Hollow cylindrical workpiece cylindrical surface semi-automatic drilling and correction integration device

A semi-automatic, cylindrical technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as large workload and cost, poor drilling quality, large deformation, etc., to achieve Guaranteed service life, improved strength, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

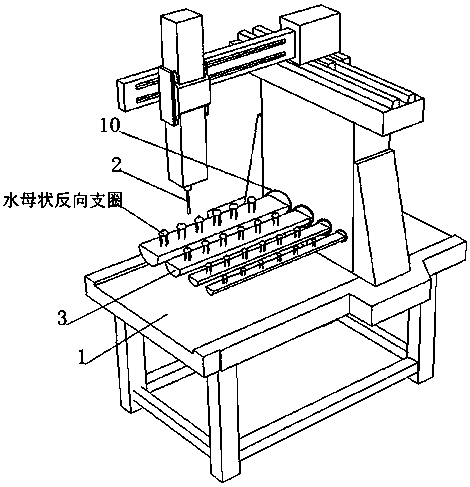

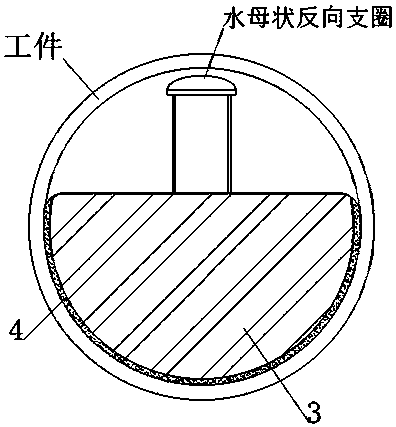

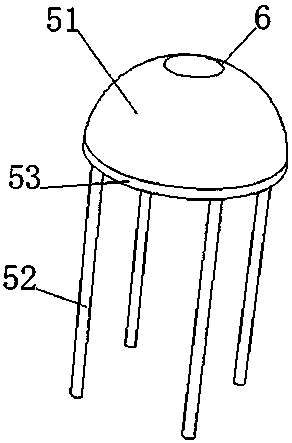

[0043] see figure 1 , an integrated device for semi-automatic drilling and correction of hollow cylindrical workpiece cylindrical surface, comprising a punching device body 1, a three-axis punching assembly and a PLC controller are installed on the working table at the upper end of the punching device body 1, and the three-axis punching assembly The lower end is equipped with a drill bit 2, and the left end of the three-axis drilling assembly is rotationally connected with a plurality of shaping struts 3 controlled by a motor, so that it can adapt to different types of hollow cylindrical workpieces. The outer surface of the shaping strut 3 is fixedly connected with multiple sizes. The multi-point correction layer 4, the left end of the three-axis punching assembly has a plurality of workpiece clamping grooves 10 corresponding to the multi-point correction layer 4, and the workpiece clamping grooves 10 are located outside the multi-point correction layer 4, and the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com