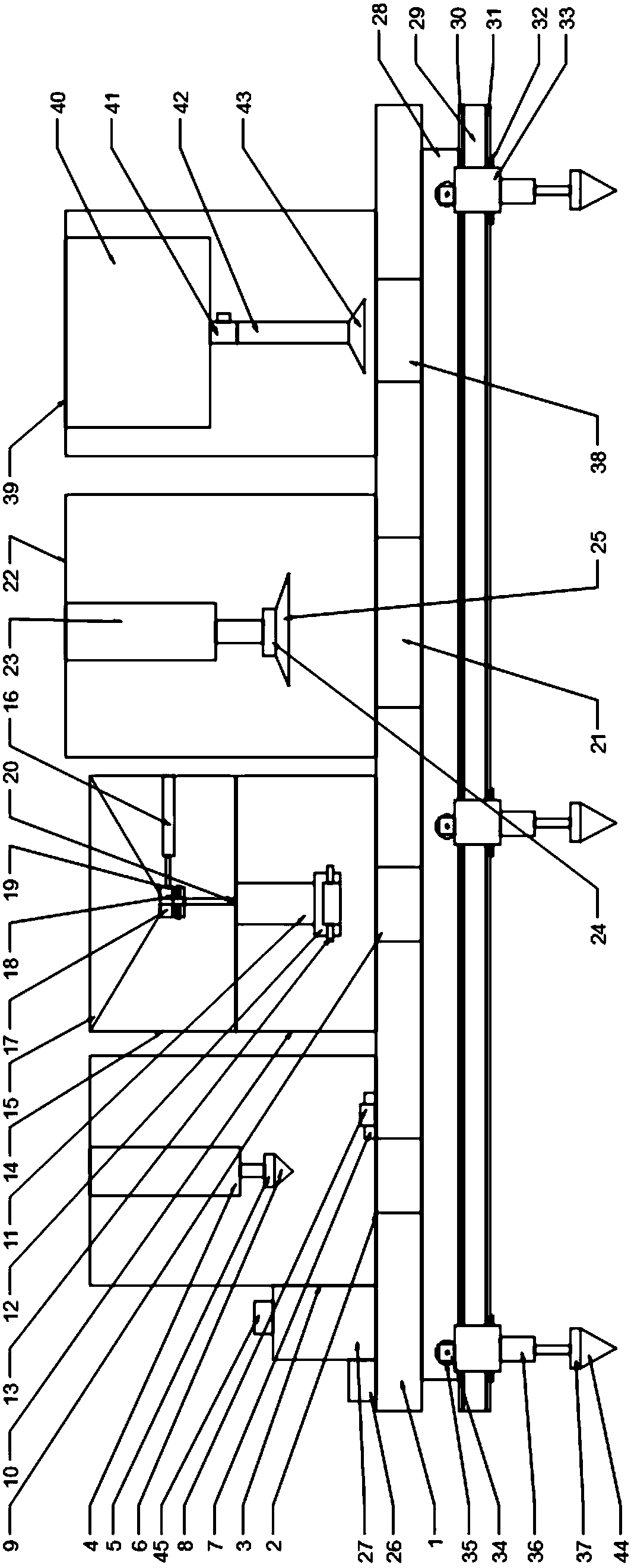

The present invention provides an integrated building artificial stone processing equipment with a reciprocating grinding function, which includes a base, a height adjustment device is fixedly connected to both ends of the base, and a support plate is fixedly connected to the top ends of the two height adjustment devices. The support plate is provided with a moving groove with the opening facing downwards, and the first moving block, the second moving block and the third moving block are arranged in the moving groove from left to right, and the first moving block, the second moving block and the The third moving block is provided with threaded through holes, and the three threaded through holes are jointly threaded with horizontal threaded rods, and the two ends of the horizontal threaded rods are erected at the two ends of the support plate. The invention has the following beneficial effects: it realizes the integrated treatment of grinding, polishing and cleaning, effectively improves the processing efficiency of stone materials, has a high degree of integration, effectively reduces labor input, keeps the operator away from the processing site, and reduces The incidence of occupational diseases among workers has been reduced.

Owner:刘丽

Process for carrying out vacuum cleaning, oil removal and wax removal by modified hydrocarbon cleaner

The invention relates to the technical field of electroplating pretreatment, in particular to a process for carrying out vacuum cleaning, oil removal and wax removal by a modified hydrocarbon cleaner. The process comprises degassing ultrasonic cleaning, vacuum cleaning, vacuum steam flushing, vacuum drying and the like. A plurality of flows are carried out in the vacuum environment with a certain vacuum degree and are matched with a degassing ultrasonic cleaning and vacuum cleaning technology and the modified hydrocarbon cleaner. For the cleaning process, in the whole process, harmful substances of halogen and the like, such as trichloroethylene, methylene chloride, tetrachloroethylene and the like, cannot be used and additional drying equipment is not required. Particularly, the process has excellent cleaning effect on irregular articles with blind holes, joints, gaps, cracks and the like. Meanwhile, the defects of oil removal and wax removal of the conventional process are overcome.

Owner:广东新球清洗科技股份有限公司

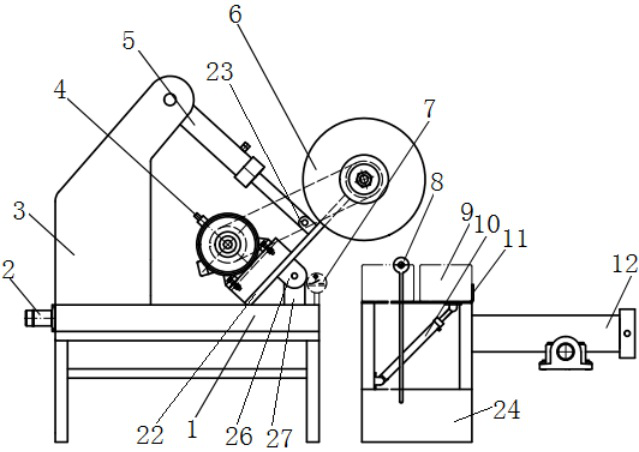

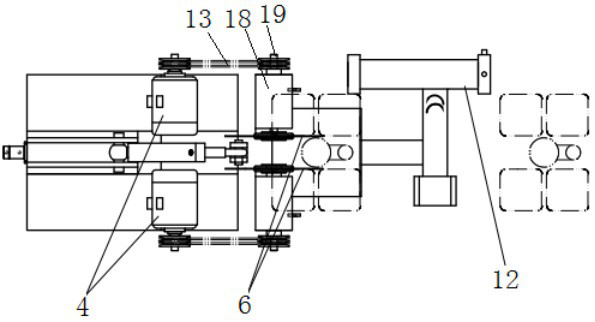

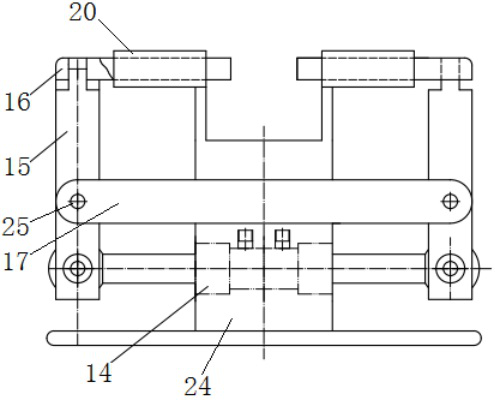

Auxiliary lifting device for material processing

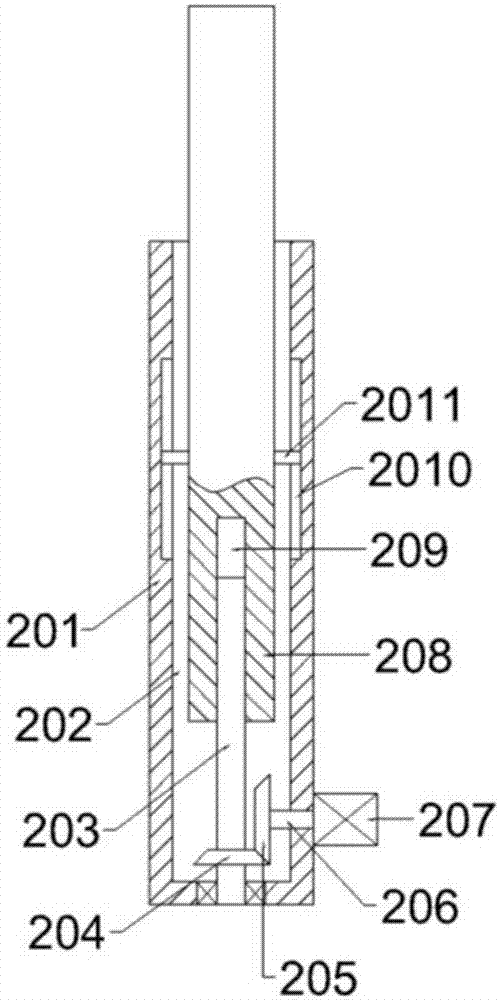

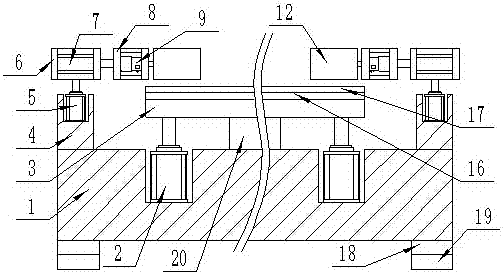

InactiveCN107297682AEasy to adjustReduce Occupational DiseasesEdge grinding machinesGrinding drivesHydraulic cylinderEngineering

The invention discloses an auxiliary lifting device for material processing, which comprises a base, and two pairs of cylinder placement grooves are opened on the upper wall of the base, and the first hydraulic cylinder with the telescopic end facing upward is fixed in the cylinder placement groove, and the two pairs of cylinder placement grooves are fixed in the cylinder placement grooves. The telescopic end of the first hydraulic cylinder is fixed to the supporting plate, and a pair of installation rods are fixed on the upper wall of the base and located on both sides of the two pairs of cylinder placement grooves. End up second hydraulic cylinder. According to the invention, the workers can be adjusted at will according to their own heights, which is convenient for people to grind, and reduces the occurrence of occupational diseases of the workers. The automatic lifting, stepping up, rotating and changing surfaces can liberate manpower and is convenient to use.

Owner:肇庆市智高电机有限公司

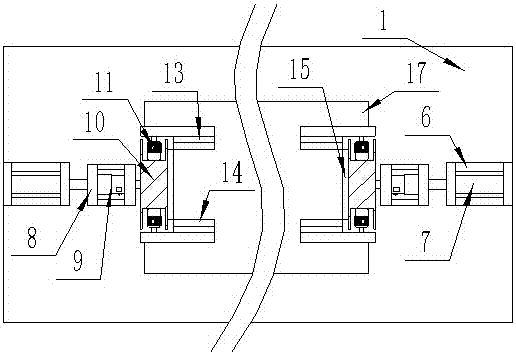

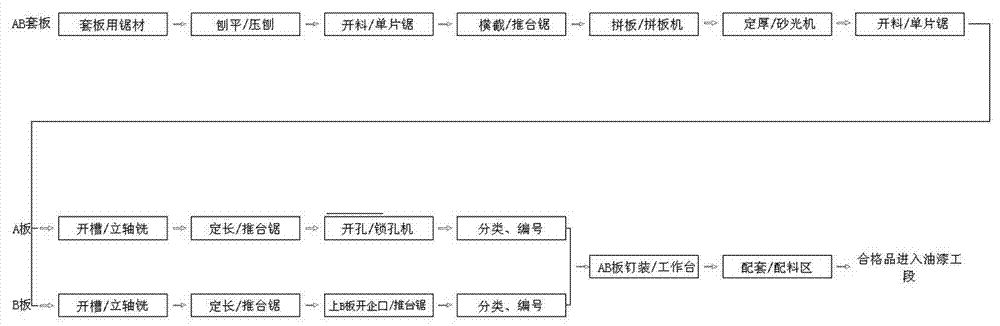

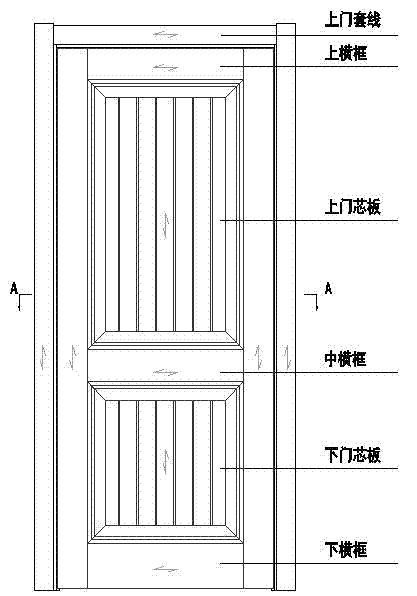

Manufacturing process of raw wood door

ActiveCN104760108AReduce the probability of shrinkage seamsAvoid late cracking defectsWood working apparatusParticulatesPollution

The invention provides a manufacturing process of a raw wood door. The manufacturing process comprises the steps of (1) synchronously preparing a door leaf, a plate A, a plate B and a door cover line; (3) painting through a paint room after preparing the parts above; maintaining; matching; warehousing a packing box. The raw wood door manufactured by the process has the advantages that the probability of contraction joints of the wood door in later use can be greatly reduced, and moreover, the defect of cracking of the raw wood door in later period can be avoided the pollution of air, in particular particles can be minimized according to the manufacturing process; 100% of high gloss paint can be achieved; 30% of energy charge can be saved; the environment is improved by 40%; operators can be protected well.

Owner:JIANGSU KENTIER SENGONG TECH

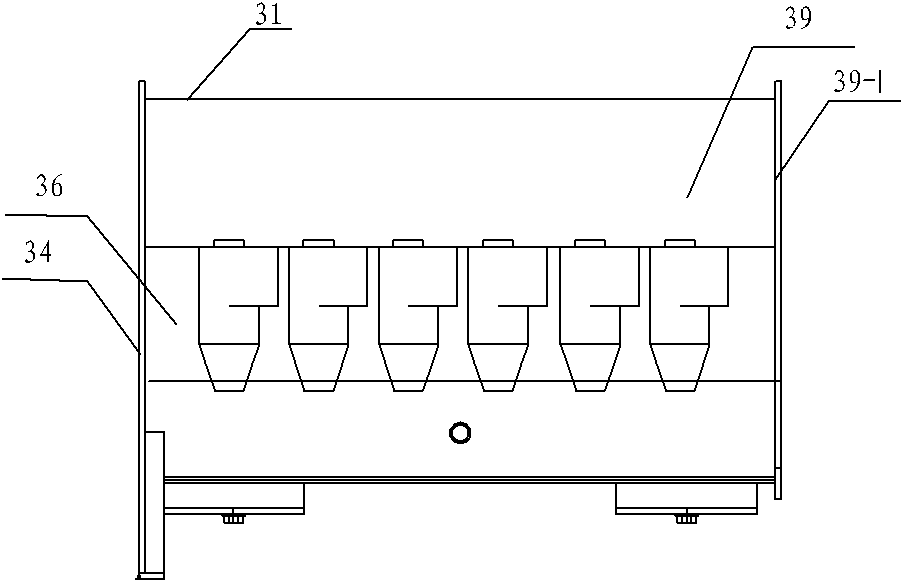

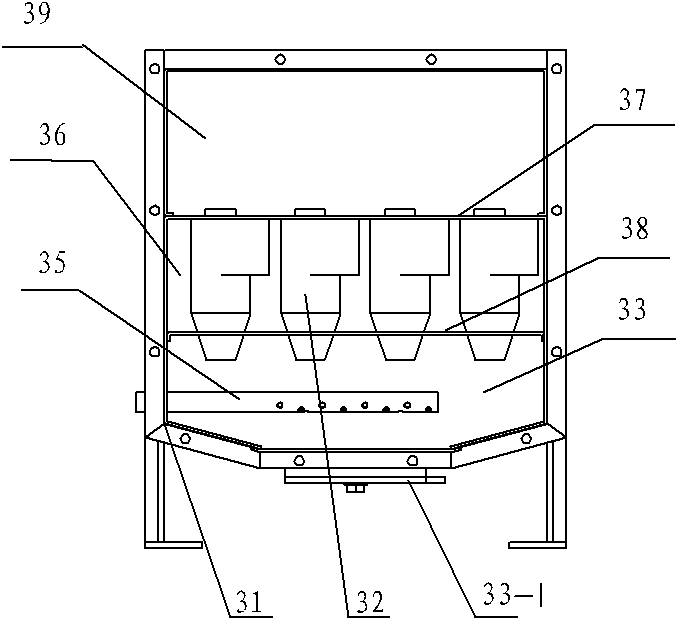

Small mining combined dust remover

InactiveCN102003200ASuction in timeImprove dust removal efficiencyCombination devicesDust removalHydraulic motorEconomic benefits

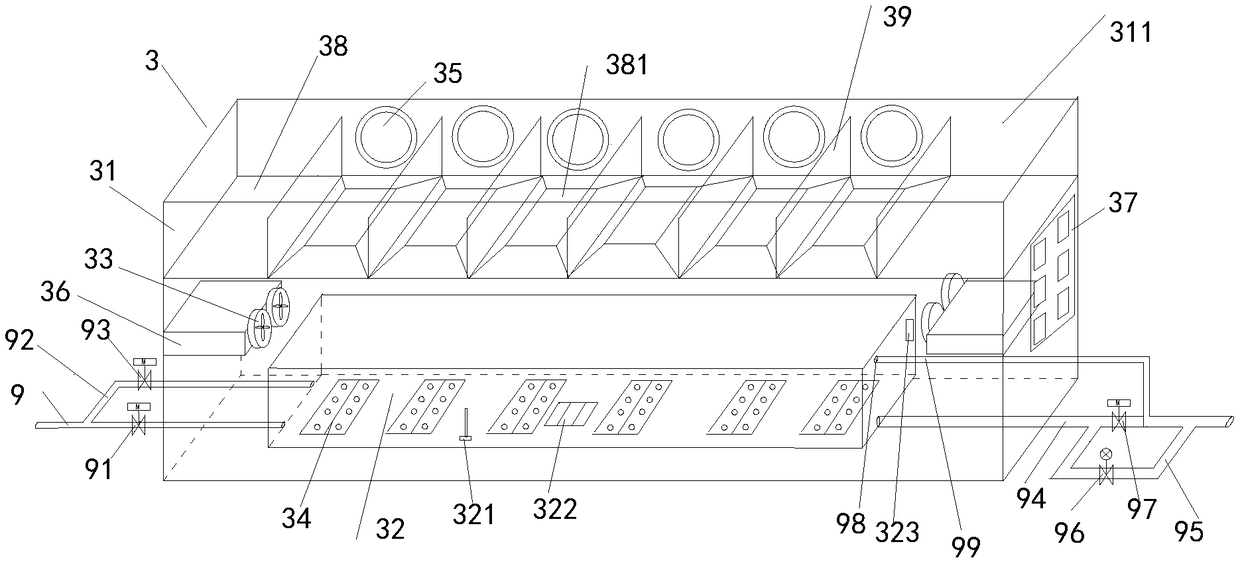

The invention claims a small mining dry combined dust remover, which is in turn provided with an air inlet component, a centrifugal induced draught fan, a cylindrical dust remover and a cylindrical filter in a flowing direction of the air. The air inlet component is in the front of the centrifugal induced draught fan. An air wheel of the induced draught fan is driven by a hydraulic motor. The centrifugal induced draught fan comprises a casing, a mounting base and a centrifugal air wheel. The cylindrical dust remover is a cylindrical small-cyclone dust remover, in which a plurality of small-cyclone separators are arranged perpendicular to an axis of the cylinder. The combined dust remover has high dust removing efficiency; and the hydraulic system of a development machine drives the hydraulic motor draught fan to work. Furthermore, the cylindrical dust remover is shaped to be mounted on the development machine so as to cooperate with the development machine. The dust remover can timely suck and remove the dust during the cutting of the development machine safely and reliably, so the dust remover is very suitable for use in mining, tunnel and subway operation. The application of the technology can change operating environments, reduce the occurrence of occupational diseases and bring greater economic benefits to enterprises.

Owner:杭州洪裕重工机械有限公司

Battery plate packing device

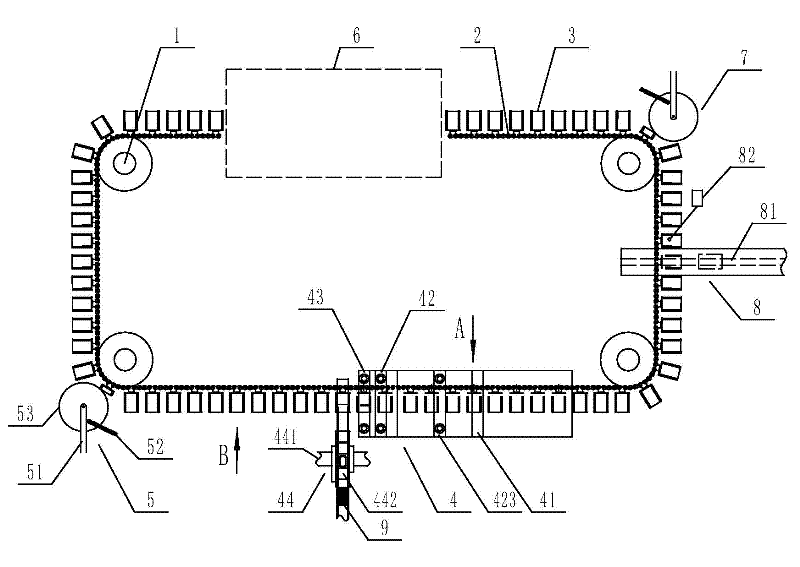

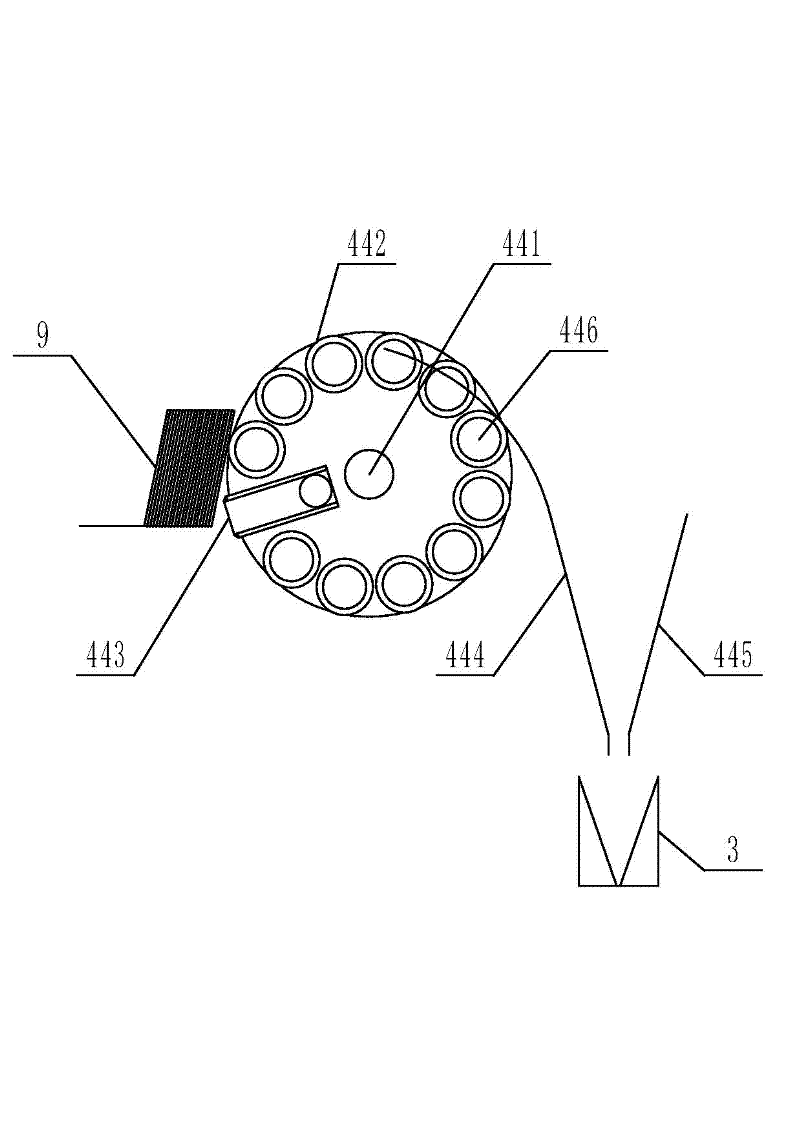

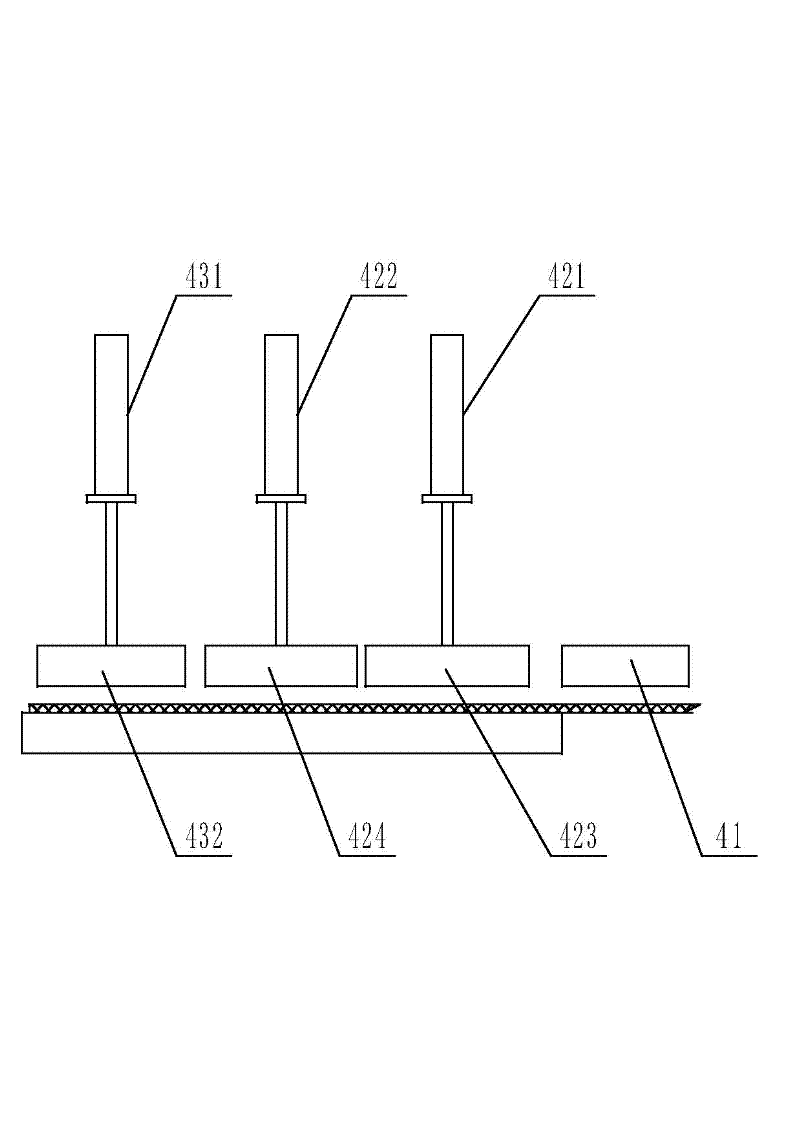

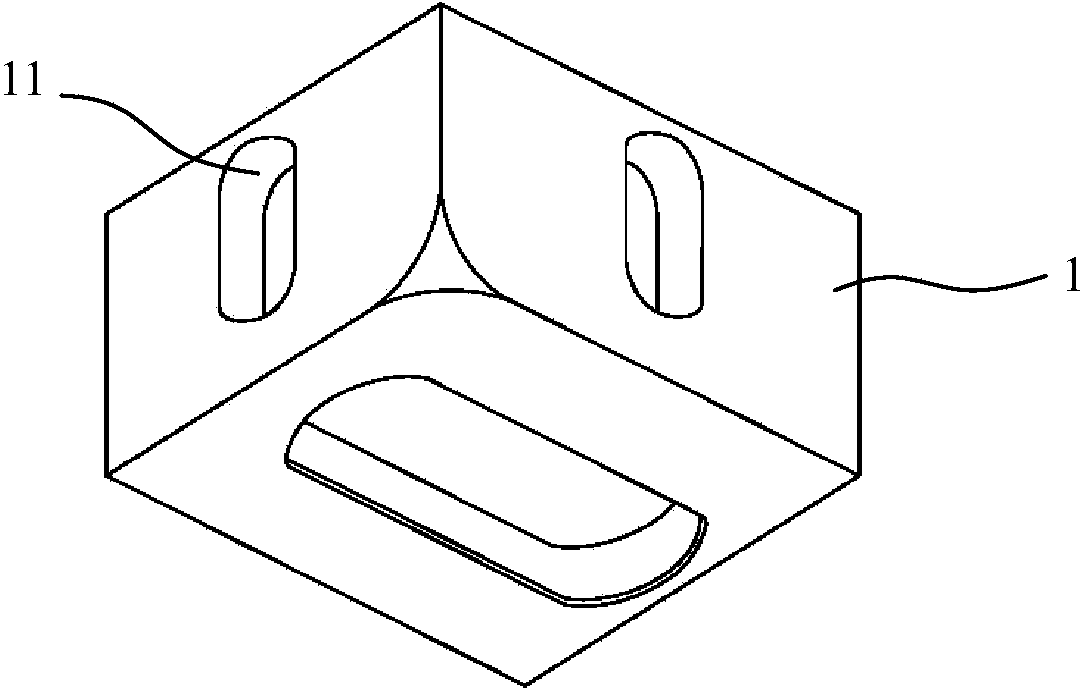

The invention discloses a battery plate packing device which comprises a rack and a conveying device, wherein the conveying device is arranged on the rack; the conveying device is a cyclic conveying channel, and mold boxes are arranged on the outside of the conveying channel; a positive plate packing device, a positive plate compressing device, a negative plate packing device, a negative plate compressing device and a discharging device are sequentially arranged in the cyclic direction of the conveying channel, wherein the structures of the positive plate packing device and the negative platepacking device are same, the structures of the positive plate compressing device and the negative plate compressing device are same; and the positive plate packing device comprises a paper feeding device, a paper cutting device, a paper folding device and an upper plate device which are sequentially arranged along the conveying direction of the conveying channel. The battery plate packing device disclosed by the invention is suitable for being used for packing battery plates.

Owner:江苏金帆电源科技有限公司

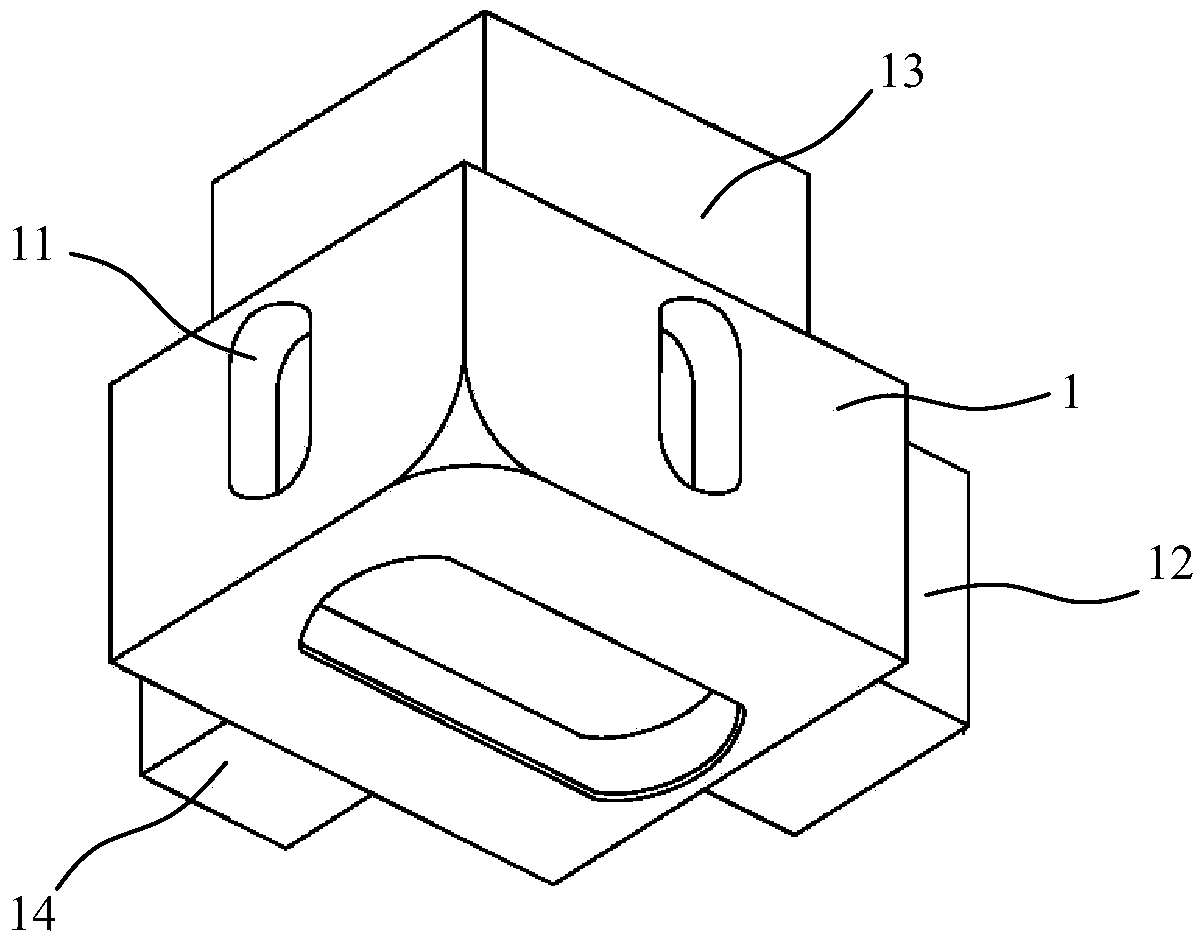

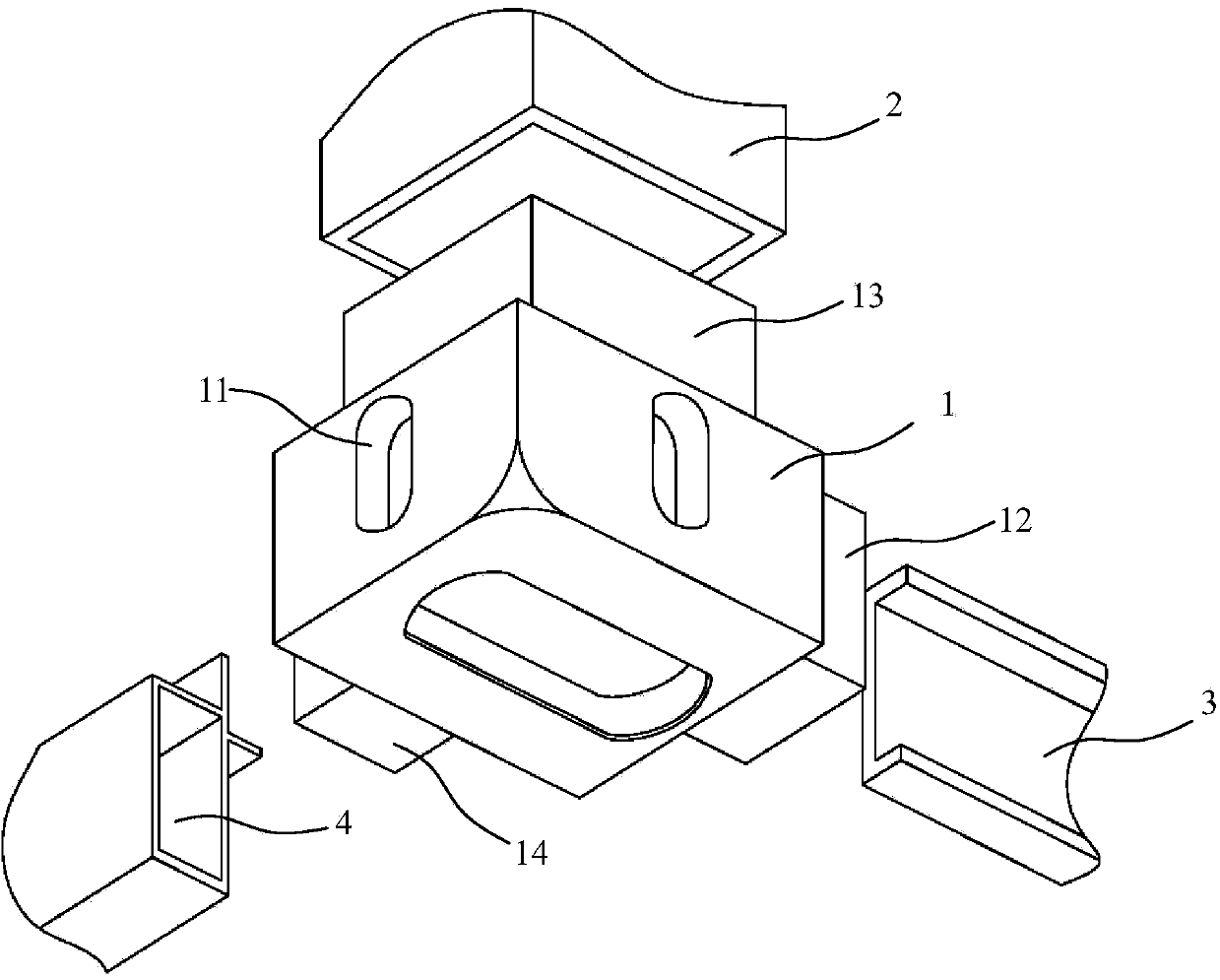

Corner fitting for container, container and container-type movable house

InactiveCN104176396ARapid productionReduce consumptionLarge containersBuilding constructionsTransportation energyAlloy

The invention discloses a corner fitting for a container, the container and a container-type movable house. A main body of the corner fitting for the container is cuboid-shaped; mounting through holes are formed in three outer end surfaces of the main body facing the outer side of the container, and the other three end surfaces of the main body can be fixedly connected with a side beam, an upright column and an end beam of the container respectively; a connecting boss is arranged on at least one end surface in the three end surfaces connected with the side beam, the upright column and the end beam of the container, can be connected with a matched beam column of the container in an insertion manner, and can be fixedly connected with the beam column of the container. According to the container and the container-type movable house with the corner fitting structure, a conventional welded structural part connecting mode can be replaced with a bond-riveted mode, the labor difficulty of a connecting process is reduced, the work efficiency is improved, and industrial pollution and energy consumption are reduced; meanwhile, a light aluminum alloy can be adopted as a base material of the container, and therefore the transportation energy consumption and the transportation cost are greatly reduced.

Owner:邵妮

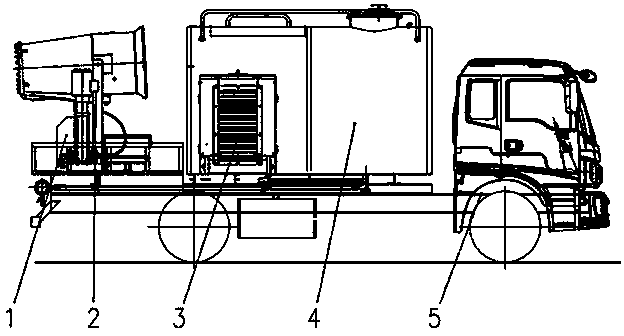

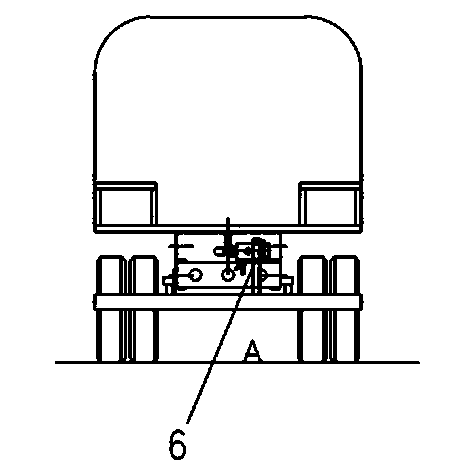

Vehicle-mounted full-hydraulic remote water-jetting dust remover

ActiveCN103469755AIncrease the level of automationQuality improvementRoad cleaningImpellerDust control

The invention discloses a vehicle-mounted full-hydraulic remote water-jetting dust remover. The vehicle-mounted full-hydraulic remote water-jetting dust remover comprises an automotive chassis, a water tank, a water-jetting device, a hydraulic system and an electrical system, wherein the water-jetting device and the water tank are arranged on the automotive chassis, and the water-jetting device is composed of a centrifugal water pump, an air duct rotating mechanism, an air duct lifting mechanism and an impeller rotating mechanism. The dust remover further comprises a power takeoff device, wherein the power takeoff device is driven by an automotive engine and connected with the hydraulic system, and the hydraulic system is connected with the centrifugal water pump, the air duct rotating mechanism, the air duct lifting mechanism and the impeller rotating mechanism respectively. The vehicle-mounted full-hydraulic remote water-jetting dust remover is suitable for dust control in factories, mines, construction sites, docks, open material plants and other application occasions.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

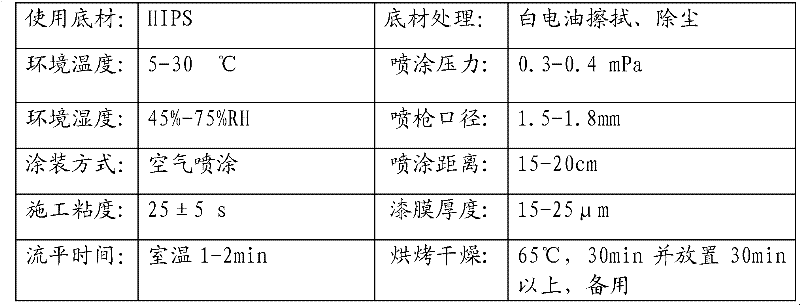

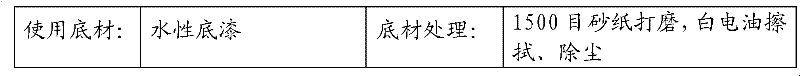

One-component waterborne thermoplastic coating matched with UV-radiation curing coating as well as production method and construction method thereof

InactiveCN102181211AReduce pollutionAvoid long-term contactPretreated surfacesCoatingsThermoplasticDiluent

The invention provides a one-component waterborne thermoplastic coating. The coating is applicable to coating ABS (acrylonitrile-butadiene-styrene), PS (polystyrene), HIPS (high impact polystyrene), PC (polycarbonate), PMMA (polymethyl methacrylate) and other types of plastic enclosures; and the coating has the advantages of good adaptability to material surfaces, good substrate adhesive force and good interlayer adhesive force, and solves difficulties such as adhesive force of the waterborne coating on the plastic substrate and a plurality of shrink holes on a UV-radiation curing finish paint matched with the waterborne coating. The coating mainly adopts a waterborne system and is safe for production and application; the coating takes water as a diluent, thus having the advantages of low toxicity, low pollution, extremely low emission of VOCs (volatile organic compounds) and the like and complying with various environmental protection laws and regulations; and meanwhile the coating can be colored with different color paste, thus providing better decorative property for the substrate without affecting the original performance. The invention further provides a production method and a construction method of the product; and the production method and the construction method are simple and convenient, and the adopted production and construction equipment is convenient to wash.

Owner:深圳市嘉卓成科技发展有限公司

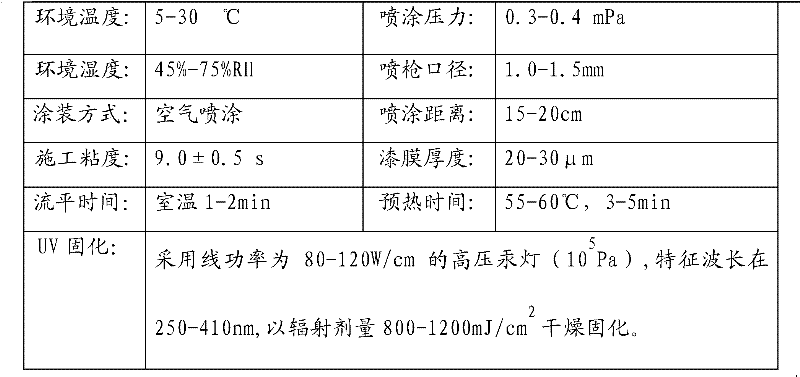

Intelligent, healthy and liftable office table and chair system

InactiveCN106923492AReduce occupational diseasesReduce medical costsStoolsOptical sensorsPhysical well beingEngineering

The invention discloses an intelligent, healthy and liftable office table and chair system. The intelligent, healthy and liftable office table and chair system comprises a table top and a chair cushion, wherein the bottom of the table top is supported by table legs, an electric push rod is mounted in each table leg, the electric push rods are in threaded fixation to four corners of the bottom surface of the table top, an electric push rod control box is mounted at the lower side of the table top, a signal receiver is mounted in the electric push rod control box, an electric push rod control panel connected with an external power supply is mounted at the edge of the bottom surface of the table top, a gravity sensing device, an optical fiber sensor, a control cabinet and a vibrator are mounted in the chair cushion, a wireless signal generator and a lithium battery are mounted in the control cabinet, and a control panel is mounted on the side surface of the chair cushion. With the intelligent, healthy and liftable office table and chair system, the work efficiency can be improved, the occurrence of the office occupational diseases is reduced, the pain caused by the diseases is alleviated, the body health of people is guaranteed, and finally, the medical cost of the society and the country is reduced.

Owner:SHANGHAI TEAMMAX FURNITURE CO LTD

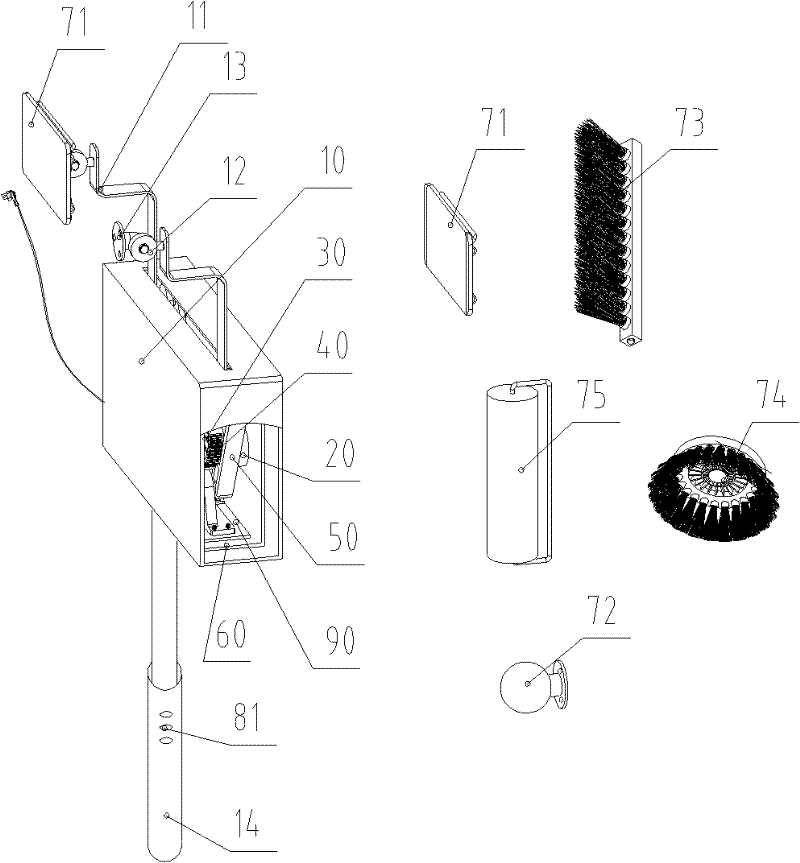

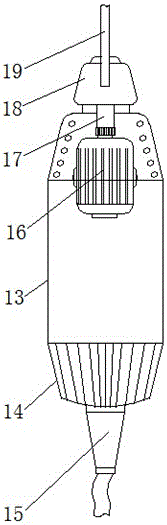

Service-type manipulator

InactiveCN102476381AReduce labor intensityEasy to cleanCarpet cleanersFloor cleanersEngineeringManipulator

The invention discloses a service-type manipulator and particularly relates to a service-type manipulator used for cleaning instead of a person. The service-type manipulator comprises a core, various cleaning hands, a shell and a connecting rod, wherein the core is used for providing power and controlling transmission; the cleaning hands are replaceable and are used in different situations; the shell is used for accommodating the core; the connecting rod is used for outputting left and right oscillating motion; a universal head and a moveable head which are used for connecting various manipulators are arranged on the connecting rod; and a damp-proof box component which is used for preventing the core from being affected with damp is arranged outside the core. The service-type manipulator has the following beneficial effects: 1) glass windows, door windows, ceilings and walls can be cleaned without a built ladder, and the dust which cannot be cleaned by using a dust collector and a cleaning robot can be cleaned completely by using the service-type manipulator; 2) the labor intensity of a cleaner can be relieved, and the old people, children, the weak people or the disabled also can clean by using the service-type manipulator; 3) the efficiency and cleanliness for cleaning large areas such as hotels, halls, production workshops, and the like, as well as stairs can be increased; and 4) the service-type manipulator is small in volume, light in weight, small in energy consumption and free from secondary pollution.

Owner:上海领派机电科技有限公司

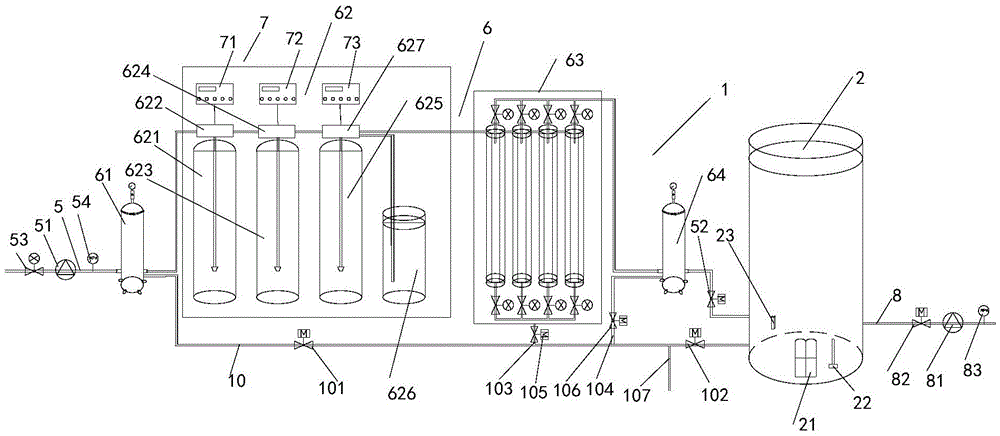

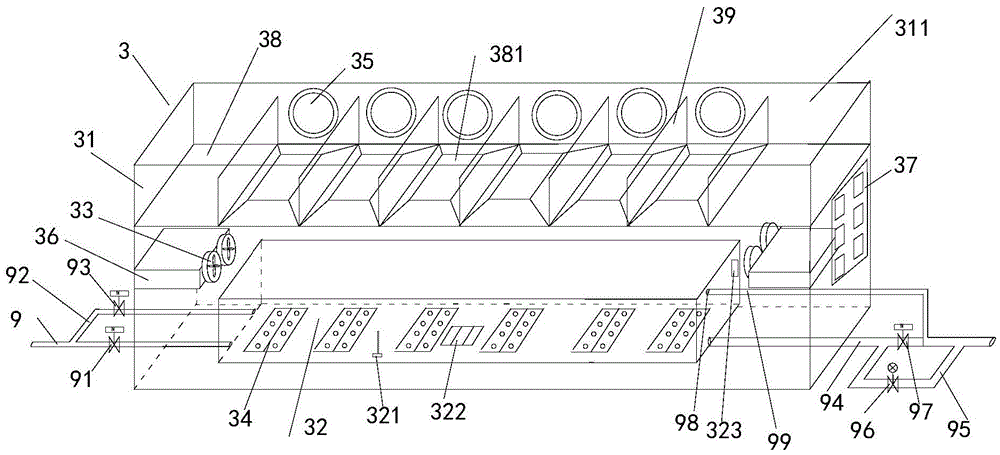

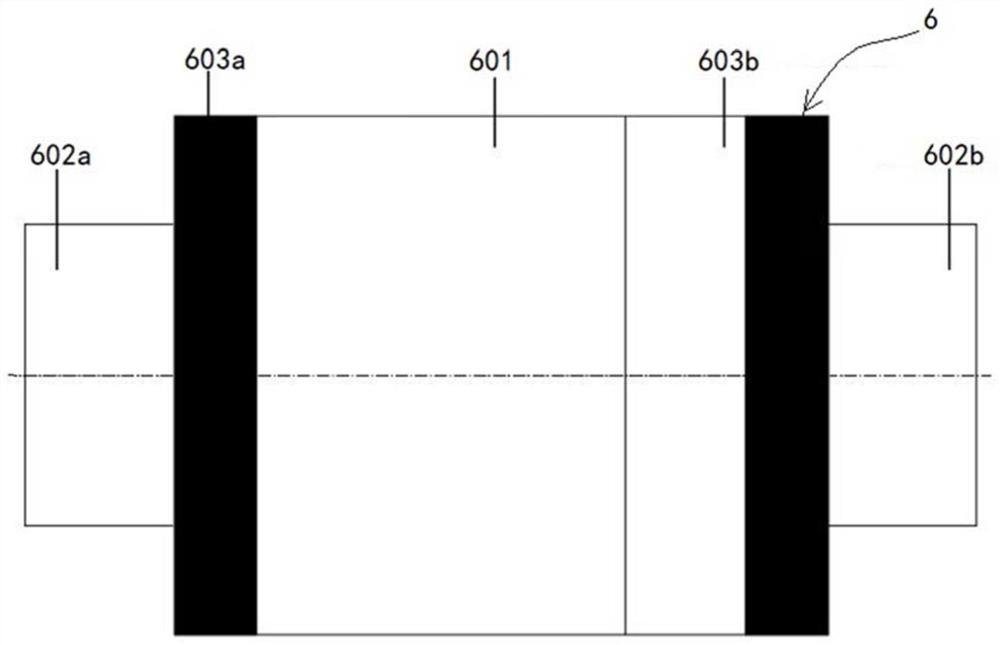

Air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method

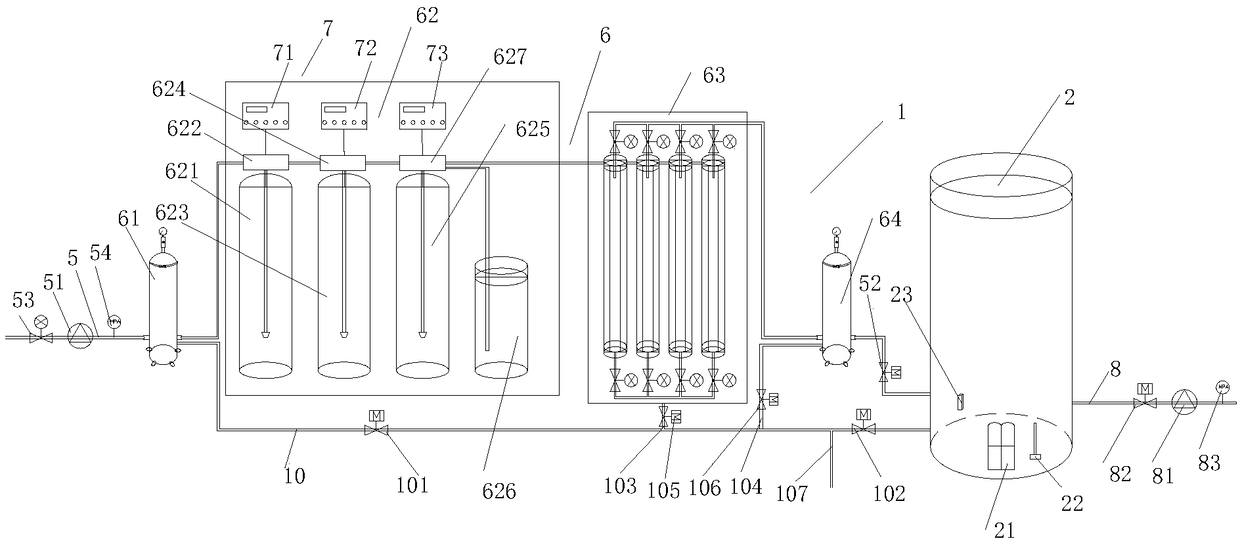

InactiveCN105617798APrecision FiltrationEasily brokenGas treatmentUsing liquid separation agentWater storage tankWater source

The invention relates to an air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method. The system comprises a water quality filtering and softening device, a water storage tank, a dry fog dust suppression device and a local controller. An adjustable atomization plate in the dry fog dust suppression device scatters and atomizes a constant-temperature water source which is filtered and softened through the water quality filtering and softening device in the water storage tank, a large amount of micron-grade dry fog and negative ions are produced, a frequency conversion high pressure centrifugal fan in the dry fog dust suppression device blows the large amount of micron-grade dry fog and negative ions out of the dry fog dust suppression device, then the dust is adsorbed, condensed and precipitated, and therefore the purpose of dust removal is achieved. Millimeter-grade visible dust particles can be effectively treated, micrometer-grade inhalable dust particles can also be effectively treated, pollution of dust on the atmosphere is lowered, the work environment of on-site workers is improved, and occupational disease occurrence rate is lowered; the system is small in occupied area, safe and convenient to operate and high in practicability and is controlled in a full-automatic mode.

Owner:刘坤

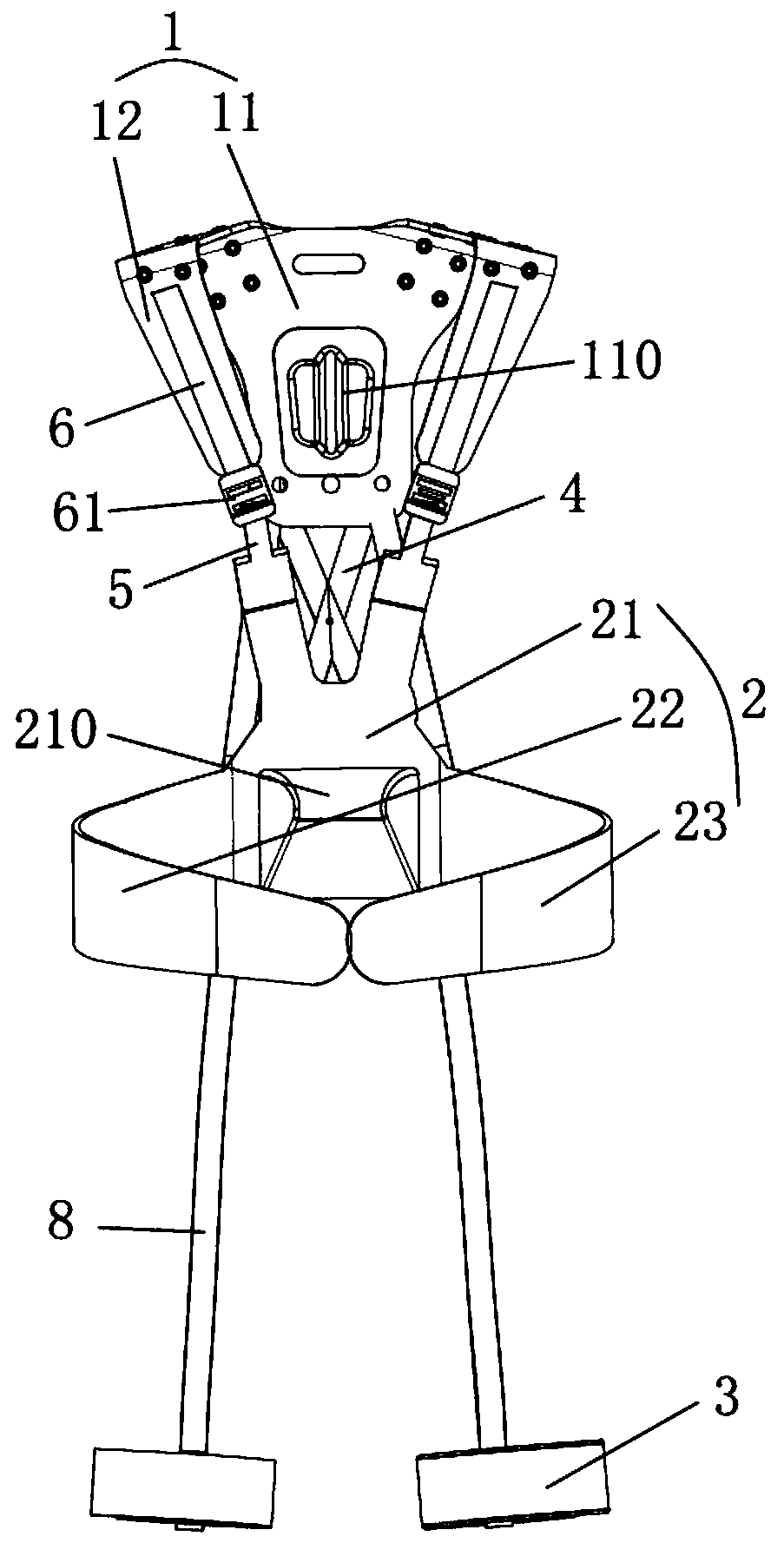

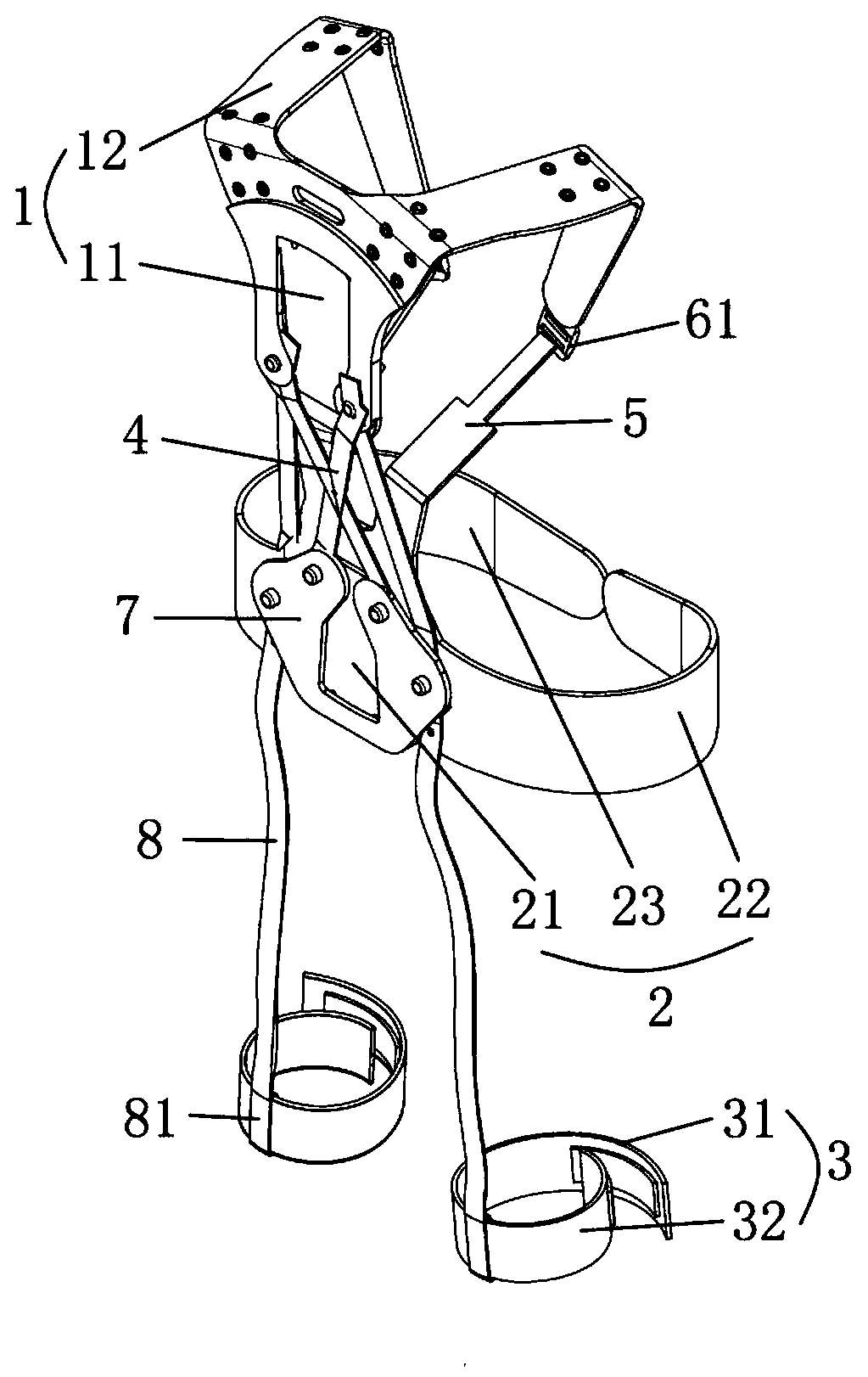

Self-adaptive flexible exoskeleton

PendingCN108748116AImprove interactivityImprove wearing effectProgramme-controlled manipulatorMan machineEngineering

The invention discloses a self-adaptive flexible exoskeleton. The self-adaptive flexible exoskeleton comprises a shoulder and back flexible binding piece, a waist flexible binding piece and two leg flexible binding pieces; the shoulder and back flexible binding piece is provided with a back tight attaching portion, and a back cushion piece is arranged on the inner side of the back tight attachingportion; the shoulder and back flexible binding piece extends to one side from the back tight attaching portion to form two shoulder connection portions; the waist flexible binding piece is provided with a waist binding portion, and a waist cushion piece is arranged on the inner side of the waist binding portion; the waist flexible binding piece extend to the two sides from the waist binding portion to form a first binding portion and a second binding portion correspondingly; the first binding portion and the second binding portion are adjustably connected; the back tight attaching portion ofthe shoulder and back flexible binding piece and the waist binding portion of the waist binding piece are connected through an elastic connection piece, and the two shoulder connection portions are adjustably connected with the waist binding portion; and the two leg flexible binding pieces are adjustably connected with the waist binding portion of the waist flexible binding piece The self-adaptiveflexible exoskeleton has the characteristics of being simple in structure, good in flexibility, large in freedom degree, high in wearing performance, self-adaptive and good in man-machine interactionperformance.

Owner:GUANG ZHOU HYETONE IND TECH CO LTD

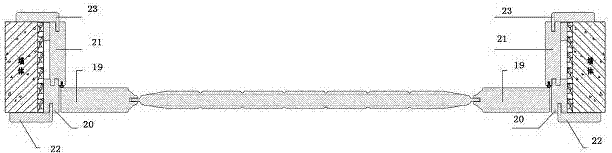

Numerical control slurry spraying yarn repair lubricator and method thereof

InactiveCN102220666ACleanlinessReduce occupational diseasesTextile treatment by spraying/projectingLubricationPositive direction

The invention relates to a numerical control slurry spraying yarn repair lubricator and a method thereof. The numerical control slurry spraying yarn repair lubricator mainly comprises a micro speed-regulating hollow shaft motor, an atomization slurry spraying chamber, a yarn clew dust cover and a numerical control metering pump which are connected in sequence. The lubricator is characterized in that the micro speed-regulating hollow shaft motor is connected with the atomization slurry spraying chamber, and the lower end of the atomization slurry spraying chamber is connected with yarn clew dust cover which is provided with a dust exhaust port and is internally embedded with a gravity pressure spring; and nozzles on two sides of the atomization slurry spraying chamber are formed by connecting a slurry supply pipeline and a high-pressure metering pump. When yarns are reeled off from cheese, a rotary balloon naturally spirally lifted in positive direction is produced, the yarns pass through the high-pressure atomization slurry spraying chamber in time, and input slurry is automatically and preciously controlled by the high-pressure metering pump according to a computer instruction; the high-pressure slurry spraying chamber is provided with two or a plurality of nozzles for balanced multidimensional stereoscopic slurry spraying with multiple surfaces, multiple points and multiple angles; the yarn sprout ratio reaches a critical point of saturation and unsaturation; after being repaired and film-formed, the yarns are flexible internally and smooth externally and are rich in elasticity; and the method is an unsaturated slashing method. The working procedures of slashing and lubrication are merged and finished in one time, and a wrapped lubricant slurry film (30) is arranged outside the yarns. The method is grain-saving, water-saving, electricity-saving, time-saving, waste water zero-discharged, energy-saving and environmentally-friendly.

Owner:崔建明

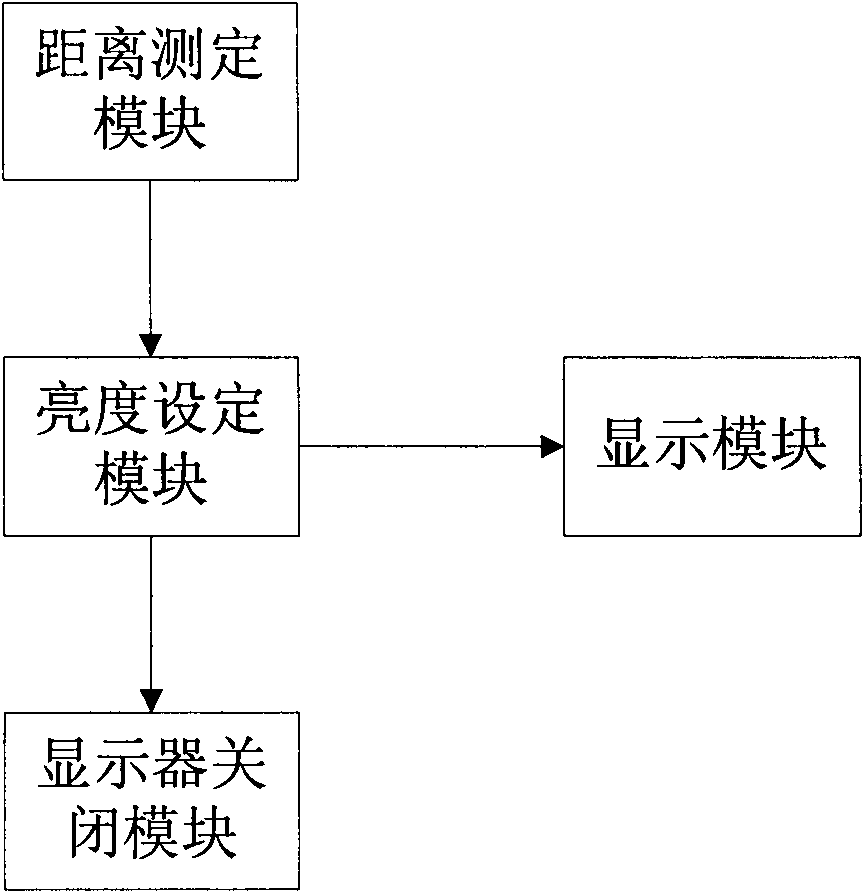

Computer energy-saving display and method thereof

InactiveCN101661736AImprove protectionProtect from glareCathode-ray tube indicatorsElectromagnetic wave reradiationHuman bodyProtecting eye

The invention provides a computer energy-saving display and a method thereof, wherein, the computer energy-saving display comprises a distance measuring module for measuring the distance between the display and a user, a luminance setting module connected with the distance measuring module for setting luminance of the display according to the measured distance, and a display module connected withthe luminance setting module for displaying according to the set luminance of the display. In the invention, as the computer display is internally provided with the distance measuring module, the display is brightest when the distance between a human body and the computer display is within a correct sitting posture range of 50-70cm; and the closer the human body gets to the display, the darker thedisplay is; and the display is automatically closed when the human body gets away, thus achieving the purpose of saving electric energy and protecting eyes of people from being damaged by hard light,reminding the people of working with a correct sitting posture so as to reduce occupational diseases, and realizing less electric energy consumption and good protection on the eyes of people.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

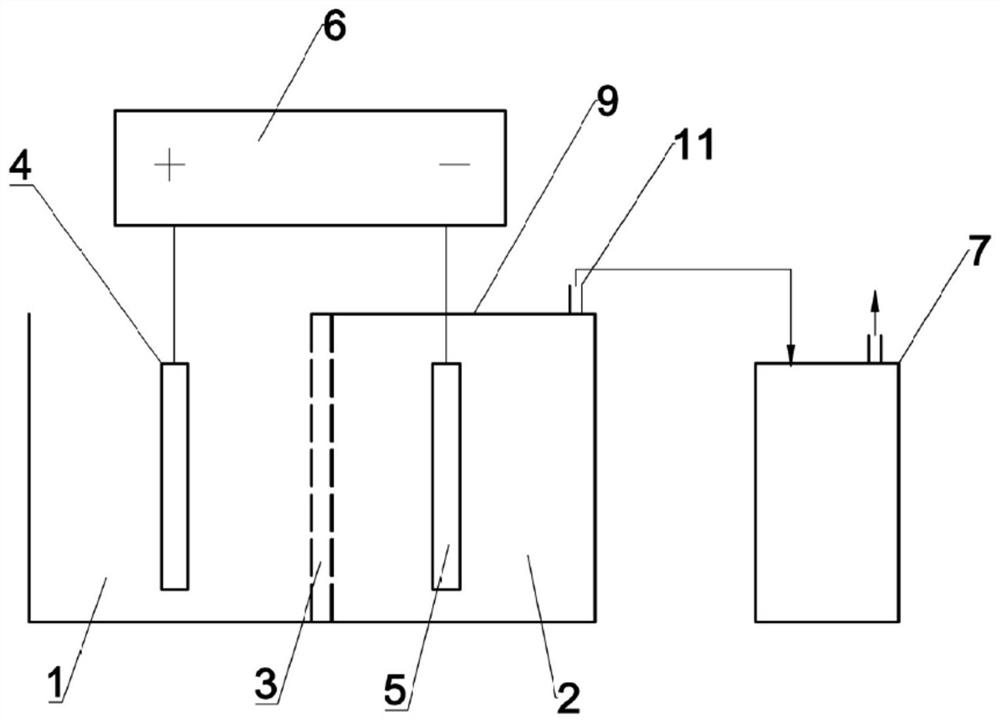

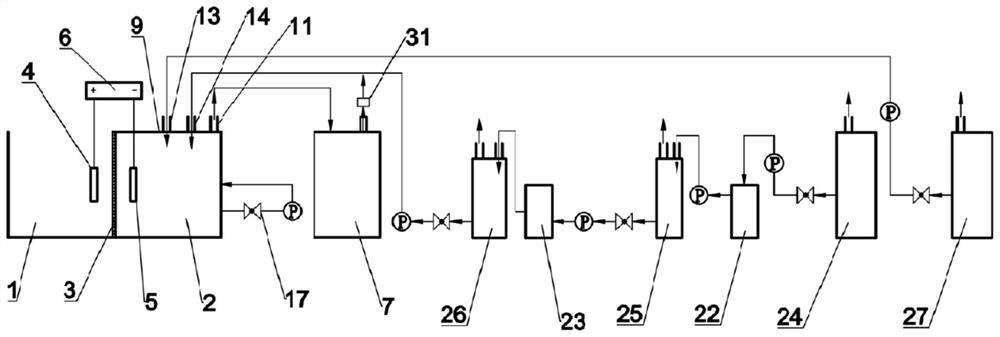

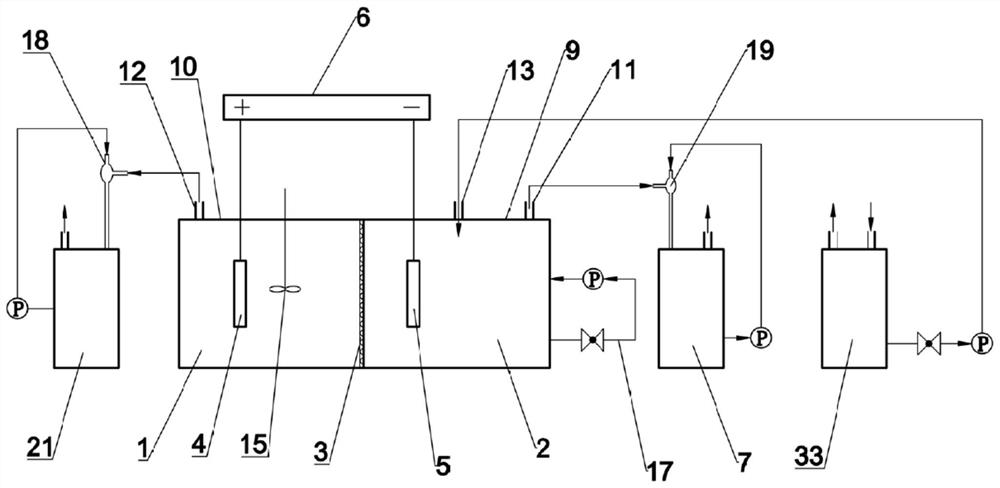

Method and device for treating nitrate-containing waste liquid

PendingCN113526621AEfficient decompositionDecomposition high speedWater contaminantsWater/sewage treatment apparatusElectrolytic agentFerrous

The invention discloses a method for treating nitrate-containing waste liquid. The method comprises the following steps of: using an electrolytic reaction tank, and arranging an electrolytic separator in the electrolytic reaction tank to form an anode region and a cathode region, wherein the anode region and the cathode region are filled with an anode electrolyte and a cathode electrolyte respectively; the electrolysis separator can effectively reduce or even prevent anions in the cathode electrolyte from migrating to the anode region under the action force of an electric field; and the cathode electrolyte is an acidic solution containing iron ions and nitrate-containing waste liquid. According to the method, iron ions are continuously converted into ferrous ions through electric synergy, so that nitrate radicals are effectively decomposed, and the effect of remarkably reducing or removing the nitrate radicals is achieved; and the treatment method of the nitrate-containing waste liquid is wide in application range and can be used for treating all nitrate-containing industrial waste liquid.

Owner:叶涛

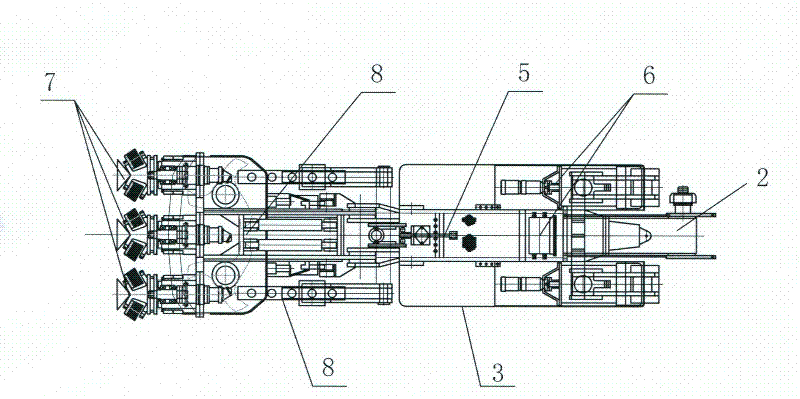

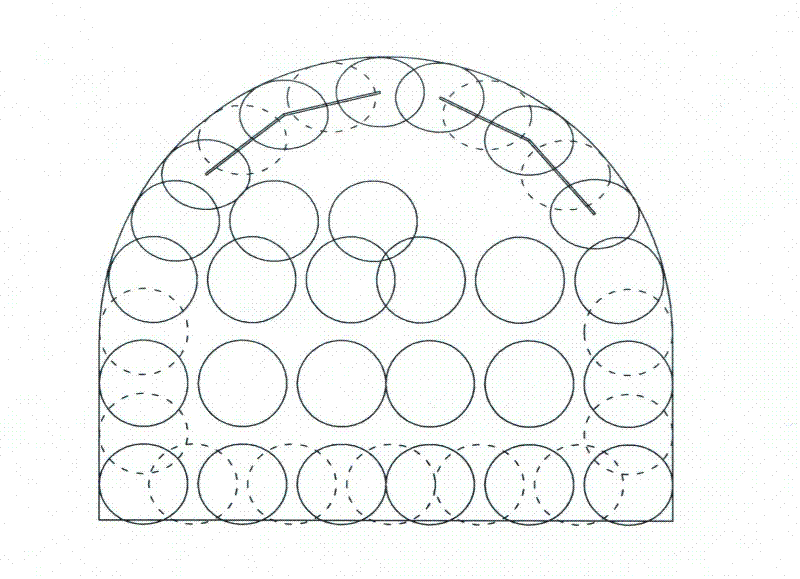

Comprehensive mechanical rock drift excavating process

ActiveCN102383795ASimplify the construction processReduce security risksSlitting machinesAnchoring boltsRock cuttingRock breaking

The invention relates to a comprehensive mechanical rock drift excavating process, which adopts a comprehensive mechanical rock drift operation line, and is characterized in that the comprehensive mechanical rock drift operation line comprises a comprehensive rock drift excavating machine, a crawler-type movable belt conveyer and a crawler-type movable wet-type mortar spraying machine, wherein the comprehensive rock drift excavating machine is used for excavation and supporting operation, the crawler-type movable belt conveyer is used for conveying rocks from a working surface to the outside, and the wet-type mortar spraying machine is used for carrying out wet-type mortar spraying sealing to a rock drift. In the rock drift excavating process, the comprehensive mechanical rock drift excavating machine which integrates rock cutting, rock loading, rock carrying and supporting is adopted for rock drift excavating, and the wet-type mortar spraying machine is used for spraying mortar, so that the rock shift operation can be carried out. According to the invention, the original blasting and rock-breaking process is cancelled, the construction process is simplified, the production with potential safety hazards can be greatly reduced, and the safety performance is greatly improved.

Owner:闫振东

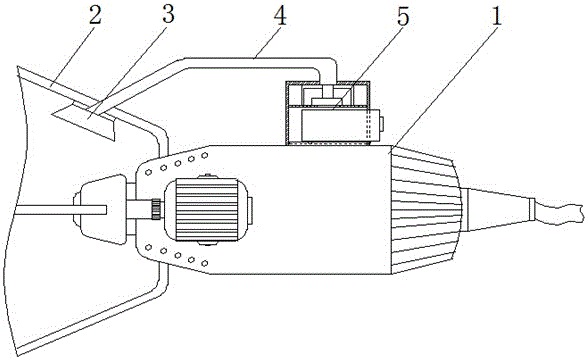

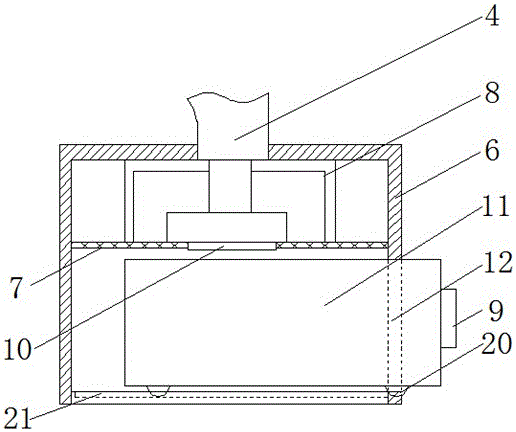

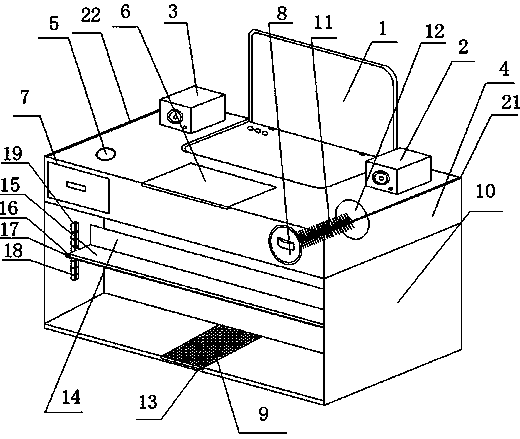

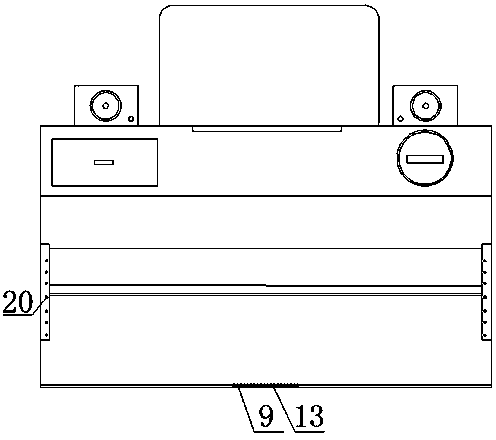

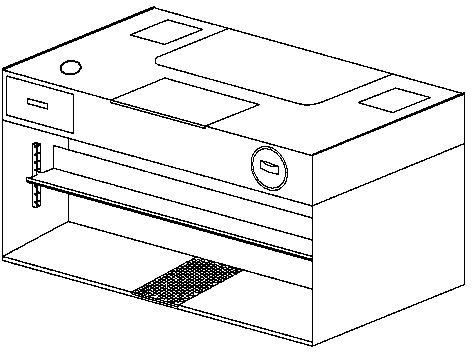

Wall perforating device capable of removing dust

InactiveCN105690333AReduce occupational diseasesImprove physical fitnessPortable power-driven toolsPortable drilling machinesCost (economic)Engineering

The invention discloses a dust-removable wall drilling device, which comprises an electric drill, the surface of the electric drill is fixedly connected with a sealing cover, and the inner wall of the sealing cover is provided with a dust port, the top of the dust port is fixedly connected with one end of a dust pipe, and The other end of the dust pipe is fixedly connected to the dust removal device, and the bottom of the dust removal device is fixedly connected to the electric drill. The dust removal device includes a casing, and the inner wall of the casing is fixedly connected with a partition, and the partition is provided with a dust outlet. A vacuum cleaner is provided on the top of the partition, and the top of the vacuum cleaner is fixedly connected to the outlet end of the dust pipe. The dust-removable wall drilling device solves the problem that the current electric drill produces a large amount of dust during use and pollutes the construction site environment, prevents construction workers from inhaling dust into their bodies, reduces the occurrence of occupational diseases, and improves the health of construction workers. It greatly facilitates the cleaning and treatment of dust, and reduces labor and economic costs.

Owner:WUXI JIANLING ELECTRIC APPLIANCE CO LTD

Active magnetic water additive used for efficient dust fall under coal mine

The invention provides an active magnetic water additive used for efficient dust fall under a coal mine and belongs to active magnetic water additives. The additive is prepared from, by weight, 30-50 parts of inorganic electrolyte, surfactant, 0.3-0.7 part of polar organic matter and 7-10 parts of polymers, wherein inorganic electrolyte comprises sodium chloride, the surfactant comprises 1-2.5 parts of anion sodium dodecyl benzene sulfonate and 0.5-2 parts of non-ionic fatty acid methyl ester ethoxylate, the polar organic matter is fatty acid, and the polymers are polyethylene glycol. A solution prepared through the additive can have a coupling and coordination action with a magnetic field easily in the 300-400 mT magnetic field environment, active magnetic water with smaller surface tension and higher wettability is generated, and coal dust under a sedimentation well can be efficiently wetted through mist spraying. The additive is simple in formula, convenient to prepare and suitable for large-scale application of underground dust removal, and has the advantages of being environmentally friendly, low in cost and the like.

Owner:CHINA UNIV OF MINING & TECH

All-in-one computer

InactiveCN104223767AImprove immunityReduce computer occupational diseasesOffice tablesDigital processing power distributionDisplay deviceComputer engineering

The invention discloses an all-in-one computer and belongs to the technical field of computer equipment. The all-in-one computer is characterized in that a display is arranged on a computer case and is connected with the same, a groove is arranged in the computer case and corresponds to the display, a keyboard, automatic lift speakers, a drawer and a tension unit are further arranged on the computer case, the lower portion of the computer case is connected with a table body, the tension unit comprises a handle, a tension spring and a fixing plate, two ends of the tension spring are respectively connected with the handle and the fixing plate, a cup heating unit is further arranged on the computer case, and a lifting motion device is arranged on the table body. The all-in-one computer is mainly applicable to people's daily life, and brings convenience to computer workers.

Owner:尚存

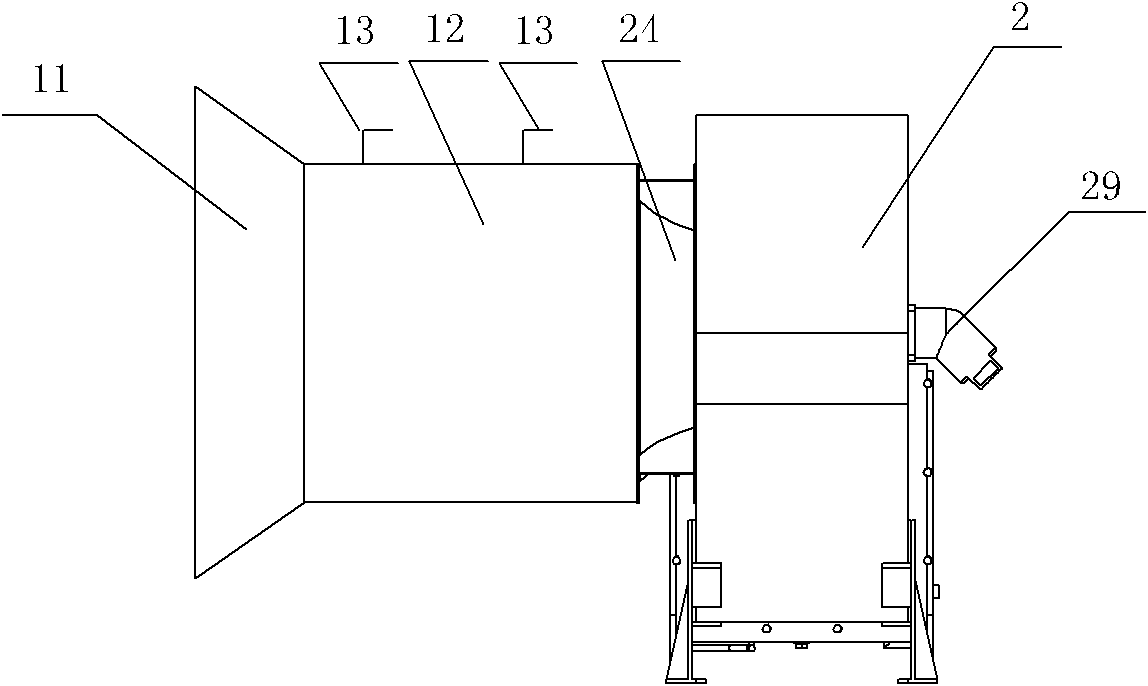

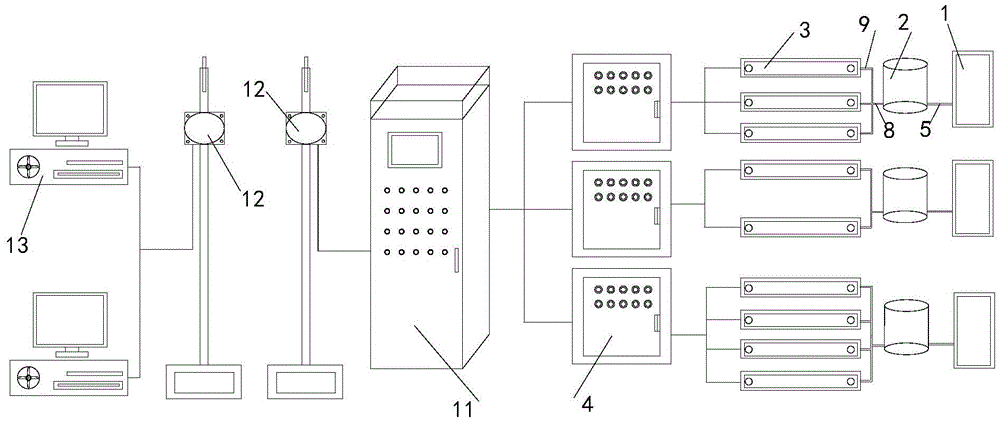

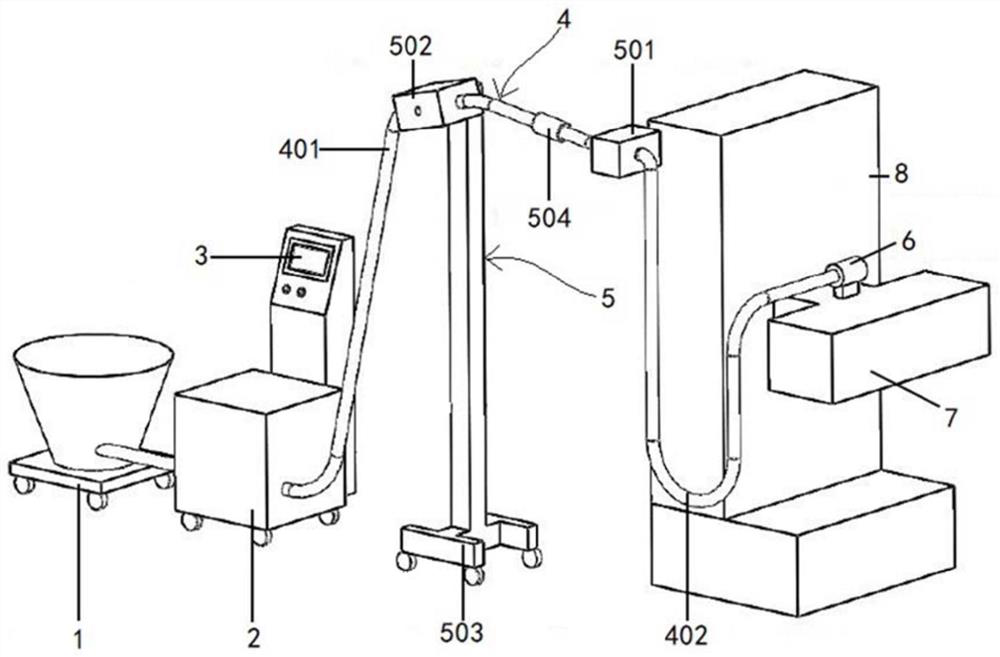

Automatic feeding system

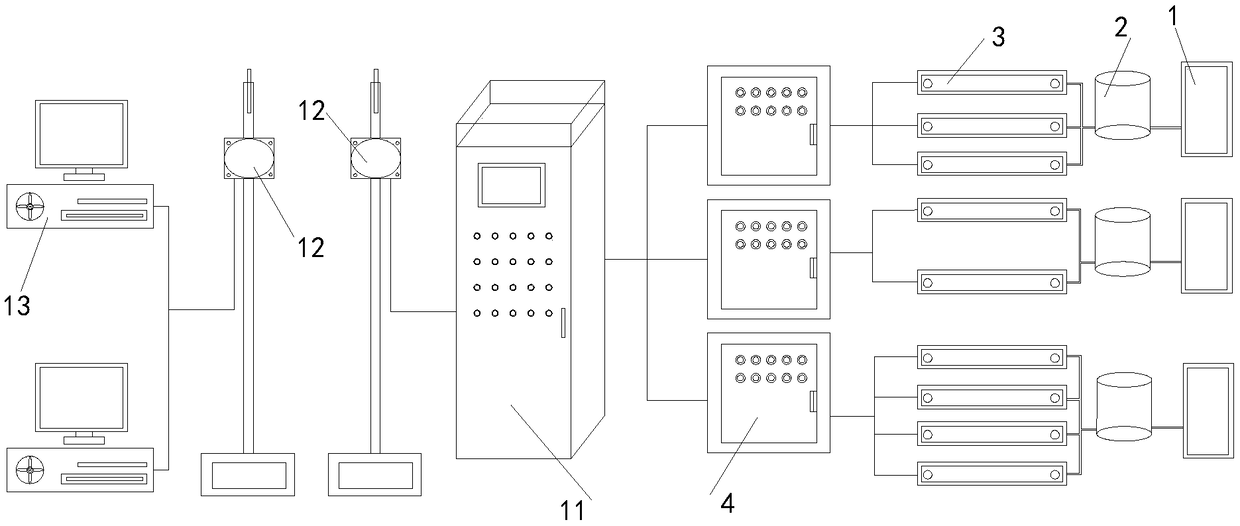

InactiveCN112356283AImprove feeding efficiencyLabor savingDischarging apparatusBuilding constructionsControl engineeringProcess engineering

The invention provides an automatic feeding system. The automatic feeding system comprises a storage device used for supplying building materials with fluidity, a pumping device, a feeding pipeline and a pumping control device, wherein the pumping device is connected with the storage device, provides power for conveying the flowing building materials, and can pump the flowing building materials from the interior of the storage device; the feeding pipeline is connected with a discharging opening of the pumping device, and the flowing building materials are conveyed to an external executing mechanism through the feeding pipeline; and the pumping control device controls starting and stopping of feeding of the pumping device, measures the flow of the feeding pipeline or the feeding pressure and weight of the executing mechanism, judges whether current feeding meets the feeding requirement or not according to a measurement result and the working efficiency of the executing mechanism, adjusts the pumping efficiency of the pumping device according to the judgment result, and achieves accurate control over feeding. According to the automatic feeding system, the feeding efficiency can be greatly improved, and labor force consumed by manual feeding is avoided; and meanwhile, feeding is accurately controlled, material waste is reduced, and the construction cost is reduced.

Owner:上海蔚建科技有限公司

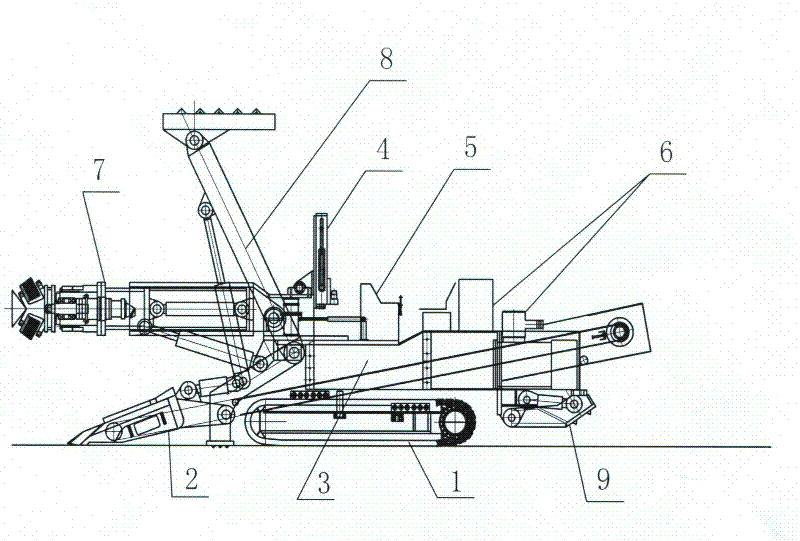

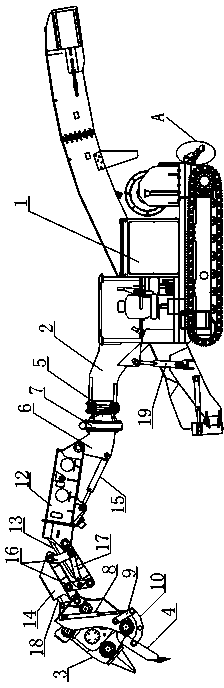

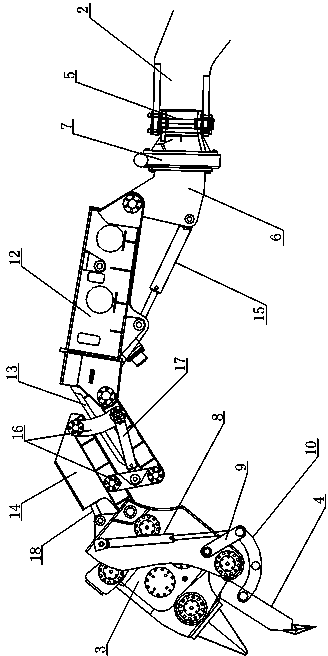

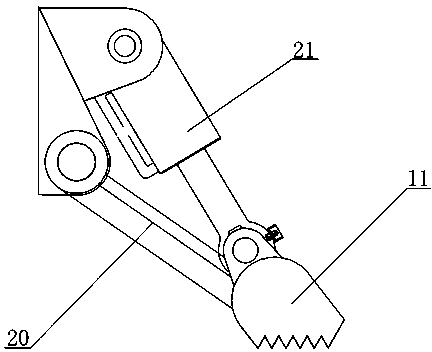

Crushing and excavation integral type backhoe loader

InactiveCN104213592AReduce professional allocationReduce occupational diseasesMechanical machines/dredgersSlewing bearingDisease injury

The invention discloses a crushing and excavation integral type backhoe loader, which comprises a main machine of the backhoe loader, wherein the main machine of the backhoe loader is provided with a rotating device, the rotating device is connected with the main machine of the backhoe loader through a gantry frame, one end, away from the main machine of the backhoe loader, of the rotating device is further connected with a telescopic device, one end, away from the rotating device, of the telescopic device is further provided with a crushing hammer, the crushing hammer is further movably connected with an excavation bucket, the rotating device comprises a rotary arm, a large arm seat and a slewing bearing, the rotary arm is connected with the gantry frame, the large arm seat is connected with the telescopic device, and the slewing bearing is connected with the large arm seat and the rotary arm, and is used for driving the large arm seat to rotate by 360 degrees relative to the gantry frame. The backhoe loader has the advantages that a tunnel can be crushed, excavated and loaded at one time, and the open crushing and loading can be completed at one time; explosives are not needed, the number of professional persons is reduced, and the occupation diseases are reduced; in addition, the one-time investment is saved, and the use cost is reduced.

Owner:四川戴克机械制造有限公司

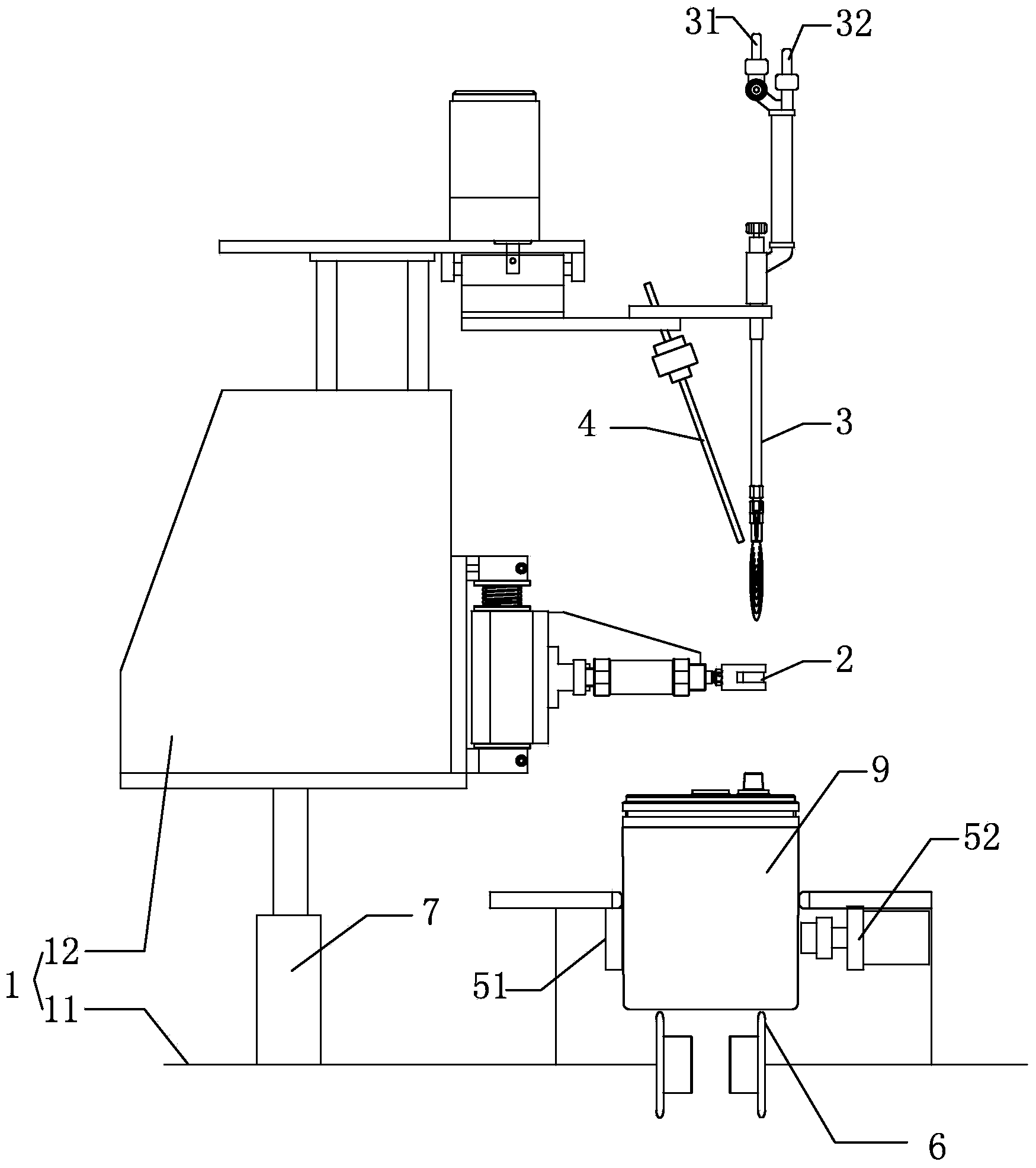

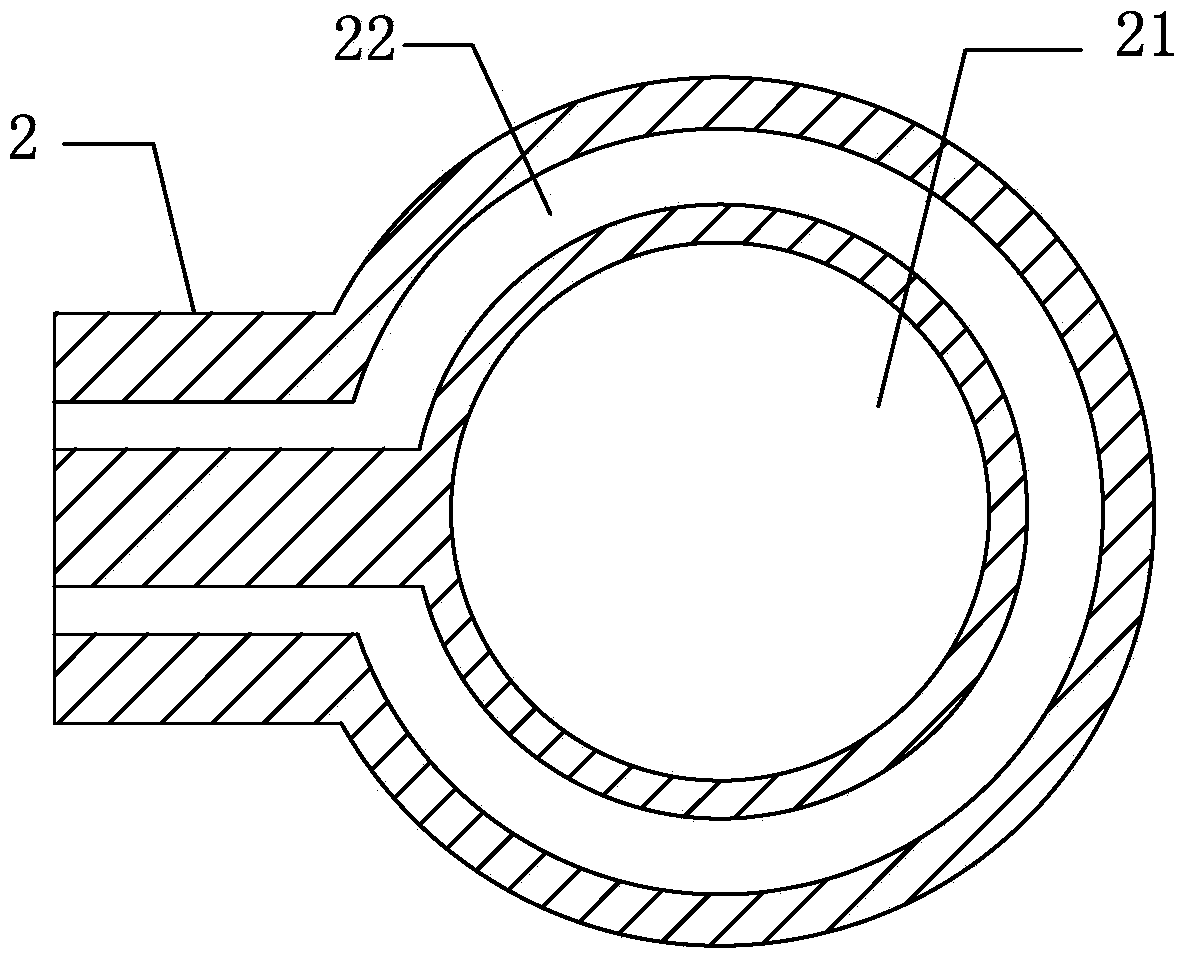

Terminal welding machine

InactiveCN103447656AReduce occupational diseasesIncrease productivityGas flame welding apparatusEngineeringSoldering gun

The invention provides a terminal welding machine, which comprises a frame, a welding mold arranged on the frame, a welding gun arranged on the frame, and an ignition device arranged on the frame and used for igniting the welding gun, wherein a through hole used for a battery pole to stretch in is arranged in the welding mold, the welding end of the welding gun points at the through hole, and a gas pipe interface and an oxygen pipe interface are arranged on the welding gun. According to the invention, manual welding is replaced by machine welding, so that occurrence of occupational disease of production personnel is reduced, and production efficiency is improved.

Owner:长兴大宇科机电有限公司

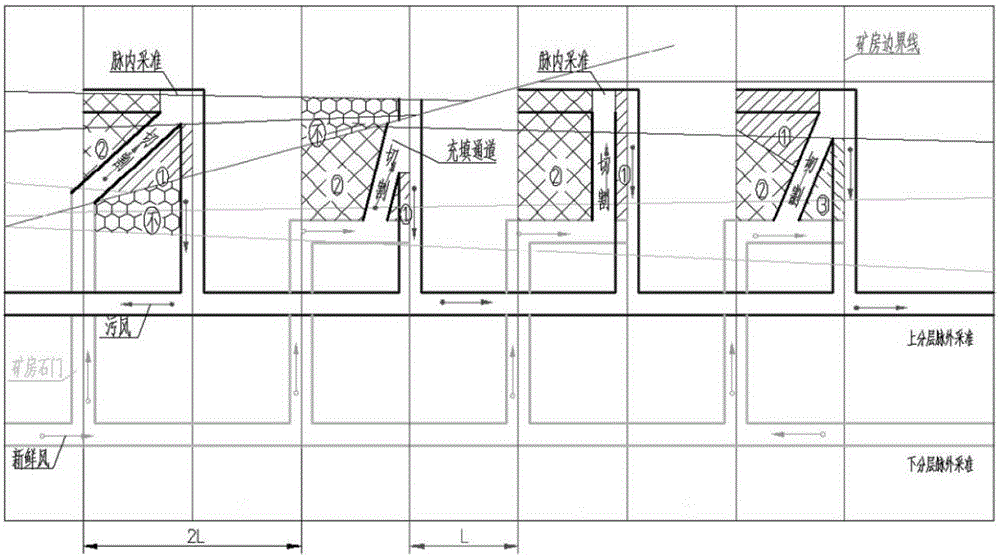

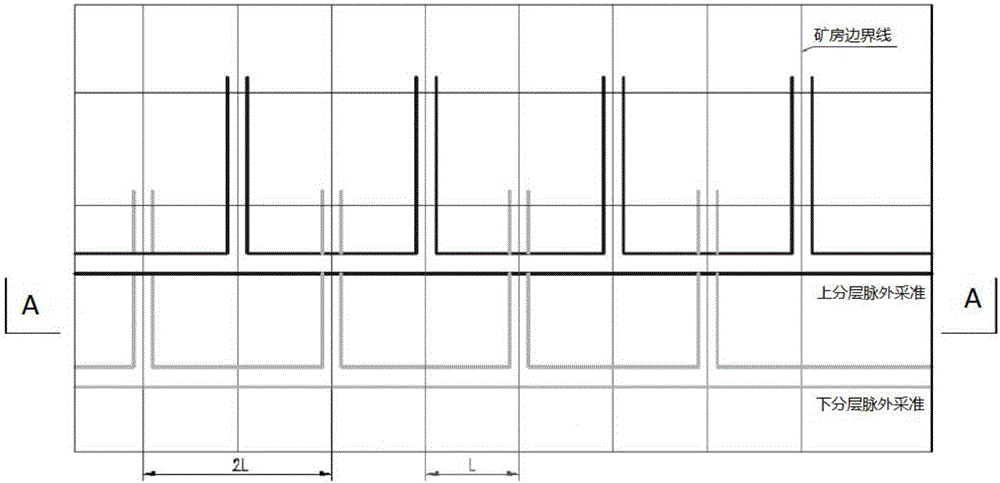

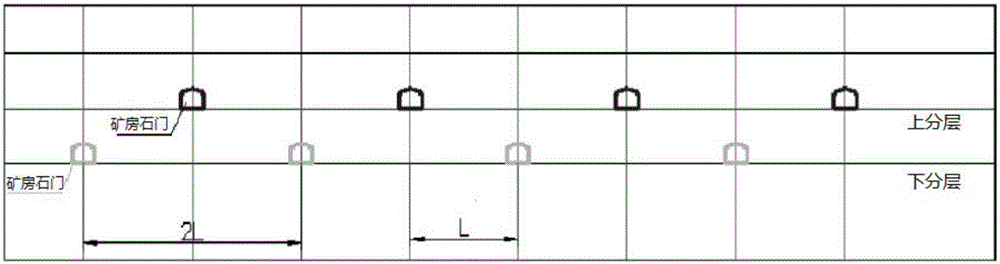

Backfill mining method with stope rooms being arranged in centering and staggered mode

ActiveCN107524442AImprove air qualityEnsure safetyUnderground miningSurface miningSilicosisEngineering

The invention provides a backfill mining method with stope rooms being arranged in a centering and staggered mode. The form that the stope rooms are arranged in the centering and staggered mode is adopted, every two adjacent stope rooms share one stope room cross drift, and a cutting channel is pulled on two adjacent lode stratifications to form an air returning channel. Through implementation of the backfill mining method, after the stope room cross drifts are arranged, the stope rooms are not affected by in-lode stope preparation of the stope rooms, a dirty air returning channel during stope room stoping is formed, air quality of a stope is improved, and the probability of occurrence of occupational disease (silicosis) is effectively reduced; by using the form that the stope rooms are arranged in the centering and staggered mode, the condition that parts of ores cannot be mined during stoping of an ore body can be prevented, and economic efficiency is improved; in addition, the over mining phenomenon is effectively avoided, and safety of mining construction is ensured; the cutting channel arranged on the adjacent stratifications in a pulling mode can not only serve as the air returning channel, but also can serve as a backfilling channel for filling after stoping, and normal carrying out of the filling process is ensured.

Owner:GUIZHOU KAILIN GRP CO LTD

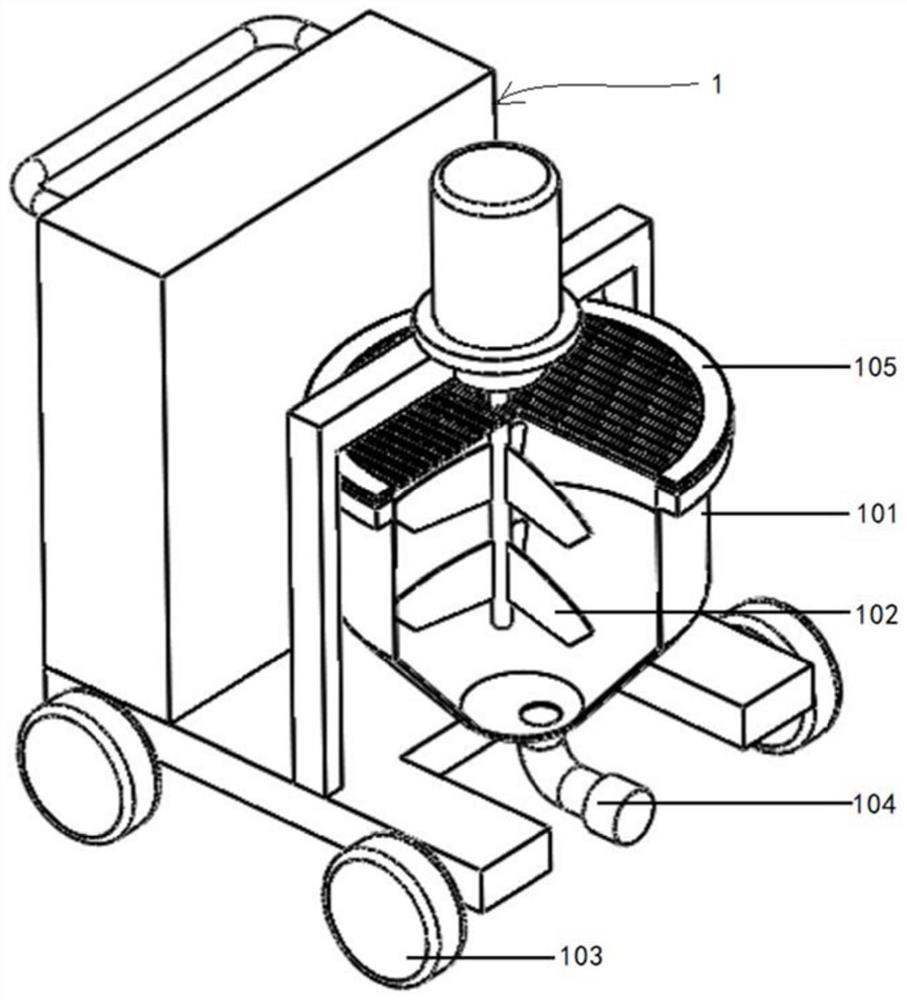

Integrated walking grass seeder

The invention discloses a walking integrated grass seed planter, which comprises a main body, a walking mechanism is arranged under the main body, and a trenching mechanism, a seeding mechanism, a landfill mechanism and a watering mechanism are respectively arranged above the main body. A controller and a battery box are arranged above, the signal input end of the controller is electrically connected with the metal sensor, the grating sensor 1 and the grating sensor 2, and the signal output end of the controller is connected with the ditching linear motor, the sieve block linear motor, The landfill linear motor, the water supply solenoid valve and the traveling mechanism are electrically connected, and the power output end of the controller is electrically connected with the trenching linear motor, the sieve block linear motor, the landfill linear motor, the water supply solenoid valve and the traveling mechanism, The power input end of the controller is electrically connected with the battery box. The beneficial effects of the invention are that the structure is simple and the practicability is strong.

Owner:新昌县羽林街道维新机械厂

Dust suppression system

InactiveCN109078425AWon't spillReduce spillageUsing liquid separation agentScale removal and water softeningWater sourceAtmospheric air

The invention relates to a dust suppression system which comprises a water filtering and softening device, a water storage tank, a dry fog dust suppression device and a local controller. An adjustablesprayer plate in the dry fog dust suppression device is used for scattering and spraying a thermostatic water source filtered and softened by the water filtering and softening device in the water storage tank, a large quantity of micron-sized dry fogs and negative ions are generated and blown out of the dry fog dust suppression device by a variable frequency high-pressure centrifugal fan in the dry fog dust suppression device, dust is adsorbed, condensed and settled, and the purpose of dust removal is achieved. Millimeter-level visible dust particles can be effectively treated, micron-sized inhalable dust particles can be effectively treated, air pollution caused by the dust is reduced, the labor environment of field operators is improved, and occupational diseases are decreased. The system is small in occupied area, safe and convenient to operate, fully automatic in control and strong in practicability.

Owner:湖南冯河大龙山茶业有限公司

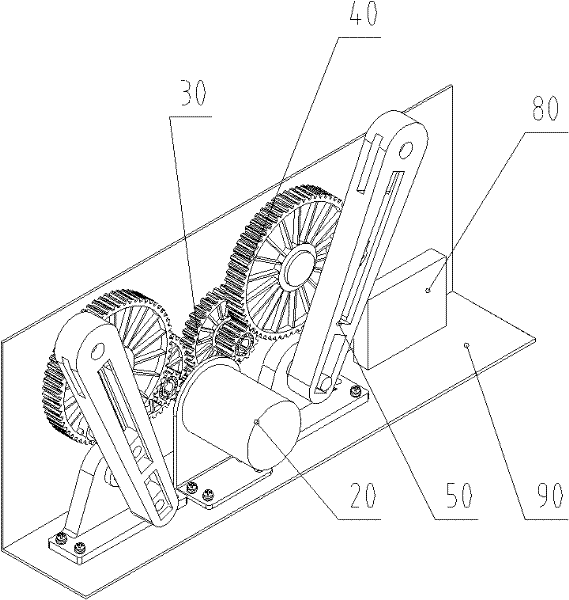

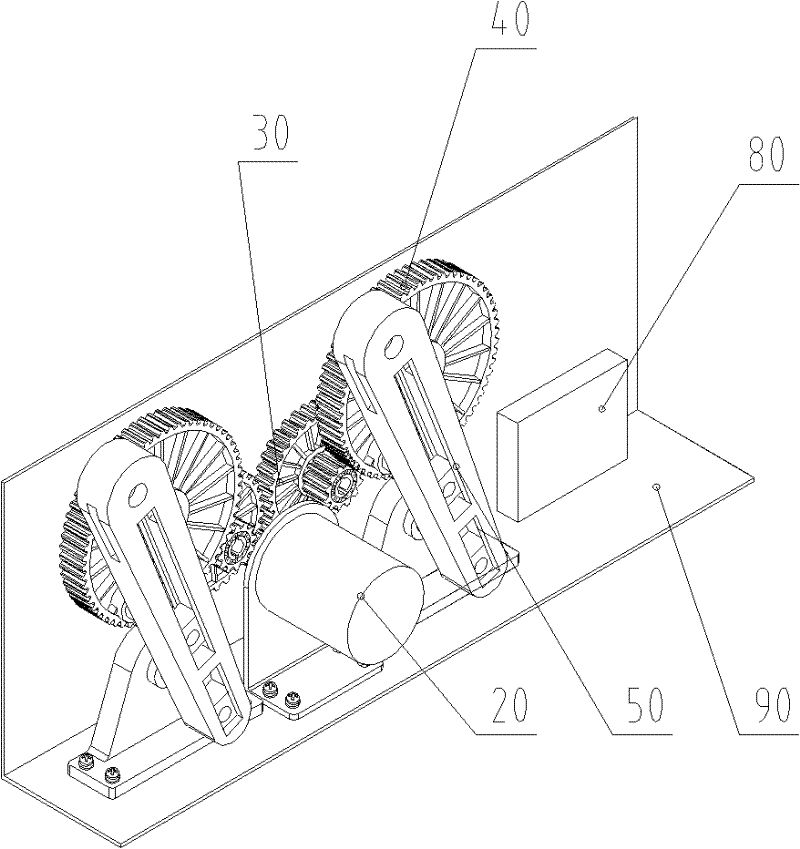

Capacitor lead welding bench

ActiveCN104493387AConvenient welding operationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineEngineering

The invention provides a capacitor lead welding bench comprising a rack and a control device. At least two guide rails and at least one bench-top are arranged on the rack. The control device comprises a controller, a servo motor, a reducer, a horizontal screw, a gear I, a gear II and a vertical screw; the controller is connected with the servo motor; the servo motor is connected with the reducer; the reducer is connected with the horizontal screw; the horizontal screw is fixedly connected with the gear I; the gear I meshes with the gear II; the gear II is fixedly connected with the vertical screw; a connecting member is disposed on each bench-top; the vertical screw is screwed to an internal thread of the connecting member; at least two sliders are arranged on each bench-top; the sliders can move up and down along the guide rails. Compared with the prior art, the capacitor lead welding bench has the advantages that the height of each bench-top of the bench can be adjusted as required, the bench is conveniently applied to welding of leads of different specifications of capacitors, operators need not change the bench, and operating efficiency is improved.

Owner:SHANGHAI SIEYUAN CAPACITOR

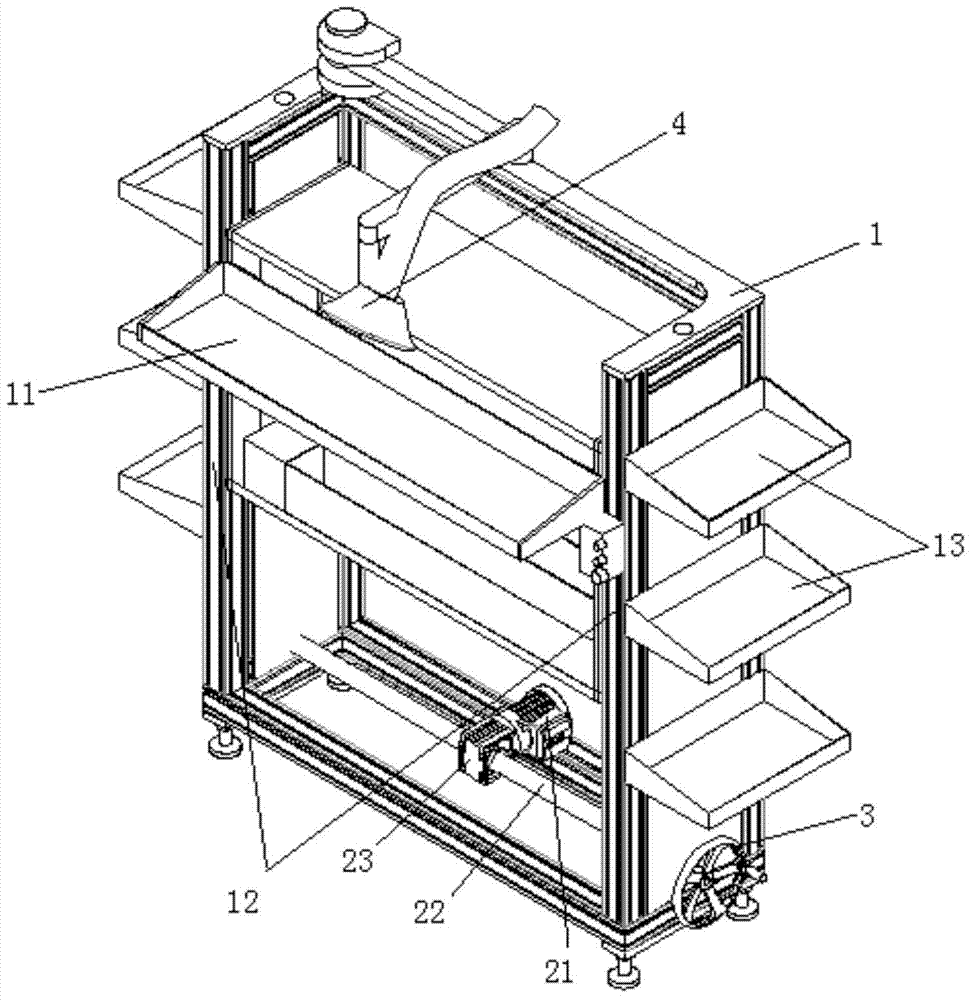

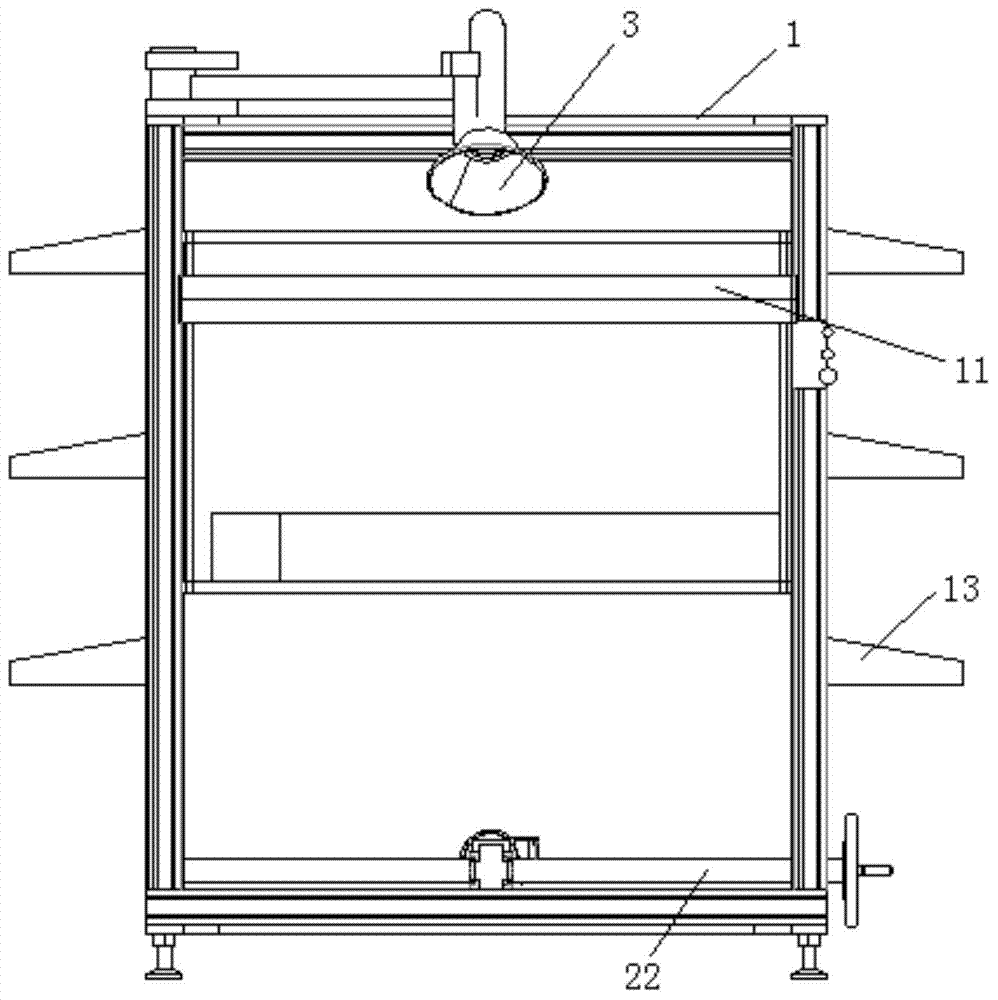

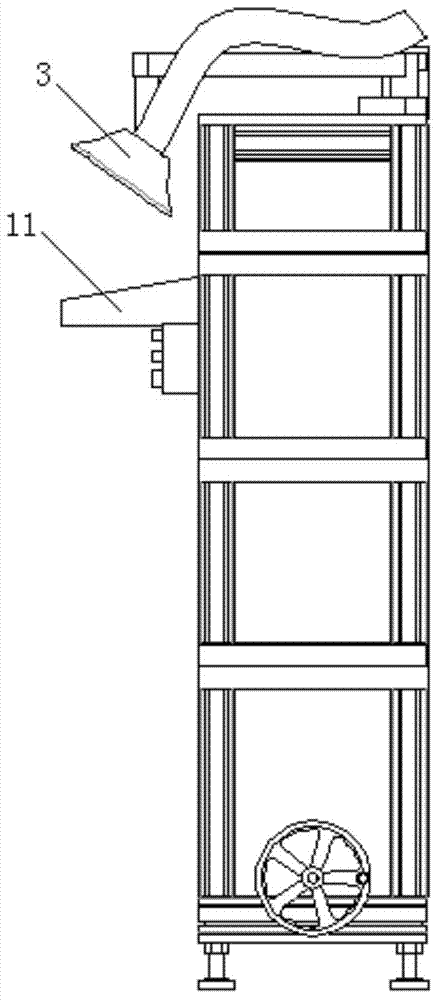

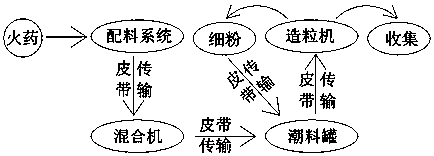

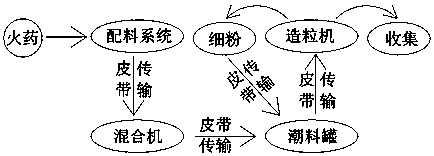

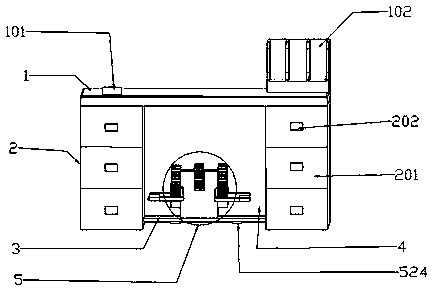

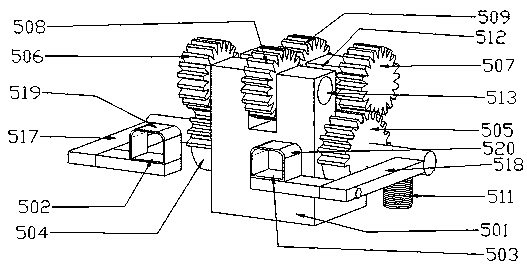

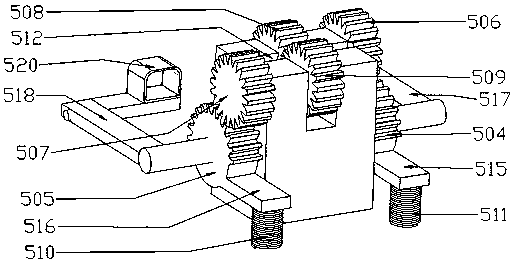

Mixing material-moisturizing granulation process for gunpowder

InactiveCN109704892ASolve problems such as sticky materialsReduce labor intensityExplosive working-up apparatusControl systemEngineering

The invention discloses a mixing material-moisturizing granulation process for gunpowder. The process particularly uses equipment such as a material preparing system, a mixing machine, a material moisturizing tank, a granulator, a belt and a control system for mixing and granulating of the gunpowder. The process provided by the invention adopts mechanized operation, material preparing, mixing, material moisturizing, granulation and sieving are integrated, and the problems of long working process time, a complicated working process, a large unit medicine addition amount (a single mixing amountis too large to facilitate production safety), uniform mixing and the like are solved; when materials are prepared, a plurality of raw material hoppers are used to put materials into to a material preparing hopper, so that the problems of a plurality of times of manual weighing and personnel health are solved; no friction occurs during mixing, material adding and discharge are performed in a sealmanner, so that the problems of heating, friction, dust rising and the like are solved; and a material moisturizing machine adopts a concentric shaft to drive the material moisturizing tank to turn over up and down and stir, and stirring is performed in a non-central-shaft manner, so that the problems that materials are bonded to a central shaft and the material moisturizing tank are solved, and the labor intensity is reduced.

Owner:LIUYANG LIUHE MACHINERY

Office desk with leg fitness device

The invention discloses an office desk with a leg fitness device. The office desk comprises a desktop and bases, a cup tube is arranged on the left side of the desktop, a file placing frame is arranged on the right side of the desktop, and the cup tube and the file placing frame are fixedly connected with the desktop; each of both left and right ends of the lower portion of the desktop is providedwith one base, and the bases are detachably connected with the desktop; a transverse baffle plate and a longitudinal baffle plate are arranged between the two bases, both left and right ends of the transverse baffle plate and the longitudinal baffle plate are detachably connected with the bases, and the upper end of the longitudinal baffle plate is detachably connected with the lower end of the desktop; the middle of the transverse baffle plate is provided with the leg fitness device, and the leg fitness device is detachably connected with the transverse baffle plate. The office desk has theadvantages of convenient achievement, diversified functions and high cost performance ratio, both working and exercising can be taken into account, and the occurrence of occupational disease can be reduced.

Owner:刘伟龙

Casting double-end cutting device

PendingCN112404583AHigh degree of automationImprove securityMetal sawing devicesMaintainance and safety accessoriesMan machineStructural engineering

The invention discloses a casting double-end cutting device. The casting double-end cutting device comprises a cutting device body and a control box used for complete machine control; the cutting device body is composed of a cutting unit and a self-centering clamping mechanism; the self-centering clamping mechanism is arranged at the front side of the cutting unit in an overturning manner througha 180-degree rack type overturning oil cylinder; and the cutting unit comprises a cutting workbench frame, a supporting arm installed on the cutting workbench frame in a sliding manner and a cutting mechanism movably connected with the supporting arm through a cutting machine ascending and descending oil cylinder. According to the casting double-end cutting device, man-machine separation can be achieved, the safety of an operator is greatly improved, the labor intensity of workers is reduced, and a large amount of manpower, material resources and cost are saved.

Owner:殷凯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com