Patents

Literature

51results about How to "Improve chamfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

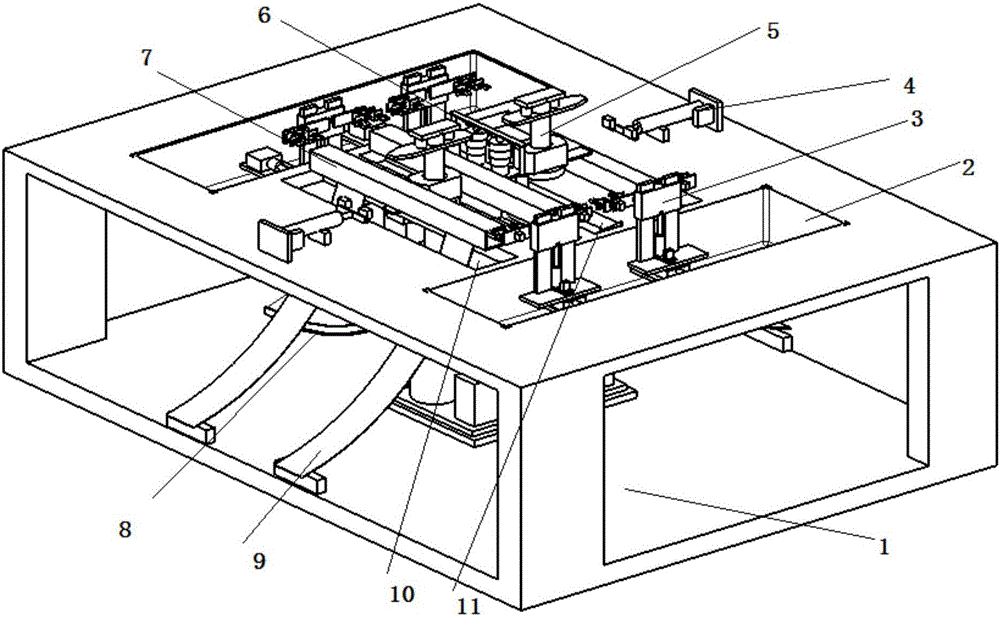

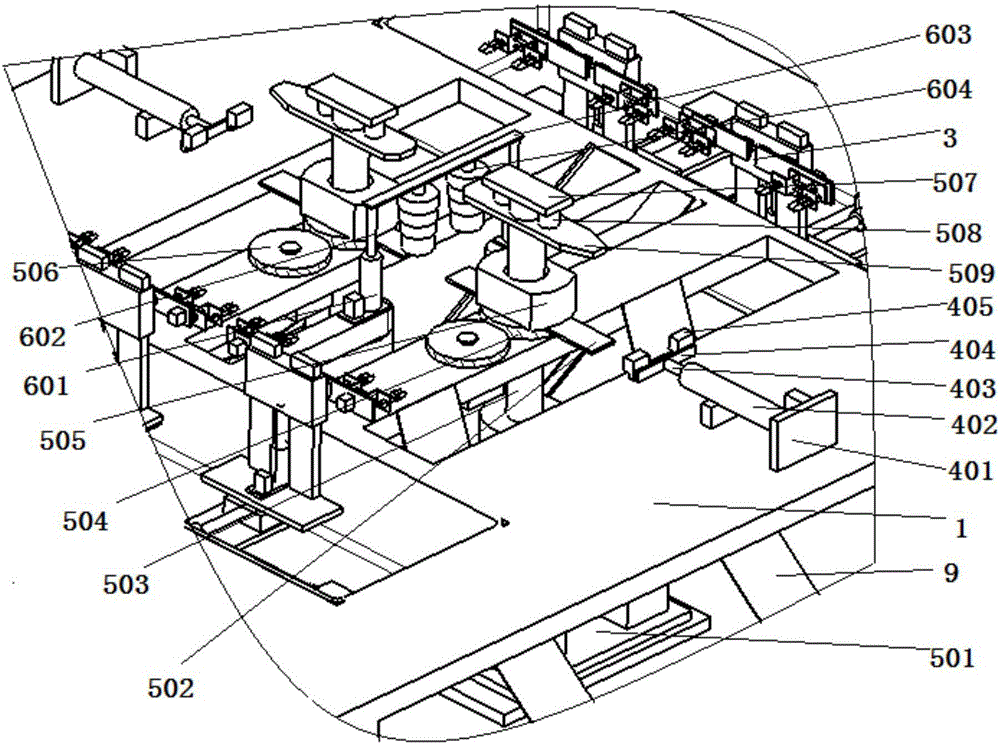

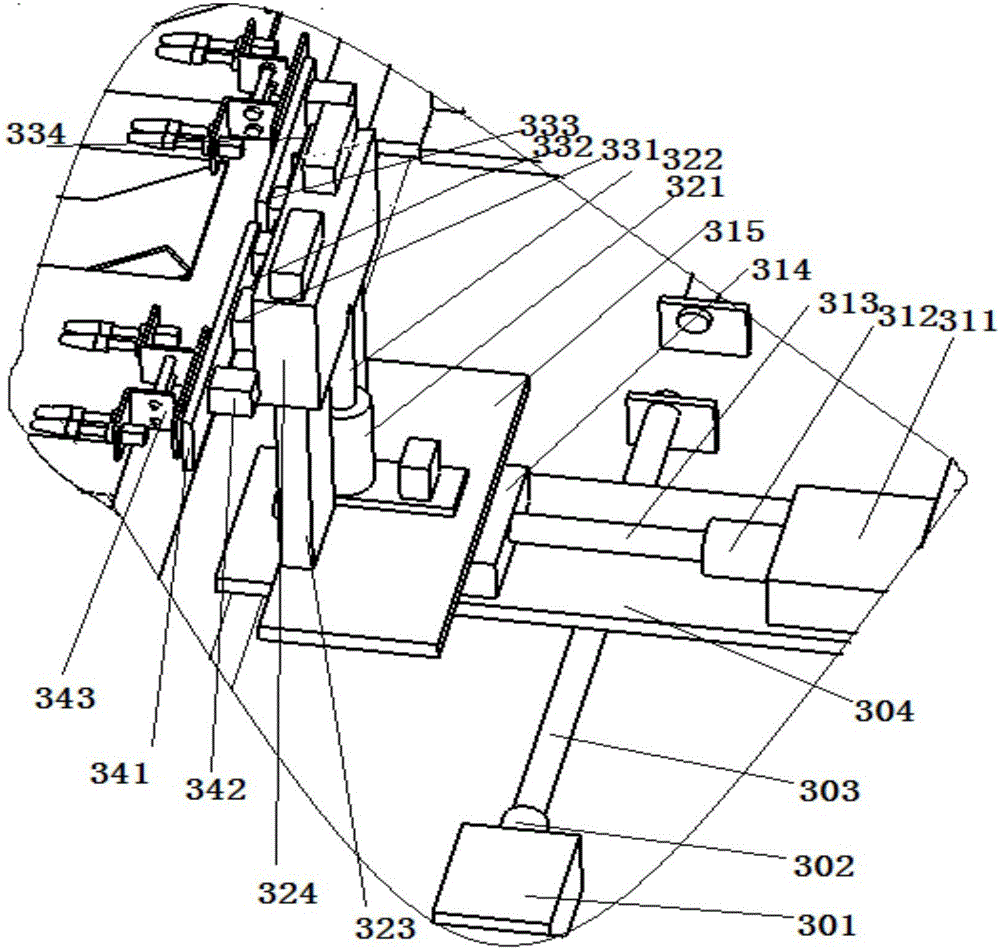

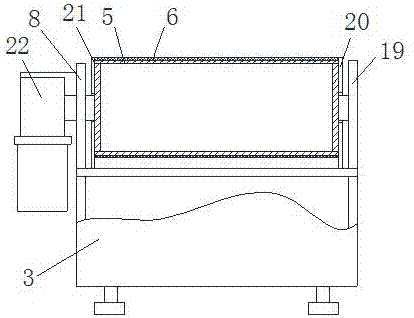

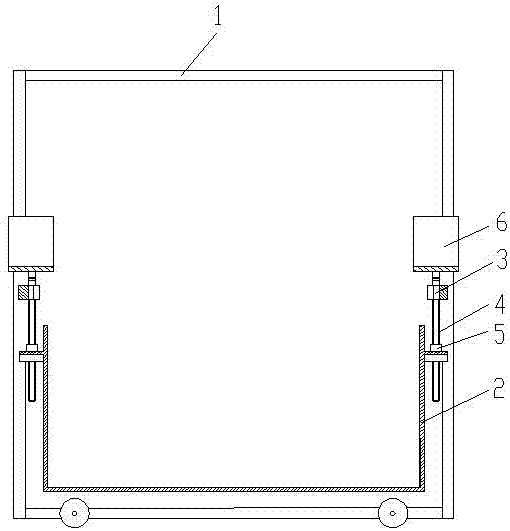

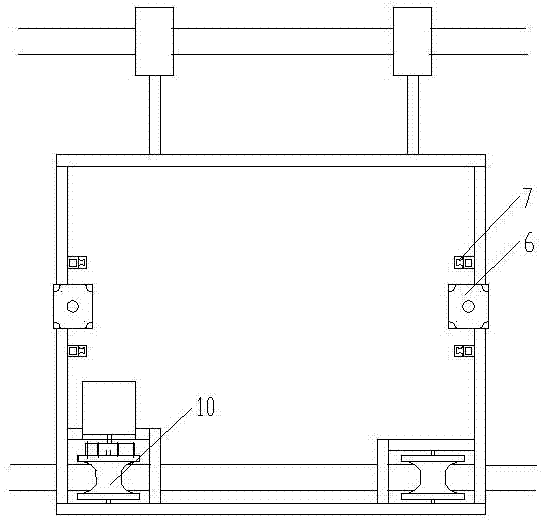

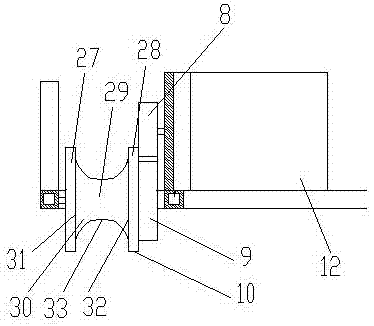

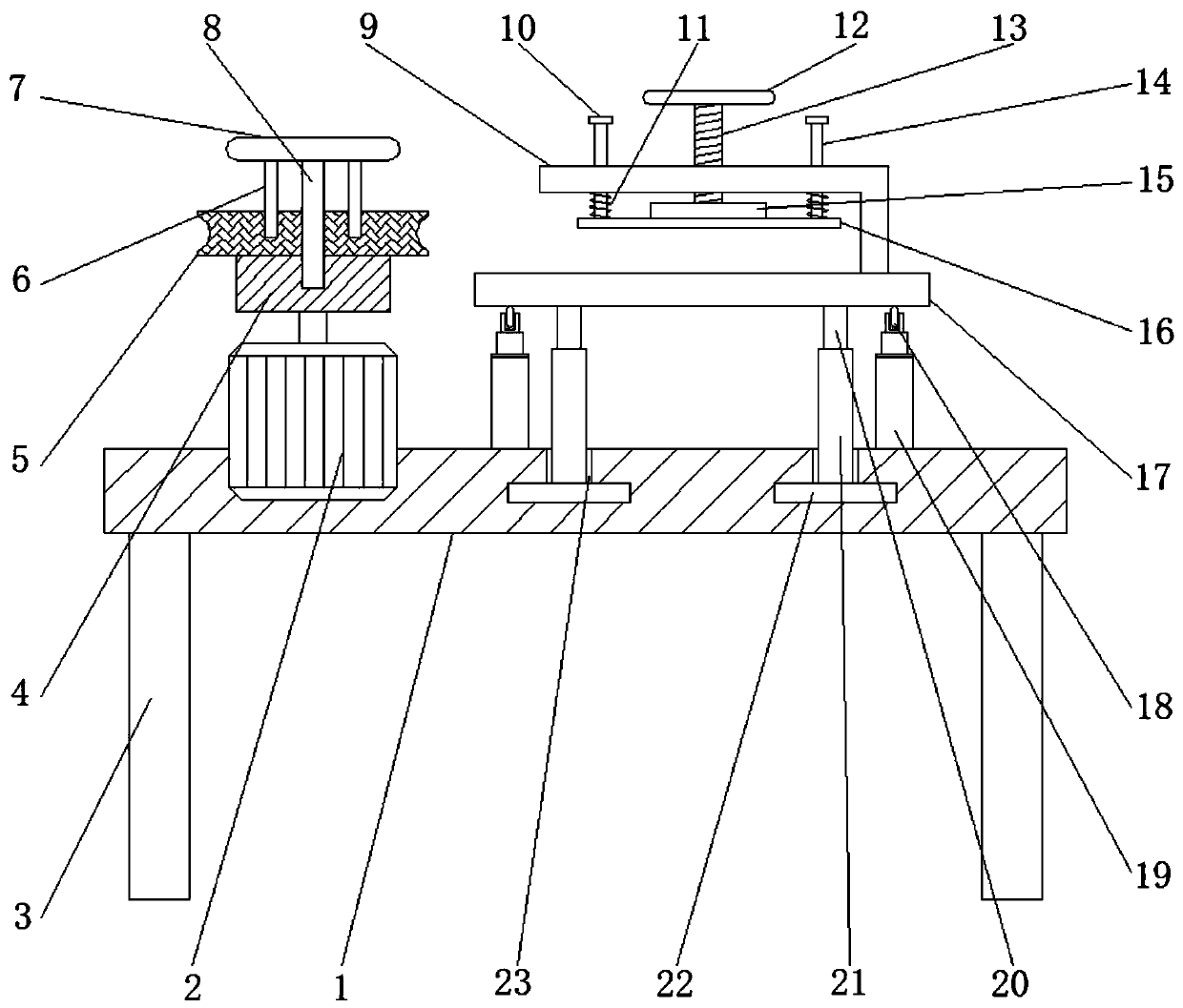

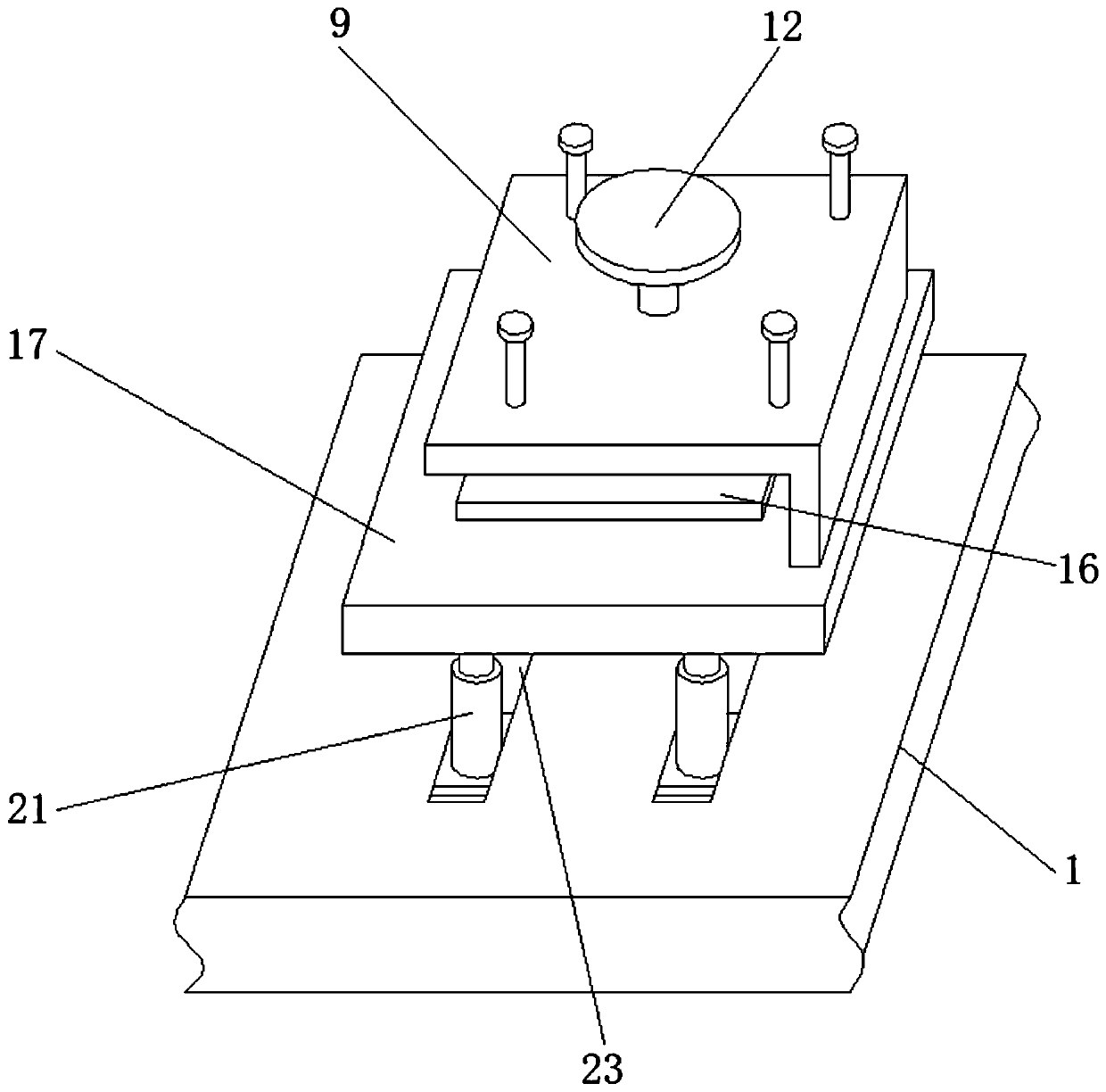

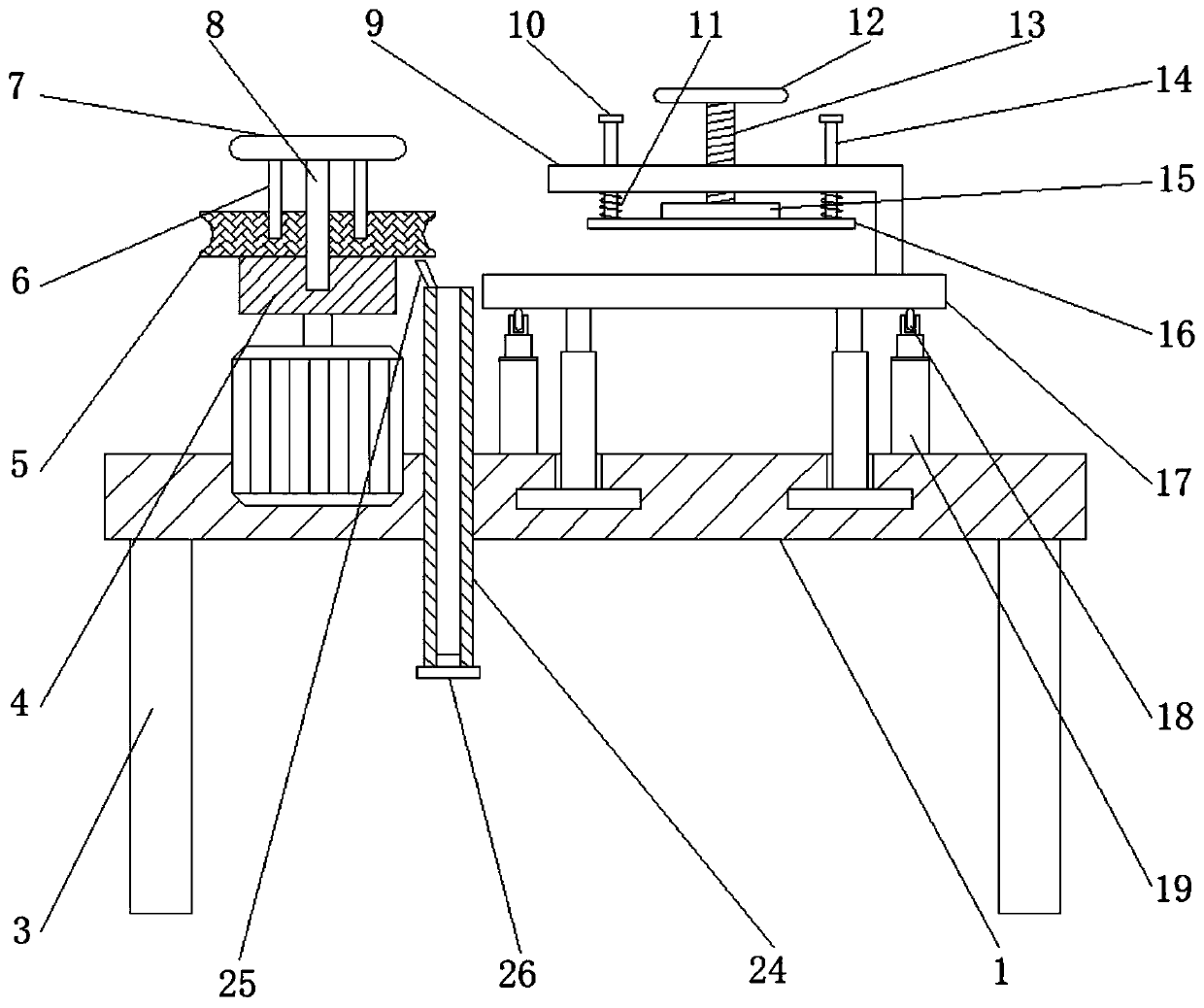

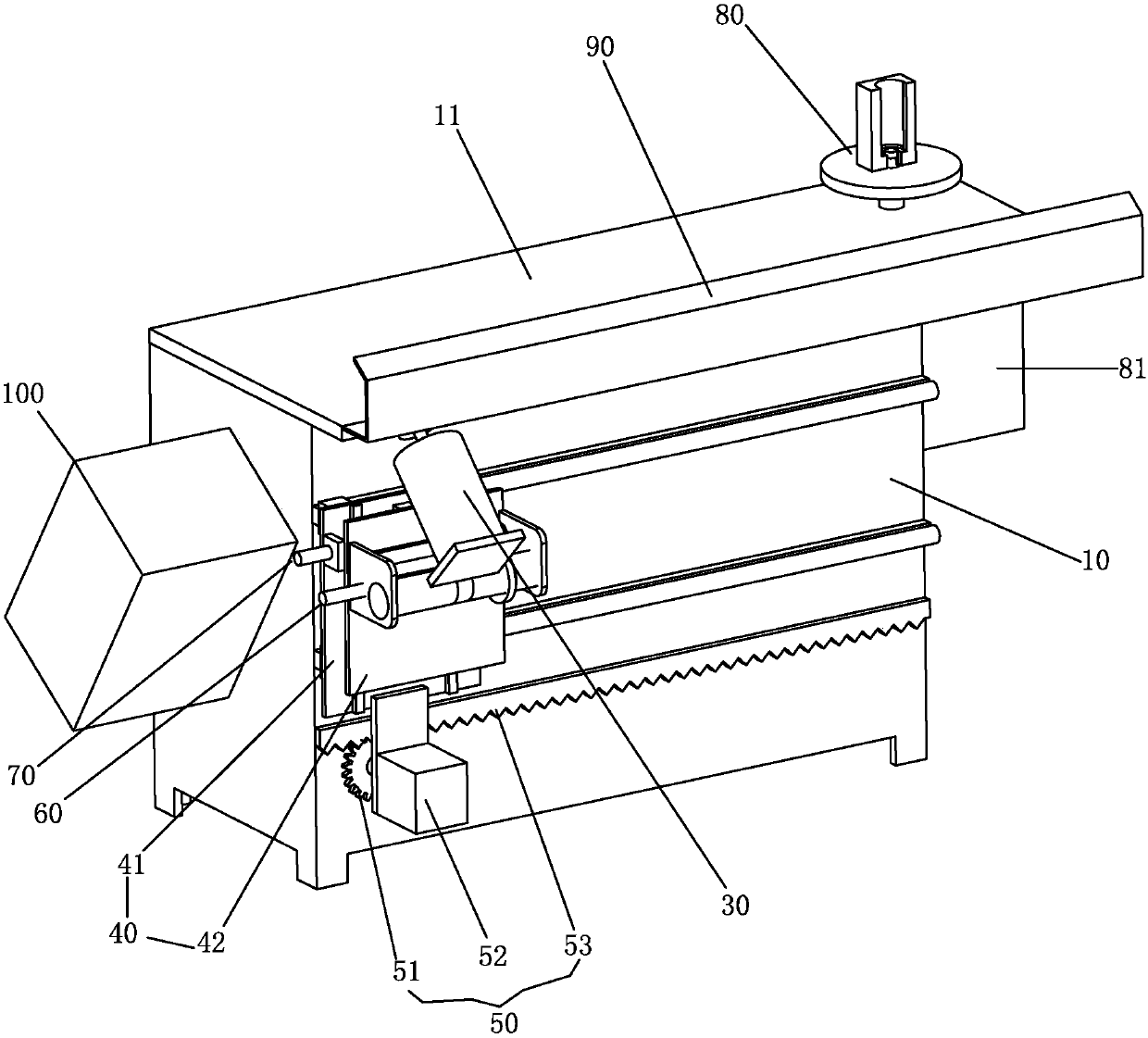

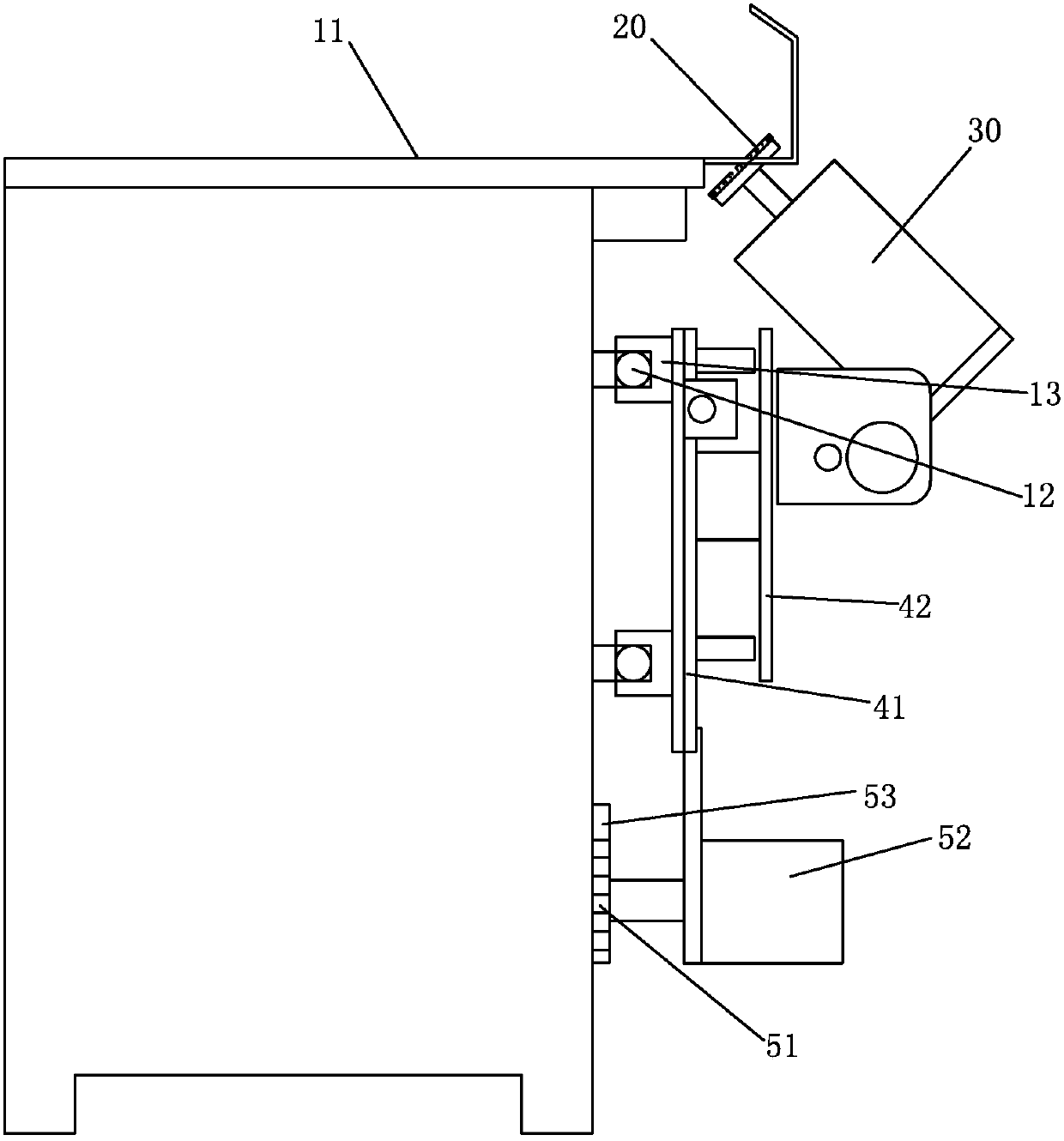

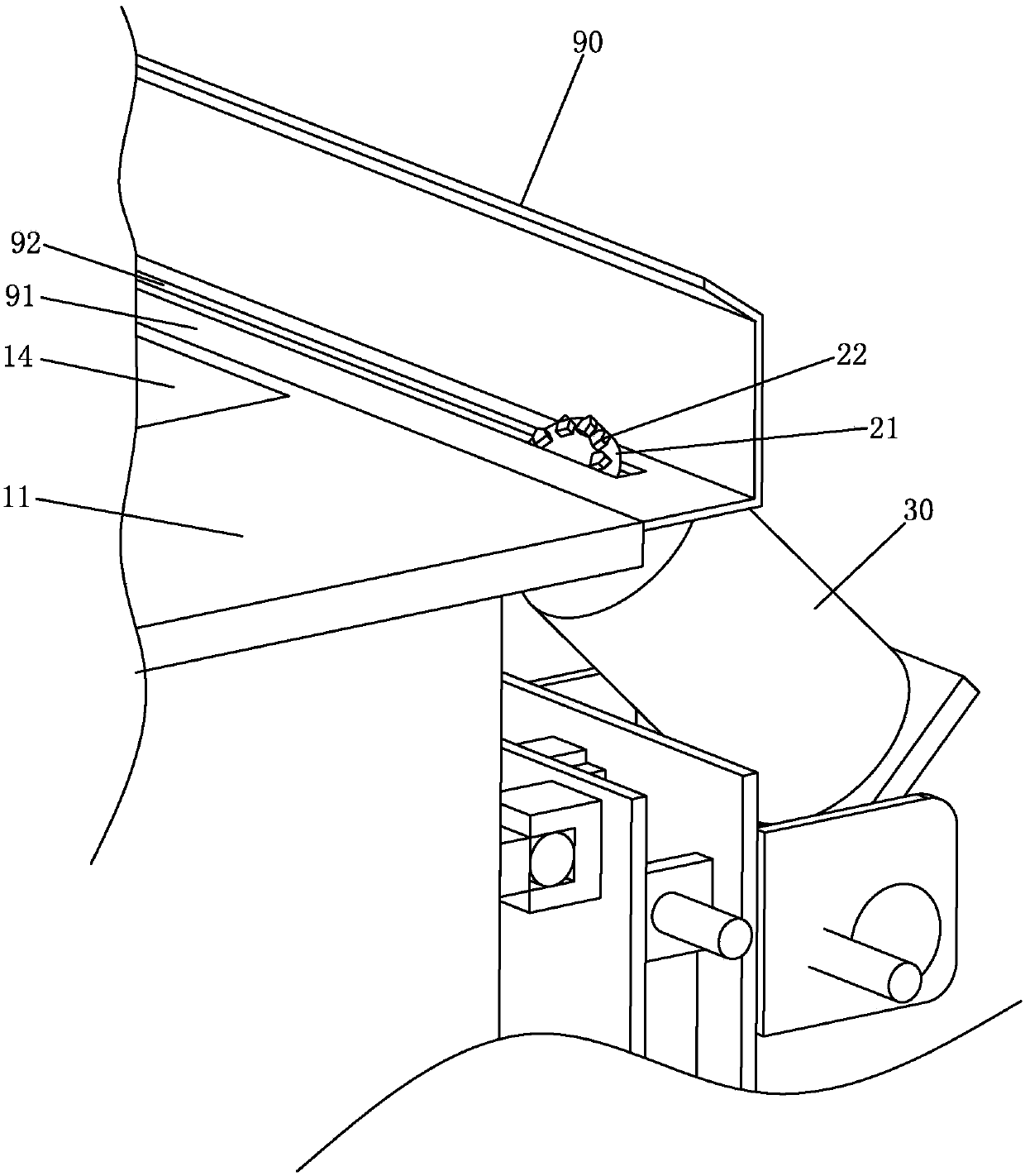

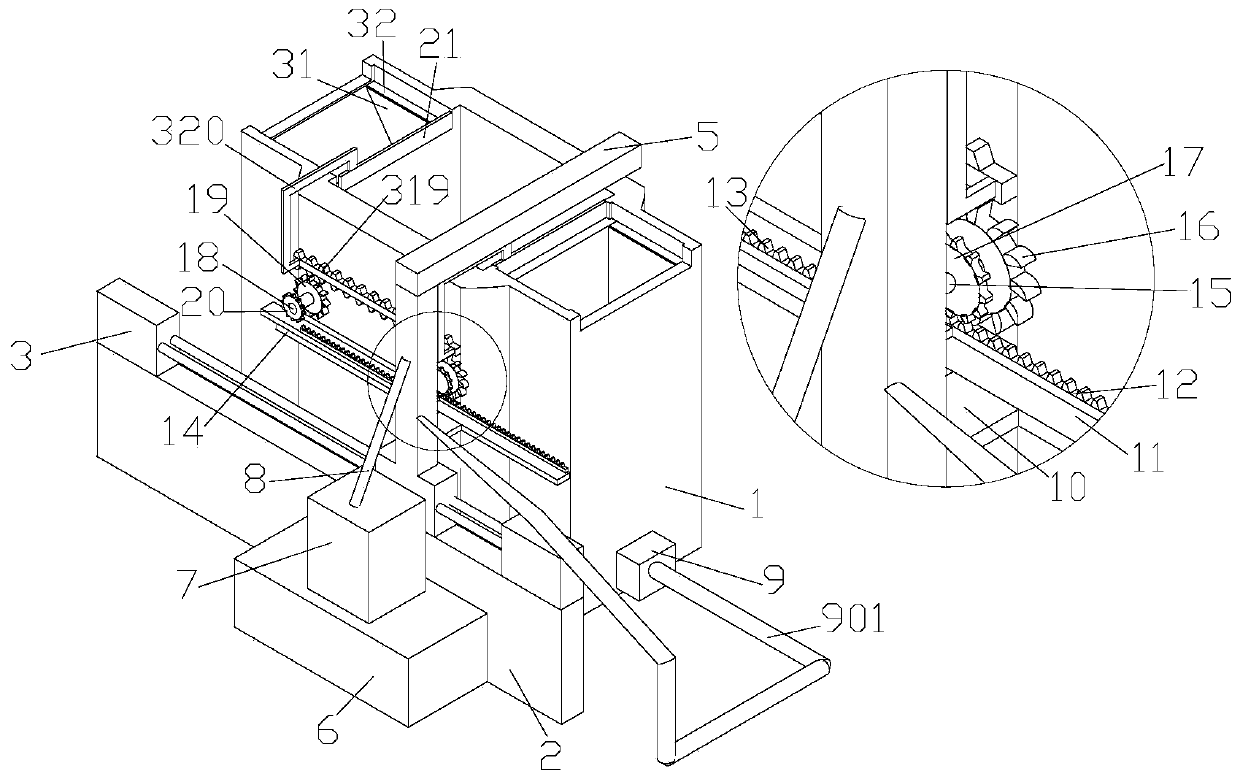

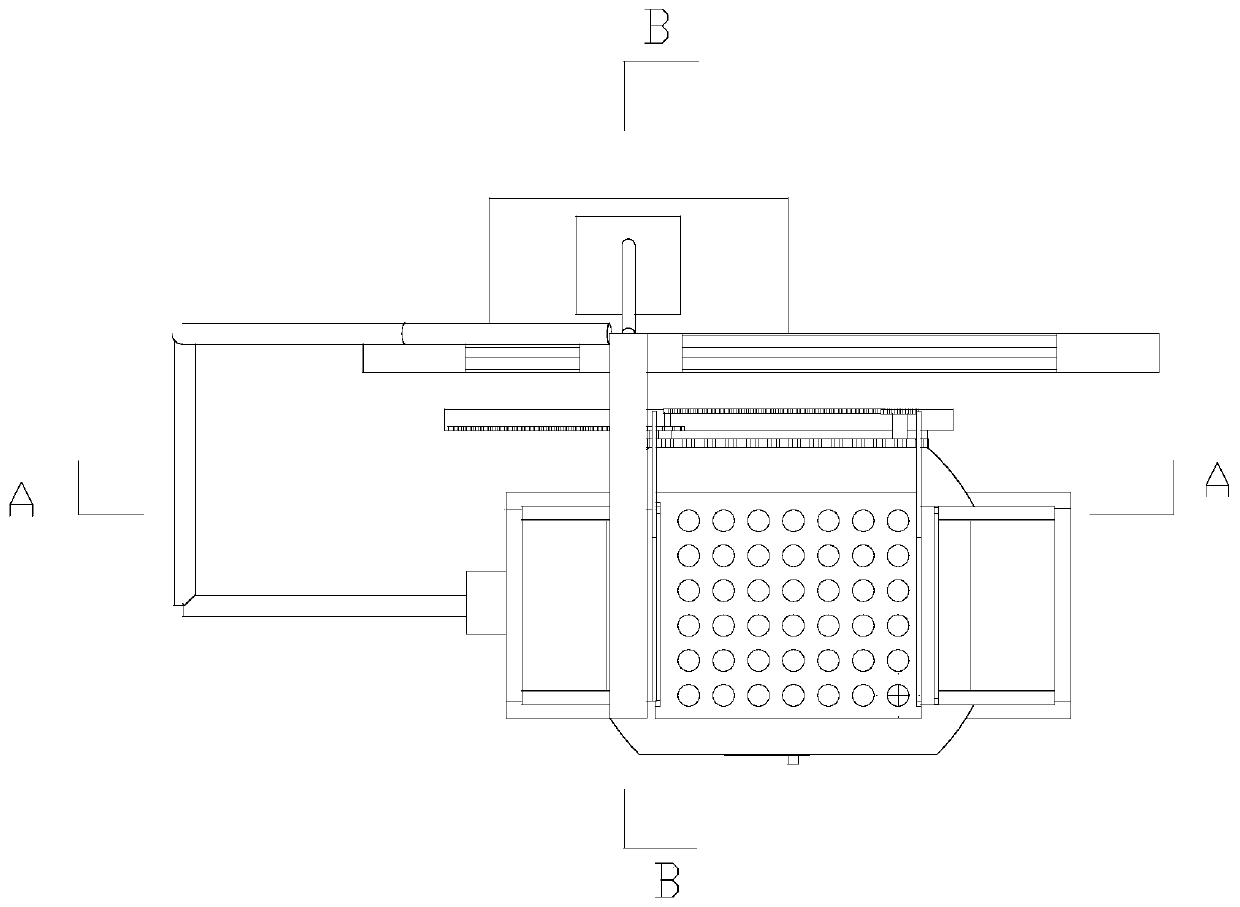

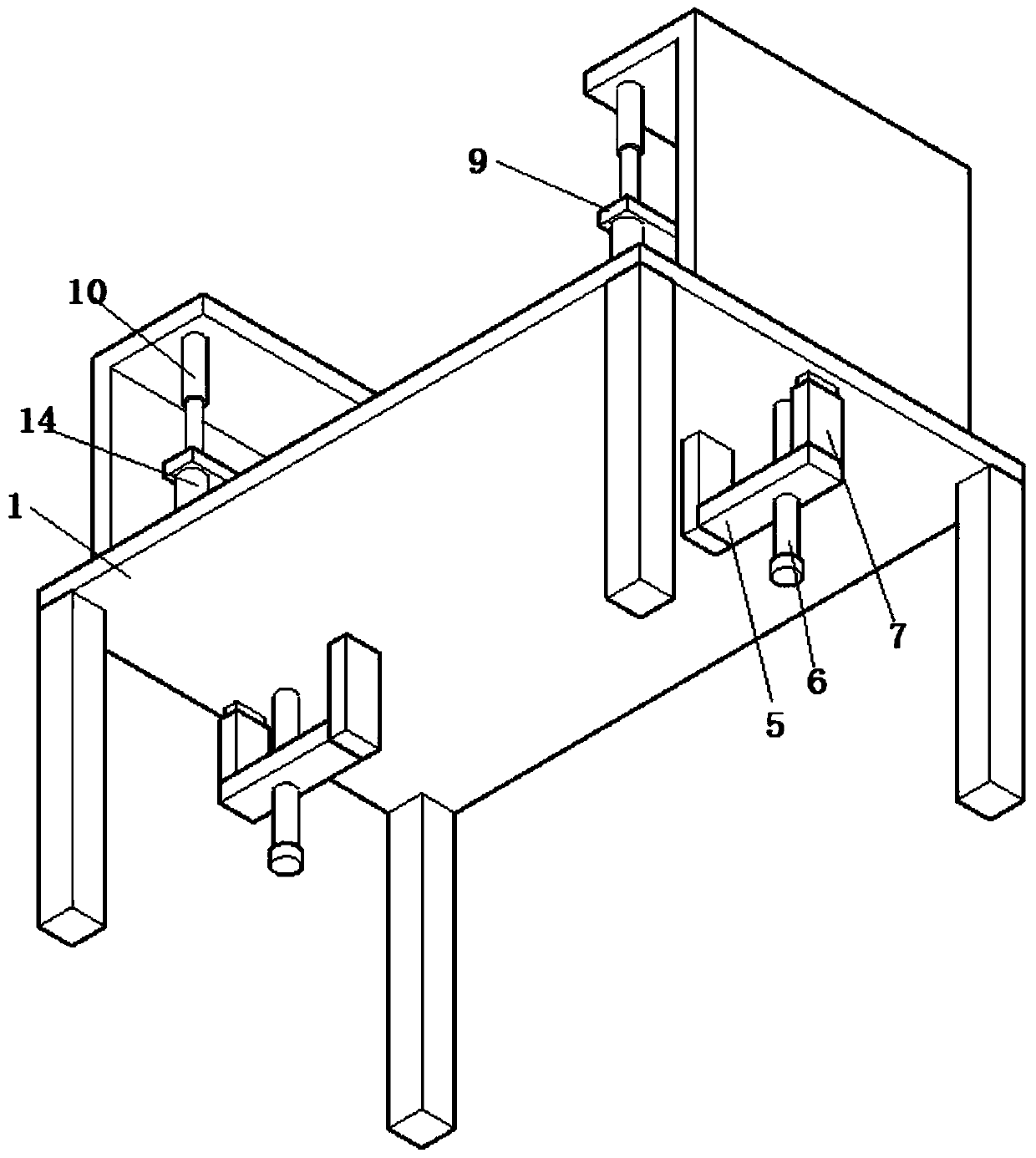

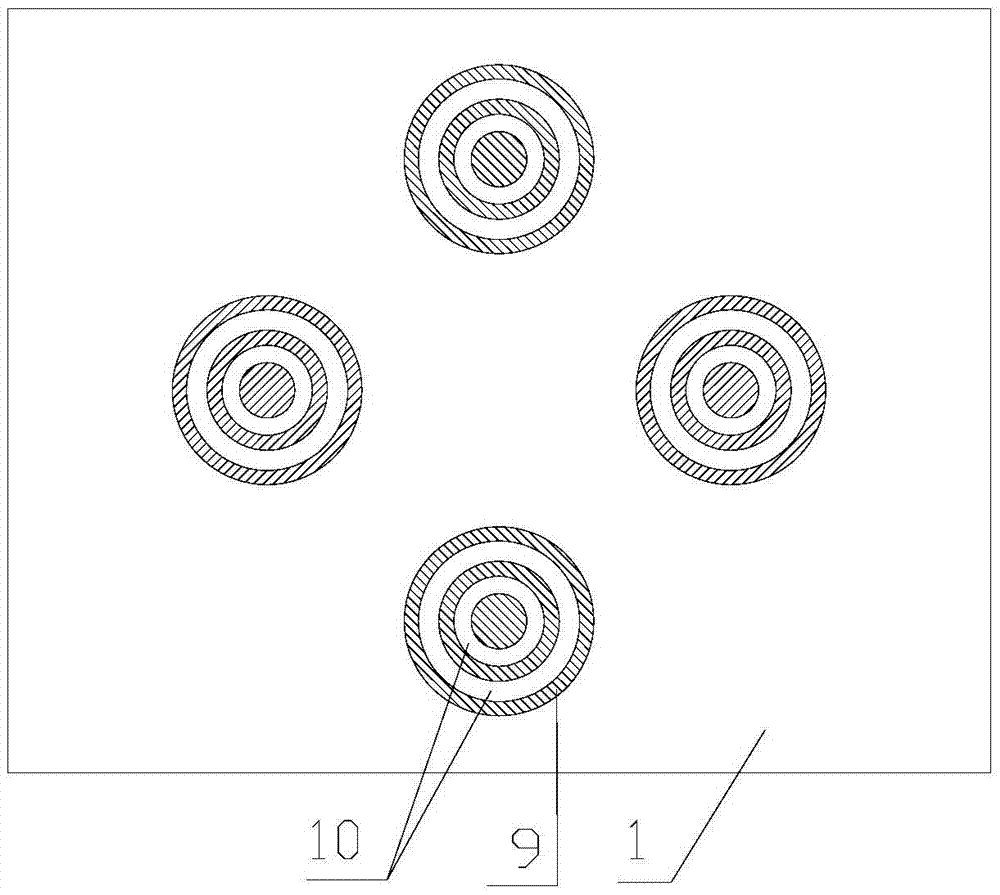

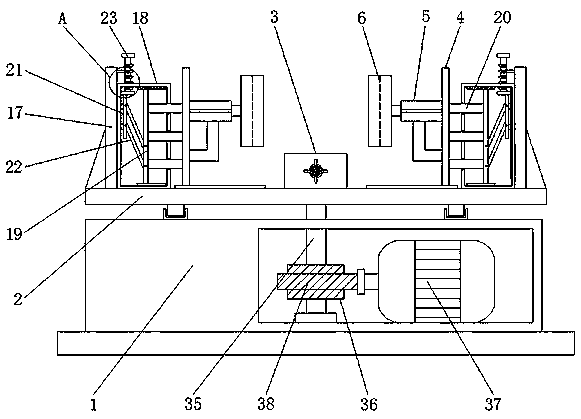

Machining equipment for square tubes

InactiveCN106624178AFully automatedImprove chamfer effectMetal working apparatusPositioning apparatusHydraulic cylinderEngineering

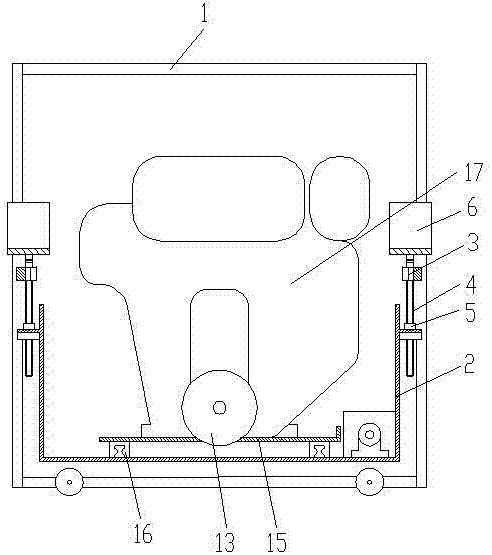

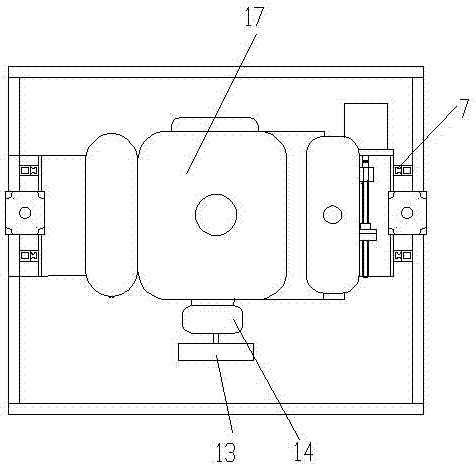

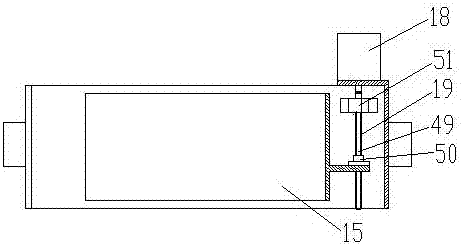

The invention provides machining equipment for square tubes. The machining equipment comprises a bracket and two clamping mechanisms arranged on the bracket. First positioning mechanisms are arranged on the two sides of the two clamping mechanisms. Chamfering mechanisms are arranged in grooves. First blanking holes and second blanking holes are formed in the bracket. A first blanking rail and a second blanking rail are arranged on the bracket. A second positioning mechanism is arranged between the two second blanking holes. The second positioning mechanism comprises first hydraulic cylinders which are arranged in a mirror manner. A through hole is formed in the position, between the two first hydraulic cylinders, of the bracket. A first support is fixedly arranged between first ejector rods of the two first hydraulic cylinders. At least two layered positioning blocks are fixedly arranged at the bottom of the first support. By means of the machining equipment for the square tubes, the square tubes can be machined in batches, inner chamfering and outer chamfering of the square tubes of various specifications can be conducted at the same time, automatic blanking and automatic discharging after machining is completed can be achieved, the degree of automation is high, the machining efficiency is improved, and the production cost is lowered.

Owner:天津福常科技有限公司

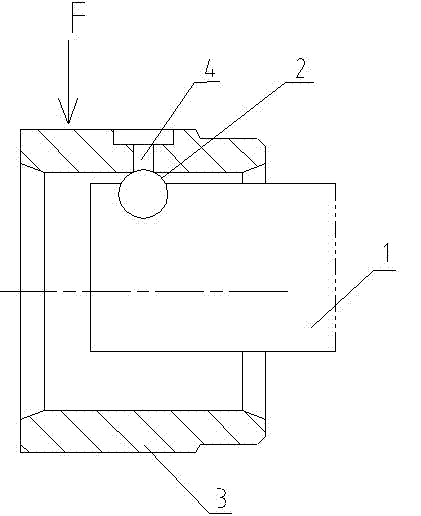

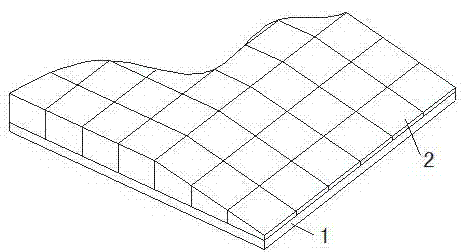

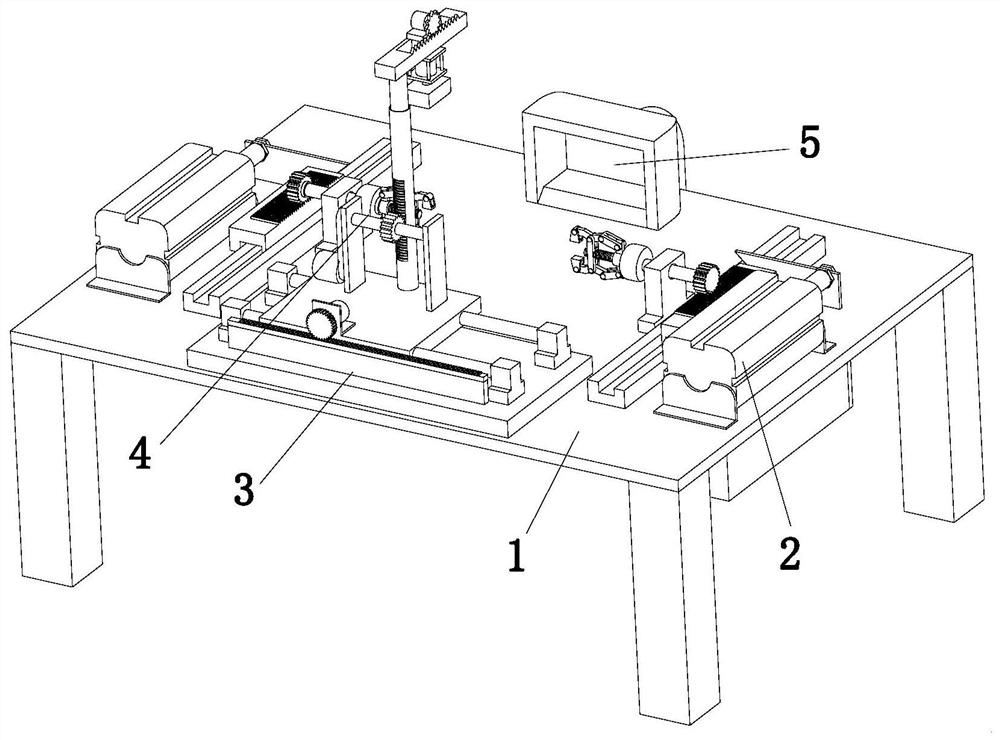

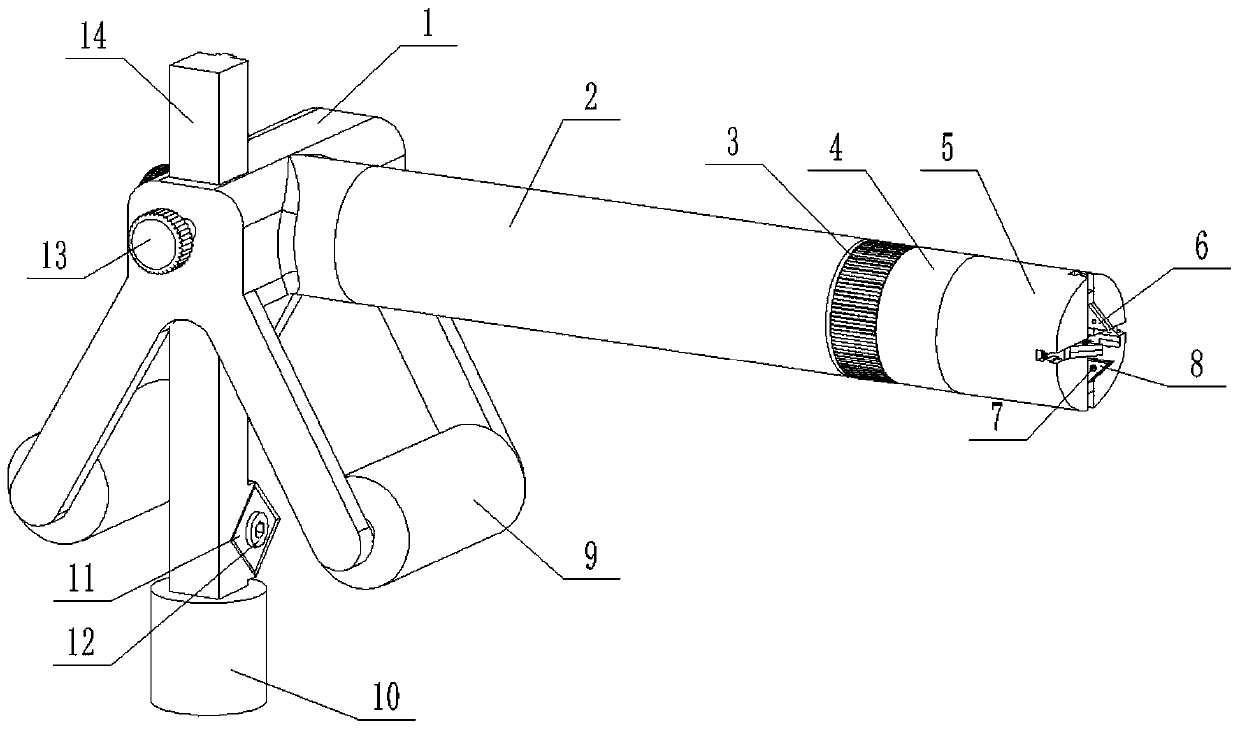

Apparatus and method for deburring ball head by chamfering

The invention relates to an apparatus for deburring a ball head by chamfering, which comprises a supporting base (1) which is fixed on a machine tool working platform, wherein an arched convex block (2) is arranged on the supporting base (1); a ball head is embedded on the surface of the supporting base (1); and one part of the ball head is exposed out of the supporting base (1) to form a crown-shaped arched convex block. The apparatus for deburring the ball head by chamfering has the advantages of simple structure, simplicity and rapidness in processing and high processing efficiency.

Owner:JIANGYIN CITY TIANRUN MACHINERY

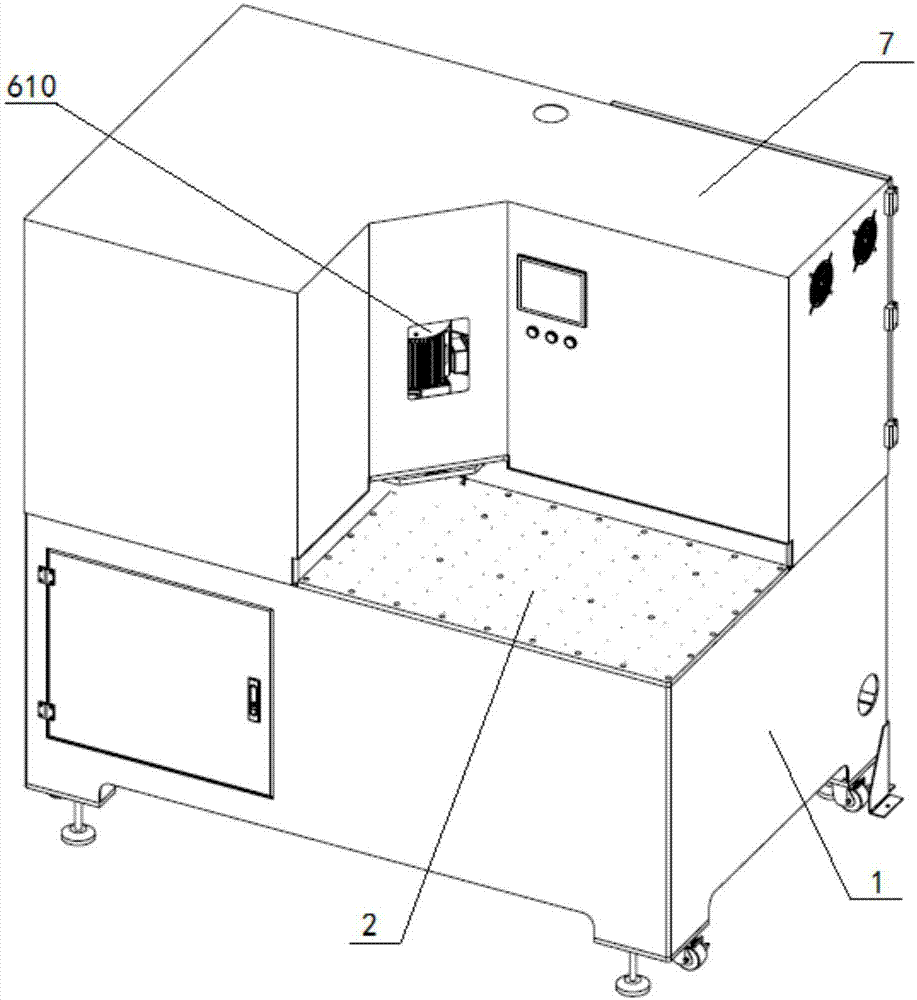

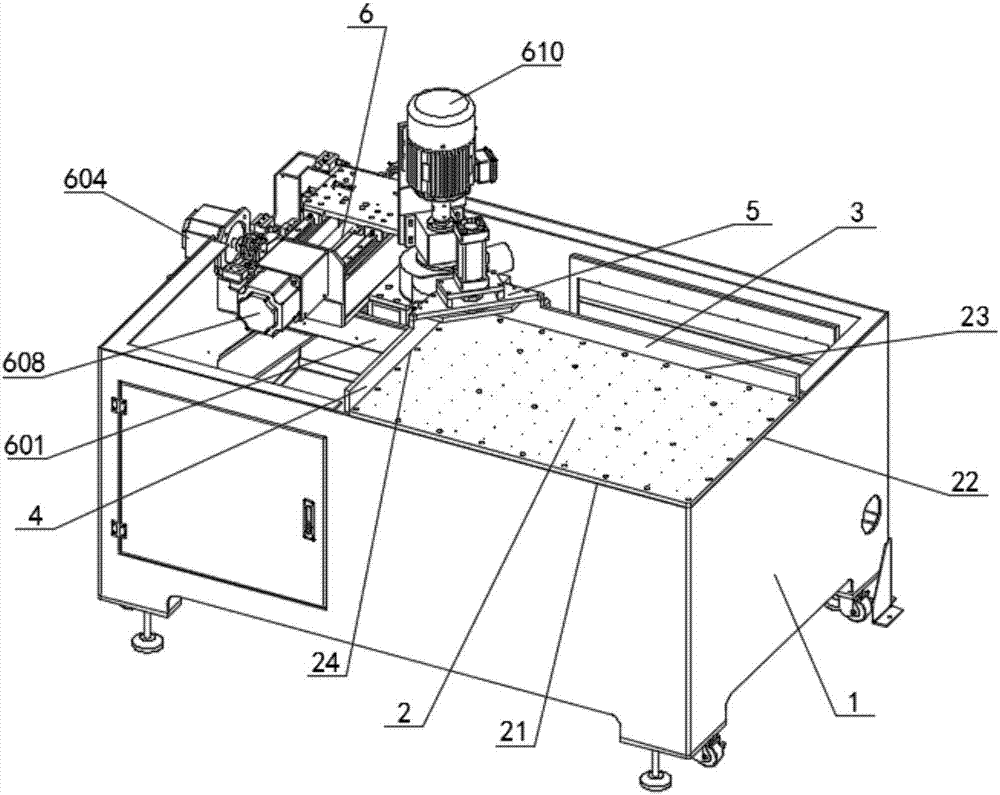

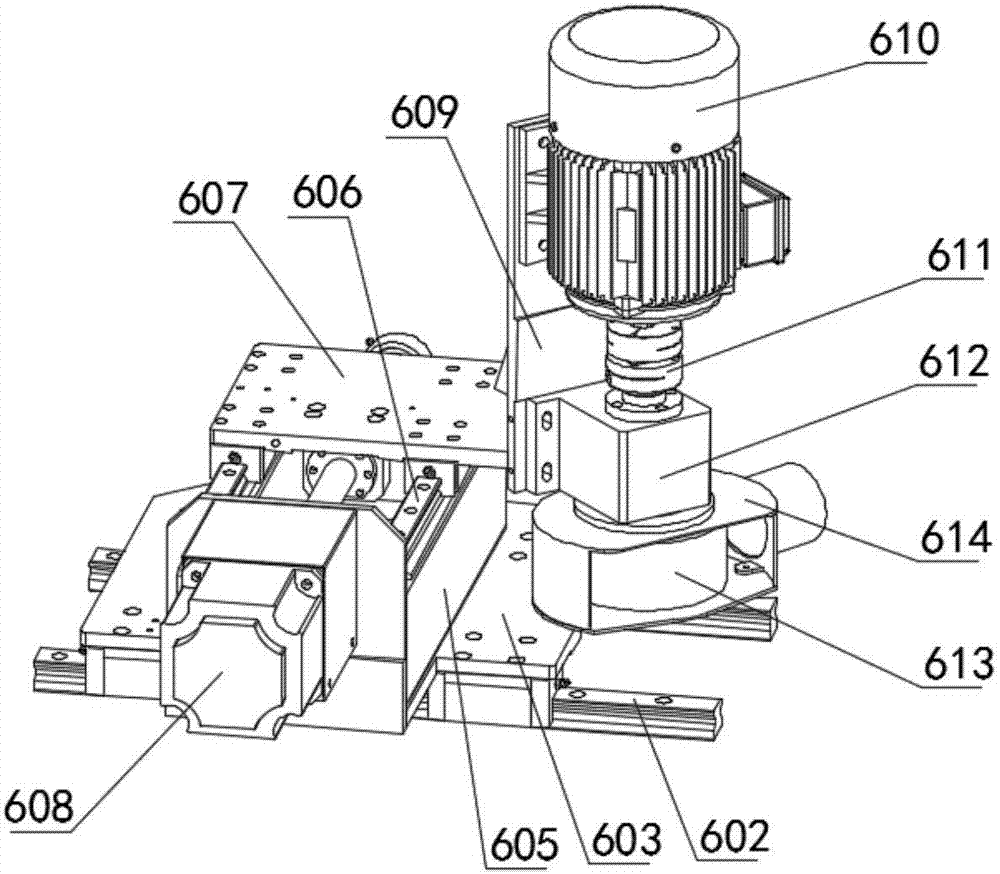

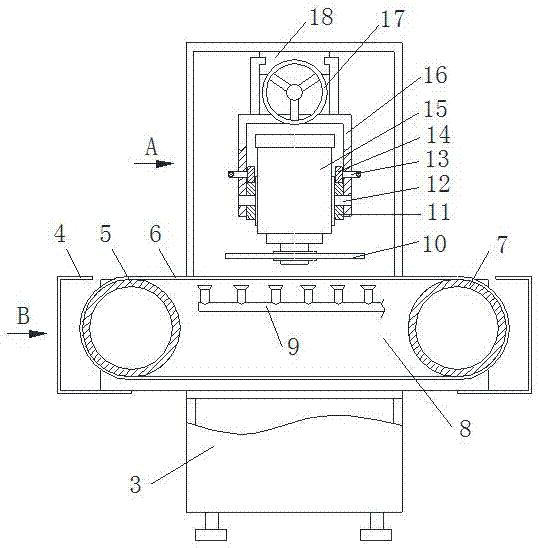

Plate chamfering machine

PendingCN107309739ARapid positioningImprove processing efficiencyEdge grinding machinesGrinding/polishing safety devicesFloating platformStructural engineering

The invention discloses a plate chamfering machine. The plate chamfering machine comprises a rack for providing a supporting base, a gas-floating platform used for placing a plate, an X-axis fixed backup side, a Y-axis fixed backup side, a beam pressing assembly used for pressing the plate, a machine head used for cutting the plate, and a machine enclosure which covers the rack, wherein the gas-floating platform is fixedly arranged on one side corner at the top end of the rack; the X-axis fixed backup side, the Y-axis fixed backup side and the beam pressing assembly are arranged on the gas-floating platform; and the machine head is arranged on a position, which is not provided with the gas-floating platform, of the rack. The plate chamfering machine has the beneficial effects that: the X-axis fixed backup side and the Y-axis fixed backup side are arranged, so that the plate can be quickly positioned, processing efficiency is high, a thin plate also can be processed, the chamfering effect is better than that of a forming knife, and the chamfering size can be freely switched by parameters; and the processed plate is free of burrs and can reduce harm on people, and the service life of a roller wheel, the service life of a pressure wheel and the service life of a conveyor belt of back-end processing equipment are not affected.

Owner:深圳市乐维机械有限公司

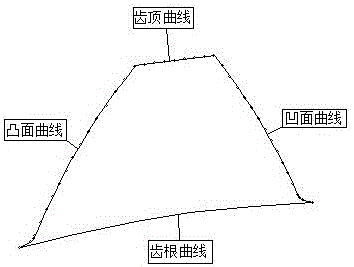

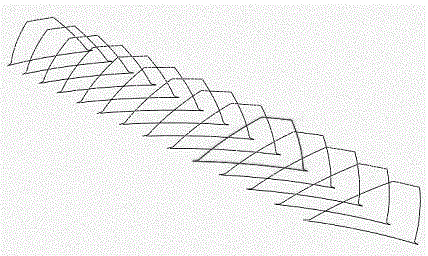

Helical bevel gear tooth crest edge chamfering method based on entity contact analysis

InactiveCN106493439AOptimized cone angleLow production setup costsGear teethNumerical controlOne pass

The invention relates to a helical bevel gear tooth crest edge chamfering method based on entity contact analysis and belongs to the technical field of gear machining. The helical bevel gear tooth crest edge chamfering method comprises the steps of gear entity modeling, edge chamfering machining parameter calculation, edge chamfering simulation machining, grinding wheel cone angle optimization and numerical control code output of edge chamfering machining. By the adoption of the helical bevel gear tooth crest edge chamfering method, various spiral bevel gears can be machined by adding a conical grinding wheel on a spindle of a five-axis machining center without manufacturing of special machine tools, and the production and preparation costs are low. According to the method, tooth crests on two side can be simultaneously machined in the one-pass process, and the machining efficiency is high. A grinding wheel cone angle is optimized by analyzing the volume of an entity model after machining, and accordingly the best edge chamfering effect is achieved.

Owner:YANGTZE UNIVERSITY

Chamfering machine

ActiveCN105904030AReduce labor costsImprove securityEdge grinding machinesPositioning apparatusMotor driveEngineering

The invention discloses a chamfering machine which comprises a rack provided with a working table, a chamfering tool, a first chamfering motor, a movable body and a walking driving device, wherein the chamfering tool is arranged on the side of the working table in an oblique manner; the first chamfering motor drives the chamfering tool to rotate; a positioning structure for positioning a workpiece is arranged on the working table; the first chamfering motor is mounted on the movable body; the movable body is connected onto the rack through a sliding guide mechanism in a sliding manner and is connected with the walking driving device; the walking driving device is used for driving the movable body and the first chamfering motor to walk so as to chamfer the workpiece positioned on the working table. According to the invention, on one hand, the human cost is saved and the security coefficient is high; on the other hand, the walking driving device drives the first chamfering motor to walk so as to enable the chamfering speed to always stay the same, the chamfering precision is high, the chamfering effect is excellent, and the stability and standard during chamfering are improved.

Owner:JOMOO KITCHEN & BATHROOM

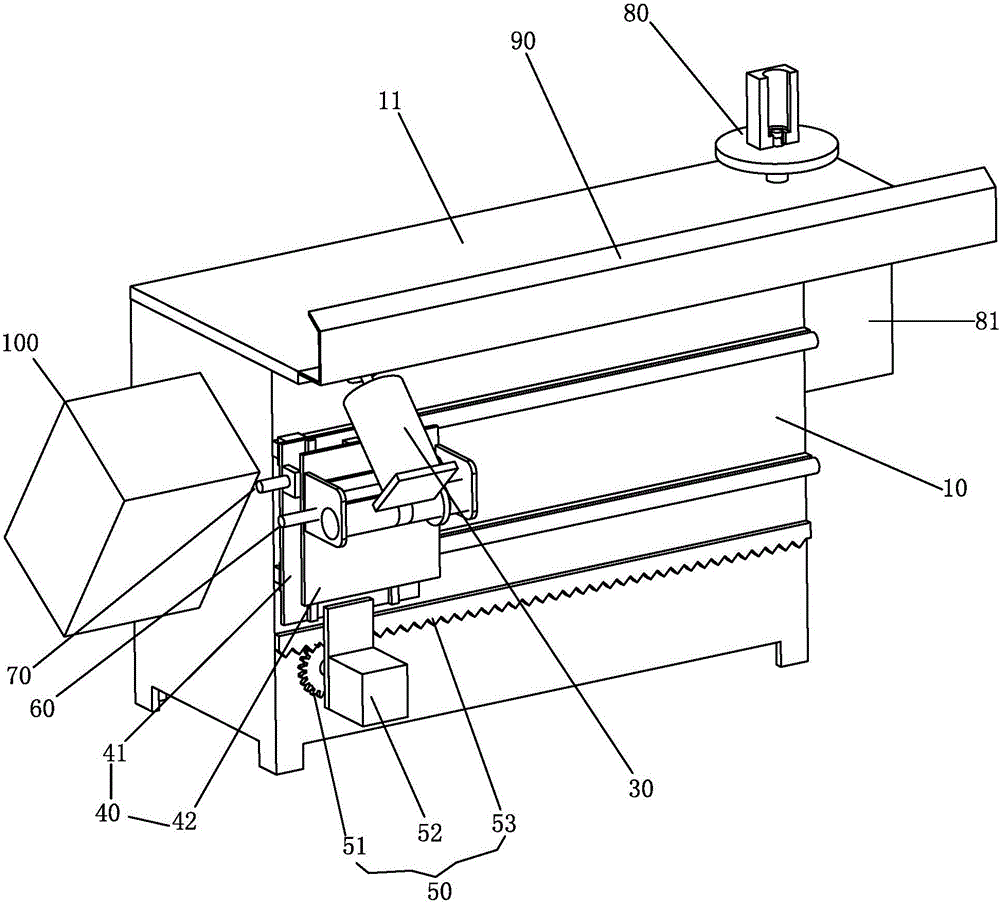

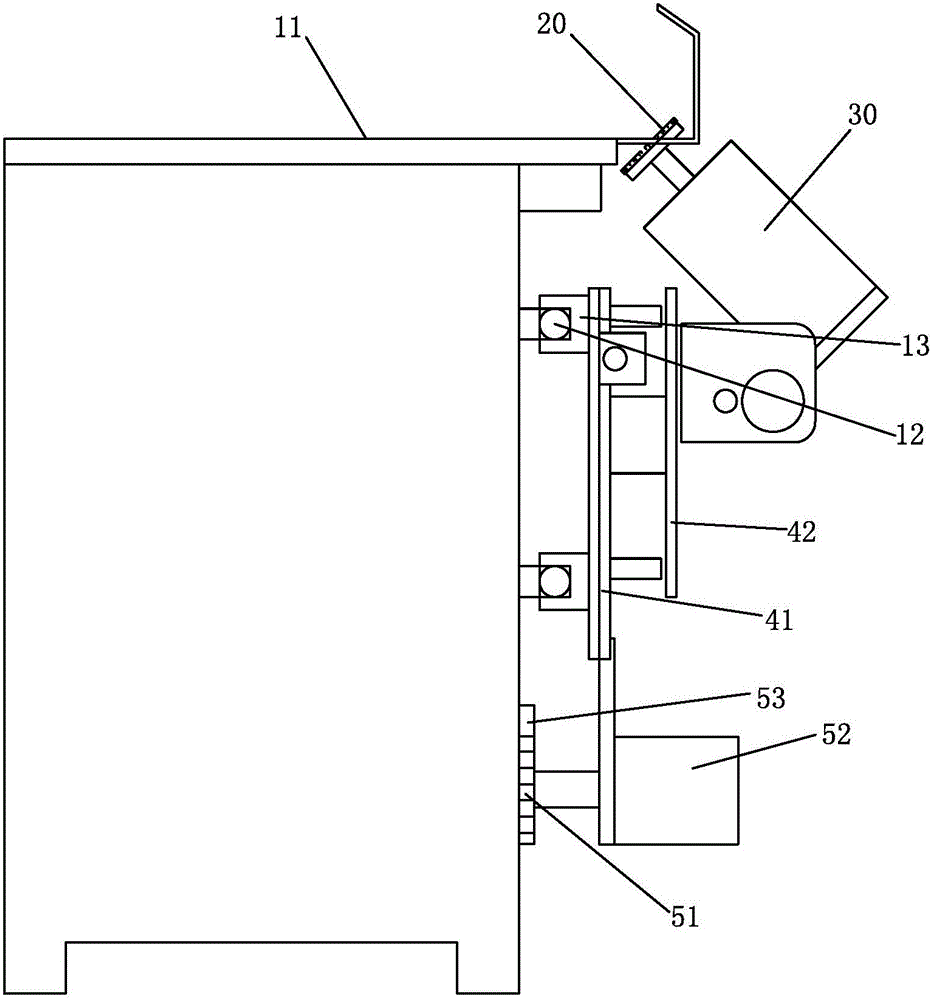

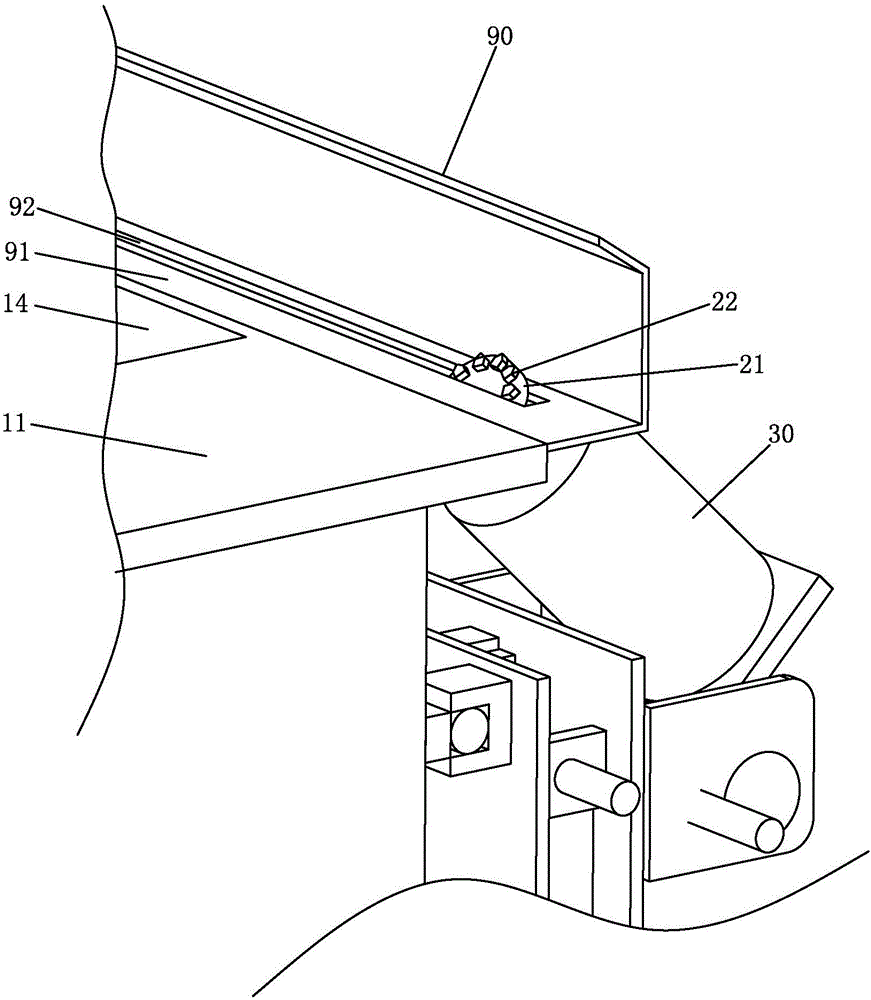

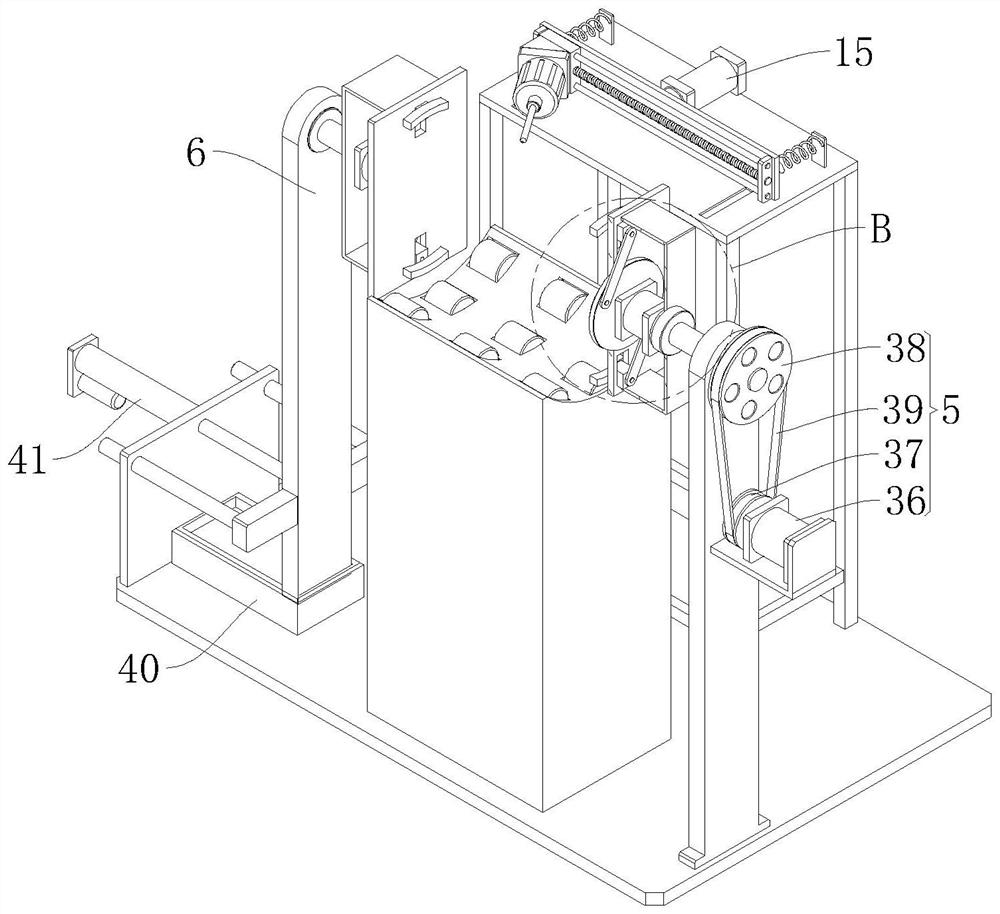

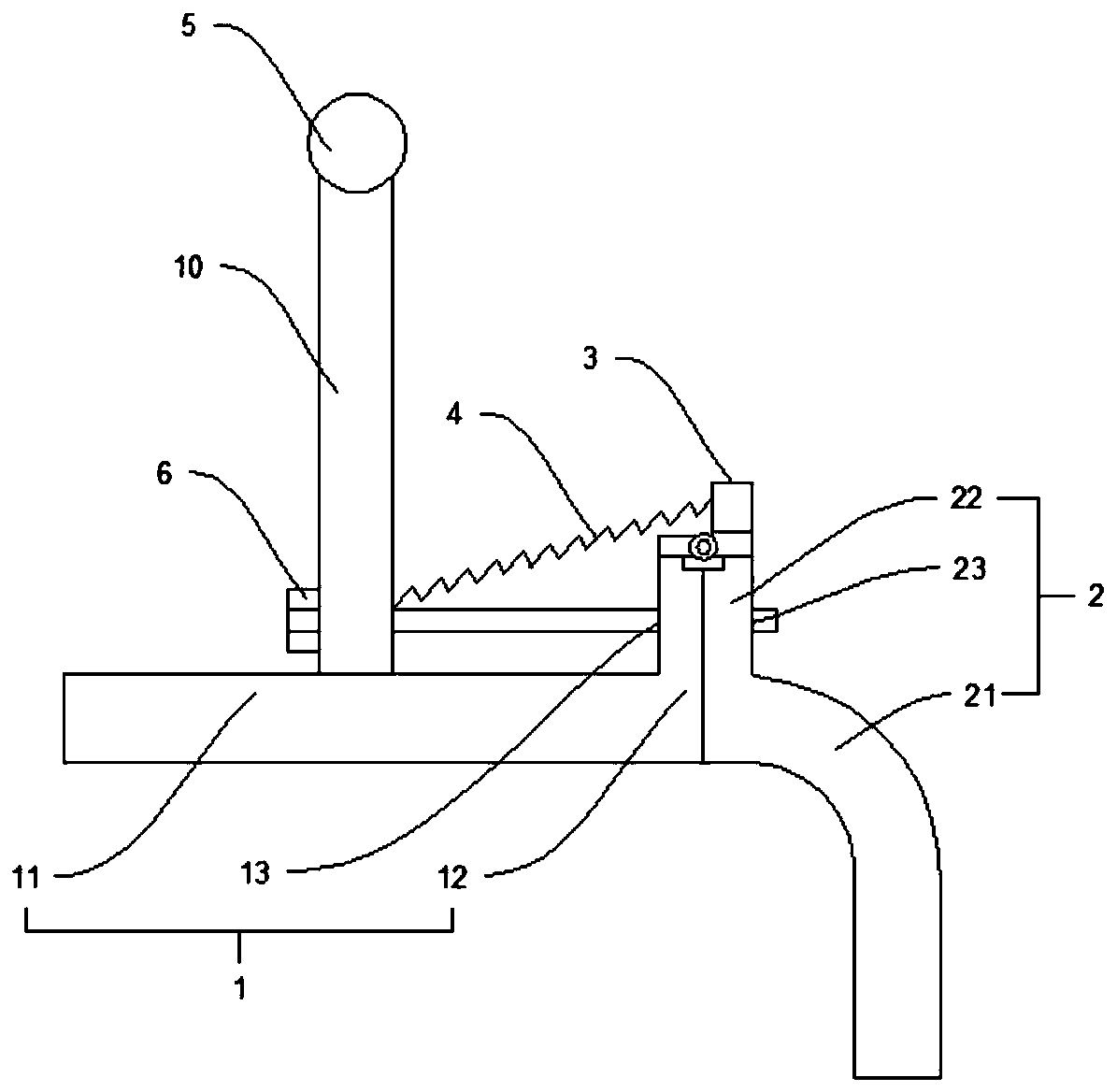

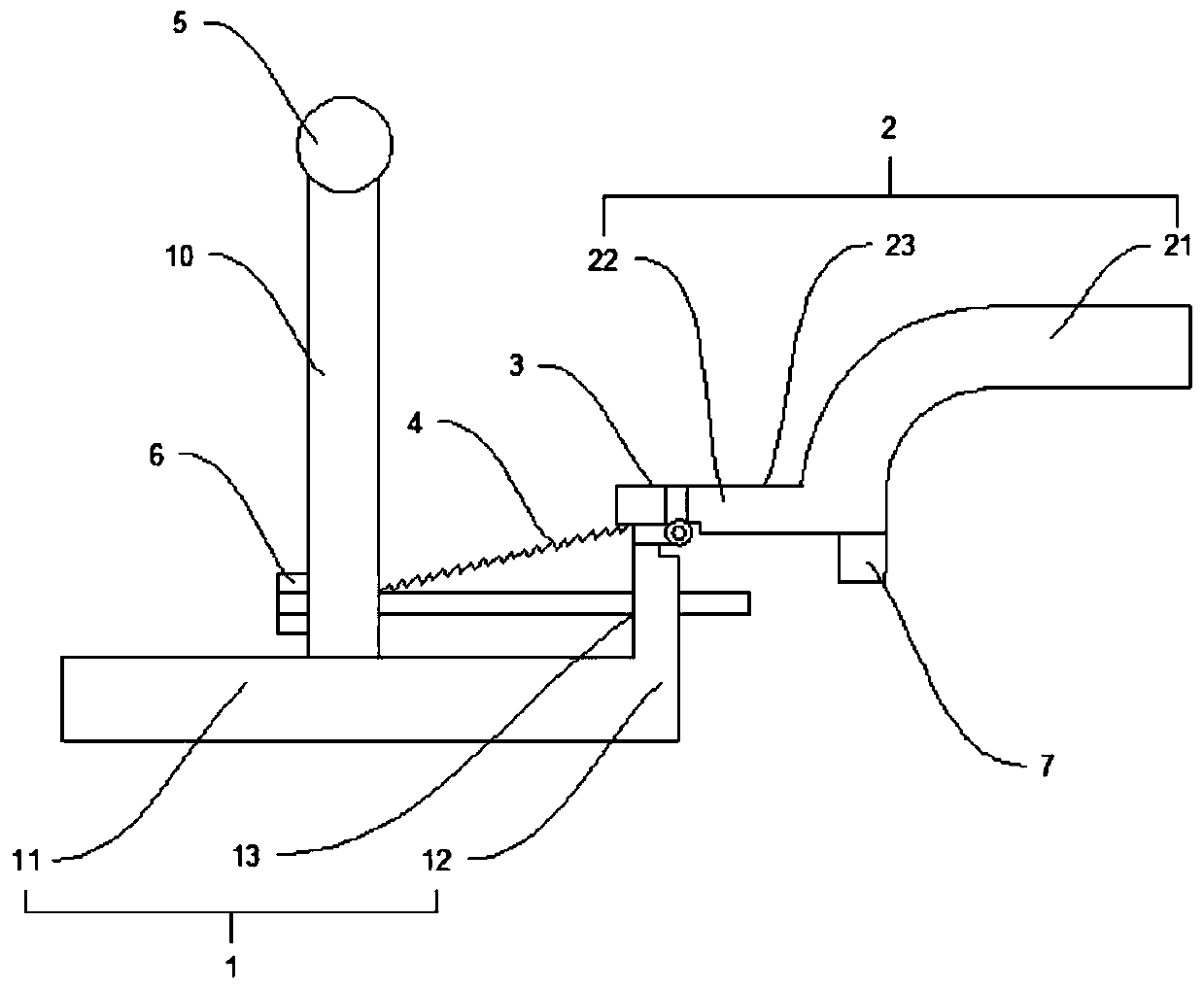

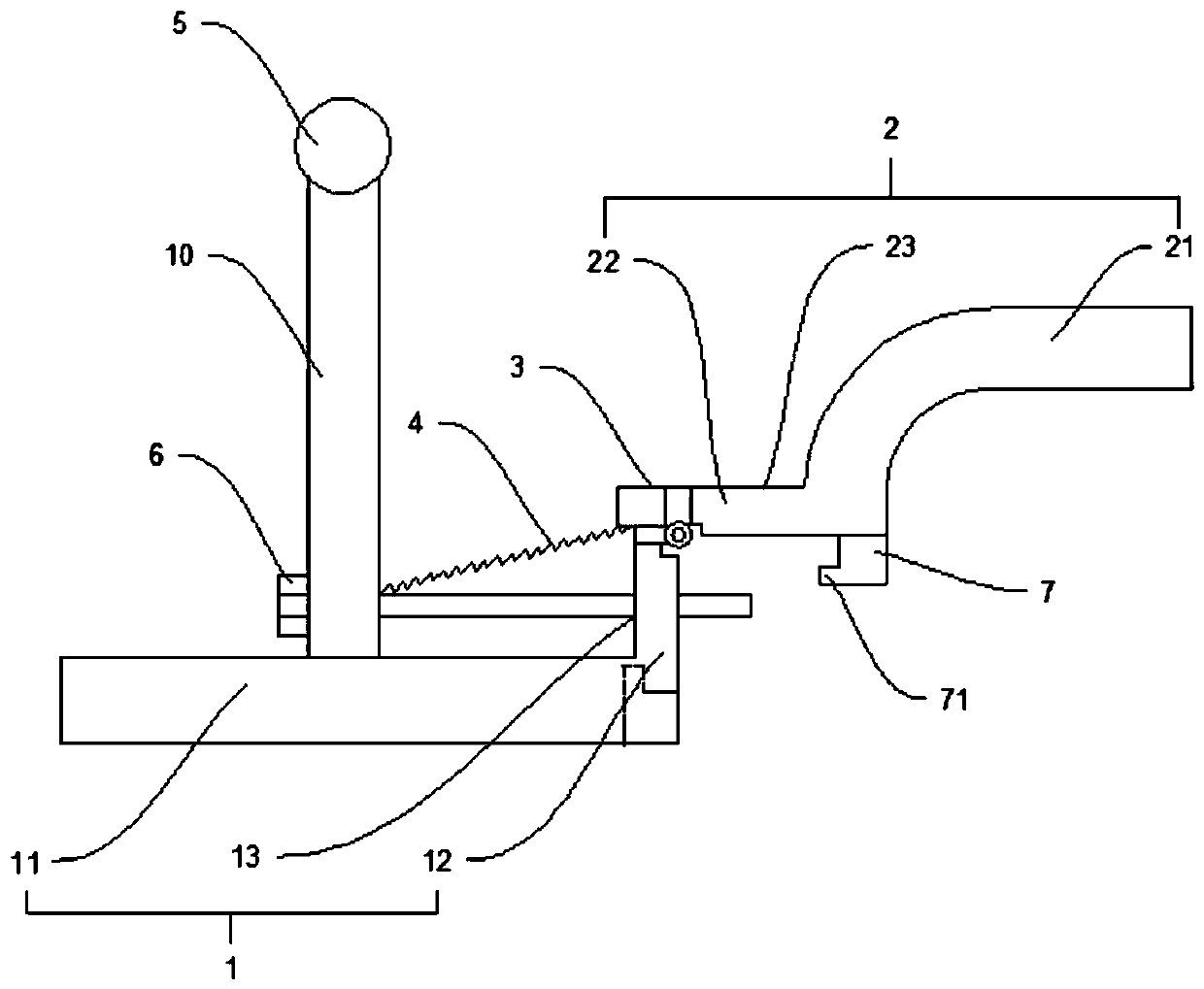

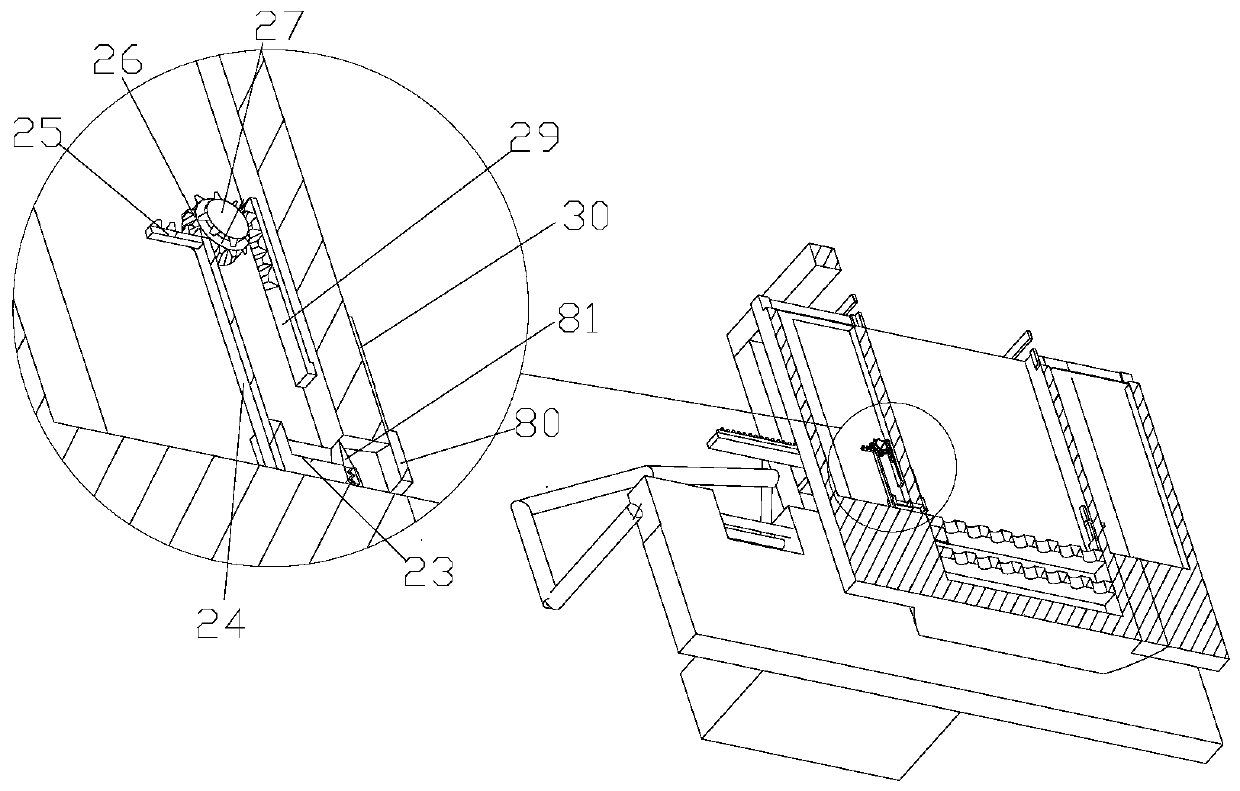

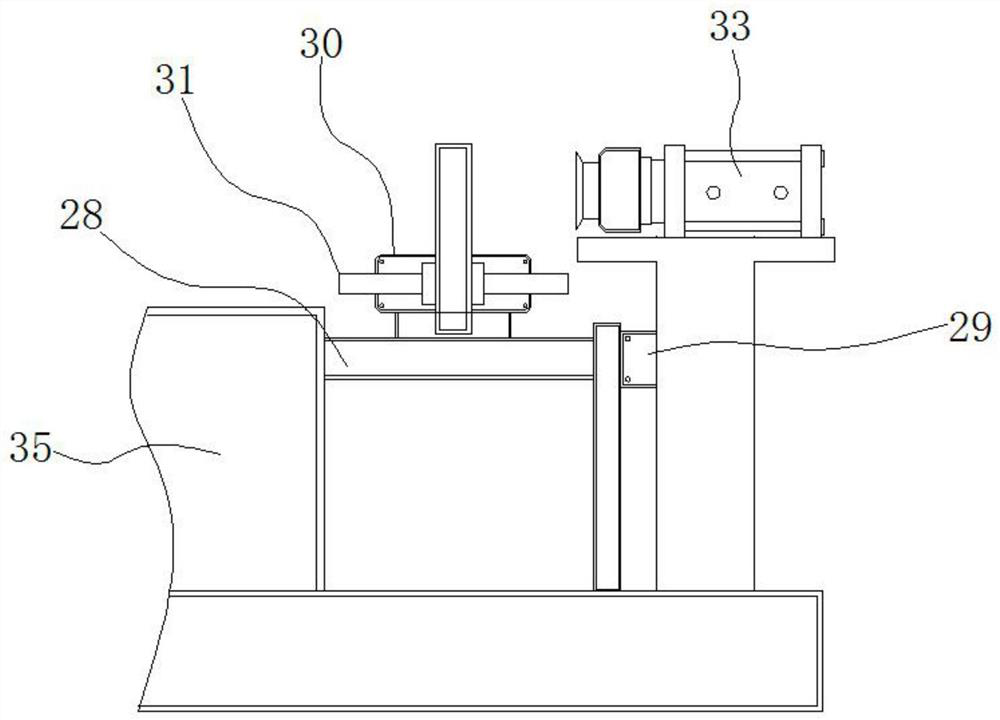

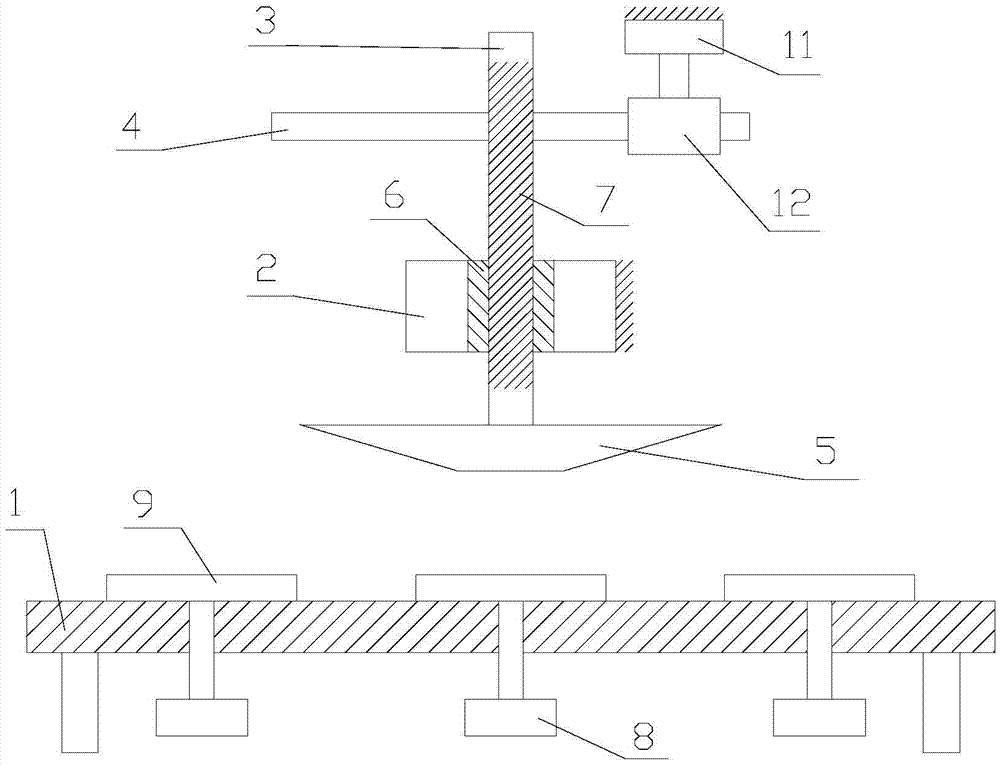

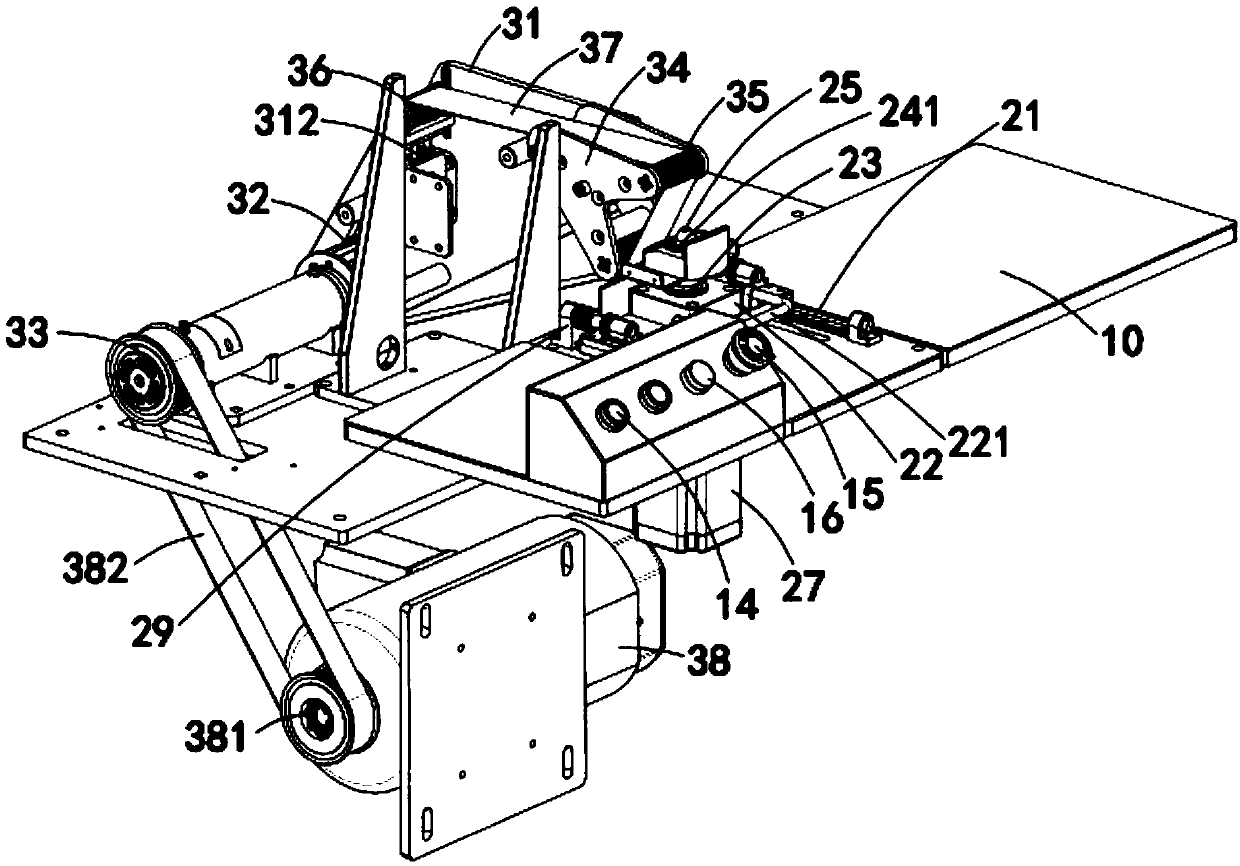

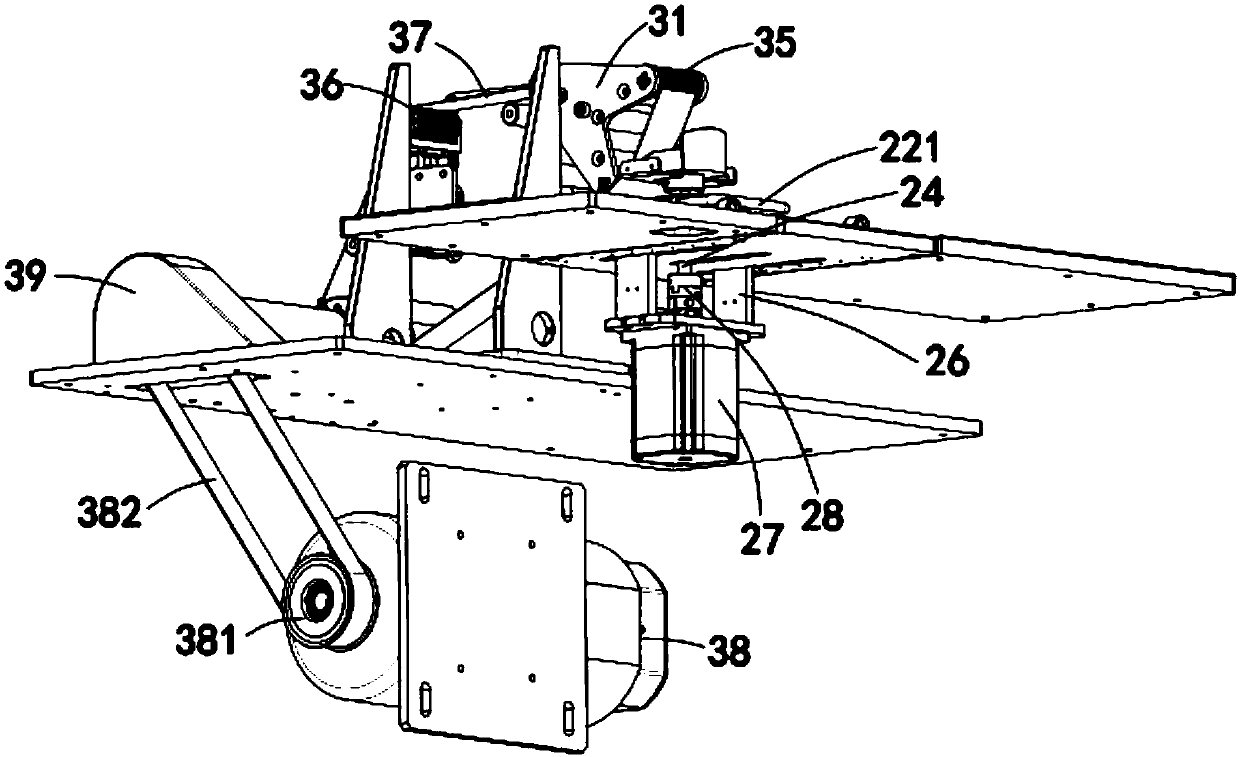

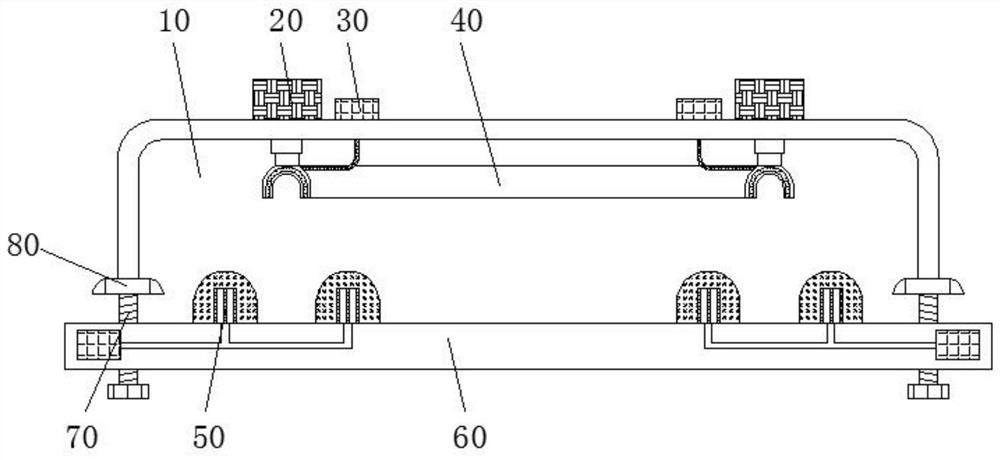

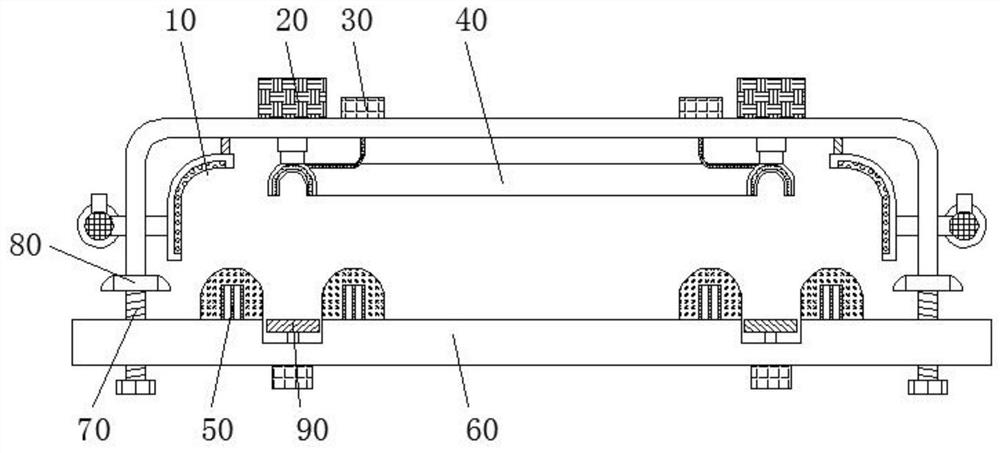

Chamfering machine for wind turbine blade lining foam board

PendingCN107351158ASimple structureGood chamfering effectMetal working apparatusTurbine bladeEngineering

The invention relates to a chamfering machine for a wind turbine blade lining foam board. The chamfering machine comprises a base, a conveying mechanism and a chamfering mechanism; the chamfering machine is characterized in that the conveying mechanism and the chamfering mechanism are installed on the base; the conveying mechanism comprises a driving roller, a driven roller, a conveying belt and a transmission device, the conveying belt is connected between the driving roller and the driven roller, one end of the driving roller is connected with the transmission device, and the transmission device is fixedly installed on the base; and the chamfering mechanism comprises a chamfering support, a guide rail, a chamfering support movement mechanism, a chamfering driving mechanism and a dip angle adjusting mechanism, the guide rail is installed at the upper portion of the base and is provided with the chamfering support movement mechanism, the chamfering support is installed on the guide rail and connected with the chamfering support movement mechanism, the chamfering driving mechanism is installed on the chamfering support and provided with a saw blade, and the chamfering support is further provided with the dip angle adjusting mechanism. The chamfering machine is simple in structure, chamfering cutting of the lining foam board is achieved, the structure is simple, the chamfering effect is good, efficiency is high, and adjustment is convenient.

Owner:山东盈九新能源科技有限公司

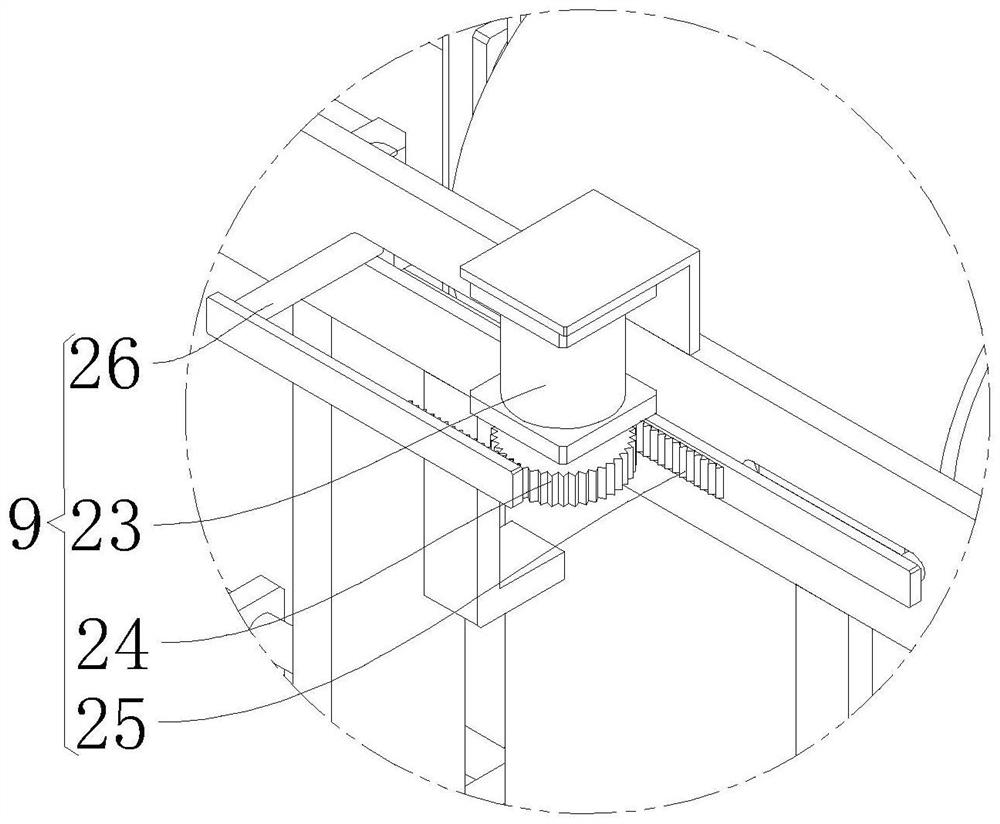

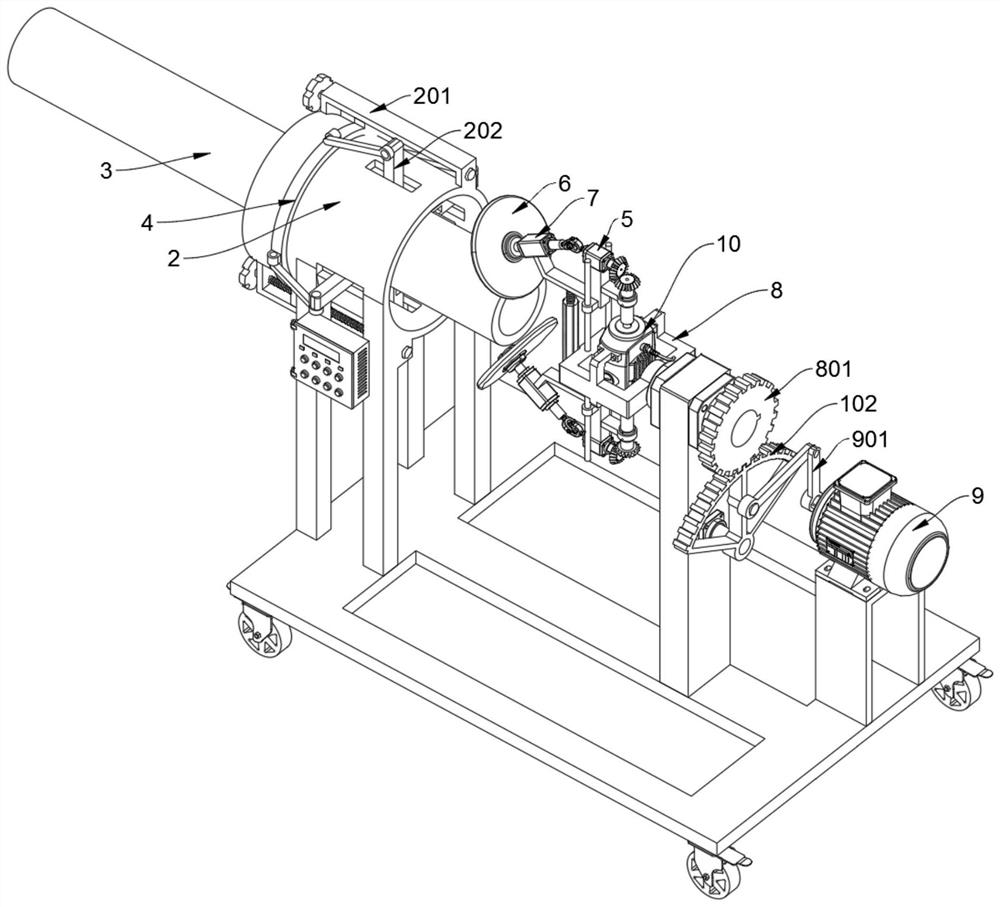

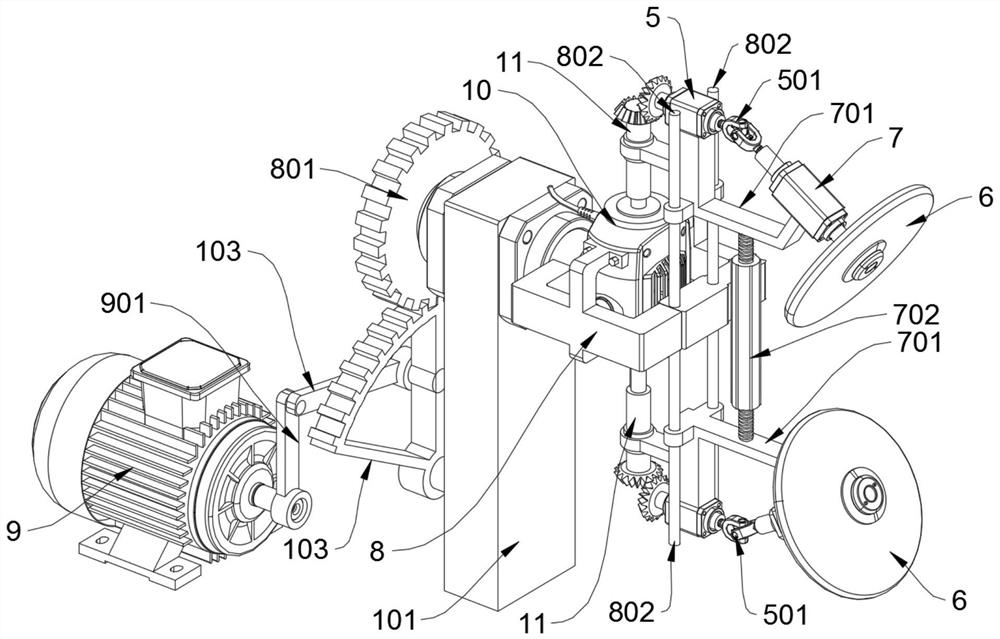

Polisher capable of adjusting polishing height of lipping of rail head

PendingCN107165008ALarge swing angleImprove swing flexibilityRailway track constructionPhysicsElectric machinery

The invention discloses a polisher capable of adjusting the polishing height of lipping of rail head, and belongs to the technical field of railway maintenance equipment. The polisher comprises a rack. The polisher is characterized by further comprising a vertically moving device and a travelling device; the vertically moving device comprises a hanging bracket, ball bearing bases, ball screws and ball nuts, stepper motors and vertically sliding blocks are arranged on the rack, and the hanging bracket is connected with the rack in a sliding mode through the vertically sliding blocks; the travelling device comprises a driving gear, a driven gear, a travelling wheel, a rolling wheel and a motor, wherein the driving gear is connected with the motor shaft of the motor, the driven gear is driven by the driving gear through gear meshing, and the travelling wheel is connected with the driven gear. According to the polisher capable of adjusting the polishing height of the lipping of the rail head, when polishing is conducted on the lipping of the rail head, the polisher can uniformly move at a low speed, and a grinding wheel is driven to automatically feed in the vertical direction, so that polishing in the vertical direction is conducted on the lipping of the rail head, and the polishing speed is uniform; moreover, the grinding wheel can vertically move, and polishing is conducted on any position of the height of the lipping of the rail head, so that the overall effect of polishing of the lipping of the rail head is improved.

Owner:西藏天仁科技发展有限公司

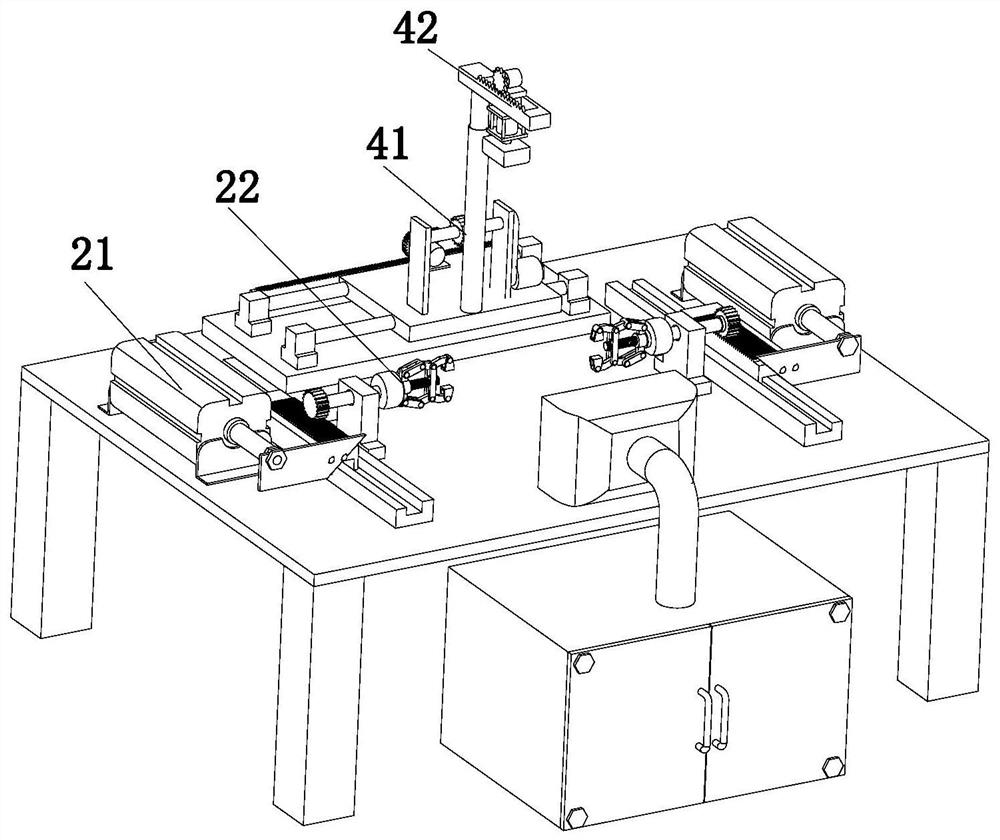

Chamfering device for machining

InactiveCN112428060AQuality assuranceReduce labor intensityEdge grinding machinesGrinding drivesMachiningWorkbench

The invention discloses a chamfering device for machining, and relates to the technical field of machining. The chamfering device comprises a workbench, two groups of rotary fixing assemblies, a moving assembly, a chamfering assembly and a scrap removing assembly, wherein the two groups of rotary fixing assemblies are symmetrically arranged on the workbench, the moving assembly are fixedly arranged on one side of the workbench, the chamfering assembly is fixedly arranged at the working end of the moving assembly, and the scrap removing assembly is fixedly arranged on the other side of the workbench. According to the chamfering device, the working efficiency is greatly improved, the quality of chamfering operation is guaranteed, the labor intensity of workers is relieved, and the practicability of the device is greatly improved.

Owner:王为

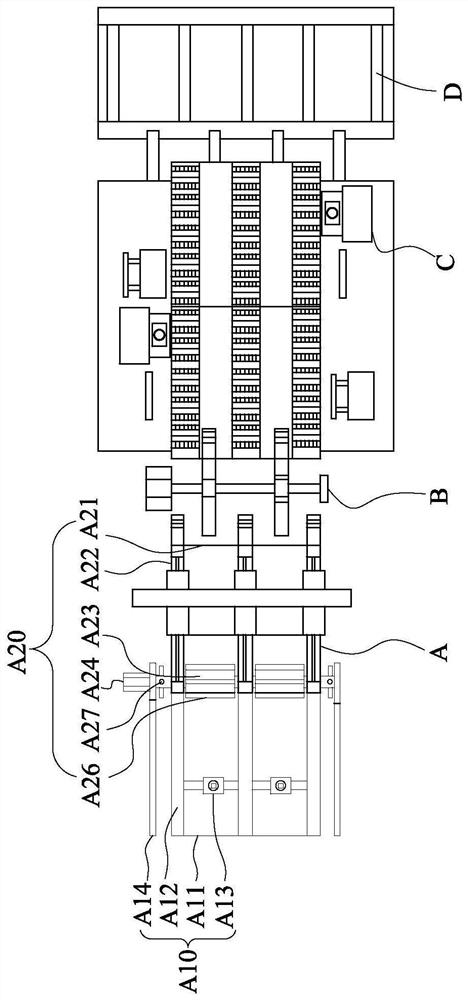

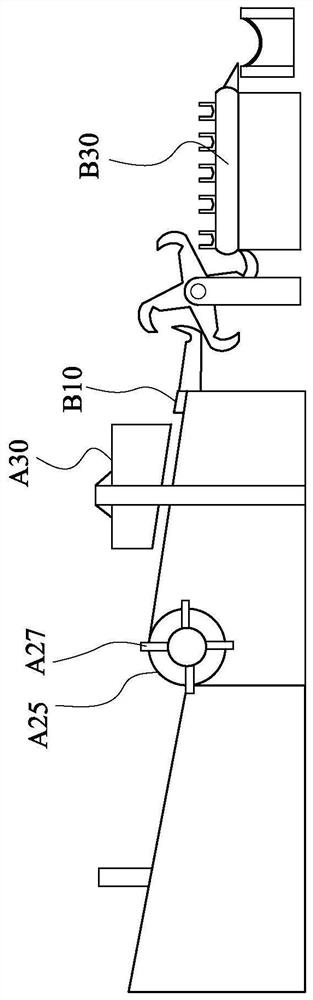

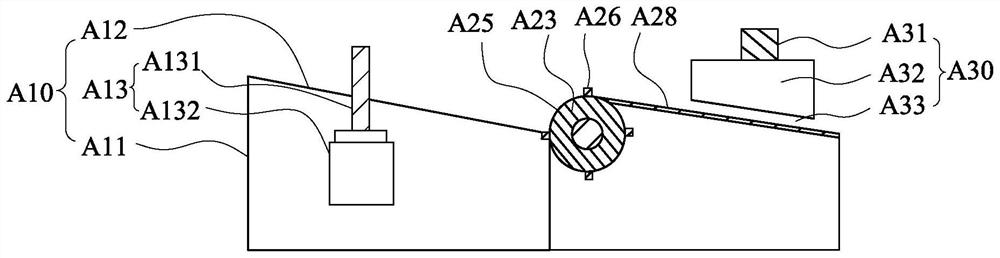

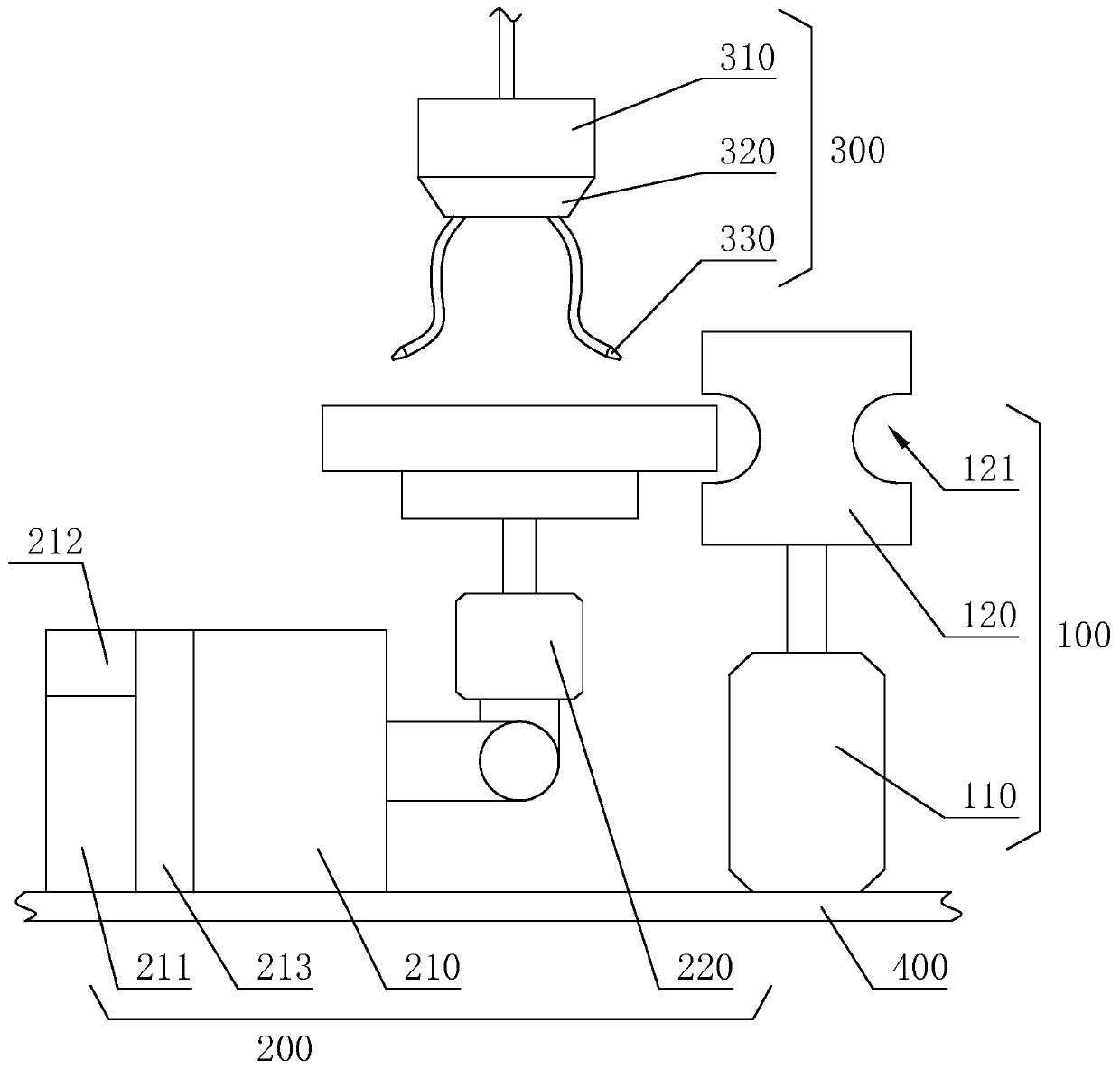

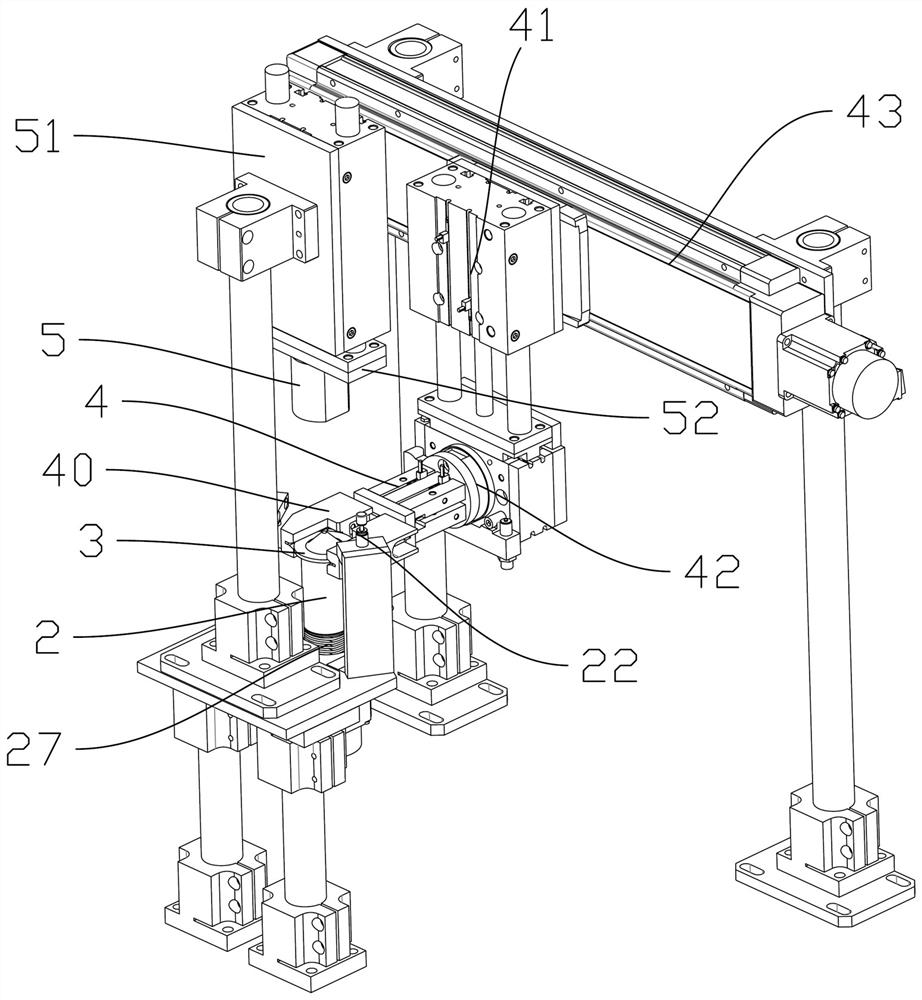

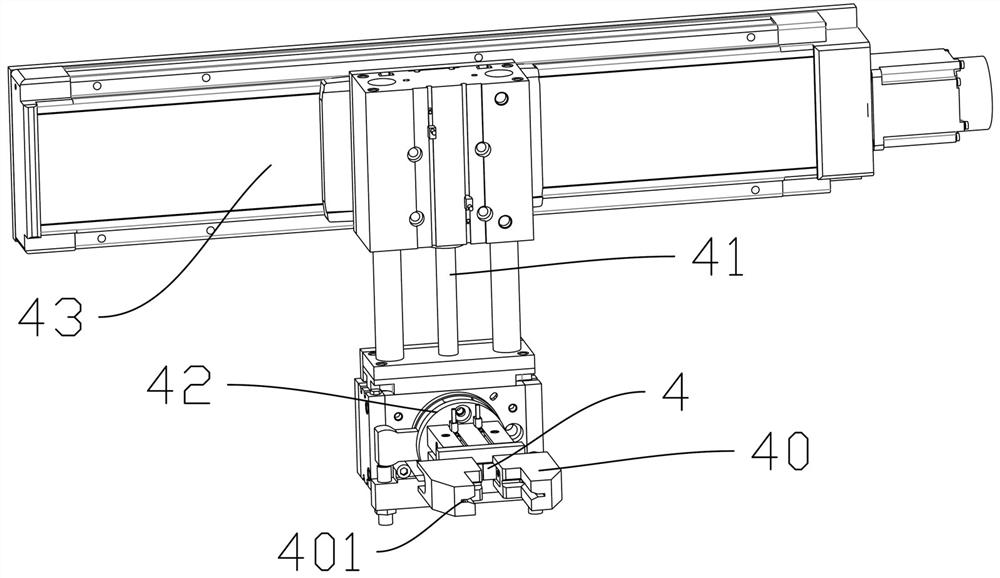

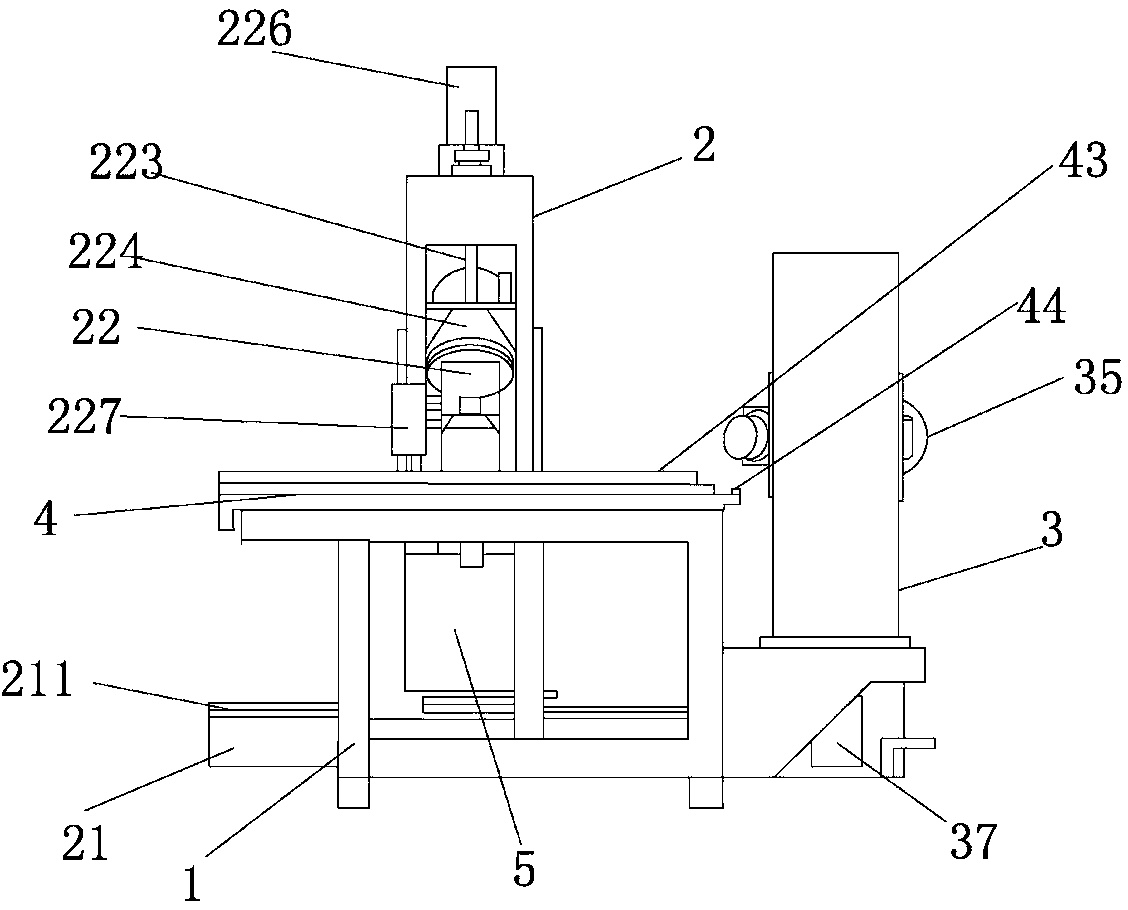

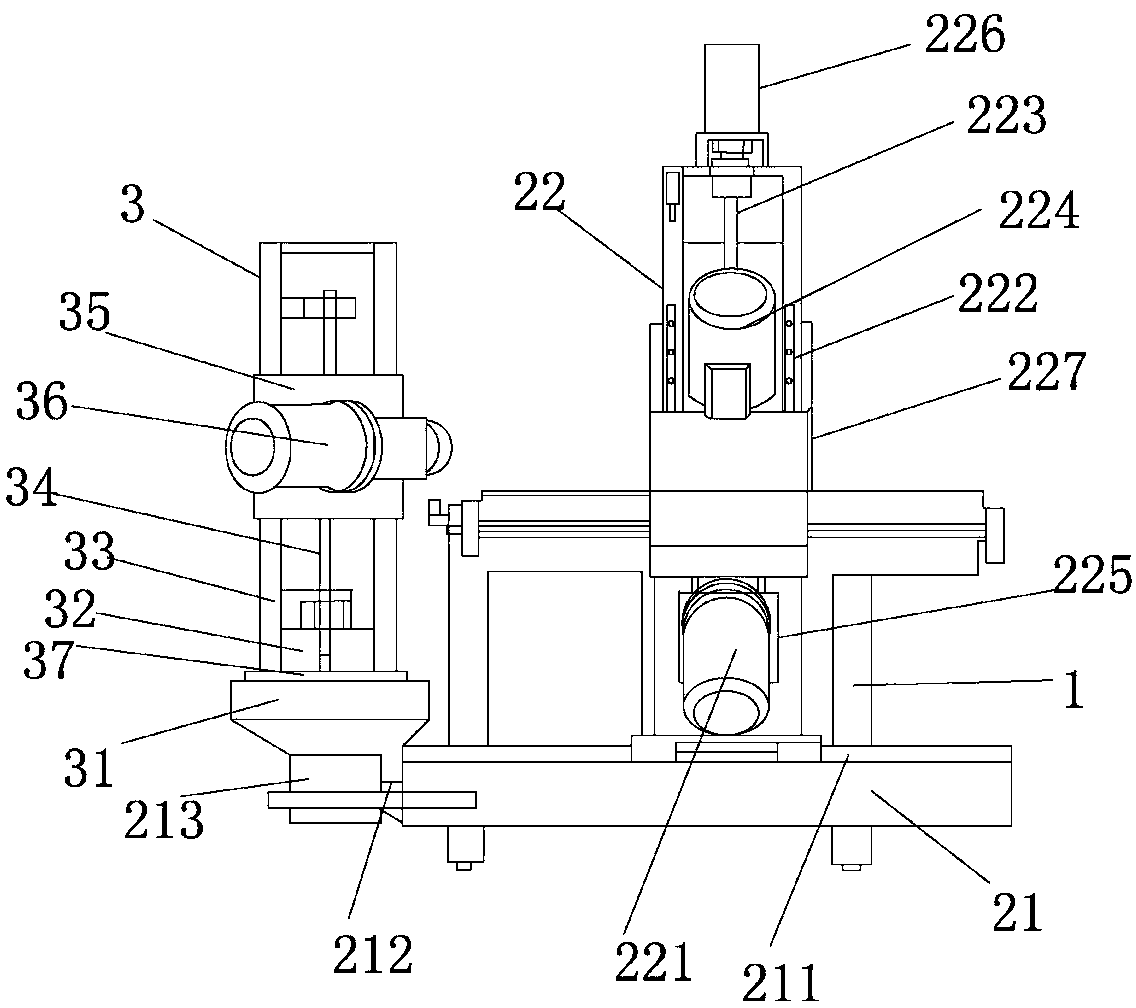

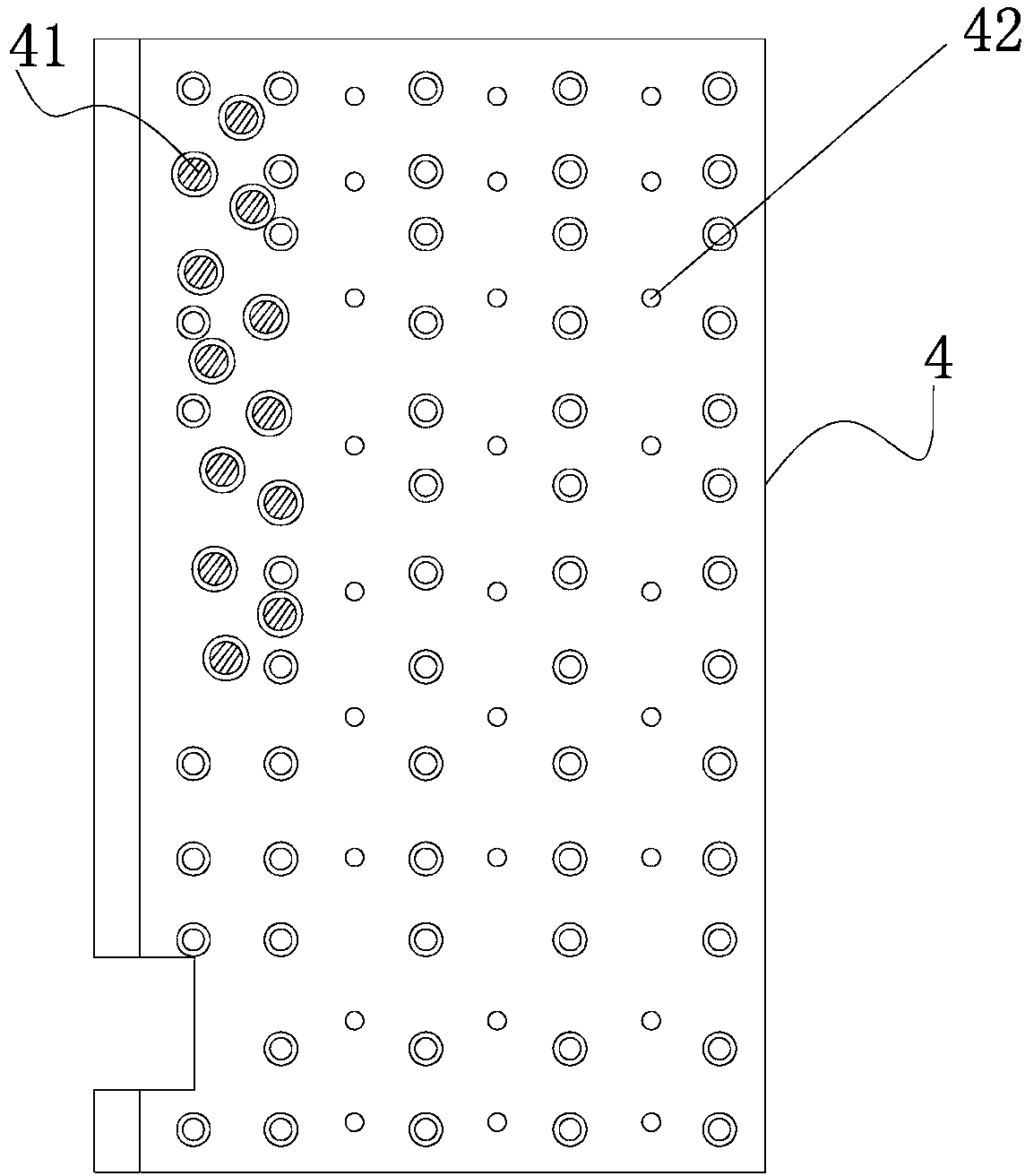

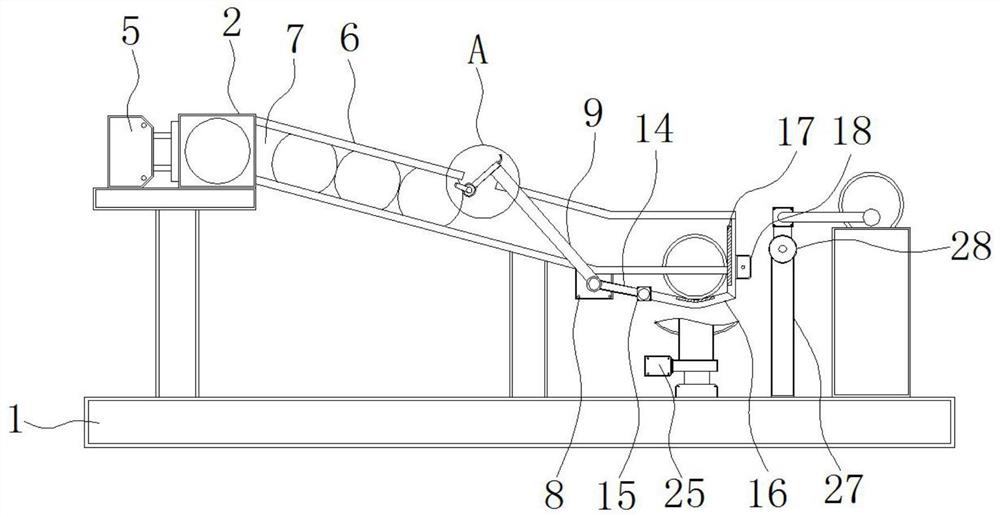

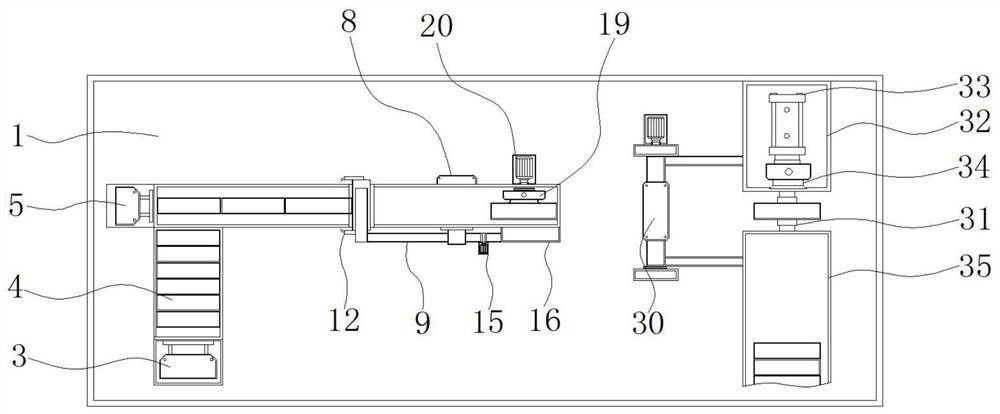

Full-automatic bidirectional chamfering system for end part of steel bar, and working method thereof

A full-automatic bidirectional chamfering system for the end part of a steel bar comprises a steel bar feeding mechanism, a steel bar turnover and transfer mechanism arranged on one side of the steelbar feeding mechanism, a steel bar bidirectional chamfering mechanism arranged on one side, far away from the steel bar feeding mechanism, of the steel bar turnover and transfer mechanism, and a steelbar discharging mechanism arranged on one side, far away from the steel bar turnover and transfer mechanism, of the steel bar bidirectional chamfering mechanism. The steel bar feeding mechanism can transfer the steel bar to the steel bar turnover and transfer mechanism, the steel bar turnover and transfer mechanism transfers the steel bar to the steel bar bidirectional chamfering mechanism, and the steel bar bidirectional chamfering mechanism transfers the steel bar to the steel bar discharging mechanism after finishing machining. The full-automatic bidirectional chamfering system for the endpart of the steel bar is high in automation degree, conveying stability is enhanced, and working efficiency is improved.

Owner:俊钛金属材料(浙江)有限公司

Edge chamfering device for furniture production

InactiveCN110877376AEasy to replaceRealize chamfering operationProfiling/shaping machinesBark-zones/chip/dust/waste removalScrew threadThreaded rod

The invention discloses an edge chamfering device for furniture production. The edge chamfering device for furniture production includes a workbench, a mounting groove is formed in the outer wall of the top of the workbench, the inner wall of the mounting groove is connected with a motor through bolts, a turntable is arranged at one end of an output shaft of the motor, a threaded groove is formedin the outer wall of the top of the turntable, the inner wall of the threaded groove is in threaded connection with a threaded rod, the outer wall of the threaded rod sleeves a chamfering wheel, an adjustment wheel is arranged on the outer wall of the top of the threaded rod, a limiting rod is welded to the outer wall of the bottom of the adjustment wheel, a limiting groove is formed in the outerwall of the top of the chamfering wheel, the inner wall of the limiting groove and the outer wall of the limiting rod are plugged in, and T-shaped grooves are formed at the four corners of the outer wall of the top of the workbench correspondingly. Replacement of the chamfering wheel is convenient, using has more flexibility, the effective limiting effect on a wood can be achieved so that the woodis less prone to shaking during chamfering, the chamfering effect is better, the chamfering position can be flexibly controlled, and the using effect of the device is further improved.

Owner:佟春梅

a chamfering machine

ActiveCN105904030BReduce labor costsImprove securityEdge grinding machinesPositioning apparatusMotor driveEngineering

Owner:JOMOO KITCHEN & BATHROOM

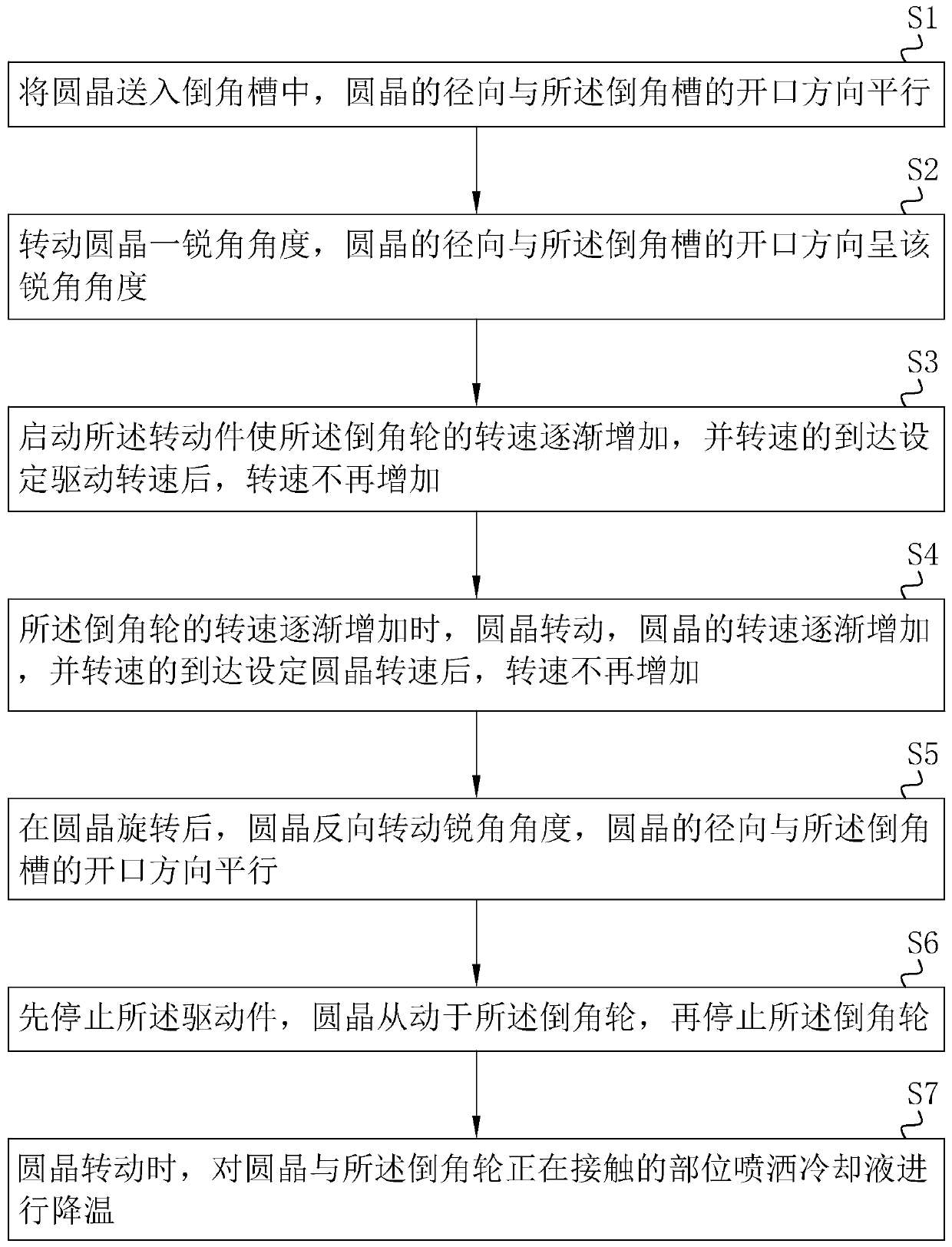

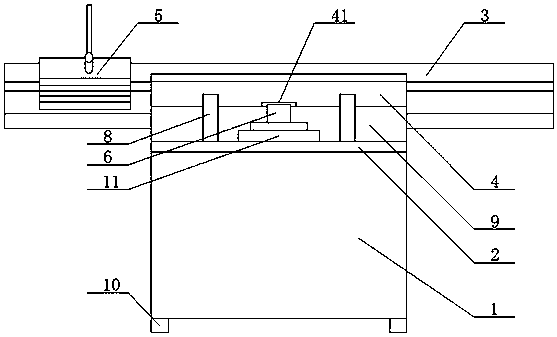

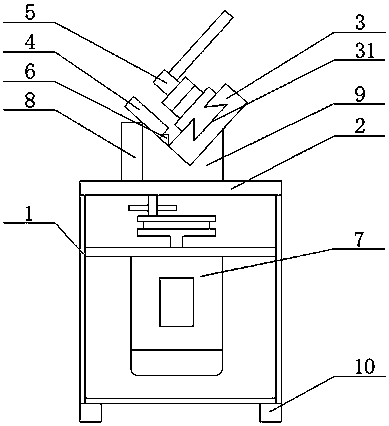

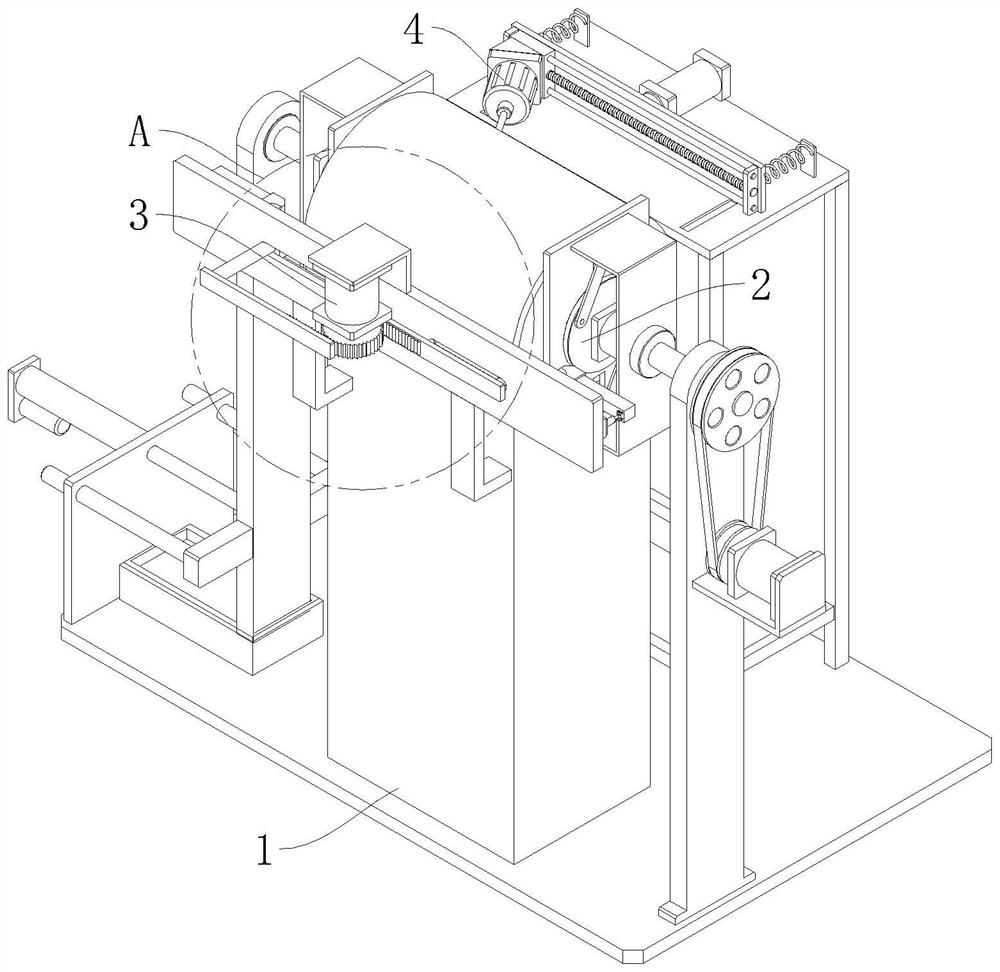

Wafer chamfering process

ActiveCN111037370AReduce the size of the siteReduce contact areaEdge grinding machinesGrinding carriagesAcute angleEngineering

The invention relates to the technical field of wafer machining, and discloses a wafer chamfering process based on a wafer chamfering device. The wafer chamfering device comprises a rotating piece, the rotating piece is connected with a chamfering wheel, the chamfering wheel is provided with a chamfering groove, and the opening direction of the chamfering groove is perpendicular to the axial direction of the chamfering wheel; the process comprises the following steps that S1, wafers are fed into the chamfering groove; S2: the radial direction of the wafers is at an acute angle with the openingdirection of the chamfered groove; S3, the rotating piece is started to gradually increase the rotating speed of the chamfering wheel, and after the rotating speed reaches a set driving rotating speed, the rotating speed is no longer increased; S4, when the rotating speed of the chamfering wheel is gradually increased, the rotating speed of the wafers is gradually increased, and after the rotating speed reaches the set wafer rotating speed, the rotating speed is no longer increased; and S5, the wafers rotate the acute angle in a reverse mode, and the radial direction of the wafers is parallelto the opening direction of the chamfering groove; and when the chamfering is conducted, the contact area between the wafers and the inner wall of the chamfering groove is reduced, the volume of theparts affected by the temperature change of the wafers is reduced, and the chamfering effect of the edge of the wafers is improved.

Owner:上海磐盟电子材料有限公司

Chamfering machine

InactiveCN107900425ASimple structureLow costFeeding apparatusMilling equipment detailsMilling cutterEngineering

A chamfering machine relates to the field of mechanical technology, in particular to a chamfering machine. It includes a box body, a workbench, a guide plate, an inclined plane, a locking device, a milling cutter, a motor, a fixing part, a support part, and a chassis. The upper surface of the support part is provided with a support part, the upper surface of the support part is a V-shaped structure, the guide plate is set on one side of the V-shaped structure on the support surface, the slope is set on the other side of the V-shaped structure on the support surface, and locked The device is arranged on the upper surface of the guide plate, a chassis is arranged at the center of the upper surface of the workbench, a milling cutter is arranged above the chassis, and fixing parts are arranged on both sides of the chassis. After adopting the above technical solution, the beneficial effects of the present invention are: the structure is simple, the cost is low, and the chamfering effect is good.

Owner:涂壹强

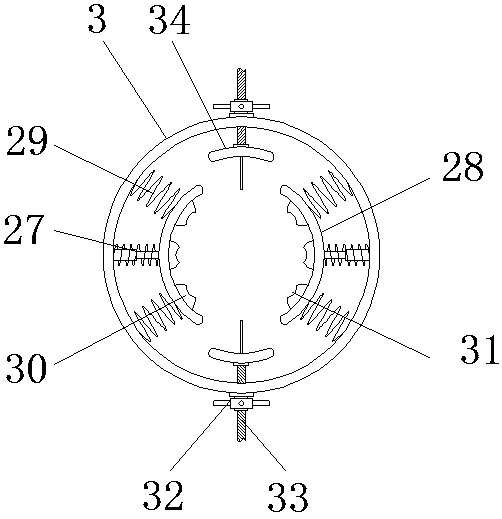

Self-adaptive chamfering and drilling equipment for sliding bearing

PendingCN114799894AIncrease the areaReduce wearWork clamping meansFeeding apparatusSlider bearingClassical mechanics

The invention relates to the technical field of sliding bearing machining, in particular to sliding bearing self-adaptive chamfering and drilling equipment which comprises a base and a material table and further comprises a controller, a clamping mechanism, a chamfering mechanism and a drilling mechanism. The chamfering mechanism comprises a driving assembly, two sliding plates, two turning tools and two angle adjusting assemblies, the drilling mechanism comprises a drill bit, a mounting table, a pushing assembly and a sliding assembly, the sliding assembly is arranged on the pushing assembly, and the drill bit is fixedly arranged on the sliding assembly; the rotating assembly, the driving assembly, the pushing assembly and all the angle adjusting assemblies are electrically connected with the controller, according to the self-adaptive chamfering drilling equipment for the sliding bearing, it can be prevented that the amount of solid lubricant embedded into the through hole is small through oblique drilling, then abrasion between a shaft sleeve and a shaft cover is reduced, and the service life of the shaft sleeve and the shaft cover is prolonged. The replacement or maintenance frequency of the sliding bearing is reduced, the use cost is reduced, and the maintenance efficiency is improved.

Owner:JIASHAN THREE STAR BEARING

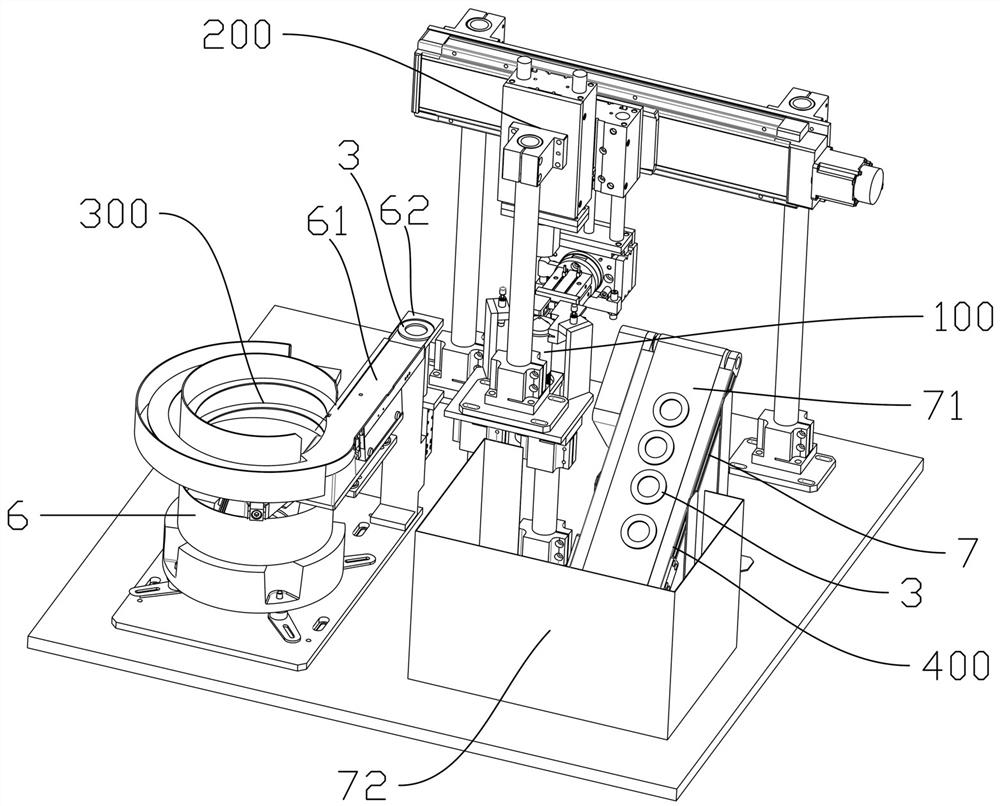

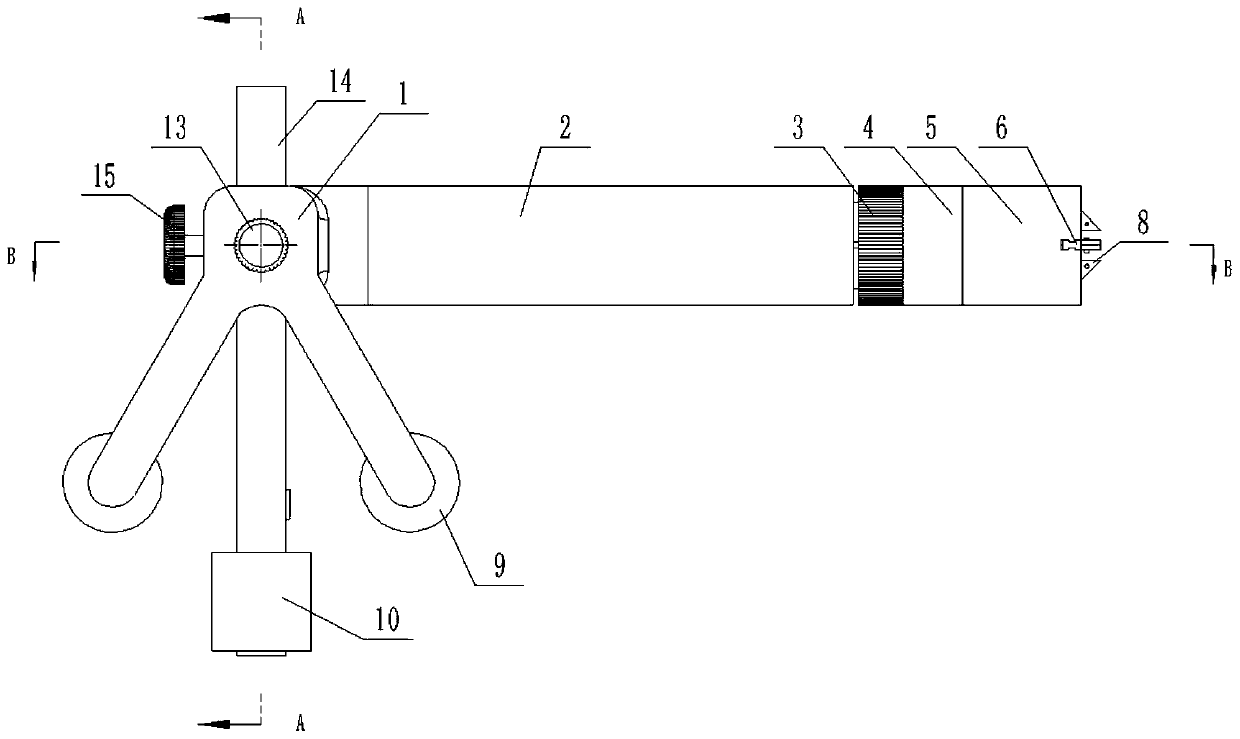

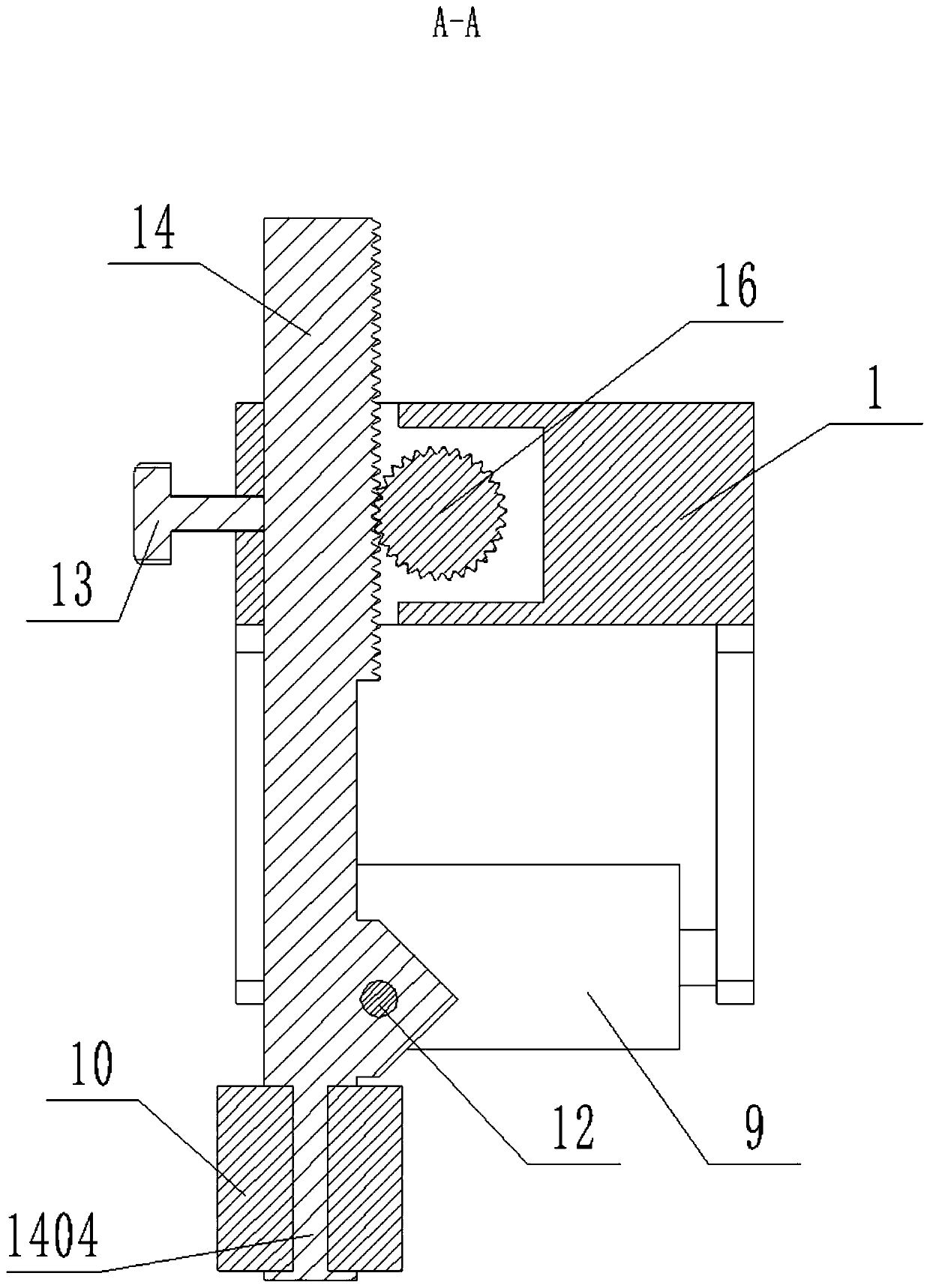

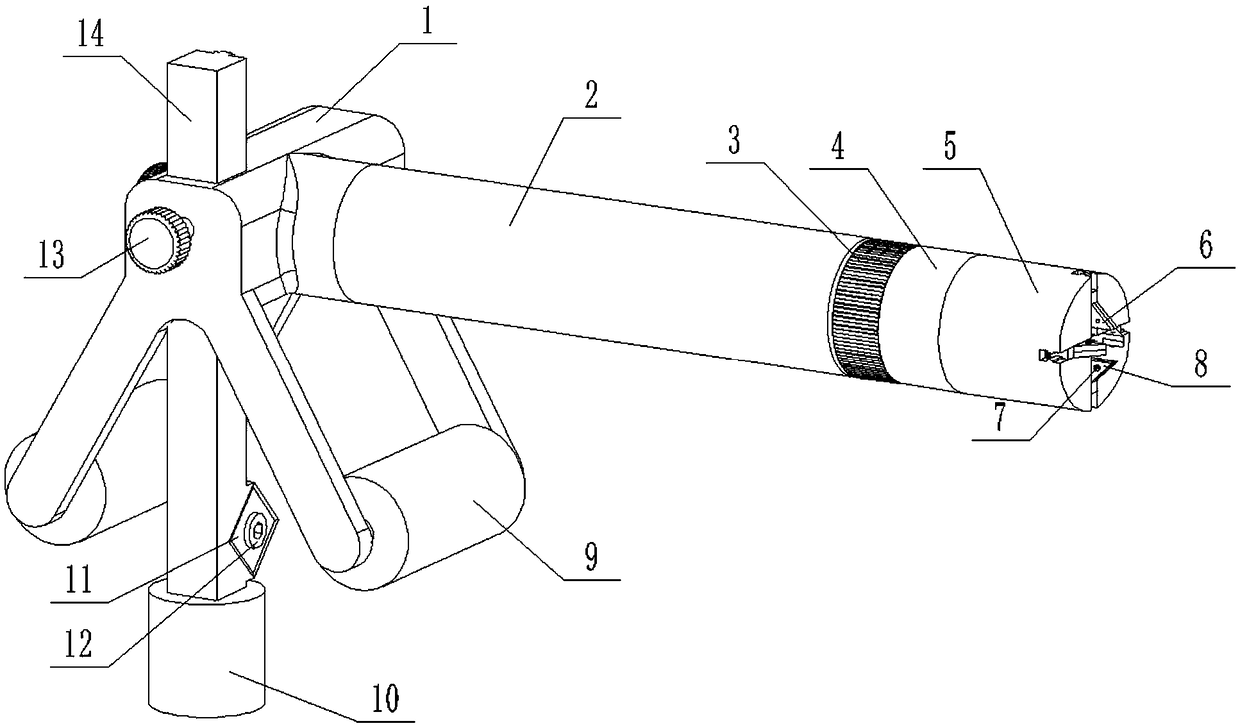

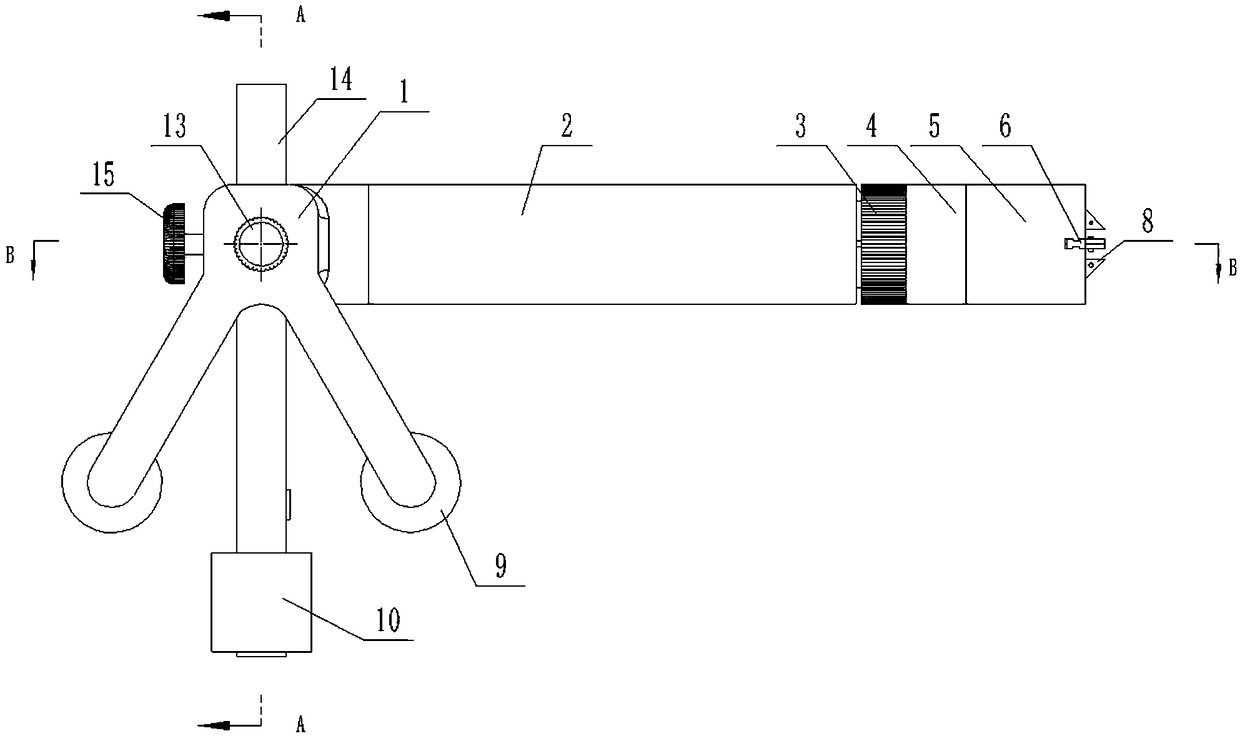

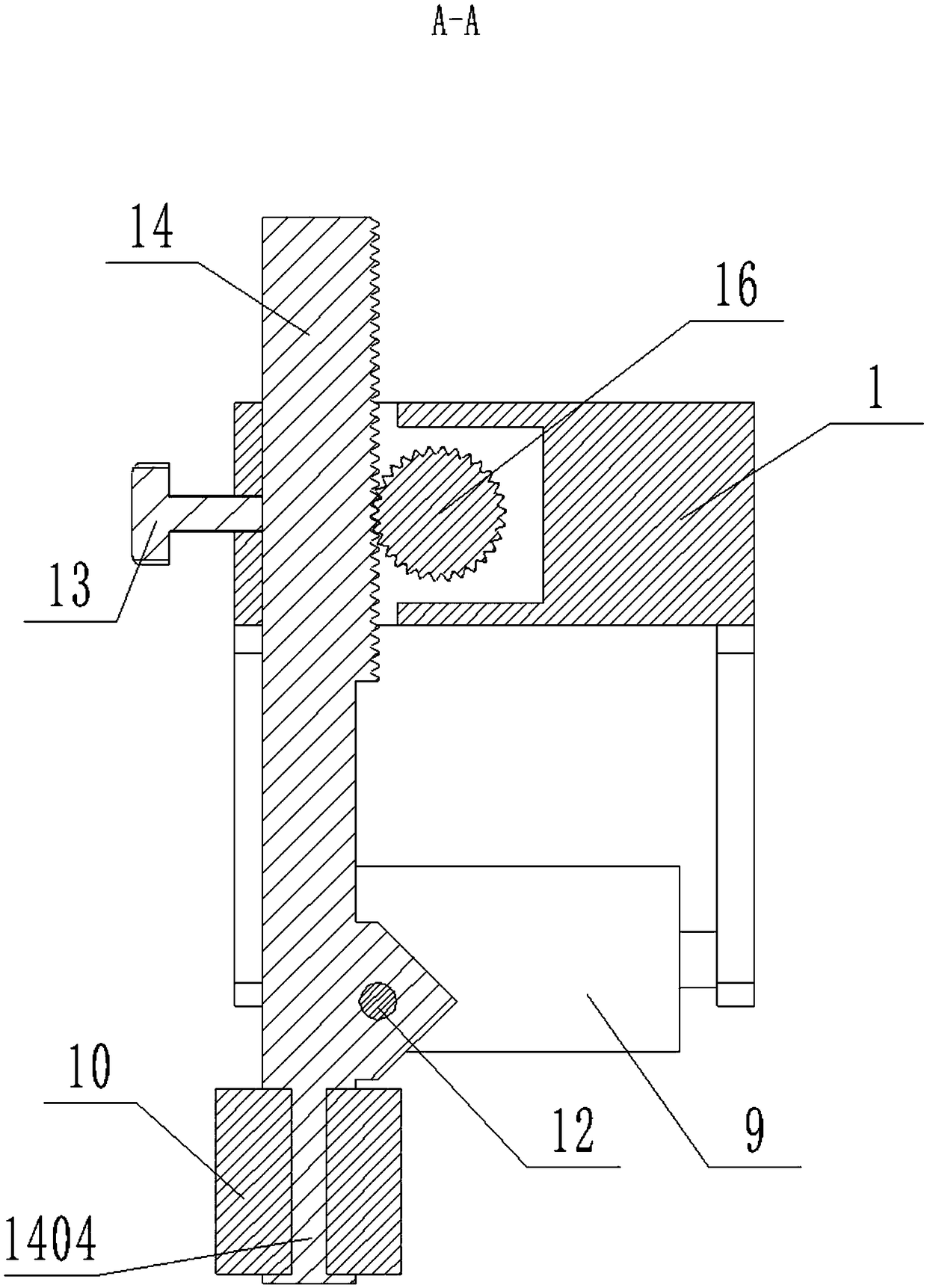

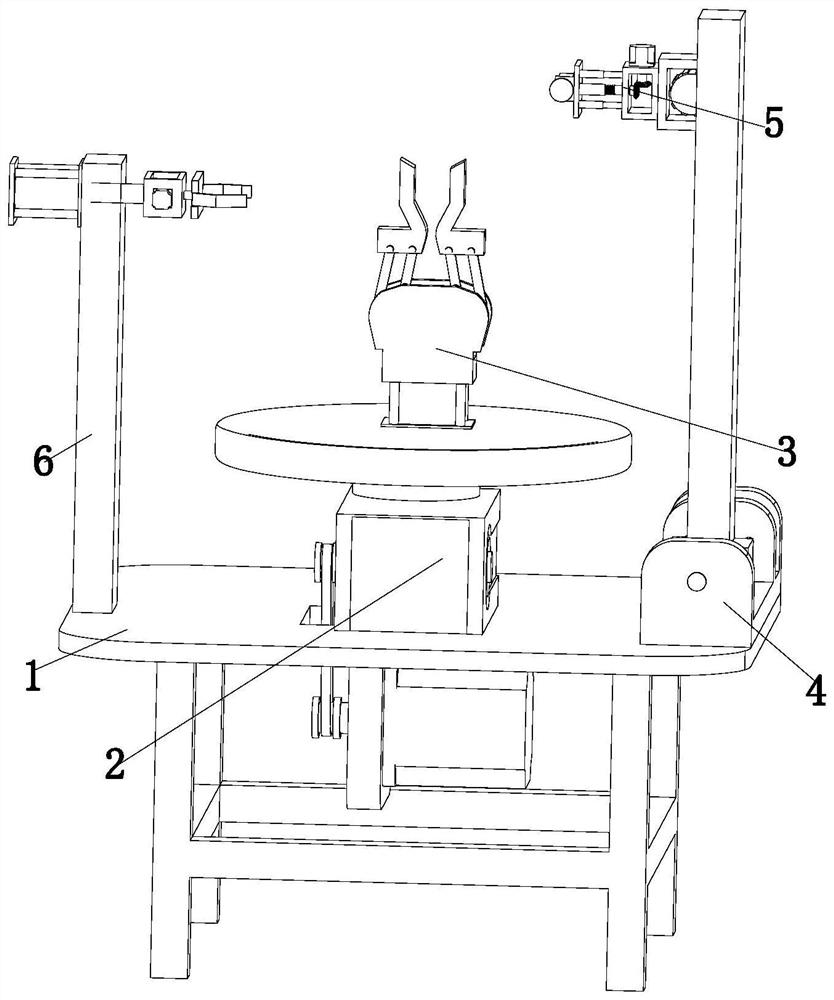

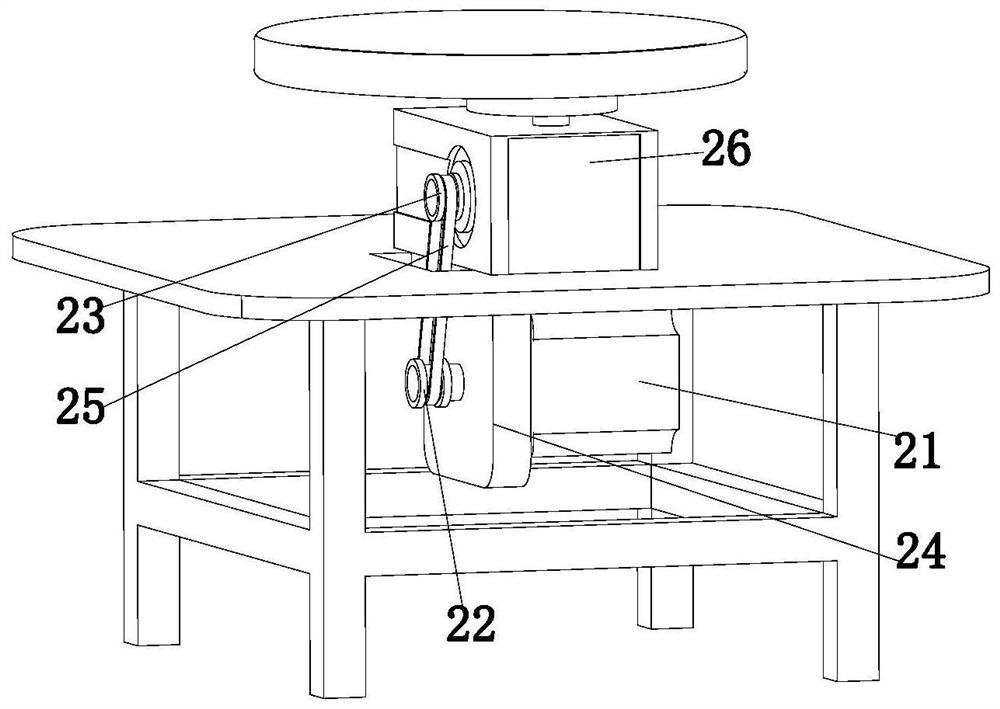

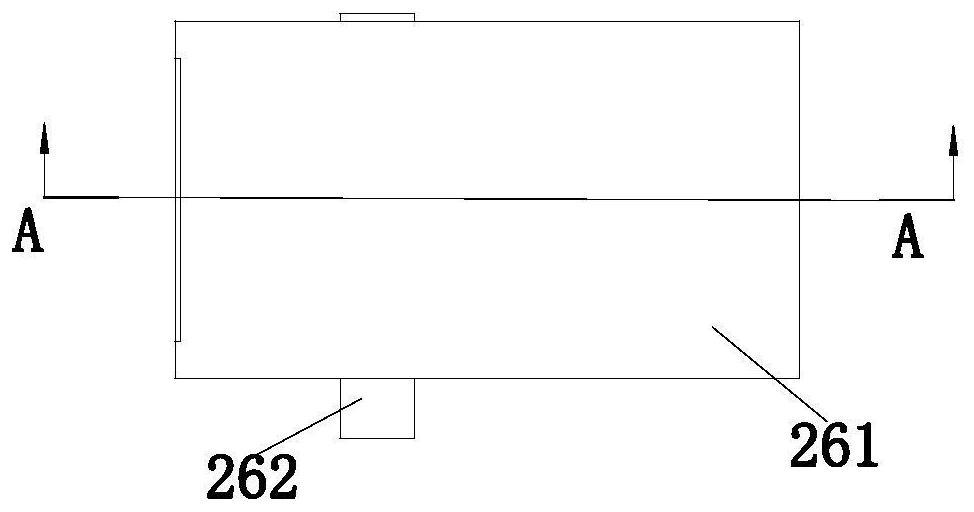

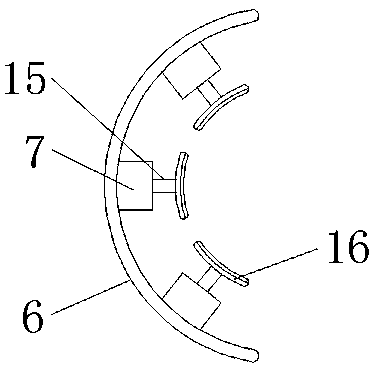

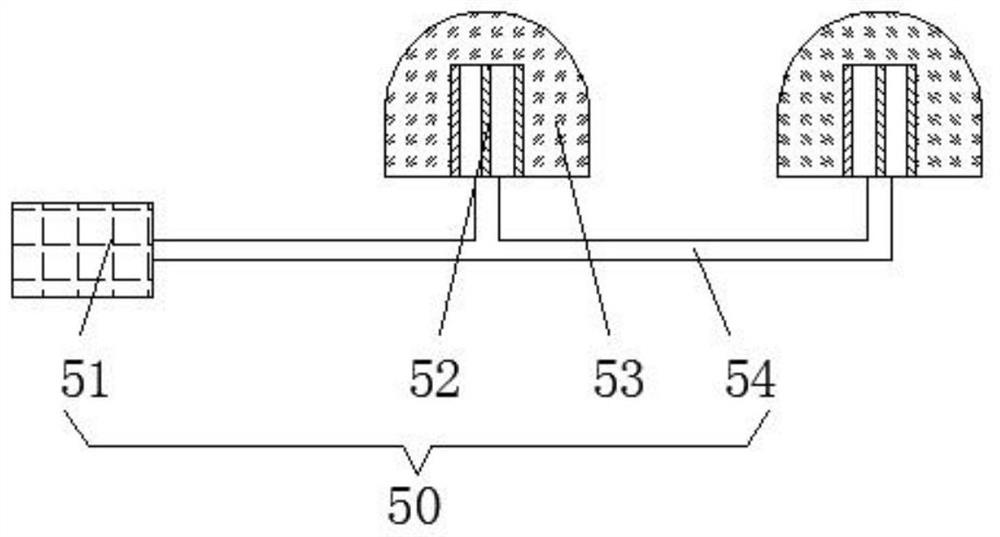

Annular workpiece inner hole chamfering device

ActiveCN111872484ARealize inner diameter chamferImprove chamfer effectMetal working apparatusPositioning apparatusMechanical engineeringPhysics

Owner:ZHEJIANG LINIX MOTOR

Concrete trowel

ActiveCN110295753ASave resources and costsReduce construction stepsBuilding material handlingEngineeringBuilding construction

The invention provides a concrete trowel and belongs to the technical field of concrete construction tools. The concrete trowel comprises a trowel body, a chamfering plate, a drive part, an elastic piece, a handle and a fastening bolt, wherein the trowel body is used to trowel a concrete surface; the chamfering plate is hinged with one side edge of the trowel body and used to chamfer a concrete edge; the fastening bolt is used for fixedly connecting the trowel body and the chamfering plate together; the drive part is fixed on the chamfering plate and used to drive the chamfering plate to turnover; two ends of the elastic piece are connected to the trowel body and the drive part respectively; the handle is arranged above the trowel body and held by hand; and a smooth transition is formed between a troweling surface of the trowel body and a chamfering surface of the chamfering plate. The concrete trowel provided by the invention has the advantages of portability, convenient constructionand good chamfering effect.

Owner:XINGTAI POWER SUPPLY +2

Crystal original stone chamfering device

ActiveCN110788760AImprove chamfer effectSimple structureSievingScreeningEngineeringHigh pressure water

The invention discloses a crystal original stone chamfering device. The crystal original stone chamfering device comprises a machine base, a machine base space arranged in the machine base, two feeding spaces on the left side and the right side of the machine base space, a vertical plate on the rear side of the machine base, a rodless air cylinder fixedly arranged on the upper end face of the vertical plate, a high-pressure water gun fixedly arranged on the output end of the rodless air cylinder, a sand box fixedly arranged on the rear side of the vertical plate, a sand pump fixedly arranged on the upper end face of the sand box, and a connecting hose communicating between the sand pump and the high-pressure water gun.

Owner:林有艺

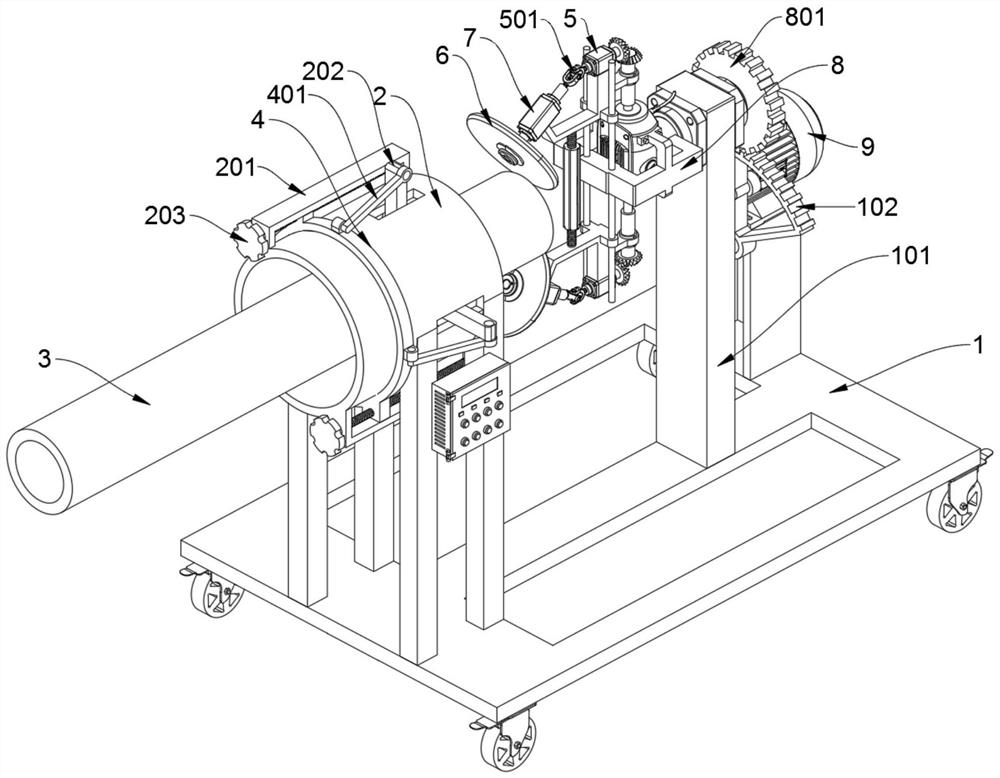

An automatic highlight chamfering equipment

ActiveCN111136533BRealize automatic back and forth rotationRealize turning back and forthEdge grinding machinesGrinding carriagesDrive shaftGear wheel

The invention discloses an automatic high-gloss chamfering equipment, which relates to the technical field of chamfering equipment, and solves the problem that the existing chamfering equipment needs to manually push the grinding and cutting mechanism to reciprocate around the pipe mouth, which is laborious and labor-intensive for workers. , The problem of low efficiency of grinding chamfering. An automatic high-gloss chamfering equipment, including a chassis and a rotating frame. The chassis includes a mounting support plate, a sector gear and a connecting rod. A swing motor is installed on a locking support at the top position of the rear side of the chassis. The swing motor An installation support plate is welded and fixed at the middle position of the front side of the chassis, and a positioning sleeve is welded and supported at the top of the middle position of the front side of the chassis, and the welded pipe is inserted and clamped in the positioning sleeve; the internal lock of the rotating frame A chamfering motor is tightly inserted, and the double-headed rotating shaft of the chamfering motor is equipped with a drive shaft sleeve in a uniform key connection sleeve. In the present invention, the four pressure blocks can press and clamp the welded pipe to the inside of the positioning sleeve under the swing and push of the push rods at the four places.

Owner:温州拓日工业设计有限公司

Arc chamfering device for steel plate machining

InactiveCN110722047APrevent slidingImprove work efficiencyMetal-working feeding devicesPositioning devicesEngineeringKnife blades

The invention discloses an arc chamfering device for steel plate machining. The arc chamfering device comprises a workbench, wherein mounting frames are arranged at the two ends of the top of the workbench, chamfering cutting assemblies are fixedly mounted on the mounting frames, clamping assemblies mounted on the workbench are arranged on the inner side of the chamfering cutting assemblies, and driving assemblies mounted on the workbench are arranged on the outer side of the clamping assemblies and located between the chamfering cutting assemblies. According to the arc chamfering device, thetail end of a transition supporting plate is fixedly connected with a telescopic plate connected with the bottom of the workbench through a connecting frame, when the telescopic plate is used, a mainpressing plate is pushed up by a rotating adjusting screw rod to drive an arc-shaped side pressing plate to jack up at the same time, the steel plate is placed between the arc-shaped side pressing plate and the workbench, the main pressing plate is put down again through rotating the adjusting screw rod, so that the arc-shaped side pressing plate is driven to clamp the steel plate at the same time, an air cylinder drives a connecting plate to drive an arc-shaped blade to move downwards, meanwhile, an arc-shaped pressing block presses the arc-shaped side pressing plate while cutting, and the steel plate is prevented from sliding during cutting.

Owner:安徽跨宇钢结构网架工程有限公司

Triple-head chamfering machine and control program thereof

ActiveCN103302357AGuaranteed stabilityGuaranteed chamfering effectProgrammable logic controllerVertical edge

The invention discloses a triple-head chamfering machine and a control program thereof. The triple-head chamfering machine includes a bed body, wherein a transverse cutting device is arranged at the back of the bed body; a vertical cutting device is arranged on the right side of the bed body; a workbench is arranged in front of the bed body; an electric control device is arranged below the workbench; and the transverse cutting device, the vertical cutting device and the workbench are all controlled by the electric control device. According to the invention, both a transverse cutting upper handpiece and a transverse cutting lower handpiece are adopted to chamfer the transverse upper and lower edges of a workpiece, a vertical cutting handpiece is adopted to chamfer the vertical edge of the workpiece, all edges of the workpiece can be chamfered without turning over the workpiece, and the chamfering efficiency is improved; a stepping motor is controlled by a programmable logic controller (PLC) of an electric controlling box, the transverse cutting upper handpiece is locked and the height of the workpiece is accurately sensed through the information fed back by a displacement sensor, so that the chamfering of the transverse upper and lower edges of the workpiece is consistent; the chamfering of the transverse edges is followed by that of the vertical edge, and size of the chamfering is adjusted through a transverse cutting pile and a vertical cutting pile; and the labor intensity is reduced through the application of an electromagnetic device and the gas floating function.

Owner:安徽新冀精密机械有限公司

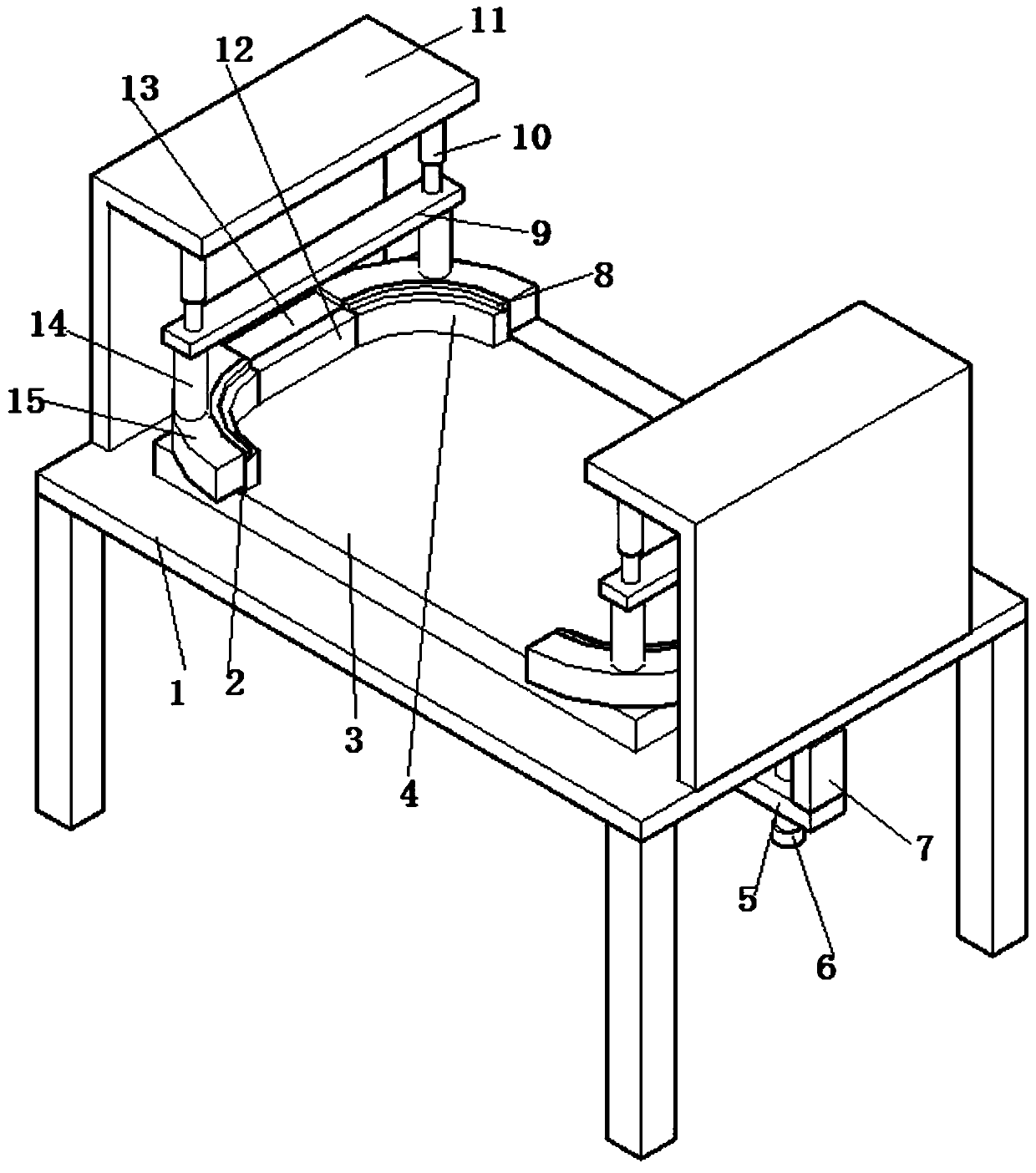

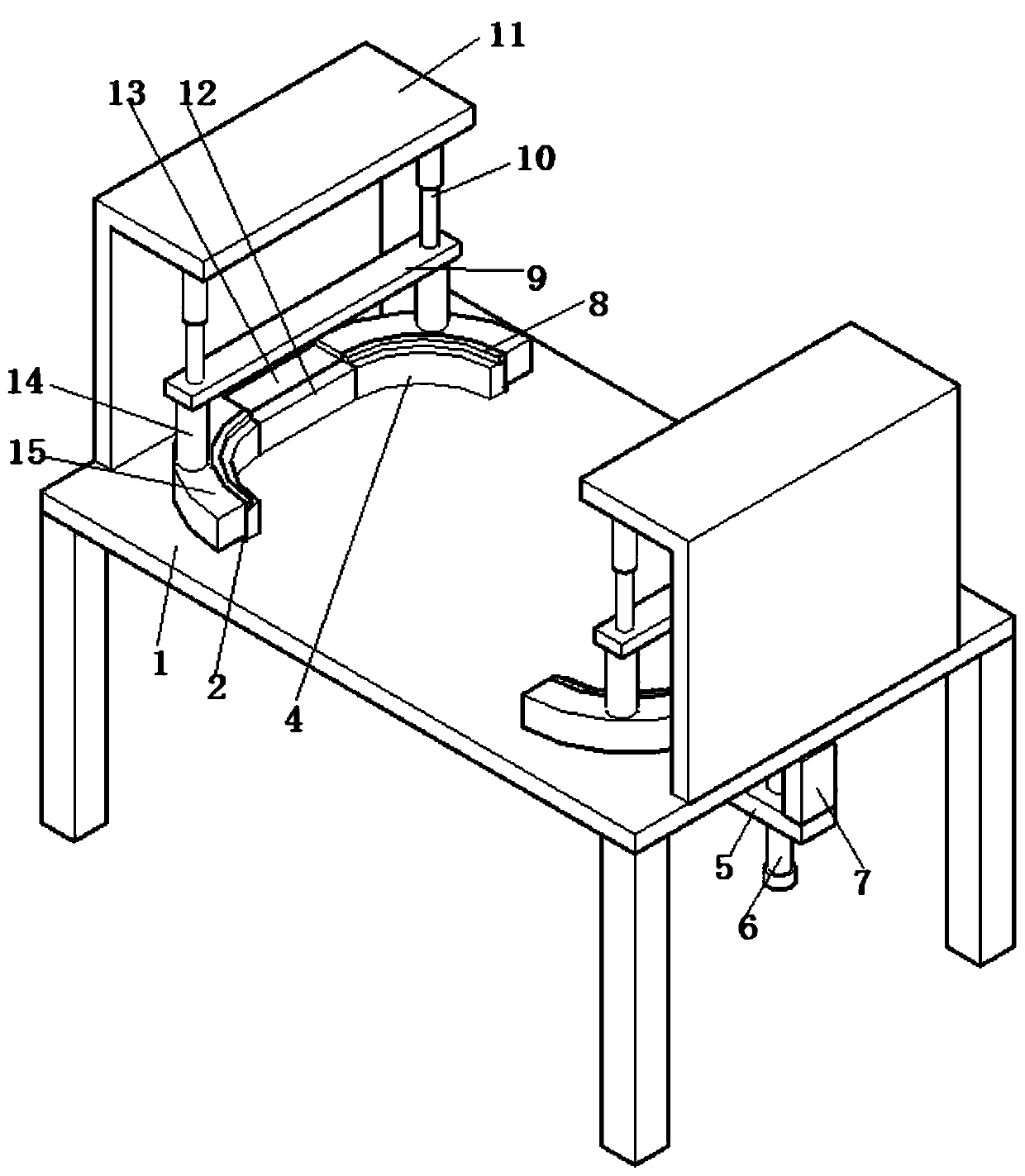

Fatty steel rail edge polishing machine

PendingCN107178016ALarge swing angleImprove swing flexibilityRailway track constructionElectric machineryBall (bearing)

The invention discloses a fatty steel rail edge polishing machine, and belongs to the technical field of railway maintenance equipment. The fatty steel rail edge polishing machine comprises a rack. The fatty steel rail edge polishing machine is characterized by further comprising a vertical moving device and a horizontal feeding device, wherein the vertical moving device comprises a hanging rack, a ball bearing seat, a ball screw rod and a ball screw nut; a stepper motor and a vertical sliding block are arranged on the rack; the hanging rack is connected with the rack through the vertical sliding block in a sliding manner; the horizontal feeding device comprises a grinding wheel, a gear acceleration tank, a moving platform, a horizontal sliding block, a driving mechanism, a pulse electromotor and a ball screw rod pair; the output shaft of the gear acceleration tank is connected with the grinding wheel; the input shaft of the gear acceleration tank is connected with the driving mechanism; and the horizontal sliding block is connected with the hanging rack in a sliding manner. By adopting the fatty steel rail edge polishing machine, a fatty steel rail edge is polished horizontally, manual adjustment is not needed, different feeding amounts can be selected according to fatty steel rails of different thicknesses, one-time polishing is achieved, the grinding wheel can be moved up and down, any position at any height of the fatty steel rail edge can be polished, and the polishing efficiency and the polishing effects are improved.

Owner:西藏天仁科技发展有限公司

A deburring device capable of adjusting the size of the chamfer

Owner:JIAXING UNIV

Angle fine adjustment type chamfering machine for optical glass processing

InactiveCN113043112ASimple structureLow costEdge grinding machinesGrinding drivesGlass chipEngineering

The invention discloses an angle fine adjustment type chamfering machine for optical glass processing, and relates to the technical field of optical glass processing equipment. The chamfering machine specifically comprises a base and a first grinding disc, wherein a feeding cavity is formed above the base; a glass body is placed in the feeding cavity; a pushing air cylinder is arranged at one end of the feeding cavity; a jacking air cylinder is arranged at one side of the other end of the feeding cavity; and a feeding rail is arranged at the right side of the jacking air cylinder. According to the angle fine adjustment type chamfering machine for optical glass processing, the arranged feeding cavity is matched with the pushing air cylinder, glass bodies can be independently pushed to the tail end of a feeding rail, the feeding cavity is matched with the jacking air cylinder to push the glass bodies into the feeding rail to be pre-stored, and the inclined feeding rail can conduct transporting and storing treatment on the multiple glass bodies at the same time; and glass sheets can slide downwards to be fed through the gravity of the glass sheets, manual matched feeding is not needed in the process, a complex transfer device does not need to be matched either, the structure is simpler, and the cost is lower.

Owner:王堂元

Deburring device capable of adjusting chamfering size

Owner:JIAXING UNIV

Fixed chamfering device for valve production

The invention discloses a fixed chamfering device for valve production and belongs to the technical field of valve processing. The fixed chamfering device for valve production comprises a workbench, arotating assembly, a fixing assembly, a lifting assembly, an extending assembly and an overturning assembly; the rotating assembly is arranged on the workbench; the fixing assembly is arranged at theworking end of the rotating assembly; the overturning assembly is arranged on the workbench; the overturning assembly is arranged on one side of the rotating assembly; the lifting assembly is arranged on the workbench; the lifting assembly is arranged on the other side of the rotating assembly; and the extending assembly is arranged at the working end of the lifting assembly. The steps of fixing,rotating, overturning and the like can be conducted on a valve through matching of the assemblies, and the valve is chamfered, so that the chamfering effect is better.

Owner:ANHUI ENDA VALVE MACHINERY CO LTD

Efficient machining device for outer bearing ring for automobile

InactiveCN106853602AImprove chamfer effectImprove efficiencyEdge grinding machinesGrinding drivesEngineeringGrinding wheel

The invention discloses a high-efficiency processing device for the outer ring of an automobile bearing, which comprises a workbench, a processing mechanism and a clamping mechanism. In the present invention, the clamp is used to clamp the outer ring of the bearing, and the drive unit is used to drive the clamp to rotate; the drive unit is used to drive the rack to move horizontally, and then to drive the connecting rod to rotate, and the fixed part does not move. Therefore, the connecting rod will rotate along the vertical direction when rotating. Then, use the grinding wheel to remove the remaining material on the outer ring of the bearing, and perform chamfering processing on the outer ring of the bearing; by setting multiple clamping units, it is possible to perform chamfering operations on multiple outer rings of the bearing each time. The invention has good chamfering effect, high efficiency, simple structure and convenient use.

Owner:WUHU HONGYAO AUTOMOBILE IND

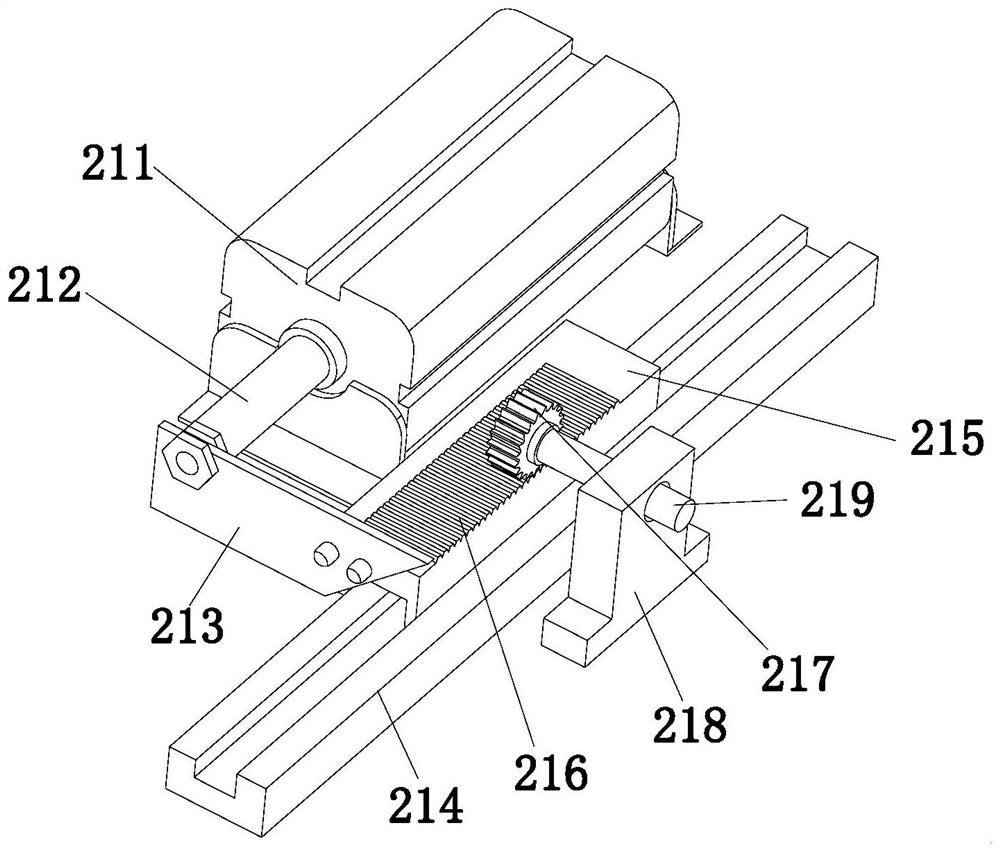

A fixture for machining process based on shaft chamfering

ActiveCN109015051BIncrease diversityEasy to useLarge fixed membersPositioning apparatusEngineeringSlide plate

The invention discloses a clamp for the shaft-type chamfering process, and relates to the technical field of shaft-type clamps. The clamp comprises a workbench; the top of the workbench is rotatably connected with a circular plate; the top of the circular plate is fixedly connected with a sleeve; sliding plates are slidably connected to the positions, on the two sides of the sleeve, of the top ofthe workbench correspondingly; one sides of the sliding plates are fixedly connected with hydraulic telescopic rods; and one ends of the hydraulic telescopic rods are fixedly connected with arc-shapedblocks. According to the clamp for the shaft-type chamfering process, shaft-type parts can be clamped well, the clamping effect is very good, the situation that the shaft-type parts move during chamfering, and consequently the chamfering quality and effect are affected is avoided, and clamping plates can be mounted and dismounted so as to be convenient to maintain; and the clamping plates with different sizes and types are convenient to mount to clamp the shaft-type parts with different sizes and types, and the comprehensiveness and usability of the shaft-type clamps are improved.

Owner:GUANGZHOU ROVMA AUTO PARTS

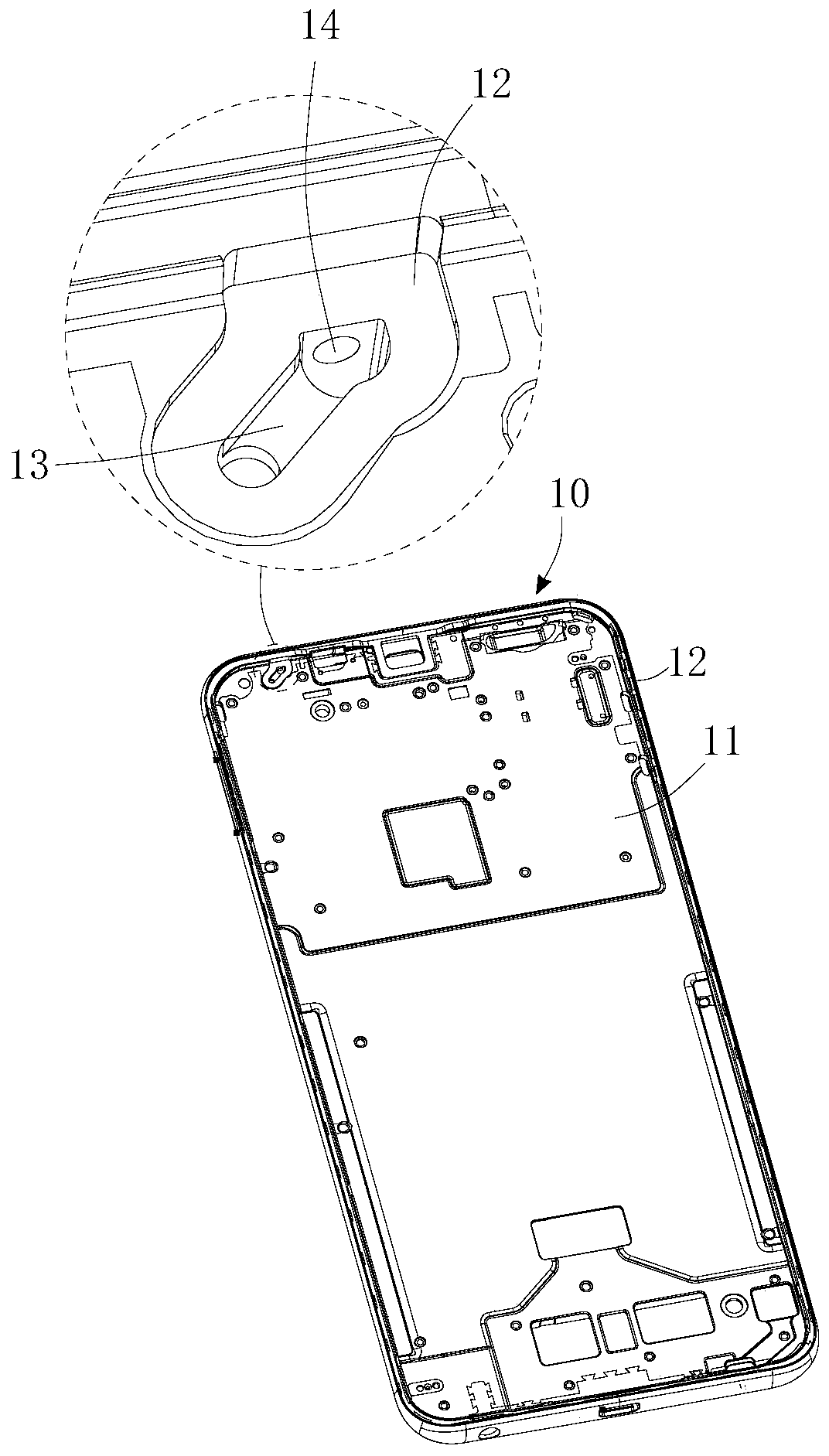

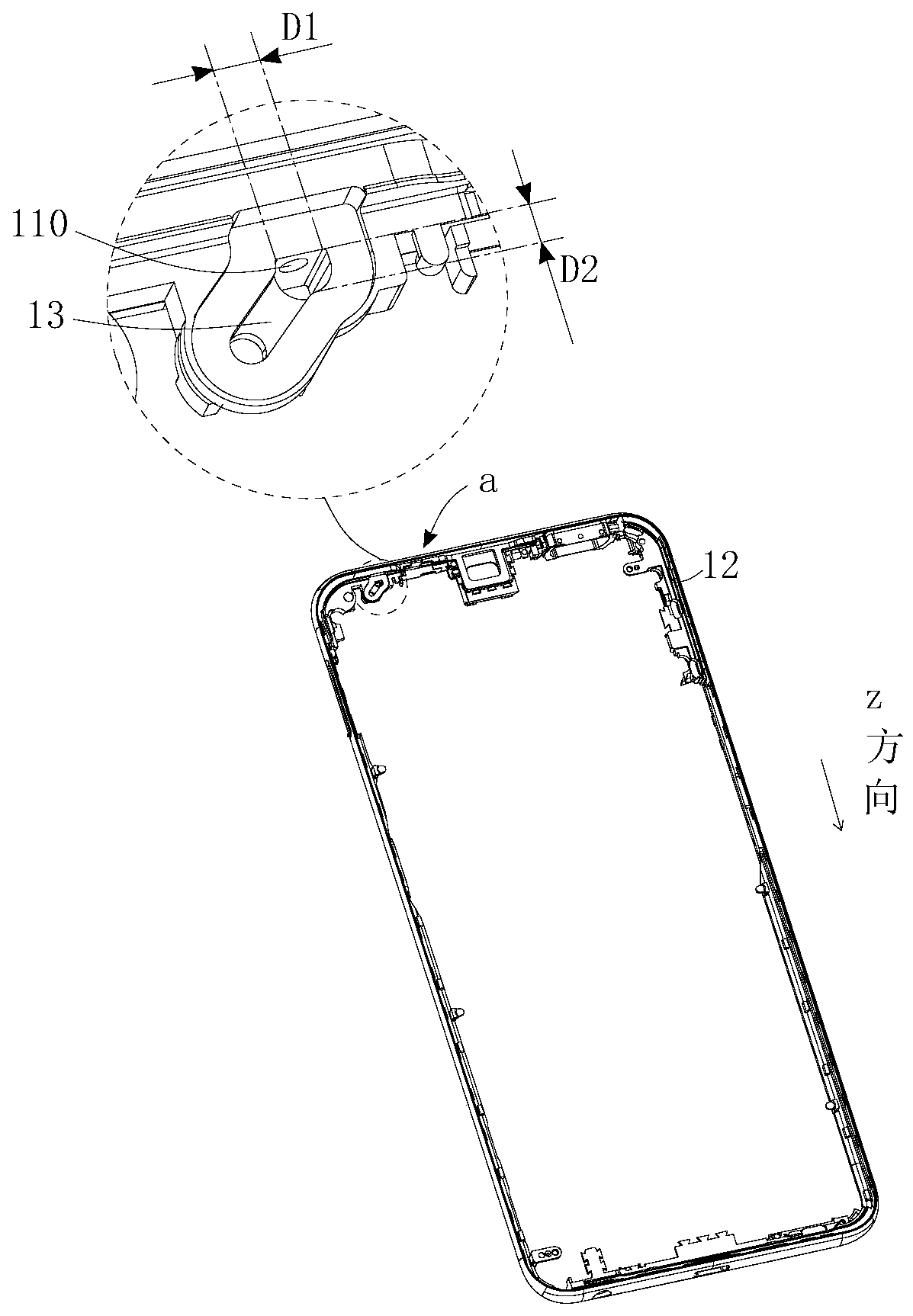

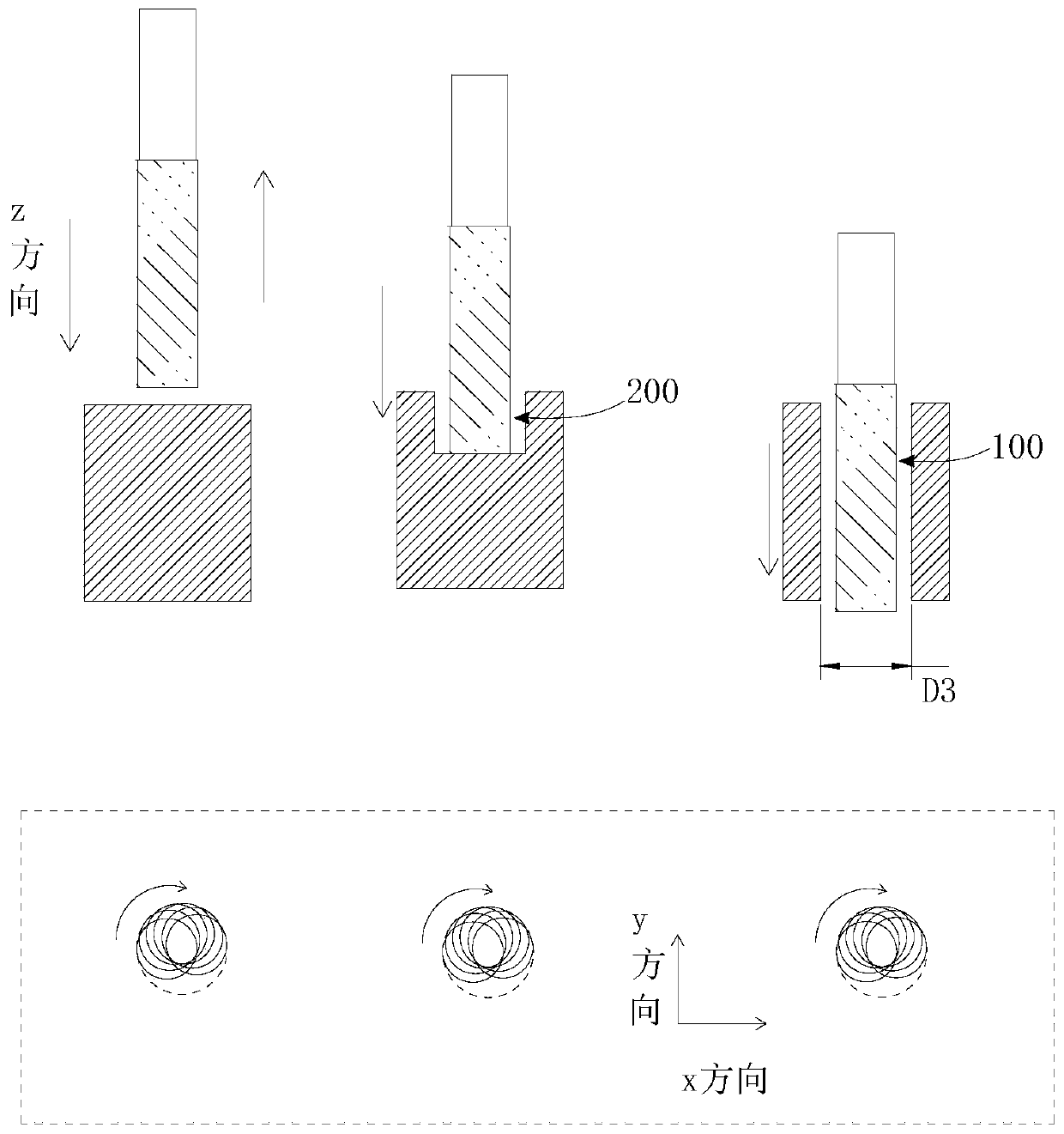

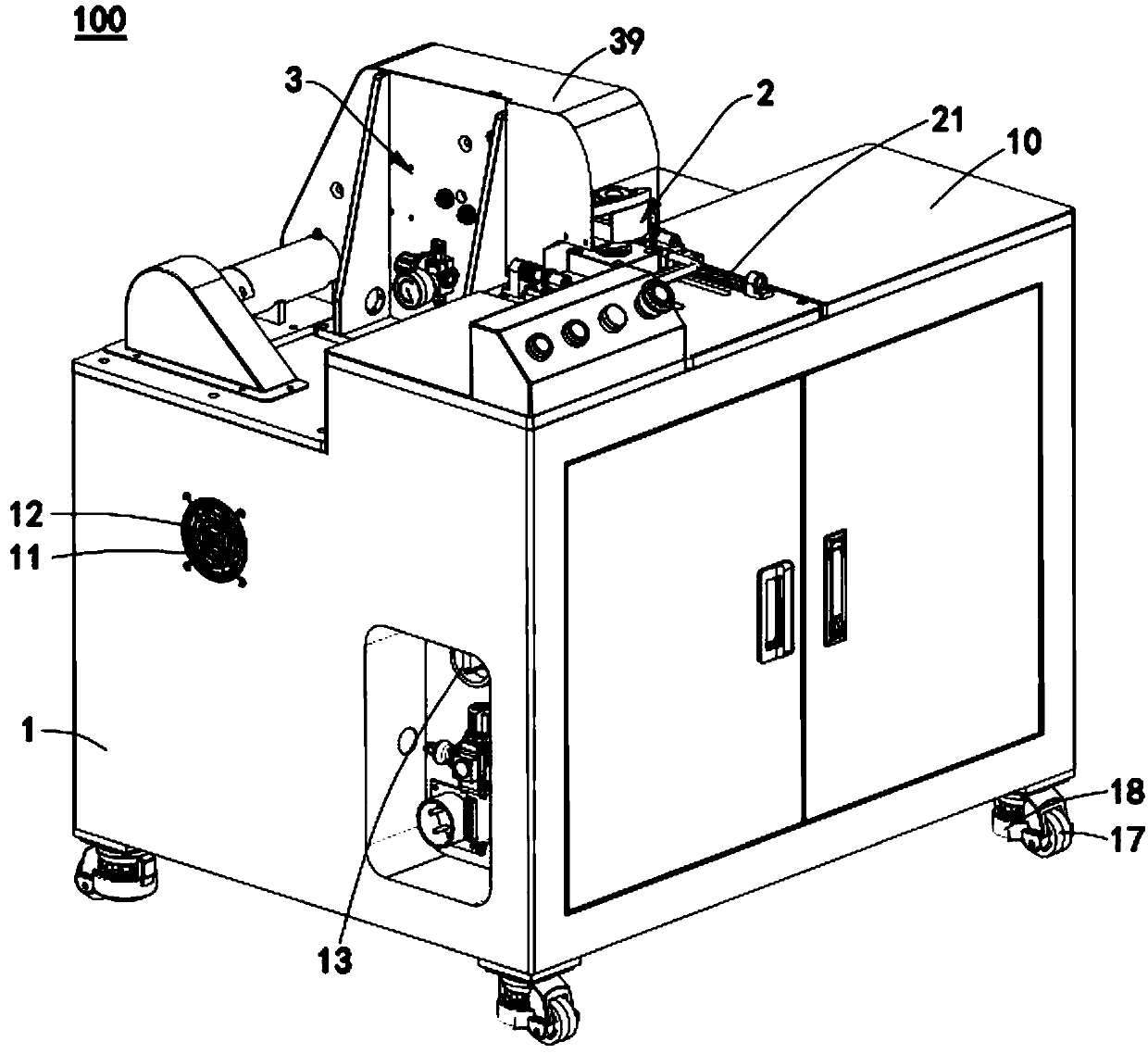

Hole drilling method for middle frame

InactiveCN110315594AEfficient removalPromote sheddingMilling equipment detailsMetal working apparatusHole drilling methodSpiral line

The invention relates to a hole drilling method for a middle frame. The method is used for drilling a basic hole in a middle frame, the basic hole is used for communicating an inner cavity in the middle frame with the outside of the middle frame, the basic hole is machined by moving a cutter along a spiral line track, and the central axis of the spiral line track is parallel to the central axis ofthe basic hole. According to the method, the cutter moves along the spiral line track to machine and obtain the basic hole, the moving track is more coherent and complete, the polishing effect is fine, the inner wall of the basic hole is polished while the basic hole is machined, plastic burrs can be effectively removed, the burrs on the inner wall of the basic hole are easier to fall off, so that the machining quality of the inner wall of the side hole is improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

Swash plate chamfering machine

The invention provides a swash plate chamfering machine. The swash plate chamfering machine comprises a rack, a worktable arranged on the rack, a swash plate positioning rotary mechanism arranged on the worktable, and a chamfering mechanism arranged on one side of the swash plate positioning rotary mechanism. The chamfering mechanism comprises a supporting seat arranged on the worktable, an abrasive belt wheel, a belt wheel, tension wheel adjusting plates, a tension wheel, an adjusting block, a supporting wheel, an abrasive belt, a spring, a chamfering motor, a driving wheel and a chamfering synchronous belt, wherein the abrasive belt wheel is mounted at one end of the supporting seat; the belt wheel and the abrasive belt wheel are coaxial and are connected; the tension wheel adjusting plates are mounted at the other end of the supporting seat; the tension wheel is mounted on the tension wheel adjusting plates; the adjusting block is mounted on the supporting seat and can rotate aroundthe supporting seat; the supporting wheel is connected with the adjusting block; the sand belt is tensioned on the tension wheel, the abrasive belt wheel and the supporting wheel; the spring is arranged between the adjusting block and the supporting seat; the chamfering motor is mounted on the rack; the driving wheel is mounted at the output end of the chamfering motor; and the chamfering synchronous belt is tensioned on the belt wheel and the driving wheel. The edge of a swash plate is automatically chamfered through the swash plate chamfering machine, the chamfering effect is good, and chamfering is convenient and efficient.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

Quick chamfering device and method for automobile ornament trimmings

ActiveCN112140420AImprove chamfer effectConvenience for subsequent useDomestic articlesMechanical engineeringIndustrial engineering

The invention provides a quick chamfering device for automobile ornament trimmings. The quick chamfering device for automobile ornament trimmings comprises a chamfering treatment bin, a hydraulic rod,a first power supply accumulator, a U-shaped heating plate, a heating mechanism, a fixed base, an adjusting bolt and a sealing plate, wherein the chamfering treatment bin is connected to the fixed base through the adjusting bolt, the sealing plate is arranged at the bottom of the chamfering treatment bin, the U-shaped heating plate is arranged in the chamfering treatment bin, and the hydraulic rod for driving the U-shaped heating plate to move up and down is arranged at the top of the chamfering treatment bin. The quick chamfering device for automobile ornament trimmings has the advantages that the heating mechanism for preheating automotive ornaments is arranged on the fixed base, and the preheated automotive ornaments are rapidly chamfered through the U-shaped heating plate; through themethod, on the one hand, chamfering treatment can be conducted on the automotive ornaments in a large scale, and therefore the chamfering treatment effect of the automotive ornaments is better; and on the other hand, the automobile ornaments can be further shaped, so that the later use effect of the automobile ornaments is better.

Owner:宣城托新精密科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com