Liquid tank container

A container and liquid tank technology, applied in the field of large rigid equipment, can solve the problems of unfavorable tank body maintenance, falling off, cracking at the welding seam of the tank body, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

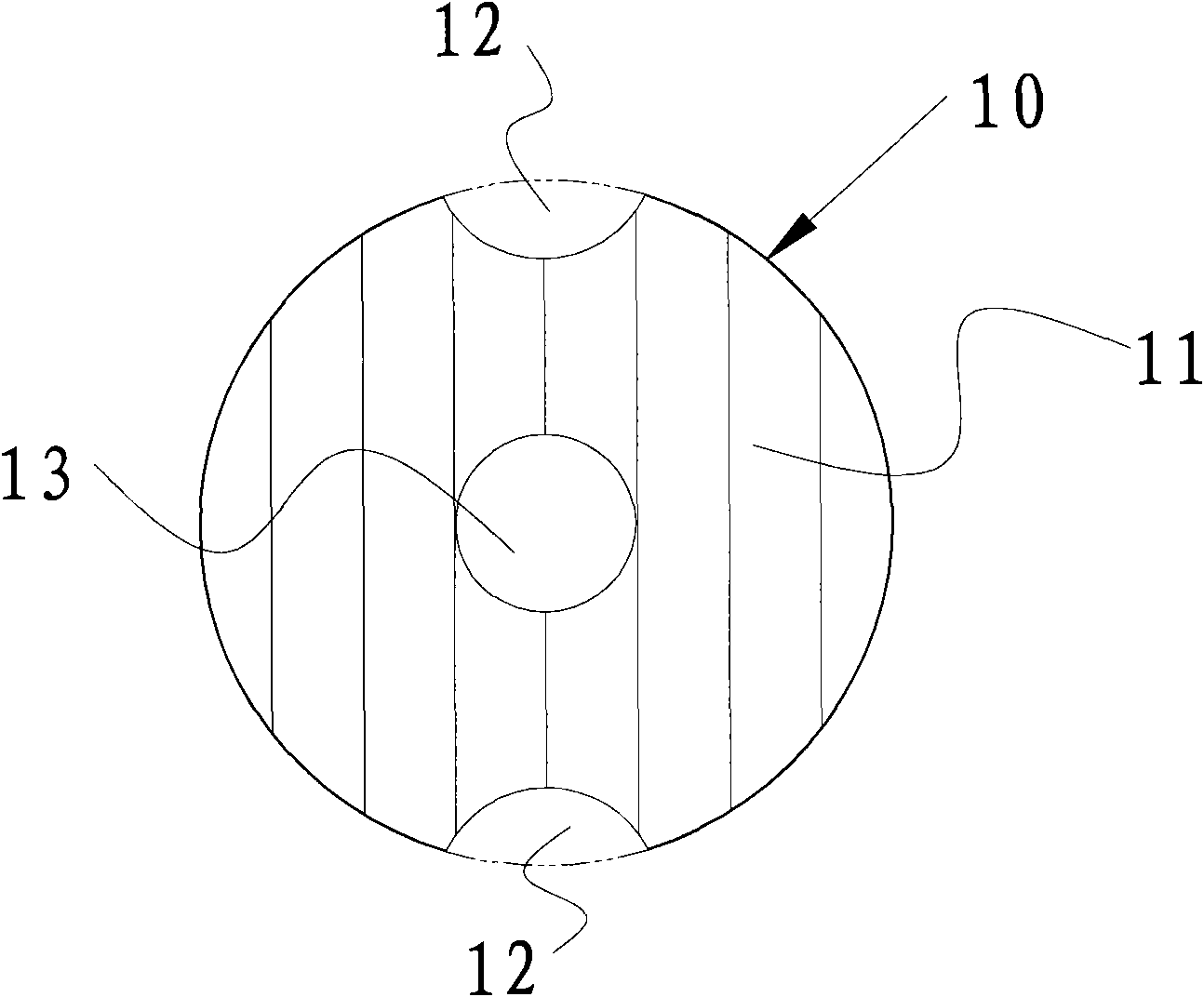

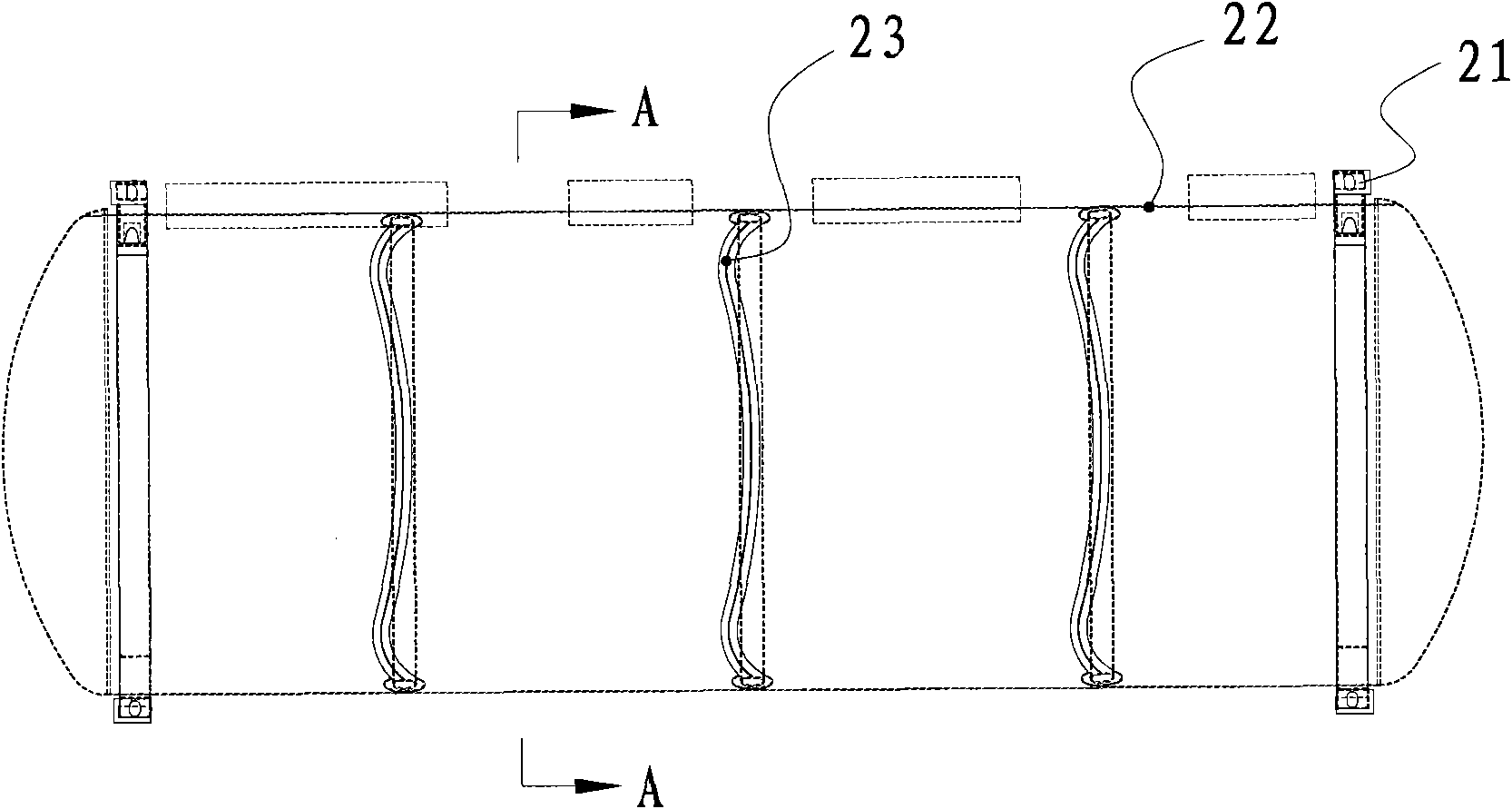

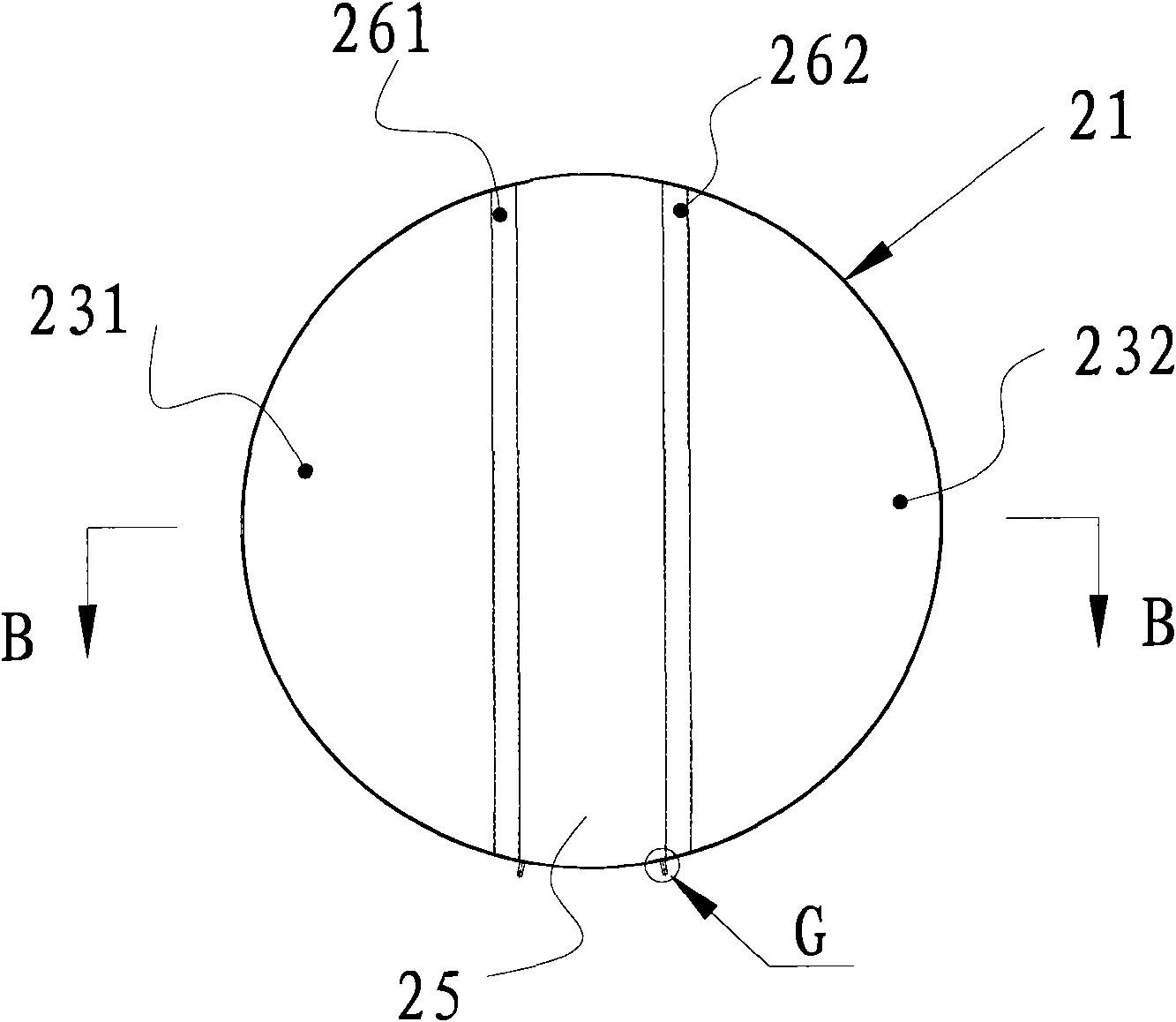

[0039] Such as figure 2 A liquid tank container is shown, which includes a rigid frame body 21 and a tank body 22 welded to the rigid frame body 21 and arranged inside the frame body 21 . The tank body 22 is provided with a wave-proof plate 23 welded along the horizontal direction of the tank body, combined with image 3 , Figure 4 , Figure 5 as well as Figure 6 As shown, the anti-wave plate 23 is composed of a left unit anti-wave plate 231 and a right unit anti-wave plate 232 with an arc-shaped cross section and left and right symmetrical arrangements. A channel 25 is formed between the left unit anti-wave plate 231 and the right unit anti-wave plate 232. One person can be allowed to walk through, on the one hand, it is convenient for maintenance personnel to pass through, and at the same time, the bottom of the tank is in a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com