Patents

Literature

69results about How to "Offset deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

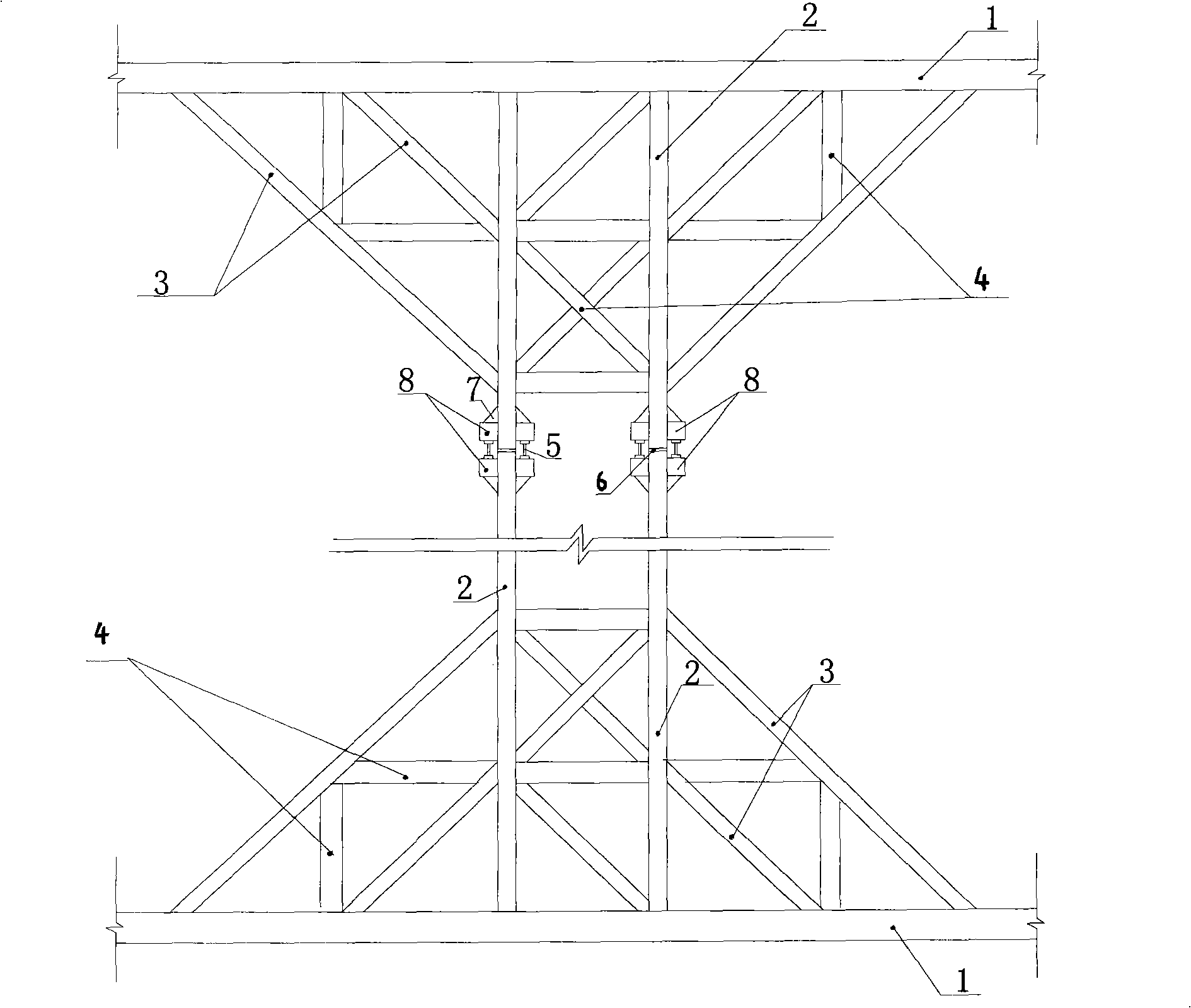

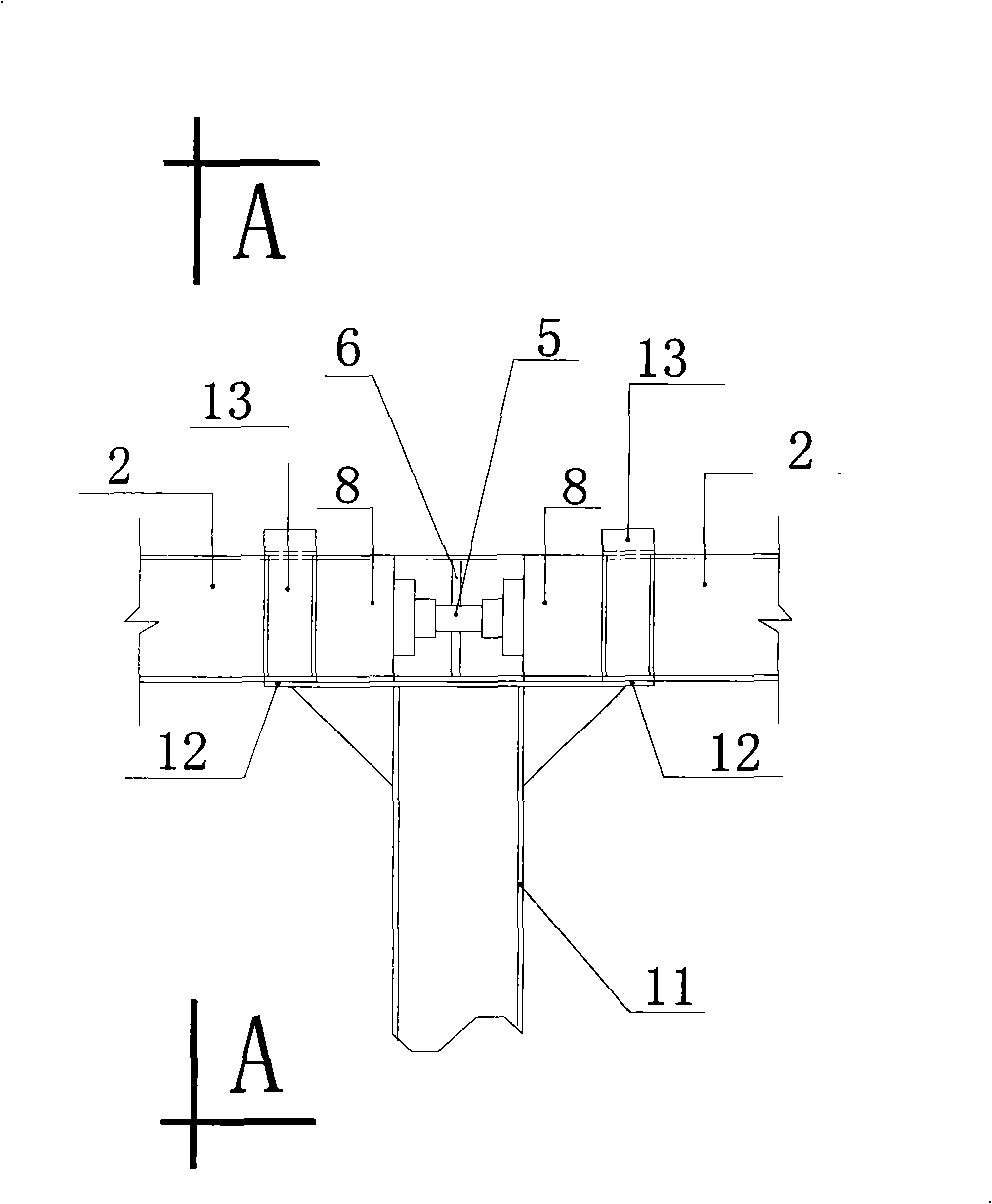

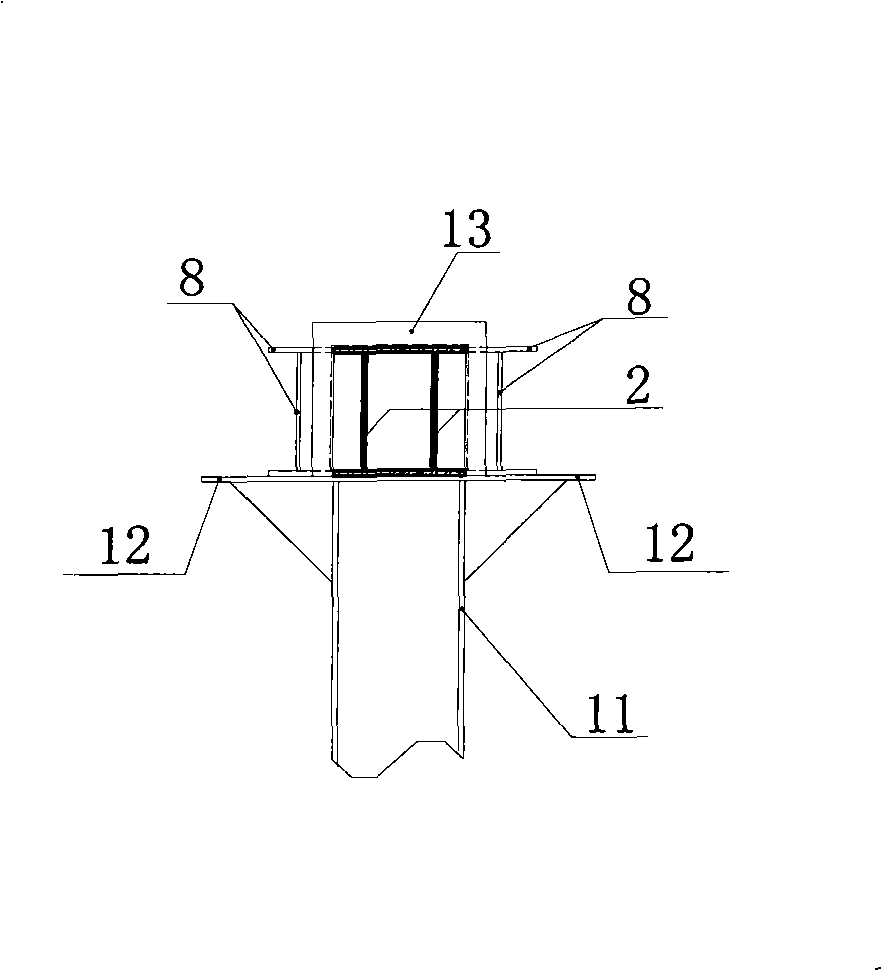

Deep building pit trussed-beam inner support integral application pre-stress method

InactiveCN101255697AWide range of applicationsIncrease the scope of applicationExcavationsPre stressingPre stress

The present invention relates to a method for wholly exerting pre-stress to the trussed internal bearing in the deep foundation pitch. The method comprises the following steps: installing an internal bearing which is composed of a principal top brace, a diagonal rod and a web rod or composed of a principal top brace and a web rod, and installing the trussed internal bearing between two pit walls of the deep foundation pitches; (2) installing a pre-stress force-transferring seat along the axial direction of the principal top brace on each principal top brace; (3) arranging a jack along the axial direction between two pre-stress force-transferring seats of each principal top brace; and (4) cutting off the principal top brace between two force-transferring seats of each principal top brace, exerting pre-stress with the jack, and when the pre-stress which should be exerted is obtained, reinforcing and welding the gap which is between the fracture surface of the cut principal top brace and is generated by exerting pre-stress with the steel material. The method has the advantages of quick installation, short time period for exerting pre-stress, being able to counteracting the compressing deformation of the member bar, and being able to quickly and effectively control the deformation in the deep foundation pitch.

Owner:CHINA FIRST METALLURGICAL GROUP

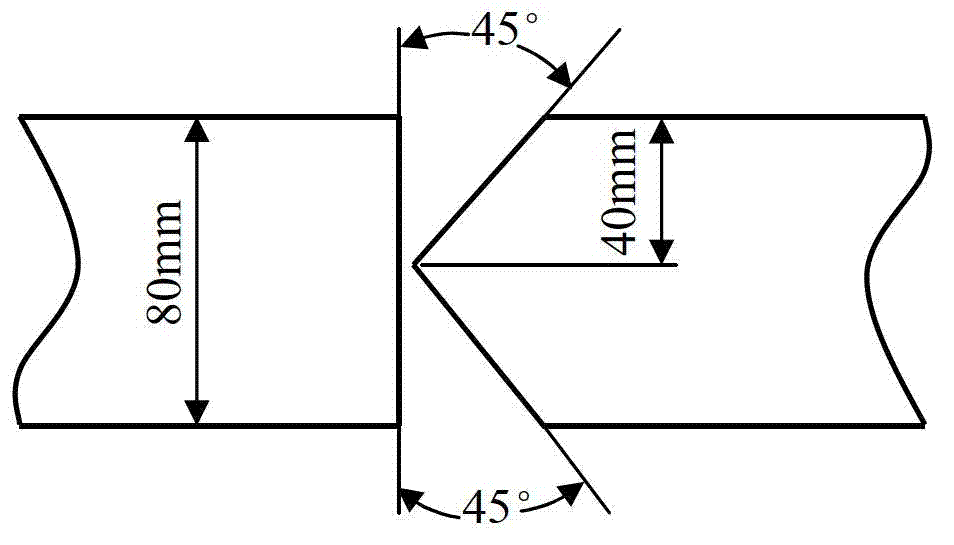

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

New process method for manufacturing mold capable of ensuring size accuracy of cast blade for large-scale water turbine

ActiveCN101716654AUnique material selectionEasy to implementFoundry mouldsFoundry coresWater turbineCasting mold

The invention relates to a new process method for manufacturing a mold capable of ensuring the size accuracy of a cast blade for a large-scale water turbine. The method is characterized by comprising the following steps of: selecting materials; designing a technical scheme for manufacturing the mold; establishing a three-dimensional model for manufacturing the mold; manufacturing a mold blank; processing the mold; and detecting the mold. The process method of the invention is unique and solves the problem that a distorted-surface blade casting mold has low manufacturing efficiency and that the kind of casting mold manufactured by the traditional manual method cannot achieve the accuracy of a design size. The method solves the deformation problem of the mold per se and ensures the size accuracy of a blade-type mold through the research and application of a new material and a new method in a mold manufacturing process.

Owner:KOCEL EQUIP

Construction method for manufacturing box type column and beam

The invention relates to the technical field of construction, and aims to provide a construction method for manufacturing a box type column and beam. The construction method can effectively reduce welding deformation and reduce the later correction cost. According to the technical scheme adopted in the method, the construction method for manufacturing the box type column and beam comprises the steps of A, marking off, B, marking out, C, discharging, D, groove machining, E, body assembling, F, end plate assembling and G, rust removing and painting. According to the construction method, throughthe reasonable welding sequence and welding manner, deformation is effectively reduced, the later correction cost is reduced, and the economic benefits are improved.

Owner:云南建投机械制造安装工程有限公司

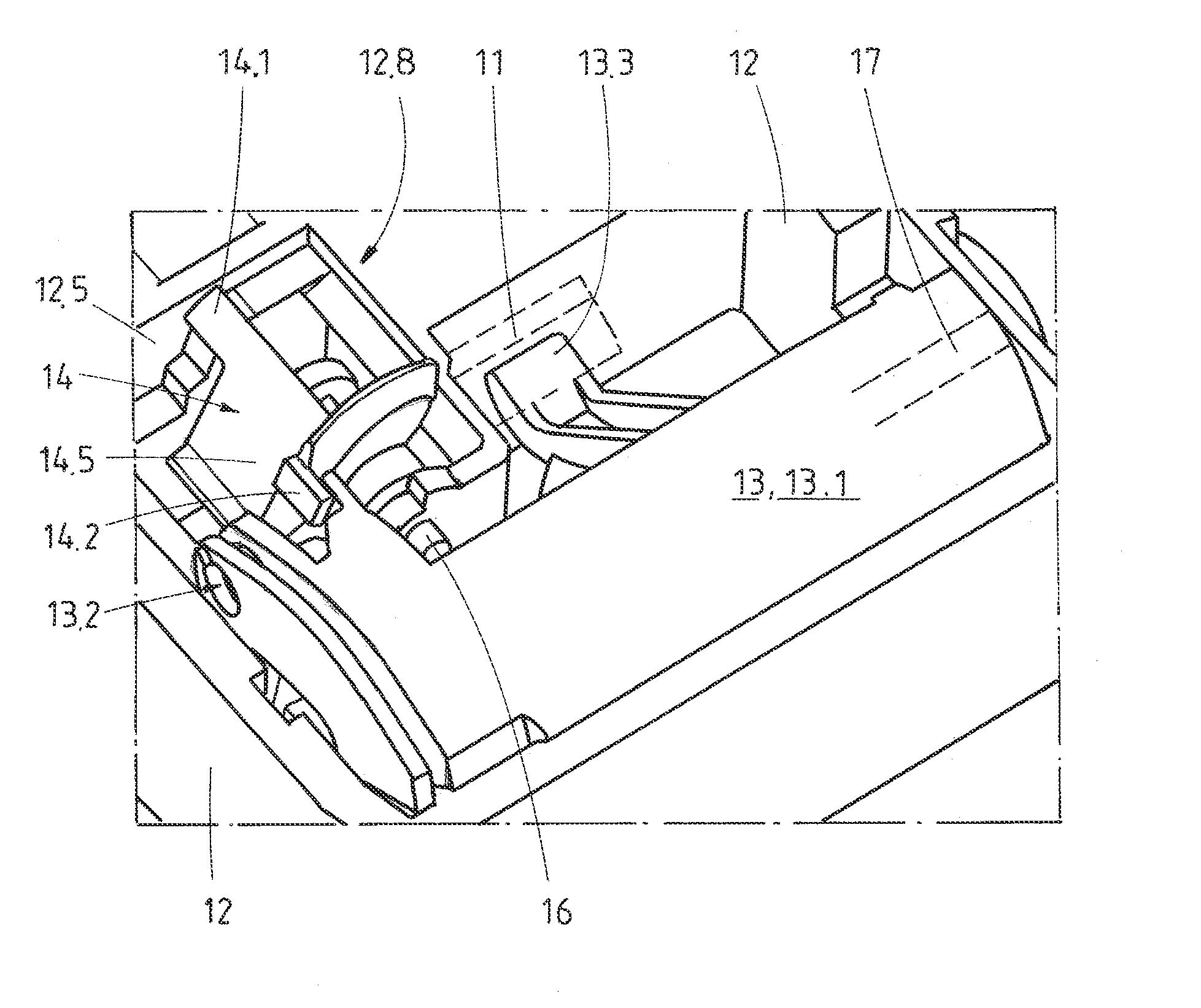

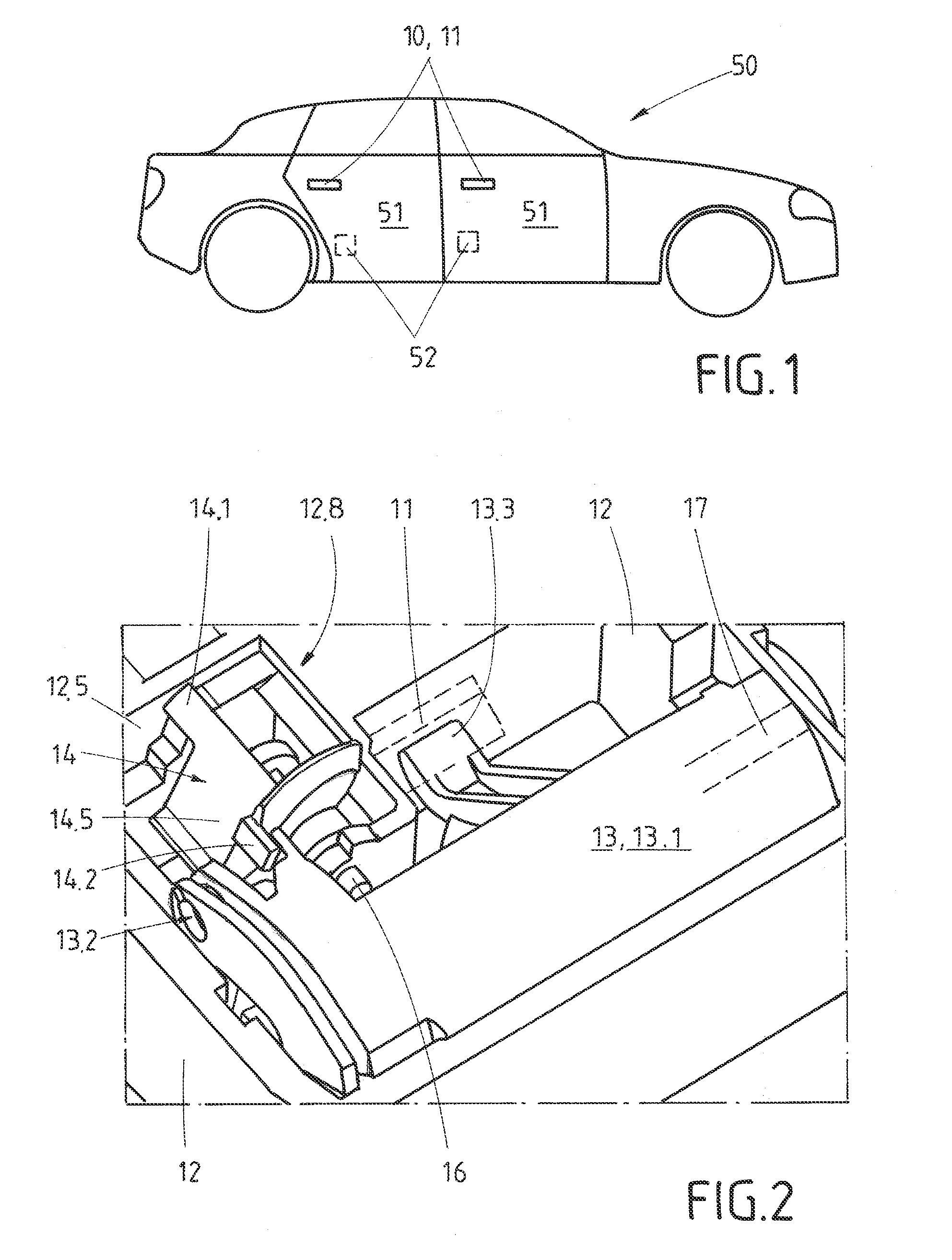

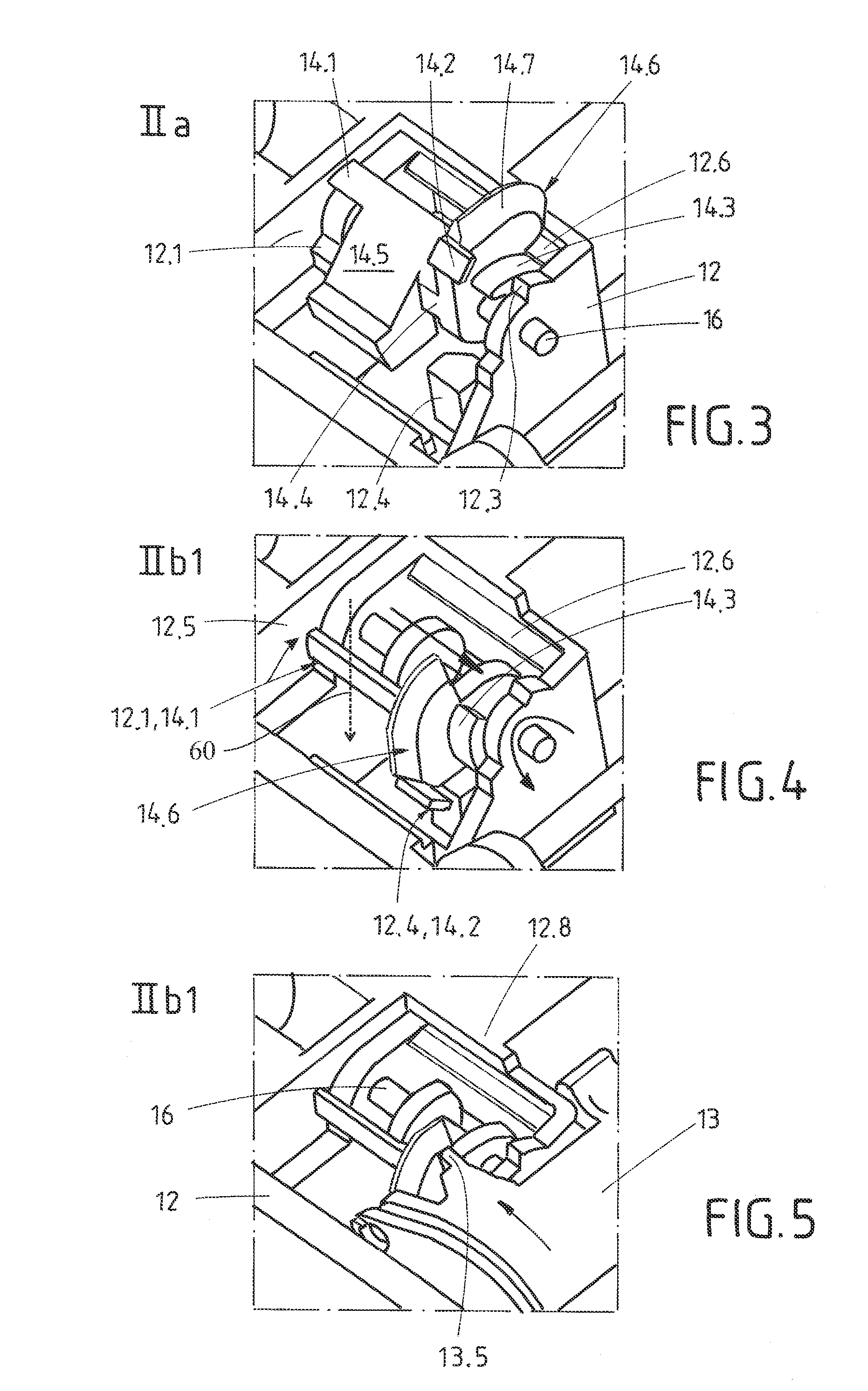

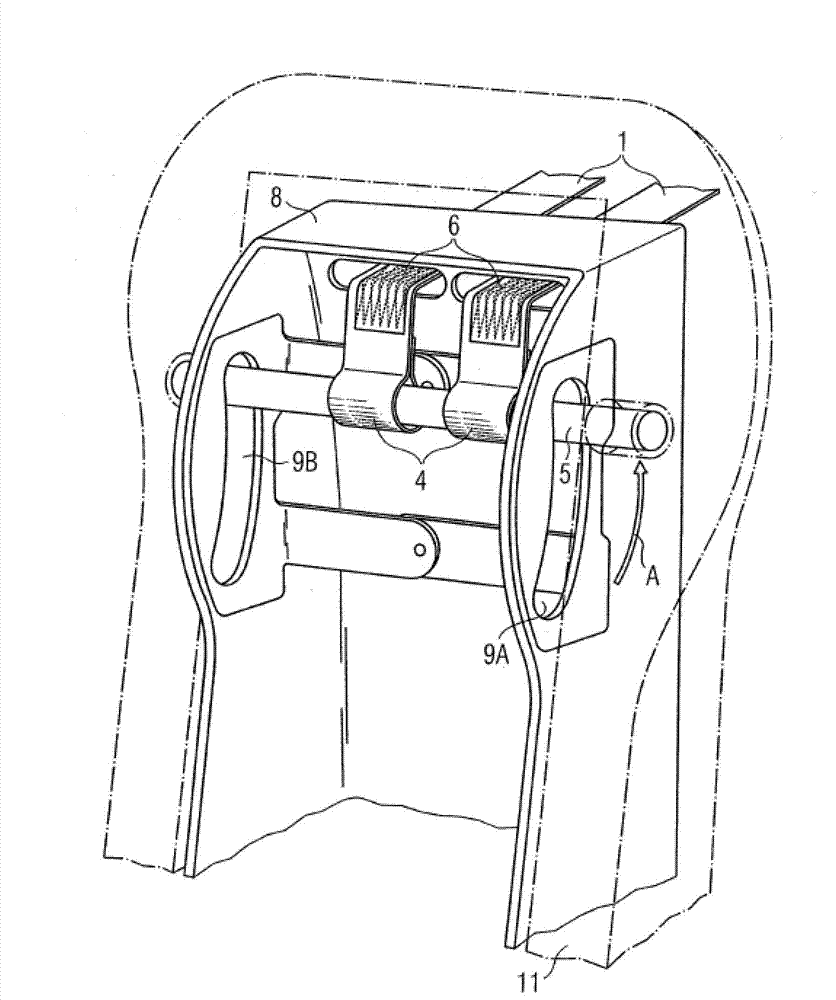

Secure door handle unit

ActiveUS9151090B2Operation is commonOffset deformationAutomatic securing/unlockingAccident situation locksRest positionCoupling

The invention relates to a door handle unit for a lock in a vehicle with a door handle to open a door by a user, an operating unit showing at least the door handle, a coupling unit, or a combination of the door handle and the coupling unit, where by the mechanical coupling unit a motion of the door handle from a resting position into a operating position can be transferred to the lock, a crash block with a normal position, allowing a motion of the operating unit to operate the lock, and with a blocking position, which results during or after the impact of a force of acceleration, blocking any motion of the operating unit such that any operation of the lock is prevented, characterized in that the crash block in its blocking position can be transferred by a motion of the operating unit into the normal position.

Owner:HUF HULSBECK & FURST GMBH & CO KG

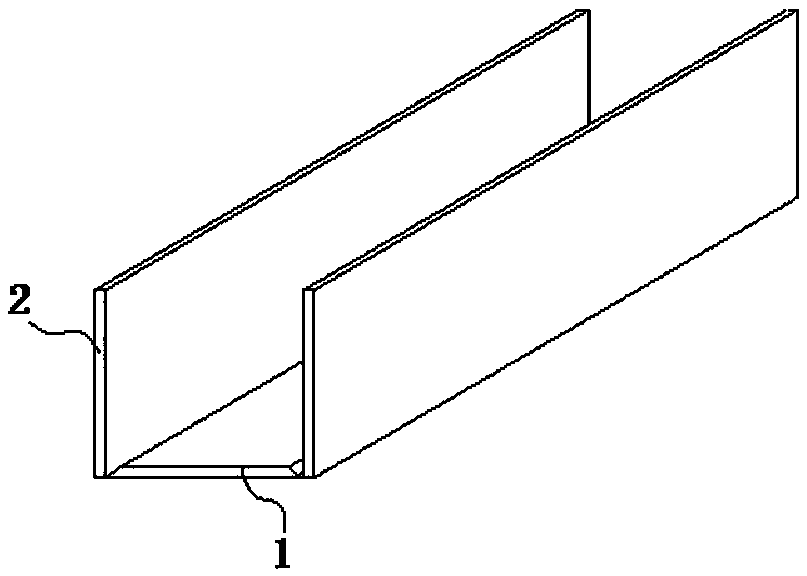

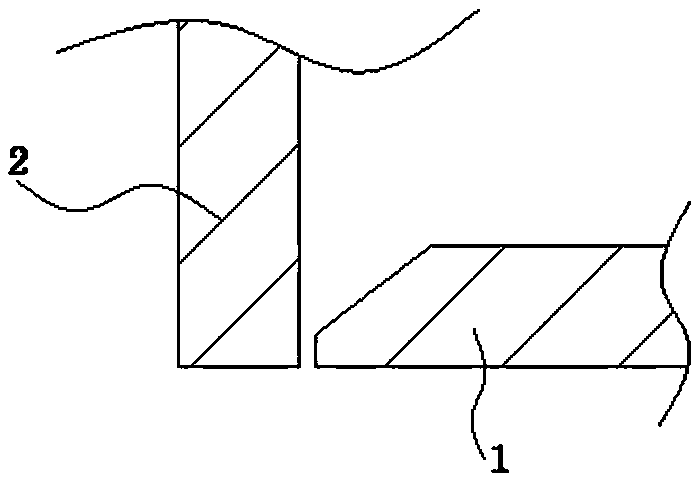

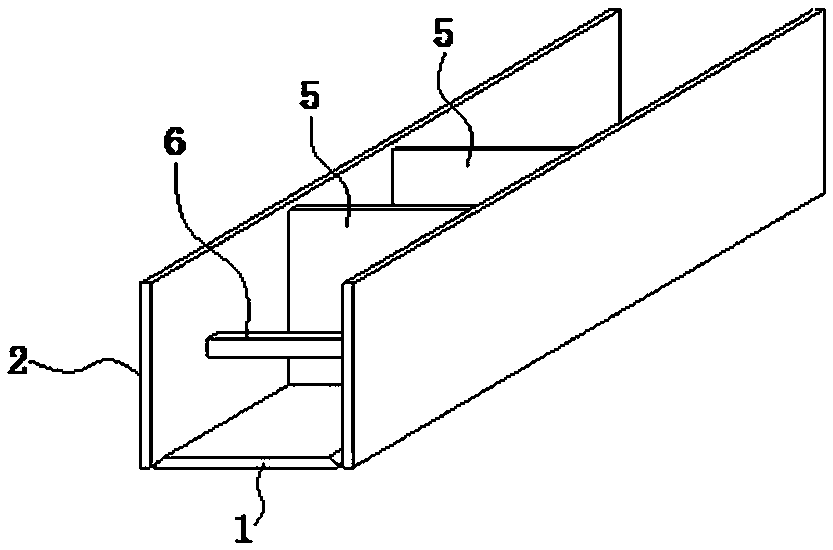

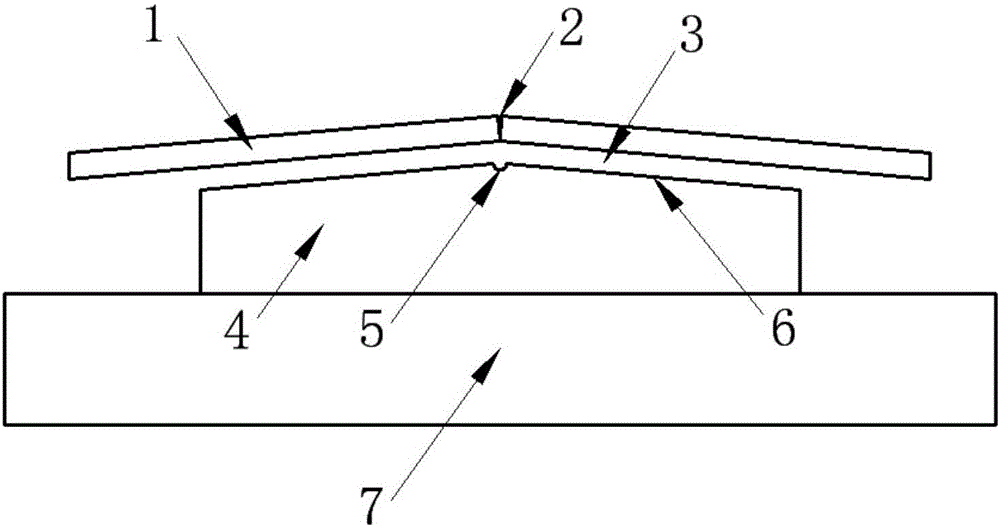

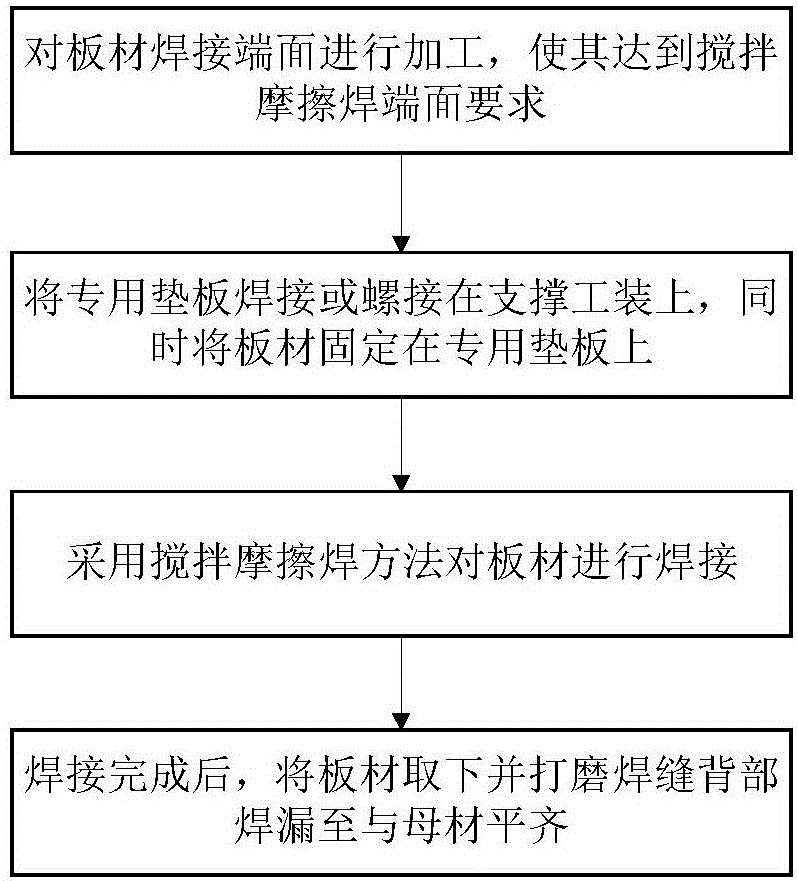

Special backing plate for friction-stir welding and welding method adopting backing plate

InactiveCN106513981AEasy to operateAdaptableWelding/soldering/cutting articlesNon-electric welding apparatusMechanical engineeringFriction stir welding

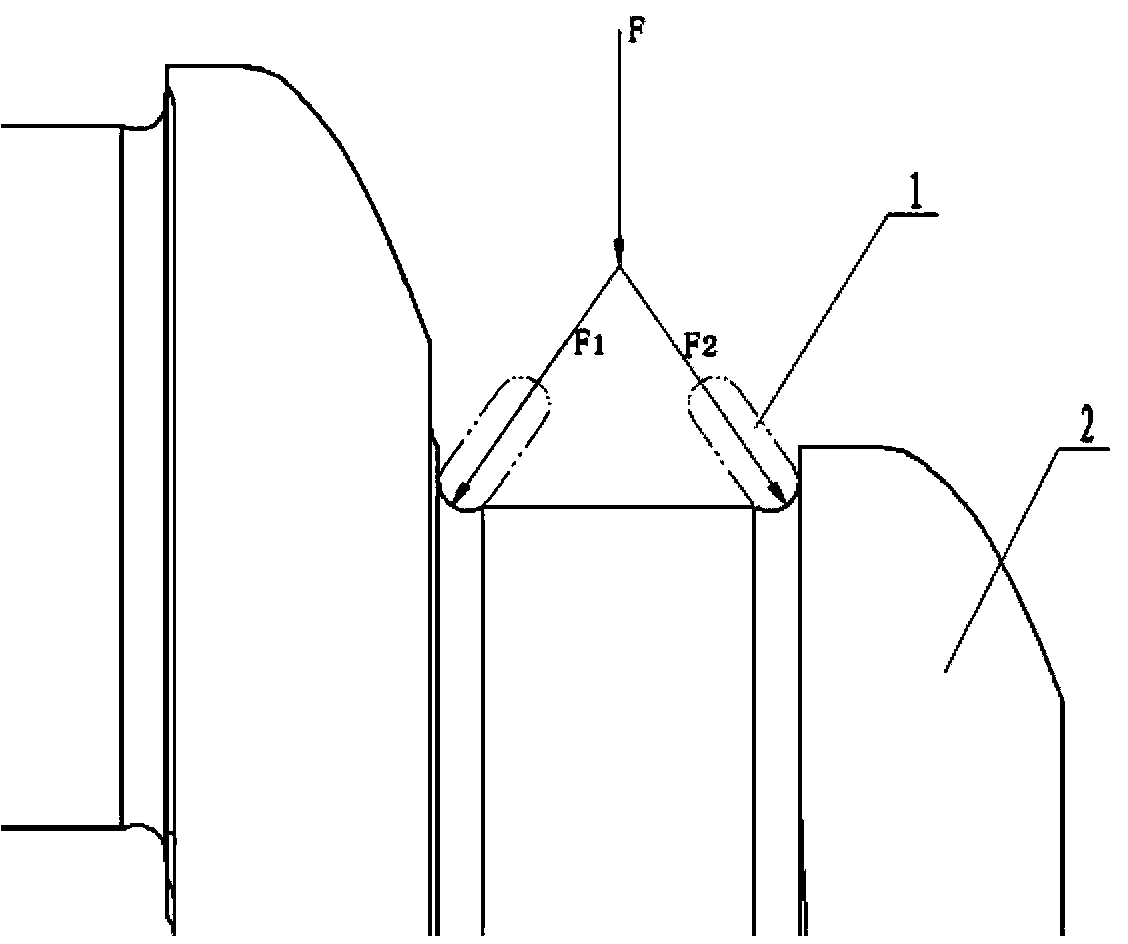

The invention provides a special backing plate for friction-stir welding and a welding method adopting the backing plate. A U-shaped or V-shaped welding leakage groove is formed in the center line of the special backing plate in the length direction. The welding leakage groove is located under a weld joint so that incomplete-penetration materials on the back of the weld joint can be squeezed into the welding leakage groove. The two sides of the welding leakage groove are bevels. The angles of the bevels are determined according to deformation of the plate. Through the special backing plate for friction-stir welding and the welding method adopting the backing plate, the incomplete-penetration materials on the back of the weld joint can be squeezed into the welding leakage groove; through the subsequent incomplete-penetration grinding procedure, the incomplete-penetration materials on the back of the weld joint are removed thoroughly, and complete penetration of the weld joint is realized. The two sides of the welding leakage groove are machined into the bevels used for conducting pre-welding predeformation on aluminum alloy plates so as to offset deformation generated in the welding process. Operation is easy. The adaptability is high.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

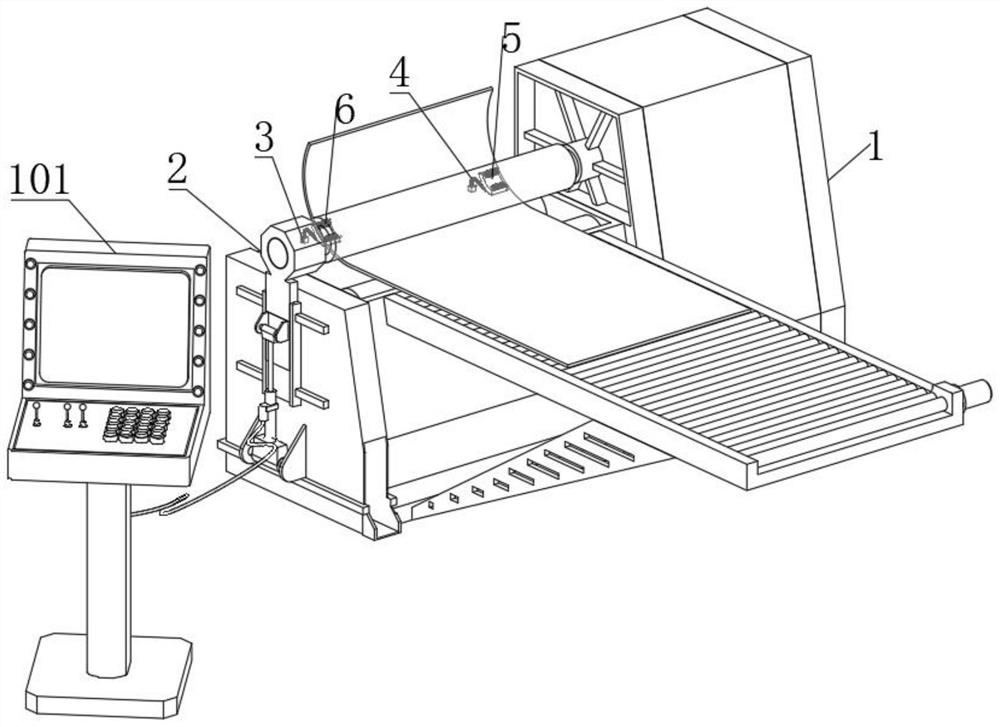

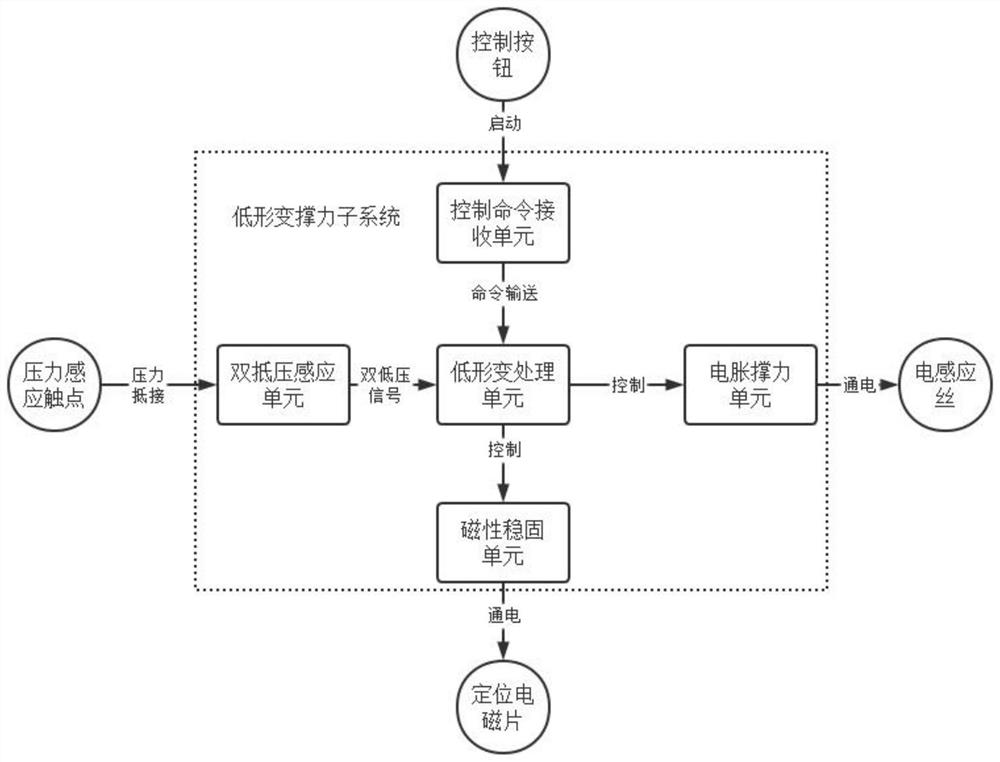

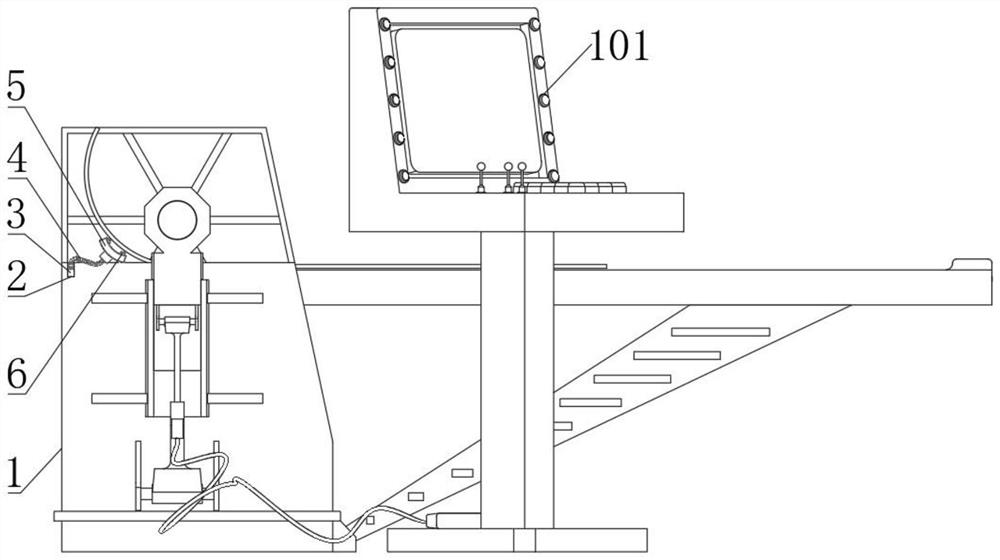

Low-deformation plate rolling machine

PendingCN114472626AEffective Surface PreservationImprove molding qualityClassical mechanicsEngineering

The invention belongs to the field of veneer reeling machines, and discloses a low-deformation veneer reeling machine which comprises a veneer reeling machine body, a supporting force rear plate is fixedly installed at the rear end of the veneer reeling machine body, a pair of cavity conversion sliding seats is slidably connected to the upper end of the supporting force rear plate, gooseneck hollow pipes are fixedly connected to the upper ends of the cavity conversion sliding seats, and the gooseneck hollow pipes are fixedly connected to the lower ends of the cavity conversion sliding seats. The right end of the gooseneck hollow pipe is fixedly connected with an isolation connector, the right end of the isolation connector is fixedly connected with an arc-shaped isolation supporting plate, and a pair of force bearing grooves are formed in the right end of the arc-shaped isolation supporting plate. Buffer and reverse acting force support is provided for a bent plate, the influence of deformation force of the plate and the pressure of a follow-up plate bending machine is reduced, the curved surface of the bent plate is effectively kept, the forming quality of the plate is improved, the bending precision of the plate is improved, and development of the plate bending machine body towards high-precision machining is facilitated.

Owner:HT METALFORMING EQUIP MFG

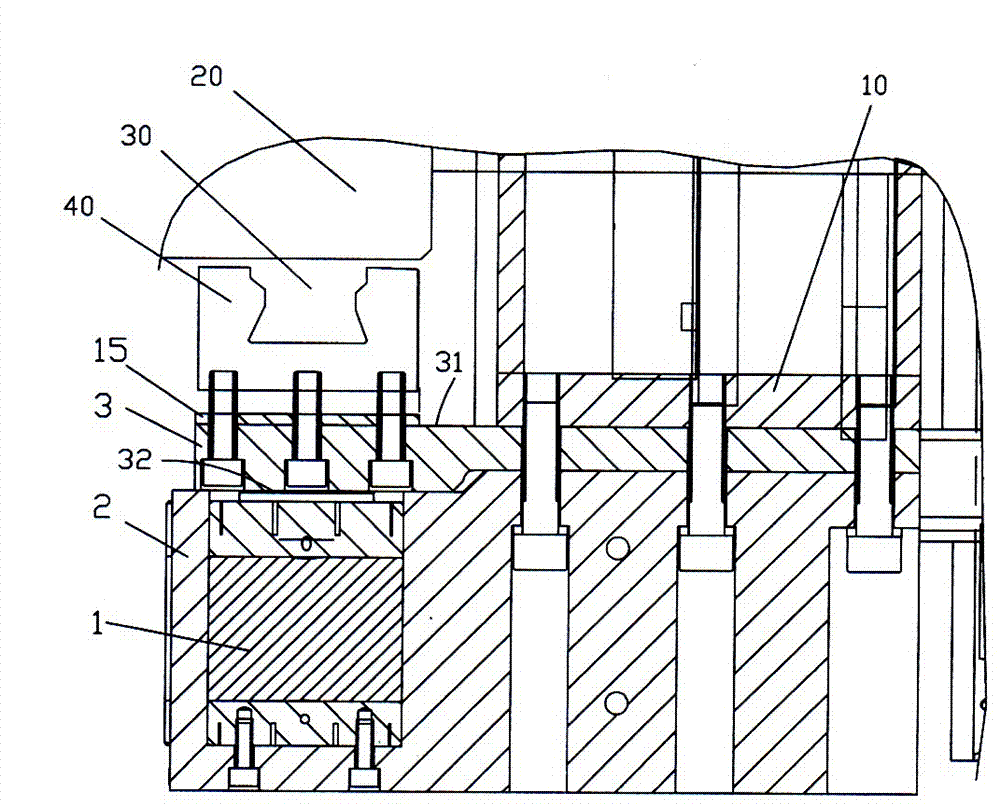

Hydrostatic pressure guide rail system with actively controllable oil film thickness

ActiveCN112077616AExcellent thickness dynamic control abilityImprove toleranceLarge fixed membersThermodynamicsReal-time data

The invention discloses a hydrostatic pressure guide rail system with actively controllable oil film thickness. The hydrostatic pressure guide rail system comprises a base, a thrust plate assembly, aslide carriage, a pressure cover plate, a temperature sensing device and a displacement sensing device, wherein the base, the thrust plate assembly and the slide carriage form a main oil film cavity;the temperature sensing device collects temperature data of the main oil film cavity; the pressure cover plate and the thrust plate assembly form an auxiliary oil film cavity; the displacement sensingdevice collects displacement data of the thrust plate assembly in the auxiliary oil film cavity to obtain thickness data of a main oil film; and the pressure and the flow rate of the auxiliary oil film cavity are regulated on the basis of the real-time data of the temperature and the thickness of the main oil film without changing the pressure and the flow rate of the main oil film cavity, so that the bearing capability and the rigidity of a hydrostatic pressure guide rail can be ensured while the thickness of the main oil film is controlled. The main oil film is indirectly controlled throughcontrolling an auxiliary oil film, so that the control on the main oil film is realized, and the change of the rigidity and the load capability of the guide rail is also avoided.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

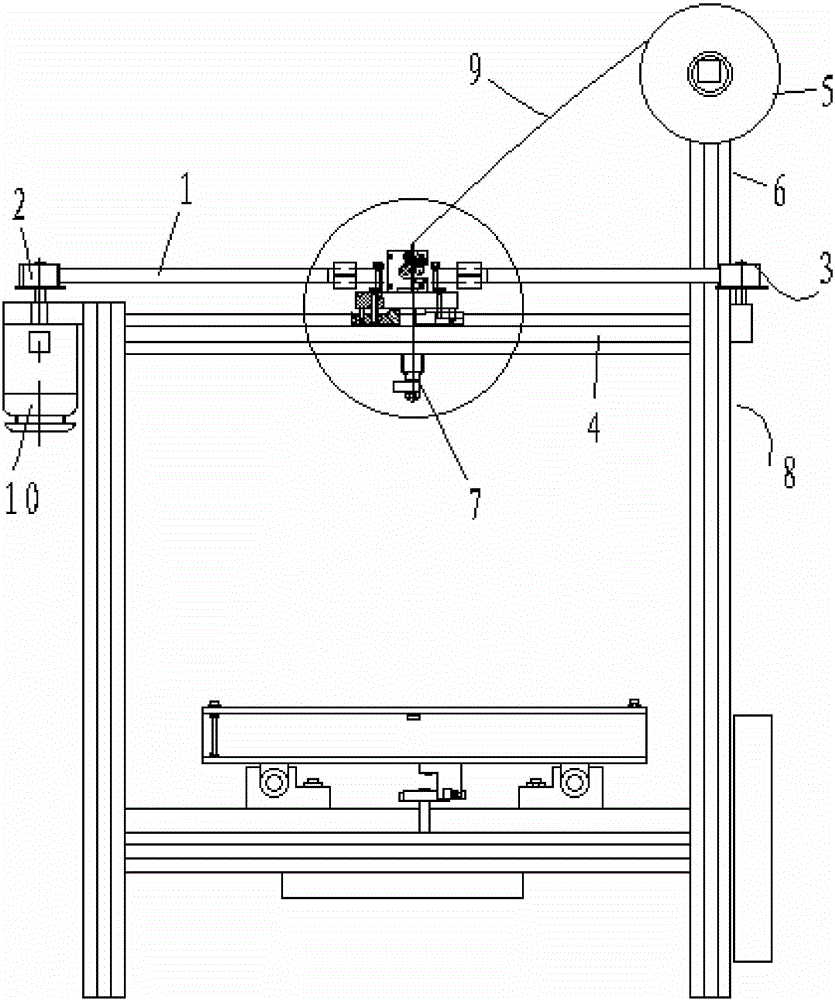

Printing head walking structure of 3D printer

InactiveCN105014969AEasy tension adjustmentExtended service lifeAdditive manufacturing apparatus3d printAgricultural engineering

Owner:UNIV OF JINAN

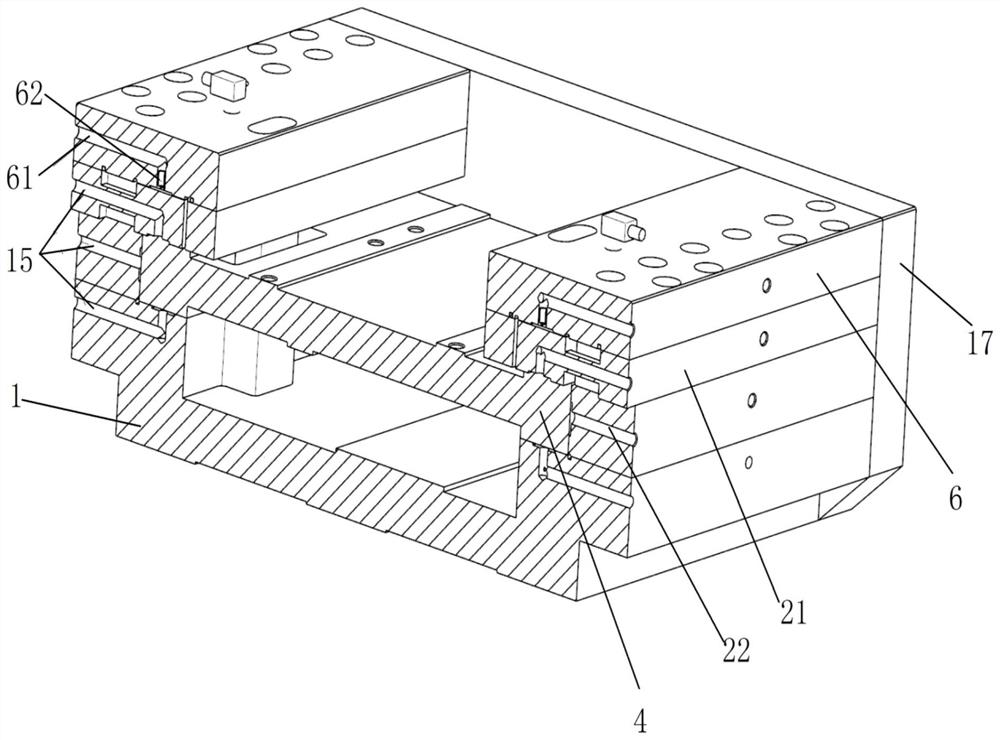

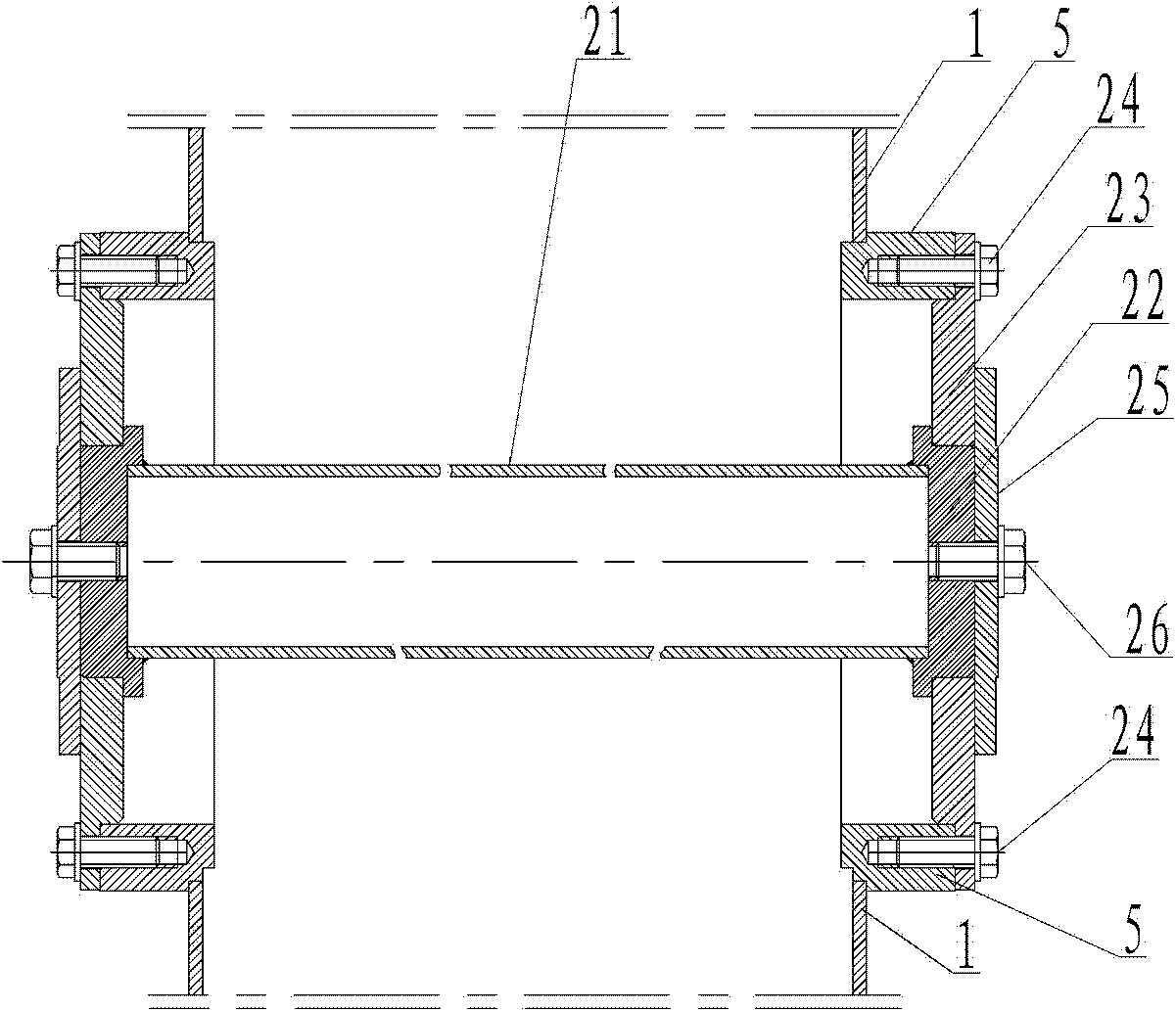

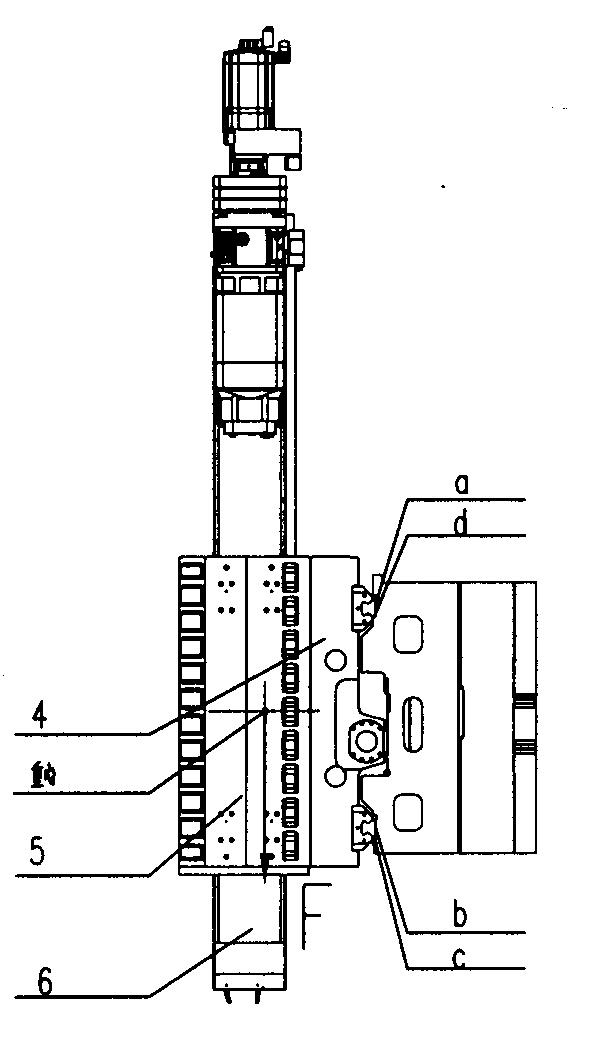

Compensation mechanism for stress deformation of spindle box of machine tool

InactiveCN102179719BOffset deformationIncrease the support pointLarge fixed membersMaintainance and safety accessoriesThermal deformationGravity center

The invention relates to a compensation mechanism for stress deformation of a spindle box of a machine tool, wherein the spindle box is arranged between two upright columns, thereby forming a gate-type thermal deformation symmetrical structure; two guide rails and sliding blocks are respectively arranged on front and back contact walls between the spindle box and the two upright columns, thereby forming a vertical guiding support; the compensation mechanism further comprises two compensation cylinders, two transition connection plates and two support shells; the two compensation cylinders arerespectively arranged in the two support shells; the two support shells are symmetrically arranged at two sides of the upper end face on the rear part of the spindle box; two ends on one side wall ofeach transition connection plate are respectively connected to two sides of the upper end face on the rear part of the spindle box and corresponding to the sliding blocks of the guide rails; the two support shells, in which the compensation cylinders are arranged, are respectively arranged on the other side walls of the transition connection plates corresponding to the sliding blocks; and the piston rod ends of the compensation cylinders prop against the other side walls of the transition connection plates corresponding to the sliding blocks. According to the compensation mechanism provided by the invention, the deformation compensation mechanism is arranged inside a sliding sleeper. The compensation mechanism provided by the invention can be used for solving the problem of suspension stretching flexible deformation caused by the change of gravity center of a spindle component in the moving process of the spindle box and can be used for dynamically compensating the stress deformation generated by the spindle box in real time.

Owner:SANY GRP

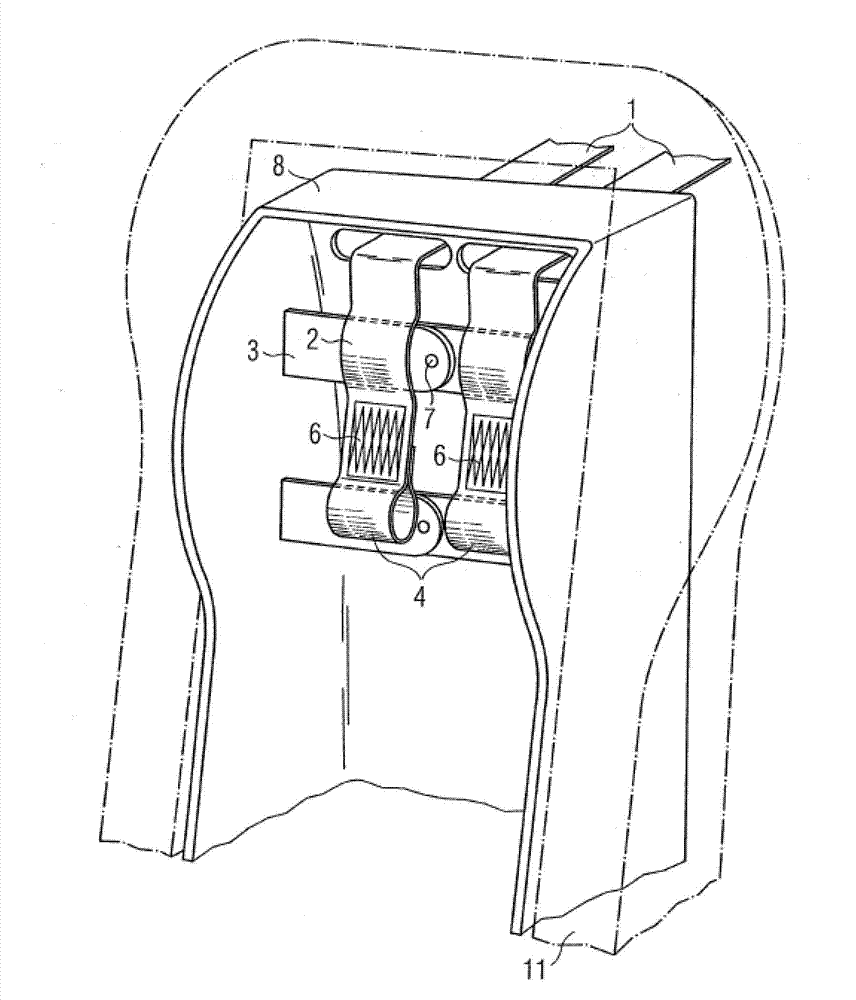

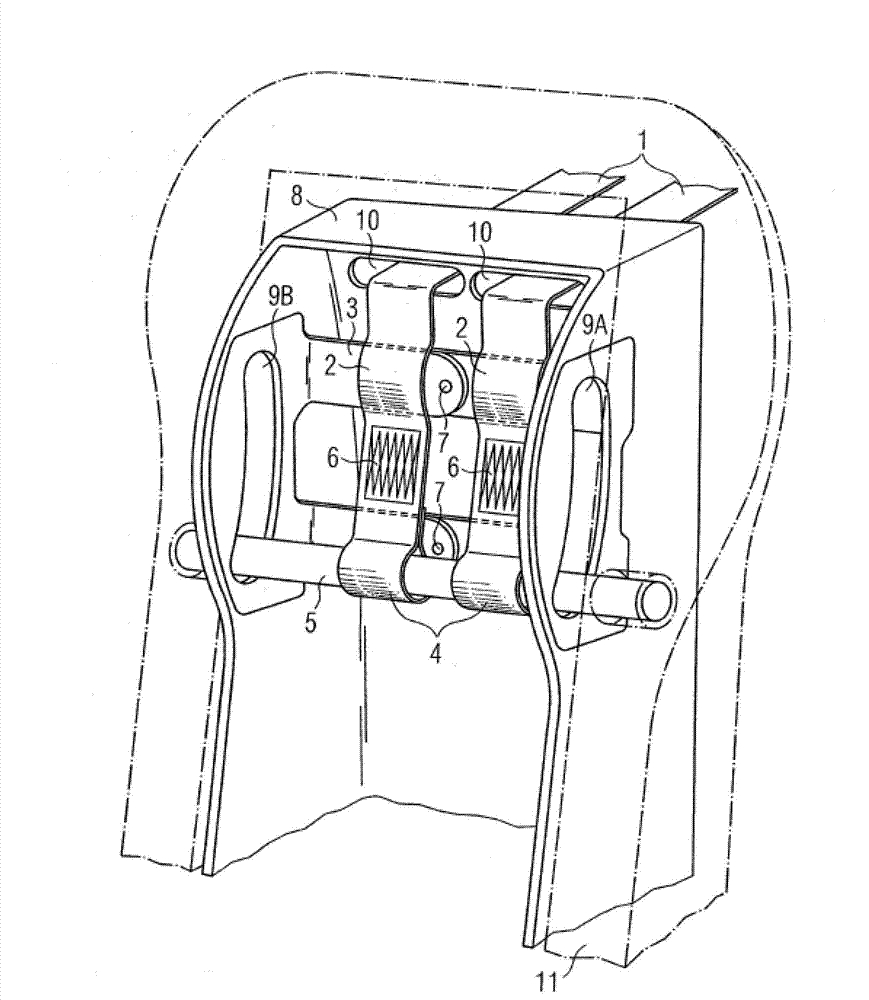

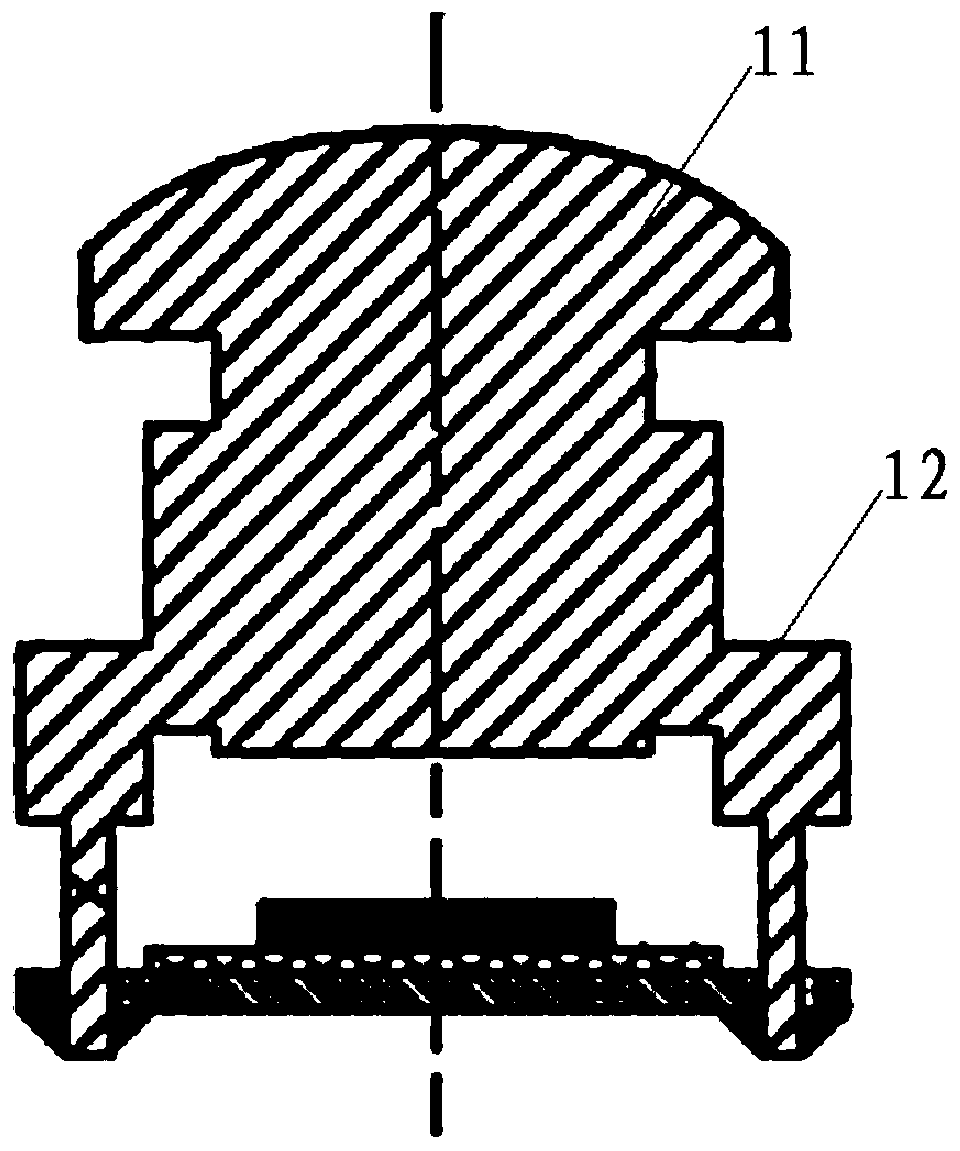

Modularized magnetic liquid sealing device

ActiveCN113108064AAvoid direct squeezing contactReduce friction and wearEngine sealsSet screwMagnetic poles

The invention discloses a modularized magnetic liquid sealing device, and belongs to the field of mechanical engineering sealing. The device comprises a shaft, a sealing ring I, a sleeve, an annular permanent magnet I, a magnetic conductive ring, an annular permanent magnet II, a box body, a sealing ring II, a sealing ring III, an inner convex shoulder sleeve cup, a left bearing, a metal gasket I, a right bearing, a metal gasket II, an end cover, a round nut I, a round nut II and a flat set screw. Contact type end face sealing is changed into magnetic liquid sealing, frictional wear and temperature rise of the two sealing surfaces are reduced, the modularized magnetic liquid sealing device does not need to be disassembled and assembled complexly and is directly replaced by spare parts after being damaged, and the shutdown time is shortened. Axial sealing is changed into radial sealing, the axial size of the sealing device is reduced, and meanwhile the sealing device can bear small-amplitude radial vibration. The two annular permanent magnets with opposite magnetic pole directions are used, so that a magnetic circuit is shortened, the magnetic field intensity of a sealing gap is enhanced, and the sealing capability is improved.

Owner:BEIJING JIAOTONG UNIV

Child's safety seat

ActiveCN103192746AResistant to torsionApproximate torsion resistanceKids chairsChild seatsEngineeringElectrical and Electronics engineering

Owner:BRITAX ROMER KINDERSICHERHEIT

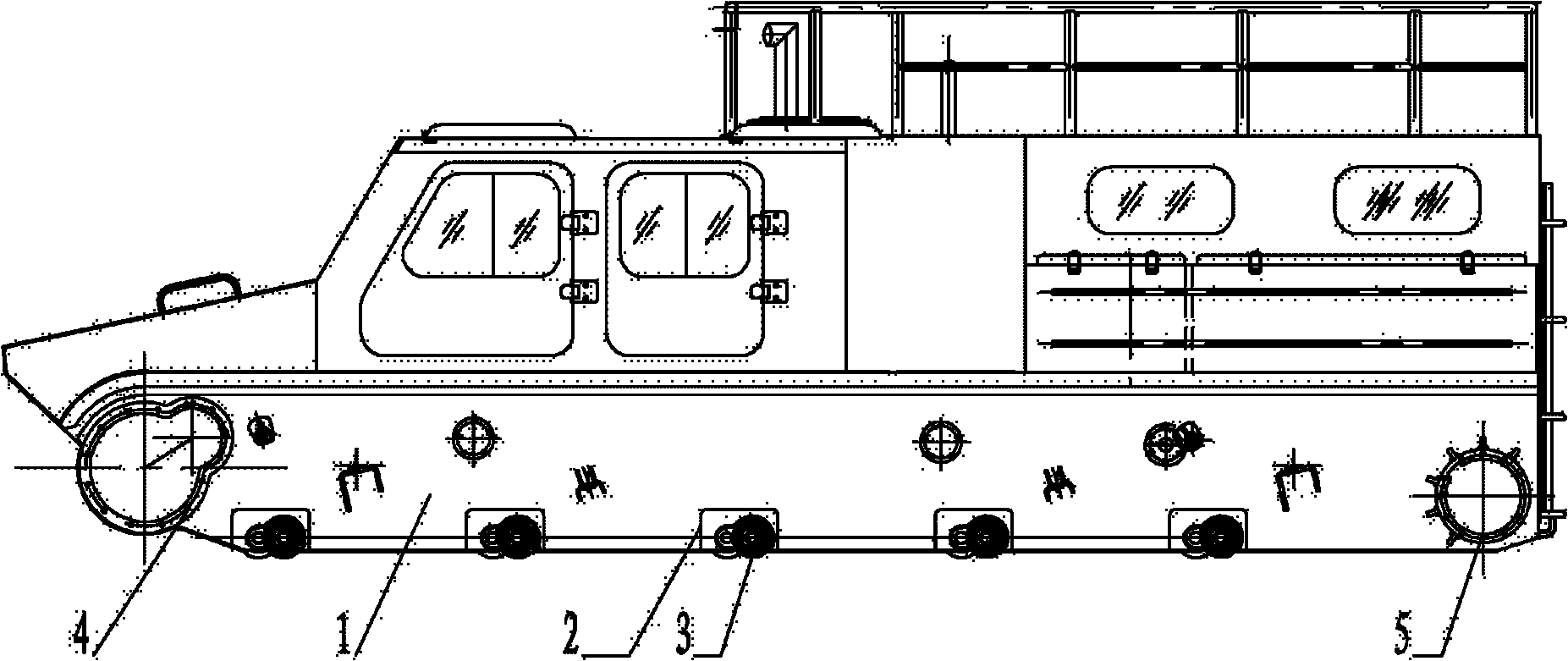

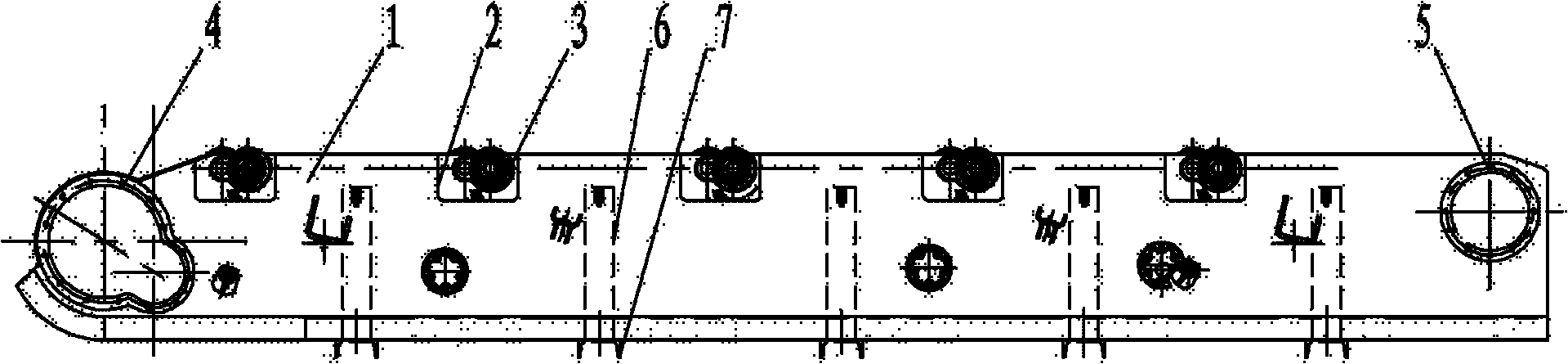

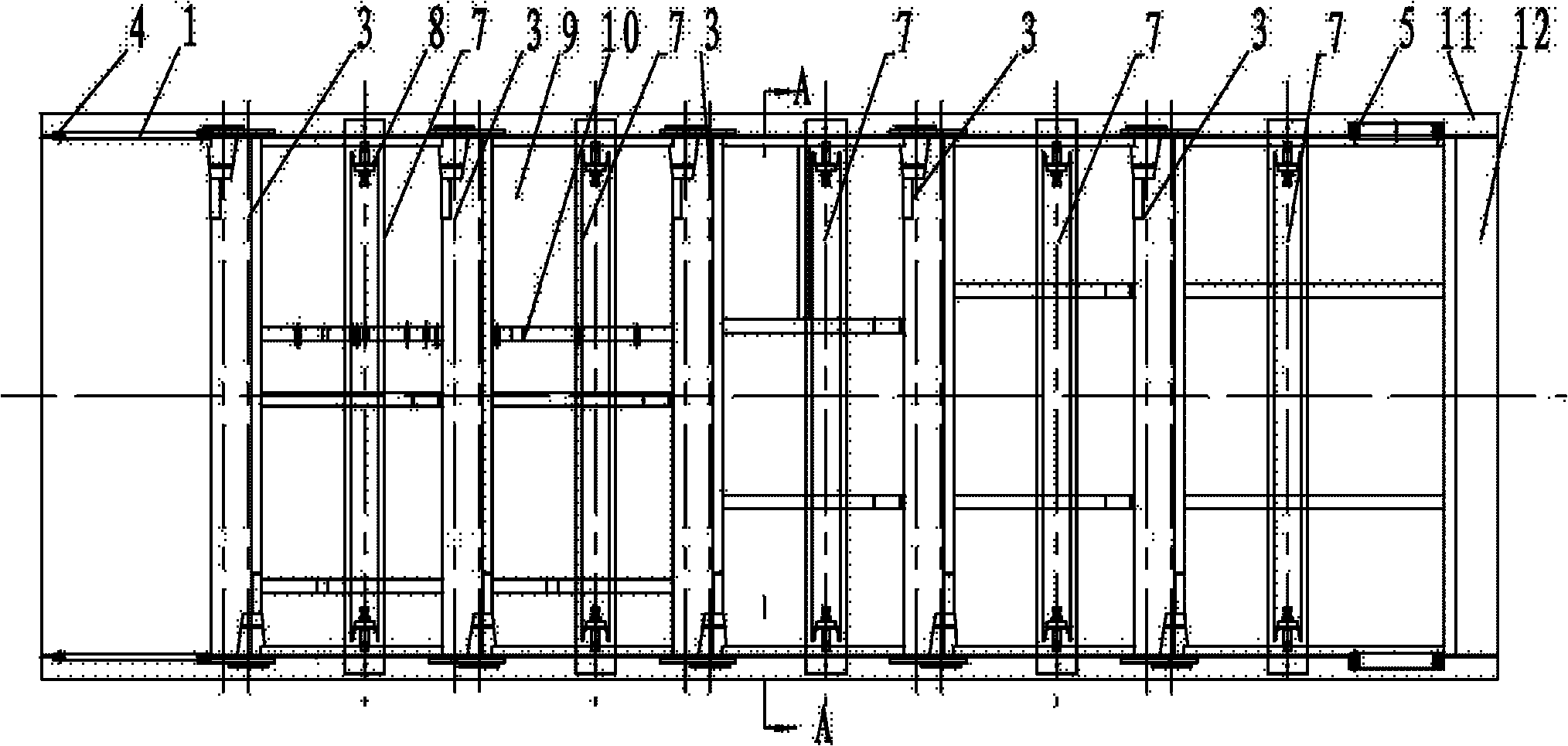

Assembly welding method of chassis assembly and assembly welding tooling clamping devices special for same

InactiveCN102179636AImprove ergonomicsLow costWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention relates to an assembly welding method of a chassis assembly and an assembly welding tooling clamping devices special for the same, mainly solving the technical problems of complexity and the like of the traditional processing method. The assembly welding method of the chassis assembly comprises the following steps of: cutting bridge openings (2) on left and right side armor plates (1) according to design requirements, and sleeving the left and right side armor plates (1) on two or more than two assembly welding tooling clamping devices in an overturning way; then welding both ends of balancing pole brackets (3) with the bridge openings (2) one by one, and then welding a back beam (12), a bottom armor plate longitudinal beam (10), a front axle ring flange (4), a rear axle ring flange (5) and a speed changing box bracket; overturning the welded left and right side armor plates (1), the balancing pole brackets (3), the back beam (12), the bottom armor plate longitudinal beam (10) and the assembly welding tooling clamping devices already connected into an integer, then welding a head bottom armor plate, and then welding a bottom armor plate (9) so as to complete the welding work of the chassis assembly. The invention can be widely used for the welding construction of the chassis assemblies of various vehicles and armored vehicles especially.

Owner:HUNAN JIANGLU SPECIAL EQUIP MFG

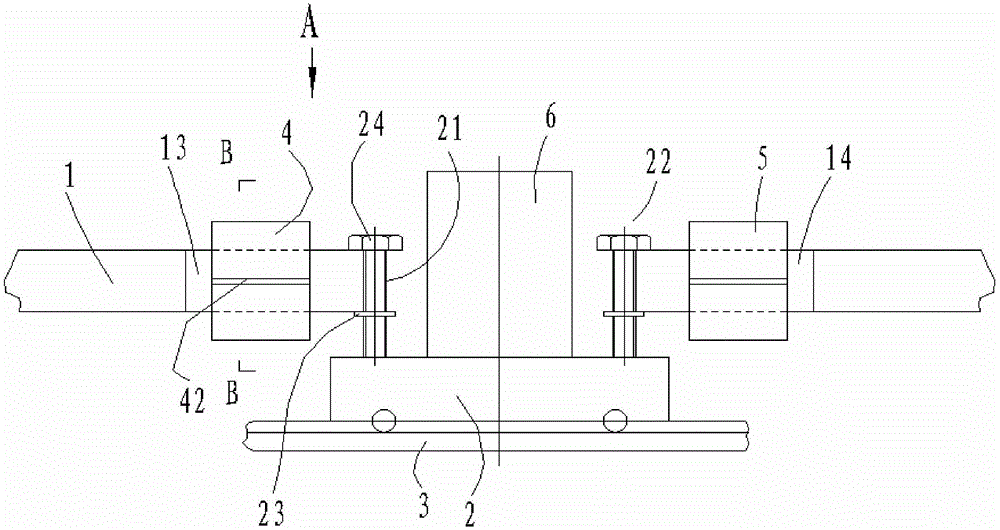

Rear axle assembly welding method and clamping device special for rear axle assembly welding tool

InactiveCN102218617BOffset deformationImprove ergonomicsWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameFlange

The invention relates to a rear axle assembly welding method and a clamping device special for a rear axle assembly welding tool, and mainly solves the technical problems of complexity, high cost and the like of a rear axle assembly welding processing method. The method comprises the following steps of: processing the clamping device of the rear axle assembly welding tool, a left side deck and a right side deck and vertically turning over; fixedly sleeving on a frame assembly welding tool clamping device according to design requirements; welding all balancing rod supports and a back beam; sleeving a rear axle flange plate in a rear axle hole; sleeving the clamping device of the rear axle assembly welding tool in the rear axle flange plate and fixing the clamping device of the real axle assembly welding tool; welding the rear axle flange plate on the side decks; welding other necessary equipment; turning over the welded frame assembly and the clamping device of the rear axle assembly welding tool; welding a vehicle head bottom deck and a bottom deck; and disassembling the frame assembly and the clamping device of the rear axle assembly welding tool. The rear axle assembly welding method can be widely applied to welding construction of the frame assembly of various vehicles, particularly armored vehicles.

Owner:HUNAN JIANGLU SPECIAL EQUIP MFG

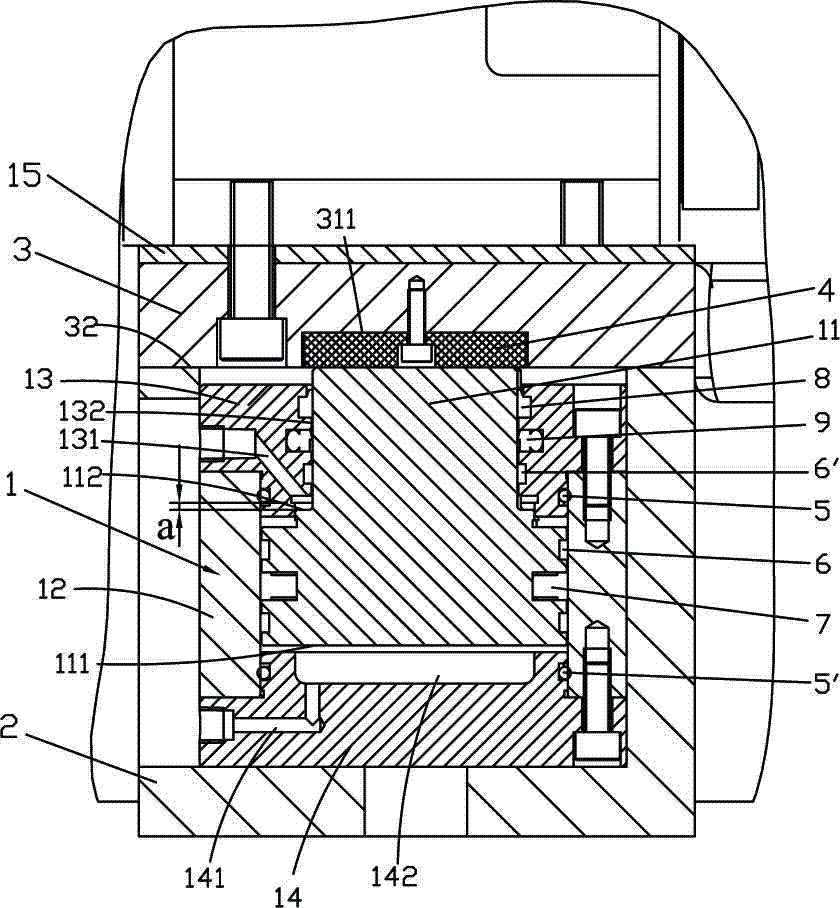

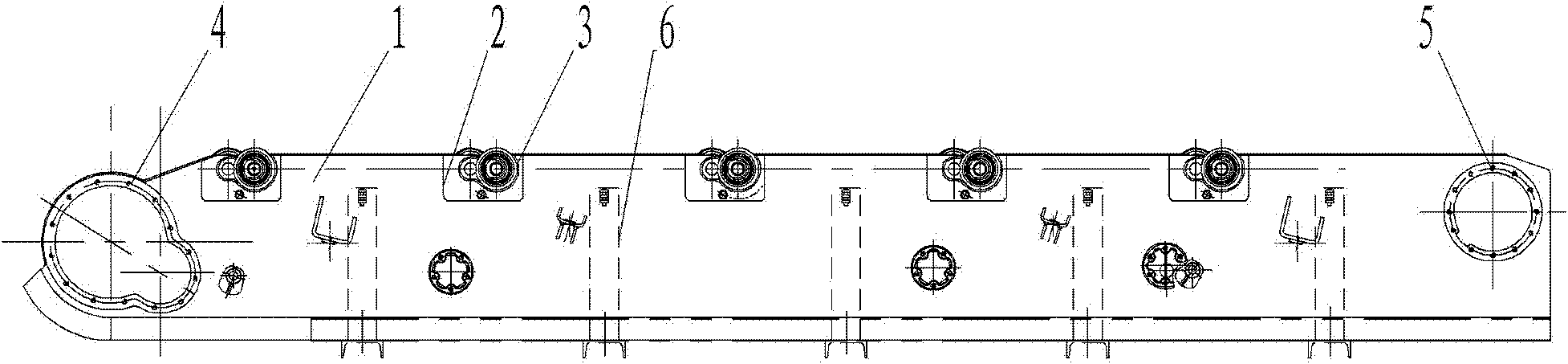

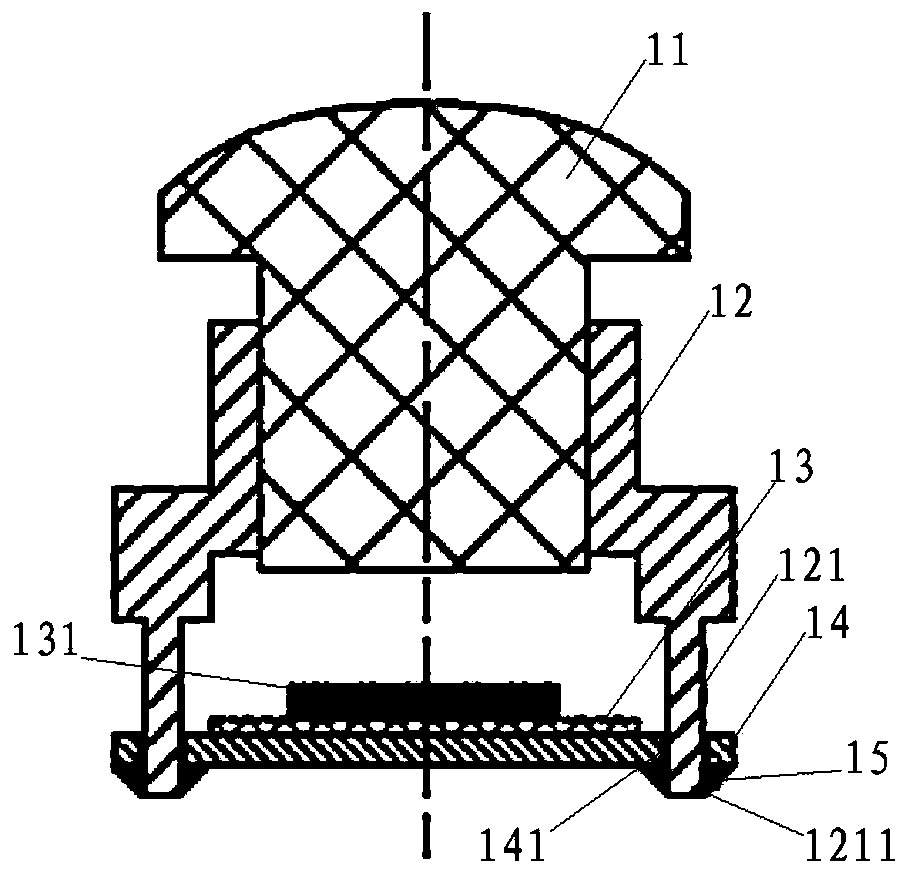

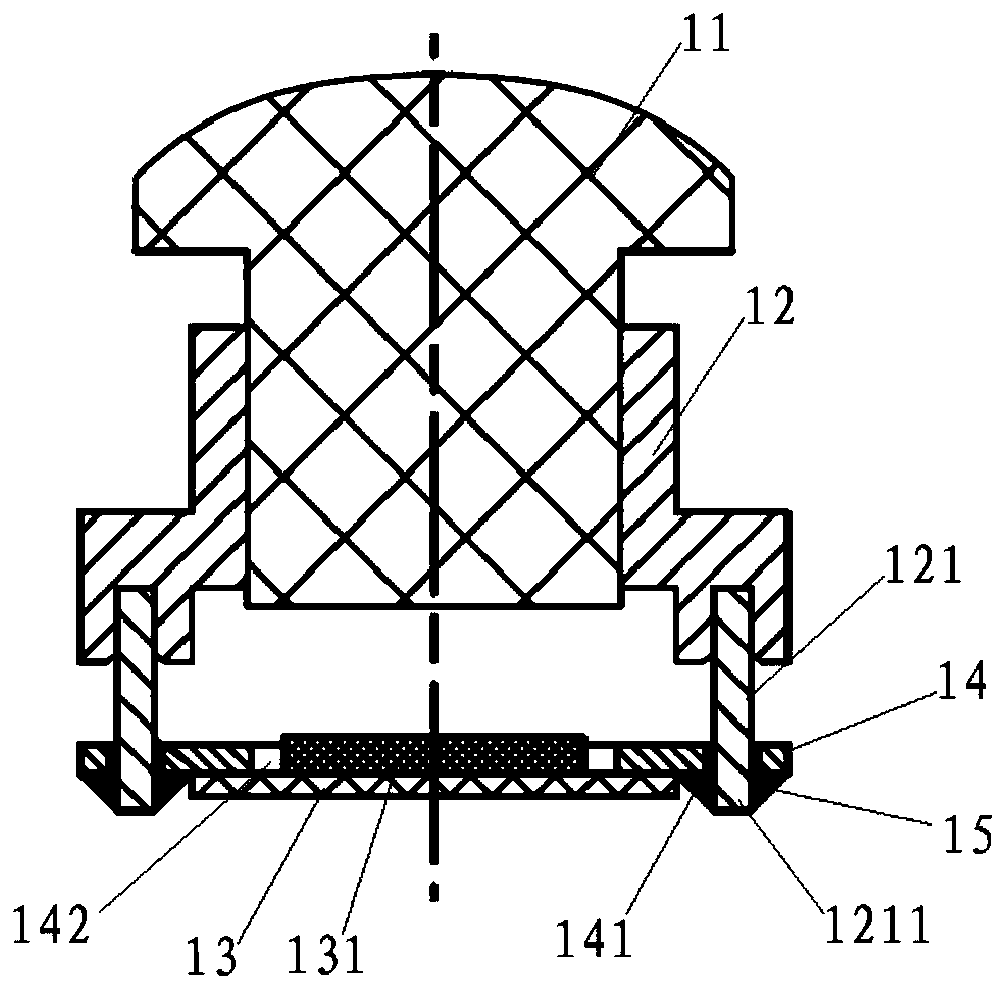

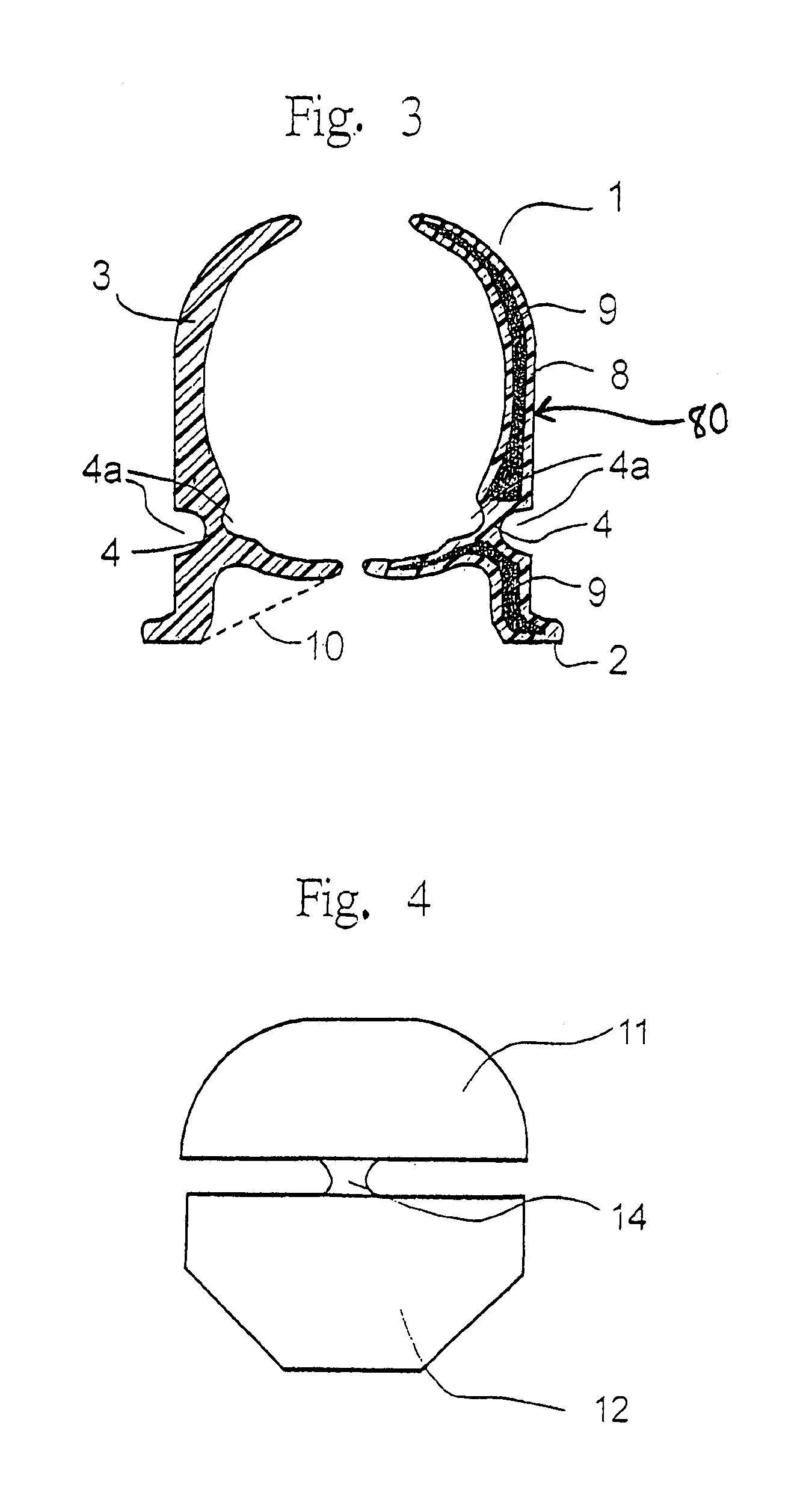

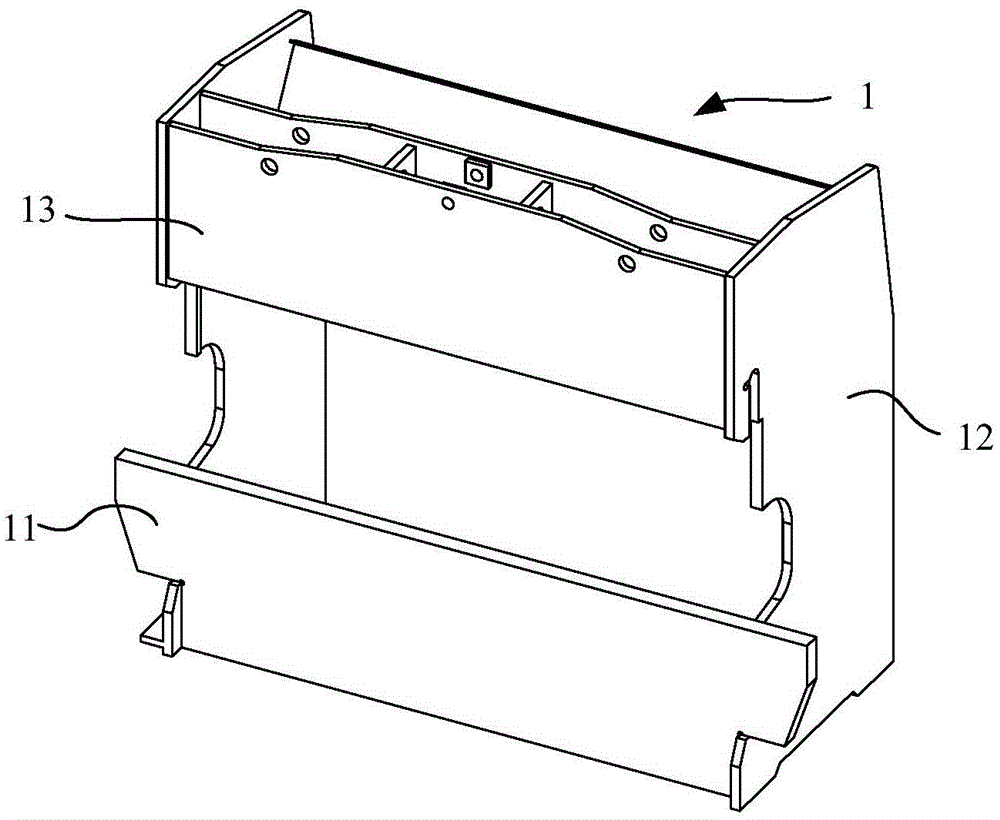

Vehicle-mounted camera module

PendingCN110769141APrevent thermal deformationAvoid deformationTelevision system detailsColor television detailsIn vehicleEngineering

The invention relates to a vehicle-mounted camera module, comprising a lens (11), a lens base (12) which is used for mounting the lens (11), a circuit board (13), and a supporting piece (14), whereinthe circuit board (13) is connected with the supporting piece (14); the supporting piece (14) is provided with a through hole (141) connected with a supporting foot (121) of the lens base (12); the supporting foot (121) penetrates through the through hole (141); and the extending end (1211) of the supporting foot (121) is fixedly connected with the side, away from the lens base (12), of the supporting piece (14). Through the supporting piece, deformation of the circuit board can be restrained, and deformation of the lens base can be restrained, and a good imaging effect is achieved under the condition that it is guaranteed that the environment temperature change is large.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

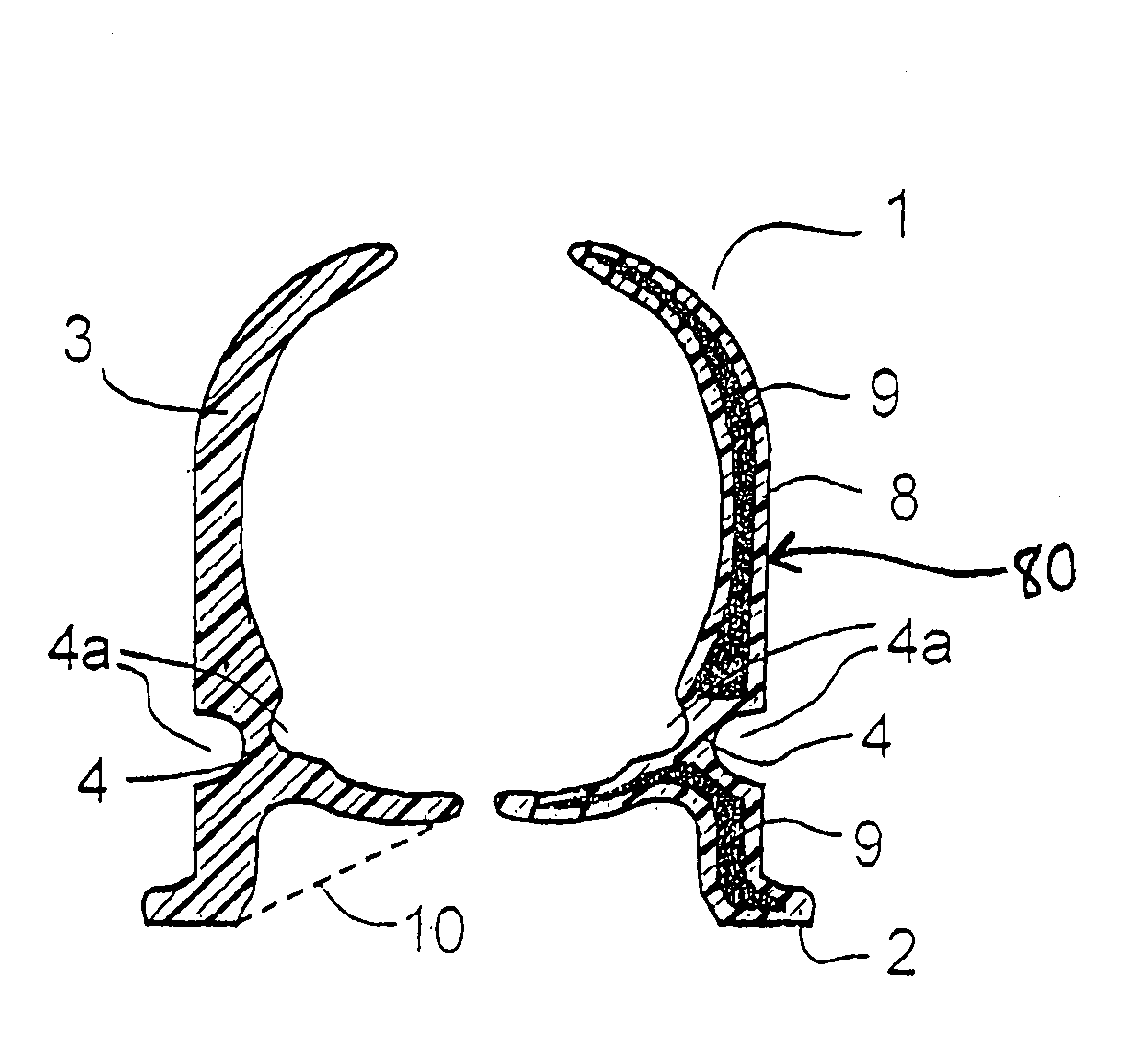

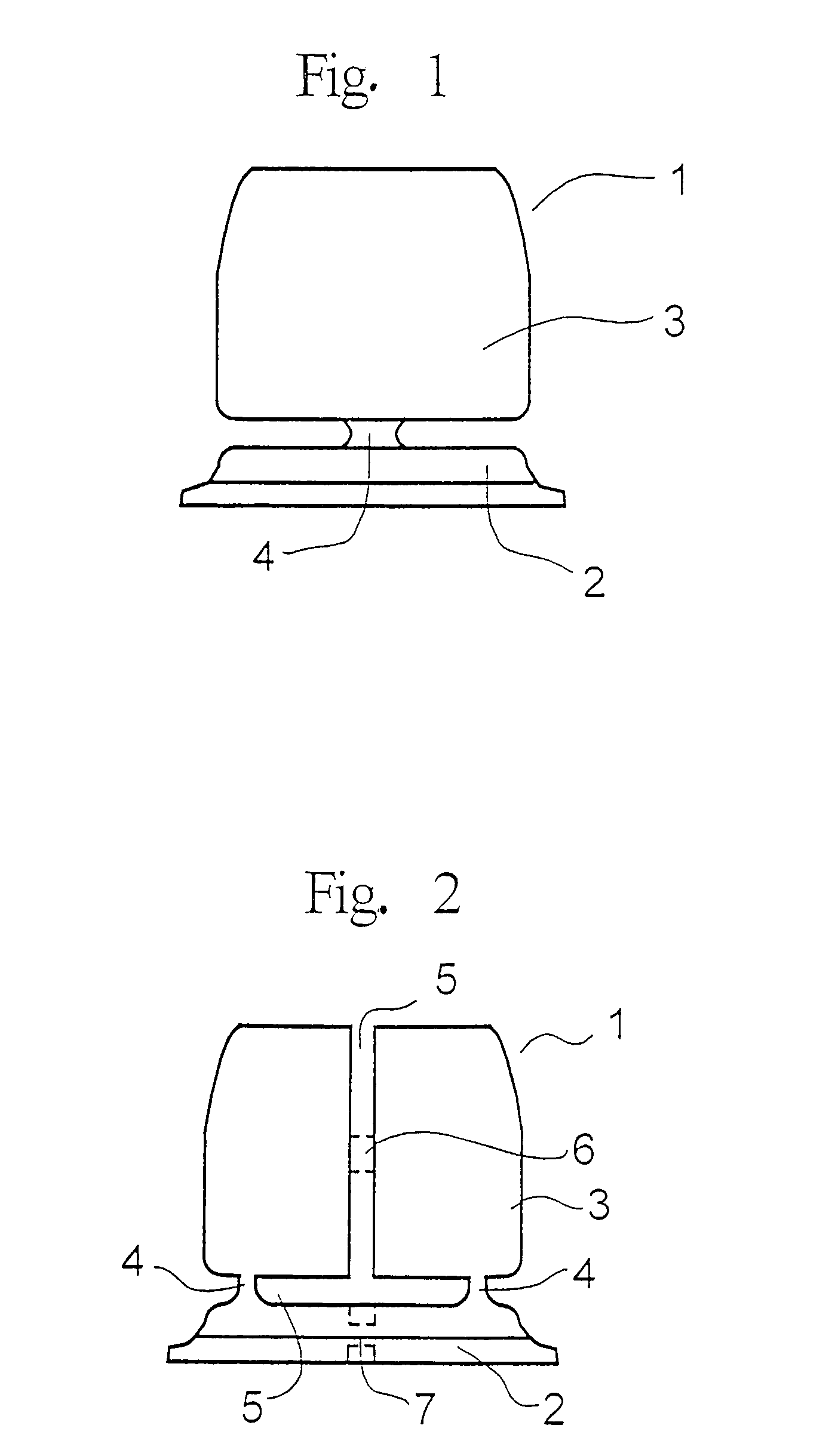

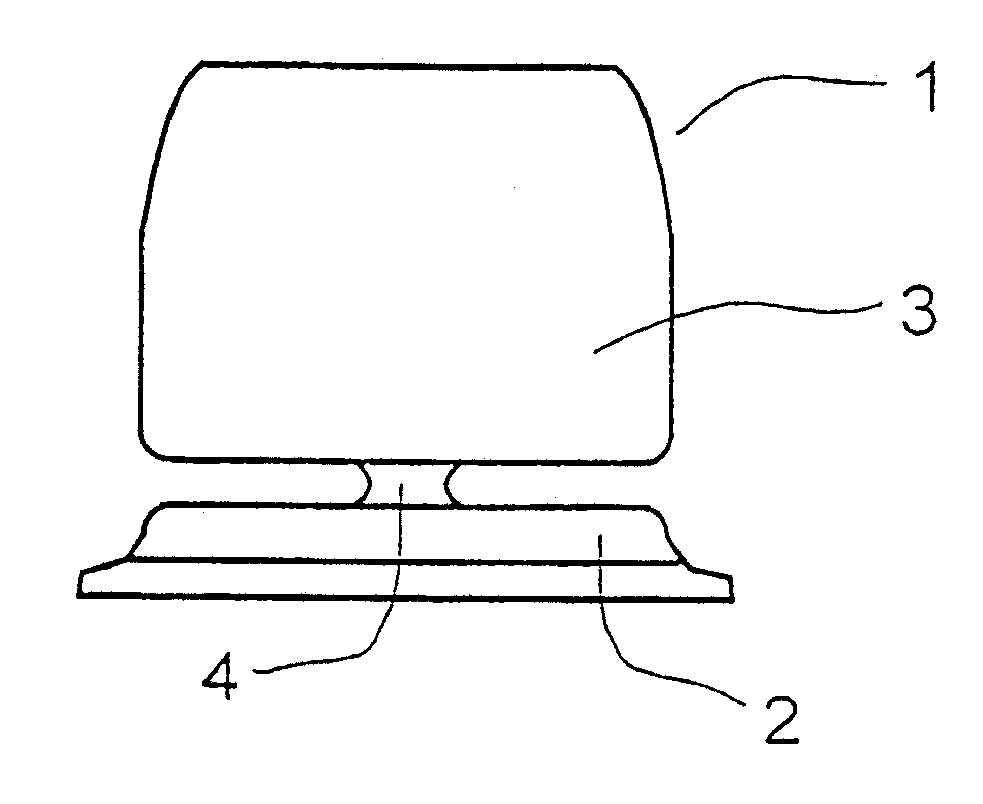

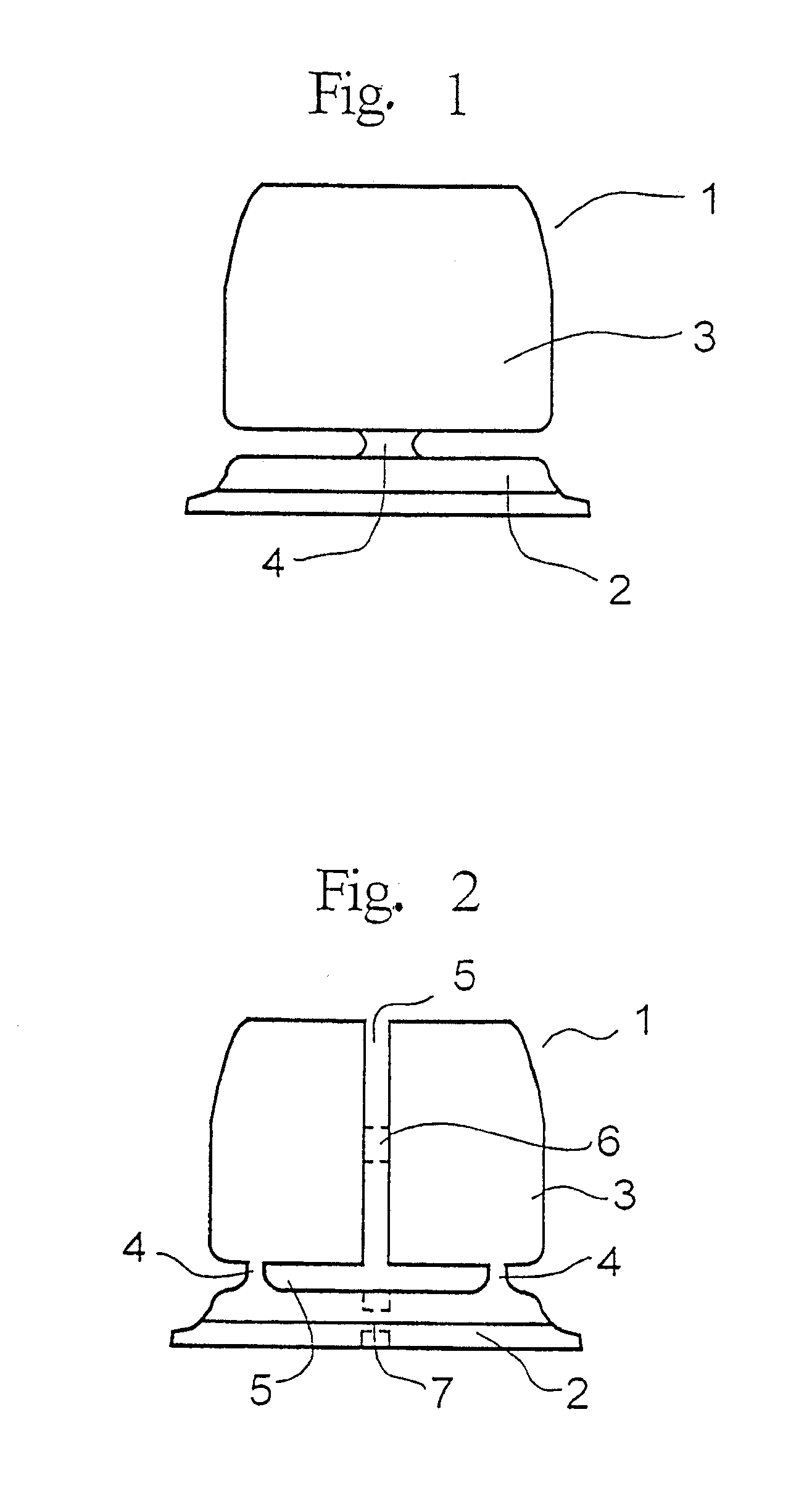

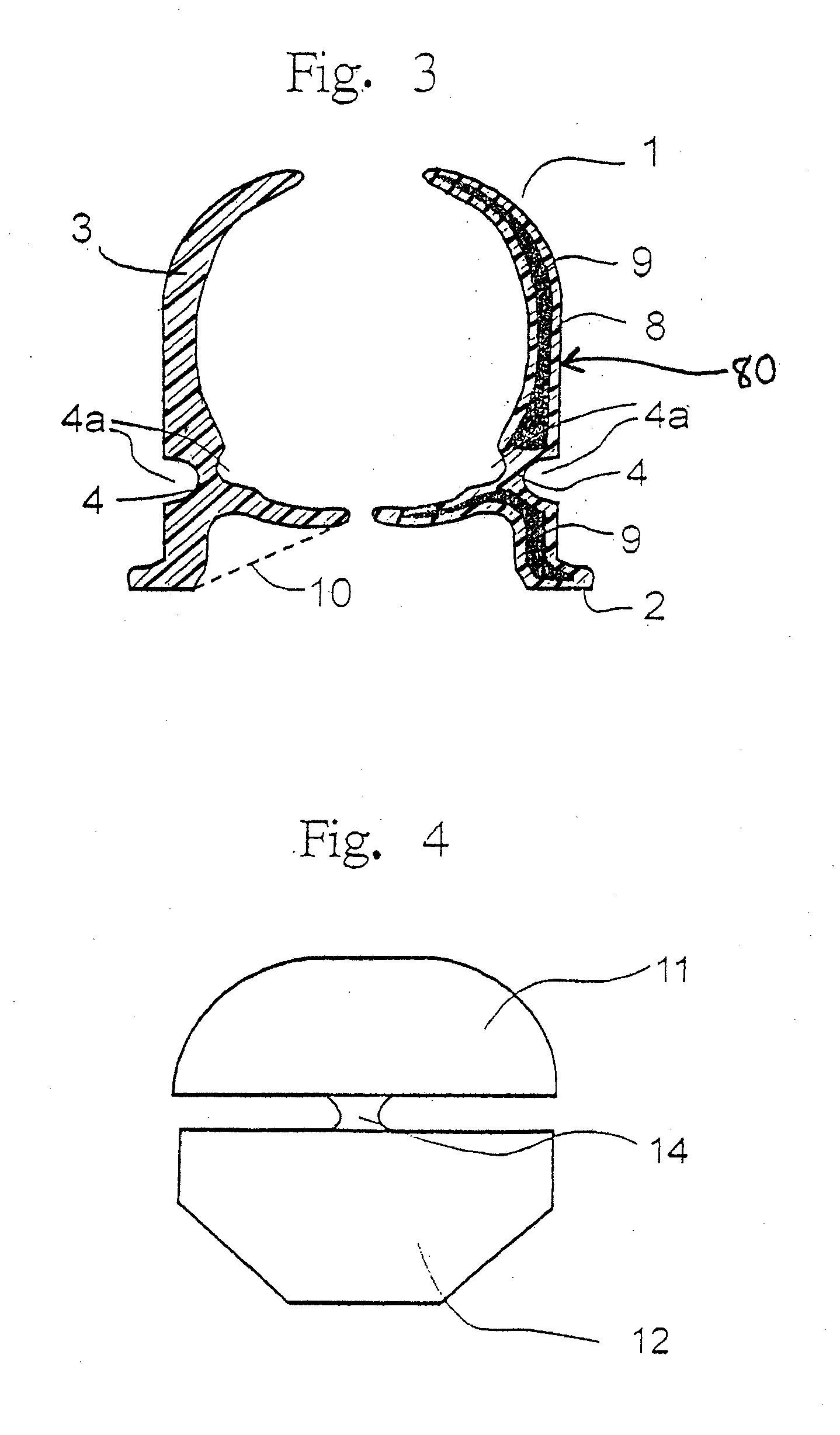

High-performance ball socket

InactiveUS7318686B2Extended service lifeIncrease flexibilityCouplings for rigid shaftsPivotal connectionsEngineeringBall and socket joint

A bearing shell for a ball and socket joint made of plastic as well as the ball and socket joint per se, wherein the bearing shell has first areas, which are subject to higher mechanical loads than the other areas of the bearing shell, wherein the material of the bearing shell forming the first areas is formed from a reinforced plastic, and the other areas are made of a less reinforced or unreinforced plastic.

Owner:ZF FRIEDRICHSHAFEN AG

Method of using radiation heating to restrain vibration of rotor

InactiveCN103216573ASolve Vibration ProblemsReduce vibrationInertia force compensationRadiant heatThermal radiation

The invention relates to a method of using radiant heat to cause partial thermal bending deformation of a rotor to restrain vibration of the rotor. The method is characterized in that an unbalanced position of the rotor is confirmed firstly, and a partial compressed surface and a partial stretched surface of the unbalanced position of the bent rotor are respectively confirmed; in an operation process of a rotor system, the partial compressed surface of the unbalanced position is heated, the radiant heat is partially absorbed through the surface of the rotating rotor, radiation absorbing paint is coated on the partial compressed surface of the unbalanced position of the rotor through coating technology, and therefore the absorption rate of the radiant heat of the coating partial surface of the rotor is improved; and when the rotor is heated through heat radiation, the temperature of the partial surface provided with the coating is raised, the partial surface provided with the coating and the rotor surface without the coating produce temperature difference, the rotor is deformed, original unbalance of the rotor is offset, and the vibration of the rotor is restrained. The method aims at restraining the vibration of the rotor system, improving operation stability of the system, and overcoming the defects of current vibration restraining technology.

Owner:NORTHEASTERN UNIV +2

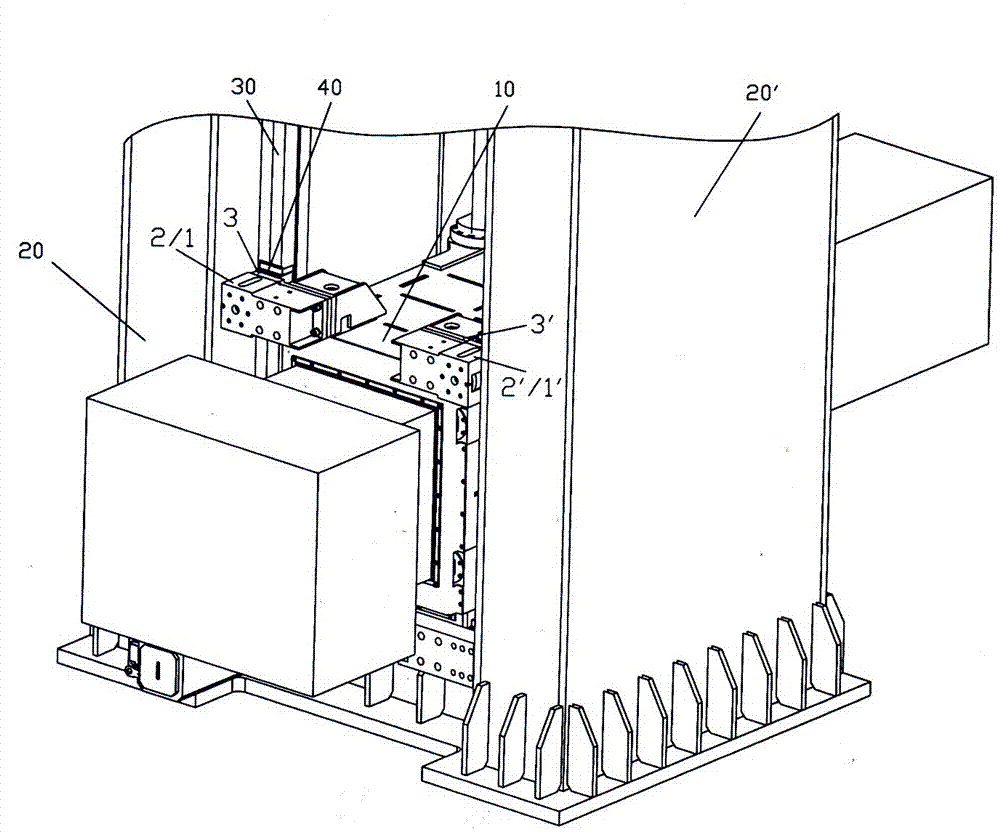

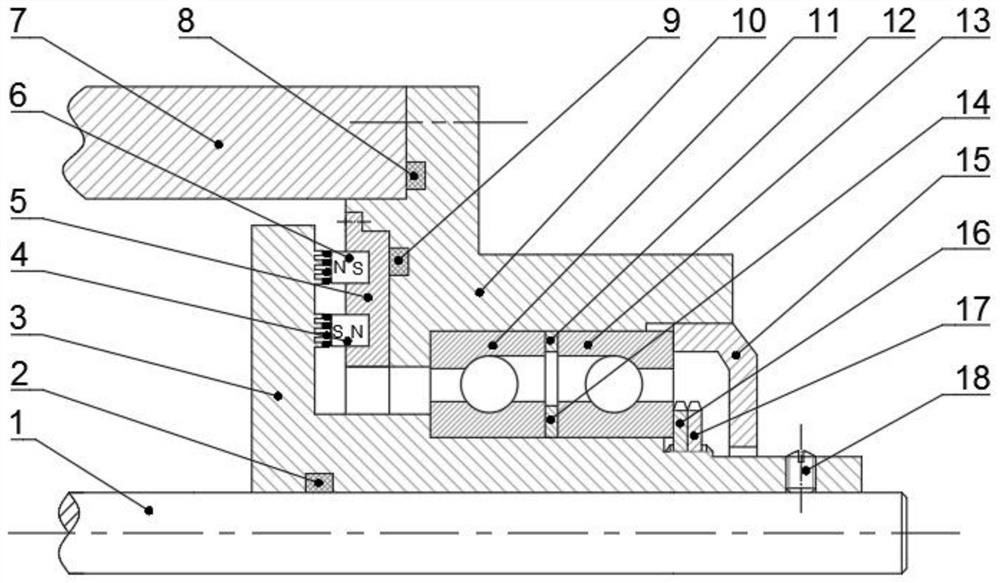

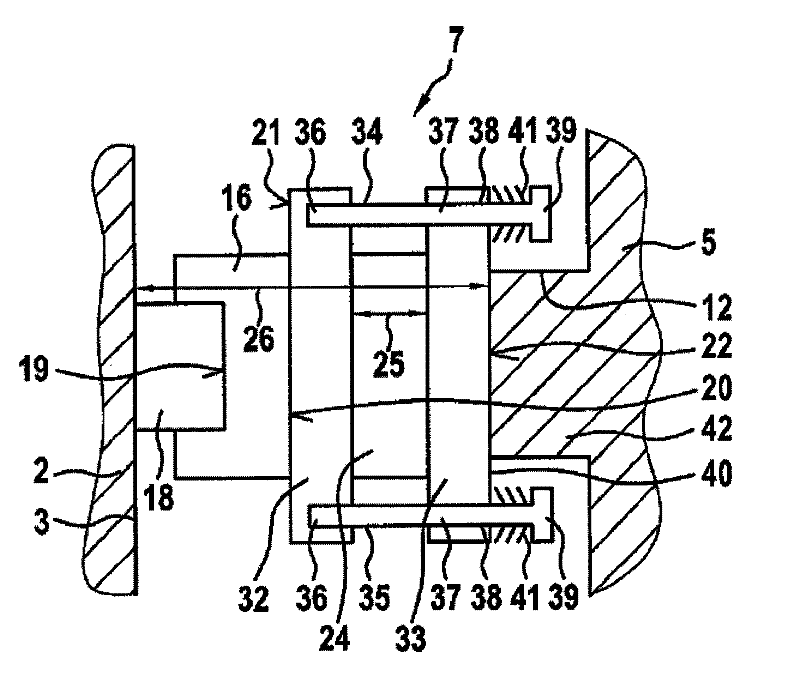

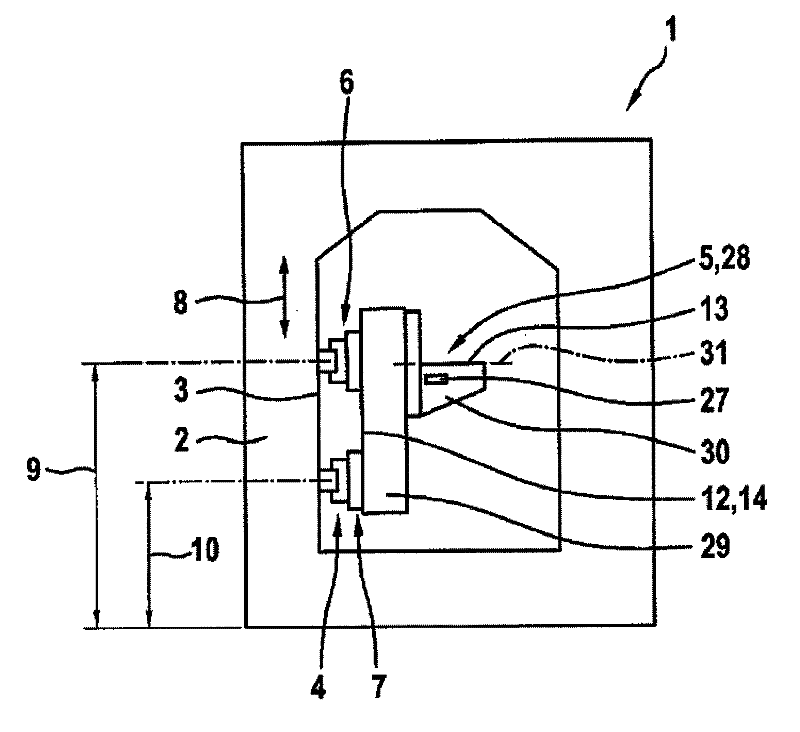

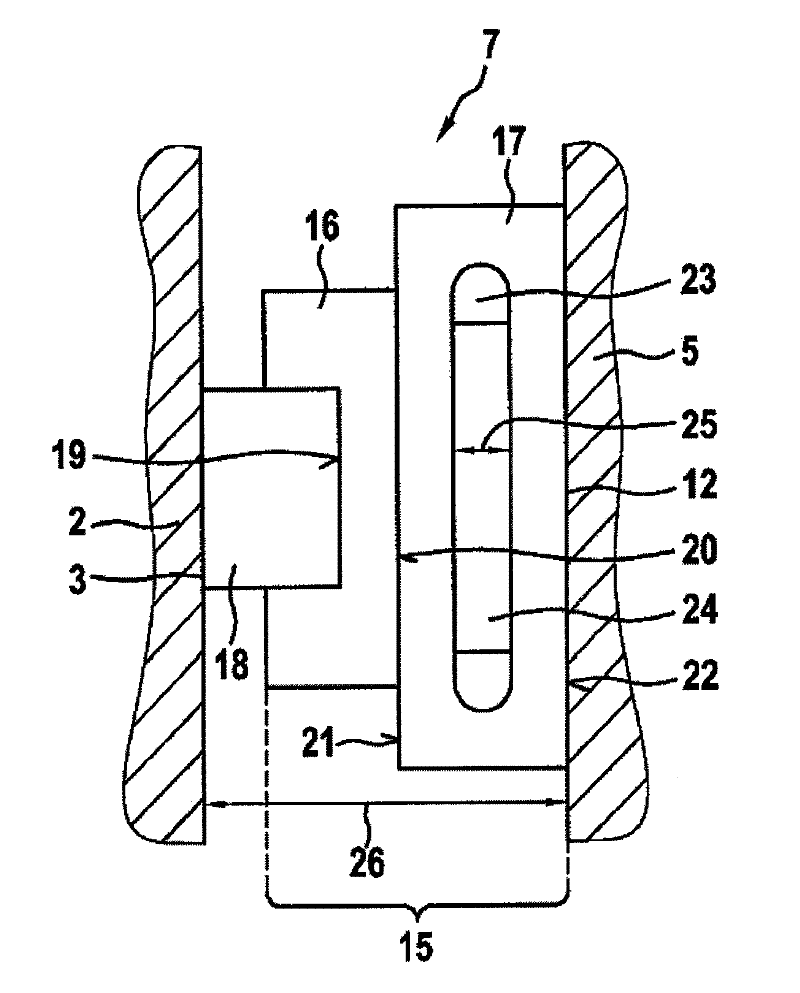

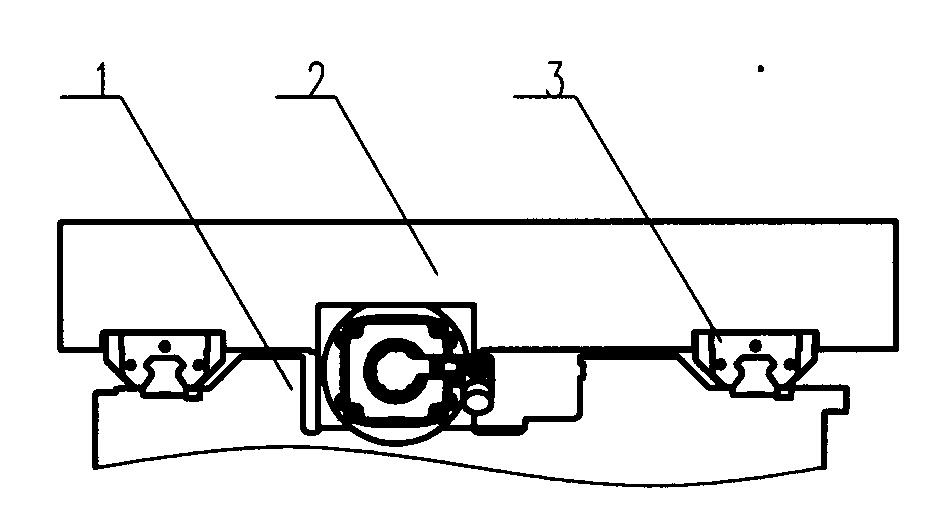

Machine tool with a workpiece table

InactiveCN102653057AIncrease stiffnessOffset deformationMeasurement/indication equipmentsOther manufacturing equipments/toolsPiezoelectric actuatorsEngineering

A machine tool having a machine frame and a workpiece table. It is provided that the workpiece table (5), on one of its sides (14), is held on the machine frame (2) by a holding device (4), the holding device (4) having at least two holding elements (6, 7), which are spaced apart from one another on the said side (14) of the workpiece table (5) and which are disposed at differing height positions (9, 10), such that an upper and a lower holding element (6, 7) is realized, and at least one of the holding elements (6, 7) being equipped with at least one piezo actuator (24) for altering its length and, associated therewith, influencing the position of the workpiece table.

Owner:MIKRON AGIE CHARMILLES

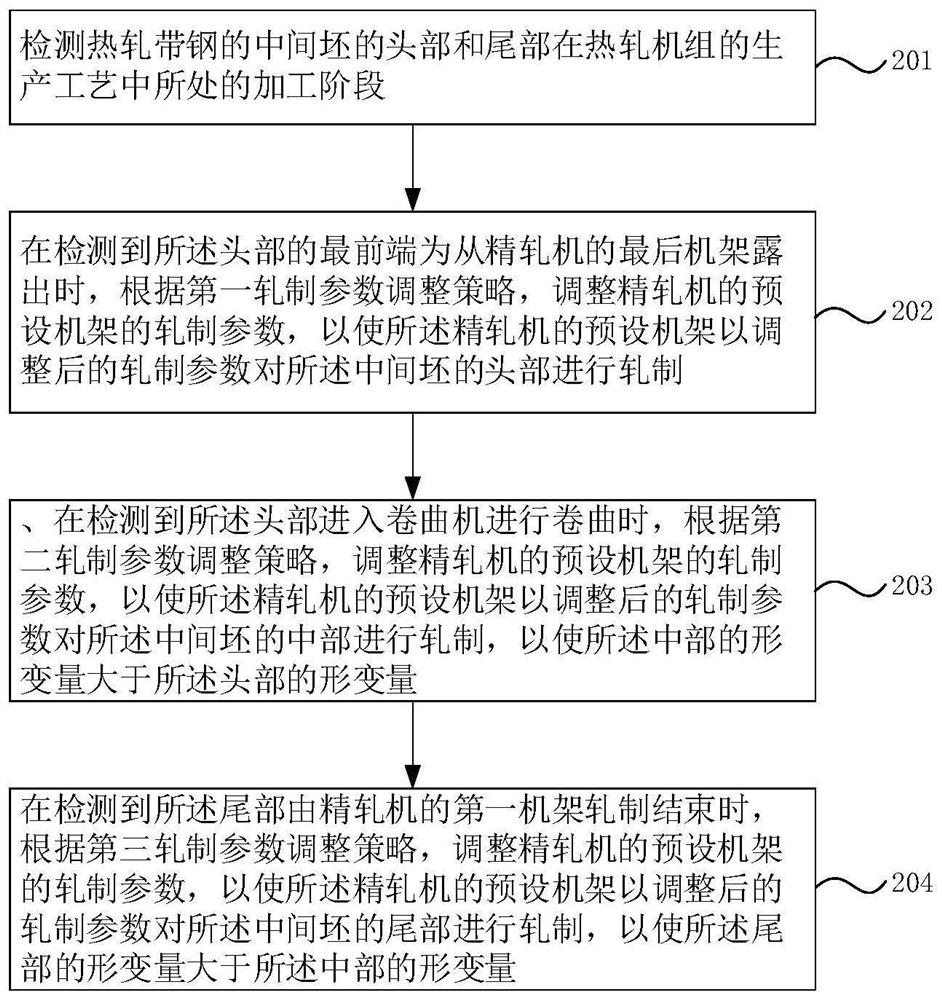

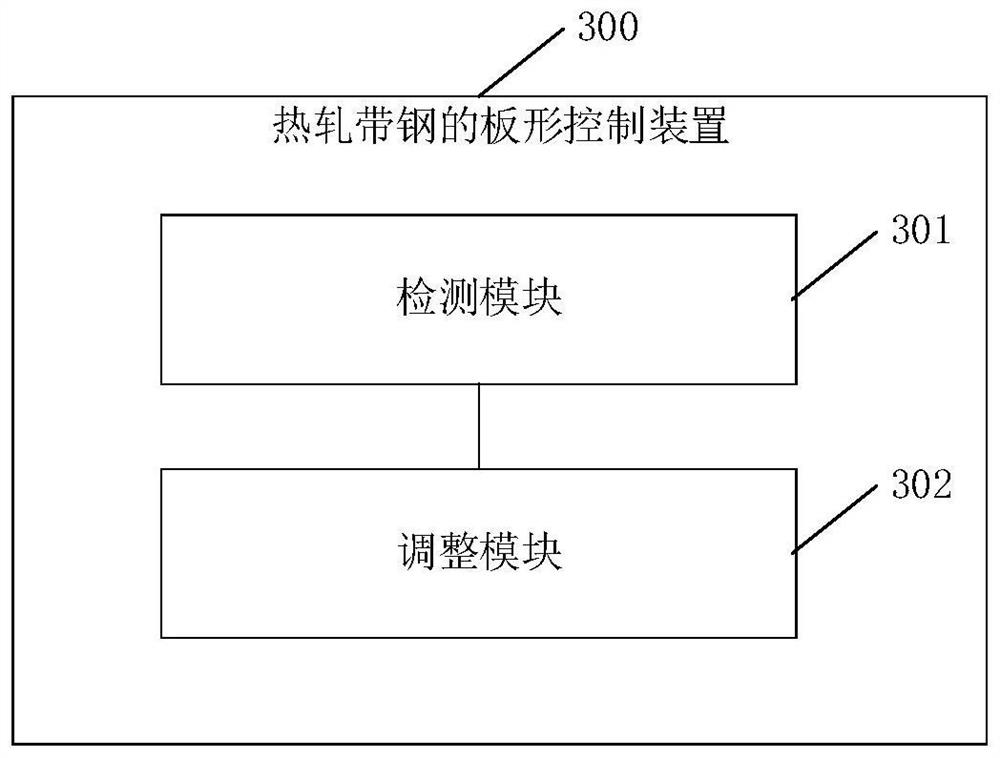

Plate shape control method, device and equipment in production process of hot-rolled strip steel

PendingCN114472542AImprove side wave defectsHigh yieldProfile control deviceStrip steelMaterials science

The invention discloses a plate shape control method, device and equipment in the production process of hot-rolled strip steel. The method comprises the following steps: detecting the processing stages of the head part and the tail part of an intermediate billet of hot-rolled strip steel in a production process of a hot rolling unit; and when it is detected that the head and the tail of the intermediate billet of the hot-rolled strip steel are located at the preset positions of the hot rolling unit, a preset rack of a finishing mill is controlled to machine the hot-rolled strip steel according to preset rolling parameters corresponding to the head and the tail of the hot-rolled strip steel at the preset positions. According to the embodiment of the invention, the problem of cooling wave shape in the production process of the hot-rolled strip steel is solved.

Owner:湖南华菱涟钢特种新材料有限公司 +1

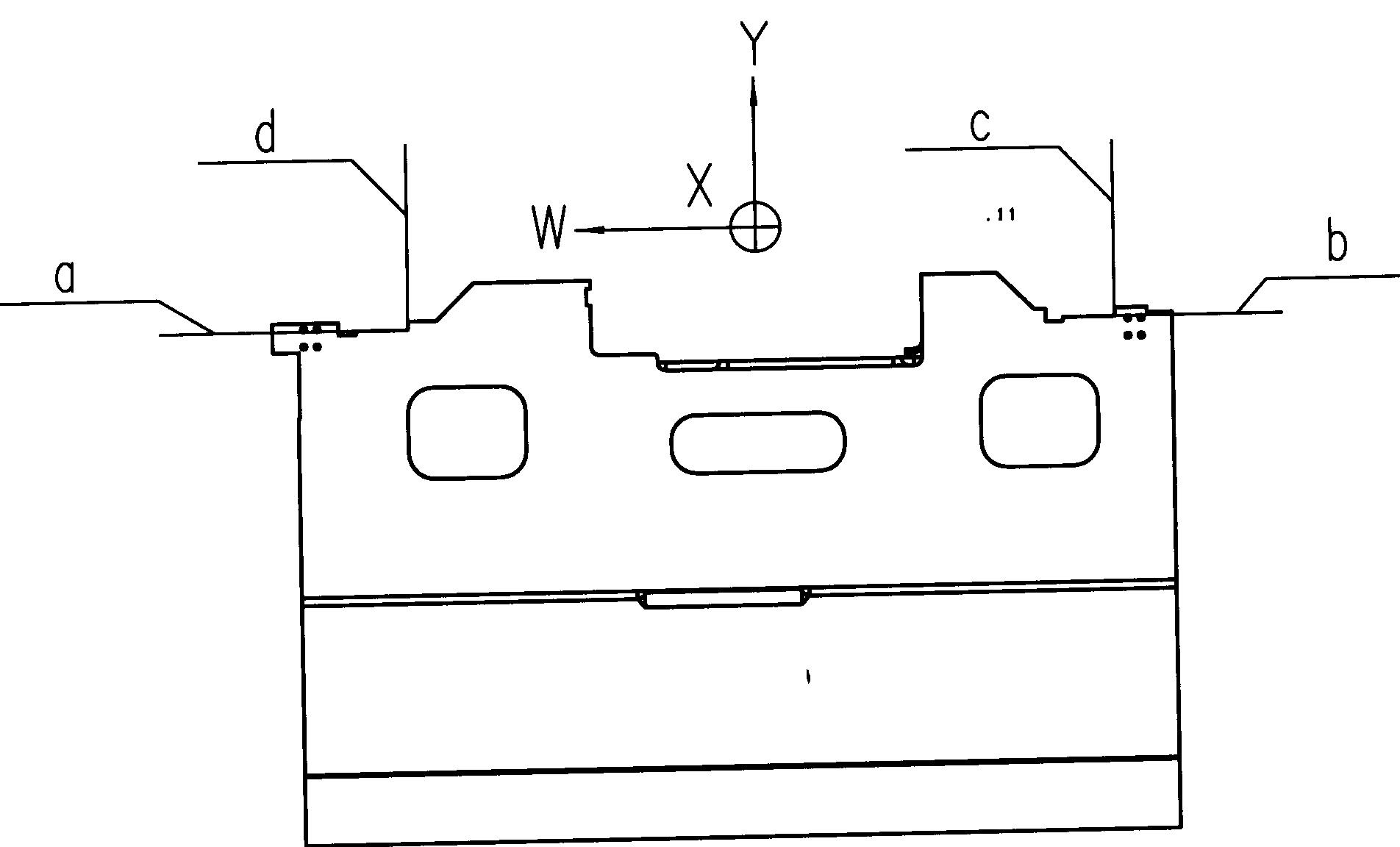

Linear guide rail copying device for lathing and milling crossbeam and manufacturing method thereof

InactiveCN102172782AImprove working precisionSimple designCopying process control systemsMilling equipment detailsVertical planeSlide plate

The invention relates to a linear guide rail copying device for lathing and milling a crossbeam and a manufacturing method thereof, wherein the linear guide rail copying device for lathing and milling a crossbeam comprises a crossbeam main body, a linear rolling guide rail and a sliding plate kit, and the maximum speed of the X-axis of a machine tool crossbeam is 16000 mm / min. The linear guide rail copying device for lathing and milling a crossbeam is characterized in that a copying curved surface is manufactured by processing the screwing surfaces and the locating surfaces of two parallel guide rails of the crossbeam main body; the curve of the curved surface is the same as that of the vertical plane of the linear rolling guide rail after the crossbeam is loaded, stressed and deformed, but is in an opposite direction; the linear rolling guide rail and the guide rail surface of the crossbeam main body are fastened into a whole by set screws and impacting blocks on the guide rail surface of the crossbeam main body, and the tight attachment of the linear rolling guide rail and the copying curved surface of the crossbeam guide rails is ensured by increasing the numbers of the screws and the impacting blocks; and the sliding plate kit is screwed on the sliding block of the linear rolling guide rail by screws, and a damping block is arranged between the linear rolling guide rail and the sliding block. The invention has the advantages of increasing the working accuracy of a machine tool, simplifying the design structure of the machine tool, reducing the processing hardness of the machine tool crossbeam and shortening the manufacturing cycle of the machine tool.

Owner:SHENYANG MASCH TOOL CO LTD

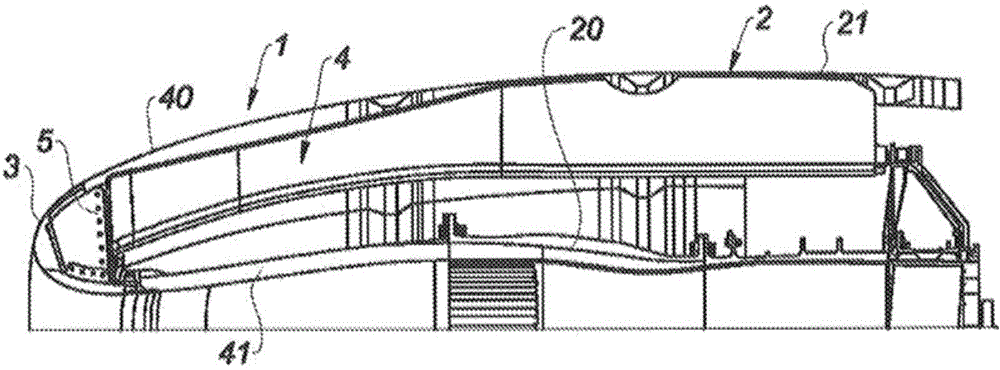

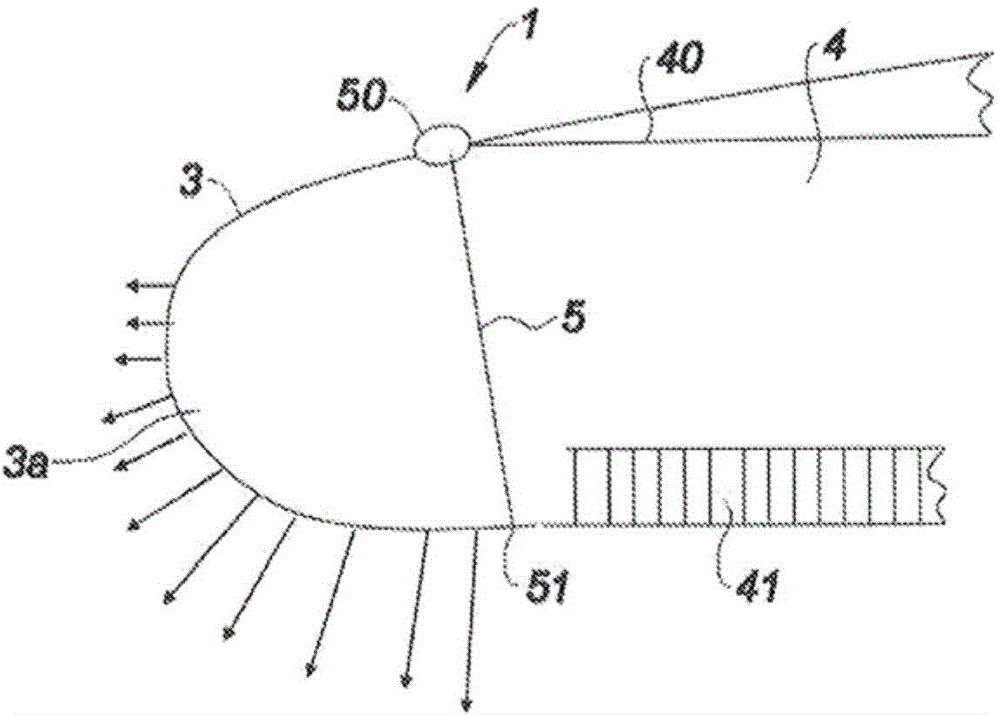

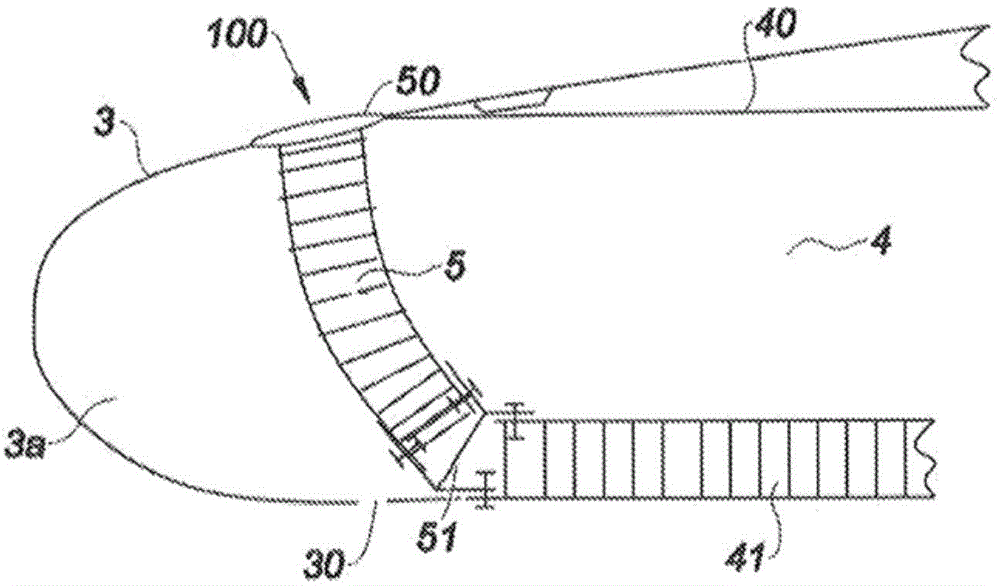

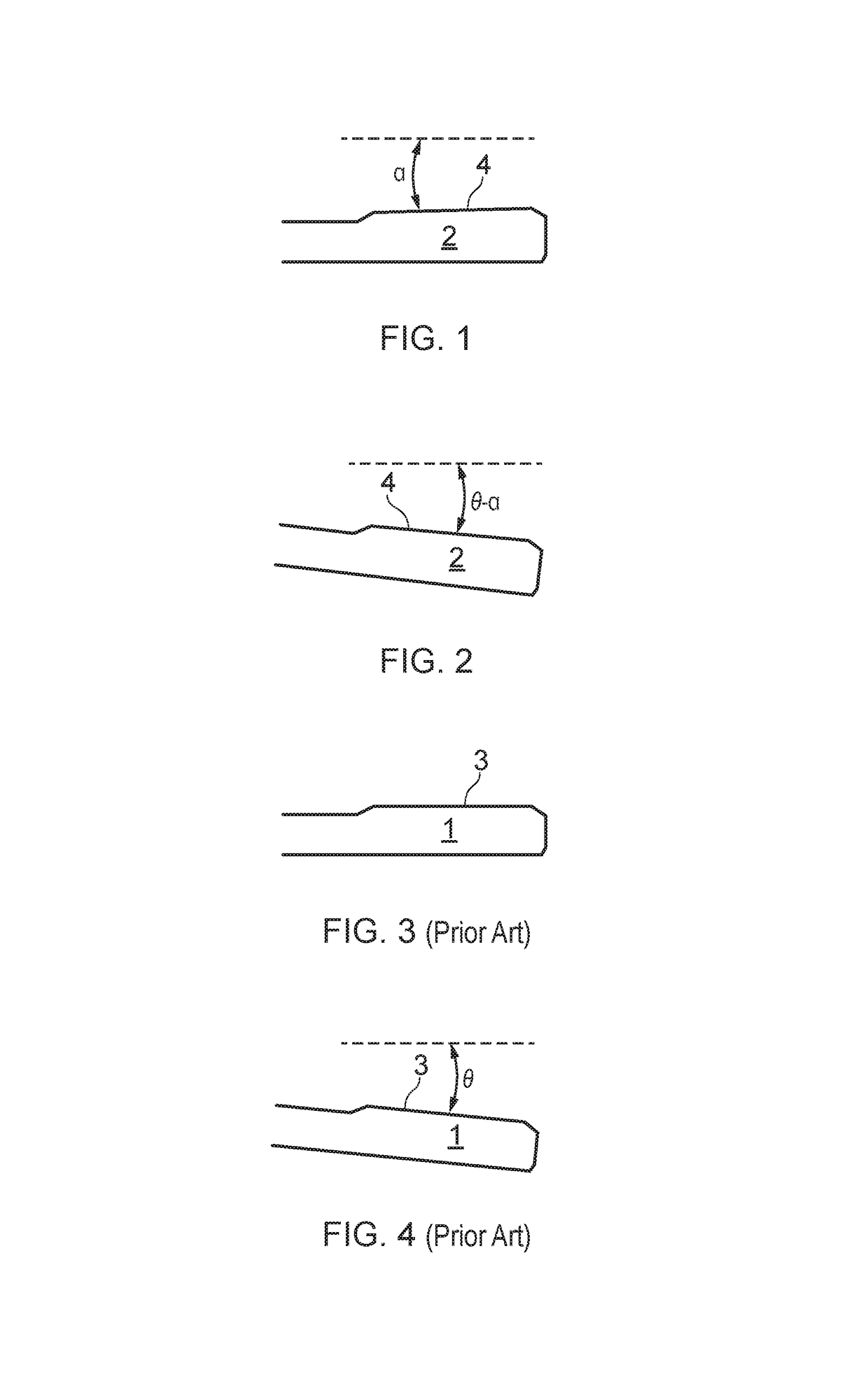

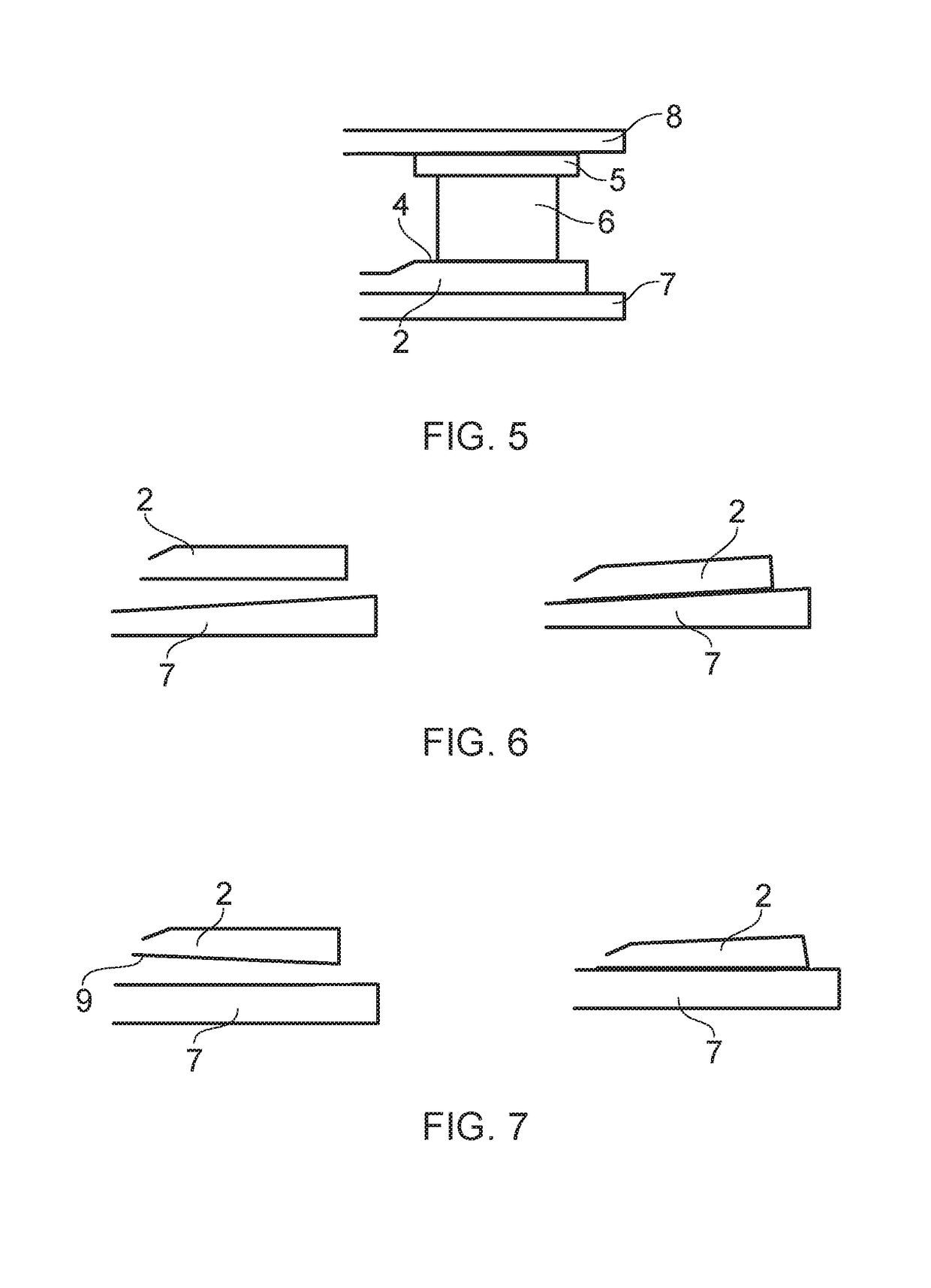

Air inlet structure for turbojet engine nacelle

InactiveCN103562068AReduce air pressureOffset deformationTurbine/propulsion air intakesThin material handlingNacelleEngineering

The invention relates to an air inlet structure (100) for a turbojet engine nacelle, comprising: (i) at least one stationary internal wall (41) intended to be attached to at least one element (20) of a mid-section (2) of the nacelle, and (ii) at least one longitudinal external wall (40) extended by an air inlet lip (3) connected to the stationary internal wall. The structure is characterised in that at least the air-inlet-lip-forming portion is provided with means (30, 60) for depressurising at least part of the lip.

Owner:AIRCELLE

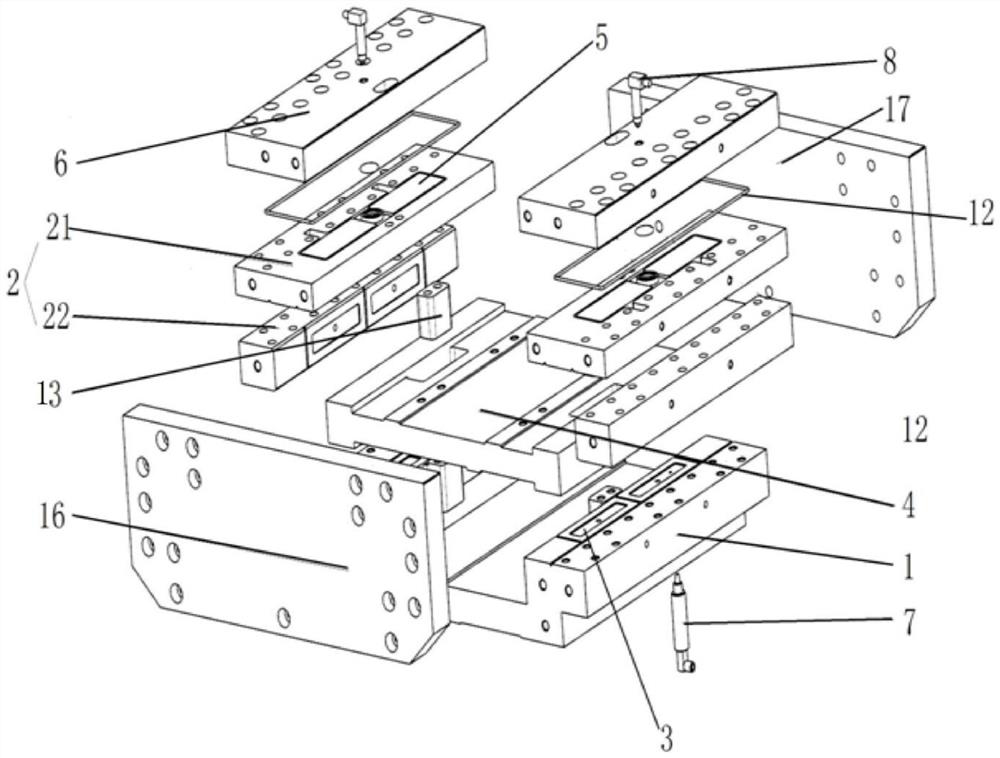

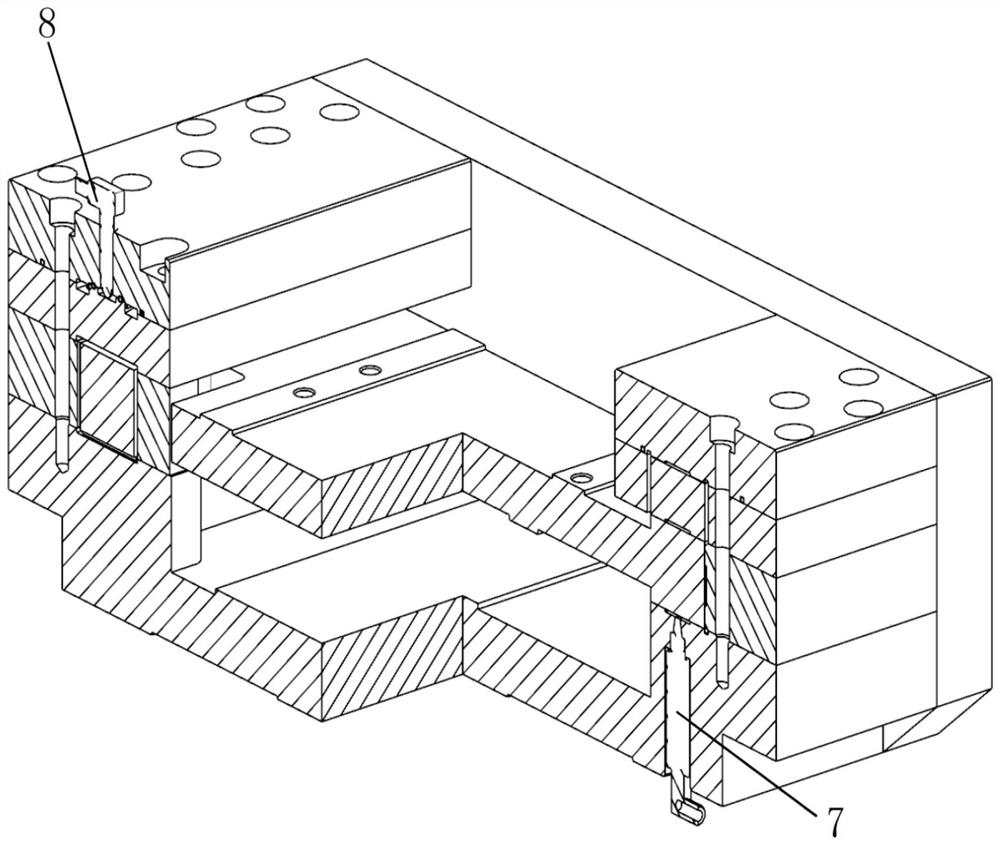

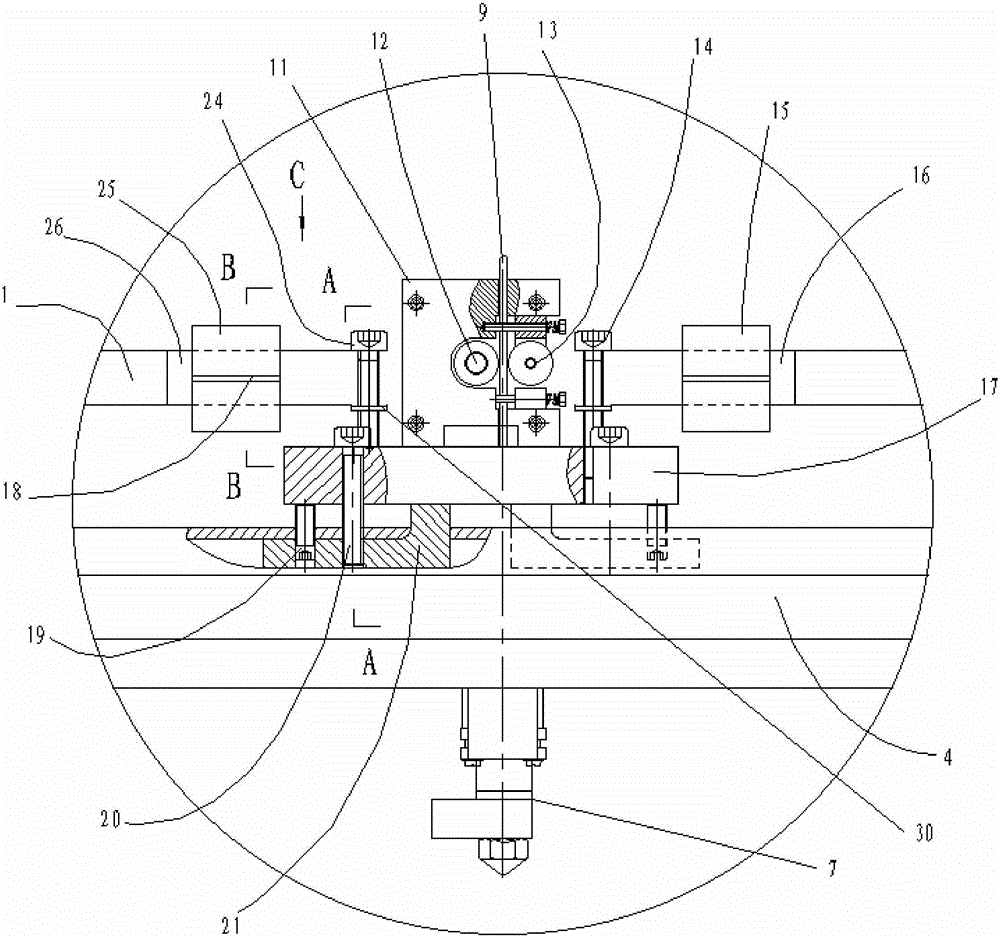

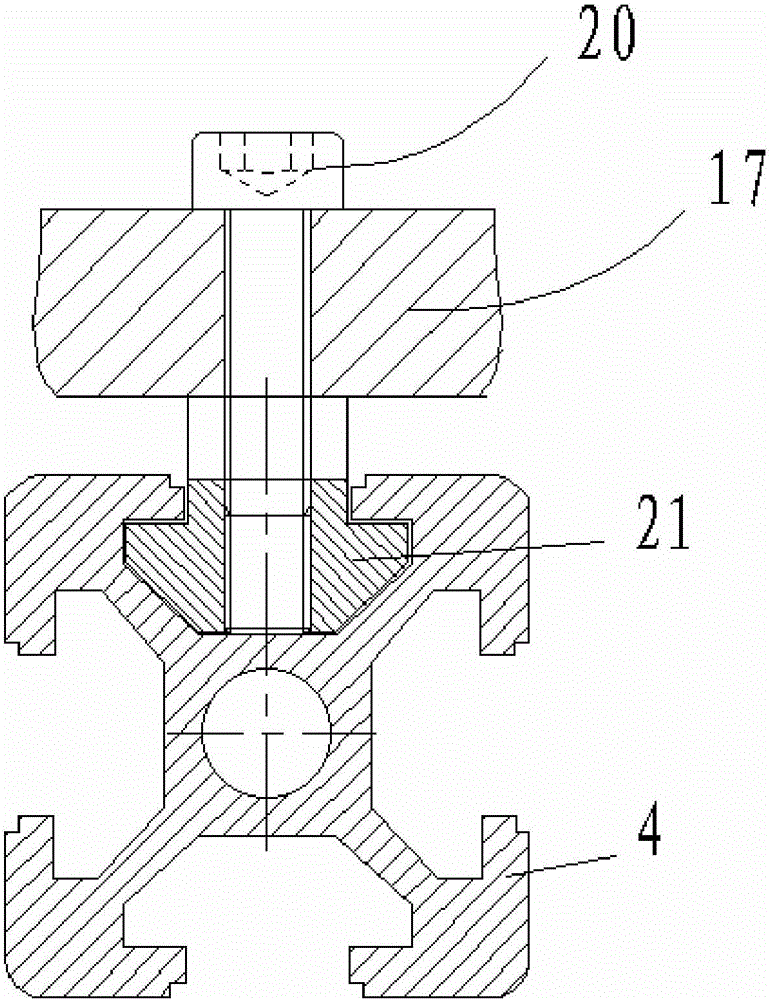

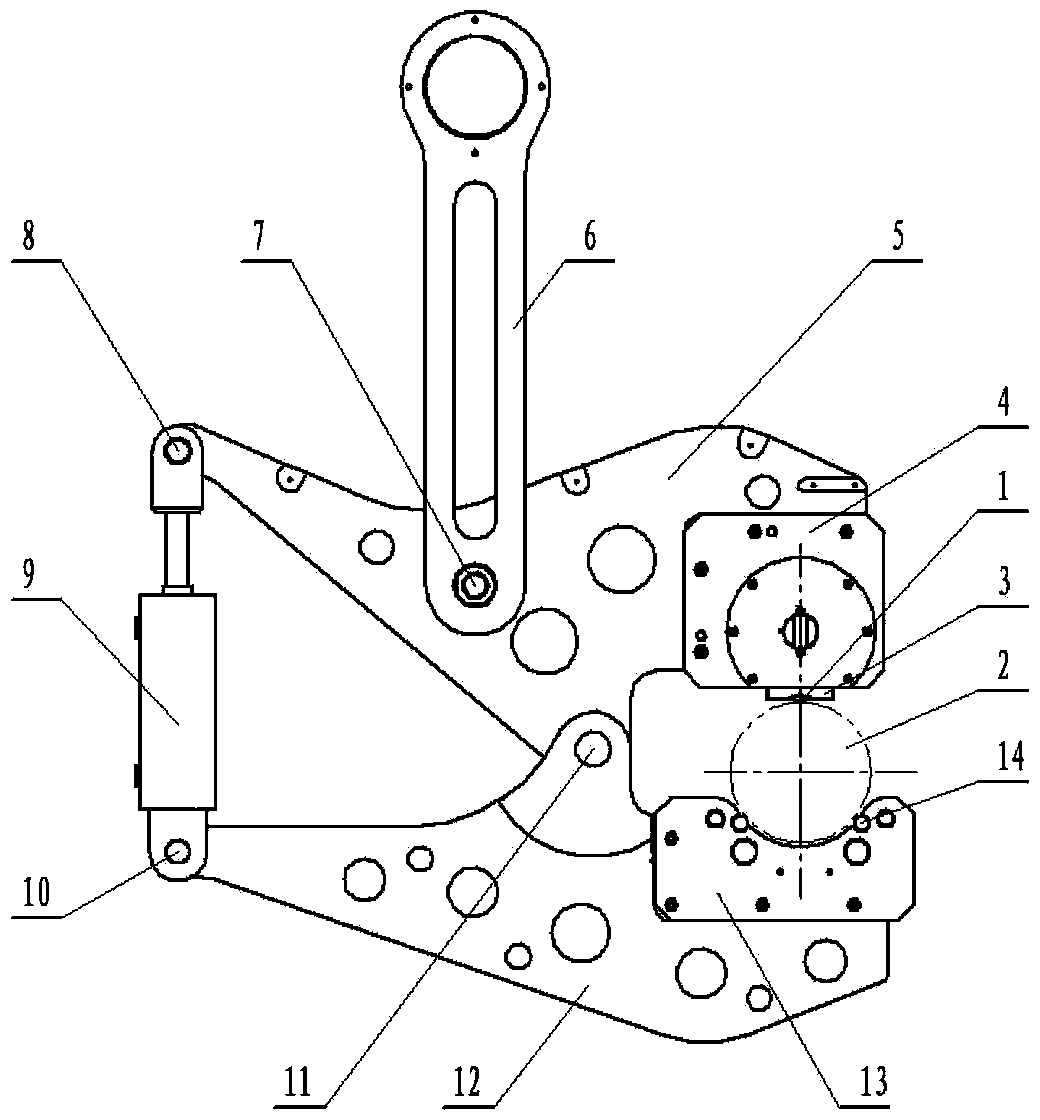

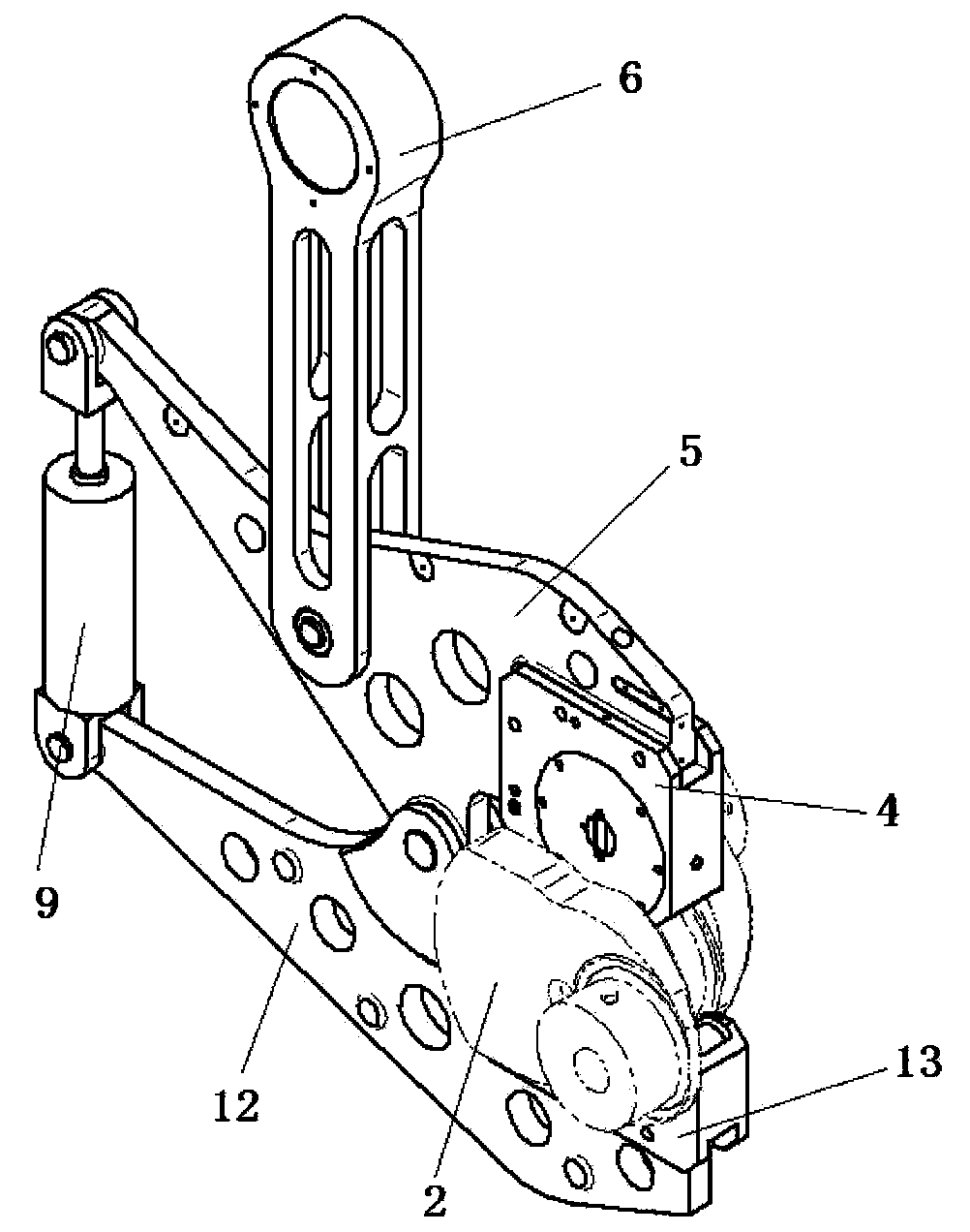

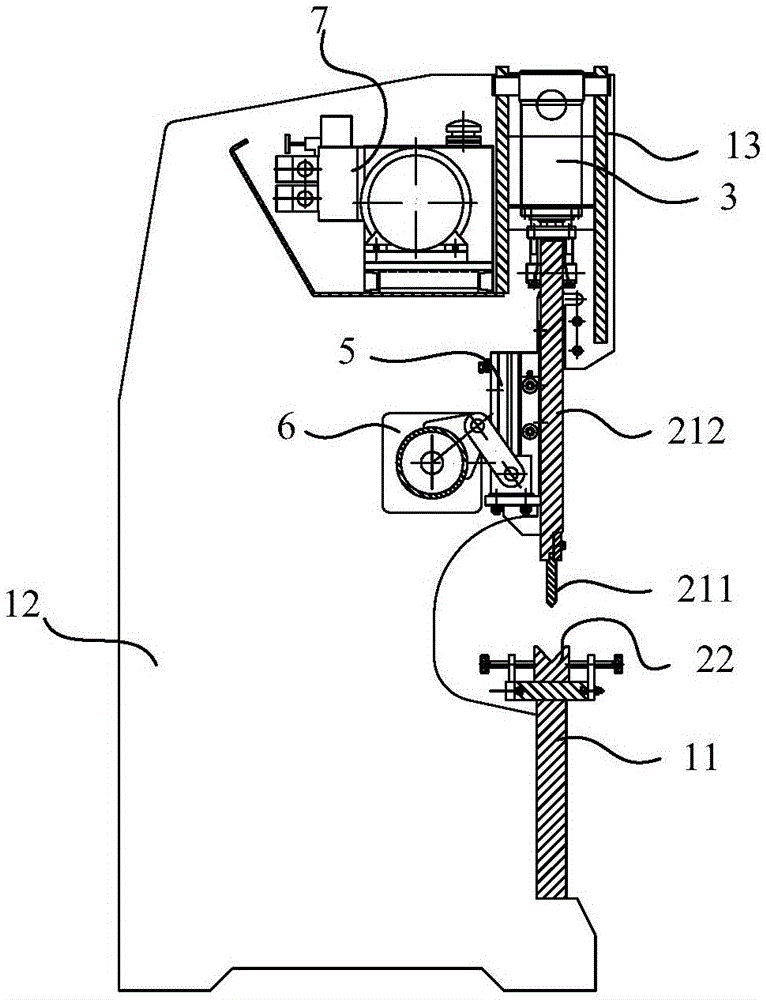

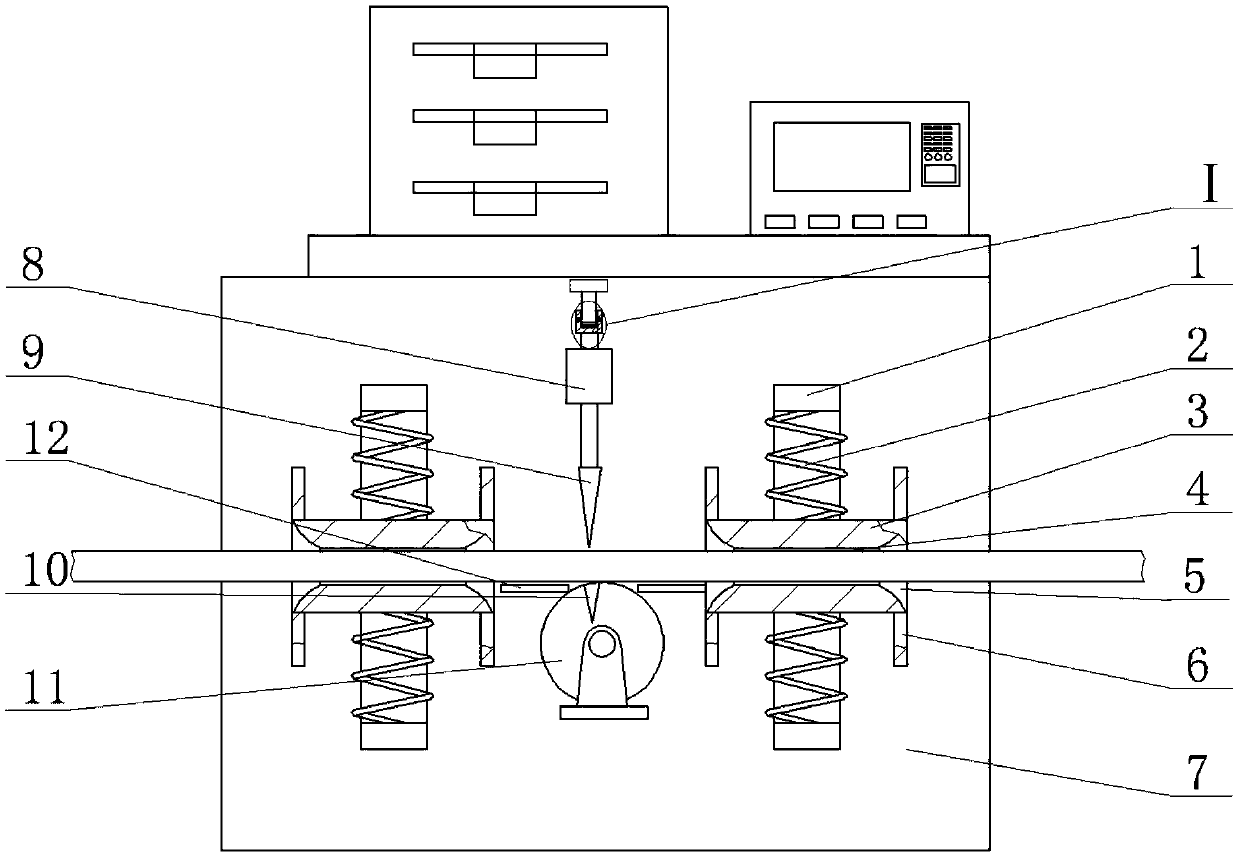

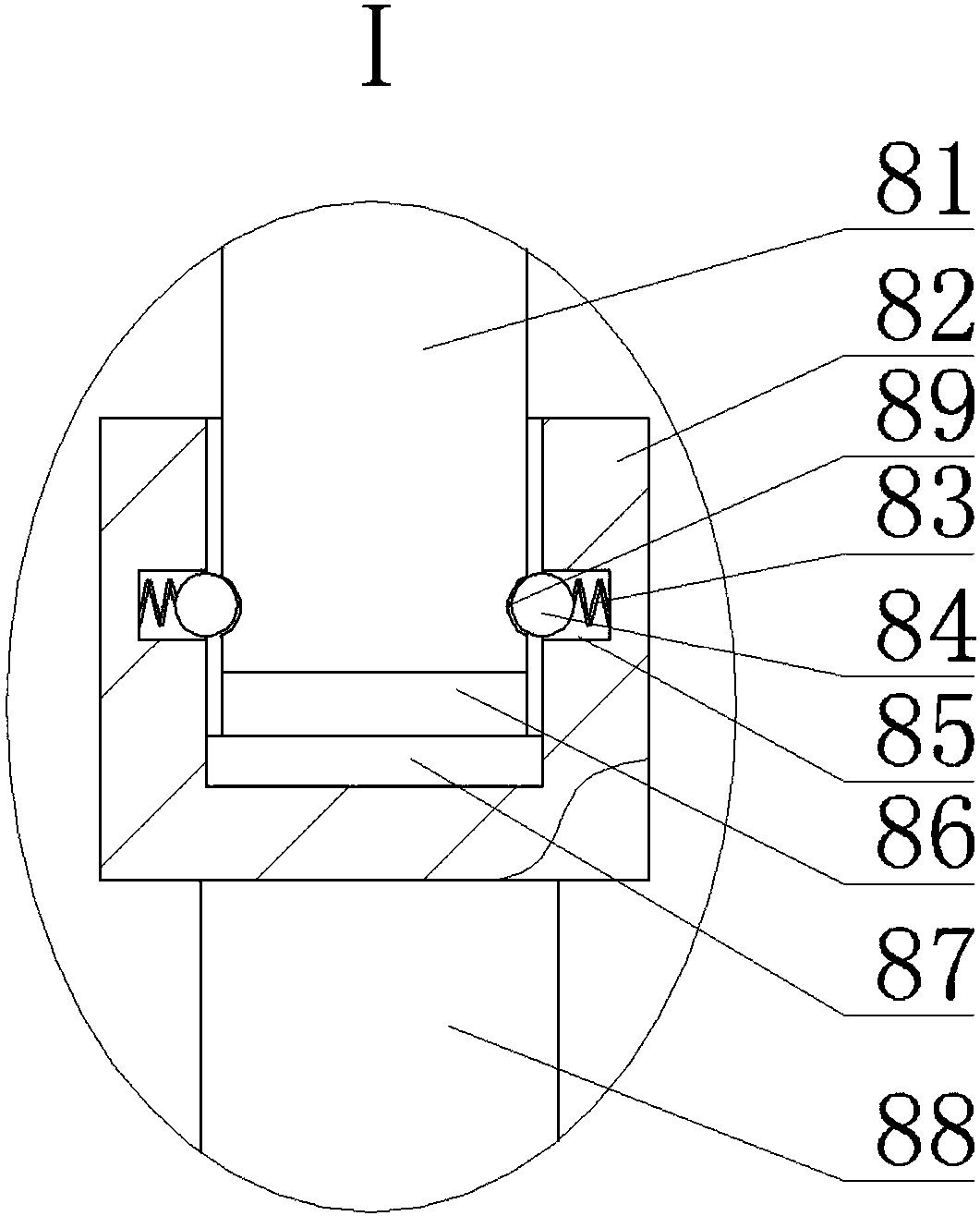

Crankshaft large fillet under cutting groove rolling mechanism

The invention discloses a crankshaft large fillet under cutting groove rolling mechanism which comprises an upper pressing plate, a lower pressing plate, a pressing head assembly and a supporting assembly. The upper pressing plate and the lower pressing plate are hinged and driven by a hydraulic oil cylinder, the pressing head assembly is located at the pressed position of the upper pressing plate and is in location connection with the upper pressing plate, a rotating shaft, a guide wheel and two rollers arranged in a splayed mode are arranged in the pressing head assembly, a rotating shaft is sleeved with a guide wheel, the guide wheel can rotate around the rotating shaft, the two rollers are respectively located at the end corner positions of the lower portion of the guide wheel, the upper ends of the rollers are attached to fillets of the guide wheel, the lower ends of the rollers protrude out of the pressing head assembly, and rolling force is transmitted to a crankshaft large fillet under cutting groove through the guide wheel and the rollers. The supporting assembly is located at the pressed position of the lower pressing plate, is in location connection with the lower pressing plate and is provided with an arc face for containing a crankshaft, and two rotatable supporting shafts are symmetrically arranged on the arc face. When rolling is carried out, the surfaces of the two supporting shafts and the rollers form a circle on a crankshaft journal in a three-point mode. The crankshaft large fillet under cutting groove rolling mechanism can be applied to the rolling technology of a large-scale ship engine and the like requiring the large rolling force.

Owner:GUANGXI YUCHAI MASCH CO LTD

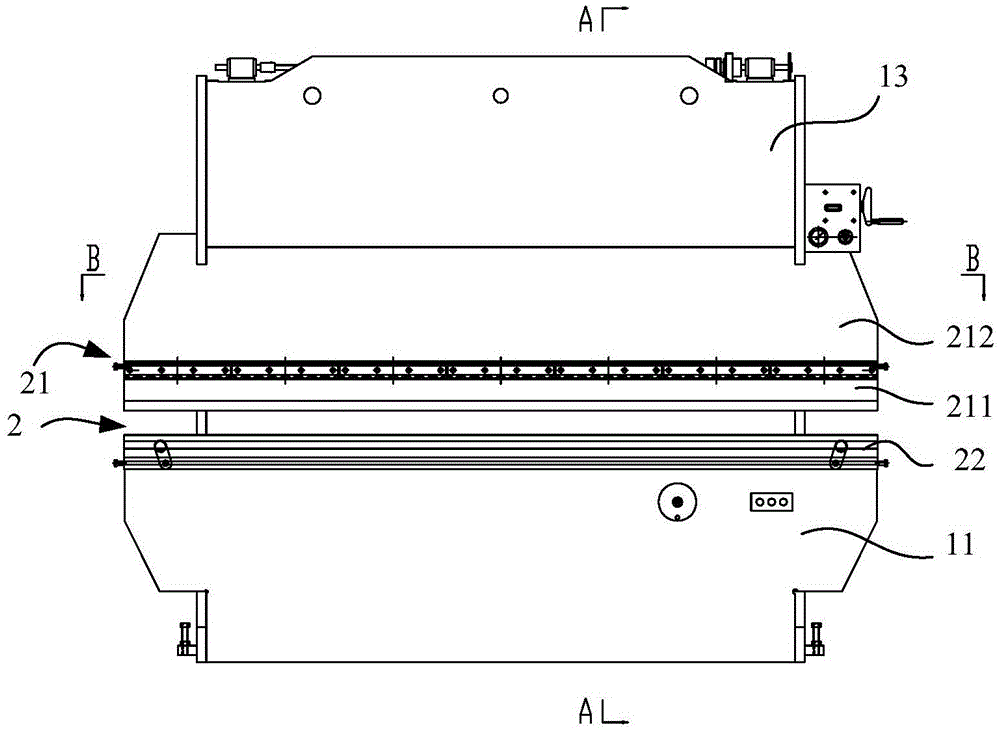

Bending machine and operation method thereof

The invention discloses a bending machine and an operation method thereof, and relates to the technical field of bending machines. The bending machine comprises a machine frame and a die arranged on the machine frame. The die comprises an upper die body and a lower die body which are matched with each other. Oil cylinders are arranged above the upper die body, can provide power for the upper die body, and can make the lower die body achieve flexibility compensation. The operation method includes the step that after the upper die body runs downwards to a lower stop point and completes workpiece bending, the three oil cylinders continue to be controlled to conduct output so that the middle of the upper die body can protrude downwards and deform, wherein the deformation amount of the middle of the upper die body can just offset the deformation amount generated when the lower die body bears force and is indented downwards. The bending machine and the operation method of the bending machine can solve the problems that in the past, the bending linearity is low and automatic flexibility compensation can not be achieved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

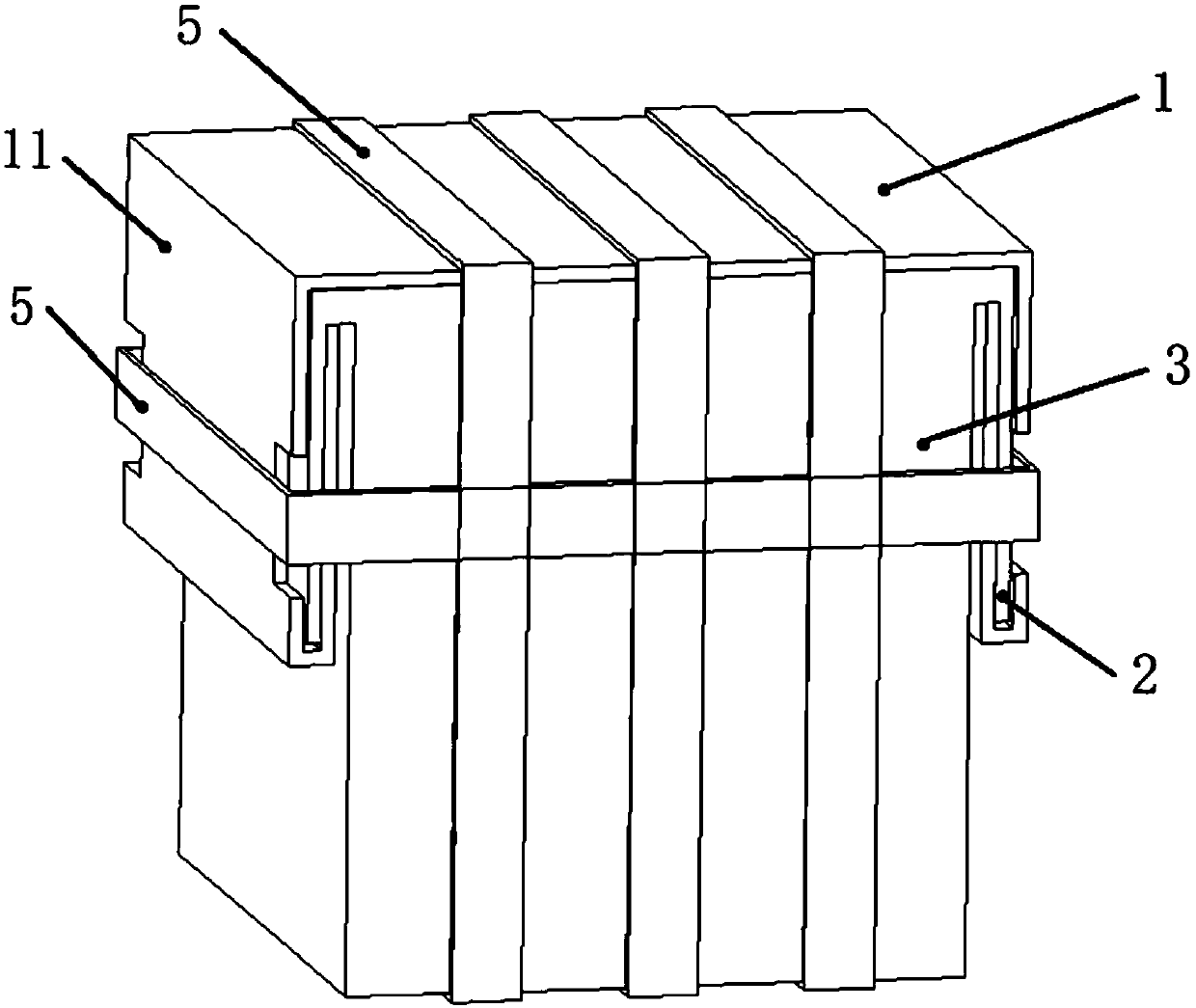

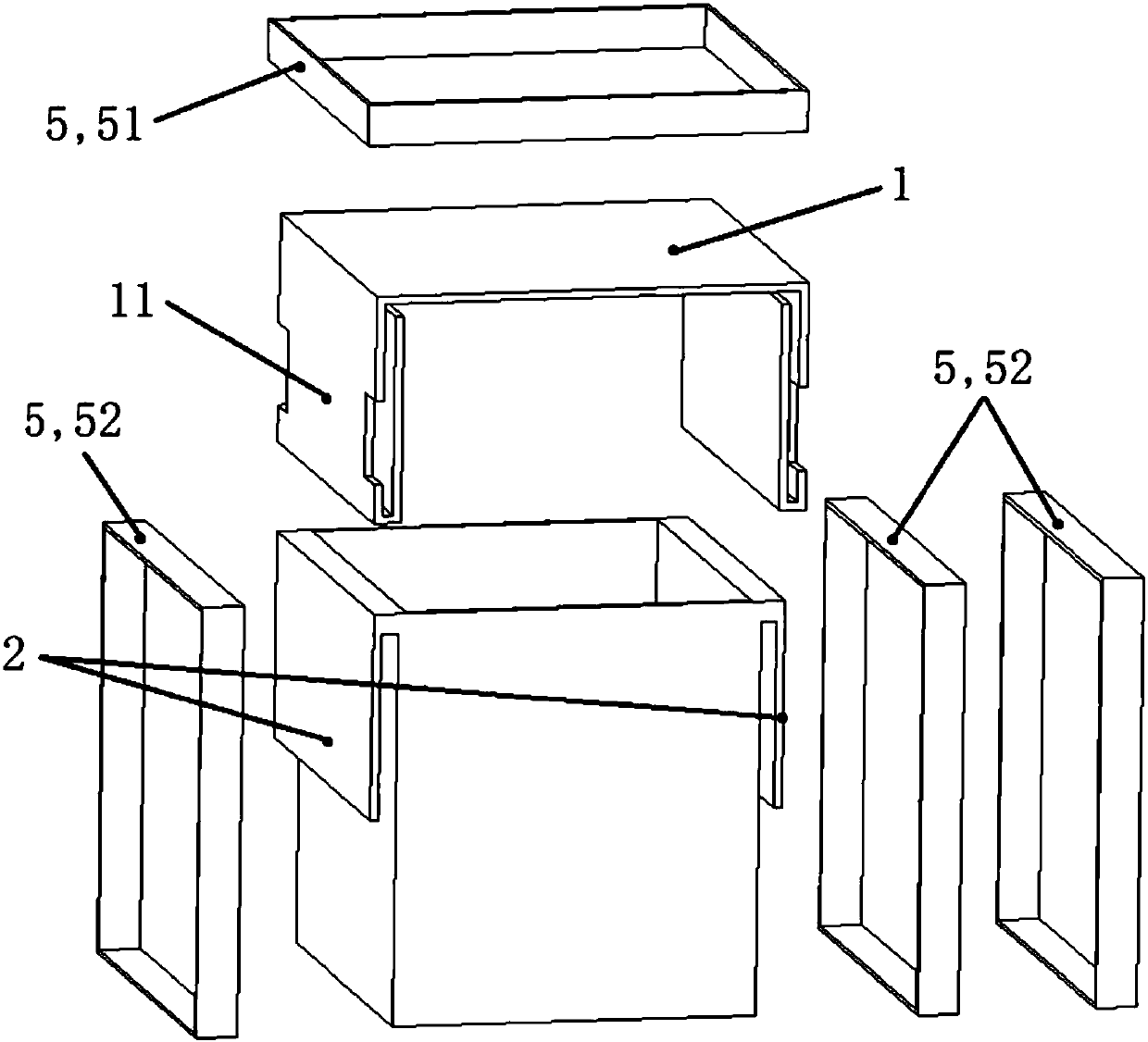

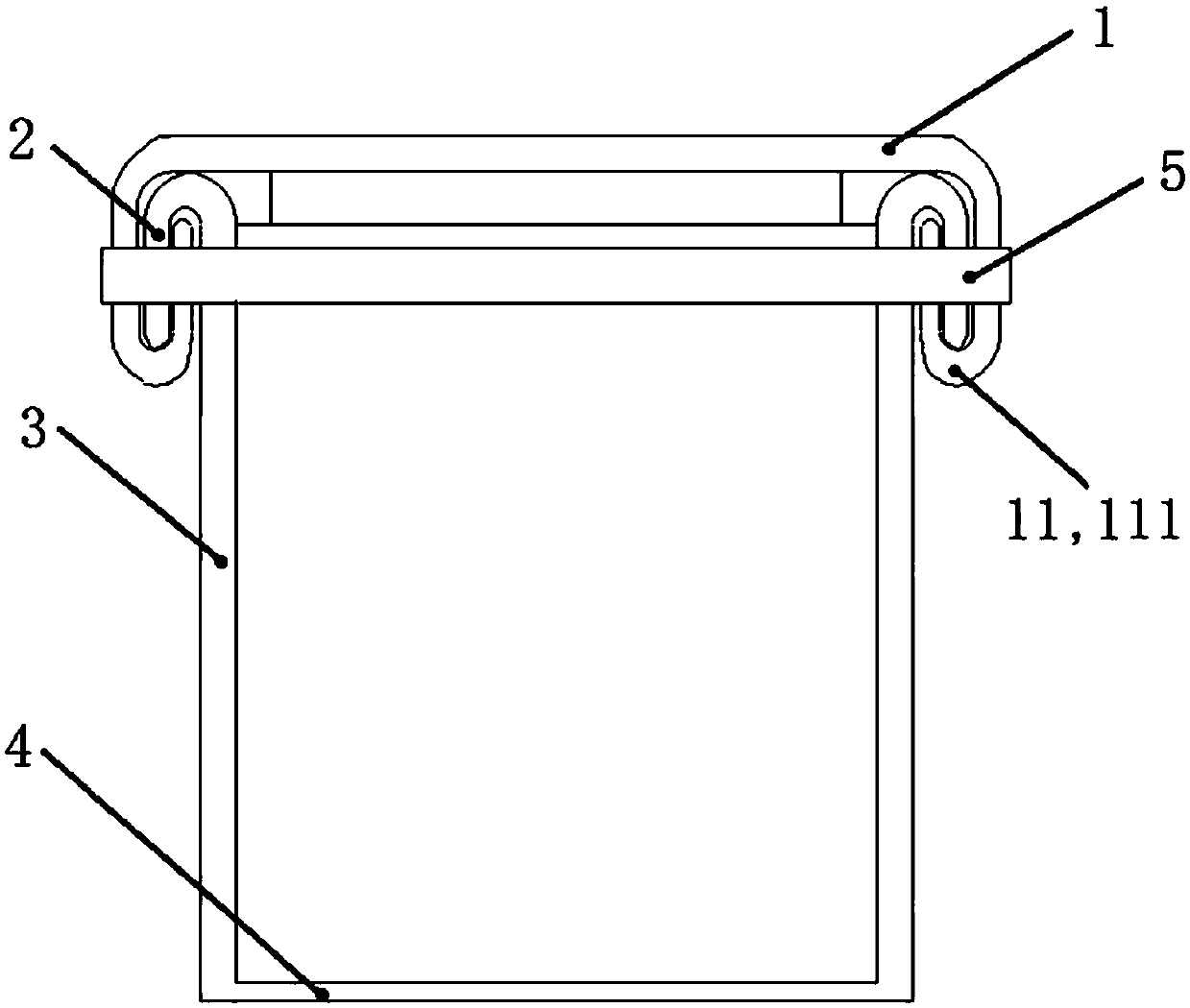

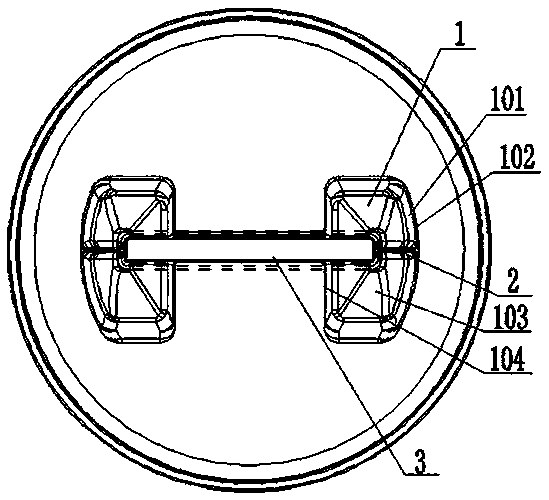

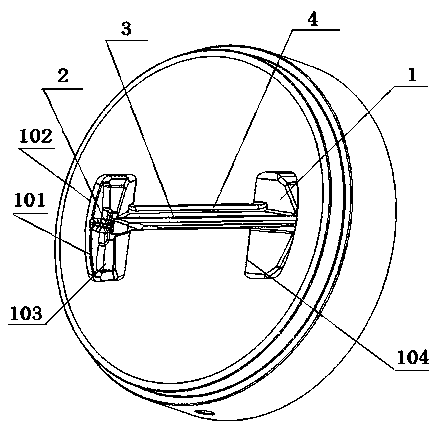

Packaging box for hoisting

ActiveCN109956159AHigh bonding strengthHigh strengthClosures with lifting/suspending meansClosure with auxillary devicesEngineering

Owner:FOSHAN HAIER DRUM WASHING MACHINE +1

7-series hard alloy row material extrusion mold

The invention discloses a 7-series hard alloy row material extrusion mold. The mold comprises a feeding opening, the feeding opening comprises a middle feeding part and side feeding parts, the side feeding parts are symmetrically arranged on the two sides of the middle feeding part to form butterfly shapes, through the mold, edge aluminum supply is ensured, and the phenomenon that the side size isnot qualified is avoided.

Owner:广西南南铝加工有限公司

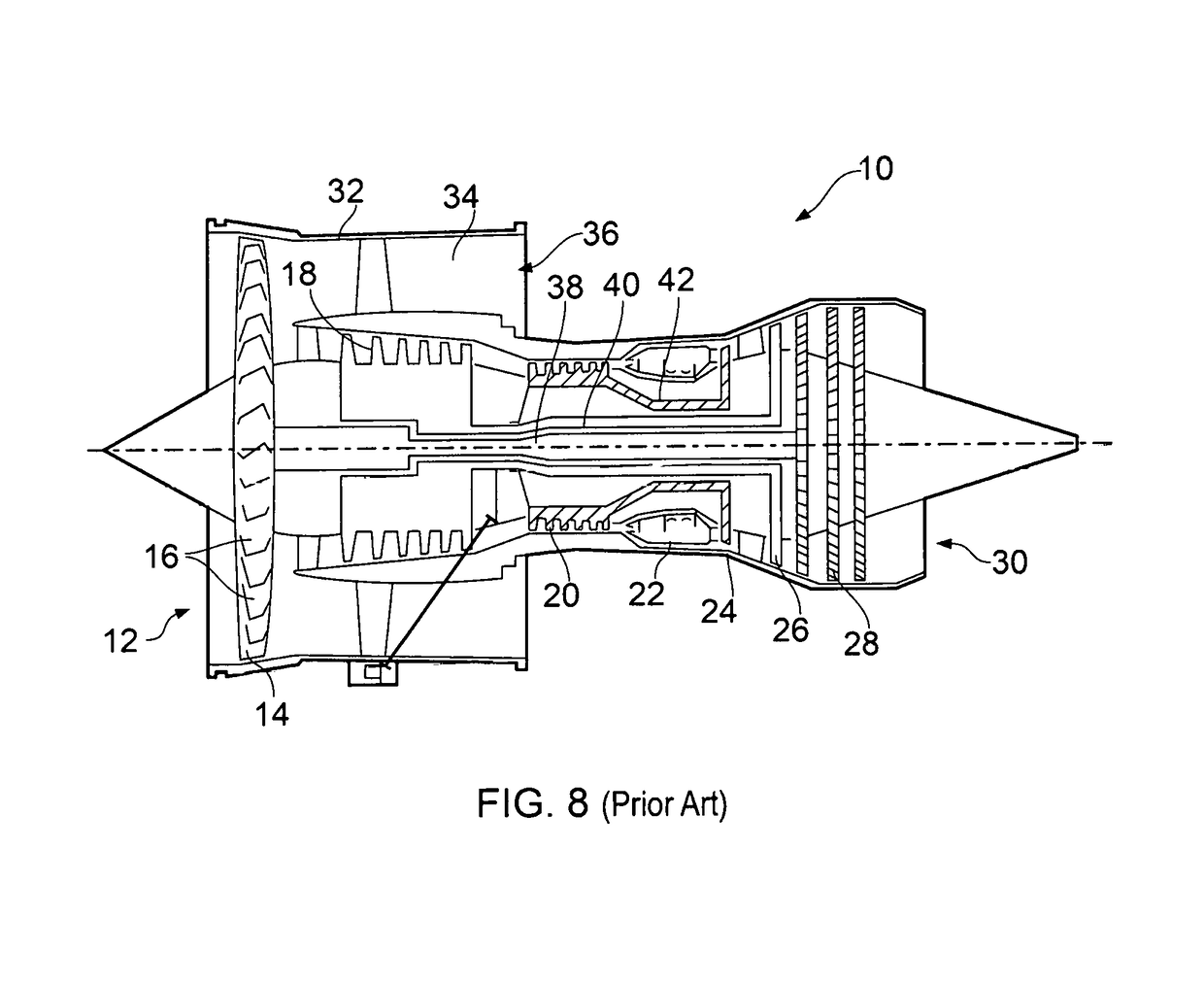

Bearing raceway and a method of manufacturing a bearing

ActiveUS10196981B2Reduce wearConvenient to accommodateRoller bearingsEngine manufactureBearing surfaceMechanical engineering

Owner:ROLLS ROYCE PLC

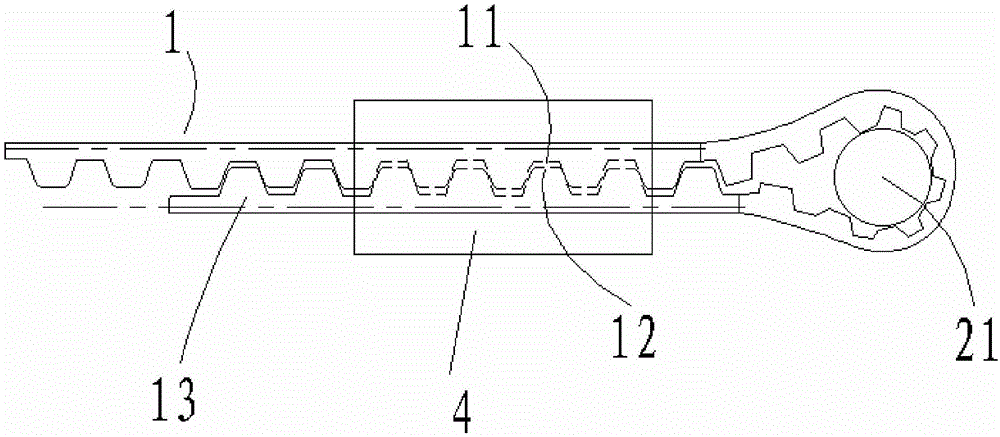

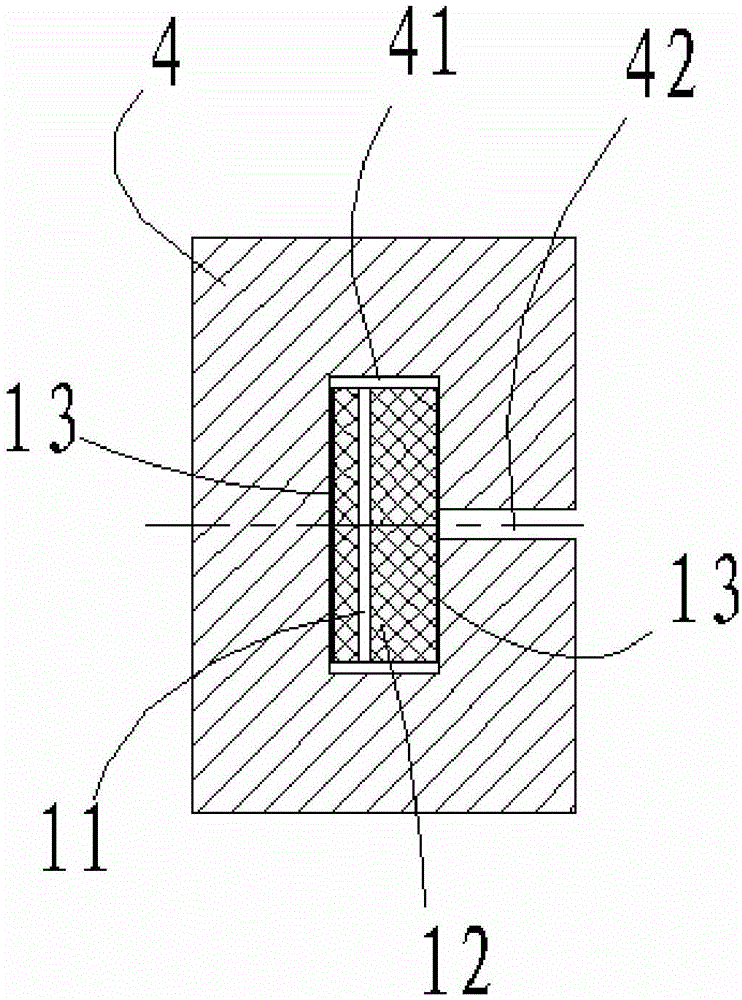

Synchronous belt connecting structure

Owner:UNIV OF JINAN

Spring guided type cutting cable mechanism of low frequency cable assembly crimping system

PendingCN107845940AImprove processing qualityOffset deformationLine/current collector detailsEngineeringContact system

The invention discloses a spring guided type cable cutting mechanism of a low frequency cable assembly crimping system. The spring guided type cable cutting mechanism comprises a base. An electric push rod, support plates, a fixing seat and two sets of high-efficiency buffer guide mechanisms are mounted at the side of the base. A cutter is mounted at a push rod end of the electric push rod. A cutter slot is formed in the fixing seat. The cutter slot is located below the cutter. The cutter slot can cooperate with the cutter. The number of support plates is two. The support plates are located between the cutter and the fixing seat. A gap is present between the two support plates. The two sets of high-efficiency buffer guide mechanisms of the invention can clamp two sides of a cable respectively when the cable is cut. After the cable is cut, springs, guide blocks, and through holes cooperate to make the cable automatically return to a straight state. In this way, the processing quality ofthe cable is improved. When the cable is cut, after the cable is deformed, the springs can bring the guide blocks up and down for fine adjustment so as to adapt to the deformation of the cable.

Owner:无锡胜维电气有限公司

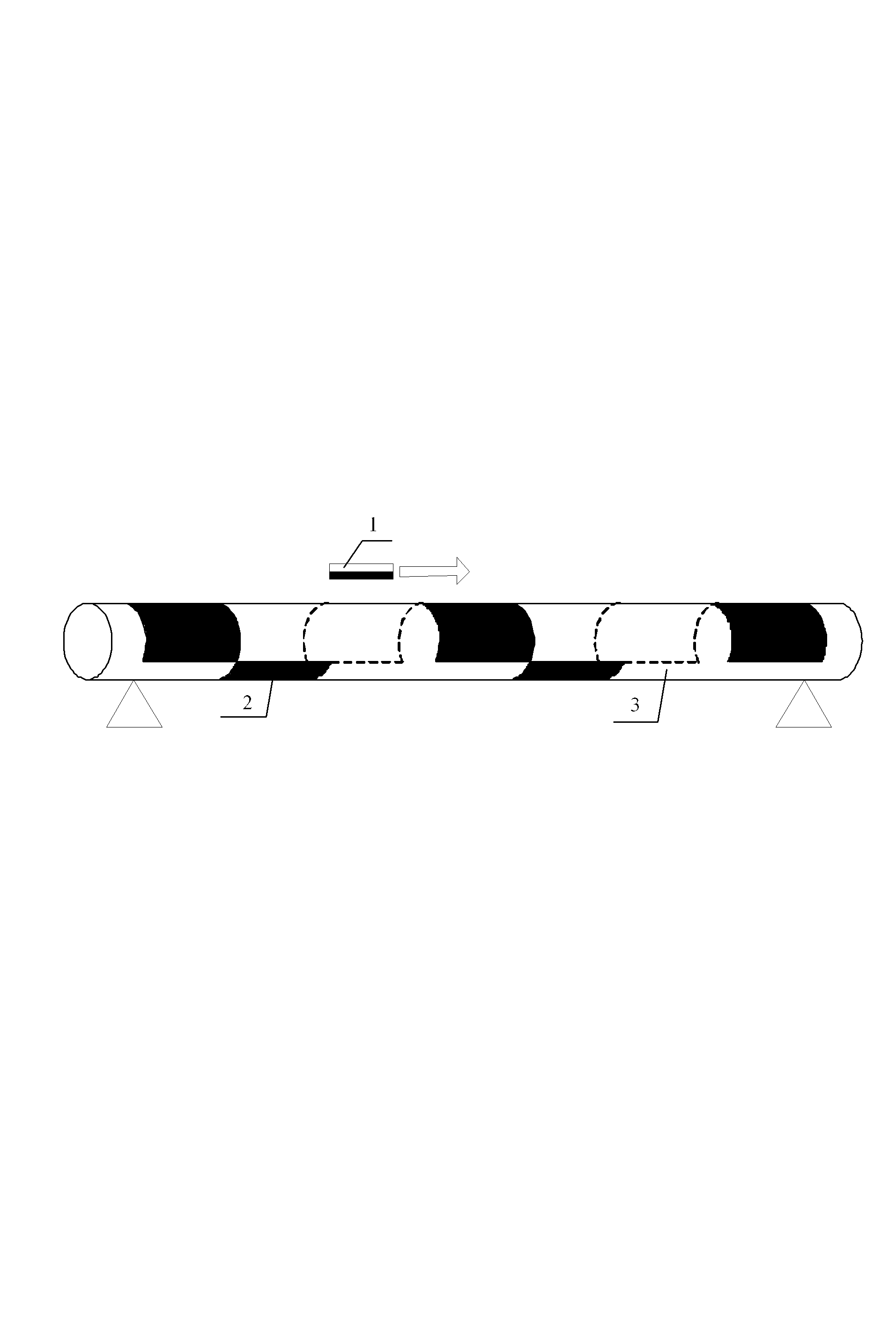

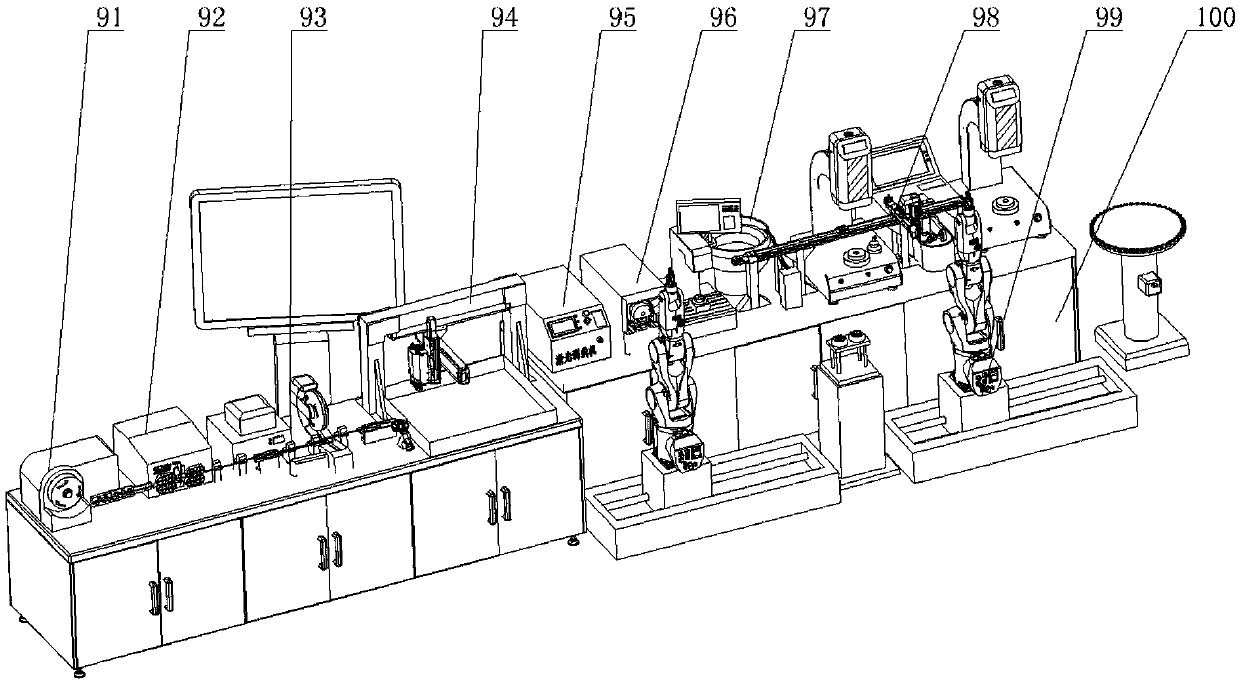

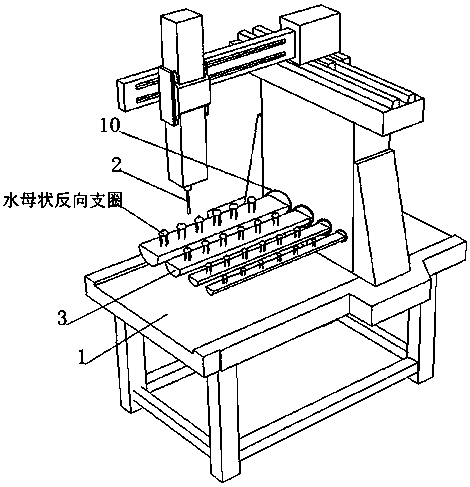

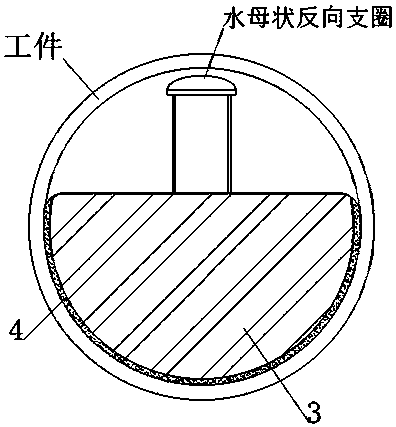

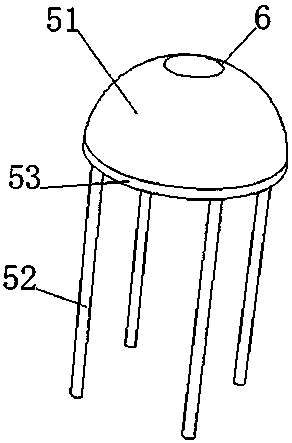

Hollow cylindrical workpiece cylindrical surface semi-automatic drilling and correction integration device

ActiveCN110842251AEnhanced inhibitory effectGuaranteed perfect circlePositioning apparatusBoring/drilling componentsMechanical engineeringJellyfish

The invention discloses a hollow cylindrical workpiece cylindrical surface semi-automatic drilling and correction integration device, and belongs to the electromechanical field. The hollow cylindricalworkpiece cylindrical surface semi-automatic drilling and correction integration device can form support force from bottom to top around workpieces needing to be drilled from internals during drilling to effectively counteract downward deformation of the workpieces during drilling; under the effect of fluctuation reinforcing chains in jellyfish type reverse support rings, the strength can be effectively improved, and the inhibition effect on downward deformation of the workpieces is improved; and meanwhile, through control of rotation of shaping support rods after drilling, correction semi-spheres in multi-point correction layers can be continuously contacted with the inner walls of the workpieces, so that the deformation of orifices after drilling is effectively corrected, the hollow cylindrical workpieces still can effectively guarantee regular circles of the sections after drilling, the drilling quality and the quality of the hollow cylindrical workpieces after drilling are improved, and the later workload for deformation correction is reduced.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

High-performance ball socket

InactiveUS20080063466A1Extended service lifeIncrease flexibilityCouplings for rigid shaftsPivotal connectionsEngineeringMechanical load

A bearing shell for a ball and socket joint made of plastic as well as the ball and socket joint per se, wherein the bearing shell has first areas, which are subject to higher mechanical loads than the other areas of the bearing shell, wherein the material of the bearing shell forming the first areas is formed from a reinforced plastic, and the other areas are made of a less reinforced or unreinforced plastic.

Owner:ZF LEMFOERDER METALLWAREN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com