Patents

Literature

178results about How to "Smoothly fall into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

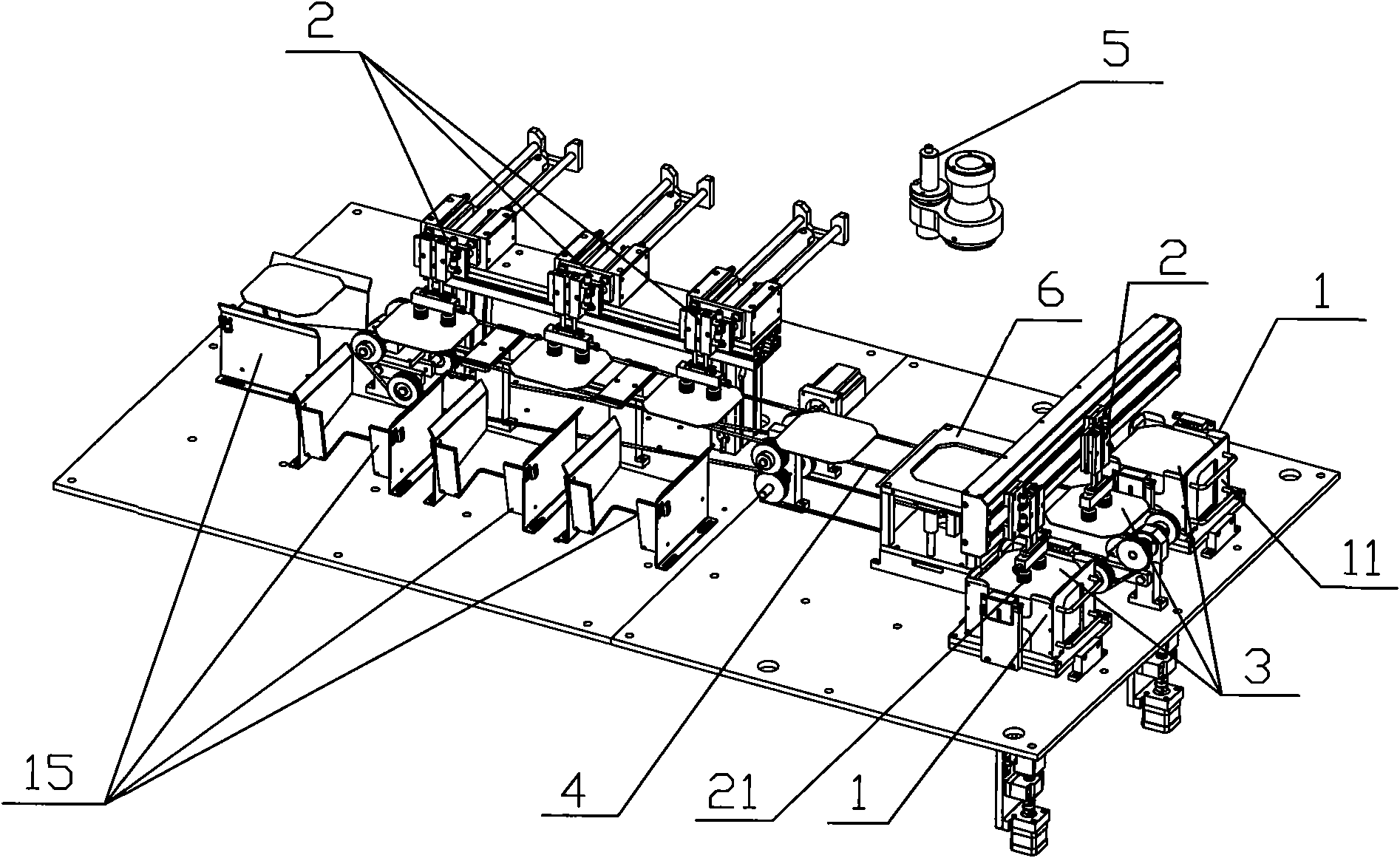

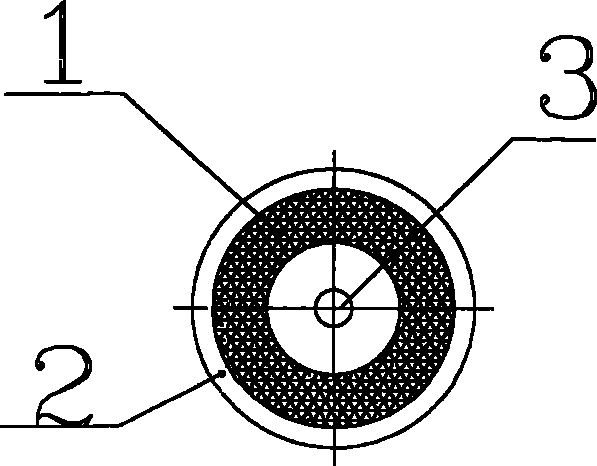

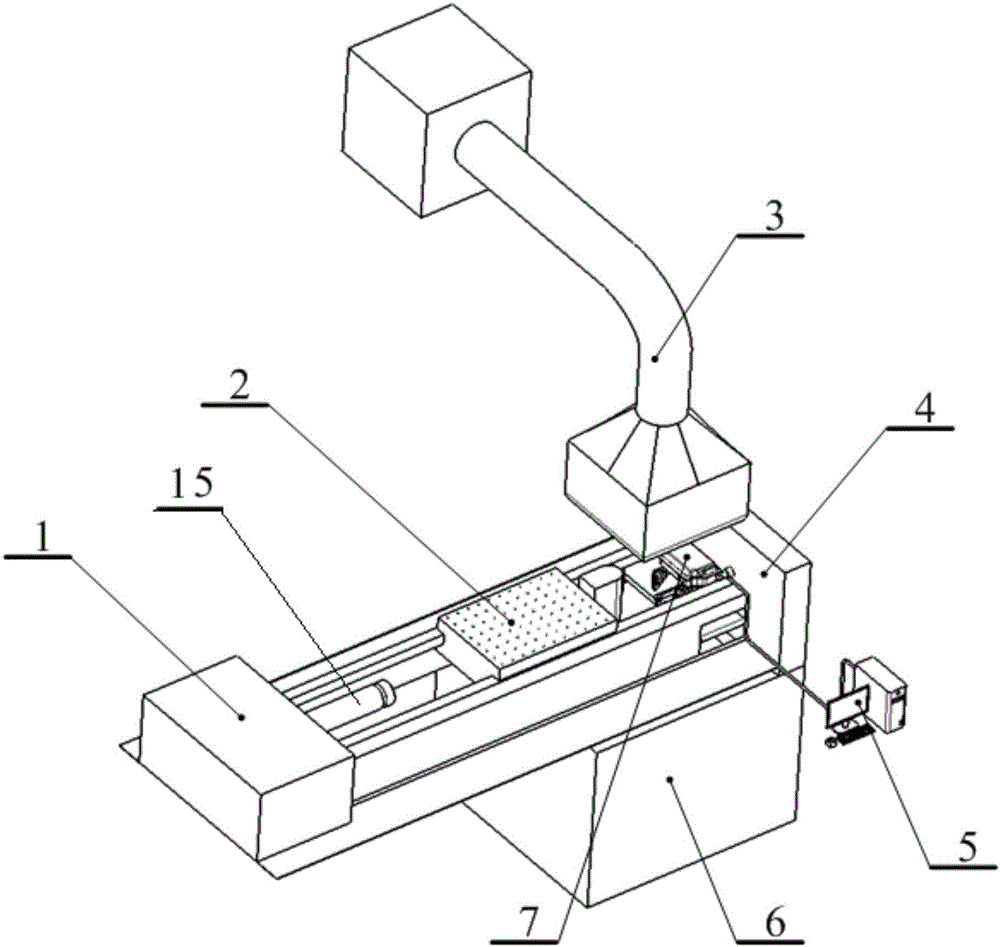

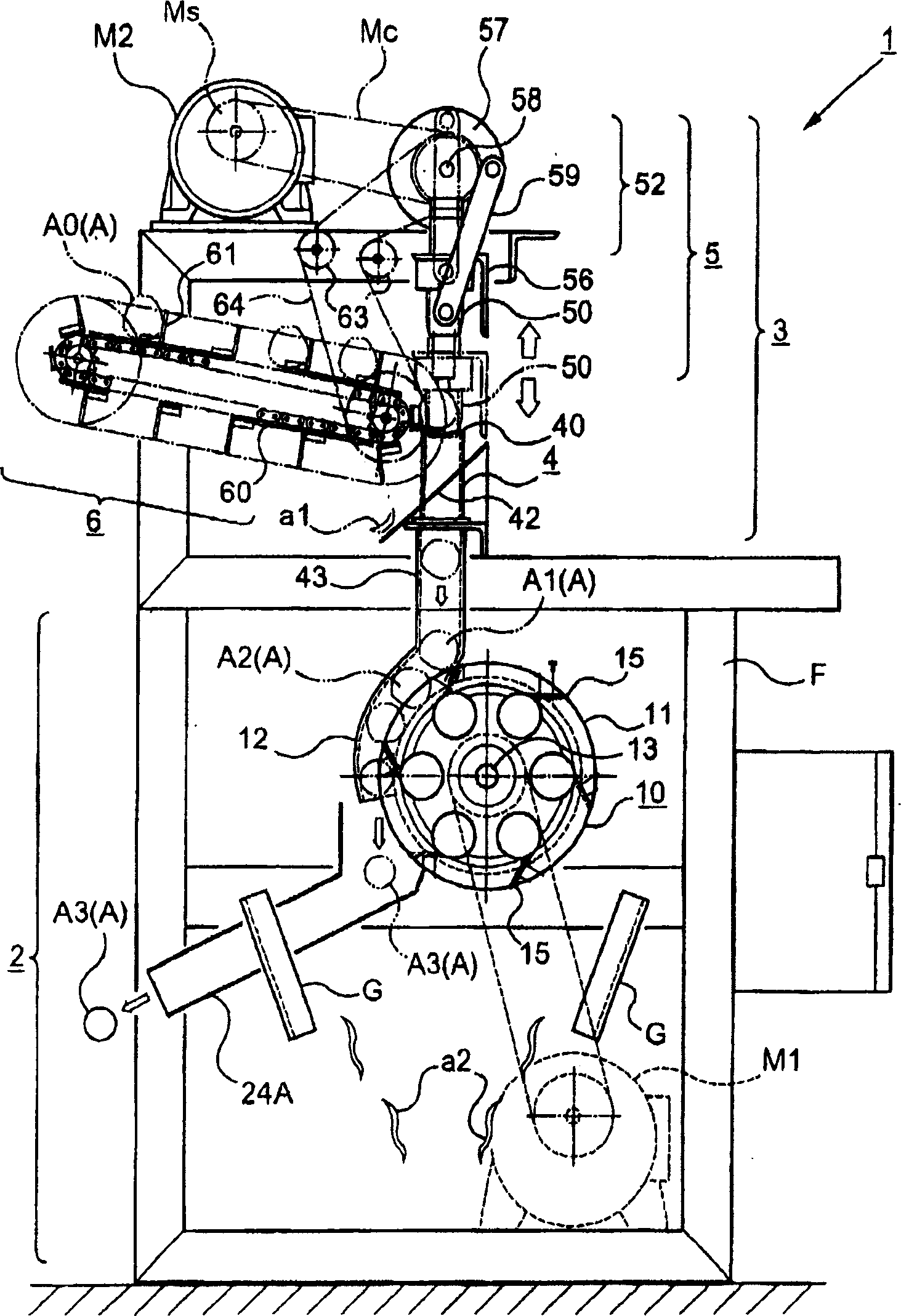

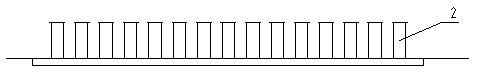

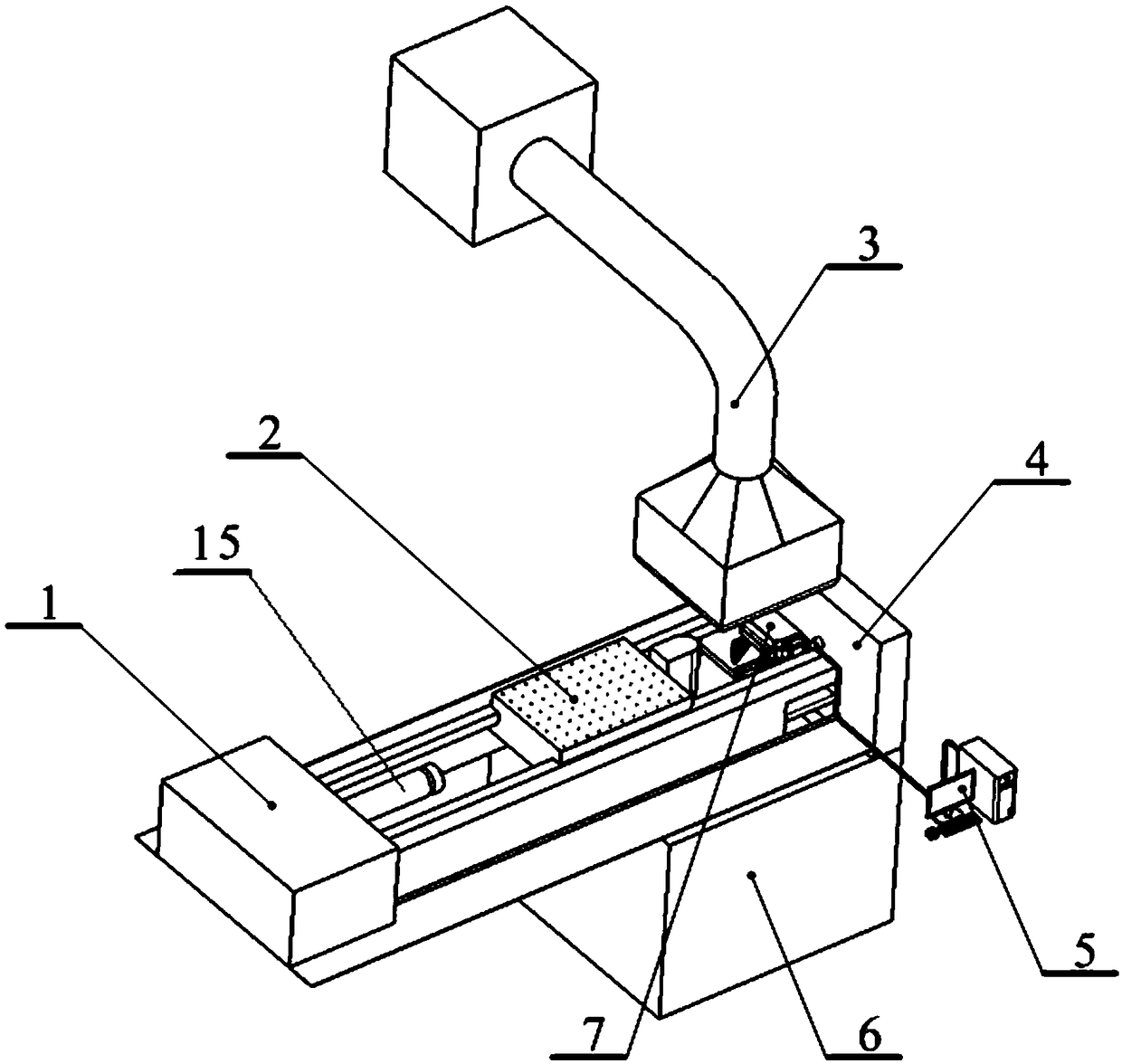

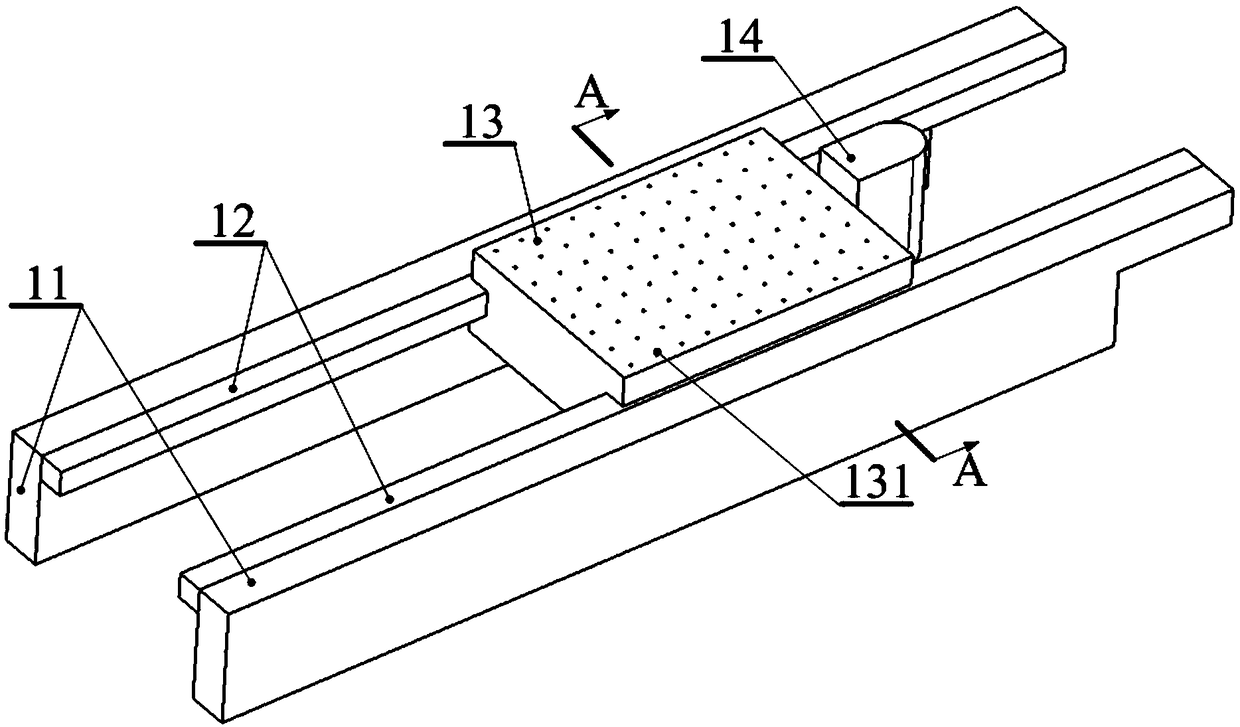

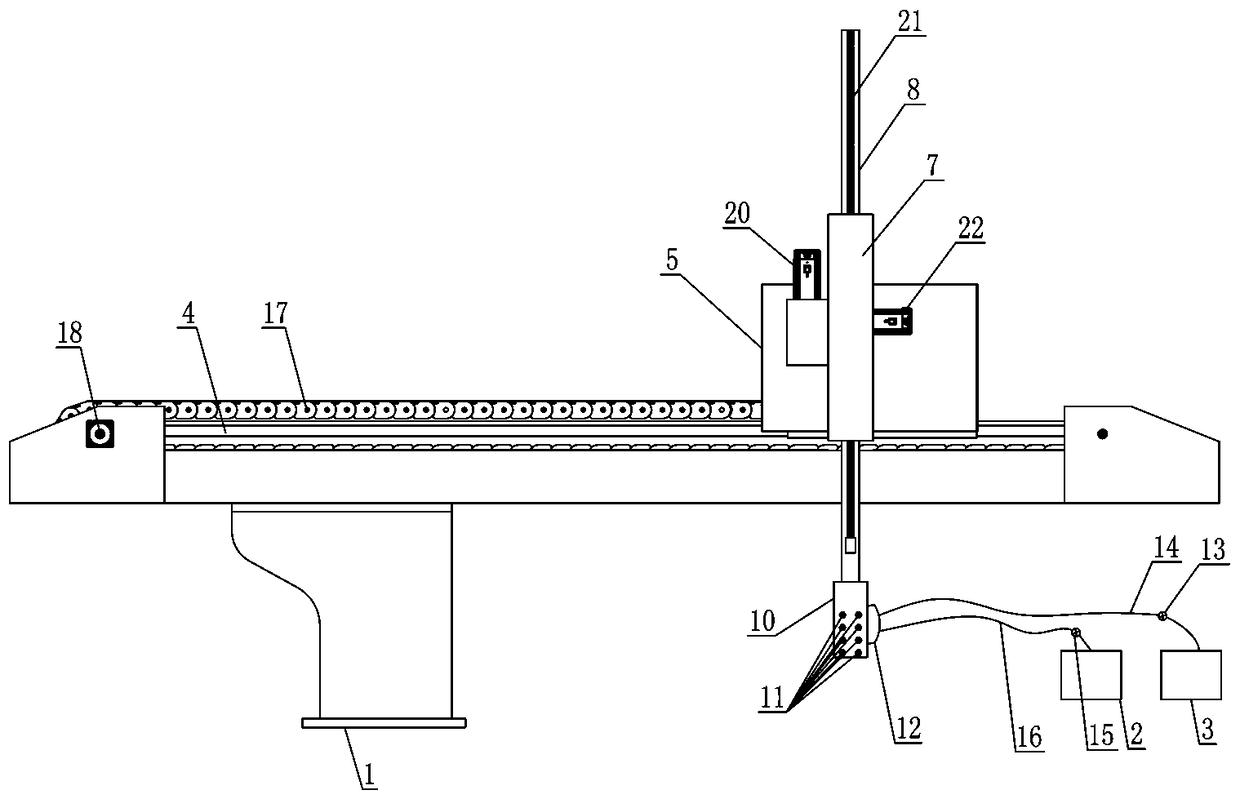

Solar cell silicon chip detecting system

ActiveCN101581671ARealize sortingGuaranteed accurate fixationOptically investigating flaws/contaminationFluorescence/phosphorescenceSolar cellSilicon chip

The invention relates to a detecting system, in particular to a solar cell silicon chip detecting system. The detecting system comprises a silicon chip conveying device; the silicon chip conveying device is provided with a feeding area, an exposure area and a sorting area along the silicon chip conveying device in sequence; the feeding area is used for arranging the silicon chips on the silicon chip conveying device; the exposure area is provided with a detecting and imaging system arranged above the silicon chips and a limiting mechanism used for limiting the silicon chips; and the sorting area is used for putting the silicon chips with different weight into corresponding material-receiving box. Compared with the prior art, the system has the beneficial effects that by adopting the structure, the detecting system can realize sorting to the silicon chips by only needing arranging the silicon chips into a feeding box of the feeding area, and is simple and practical.

Owner:武汉中导光电设备有限公司

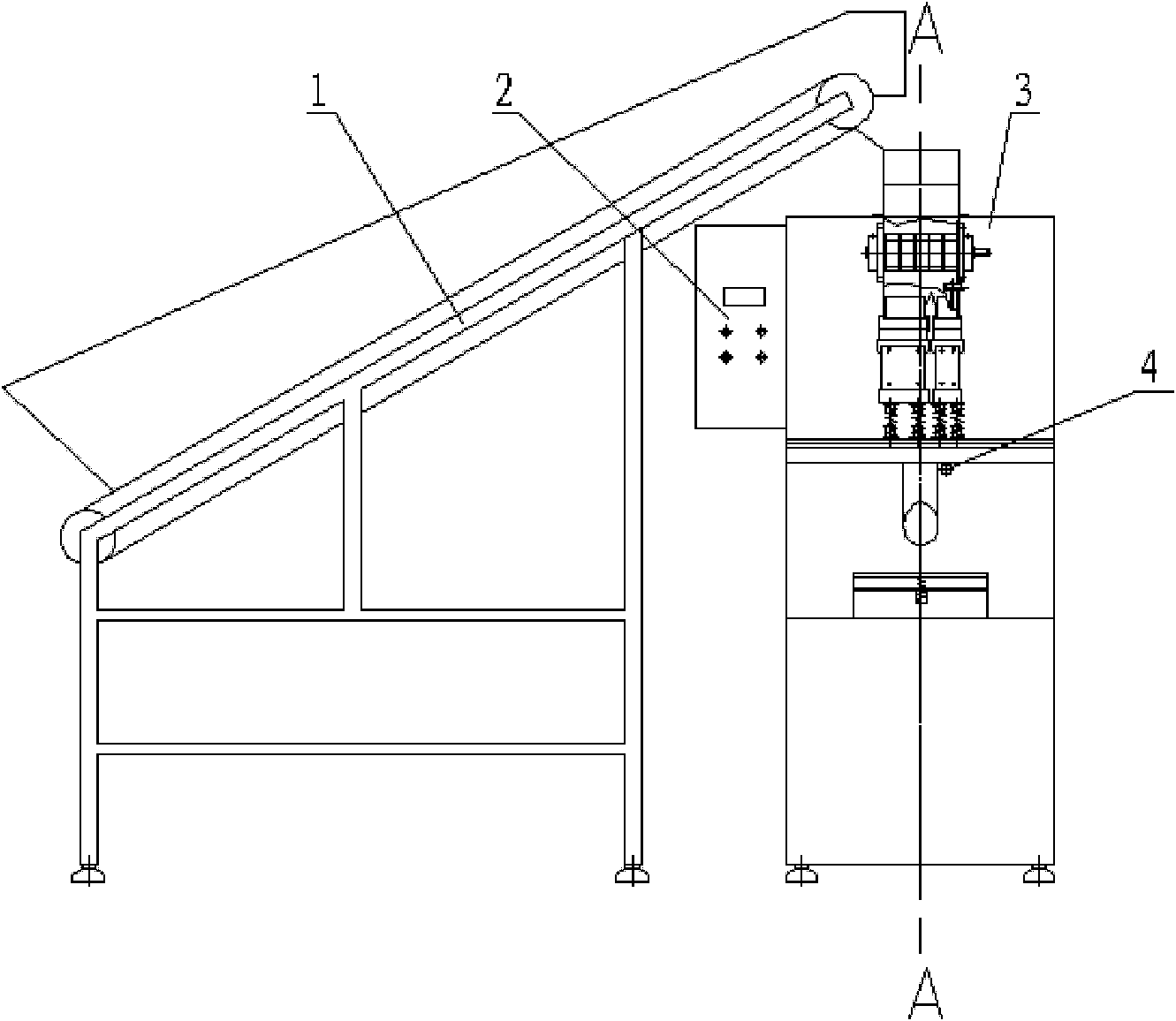

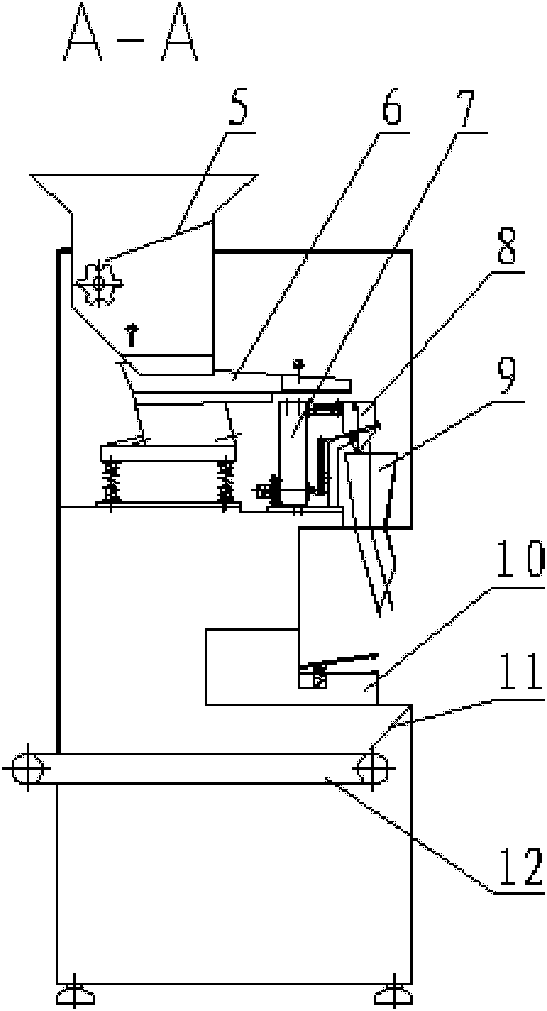

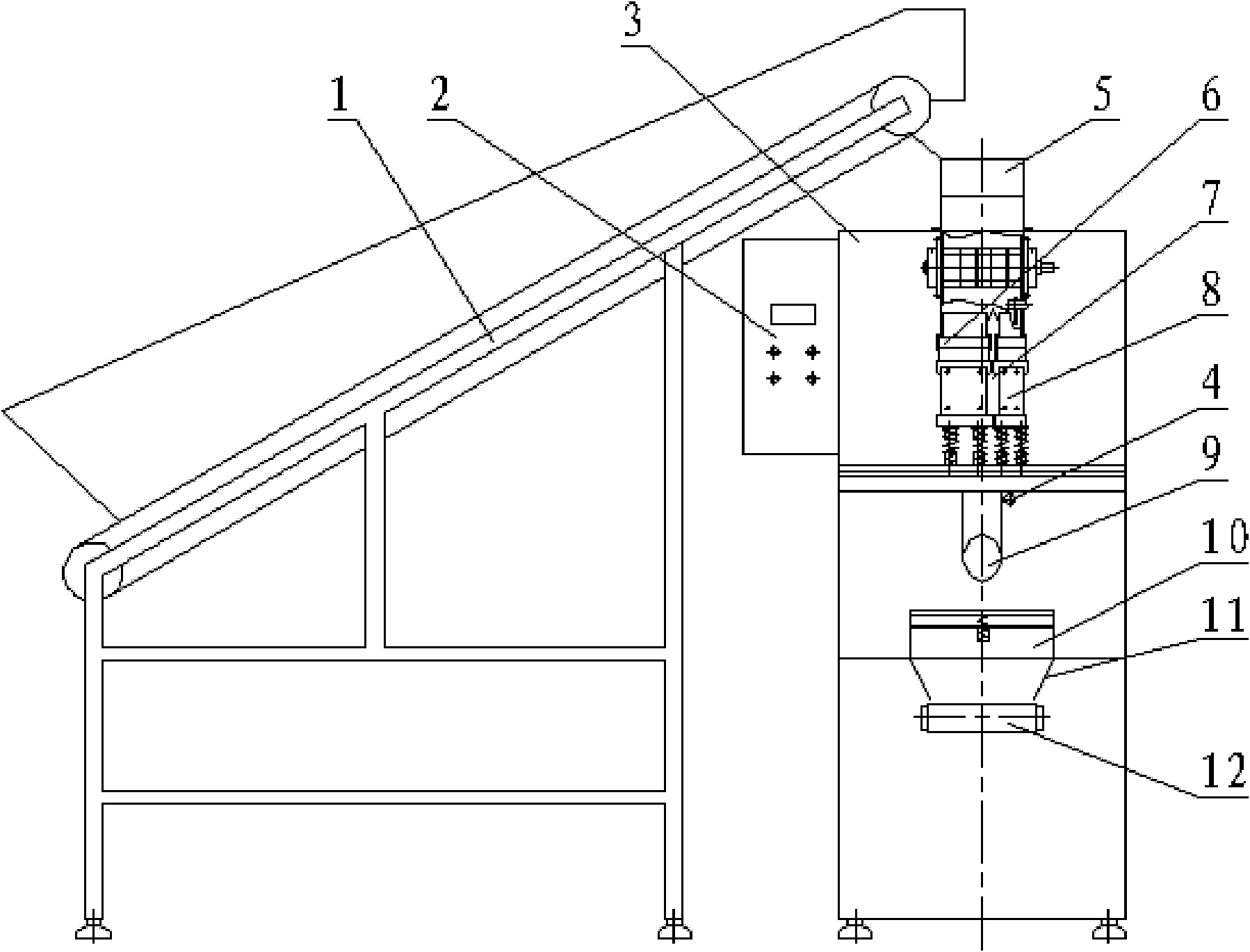

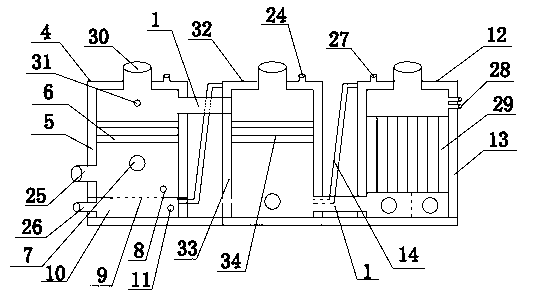

Semi-automatic packaging machine for irregular bulk foods

InactiveCN102180273ASmoothly fall intoIn line with the principles of ergonomicsPackaging automatic controlSolid materialTransport systemSemi automatic

The invention relates to a semi-automatic packaging machine which is suitable for irregular bulk foods such as short chips, spicy hot fishes, potato chips, short fried strips and the like which are cooked foods with a certain hardness and brittleness and are made from flour puffing and also suitable for solid bodies with very small particle diameters or powdery materials. The food packaging machine comprises a material storing and transporting system, a control system, a machine case, a photoelectric sensor, a top hopper feeding mechanism, a vibrating feeding system, a door opener, an electronic weighing device, a nozzle module, a clamping-type sealing machine, a sliding plate, a belt conveyer and the like and is characterized in that forms of a big / small vibrating feeder, a duplex twisting feeder, a twisting shaft and an elastic steel sheet are adopted to guarantee rapid and accurate feeding to the weighing device, wherein the period of weighing, packaging and sealing at a time is generally within 2-4s; a weighing hopper is divided into a fixed side and a movable side, wherein the movable side is hinged on the fixed side, the load of a transmission mechanism for realizing execution actions of the movable side is not applied on the weighing hopper and the sensitivity is high; the door opener is of a structure that an execution part does planar motions without a fixed pivot; and installation positions of the lower body of the nozzle, the photoelectric sensor, the clamping-type sealing machine and a seat accord with ergonomics principles. The machine provided by the invention also has the advantages of simple structure, light weight, high efficiency and the like.

Owner:朱桂华

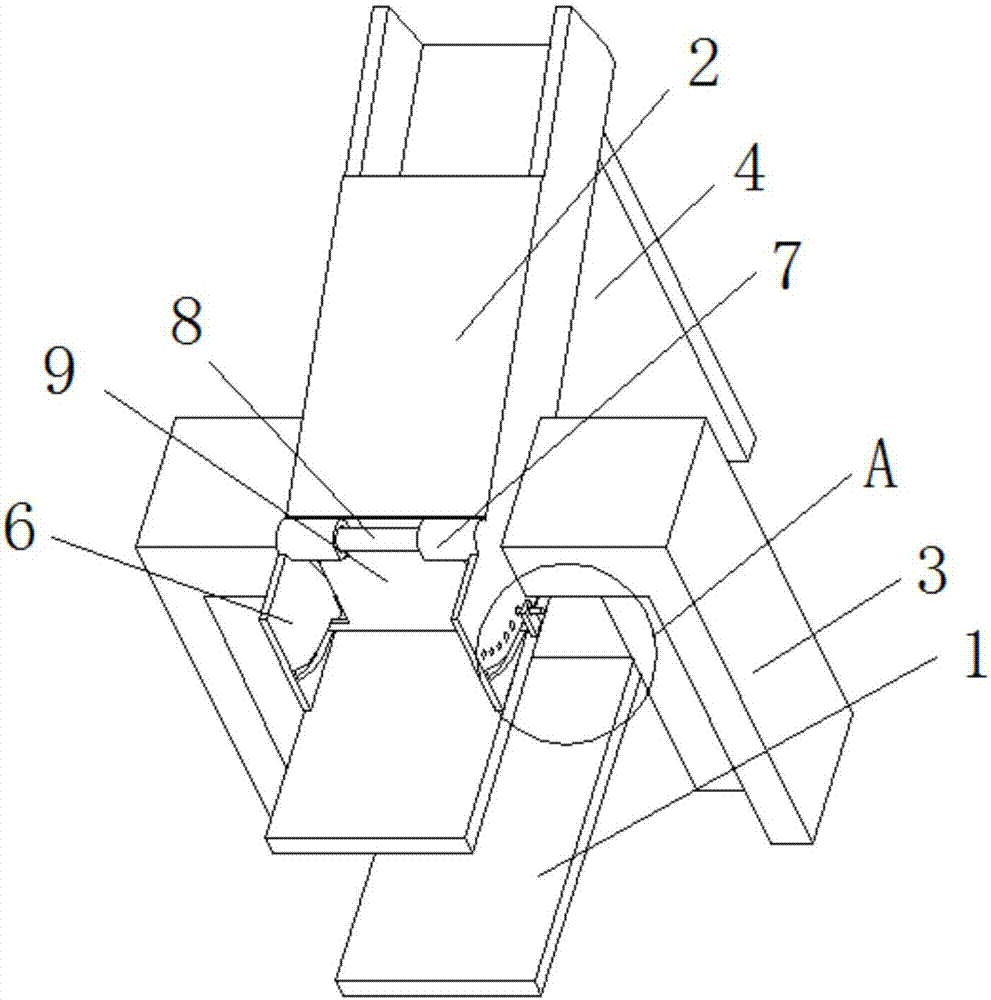

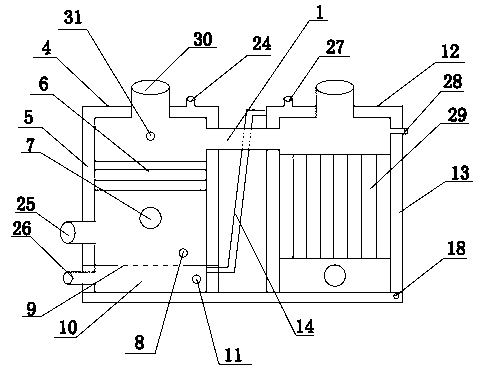

Multi-coin sorting and packing device

The invention relates to a multi-coin sorting and packing device. The multi-coin sorting and packing device includes a coin entrance container, a coin layered transmission mechanism, a coin authenticity check and sorting mechanism, coin counting and packing mechanisms and a control module which is connected with the coin layered transmission mechanism and the coin counting and packing mechanisms, wherein the coin entrance container, the coin layered transmission mechanism, the coin authenticity check and sorting mechanism and the coin counting and packing mechanisms are sequentially arranged from top to bottom; the coin authenticity check and sorting mechanism includes a plurality of coin sorting slope channels which are arranged obliquely, strong magnets and counterfeit coin collection tubes; the tops of the coin sorting slope channels are aligned with the exit of the coin layered transmission mechanism; counterfeit coin attraction slot holes are formed at side walls at the middle portions of the coin sorting slope channels; the strong magnets are arranged at the outer sides of the counterfeit coin attraction slot holes; the counterfeit coin collection tubes are aligned with the counterfeit coin attraction slot holes; a plurality of sorting slot holes of which the widths are increased progressively are formed at the bottoms of the coin sorting slope channels, wherein the sorting slot holes are distributed from top to bottom along the oblique direction of the coin sorting slope channels; a plurality of coin counting and packing mechanisms are adopted; and the coin counting and packing mechanisms are aligned with the sorting slot holes in various sizes. Compared with the prior art, the multi-coin sorting and packing device of the invention has the advantages of high simplicity, low manufacture cost, high efficiency, convenience and the like.

Owner:SHANGHAI UNIV OF ENG SCI

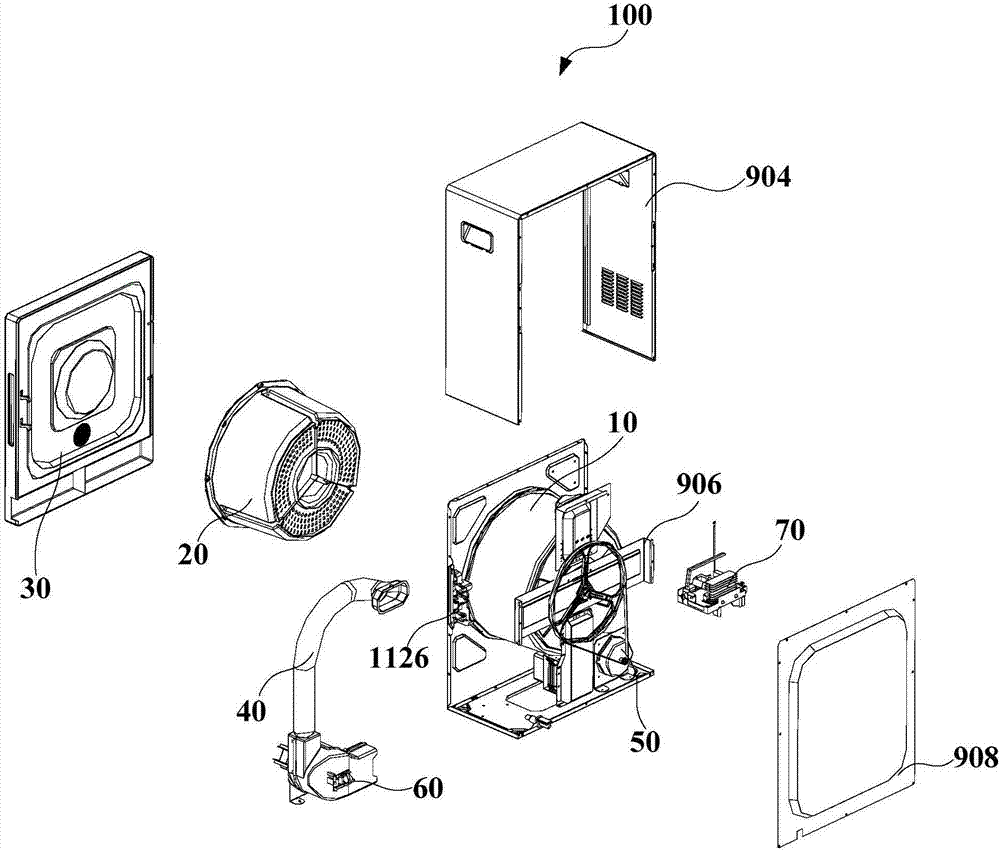

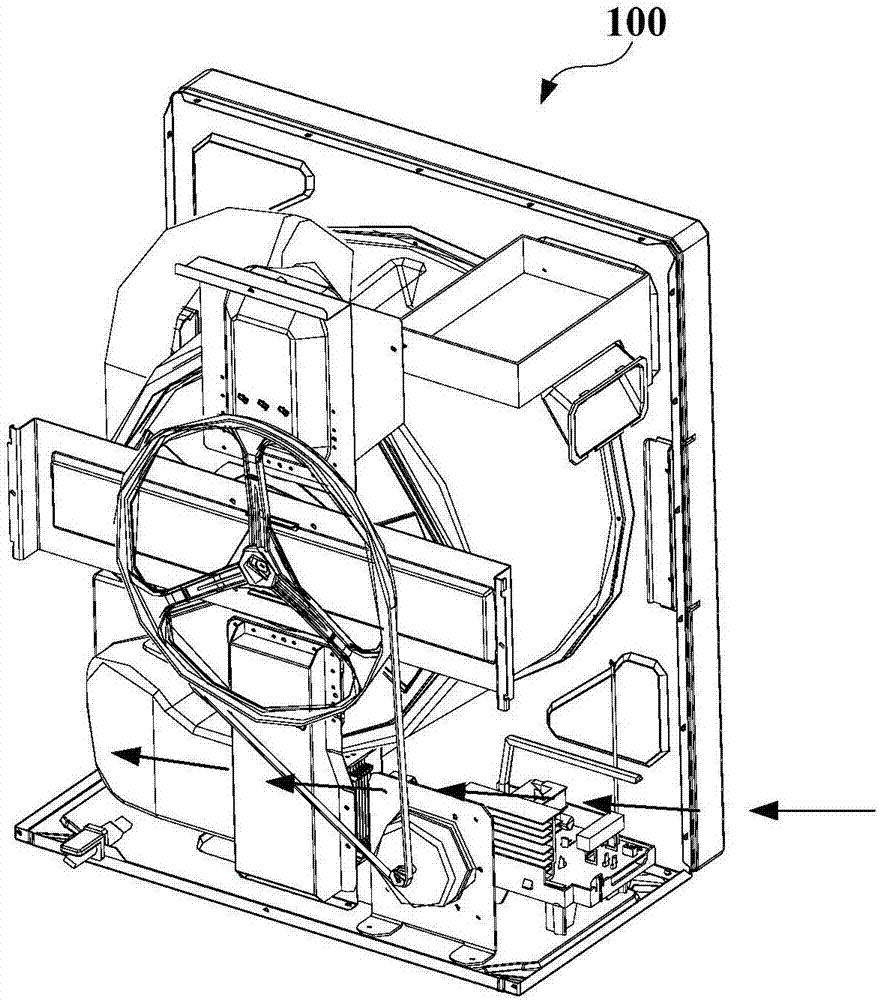

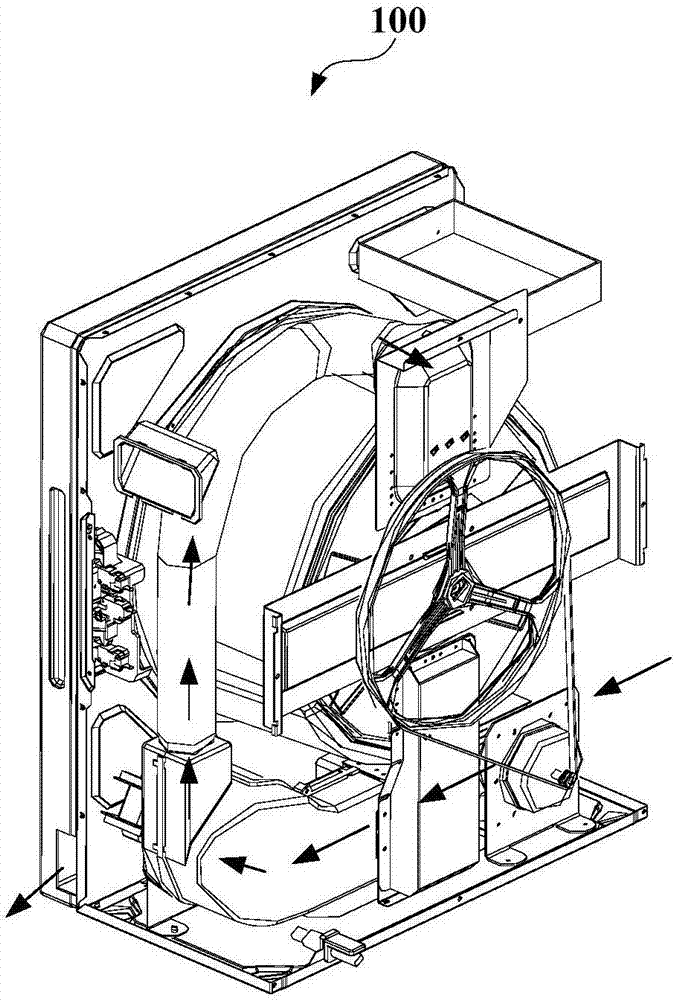

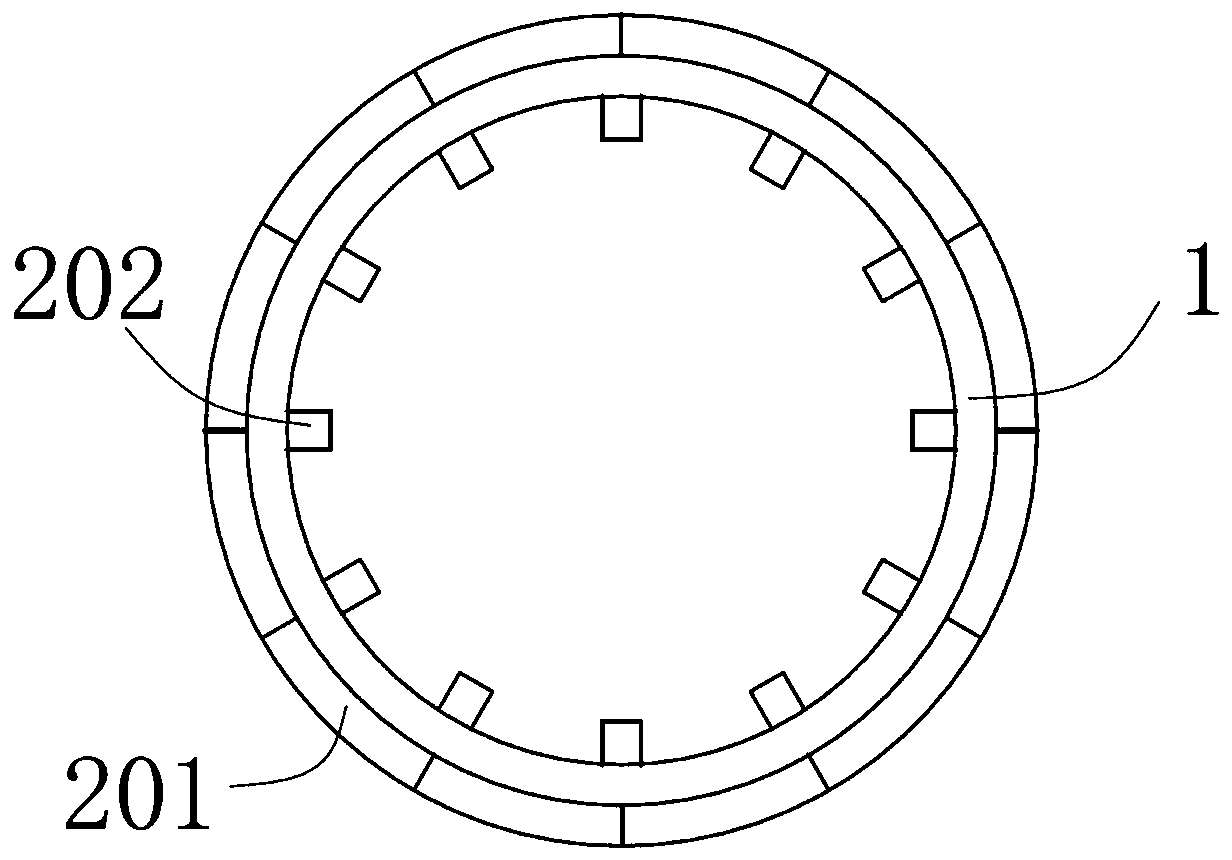

Microwave clothes dryer

ActiveCN106868827AGuaranteed aestheticsImprove satisfactionTextiles and paperHome appliance efficiency improvementMechanical engineeringEngineering

The invention provides a microwave clothes dryer which comprises a cavity assembly, an air suction assembly, a roller assembly and a machine door assembly. An air inlet hole is formed in one end of the bottom of the cavity assembly, and a first opening is formed in the other end of the cavity assembly. The air suction assembly is located outside the cavity assembly and communicated with the air inlet hole. The roller assembly is mounted in the cavity assembly, a first vent hole is formed in one end of the bottom of the roller assembly, and a second vent hole is formed in the other end of the roller assembly. The machine door assembly is mounted on the first opening and is in matching connection with the cavity assembly, and the machine door assembly is provided with a third vent hole and an air outlet hole. External air is guided in through the air suction assembly, flows into the cavity assembly through the air inlet hole, passes through the first vent hole, the second vent hole and the third vent hole and flows out through the air outlet hole. According to the microwave clothes dryer, soft flocks generated in the clothes washing process are discharged out of the roller assembly along with air flow, it is avoided that the soft flocks are scattered to the position between the roller assembly and the cavity assembly along with the air flow and cannot be cleared away, and consequently a pollution source is caused, and the use experience of a user is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

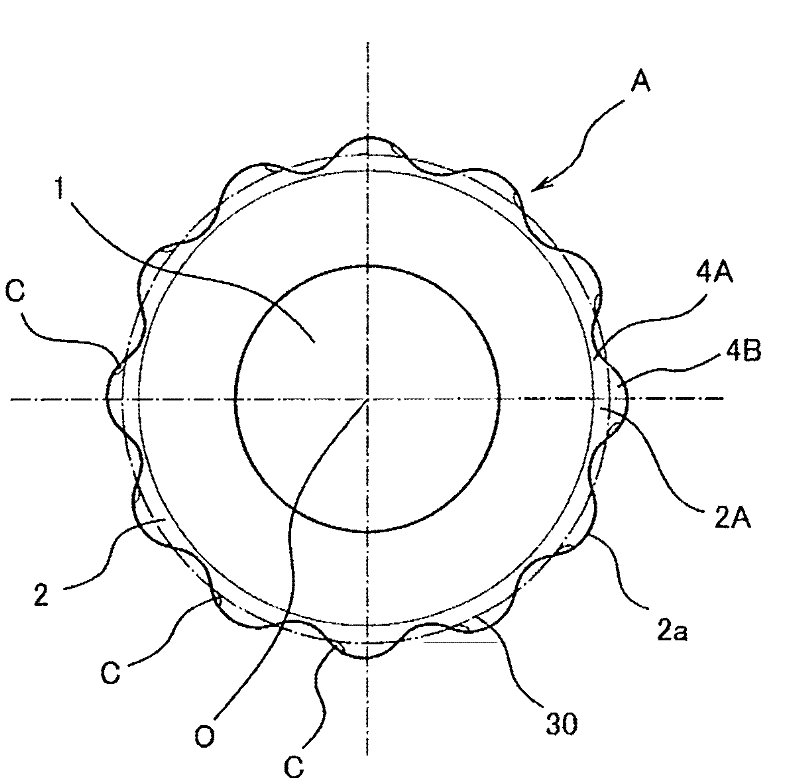

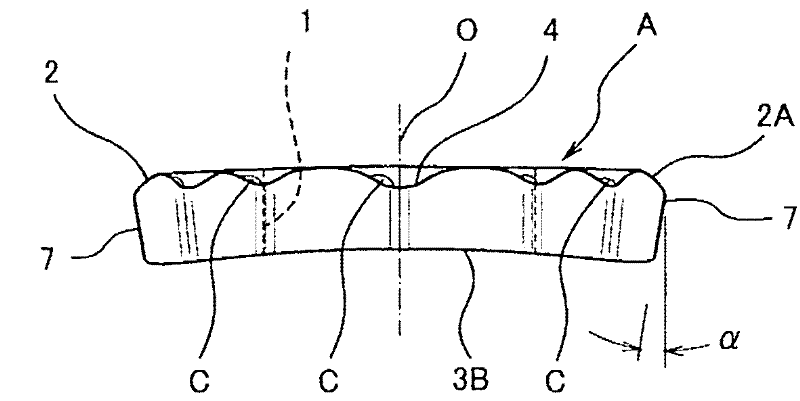

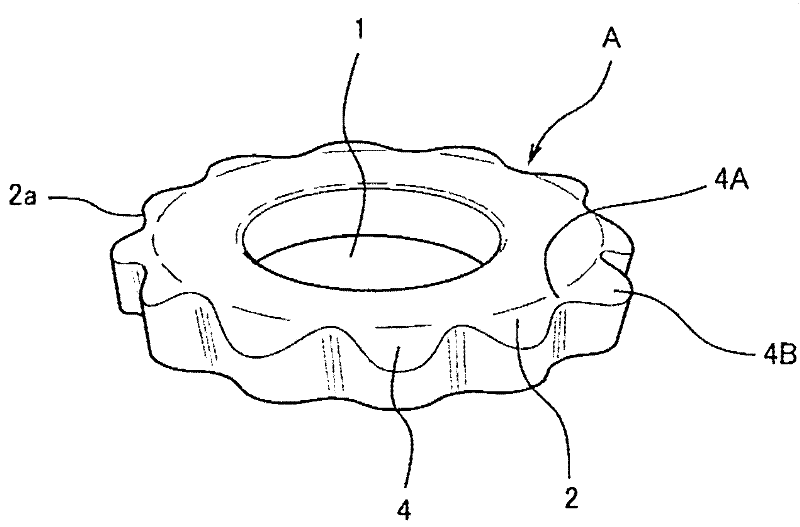

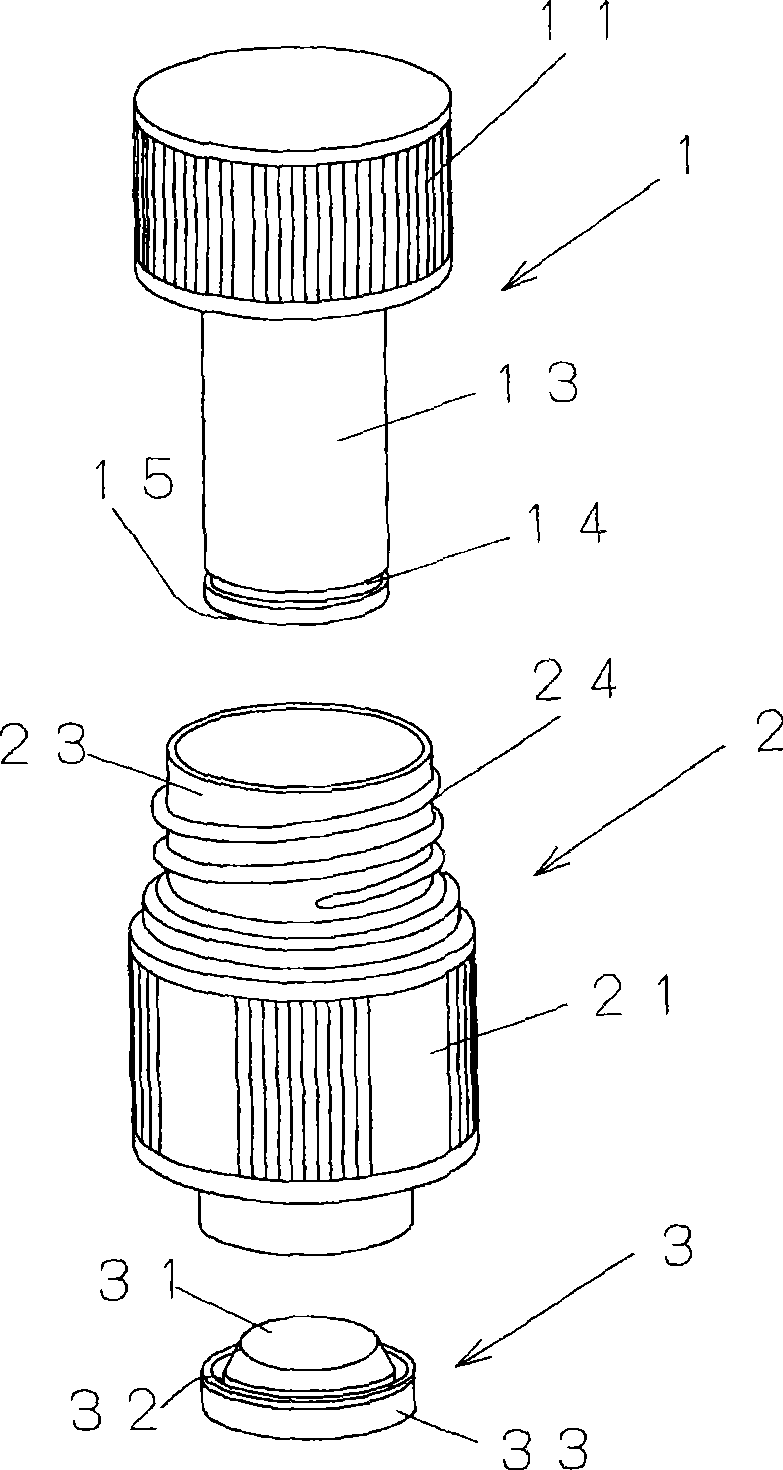

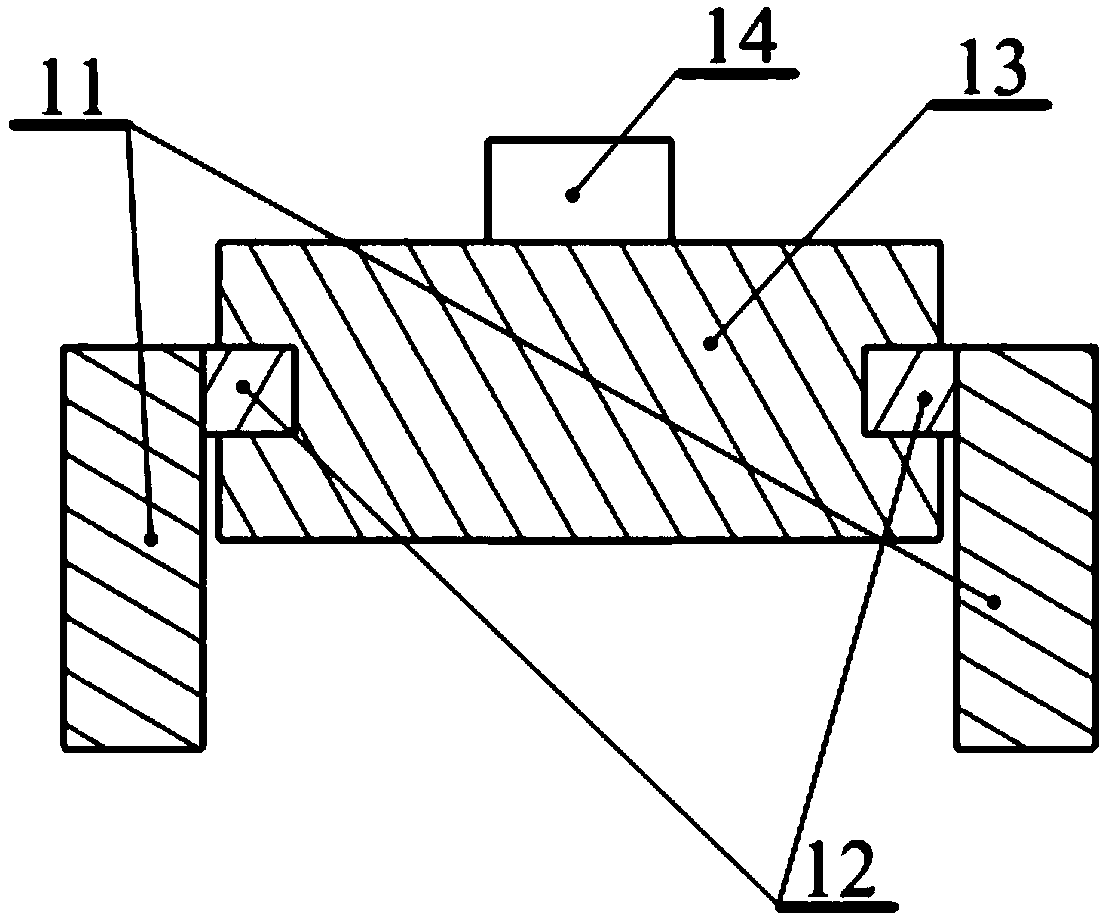

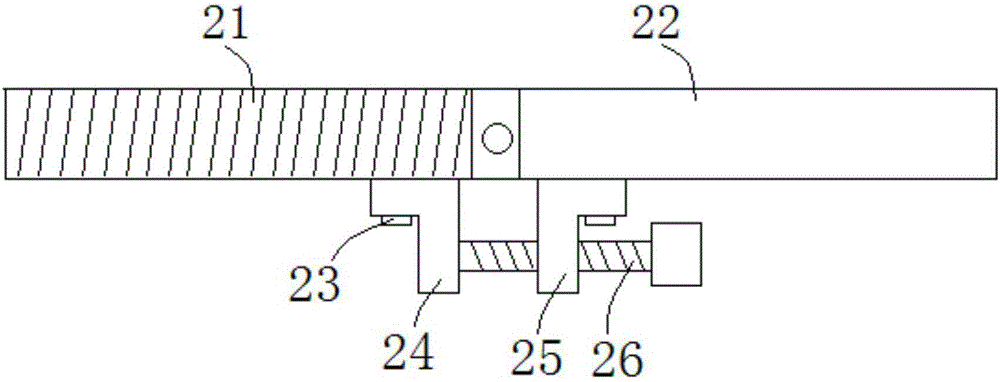

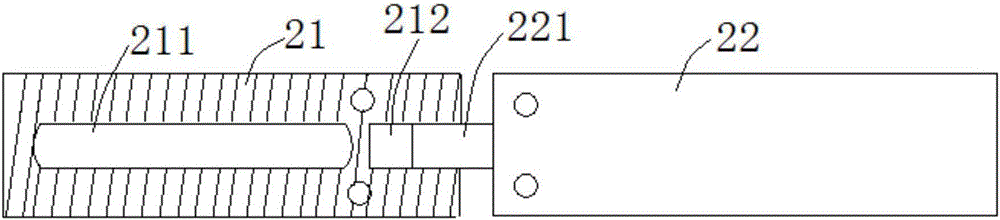

Sleeve for connection and washer for supporting used reacting force and connecting structure

The invention provides a sleeve for connection and a washer for supporting used reacting force, and connection can be made only via nut fixing without washer fixing, furthermore, a connecting structure is provided to connect in a mode that a nut and a bolt are not in a ''corotation''. A sleeve (B) used for a nut connection is provided with: an inner sleeve part provided with a clamping mechanism clamping with a nut, etc.; an outer sleeve part clamping with a washer (A) provided with an outer edge part (2), the outer edge part is provided with clamping tooth and the surface is formed to be a conical surface close to the bottom surface side at the outer edge side; an inner sleeve part (21)and an outer sleeve part (22) are mutually connected via mechanisms capable of rotating in reverse directions. The outer sleeve part is provided with clamping pawls (24) clamping with the clamping tooth, the lower end of the clamping pawl (24) is formed by a conical surface close to the base end side at the inner diameter side. Friction factor increase processing is applied to the face of a bolt head in a contact with the surface of the connected subject.

Owner:YUNITAITO

Cooling device

A cooling device comprises a cooling bin. The cooling bin is provided with a front end cover, a rear end cover, a material inlet, a material outlet, a cooling air inlet, a cooling air outlet and a helical mixing conveyor, wherein the helical mixing conveyor comprises a transmission shaft connecting the front end cover and the rear end cover; the transmission shaft is provided with positive helical slices and reverse helical slices; and the transfer directions of the positive helical slices and the reverse helical slices are opposite. The cooling device solves the problem that the materials are piled at the ends because the helical mixing conveyors arranged in the cooling devices in the prior art transfer the materials only towards one direction, and the problem of indirect cooling effect of the cooling air in the prior art, and can avoid the transfer efficiency from being affected because the materials are piled at the ends of the helical mixing conveyors and improve the cooling effect of the cooling air while ensuring normal transfer of the materials.

Owner:TIBET QIZHENG TIBETAN MEDICINE

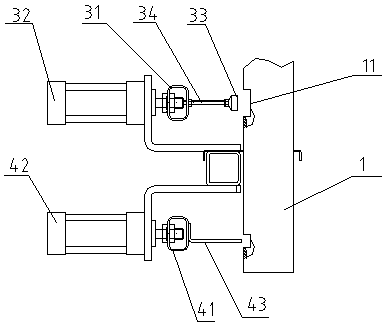

Machining equipment for square tubes

InactiveCN106624178AFully automatedImprove chamfer effectMetal working apparatusPositioning apparatusHydraulic cylinderEngineering

The invention provides machining equipment for square tubes. The machining equipment comprises a bracket and two clamping mechanisms arranged on the bracket. First positioning mechanisms are arranged on the two sides of the two clamping mechanisms. Chamfering mechanisms are arranged in grooves. First blanking holes and second blanking holes are formed in the bracket. A first blanking rail and a second blanking rail are arranged on the bracket. A second positioning mechanism is arranged between the two second blanking holes. The second positioning mechanism comprises first hydraulic cylinders which are arranged in a mirror manner. A through hole is formed in the position, between the two first hydraulic cylinders, of the bracket. A first support is fixedly arranged between first ejector rods of the two first hydraulic cylinders. At least two layered positioning blocks are fixedly arranged at the bottom of the first support. By means of the machining equipment for the square tubes, the square tubes can be machined in batches, inner chamfering and outer chamfering of the square tubes of various specifications can be conducted at the same time, automatic blanking and automatic discharging after machining is completed can be achieved, the degree of automation is high, the machining efficiency is improved, and the production cost is lowered.

Owner:天津福常科技有限公司

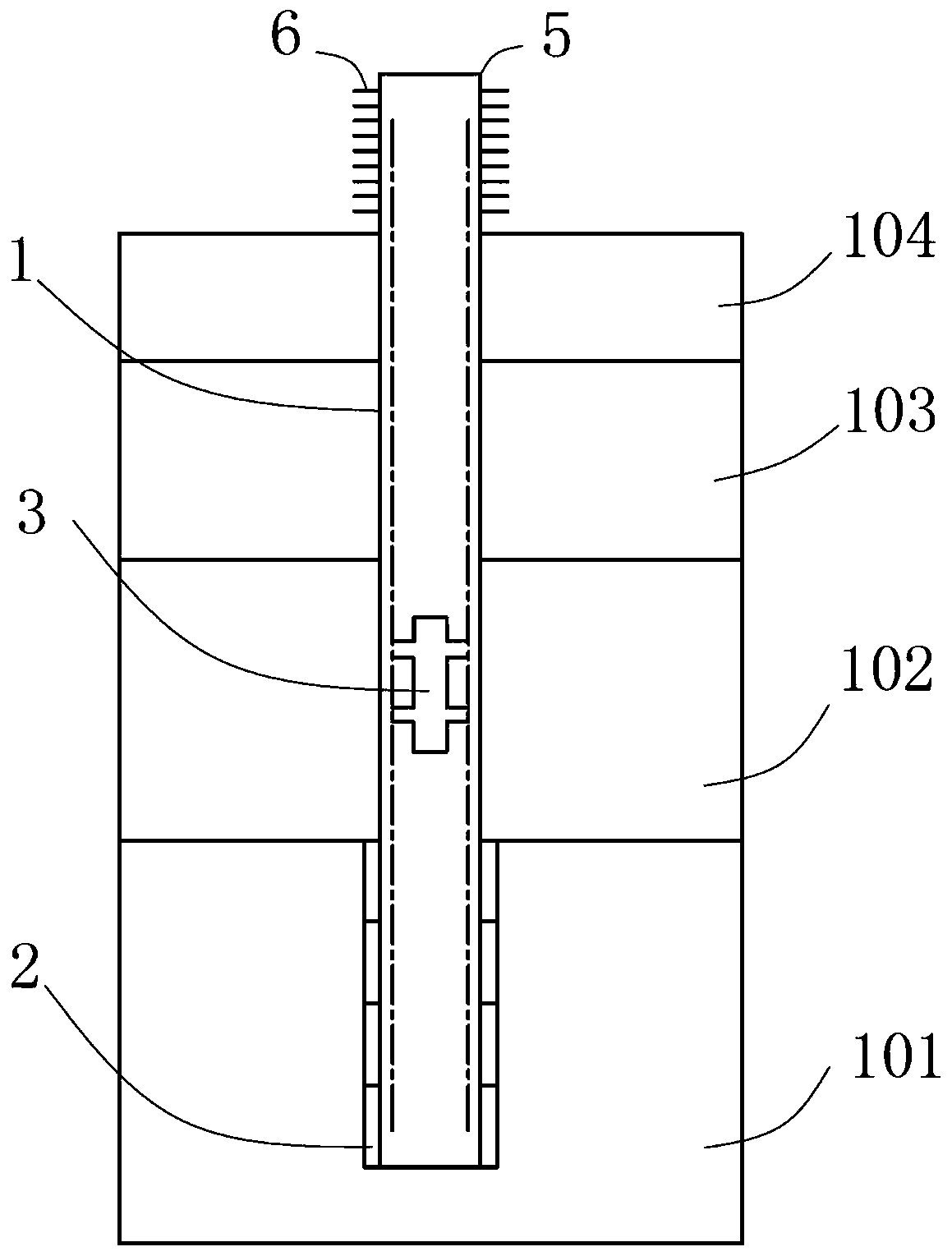

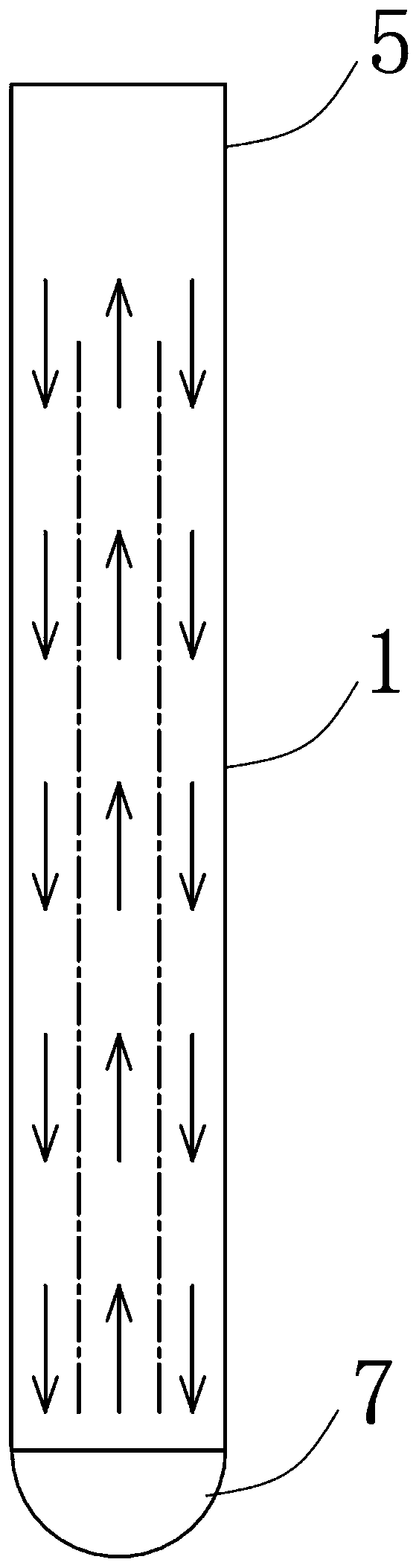

In-situ geothermal power generation system

PendingCN111207047AReduce lossImprove power generation efficiencyGeothermal energy generationMachines/enginesThermodynamicsMechanical engineering

The invention provides an in-situ geothermal power generation system. The system comprises a heat pipe, a thermoelectric temperature difference power generation device and a magnetic levitation powergeneration device. The upper end of the heat pipe extends to the earth's surface or a water body. The lower end of the heat pipe is located at a geothermal source. A circulating cavity is formed in the heat pipe. A circulating working medium is arranged in the circulating cavity. The thermoelectric temperature difference power generation device is located at the lower end of the heat pipe. The magnetic levitation power generation device is located in the middle of the heat pipe. The thermoelectric temperature difference power generation device and the magnetic levitation power generation device output electric energy outwards through electric energy output ports correspondingly. According to the system provided by the invention, the heat pipe is directly buried deep underground, the heat pipe is located at the geothermal source, on the one hand, the thermoelectric temperature difference power generation device located on the lower segment of the heat pipe can directly convert geothermal energy into electric energy, on the other hand, a formed upward gaseous working medium drives the magnetic levitation power generation device in the middle of the heat pipe when the circulating working medium becomes the gaseous working medium during phase changing, geothermal energy is converted into mechanical energy which is then converted into electric energy, and the system has the advantages of geothermal in-situ power generation, low energy loss, high power generation efficiency and the like.

Owner:SHENZHEN UNIV +2

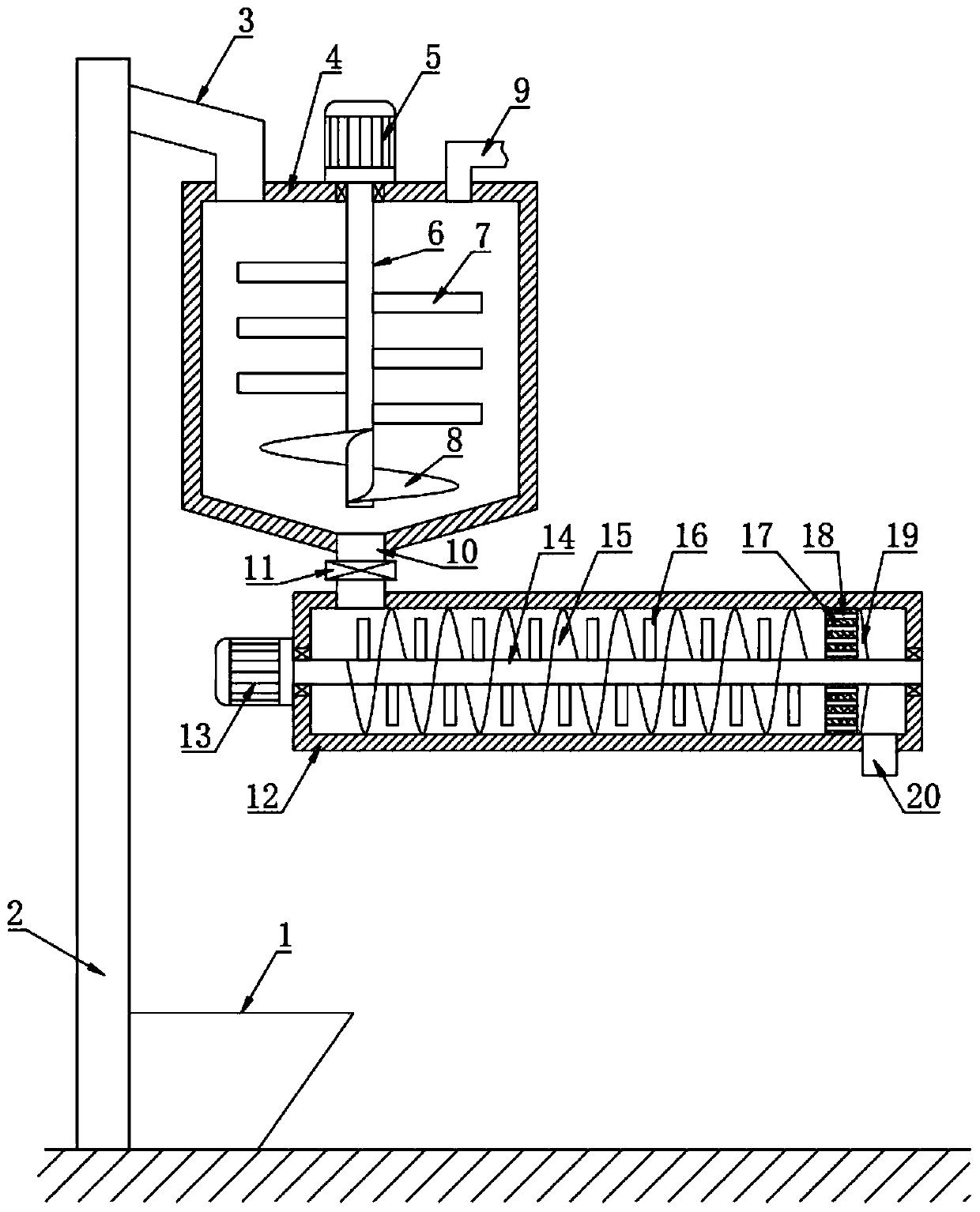

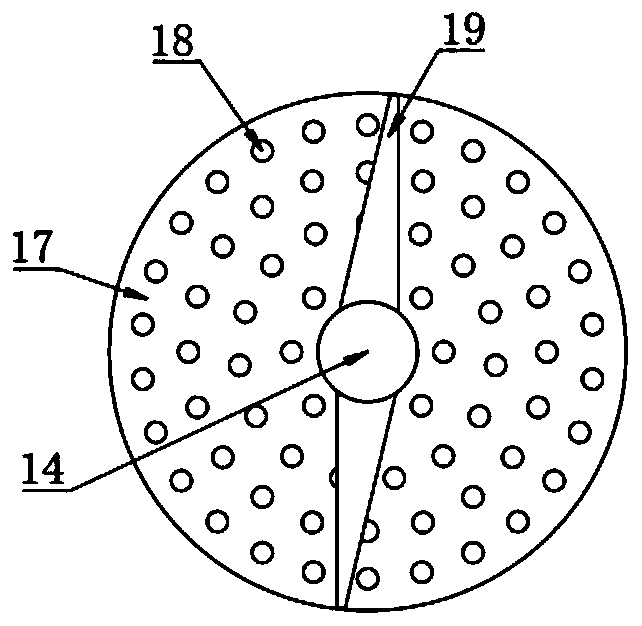

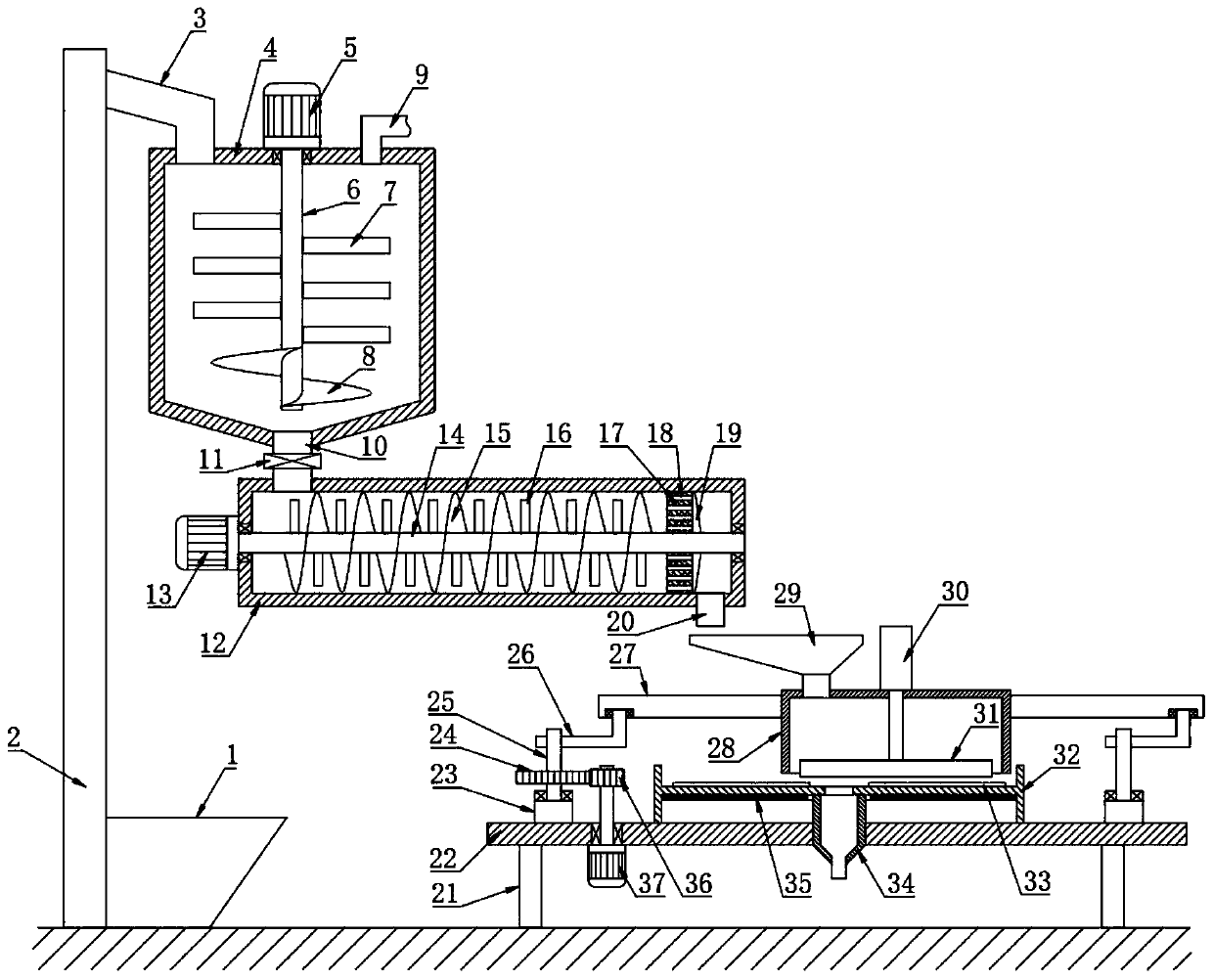

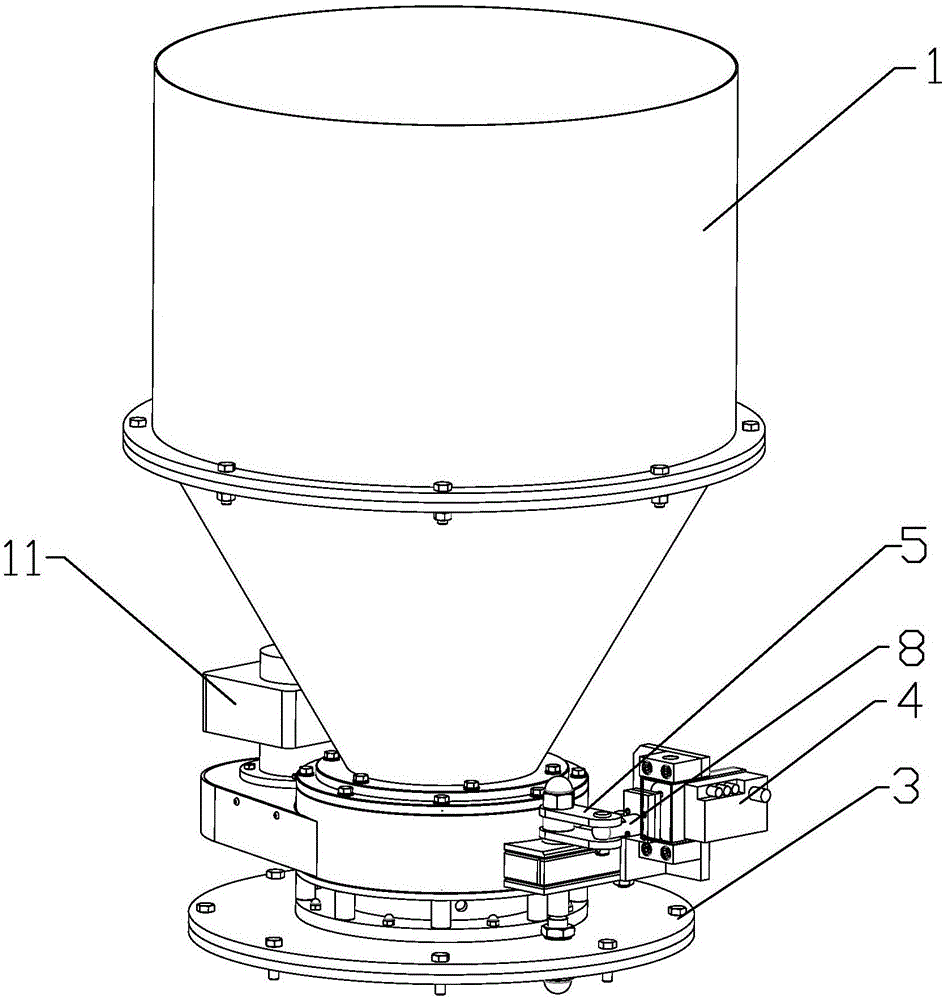

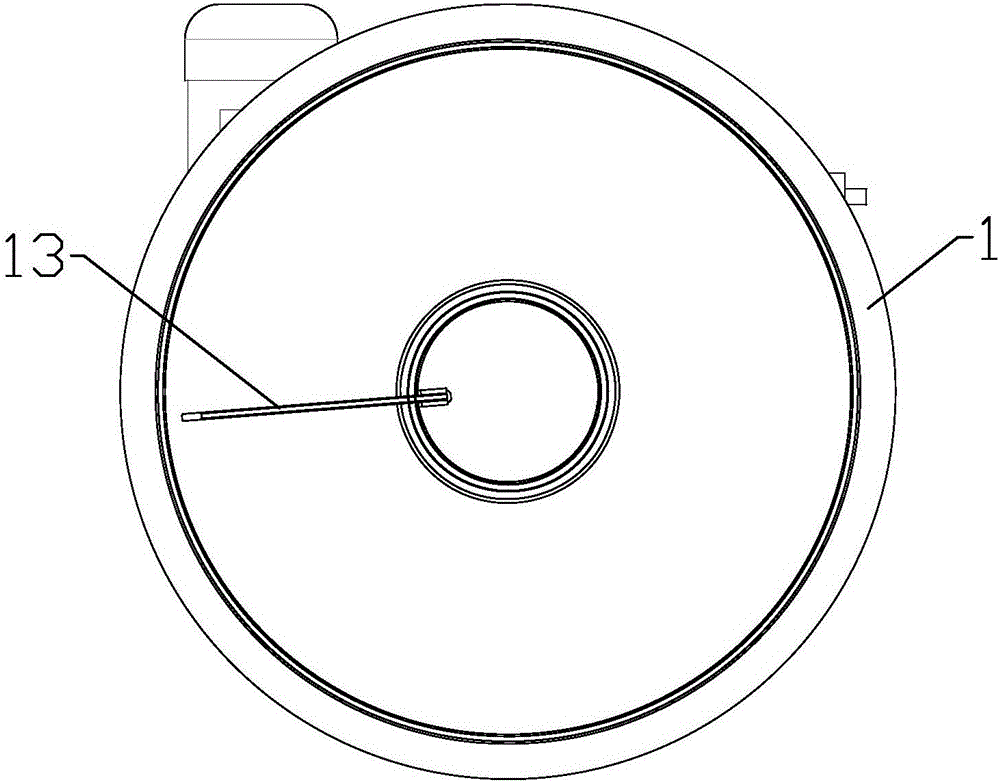

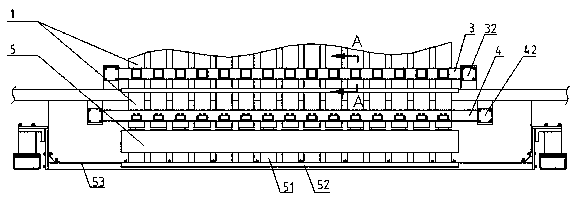

Aluminum oxide ball production line

PendingCN110756117AImprove granulation efficiencyReduce manual labor intensityTransportation and packagingMixersCrankEngineering

The invention discloses an aluminum oxide ball production line, and relates to the field of aluminum oxide ball production machineries, the aluminum oxide ball production line comprises a support plate and a storage barrel, a rubbing disc is fixedly arranged at the top of the support plate; a plurality of supporting arms are fixedly connected to the outer surface of the storage barrel, cranks areconnected to the bottoms of the supporting arms through bearings, a plurality of third rotating shafts matched with the cranks are rotatably connected to the top of the support plate through plummer blocks, and the top ends of the third rotating shafts are fixedly connected with the corresponding cranks respectively; an electric push rod is fixedly arranged in the center of the top of the storagebarrel, and a push rod of the electric push rod penetrates through the top of the storage barrel to be fixedly connected with a rubbing plate; a circular through hole is formed in the center of the rubbing disc, and a discharging hopper is fixedly connected to the lower portion of the circular through hole in the top of the rubbing disc. Aluminum oxide particles gradually fall into the rubbing disc through a gap between the storage barrel and the rubbing plate to be rubbed, new raw material particles are supplemented after aluminum oxide balls are discharged, accordingly, the aluminum oxide balls can be continuously produced, and the production efficiency is higher.

Owner:山东中金金石科技股份有限公司

Impact testing device for battery pack

ActiveCN106323577AAvoid influenceEffective fire extinguishing treatmentShock testingElectrical batteryPower apparatus

The present invention relates to an impact testing device for a battery pack. The device comprises a collision barrier used for placing the battery pack, a movable sliding table with an impact head, a hydraulic power device used for pushing the movable sliding table to slide, and a monitoring device in communication connection with a sensor inside the battery pack. The movable sliding table is positioned between the hydraulic power device and the collision barrier. The impact head of the movable sliding table is oriented towards a support assembly for placing the battery pack and positioned on the side surface of the collision barrier. The monitoring device controls the starting and the stopping of the hydraulic power device. The device further comprises a solution tank positioned right below the support assembly and used for the fire extinguishing of the battery pack. The monitoring device also controls the support assembly to release the battery pack so as to enable the battery pack to fall into the solution tank. According to the technical scheme of the invention, the fire extinguishing problem of the battery pack during the impact test in the prior art can be solved.

Owner:深蓝汽车科技有限公司

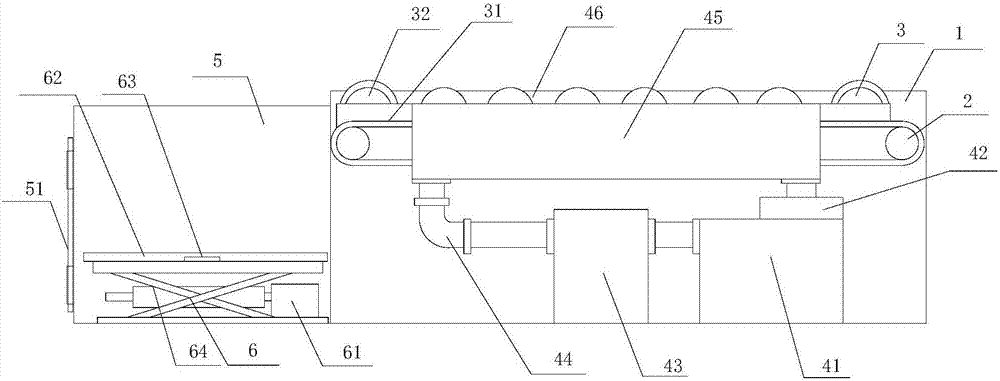

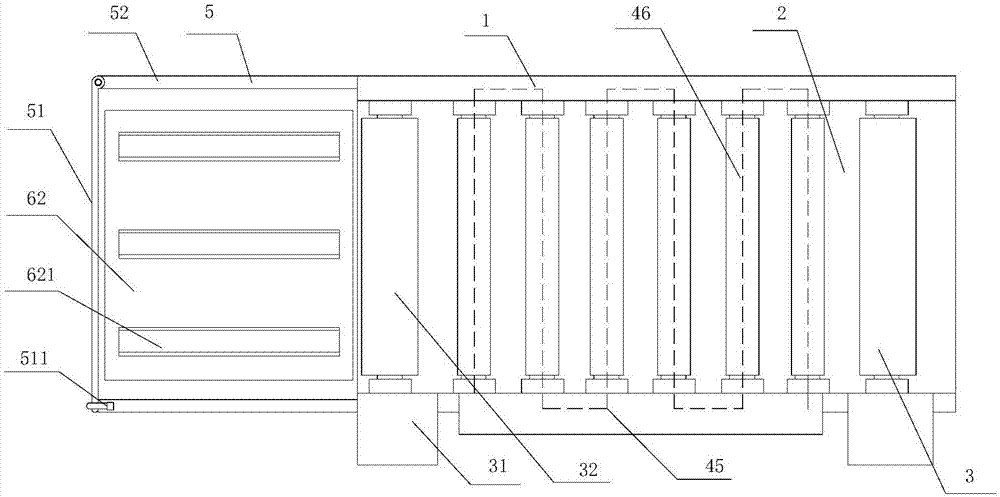

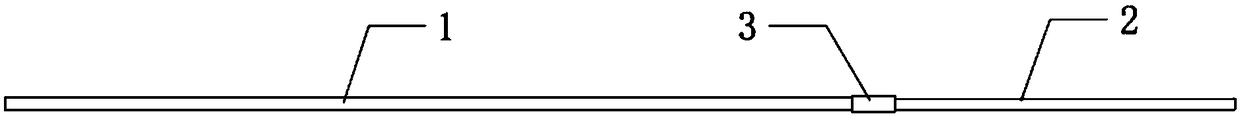

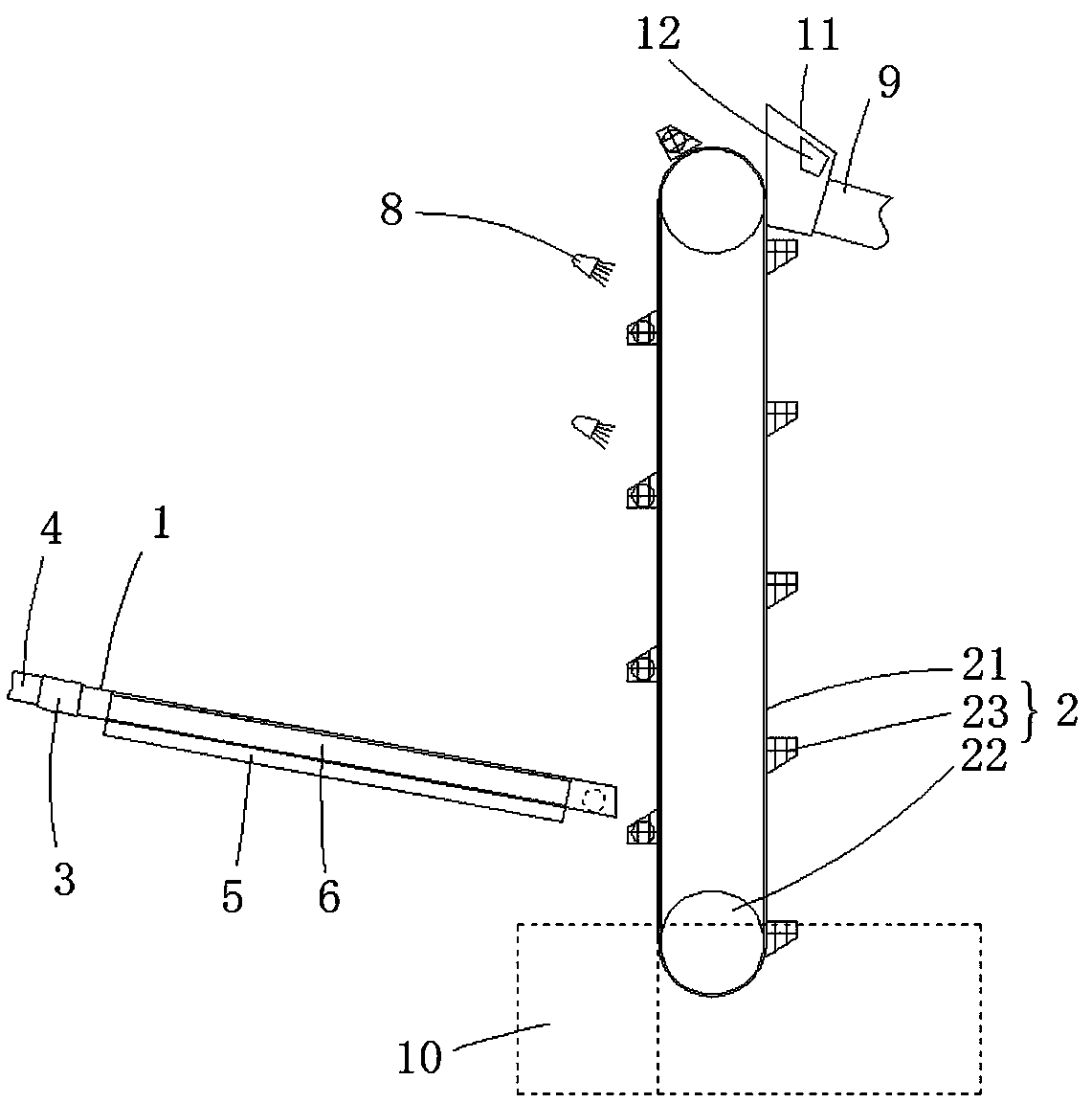

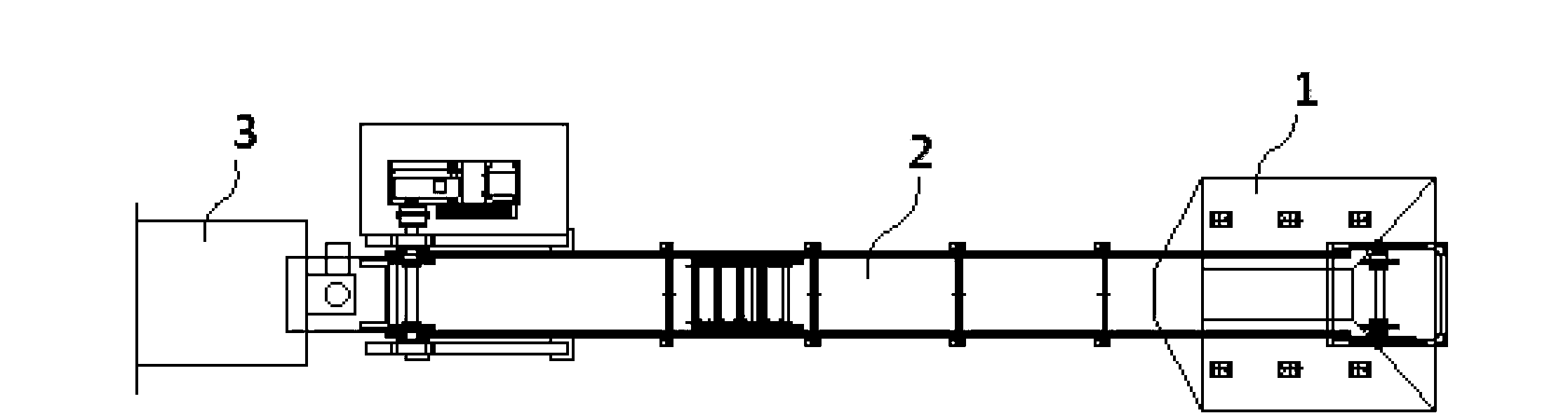

Conveying and discharging device for film laminating machine

PendingCN107415419ASmoothly fall intoCool down thoroughlyLamination ancillary operationsLaminationEngineeringMachine

The invention discloses a conveying and discharging device for a film laminating machine. The conveying and discharging device comprises a machine frame, a conveyer belt mechanism, conveying roller assemblies, a cooling and circulating device, a discharging box and a lifting bench device, wherein the conveyer belt mechanism is arranged on the machine frame, a plurality of cooling roller assemblies are arranged on the cooling and circulating device, the cooling roller assemblies are evenly distributed between the two conveying roller assemblies, the two conveying roller assemblies are respectively arranged at the two ends of the conveyer belt mechanism, the discharging box is arranged on one side of the conveying belt mechanism, the lifting bench device is arranged in the discharging box, a supporting plate is arranged on the lifting bench device, a plurality of tray locating grooves are formed in the supporting plate, a weight sensing unit is arranged under the support plate, and the lifting bench device is matched with the conveyer belt mechanism. The plurality of cooling roller assemblies are utilized to cool, so that cooling completeness is guaranteed. A lifting bench can be used for adjusting heights of material storage trays according to need, the material storage trays can be transferred by a hand fork lifter, and simple operation is achieved.

Owner:ZHEJIANG MINGJIA ENVIRONMENTAL PROTECTION TECH CO LTD

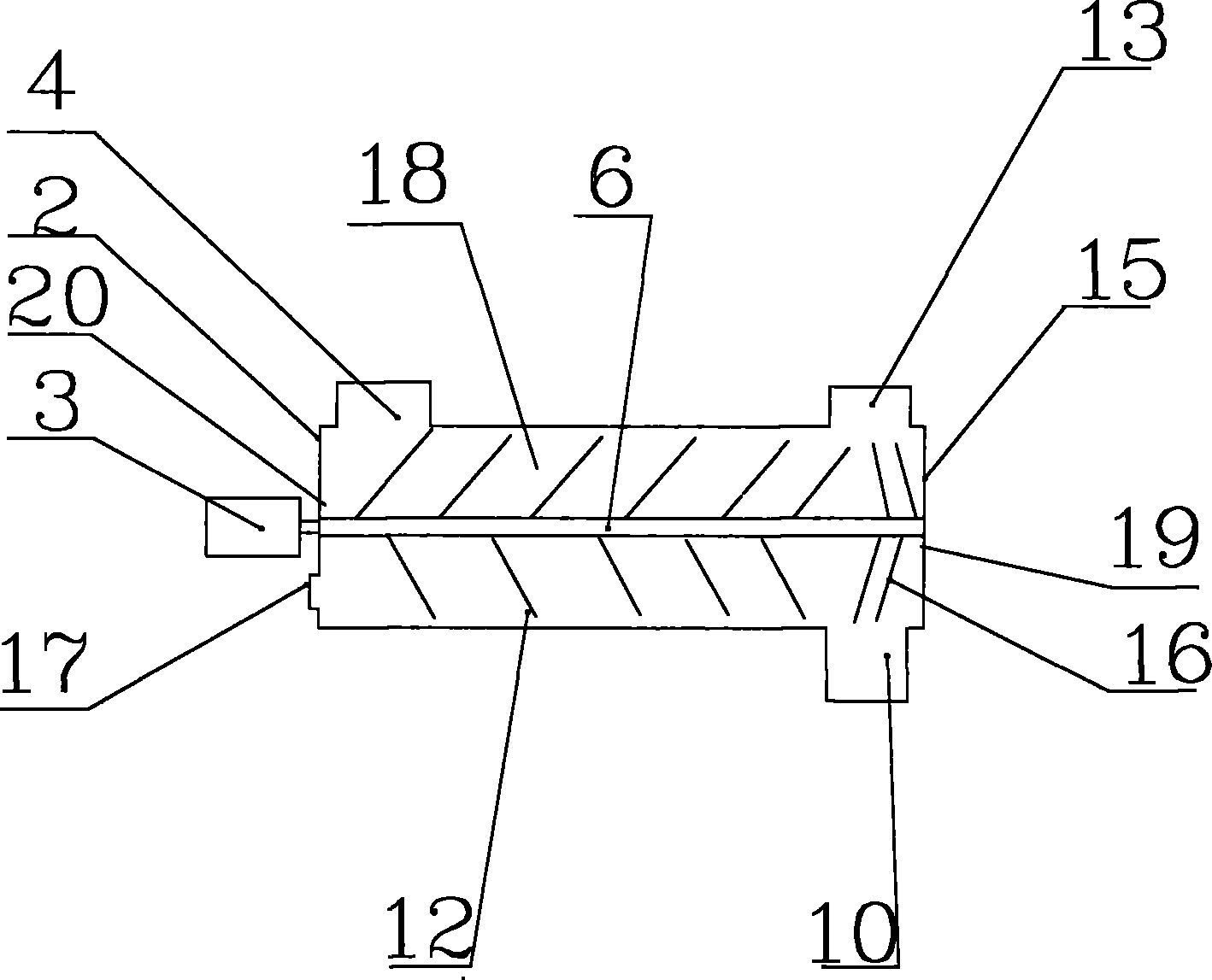

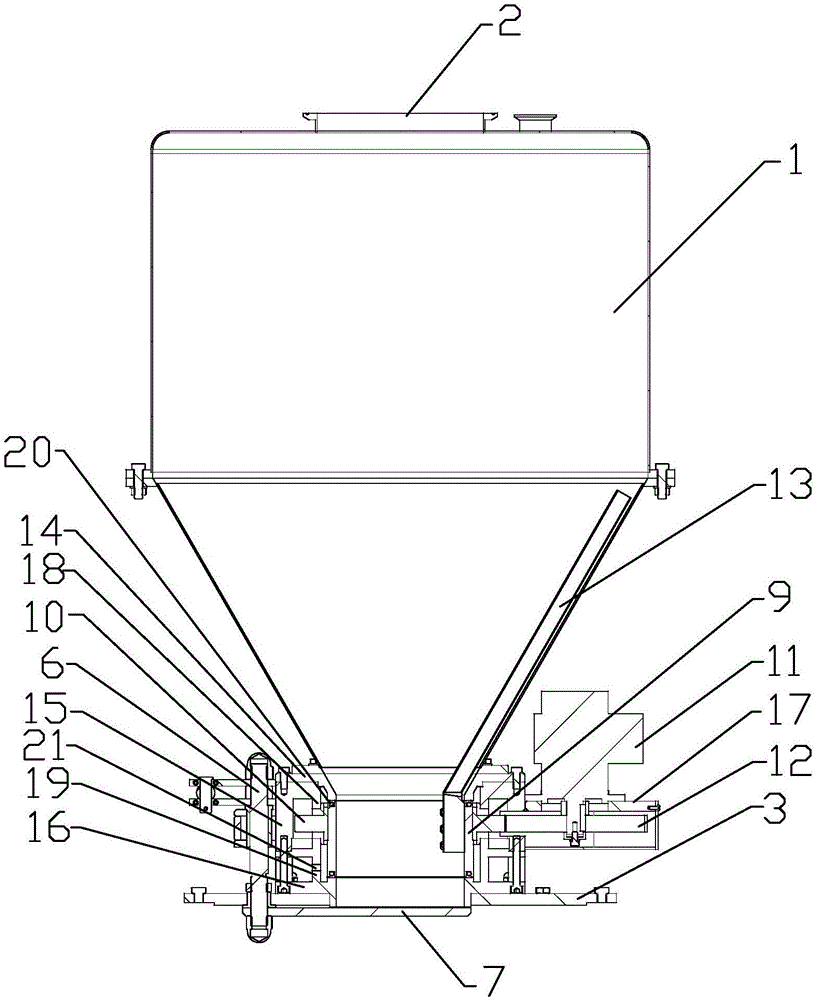

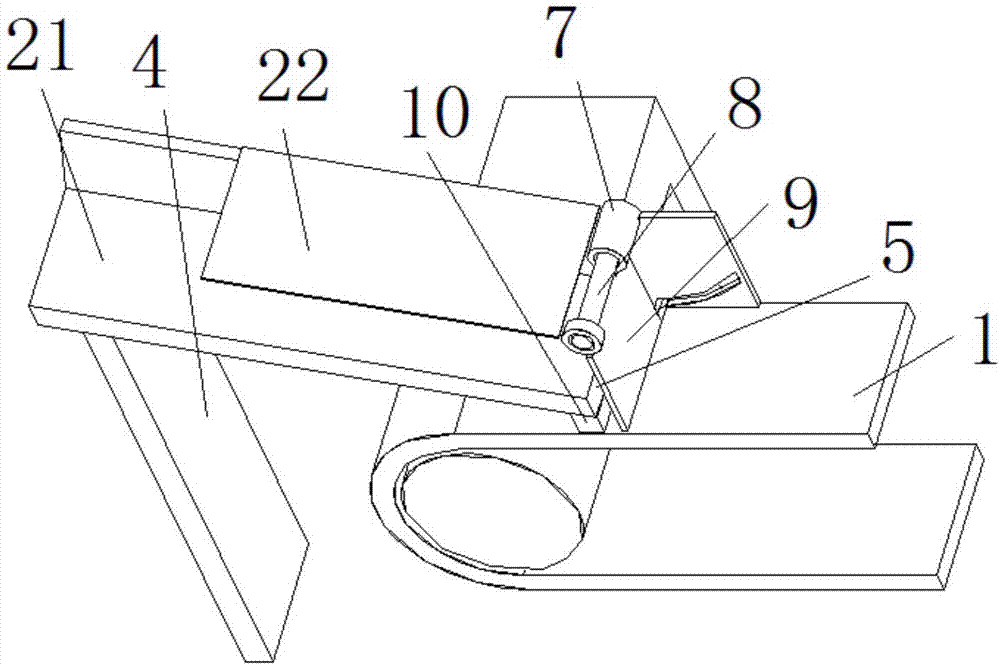

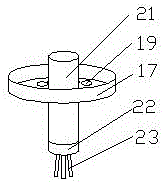

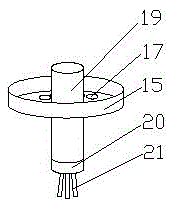

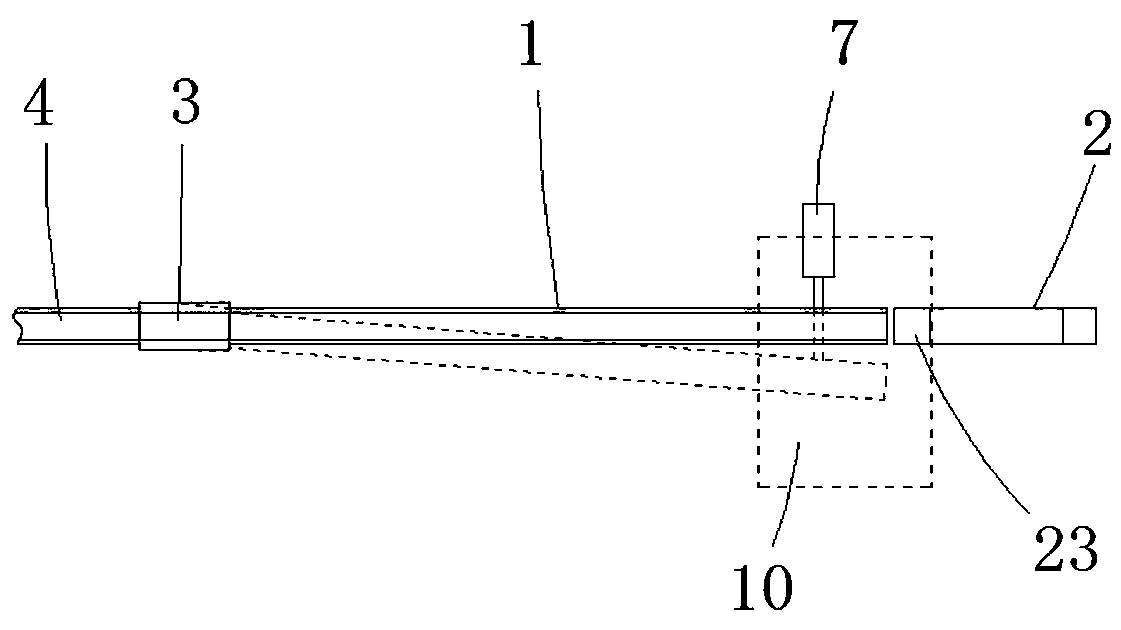

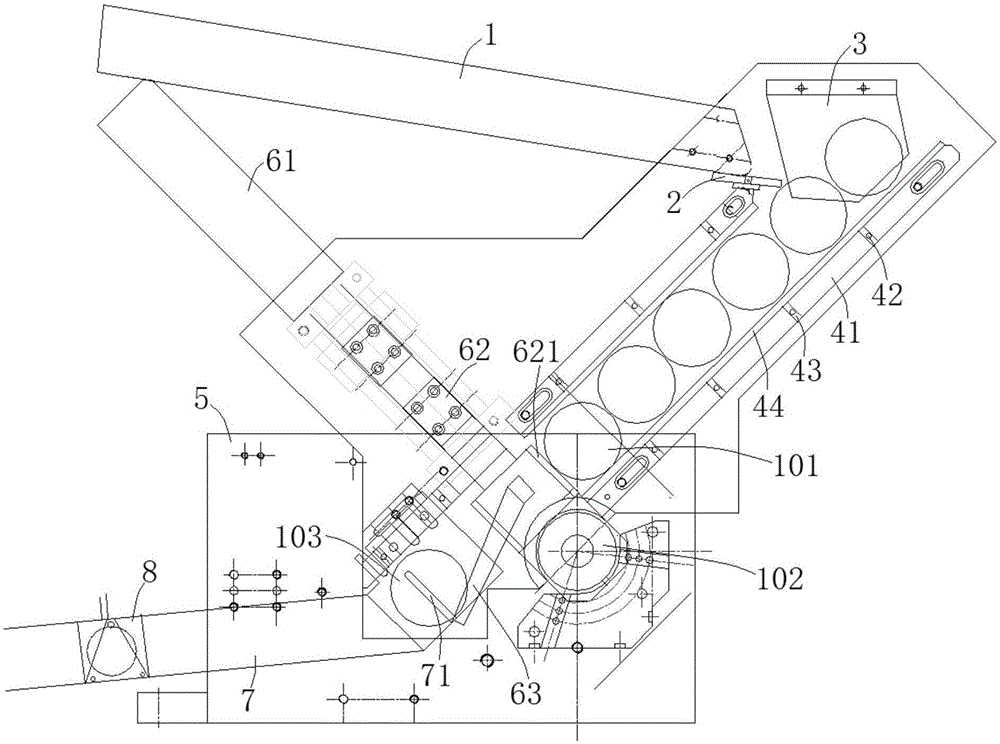

Weighing and batching system

ActiveCN106840343AControl the amount of blankingAchieve openWeighing auxillary devicesSpecial purpose weighing apparatusRotational axisEngineering

The invention provides a weighing and batching system, and relates to a batching system. The invention aims at solving the problem that an existing weighing and batching mode is low in weighing and batching precision and long in weighing and batching time consuming. The bottom end of a feed storage bucket (1) is provided with a feed outlet, an empting hole is formed in a flange disc (3), the feed outlet is communicated with the empting hole, a multi-point positioning air cylinder (5) is installed above the flange disc (3), a rotation shaft (6) vertically penetrates through the flange disc (3) and is rotatably matched with the flange disc (3), the top end of the rotation shaft (6) is hinged to one end of a connecting rod (5), the other end of the connecting rod (5) is hinged to a piston rod (8) of the multi-point positioning air cylinder (4), the bottom end of the rotation shaft (6) is fixedly connected to an empting baffle (7), and the upper surface of the empting baffle (7) is tightly attached to the lower surface of the flange disc (3). According to the weighing and batching system, the empting baffle is controlled by the multi-point positioning air cylinder, thus the purpose of opening empting holes with any size is quickly achieved, and the amount of fallen feed of the feed storage bucket is controlled. The weighing and batching system is used for weighing and batching materials.

Owner:NANO PHARM TECH MACHINERY EQUIP

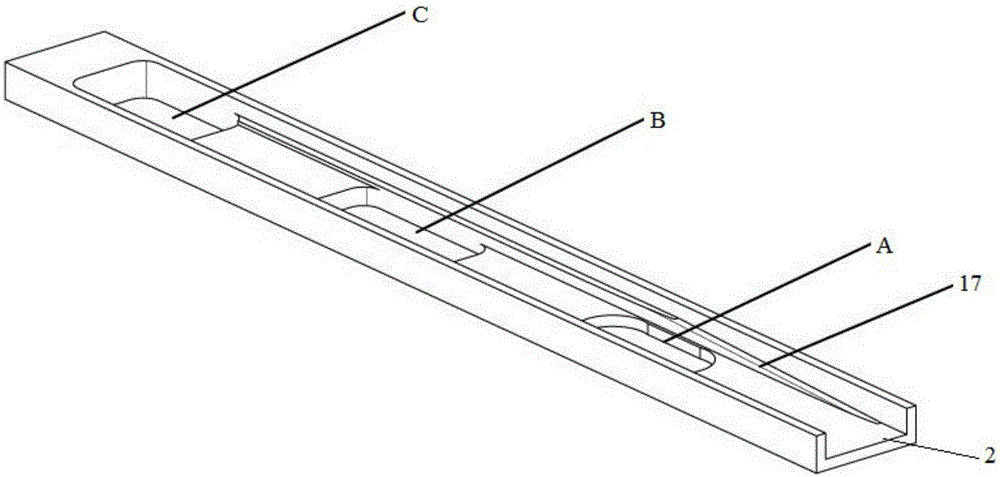

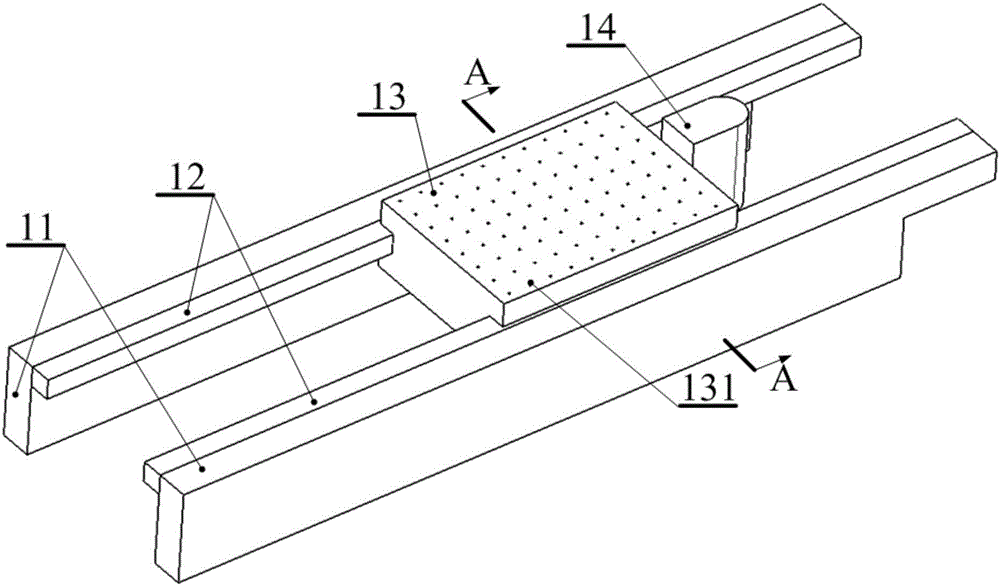

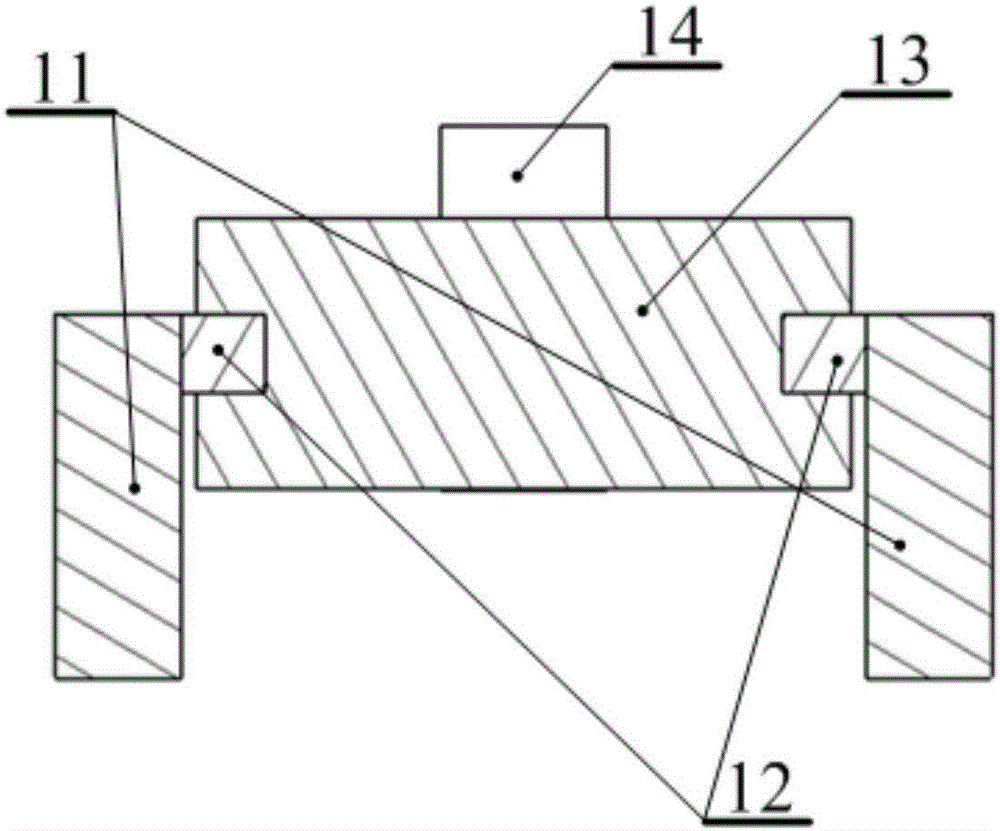

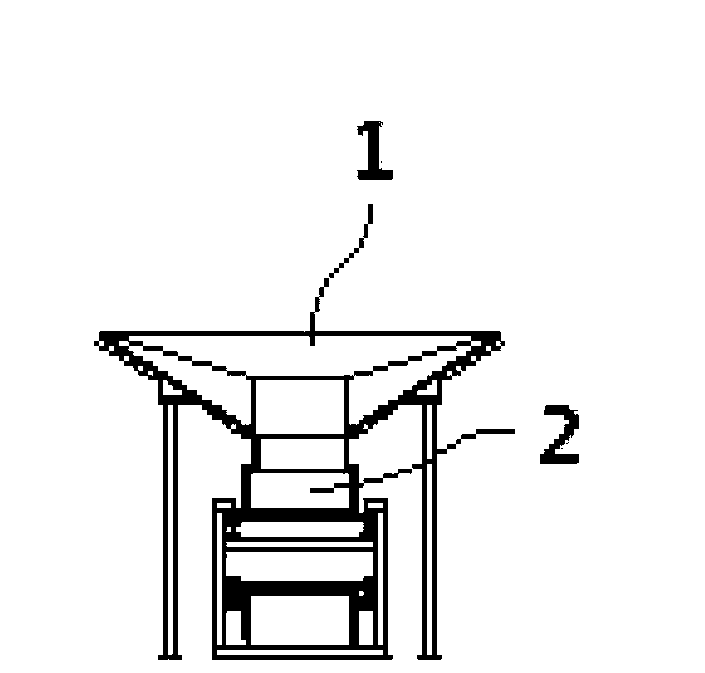

Belt type drier feeding frame

InactiveCN107328228ASmoothly fall intoPrevent fallingDrying solid materialsMechanical engineeringEngineering

Owner:中山市程博工业产品设计有限公司

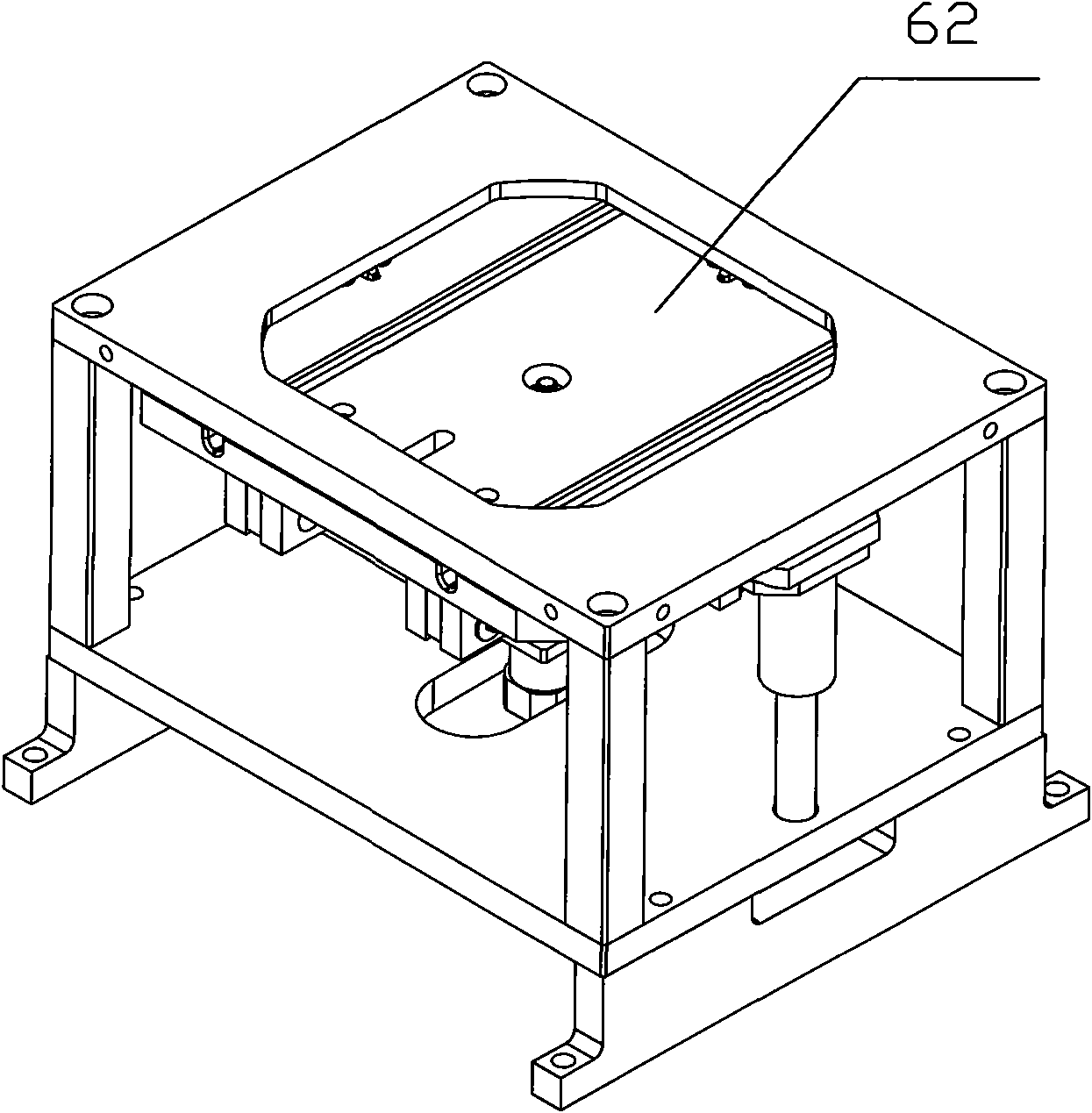

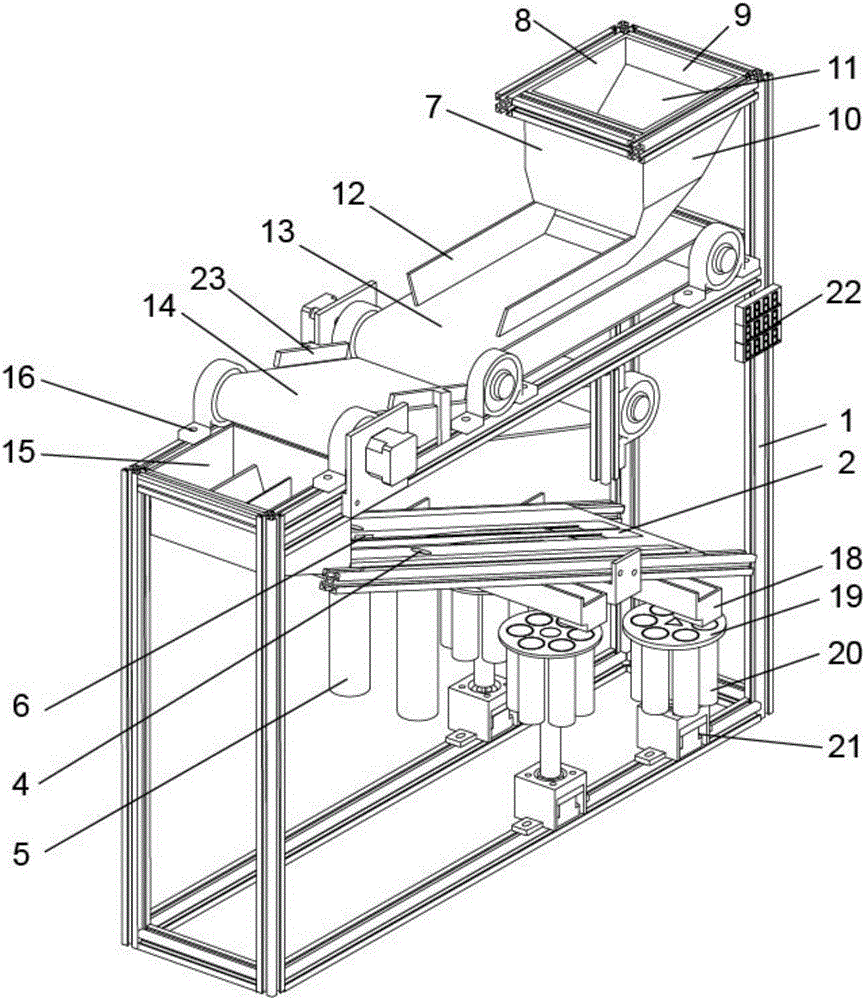

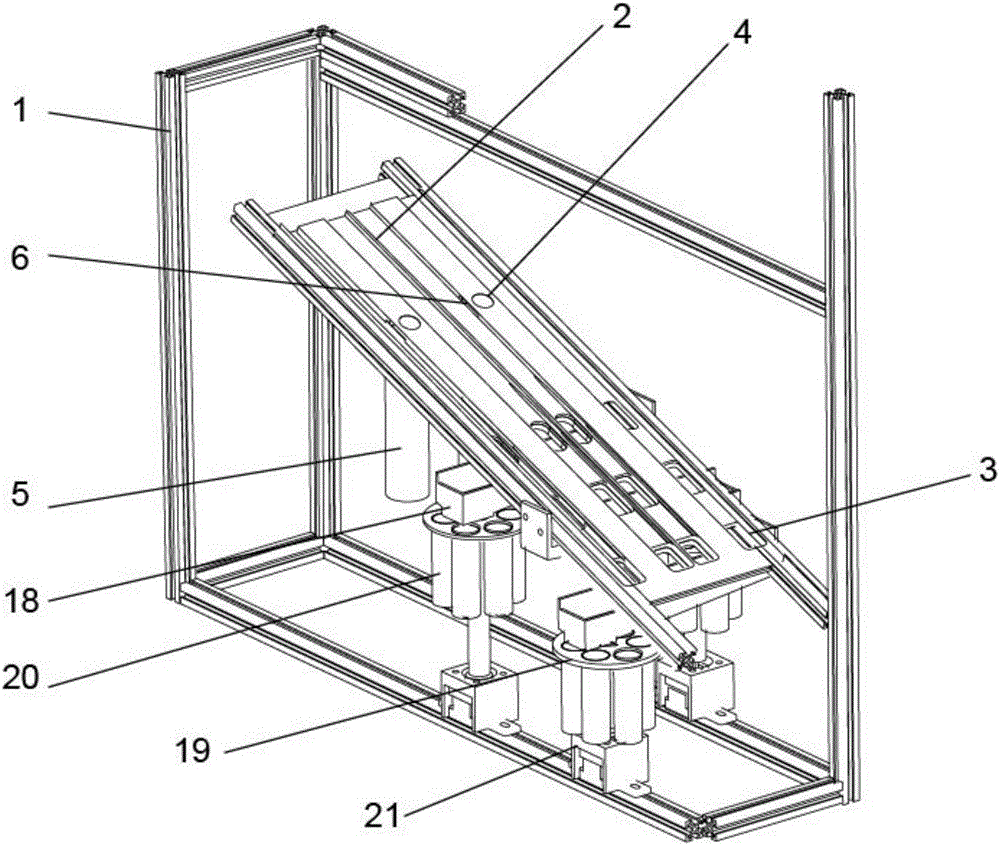

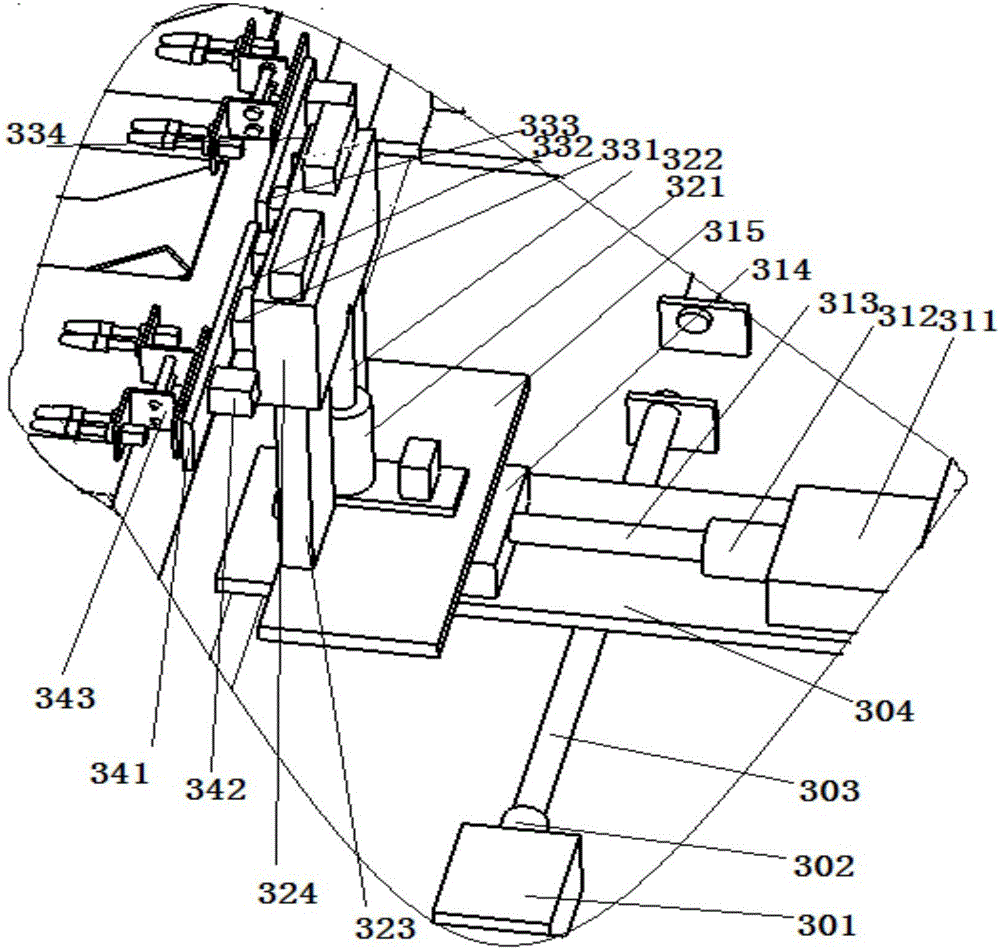

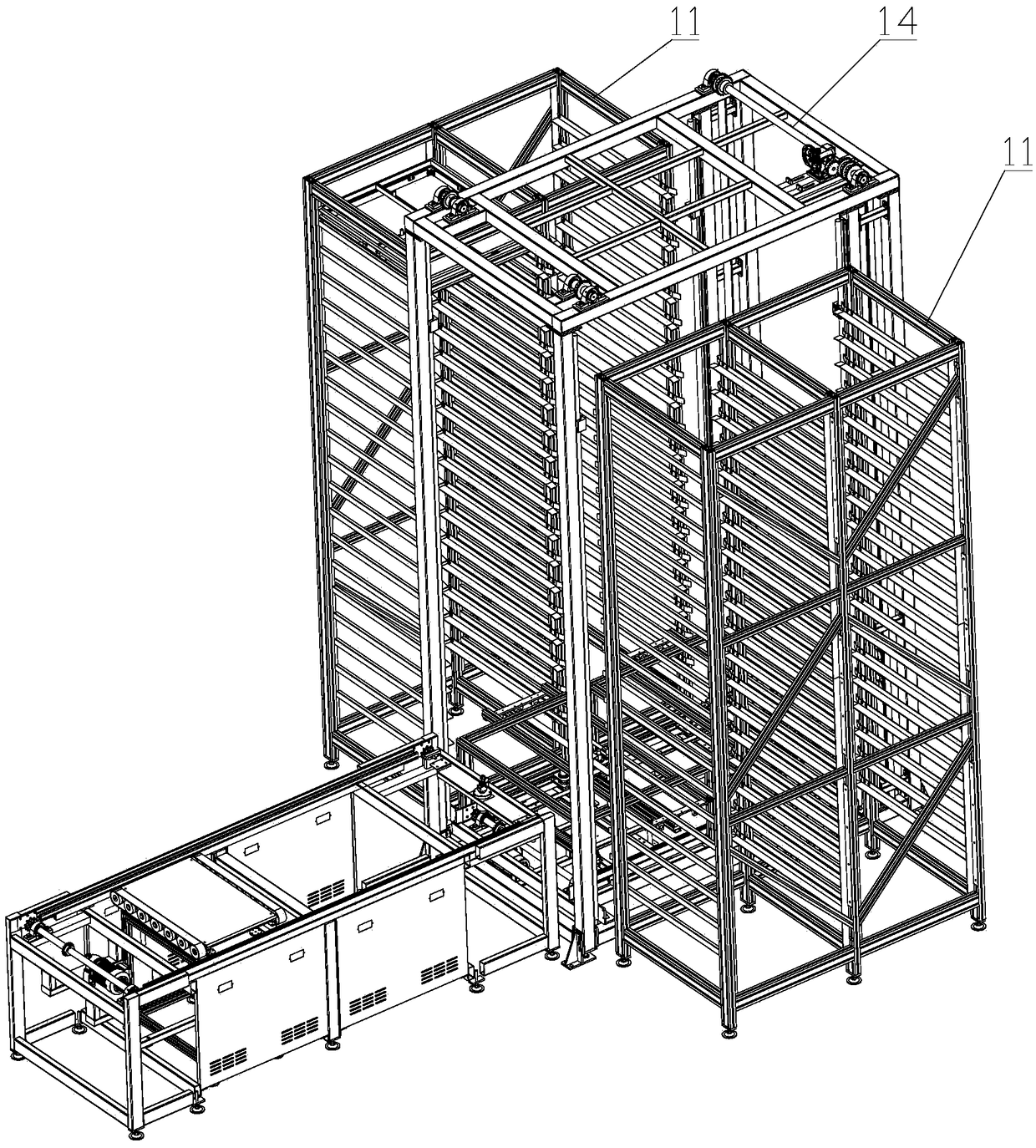

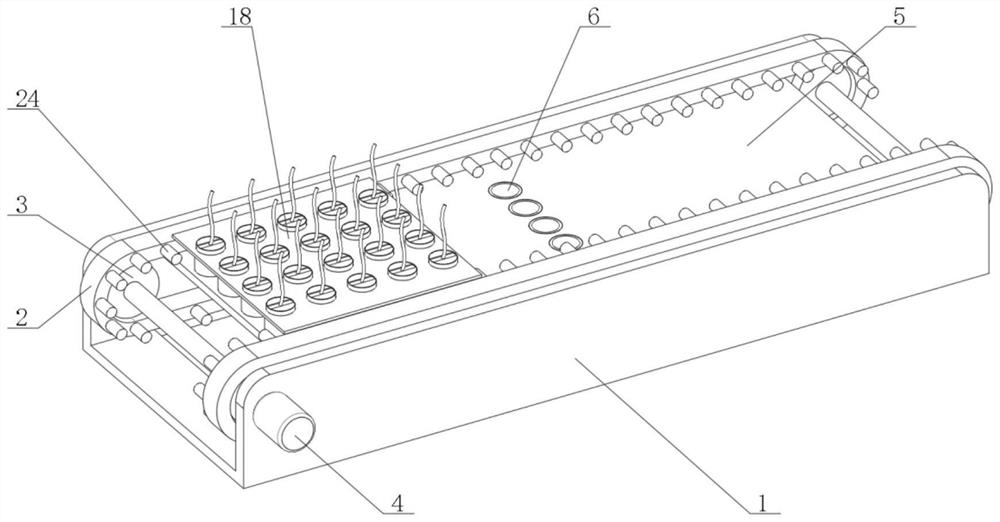

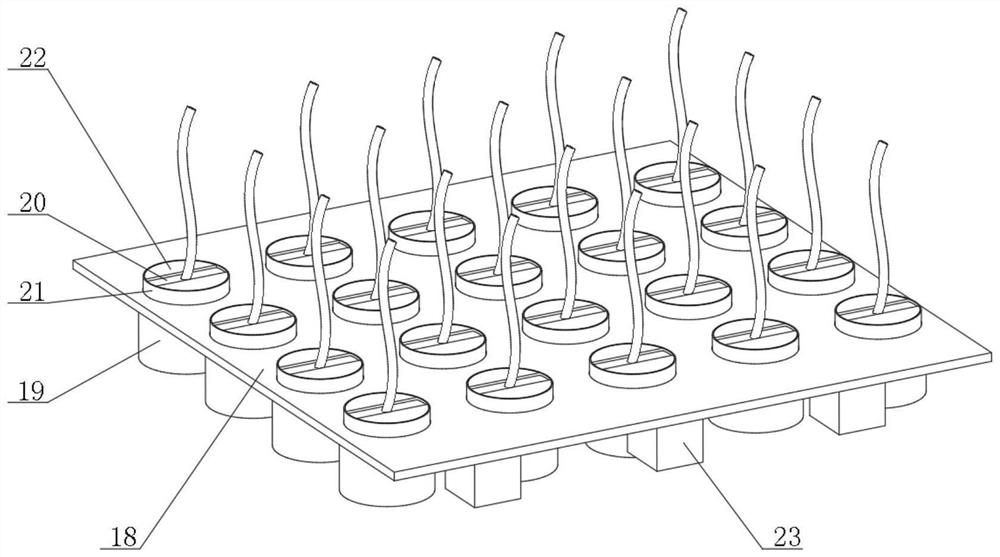

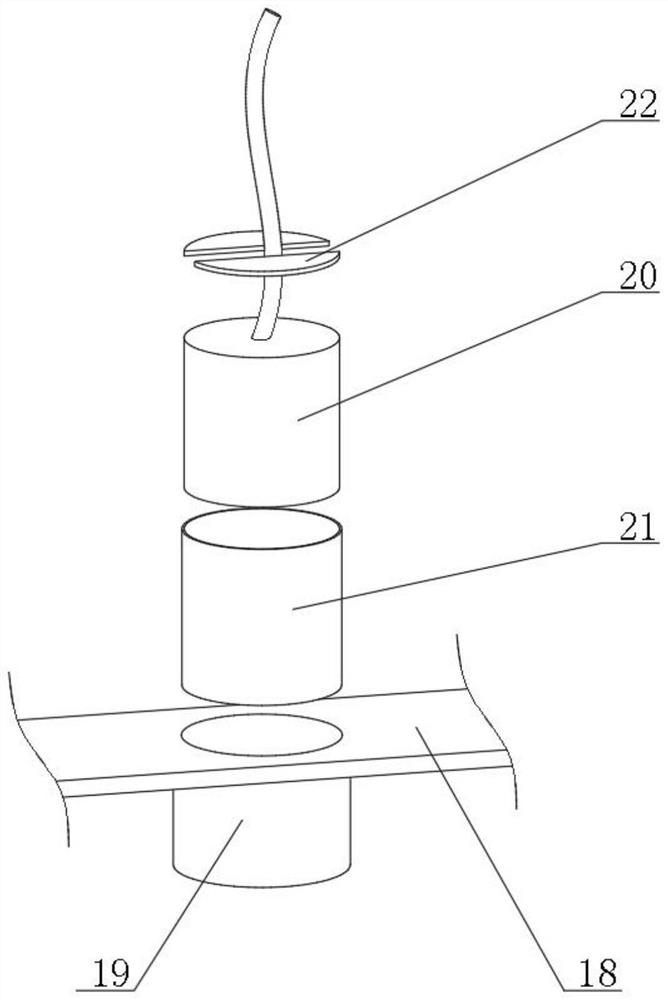

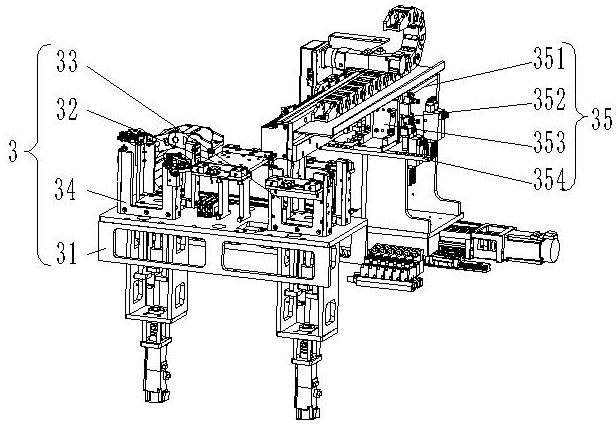

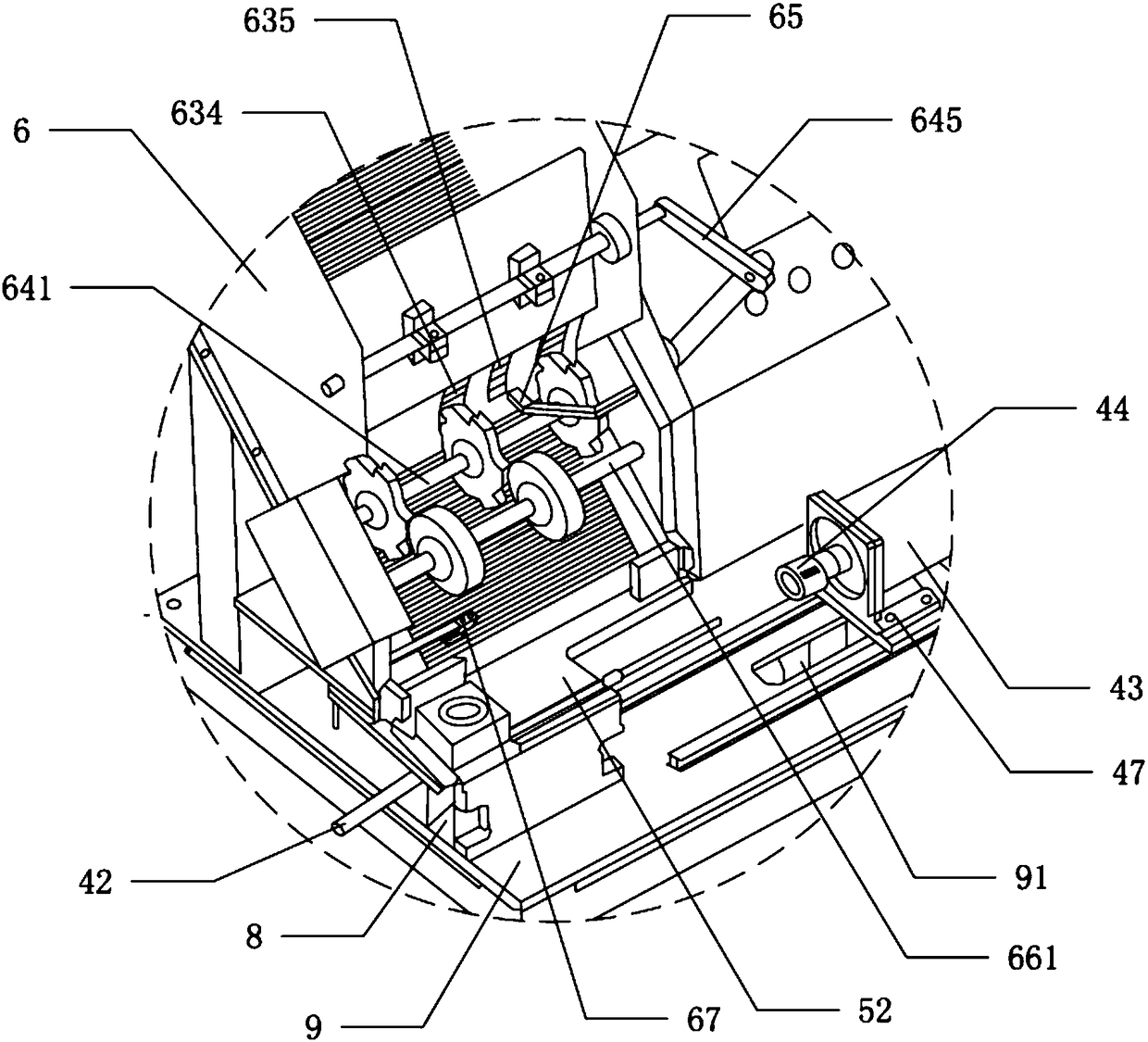

Silkworm culture mechanism assembly

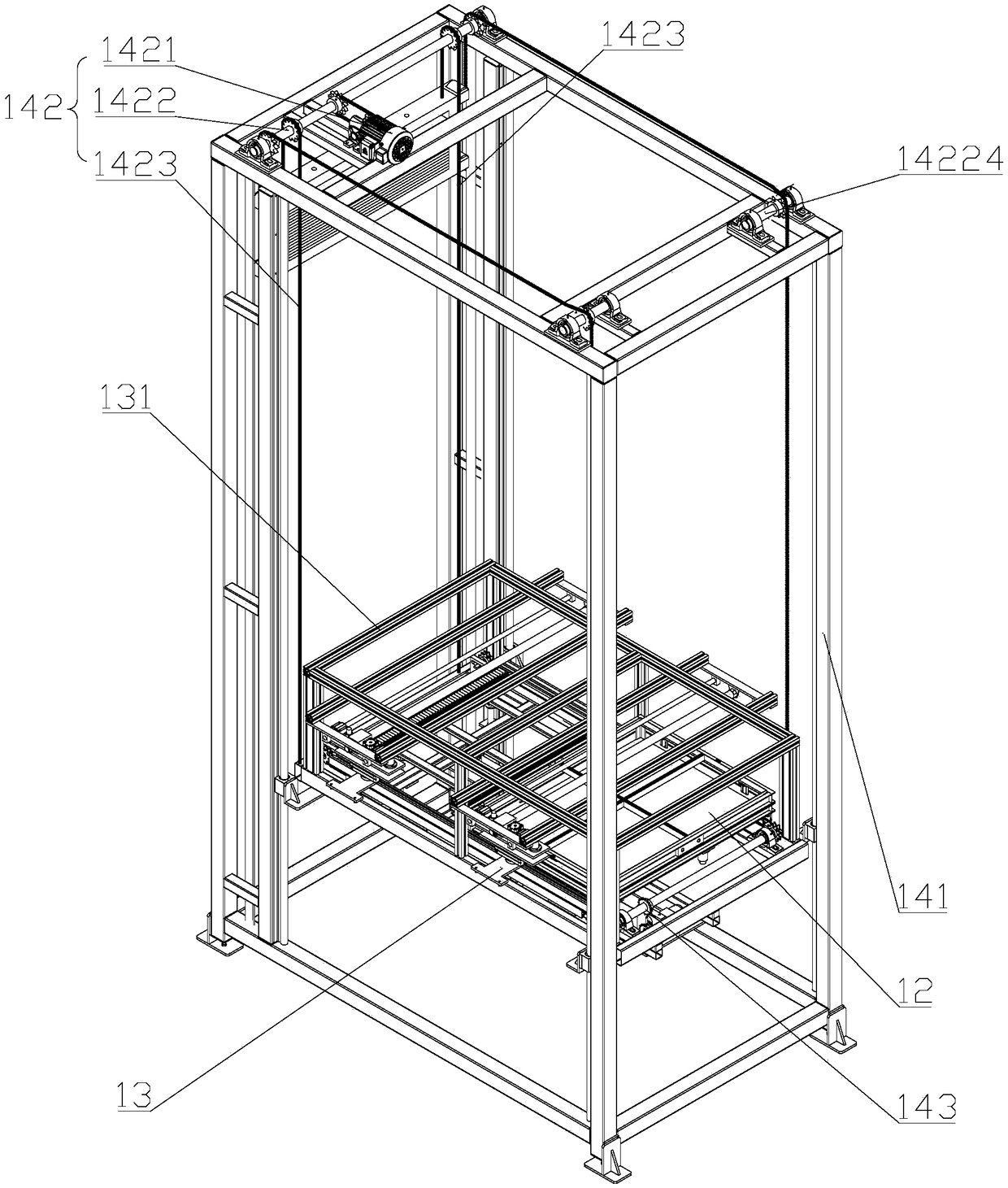

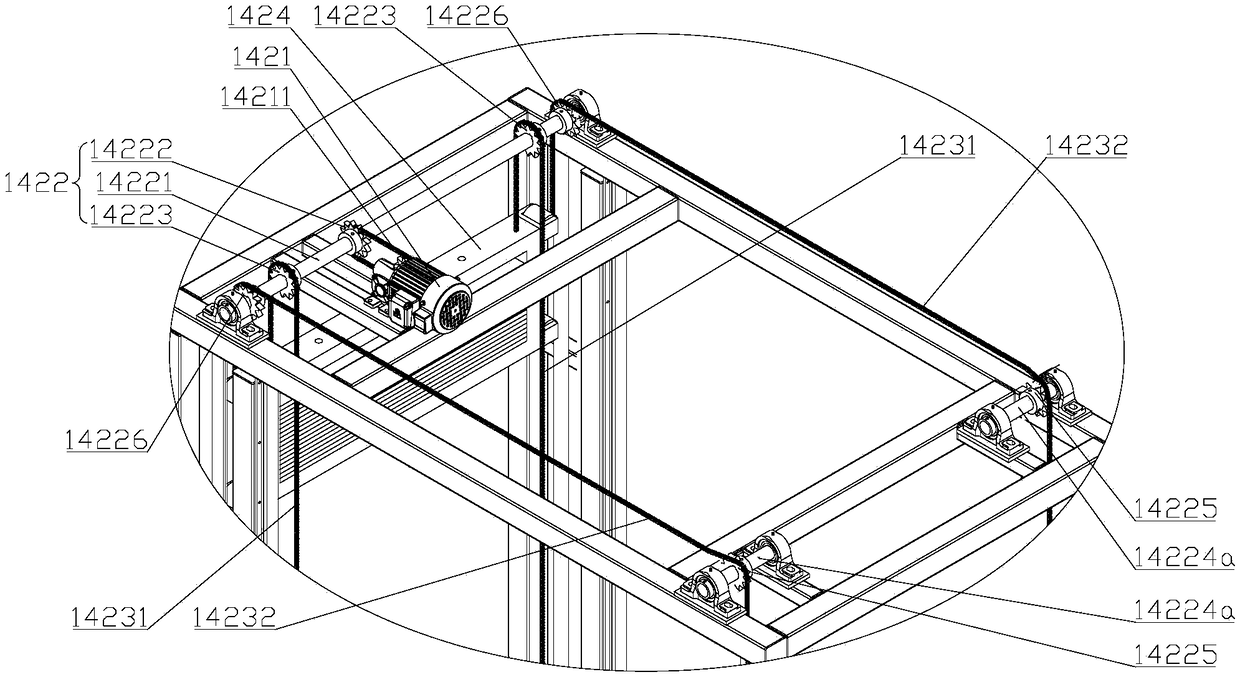

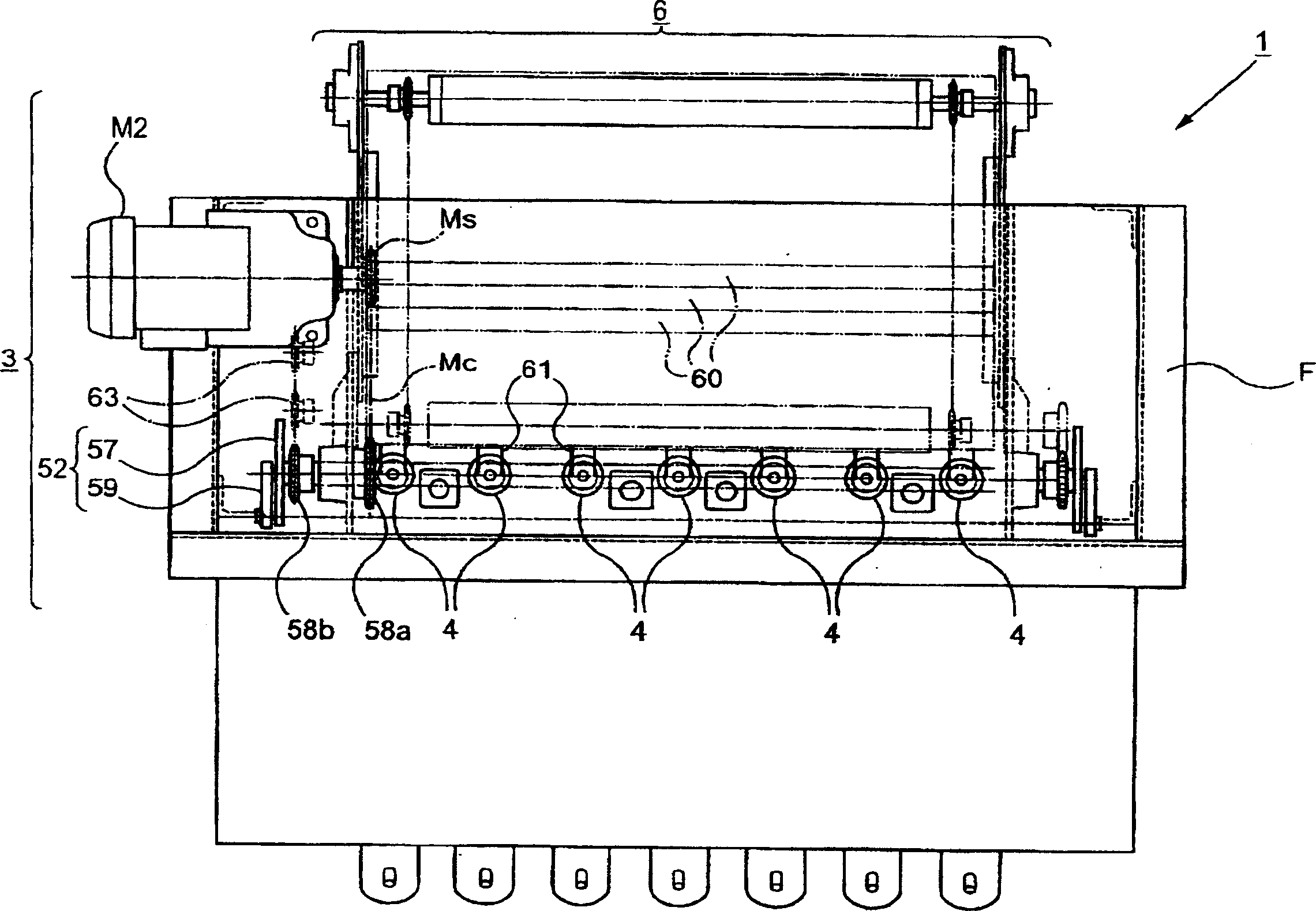

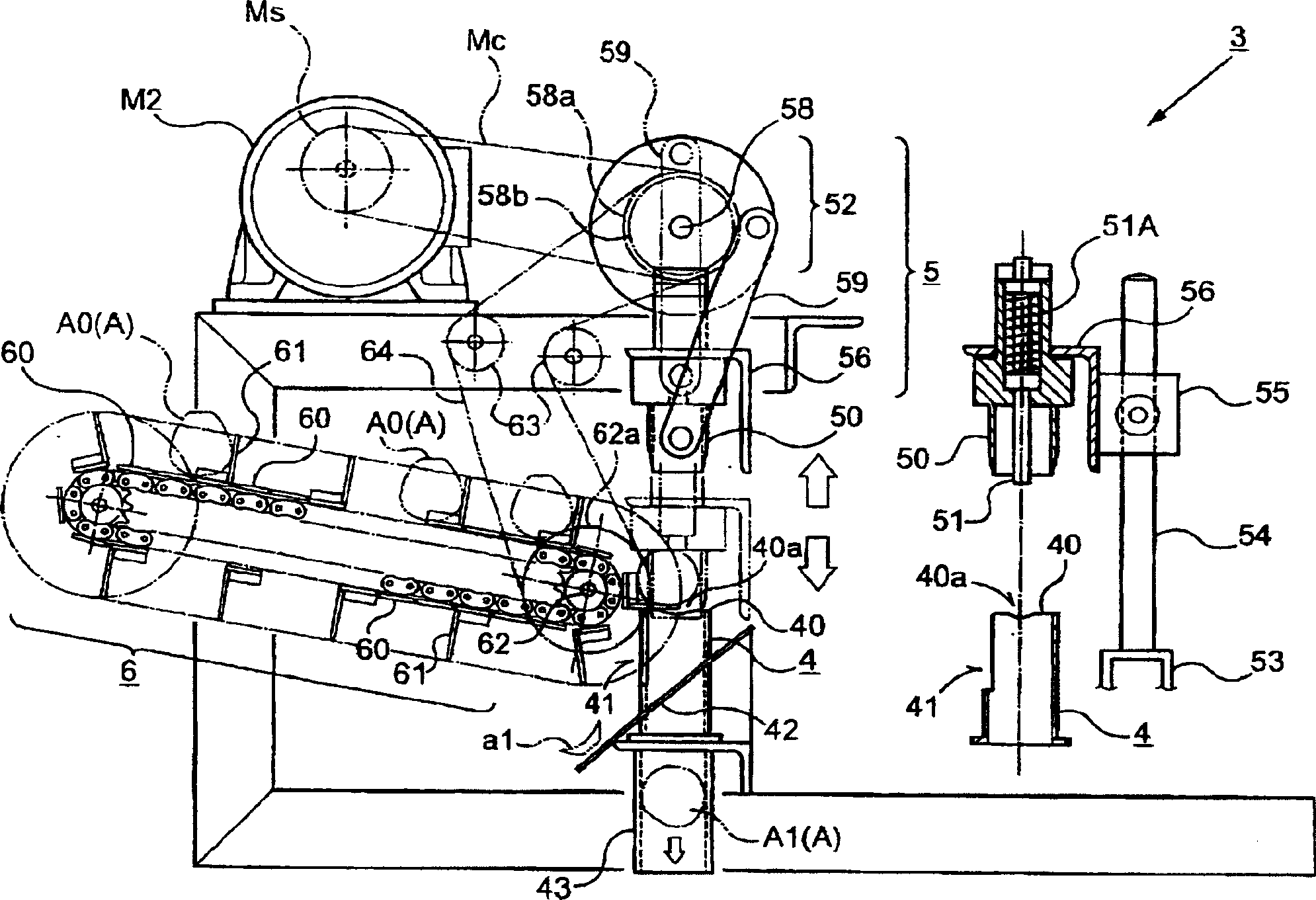

ActiveCN109258582ASave space for silkworm rearingSave spaceAnimal husbandryTransfer procedureEngineering

The invention discloses a silkworm culture mechanism assembly. The assembly comprises a silkworm tray shelf for placing a silkworm culture tray and a silkworm tray transfer mechanism for grabbing andtransferring the silkworm culture tray. The silkworm tray transfer mechanism comprises a transfer frame. The transfer frame is provided with a tool frame capable of moving up and down. A vertical transfer assembly is fixed on the upper portion of the transfer frame, and a lifting chain of the vertical transfer assembly is connected with the tool frame. A silkworm tray grabbing mechanism for grabbing the silkworm culture tray horizontally and transversely and a horizontal transfer assembly for transferring the silkworm culture tray vertically and horizontally are arranged in the tool frame. Thesilkworm tray is placed on the grabbing side of the silkworm tray grabbing mechanism, and the transfer side of the horizontal transfer assembly is provided with a silkworm tray receiving device. Theassembly has the advantage that all the work from silkworm culture to feeding and conveying processes can be achieved; the silkworm tray is placed on the silkworm tray shelf; during mulberry leaf feeding or cocooning, the silkworm tray transfer mechanism sends the silkworm tray to make the silkworm tray smoothly fall into the position of subsequent processing to facilitate subsequent operations.

Owner:重庆京渝瑞基测控仪器仪表制造有限公司

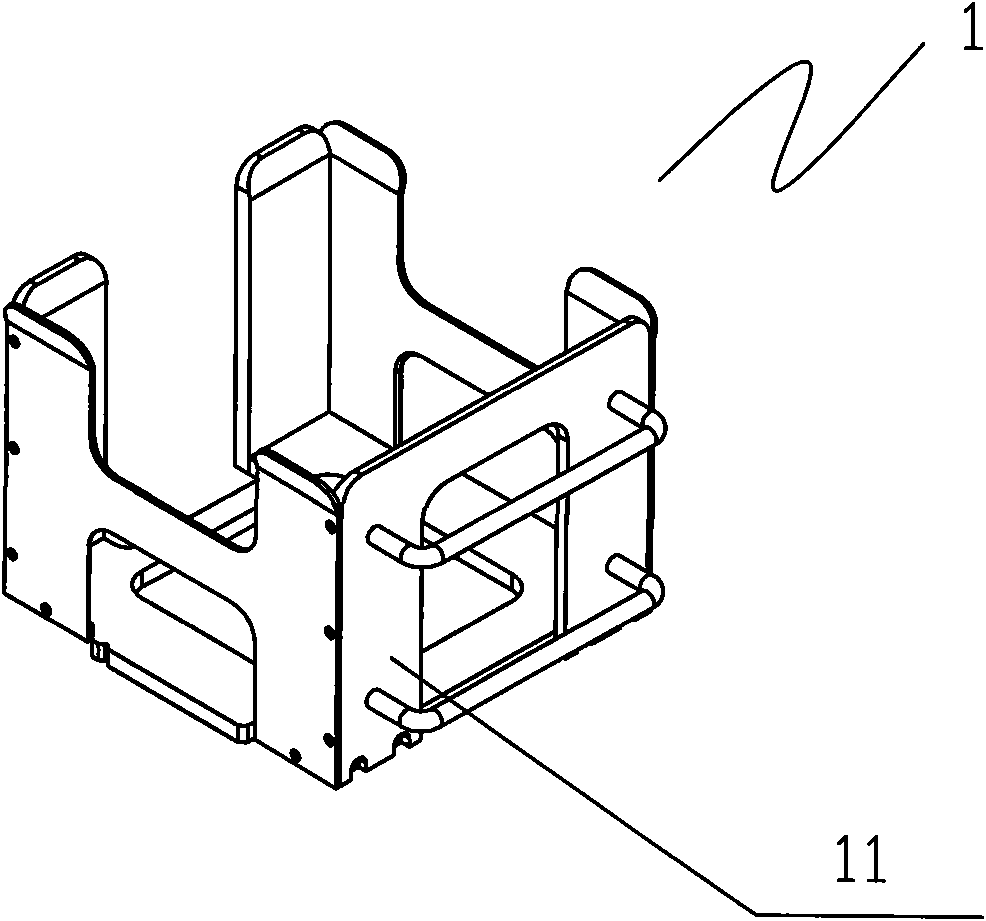

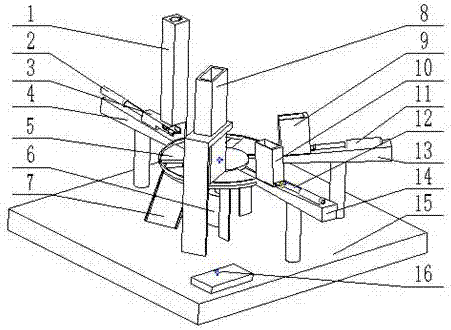

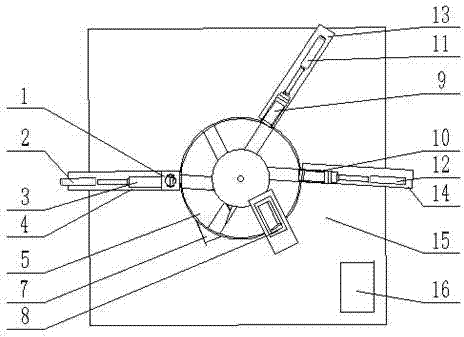

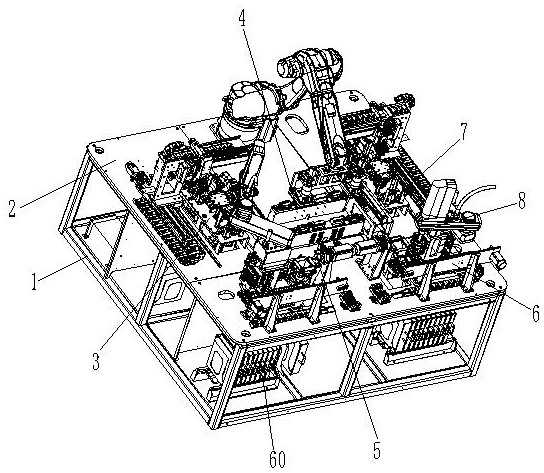

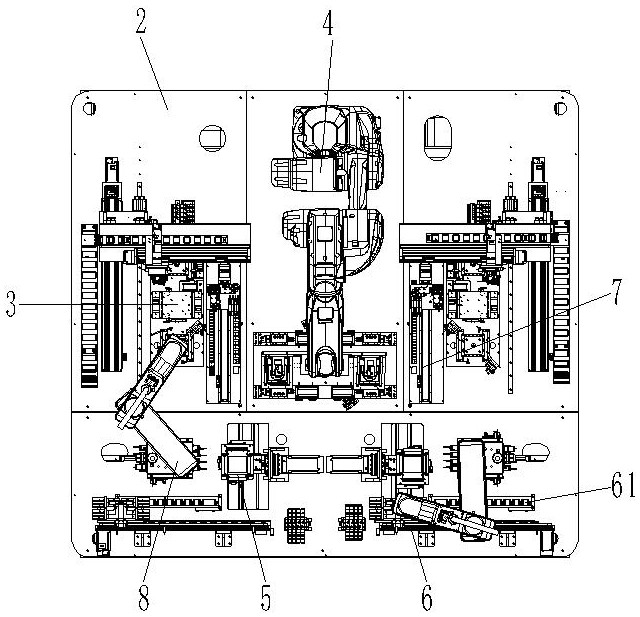

Medical film production clamp automatic assembling robot

InactiveCN107150216ARealize circular supplyDrop bufferMetal working apparatusCylindrical channelEngineering

The invention discloses a medical film production clamp automatic assembling robot, and belongs to the field of medical instruments. The robot is composed of a cylindrical channel, hydraulic cylinders, a push head, inclined bases, a rotating disc set, a stepping motor, a guide-out groove, a base channel, film grooves, a rack and a controller; the controller, the base, the stepping motor and the inclined bases are fixed to the rack, the push head, the hydraulic cylinders, the cylindrical channel and the film grooves are mounted on the inclined bases, the rotating disc set is mounted on the stepping motor and fixed to the rack, the guide-out groove is fixed to the position below the rotating disc set, and the robot is characterized in that the rotating disc set is composed of a rotating disc and a chassis which are coaxially matched, the rotating disc is mounted on the chassis, and parallelogram gaps are formed in the rotating disc, and are connected through a fan-shaped slope. The robot has the beneficial effects that a film production clamp base can be circularly fed through the robot, the slope on the rotating disc enables falling of the base to buffered, and the base can smoothly fall in the gaps.

Owner:柴传程

Walnut seedling transplanting device and method

PendingCN113575204AReduce damageShorten seedling periodCultivating equipmentsForestryEnvironmental geologyElastic plastic material

The invention discloses a walnut seedling transplanting device and method. The walnut seedling transplanting device comprises a seedling raising device and a seedling taking and transplanting device; the seedling raising device comprises a seedling raising support plate, a plurality of through holes are distributed in the seedling raising support plate in a rectangular shape, the bottom end of the seedling raising support plate is fixedly connected with a plurality of seedling raising cylinders corresponding to the through holes, the bottom of each seedling raising cylinder is detachably connected with a flat plate, and the inner wall of each seedling raising cylinder and the upper surface of the corresponding flat plate form a seedling raising hole; the seedling taking and transplanting device comprises a seedling conveying assembly and a seedling taking assembly, the seedling raising cylinders are made of an elastic plastic material, seedling raising bags are arranged in the seedling raising holes, and plug seedlings are placed in the seedling raising bags; the seedling taking assembly comprises a fixing plate, and a plurality of seedling guiding pipes corresponding to the seedling raising cylinders are slidably connected to the fixing plate in the vertical direction. According to the walnut seedling transplanting device, non-contact seedling taking can be completed, a mechanical arm does not need to be used for pushing and clamping plug seedling pots and seedlings, damage to the plug seedlings is small, and the seedling recovering period after the plug seedlings are transplanted can be effectively shortened.

Owner:濮阳市林业科学院

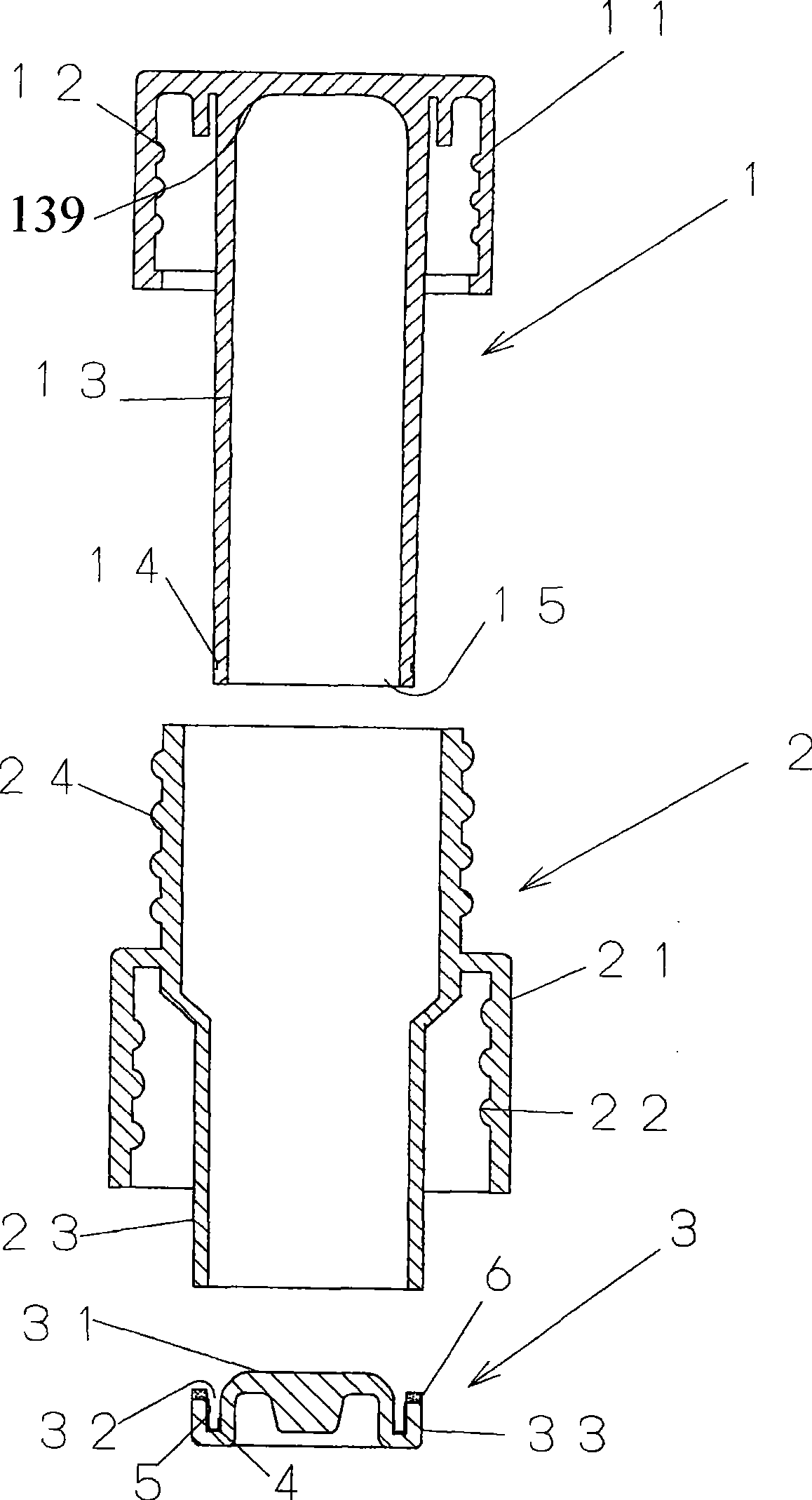

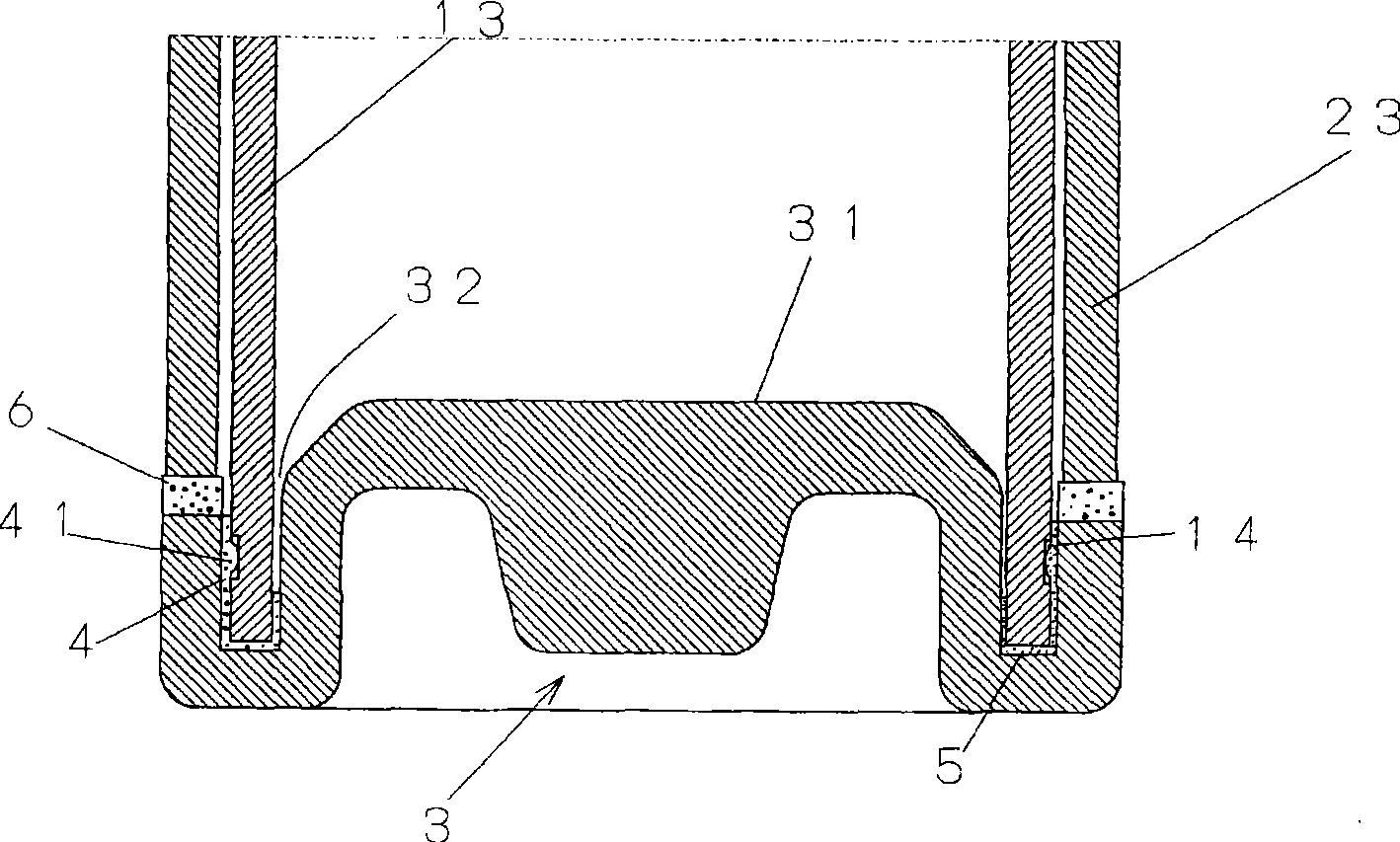

Bottle cap for storing raw material

InactiveCN101391679ANot corrodedAvoid enteringClosure with auxillary devicesContainers with multiple articlesPulp and paper industryBottle cap

The invention discloses a material-containing type bottle cap which comprises a lower cap arranged on the bottle opening and an upper cap arranged on the upper part of the lower cap. The bottle cap is characterized in that a material-containing cylinder and the upper cap of a switching cap used for sealing an opening lower end of the material-containing cylinder are provided; the lower cap communicating with a guiding cylinder of the material-containing cylinder is provided; the switching cap forming an annular embedding slot between an outer wall and the inner side of the outer wall is provided; the lower end of the material-containing cylinder is embedded into the embedding slot so as to lead the switching cap to seal the material-containing cylinder; when the upper cap is opened the material-containing cylinder moves upwards and then the lower end of the guiding cylinder presses the upper end of the outer wall of the switching cap so as to lead the switching cap to break away from the lower end of the material-containing cylinder, and then the material in the material-containing cylinder falls into the liquid inside the bottle; the bottom of the embedding slot of the switching cap is covered by a bottom pad; when the upper cap is opened, the upper end of the outer wall of the switching cap is covered by the pad with adequate thickness in the clearance between the lower end of the guiding cylinder and the upper end of the outer wall of the switching cap.

Owner:臧海平

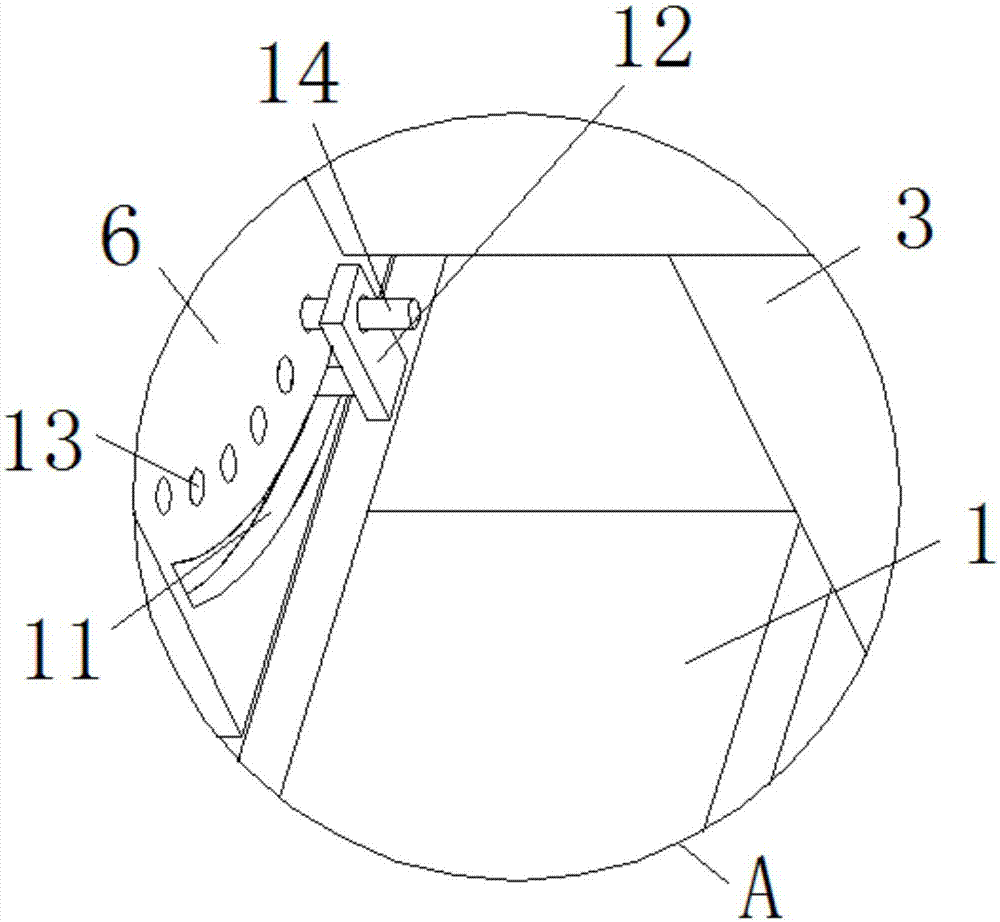

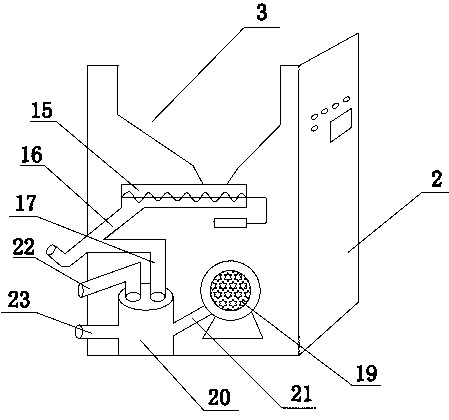

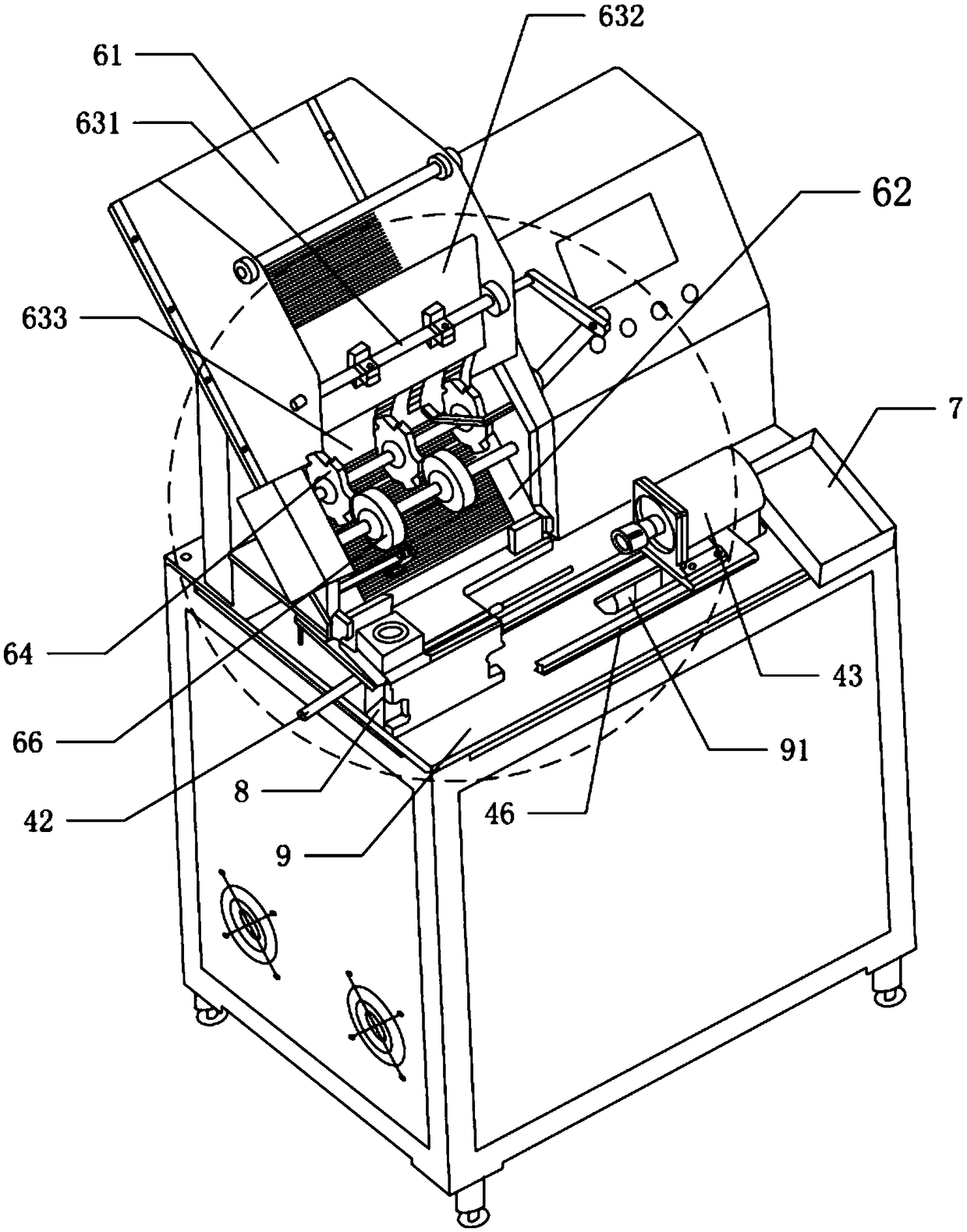

Method and device for shaping foodstuffs and the like, and shaped product

InactiveCN1642699AReasonable designGuaranteed work efficiencyArm restsStoolsEngineeringSurface shape

A method for shaping foodstuffs and the like, which improves operating efficiency and economic efficiency when a foodstuff, such as taro, is to be shaped spherical; and a device therefor. A shaping procedure using a cutter blade (15) applied to a process subject article (A) to shape the surface of the subject process article (A), wherein the subject process article (A) and the cuter blade (15) are relatively moved and the subject process article (A) can be held in a floating state when it is subjected to the cutter blade (15). Since the subject process article (A) is maintained in a floating state, as soon as the process subject article (A) comes into contact with the cutter blade (15) to have its surface cut, a floating state or a rotative state is imparted to the subject process article (A) to some extent by the cutter blade (15), and such state is continued, whereby the surface is thoroughly cut spherical or the like.

Owner:HIRAGAKI

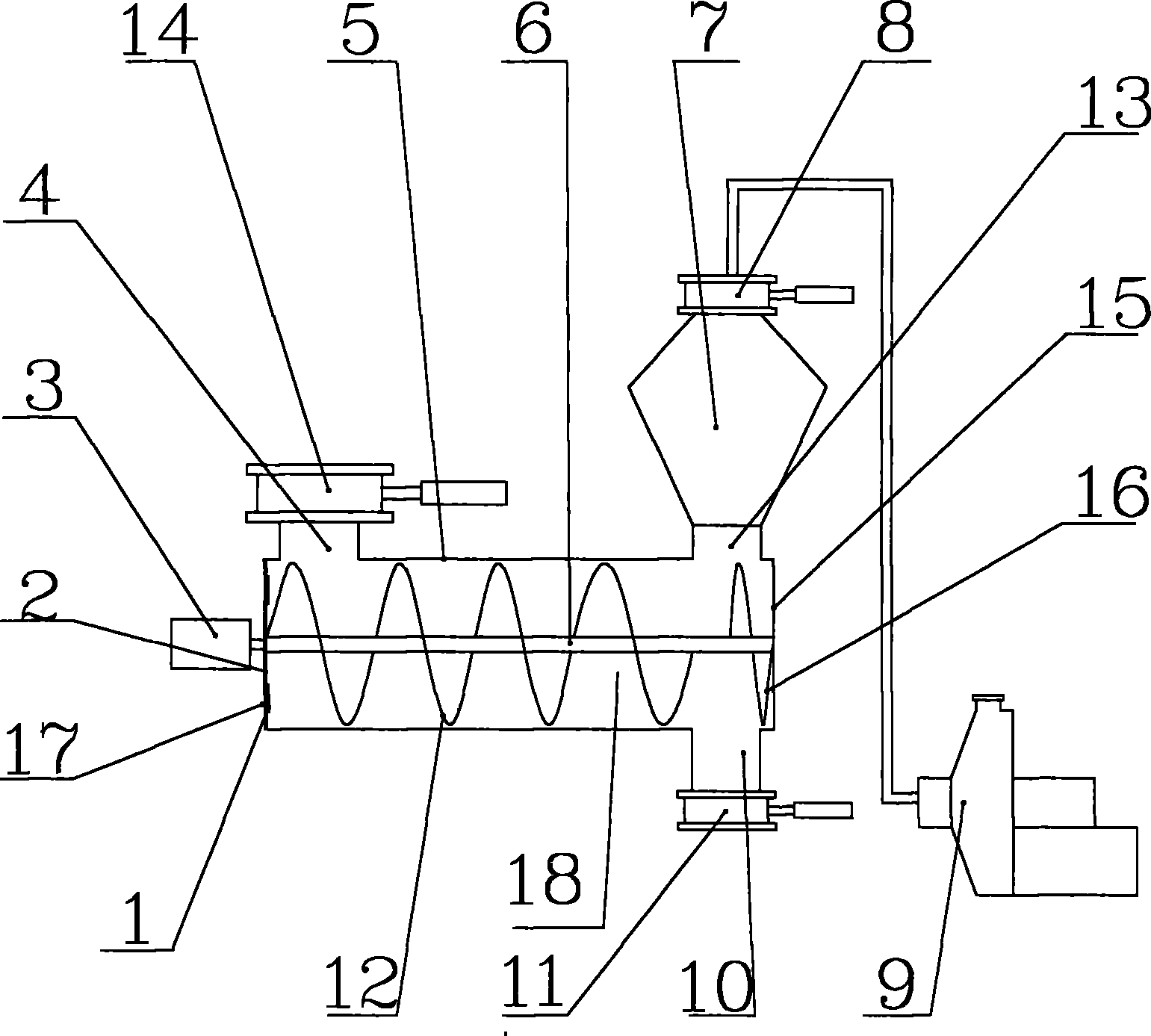

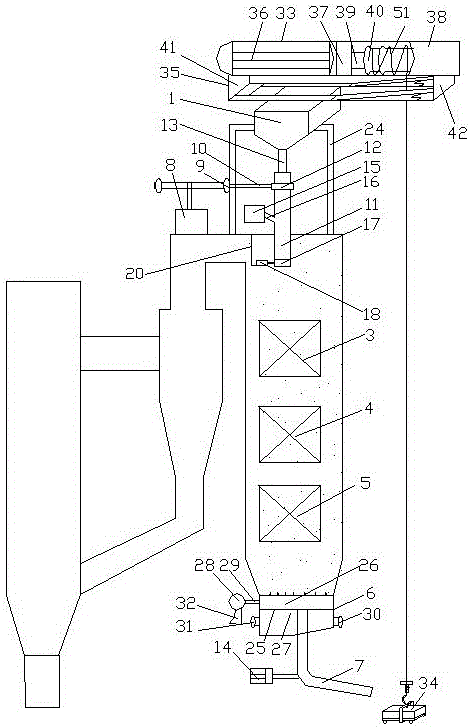

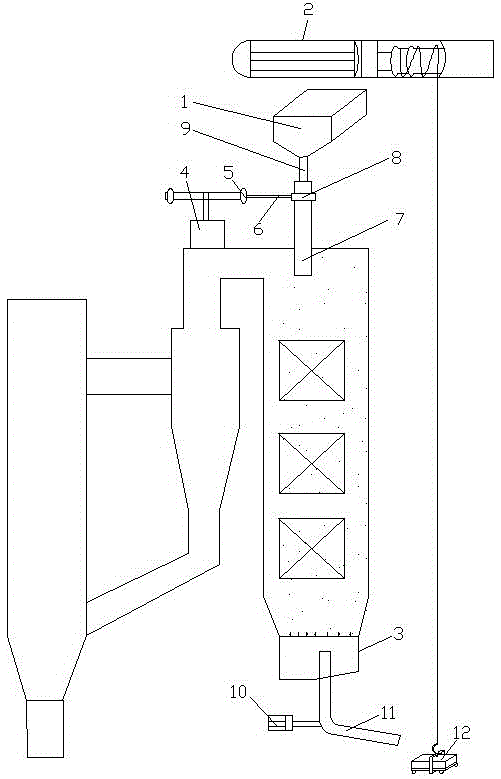

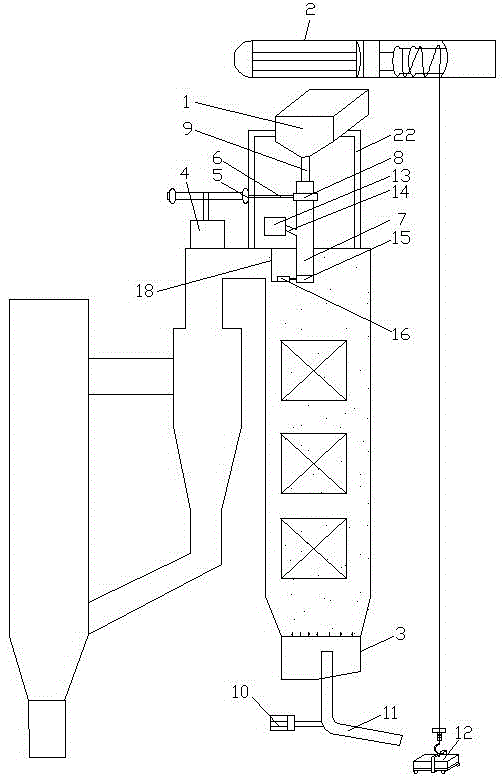

Circular ash removing method suitable for fluidized bed boiler

ActiveCN105737143AEffective flushingAvoid damageFluidized bed combustionSolid removalSand blastingFluidized bed

The invention discloses a circular ash removing method suitable for a fluidized bed boiler, and belongs to the technical field of ash removal of boiler equipment. The circular ash removing method suitable for the fluidized bed boiler comprises a sand loading step and a recycling step, and is characterized in that in the sand loading step, sand is loaded in a sand hopper of a circular sand ash blower; in a sand blasting step, the sand in the sand hopper is placed in a sandblast, and is sprayed in a shaft at the tail by the sandblast; in the recycling step, after scouring a superheater, an economizer and an air pre-heater, the sand sprayed in the shaft at the tail flows into a fluidized bed of the circular sand ash blower, and is recycled via an auger connected to the fluidized bed; and in a sand lifting step, the sand recycled by the auger is elevated and moves to a position above the sand hopper through an electric hoist, and is discharged into the sand hopper through a sand discharging trolley to form a circular ash removal cycle. By the circular ash removing method suitable for the fluidized bed boiler, the sand can be circularly used to remove ash on a heat exchange component in the shaft at the tail, the heat exchange efficiency is improved, and boiler steam rate is increased. The circular ash removing method suitable for the fluidized bed boiler has the features of low energy consumption and good ash removal effect.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

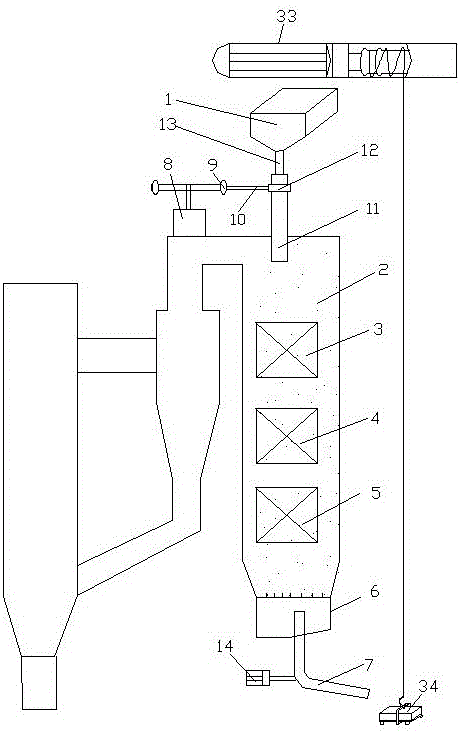

Circulating sand dust blowing device

ActiveCN105570913AImprove heat transfer efficiencyEfficient removalSolid removalFluidized bedEngineering

The invention discloses a circulating sand dust blowing device, and belongs to the technical field of boiler dust removing equipment. The circulating sand dust blowing device comprises a sand hopper and an electric hoist connected to a boiler top. The circulating sand dust blowing device is characterized in that a sand blower connected to the top of a tail vertical well and a fluidized bed connected to the bottom of the tail vertical well are further included; the sand blower comprises a speed regulation motor, a belt wheel, a transmission belt, a sand blowing pipe and a bearing connected to the sand blowing pipe; the sand hopper is connected with the sand blowing pipe through a sand inlet pipe; a motor shaft of the speed regulation motor is in transmission connection with the belt wheel; the belt wheel is in transmission connection with the bearing through the transmission belt; the sand blowing pipe communicates with the tail vertical well; a packaging auger driven through a motor is connected to the fluidized bed; and a sand discharge trolley is connected to the electric hoist. According to the circulating sand dust blowing device, dust on a heat exchange component in the tail vertical well can be effectively removed, heat exchange efficiency is improved, and the circulating sand dust blowing device has the beneficial effects of being low in energy consumption, good in dust blowing effect and high in use safety.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Energy-saving boiler

ActiveCN103267349AImprove burnout rateHigh thermal efficiencyWater heatersThermal energyBoiler furnace

The invention discloses an energy-saving boiler, and belongs to the technical field of boilers. The energy-saving boiler comprises a feeding blower device and a heating device. The heating device comprises a heating furnace and a pre-heating furnace. The feeding blower device comprises a feeding hinged wheel and a blower system, wherein the feeding hinged wheel is used with a stock bin in a matched mode. A discharging pipe is placed at one end of the feeding hinged wheel, and a fuel blast pipe is arranged on the discharging pipe which is connected with a fuel inlet in a matching mode. A water inlet is formed in the lower portion of a pre-heating furnace body and is communicated with a cold water sleeve. Fuel can be fully mixed with oxygen before entering a boiler furnace through the arrangement of a material feeding device, and the burn-off rate of the fuel is improved. Cold water is heated in advance through the pre-heating furnace body, the reserved time of exhausted gas is prolonged, thermal conversion efficiency is improved, resources are saved, and heating time is shortened. A smoke journey is lengthened through heating pipes which are connected in series, the thermal energy is fully absorbed by the water, and the circulation of the water in the boiler water sleeve is accelerated. Meanwhile, enough time is reserved for the ash in smoke to fall down into an ash discharging chamber, air pollution is reduced, energy is saved, and environment is protected.

Owner:ZHEJIANG DONGDU ENERGY SAVING TECH

Discharging device and discharging method

PendingCN109677903ANo stackingEasy to operateConveyor partsSmall footprintElectrical and Electronics engineering

Owner:远大可建科技有限公司

A battery pack impact test device

ActiveCN106323577BEffective fire extinguishing treatmentInsulate the airShock testingElectrical batteryPower apparatus

The present invention relates to an impact testing device for a battery pack. The device comprises a collision barrier used for placing the battery pack, a movable sliding table with an impact head, a hydraulic power device used for pushing the movable sliding table to slide, and a monitoring device in communication connection with a sensor inside the battery pack. The movable sliding table is positioned between the hydraulic power device and the collision barrier. The impact head of the movable sliding table is oriented towards a support assembly for placing the battery pack and positioned on the side surface of the collision barrier. The monitoring device controls the starting and the stopping of the hydraulic power device. The device further comprises a solution tank positioned right below the support assembly and used for the fire extinguishing of the battery pack. The monitoring device also controls the support assembly to release the battery pack so as to enable the battery pack to fall into the solution tank. According to the technical scheme of the invention, the fire extinguishing problem of the battery pack during the impact test in the prior art can be solved.

Owner:深蓝汽车科技有限公司

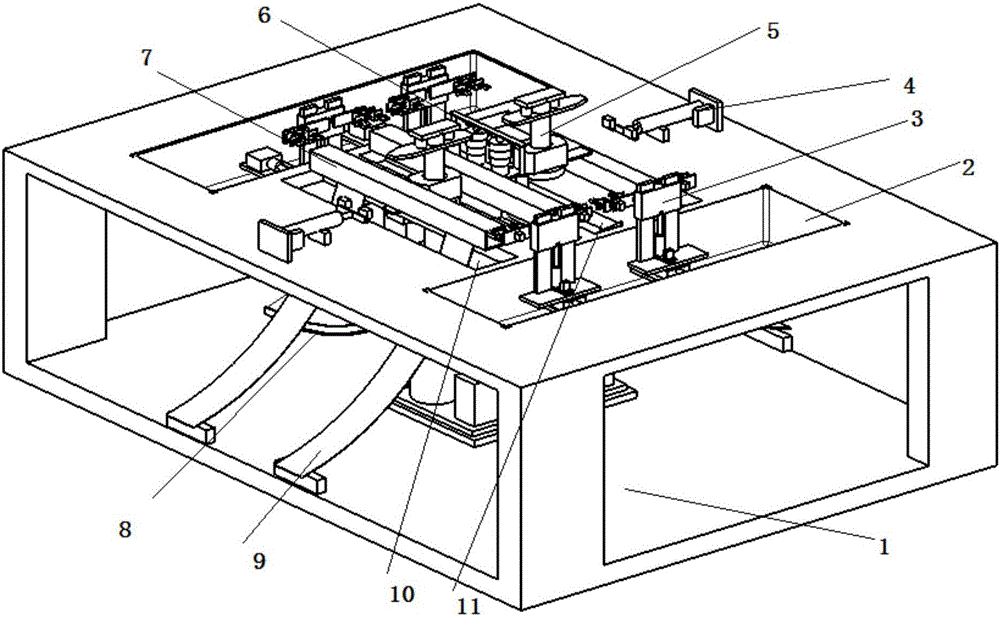

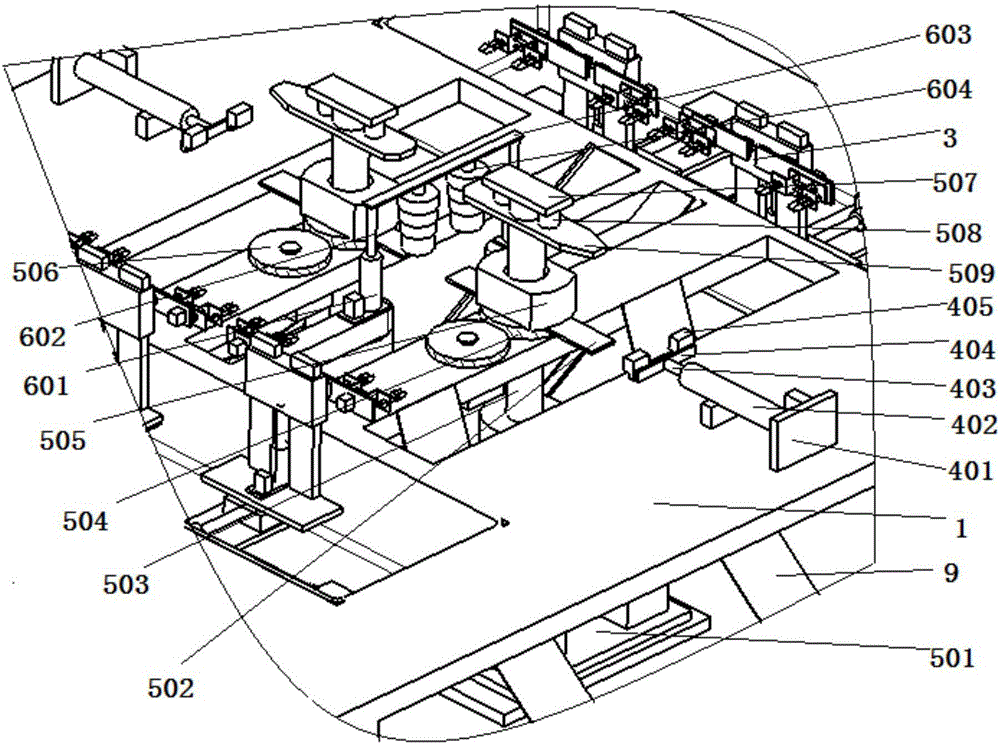

Mobile phone internal support plate appearance visual inspection device

ActiveCN113252696AComprehensive and precise shootingComprehensive and accurate detectionOptically investigating flaws/contaminationSortingVisual inspectionMechanical engineering

The invention relates to a mobile phone internal support plate appearance visual inspection device which is provided with a rack and a working platform, the working platform is provided with a feeding station, a detection station, a carrying station and a discharging station, the feeding station is provided with two feeding mechanisms which are oppositely arranged, the detection station is provided with a first detection mechanism and two oppositely-arranged second detection mechanisms, the carrying station is provided with two oppositely-arranged carrying mechanisms, the discharging station is provided with two oppositely-arranged discharging mechanisms, and the feeding mechanisms are in one-to-one correspondence with the carrying mechanisms and the discharging mechanisms; and the support plates on all the feeding mechanisms are transferred to the first detection mechanisms through the corresponding carrying mechanisms, the support plates are transferred to the corresponding second detection mechanisms through the corresponding carrying mechanisms to be detected after detection is completed, and the support plates are carried to the corresponding discharging mechanisms to be distributed and discharged after detection is completed. The device can realize comprehensive, rapid and accurate detection of the support plate, and is efficient and practical.

Owner:CHANGZHOU MICROINTELLIGENCE CO LTD

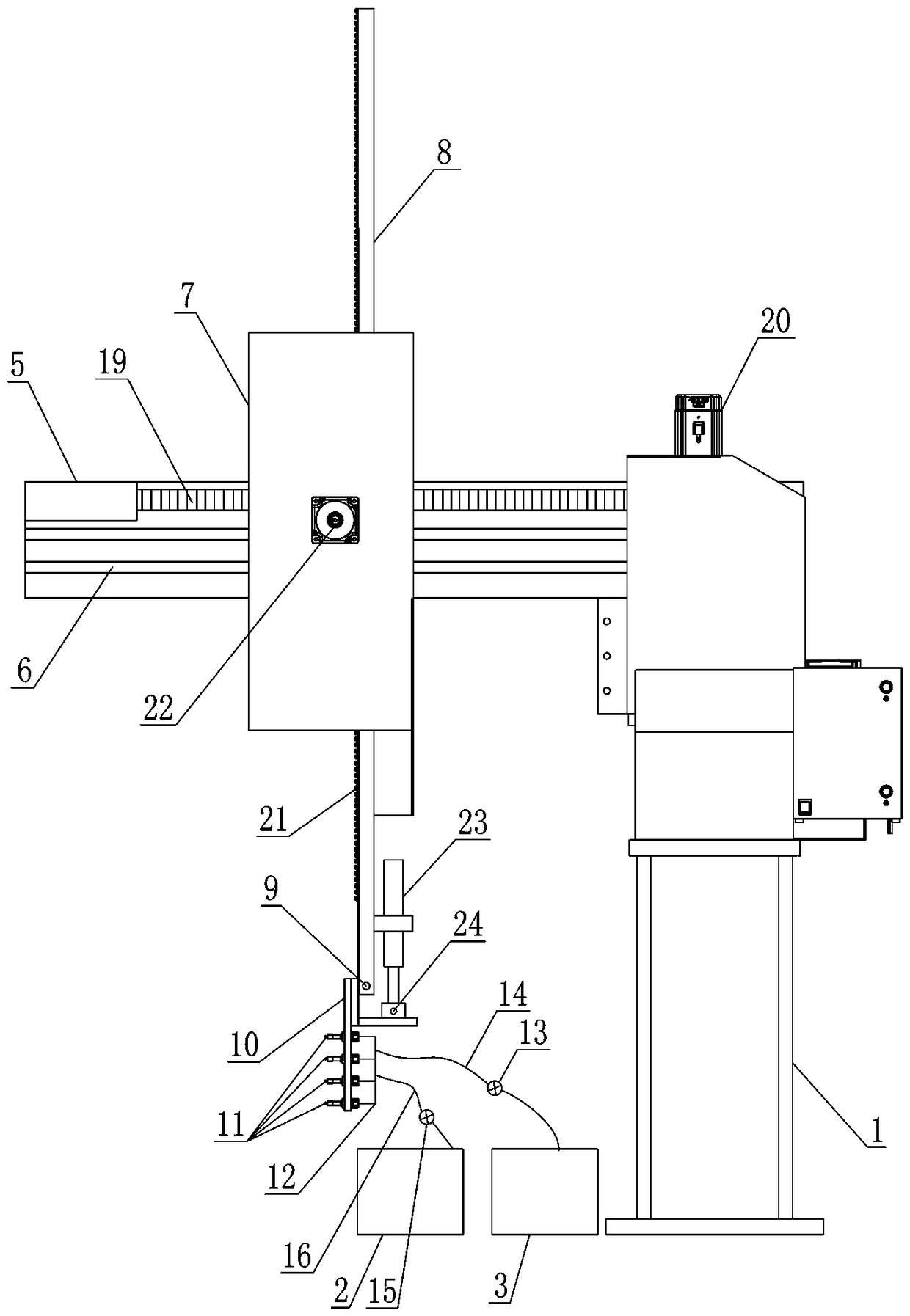

Automatic material taking device of injection molding machine

The invention discloses an automatic material taking device of an injection molding machine. The automatic material taking device comprises a machine frame, a negative pressure air source and a positive pressure air source, wherein a first guide rail set is arranged in the machine frame, a first movable frame driven by a first driving mechanism to move is arranged on the first guide rail set, anda second guide rail set is arranged on the first movable frame; a second movable frame driven by a second driving mechanism to move is arranged on the second guide rail set in a sliding mode, a vertical guide rail set is arranged on the second movable frame, and a longitudinal movable frame driven by a third driving mechanism to move is arranged on the vertical guide rail set in a sliding mode; anoverturning frame is hinged to the bottom of the longitudinal movable frame through a rotating shaft, and the overturning frame is driven by a fourth driving mechanism to overturn around the rotatingshaft; and a plurality of nozzles corresponding to material bags on a material distribution frame are arranged on the overturning frame, all the nozzles communicate with a main air pipe, and the mainair pipe communicates with the positive pressure air source through an air blowing air pipe with an air blowing valve, and meanwhile communicates with the negative pressure air source through an airsuction air pipe with an air suction valve. The automatic material taking device of an injection molding machine has the advantages of being high in production efficiency and low in labor intensity ofworkers.

Owner:江苏顺航电子科技有限公司

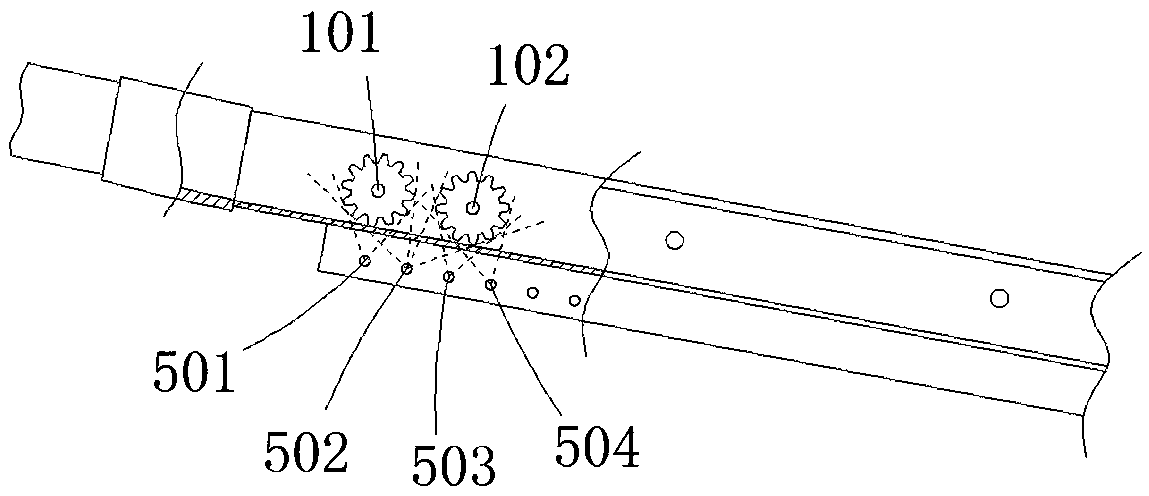

Automatic chopstick detachment machine

ActiveCN108772682AHigh speedNo human intervention requiredMetal working apparatusEngineeringTransfer mechanism

The invention discloses an automatic chopstick detachment machine. The automatic chopstick detachment machine comprises a feeding mechanism, a transfer mechanism and a chopstick detachment assembly, wherein combined chopsticks are placed in the feeding mechanism; the feeding mechanism is used for providing the combined chopsticks; the transfer mechanism is used for transferring the combined chopsticks discharged by the feeding mechanism to the space of the chopstick detachment assembly; and the chopstick detachment assembly is used for detaching bamboo parts from the combined chopsticks. Withthe adoption of automatic chopstick detachment equipment, the chopstick detachment speed is increased, and the amount of wastes generated in a chopstick detachment process is reduced; and a chopstickdetachment procedure can further be better matched with upstream automatic production equipment and downstream automatic production equipment, so that production control is facilitated.

Owner:成都中箸筷业有限公司

Appearance screening and cleaning integrated device for gears and work method of appearance screening and cleaning integrated device

InactiveCN108465650ASimple structureImprove work efficiencyDrying gas arrangementsCleaning using liquidsFace detectionChain structure

An appearance screening and cleaning integrated device for gears comprises a detection channel which is obliquely arranged, and a conveying chain structure which is vertically arranged. The detectionchannel is connected with a feeding port through a flexible piece, a tooth face detecting device is arranged at the bottom of the detection channel, end face detection devices are arranged on the twoside walls, and the detection channel is provided with a position changing drive device. The conveying chain structure comprises a circular movement chain, a set of chain wheels engaged with the chain, and a set of loading frames arranged on the chain, the chain wheels are connected with a chain wheel drive device, and the opening direction of the loading frames is consistent to the moving direction. The side, close to the detection channel, of the conveying chain structure is provided with a cleaning device, and a discharging channel is arranged at the upper end of the other side of the conveying chain structure. Tooth face and end face appearance detecting and screening and automatic qualified piece cleaning and unloading integrated actions are achieved, the integral structure is simple,the work efficiency is high, and the automation degree is high.

Owner:苏州聿知新机械科技有限公司

Device and method for making kelp paste

ActiveCN108433087AUnique flavorRealize streamlined operationFood shapingFood dryingFlavorTransmission belt

The invention relates to a device and method for making kelp paste. The device comprises a first transmission belt, a cutting unit, a softening unit, a washing unit, a slurrying unit, a drying unit and a material mixing unit, wherein the cutting unit is used for cutting dried kelps on the first transmission belt into blocks; the softening unit is used for softening the dried kelps; the washing unit is used for washing the softened kelps; the slurrying unit is used for crushing the kelps to form kelp pulp; the drying unit is used for drying the kelp pulp to form kelp blocks; and the material mixing unit is used for crushing the kelp blocks to form kelp powder, and mixing the kelp powder with auxiliary materials. Through the adoption of the device disclosed by the invention, deep-processingtreatment of kelps is realized; the kelp paste made by the device is clean, hygienic and unique in flavor; and in the processing course, streamline operation is realized, the continuity is high, manual participation is not needed, and the production efficiency is high.

Owner:天津鼎拓恒远知识产权服务有限公司

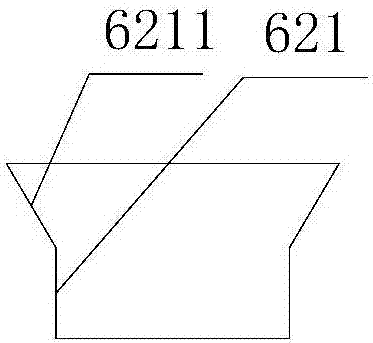

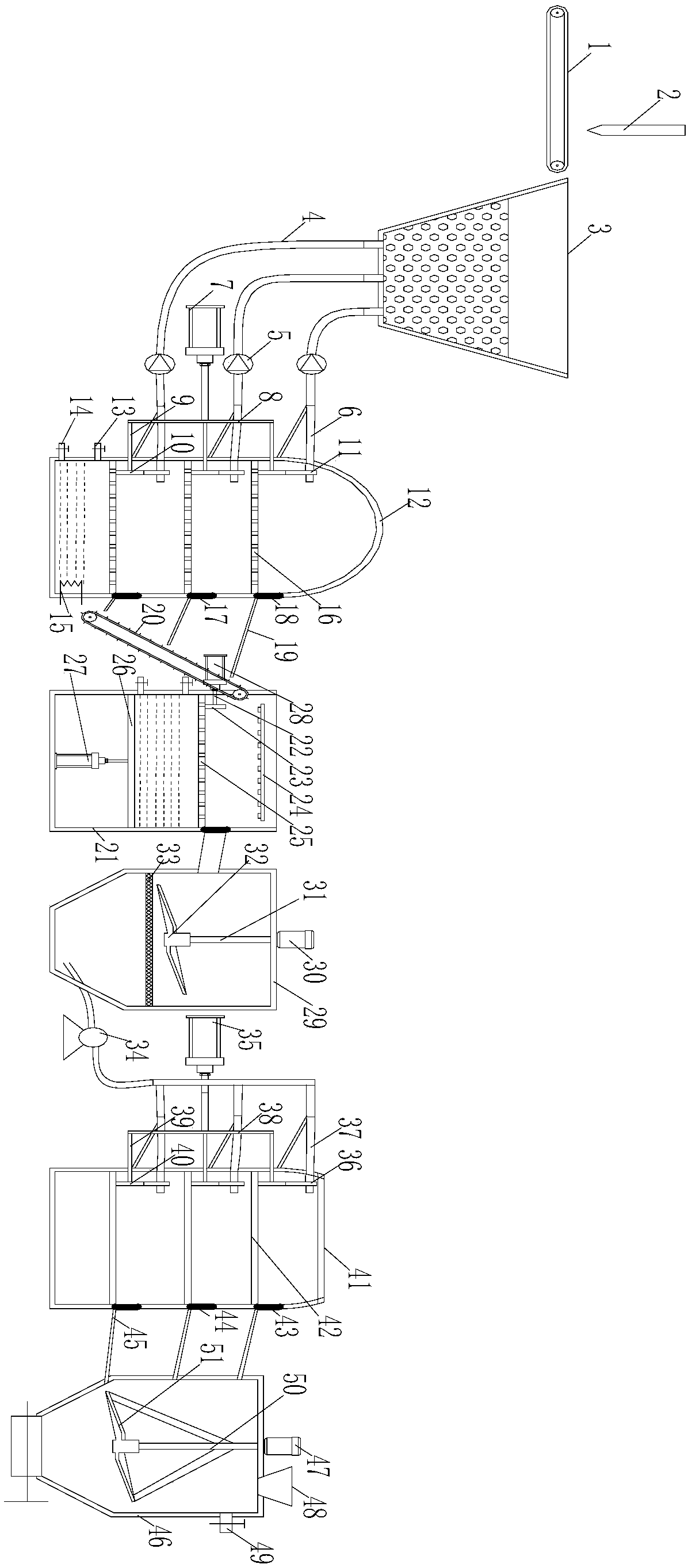

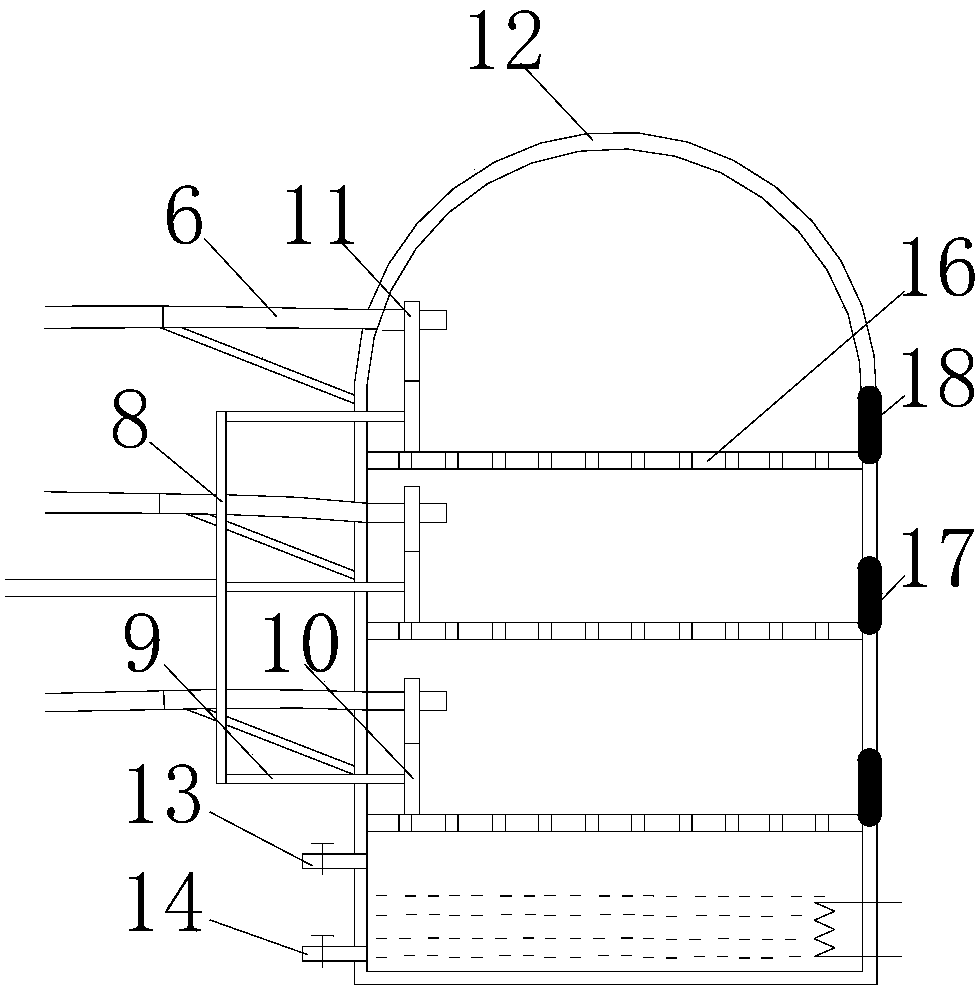

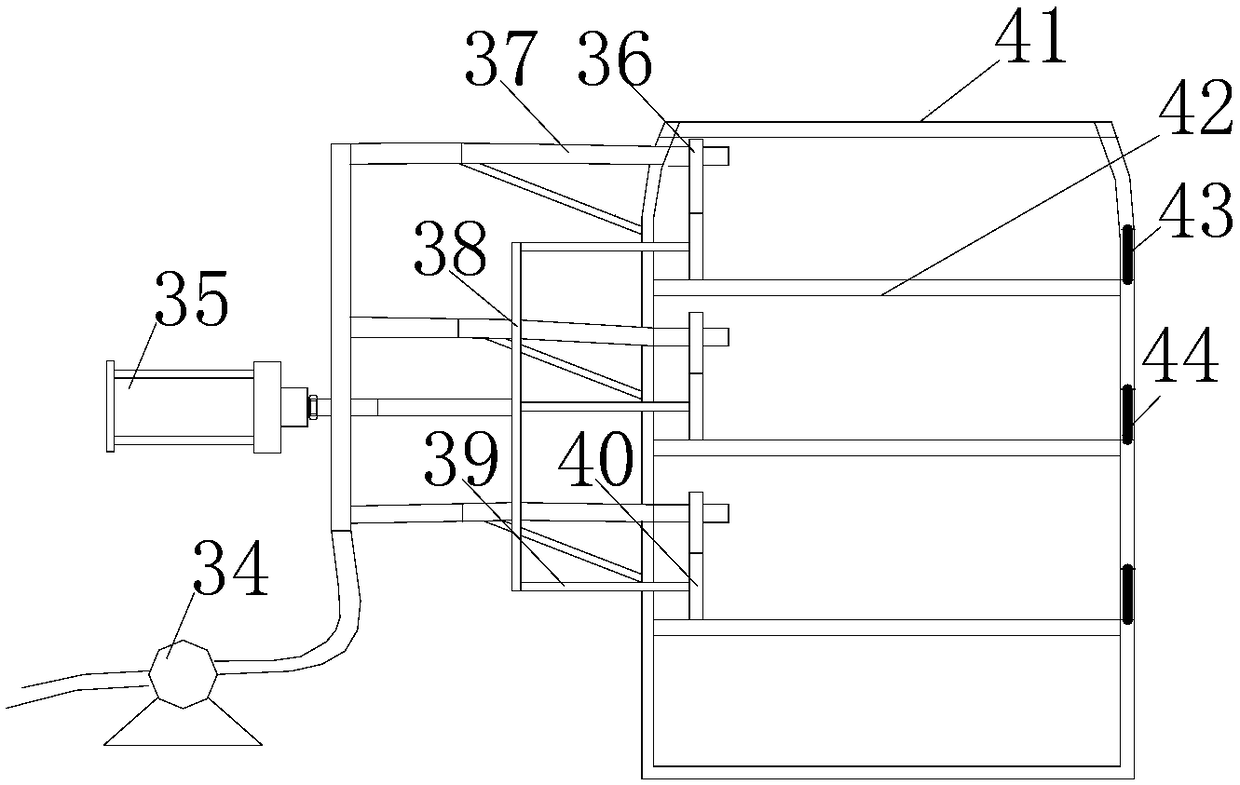

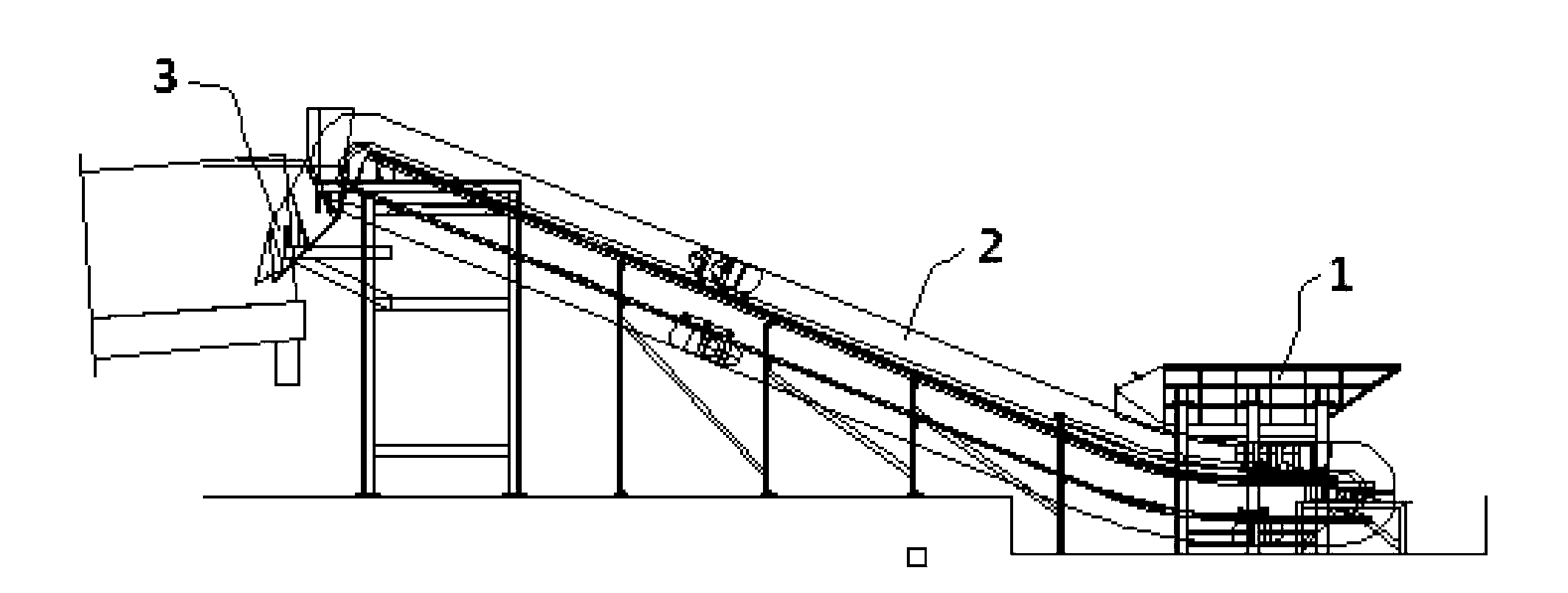

Chain scraper conveyor system for conveying waste purple impure copper

InactiveCN103010664APrevent stuck situationsPrevent embeddingConveyorsControl devices for conveyorsLowering plantsEngineering

The invention relates to a chain scraper conveyor system for conveying waste purple impure copper. The chain scraper conveyor system comprises a feeding hopper, a chain scraper conveyor, a discharging chute and a blanking hopper; a material supporting chain scraper and a chain hopper lateral chain scraper both have a series of chain plates; in each series of chain plates, a tail part of a front chain plate is covered on a hinge part of a rear chain plate along a conveying direction; the feeding hopper has a shape of truncated rectangular pyramid; a lower opening of the truncated rectangular pyramid platform is of rectangular shape; the length along the conveying direction at least spans three chain plates; the width along the direction vertical to the conveying direction is at least 0.1m less than the width of the chain plates; the discharging chute is covered between a position of an end chain plate of the chain scraper conveyor and the blanking hopper; the chain plate width of the chain scraper conveyor is at least 1m less than the width of the discharging chute; and the width of the discharging chute is at least 1m less than the upper width of the blanking hopper. The chain scraper conveyor system for conveying the waste purple impure copper can continuously and efficiently work in a lower plant and can prevent the chain scraper conveyor from being tightly blocked by the wound or embedded materials.

Owner:GANZHOU JIANGWU NEW TYPE ALLOY MATERIAL

Automatic workpiece inner hole machining method

ActiveCN106041653AImprove processing efficiencyEfficient cooperationRevolution surface grinding machinesEngineeringMachining

The invention discloses an automatic workpiece inner hole machining method and belongs to the technical field of inner hole machining. According to the method, a feeding channel, a workpiece pushing mechanism and a discharging channel are included. A to-be-ground workpiece is conveyed to a gripping station of the workpiece pushing mechanism through the feeding channel. When the workpiece pushing mechanism pushes a ground workpiece to an inner hole machining station, the to-be-ground workpiece is limited; and meanwhile, limitation on the ground workpiece is released, and the ground workpiece is output through the discharging channel. After machining of an inner hole is completed, the workpiece pushing mechanism carries the ground workpiece to return; and the ground workpiece automatically falls out of the gripping station and is limited by the workpiece pushing mechanism. The to-be-ground workpiece in the feeding channel enters the gripping station automatically as supplement. According to the automatic workpiece inner hole machining method, the structure is simple; control is conducted conveniently; automatic circulation of the whole process including feeding, machining and discharging can be achieved; products are stable in quality; and the automation degree of equipment is further improved.

Owner:马鞍山市恒永利机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com