Patents

Literature

687results about How to "Convenient welding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-side welding and double-side forming welding method for ceramic gasket

The invention discloses a single-side welding and double-side forming welding method for a ceramic gasket, and belongs to the welding field of material processing engineering. The method comprises the following steps of (1) treatment of grooves of abutted plates; (2) installation of the plates, and spot-welding fixing; (3) adding of the ceramic gasket; (4) baking for dehumidifying; (5) groove welding. The method does not need to carry out the operation that the welds of the back side are subjected to cleaning and welding operations after the structure is turned over, after the welds of the front side are welded, the double-side forming effect is directly realized, and the required matching of hoisting equipment and the required man-hours during turnover of the structure are reduced. The number of welds is reduced, and the operation of overhead welding positions is avoided. Therefore, the labor strength of workers is reduced, the welding difficulty is reduced, the production efficiency is greatly improved, and the production cost is reduced.

Owner:中船桂江造船有限公司

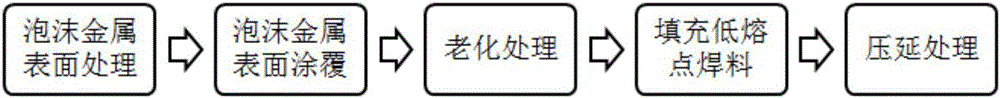

Preparation method of foam metal composite solder piece

ActiveCN106825999AOvercoming the lack of low strengthHigh strengthHot-dipping/immersion processesWelding/cutting media/materialsPorosityChemical plating

The invention discloses a preparation method of a foam metal composite solder piece. According to the method, firstly, the surface of foam metal is treated, the surface of a foam metal matrix is coated with one or more layers of active metal with an electroplating or chemical plating process, annealing treatment is performed, the foam metal with an active metal plating layer is infiltrated into molten solder and taken out after filling is performed, foam metal enhanced low-melting-point composite solder is obtained, finally, calendaring machining is performed, metal solder foil with certain thickness is obtained, and the purposes of improving the strength and the welding performance of foam metal composite solder are achieved. The foam metal is used for enhancing Sn-based or Zn-based solder, and the applied active metal plating layer can improve the strength of the foam metal matrix to a certain extent and make up the influence of foam metal porosity on the strength of the foam metal. Besides, the active metal plating layer is also beneficial to filling of low-melting-point solder to the foam metal and relieves the unfavorable situation that tin and matrix metal are difficult to infiltrate and interface bonding is not firm.

Owner:无锡继平新材料科技有限公司

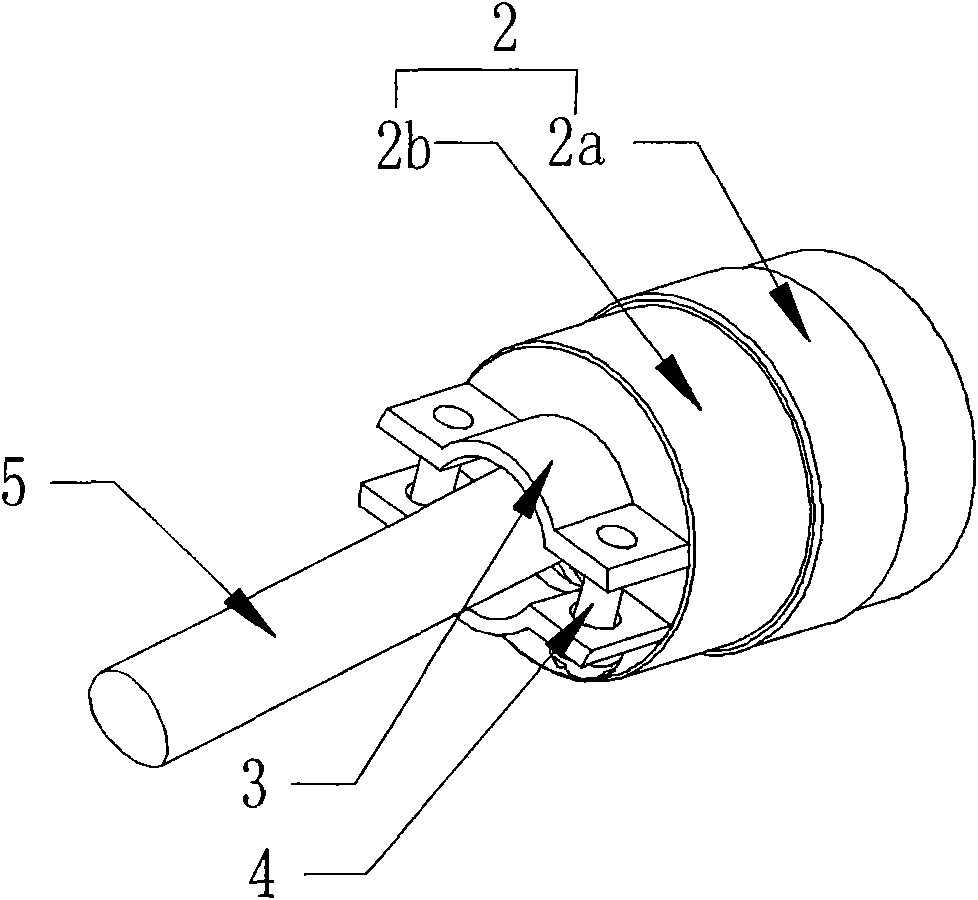

Light-emitting board welding and fixing device

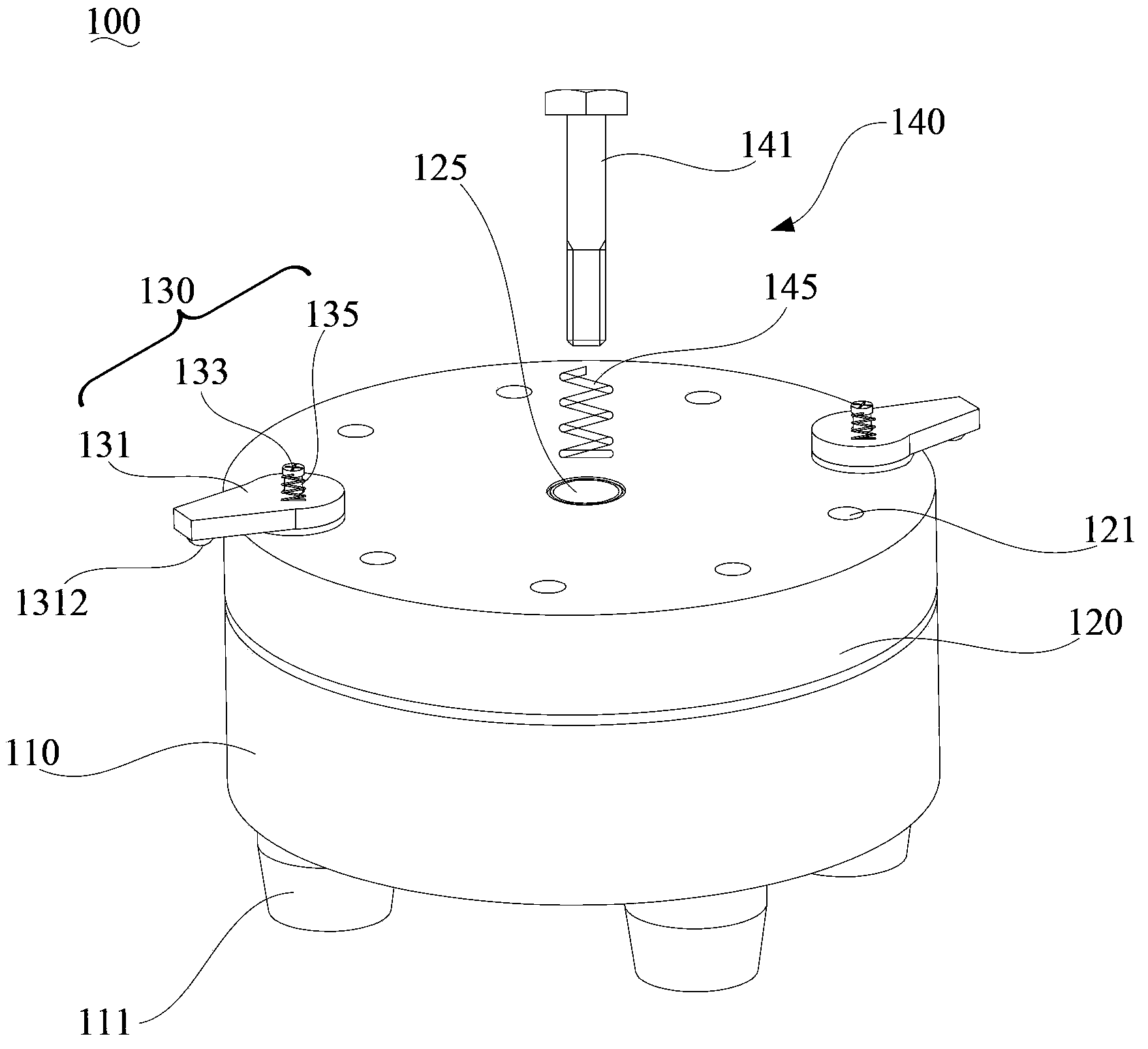

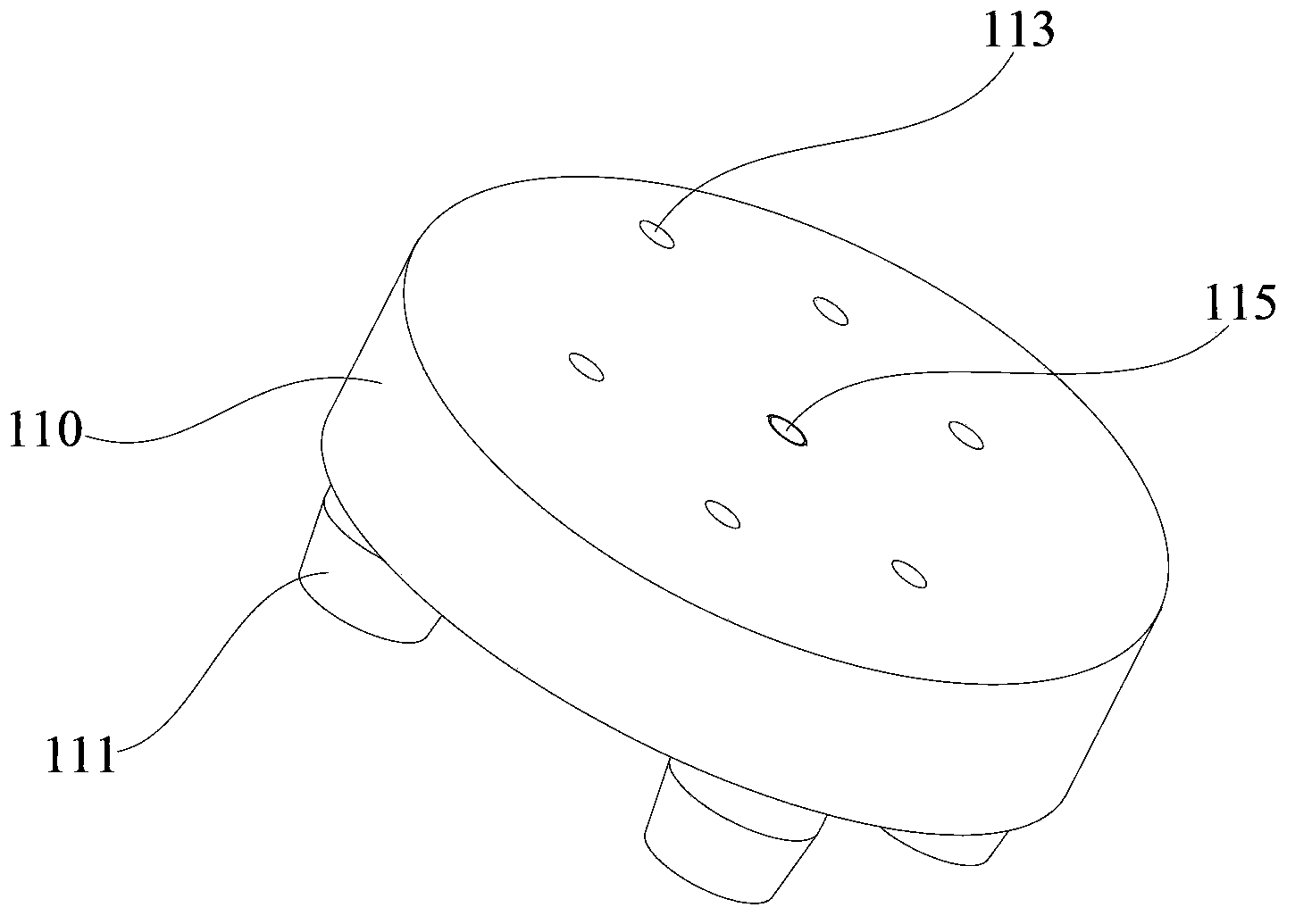

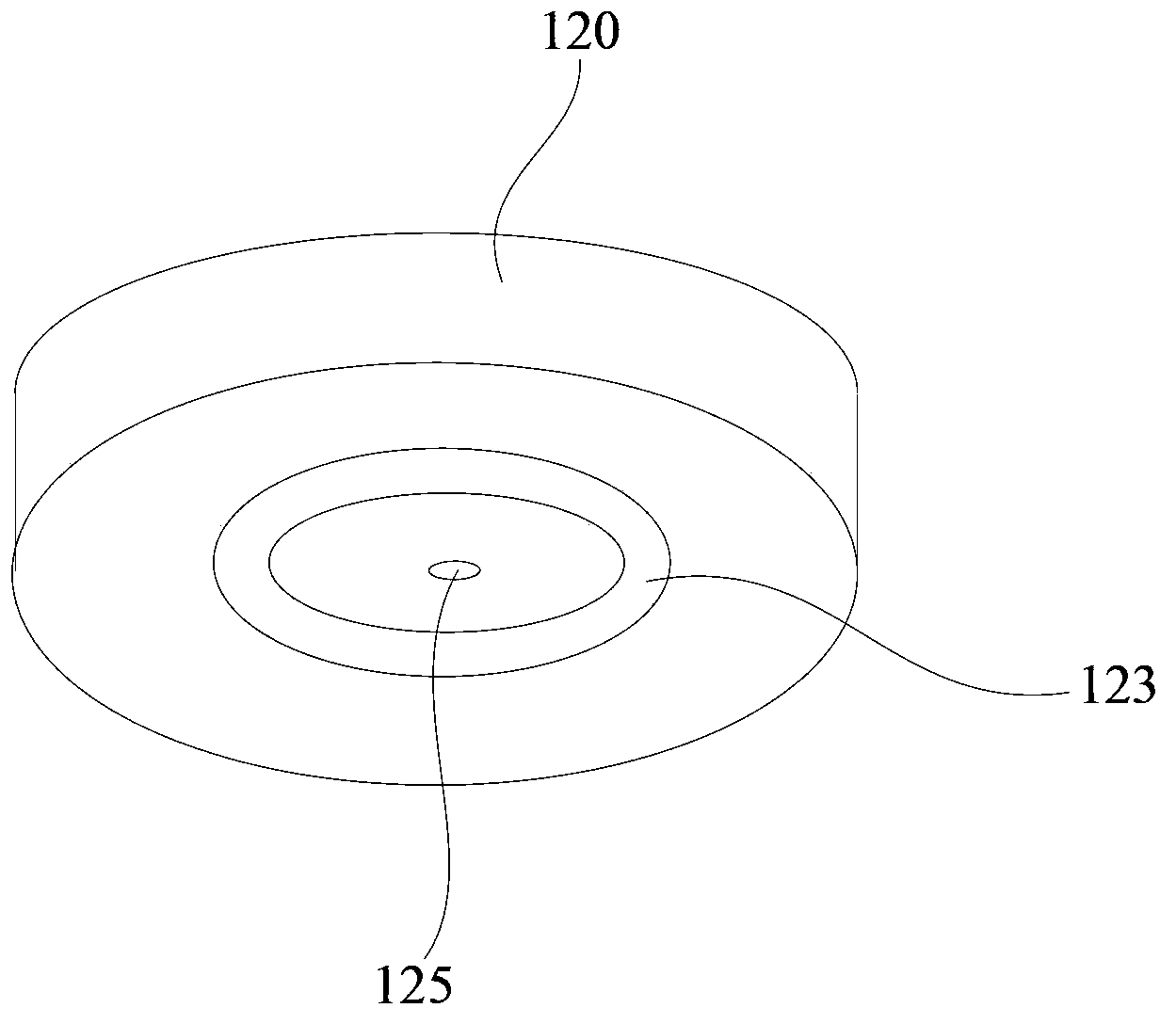

InactiveCN103831560ALess prone to displacementImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Disclosed is a light-emitting board welding and fixing device. The light-emitting board welding and fixing device comprises a rotary disc, a positioning disc and a buckling assembly, wherein the positioning disc is rotably arranged on the rotary disc. The face, away from the rotary disc, of the positioning disc is a bearing face used for bearing a PCB, and the bearing face is provided with a plurality of poisoning holes, wherein the positioning holes and LEDs can be connected in a clamped mode. When a light-emitting board is manufactured, the LEDs are placed on preset positions of the PCB, the PCB is placed on the positioning disc, and the buckling assembly is rotated to compress the PCB to the positioning disc and clamp the LEDs into the positioning holes. In the welding process, the positioning disc is rotated so that all the LEDs can be welded to the PCB. Because the PCB is compressed to the positioning disc, and the LEDs are clamped into the positioning holes, the LEDs do not move easily in the welding process, operators do not need to position the LEDs again, and welding efficiency is improved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

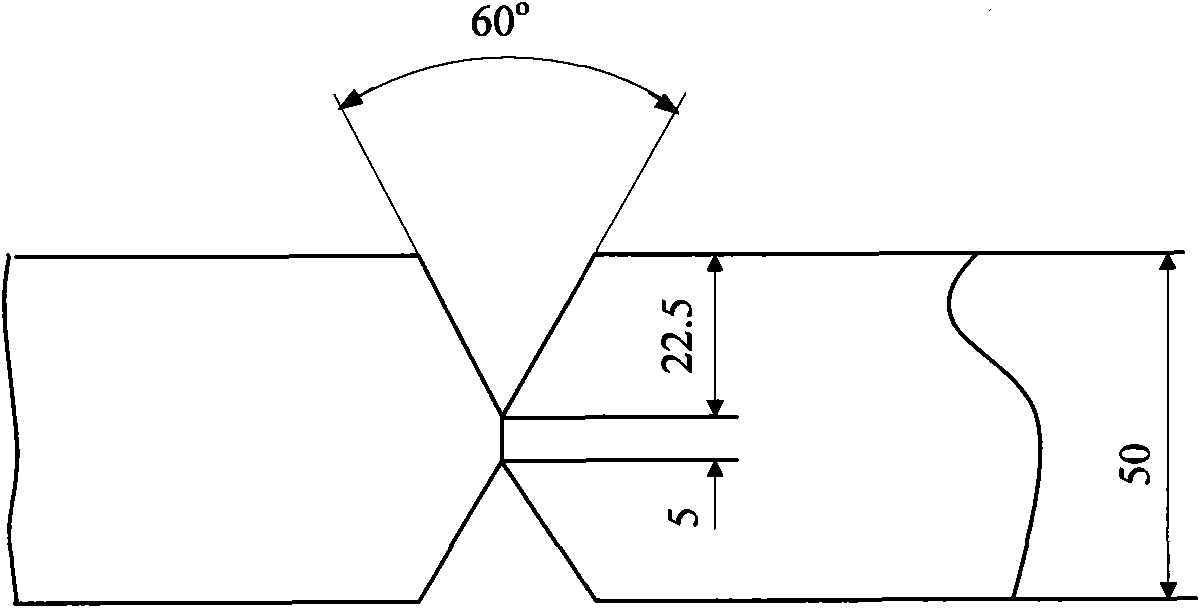

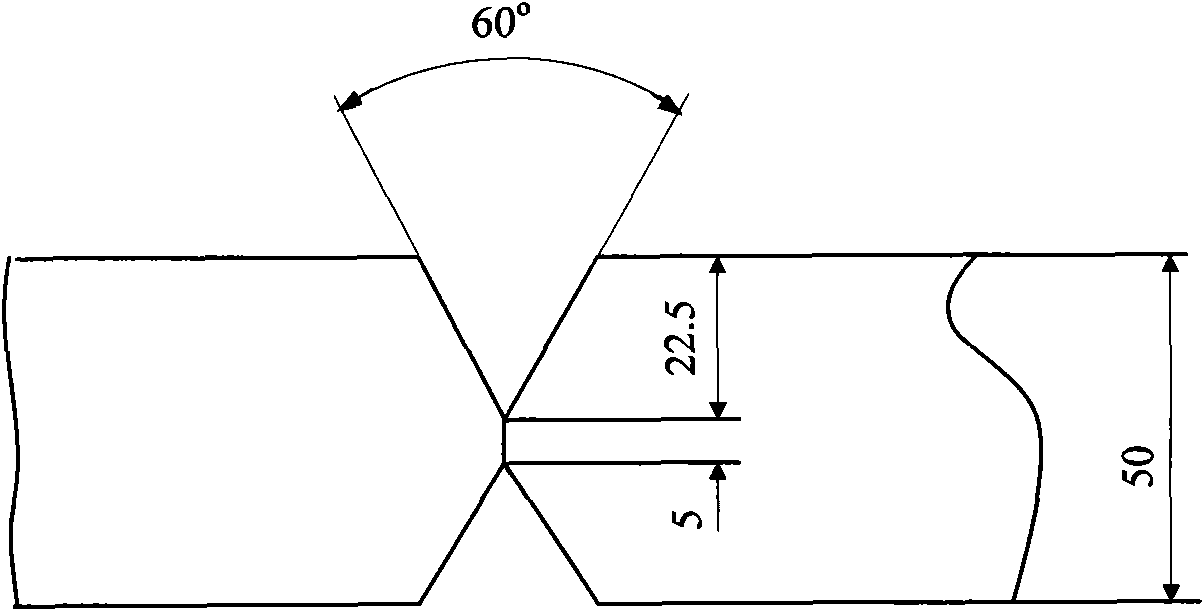

Method of submerged-arc welding of thick sheet S355NL for low-temperature wind tower

InactiveCN101862887AImprove low temperature impact toughnessImprove securityArc welding apparatusWelding/cutting media/materialsMechanical propertyHeat treated

The invention discloses a method of submerged-arc welding of a thick sheet S355NL for a low-temperature wind tower, which comprises the following steps: adopting an S355NL thick sheet satisfying requirements for chemical composition, weight percentage and technical conditions, wherein the carbon equivalent Ceq of steel is less than or equal to 0.42 percent; using welding wires satisfying requirements for chemical composition and weight percentage; adopting symmetric double-sided X type grooves as submerged-arc welding groove, wherein the groove angle is 60 degrees, the groove gap is 0.5mm, and when the thickness of the sheet is less than or equal to 50mm and the ambient temperature is no lower than 10 DEG C, no preheating is needed for welding; and selecting welding parameters, wherein the welding heat input is less than or equal to 50kJ / cm. The invention realizes the welding process that no preheating is needed prior to welding and no heat treatment is needed after welding during manufacture of the thick sheet structure of the butt joint of the steel plate S355NL for the low-temperature wind tower in marine and cold regions. Due to the multi-layer multi-channel continuous welding, the welded joint has excellent comprehensive mechanical properties, and weld joints and weld heat-affected zones has large impact toughness reserves and safety margins. Therefore, the invention is suitable for promotion and application in the manufacture of the low-temperature wind tower in the factory.

Owner:NANJING IRON & STEEL CO LTD

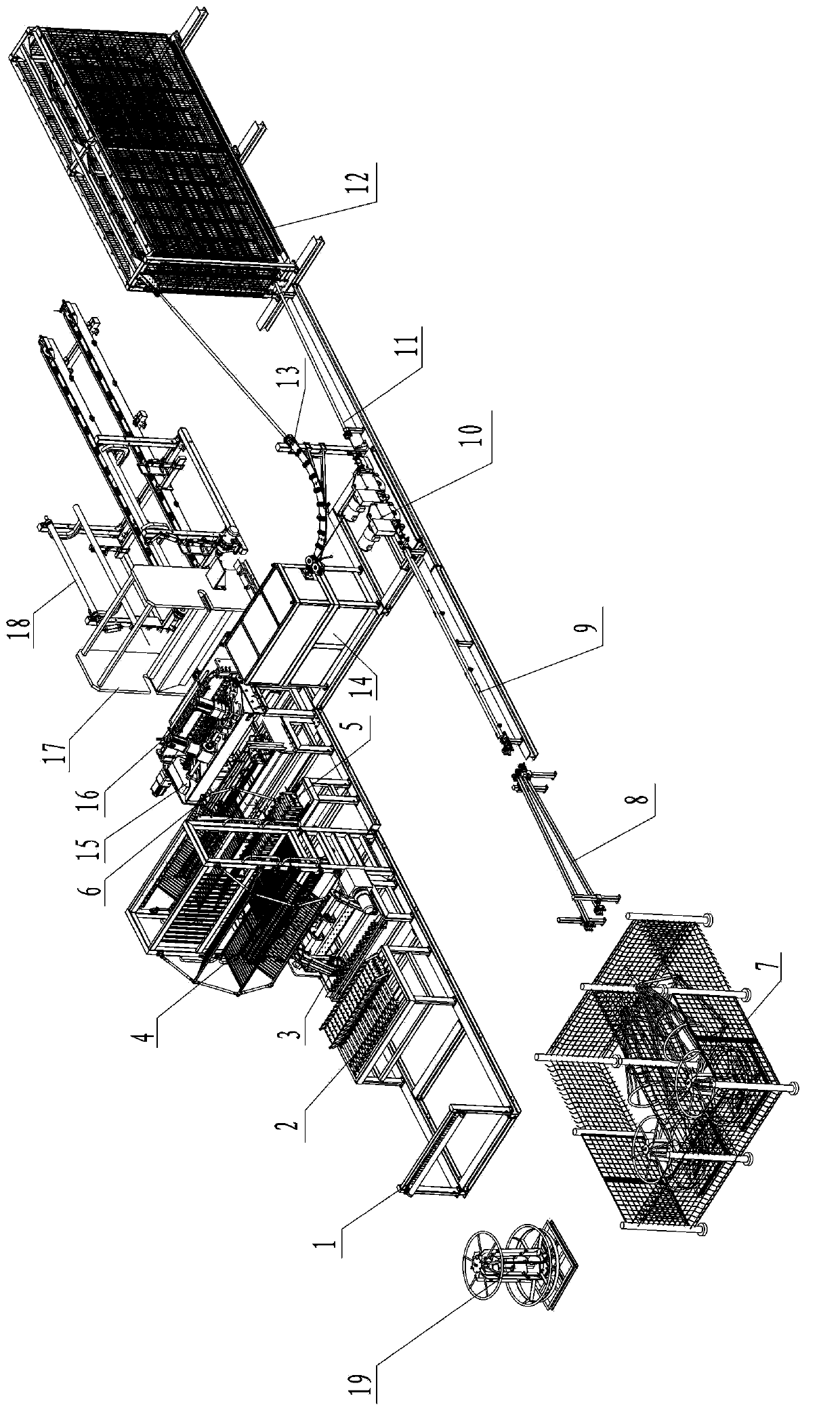

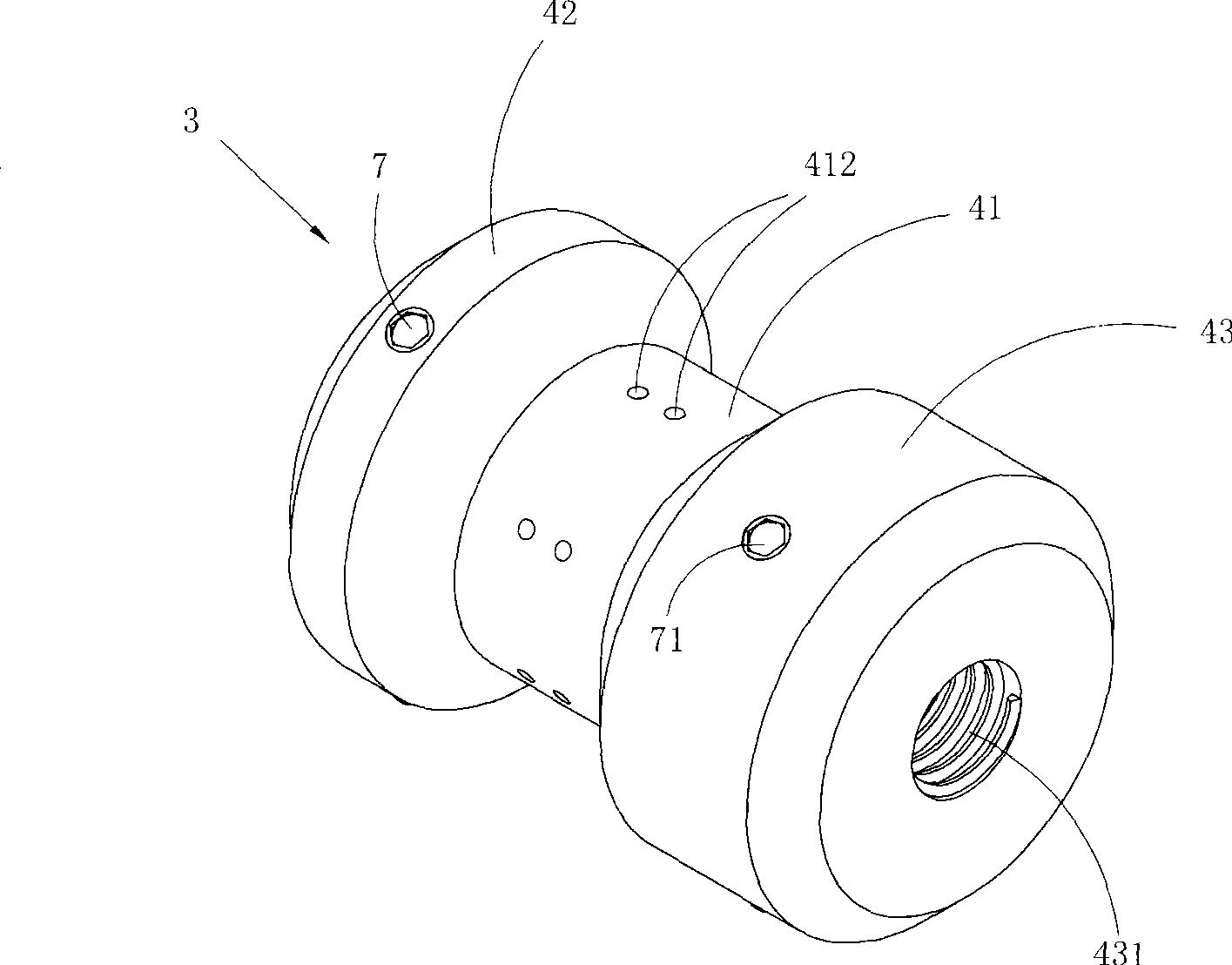

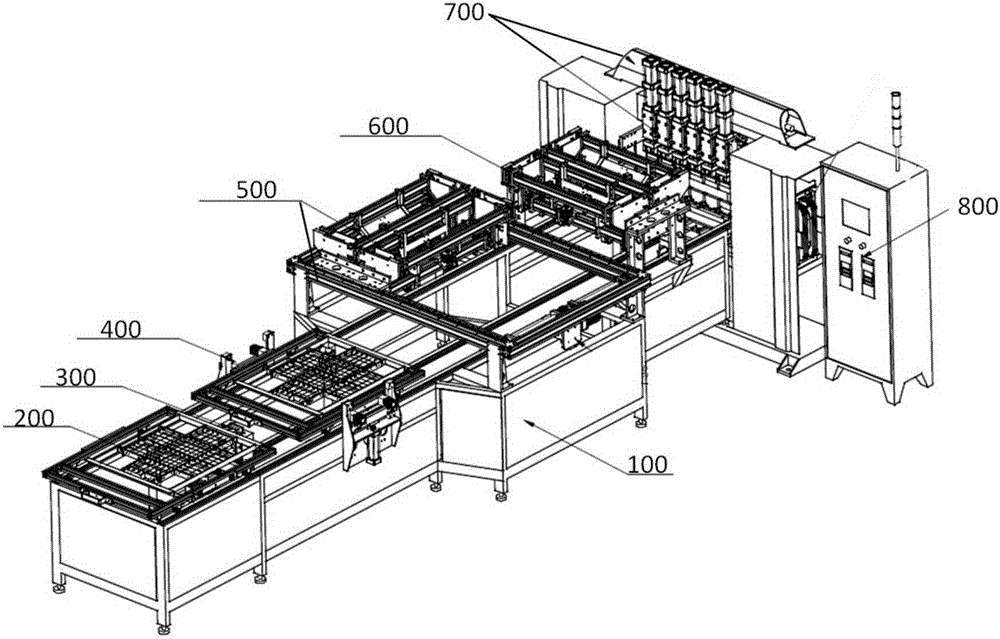

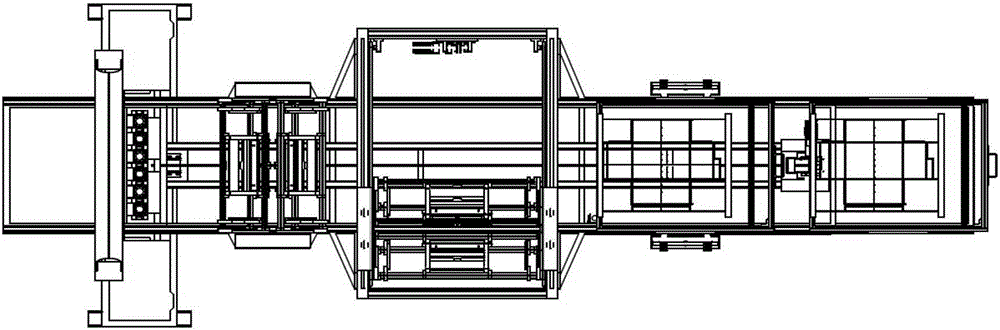

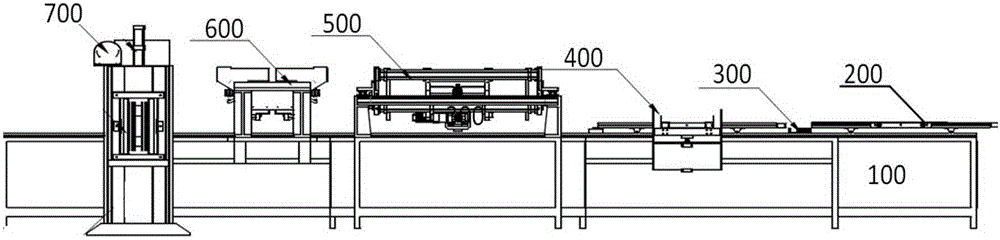

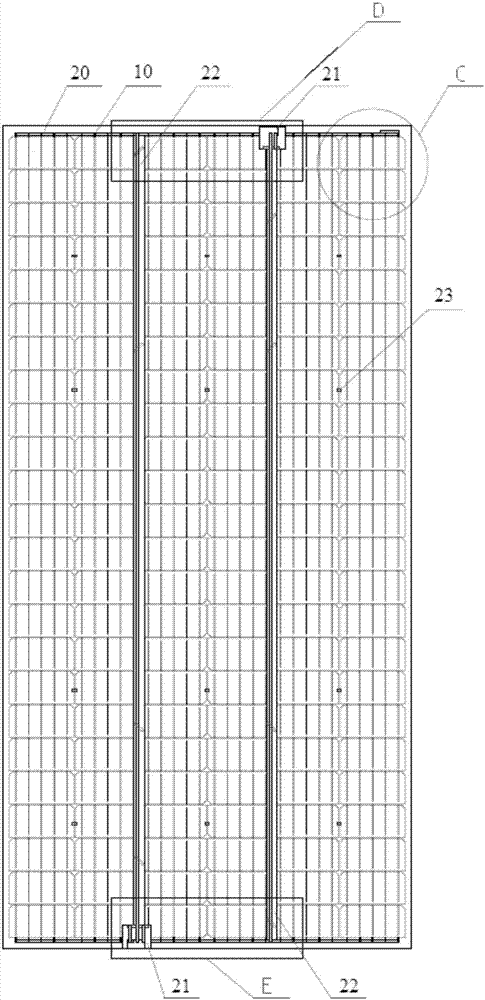

Full-automatic reinforcing mesh welding production line

ActiveCN104209432AHigh degree of automationReduce labor intensityWire networkProduction lineEngineering

The invention discloses a full-automatic reinforcing mesh welding production line which comprises a longitudinal line production section for machining longitudinal lines, a transverse line production section for machining transverse lines and a welding output section for welding and outputting the longitudinal lines and the transverse lines. The full-automatic reinforcing mesh welding production line has the advantages of being high in automatic degree, low in labor intensity and convenient and fast in welding operation and greatly increasing production efficiency and production capacity. In addition, the smoothness and quality of a welded reinforcing mesh are high.

Owner:河北骄阳焊工有限公司

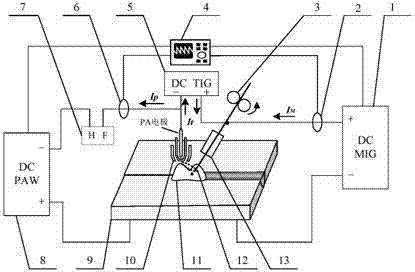

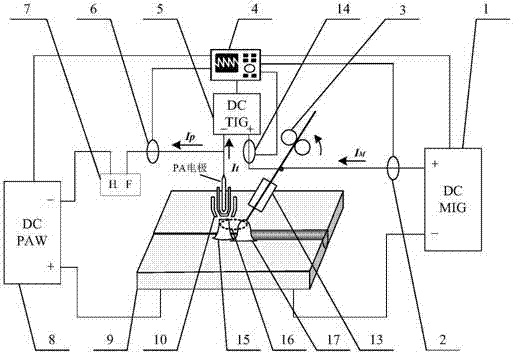

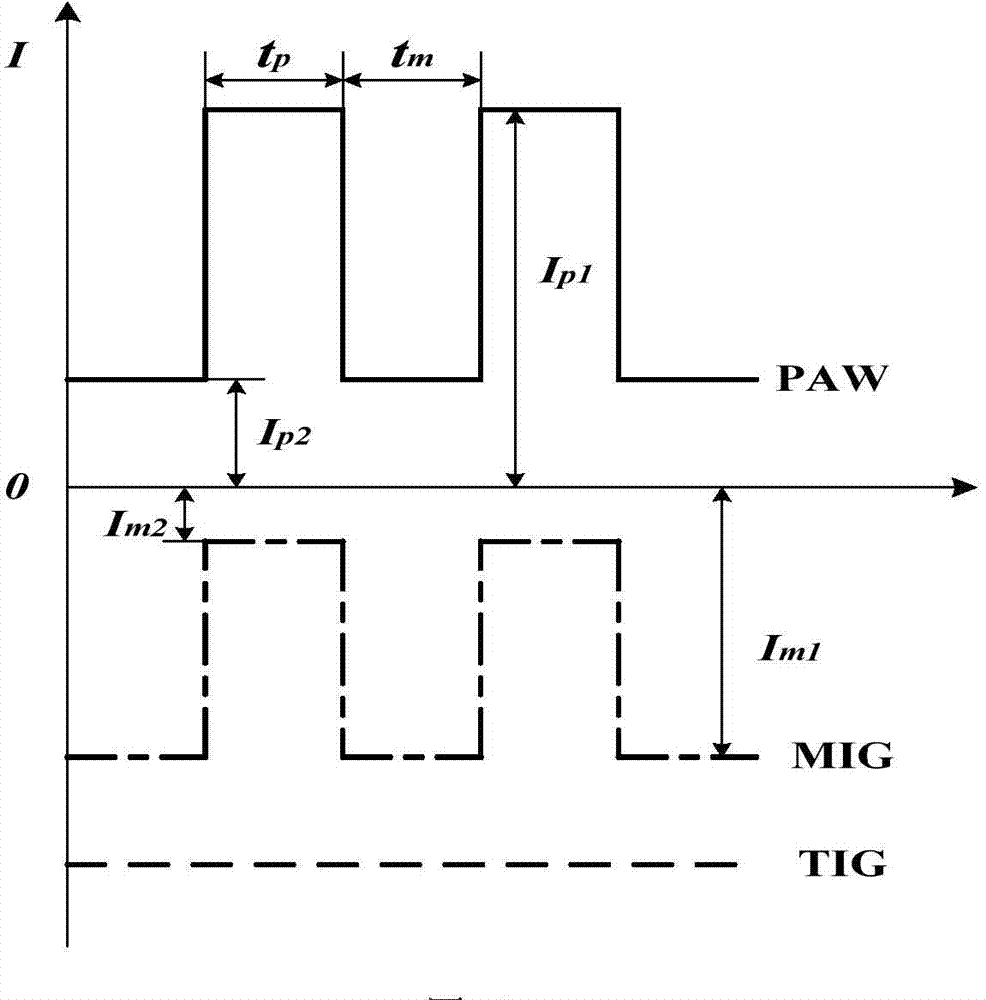

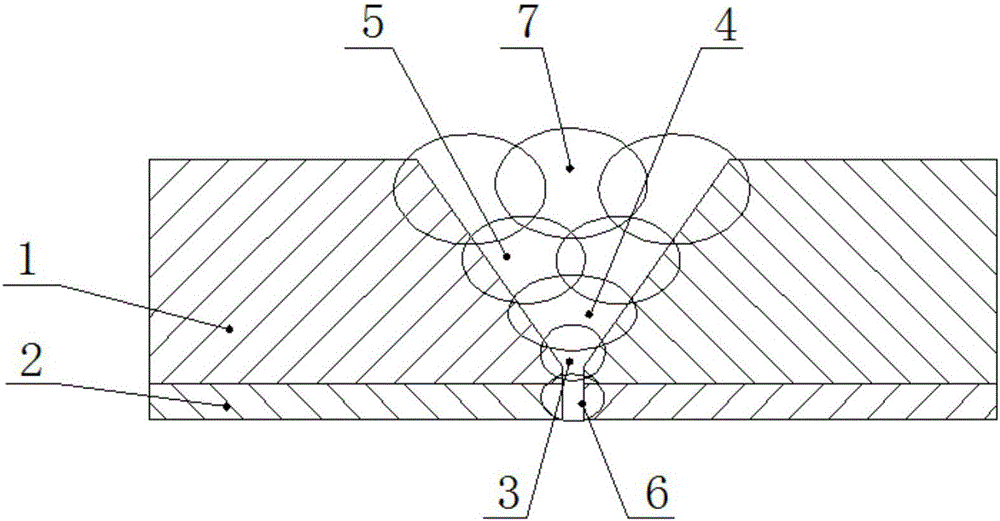

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

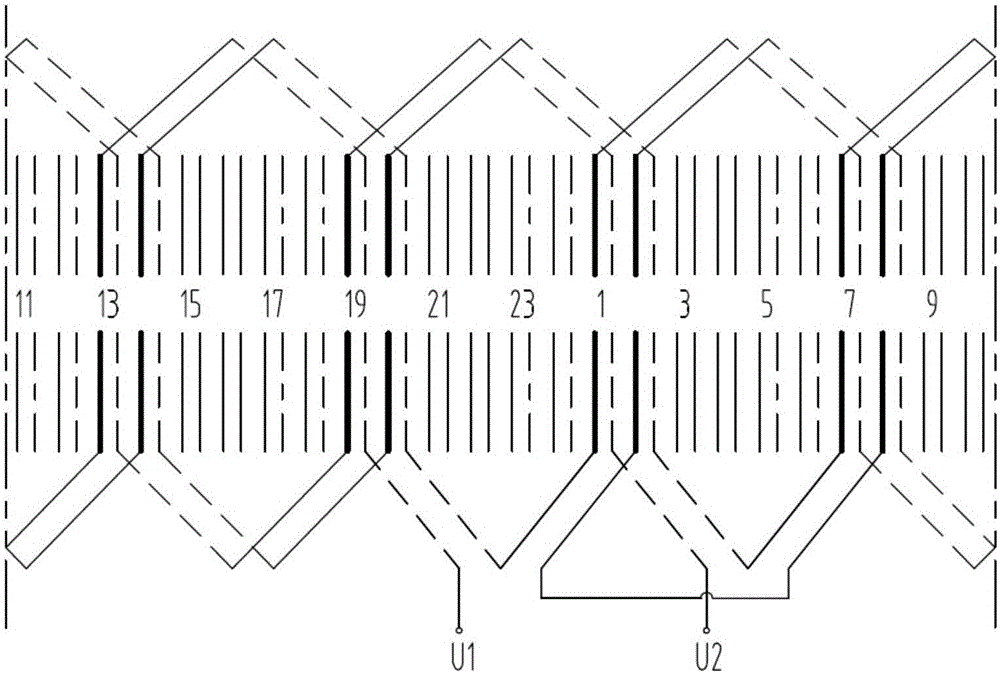

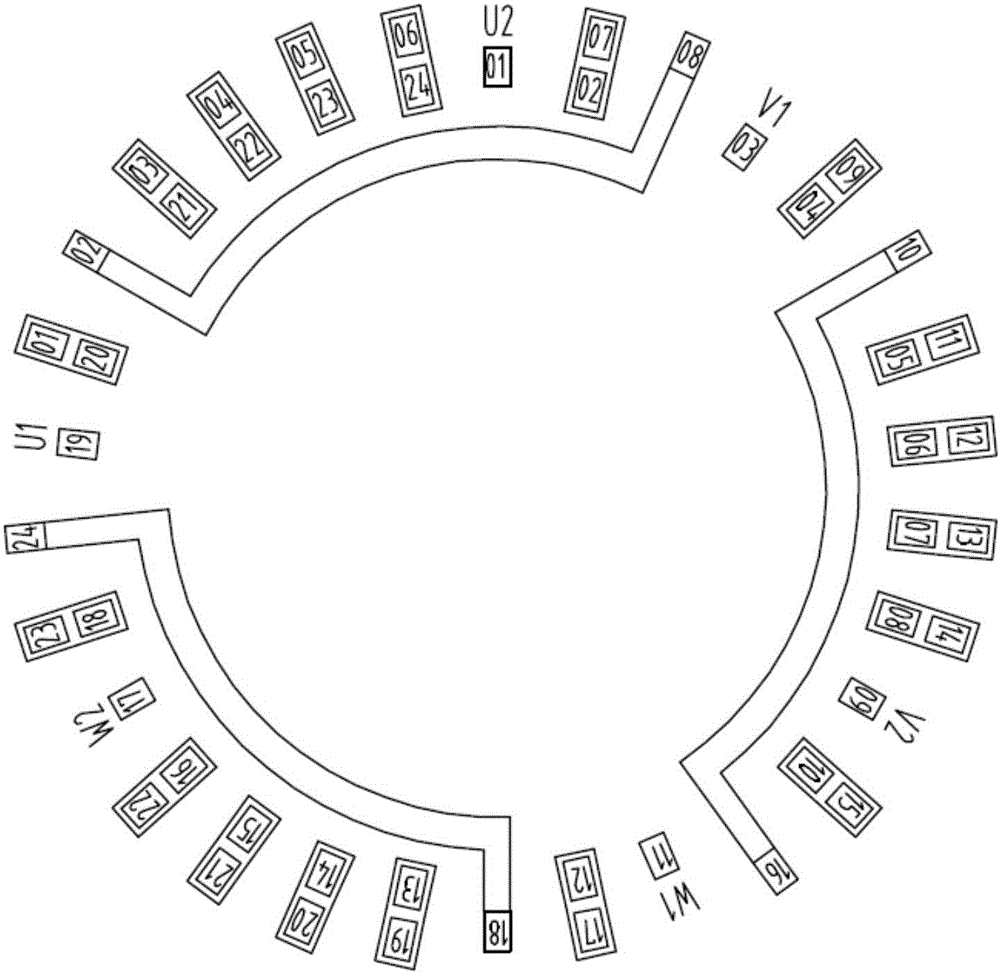

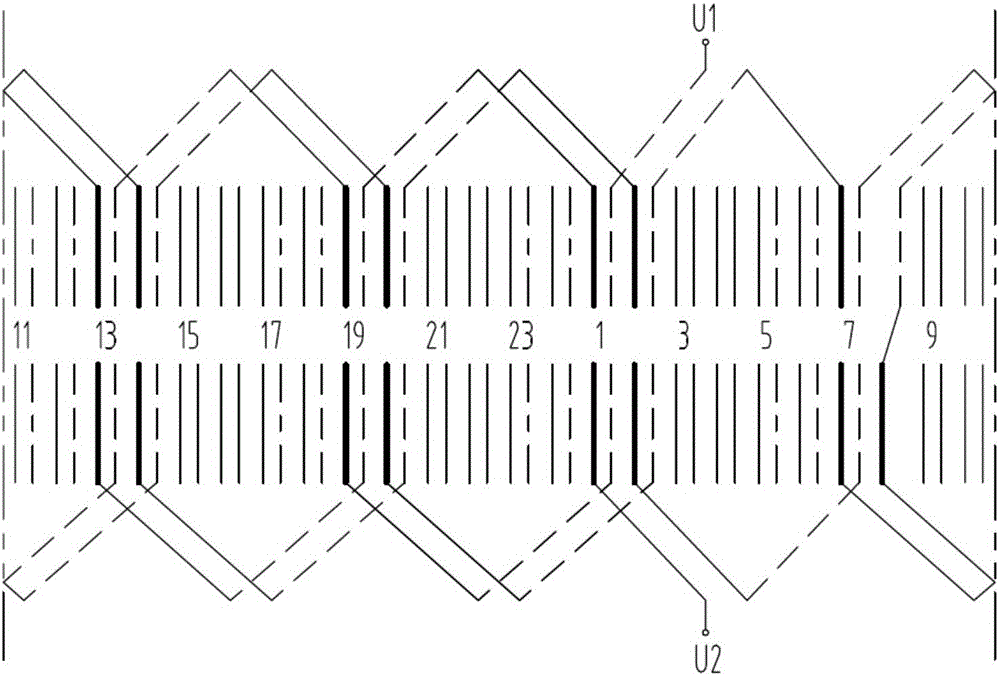

Novel double-layer wave winding method capable of saving wiring space of outlet terminal

ActiveCN106787337AAlleviate the problem of tight wiring spaceLarge operating spaceWindings conductor shape/form/constructionMultiple methodsElectrical and Electronics engineering

The invention discloses a novel double-layer wave winding method capable of saving wiring space of an outlet terminal. The novel double-layer wave winding method capable of saving the wiring space of the outlet terminal adopts multiple methods such as a full pitch one route connection method of a 4-pole 24-slot rotator, and the connection method includes: from the beginning of connection performed by using U1 as a leading wire, first connecting for 1-8 long pitches, then connecting for 3 whole pitches, next connecting for 2-7 short pitches, finally connecting for 3 whole pitches, completing connection of coils belonging to the same phase under U phase N pole, connecting coils under U phase S pole through steps as same as above steps, and finally connecting the coils of the two large groups in series according to the current direction in a slot, and then forming a phase of winding. The novel double-layer wave winding method capable of saving the wiring space of the outlet terminal has advantages of evenly distributing line outgoing heads of the same quantity as rotor slots at a line outgoing terminal by changing a connection mode of the double layer wave winding, alleviating the problem that wiring space is limited at the end of the line outgoing terminal to obtain the maximum distance between each two adjacent line outgoing heads and the maximum operation space of uniform head welding, facilitating uniform head welding operation to the utmost, placing head and tail connection lines of both the phases at one end, and connecting outgoing lines through a Y connecting method and a delta connection method.

Owner:江西江特电机有限公司 +1

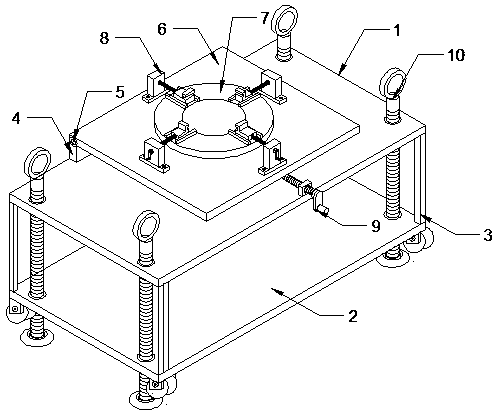

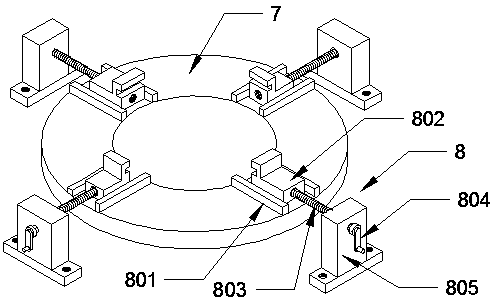

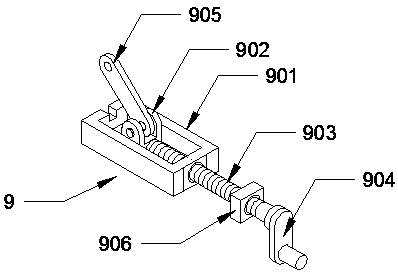

Simple automobile welding fixture

InactiveCN109570890ASecure clamping operationSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention discloses a simple automobile welding fixture. The simple automobile welding fixture comprises a top panel and a bottom panel. Four supporting legs are fixedly arranged at four corners of the bottom end of the top panel, the other ends of the four supporting legs are fixedly connected to four corners of the bottom panel correspondingly, a support plate is fixedly arranged on the middle part of one side of the top end of the top panel, the support plate is rotatably connected with a worktable through a rotating shaft, an annular piece is arranged at the top end of the worktable, and four clamping mechanisms are equidistantly arranged at the top end of the annular piece. According to the simple automobile welding fixture, a first rotating handle is rotated to drive a first threaded rod to rotate, the first threaded rod rotates to drive a first sliding block which is in threaded connection with the first threaded rod to move in a sliding groove, and clamping operation of annular workpieces of different sizes is carried out by adjusting the position of the first sliding block inside the sliding groove; and the overall structure is relatively simple, the operation is relatively convenient, the cost is low, and clamping operation of the annular workpieces can be carried out stably.

Owner:广州市富鑫机械设备有限公司

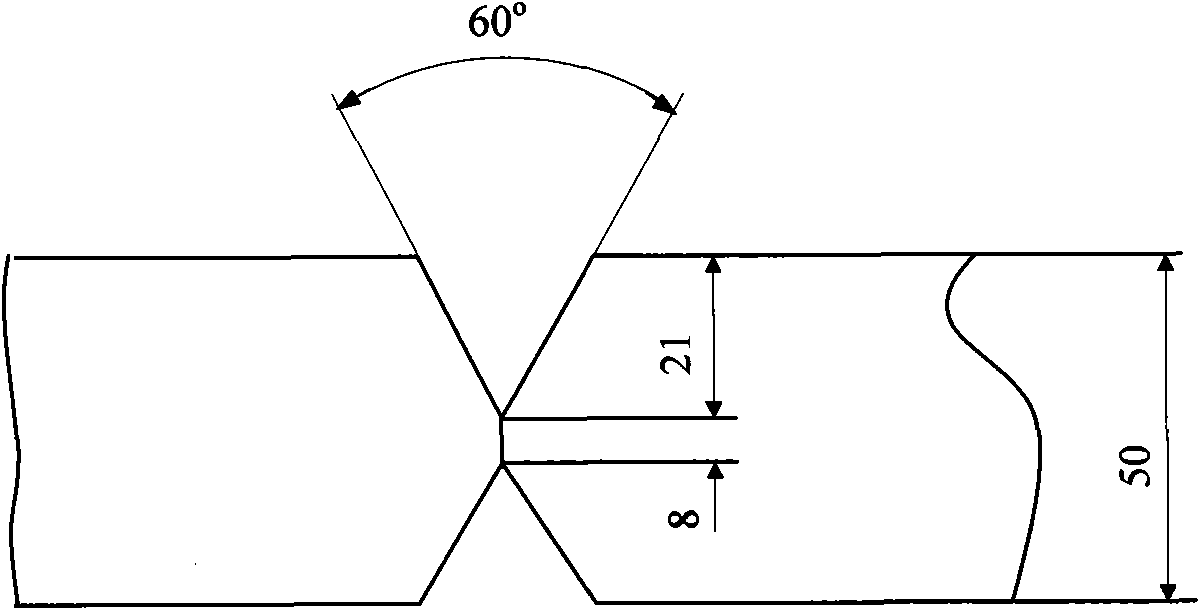

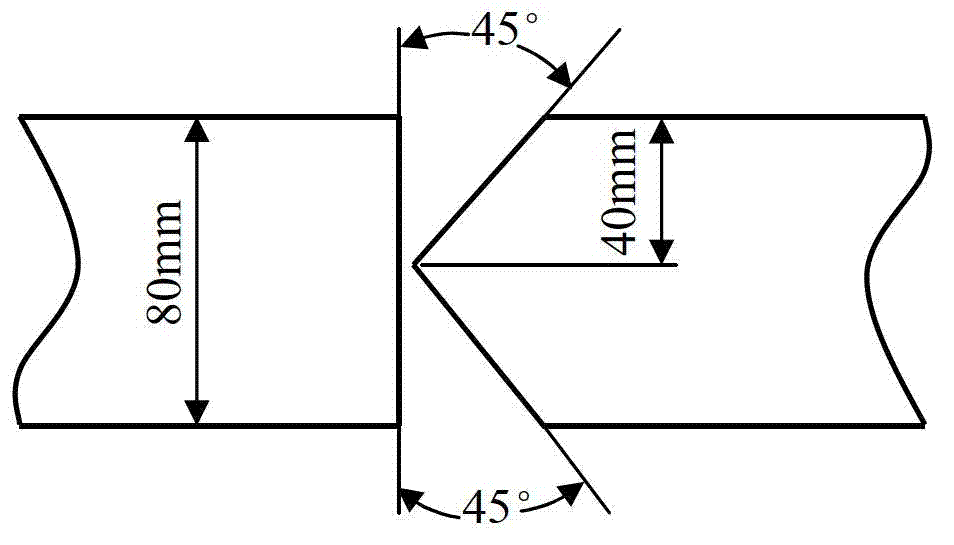

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

Welding process for red copper and stainless steel dissimilar materials

ActiveCN102962543AMeet the use requirementsImprove mechanical propertiesArc welding apparatusFurnace typesForeign matterDehydrogenation

The invention discloses a welding process for red copper and stainless steel dissimilar materials. The welding process comprises the following steps of: (A) machining grooves on the opposite sides of a red copper component and a stainless steel component, cleaning foreign matters on the edges of the grooves, placing the red copper component and the stainless steel component on the same plane for pairing, and reserving a gap; (B) performing before-welding preheating on one side of the red copper component at 600 to 680 DEG C; (C) tackingperforming point fixing in a plurality of positions between the red copper component and the stainless steel component according to a tacking sequence; (D) welding the red copper component and the stainless steel component by adopting shielded metal arc welding direct current electrode positive; (E) heating a welding joint to 130 to 180 DEG C after the red copper component and the stainless steel component are welded, cooling the welding joint to room temperature, and performing dehydrogenation treatment to reduce hydrogen content in a welding seam; and (F) after the dehydrogenation treatment and cooling, performing stabilization treatment on one side of the stainless steel component at 840 to 890 DEG C, and quickly cooling the stainless steel component to reduce the formation of chromium carbide and improve the plasticity and toughness of the welding seam.

Owner:PETROCHINA CO LTD

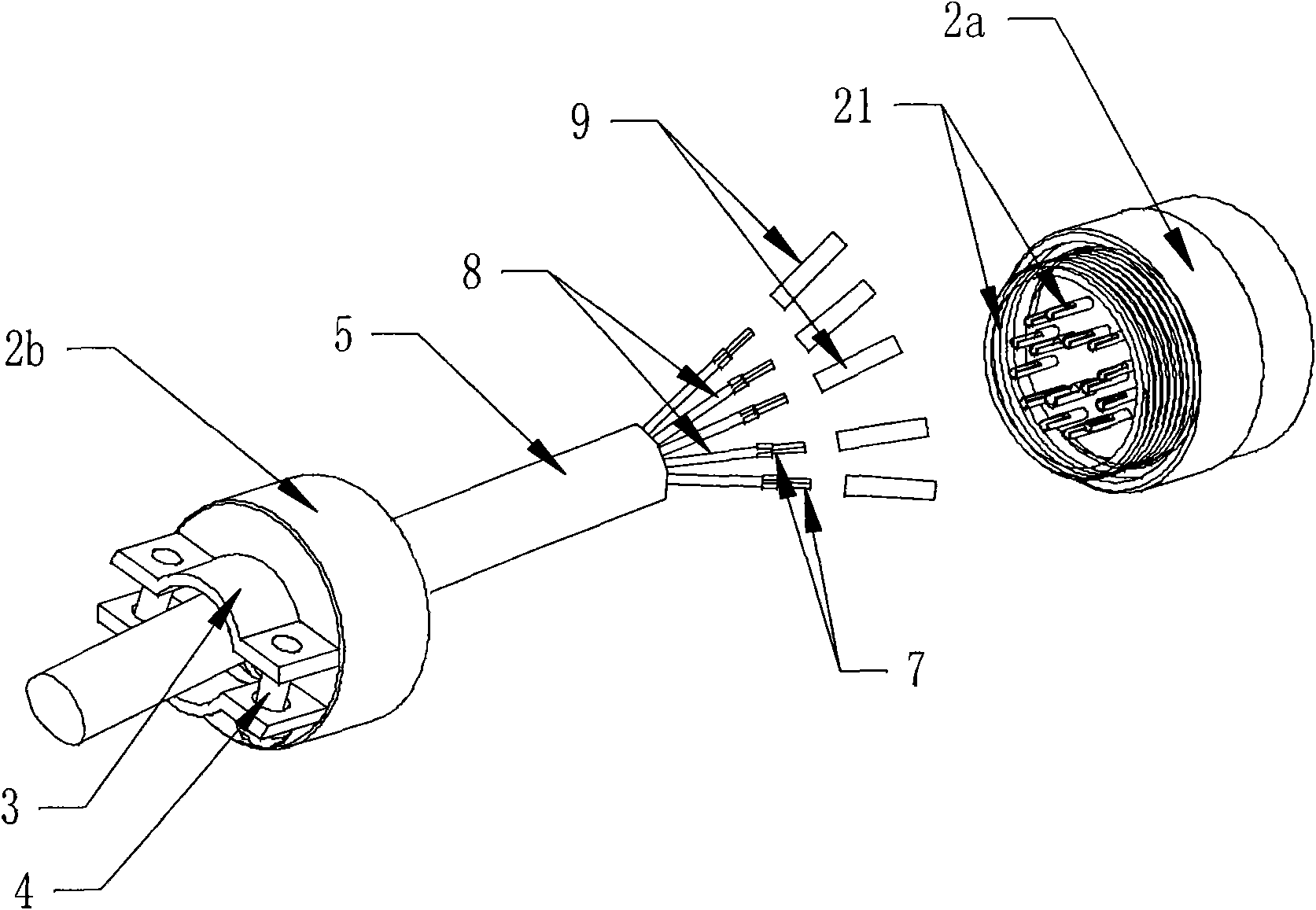

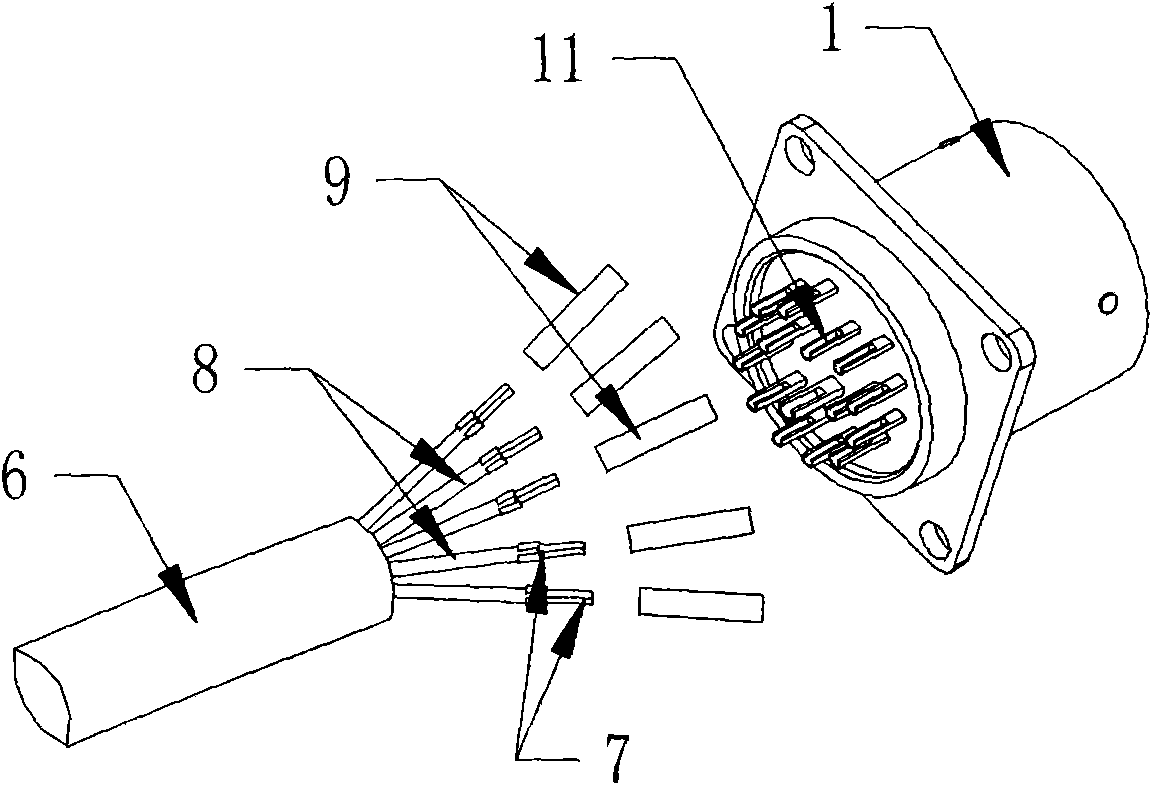

Electric connector and wire connecting method thereof

ActiveCN101989726AAvoid breakingEasy connection strengthLine/current collector detailsSoldered/welded conductive connectionsElectricityEngineering

The invention discloses an electric connector and a wire connecting method thereof. The connecting method comprises the step of connecting socket wires or plug wires and comprises the following concrete steps: strengthening the end parts of wires; welding and protecting each wire after the end parts of the wires are welded with a socket or a plug; and protecting the integrated wires connected with the socket or the plug. The electric connector comprises a socket, a plug, a first wire cable and a second wire cable, wherein the first wire cable and the second wire cable are respectively connected with the plug or the socket; metal terminals are fixed at the end parts of the wires and are welded together with pins on the plug or the socket; a small thermal shrinkable sleeve is sleeved at thewelding part of the wires; a big thermal shrinkable sleeve is sleeved outside the second wire cable; and the sheath of the first wire cable is clamped by a tail clamp of the plug. The connecting method of the invention can enhance the connecting strength, can enhance the tensile resistance and the torsion resistance, and completely can ensure the reliability requirement of a reinforced computer. The electric connector of the invention has high connecting strength, tensile resistance and torsion resistance, and the wires can not be broken easily.

Owner:深圳市研祥智慧科技股份有限公司

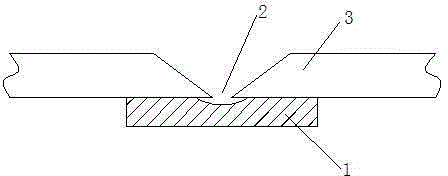

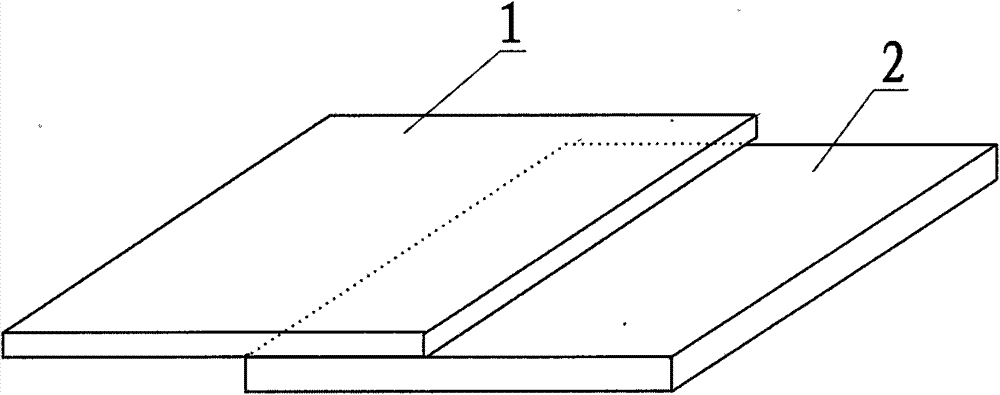

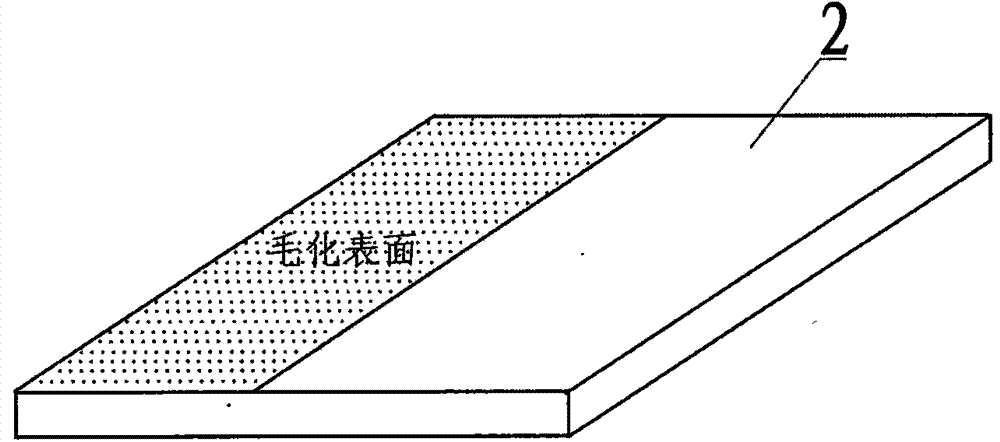

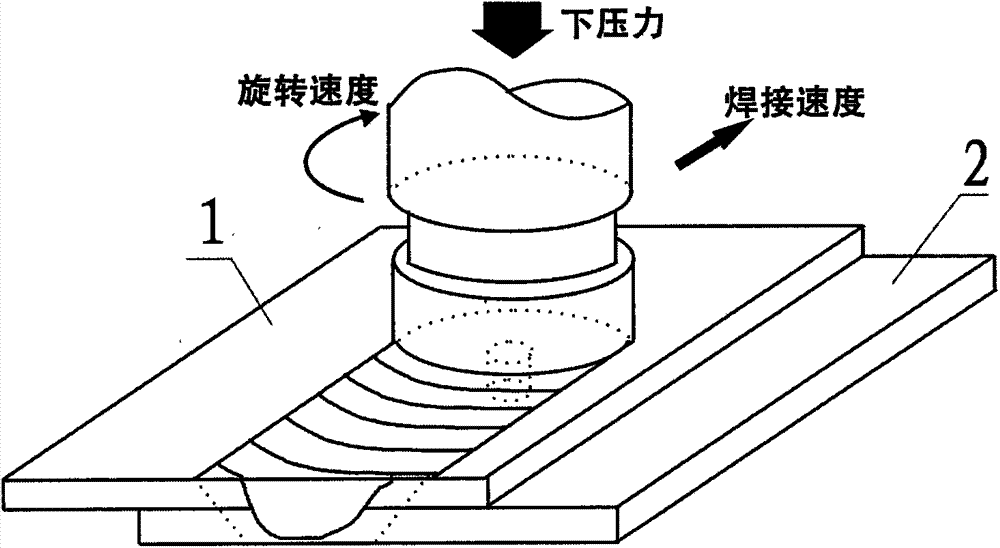

Steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection

InactiveCN103894724AImprove mechanical propertiesReliable strengthWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingSheet steel

The invention relates to a steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection. A fine convex-concave structure is obtained on the surface of a lap connection position of a steel plate through a roughing method, heat is generated through friction and plastic deformation of a stirring head and an aluminum plate, softened aluminum alloy is combined with the convex-concave structure of the surface of the roughed steel plate, the effective combination area is increased, a brittle intermetallic compound is suppressed from being formed between aluminum and steel, and effective and high-quality lap connection is formed between the steel plate and the aluminum plate. An aluminum steel dissimilar connector with beautiful formed welding joints, a good mechanical property and reliable strength is finally obtained, the welding operation process is simple, the welding cycle is effectively shortened, and automation is achieved easily.

Owner:HARBIN INST OF TECH

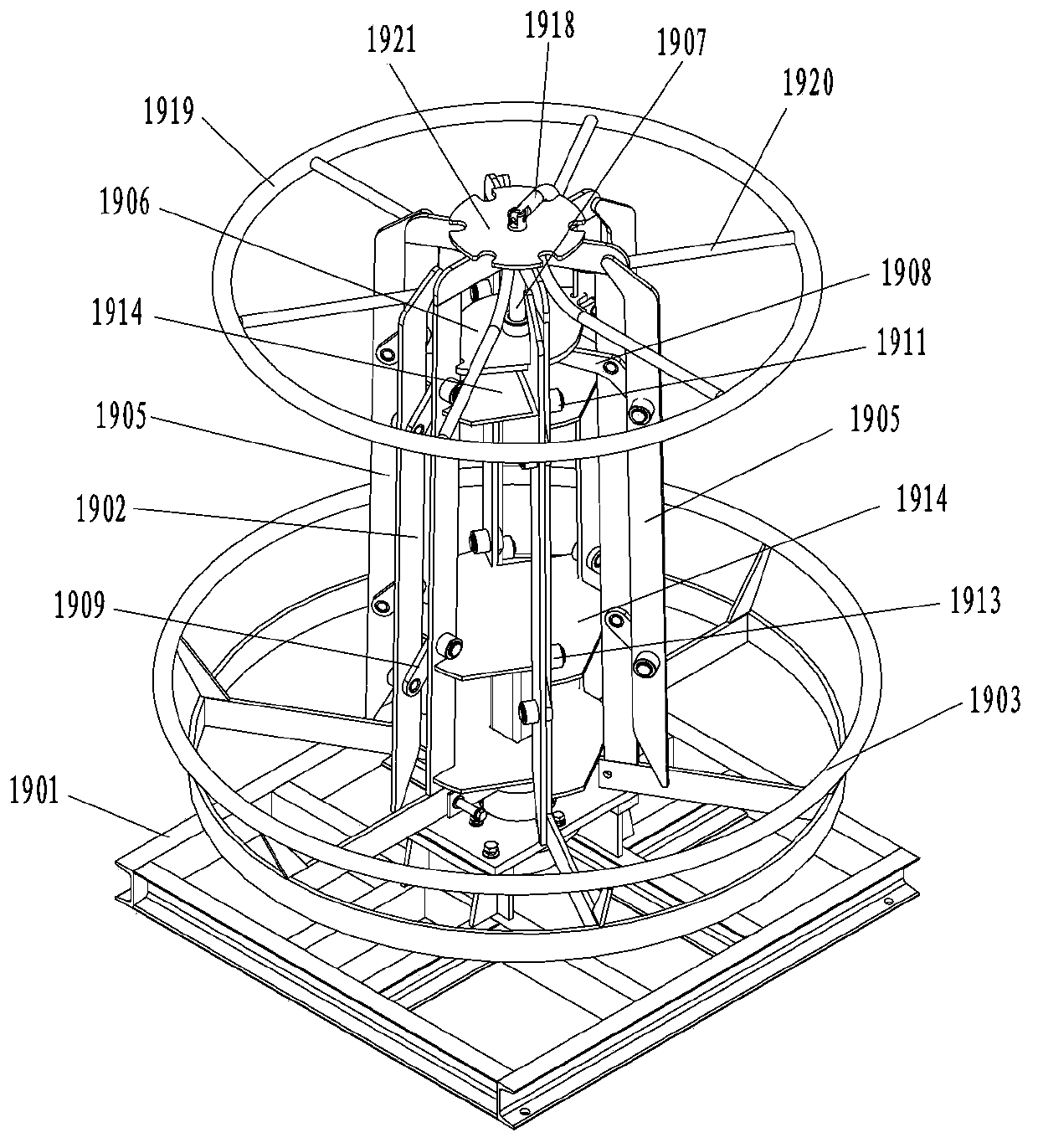

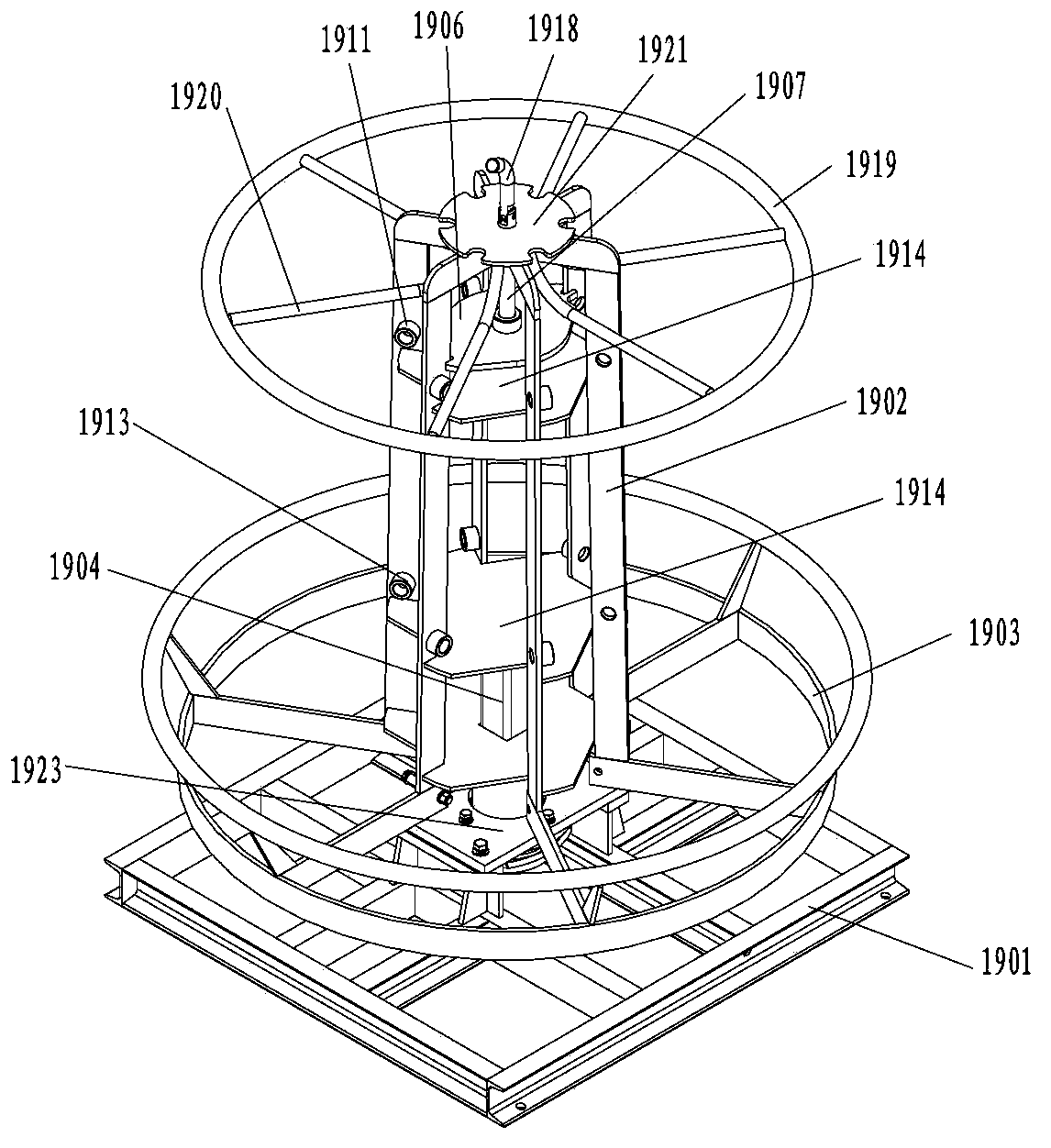

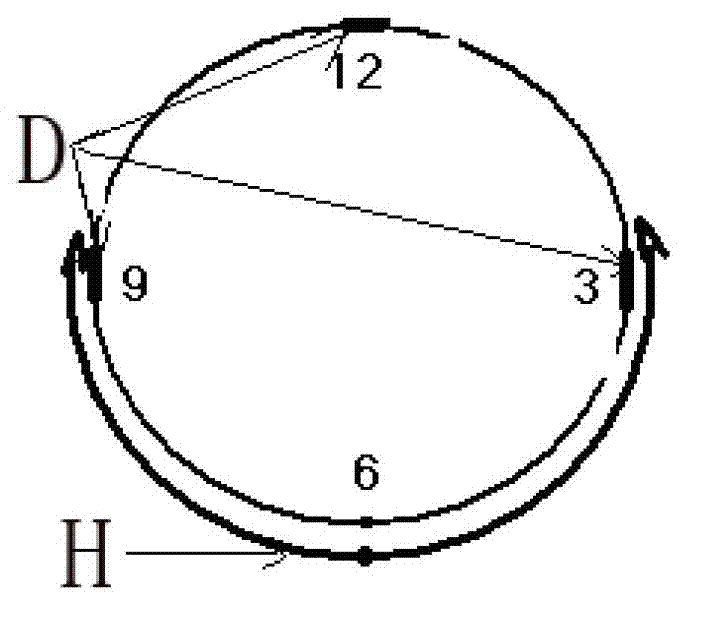

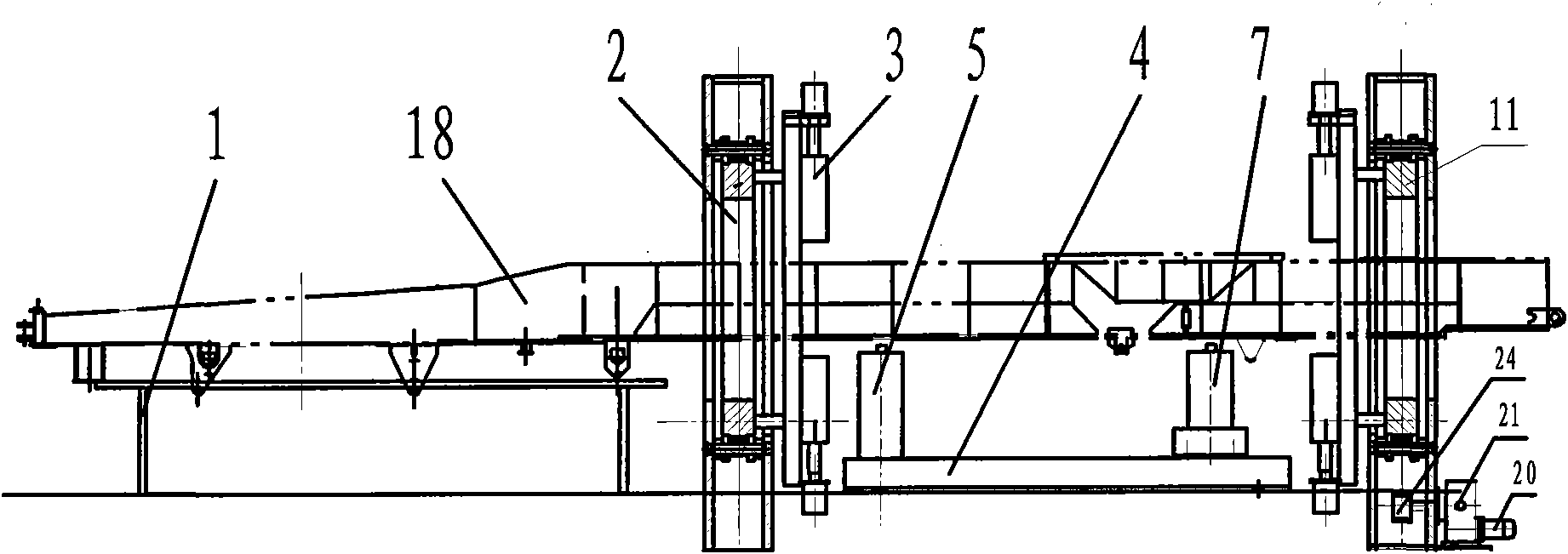

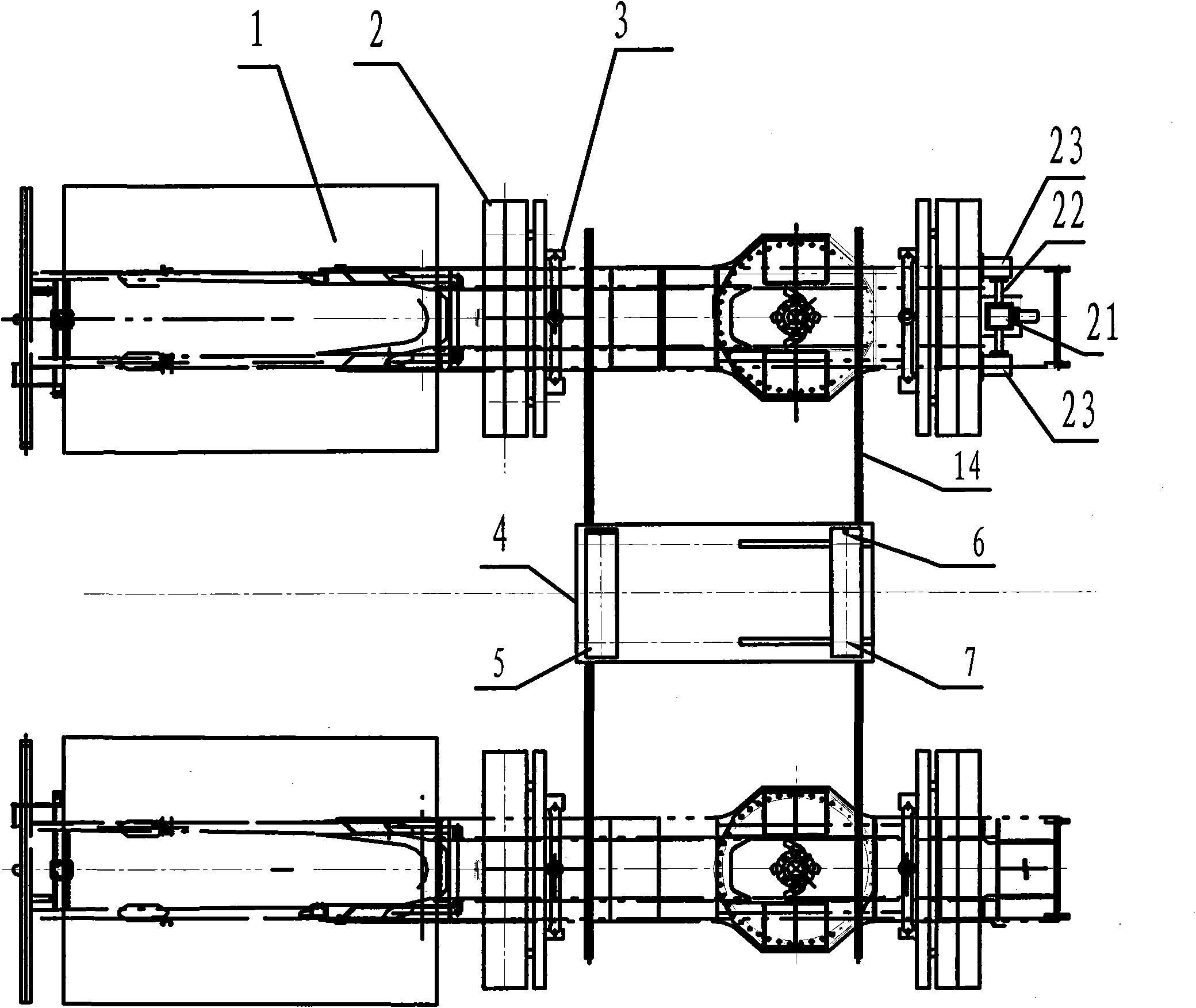

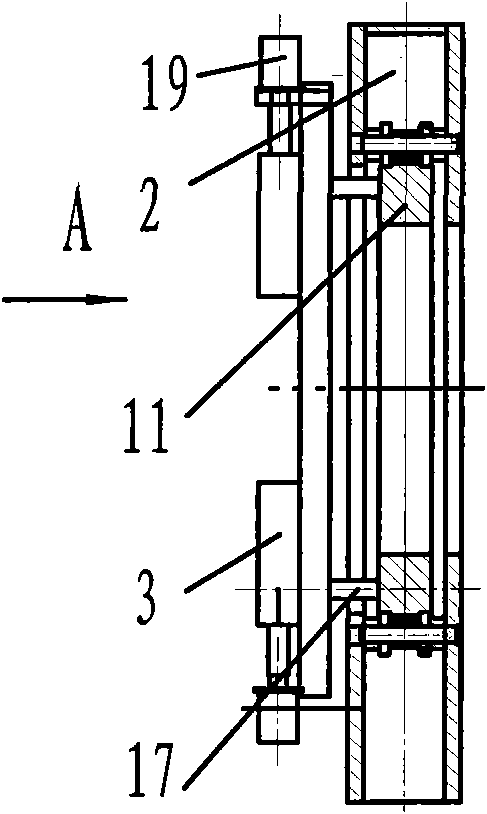

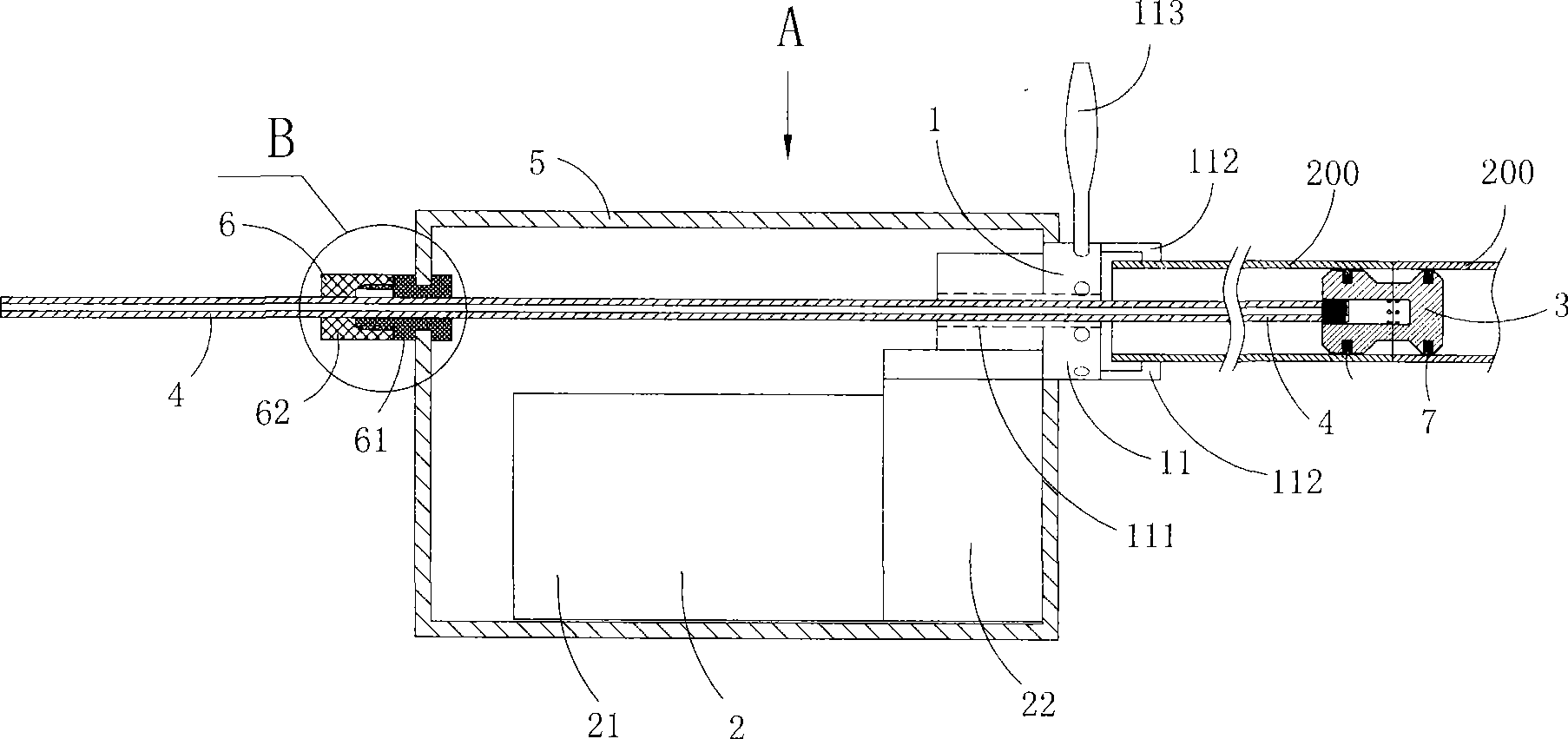

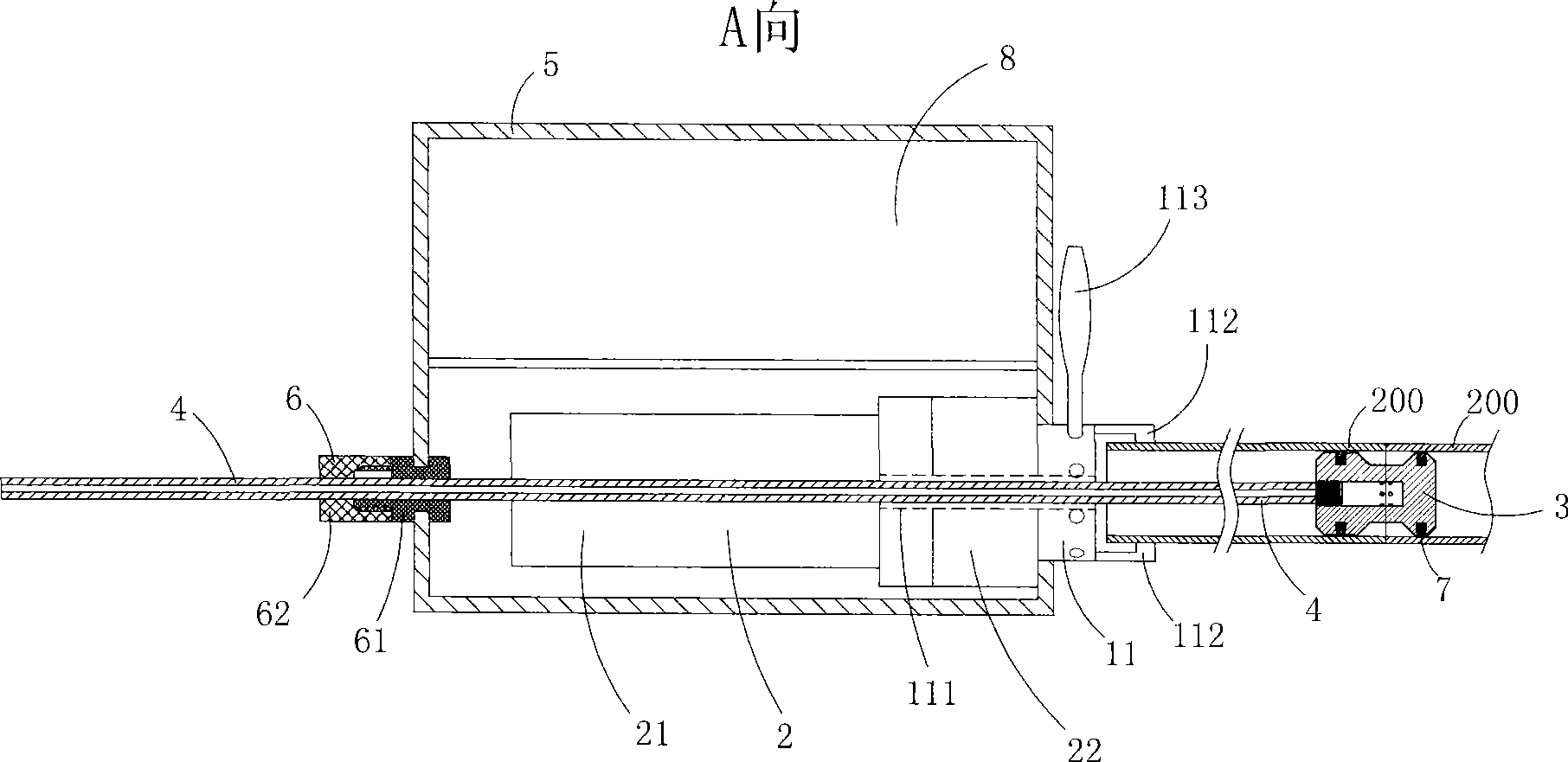

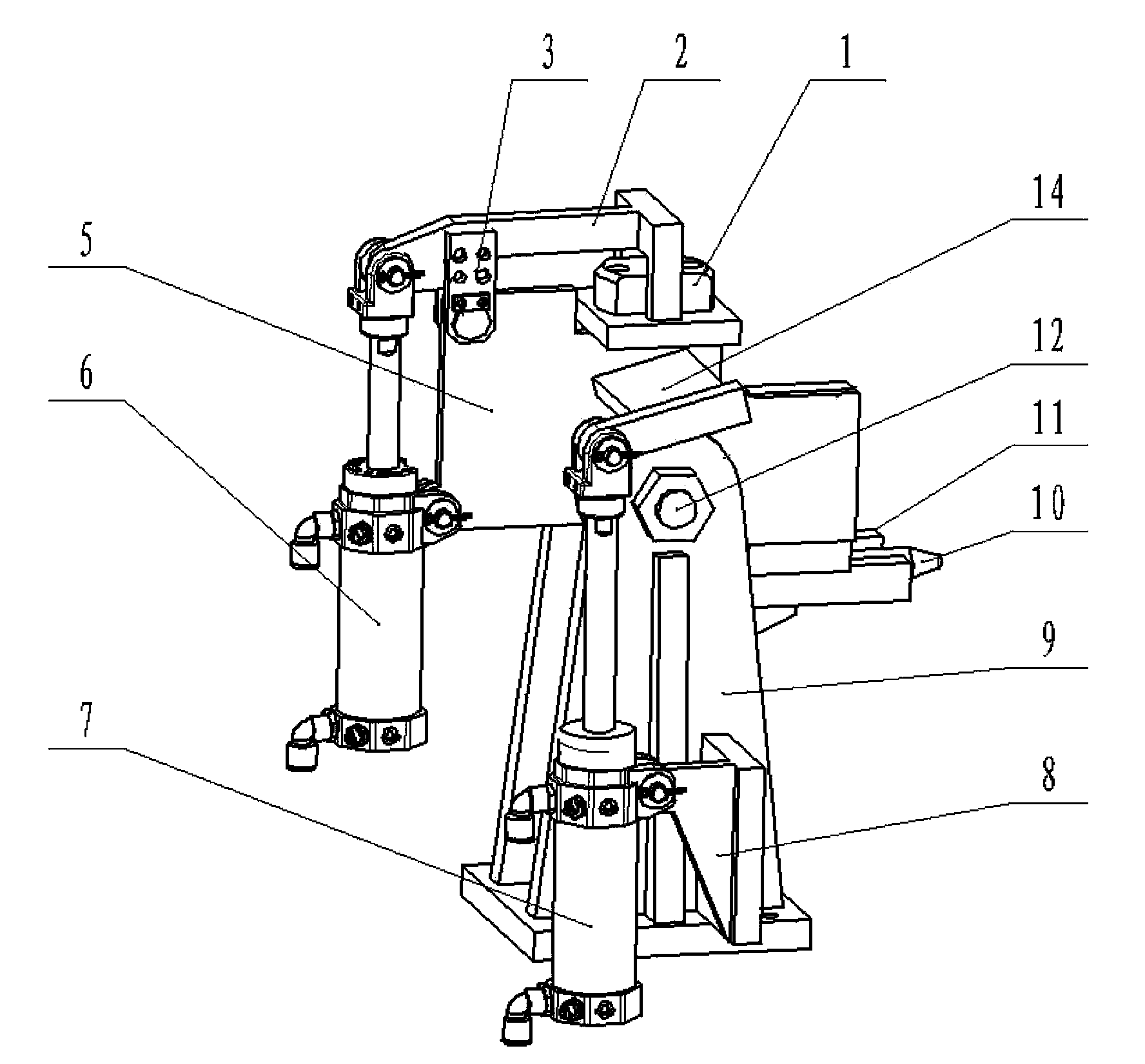

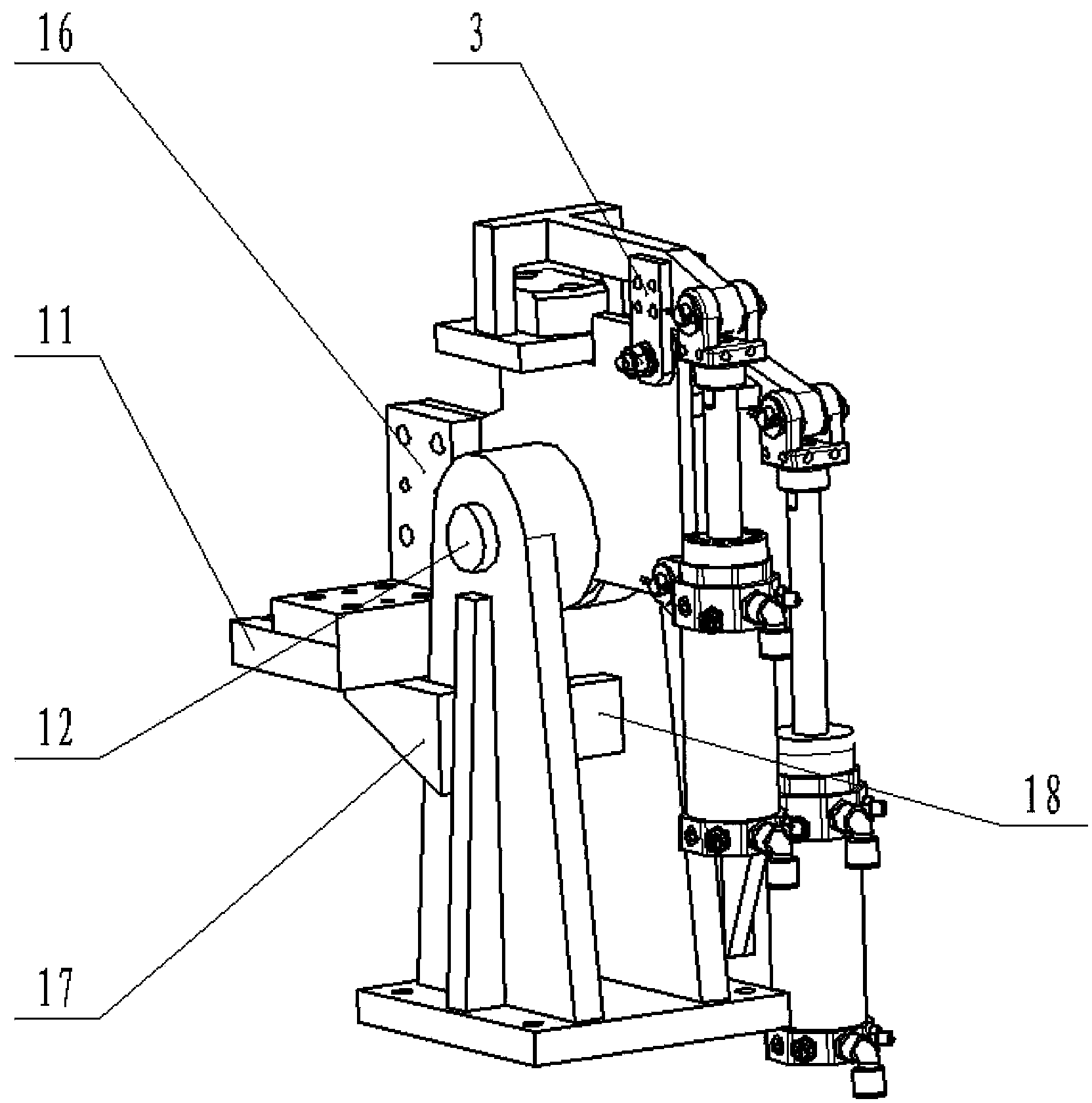

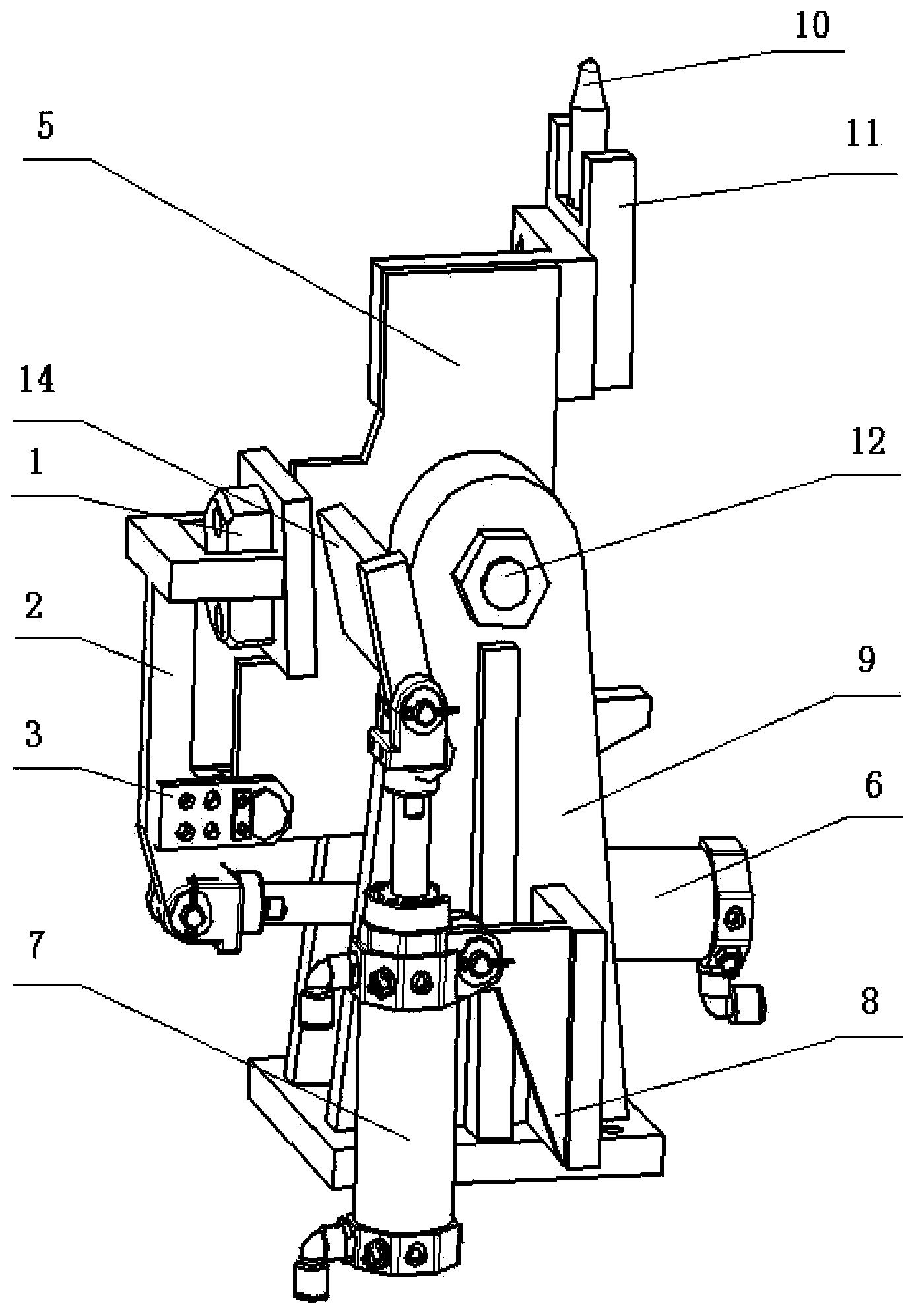

Side open type carriage welding turnover work center

InactiveCN101890608AConvenient welding operationGuaranteed coincidenceWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a side open type carriage welding turnover work center belonging to automobile crane carriage welding displacement equipment. The turnover center comprises a side open welding positioner, a three-dimensional feeding trolley, a lifting platform and an electric control system, wherein the three-dimensional feeding trolley is located in the middle of the side open welding positioner, the lifting platform is arranged in front of the side open welding positioner, the three-dimensional feeding trolley is arranged on rails which are perpendicular to the side open welding positioner, and the electric control system is simultaneously connected with the three-dimensional feeding trolley, the lifting platform and the side open welding positioner. The side open type carriage welding turnover work center has the advantages that firstly, two side open tilters commonly use one feeding trolley, thus the turnover work center is compact in structure, secondly, the lateral faces of the tilters are open for realizing the positioning of work-pieces, thirdly, the work-pieces can be automatically clamped, and production efficiency are high, fourthly, 180-degree idle rotation can be realized in a turnover ring, which realizes the requirement that carriages are positively fed and reversely discharged, and fifthly, welding operations of workers are convenient.

Owner:XUZHOU HEAVY MASCH CO LTD

Filigree enamel silverware and manufacturing method thereof

PendingCN106240217AWeld firmlyDoes not affect appearanceDecorative surface effectsSpecial ornamental structuresMaterials sciencePigment

The invention relates to the technical field of silverware manufacturing processes, in particular to filigree enamel silverware and a manufacturing method thereof. The manufacturing method for the silverware comprises the following steps in sequence: preparing a blank, whisking, filigreeing, welding, dispensing a blue pigment, and grinding the blue pigment; the step of dispensing the blue pigment comprises the following processes: filling a pattern which is formed by silver wires on the surface of a silver blank which is welded in the step (4) with glazes, then performing high-temperature sintering, namely, sintering a low-temperature glaze for 3 to 6 minutes at the temperature of 710 to 790 DEG C, sintering a high-temperature glaze for 2 to 5 minutes at the temperature of 780 to 830 DEG C, and repeating the processes of filling the glazes and sintering for 3 to 4 times. The filigree enamel silverware provided by the invention is attractive in appearance and colour, long in storage time and wide in spreading degree; colours are rich and are not single. The manufacturing method for the filigree enamel silverware provided by the invention is easy and quick to operate, and is suitable for industrial popularization.

Owner:河南梦祥纯银制品有限公司

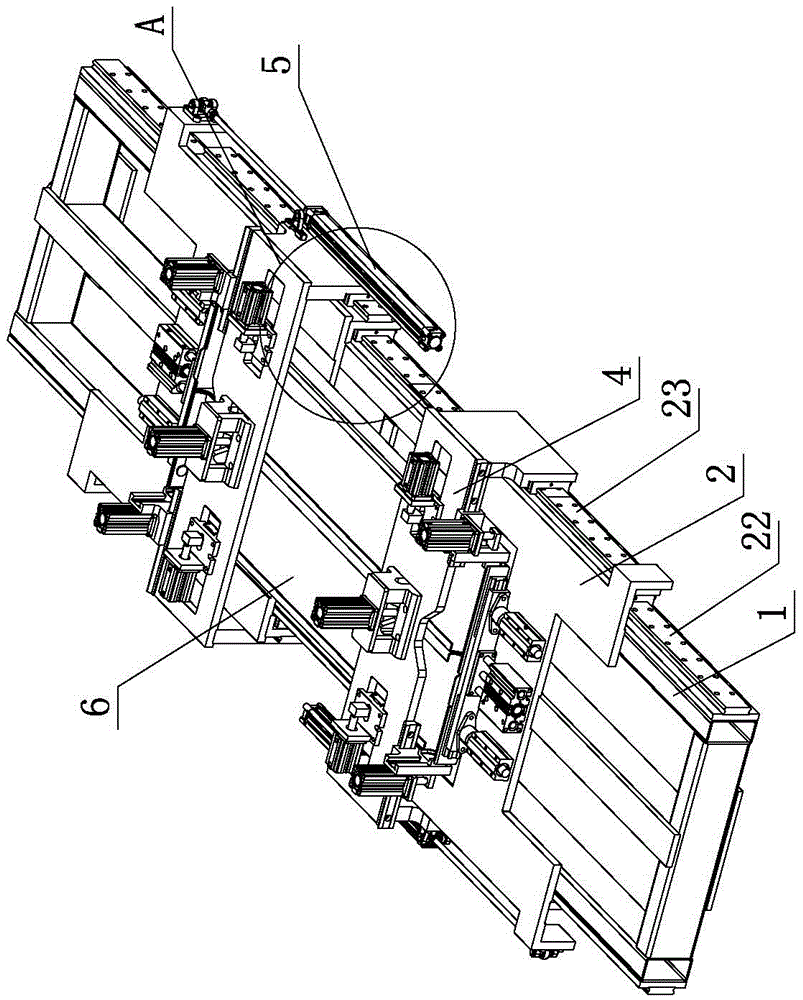

Shield-arc welding device with aerating device inside tube

InactiveCN101486125AEasy to useGuarantee welding qualityWelding accessoriesGas-filled tubeArc welding

The invention discloses a gas shielded welding device with an air charging device inside a tube. The gas shielded welding device comprises a locking device with a chuck for clamping a pipeline to be welded, a drive mechanism for driving the chuck to rotate, the air charging device inside the tube for charging protective gas from a pore space of the pipeline to be welded, and an air charging pipe communicated with the air charging device inside the tube. The gas shielded welding device has the advantages that the device has a semiautomatic structure and convenient operation, and can improve welding quality.

Owner:浙江天力久田管业有限公司

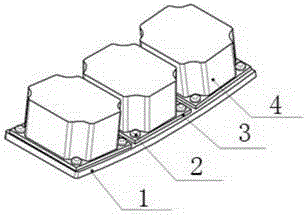

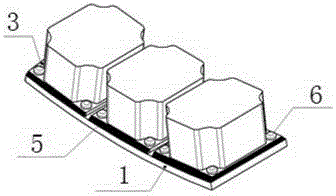

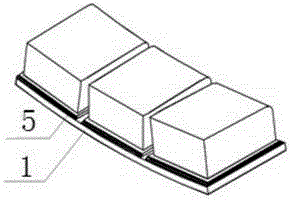

Multi-plate splicing welding tooling

ActiveCN106541240AAvoid misalignmentPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention discloses a multi-plate splicing welding tooling in the field of a welding tooling. The multi-plate splicing welding tooling comprises a base, wherein the base is movably connected with lower transverse plates; upper transverse plates are movably connected onto the base in a way of corresponding to the lower transverse plates; a framework to be welded is arranged between the upper transverse plates and the lower transverse plates; the framework to be welded consists of two C-shaped plates and two end plates; a third air cylinder is arranged on each lower transverse plate; a piston rod extension end of each third air cylinder is provided with an end plate positioning block; each upper transverse plate is provided with a fourth air cylinder; the piston rod extension end of each fourth air cylinder is provided with a locking seat; the lower part of the locking seat is provided with a first positioning groove; each upper transverse plate is provided with a fifth air cylinder; the piston rod extension end of each fifth air cylinder is provided with an outwards folding bent edge positioning block; crossed slide seats are movably connected with the left side and the right side of the upper transverse plates; edge and corner positioning blocks are movably connected onto the crossed slide seats; a compression part is arranged on each edge and corner positioning block. The two parallel and attached C-shaped plates and the two rectangular end plates can be positioned; the welding efficiency and the welding precision can be improved.

Owner:YANGZHOU JINYUAN ROBOTICS AUTOMATION

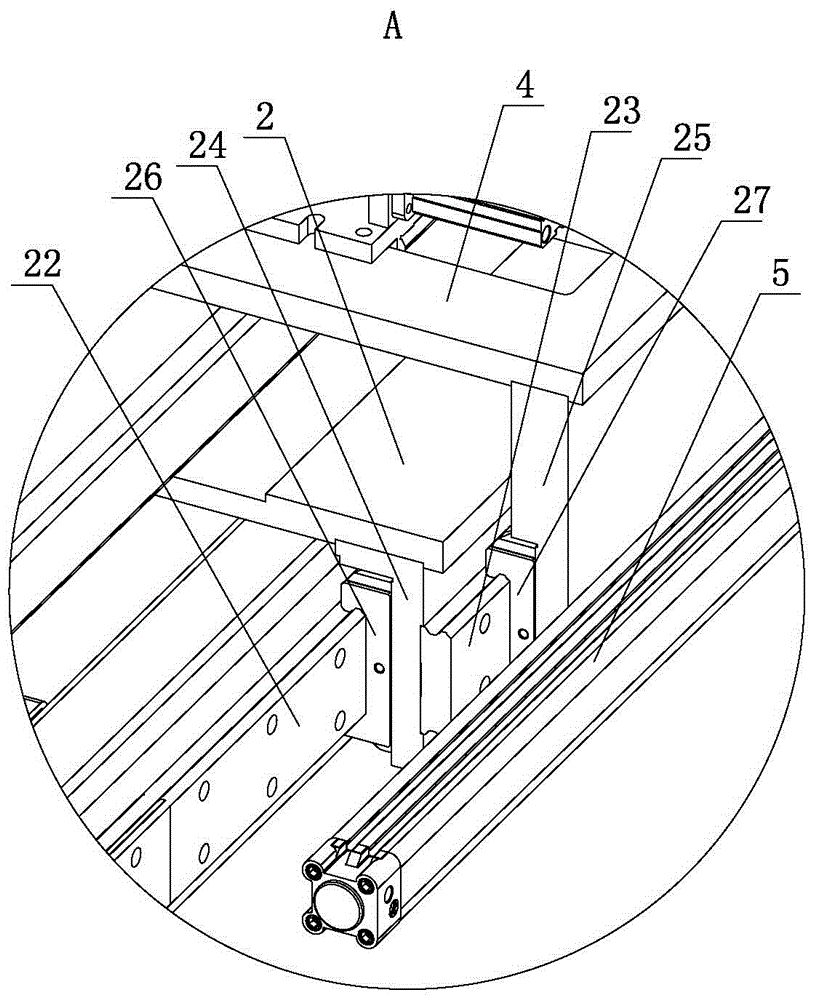

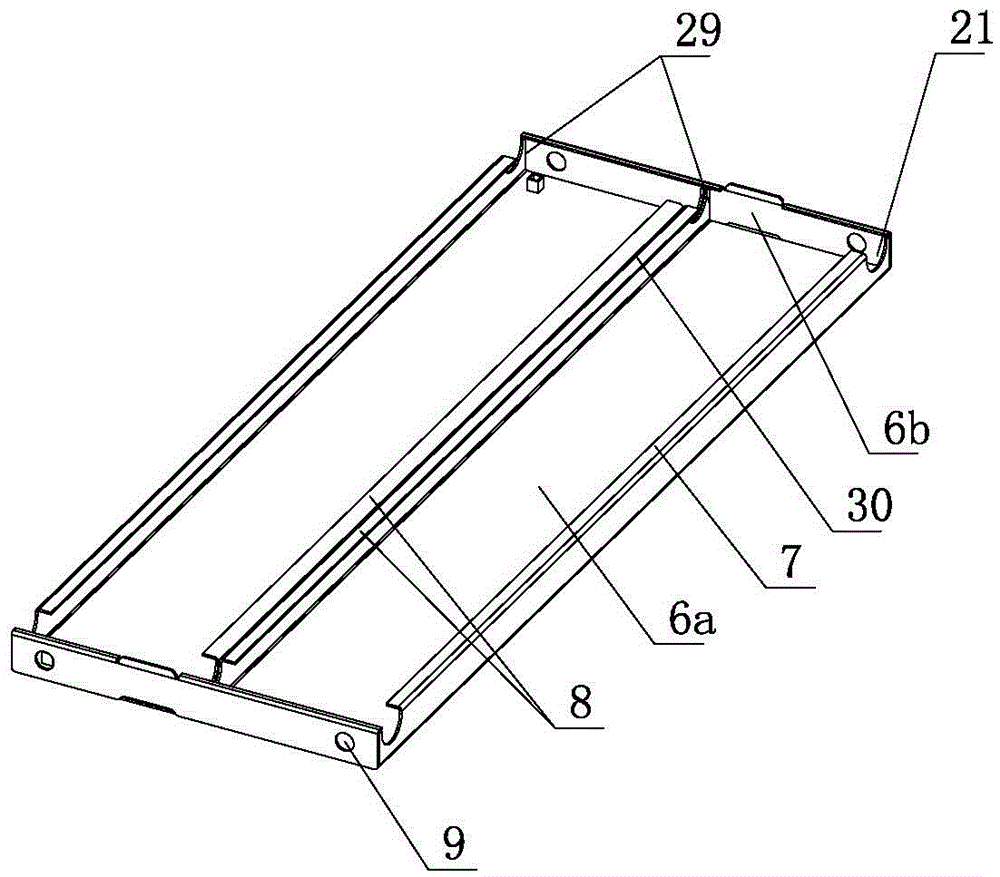

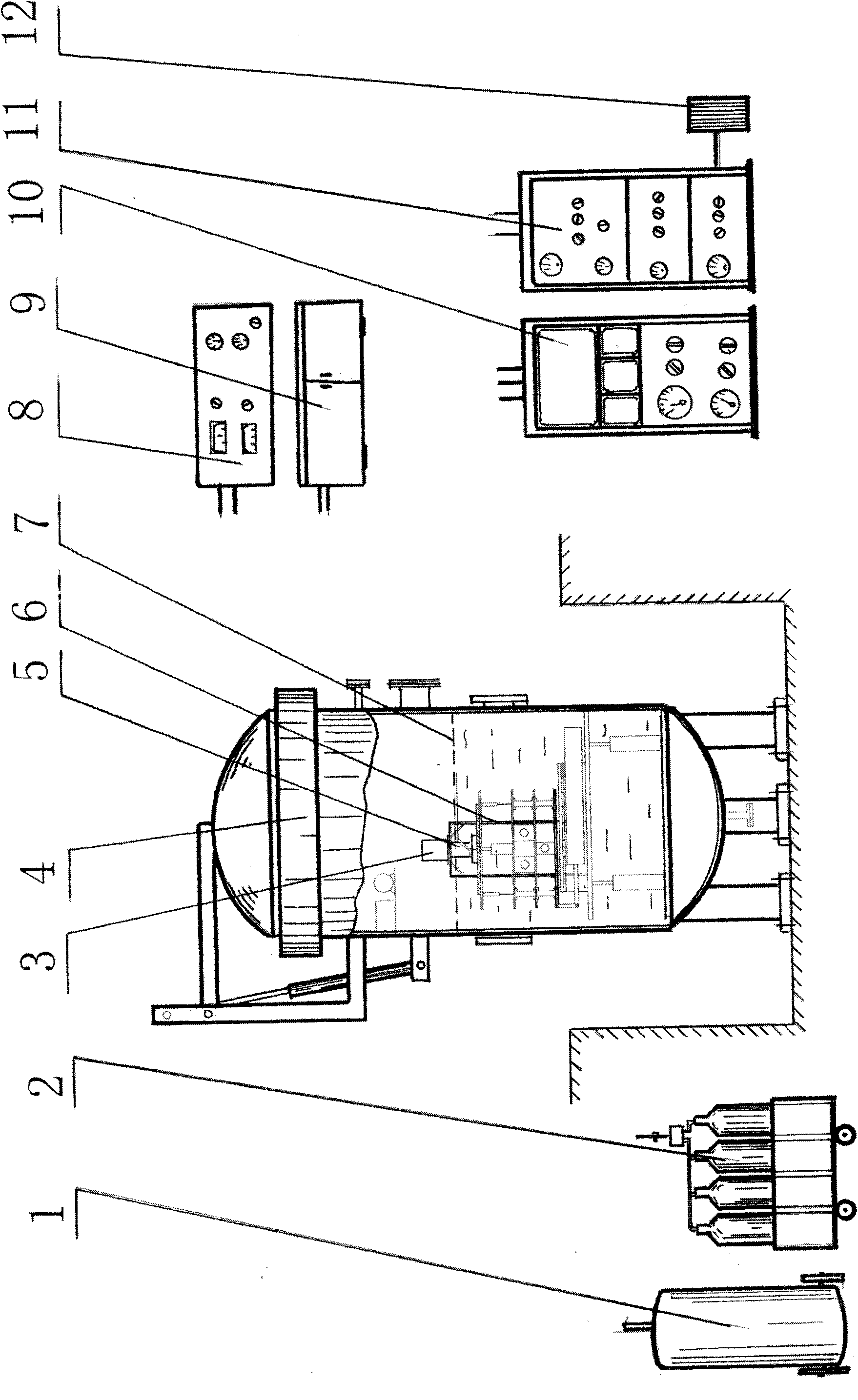

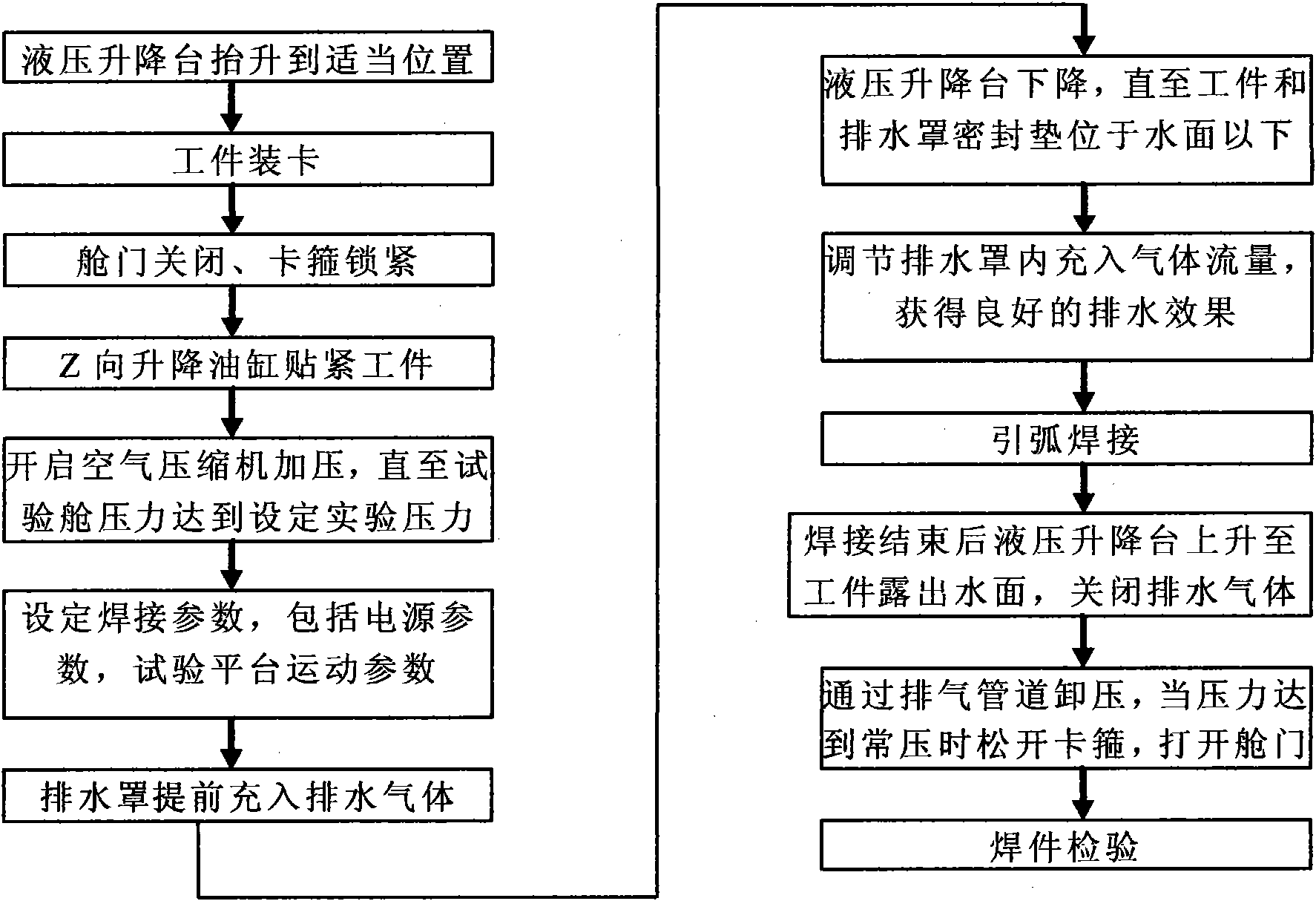

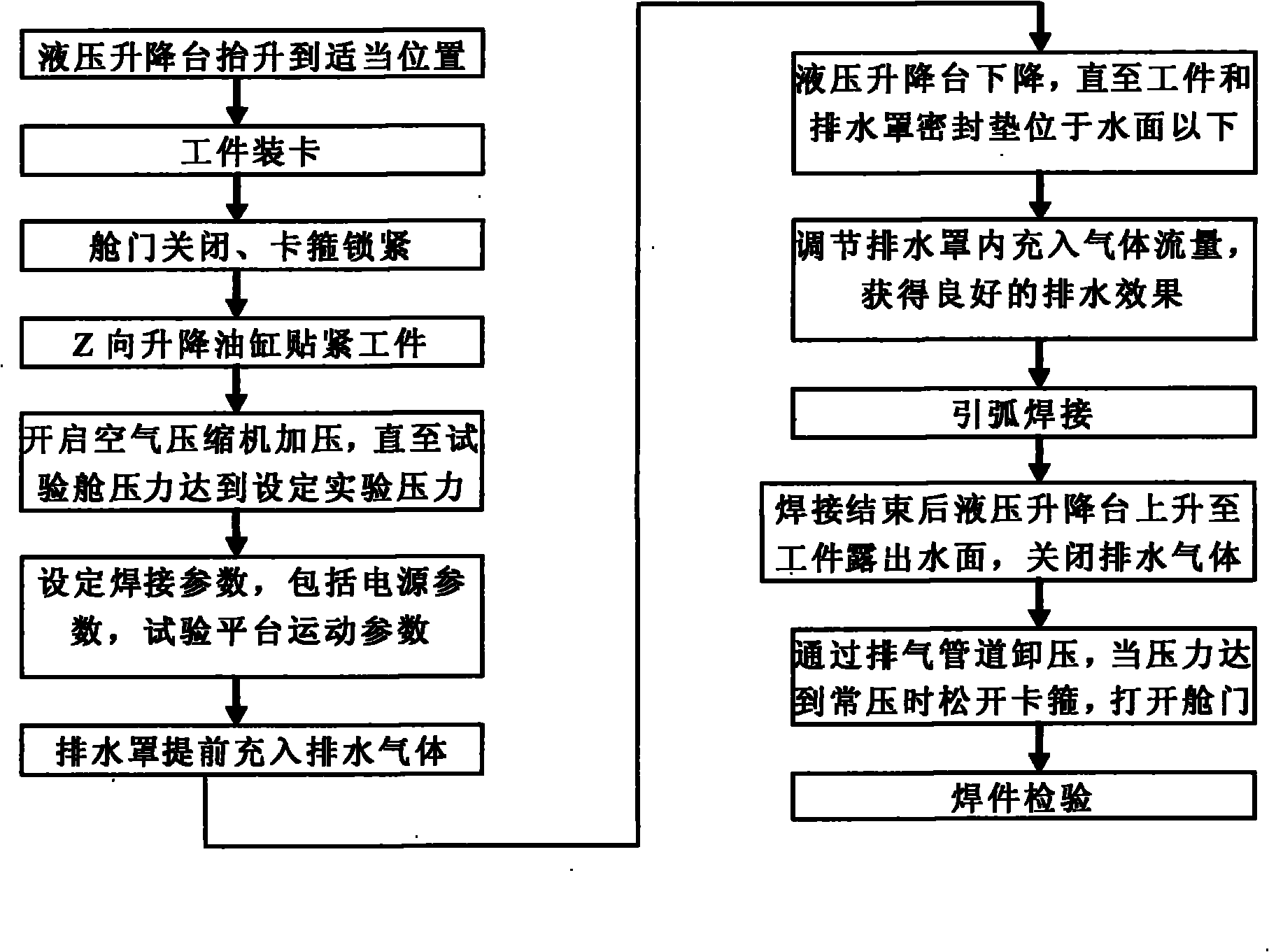

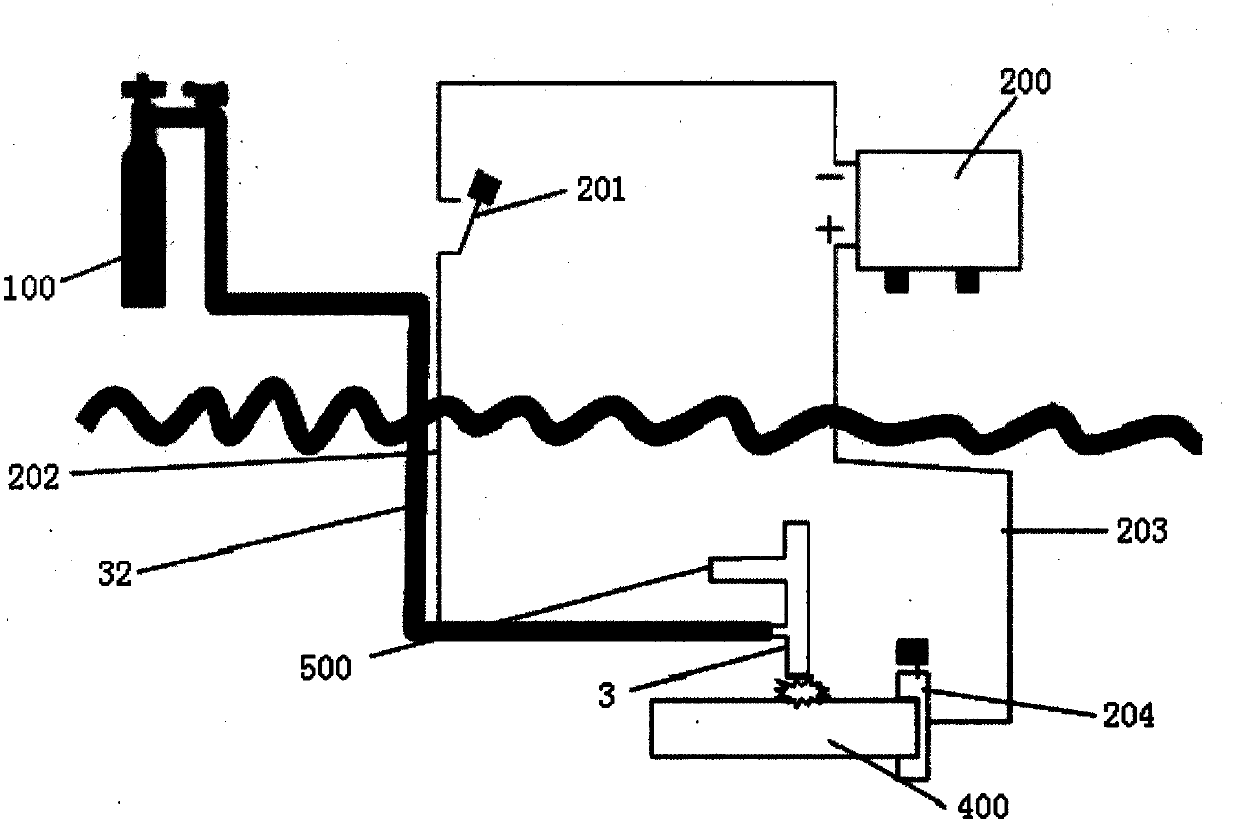

Full-automatic underwater welding method

InactiveCN101767244ARealize remote control of fully automatic partial dry underwater welding operationLarge protected areaArc welding apparatusButt weldingGas cylinder

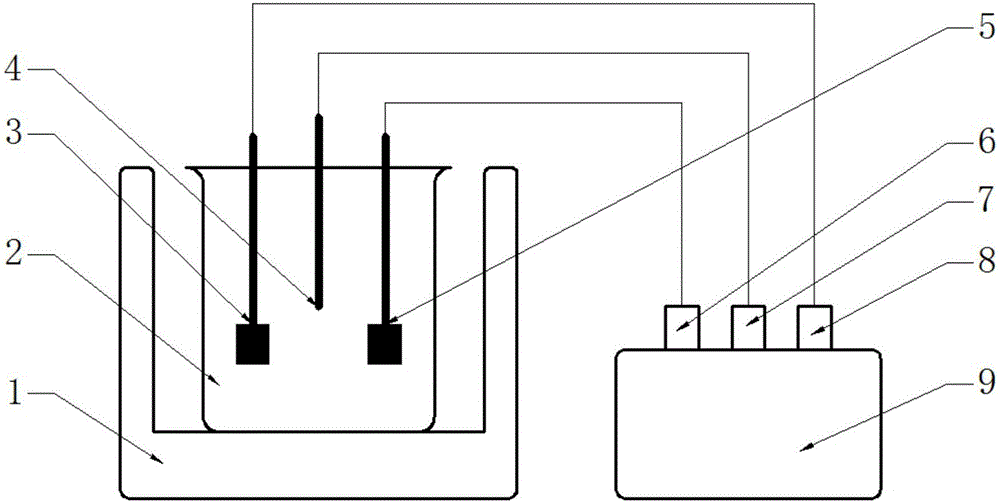

The invention provides a full-automatic underwater welding method and equipment. The equipment comprises an air compressor (1), a gas cylinder (2), a welding camera (3), a welding test chamber (4), a water drain device (5), a hydraulically-driven automatic welding platform (6), a water surface (7), a welding analyzer (8), a welding power supply (9), a monitoring television cabinet (10), a control system cabinet (11), and a manual control box (12). A local dry underwater welding method is used for underwater surfacing and groove butt welding; during welding, the unitary pulse metal inert gas arc welding is adopted; the gas used for water drainage during the welding is also used as the welding shielding gas; before welding, the welding parameters including welding method, welding speed, swinging speed, swinging amplitude, left-right standstill time and the like are set through the manual control box (12) as required, wherein the parameters can be regulated in real time according to the actual condition; the camera system is used for performing omnibearing remote monitoring on the inside of the welding test chamber (4); and the welding analyzer (8) is used for acquiring welding electric parameters and performing statistical analysis in real time. The equipment can be used in the places where the personnel cannot reach, such as deep water area, radiant environment and the like, thereby not only realizing remote control of fully-automatic underwater welding operation, but also ensuring good formation of seams to further ensure the obtaining of high-quality underwater welding joint.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

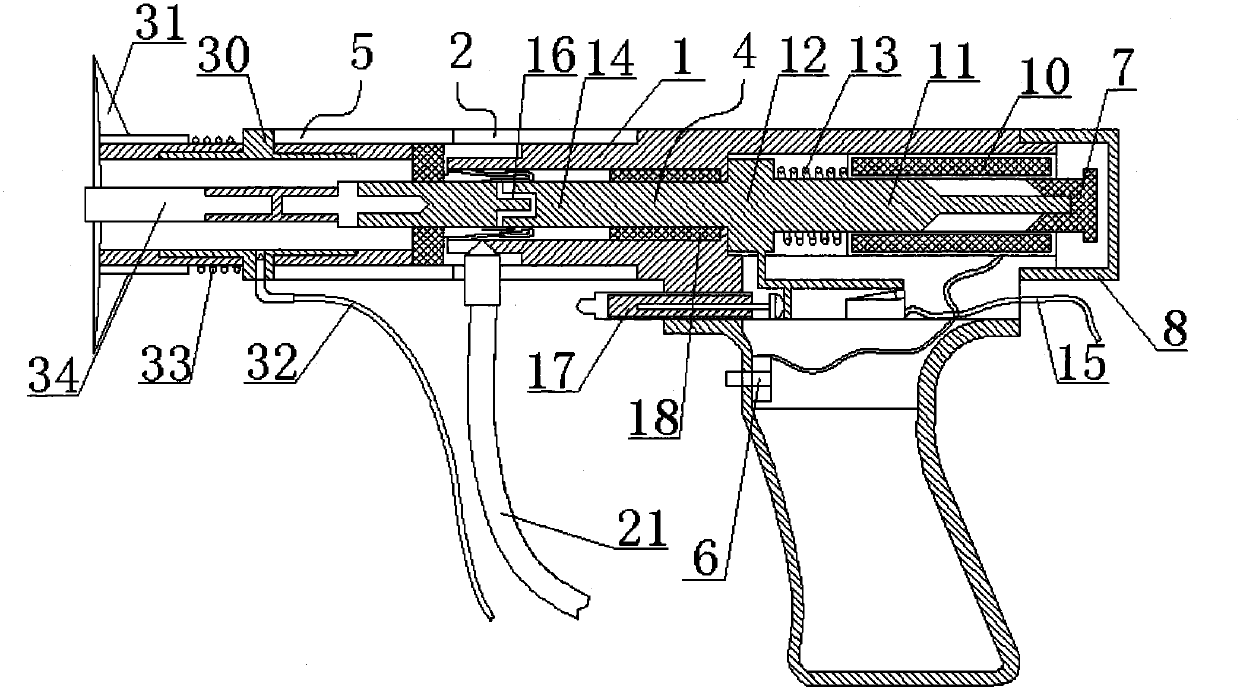

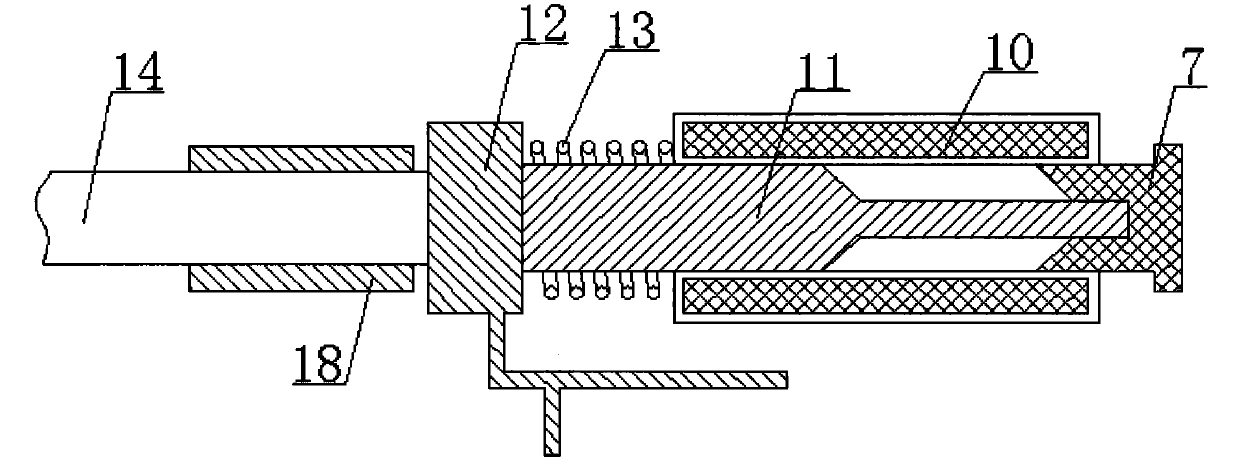

Underwater multifunctional stud welding device and welding method thereof

ActiveCN104259637AQuick repairShort welding timeShielding gas supply/evacuation devicesWelding/cutting media/materialsWelding power supplyStud welding

The invention belongs to underwater welding cutting equipment, in particular relates to a underwater multifunctional stud welding device and a welding method thereof. The underwater multifunctional stud welding device mainly consists of a high-power welding power supply, a welding cutting set, an air supply system, a welding cable and a control system, wherein the air supply system comprises an air storage bottle, a pressure reducer and a corresponding air supply pipeline; and the welding cable comprises a welding ground, a cable fixing clamp, a welding gun welding cable and a welding gun control cable. The underwater multifunctional stud welding device has such characteristics as short welding time, good underwater welding quality, no need of operation by special underwater welders, reduction of fastening pieces and all-position welding, can realize such multiple functions as underwater stud welding, underwater manual arc welding and underwater electricity-oxygen cutting, and provides a whole set of solutions for such underwater emergency repair as damaged part repairing, repair plate stud fixation and reinforcement seal welding of damaged ships. The underwater multifunctional stud welding device can perform quick underwater repair without needing the ships to dock for drainage, so that the repair resource and cost are largely reduced, and the repair efficiency is improved.

Owner:THE PLA NAVY SUBMARINE INST

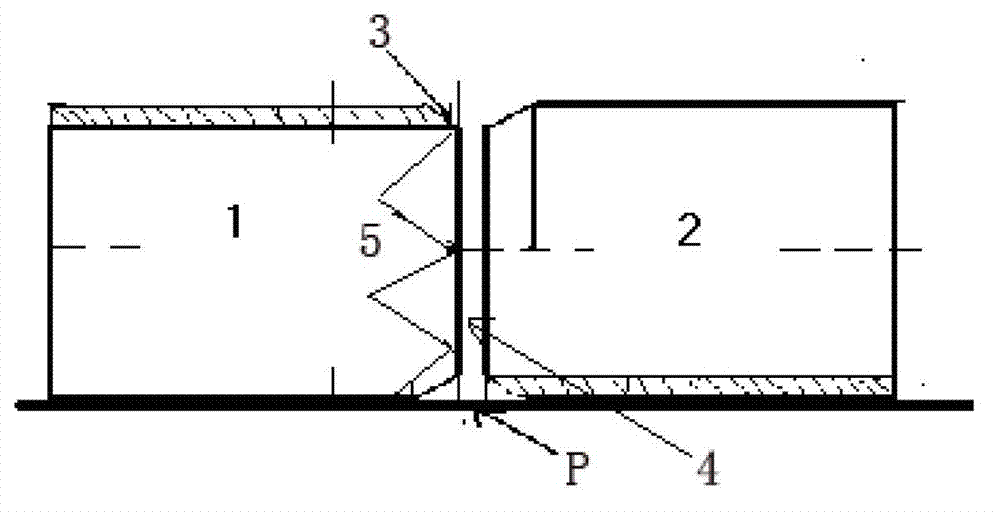

Sleeve welding repair method in blast-furnace tuyere

ActiveCN103801805AFast welding speedGuarantee the quality of weld seamArc welding apparatusEngineeringSlow cooling

The invention discloses a sleeve welding repair method in a blast-furnace tuyere. According to the technical scheme, the sleeve welding repair method comprises the steps of (1) cleaning a repair area, (2) determining the position of a crack, (3) opening a narrow gap groove, (4) selecting welding materials and devices, (5) adjusting a welding current, the gas flow and a polishing tungsten electrode in advance, (6) conducting welding, (7) conducting heat preservation and cleaning after welding, coating a weld joint obtained after welding with asbestos, conducting slow cooling until the room temperature is reached, after the weld joint is slowly cooled and the temperature of the weld joint reaches the room temperature, using a polishing machine for cleaning the weld joint and clean away splashes near the weld joint, and meanwhile enabling polishing weld reinforcement of the weld joint to range from 2 mm to 3 mm. According to the sleeve welding repair method in the blast-furnace tuyere, under the situation that preheating is not carried out, the welding speed is high, the quality of the weld joint is ensured, the welding operation is easy and convenient, and the weld joint basically meets the level of a new spare part through welding repair.

Owner:ANHUI MASTEEL ENG & TECH GRP

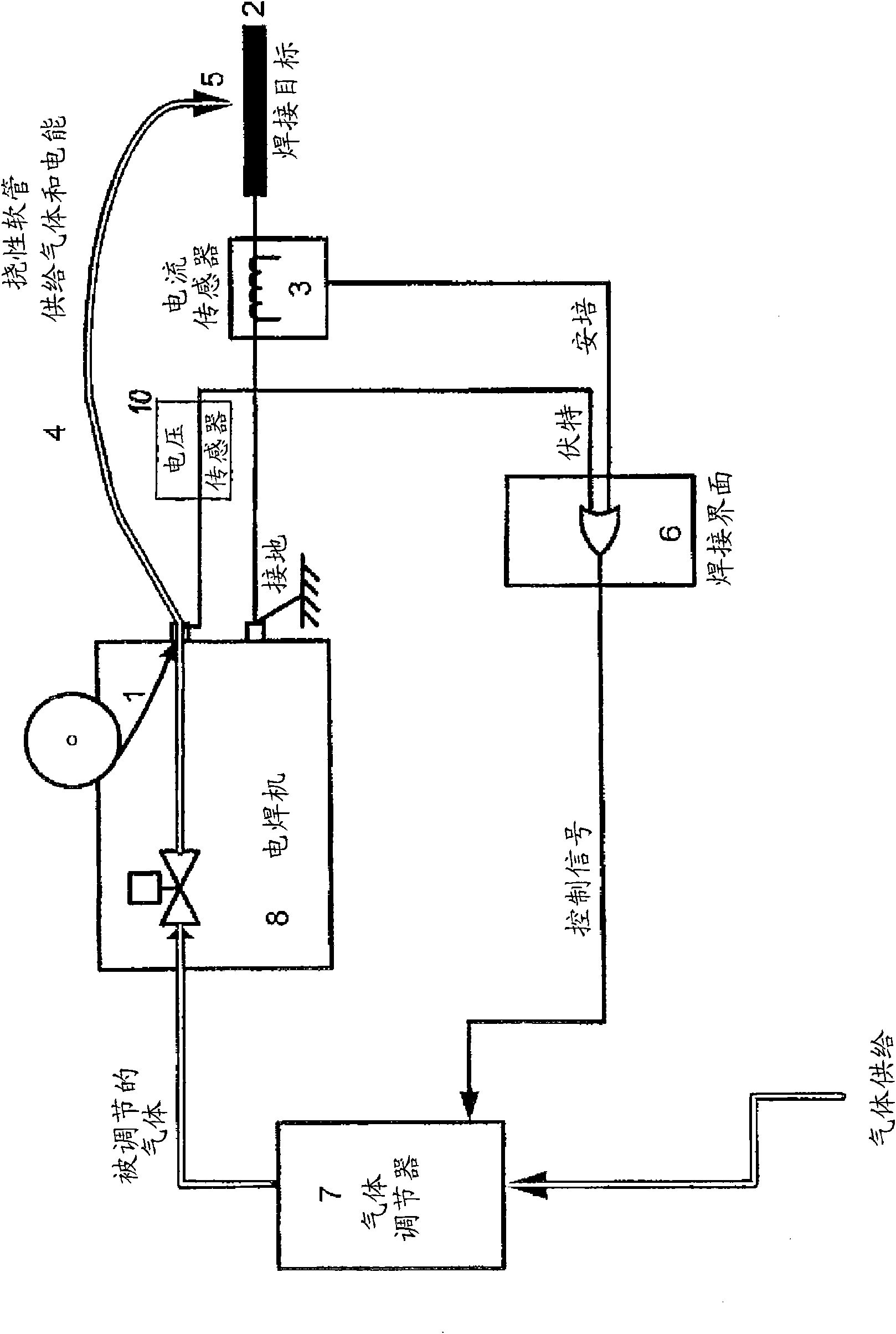

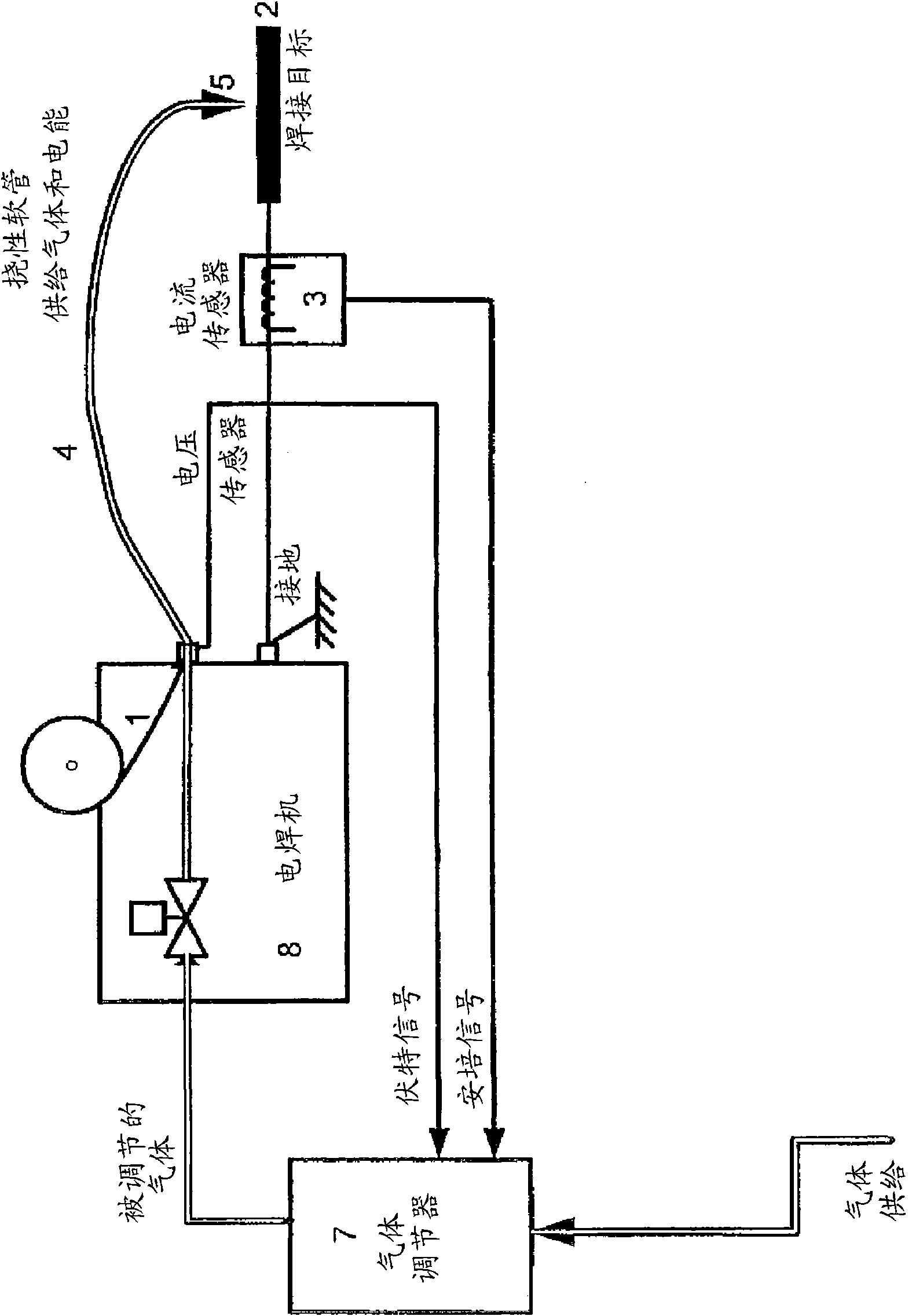

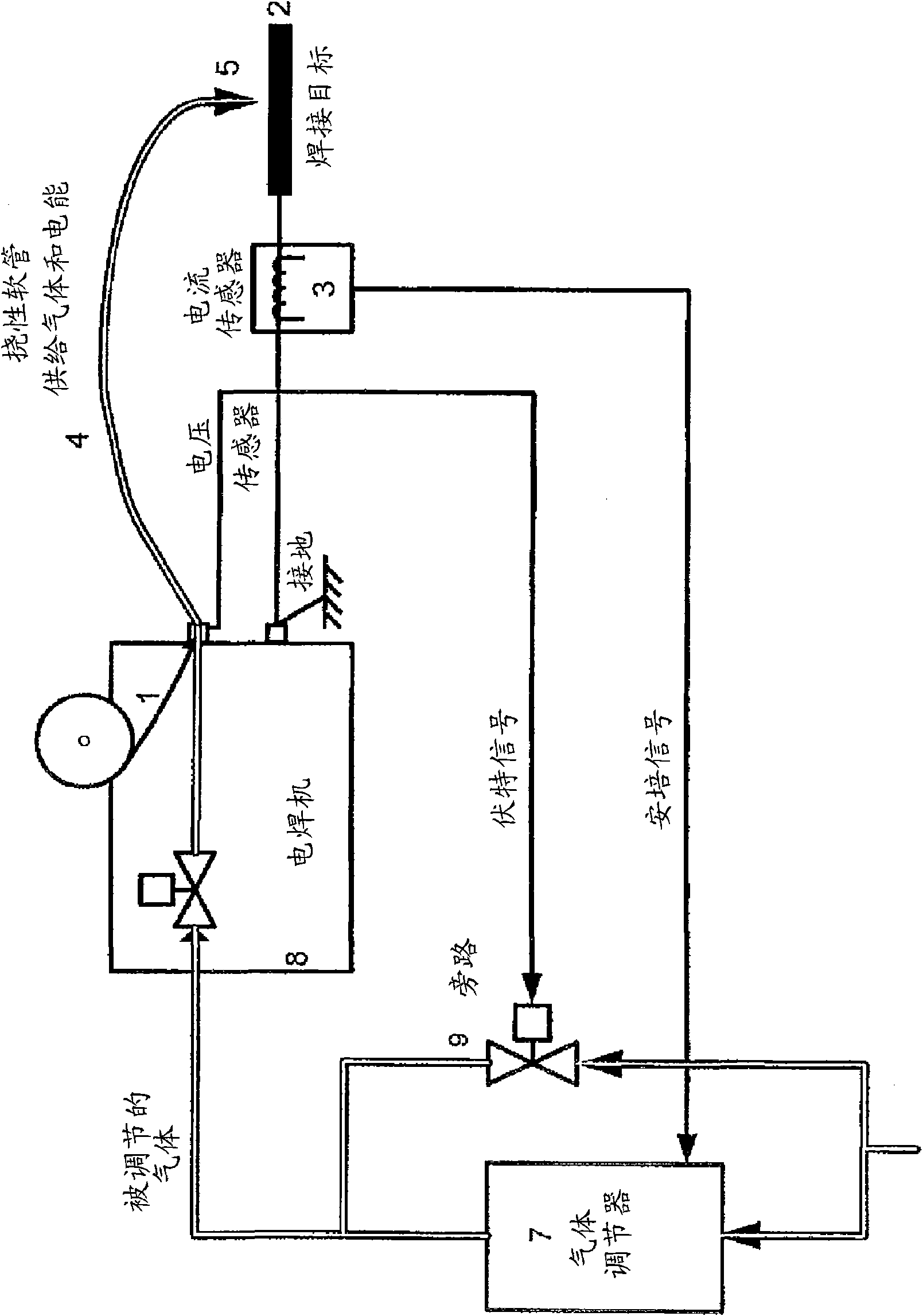

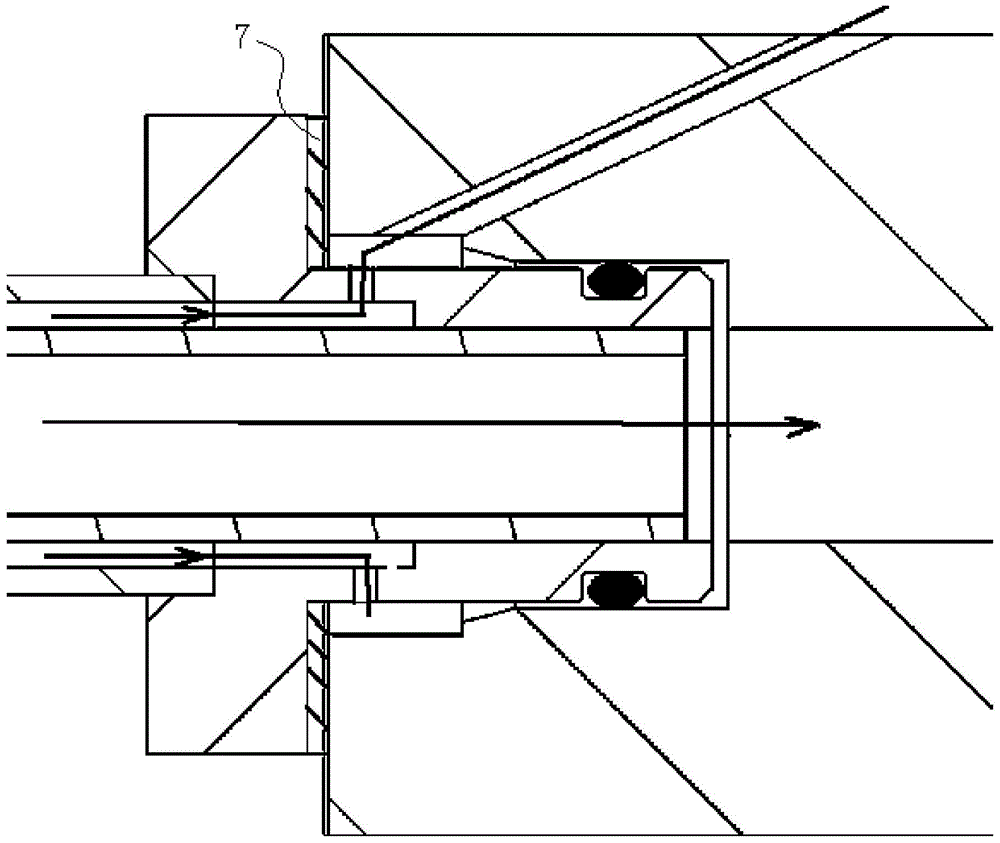

Arrangement and method for blanket gas supply control for an electrical welding apparatus

Apparatus and method for use in controlling blanket gas flow in an electrical welding facility, wherein welding is performed using a welding electrode in electrical connection with a welding machine unit. The apparatus comprises an electric measuring device having a current sensor 3 adapted to determine the magnitude of an electrical welding current carried in a circuit incorporating the welding electrode and having a current sensor output adapted to provide a I signal indicating the current magnitude, and a voltage sensor 11 adapted to determine the magnitude of an electrical voltage being applied to the welding electrode and having a voltage sensor output for providing a U signal indicating the voltage magnitude, and a control device 6. The control device 6 has inputs connected to the current sensor output and the voltage sensor output, respectively, and a control signal output for providing a control signal to a blanket gas flow controller 7, and a controller adapted to provide thecontrol signal as a) a control signal of a predetermined first magnitude when the U signal is larger than the first U threshold and the I signal is less than a first I threshold, and b) a control signal of a magnitude varying proportionally with the I signal when the I signal is greater than the first I threshold.

Owner:ALEXANDER BINZEL SCHWEISSTECHN GMBH & CO

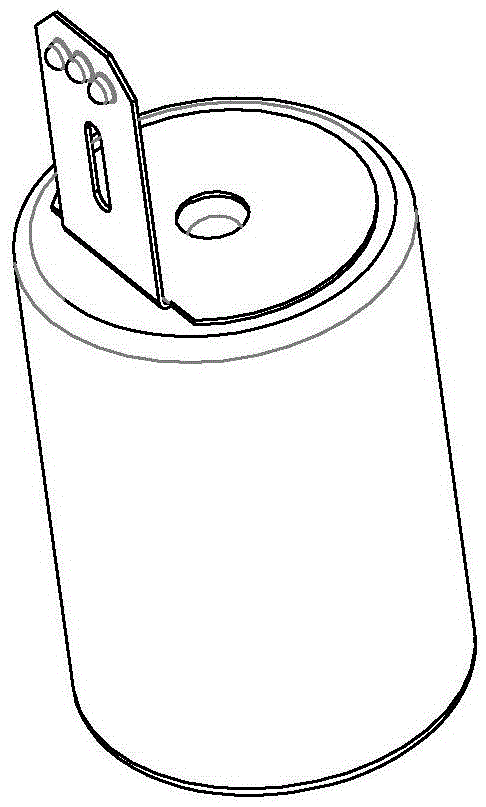

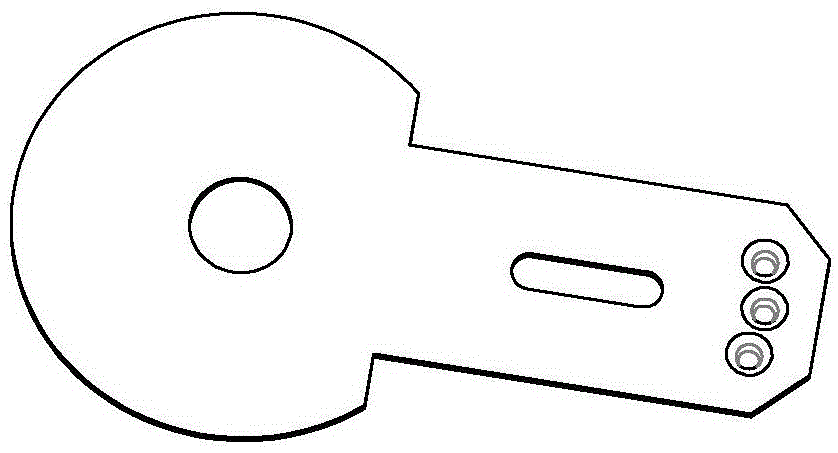

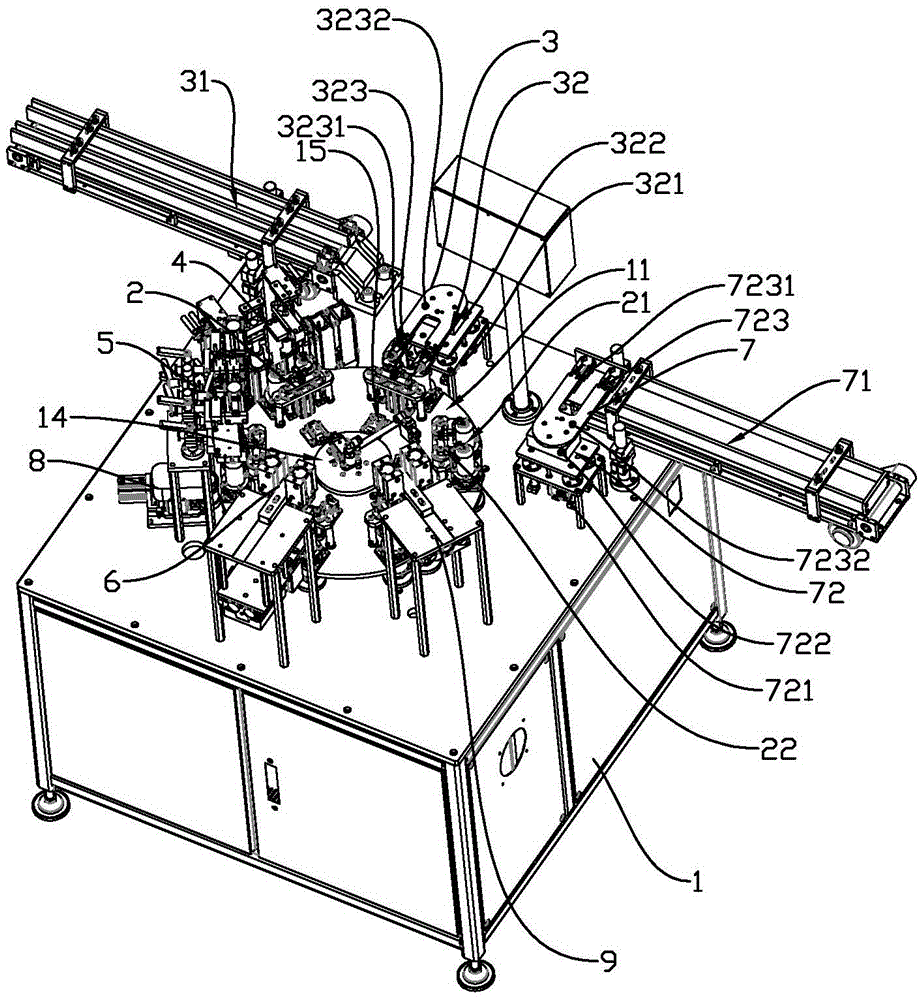

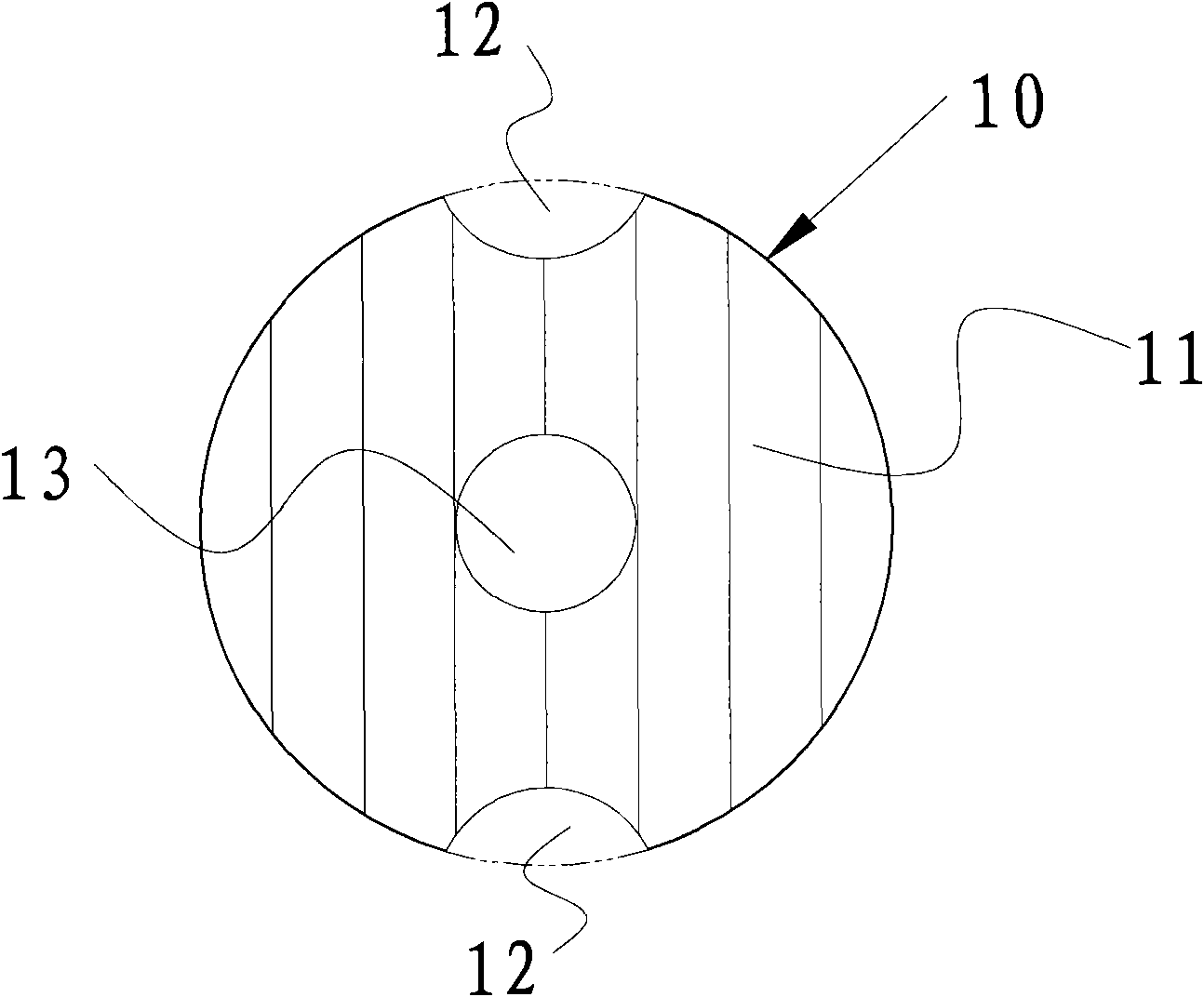

Cylindrical lithium battery and collector welding machine achieving reliable battery cell feeding

InactiveCN105643178AImprove work efficiencyEasy to processPrimary cell manufactureFinal product manufactureProduction lineTransfer mechanism

The invention relates to a cylindrical lithium battery and collector welding machine achieving reliable battery cell feeding. A collector welding production line comprises a conveying line, a material positioning device arranged on the conveying line, a battery cell feeding device, a collector feeding device, a welding device, a collector bending device and a finished product discharging device, wherein the battery cell feeding device, the collector feeding device, the welding device, the collector bending device and the finished product discharging device are arranged along the conveying line in sequence, and transfer working positions of the battery cell feeding device, the collector feeding device, the welding device, the collector bending device and the finished product discharging device are matched with the material positioning device. The battery cell feeding device comprises a battery cell conveying track and a battery cell transfer mechanism. The battery cell transfer mechanism comprises a battery cell feeding lifting air cylinder, a battery cell transfer rotating driving motor and a battery cell clamping manipulator. The battery cell clamping manipulator is provided with a battery cell chuck capable of being opened and closed and a battery cell chuck installation arm installed on a motor shaft of the battery cell transfer rotating driving motor. The battery cell transfer rotating driving motor is installed on a telescopic arm of the battery cell feeding lifting air cylinder. The cylindrical lithium battery and collector welding machine achieving reliable battery cell feeding is used for automatically welding collectors to battery cells and automatically bending the collectors, and has the advantages of being good in product processing quality, compact in structure and high in working efficiency.

Owner:周胡琴

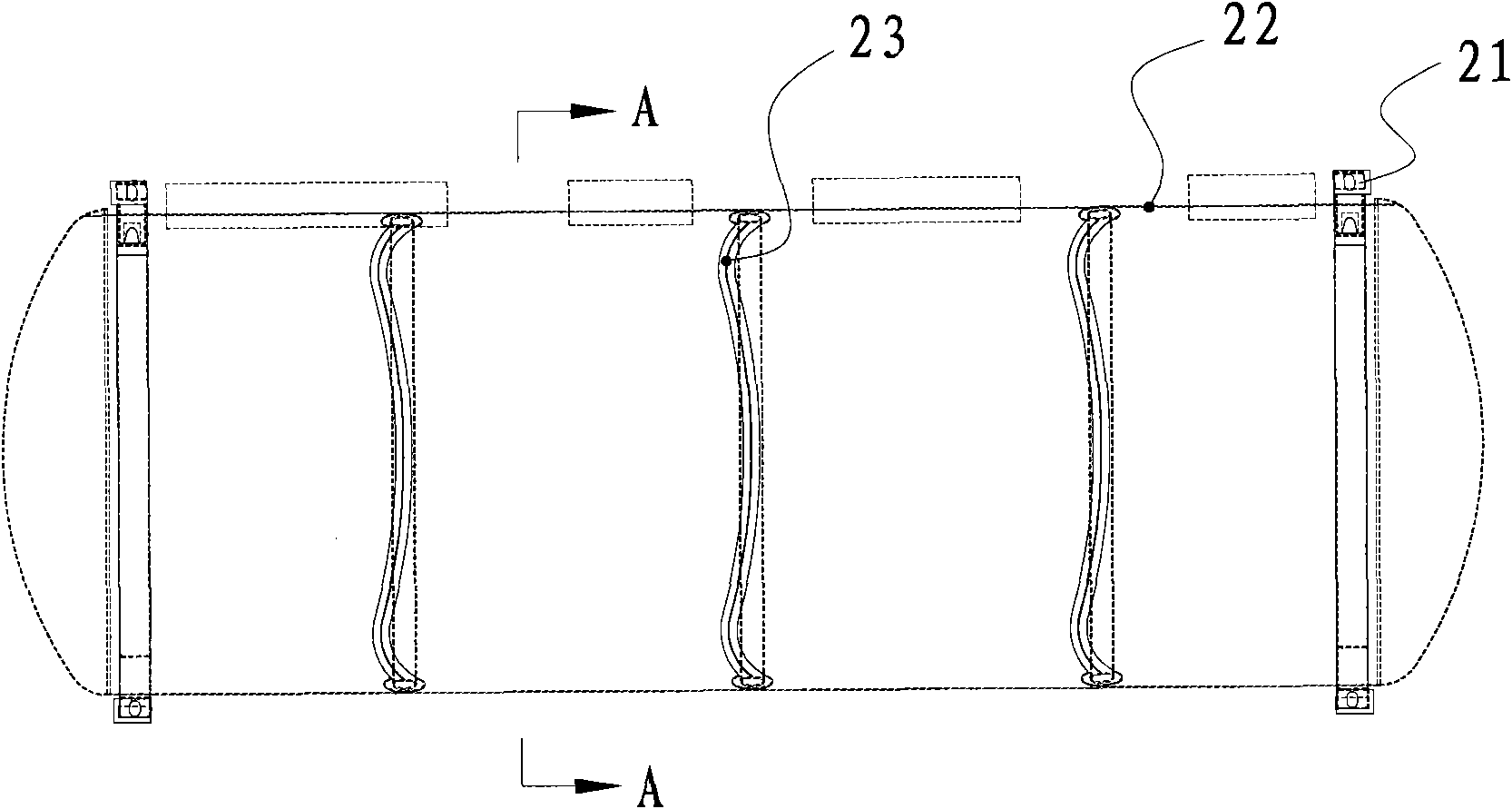

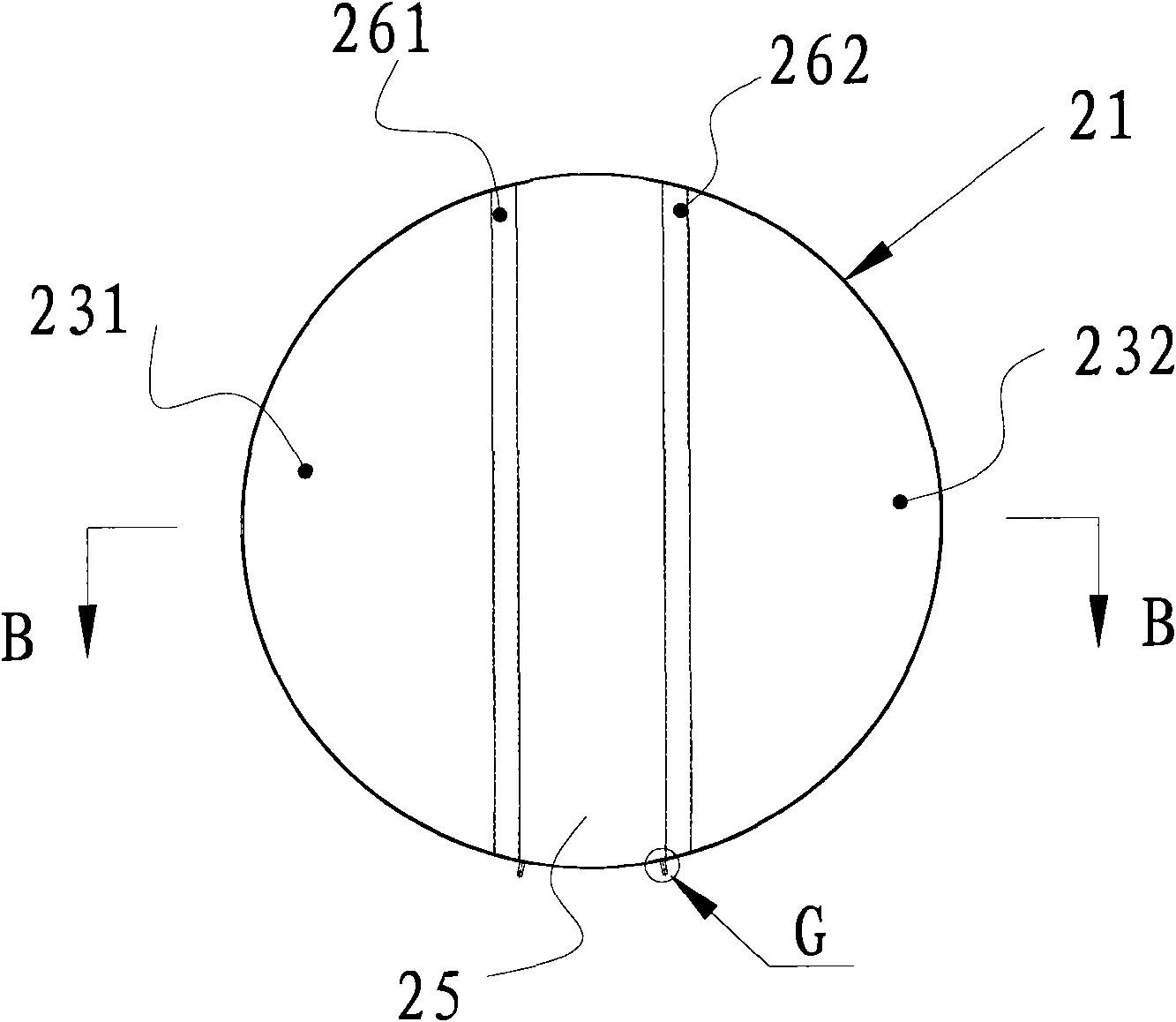

Liquid tank container

The invention discloses a liquid tank container, comprising a framework body and a tank body which is fixedly connected with the framework body, wherein at least one group of breakwaters are laterally and fixedly arranged in the tank body along the tank body and comprise at least two breakwater units, a gap between at least two unit breakwaters can at least allow one person to pass through, and the bottom of the tank body is communicated at least. Compared with the prior art, the liquid tank container has simple and reliable structure, easy processing and manufacturing and convenient maintenance in the tank body by the maintenance personnel.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

Automatic wire arranging welding device

ActiveCN105149758ASolve the problem of manual solderingImprove welding qualityResistance welding apparatusControl systemEngineering

The invention provides an automatic wire arranging welding device. The automatic wire arranging welding device comprises an automatic welding system, a wire arranging system, a support main body, a material rack lifting system, a material rack moving system, a welding material rack and a control system. The automatic welding system, the wire arranging system, the material rack lifting system, the material rack moving system, the welding material rack and the control system are all arranged on the support main body. The material rack lifting system is located on the front portion of the support main body. The automatic welding system is located on the rear portion of the support main body. The wire arranging system is located between the material rack moving system and the automatic welding system. The material rack moving system is arranged in the support main body and capable of driving the welding material rack to move forwards and backwards on the support main body. The control system is connected with the automatic welding system, the wire arranging system, the material rack lifting system and the material rack moving system, and controls the automatic welding system, the wire arranging system, the material rack lifting system and the material rack moving system. According to the automatic wire arranging welding device, the support main body, the welding material rack, the wire arranging system, the moving system and the automatic welding system are all designed innovatively, so that the whole welding device is capable of conducting the automatic wire arranging welding effectively and in high quality, and the device can be widely popularized in the technical field of welding, so that the market prospects are very broad.

Owner:GUANGDONG HWASHI TECH INC

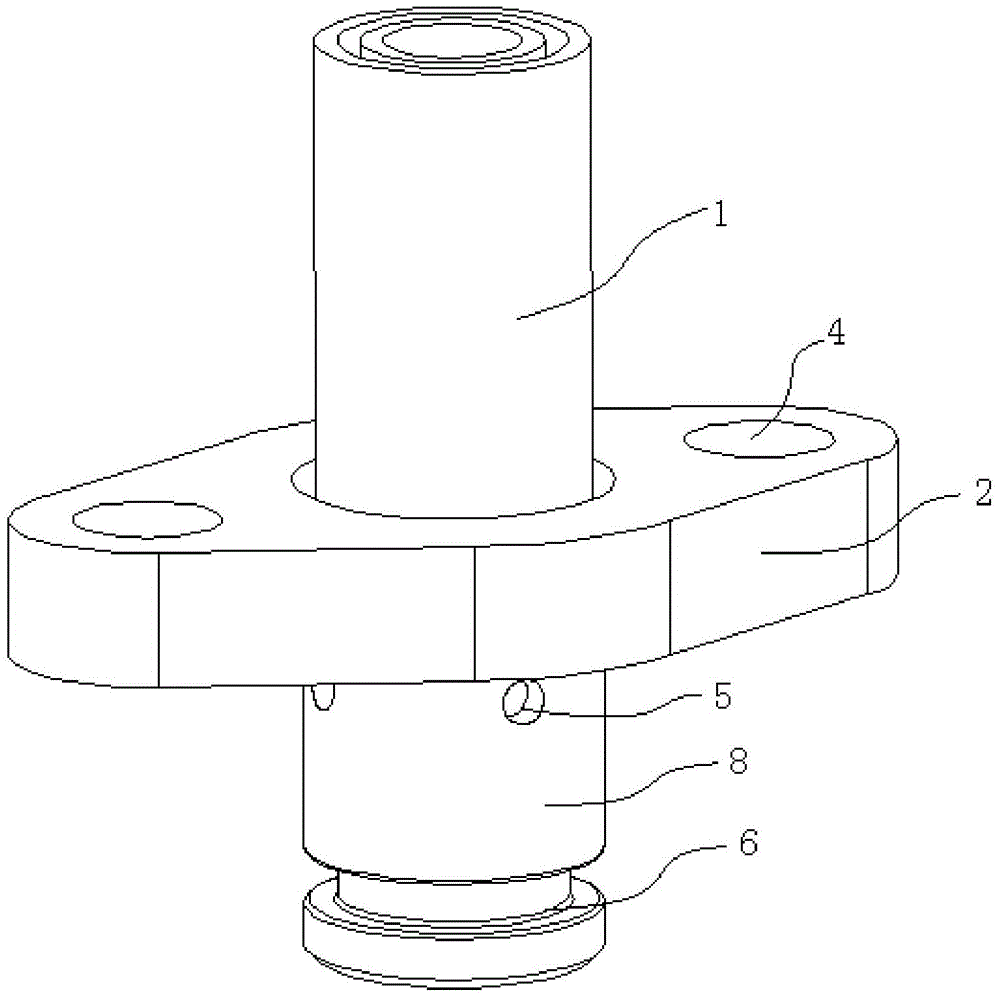

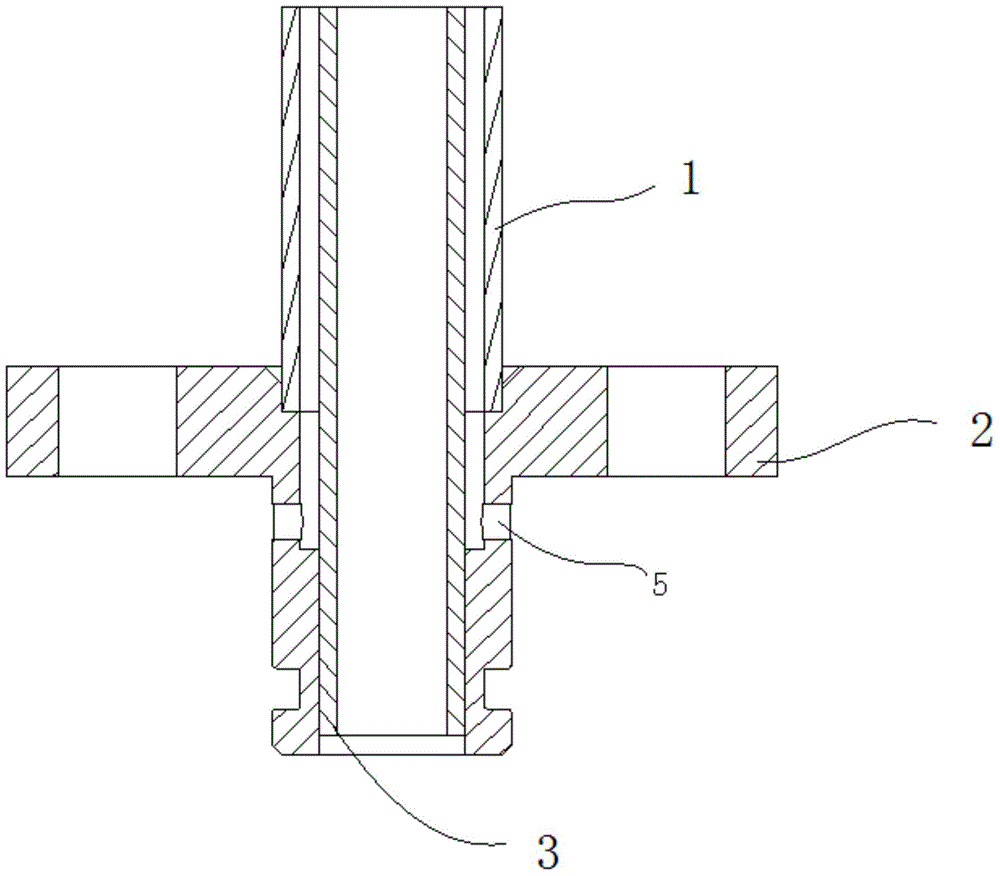

Double-layer pipe joint for engine gas supply system

ActiveCN104989558ASave installation spaceImprove sealingInternal combustion piston enginesFuel supply apparatusDouble-walled pipeControl engineering

The invention discloses a double-layer pipe joint for an engine gas supply system. The double-layer pipe joint for the engine gas supply system comprises an outer pipe, an inner pipe and a flange. The upper section of the inner pipe is arranged in an inner cavity of the outer pipe to form a ventilation interlayer. The flange comprises a flange plate and an inner pipe sleeve. An inner pipe penetrating hole is formed in the center of the flange plate. An outer pipe welding groove is formed in the upper end of the inner pipe penetrating hole. The lower section of the inner pipe is inserted in the inner pipe penetrating hole to form a ventilation gap. The ventilation interlayer is communicated with the ventilation gap. Multiple vent holes are formed in the peripheral side of the upper side of the inner pipe sleeve at intervals and communicated with the ventilation gap. By the adoption of the double-layer pipe joint for the engine gas supply system, the vent holes communicated with the ventilation interlayer of a double-layer pipe are formed in the peripheral side of the flange, the installation positions of the double-layer pipe joint are reduced, a double sealing structure of a gasket and an O-shaped ring is adopted in the double-layer pipe joint, and sealing performance is good.

Owner:广西玉柴船电动力有限公司

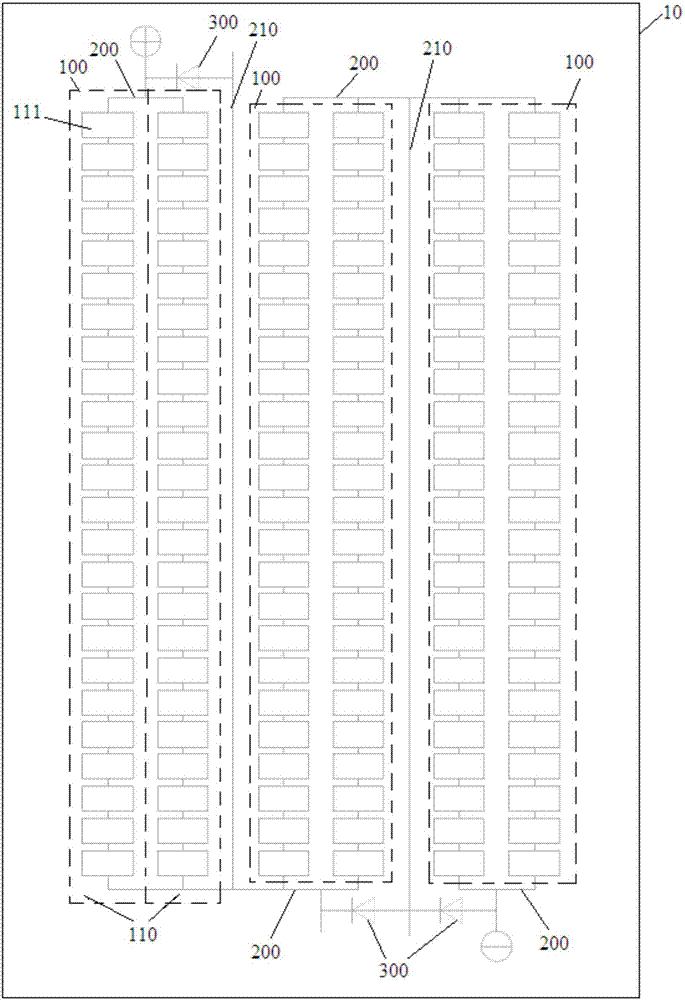

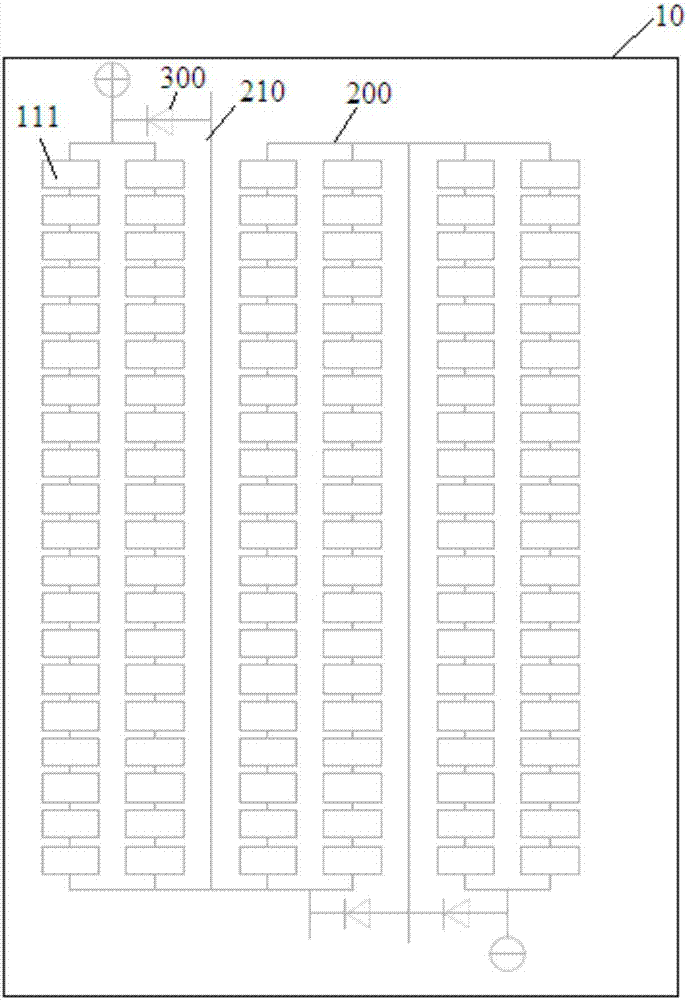

Semi-slice photovoltaic module circuit and semi-slice photovoltaic module

ActiveCN107275420AIncrease powerReduce hot spot effectPhotovoltaic energy generationSemiconductor devicesBattery cellDiode

The invention discloses a half-slice photovoltaic component circuit, wherein the half-slice photovoltaic component circuit includes multiple sets of battery string units, each adjacent two sets of battery string units are connected in series through a first bus bar, and each set of battery string units The two ends of the two ends are respectively connected in parallel with a diode through the second bus bar. Each battery string unit includes two battery strings connected in parallel, and each battery string includes a plurality of batteries connected in series. The first battery string unit in the plurality of battery string units The first end of the battery string unit in one group is formed as the positive pole of the half-slice photovoltaic module circuit, and the tail end of the last group of battery string units in multiple groups of the battery string unit is formed as the half-slice photovoltaic module circuit the negative pole. The invention also discloses a half-slice photovoltaic module. When the half-slice photovoltaic component circuit provided by the present invention is applied to the photovoltaic component, it not only solves the hot spot effect, but also facilitates welding operation and mass production.

Owner:WUXI SUNTECH POWER CO LTD

High-toughness and high-strength steel electrode for 60kg all position welding

ActiveCN102689115AImprove mechanical propertiesStable in natureWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to a high-toughness and high-strength steel electrode for 60kg all position welding, and the high-toughness and high-strength steel electrode is composed of a welding core and an electrode coating, wherein the electrode coating comprises the following components in percentage by weight: 32-40% of CaCO3, 16-24% of CaF2, 5-9% of TiO2, 3-8% of SiO2, 5-11% of ferro titanium, or 3- 4.5% of ferro chromium, 5-8% of metal manganese and ferro manganese, 3-6% of ferro molybdenum, 0-9% of ferrosilicon, 2-5% of, metal nickel, 8-17% of and iron powder; the high-toughness and high-strength steel electrode can satisfy the welding of 60kg intensity steels, the low temperature impact toughness is excellent, the mechanical property and the comprehensive mechanical properties are very excellent, especially the predominance is very outstanding in an operational environment that the temperature is minus 60 DEG, simultaneously the production cost is low, the welding technology is superior, and the welding operation is easy to perform.

Owner:TIANJIN BRIDGE WELDING MATERIALS GROUP

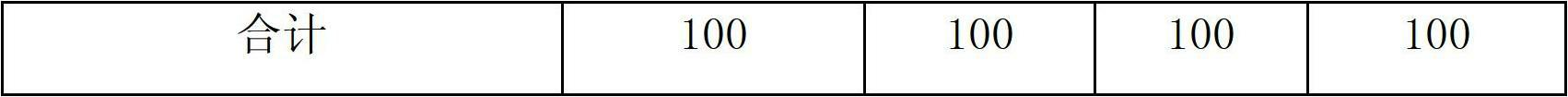

Welding method of double-metal composite pipe

ActiveCN106695079AReduce welding costsConvenient welding operationArc welding apparatusWelding/soldering/cutting articlesCorrosionBimetal

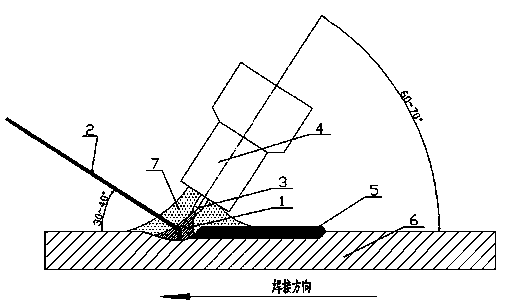

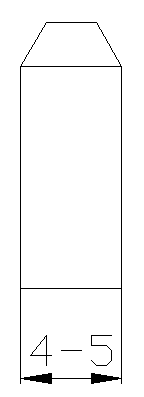

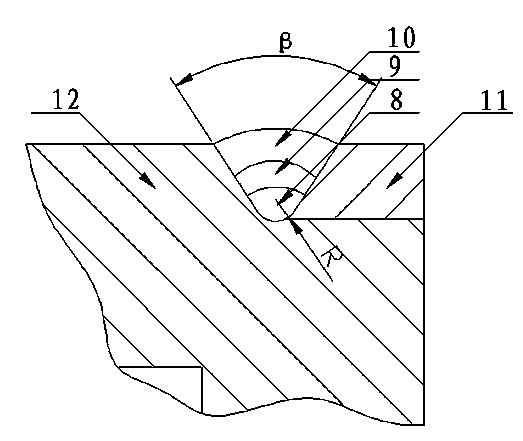

The invention discloses a welding method of a double-metal composite pipe. The welding method comprises the following steps: (1) welding groove treatment: a basic welding surface is machined; a groove is a Y-shaped groove; a single-edge groove angle beta is 30+-5 degrees; and an obtuse edge thickness h is 2-4 mm; (2) prewelding: the TIG or MIG welding is performed; and a lining layer is prevented from being molten in the welding process; (3) the fill welding is performed; (4) welding of the lining layer: the low-current TIG welding is adopted; and (5) the cover surface welding is performed. The welding method improves the joint corrosion resistance, and is simple and convenient in welding process, high in welding efficiency, low in welding cost, free of crisp and hard layers in welding lines and excellent in welding line quality.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Powder metallurgy brake shoe with bent welded structure

The invention relates to a powder metallurgy brake shoe, in particular to a powder metallurgy brake shoe with a bent welded structure, which comprises a steel backing, a skeleton, a plurality of friction blocks, a brake shoe nose and a stopping block, wherein a brake block is formed on one skeleton by sintering friction blocks; the skeleton is welded onto the steel backing. According to the invention, a plurality of friction blocks are welded onto one whole skeleton at the same time, and then, the whole skeleton is welded onto the steel backing, the powder metallurgy brake shoe has the benefits of large friction area, simple structure, high convenience for processing, short processing periods, low cost, low possibility of looseness and flaking off for brake blocks, and high safety.

Owner:贵州新安航空机械有限责任公司

Welding tool for rear installation supporting base of truck body

ActiveCN103801869AReduce welding distortionEasy to assembleWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyEngineering

The invention relates to the technical field of automobile manufacturing, in particular to a welding tool for a rear installation supporting base of a truck body. The welding tool for the rear installation supporting base of the truck body comprises the base, a first air cylinder, a compressing arm, a connection board, a locating base, a second air cylinder, a rotary shaft and a locating pin, wherein the first air cylinder is fixed to the connection board; one end of the compressing arm is in rotary connection with the telescopic end of the first air cylinder; the other end of the compressing arm is fixedly connected with the locating base; the compressing arm is further in rotary connection with the connection board; the second air cylinder is fixed to the base; the telescopic end of the second air cylinder is in rotary connection with the connection board; the connection board is connected with the base through the rotary shaft; the locating pin is located on the connection board. As certain compressing force is exerted on the rear installation supporting base of the single-row truck body, the welding deformation of the rear installation supporting base of the single-row truck body is reduced, the assembly of an assembly shop is improved, and meanwhile through simple and rapid switching, accurate locating and space receding are carried out on third-section longitudinal beams of row-and-a-half truck bodies and double-row truck bodies, and welding is convenient.

Owner:BEIQI FOTON MOTOR CO LTD

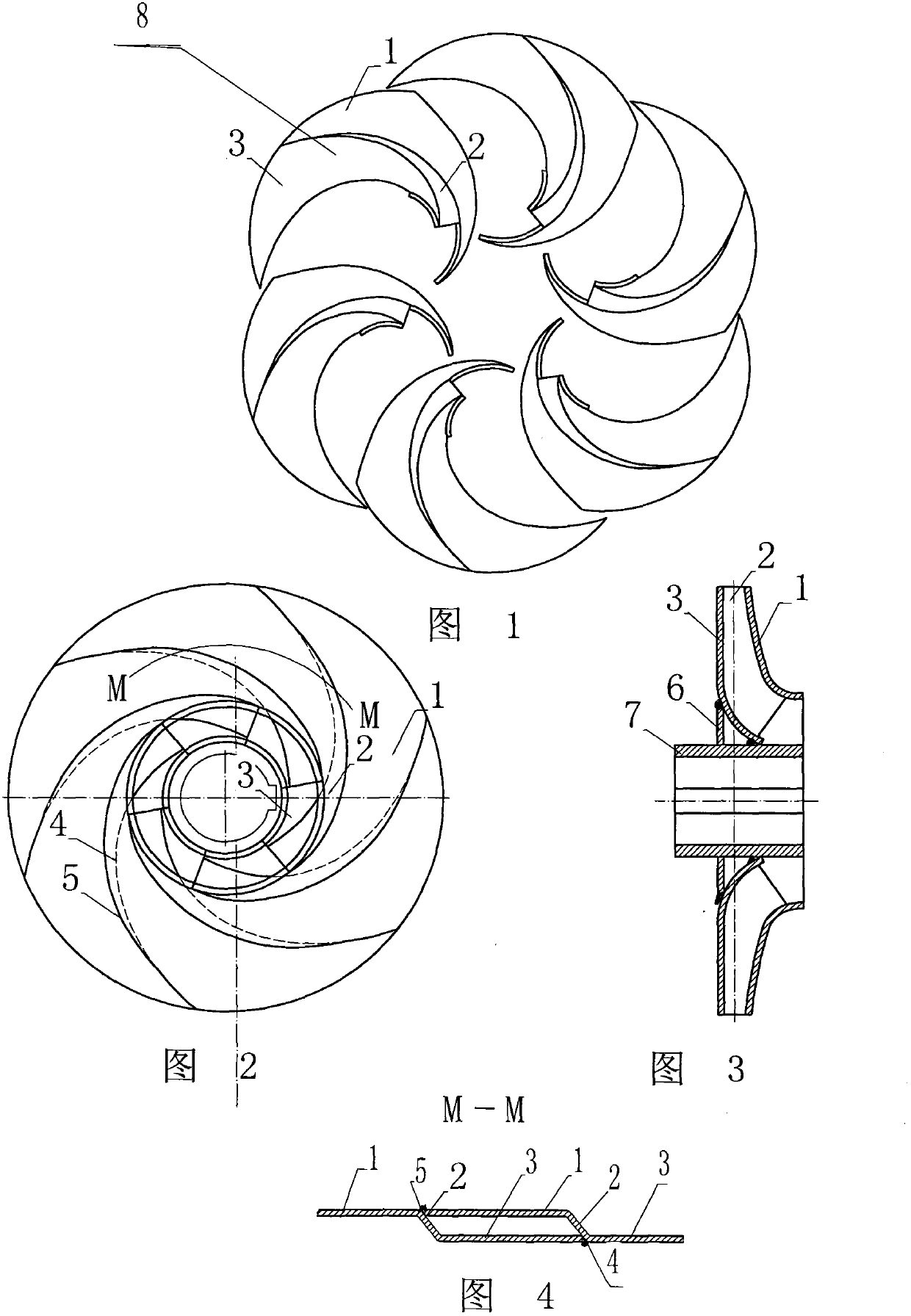

Combined welding type water pump impeller and forming method thereof

ActiveCN102996502AConvenient welding operationSimple welding and formingPump componentsPumpsWeld seamImpeller

The invention discloses a combined welding type water pump impeller and a forming method thereof. The combined welding type water pump impeller is formed by welding a hub, a reinforcing plate and a plurality of impeller flaps; each impeller flap which consists of a rear cover plate flap, a blade and a front cover plate flap is stamped on one plate by using a die; the intersecting lines between the edge line of each rear cover plate flap and the rear cover plate flap as well as between the blade of another rear cover plate flap and the rear cover plate flap are abutted to form a rear welding seam; the intersecting lines between the edge line of each front cover plate flap and the front cover plate flap as well as between the blade of another front cover plate flap and the front cover plate flap are abutted to form a front welding seam; and all the impeller flaps are welded into a whole at the outer sides of the welding seams, and then the hub and the reinforcing plate are welded, therefore the combined welding type water pump impeller can be obtained. According to the combined welding type water pump impeller, the welding seams are formed outside the impeller, so that the welding operation is easily implemented, and no weld beading is generated in a runner. Therefore, the combined welding type water pump impeller is simple to form by welding, the blades are not deformed, the runner is free of resistance, and the technical level and working efficiency of a water pump are improved.

Owner:兴城市水泵制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com