Patents

Literature

258results about How to "Reduce construction steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

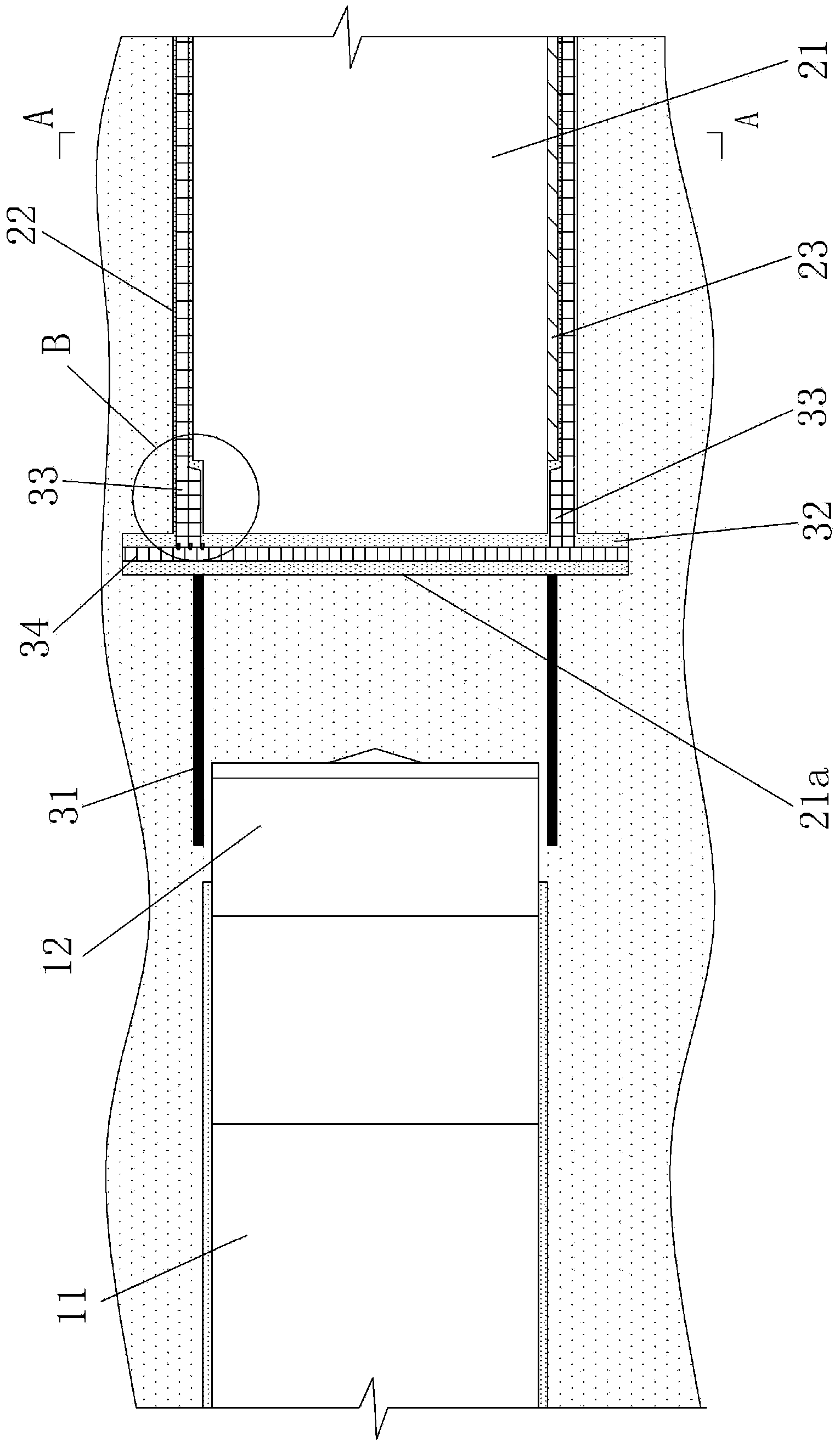

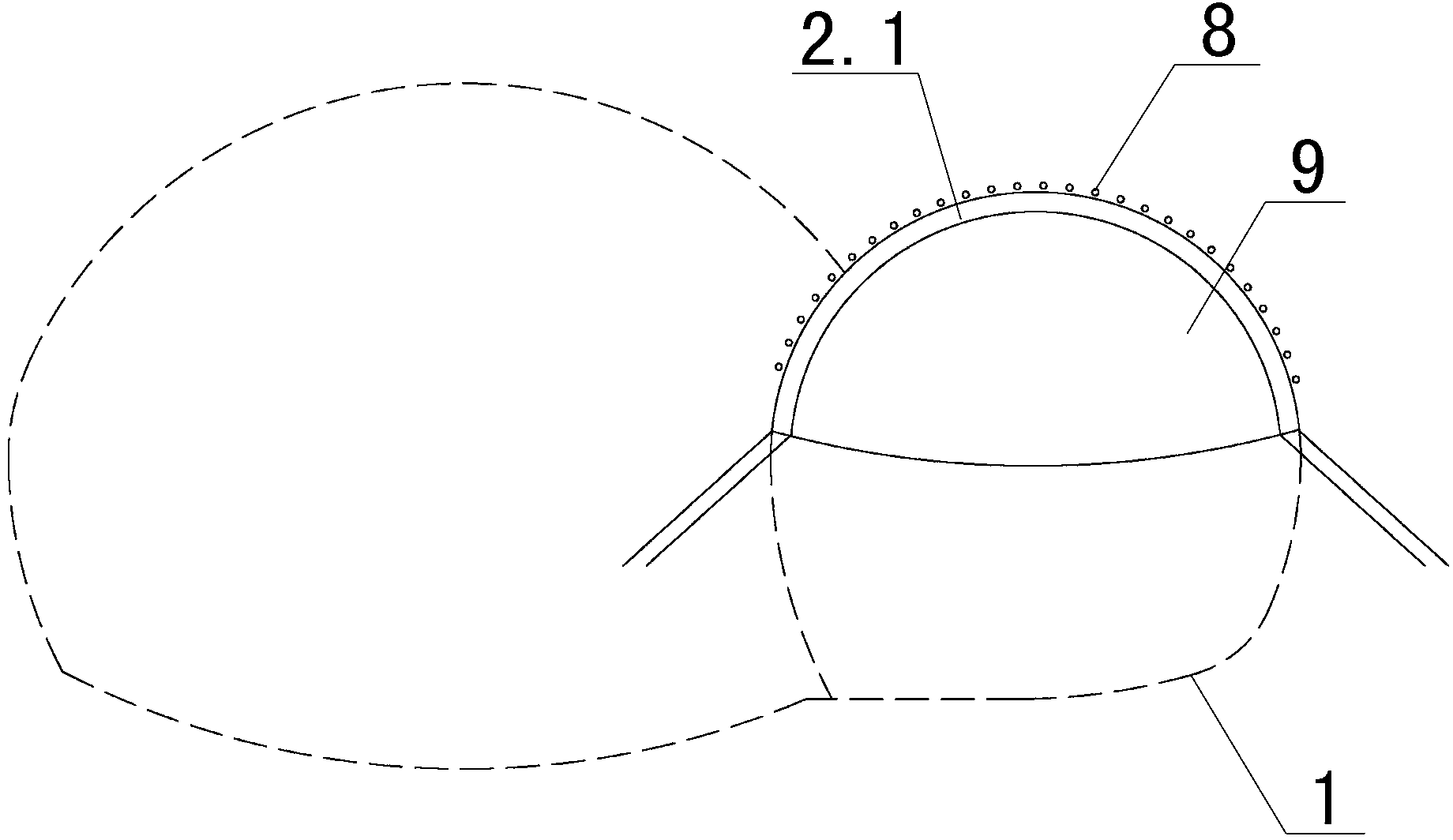

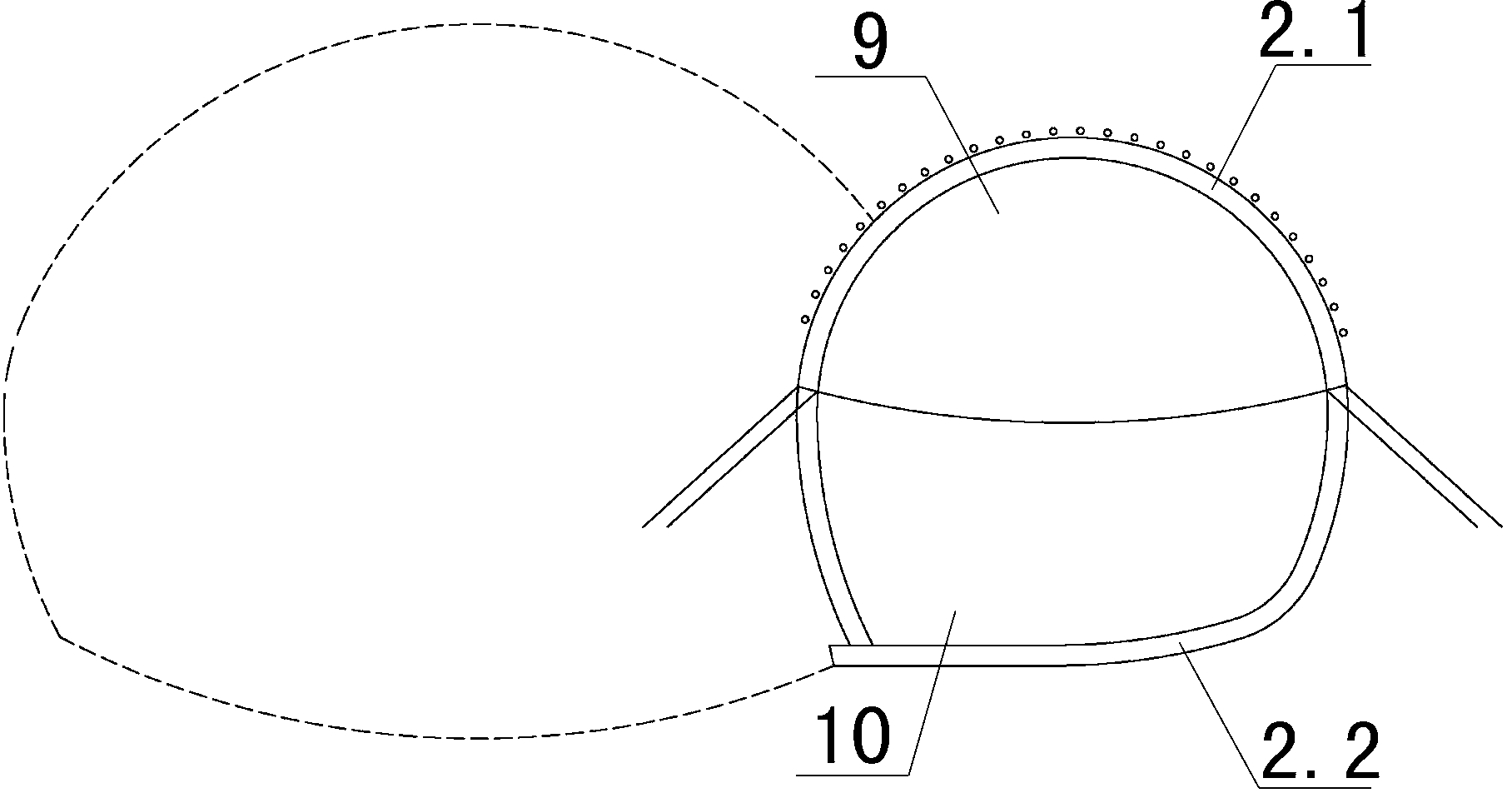

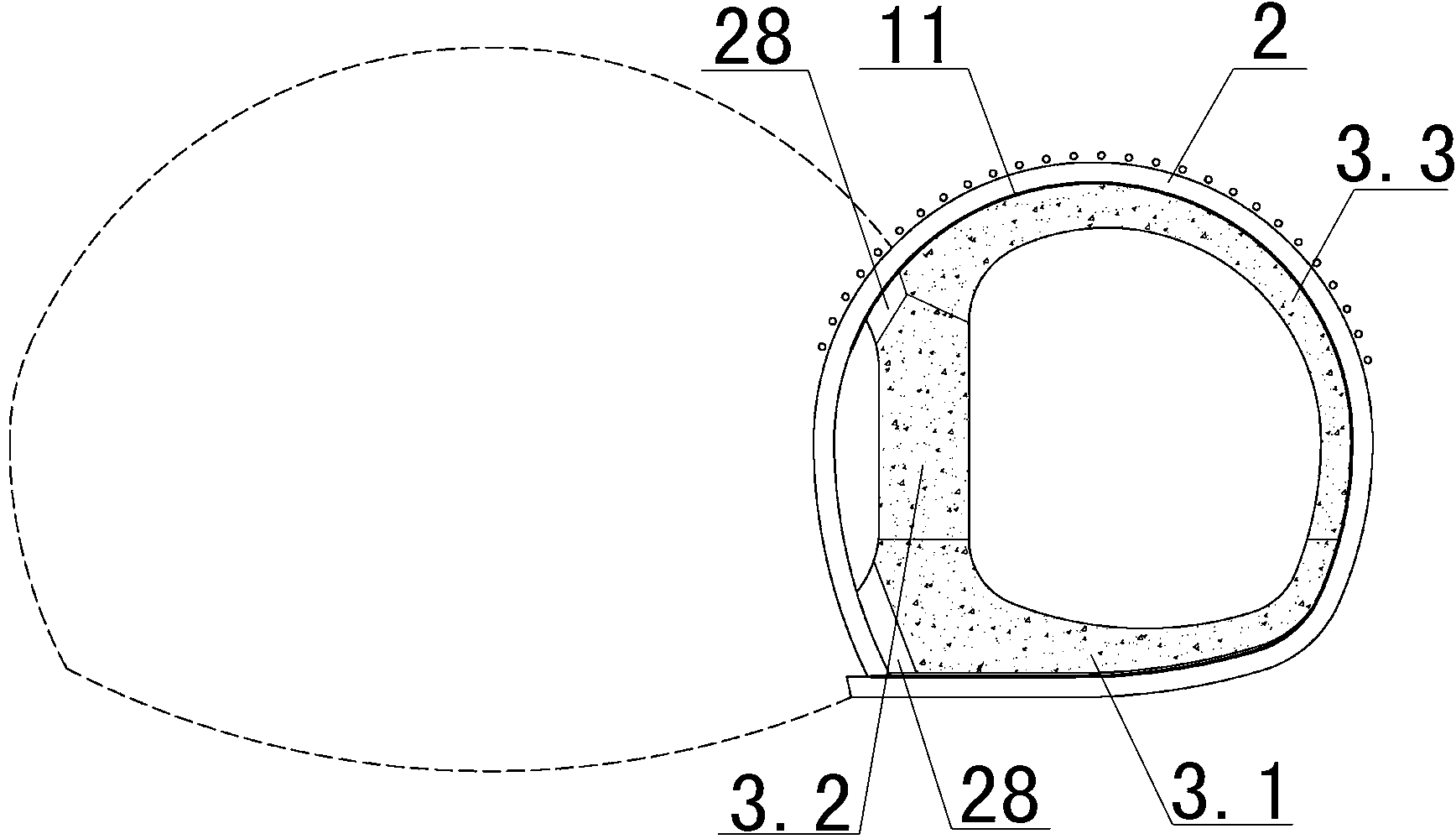

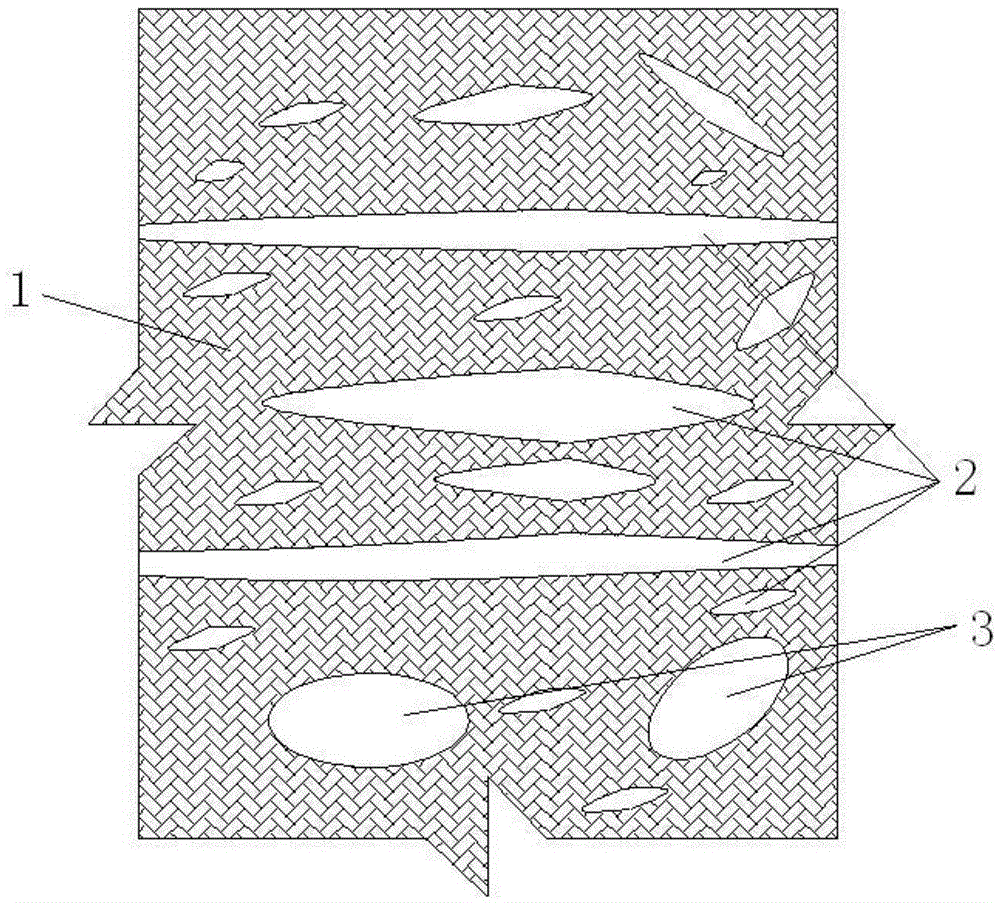

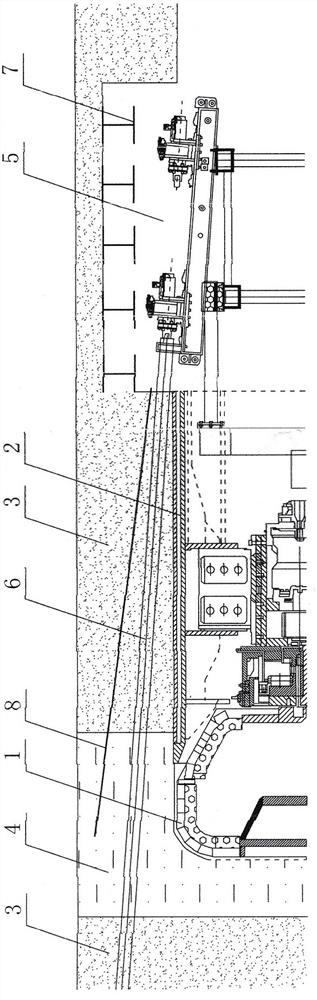

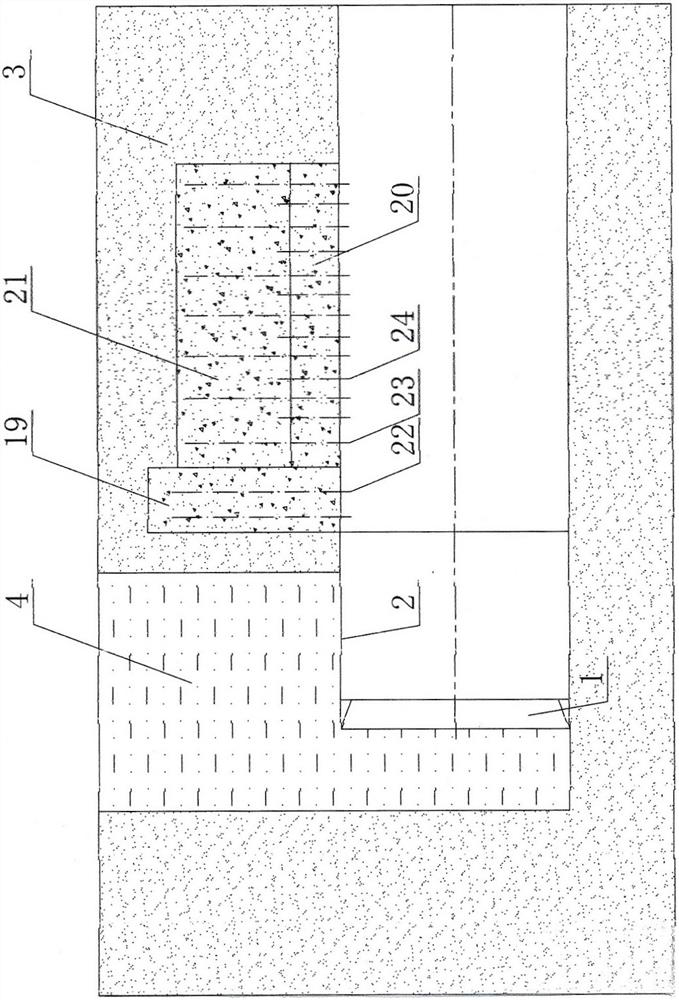

Propelling method for combined portion between shield tunnel segment and mine tunnel segment in subway tunnel

InactiveCN103711504ALow bond strengthLow elastic modulusUnderground chambersTunnel liningGlass fiberShotcrete

Provided is a propelling method for a combined portion between a shield tunnel segment and a mine tunnel segment in a subway tunnel. The propelling method includes the first step that a steel sleeve is horizontally struck into the surrounding rock in front of a tunnel face of the mine tunnel segment after construction of the mine tunnel segment is finished, and then a shotcrete support is applied on the tunnel face; the second step that glass fiber ribs of separation end walls are bound tightly close to the shotcrete support, the glass fiber ribs and steel bars for ring beams behind the glass fiber ribs are connected in a bound mode, next the steel bars for the ring beams are connected with reserved steel bar heads of a primary support of the mine tunnel segment in a welded mode, and then the separation end walls and the ring beams are poured; the third step that an arc-shaped concrete guiding platform is poured at the bottom of the mine tunnel segment; the fourth step that when a shield tunneling machine approaches to the mine tunnel segment, the propelling speed is lowered, the shield tunneling machine is accommodated in the steel sleeve, and then the shield tunneling machine is used for directly cutting and removing the surrounding rock in the steel sleeve, the shotcrete support of the tunnel face and the separation end walls and carrying out grouting and slag removing until the shield tunneling machine passes through the ring beams and is accommodated on the arc-shaped concrete guiding platform. According to the propelling method, construction risks are low, construction is easy, efficiency is high and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

Protection method for rust removal, paint removal and anticorrosion of metal surface

InactiveCN102218386ASolve the work of rust removal and rust preventionReduce labor intensityPretreated surfacesCoatingsBenzeneKetone

The invention relates to a protection method for rust removal, paint removal and anticorrosion of a metal surface. The method comprises three steps of (1) metal surface lossless rust removal technology, (2) conversion of rust iron on a metal surface and antirust processing, (3) painting of anticorrosion paint on the metal surface. Compared with prior art, the protection processing on the metal surface of the invention employs a high-pressure water-sand blending technology to remove rust, so that rust removal efficiency is higher and the method is safe and environment-friendly. Free rust on the metal surface can be conversed into antirust priming paint when a rust removal transforming agent is being painted, so as to complete metal rust removal and rust prevention by one step, and solve problems, that harm antirust quality, such as local corrosion and free rust at one time. The rust transforming agent employed in the technology belongs to an aqueous system, is without harmful solvents of benzene, ketone, etc., or heavy metal compositions and is nontoxic and environmental-friendly, so that base materials with rust can be used in construction to save costs and raise efficiency. Anticorrosion coating on the metal surface employs a high-pressure air-free coating spraying, so that construction quality is more reliable and the efficiency is higher.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

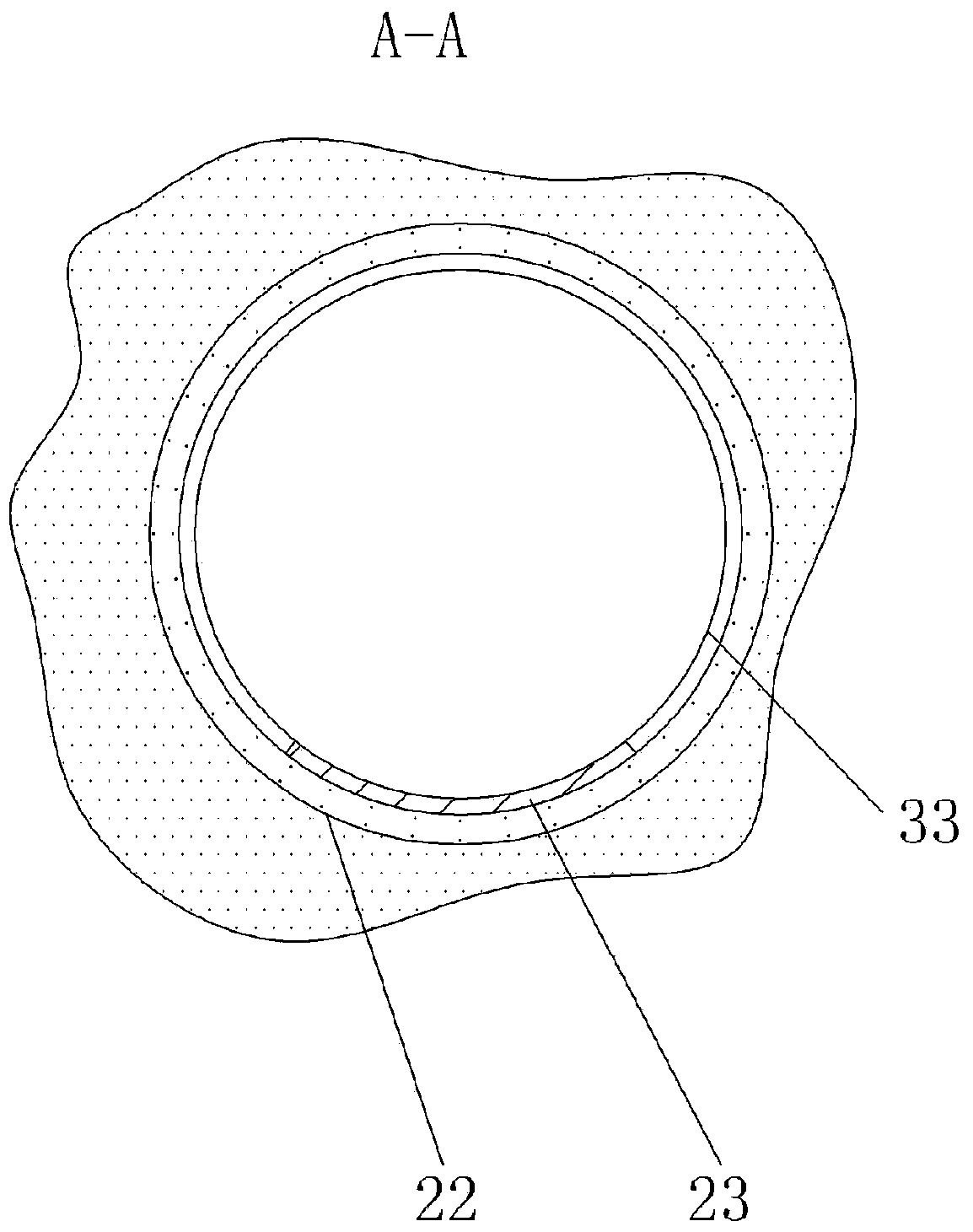

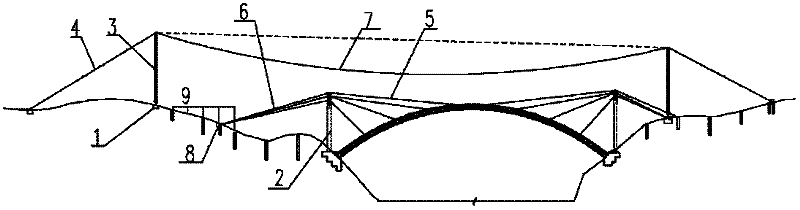

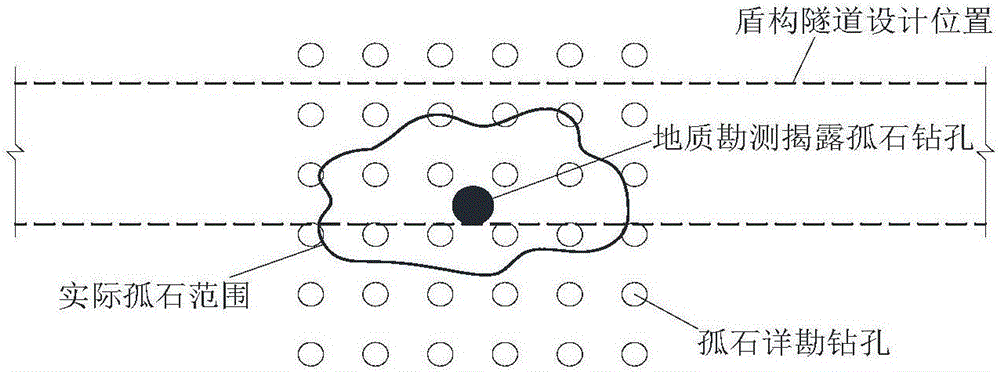

Construction method for concrete-filled steel tube arched bridge with large low-buckle tower erection bridge width

InactiveCN102418315AReduce tensile stressReduce security risksBridge erection/assemblyCable stayedTower

The invention discloses a construction method for a concrete-filled steel tube arched bridge with a large low-buckle tower erection bridge width. In order to solve the problems of structure safety and concrete cracking risks in a chord in a construction process of performing cable-stayed buckling and hanging on a low-buckle tower of a large-span concrete-filled steel tube arched bridge, in the construction method, in the process of performing the cable-stayed buckling and hanging on a steel tube arch rib, the front-end control point of an arch rib segment, close to 1 / 2 to 3 / 5 of the length ofan arch foot section, of the arch rib is put in place by adopting the elevation with the downward allowable deviation which is less than the upward allowable deviation; after the steel tube arch rib is folded and before concrete is poured in the chord of the arch rib, a buckle rope and an anchor rope are loosened and removed; and spandrel building construction of the arched bridge is performed symmetrically from the arch crown to the two banks in classifications and strips. By the construction method, not only the security risk of a construction process structure is effectively reduced and the high quality and high precision reach the designed goals of arched bridge alignment and internal force, but also the workload of adjusting the buckle rope and the anchor rope is reduced, construction organization of the spandrel building is performed orderly and reasonably, and the construction cost is saved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

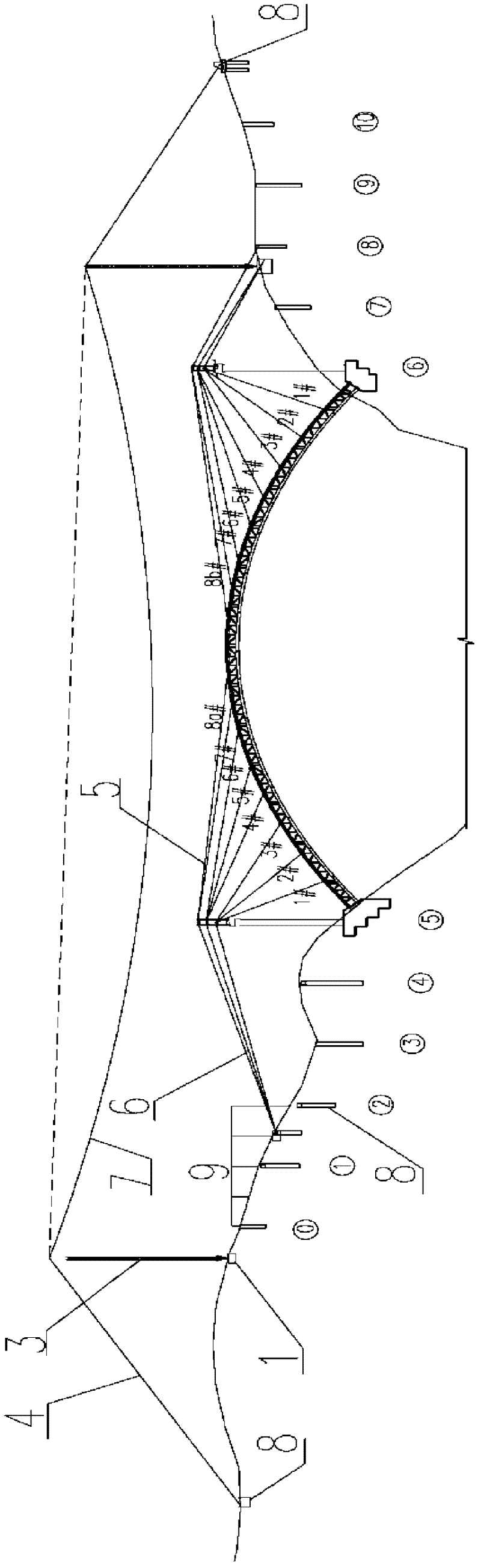

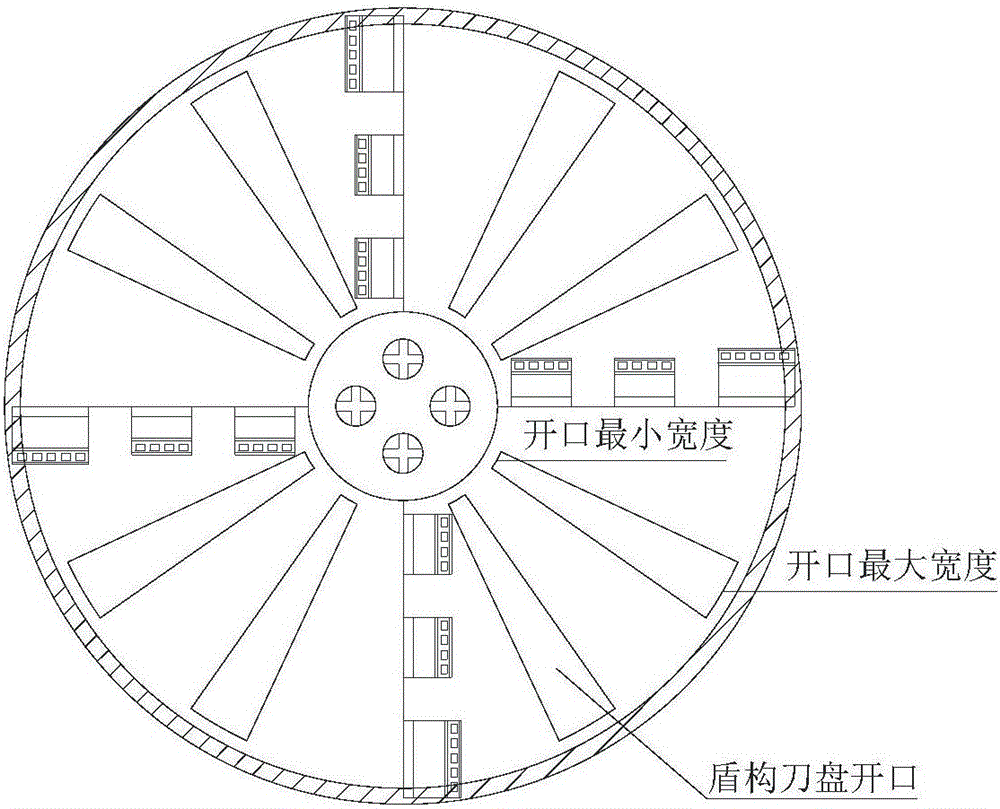

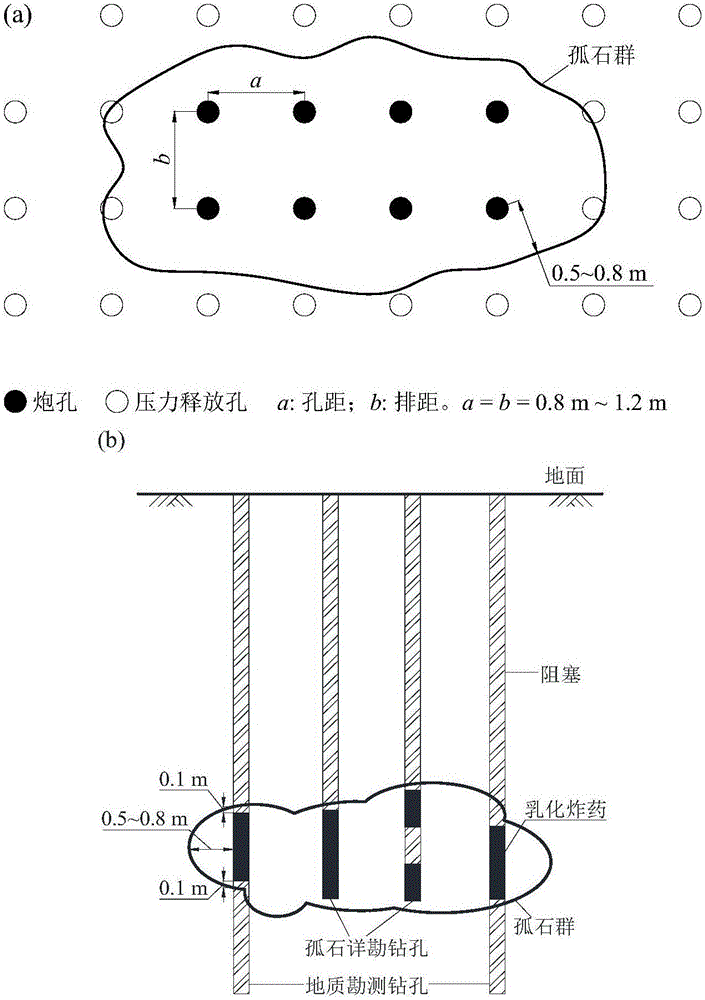

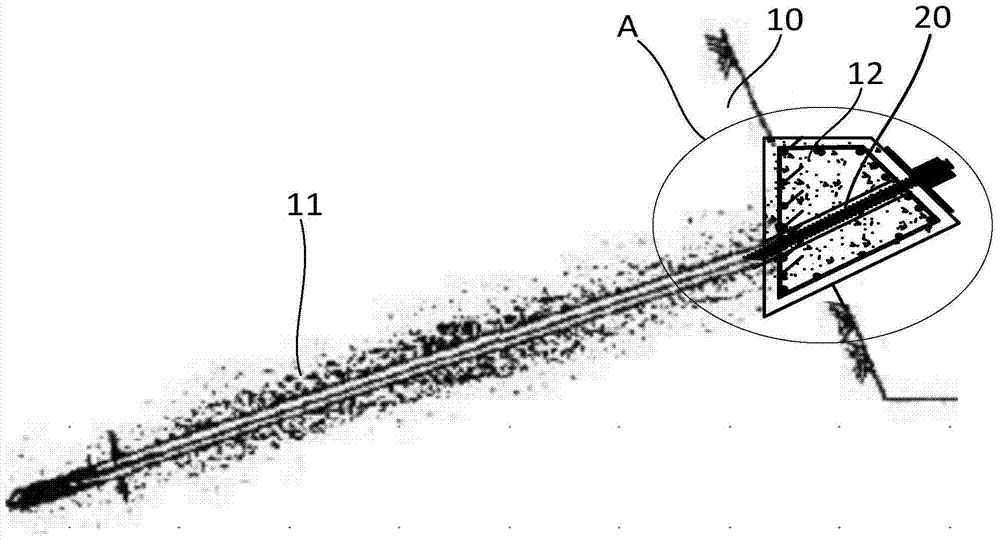

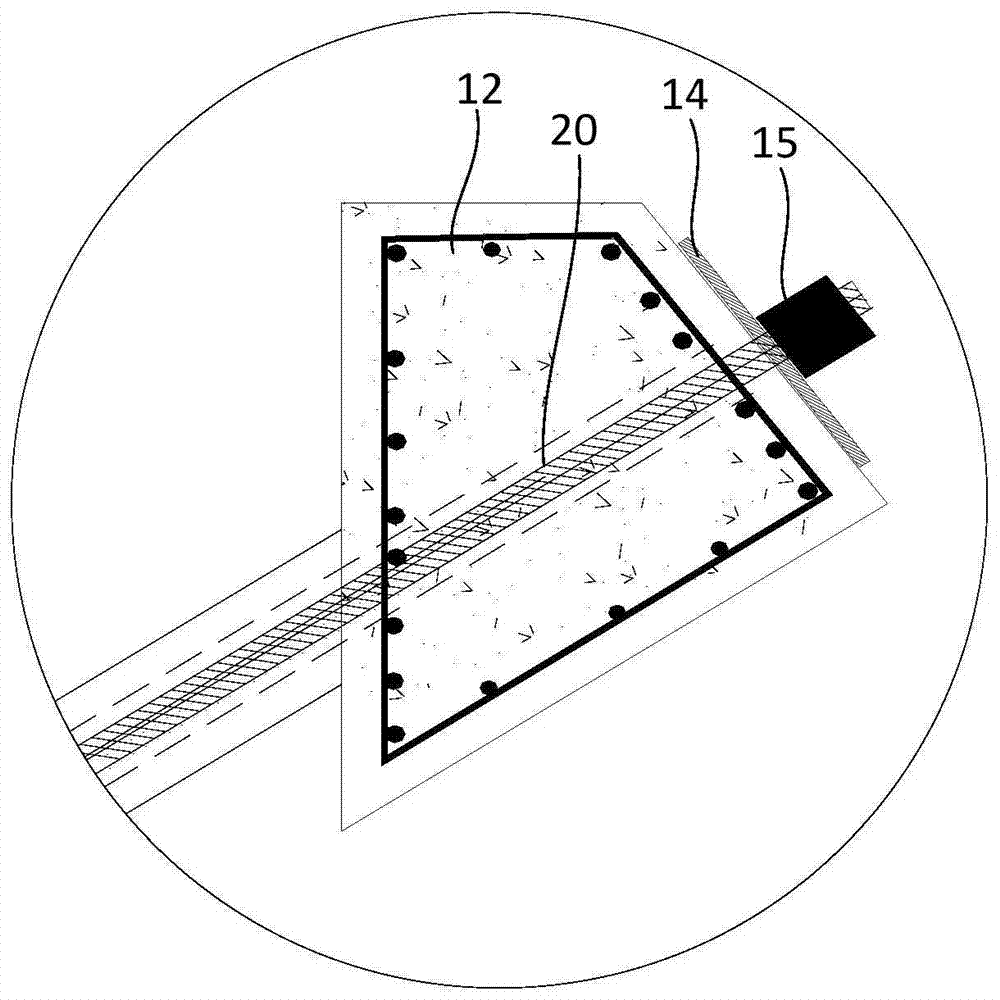

Construction method for shield tunnel boulder exploration and blasting treatment

ActiveCN106524844AReduce construction stepsShorten the construction periodBlastingTunnelsDrill holeTreatment costs

The invention provides a construction method for shield tunnel boulder exploration and blasting treatment. The method comprises the following steps: the boulder detailed exploration is performed around a geologic drilling hole for exposing a boulder; after boulder burying information is proved, the geologic drilling hole for the boulder detailed exploration is used as a boulder blasting gun hole and a pressure release hole; stemming is used for filling in the gun hole; liquid-state explosive is precisely put in the gun hole; a blasting protector is distributed on the gun hole; safety alert is arranged around the blasting area; after the blasting is finished, the safety alert is relieved; and the grouting sealing is performed for the gun hole and the pressure release hole. The construction method reduces construction steps, shortens the construction period, largely reduces the boulder treatment cost, and improves the blasting control precision.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

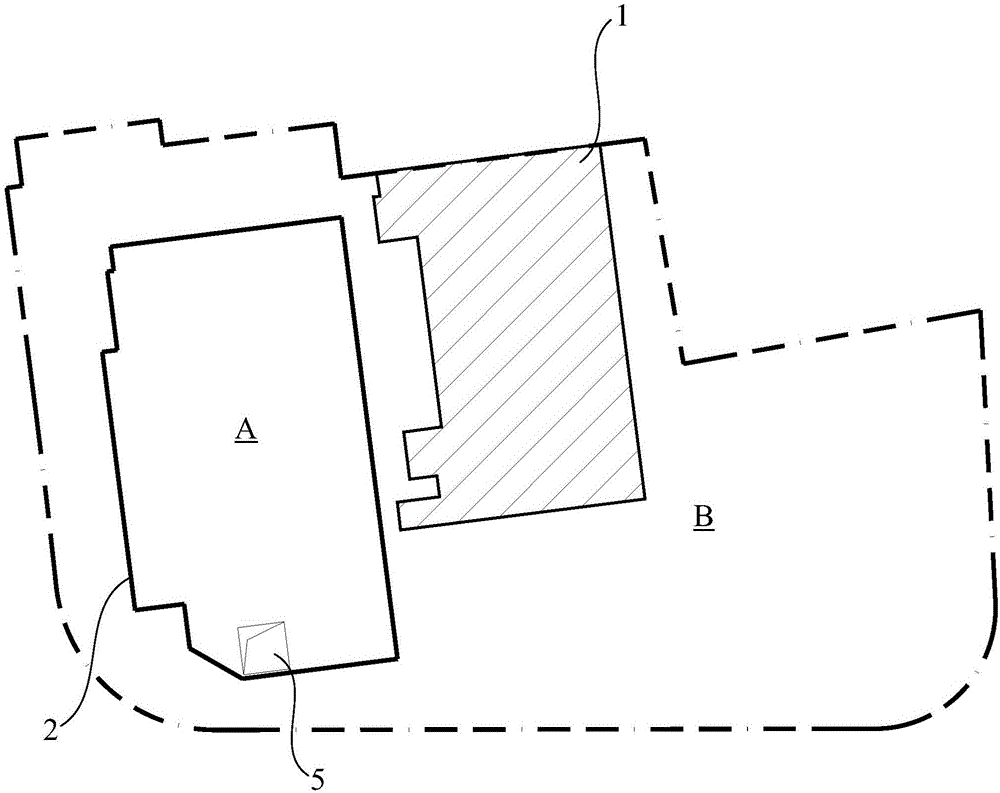

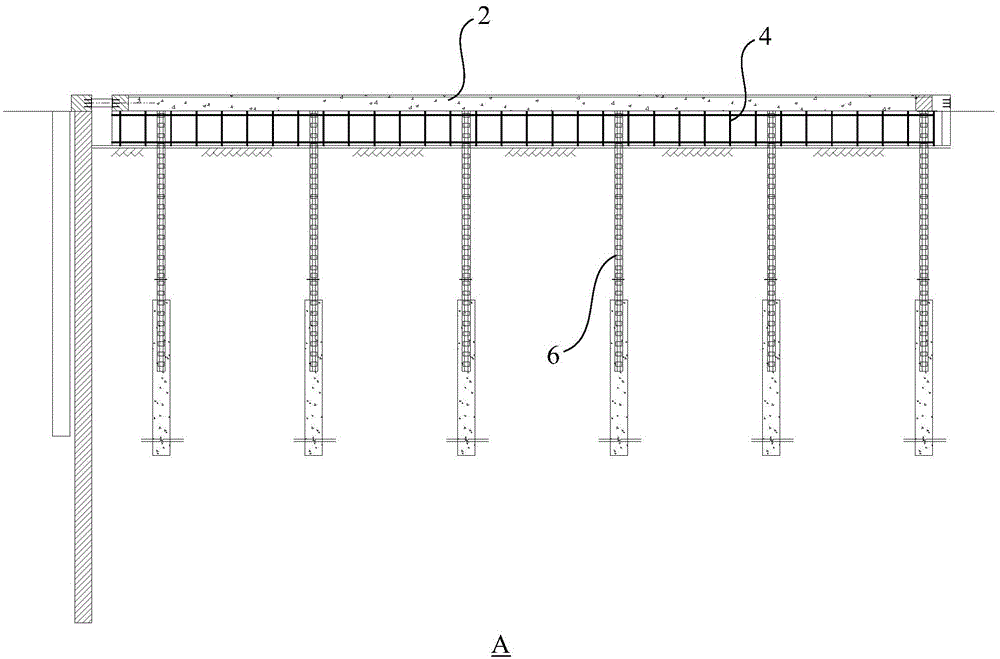

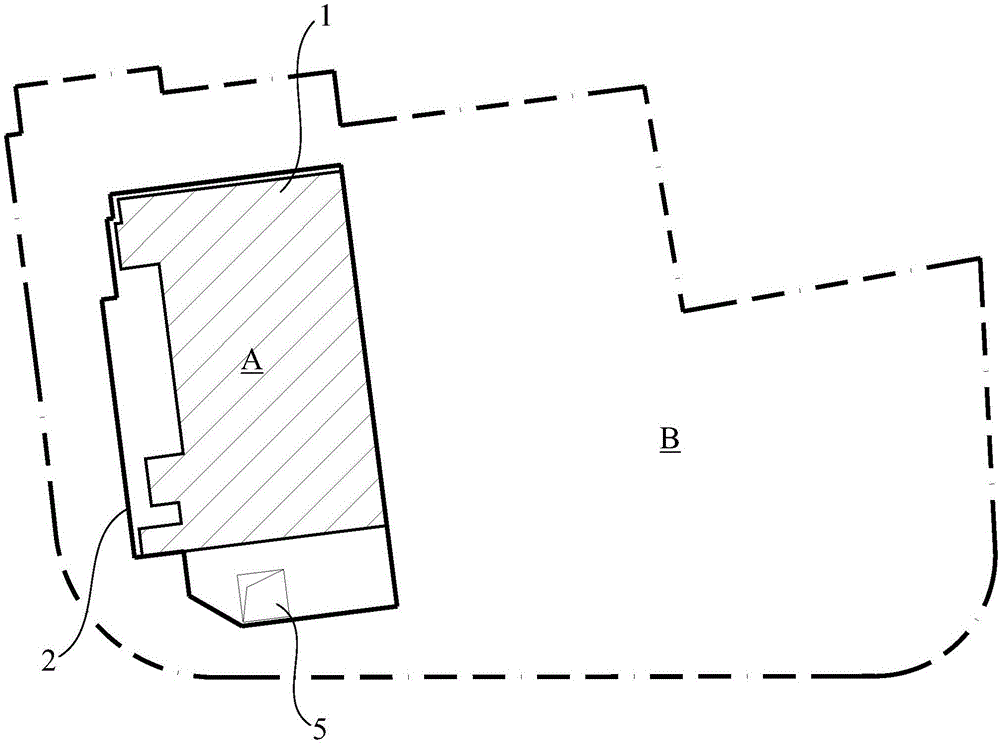

Construction method for newly-built large deep foundation pit basements under protection building

The invention provides a construction method for newly-built large deep foundation pit basements under a protection building. According to the construction method, on the premise that the protection building is not disassembled, within a limited foundation range, a mature building translation technology and a reverse foundation pit construction method are combined, and overall construction of the first-region and second-region basements is directly performed after the protection building and a top plate of the first-region basement are connected in an anti-seismic butt joint mode. On the basis of guaranteeing structural stability of the protection building, construction working conditions and construction steps of the basements are reduced, the construction period is shortened, safety and stability of the protection building are improved, overall construction quality and efficiency are improved, ambient environment is effectively controlled, the number of dividing strips between first and second regions is reduced, and time benefits, space benefits and stable benefits are maximized.

Owner:SHANGHAI YUBANG CONSTR ENG CO LTD

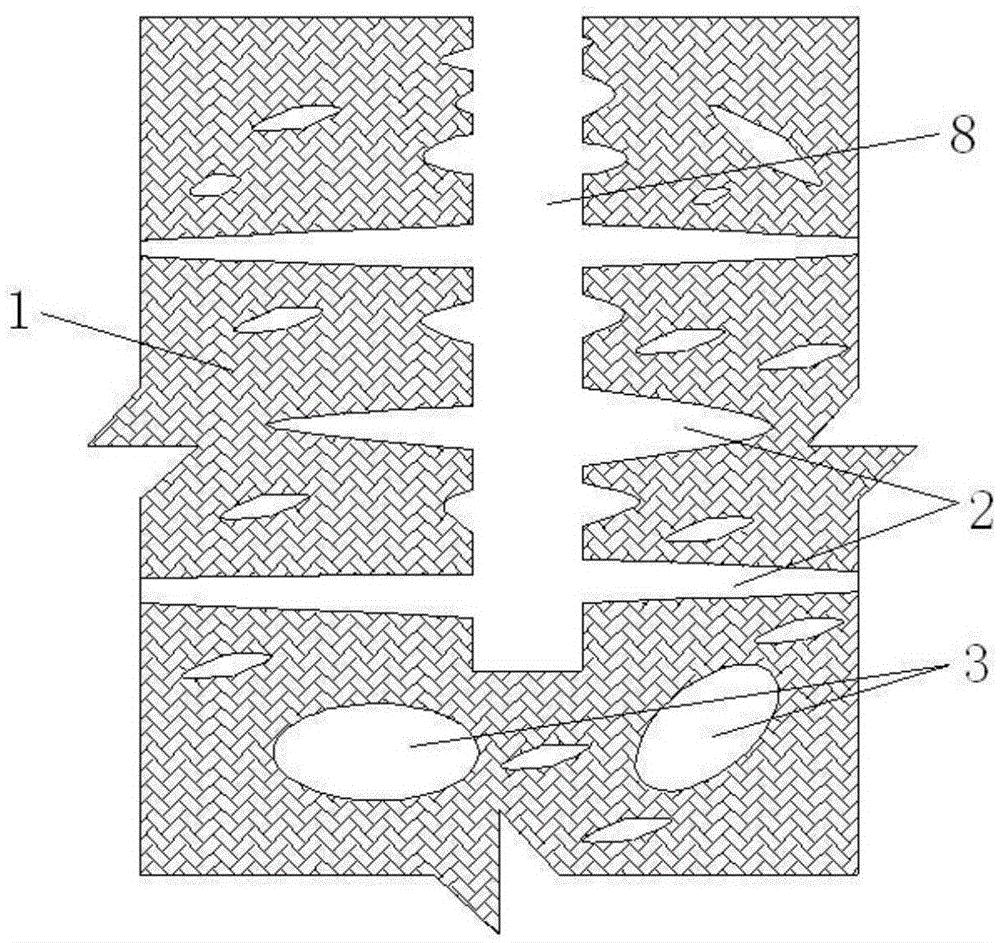

Dissymmetric double-linking-arch tunnel structure and construction method thereof

ActiveCN103174434AReduce the overall heightReduce spanUnderground chambersTunnel liningTunnel constructionBuilding construction

Disclosed are a construction method of the dissymmetric double-linking-arch tunnel structure. The structure comprises a small cave and a big cave, wherein the big cave is connected with the small cave. The construction method of the dissymmetric double-linking-arch tunnel structure successively includes the following steps: constructing a small cave advance support, constructing a small cave preliminary support, conducting construction of a preliminary support piece being embedded on the small cave preliminary support, constructing a small cave secondary lining, constructing a big cave advance support, constructing a big cave preliminary support, constructing big cave temporary middle partitioning walls, conducting integral connection of preliminary support connecting pieces on the big cave preliminary supporting and the small cave preliminary supporting, dismantling the big cave temporary middle partitioning walls at interval, and constructing a big cave secondary lining. The dissymmetric double-linking-arch tunnel structure and the method resolve the technical problems that in a traditional dissymmetric double-linking-arch tunnel construction process, abandoned work amount is large, cost is high, construction process is slow, and construction safety cannot be guaranteed.

Owner:中国建筑土木建设有限公司

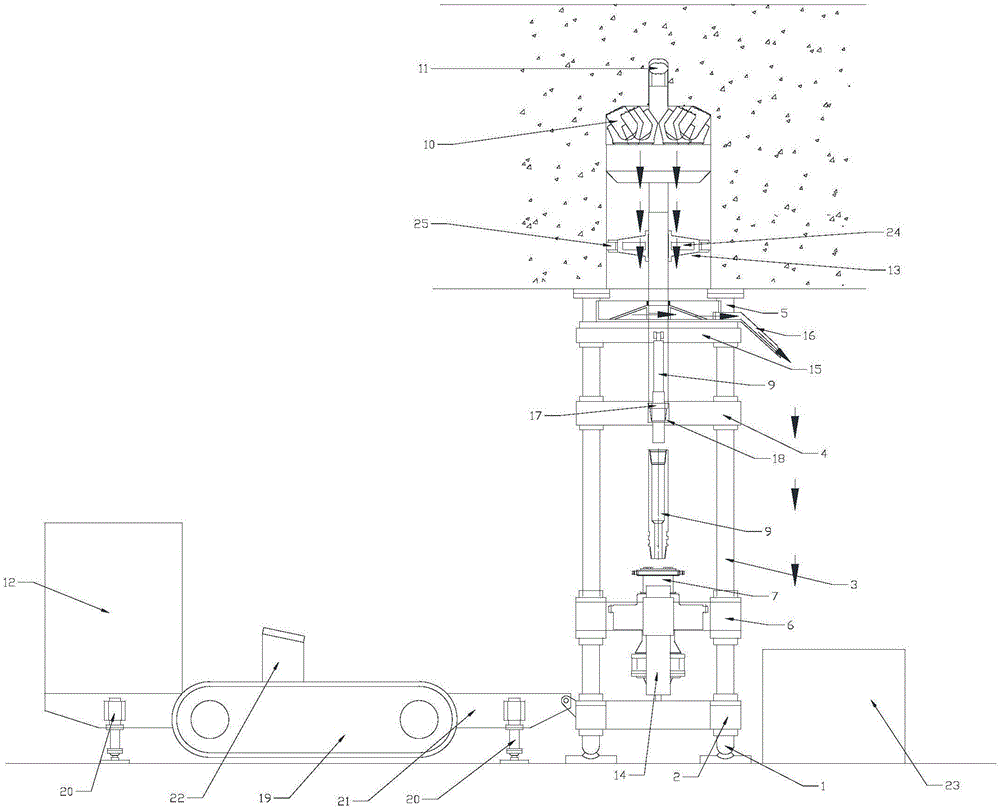

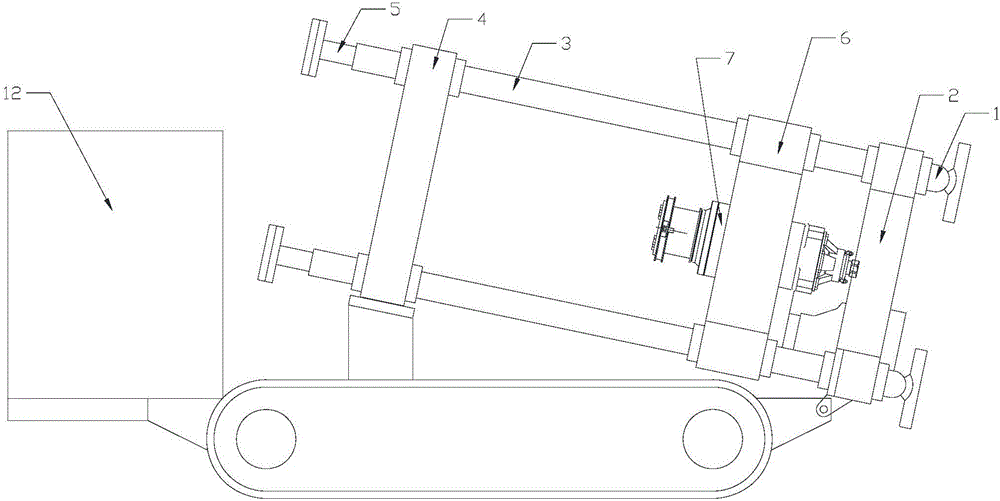

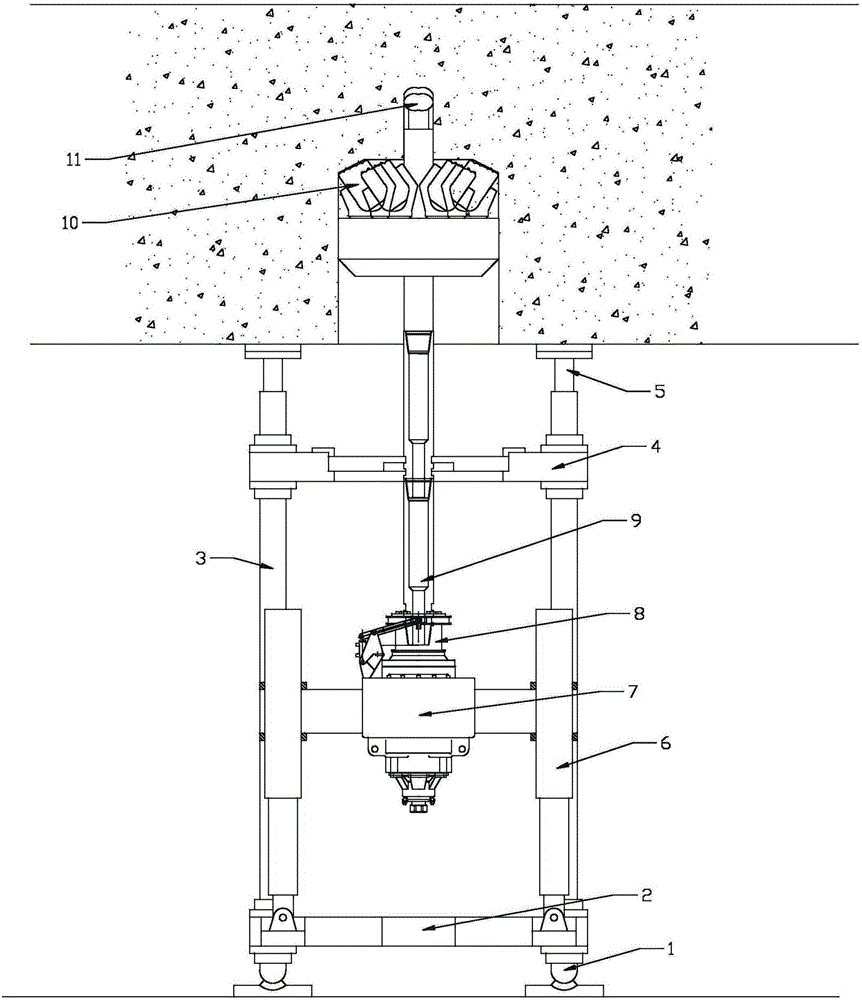

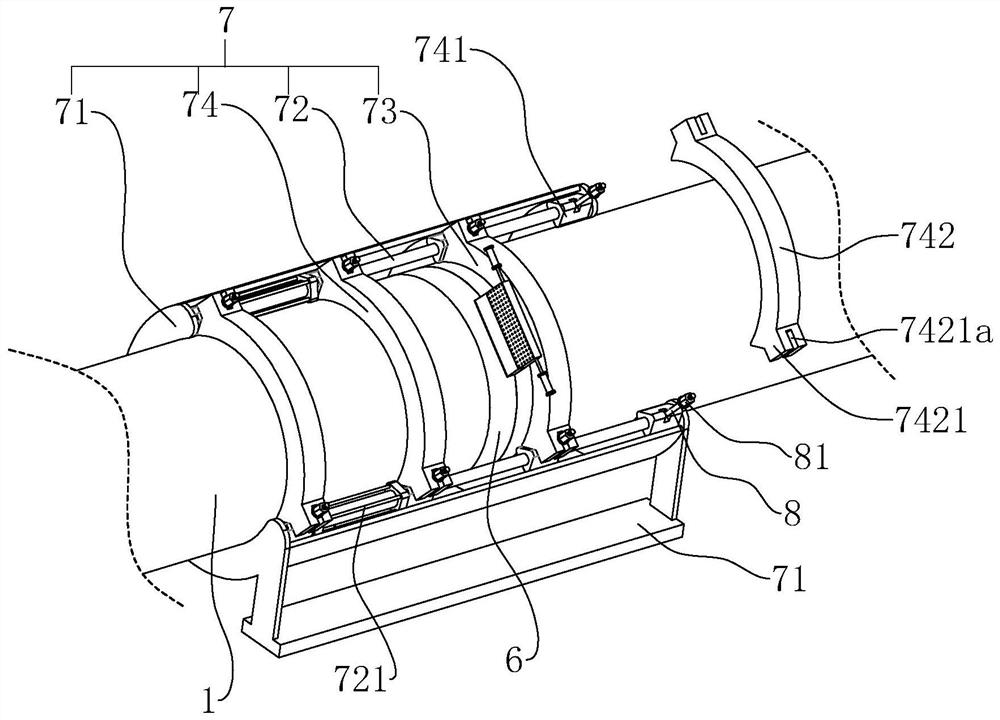

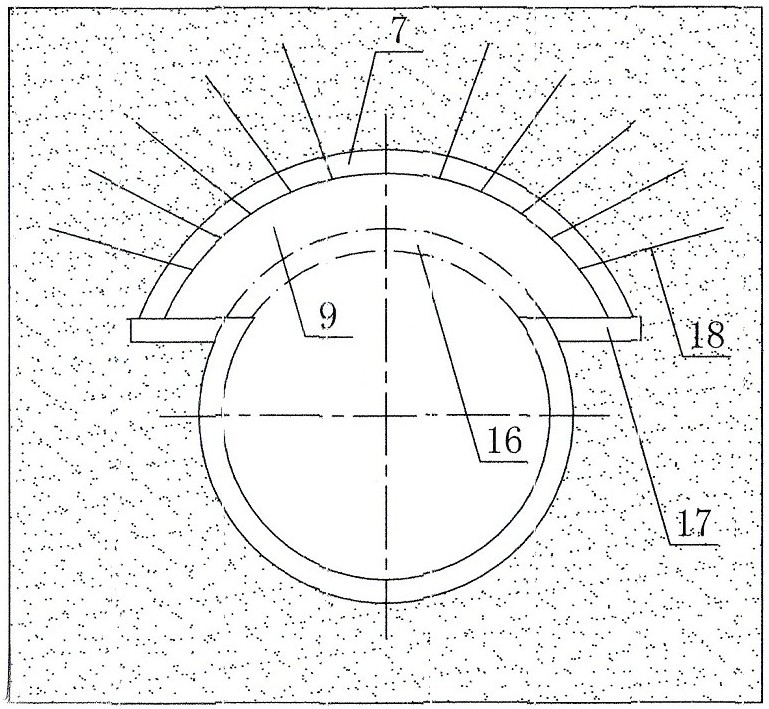

Movable upward raise boring machine

InactiveCN105041204ASimple processDrilling speed is fastDrilling rodsConstructionsUnderground tunnelWell drilling

The invention discloses a movable upward raise boring machine. The movable upward raise boring machine comprises a machine supporting mechanism, a main thrust oil cylinder, a power head, a crawler type traveling portion and a drilling rig, wherein the machine supporting mechanism comprises a lower support, a base, a guiding column, a top beam and an upper support; the upper end of the lower support is fixedly connected with the bottom surface of the base; the top surface of the base is fixedly connected with the lower end of the guiding column; the upper end of the guiding column is fixedly connected with the bottom surface of the top beam; the top surface of the top beam is fixedly connected with the lower end of the upper support; the top surface of the base is hinged to the main thrust oil cylinder; a retractable portion of the main thrust oil cylinder is fixedly connected with the power head; and the power head is slidably connected with the guiding column and is in transmission connection with the drilling rig. Well drilling construction can be performed from bottom to top, requirements of well drilling construction in the existing underground tunnel on a rock formation or a formation positioned below the underground tunnel are met, and requirements of well drilling construction on a rock formation or a formation above the underground tunnel can also be met.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

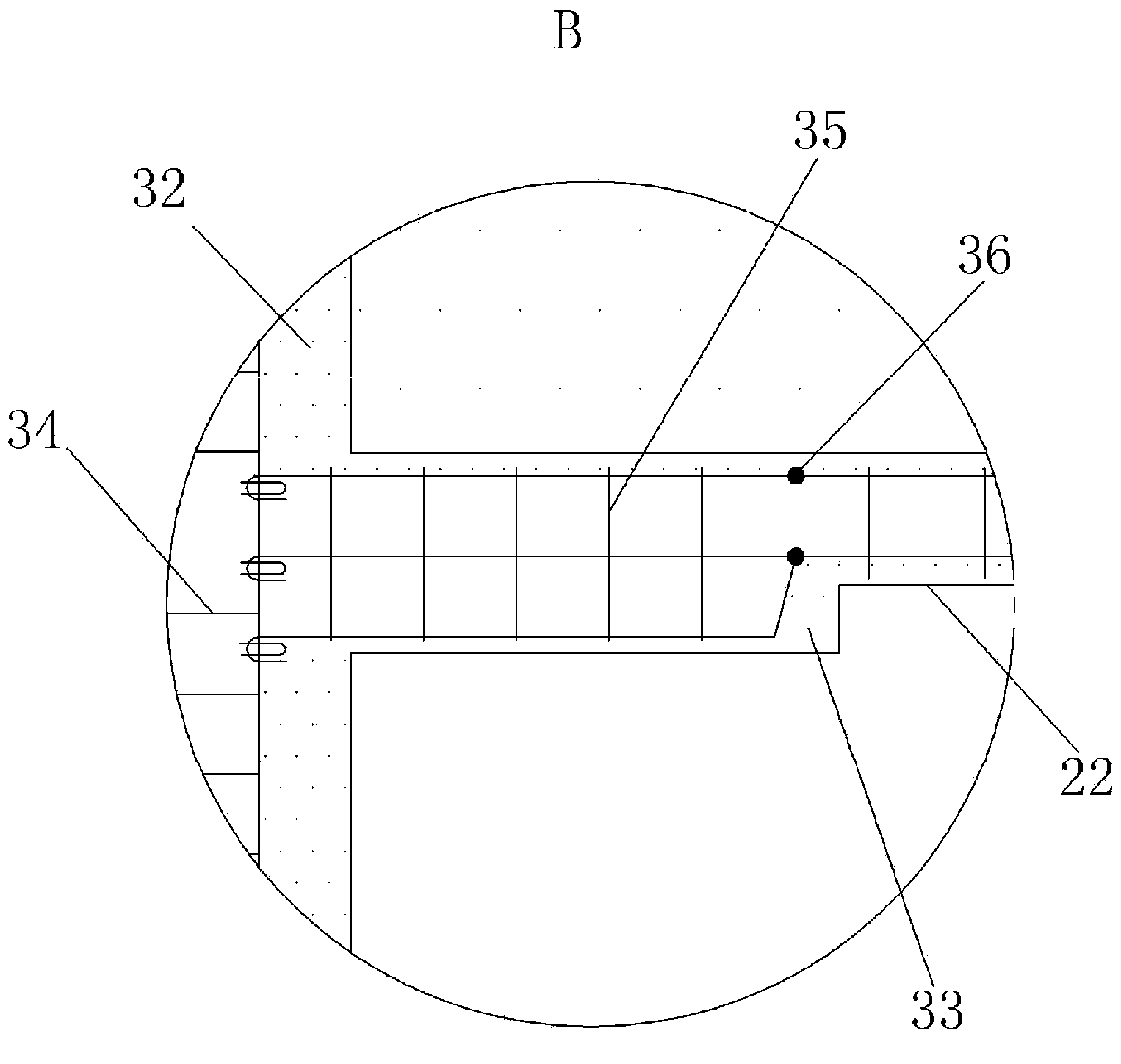

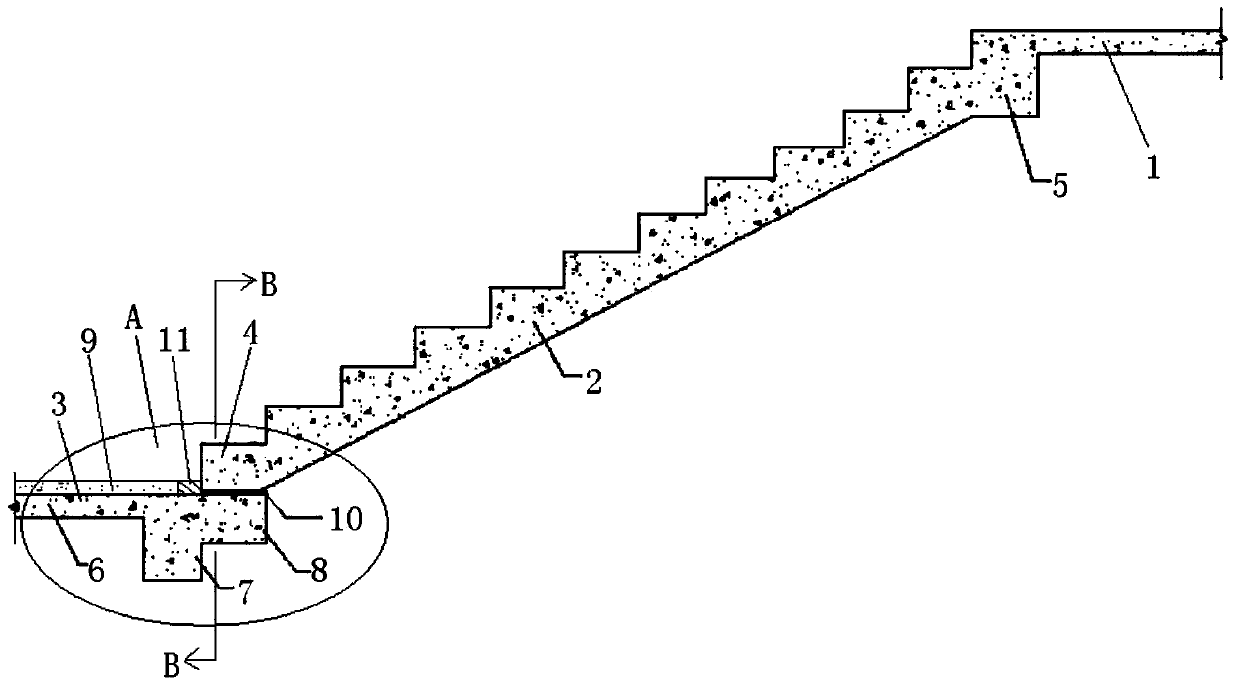

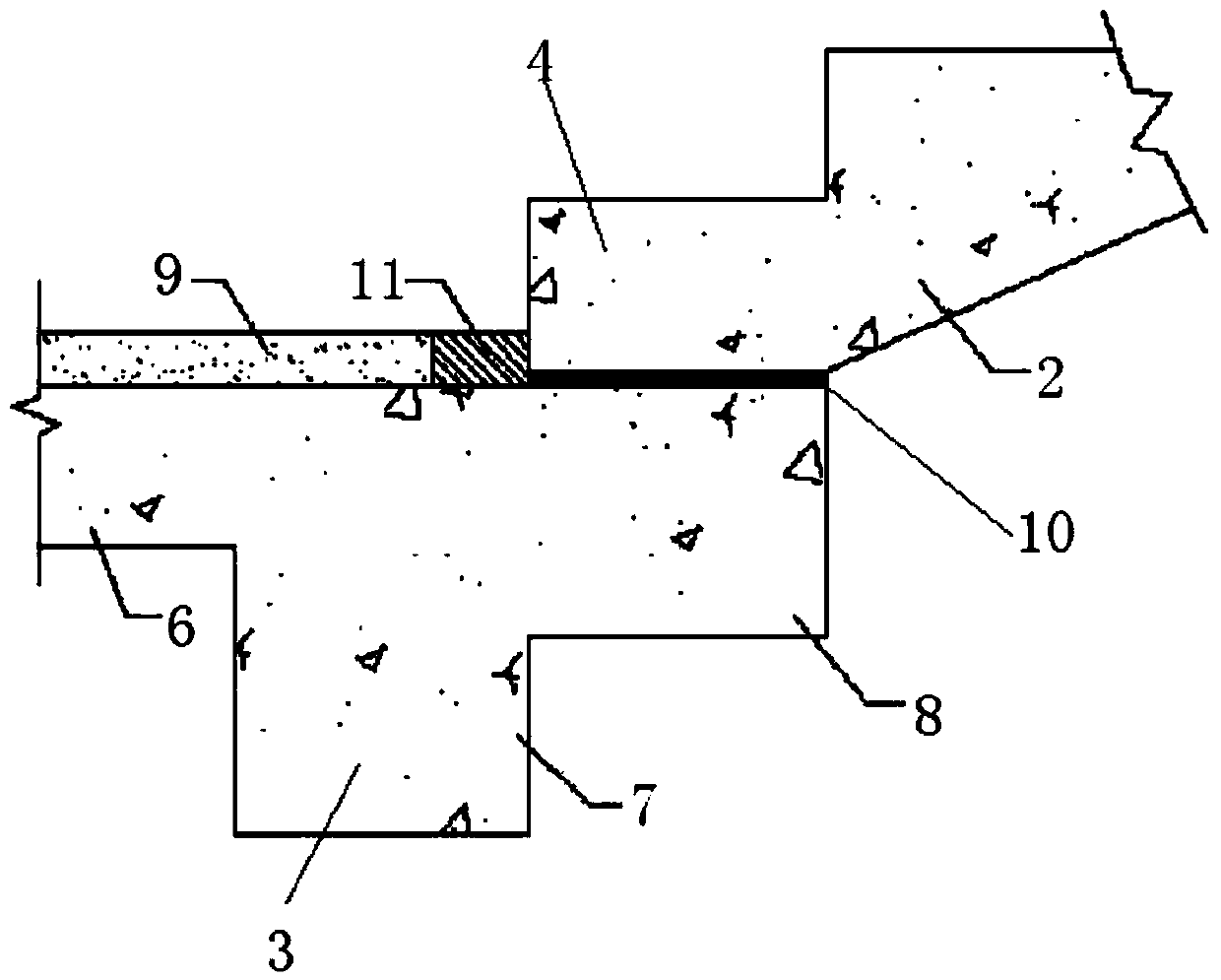

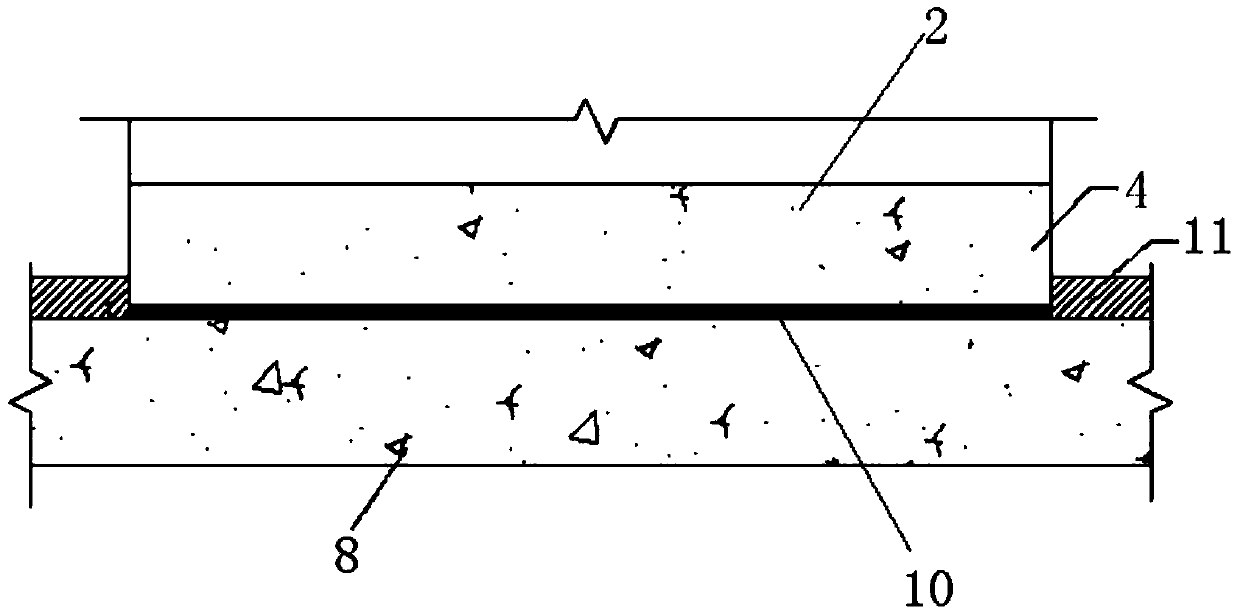

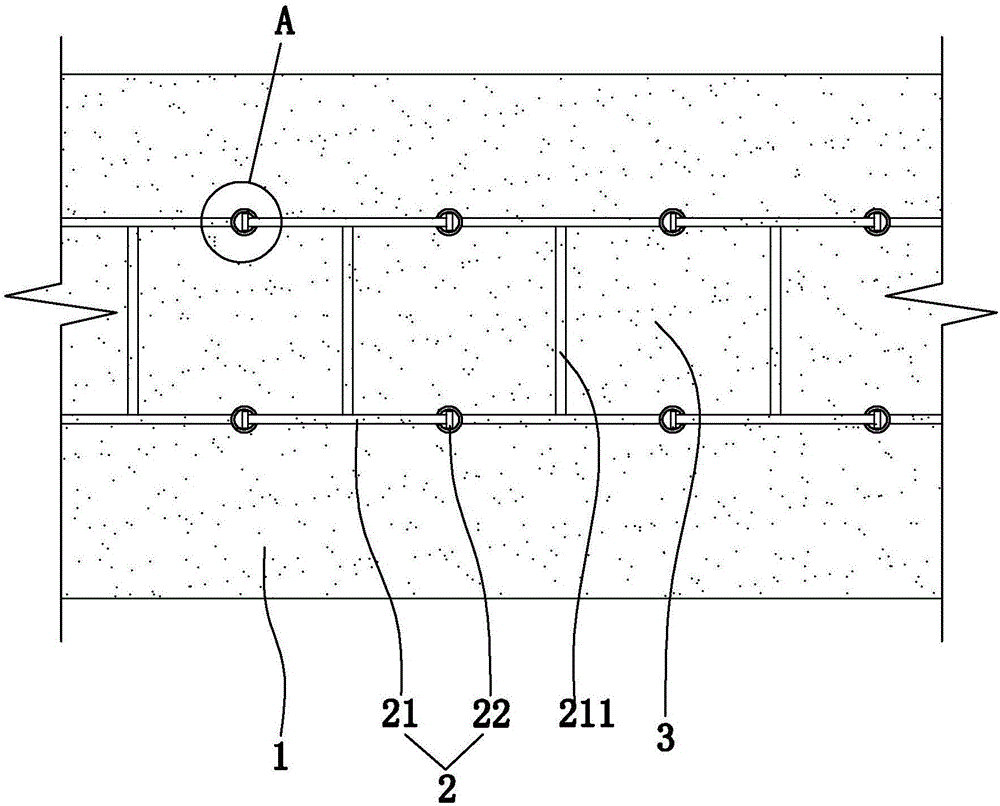

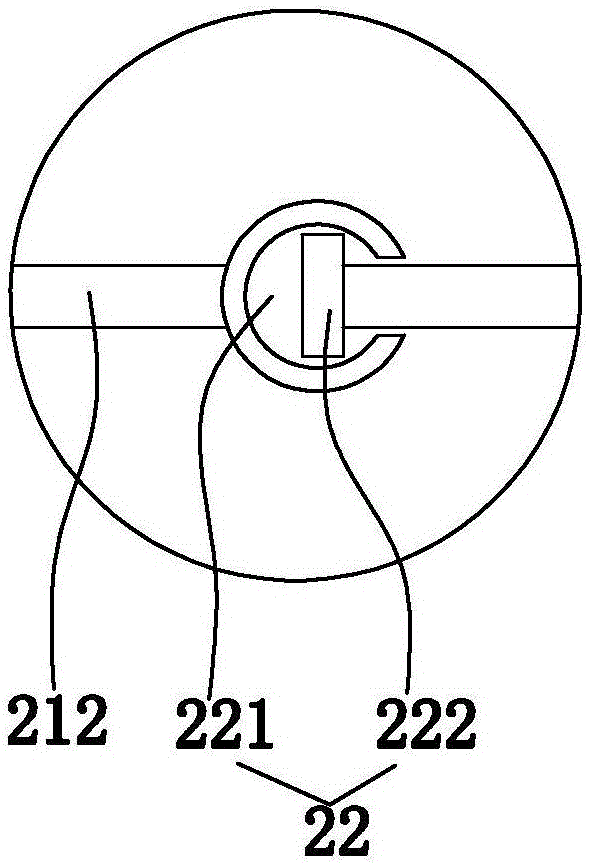

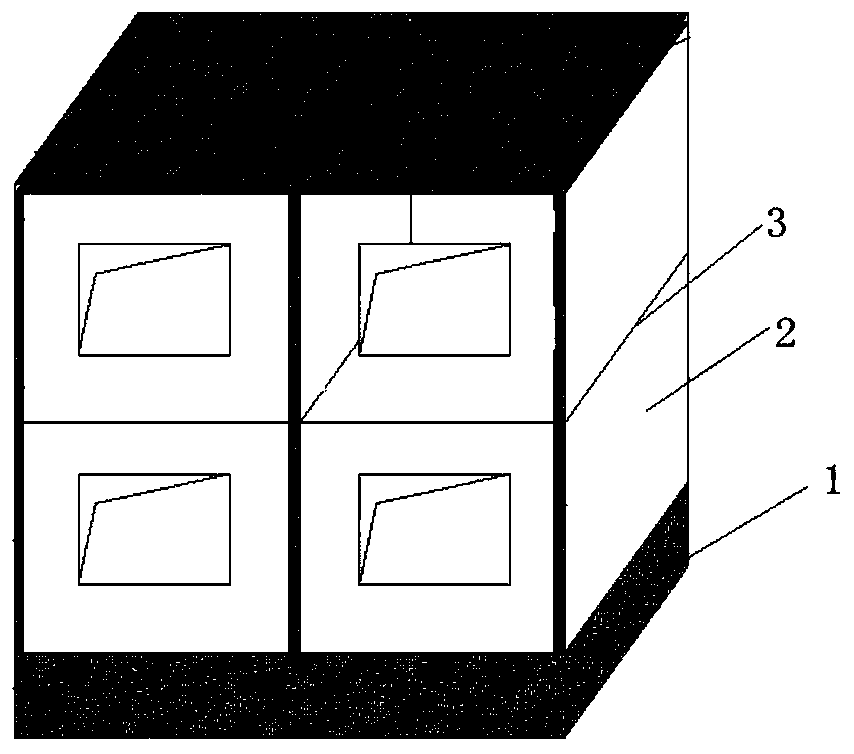

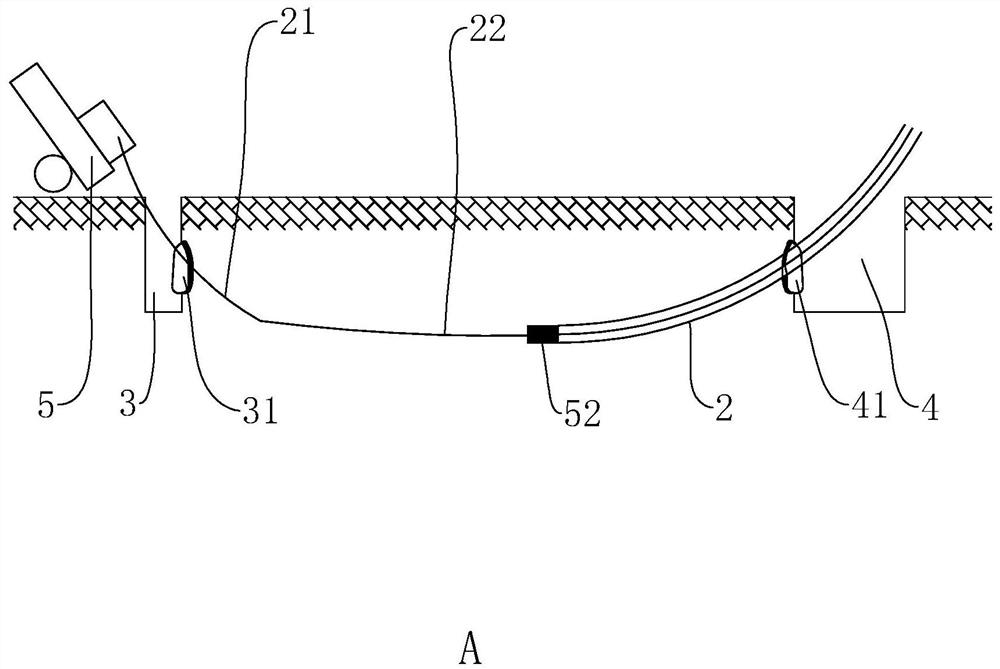

Anti-seismic stairs with sliding support and construction method thereof

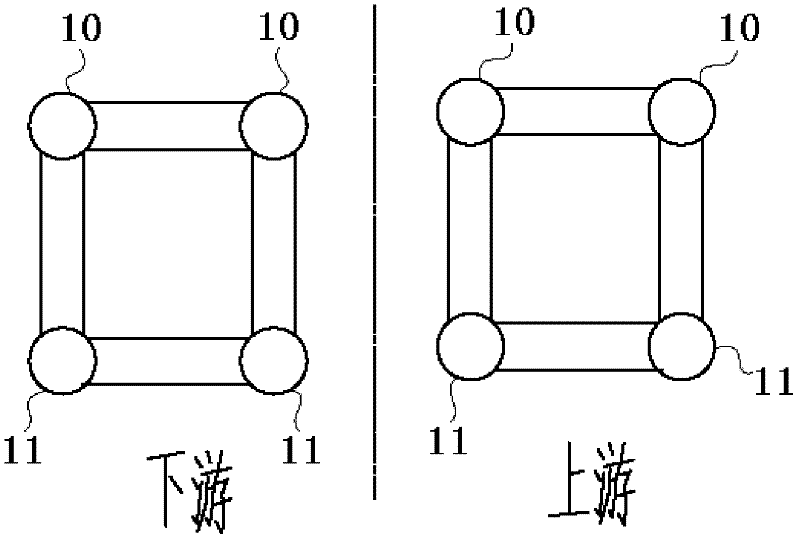

ActiveCN103758299AImprove earthquake resistanceReduce coefficient of frictionStairwaysStairsBearing capacity

The invention discloses anti-seismic stairs with a sliding support and a construction method thereof. The anti-seismic stairs with the sliding support are characterized in that the anti-seismic stairs with the sliding support comprise an upper platform (1), a stair bench slab (2) and a lower platform (3) which are connected in sequence, the lower platform (3) is connected with the lower end of the stair bench slab (2) through the sliding support, and the sliding support comprises a first sliding pad layer (10) and a second sliding pad layer (11). The anti-seismic stairs with the sliding support is provided with the sliding support, and has the advantages of being high in seismic resistance capacity, extremely low in friction coefficient, free of maintenance, strong in adaptability, resistant to friction and long in service life, high in bearing capacity, simple in structure and convenient in construction. The construction method has the advantages that construction procedures are few, operation is easy and convenient, and the anti-seismic capacity of stairs and a main body structure can be improved greatly.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

Permanent rigid cement soil enclosure wall for foundation pit and construction method thereof

InactiveCN106120807AReduce construction stepsShorten the construction period of the buildingArtificial islandsExcavationsEngineeringUltimate tensile strength

The invention discloses a permanent rigid cement soil enclosure wall for a foundation pit and a construction method thereof, and aims at effectively decreasing the construction steps and reducing the building construction period on the premise that the intensity of a foundation pit enclosure and the permanent sidewalls of a building foundation pit cannot be influenced. The permanent rigid cement soil enclosure wall for the foundation pit comprises a continuous cement-soil wall, and a combined profile steel supporting structure which is inserted into the continuous cement-soil wall, wherein the combined profile steel supporting structure comprises a plurality of vertical profile steels which are sequentially arranged and distributed; every two adjacent vertical profile steels are connected through an inserting buckle connecting structure. The construction method of the permanent rigid cement enclosure wall for the foundation pit comprises the following steps: 1, constructing a continuous cement-soil wall section with set length; 2, inserting each vertical profile steel into the continuous cement-soil wall, and connecting the every two adjacent vertical profile steels through the inserting buckle connecting structure; and 3, returning to step 1 to continuously construct.

Owner:DONGTONG ROCK SOIL SCI & TECH HANGZHOU

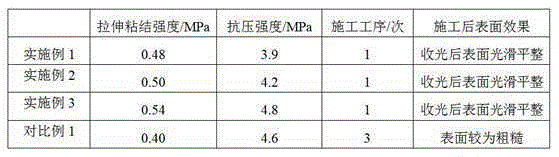

Putty leveling integrated gypsum mortar

The invention discloses putty leveling integrated gypsum mortar. The mortar is formed by mixing and stirring, by weight, 60-70 parts of desulfurized gypsum, 10-15 parts of 250-mesh heavy calcium carbonate, 6-10 parts of quartz sand of 20-30 meshes, 10-15 parts of 40-mesh quartz sand, 2-5 parts of glass bead heat preservation lightweight aggregate, 1-2 parts of redispersible emulsion powder VAE, 0.2-0.5 part of hydroxyethyl methylcellulose ether and 0.03-0.05 part of modified protein retarder. By means of the putty leveling integrated gypsum mortar, the traditional indoor leveling construction is greatly simplified, multiple construction procedures such as existing adhesion agents, leveling mortar and putty are replaced, forming can be completed at a time, the maintenance period is short, the construction period is greatly shortened, and the construction efficiency is improved.

Owner:上海曹杨建筑粘合剂厂

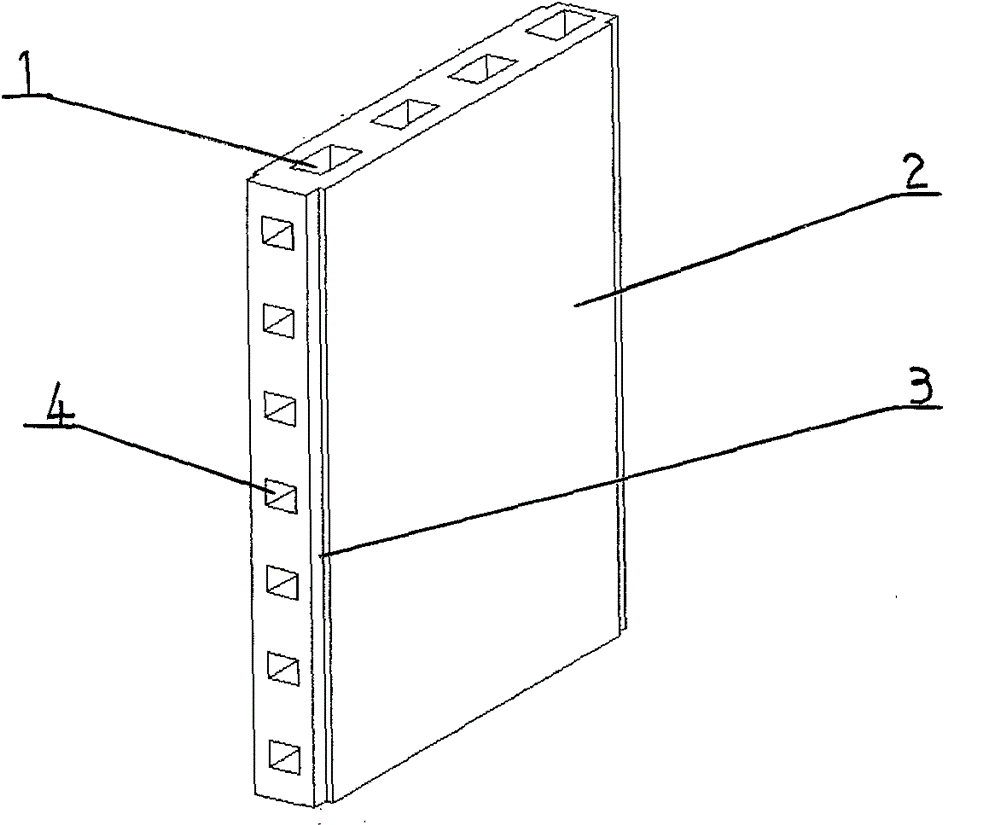

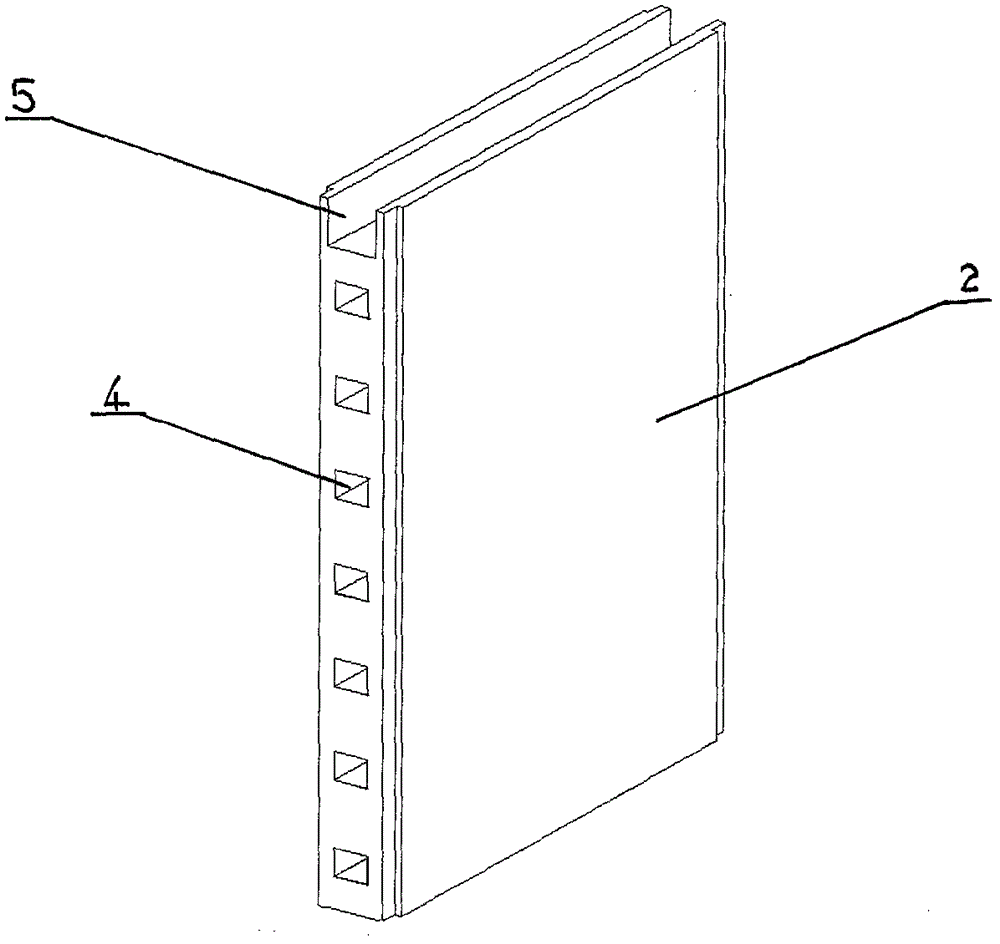

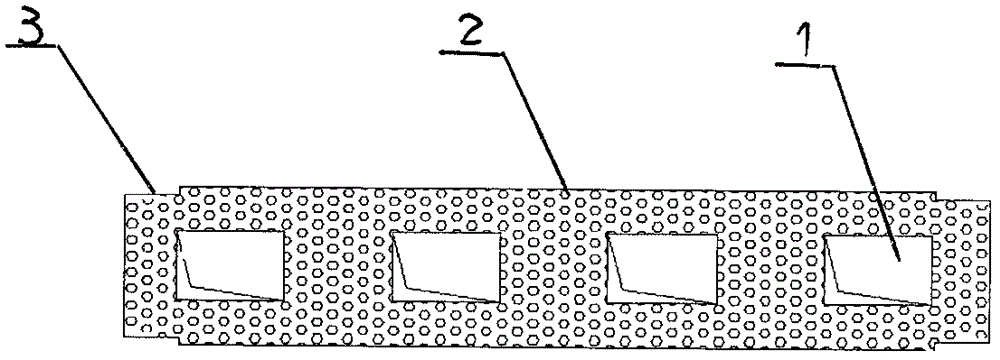

Heat preservation and fire prevention integrated template and preparation and installation method thereof

InactiveCN102080422AWith thermal insulation and fire performanceSmallSolid waste managementWallsCellulosePolyvinyl alcohol

The invention belongs to a heat preservation and fire prevention integrated template and a preparation and installation method thereof. The heat preservation and fire prevention integrated template comprises the following materials in part by weight: 215 to 220 parts of cement, 100 to 105 parts of coal ash, 13 to 15 parts of particle lightweight heat preservation material, 1 to 1.2 parts of polyvinyl alcohol, 0.3 to 0.4 part of cellulose ether, 0.4 to 0.5 part of redispersible glue powder, 0.5 to 0.6 part of early strength agent and a proper amount of water. The heat preservation and fire prevention integrated template can be arranged on a single face or double faces of a concrete cast-in-situ wall body according to design requirements. The heat preservation and fire prevention integrated template has heat preservation and fire prevention properties, serves as a building template which is not disassembled and is used together with the building with the same service life, and has the advantages of saving the materials, changing waste into treasure, reducing pollution and saving energy, along with light weight, fire prevention, high surface strength, good heat preservation effect and low cost. The invention also provides the preparation and installation method of the heat preservation and fire prevention integrated template. The method is practicable, simple and convenient; the cost is low; and construction steps are saved.

Owner:付振顶

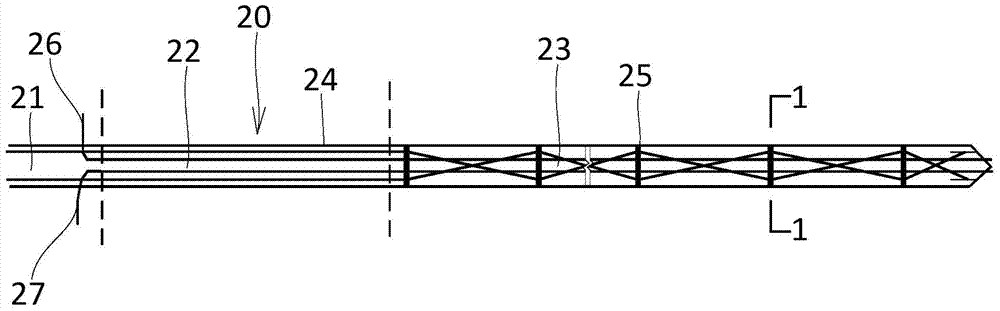

Tunnel support structure

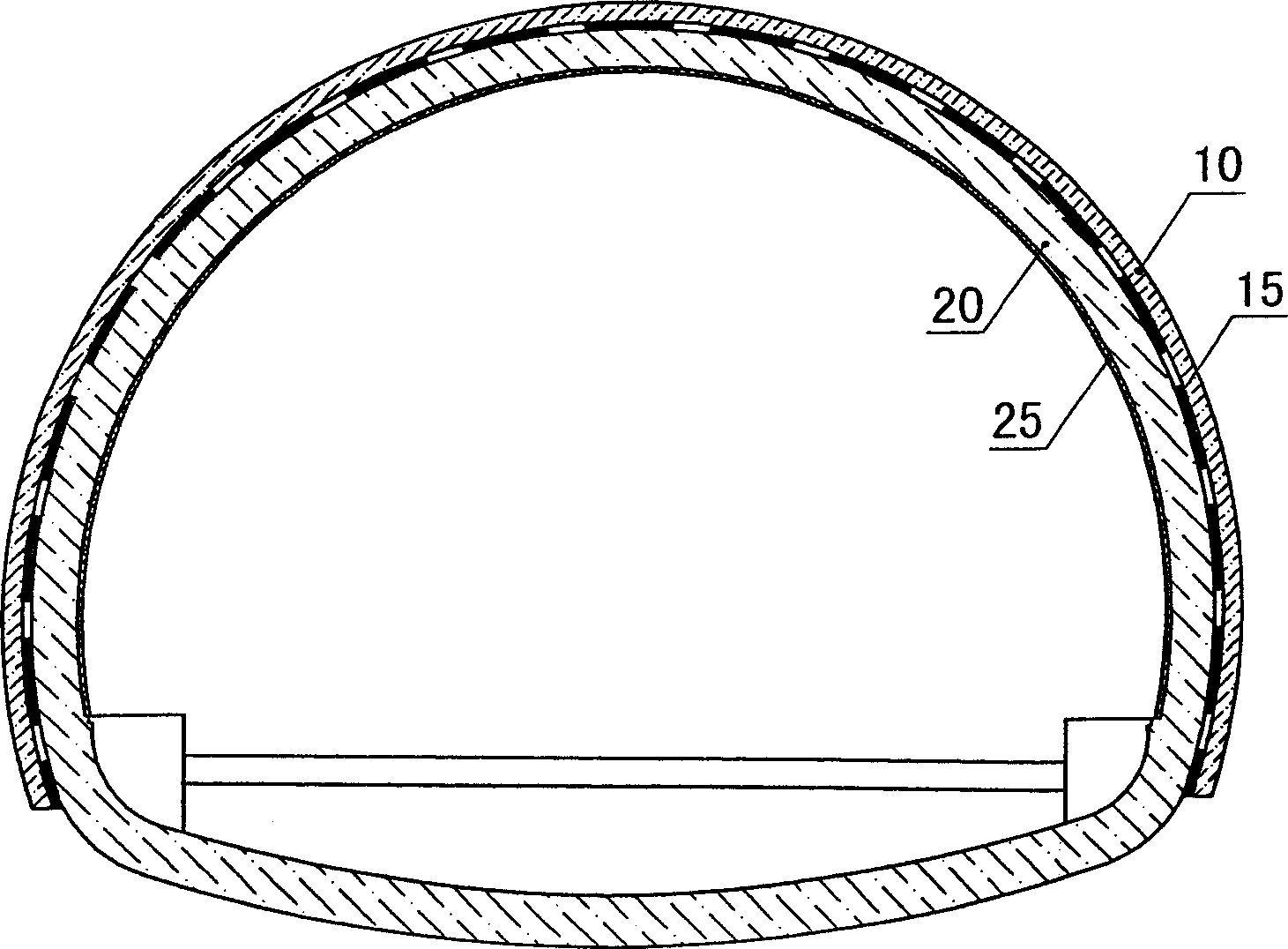

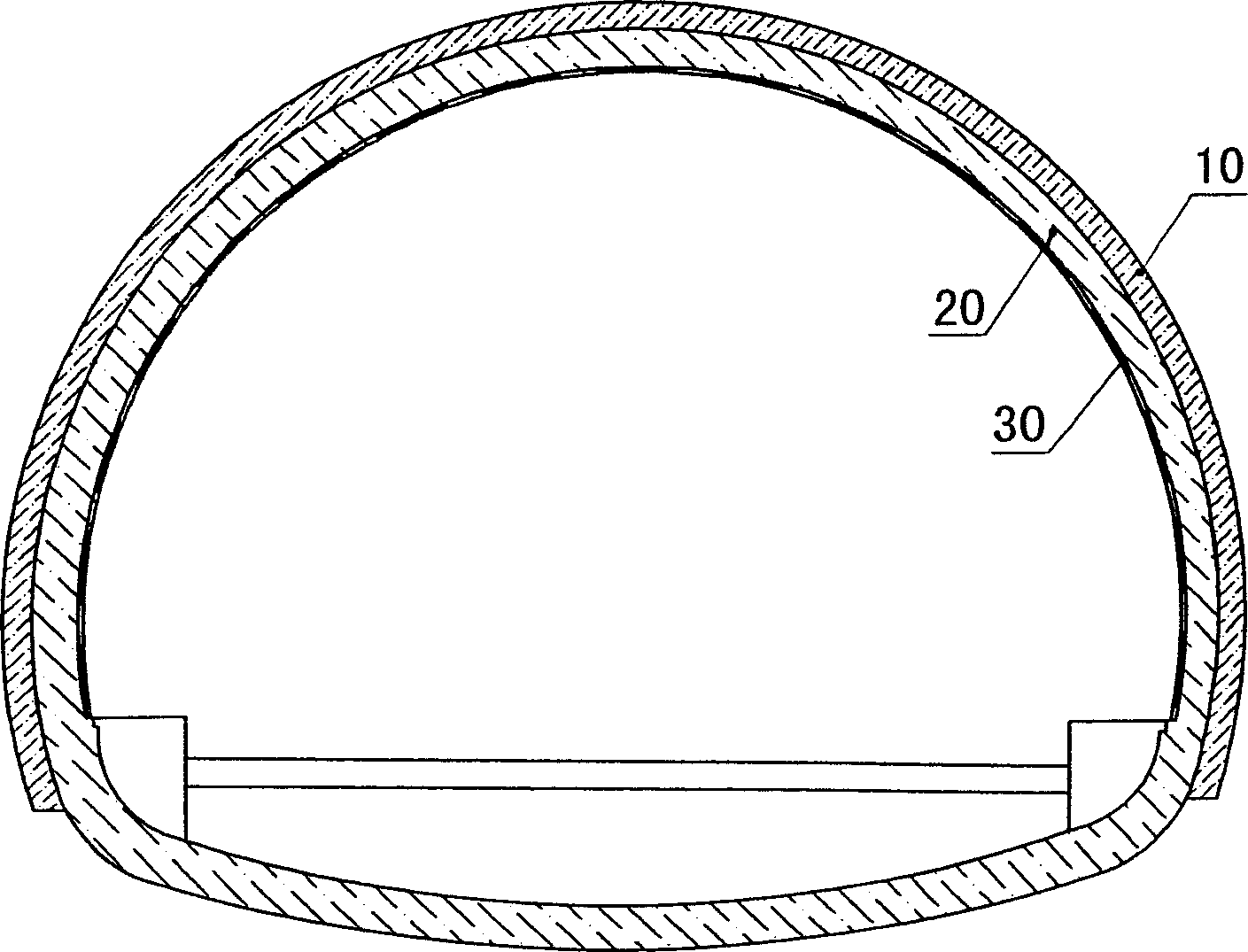

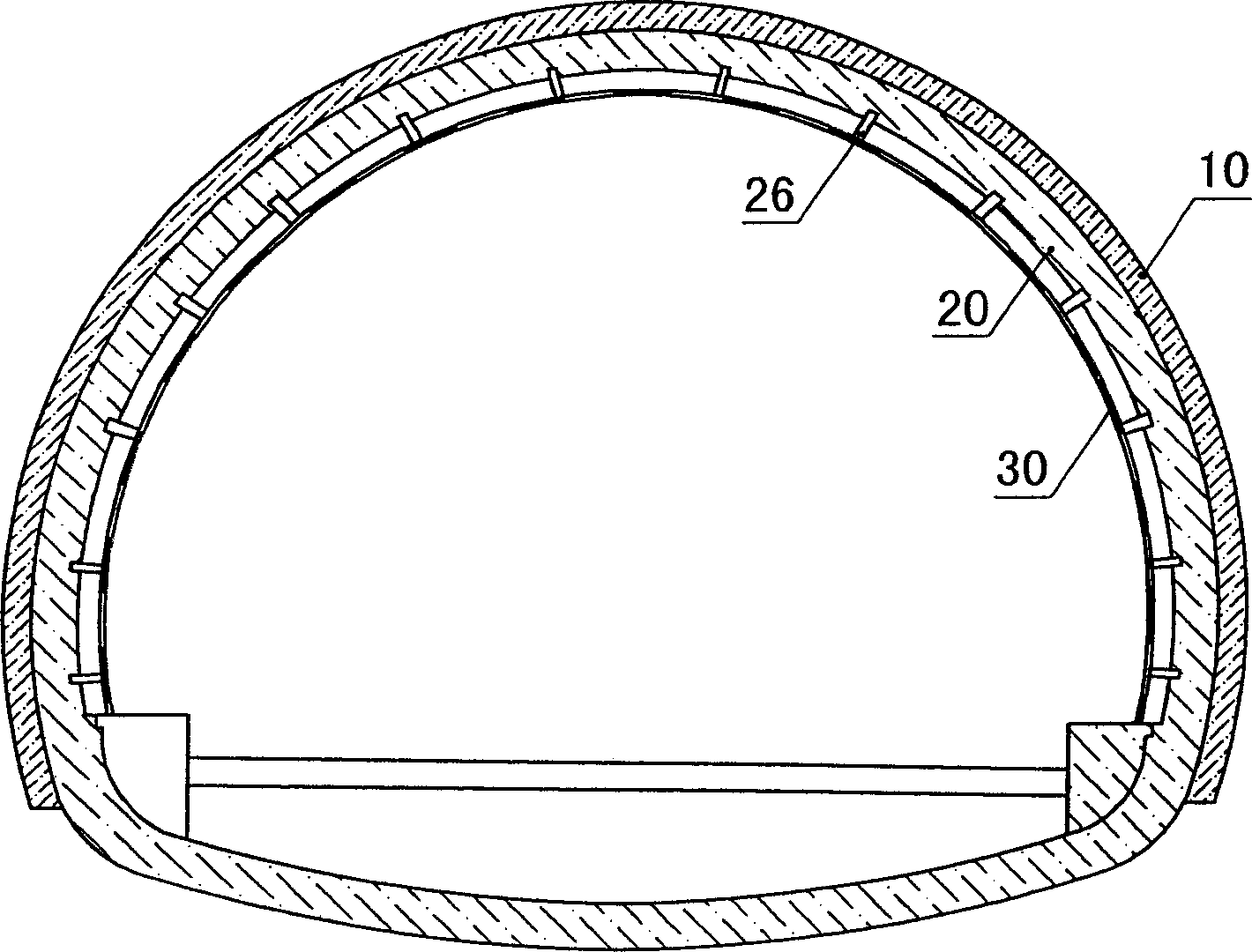

InactiveCN1858403AReduce construction costsImprove carrying capacityUnderground chambersTunnel liningShotcreteMaintainability

The present invention discloses a kind of tunnel support structure, and aims at providing tunnel support structure with raised integral bearing capacity, simple construction and excellent maintainability. The tunnel support structure includes a sprayed concrete layer combined to tunnel wall rock as the initial support; and a secondary laid and molded concrete layer combined with the inner wall of the sprayed concrete layer as the initial support. The present invention has the advantages of raised integral bearing capacity, simple construction, low cost, excellent maintainability, simple operation and capacity of ensuring the integral durability of the tunnel structure.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

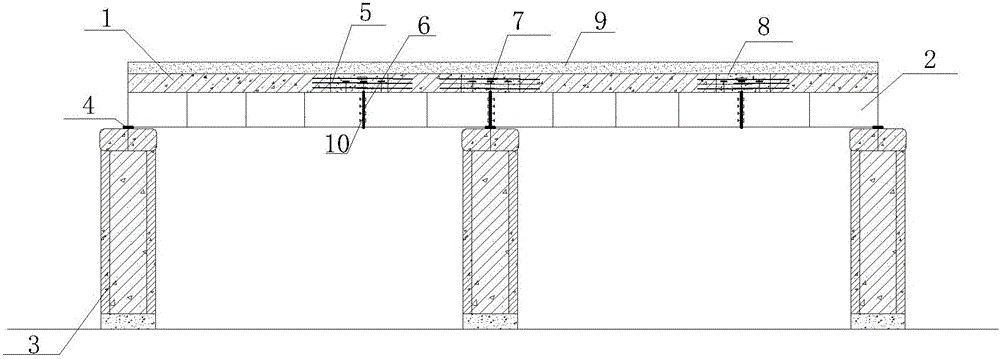

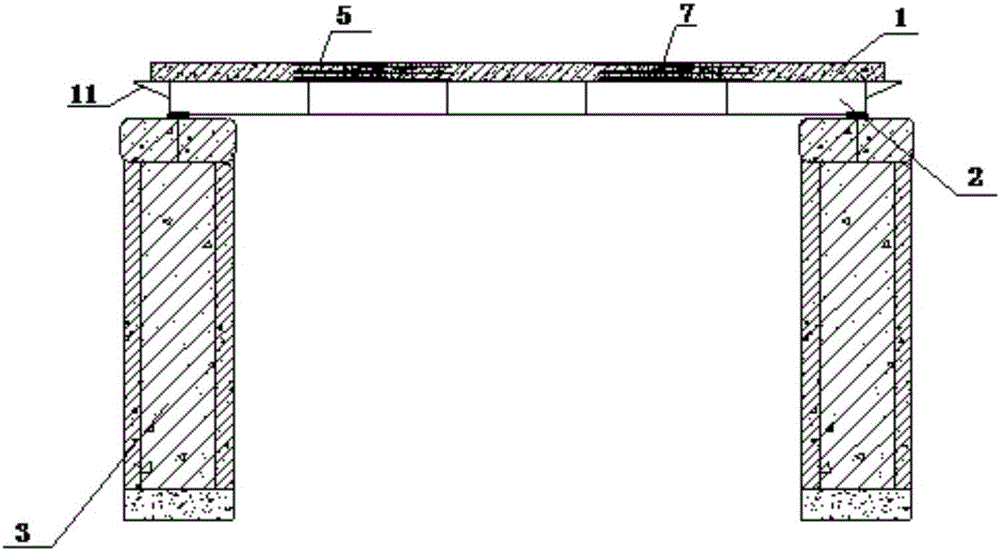

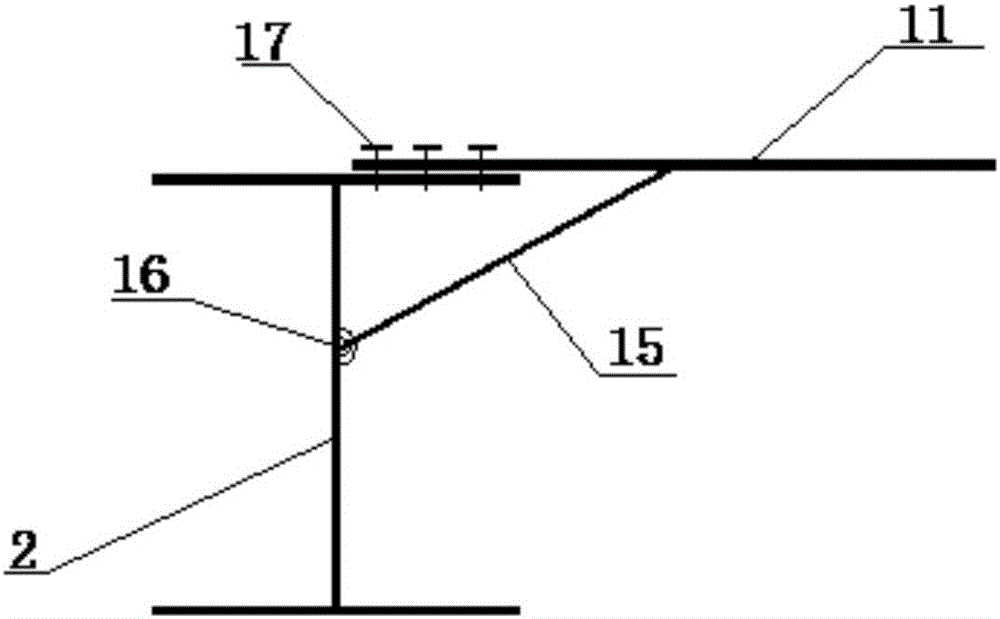

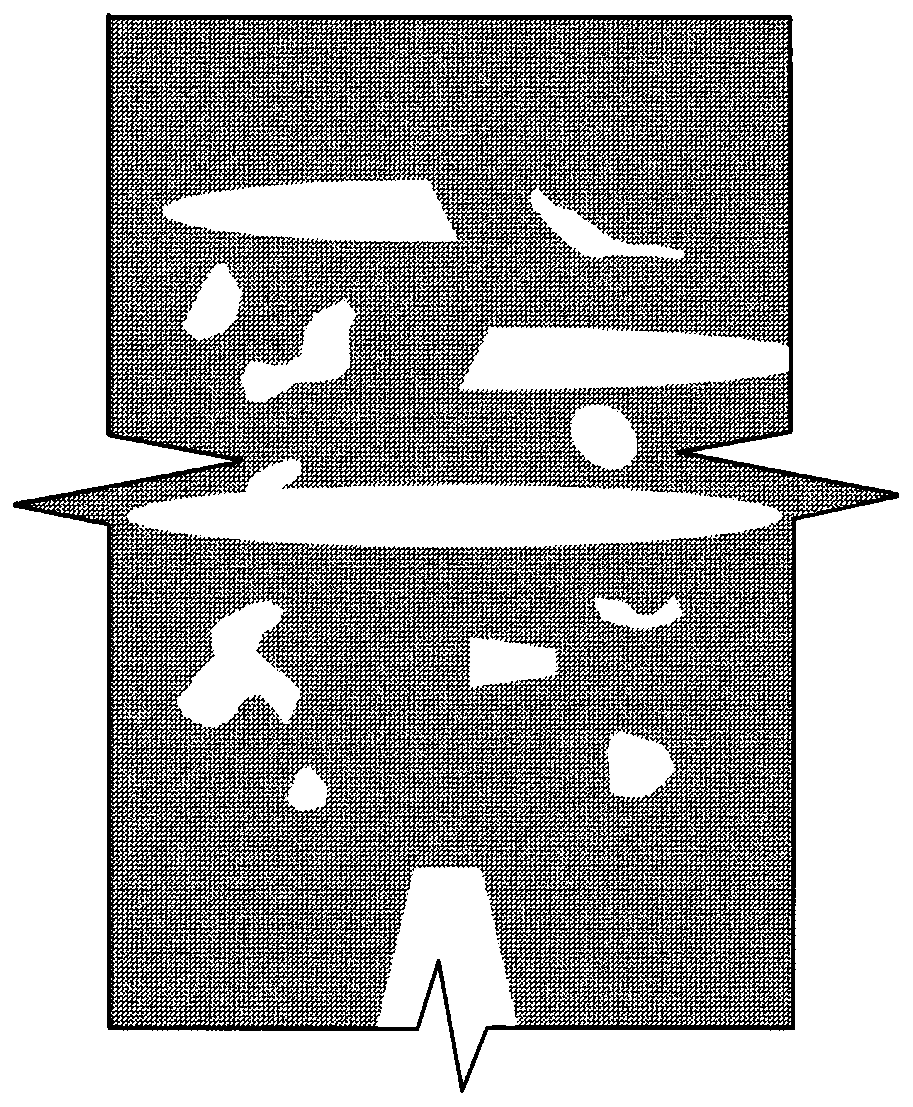

Profile steel and reinforced concrete slab assembled light composite beam bridge and construction method thereof

ActiveCN105064202AReduce construction stepsImprove construction safetyPortable bridgeBridge erection/assemblyRebarWeld seam

The invention discloses a profile steel and reinforced concrete slab assembled light composite beam bridge and a construction method thereof. The composite beam bridge is mainly composed of precast reinforced concrete slabs, profile steel beams, precast pier columns and a pavement structure layer, wherein the profile steel beams are connected through high-strength bolts and are combined with welded seams to be reinforced; reserved ribs are preset in the precast reinforced concrete slabs, the precast reinforced concrete slabs are welded and connected by adopting straight thread sleeves and the reserved ribs, and the precast reinforced concrete slabs are connected with the profile steel beams through pegs, the reserved ribs and micro-expansion concrete; the profile steel beams are fixedly connected with the precast pier columns. The composite beam bridge disclosed by the invention is convenient in construction, short in construction period, high in structure safety coefficient; and according to the invention, the construction problem of a high-altitude composite beam bridge is solved effectively.

Owner:ANHUI HIGHWAY ENG CORP

Bored cast-in-place pile suitable for karst areas with connectivity channels and pile forming method thereof

The invention relates to a bored cast-in-place pile suitable for karst areas with connectivity channels and a pile forming method thereof. The bored cast-in-place pile comprises a pile body and a wrapping piece, wherein the pile body at least comprises a concrete pile body and a reinforcing cage, the wrapping piece is a composite geotextile with a closed bottom and an open top, the wrapping piececoats the reinforcing cage before the pile body is formed into the pile, the wrapping piece is arranged around and lightly buckled on the reinforcing cage through an annular iron wire, concrete groutis injected into the reinforcing cage under high pressure, the high-pressure concrete grout pushes part of the wrapping piece to bulge towards the connectivity channels to form a dendritic structure in a branch-like form, and the pile is formed after the grout is solidified and hardened; and the diameter of the wrapping piece is larger than the diameter of the reinforcing cage, and the length of the wrapping piece is larger than the length of the reinforcing cage. The bored cast-in-place pile is provided with the wrapping piece to wrap grout, so that the phenomena of grout leakage, diameter shrinkage and the like in the process of manufacturing the bored cast-in-place pile in the karst areas are avoided, the pile forming quality is effectively guaranteed, the integrity of the pile and karst with the connectivity channels is improved, and the bearing capacity of the pile is greatly improved.

Owner:GUANGXI UNIV

Cast-in-place pile applicable to karst region having communicating channels

The invention discloses a cast-in-place pile applicable to a karst region having communicating channels. The cast-in-place is applicable to the karst region having the communicating channels, and comprises a pile body that is arranged in the karst region having the communicating channels, and a covering part that covers a steel reinforcement cage of the pile body before pile forming; a diameter of the covering part is greater than a diameter of the steel reinforcement cage of the pile body before pile forming, and a length of the covering part is greater than a height of the steel reinforcement cage of the pile body before pile forming; in a use state, the covering part extends into the communicating channels in the karst region, and the covering part extending into the communicating channels is filled with concrete slurry. The cast-in-place pile of the present invention is capable of better combining with integral rock in the communicating karst region for bearing together, and also capable of remarkably increasing the pile side frictional resistance of a pile foundation, thereby improving the integral bearing capability of the foundation.

Owner:GUANGXI UNIV

Building structure system based on prefabricated thermal insulating wall

PendingCN110453777AImprove structural stabilitySimplified Rebar Cage LashingHeat proofingBuilding insulationsFloor slabRebar

The invention discloses a building structure system based on a prefabricated thermal insulating wall. The building structure system comprises a foundation and floor wallboard units, all floor wallboard units are connected sequentially, the floor wallboard unit on the lowest layer is connected with the foundation through a foundation connecting longitudinal rib, the floor wallboard units comprise aplurality of prefabricated wallboards and composite floor slabs, the adjacent wallboards are connected through I-shaped joints, L-shaped joints and T-shaped joints, the prefabricated wallboards are divided into outer walls and inner walls, the outer walls are prefabricated sandwich thermal insulating walls, the inner walls are prefabricated double-surface composite walls, and all the floor wallsand the composite floor slabs are connected through upper-lower composite floor slab joints. According to the building structure system based on the prefabricated thermal insulating wall, the problemsof steel cage binding and hoisting of all components are simplified, and the construction efficiency is high; meanwhile, connection of all the prefabricated components is simple, construction is convenient, and practicability adjustment can be conducted according to the force bearing condition of the building system; and whole pouring is conducted after connection of all the components, the structure stability of the whole building is improved, consumables are saved, and building waste is reduced.

Owner:美好建筑装配科技有限公司

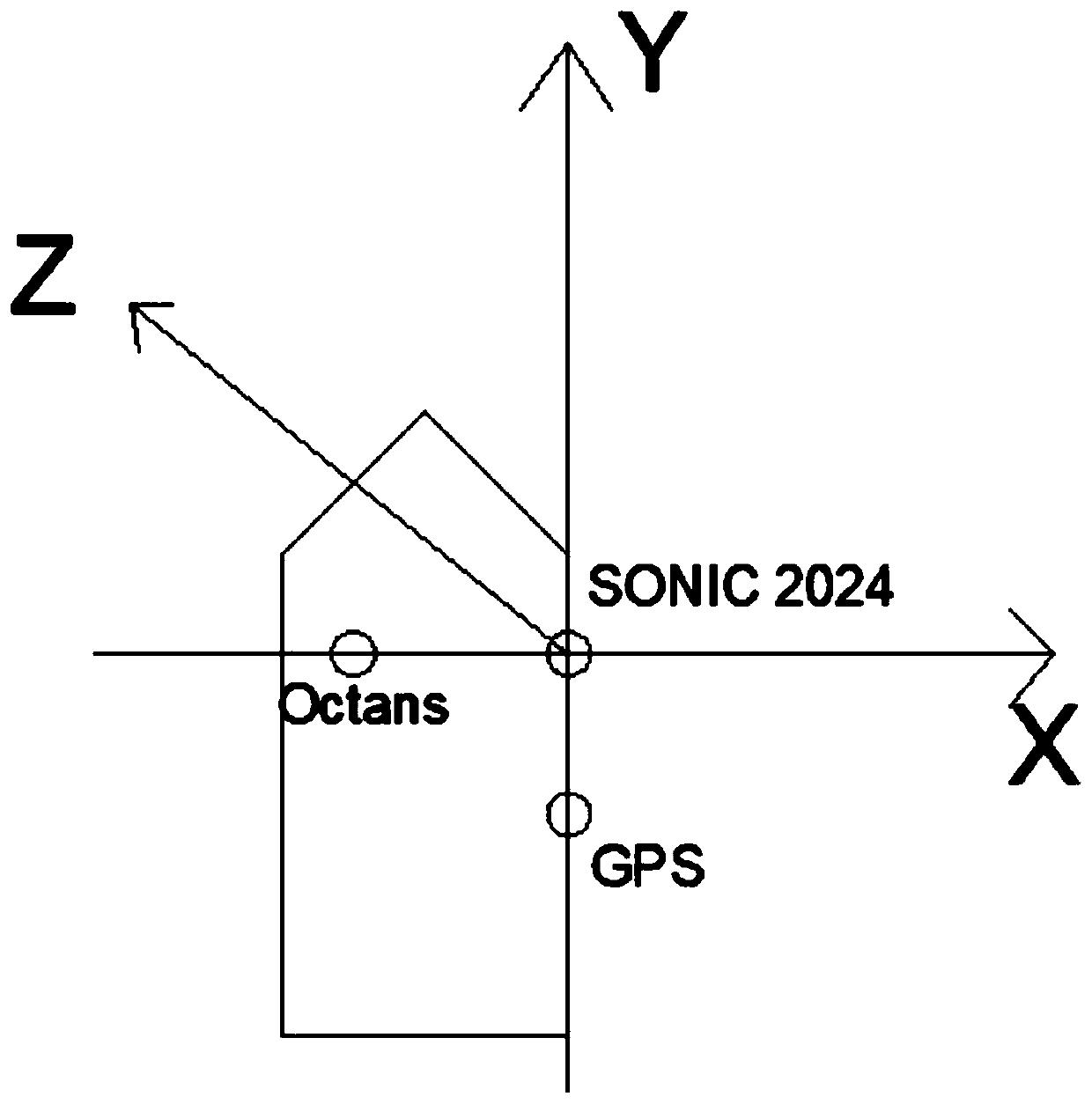

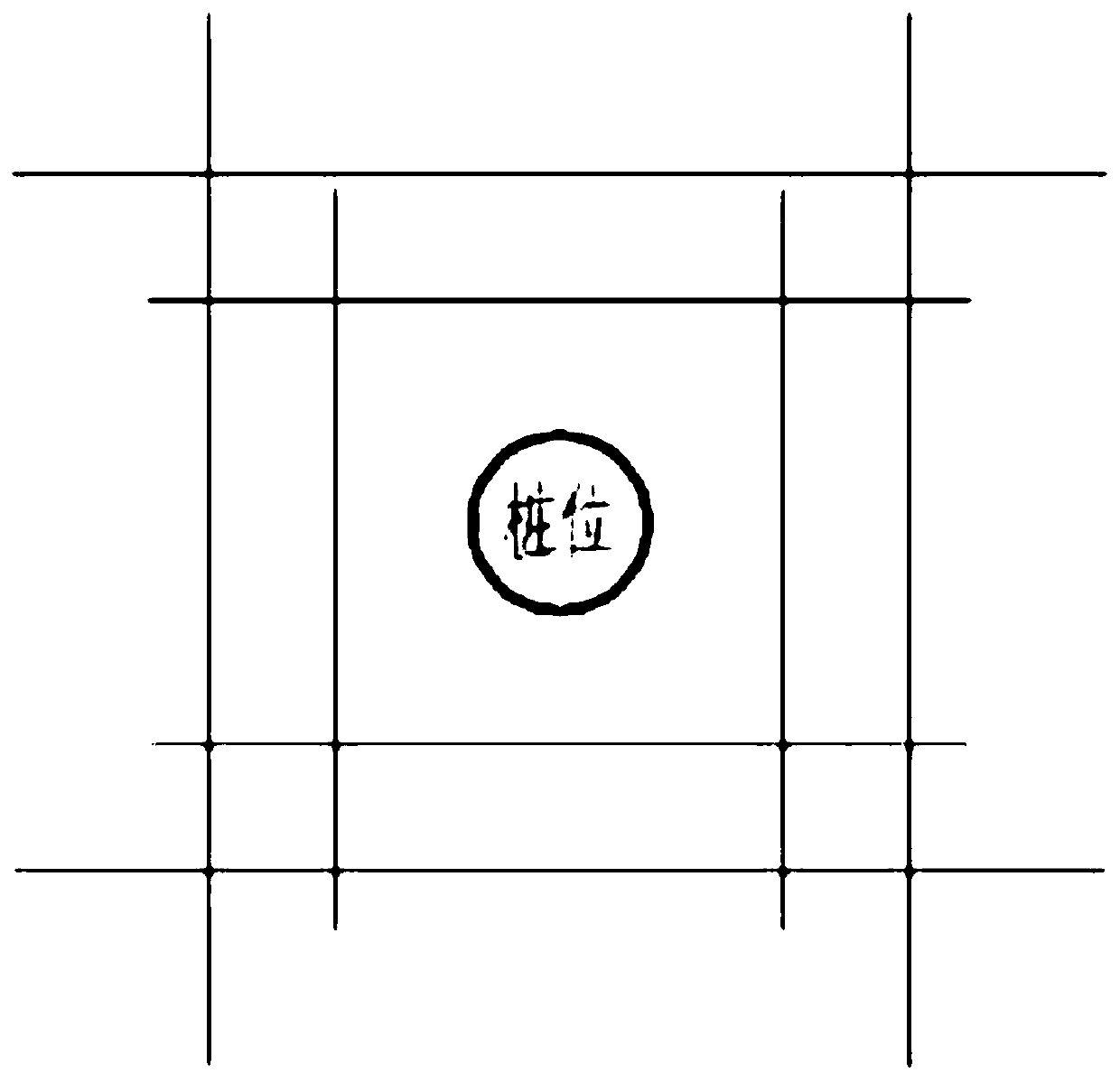

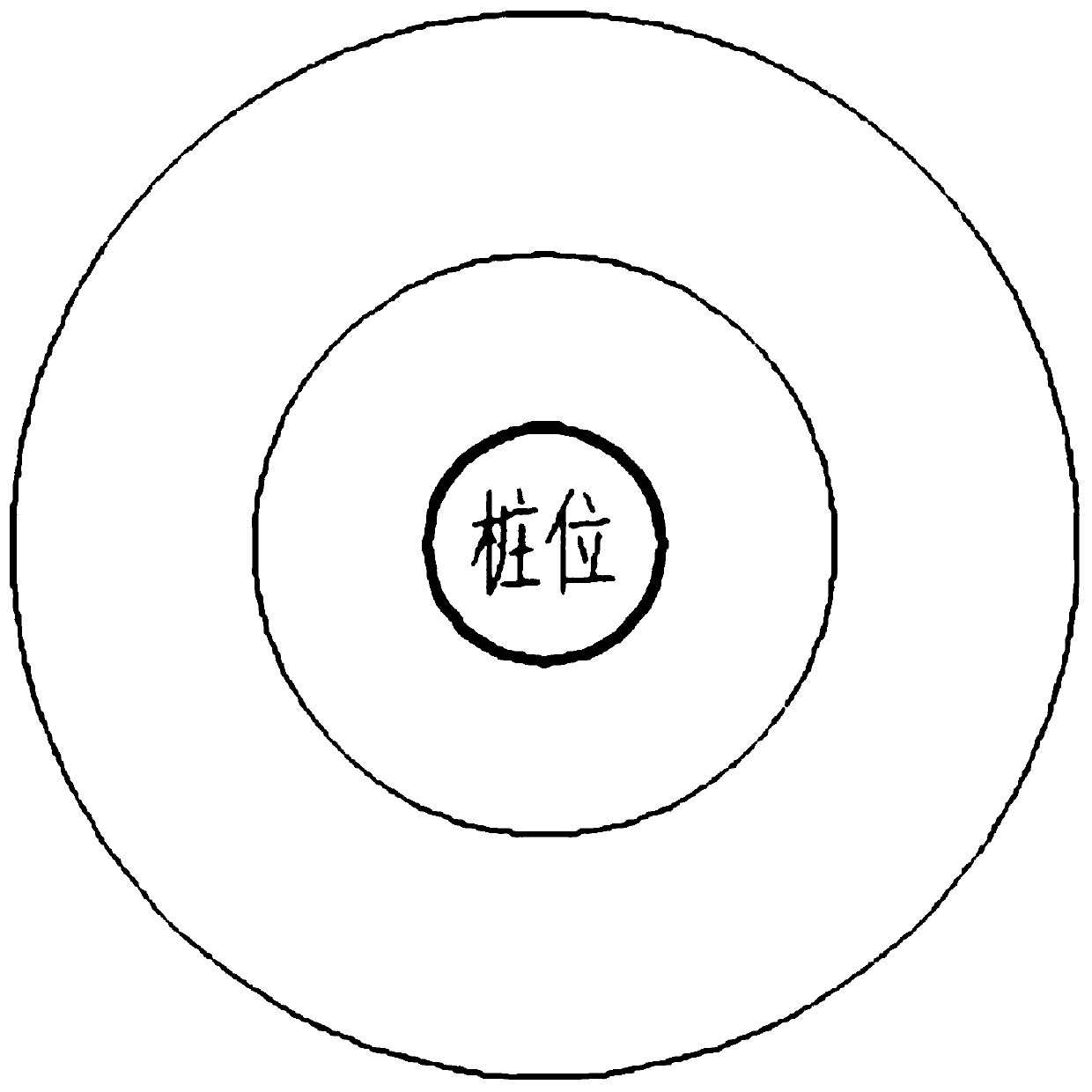

Multi-beam underwater steel pipe pile position measuring method

ActiveCN111350214AAccurate measurementEasy to manufactureFoundation testingBulkheads/pilesMarine engineeringArchitectural engineering

The invention discloses a multi-beam underwater steel pipe pile position measuring method. The method adopts a multi-beam depth finder, a compass movement sensor and a GPS for underwater steel pipe pile position measuring, through three steps of measuring line arranging, equipment mounting and parameter measuring, a pile body inclination parameter, top center plane and elevation coordinates and aplane distance between a four-pile guide pipe frame meeting the precision need are obtained, and steel pipe pile position measuring is achieved. According to the method, the underground measuring inspecting efficiency is improved, the influence of water depth, waves, flow speed, visibility and other factors on underground measuring inspection can be greatly reduced, meanwhile, the underground inspecting efficiency is improved, the measuring inspecting process is simplified, it is ensured that the measuring precision meets the needs, and the construction measuring cost is reduced.

Owner:CCCC THIRD HARBOR ENG

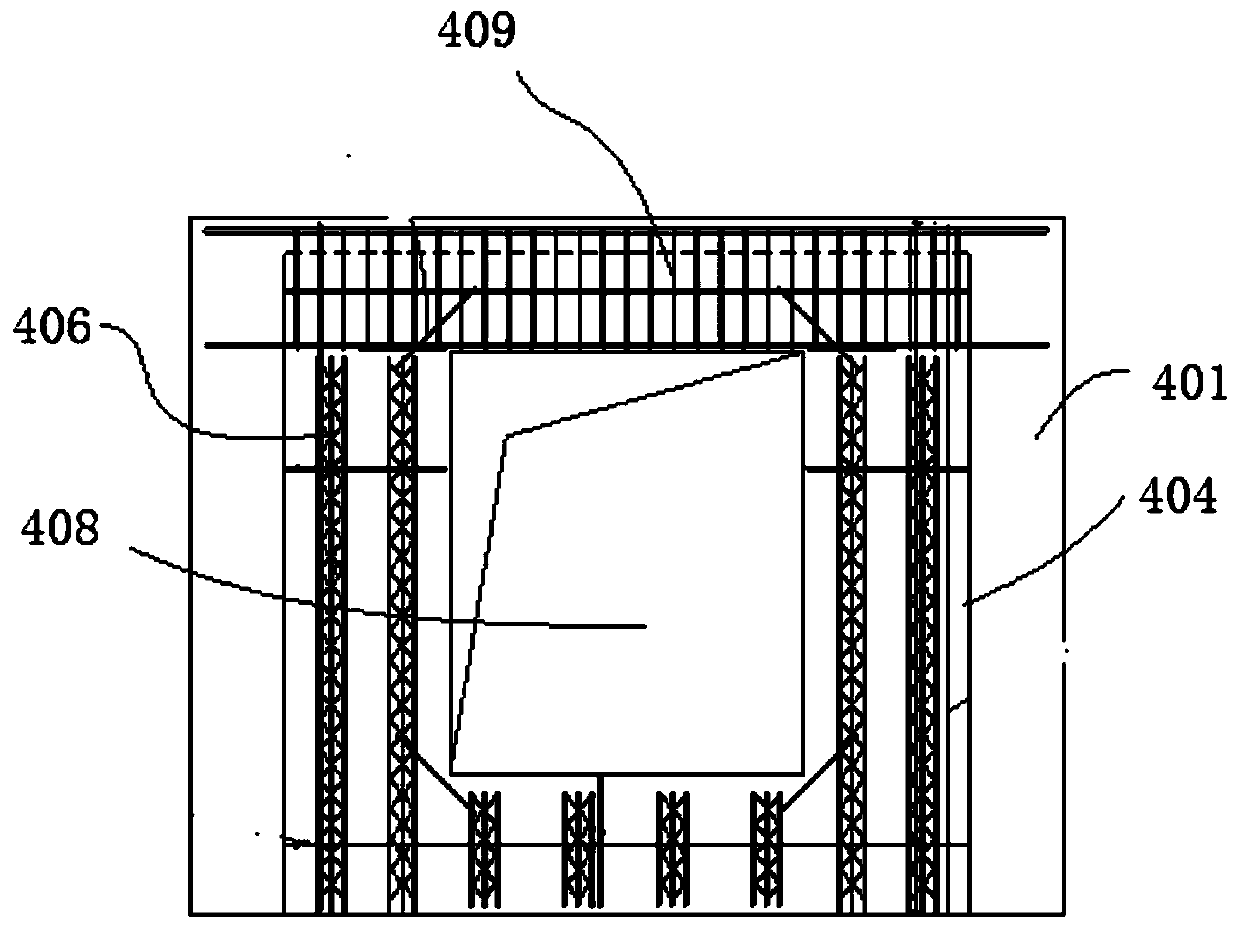

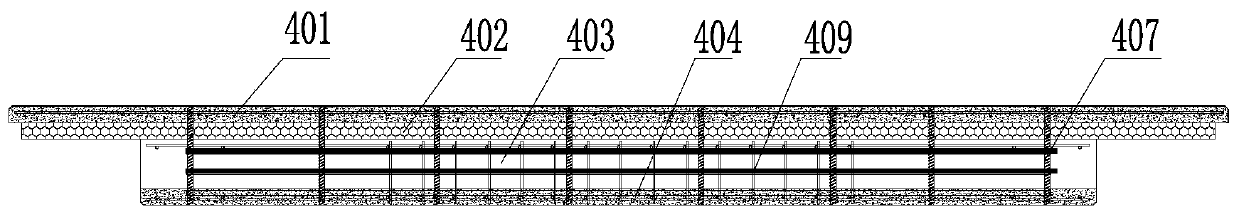

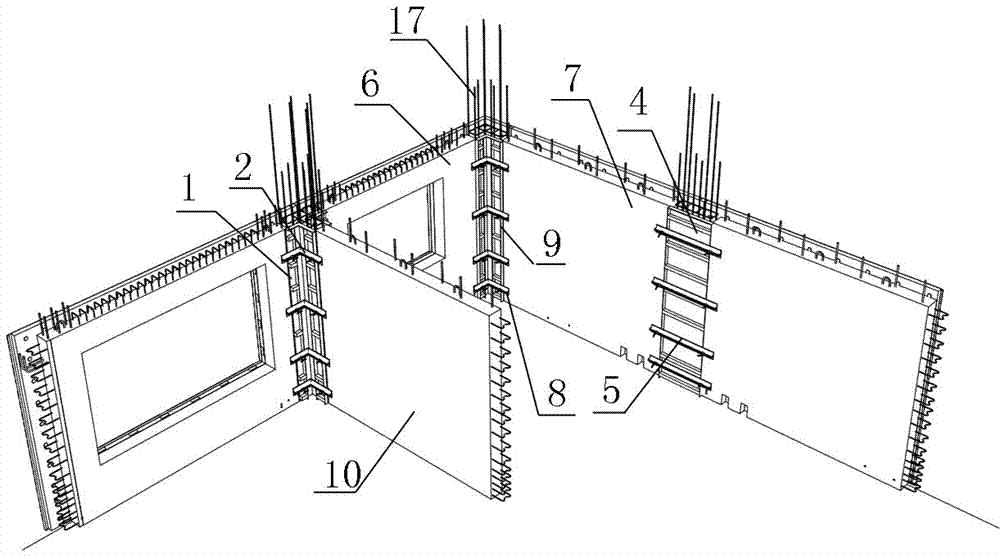

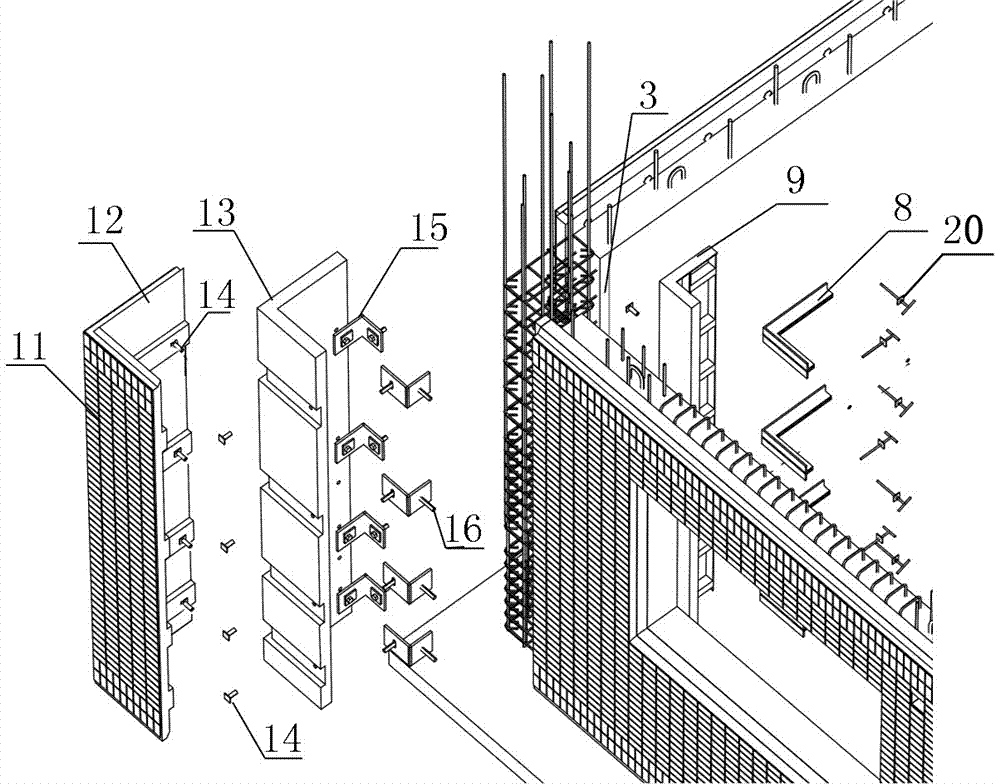

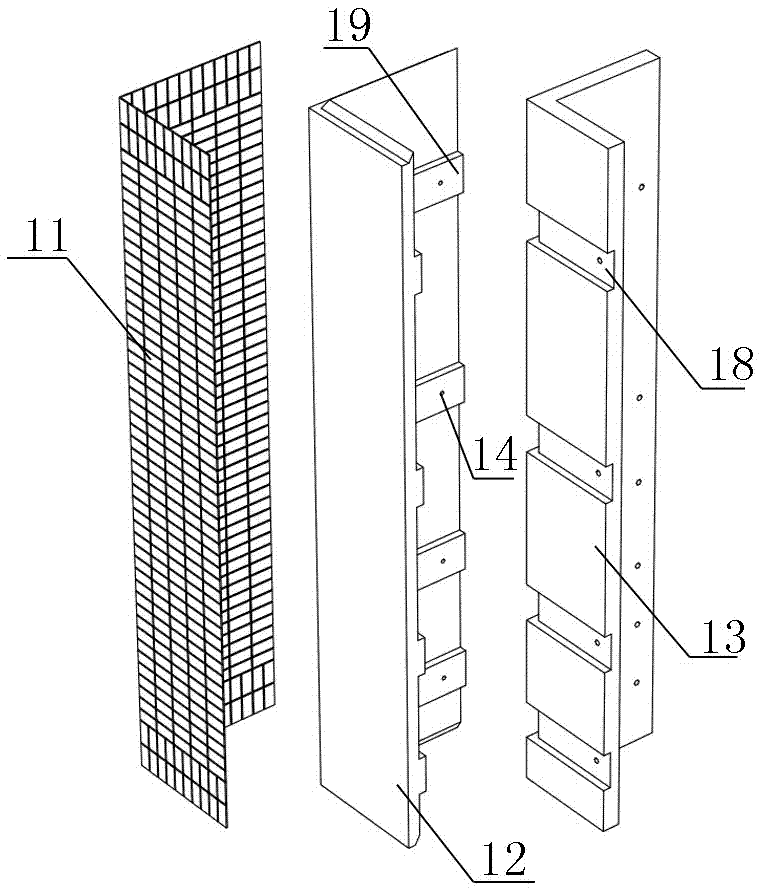

Formwork structure of shear wall corner joint, shear wall cast-in-situ system and construction method

ActiveCN107119901AAvoid technical problems that damage exterior facing tilesReduce construction stepsWallsClimate change adaptationBrickBoard structure

A formwork structure of a shear wall corner joint, a shear wall cast-in-situ system and a construction method are disclosed. The formwork structure of the shear wall corner joint comprises a corner external formwork, a corner internal formwork and corner dorsal bars, wherein the corner external formwork is mounted on the outer portion of a shear wall corner, the corner internal formwork is mounted on the inner side of the shear wall corner, and the corner dorsal bars are parallelly mounted on the inner side of the corner internal formwork at intervals in the vertical direction; the horizontal section of the corner external formwork is in an L shape; the corner external formwork is a PCF slab, and comprises an insulation board, an external leaf wall board and external face bricks which are sequentially arranged from inside to outside; horizontally-through grooves are parallelly formed in the outer side surface of the insulation board at intervals in the vertical direction; horizontally-penetrating concrete ribs are arranged on the positions, corresponding to the grooves, on the inner side surface of the external leaf wall board; and the external leaf wall board is tightly attached to the outer side surface of the insulation board, and the concrete ribs on the external leaf wallboard are embedded in the grooves correspondingly. According to the formwork structure of the shear wall corner joint and the shear wall cast-in-situ system and the construction method, the technical problems that when a traditional formwork structure construction is conducted, an external veneer is prone to being damaged, the integrality of external face bricks is poor, and structure attractiveness is poor are solved.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Trenchless directional drilling construction method for pipeline burying channel

InactiveCN112252973AAvoid destructionLow costArtificial islandsPipe laying and repairArchitectural engineeringPipe

The invention relates to a trenchless directional drilling construction method for a pipeline burying channel. The trenchless directional drilling construction method comprises the following steps that 1, pipe distribution is conducted, specifically, hot melting connection is conducted on the end faces of two PE solid-wall pipes; 2, directional drilling is conducted, specifically, a working pit and a receiving pit are manufactured, and a directional drilling machine is adopted for hole drilling; 3, back chambering construction is conducted, specifically, chambering is conducted in a step-by-step chambering mode to form a pipeline; 4, the pipe is pulled back, specifically, the pipe is pulled by adopting a pipe puller; and 5, inspection wells are manufactured, specifically, foundation pits are excavated in the two sides of an effective pipe section, the prefabricated inspection wells are installed, the prefabricated inspection wells are in waterproof connection with the PE solid-wall pipes, and then the foundation pits and the peripheries of the prefabricated inspection wells are backfilled. Only the working pit and the receiving pit need to be excavated in the ground, drilling, chambering and pipe pulling operations are carried out at the positions of the working pit and the receiving pit, and environmental influences such as multiple construction technology procedures, a largeamount of road surface damage and traffic obstruction caused by pipeline open excavation construction can be avoided.

Owner:广东省构建工程建设有限公司 +1

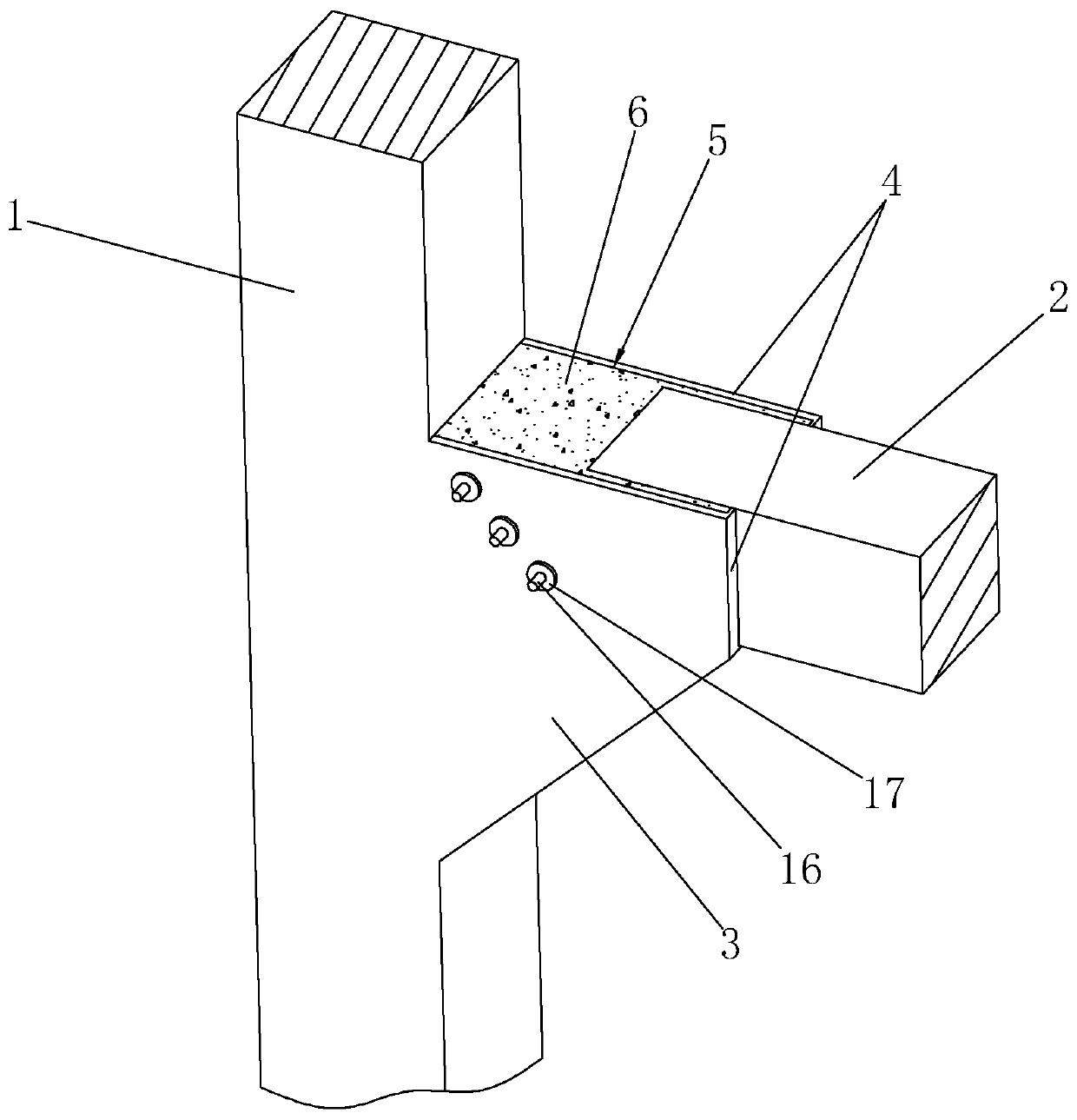

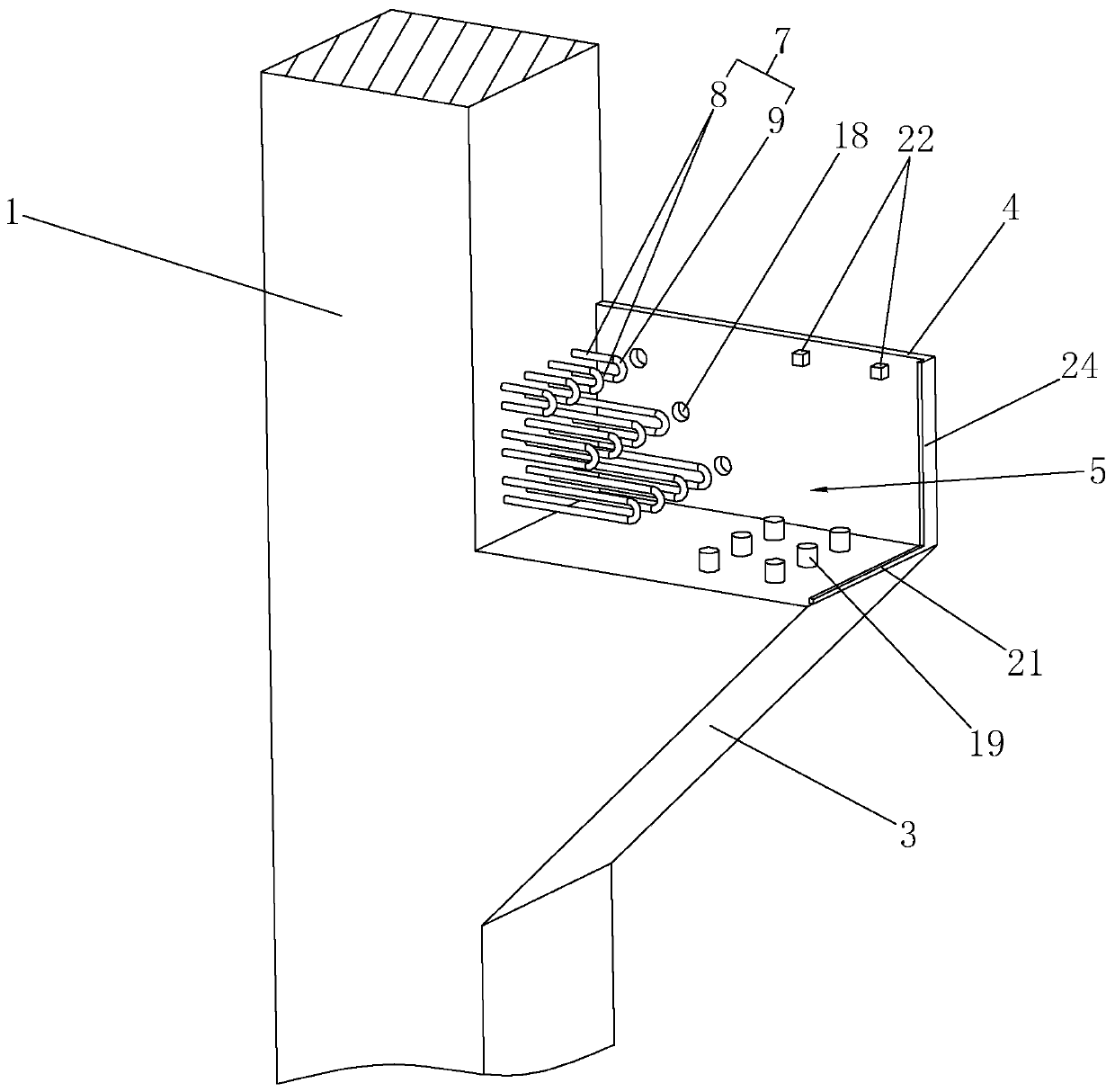

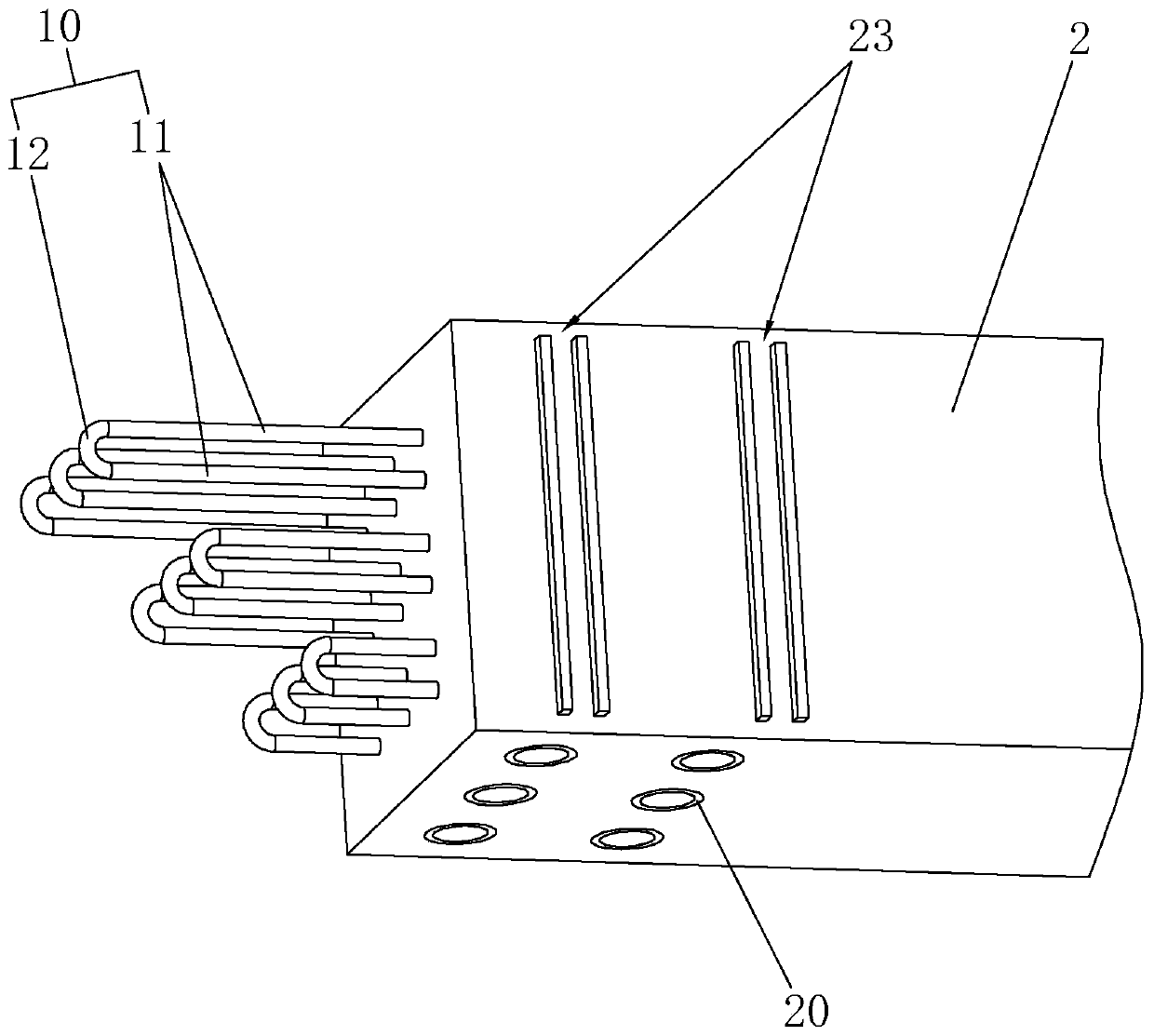

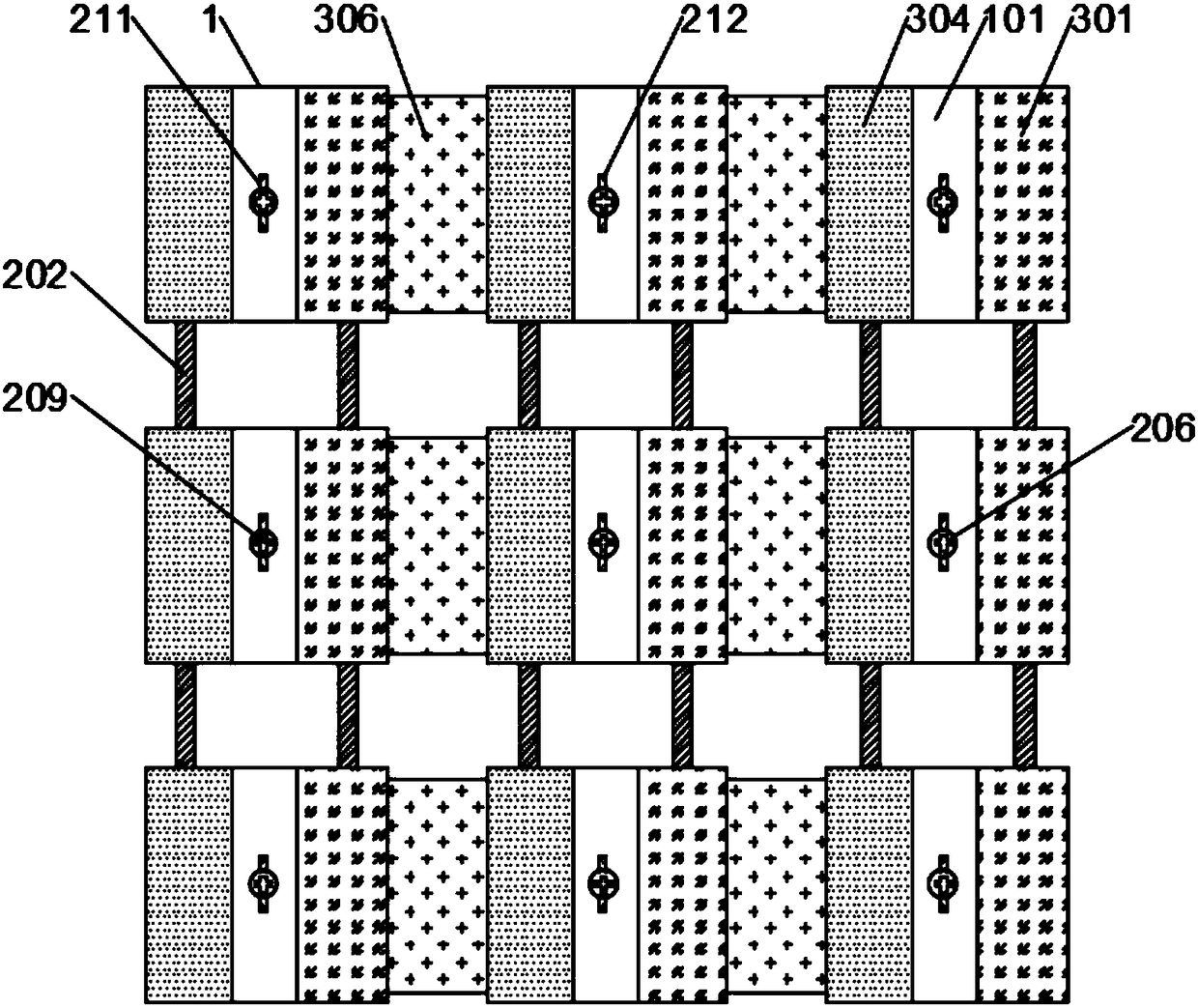

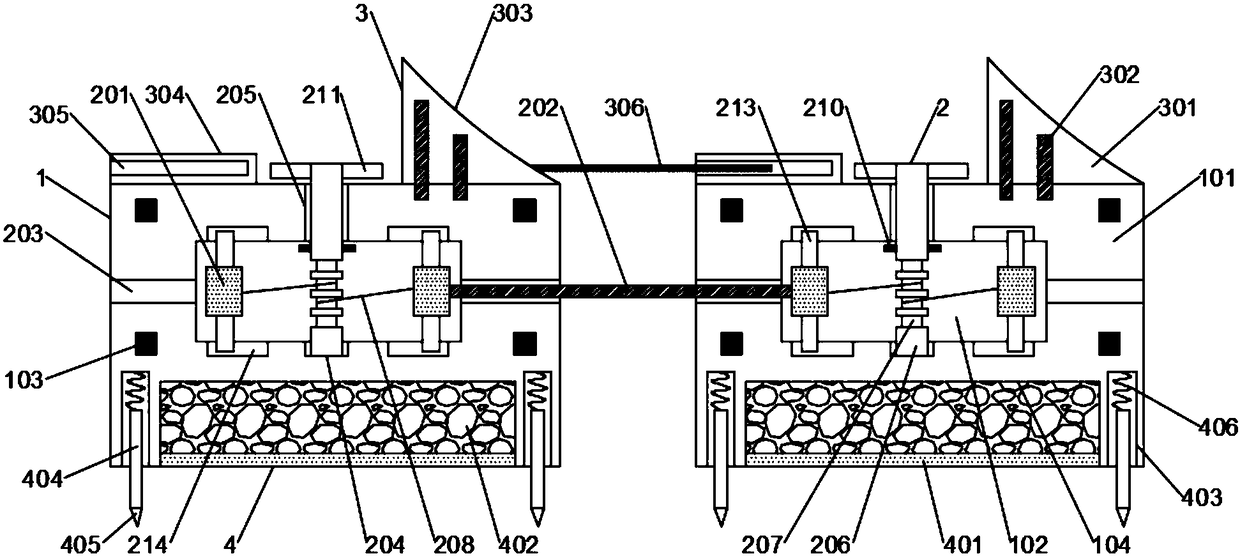

Prefabricated concrete beam column connecting node structure and construction method thereof

ActiveCN110644616AReduce construction stepsReduction procedureBuilding material handlingConcrete beamsArchitectural engineering

The invention discloses a prefabricated concrete column beam column connecting node structure and a construction method thereof, and relates to the technical field of assembly type building construction. The prefabricated concrete column beam column connecting node structure comprises a bearing table arranged on a prefabricated concrete column and a wing plate arranged on the bearing table, wherein three rows of column connectors are arranged on the prefabricated concrete column; three rows of beam connectors are arranged on the prefabricated concrete beam; the three rows of column connectorsand the three rows of beam connectors are horizontally arranged in a staggered mode, and are connected and fixed by locking rods; and the wing plate, the prefabricated concrete column, the prefabricated concrete beam and the bearing table are enclosed to define a pouring area, and a template does not need to erect, so that construction steps are a few, and connection is reliable.

Owner:福建源竑建设工程有限公司

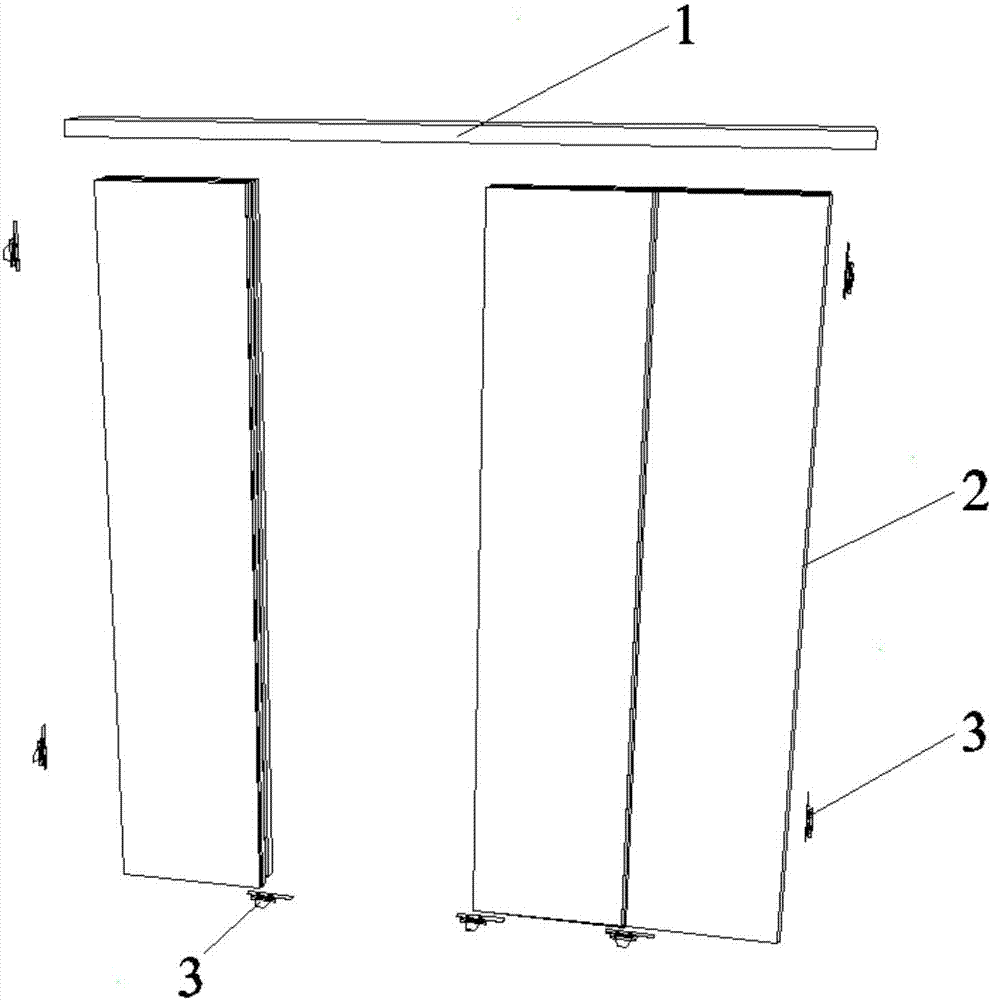

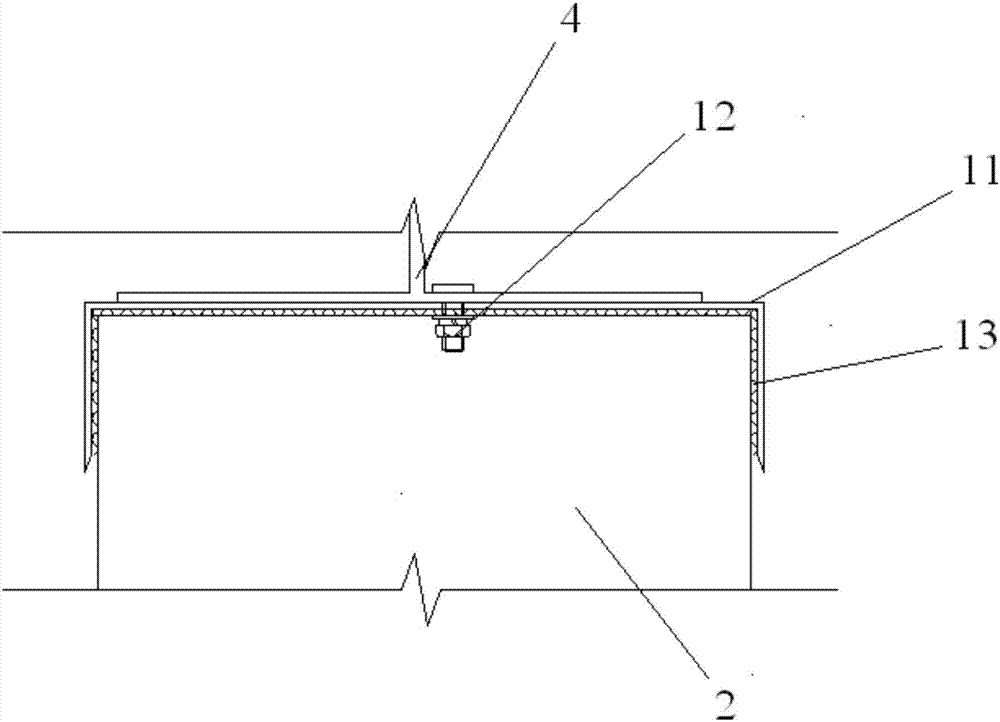

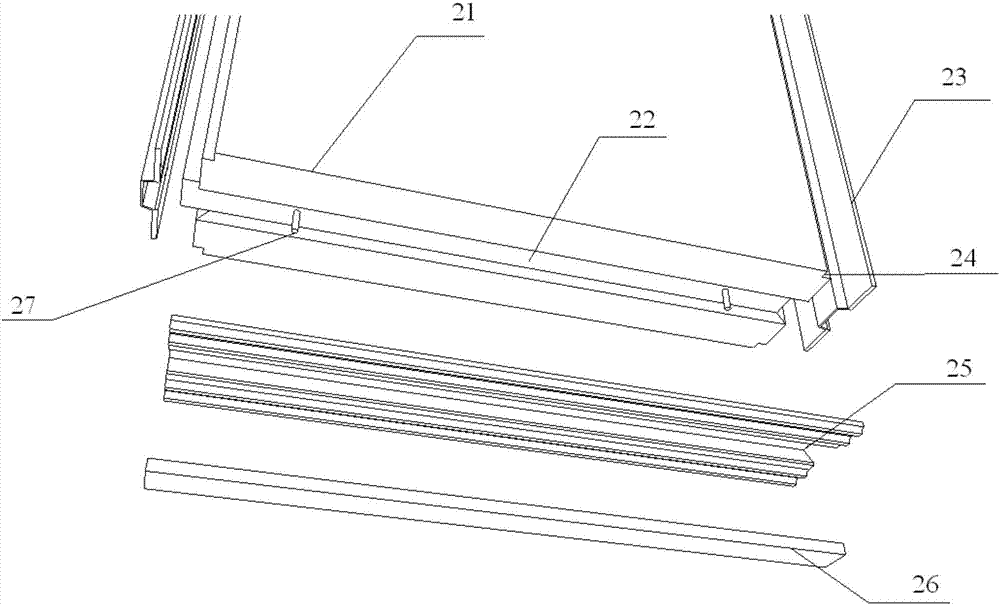

Non-bearing assembling type sound insulation partition wall suitable for steel structure building

ActiveCN107419827AHigh degree of prefabricationReduce construction stepsWallsAdhesiveClassical mechanics

The invention discloses a non-bearing assembling type sound insulation partition wall suitable for a steel structure building. The non-bearing assembling type sound insulation partition wall suitable for the steel structure building comprises a fixing groove, a partition wall plate and a connecting part. The fixing groove is used for fixing the partition wall plate and consists of a steel groove, a first fixing bolt and a rubber blanket. The steel groove is fixed on the lower portion of a steel beam through the first fixing bolt. The rubber blanket is arranged in the steel groove through an adhesive. The partition wall plate is composed of a partition wall plate material, an adhesive layer, a rubber blanket layer and a sound absorbing mineral wool strip. Grooves are formed in the bottom of the partition wall plate materialand one side of the side edge. Bulges matched with the shapes of the grooves are formed in the other side of the side edge of the partition wall plate material. Square grooves are formed in the four corners of the partition wall plate material. The rubber blanket layer and the sound absorbing mineral wool strip are arranged in the grooves from inside to outside in sequence. The connecting part is composed of a supporting plate, a hinge piece, a rotating shaft, a fixing plate and a second fixing bolt. According to the non-bearing assembling type sound insulation partition wall suitable for the steel structure building, by advancing an installing way and a structural joint of the partition wall, dry type operation is adopted, construction procedures are reduced, the construction speed is improved, and meanwhile, the good sound insulation effect is achieved.

Owner:TIANJIN UNIV

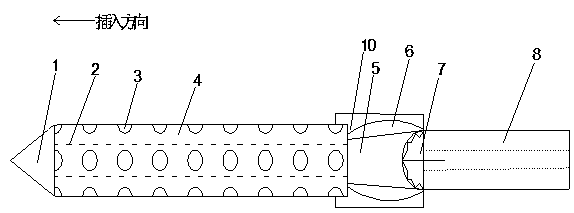

Fiber material friction type drainage anchor rod

The invention relates to a fiber material friction type drainage anchor rod, and belongs to the technical field of anchor rod support. The fiber material friction type drainage anchor rod comprises ananchoring end, a water filtering film, water inlet holes, a fiber material anchor rod body, a burst cone, an elastic rubber dense ring, a circular serrated joint, a steel tube expansion anchor rod, ahollow drainage hole and a rigid protective sleeve; the anchoring end and the fiber material anchor rod body form an integrated structure; the anchoring end is of a solid structure; the water inlet holes are uniformly formed in the fiber material anchor rod body and the water filtering film; the water filtering film surrounds the outer side of the hollow drainage hole; the periphery of the burstcone is surrounded with the elastic rubber dense ring; the circular serrated joint is arranged at the tail of the burst cone; the outer sides of the elastic rubber dense ring and the circular serratedjoint are sleeved with the rigid protective sleeve; the anchor rod proposed by the invention has a prominent drainage function, has a preventive effect on gushing water in a tunnel, has a good filtering effect, can also grout an anchor body, fills in positions of water flowing in surrounding rock, and timely controls the deformation of the surrounding rock.

Owner:SHENYANG JIANZHU UNIVERSITY

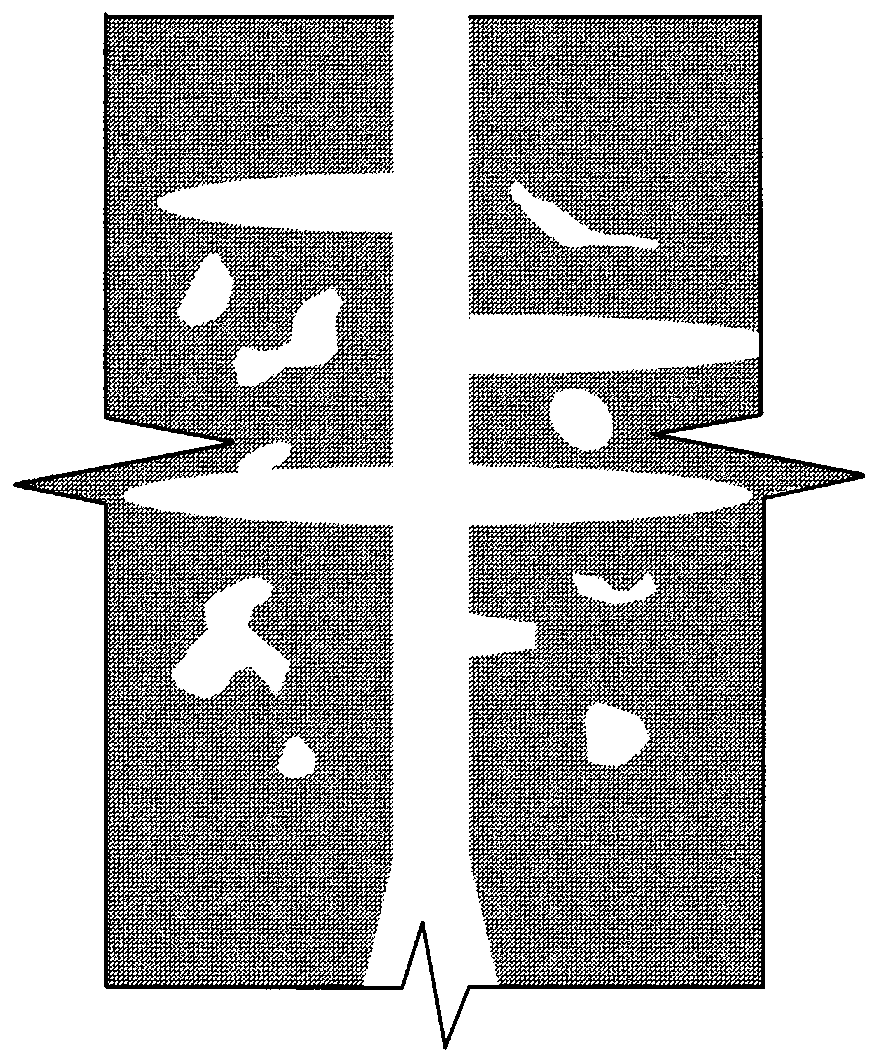

Construction method for bailing out stuck single-shield tunnel boring machine

PendingCN112502723AImprove securityReduce construction stepsUnderground chambersTunnel liningSlagTunnel boring machine

The invention discloses a construction method for bailing out a stuck single-shield tunnel boring machine. The construction method is invented mainly for solving the problems that an existing TBM escape method is complex and involves a large workload. The method comprises the following steps that a hollow anchor pipe is arranged behind a shield for grouting, and surrounding rock of an operation area is solidified; expanding excavation and arch replacement supporting are conducted on a pipe roof drilling machine working area; an advanced pipe shed is constructed in a collapse influence area infront of a tunnel face; pilot tunnels are excavated in the two sides of a shield; accumulated slag in a collapse area in front of a cutterhead is manually cleaned in the cutterhead and through pilot tunnels in the two sides; and collapsed slag in front of the cutter head is cleaned until the cutter head can rotate normally, and the tunnel boring machine is saved. The method has the advantages thatthe operation of bailing out the tunnel boring machine is safe, the stuck tunnel boring machine can be released in an extremely short time, and the cost and the time are saved.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG +1

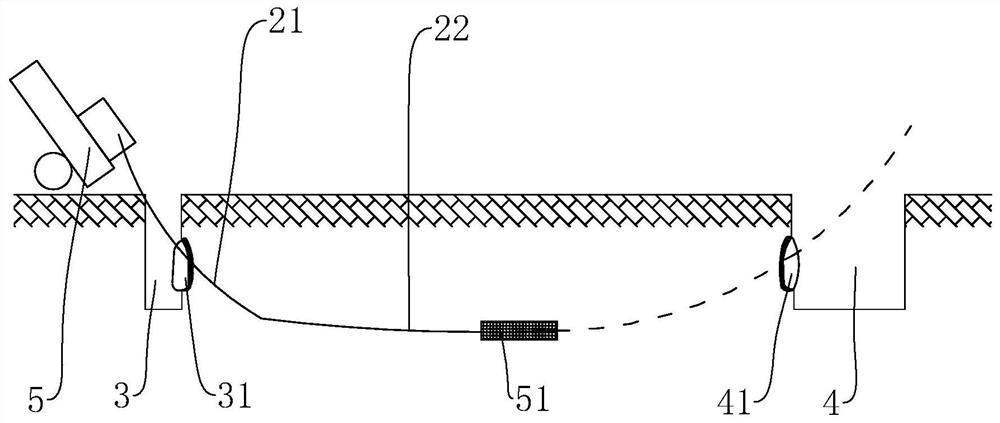

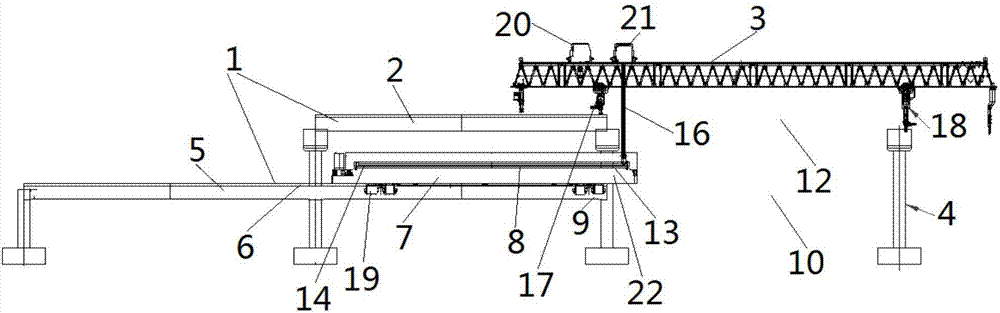

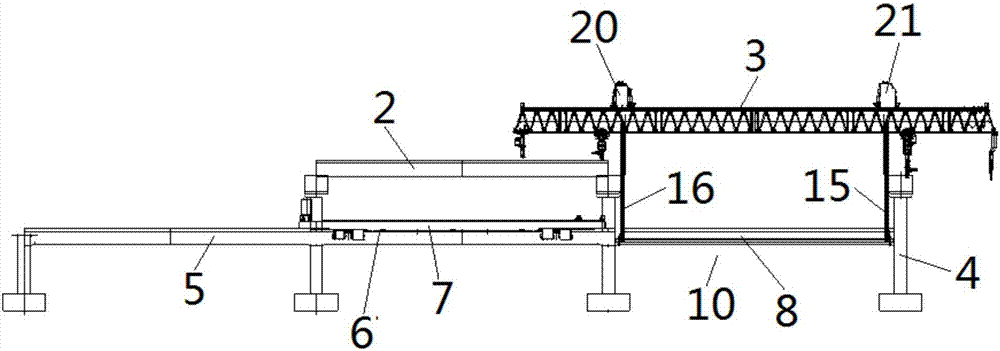

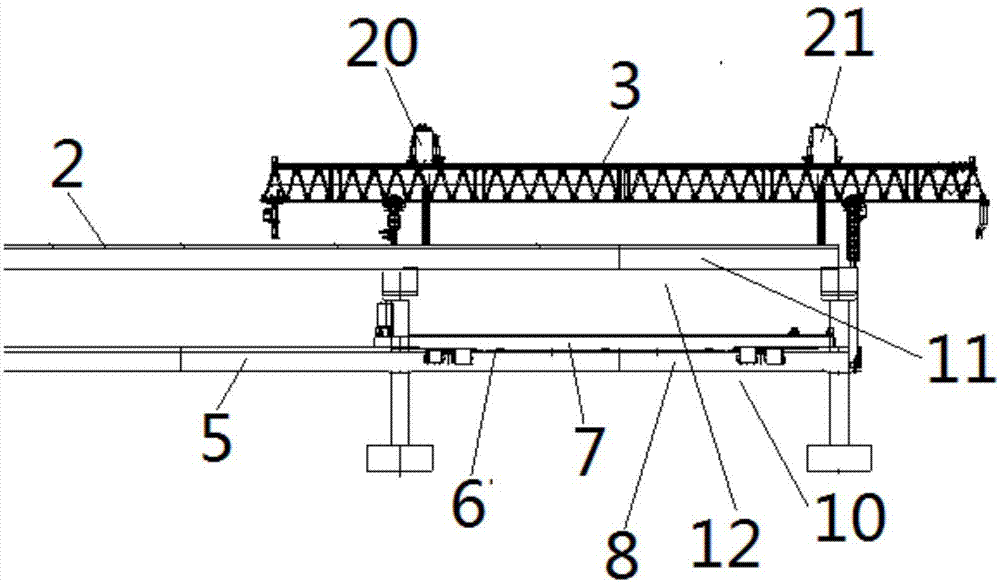

Beam transporting method for building of double-deck bridges

ActiveCN107313356AReduce labor intensityReduce construction costsBridge erection/assemblyBridge deckEngineering

The invention provides a beam transporting method for building of double-deck bridges. The beam transporting method includes the steps of firstly, supporting one end of a main beam (3) on an upper deck (2) and supporting the other end of the main beam (3) on a bridge pier (4); secondly, transporting a lower-deck U-beam (8) to the position of a tip (9) of the lower deck through a beam transporting vehicle (7); thirdly, lifting the lower-deck U-beam (8) to move to a lower-deck falling position (10); fourthly, paving a lower-deck rail (6) on the lower-deck U-beam (8), transporting an upper-deck U-beam (11) to the lower-deck rail (6) through a beam transporting vehicle (5), and lifting the upper-deck U-beam (11) and moving it to an upper-deck falling position (12). By the beam transporting method for building of double-deck bridges, the lower-beck U-beam needed to be transported can be transported to the position right above the lower-deck falling position conveniently rapidly, and the upper-deck U-beam for the upper deck can be transported by the aid of the lower-deck rail conveniently rapidly.

Owner:安徽省中冶重工机械有限公司 +2

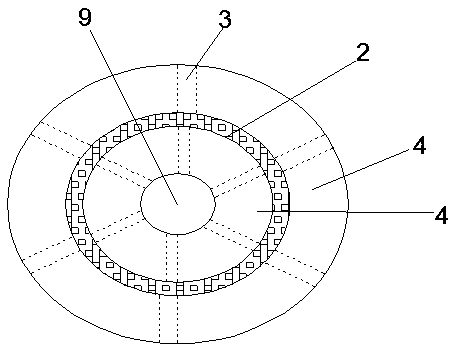

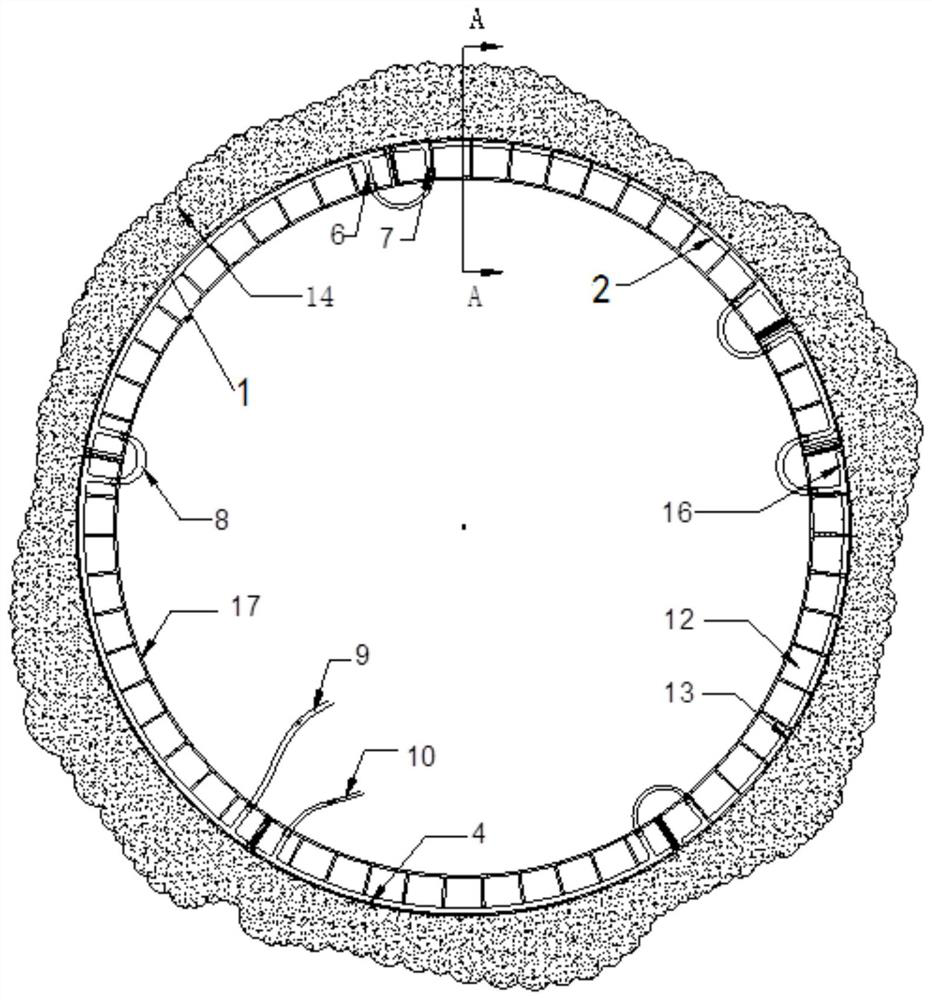

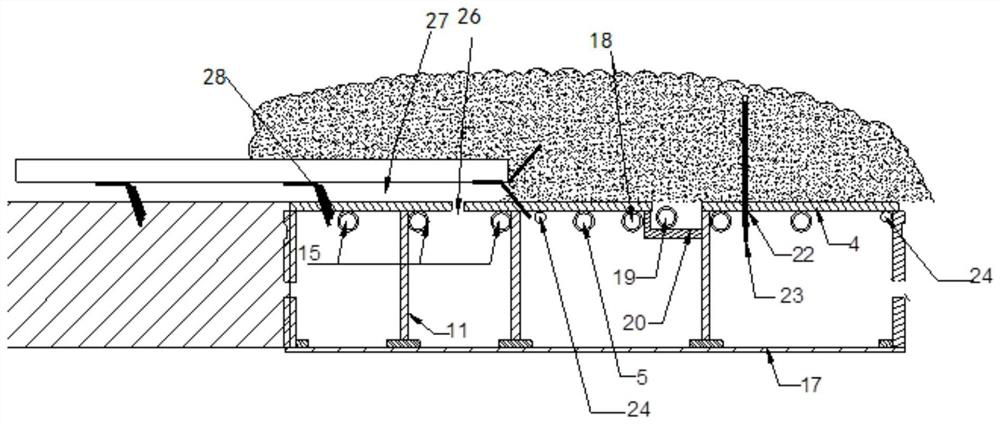

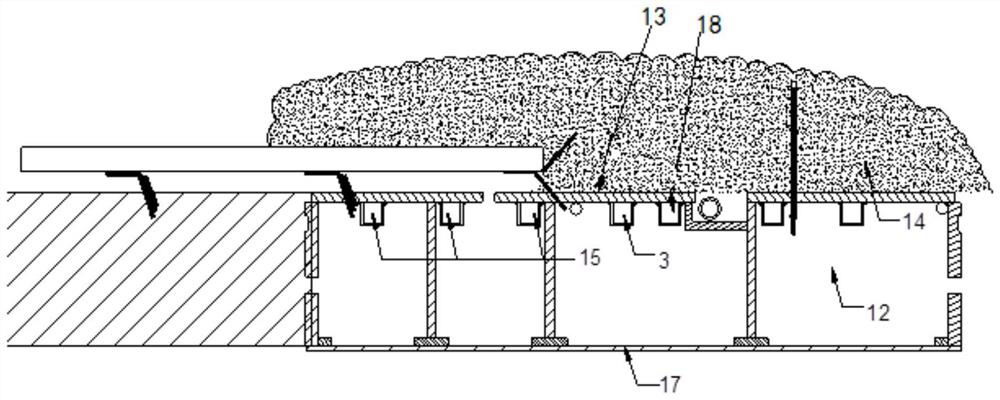

Steel pipe piece device for freezing soil around tail of shield tunneling machine and construction method of steel pipe piece device

PendingCN112065403AReduce the temperatureIncrease contact areaUnderground chambersThermometer applicationsOil and greaseShield tunneling

The invention discloses a steel pipe piece device for freezing soil around the tail of a shield tunneling machine. The steel pipe piece device comprises a plurality of arc-shaped steel pipe pieces, freezing pipelines and rib plates, wherein the arc-shaped steel pipe pieces are sequentially connected to form annular steel pipe pieces; a plurality of rows of freezing pipelines are arranged on the inner surface of each arc-shaped steel pipe piece along an arc line, the freezing pipelines on the same row of the adjacent arc-shaped steel pipe pieces are connected through first pipes to form a plurality of annular freezing pipelines, and secondary refrigerants in the annular freezing pipelines enable the temperature of the annular steel pipe pieces to be reduced, so that the soil around the annular steel pipe pieces is frozen; and the rib plates are arranged on the inner surfaces of the arc-shaped steel pipe pieces, rib plate cavities are formed, the rib plate cavities are filled with greasewith low freezing point, and an annular thin plate is arranged at the end of each rib plate and used for blocking the corresponding rib plate cavity so as to prevent the grease from falling off. Thedevice can efficiently freeze the soil around the tail of the shield tunneling machine, so that a circle of uniform freezing curtain is formed at the tail of the shield tunneling machine, and water and soil outside a shield tail gap are blocked. The invention further discloses a construction method for replacing a tail brush of the shield tunneling machine.

Owner:CCCC SECOND HARBOR ENG

Novel concrete hinged mattress

ActiveCN108589653AImprove general performanceReduce construction stepsCoastlines protectionTerrainRebar

The invention discloses a novel concrete hinged mattress. The novel concrete hinged mattress comprises multiple concrete bricks which are evenly distributed, adjacent concrete bricks are connected through an adjustable hinge joint mechanism, each concrete brick comprises a square concrete base plate, hollow cavities are formed in the concrete base plates, the outer portions of the hollow cavitiesare provided with reinforcing steel bar skeleton frames embedded in the concrete base plates, dual-way slope protection mechanisms are arranged on the tops of the concrete base plates, inner sunken bottom grooves are formed in the bottoms of the concrete base plates, and high-adaptation self-adjusting base mechanisms are arranged on the inner sunken bottom grooves. According to the difference of the terrain, the length of a hinge between adjacent concrete bricks is changed, device generality is higher, meanwhile, the riverway slope surface does not need to be leveled, the concrete hinged mattress is placed, construction efficiency is higher, in addition, the concrete hinged mattress can protect the slope face from two aspects, and the device slope protection effect is better.

Owner:CHINA ROAD & BRIDGE

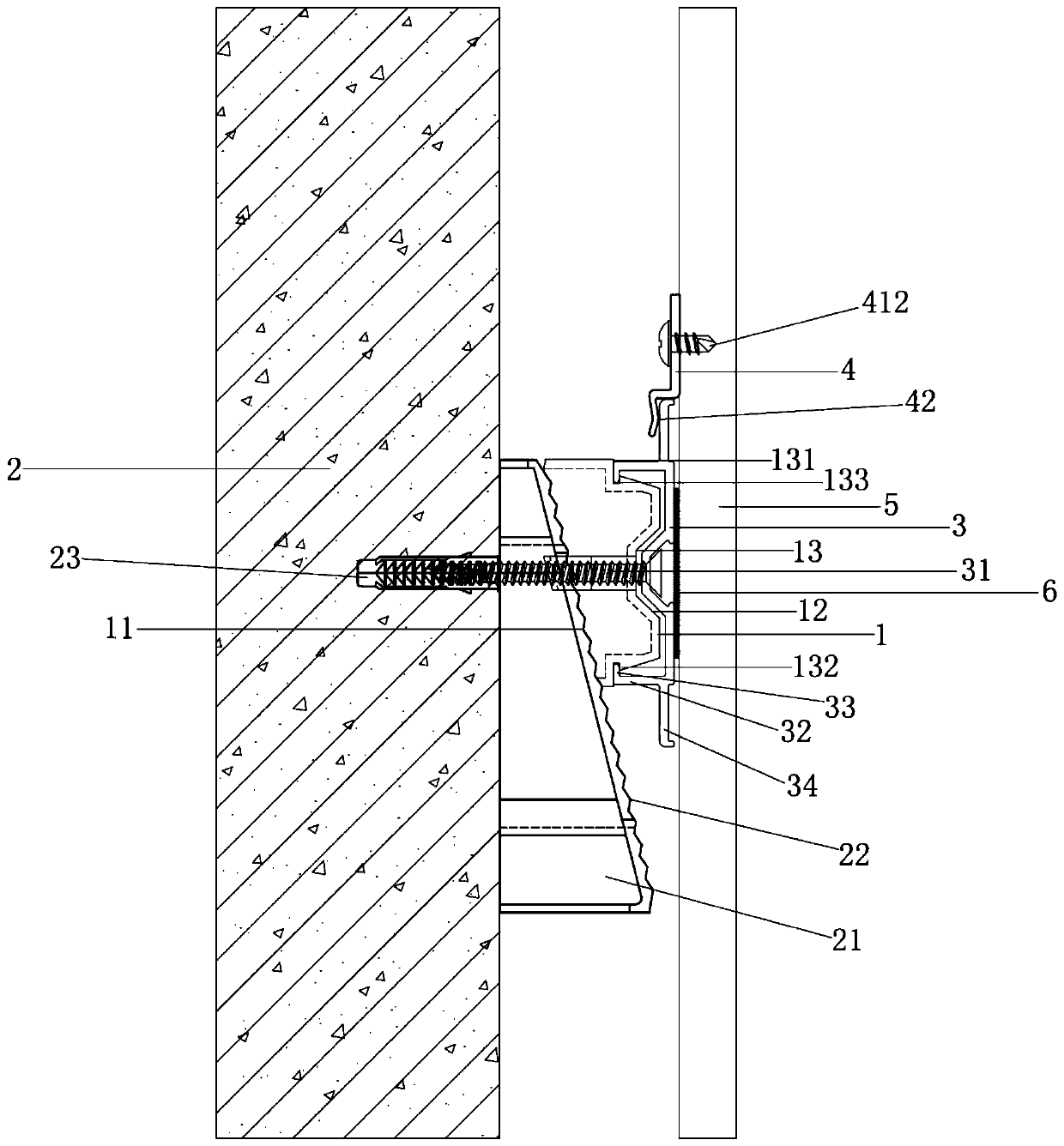

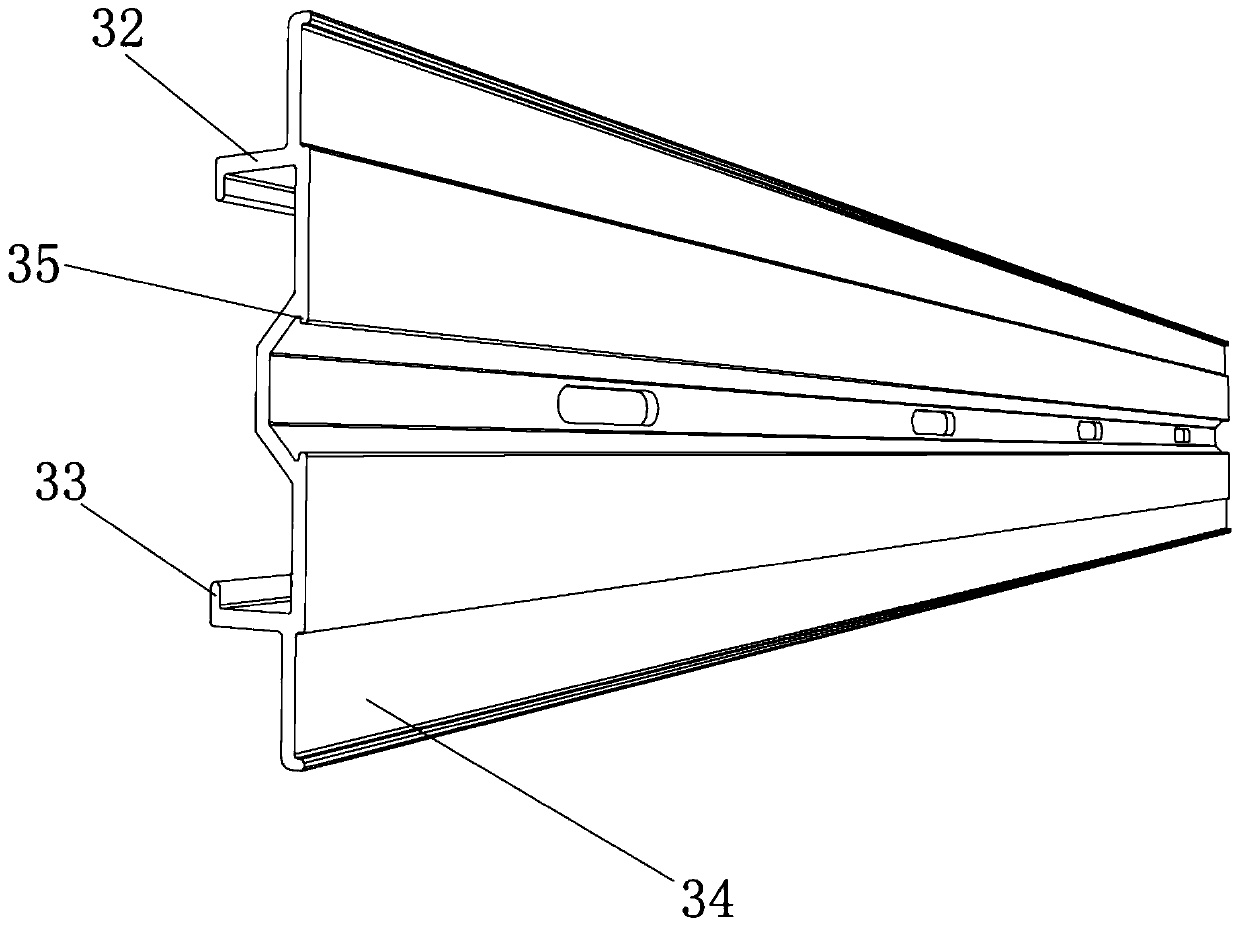

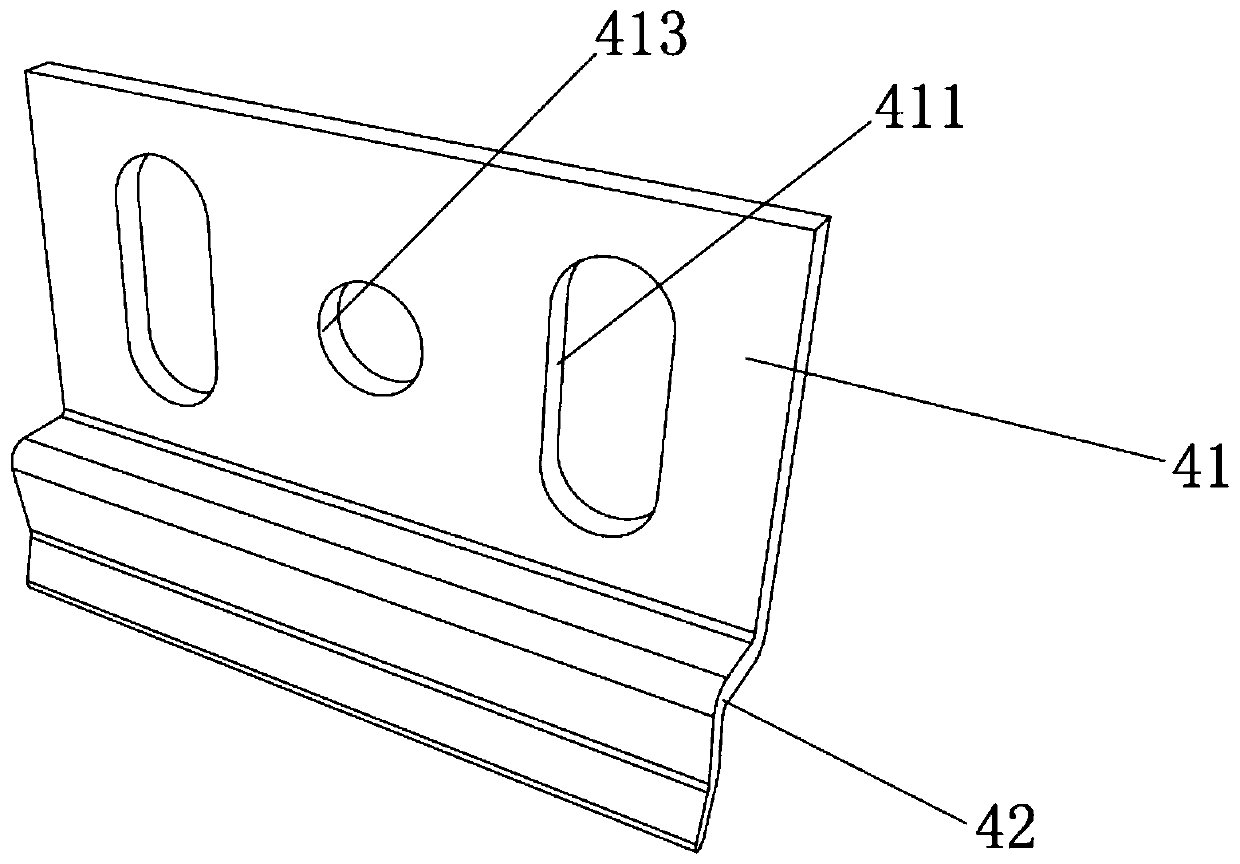

Convenient wall panel dry hanging installation structure and method

PendingCN110761515AReduce construction stepsReduce construction costsCovering/liningsKeelScrew joint

The invention provides a convenient wall panel dry hanging installation structure. The convenient wall panel dry hanging installation structure includes a first transverse keel, a second transverse keel, an adjustable dry hanging piece and a wall panel, wherein the first transverse keel is connected to a wall, the first transverse keel is provided with a W-shaped bending surface, the two oppositesides of the W-shaped bending surface are correspondingly connected with the edges of second connecting surfaces through a step, the edges of the W-shaped bending surface form chamfered surfaces extending outwards at the step, and clamping grooves are formed between the end parts of the chamfered surfaces and the step; the second transverse keel is bent into a W shape, the center part of the second transverse keel is connected to the center part of the first transverse keel through screws in a screw joint mode, and two right angle bending hooks are correspondingly arranged on the two oppositesides of the second transverse keel and are clamped into the clamping grooves; the adjustable dry hanging piece includes a dry hanging piece body and an elastic plate, the side of the dry hanging piece body is in an L shape, and the elastic plate is fixedly connected to the bottom end of the dry hanging piece body; and the wall panel is fixedly connected to the dry hanging piece body. The invention further provides an installation method. According to the convenient wall panel dry hanging installation structure and method, the construction cost can be reduced, manual positioning is not required, the construction is more convenient, and the loosening phenomenon is reduced.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

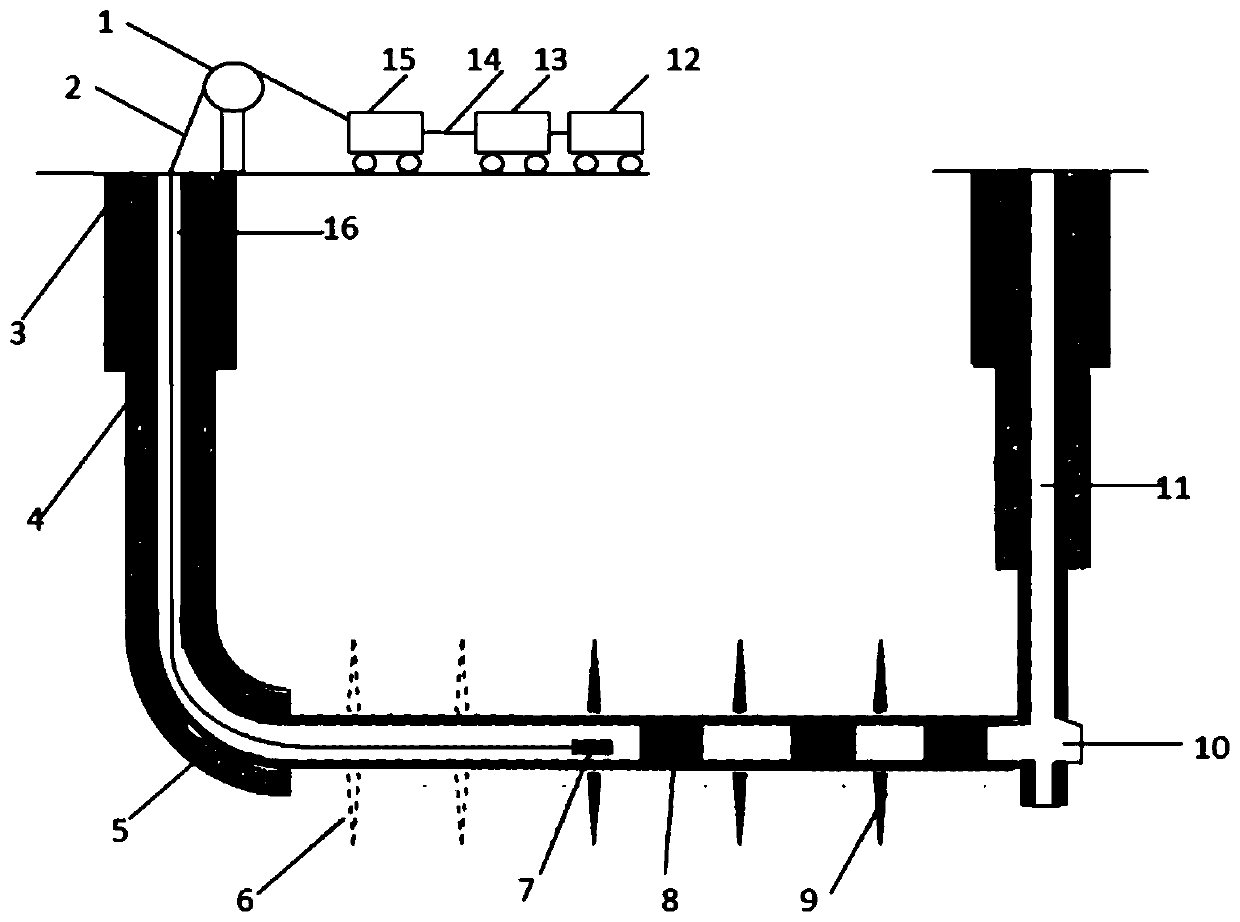

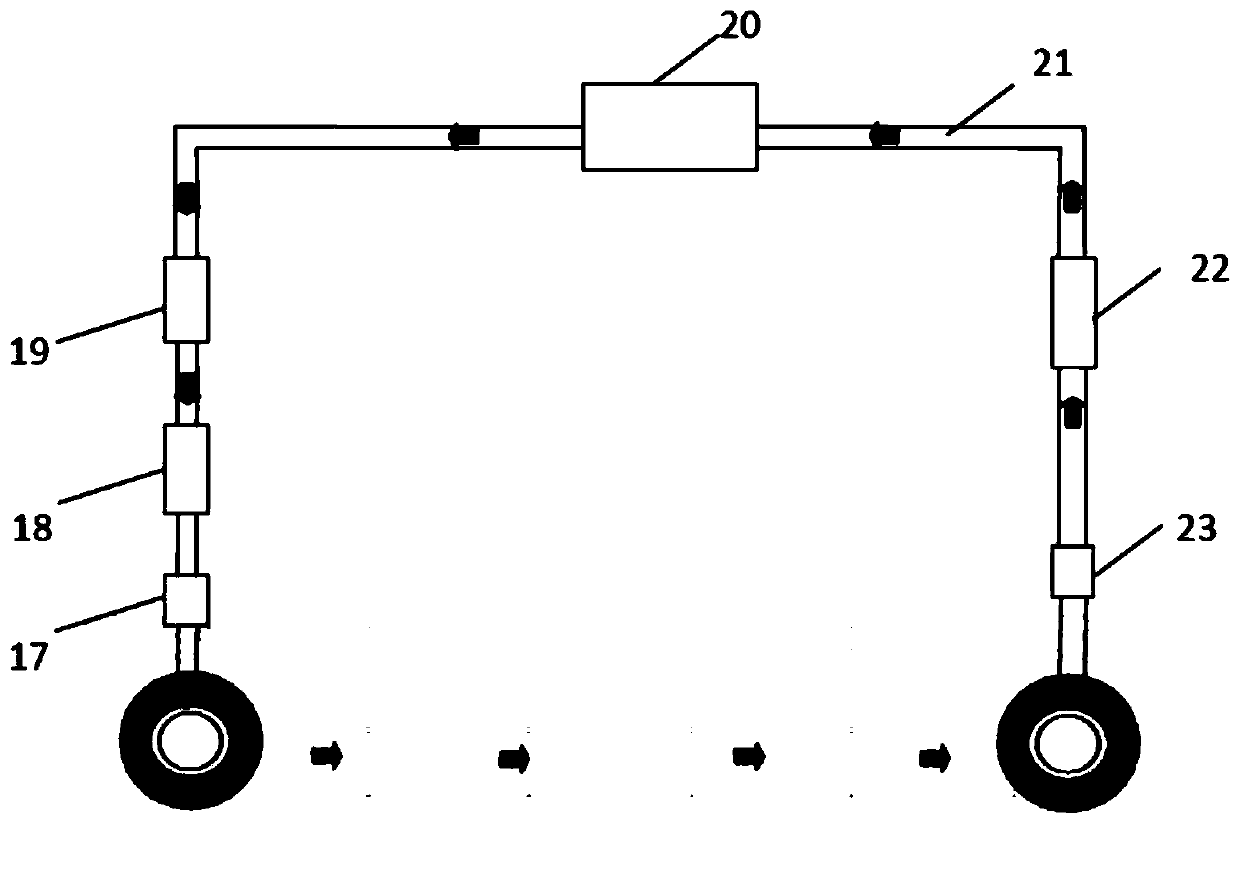

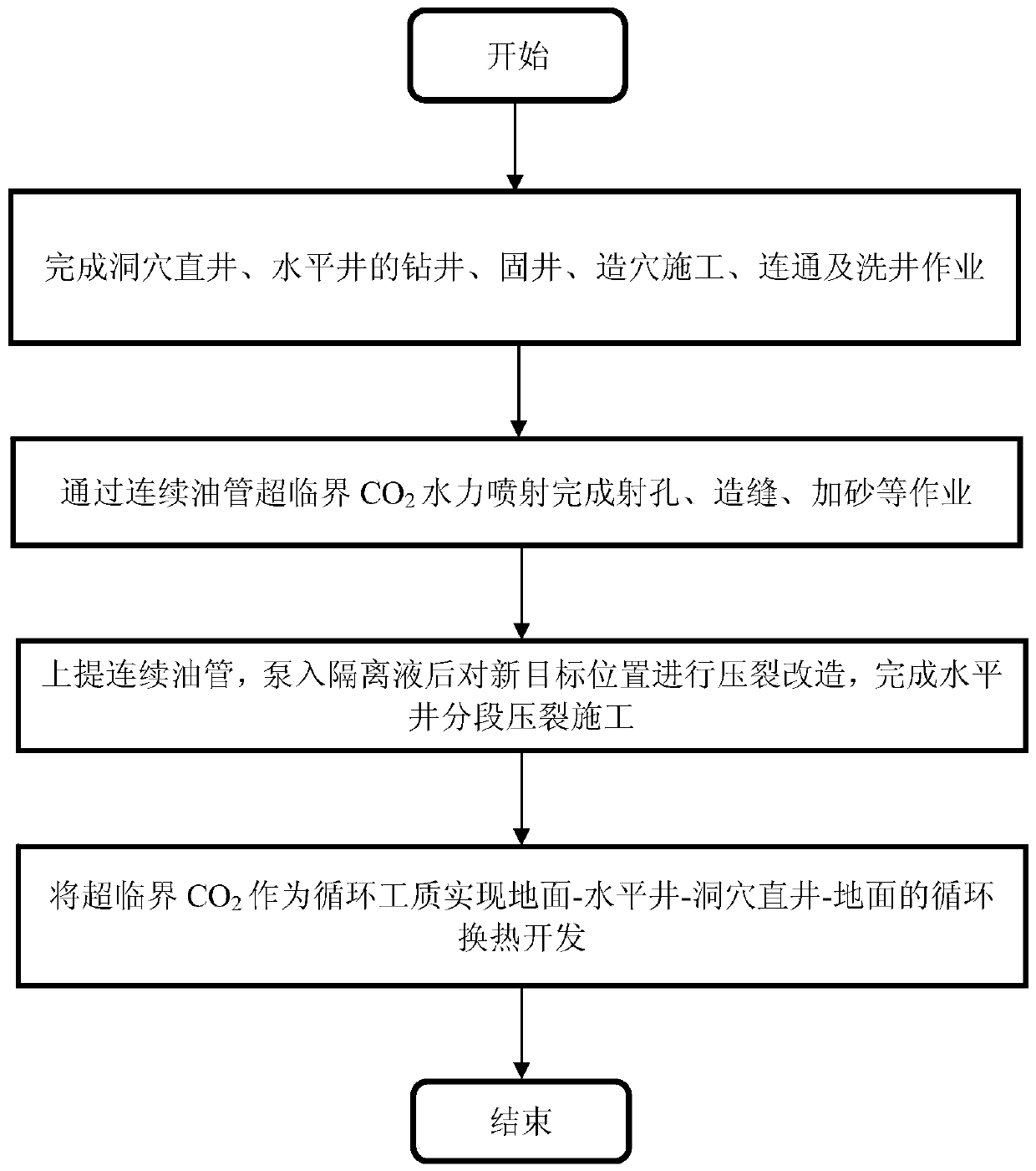

Horizontal well supercritical CO2 fracture development enhanced geothermal method and system

ActiveCN111520110AIncrease the heat exchange areaImprove heat transfer efficiencyLighting and heating apparatusGeothermal energy generationHorizontal wellsFracturing fluid

The invention provides a horizontal well supercritical CO2 fracture development enhanced geothermal method and system. The method comprises the steps that after liquid CO2 and a grinding material aresufficiently mixed, the obtained mixture is placed down to the position to be perforated, the mixed solution of the grinding material and the supercritical CO2 forms high-pressure jet after passing through a hydraulic injection nozzle, and a sleeve, a cement sheath and a hot dry rock are broken to form a perforated hole; the pure-liquid CO2 is pumped to the position to be perforated to form a manual crack; a propping agent and the supercritical CO2 are sufficiently stirred inside a sand mixing vehicle, the mixed fracture liquid is pumped into a well through a fracturing truck, the propping agent is carried into the crack through the supercritical CO2 to complete first-section fracturing; the hydraulic injection nozzle is moved to the next position to be modified, a spacer fluid is pumped in to protect a fractured well section, the operations are sequentially executed repeatedly till the horizontal well is completely fractured and modified; after modification, the supercritical CO2 continues to be adopted as a circulating working medium to perform hot dry rock heat exchange production to achieve repeated heating and power generation.

Owner:PETROCHINA CO LTD

Heat insulation structure prefabricated integrated assembly wall panel and overall building forming method

InactiveCN104060720AQuick installationLess componentsWallsBuilding material handlingEngineeringSlurry

The invention belongs to a heat insulation structure prefabricated integrated assembly wall panel and an overall building forming method. A panel body is made by injecting a heat insulation slurry formed by stirring cement, polystyrene particles, additives and water into a mold, and demolding after drying, and slab joint connecting grooves are respectively formed in the peripheries of two side planes of the panel body; ring beam connecting grooves are formed in the upper end surface of the panel body, and longitudinal through holes in parallel with the slab joint connecting grooves are longitudinally formed in the panel body at intervals; transverse through holes are transversely formed in the panel body at intervals, and are communicated with the horizontal through holes, and a reserved window frame opening and a reserved door frame opening which are sunken into the panel body are respectively formed in one side of a plurality of panel bodies. Prefabricated pieces are quickly assembled into a house by the heat insulation structure prefabricated integrated assembly wall panel provided by the invention. The heat insulation structure prefabricated integrated assembly wall panel has the advantages of fewer components, unified production standards, short construction period, light weight, raw material saving, high strength, low cost, convenience in transport and use, good heat insulation and noise isolation, impact resistance, effective shock resistance and convenience in installation.

Owner:付佩茹

A kind of prestressed anchor cable and prestressed anchor cable one-time forming construction method

ActiveCN104895072BAvoid the problem of easy hole collapseReduce construction stepsBulkheads/pilesAnchoring boltsPre stressPre stressing

The invention provides a pre-stressed anchor cable and a pre-stressed anchor cable one-time forming construction method. The method comprises the steps of: 1) providing an anchor cable and a rotary jet grouting drilling machine comprising a hollow drill stem provided with a drill bit at the front end; 2) installing the anchor cable in the hollow drill stem; 3) using the rotary jet grouting drilling machine to perform rotary jet grouting drilling in soil layers to form an anchor cable hole, the anchor cable entering the anchor cable hole along the hollow drill stem; 4) pulling the hollow drill stem out from the anchor cable hole after the drilling of the rotary jet grouting drilling machine reaches a target depth; 5) performing grouting in the anchor cable hole; 6) stretching and drawing and locking the anchor cable. The pre-stressed anchor cable one-time forming construction method enables the drilling, the anchor cable installing and the grouting to be performed simultaneously. The pre-stressed anchor cable one-time forming construction technology prevents the problem of hole collapse caused by anchor cable installation after drilling, and reduces construction steps and saves time.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com