Patents

Literature

1538 results about "Semi automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-Automation is a process or procedure that is performed by the combined activities of man and machine with both human and machine steps typically orchestrated by a centralized computer controller. Within manufacturing, production processes may be fully manual, semi-automated, or fully automated. In this case, semi-automation may vary in its ...

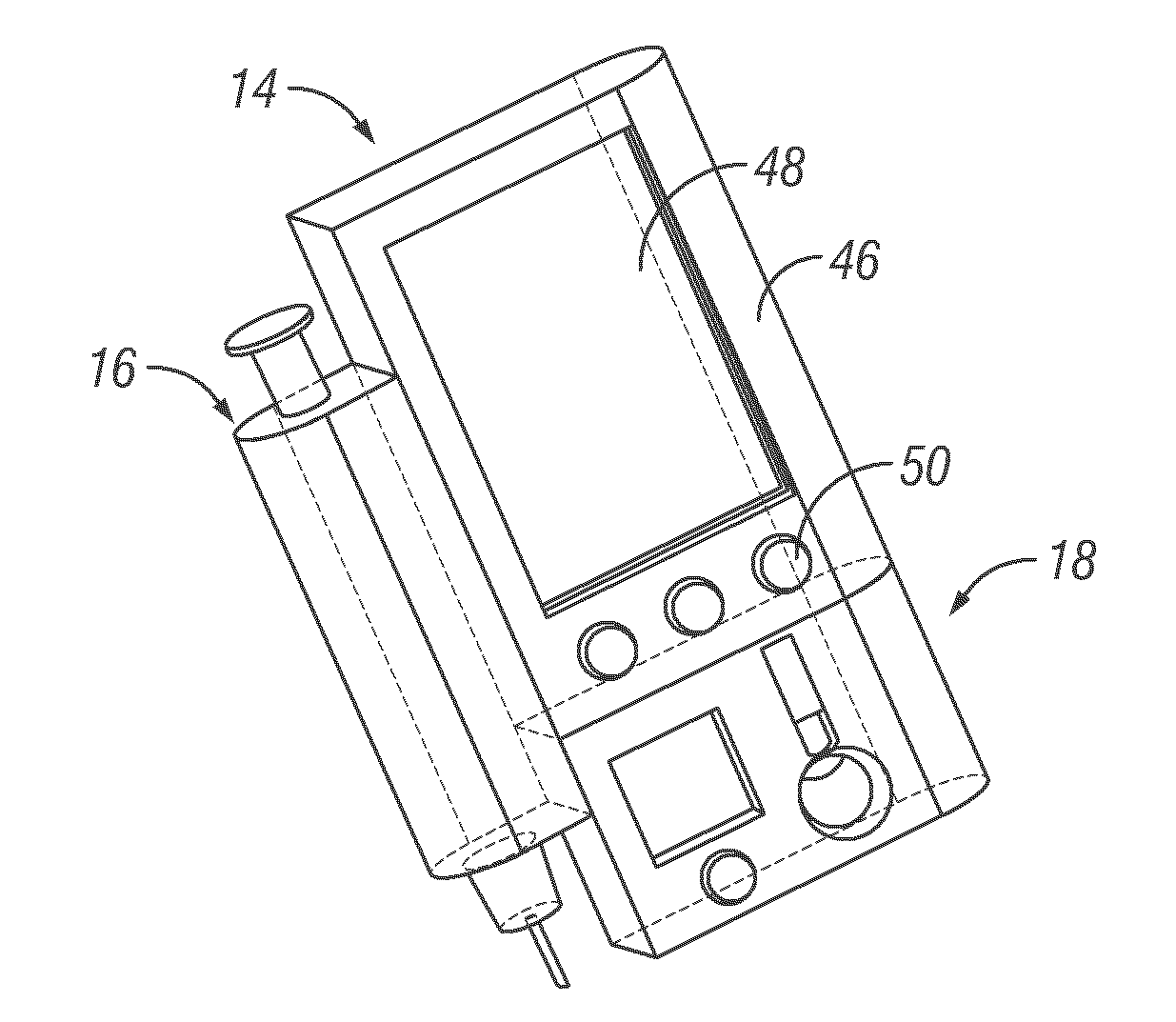

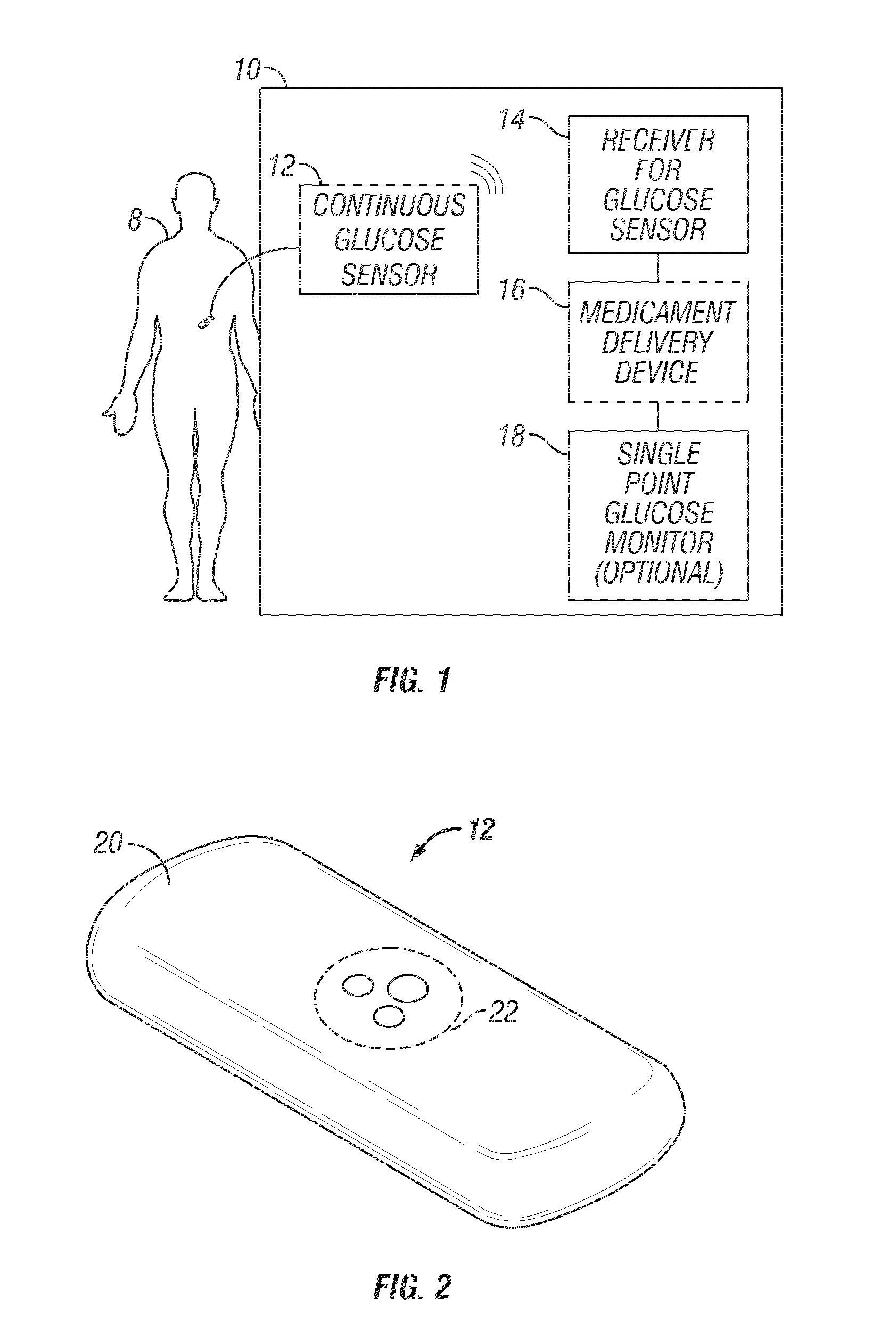

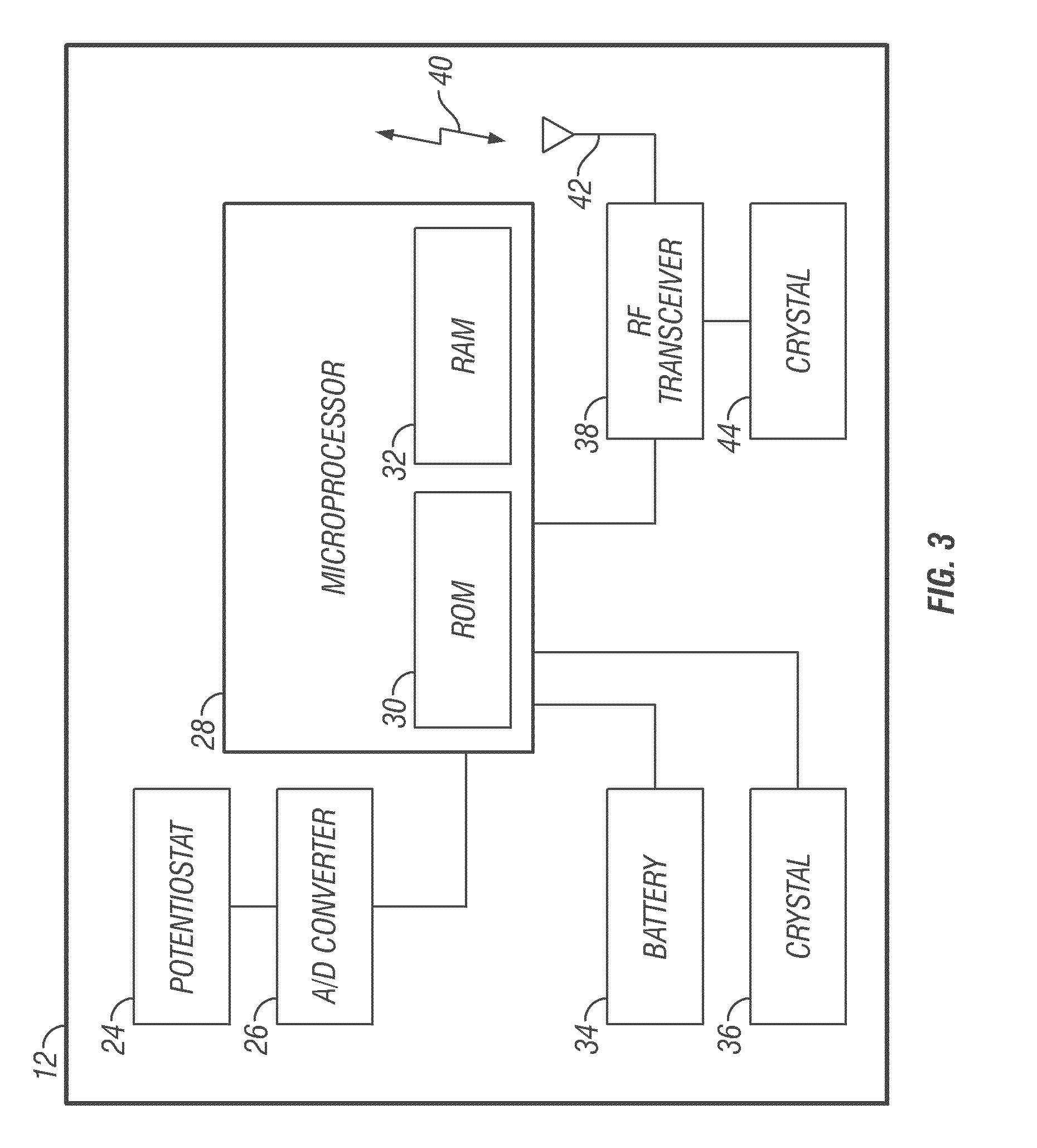

Integrated delivery device for continuous glucose sensor

Systems and methods for integrating a continuous glucose sensor, including a receiver, a medicament delivery device, and optionally a single point glucose monitor are provided. Manual integrations provide for a physical association between the devices wherein a user (for example, patient or doctor) manually selects the amount, type, and / or time of delivery. Semi-automated integration of the devices includes integrations wherein an operable connection between the integrated components aids the user (for example, patient or doctor) in selecting, inputting, calculating, or validating the amount, type, or time of medicament delivery of glucose values, for example, by transmitting data to another component and thereby reducing the amount of user input required. Automated integration between the devices includes integrations wherein an operable connection between the integrated components provides for full control of the system without required user interaction.

Owner:DEXCOM INC

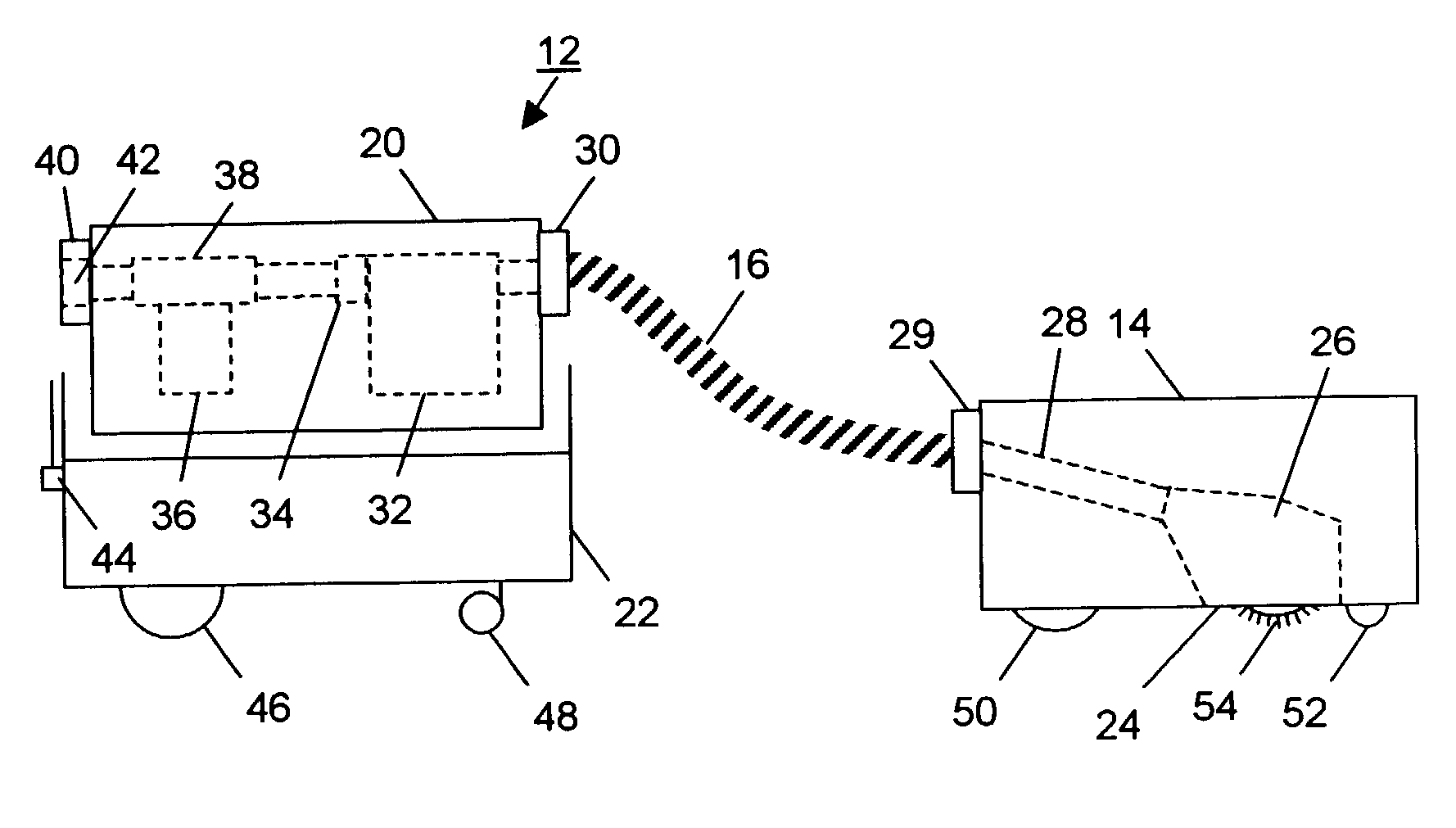

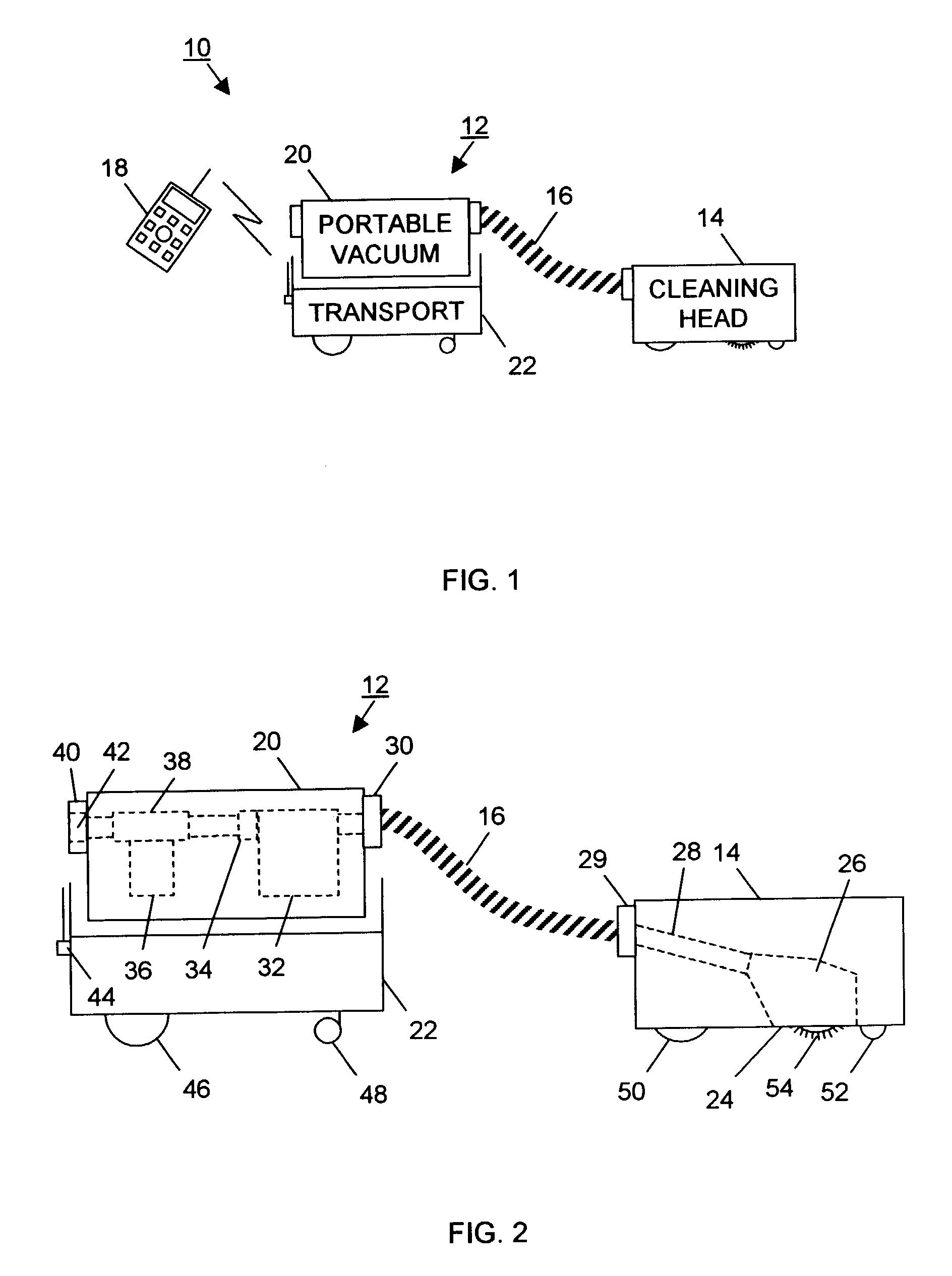

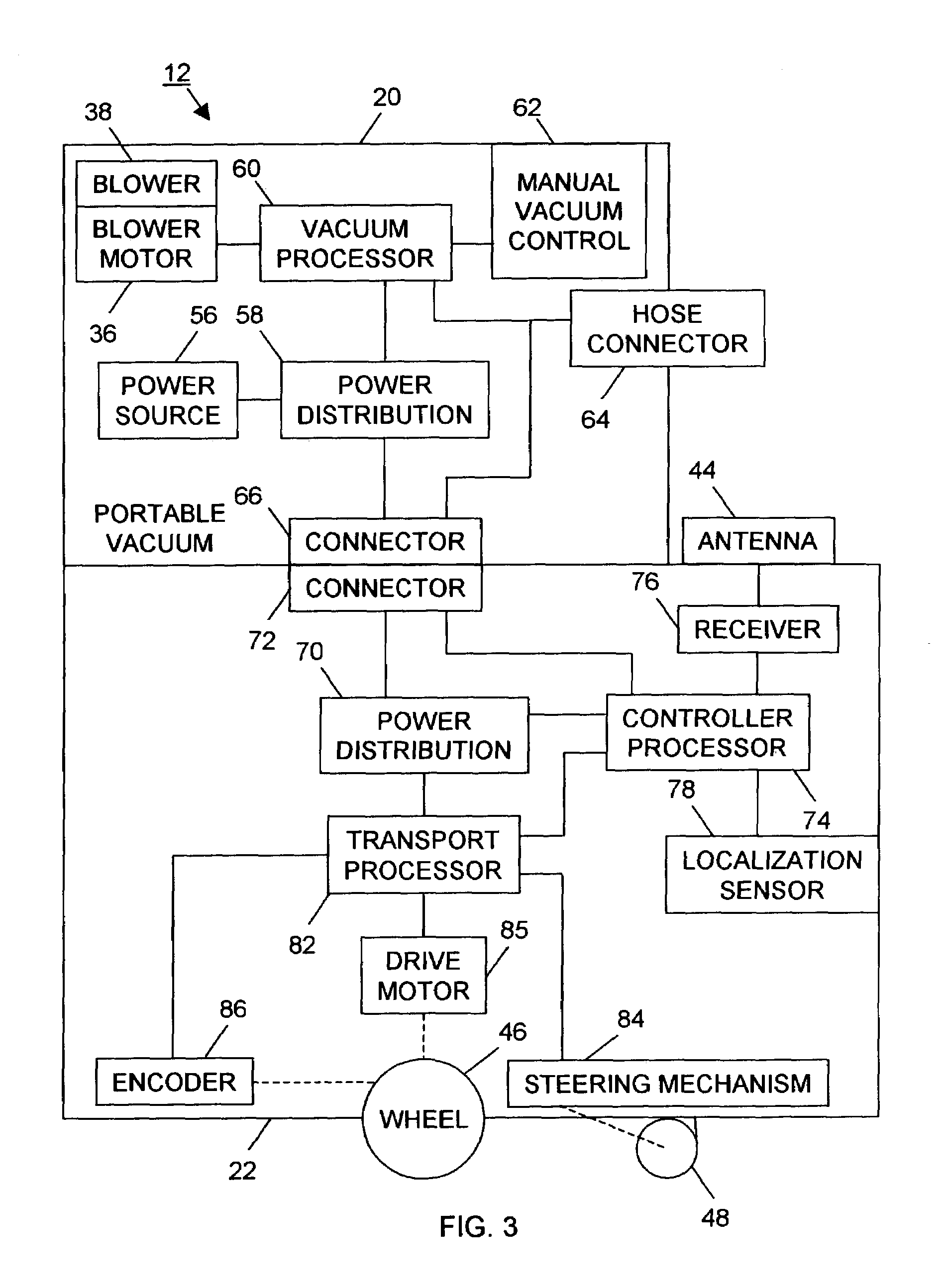

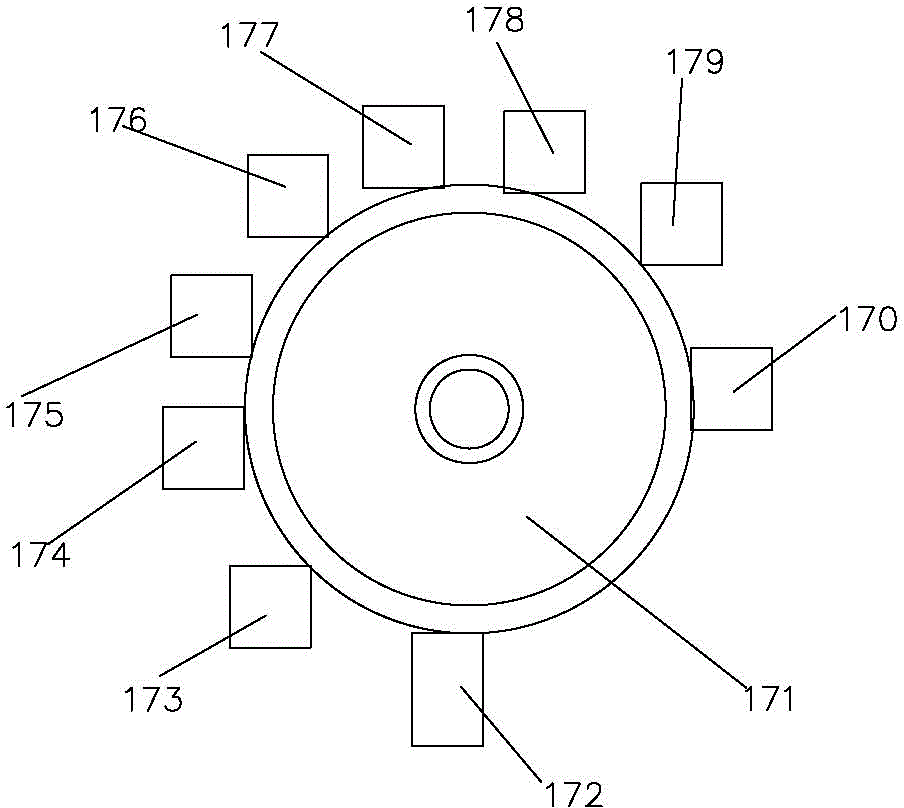

Robotic vacuum with removable portable vacuum and semi-automated environment mapping

ActiveUS7113847B2Programme-controlled manipulatorAutomatic obstacle detectionRemote controlRobotic arm

A robotic vacuum cleaner (10) with a self-propelled controller (12) with a vacuum source (36, 38) and a dirt receptacle (32), a self-propelled cleaning head (14) with a suction inlet (24), and an interconnecting hose (16) is provided. The controller and cleaning head cooperatively traverse a surface area in tandem when the interconnecting hose is connected between the cleaning head and the controller. In one embodiment, the controller includes a power source (56) making the robotic vacuum autonomous. In another embodiment, the controller includes a power cord dispense / retract assembly (168) to provide access to utility power. In another aspect, the controller includes a portable vacuum (20) that is removed for manual operations. In still another aspect, a method of semi-automated environment mapping for a self-propelled robotic vacuum is provided. With respect to the method, the robotic vacuum also includes a remote control (18).

Owner:ROYAL APPLIANCE MFG

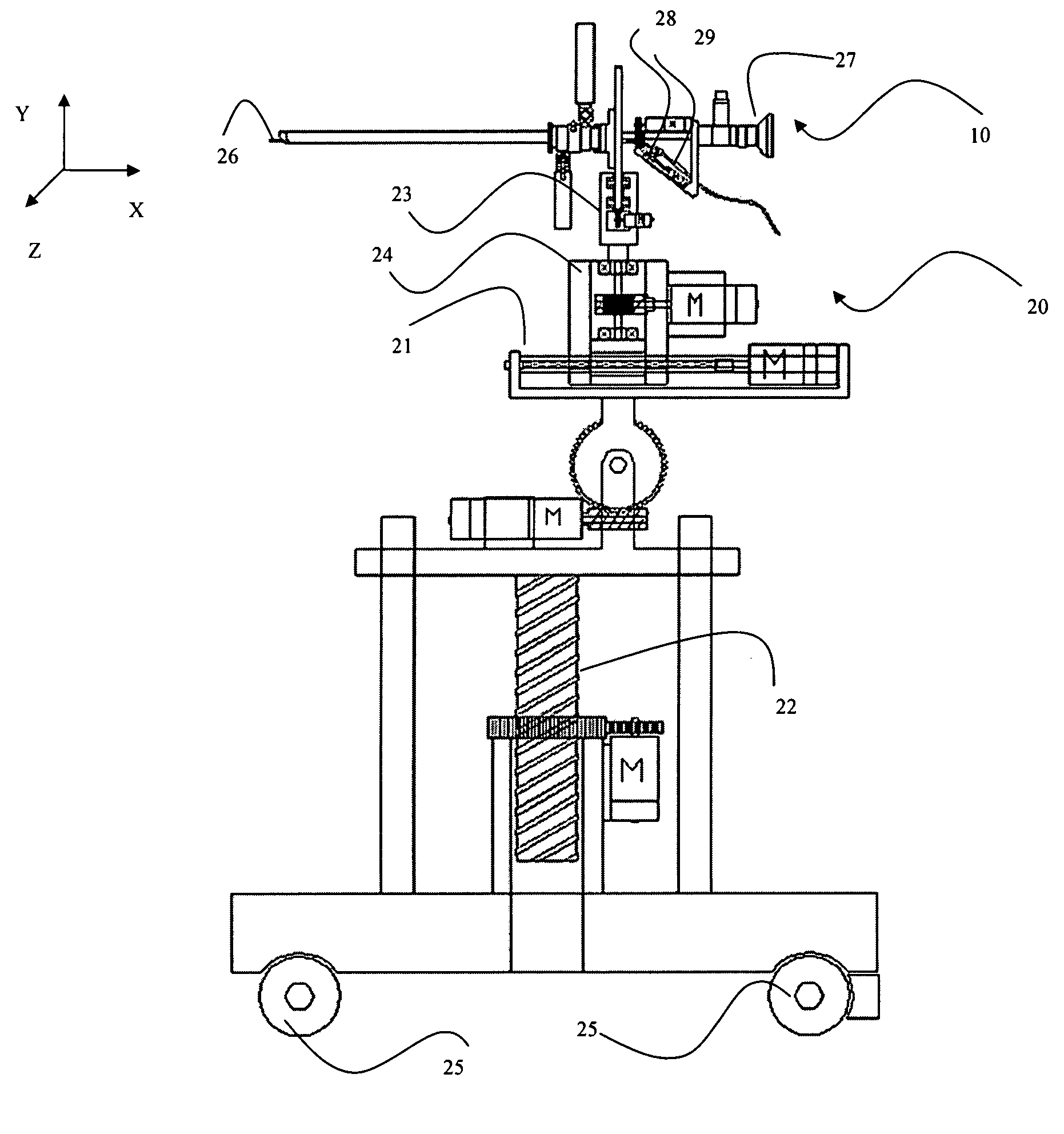

Robotic surgical system

InactiveUS20090228019A1Quicker procedureDiagnosticsSurgical instrument detailsSurgical operationEngineering

It is an object of the present invention to provide an automated, a semi-automated, a surgeon-guided quasi-automated and / or a fully surgeon's controlled surgical system surgical system useful for performing a fully automated medical procedure within a body cavity such that faultless and quick medical procedure is obtained. Each of the surgical systems comprises: (a) at least one effecter for performing the medical procedure; (b) at least one maneuverable platform reversibly coupled with the effecter; the platform provides the effecter with a scheduled set of independent displacements selected from a group consisting of up to six (degrees of freedom) DOFs, namely linear movement along the X,Y,Z-coordinates, and radial movement around the X,Y,Z coordinates, such that the time-resolved spatial position of the effecter is defined by the up to six coordinates (three-dimensional spatial position, 3DSP); and (c) sensing and processing means.

Owner:GROSS YOSEF +4

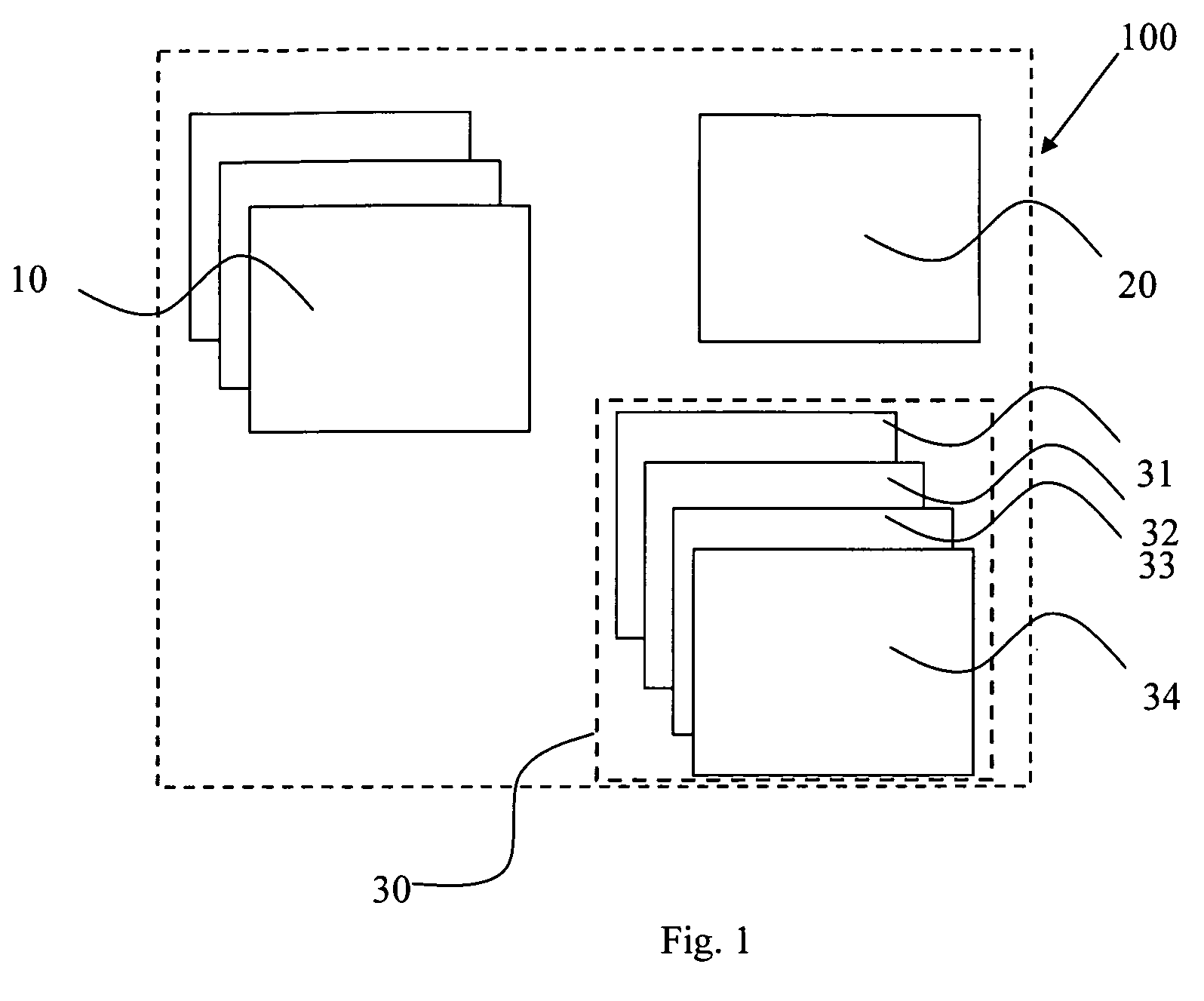

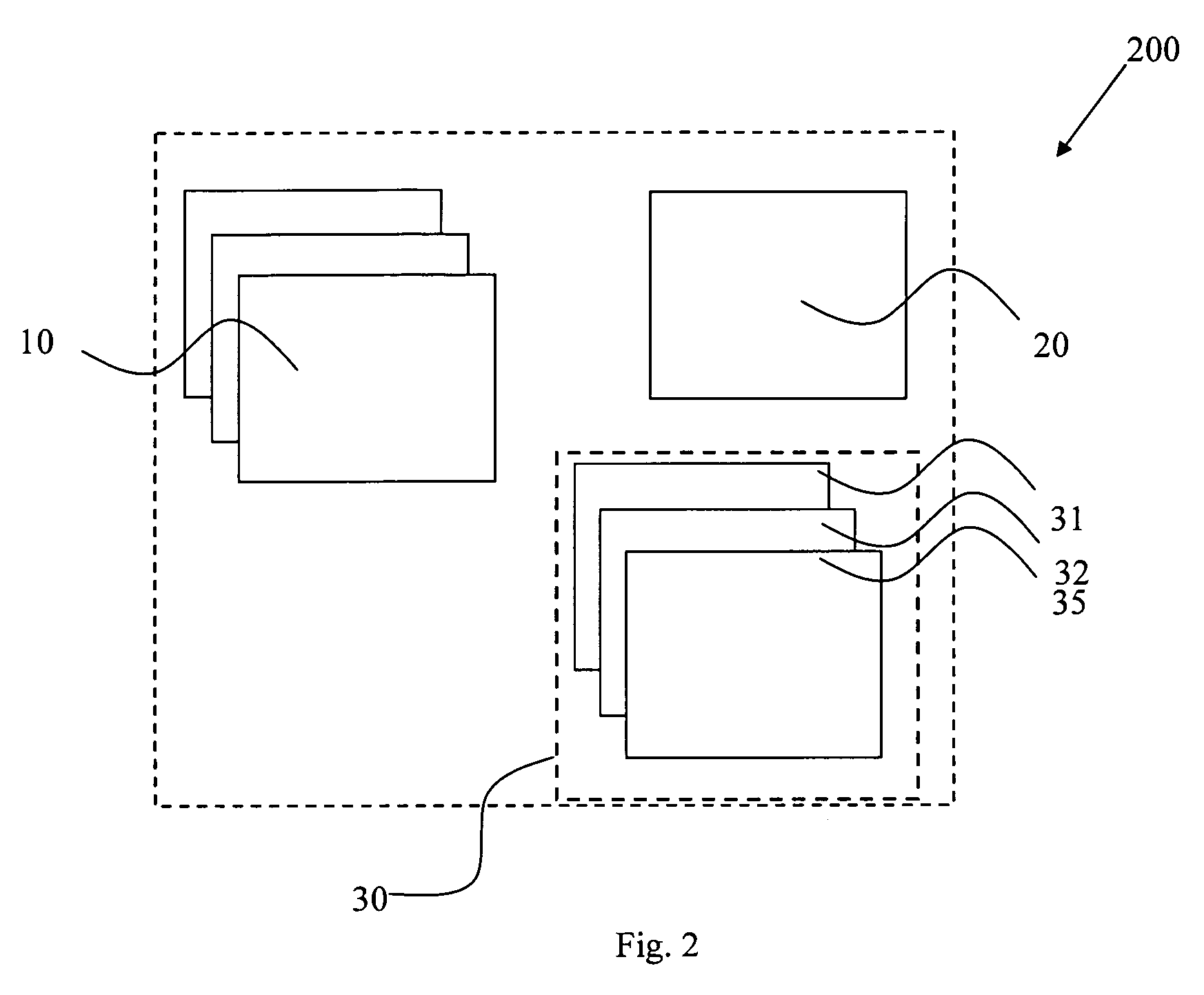

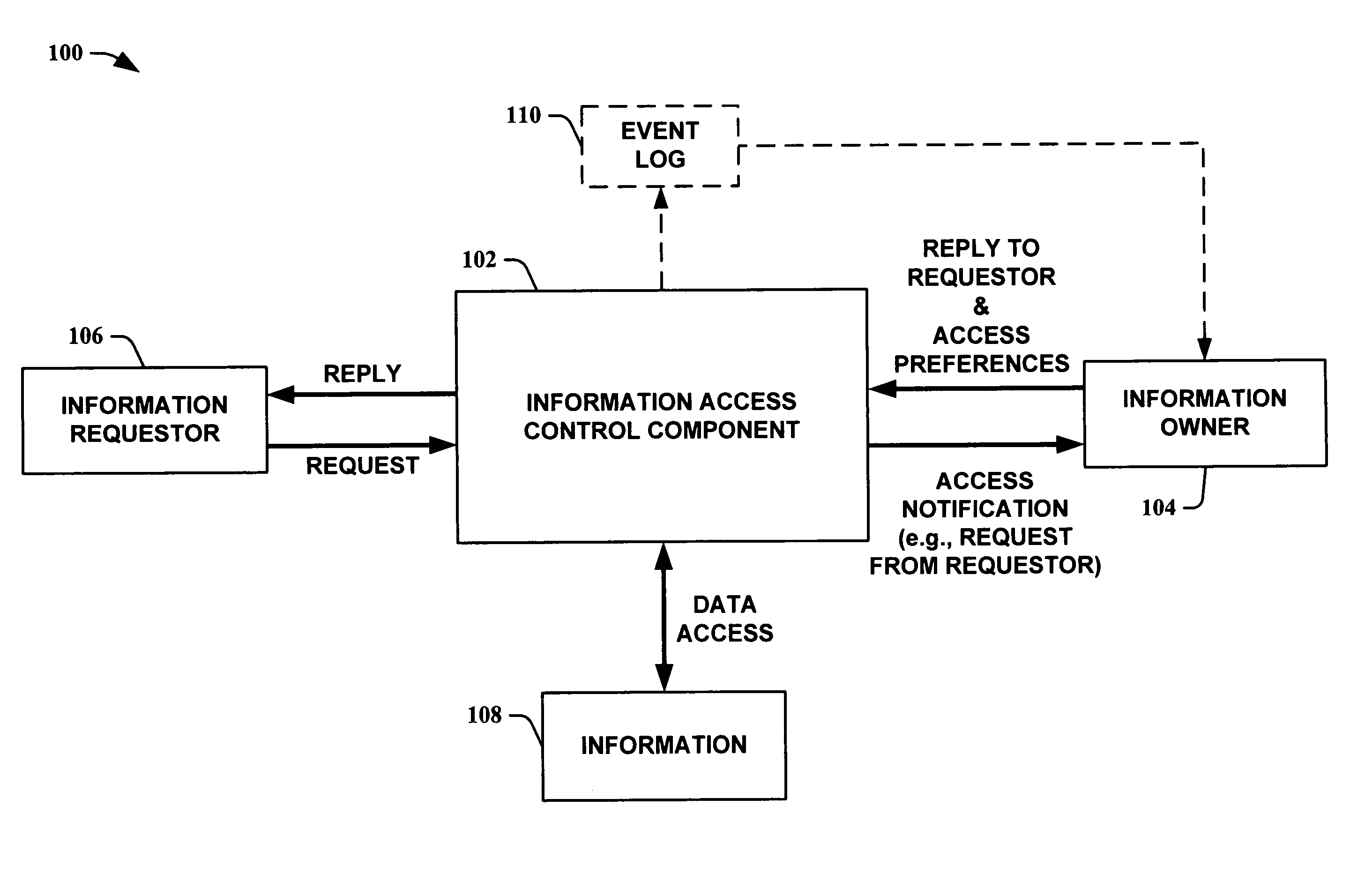

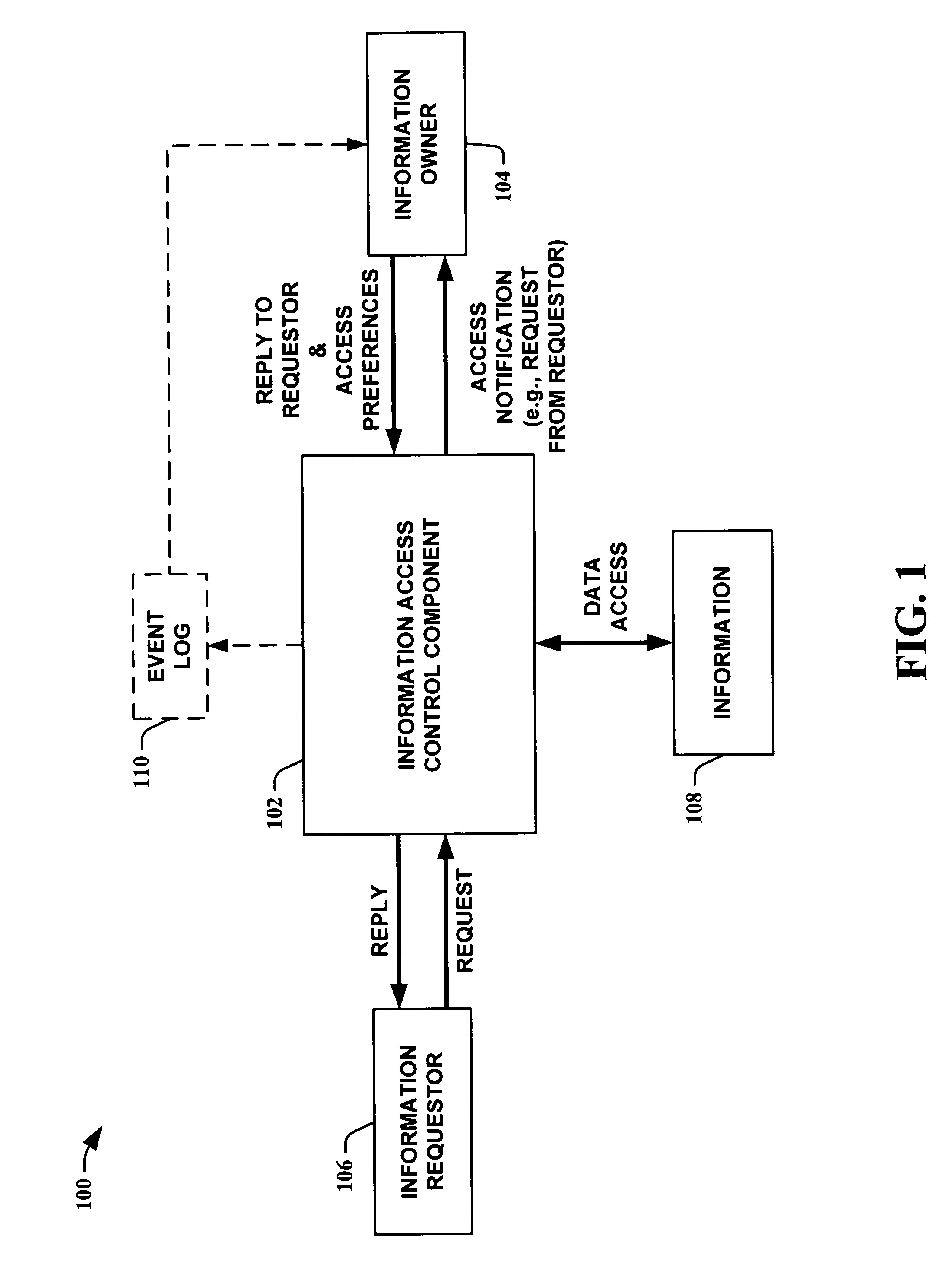

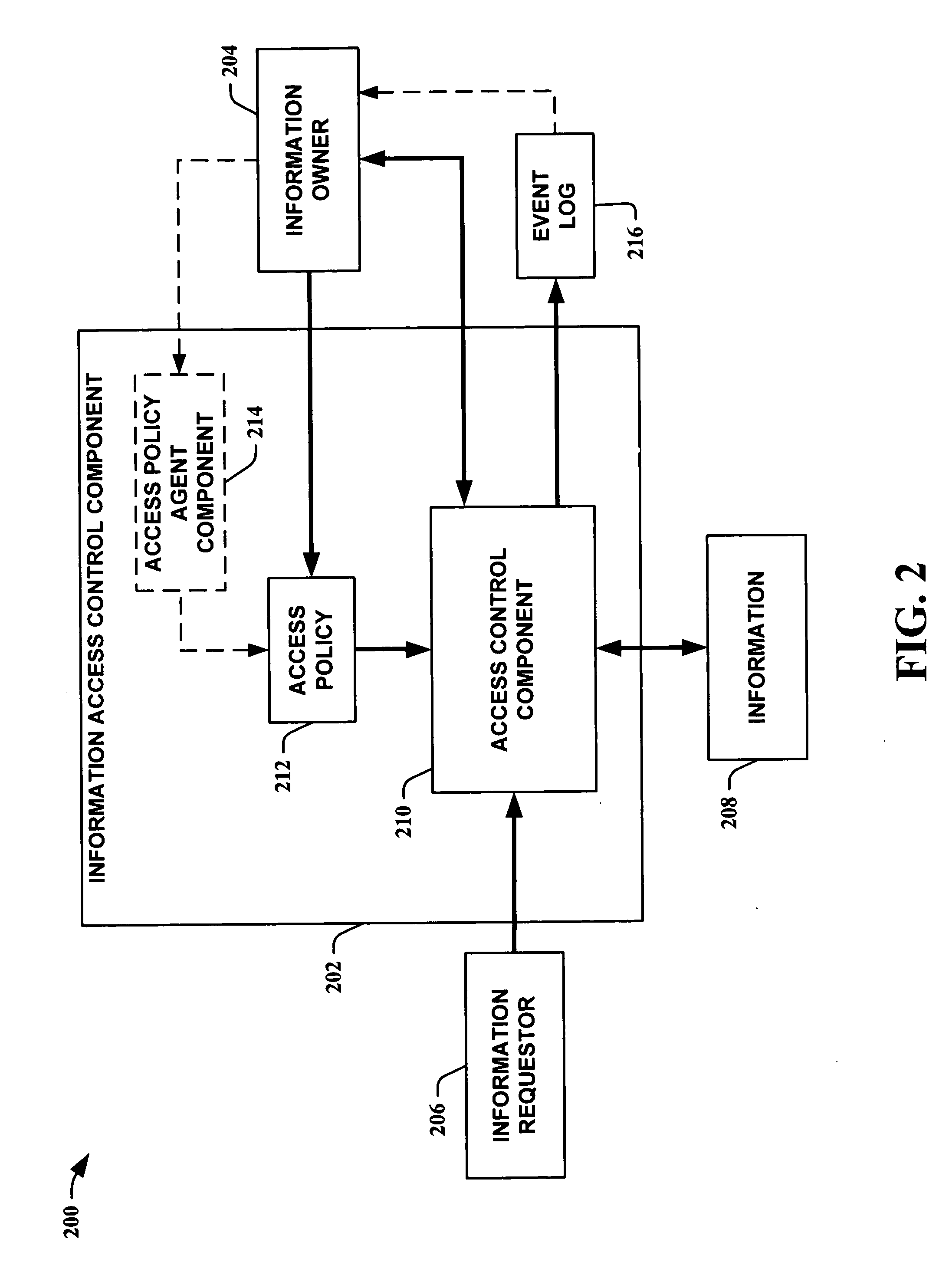

Abstractions and automation for enhanced sharing and collaboration

InactiveUS20050232423A1Optimal information privacyReduce the burden onDigital data processing detailsUser identity/authority verificationInformation sharingCrowds

The present invention provides methods for using abstractions of people, including dynamic and static groups of people, to enhance the efficiency of the specification and automation of policies for sharing information between users with a “need-to-know.” An instance of the present invention can also provide these users information based on a “time-to-know.” By providing access to information based on group affiliation and properties of the content of the information, the present invention maintains optimal information privacy while minimizing encumbrances to sharing data with appropriate users and even at appropriate times. The present invention can be integrated with other communication technologies to facilitate access to information in a time appropriate manner. Other instances of the present invention employ automated and semi-automated, mixed-initiative techniques, to make information-sharing decisions. Additional instances of the present invention include the employment of machine-learning techniques to facilitate construction of access policies from the actions or profile of a single user or a community of users, including the construction of automated sharing agents that work in an automated or mixed-initiative manner to respond to real-time requests for information.

Owner:MICROSOFT TECH LICENSING LLC

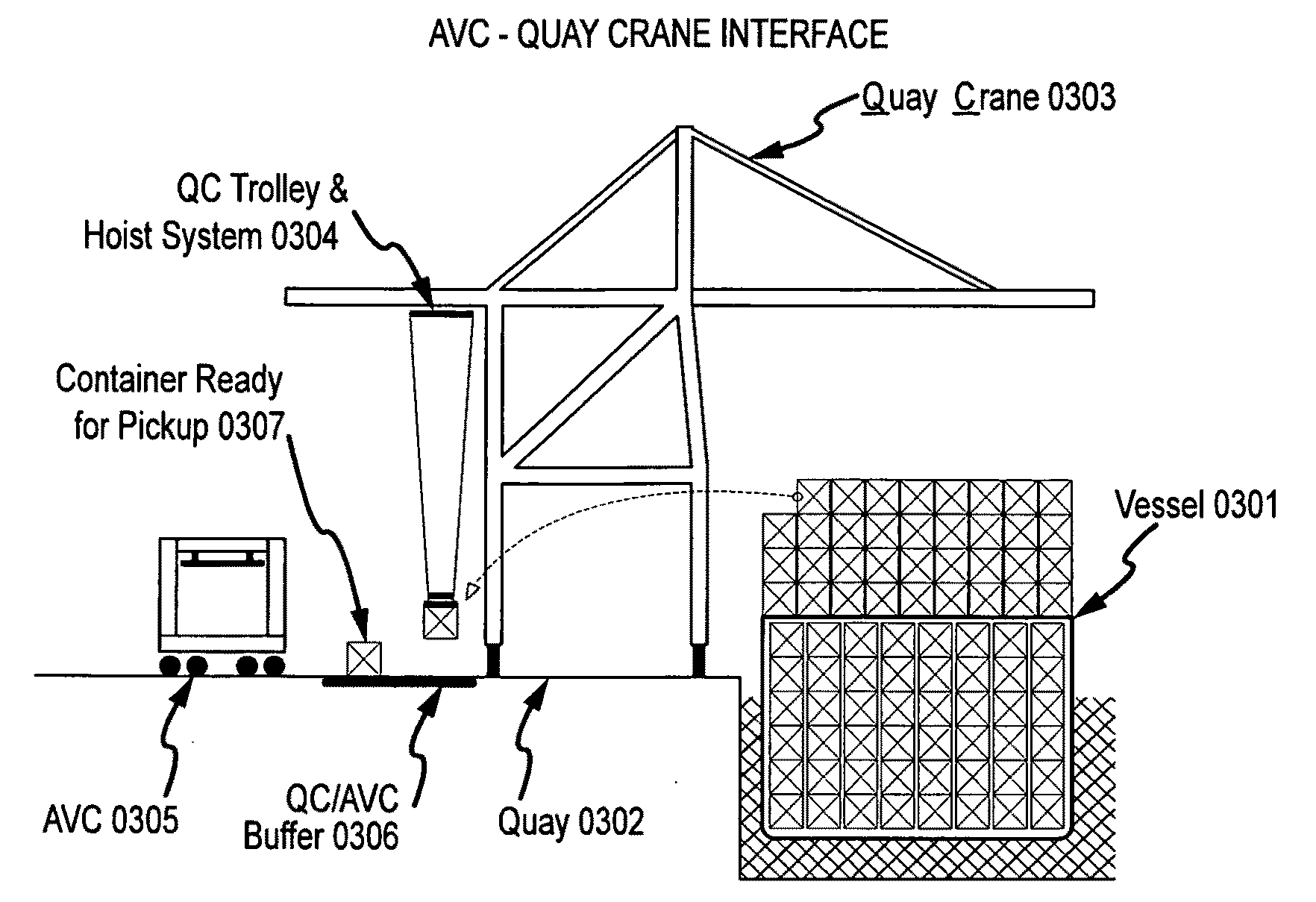

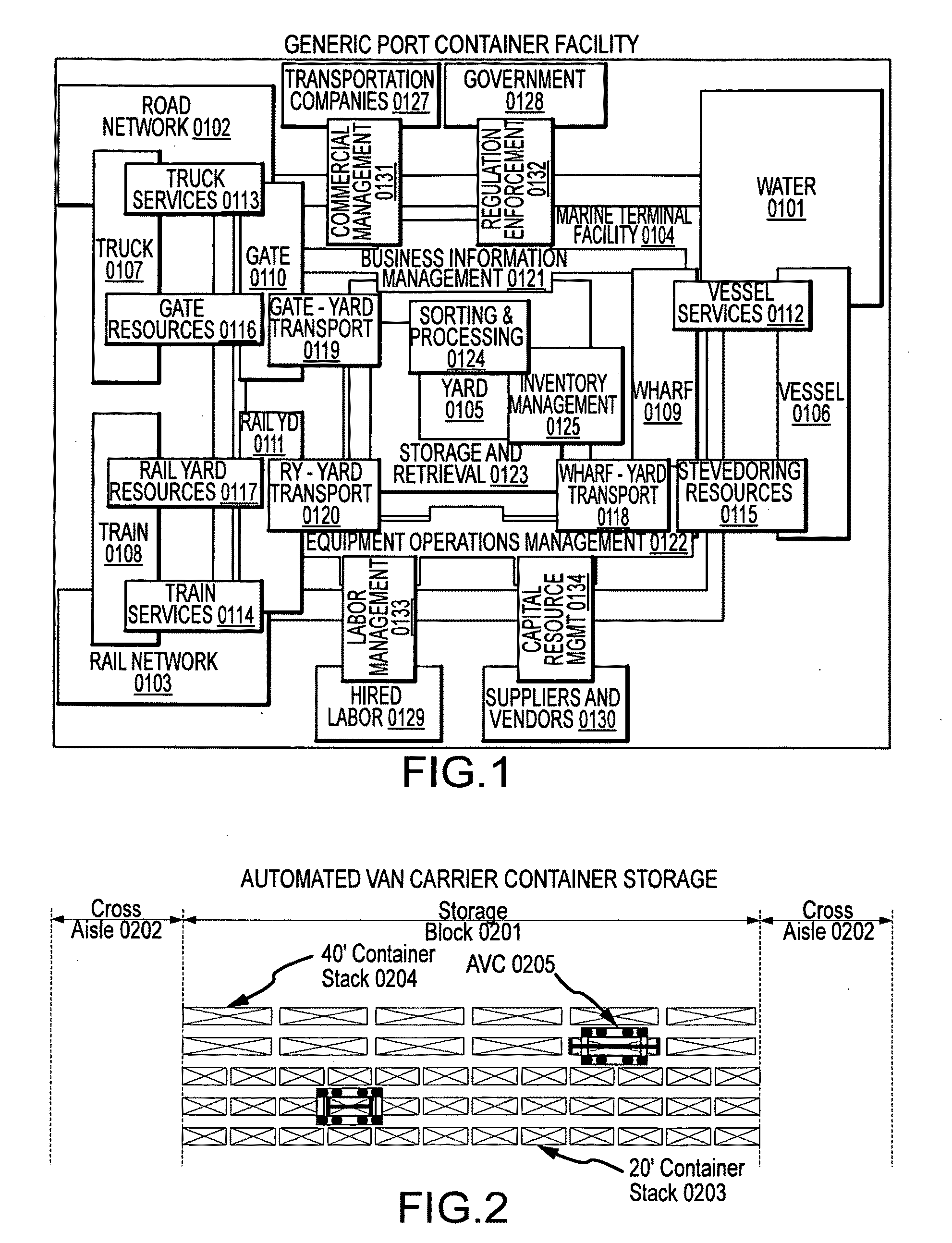

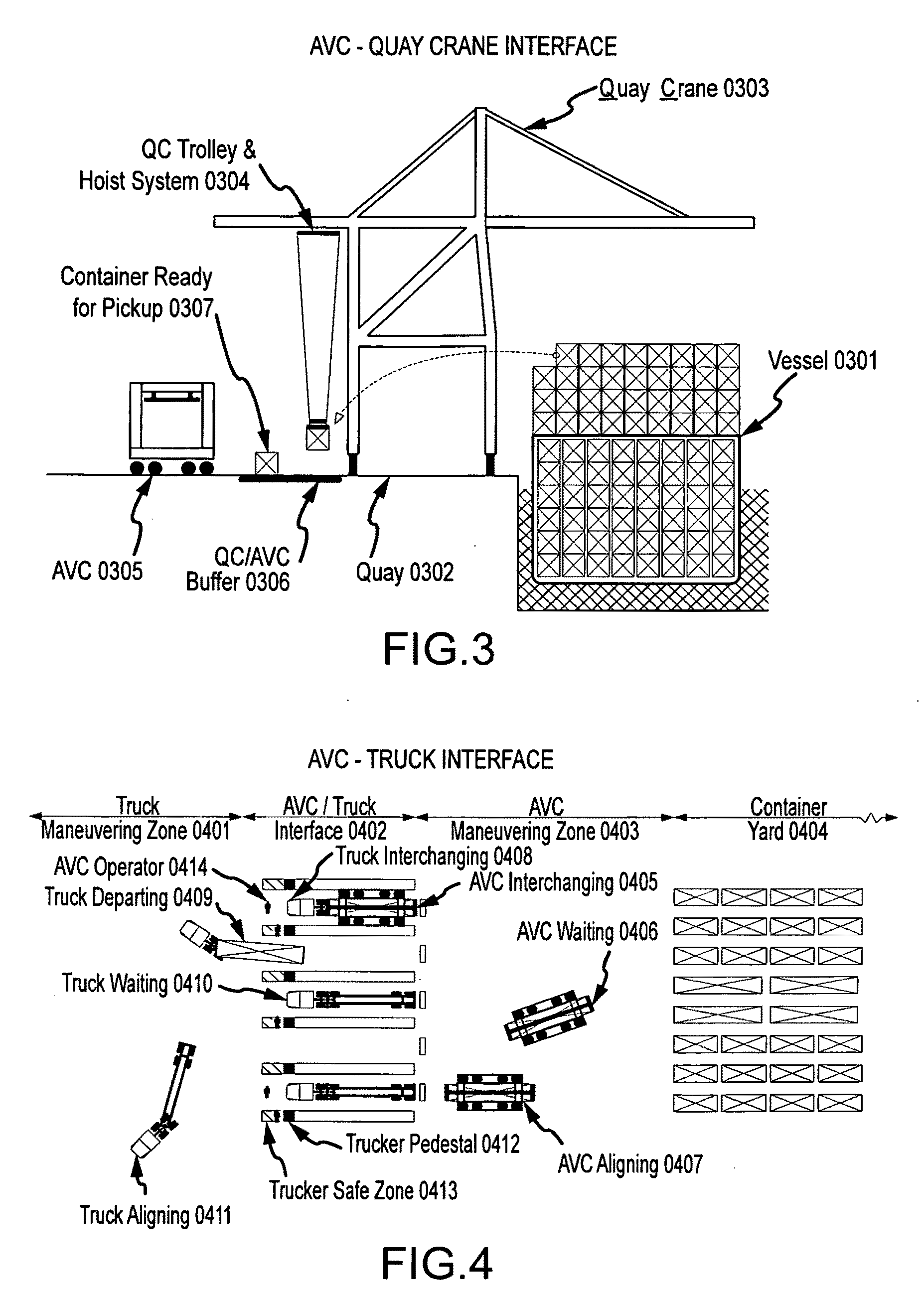

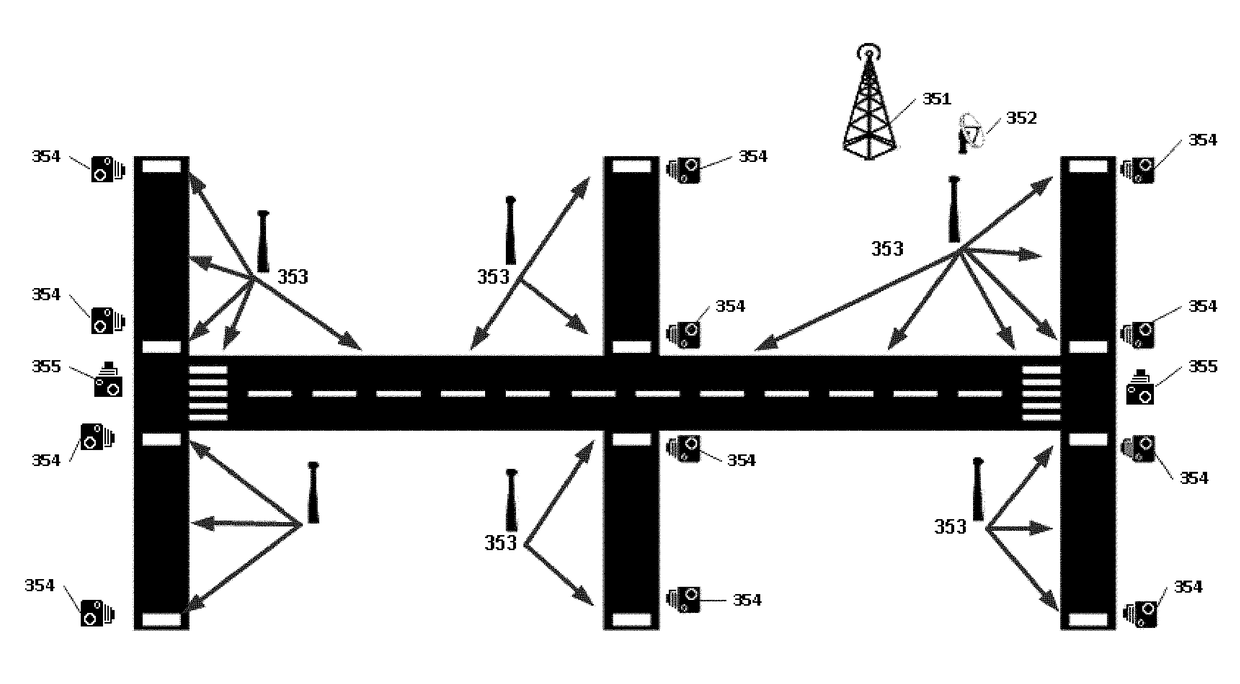

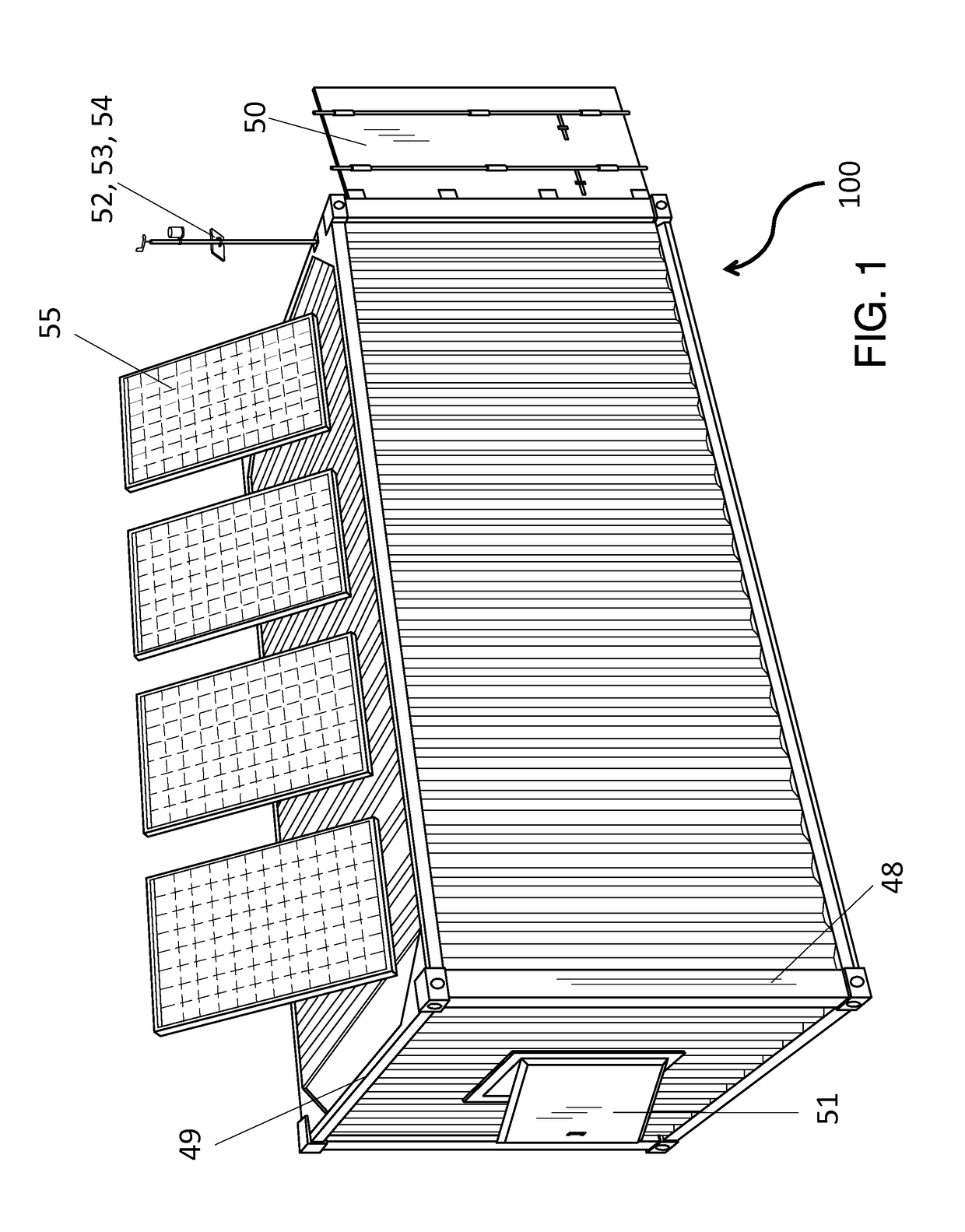

Automated marine container terminal and system

ActiveUS20100021272A1Isolation performanceReduce environmental footprintCargo handling apparatusDigital data processing detailsTruckRobot control

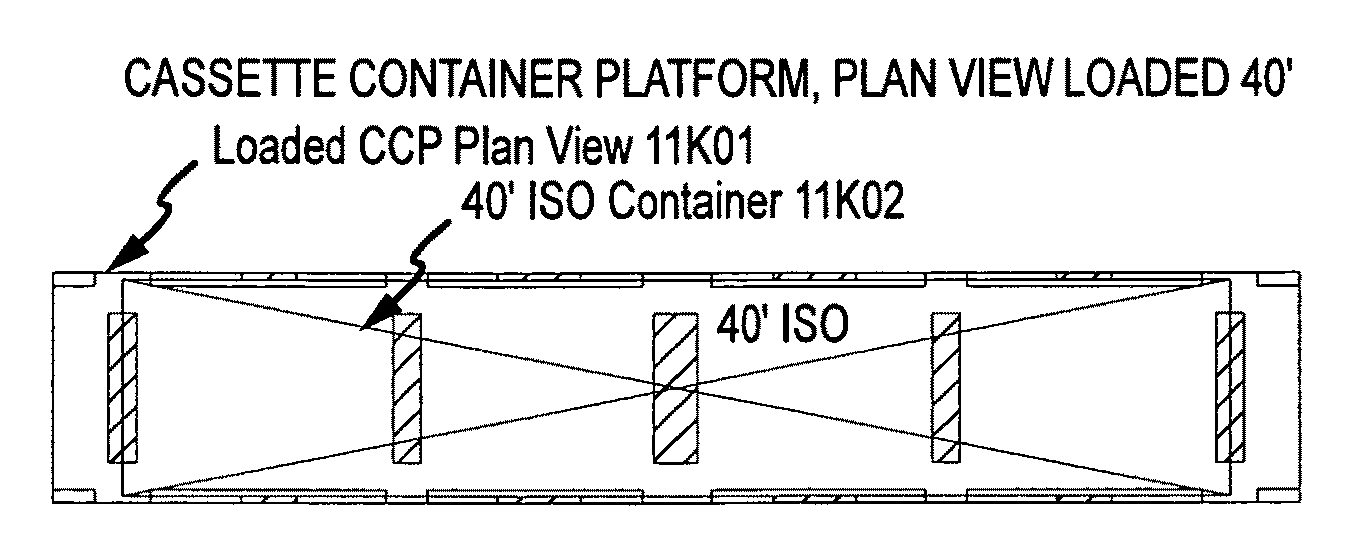

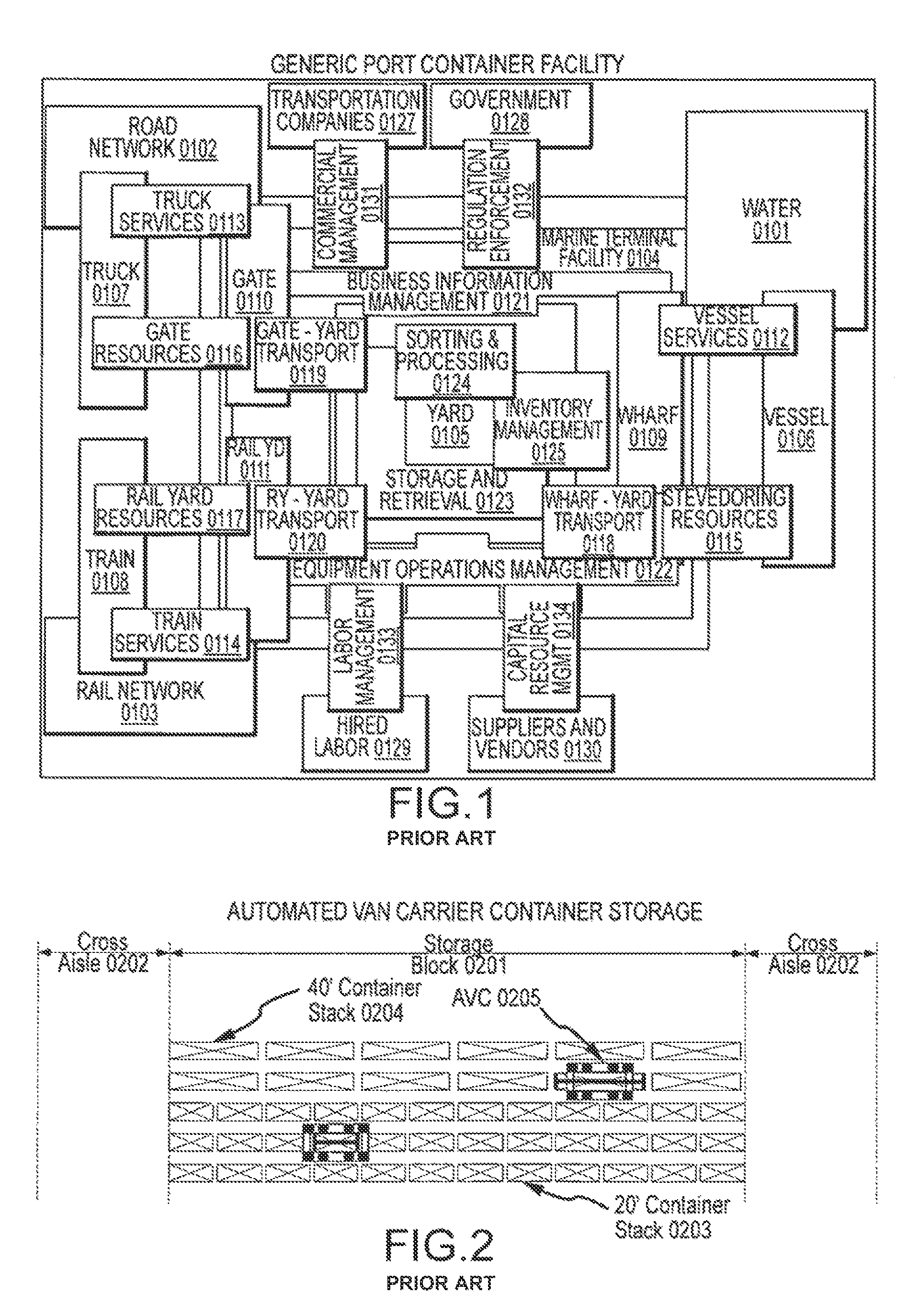

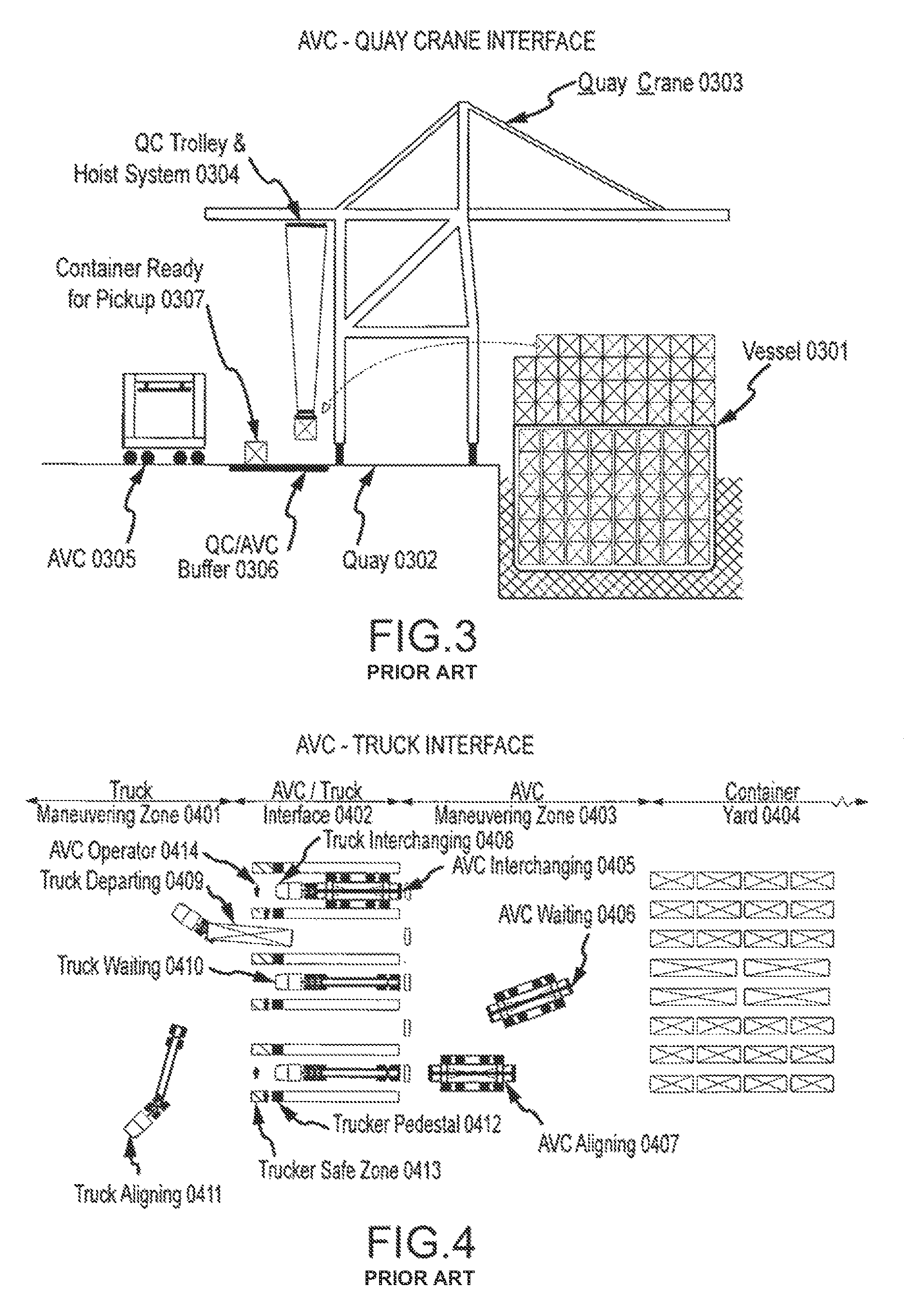

A system, equipment, and processes for extending the scope of automation in port container facilities, and thereby increasing port capacity within fixed land resources, increasing operational productivity, increasing safety, increasing the velocity and reliability of goods movement, increasing freight security, reducing negative environmental impacts, and reducing the overall cost of goods movement. A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform. The use of a single vehicle type with interchangeable platforms allows for maximum flexibility and efficiency. The automation of the vehicle allows for complete contamination within the storage portion of the system.The system thus substantially extends the reach of automation to cover both landside and waterside intra-terminal transfer operations. By this extension, the interface of workers and machines is greatly reduced, increasing safety, productivity, security, and capacity. By this extension, the robotic control process can be fully optimized, increasing velocity and reliability while reducing the terminal's environmental footprint.

Owner:MARINE TERMINALS CORP

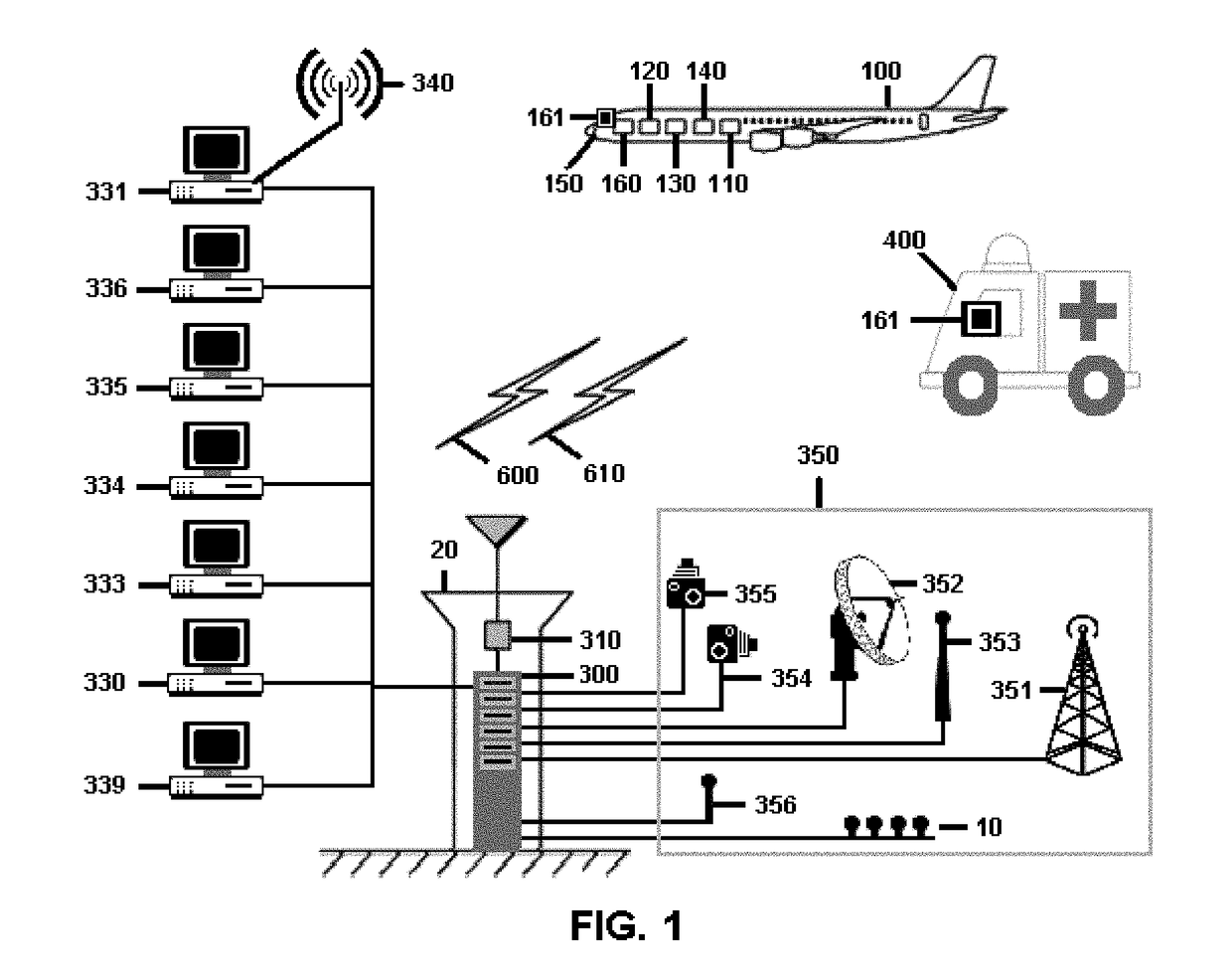

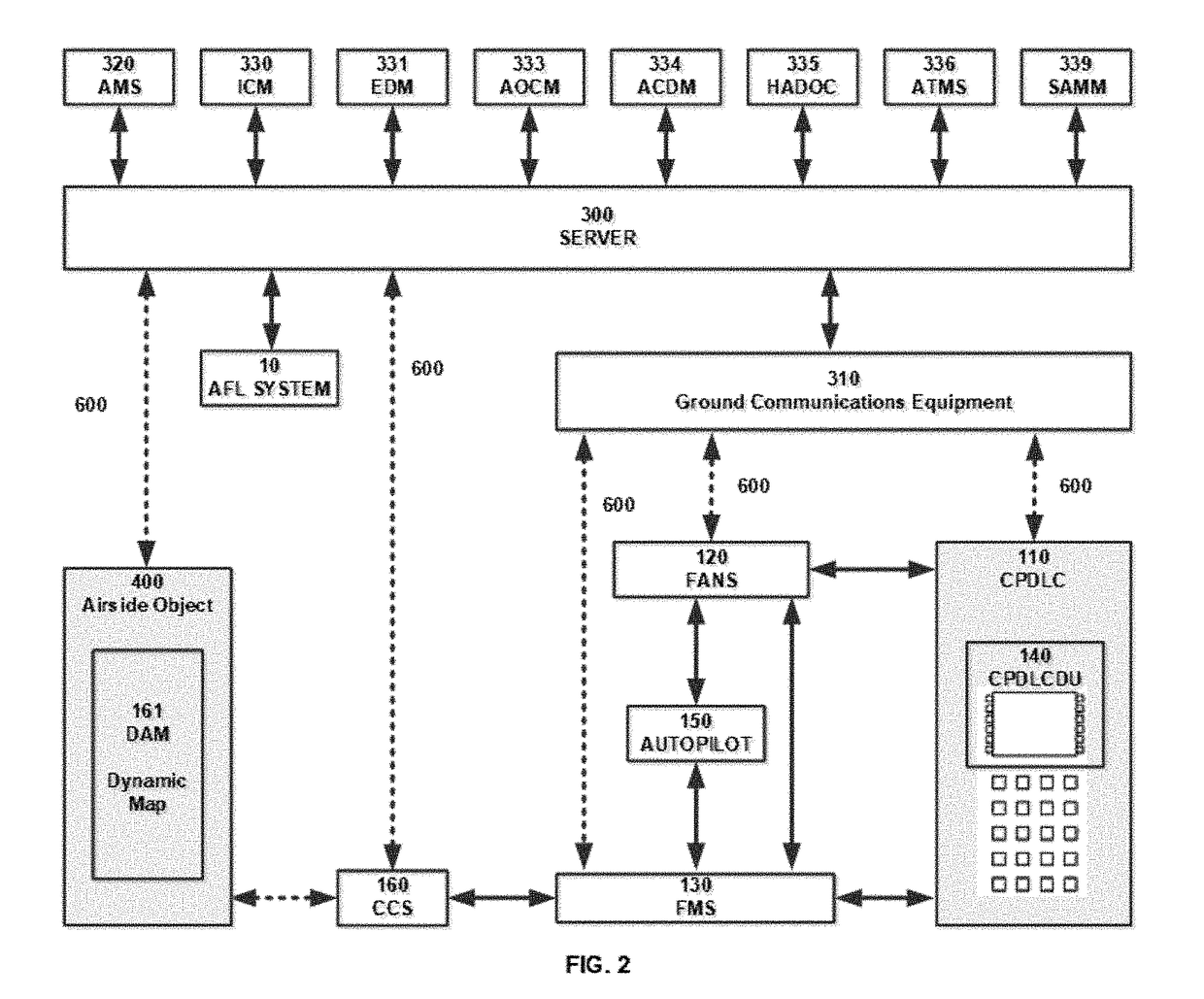

System and methods for automated airport air traffic control services

InactiveUS20180061243A1Extension of timeMaximized situational awarenessNatural language translationTelevision system detailsNetwork operations centerAirplane

A system and method for automating Air Traffic Control operations at or near an airport. as a complete standalone automated system replacing the need for a human controller to make aircraft movement decisions nor the need communicate with pilots, or as semi-automated, where a controller controls how the system operates. The system with related methods and computer hardware and computer software package, automatically manages manned aircraft, remote controlled UAV and airborne-able vehicles traffic at or near an airport, eliminates ATC-induced and reduce pilot-induced runway incursions and excursions, processes control messages related to aircraft or Pilots, communicates with Pilot over ATC radio frequency, receives aircraft positions, communicates control messages with the aircraft avionics, provides pilots a dynamic map with continuous display of nearby traffic operations, shows clearance and information related to runway operations, warns pilot of runway conditions and turbulence from other operations, warns when landing gear is not locked, displays the pilot emergency exits during takeoff roll, shows the pilot when and where to exit from the runway, shows the pilot where and when to cross a junction, calculates and displays pilot optimal speed and timing on taxiways and junctions for saving fuel, calculates congestions, calculates best taxiway routes, calculates when aircraft can cross a runway, provides directives and information to pilot over CPDLC display or dynamic map for airside operations, alerts and triggers breaks of the aircraft on wrong path or when hold-short bar is breached, displays emergency personnel with routing map and final aircraft resting position for emergency operations, takes over an aircraft operation when aircraft is hijacked or deviates from the flight plan, provide standalone or manned Remote Tower functionality, Records and retains all information related to airport airside operations including aircraft positions and conditions from sensors and reports for runways, junctions and taxiways, Records and retains aircraft data and cockpit voice to ground-based servers to eliminate black-box requirements, calculate future weather and airport capacity from aircraft at or nearby airport, coordinates handoff operations with other ATC positions, interfaces with ACDM systems, airport operations center, flow center and network operations center.

Owner:IATAS AUTOMATIC AIR TRAFFIC CONTROL

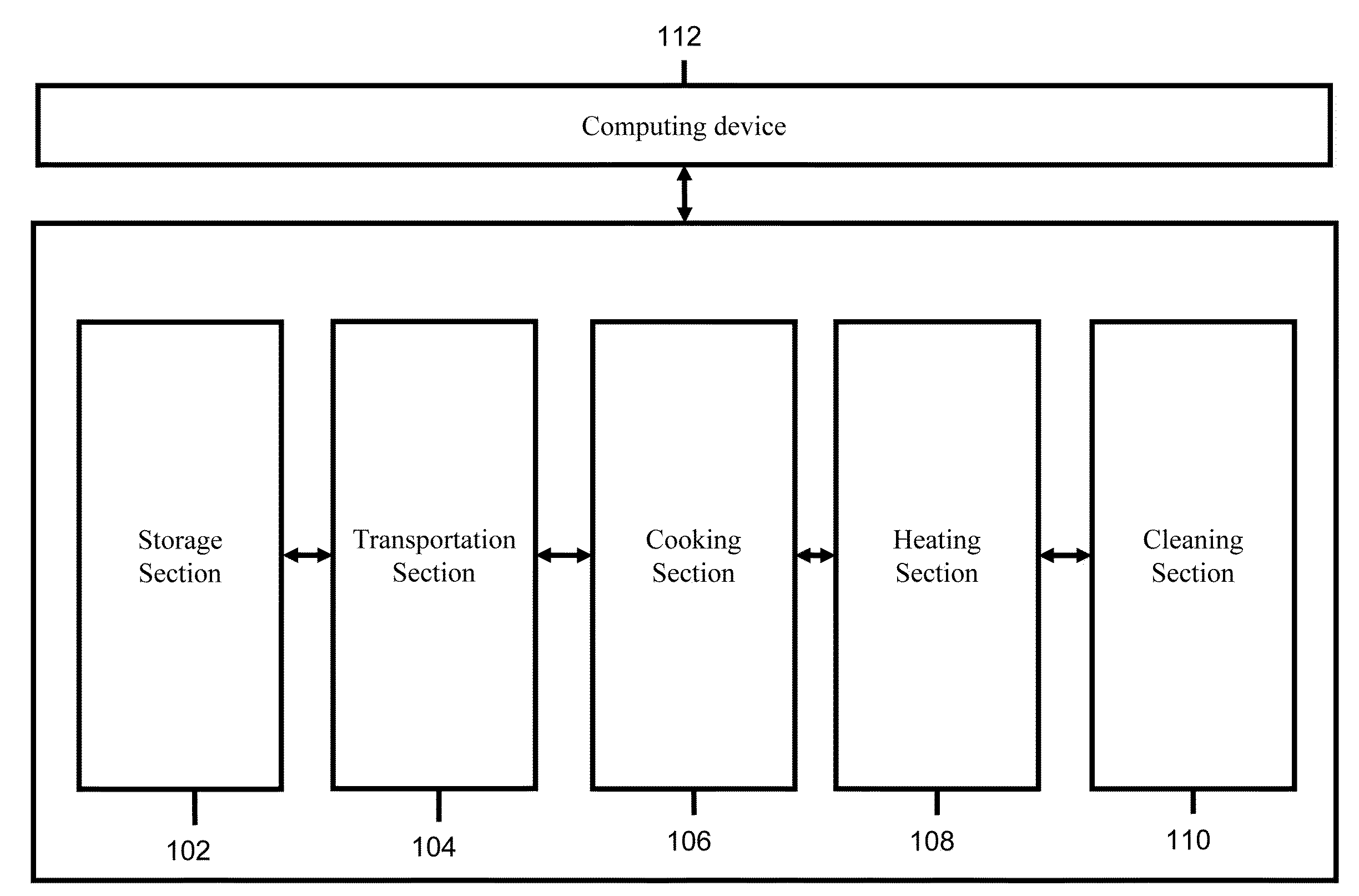

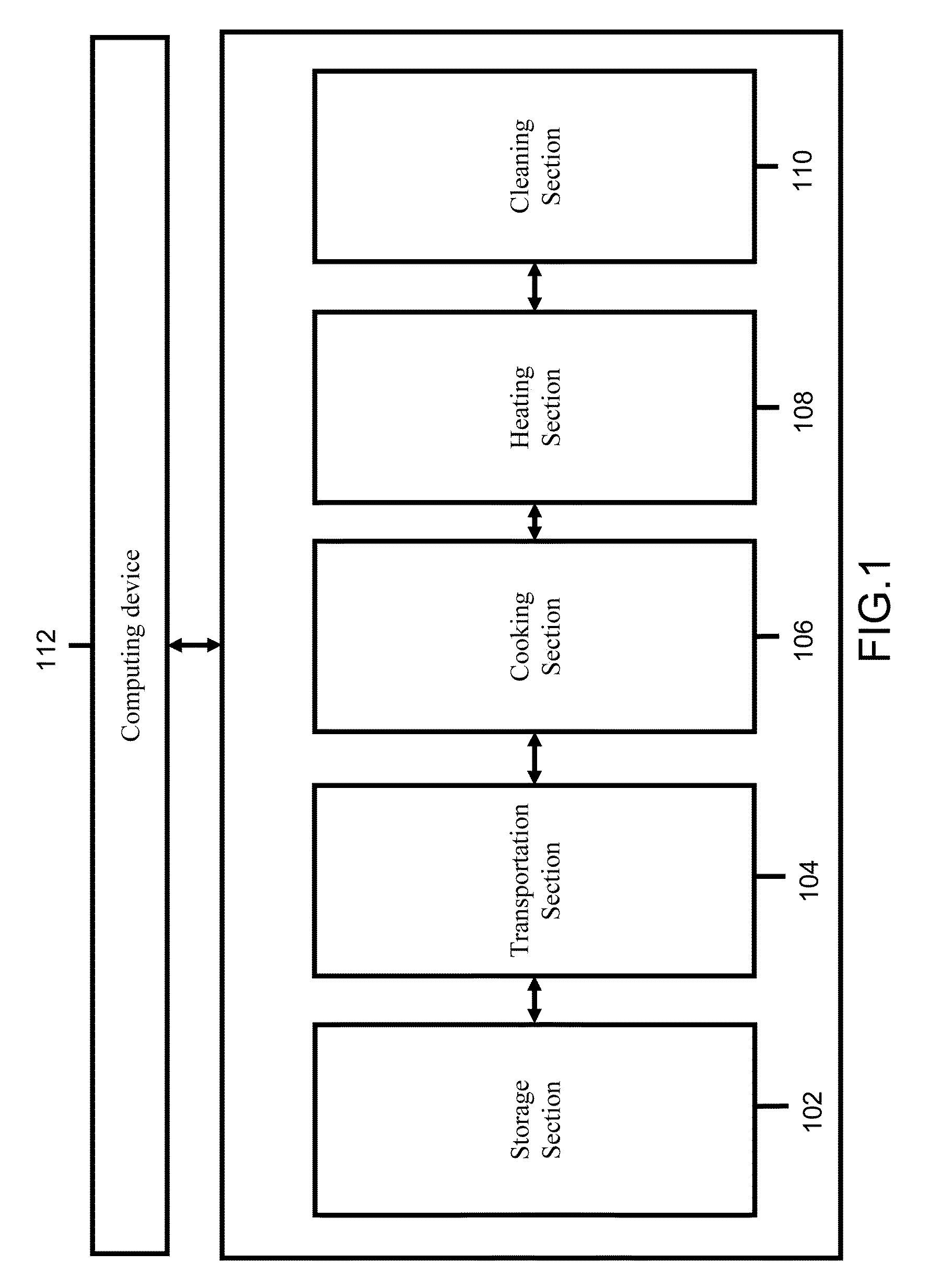

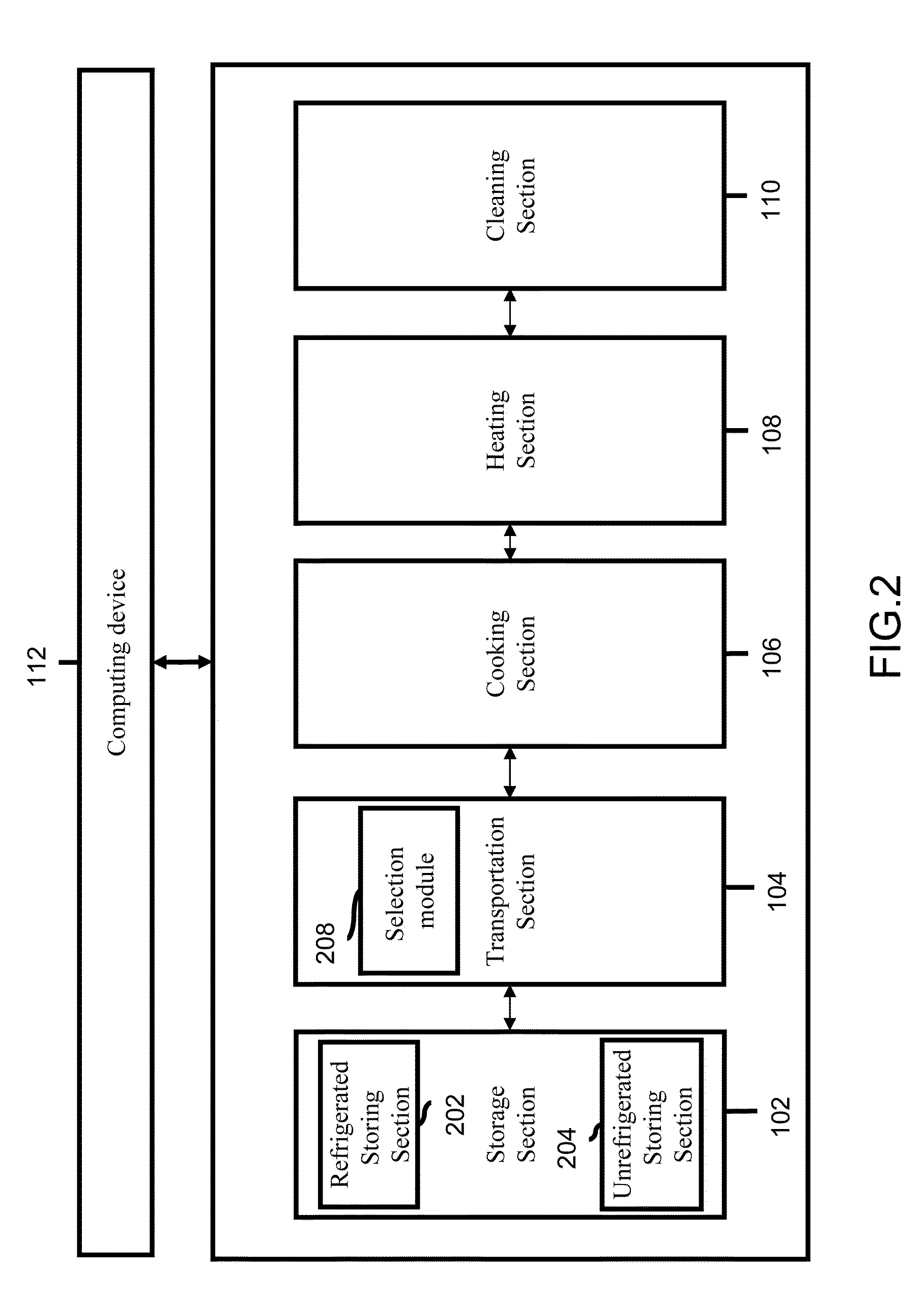

Method and System for Food Preparation

InactiveUS20100303972A1Easy to prepareQuality improvementMilk preservationBoiling over preventionHealthy foodBiomedical engineering

A system for preparation of high quality and healthy food by automatic means is provided. The system includes one or more sections for carrying out the one or more operations required for the preparation of food. The food is prepared using automated or semi-automated processes using one or more processing devices.

Owner:SRIVASTAVA SIDDHARTHA

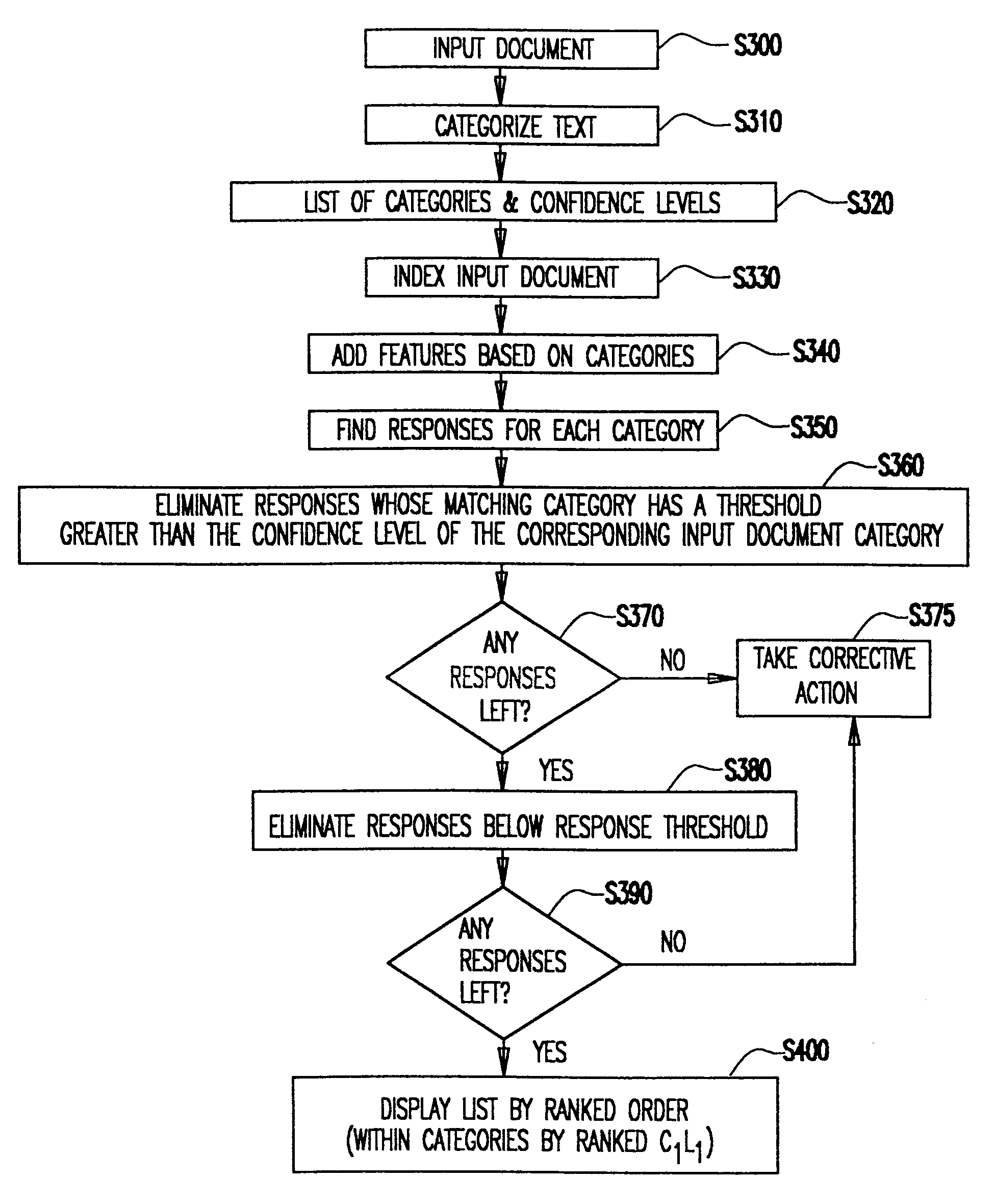

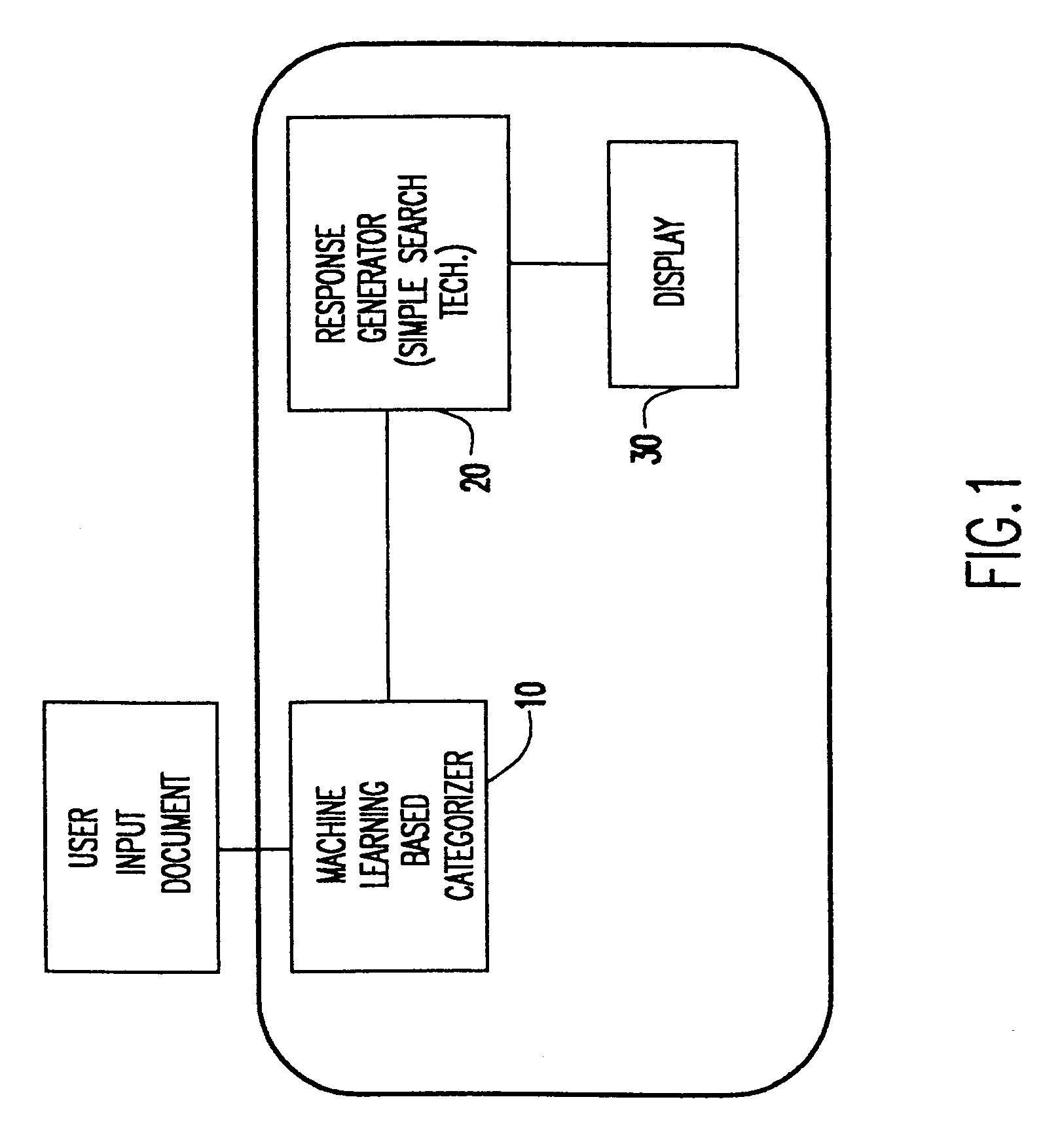

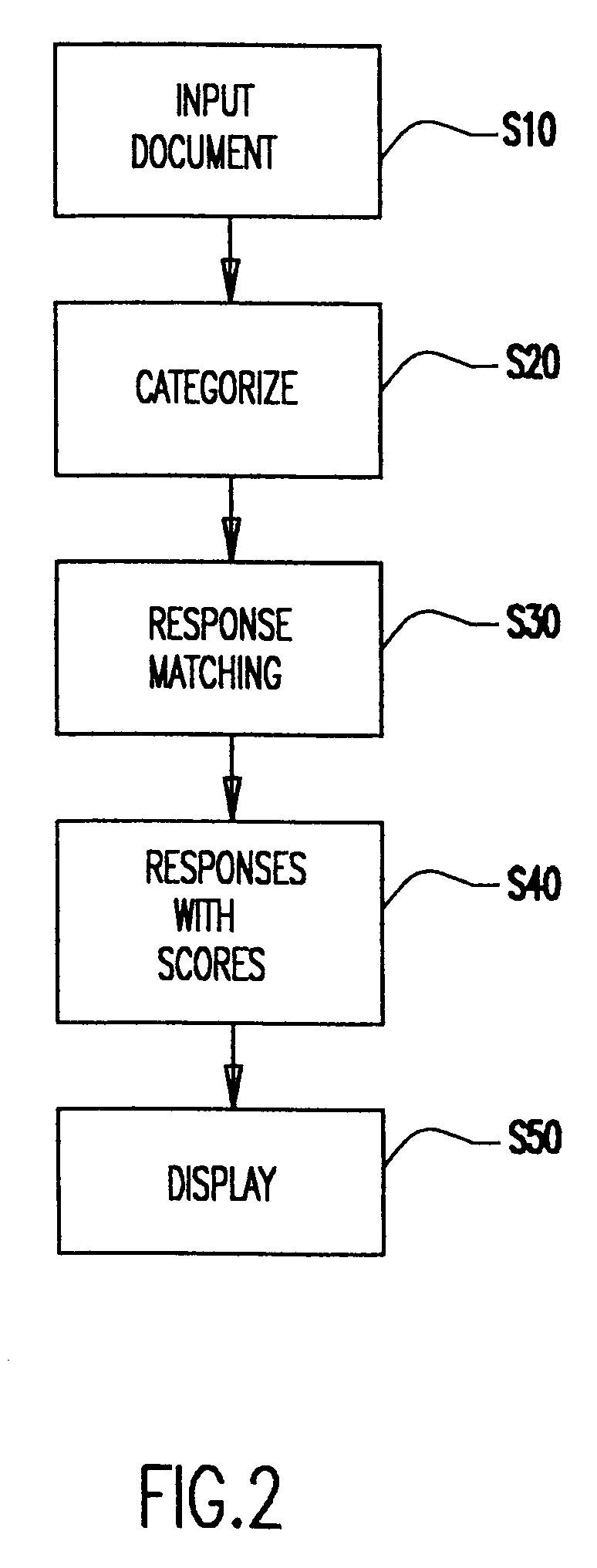

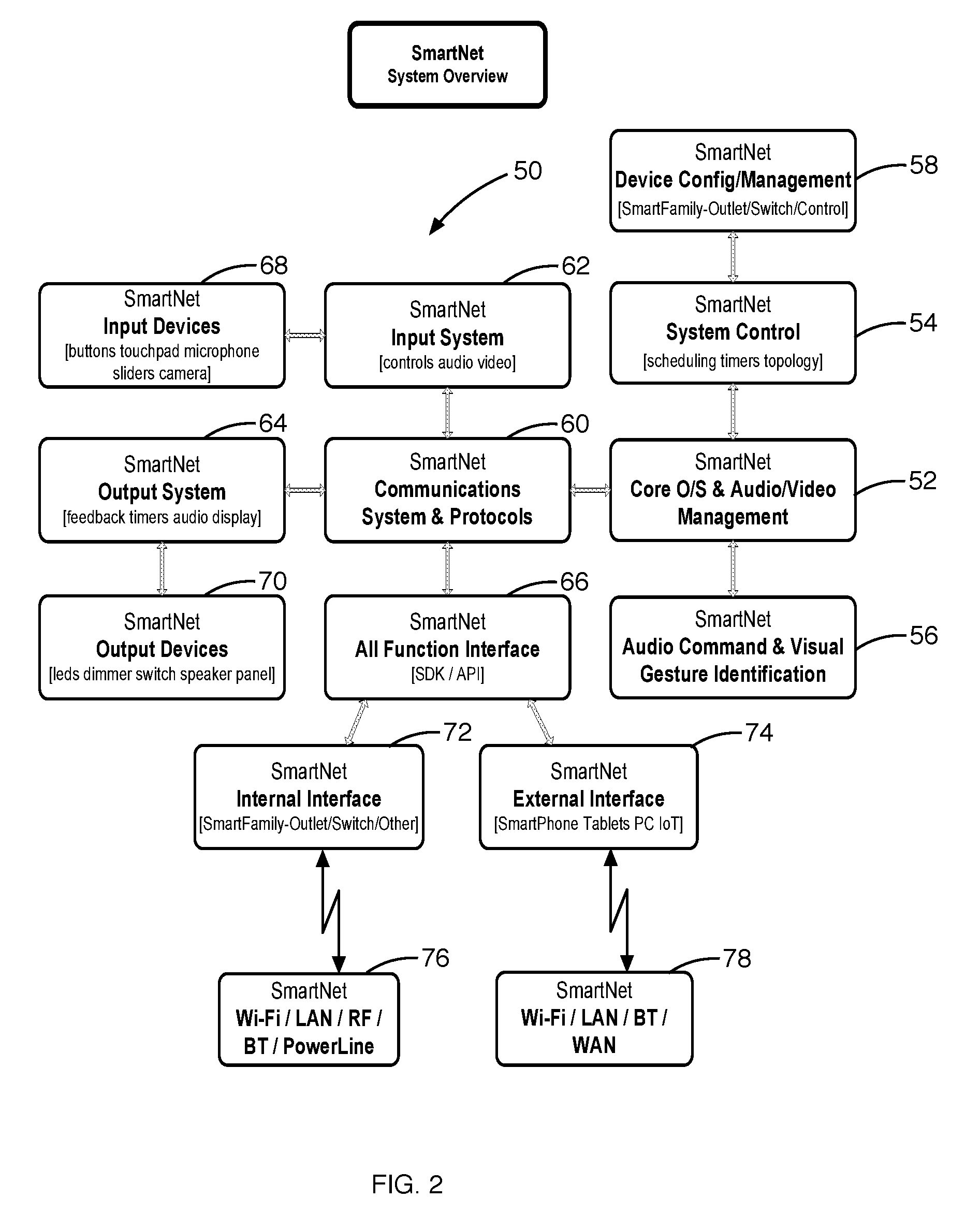

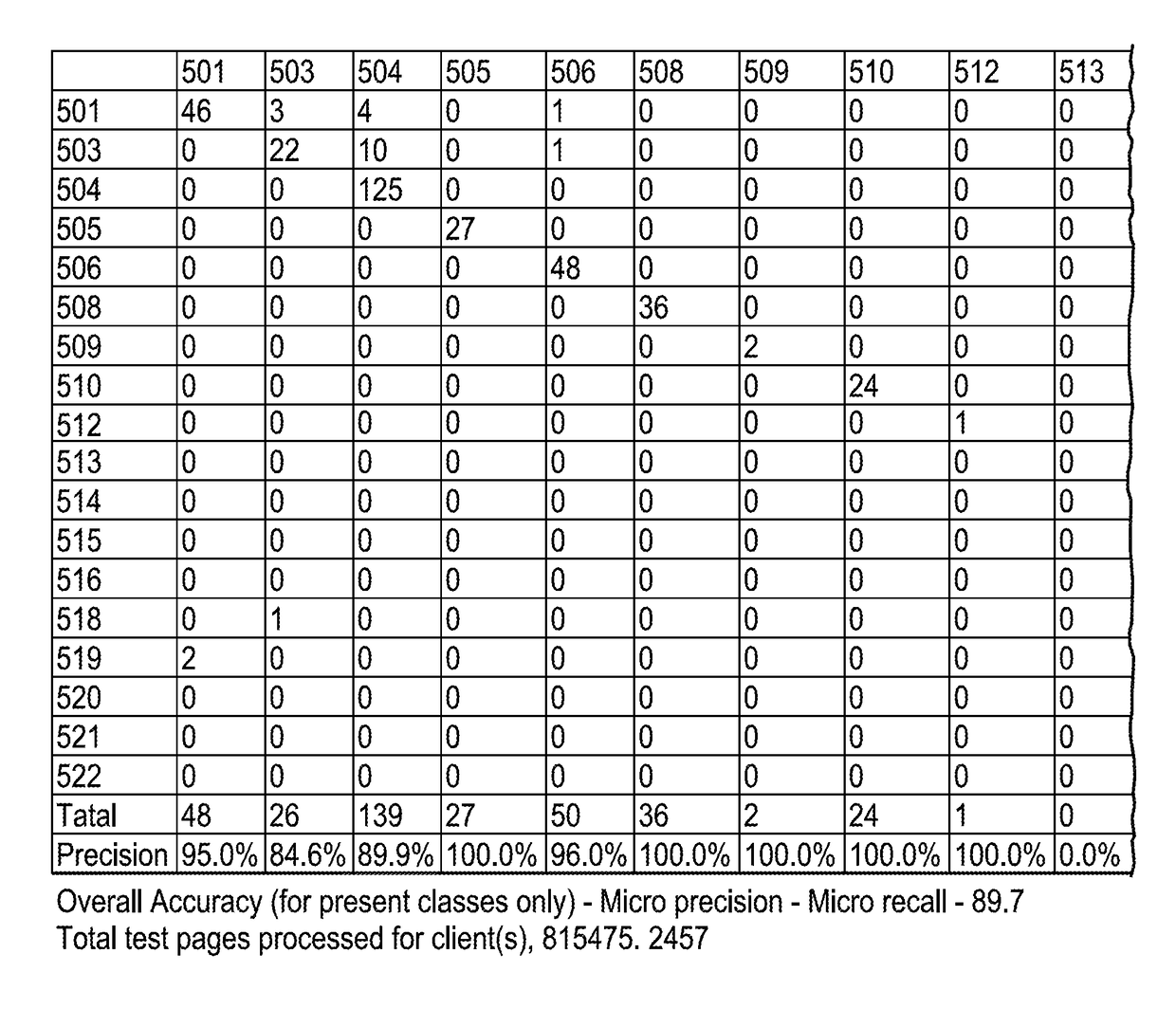

Two stage automated electronic messaging system

InactiveUS6418434B1Accurate informationImproved oddsData processing applicationsDigital data information retrievalWeb siteCustomer representative

A two stage electronic messaging system and method of use that automatically and accurately responds to user queries (e.g., input documents) using a two stage searching and retrieval system. The two stages system includes fast document-matching techniques (e.g., "weak" search techniques) in combination with more advanced categorization and text-search techniques (e.g., machine learning and other semi-automated techniques). The two stage searching and retrieval system may be used via the Internet, an intranet, LAN or other similar system, and may be used for providing requested information to a user (e.g., customer, employee, customer representative and the like) via a content rich web site, a propriety database or any computer related help system.

Owner:IBM CORP

Automated marine container terminal and system

InactiveUS7972102B2Reduced footprintLow costCargo handling apparatusPassenger handling apparatusAutomated guided vehicleOverhead crane

A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform.

Owner:MARINE TERMINALS CORP

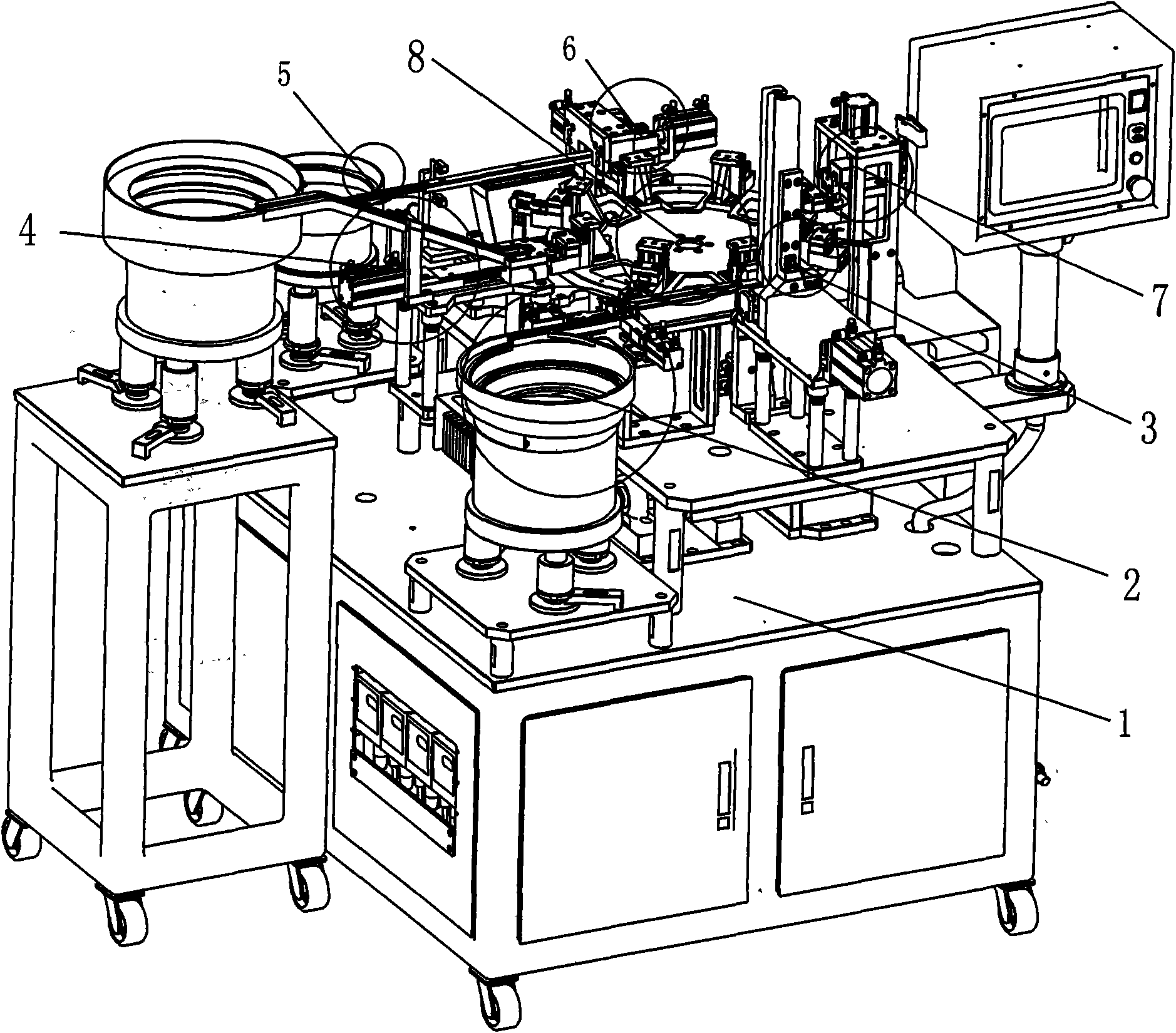

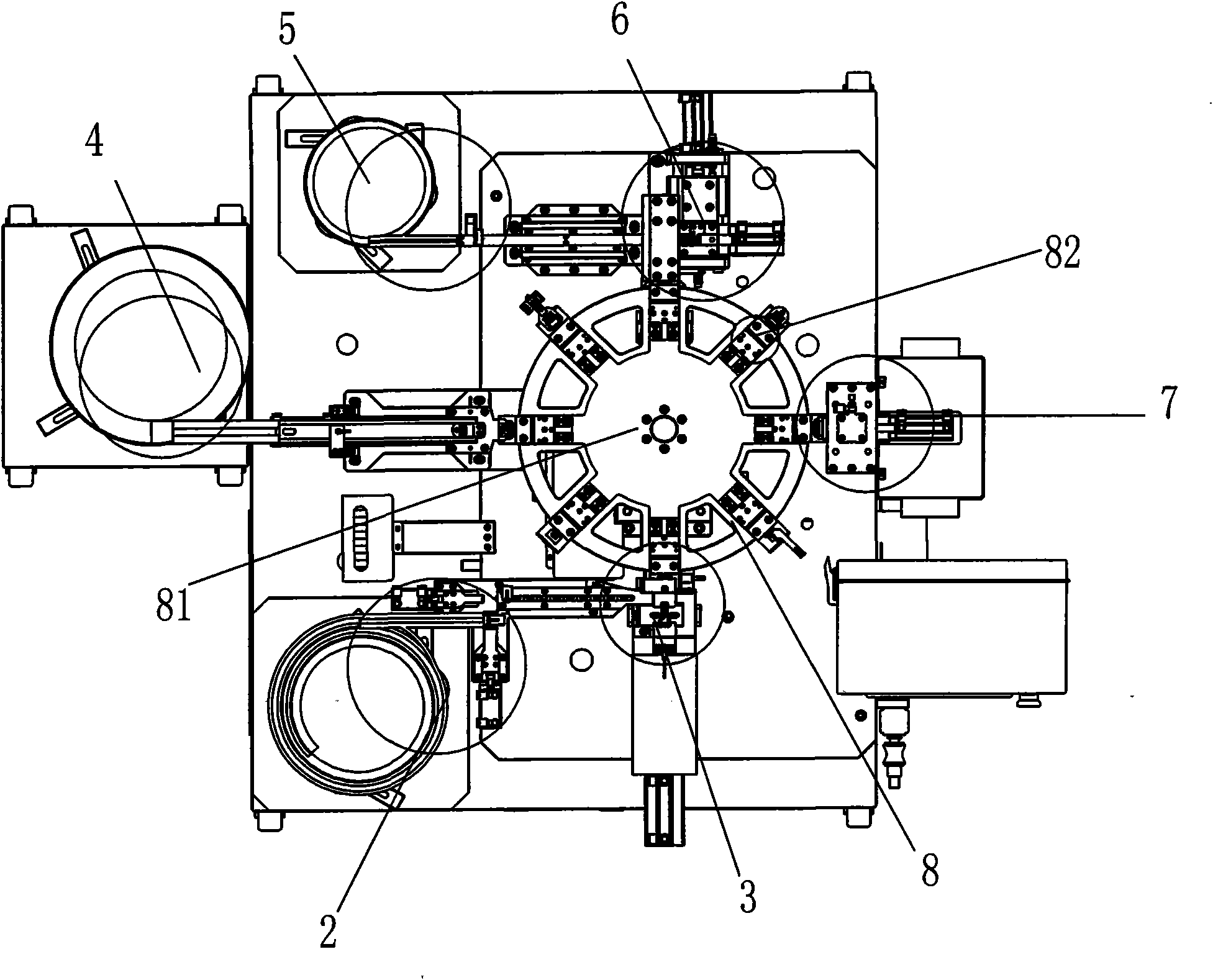

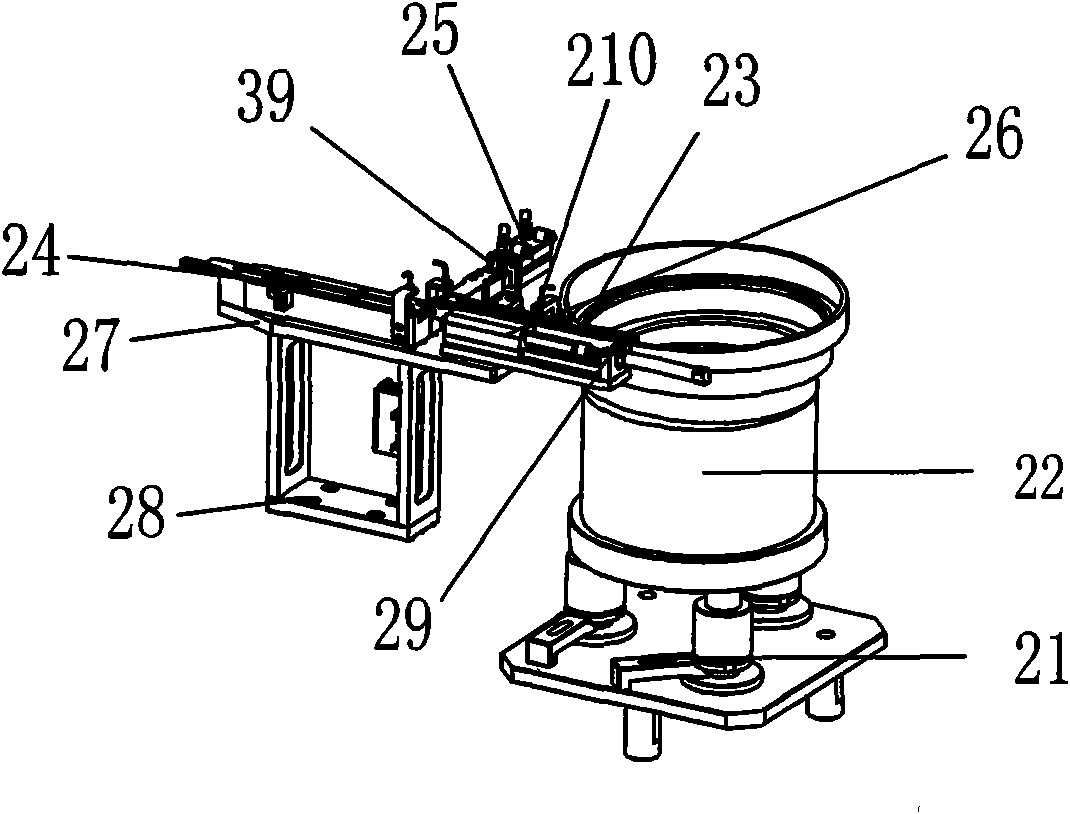

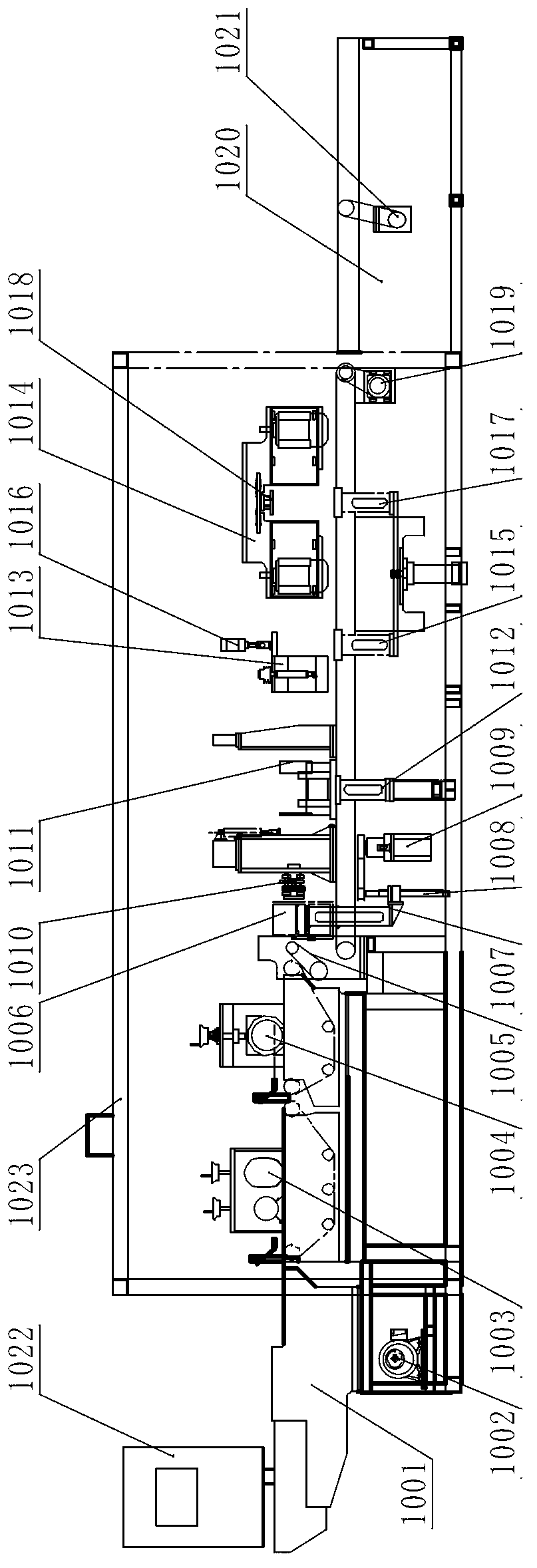

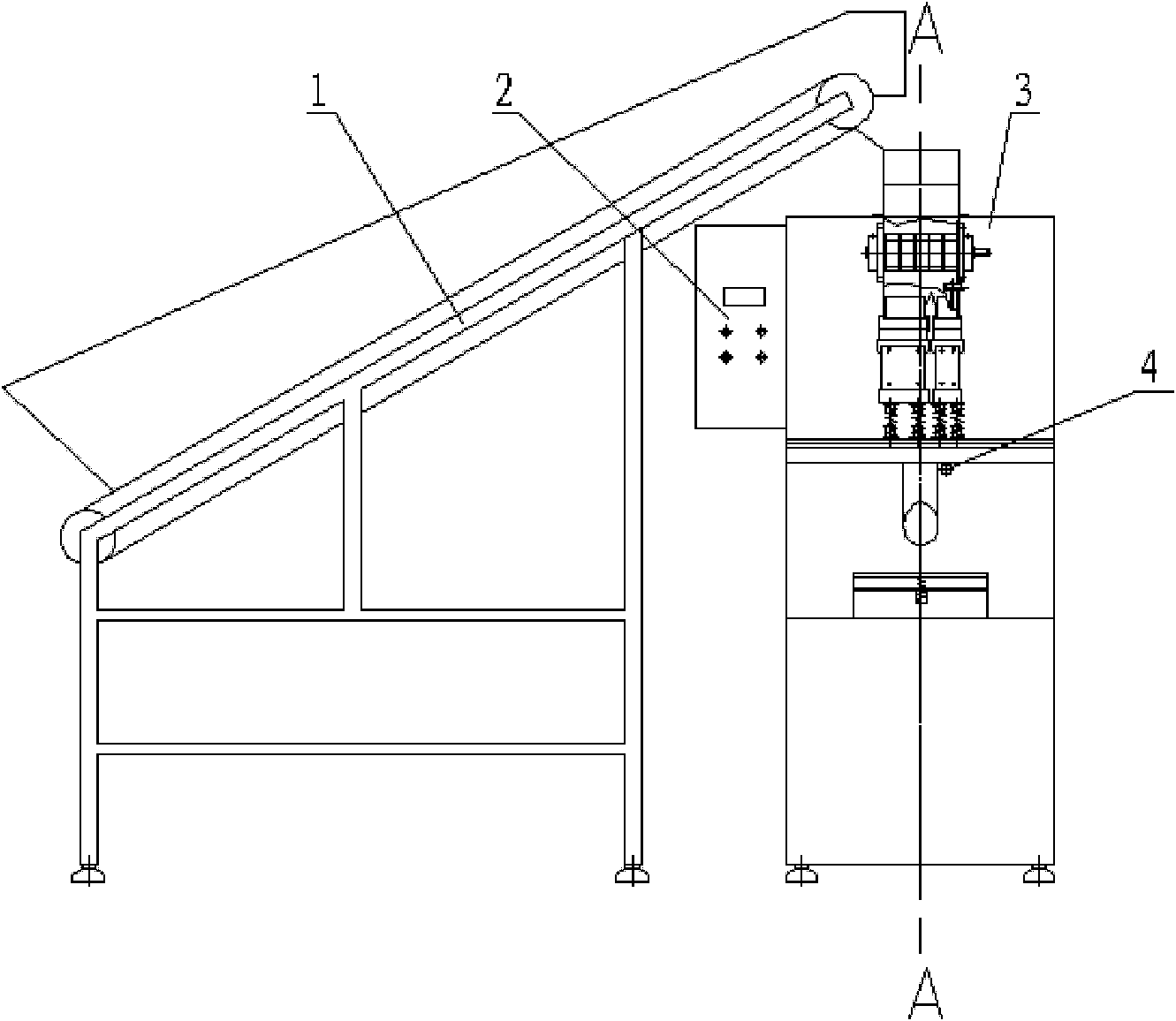

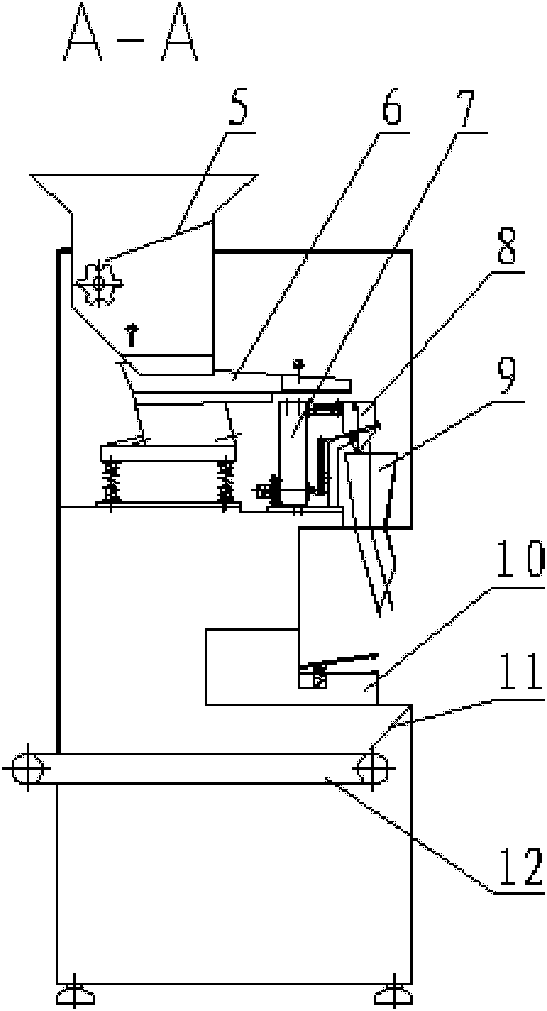

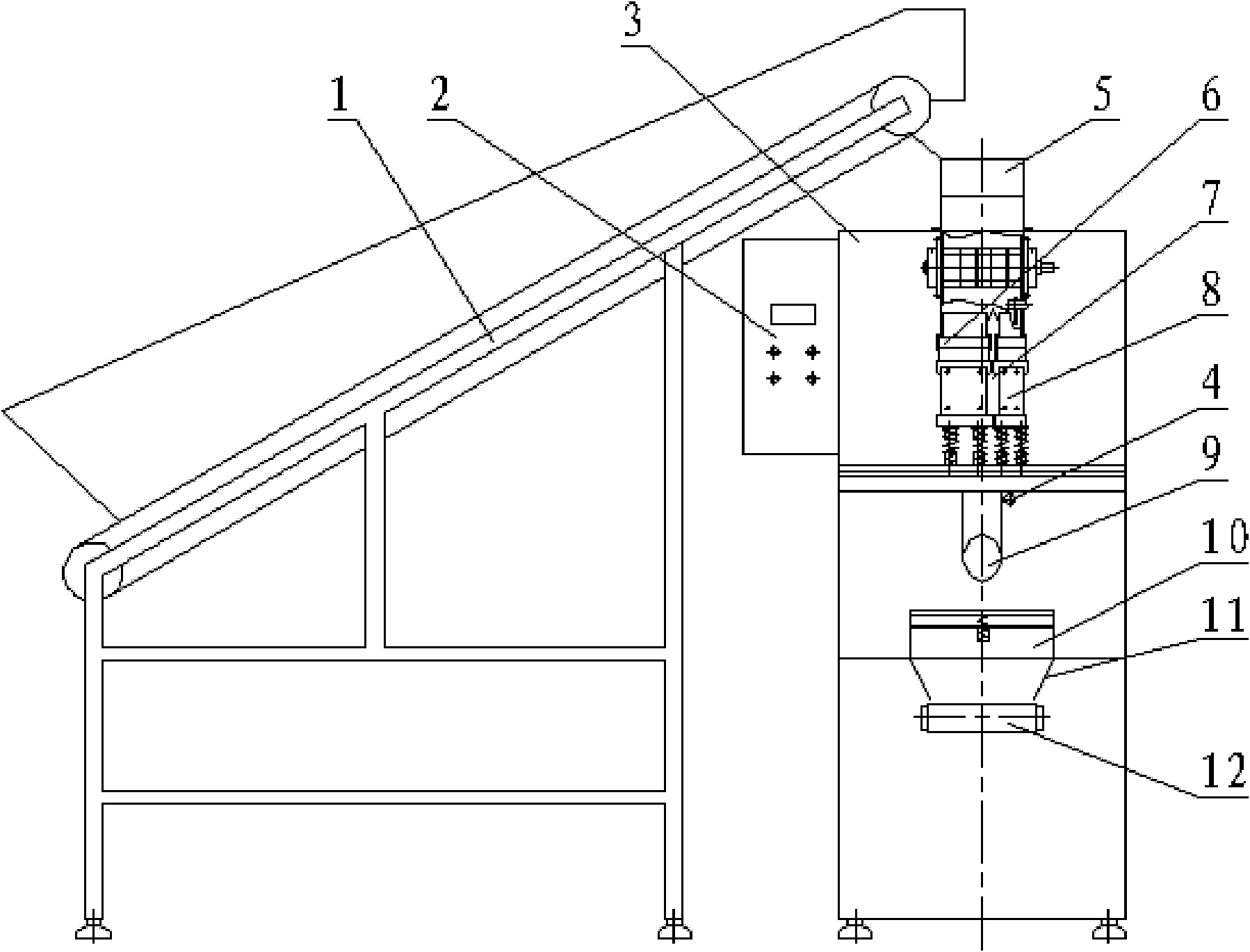

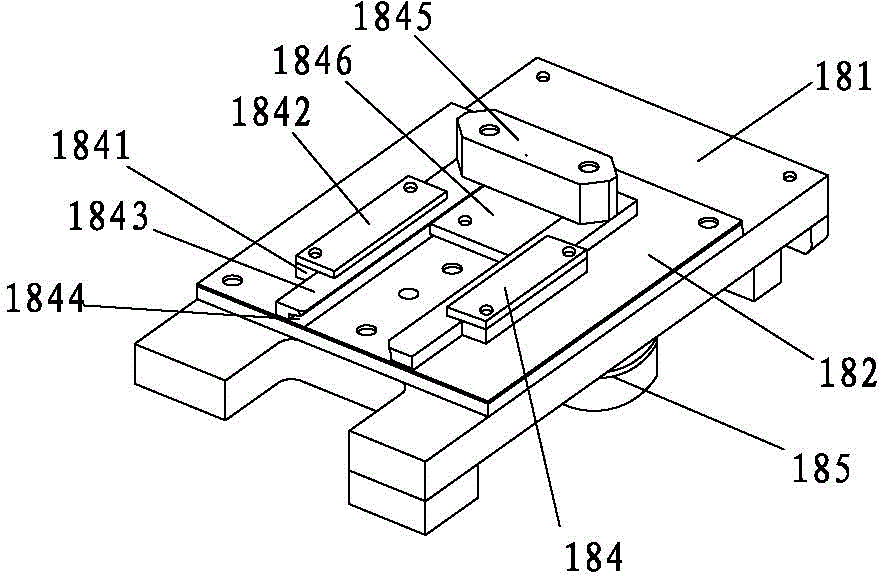

Folding key assembling machine

InactiveCN101972932ARealize automatic feedingRealize the assemblyAssembly machinesSemi automaticControl circuit

The invention relates to a folding key assembling machine, which comprises a worktable, and a plastic head feeding mechanism, a hardware press-in mechanism, a key handle feeding mechanism, a pin feeding mechanism, a pin pressing mechanism, a loading mechanism and an assembling and conveying mechanism which are arranged on the worktable, wherein the assembling and conveying mechanism is provided with a key holder; the hardware press-in mechanism, the key handle feeding mechanism and the pin pressing mechanism are connected with the assembling and conveying mechanism in turn; the output end of the plastic head feeding mechanism is connected with the hardware press-in mechanism; the output end of the pin feeding mechanism is connected with the pin pressing mechanism; and the mechanisms are connected with the main control circuit electrically. In the invention, the automatic feeding mechanism and the automatic assembling mechanism are combined scientifically; the operation mechanicals form a continuous operation streamline for automatically feeding and assembling folding keys in place of the manual and semi-automatic ways of assembling the folding keys; thus, the production efficiency of the folding keys is improved obviously, assembly quality is improved, production cost is saved and labor intensity is lowered.

Owner:周俊雄

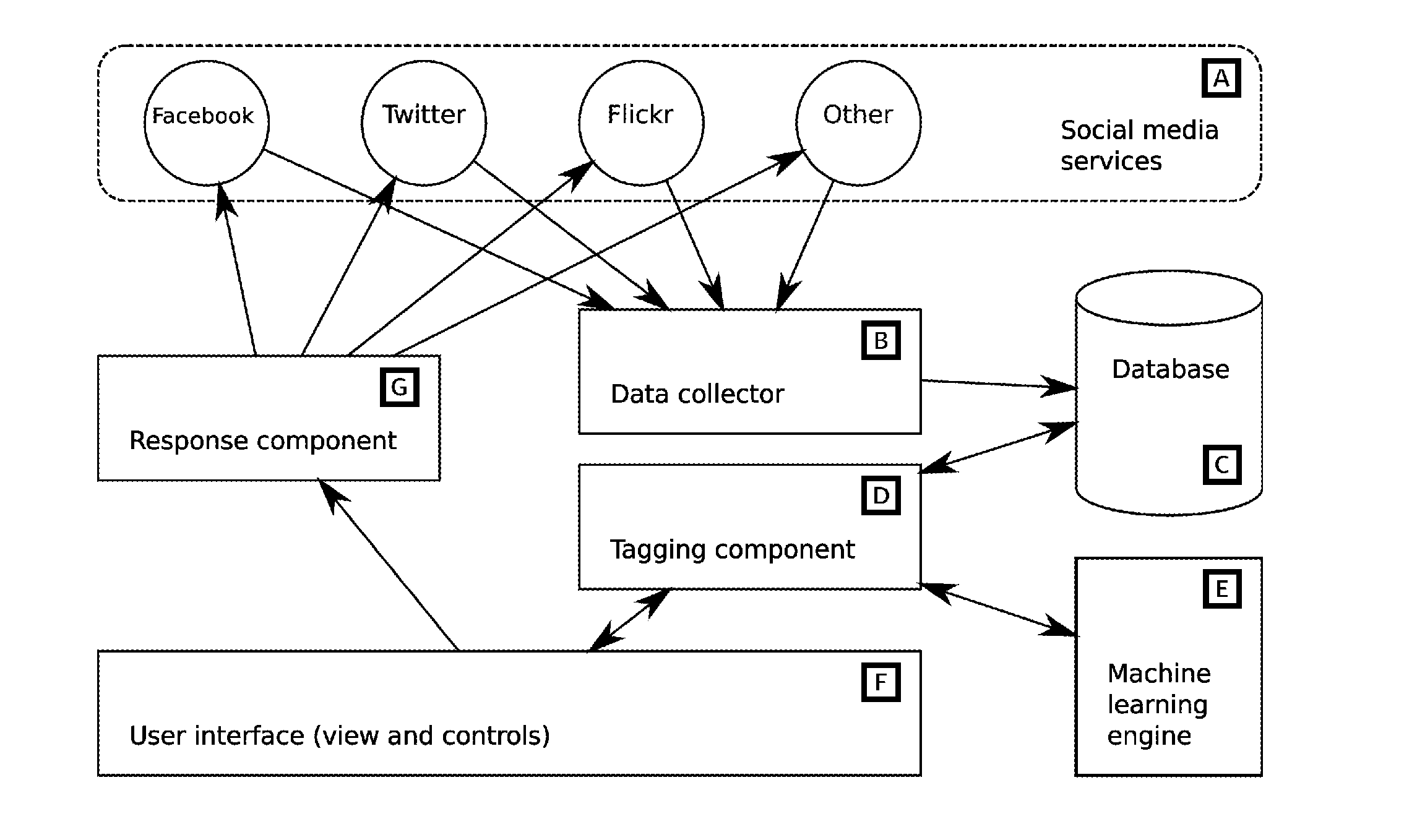

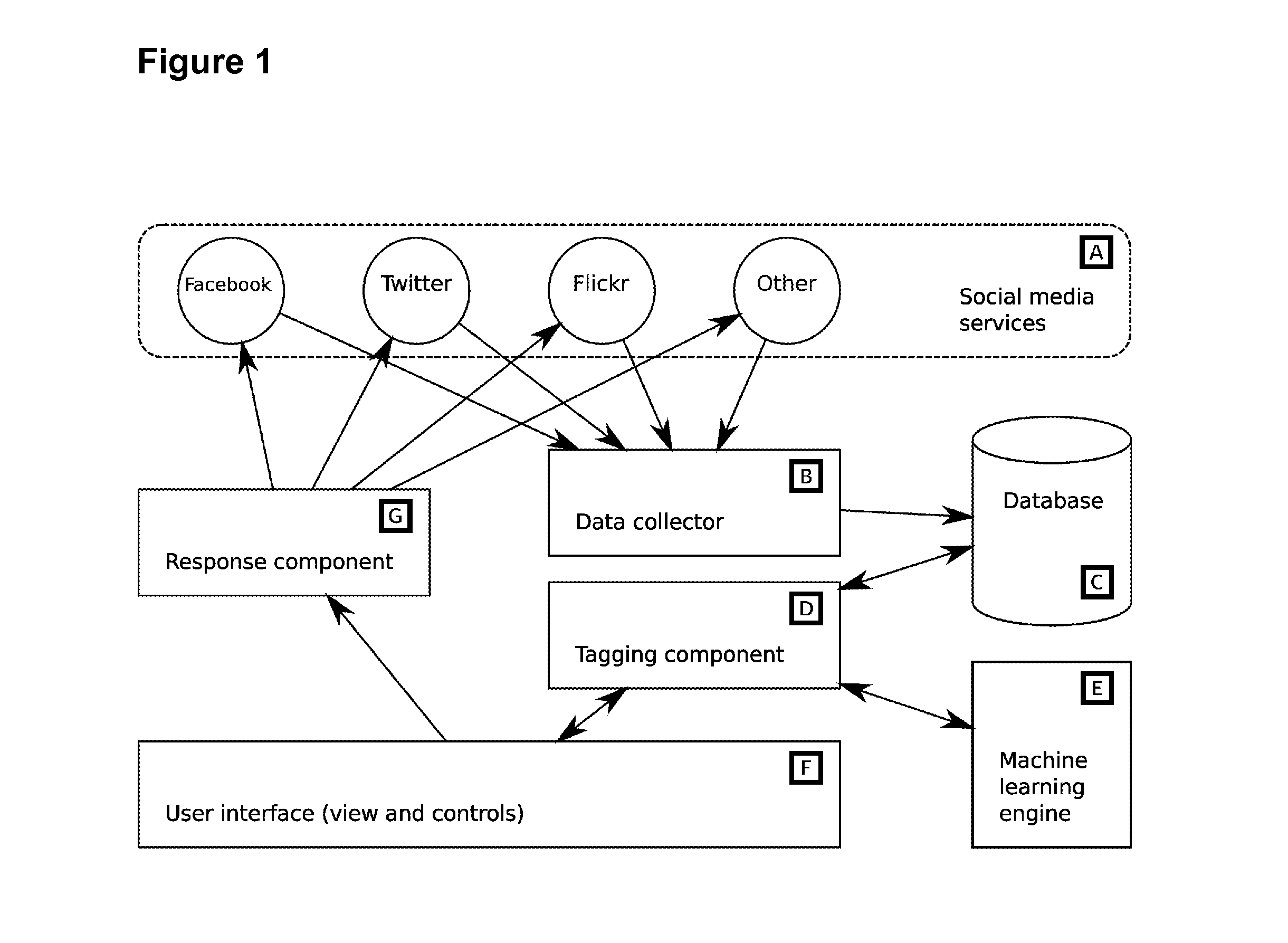

System for organising social media content to support analysis, workflow and automation

InactiveUS20110078584A1Optimize volumeEasy to handleInput/output for user-computer interactionDigital computer detailsSocial mediaApplication software

A social media workflow application includes a social media search component executable by a computing system, a tagging system for annotating search results with textual tags, and a user interface enabling the display of filtered results based on tag, and potentially other, criteria. The new invention is a system to automate tagging and other actions, and the use of such automation to provide a flexible semi-automated workflow tool for the improved use of social media, with particular relevance for marketing and public communications business functions.

Owner:WINTERWELL ASSOCS

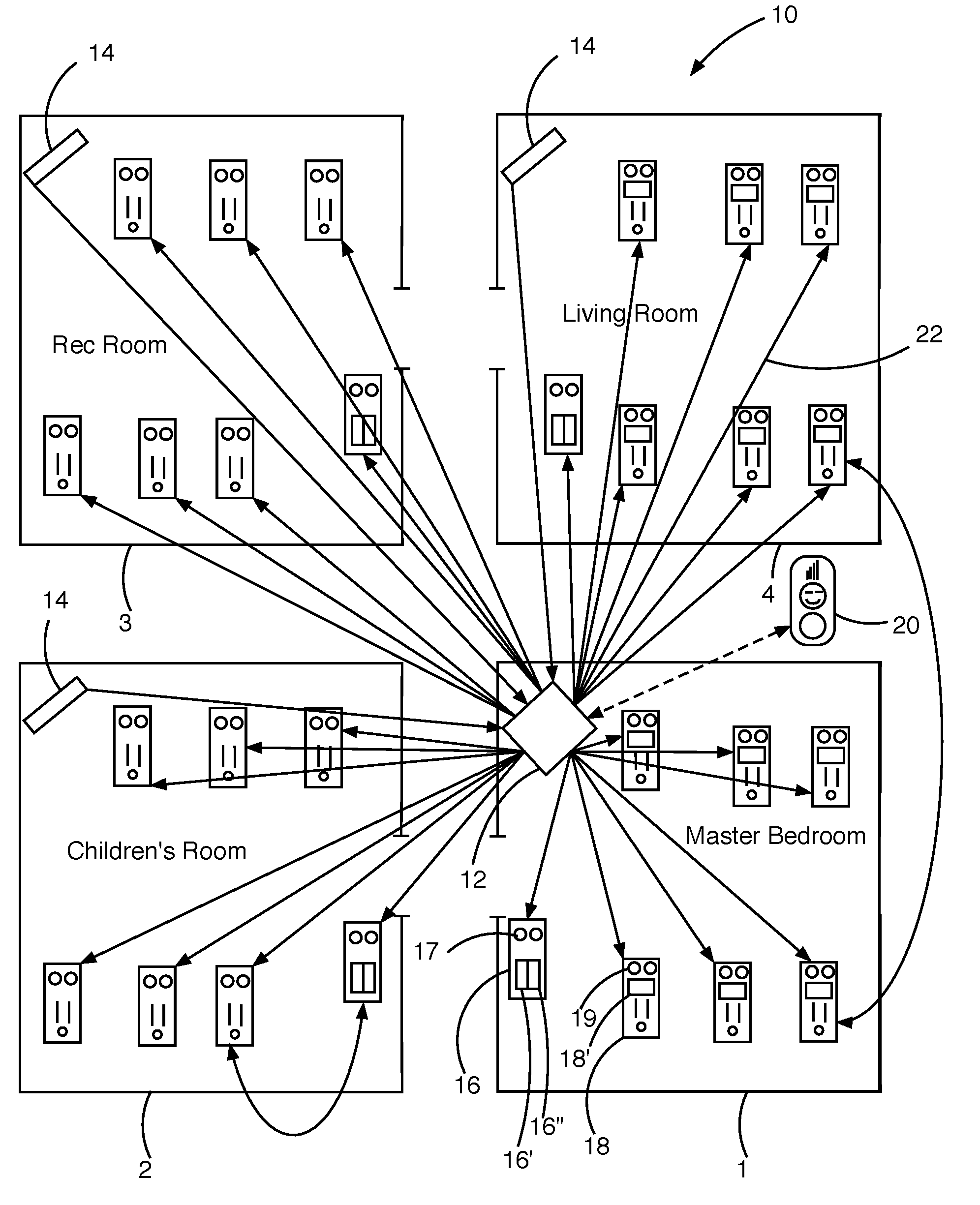

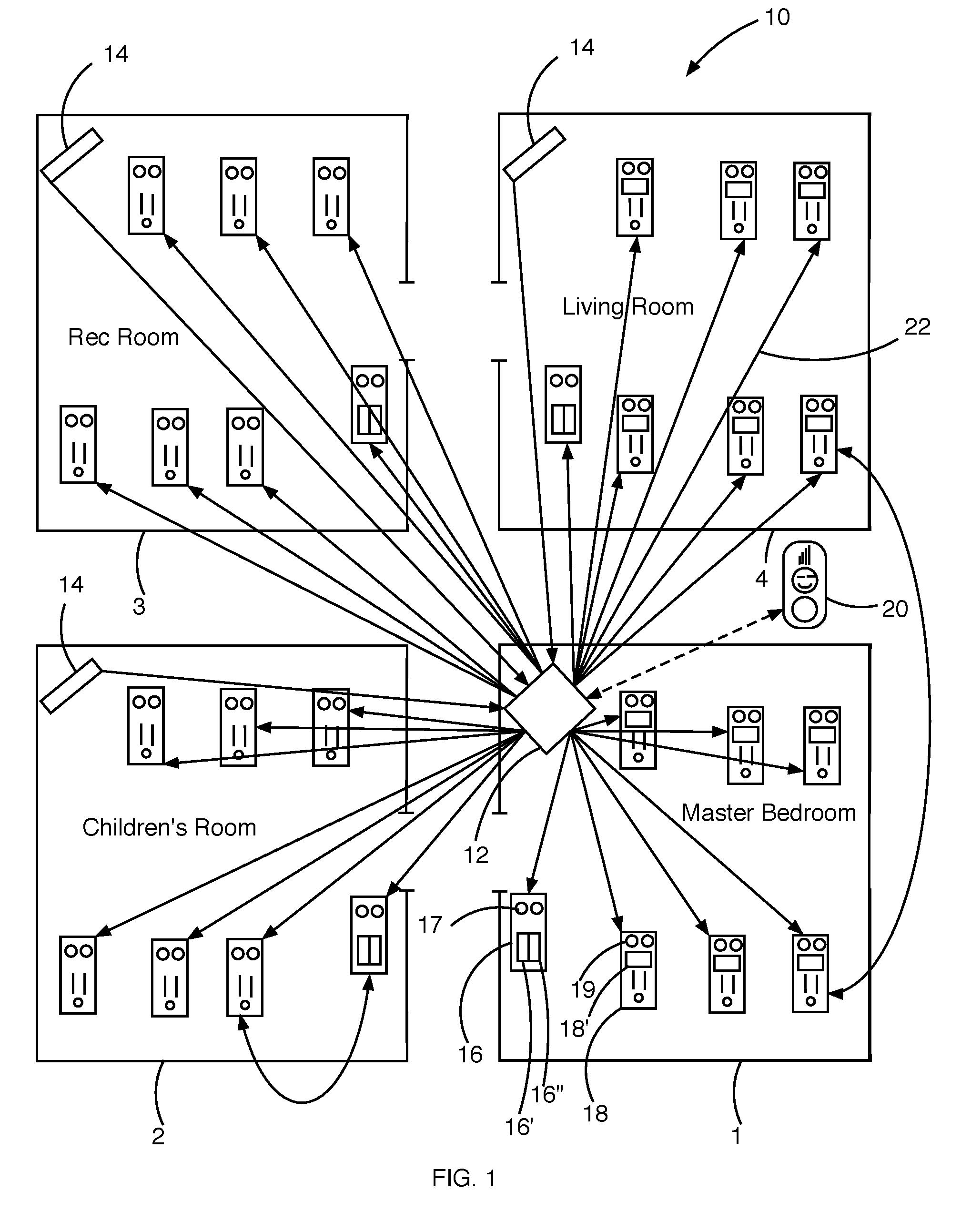

Home automation system

A home automation system comprises a central processing unit controlling a network in communication with a plurality of smart devices comprising one or more of a switch or an outlet. Each smart device comprises a processor, a communication device in communication with the central processing unit via the network and a user interface for controlling or setting an operating parameter of the smart device.

Owner:ANDERSEN DAVID C

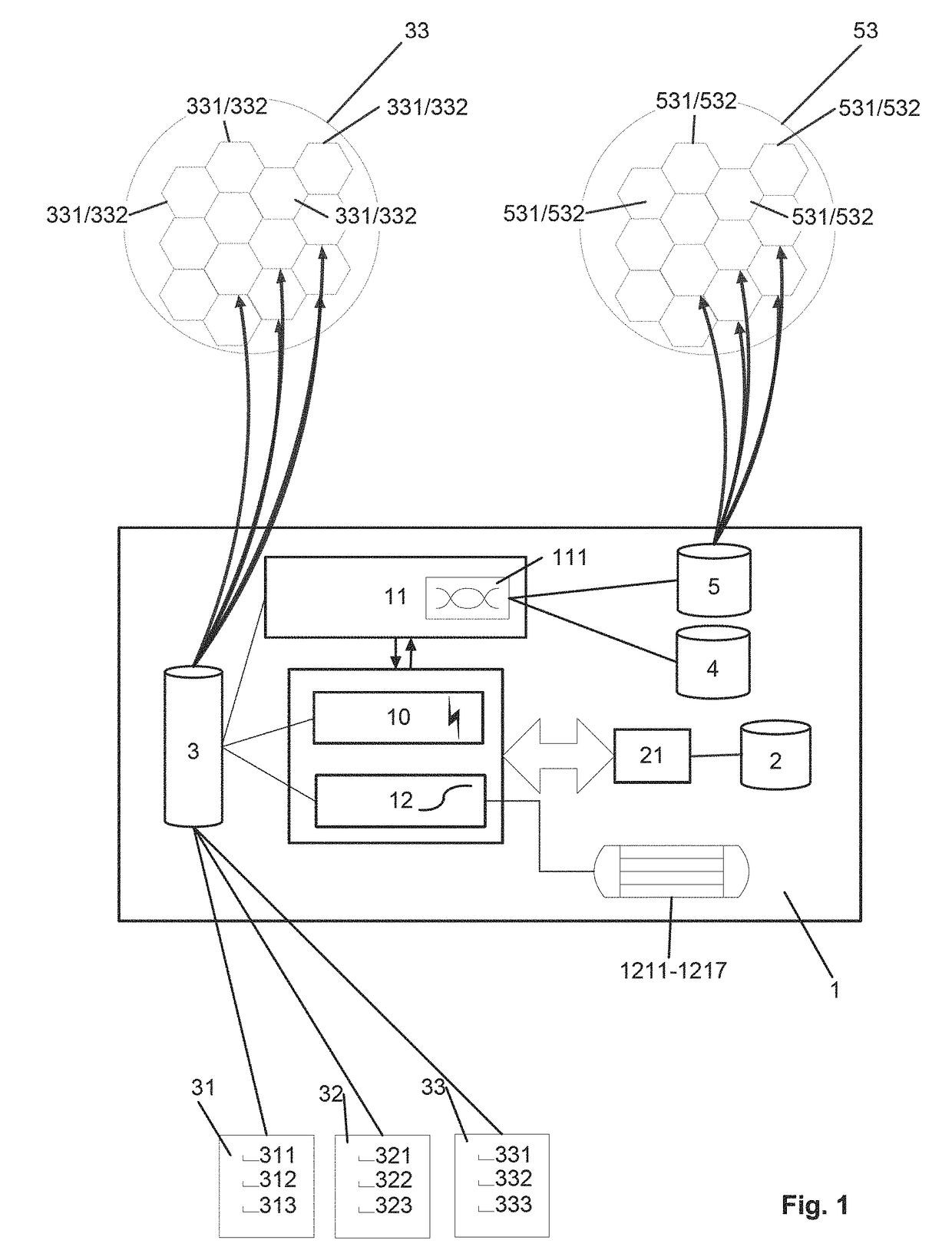

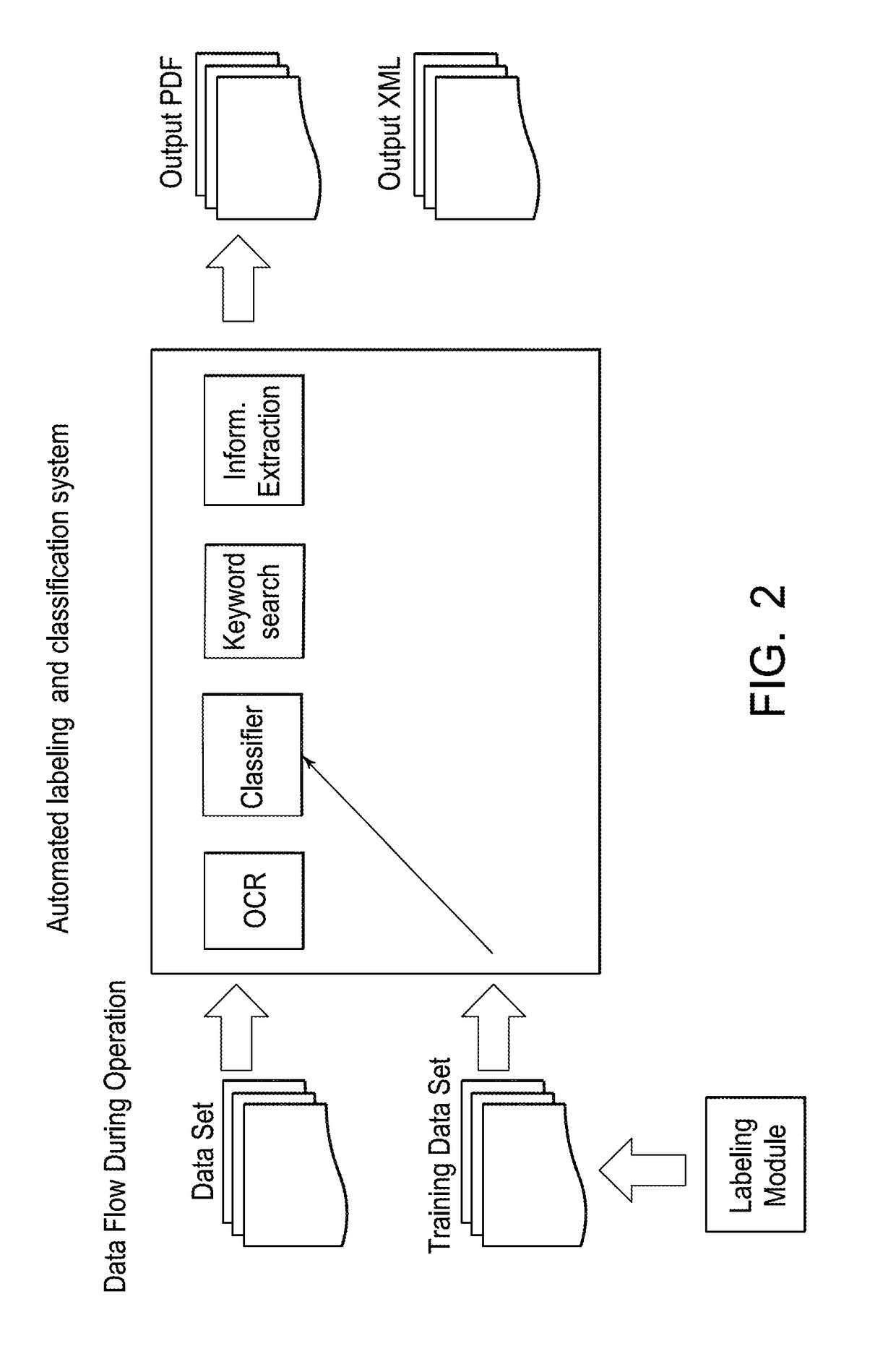

Data extraction engine for structured, semi-structured and unstructured data with automated labeling and classification of data patterns or data elements therein, and corresponding method thereof

ActiveUS20180114142A1Easy to implementNovel level of efficiencyKernel methodsCharacter and pattern recognitionData ingestionFeature vector

A fully or semi-automated, integrated learning, labeling and classification system and method have closed, self-sustaining pattern recognition, labeling and classification operation, wherein unclassified data sets are selected and converted to an assembly of graphic and text data forming compound data sets that are to be classified. By means of feature vectors, which can be automatically generated, a machine learning classifier is trained for improving the classification operation of the automated system during training as a measure of the classification performance if the automated labeling and classification system is applied to unlabeled and unclassified data sets, and wherein unclassified data sets are classified automatically by applying the machine learning classifier of the system to the compound data set of the unclassified data sets.

Owner:SWISS REINSURANCE CO LTD

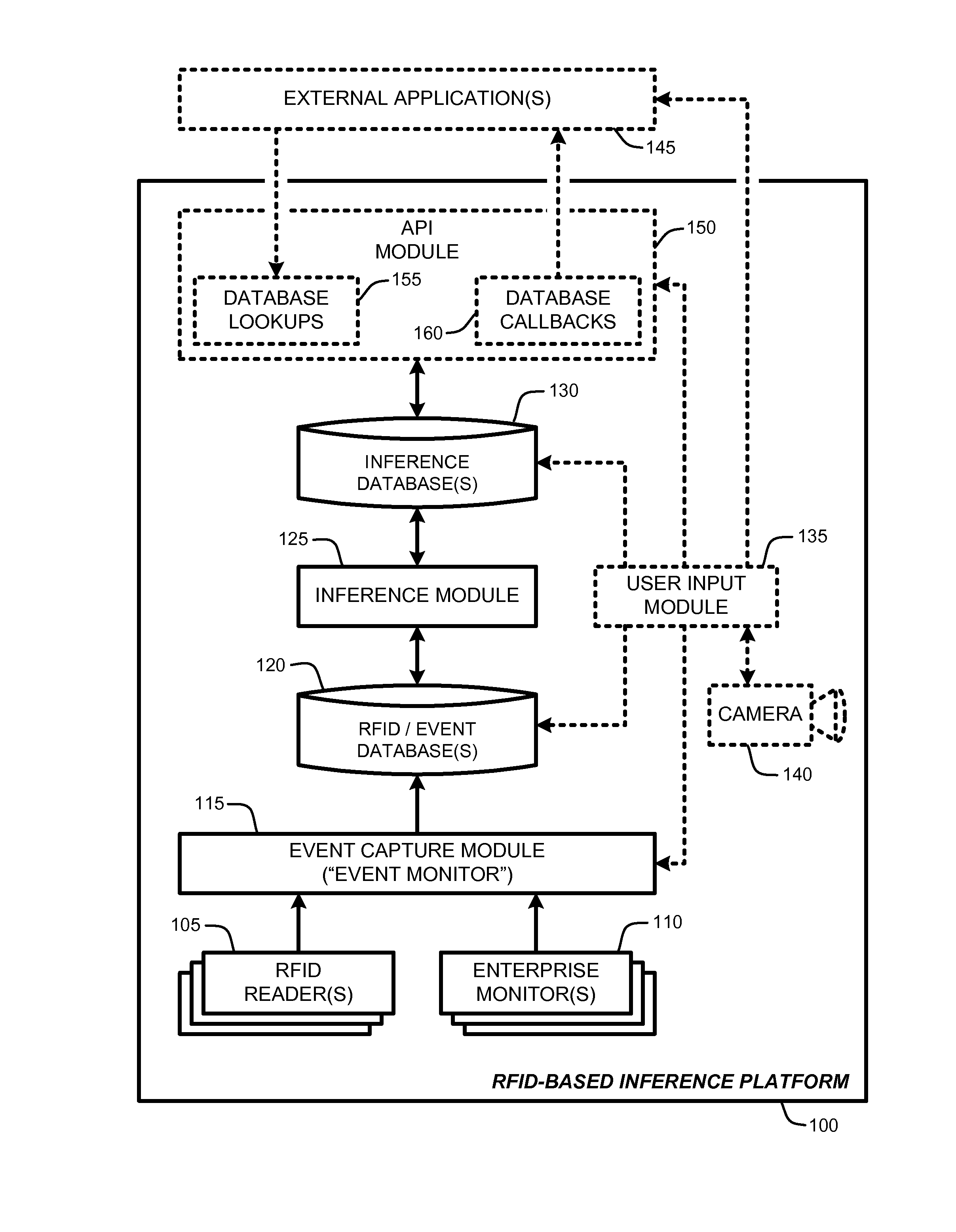

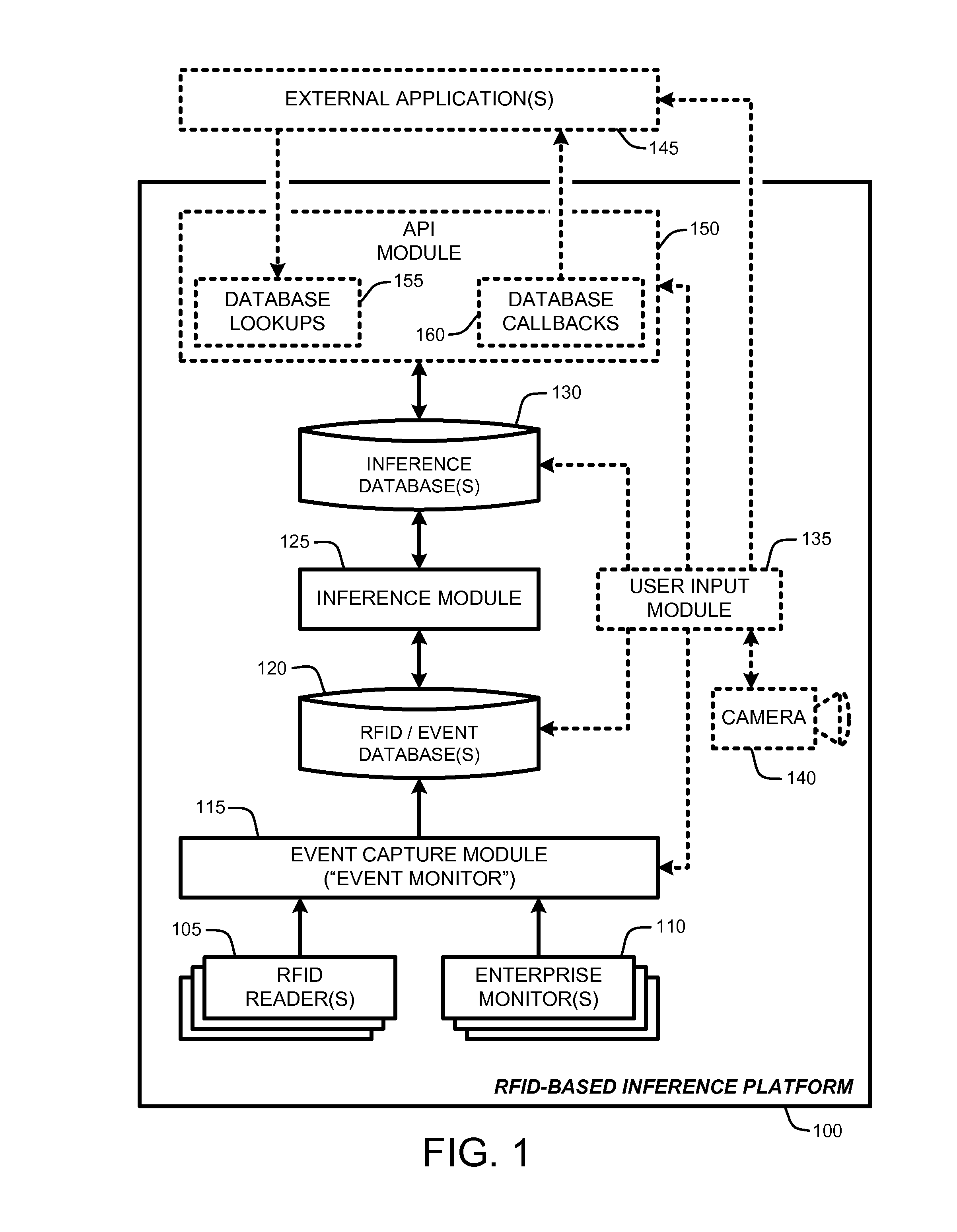

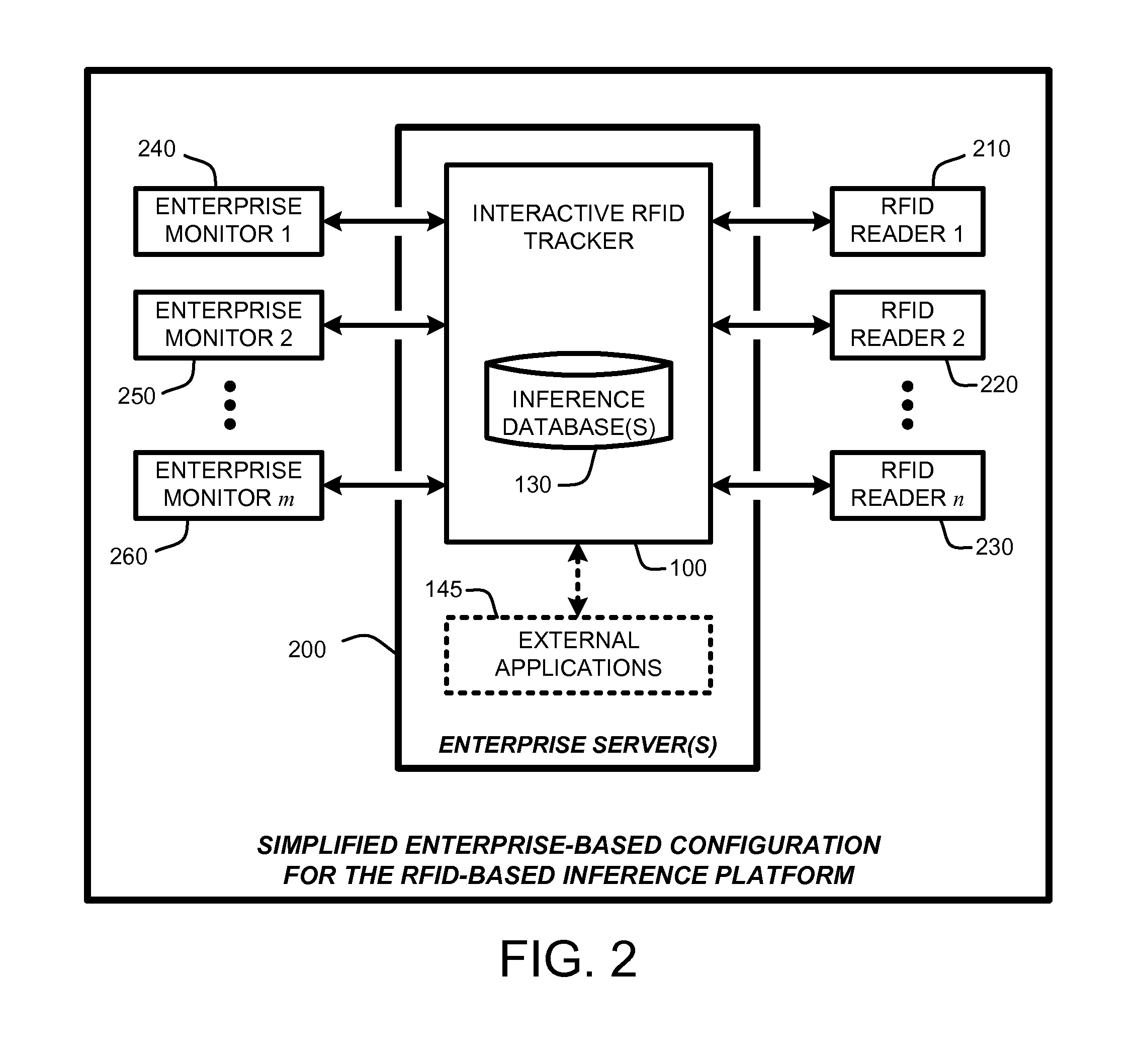

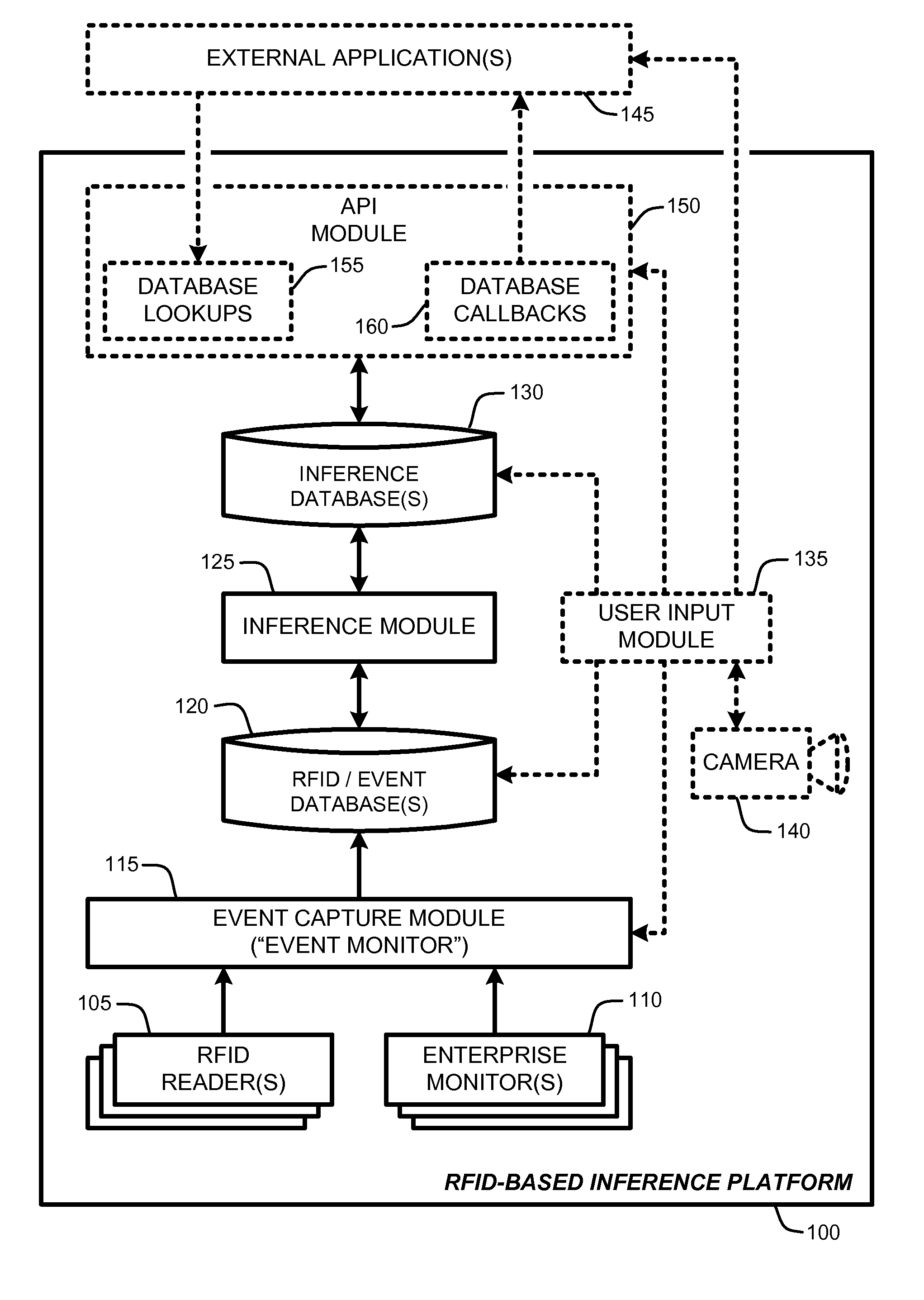

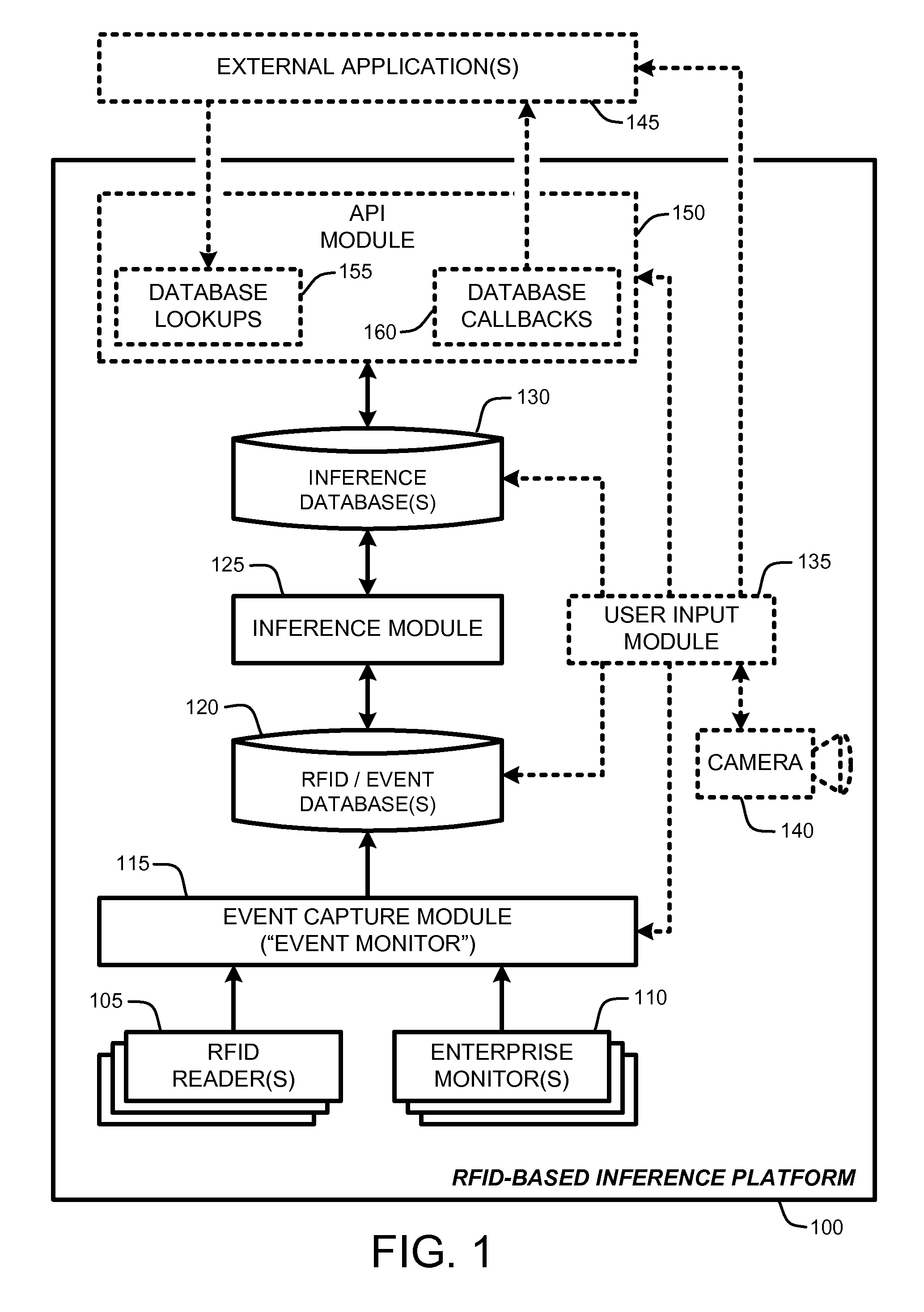

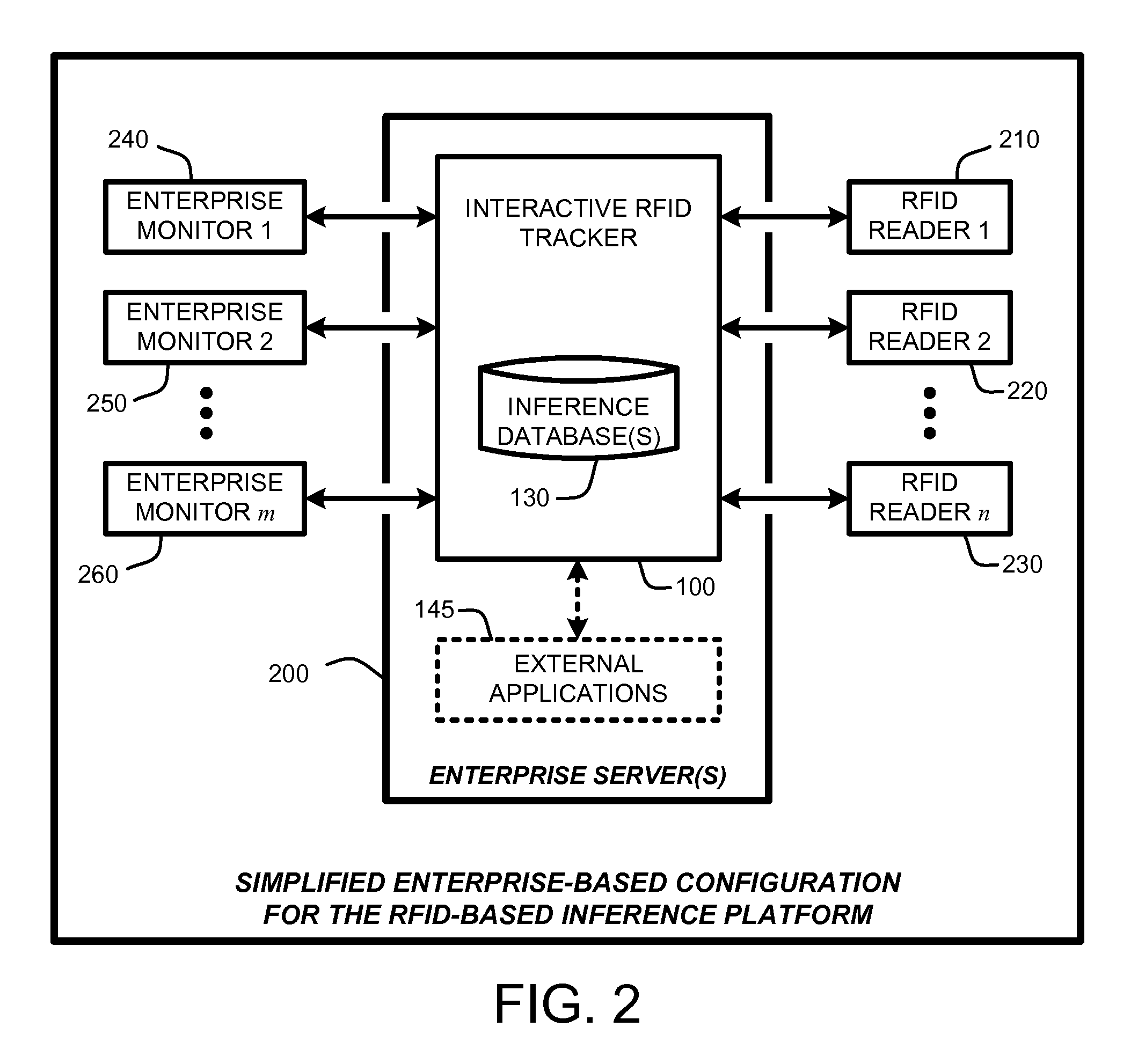

Rfid-based enterprise intelligence

ActiveUS20110227704A1Low costElectric signal transmission systemsDigital data processing detailsWorkspaceCataloging

An “RFID-Based Inference Platform” provides various techniques for using RFID tags in combination with other enterprise sensors to track users and objects, infer their interactions, and provide these inferences for enabling further applications. Specifically, observations are collected from combinations of RFID tag reads and other enterprise sensors including electronic calendars, user presence identifiers, cardkey access logs, computer logins, etc. Given sufficient observations, the RFID-Based Inference Platform automatically differentiates between tags associated with or affixed to people and tags affixed to objects. The RFID-Based Inference Platform then infers additional information including identities of people, ownership of specific objects, the nature of different “zones” in a workspace (e.g., private office versus conference room). These inferences are then used to enable various applications including object tracking, automated object ownership determinations, automated object cataloging, automated misplaced object alerts, video annotations, automated conference room scheduling, semi-automated object image catalogs, object interaction query systems, etc.

Owner:MICROSOFT TECH LICENSING LLC

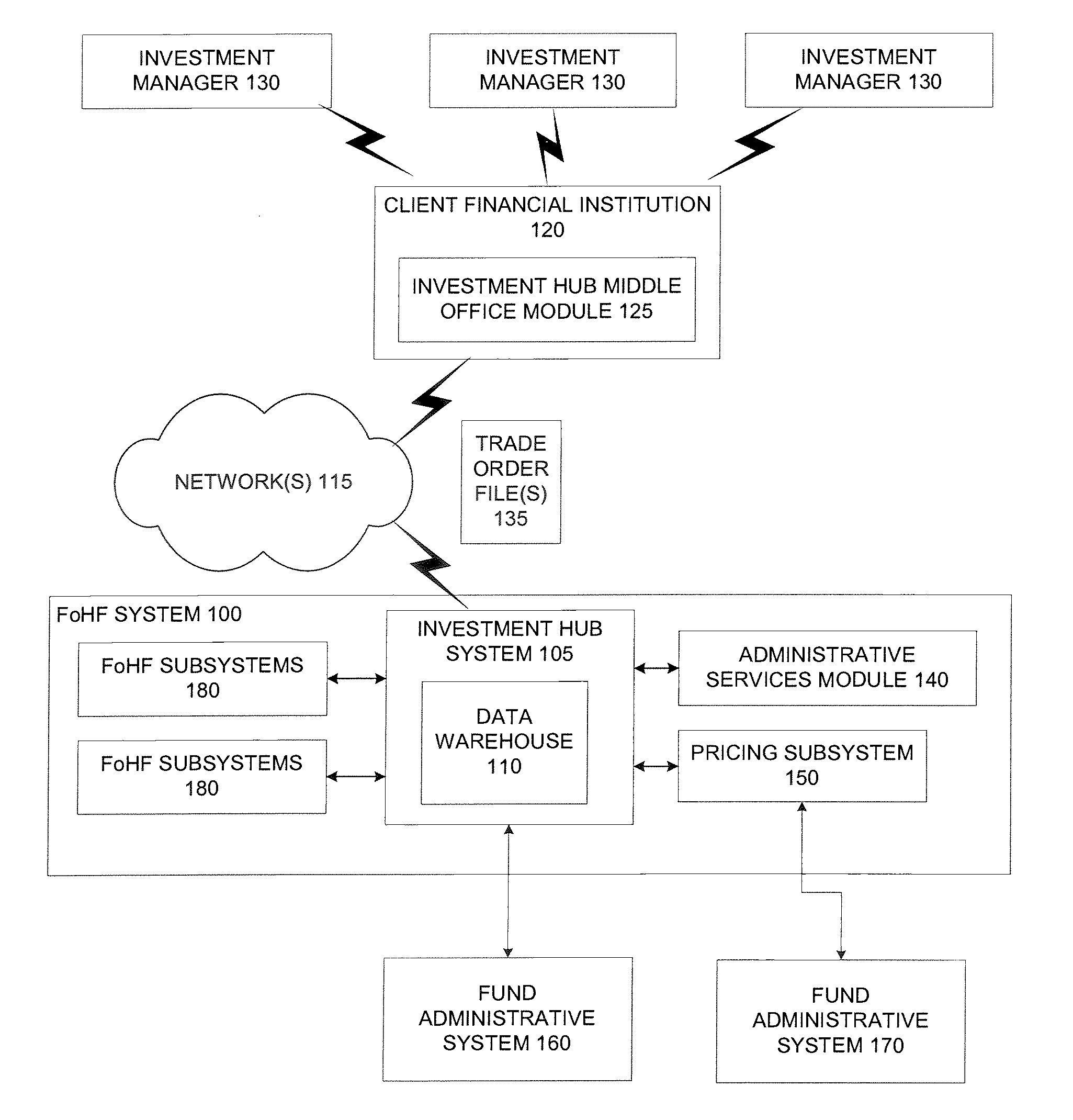

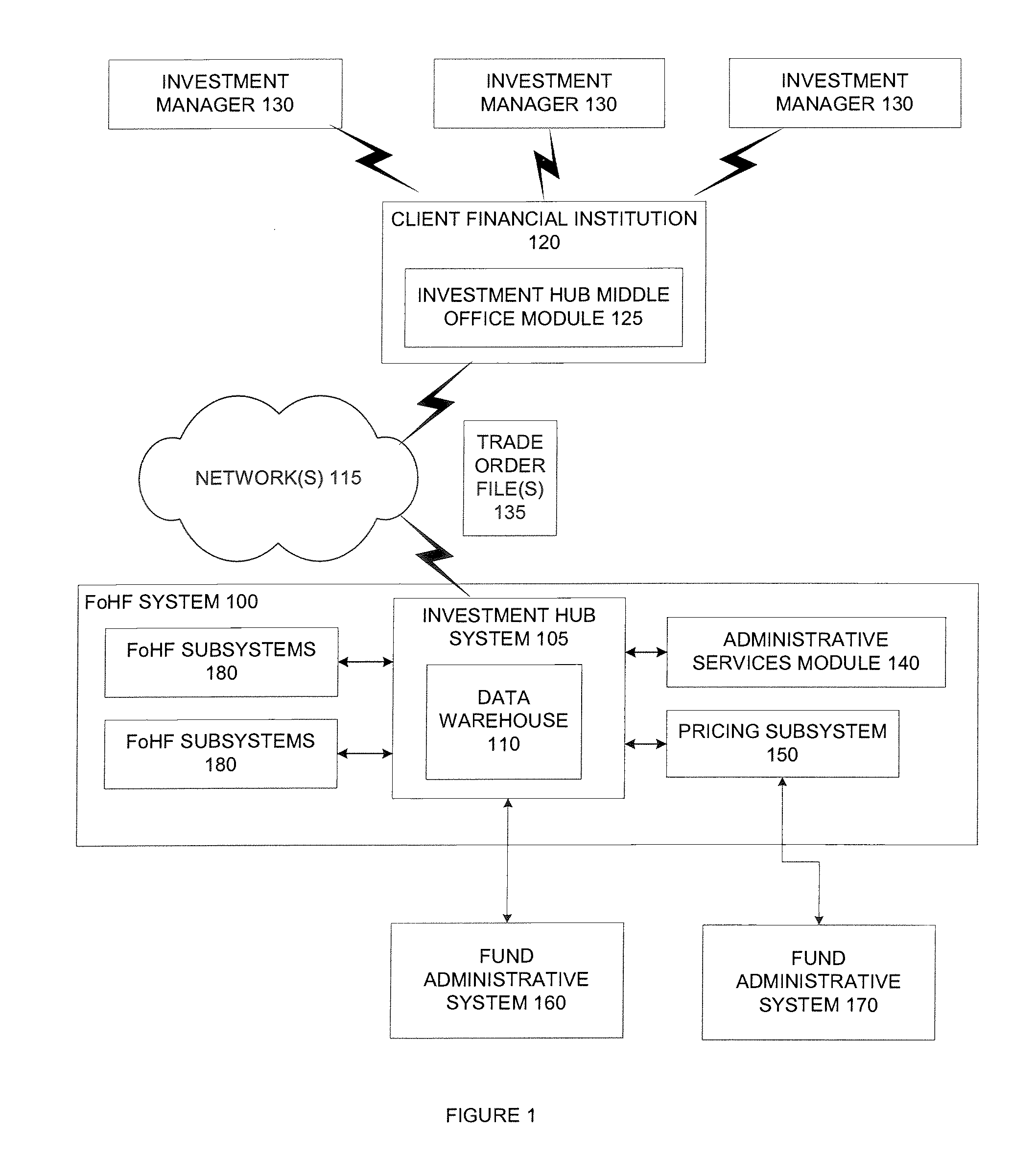

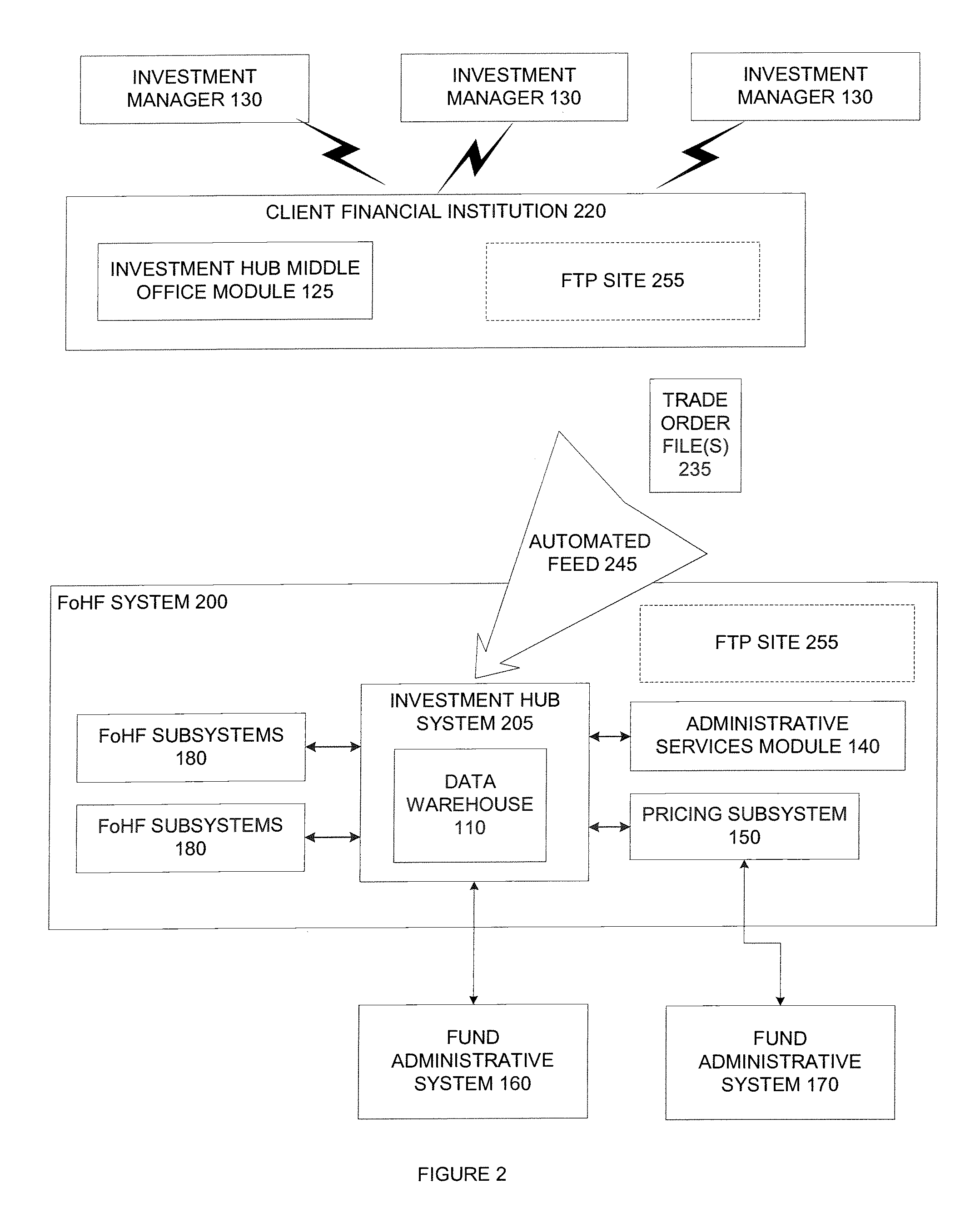

Methodologies and systems for trade execution and recordkeeping in a fund of hedge funds environment

ActiveUS20080140547A1Reduce the amount requiredComplete banking machinesFinanceHuman operatorOperating system

A system provides automation or semi-automation of trade execution and recordkeeping services for a fund of funds, in particular, a fund of hedge funds. In providing such features for trade execution and recordkeeping, various transaction processes may be automated or semi-automated, thus, reducing an amount of human operator action and introduction of associated delay and possibility of error. Moreover, such a system may have further utility in providing access to lot-level records.

Owner:THE BANK OF NEW YORK MELLON

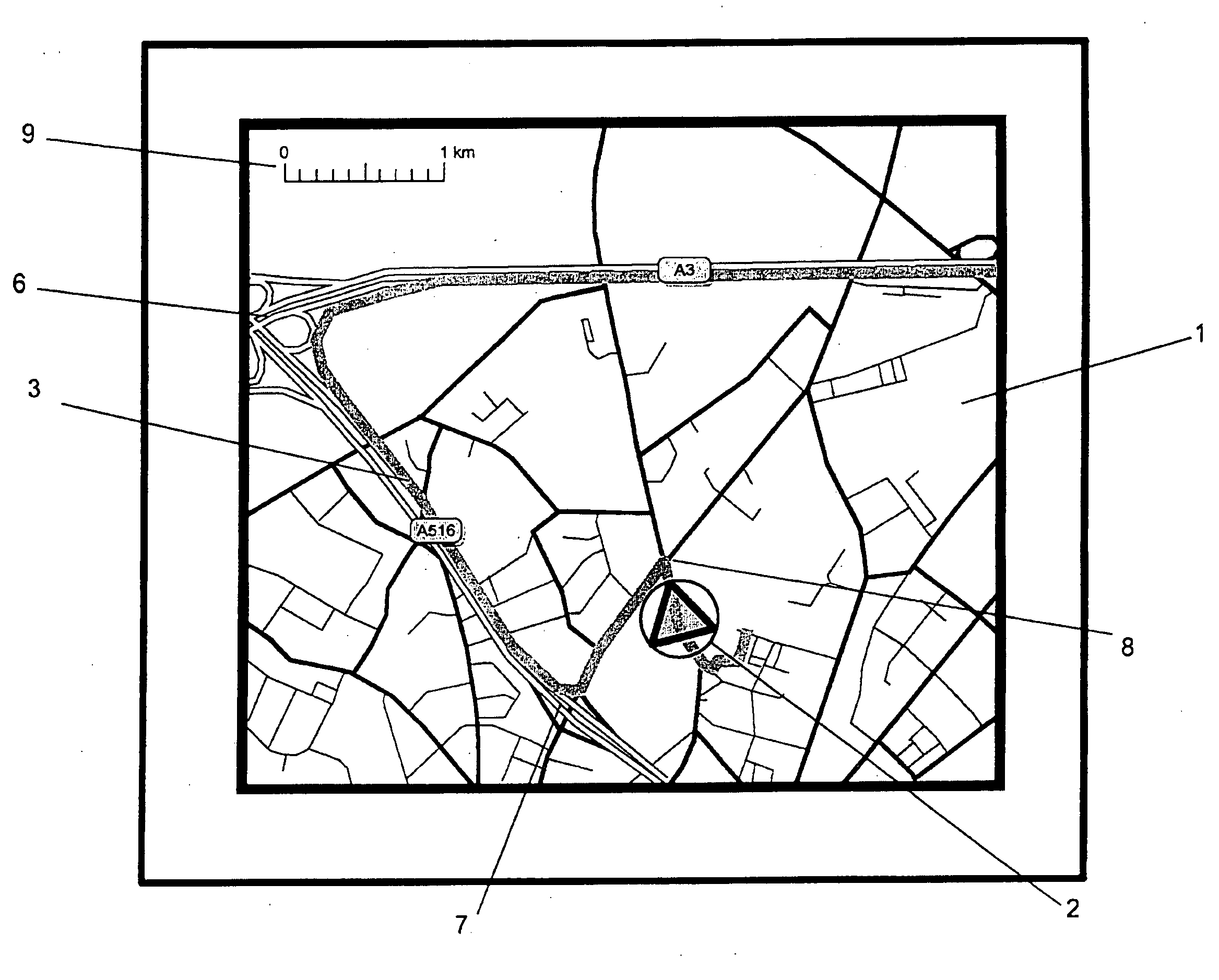

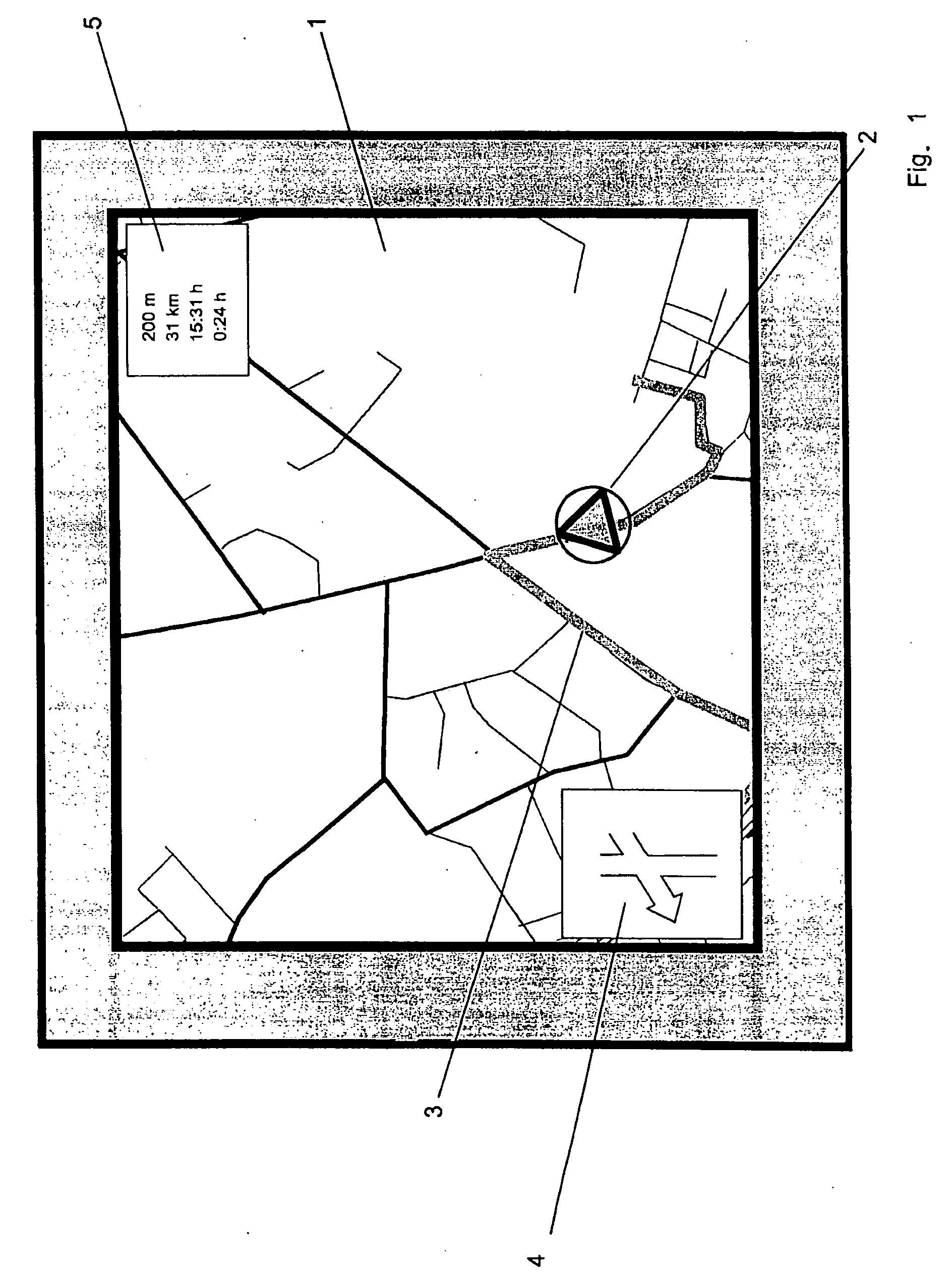

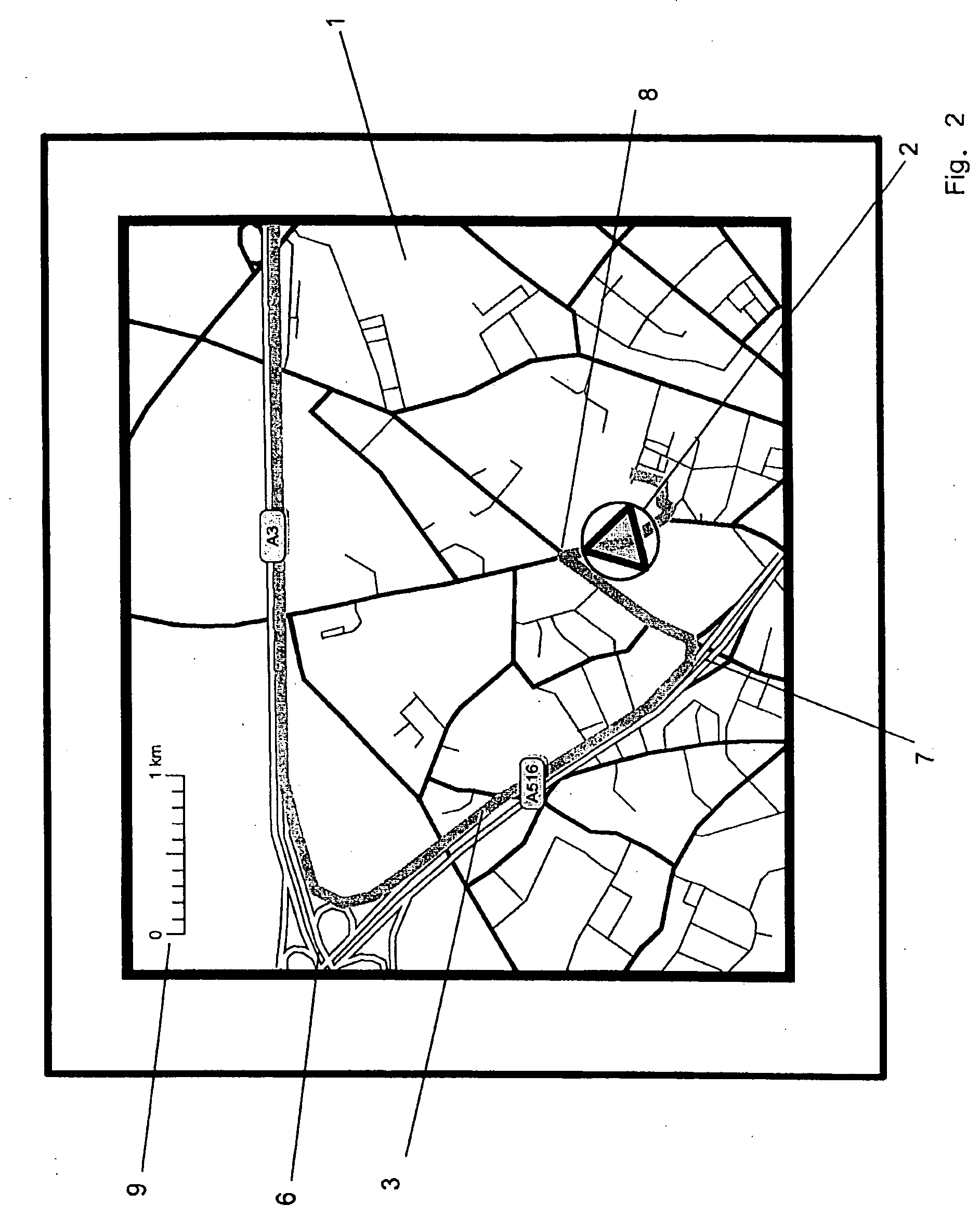

Method For Operating A Device

ActiveUS20090046111A1Instruments for road network navigationRoad vehicles traffic controlDriver/operatorOperation mode

A method for operating a navigation device provides a driver with the option of being presented with an overview of the route lying ahead in addition to a detailed illustration of the current position along the route section, namely without any complicated interactions with the navigation device. This navigation device independently changes the scale of the display of the route on the display means in dependence on a manually selected operating mode. The advantage of this method can be seen in a semi-automated solution that always enables the driver to decide exactly which information should be displayed by his navigation device at which time.

Owner:NAVIGON AG

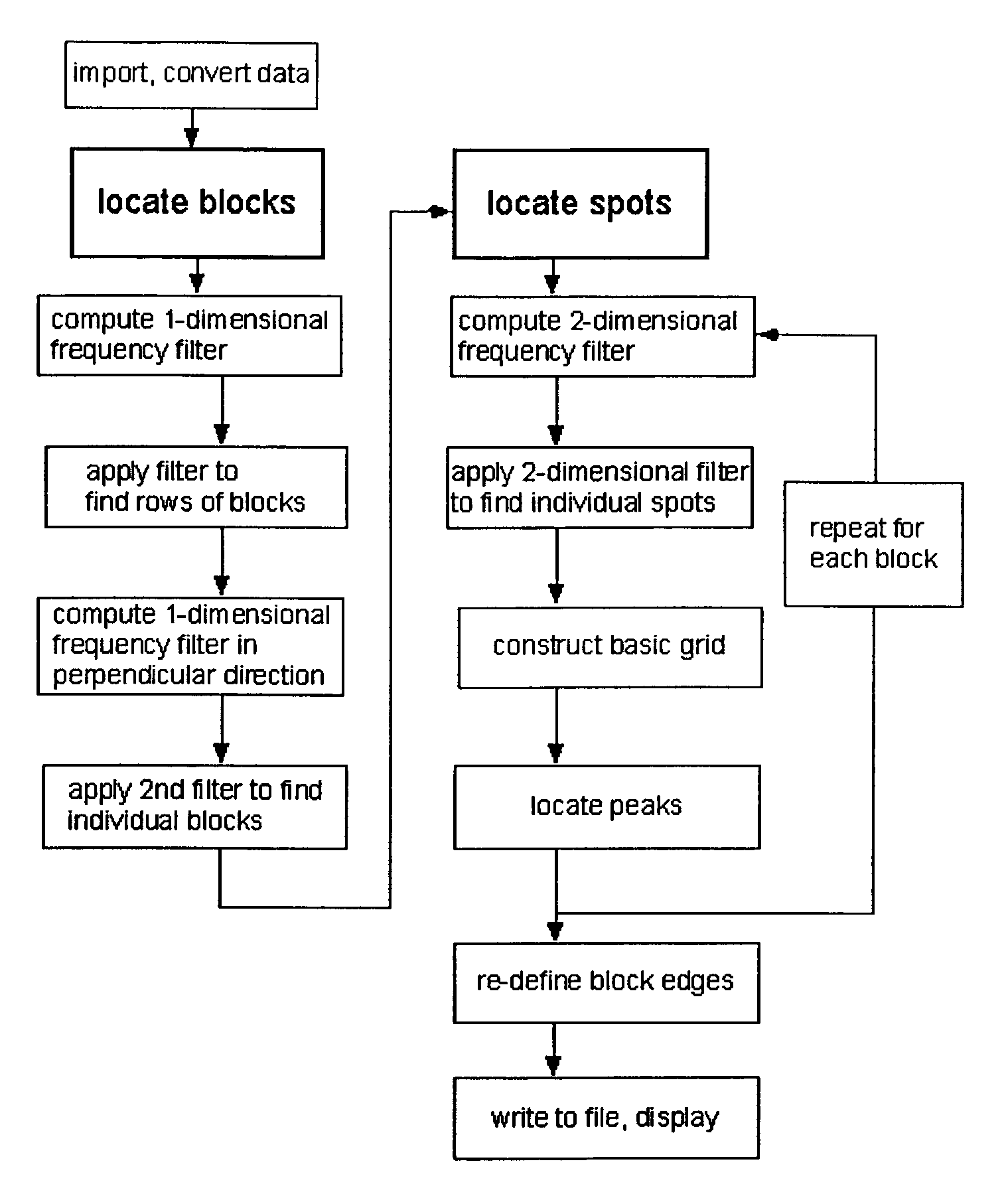

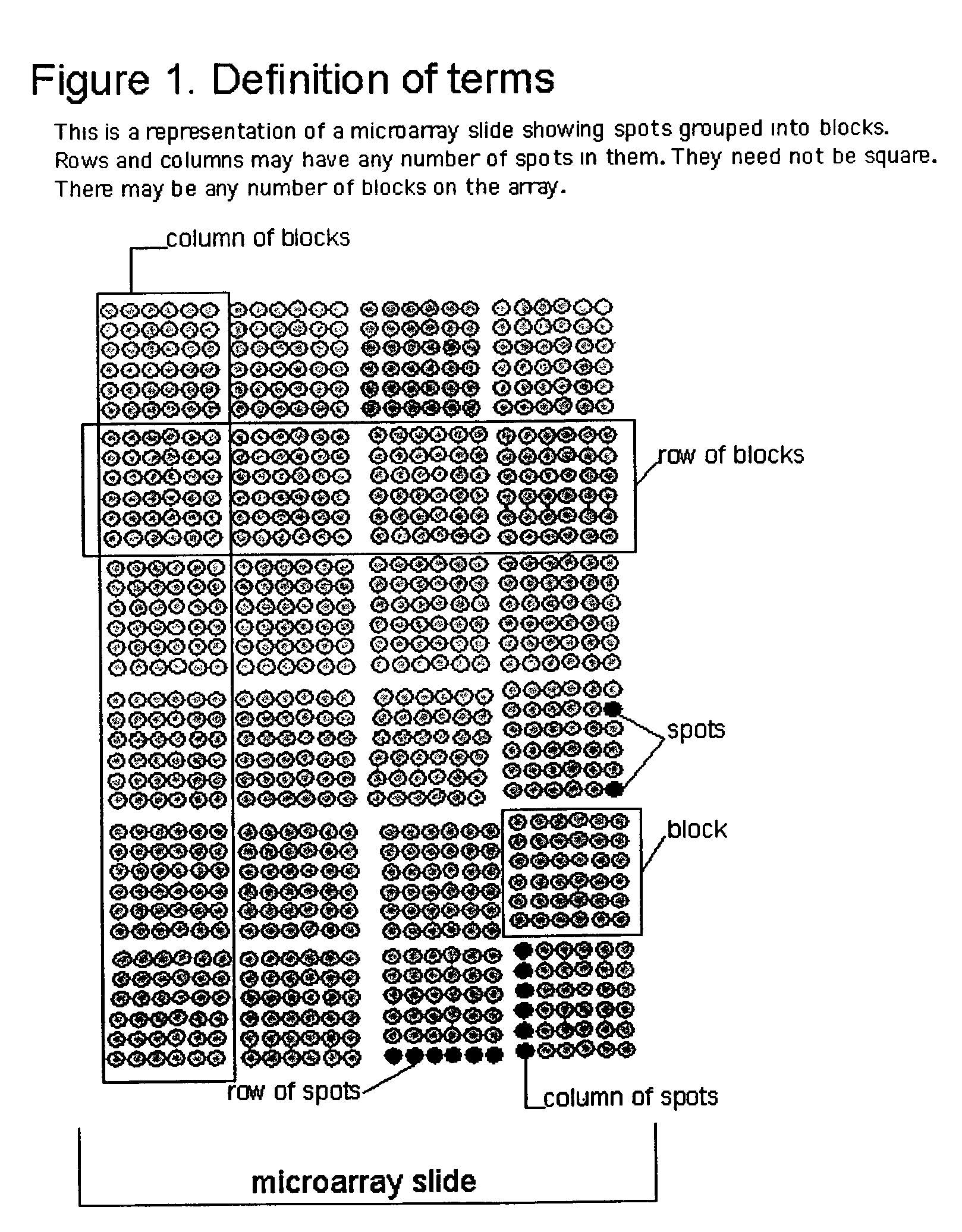

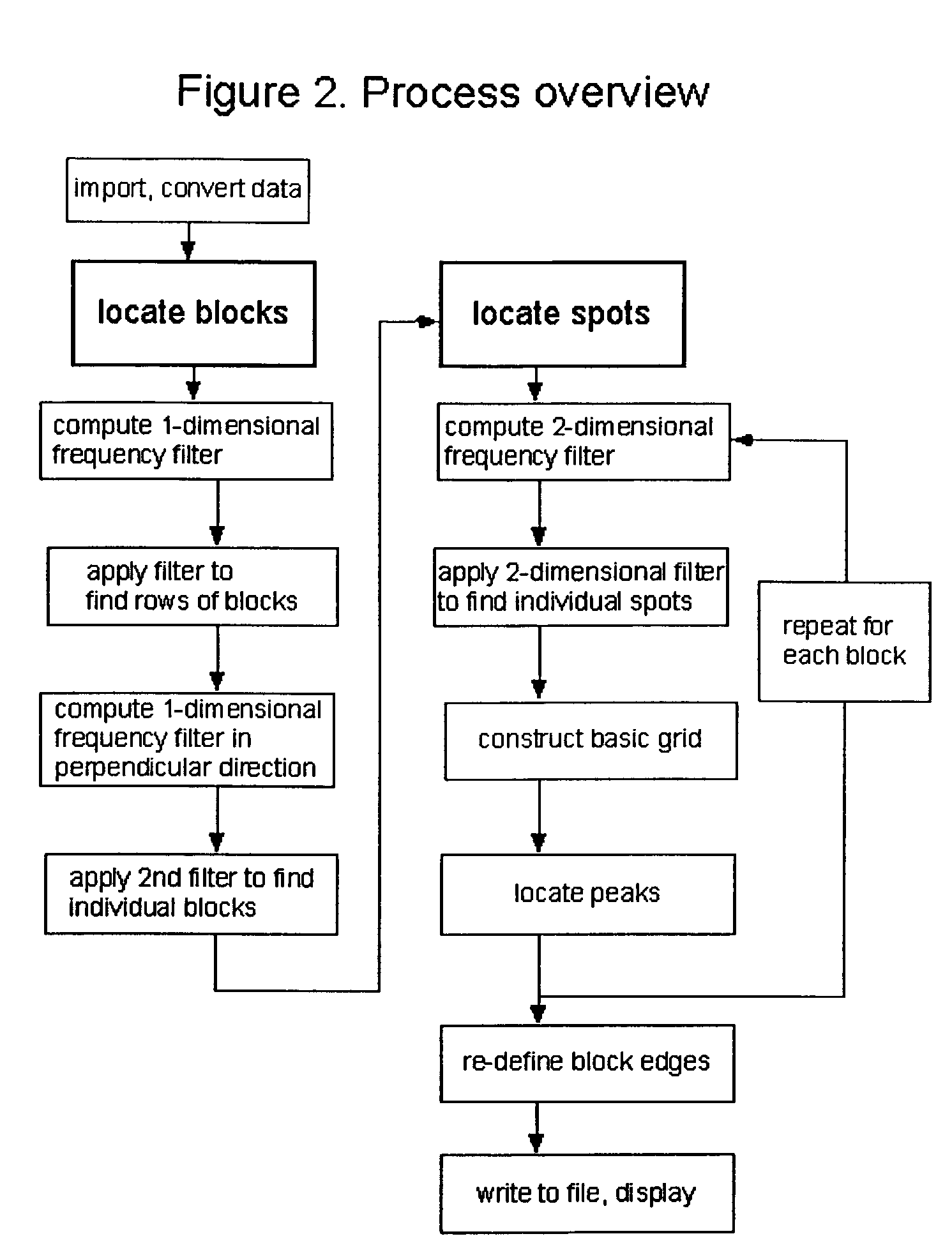

Method, system, and computer code for finding spots defined in biological microarrays

InactiveUS6980677B2Wide rangeEnhance the imageImage enhancementImage analysisMathematical ComputingFrequency filtering

A method (and system) for using information contained within the scanned image to create, in an automated (or semi-automated) process, an accurate data grid. The process has steps: enhance the image; locate blocks of spots; and find each individual spot in each of the blocks. Preferably, the method makes use of image filtering using a“Principal Frequency Filter” based on a mathematical determination of major periodic elements in the image to eliminate noisy, non-periodic signals, and of smoothed intensity profiles of the filtered image data. Here, the term Principal Frequency Filter is used to indicate an image-enhancing filter based upon a mathematical operation which identifies the major periodic components of the image.

Owner:NILES SCI

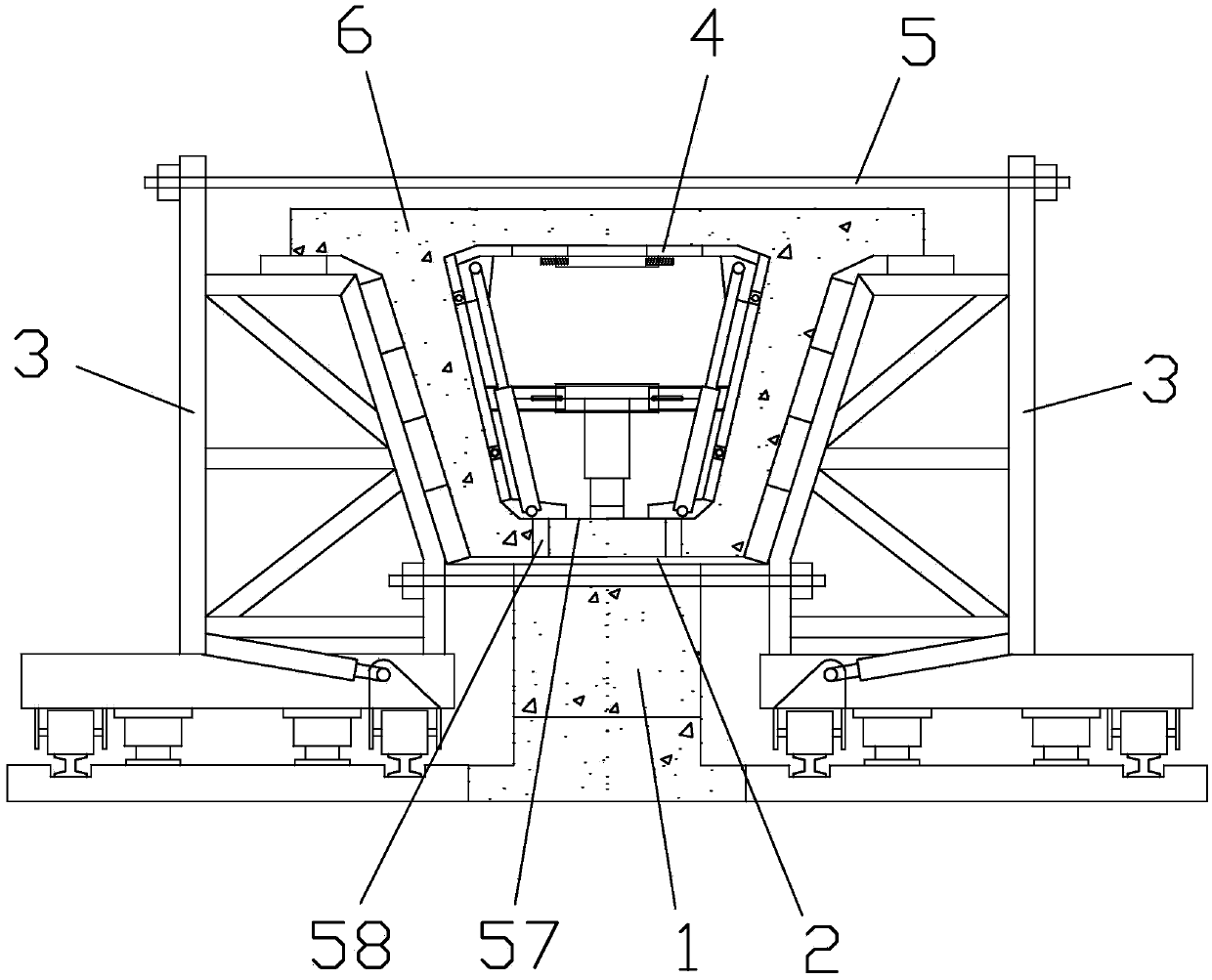

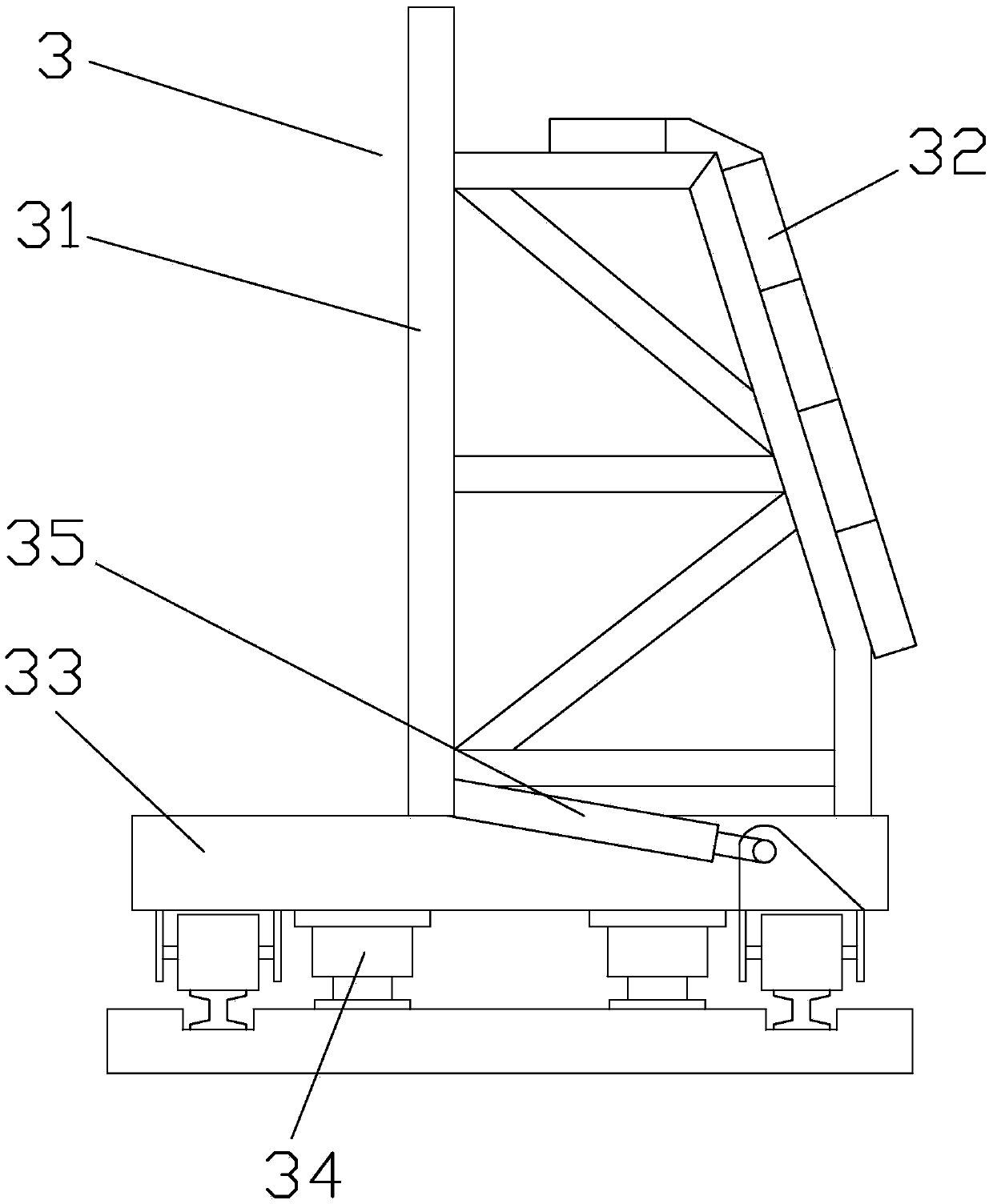

Manufacturing method of small prefabricated box girder

ActiveCN105365042AQuick releaseFast mold closingDischarging arrangementMouldsHydraulic actionEngineering

The invention discloses a manufacturing method of a small prefabricated box girder. The manufacturing method includes the following steps that firstly, a pedestal is prefabricated; secondly, mold plates are installed, wherein the mold plates are installed in the following sequence of bottom mold installation, side mold installation, inner mold installation, end mold installation and flange plate installation on side molds; thirdly, concrete is poured and cured; fourthly, demolding is conducted, wherein demolding includes detaching of end molds at the two ends of a girder body, inner mold demolding and side mold demolding; and fifthly, the girder body is cured. According to the manufacturing method, fully-hydraulic actions are achieved through the outer mold plates, the use effect is improved greatly, and labor intensity is lowered; and semi-automation is achieved through an inner mold, quick demolding and mold combination of the mold plates are facilitated, the operation intensity of workers in small space in the girder body is lowered, and the potential safety hazards of working under the high temperature are reduced. The mold plates are firm and general in structure, quick and convenient to use and advanced in design manufacturing and construction process idea.

Owner:FOSHAN HIGHWAY&BRIDGE CONSTR PREFAB CO LTD

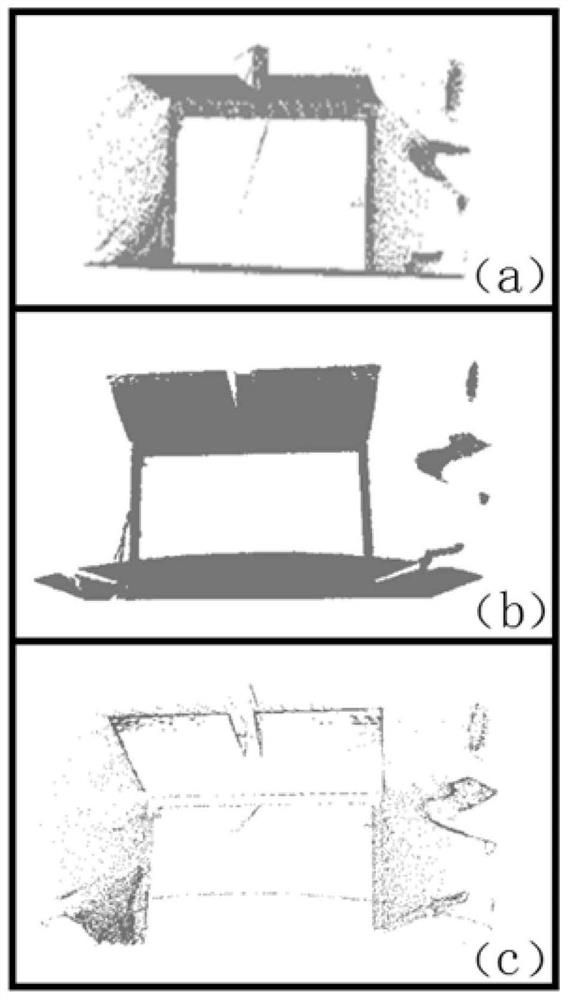

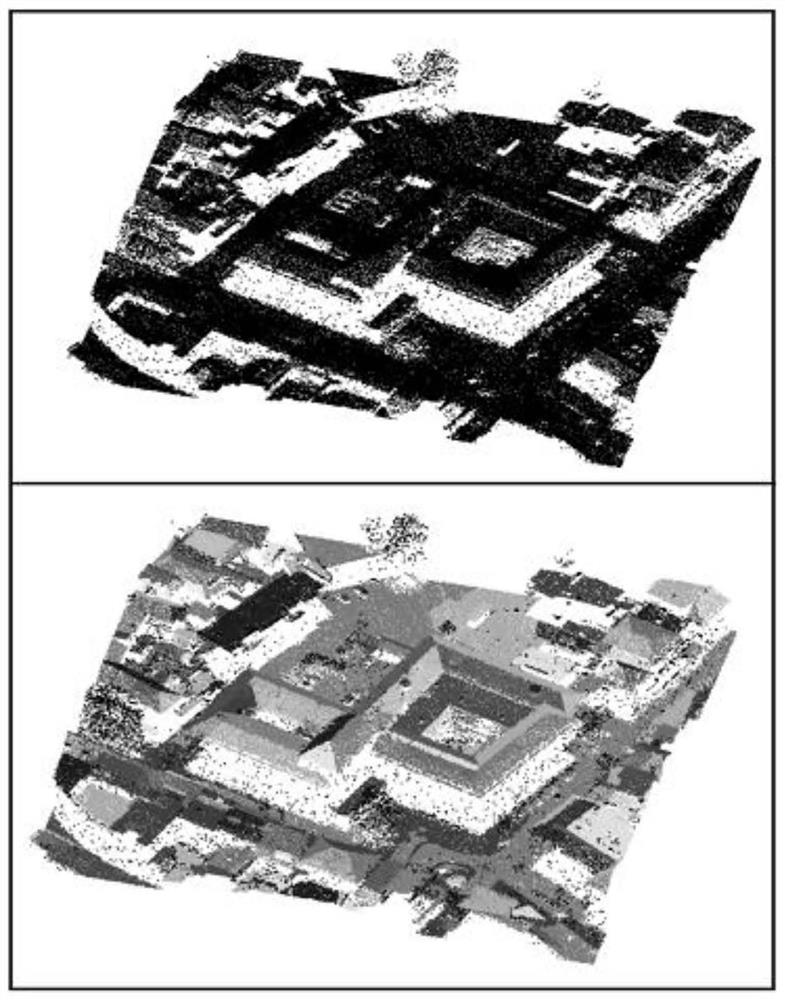

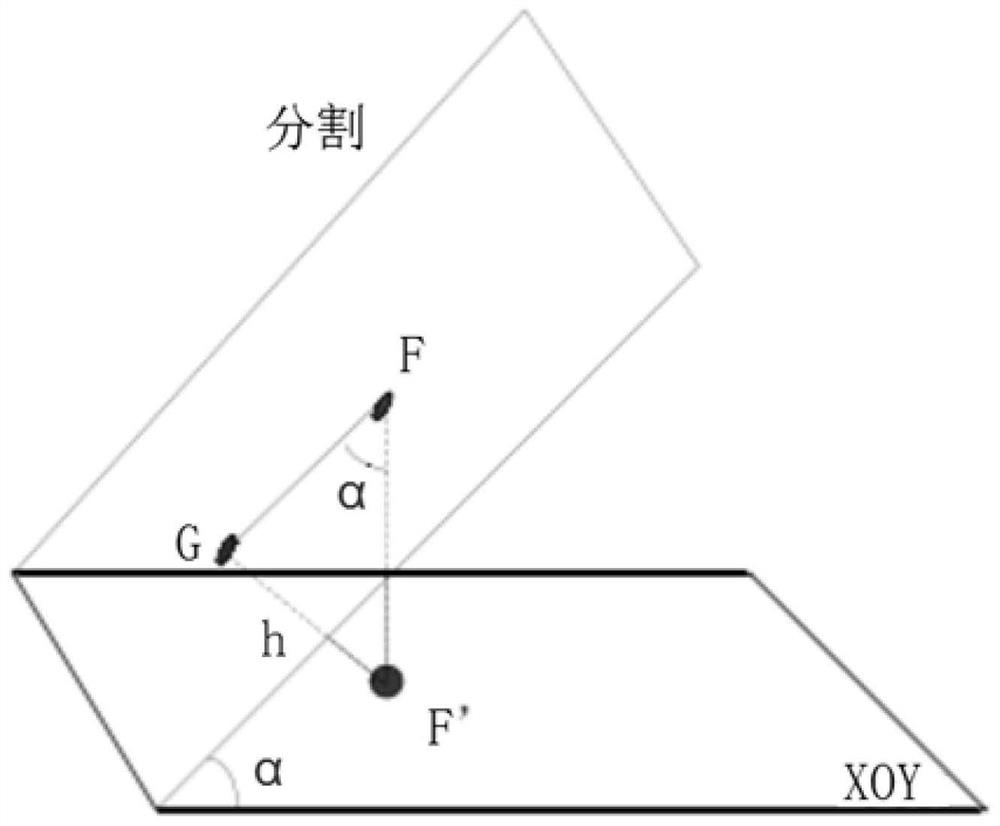

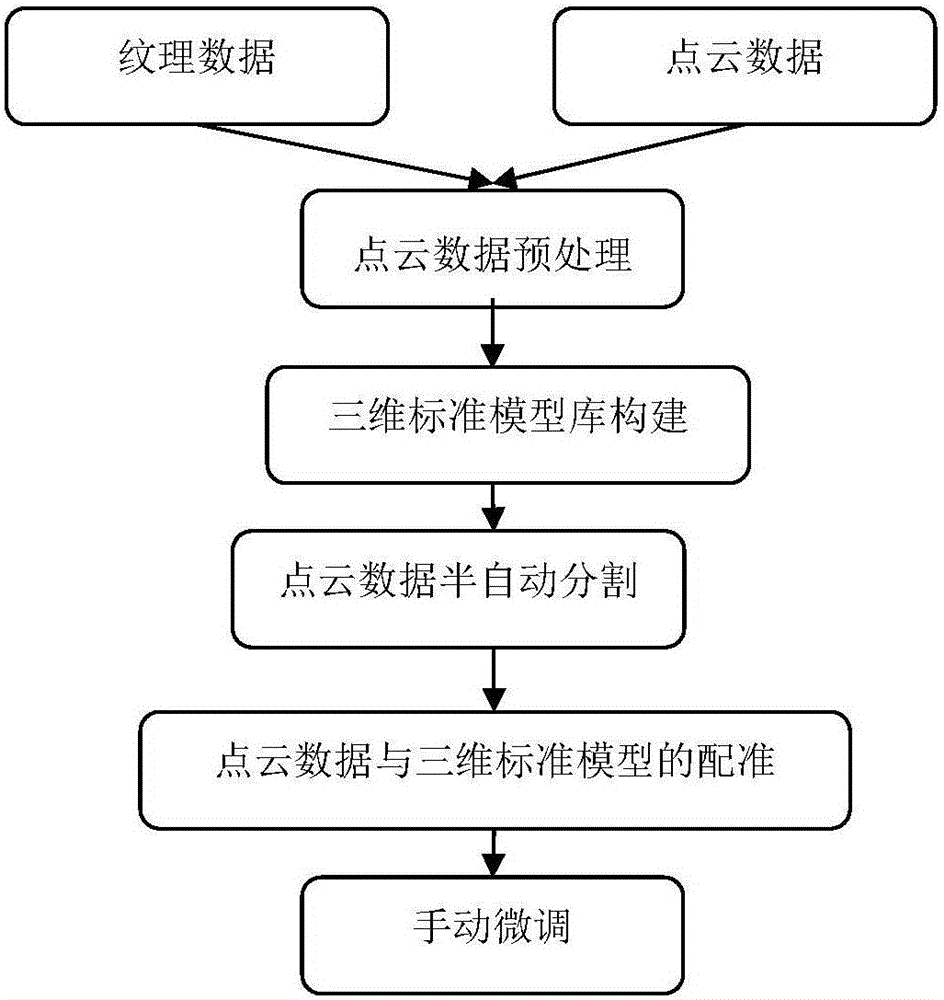

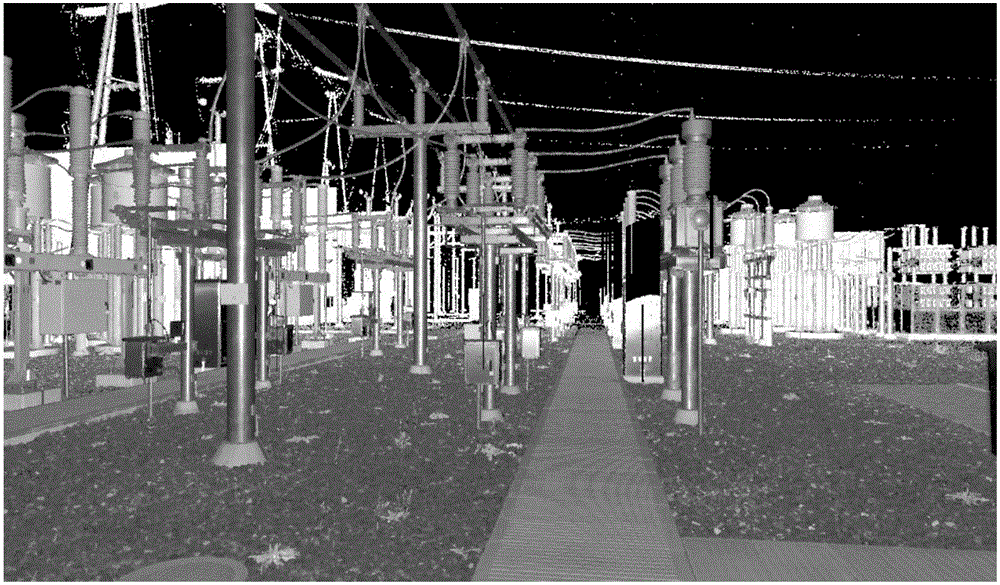

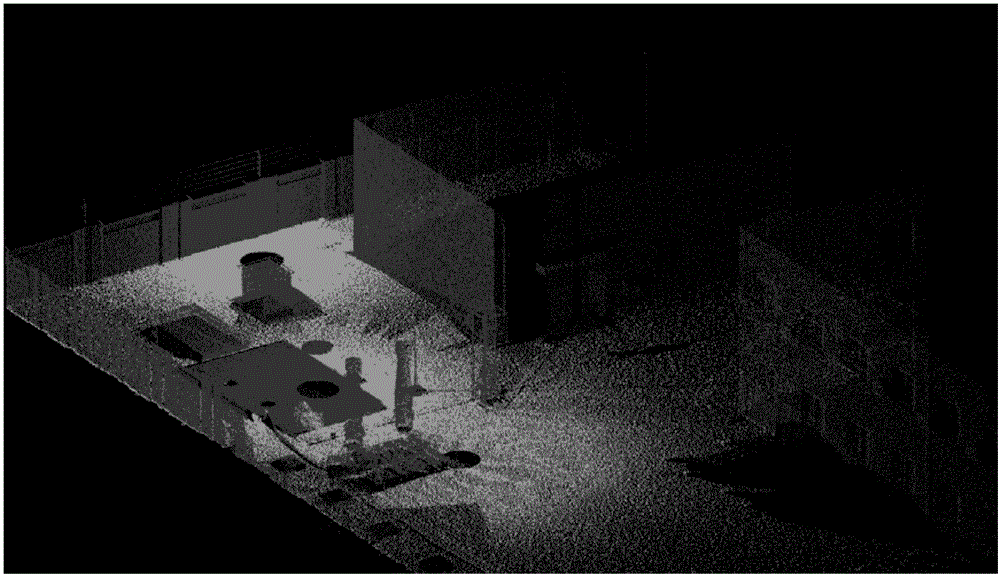

Three-dimensional entity model reconstruction method based on dense point cloud data

PendingCN111932671ALower acquisition costsAcquisition speed is fastImage enhancementImage analysisAlgorithmLaser scanning

The invention provides a three-dimensional entity model reconstruction method based on dense point cloud data. The dense point cloud data is acquired by a laser 3D scanner; 3D laser scanning can rapidly acquire three-dimensional coordinate data of the surface of a measured object in a large-area and high-resolution manner; a rapid and high-precision modeling method is matched, so that the characteristics of rapidness, non-contact, initiative, accuracy and the like are highlighted, data obtained in real time has the characteristics of high accuracy, high density and the like, reconstruction ofa three-dimensional model becomes more convenient, a digital model of an actual object can be created in the virtual world, and rapid and high-accuracy three-dimensional entity model reconstruction based on dense point cloud data is achieved; according to the semantic-based feature extraction method, a large amount of working time is saved, the semi-automatic mode is adopted for operation, the feature extraction precision and accuracy are effectively improved, the cost is greatly reduced, and the precision of the reconstructed three-dimensional solid model is obviously improved.

Owner:扆亮海

Automatic lug brushing-cutting and frame-brushing machine for storage battery plate

ActiveCN103066245AReduce deformation, loose lugs and other defectsReduce pollutionLead-acid accumulator electrodesOperational costsEngineering

The invention relates to a lug brushing-cutting and frame brushing machine for a high-dense storage-battery plate, and particularly relates to equipment for automatically brushing and cutting lugs and brushing four sides of a high-dense pole plate in the lead-acid battery production process. The lug brushing-cutting and frame brushing machine is a streamline device which formed by successive connection of a plate delivering device, a pole plate conveying device, a lug brushing device, a lug cutting device, a transition device, a laminating device, a reshaping device, a frame brushing device and a plate folding device, and the streamline device automatically cooperates under electric control. The lug brushing-cutting and frame brushing machine provided by the invention achieves the automatic lug brushing-cutting and frame brushing of a high-dense lead alloy pole plate, and finishes the transition of a production flow from a semi-automation operation to a full automatic serialization operation, so that labour operation intensity and operational cost are greatly reduced, the labour productivity is improved, and the damage to human bodies caused by the environmental pollution and lead dust can be alleviated.

Owner:武汉深蓝自动化设备股份有限公司

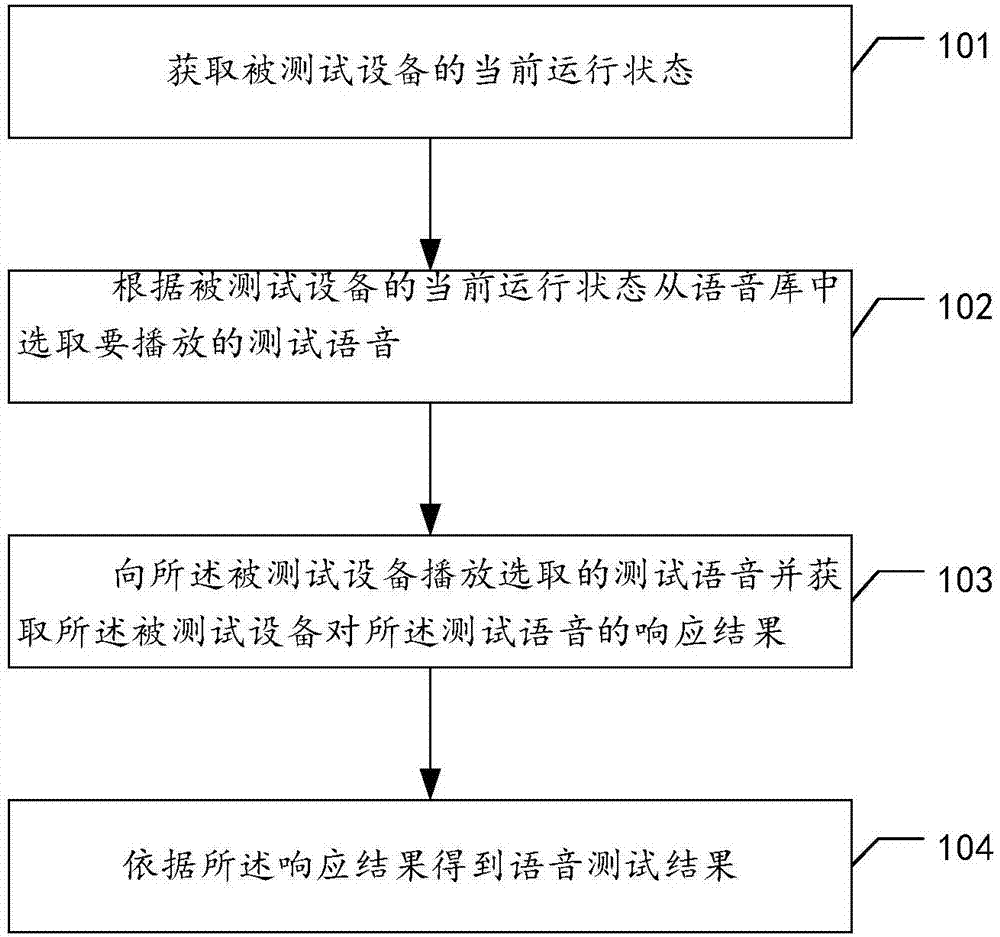

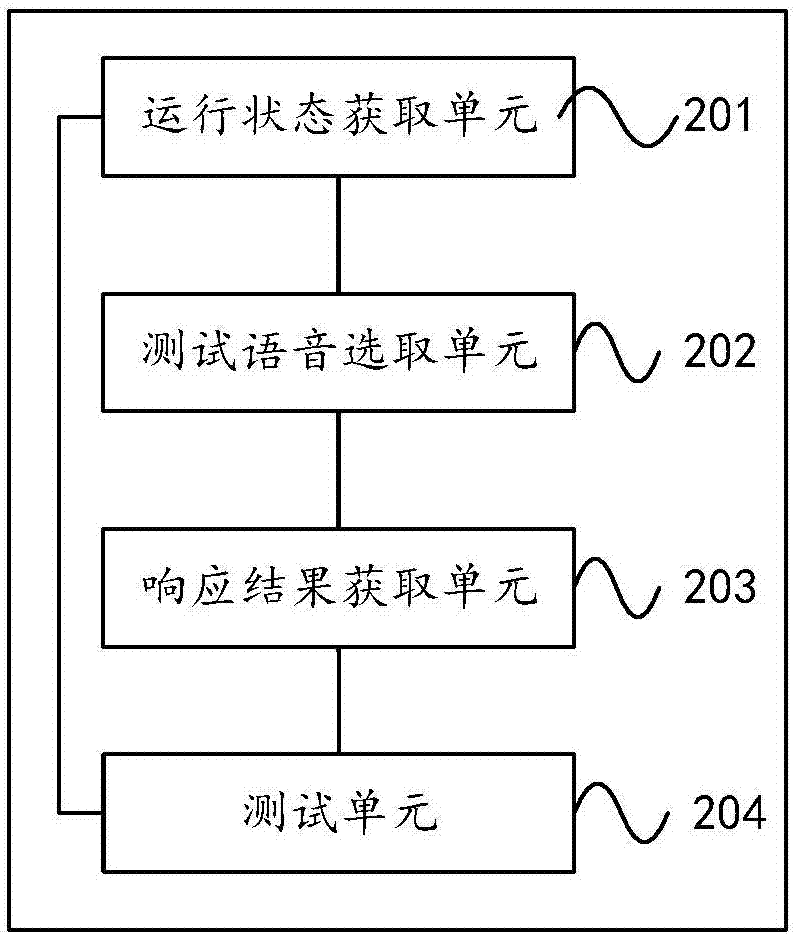

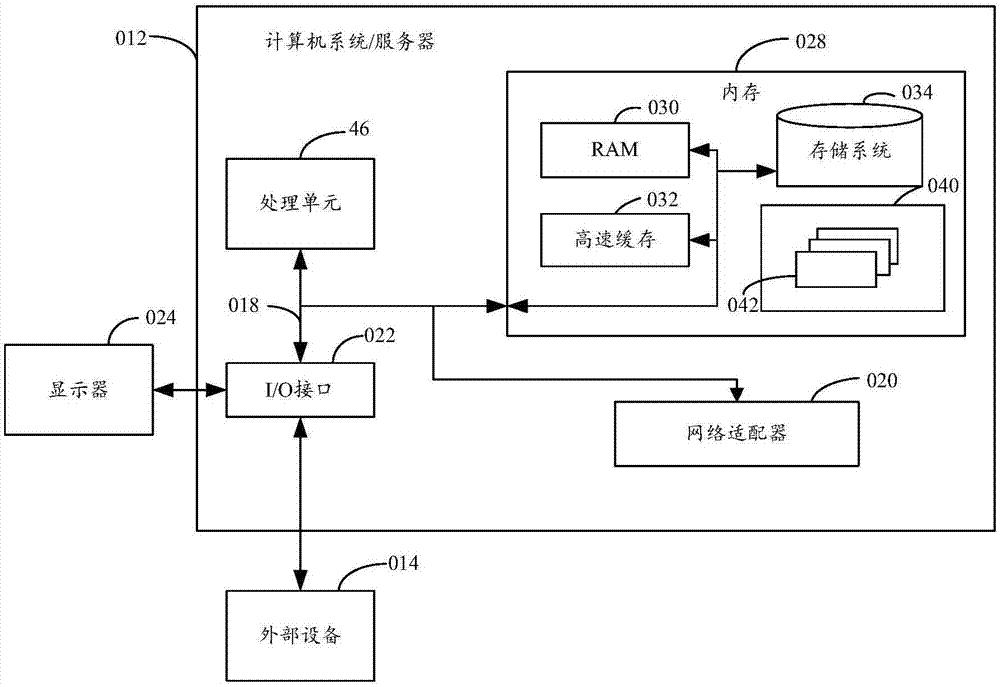

Automatic speech test method and device for intelligent equipment

ActiveCN107516510AImprove test efficiencyImprove accuracySpeech recognitionTest efficiencySemi automatic

The invention discloses an automatic speech test method and a device for intelligent equipment. The method comprises steps: the current operation state of tested equipment is acquired; according to the current operation state of the tested equipment, a to-be-played test speech is selected from a speech library; the selected test speech is played to the tested equipment and a response result for the test speech by the tested equipment is acquired; and according to the response result, a speech test result is obtained. When the scheme is applied, the proper test speech can be selected from the speech library according to the current operation state of the tested equipment; compared with a mode of mechanically and circularly playing a test speech in the prior art, the mode of the invention more coincides with the operation state of the tested equipment, and various abnormities possibly generated during manual test and semi-automatic test processes can be reduced. Besides, compared with a manual test mode, the mode of the invention greatly enhances the test efficiency.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD +1

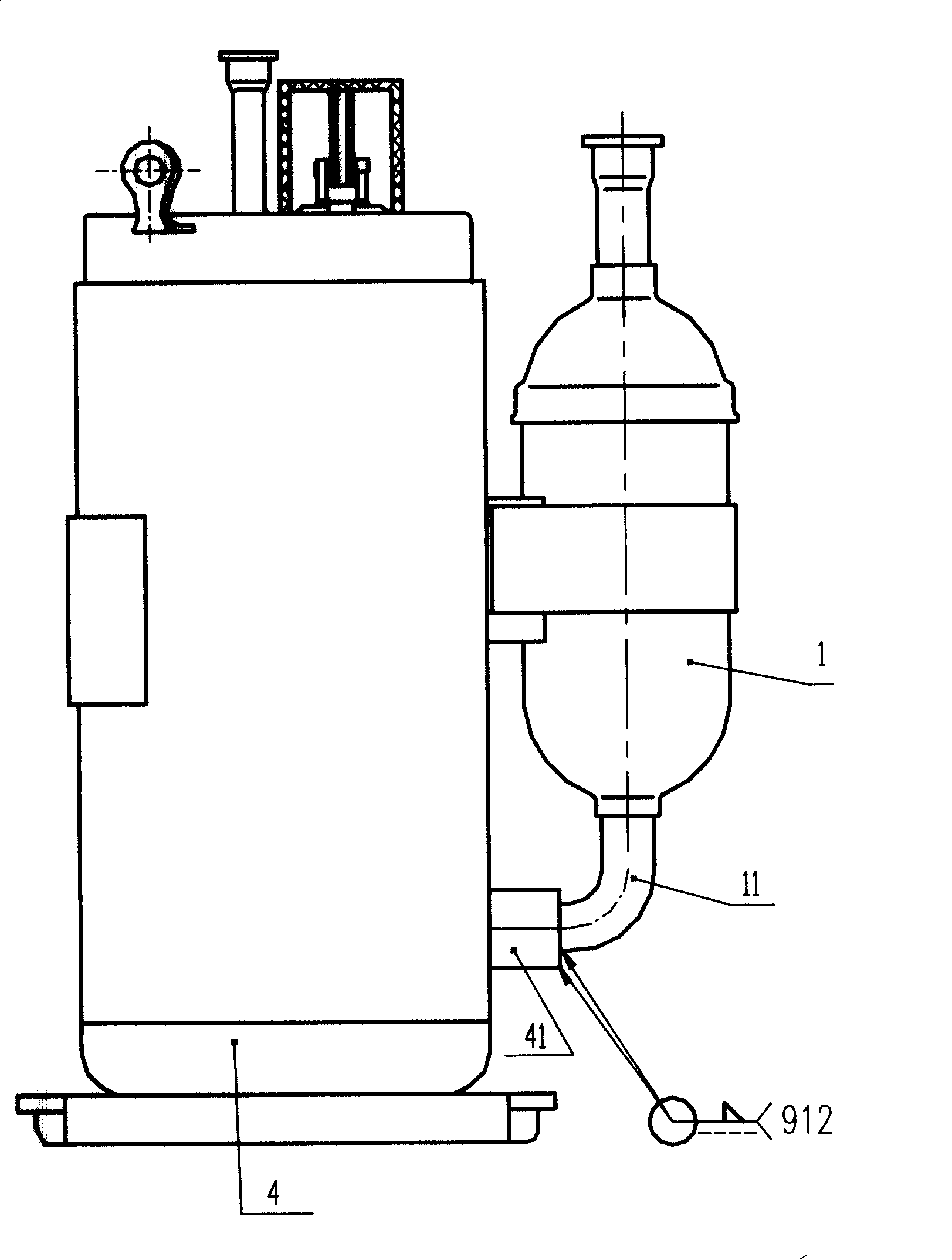

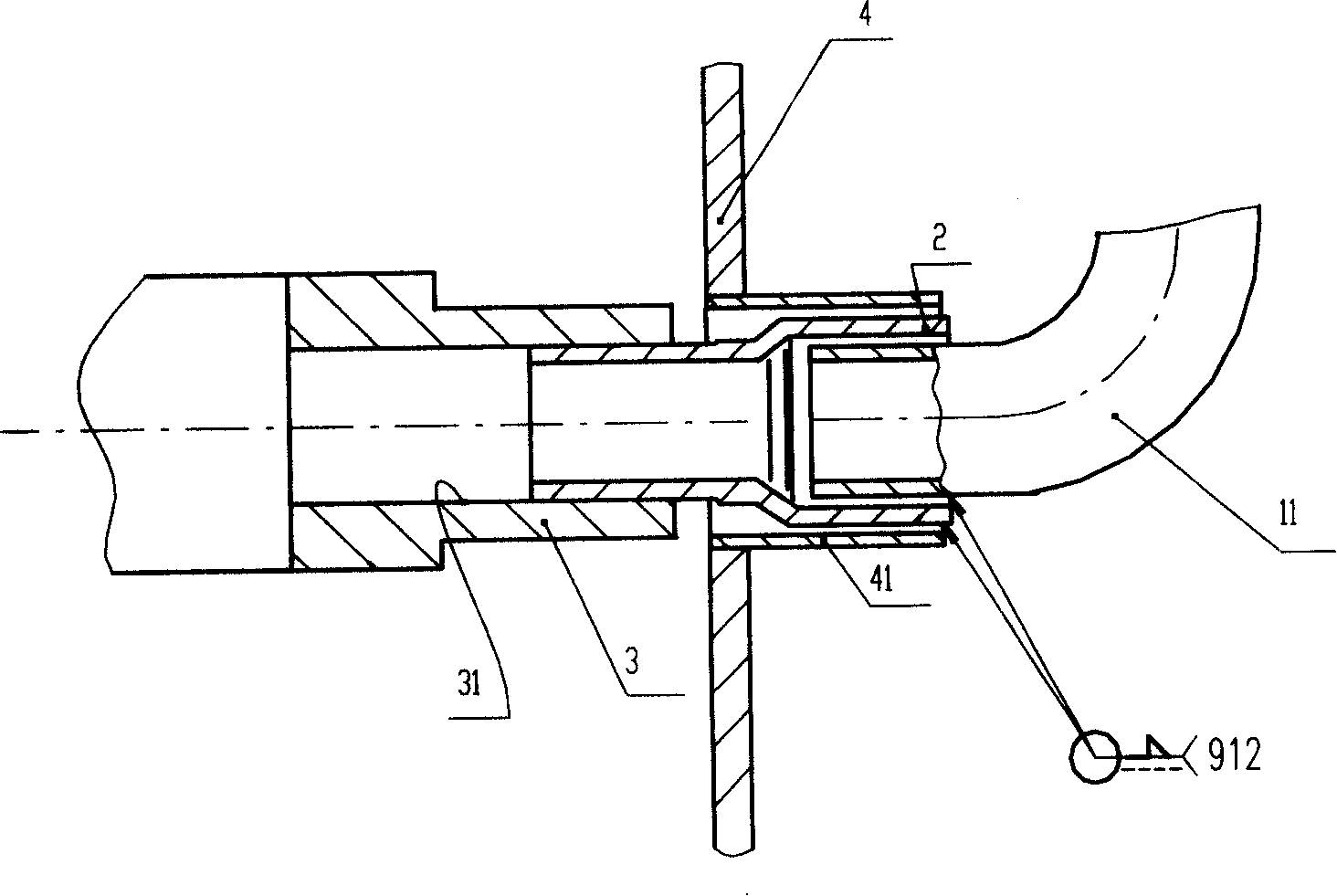

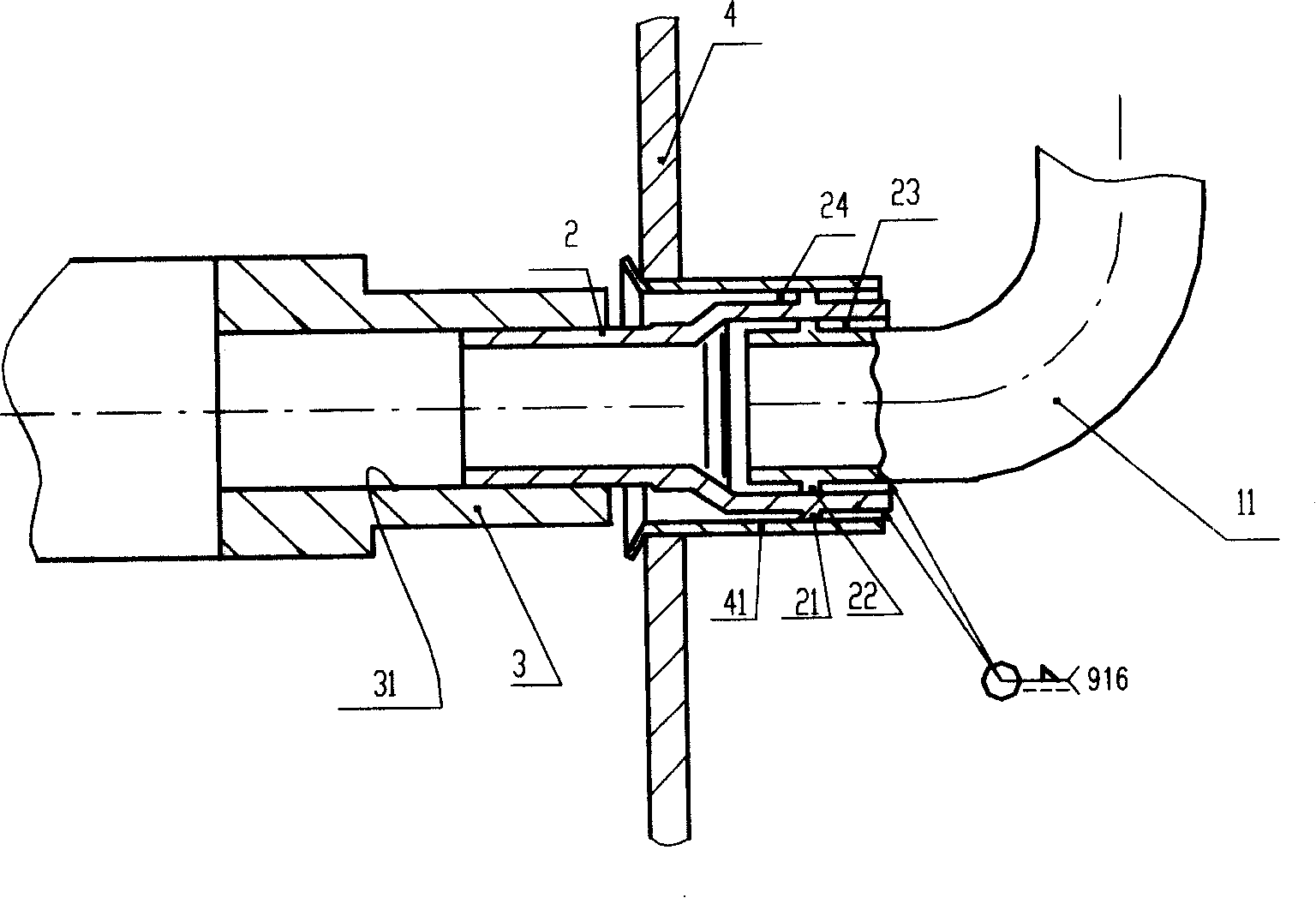

Totally-enclosed -type compressor suction duct connecting mechanism

ActiveCN101235812AReduce manufacturing costGood welding performancePositive displacement pump componentsHigh frequency current welding apparatusWeld seamInduction welding

The invention relates to a connecting structure of a fully-closed compressor suction pipe, wherein gaps of welding seams are evenly distributed, which are guaranteed through a raised girdle is designed on a welding gap position of a connecting pipe, a cylinder inserting pipe and an L-shaped pipe which are arranged on a closed shell or is designed on the welding gap position between the connecting pipe and the cylinder inserting pipe. When a connecting mechanism of the fully-closed compressor suction pipe is welded, a solenoid whose two ends are an U shape in a same rotating direction is used, and a high frequency induction welding of an induction coil of a soft magnetic material is plugged between the U shapes which are arranged on the two sides. When welding, an U-shaped open of the U-shaped induction coil is aimed to the outer circle of the connecting pipe to achieve the circumferential weld of the three. The connecting mechanism of the fully-closed compressor suction pipe is capable of increasing the welding performance, achieving the automation or the semi-automation of welding, increasing the productivity effect, and saving produce cost.

Owner:XIAN QINGAN REFRIGERATION EQUIP CO LTD

RFID-based enterprise intelligence

Owner:MICROSOFT TECH LICENSING LLC

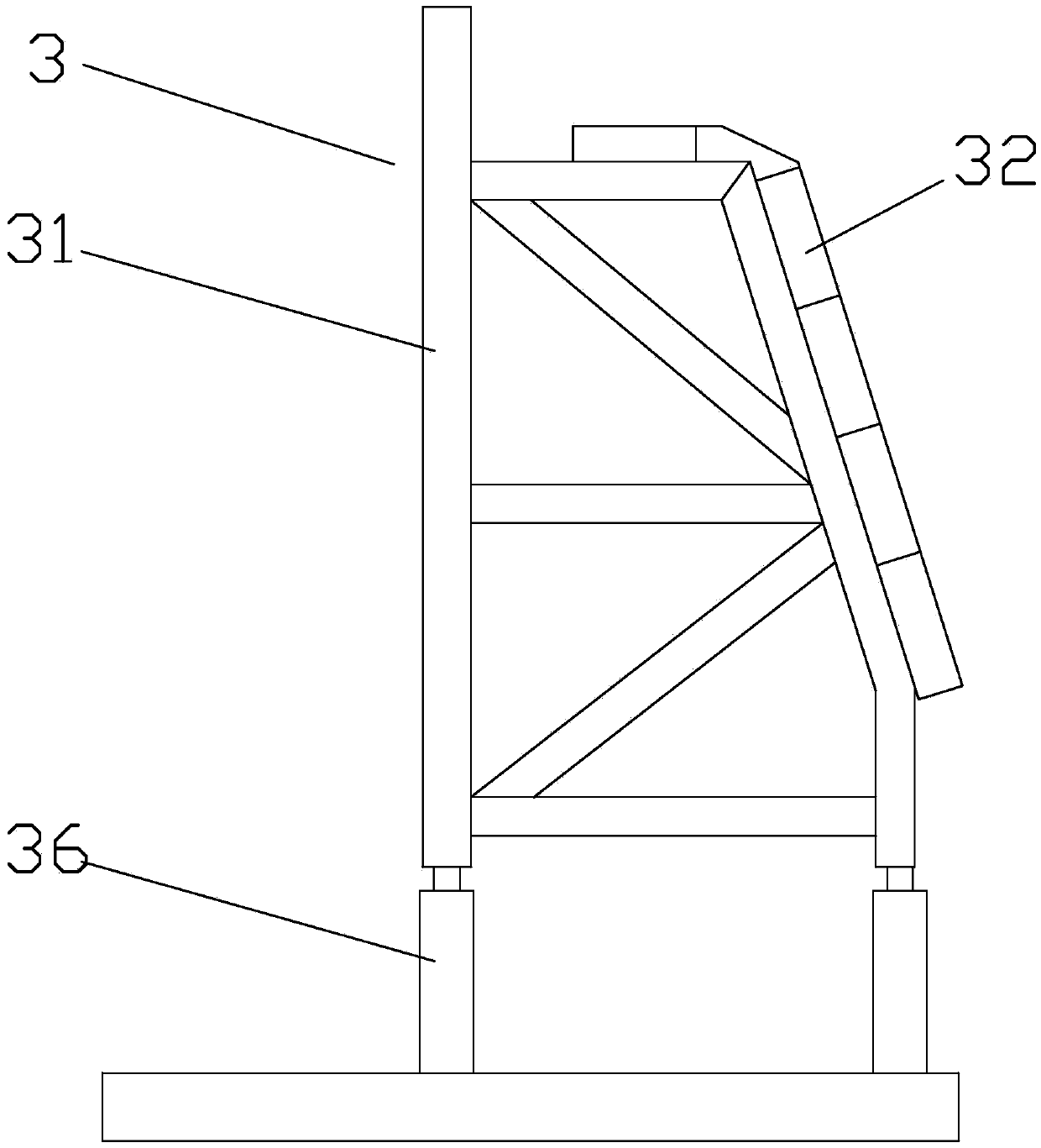

Three-dimensional transformer station semi-automatic reconstruction method based on laser point cloud data

InactiveCN105844064ARealize semi-automationReduce manual interventionDetails involving processing stepsSpecial data processing applicationsTransformerReconstruction method

Owner:XIAMEN GREAT POWER GEO INFORMATION TECH +1

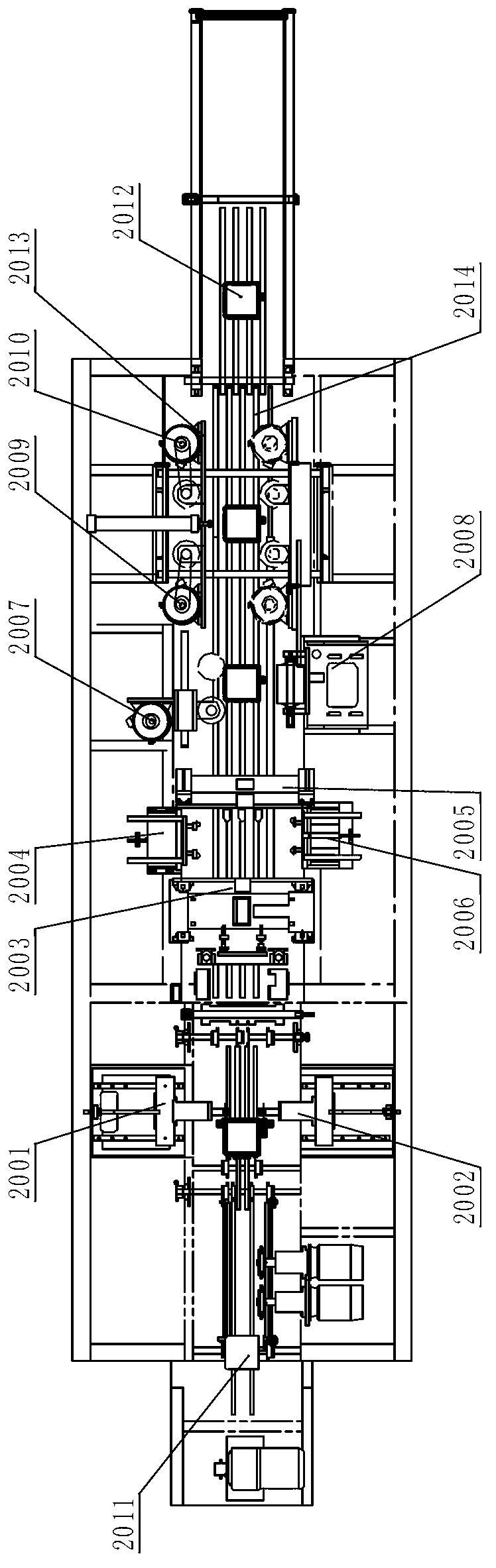

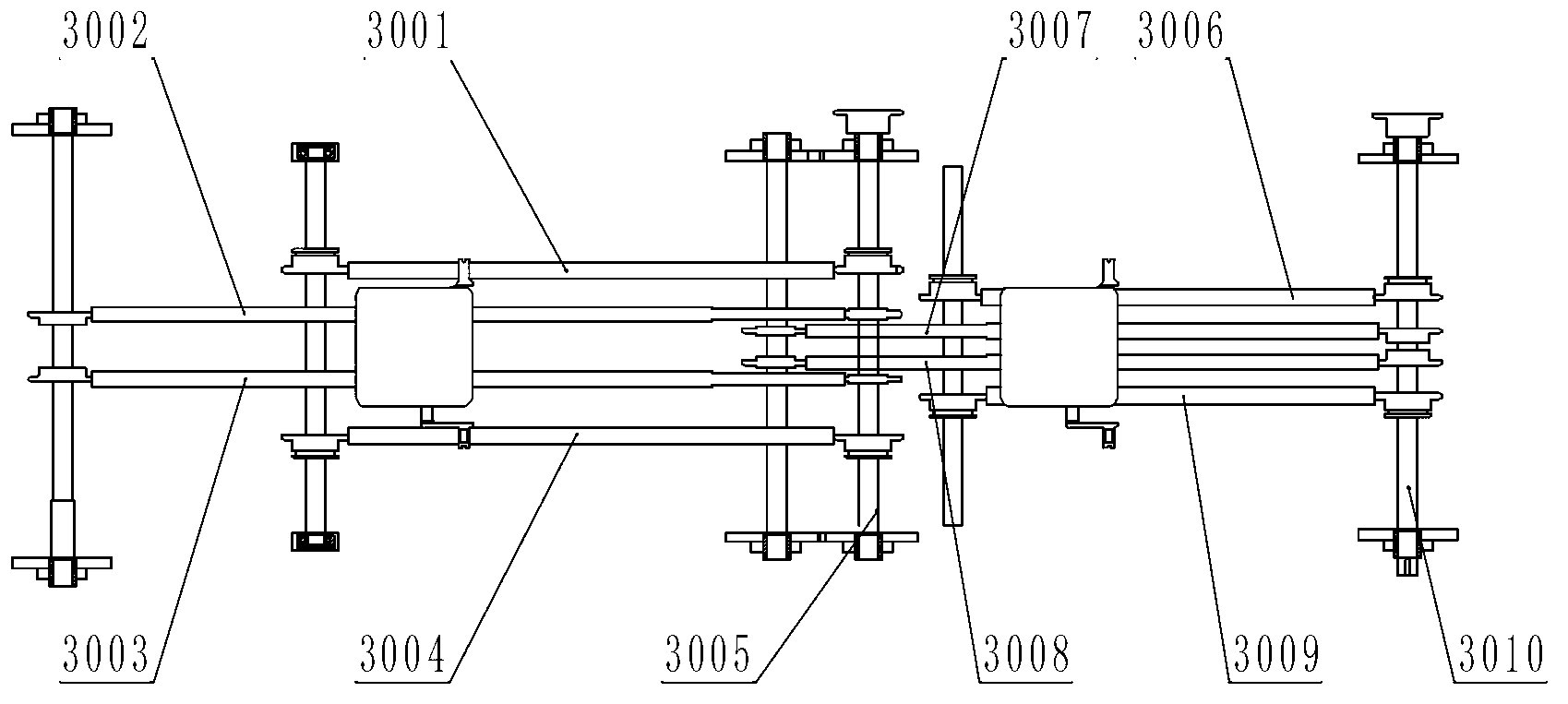

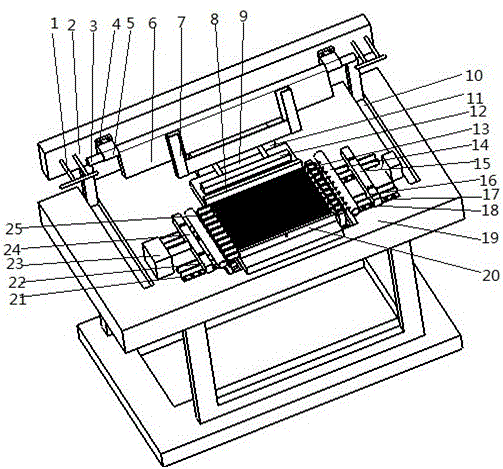

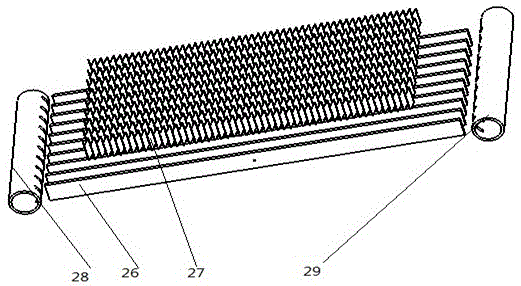

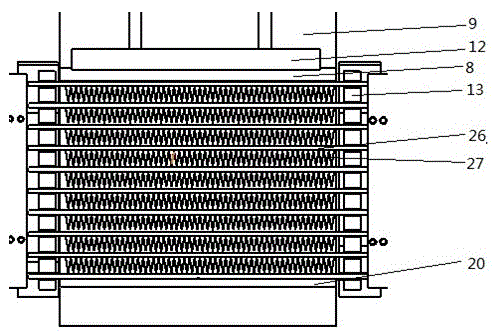

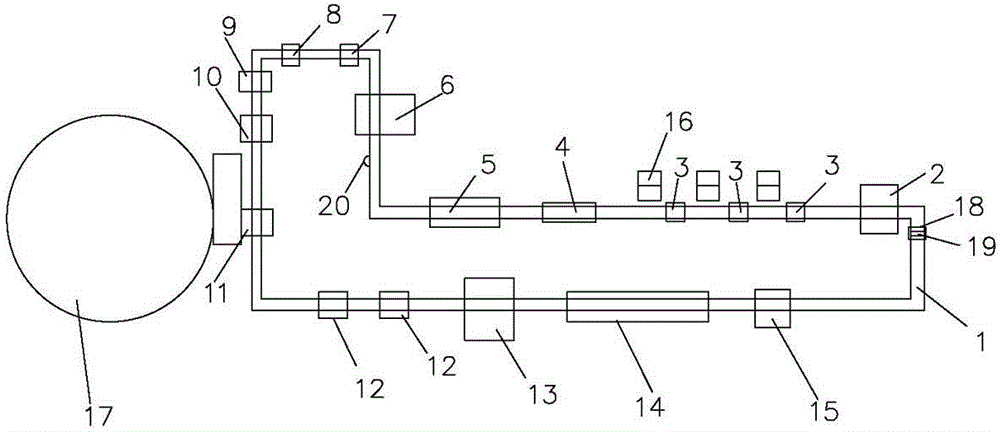

Collecting pipe, flat pipe and fin assembling device and process for heat exchanger of air conditioner of automobile

The invention discloses a collecting pipe, flat pipe and fin assembling device and a process for a heat exchanger of an air conditioner of an automobile. The assembling device comprises a blanking device body, a rotary shaft, a fixed seat, a rotary main plate, a blanking bin, a rear free pressure plate, a workpiece table, a blanking chute, a rear clamp pneumatic device, a rear clamp body, a flat pipe positioning groove, a right clamp pneumatic device, a right clamp body, a right guide rail, a right sliding block, a frame, a front positioning bump, a left sliding block, a left clamp pneumatic device, a left clamp body, a flat pipe left positioning groove, a flat pipe, a fin, a right collecting pipe, a left collecting pipe, a right positioning groove pneumatic device, a right positioning groove pneumatic device and the like. According to the collecting pipe, flat pipe and fin assembling device and the process for the heat exchanger of the air conditioner of the automobile provided the invention, semi-automatic assembly among the collecting pipe, the flat pipe and the fin of the heat exchanger of the air conditioner is realized, and the process device is simple and practical, the technical process is high in production efficiency, low in production cost, low in requirements to technical skills of operators, and low in labor intensity of operators. The collecting pipe, flat pipe and fin assembling device provided by the invention is suitable for large scale production in batches.

Owner:ZHEJIANG CHUANGXIN AUTO AIR CONDITIONER

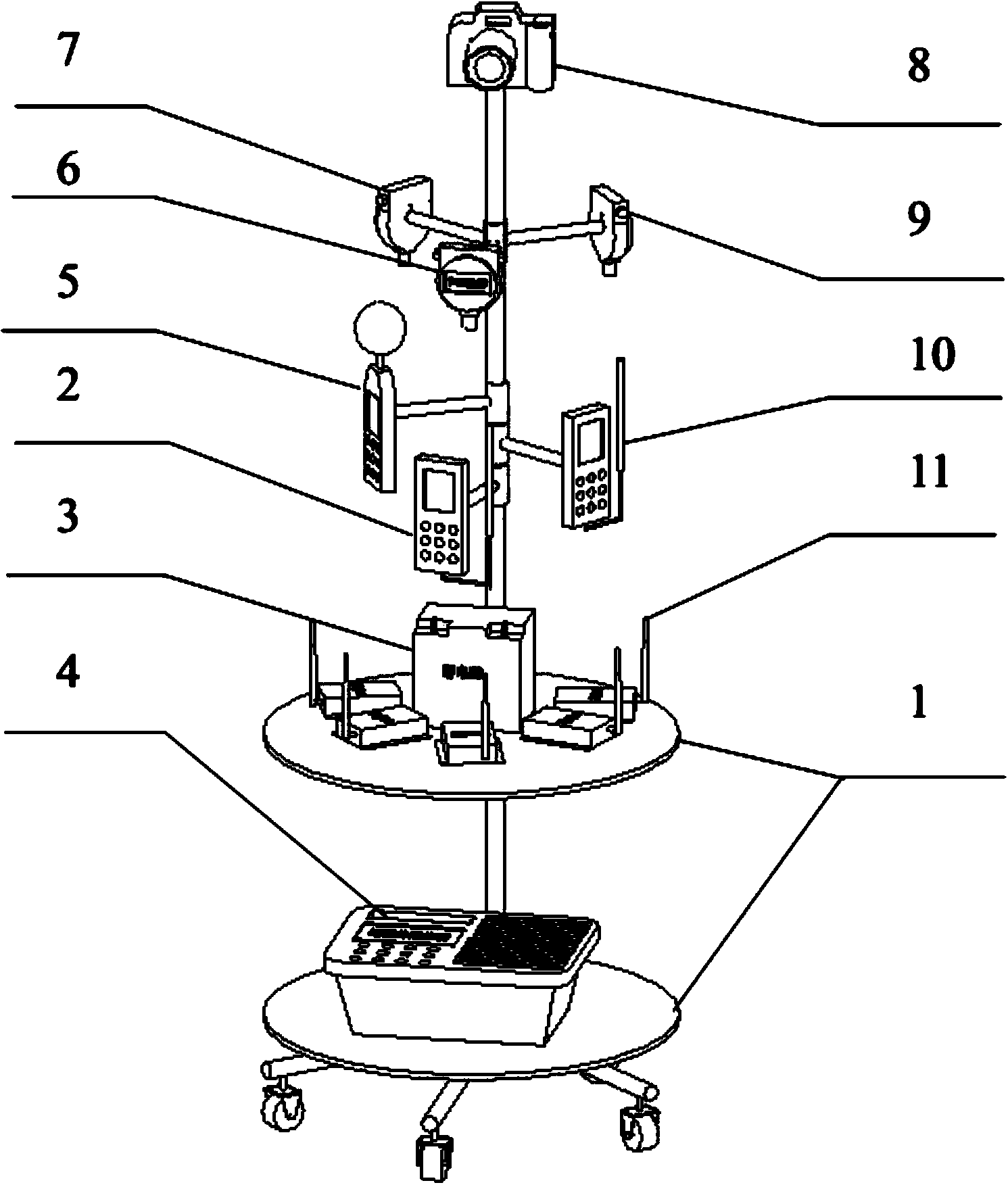

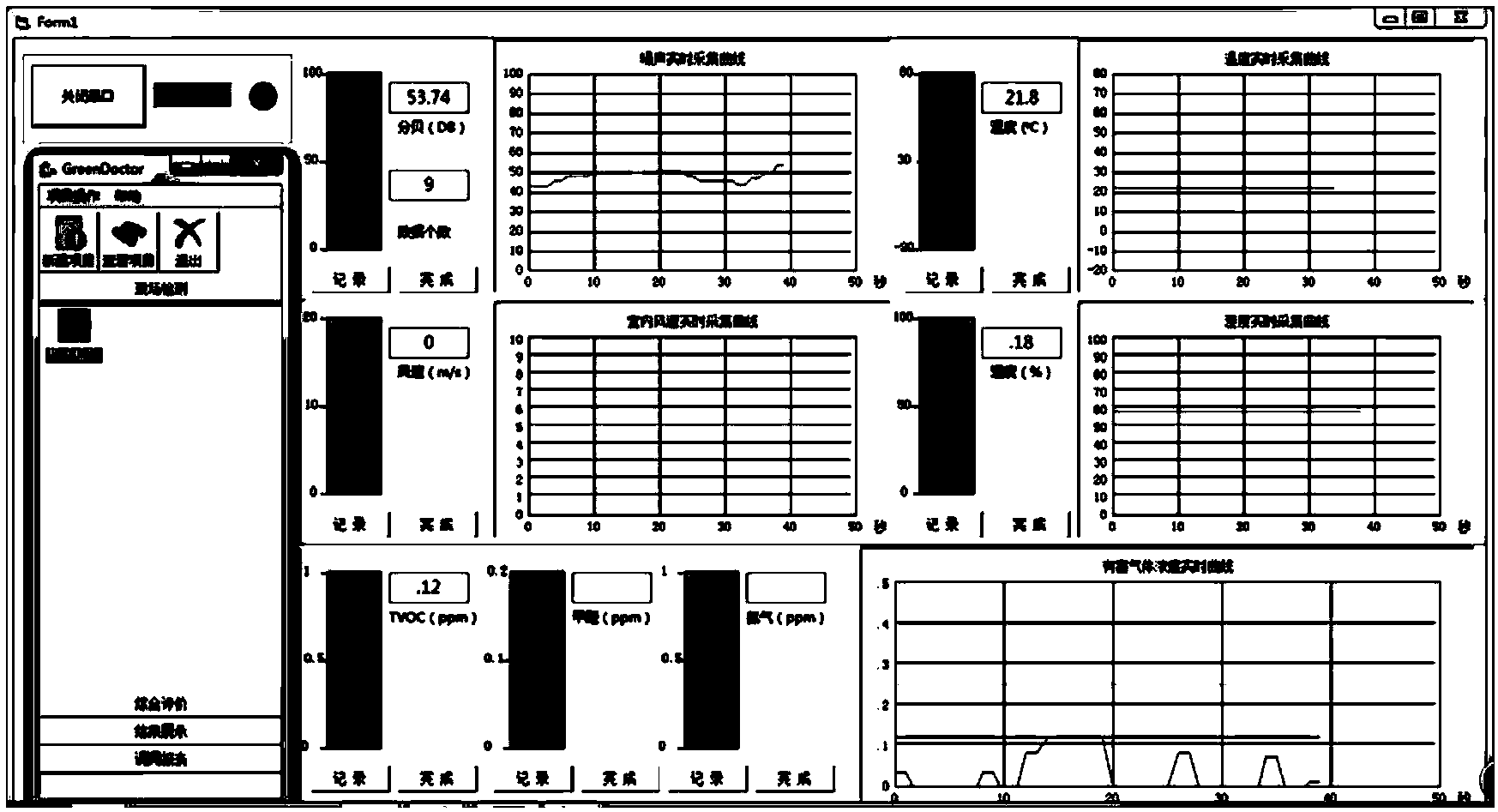

Green building comprehensive detection device based on Zigbee

InactiveCN103674114AAchieve integrationIncreased complexityMeasurement devicesTransmission systemsWireless transmissionData acquisition

The invention relates to a green building comprehensive detection device based on Zigbee. The green building comprehensive detection device comprises a support, a data acquisition module, a Zigbee wireless transmission module, a mobile power supply, a transformation module and an upper computer. The data acquisition module, the Zigbee wireless transmission module, the mobile power supply and the transformation module are all installed on the support, the mobile power supply and the transformation module are connected with the data acquisition module and the Zigbee wireless transmission module respectively through a power line, and the data acquisition module is connected with the upper computer through the Zigbee wireless transmission module. Compared with the prior art, the green building comprehensive detection device has the advantages that various detection functions are integrated, various detection data are integrated through a Zigbee wireless data transmission technology, semi-automatic control of a detection instrument is achieved, detection early-stage preparation work is effectively reduced, an assembled structure is adopted, and the green building comprehensive detection device is easy to demount and assemble and convenient to carry.

Owner:TONGJI UNIV

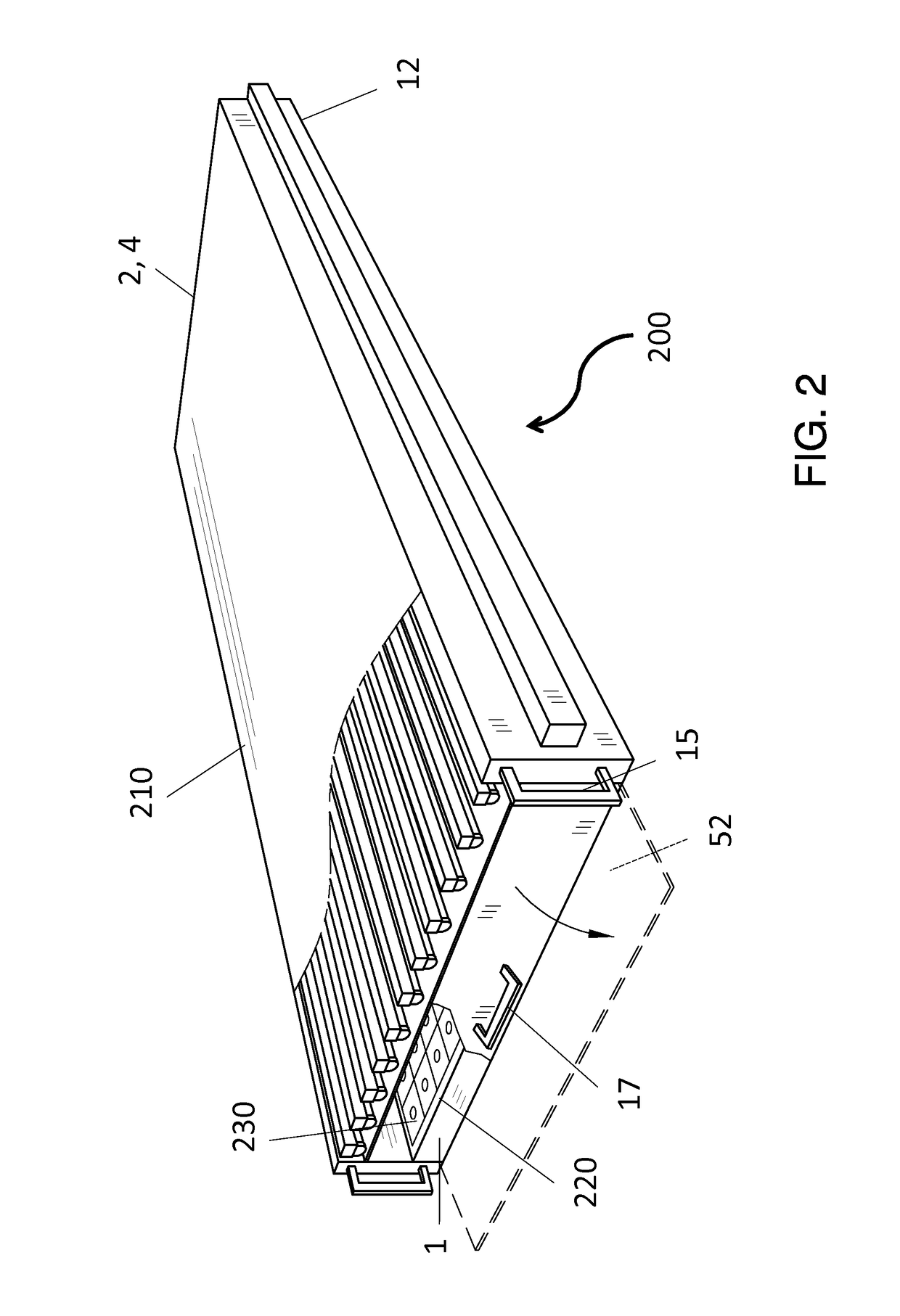

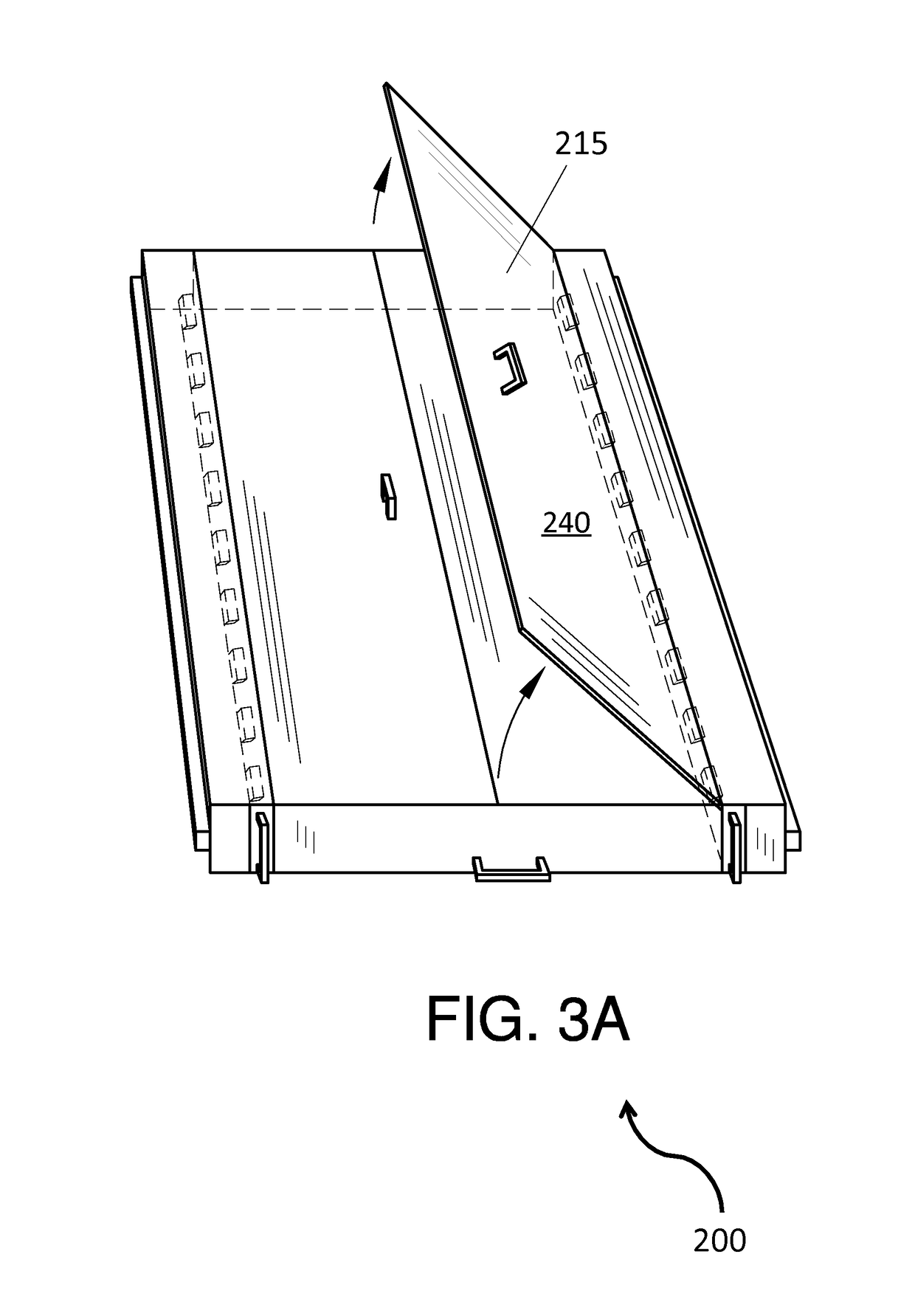

Semi-automated crop production system

A semi-automated crop production featuring a growing module with grids of cells for growing plants and a lighting and airflow fixture positioned above each cell. The lighting and airflow fixture features a fan disposed in a housing, a light emitting diode (LED) assembly board comprising LEDs disposed below the fan; a light diffuser disposed below the LED assembly board, and an adjustable air flow nozzle extending downwardly from the fan and protruding through the LED assembly board and the light diffuser. The adjustable air flow nozzle provides directed air flow downwardly toward a bottom area of the housing.

Owner:LEWIS MYLES D

Semi-automatic packaging machine for irregular bulk foods

InactiveCN102180273ASmoothly fall intoIn line with the principles of ergonomicsPackaging automatic controlSolid materialTransport systemSemi automatic

The invention relates to a semi-automatic packaging machine which is suitable for irregular bulk foods such as short chips, spicy hot fishes, potato chips, short fried strips and the like which are cooked foods with a certain hardness and brittleness and are made from flour puffing and also suitable for solid bodies with very small particle diameters or powdery materials. The food packaging machine comprises a material storing and transporting system, a control system, a machine case, a photoelectric sensor, a top hopper feeding mechanism, a vibrating feeding system, a door opener, an electronic weighing device, a nozzle module, a clamping-type sealing machine, a sliding plate, a belt conveyer and the like and is characterized in that forms of a big / small vibrating feeder, a duplex twisting feeder, a twisting shaft and an elastic steel sheet are adopted to guarantee rapid and accurate feeding to the weighing device, wherein the period of weighing, packaging and sealing at a time is generally within 2-4s; a weighing hopper is divided into a fixed side and a movable side, wherein the movable side is hinged on the fixed side, the load of a transmission mechanism for realizing execution actions of the movable side is not applied on the weighing hopper and the sensitivity is high; the door opener is of a structure that an execution part does planar motions without a fixed pivot; and installation positions of the lower body of the nozzle, the photoelectric sensor, the clamping-type sealing machine and a seat accord with ergonomics principles. The machine provided by the invention also has the advantages of simple structure, light weight, high efficiency and the like.

Owner:朱桂华

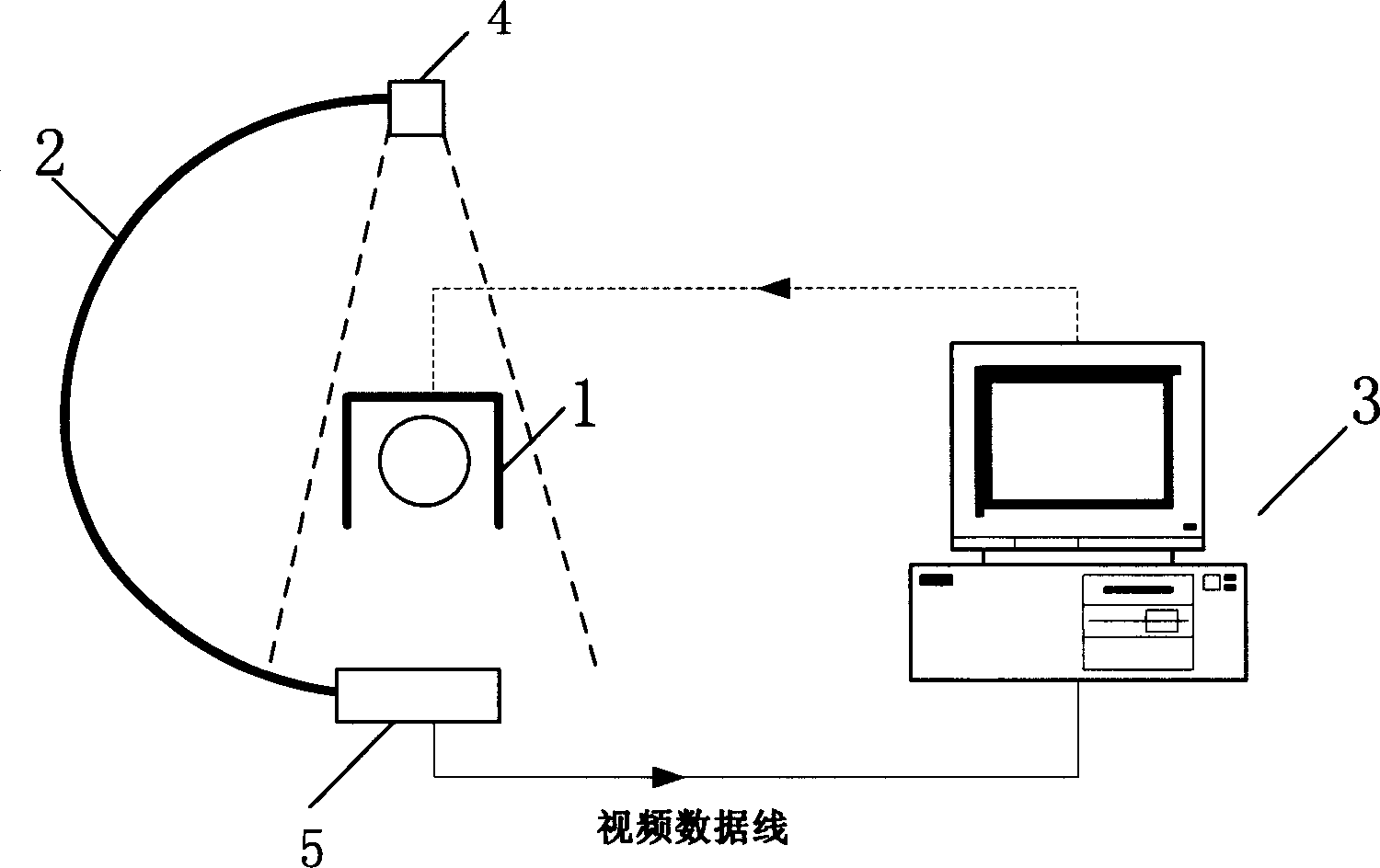

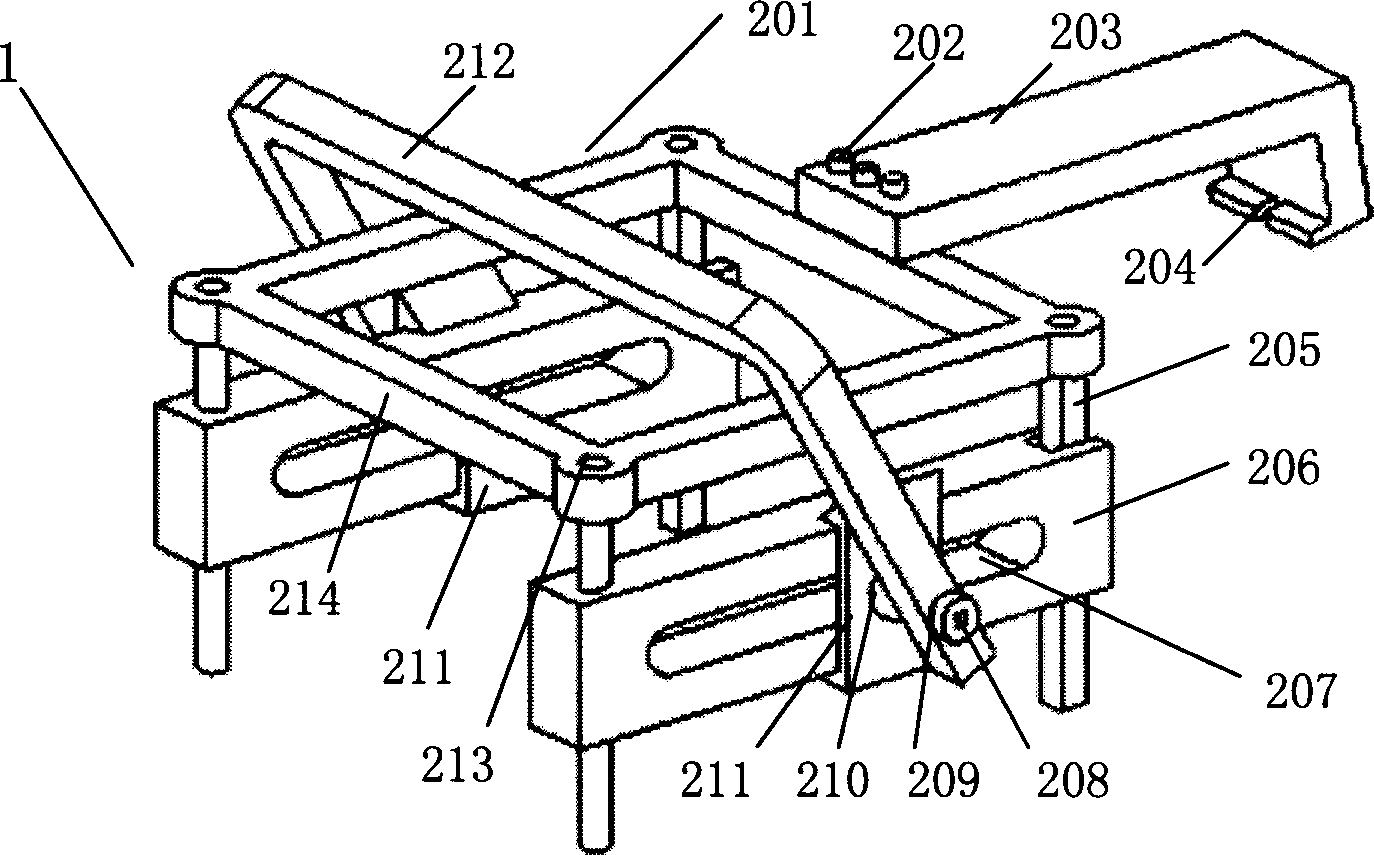

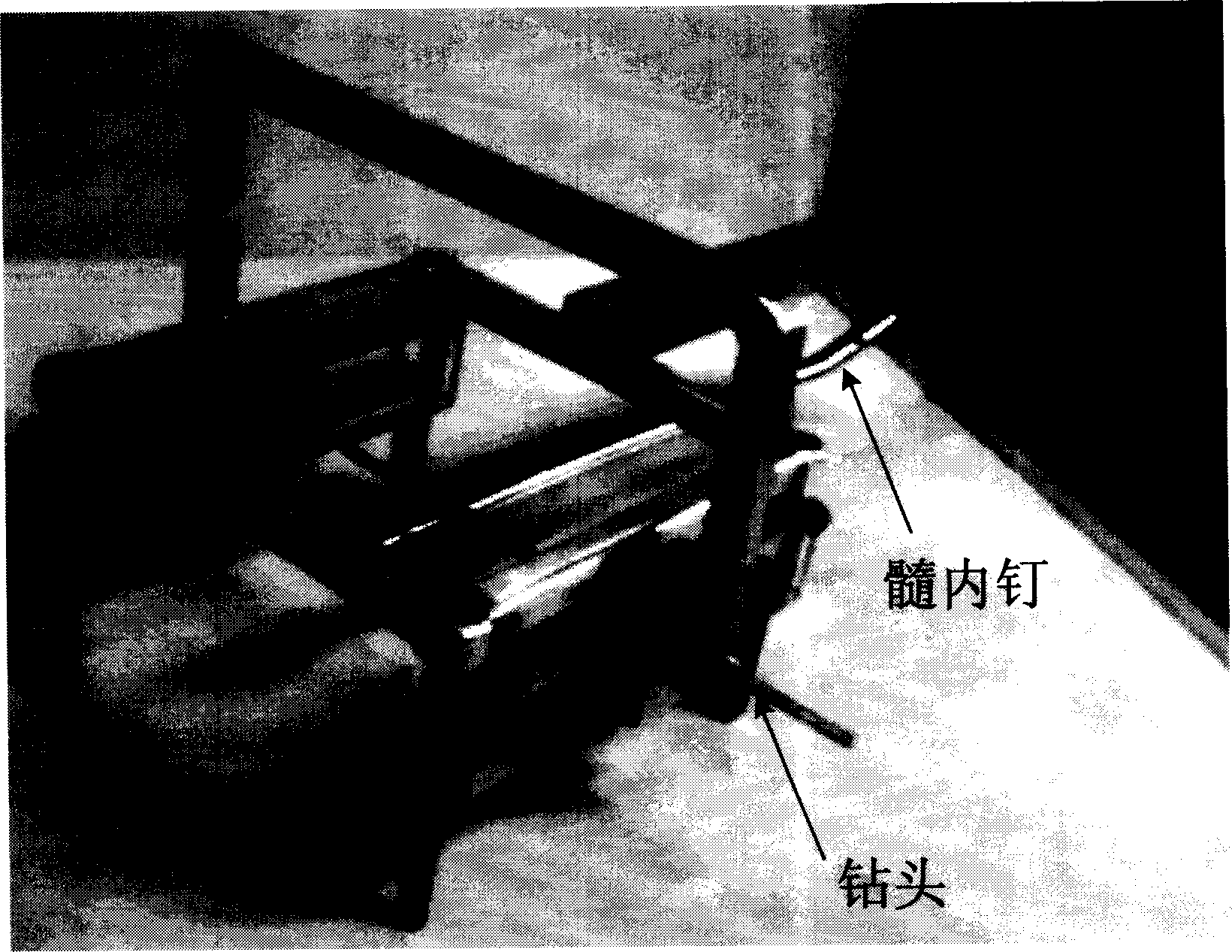

Computer aided system for locking far terminal of intramedullary nail

InactiveCN1424673ARealize semi-automationPrecise positioningSpecial data processing applicationsIntramedullary rodX-ray

This invention discloses a computer assistant far end locking system of nail in marrow, including C-typed arm, positioning frame, computer and software of image controlling operation. The image collected by the X-ray imaging device on the C-type arm is transmitted by visual data line to the computer and calcualted and processed by the software of image controlling operation so as to determine the route of the operation, then the operation can be performed. The invention combines a plural subjects and technologies such as medicine, mechanics, computer visual sense and digital image process, etc, achieves the key technique of measurement of position of nail in marrow using single image and simplifies complicated operating process of fixing the nail in marrow in pure mechanical method.

Owner:BEIJING TINAVI MEDICAL TECH

Automatic shoemaking production line for injection moulded shoes

ActiveCN103330337AStructural standardizationGuaranteed stabilityShoemaking devicesLastingCircular discProduction line

The invention discloses an automatic shoemaking production line for injection moulded shoes. The automatic shoemaking production line comprises a conveyor line, wherein at least one shoe last pallet is arranged on the conveyor line; a shoe last is arranged on the shoe last pallet; a first manipulator lubricant spraying work platform, a shoe last work platform, a steam heating box, a first baking oven, a second manipulator roughing platform, a latex spraying platform, an outsole processing elastic piece platform, a compressing platform, a rough selvedge firing platform, a third manipulator carrying platform, a finished product flashing platform, a fourth manipulator paint spraying platform, a freezer and an outsole cutting processing platform are arranged on the conveyor line at an internal in sequence from an input end to an output end of the conveyor line; a disc injection molding device is arranged on one side of the third manipulator carrying platform. According to the automatic shoemaking production line for injection moulded shoes, the mechanical automation and the mechanical semi-automation are adopted by each manufacturing procedure; each manufacturing procedure is operated by one person; the whole automatic shoemaking production line structure is standardized through the cooperating production of each heating device and the cooling device; the stability of the shoe quality is guaranteed.

Owner:JIESHENG INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com