Collecting pipe, flat pipe and fin assembling device and process for heat exchanger of air conditioner of automobile

A technology for heat exchangers and automotive air conditioners, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, high labor intensity for operators, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

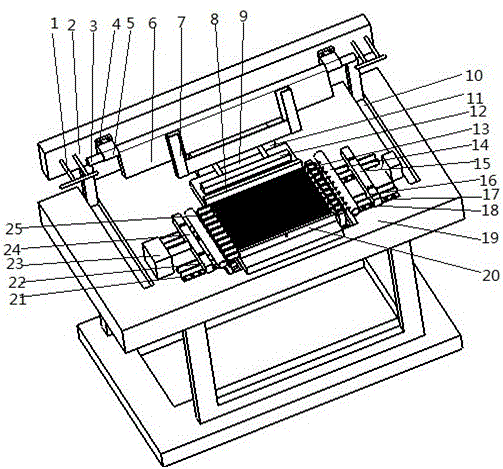

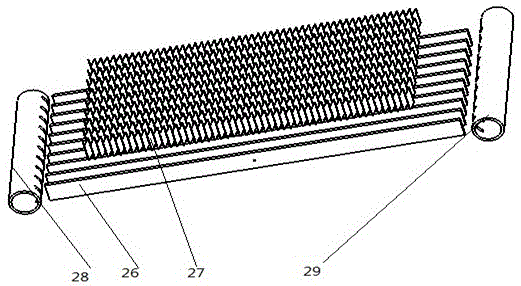

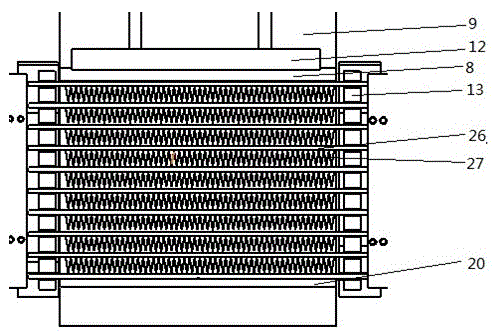

[0024] Such as Figure 1~5 As shown, the collecting tube, flat tube and fin assembly equipment in the air conditioner radiator includes a handle 1, the main body of the unloading device 2, the rotating shaft 3, the bolt 4, the fixing seat 5, the rotating main board 6, the unloading bin 7, the rear free Pressing plate 8, workpiece table 9, blanking chute 10, rear clamp pneumatic device 11, rear clamp body 12, flat tube positioning groove 13, right clamp pneumatic device 14, right clamp body 15, right guide rail 16, right slider 17, Right guide rail fixing bolt 18, frame 19, front positioning protrusion 20, left guide rail fixing bolt 21, left slider 22, left clamp pneumatic device 23, left clamp body 24, flat tube left positioning groove 25, flat tube 26, wing Sheet 27, right manifold 28, left manifold 29, right positioning slot pneumatic device mounting plate 30, right positioning slot pneumatic device 31, left positioning slot pneumatic device mounting plate 32, right positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com