High-toughness and high-strength steel electrode for 60kg all position welding

An all-position welding, kilogram-level technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor welding process of electric electrode and unstable weld metal toughness, and achieve low manufacturing cost, Excellent comprehensive mechanical properties and stable weld metal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0016] Embodiment 1-4 prepares electrode of the present invention

[0017] The welding core is made of carbon steel core, and its chemical composition and mass fraction are as follows:

[0018] C

mn

Si

S

P

≤0.10

0.35-0.60

≤0.03

≤0.010

≤0.010

[0019] Get each component of drug skin by table 1 and mix homogeneously, add potassium sodium mixing water glass and stir, add-on is: embodiment 1, drug skin total amount 18%; Embodiment 2, drug skin total amount 20%; Embodiment 3, the total amount of the drug skin is 22%; embodiment 4, the total amount of the drug skin is 26%. Afterwards, special equipment for the production of welding rod industry is used to evenly coat it on the welding core. After grinding out the clamping end and arc starting end, it is sent to the welding rod drying furnace through low temperature 50-90 ℃, medium temperature 90-150 ℃, high temperature 350 Dry at -400°C in three stages, each st...

experiment example 1

[0023] Experimental Examples 1-4 The properties of the electrodes prepared in Examples 1-4 were tested.

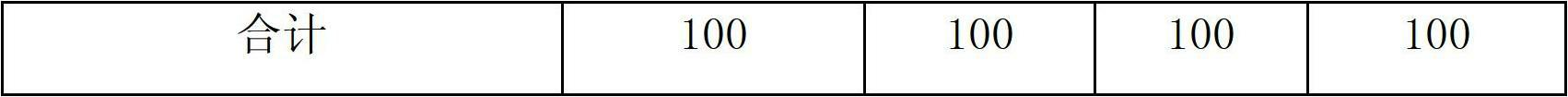

[0024] The mechanical properties of the deposited metal of the low-temperature structural steel electrode prepared in Examples 1-4 were tested according to conventional methods in the industry, and the results are shown in Table 2.

[0025] Table 2

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com