Full-automatic reinforcing mesh welding production line

A welding production line, fully automated technology, applied in the direction of wire mesh, wire processing, and other household appliances, can solve the problems of non-continuous work, inconsistent solder joint pressure, and long operation time, so as to improve production efficiency and production capacity. The welding operation is convenient and fast, and the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

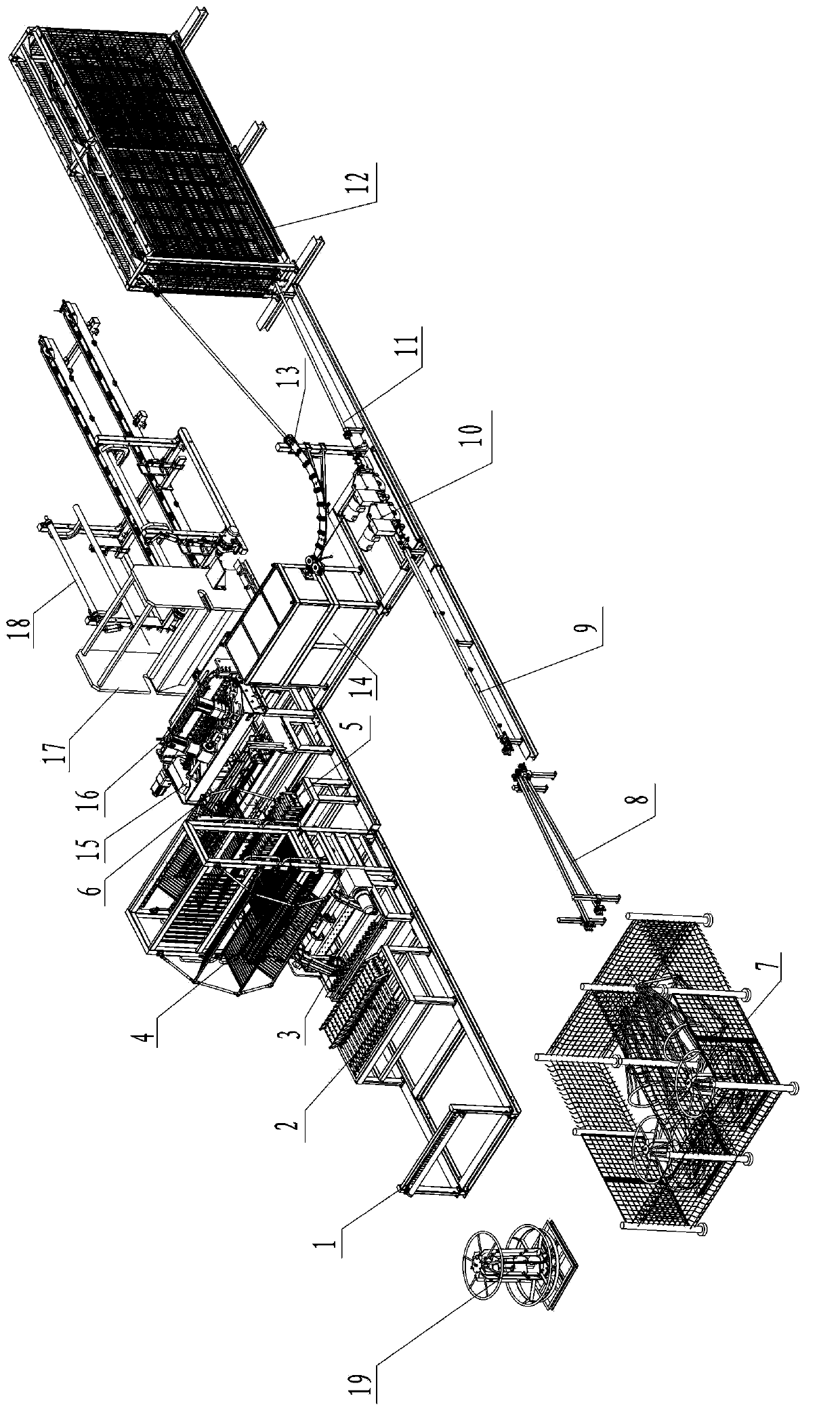

[0097] The fully automatic steel mesh welding production line of the present invention includes a longitudinal wire production section for processing longitudinal wires, a horizontal wire production section for processing horizontal wires, and a welding machine for welding and outputting vertical wires and horizontal wires output section. Such as figure 1 As shown, the vertical line production section and the horizontal line production section are two in parallel.

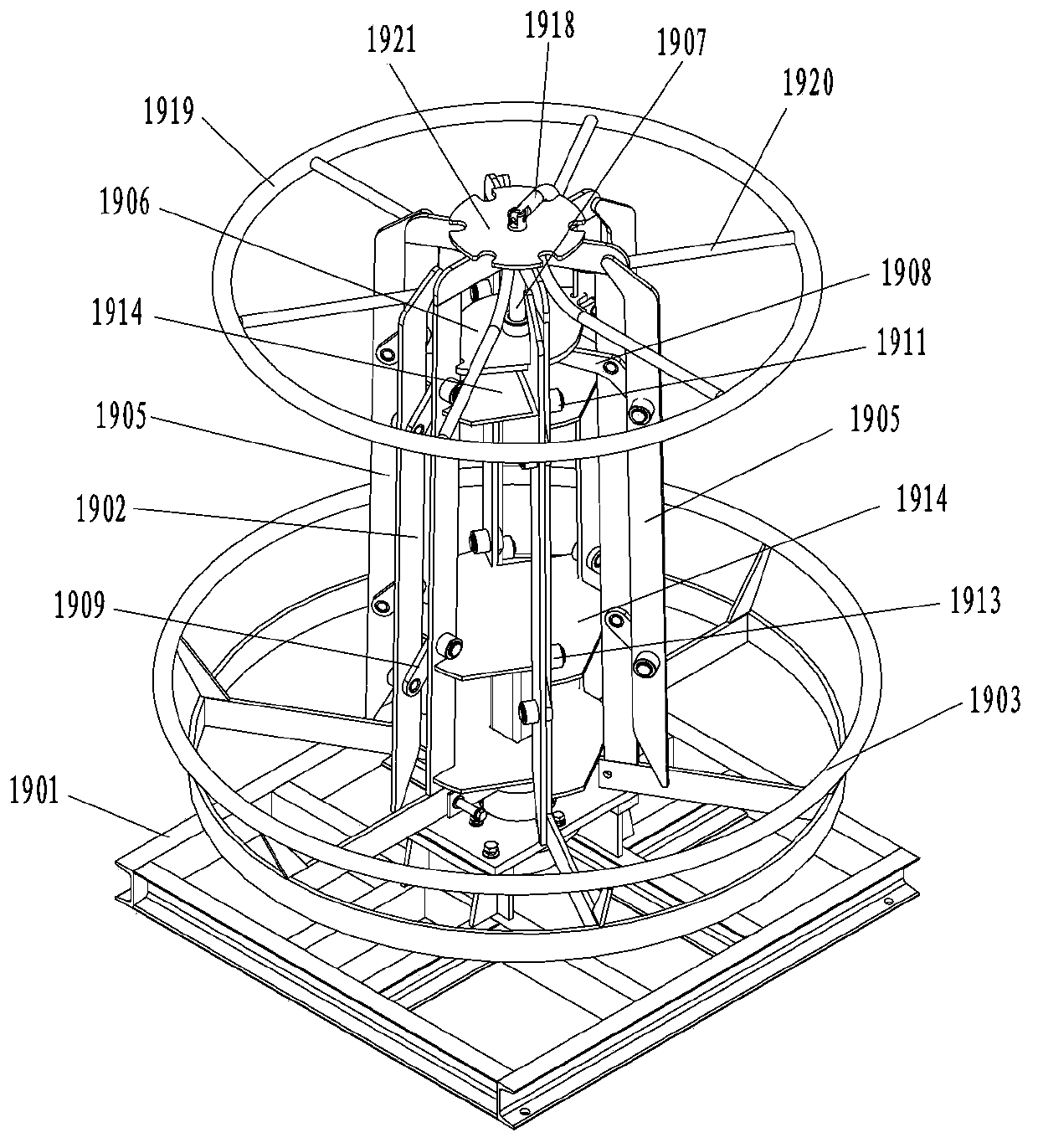

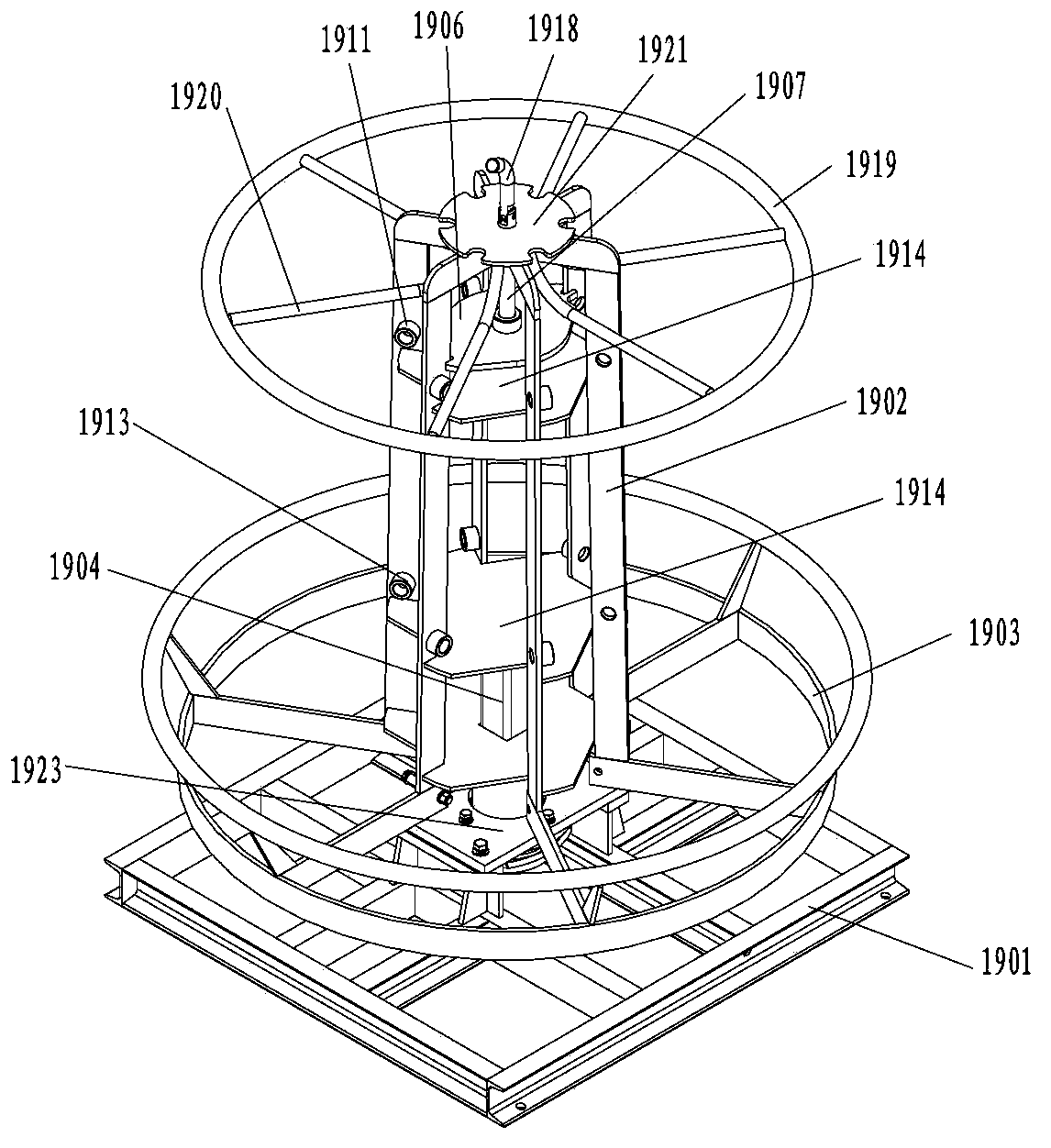

[0098] The longitudinal thread production section includes: a longitudinal thread pay-off reel 19 arranged in sequence for winding and storing the longitudinal thread, and a double-row straightening device for straightening the longitudinal thread conveyed by the longitudinal thread pay-off reel 19 2. Longitudinal wire st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com