Simple automobile welding fixture

A welding jig, automobile technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high manufacturing cost, troublesome operation, complicated structure, etc., and achieve convenient operation, low cost and simple overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

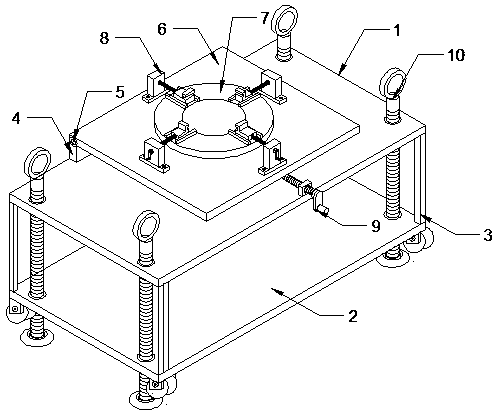

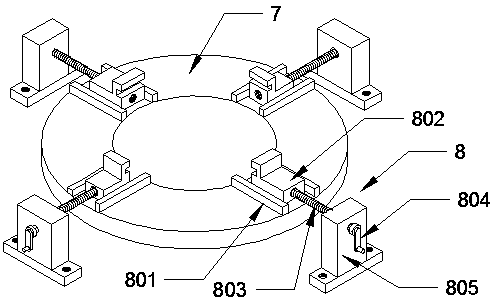

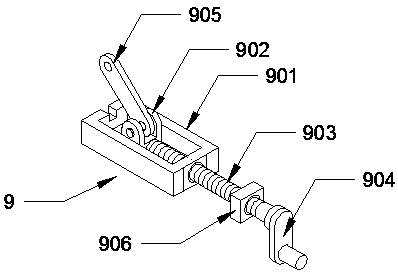

[0028] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a simple automobile welding fixture of the present invention comprises a top panel 1 and a bottom panel 2, four corners at the bottom of the top panel 1 are fixedly provided with support legs 3, and the other ends of the four support legs 3 are respectively connected to The four corners of the bottom panel 2 are fixedly connected, and the middle part of the top side of the top panel 1 is fixedly provided with a support plate 4, and the support plate 4 is connected to the workbench 6 through the rotating shaft 5, and the top of the workbench 6 is provided with an annular piece 7, Four clamping mechanisms 8 are equidistantly arranged on the top of the annular piece 7, and each clamping mechanism 8 all comprises a chute 801, a first slider 802, a first threaded rod 803, a first rotating handle 804 and a T-shaped The connecting block 805, the chute 801 is located on the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com