Rear axle assembly welding method and clamping device special for rear axle assembly welding tool

A clamping device and assembly welding tooling technology, which is applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of expensive processing costs, long processing period, deformation of the car body, etc., and achieve the effect of saving costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

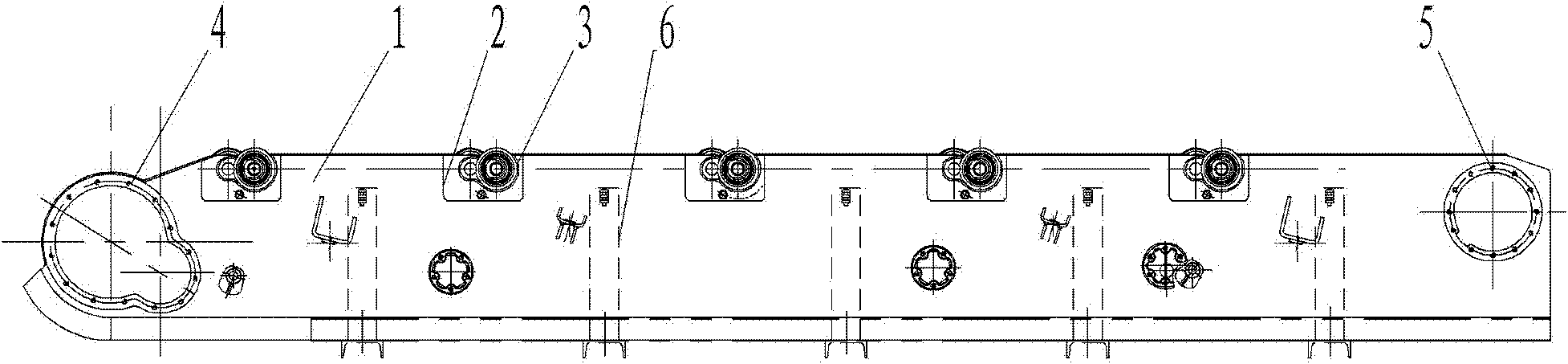

[0013] Embodiment 1, the first step of the present invention, according to the design requirements, process the rear axle assembly welder's clamping device, and cut out each bridge hole 2 including the front and rear axles and the balance bar bracket 3 on the left and right side decks 1 according to the design requirements, Then weld other attachments required by the design, that is, complete the preliminary processing of the side deck 1; in the second step, turn the left and right side decks 1 up and down according to the design requirements and fix them on the frame assembly welding fixture clamping device 6, and After all the balance bar brackets 3 and the rear beam are welded; the third step is to set the rear axle flange 5 in the rear axle hole, and then set the rear axle welder's clamping device in the rear axle flange 5 And fix it; the fourth step is to weld the rear axle flange 5 on the side deck, and weld the front axle flange 4 and the transmission bracket at the same...

Embodiment 2

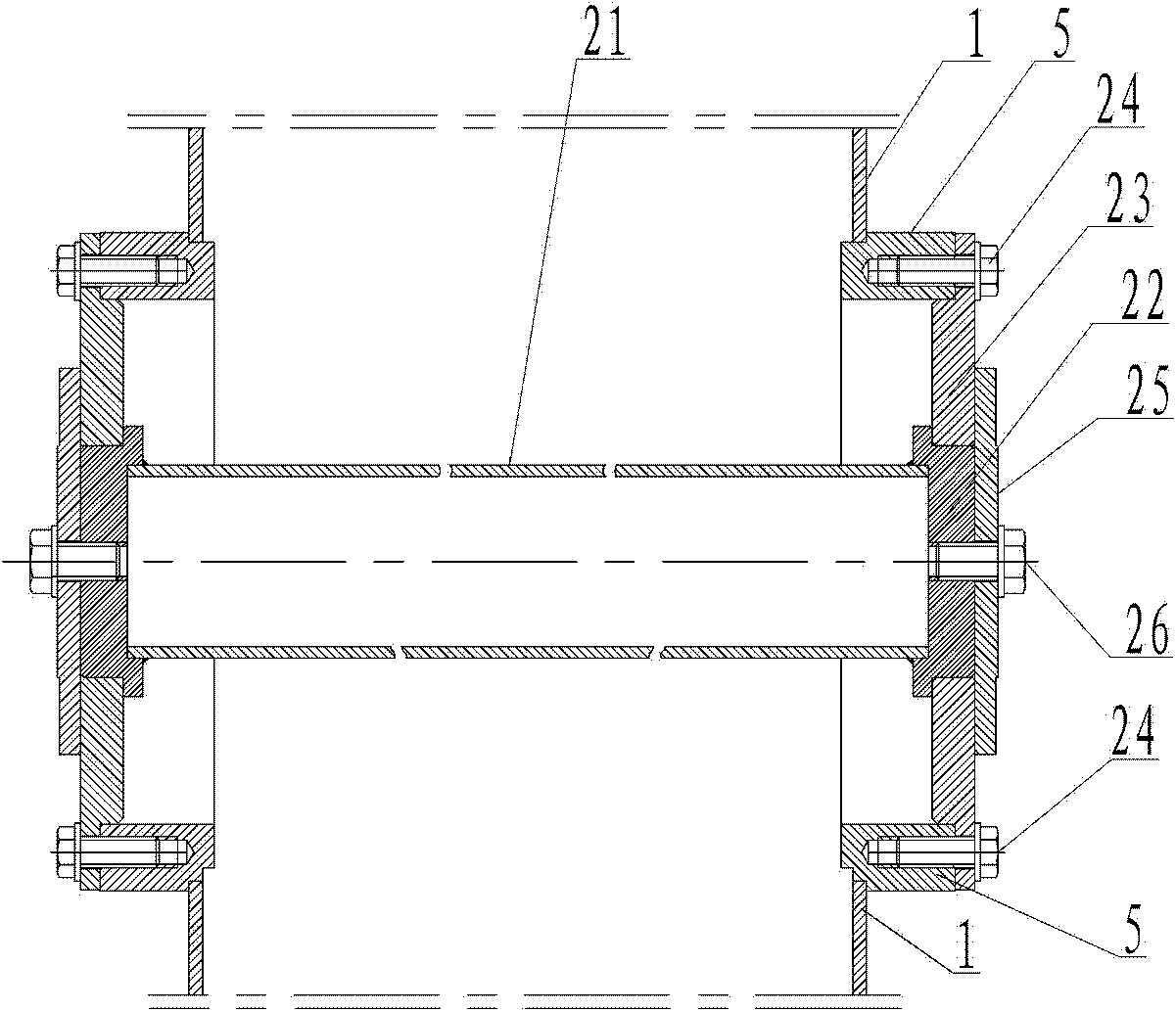

[0014] Embodiment 2, the present invention can use a special rear axle assembly welding tool clamping device for processing to further improve work efficiency. It comprises a rear axle positioning shaft 21, a conical rear axle positioning shaft notch 22, a rear axle positioning plate 23 and a gland 25, and the two ends of the rear axle positioning shaft 21 are fixedly connected with a trapezoidal circular frustum with a thick inner end and a thinner outer end. Bridge locating shaft seam 22, the trapezoidal conical rear axle locating disk 23 that cooperates suit outer end thick inner end thin on rear axle locating axle seam 22, gland 25 is installed in the outer end of rear axle locating disk 23. The rear axle positioning shaft 21 can be a round shaft, a square shaft, or a straight shaft of irregular shape. The diameter of the outer end of the rear axle positioning shaft notch 22 is equal to or slightly smaller than the inner diameter of the rear axle positioning disc 23, so th...

Embodiment 3

[0016]Embodiment 3, the present invention also can be provided with the screw hole corresponding to rear axle flange plate 5 screw holes on the outer end circumference of rear axle positioning plate 23, adopt gland fixing screw 26 to connect rear axle positioning plate 23 with rear axle method The blue plate 5 is connected as a whole. Also can be respectively provided with screw hole at the two ends center of rear axle positioning shaft notch 22, be provided with the through hole that cooperates with the two ends screw holes of rear axle notch 22 on gland 25, adopt positioning disc to fix Screw 24 connects gland 25 with rear axle positioning shaft notch 22 as a whole. refer to figure 1 and figure 2 .

[0017] In the present invention, the flange plate of the rear axle is assembled and fixed on the car body by adopting special tooling for the rear axle and then welded, thereby ensuring the size and tolerance of the inner hole of the rear axle and the position and shape accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com