Non-bearing assembling type sound insulation partition wall suitable for steel structure building

A non-load-bearing, steel structure technology, used in buildings, building components, building structures, etc., can solve problems such as prolonging construction time, reducing construction speed, and difficult to control the quality of caulking, saving installation time and improving construction efficiency. , good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

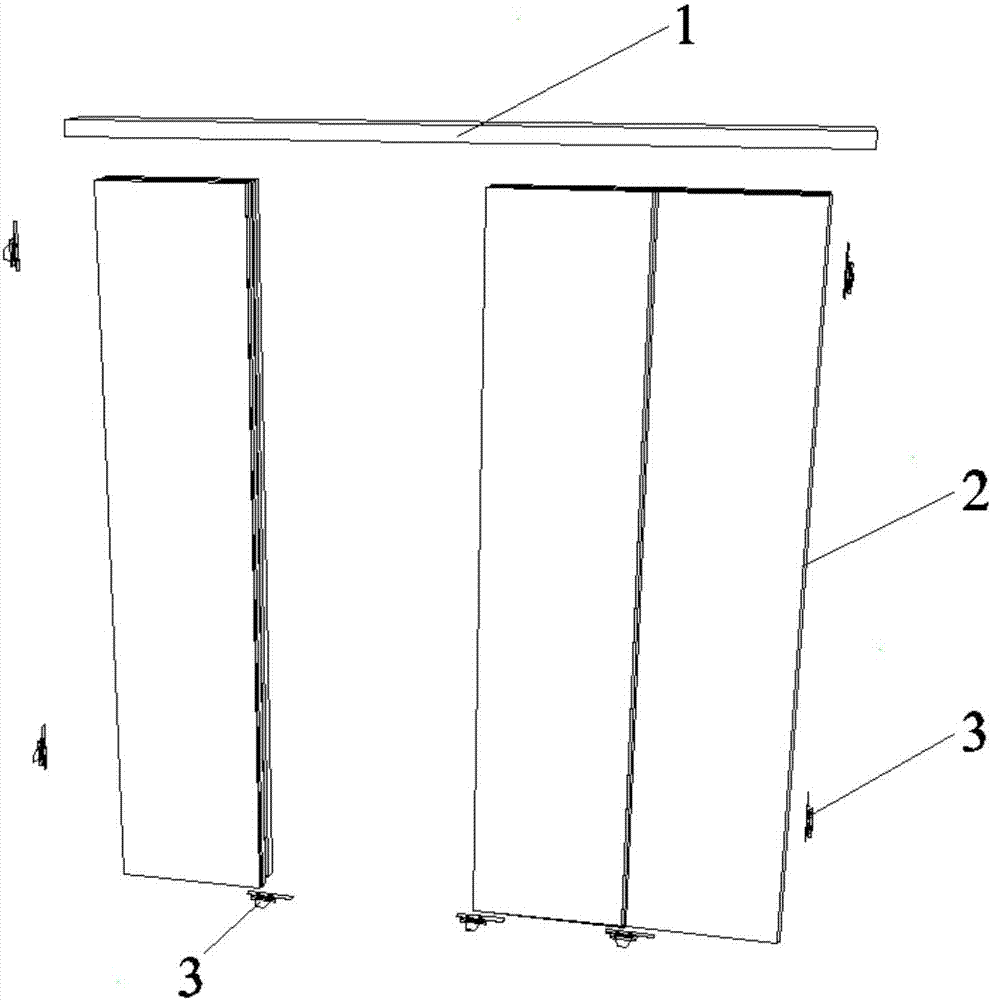

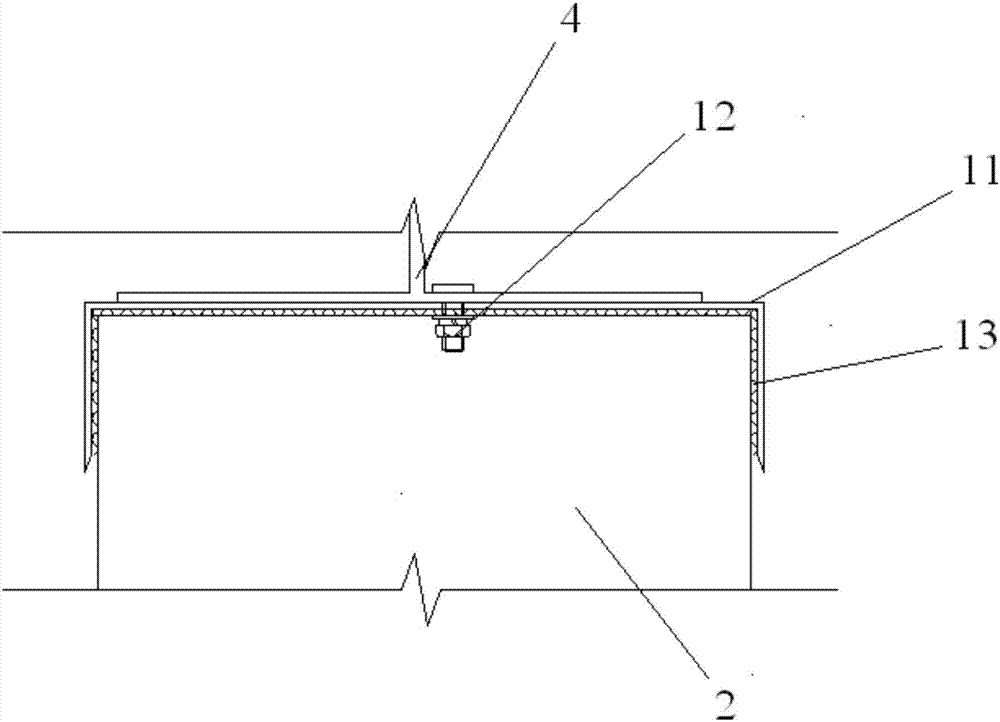

[0023] Such as figure 1 As shown, the present invention mainly comprises three parts, and the first part is the fixed groove 1 under the steel beam 4, is specifically made up of steel groove 11, the first fixed bolt 12 and rubber pad 13; The groove 11 is fixed under the steel beam 4, and the rubber pad 13 is prefabricated in the steel groove 11 using an adhesive, and the rubber pad 13 can also be placed on the prefabricated partition board 2 on the spot and inserted into the steel groove 11, see figure 2 . The size difference between the steel channel 11 and the partition wall plate 2 should be slightly smaller than the thickness of the rubber pad 13, so as to ensure that the rubber pad 13 is in a squeezed state and improve the sound insulation performance of the joint.

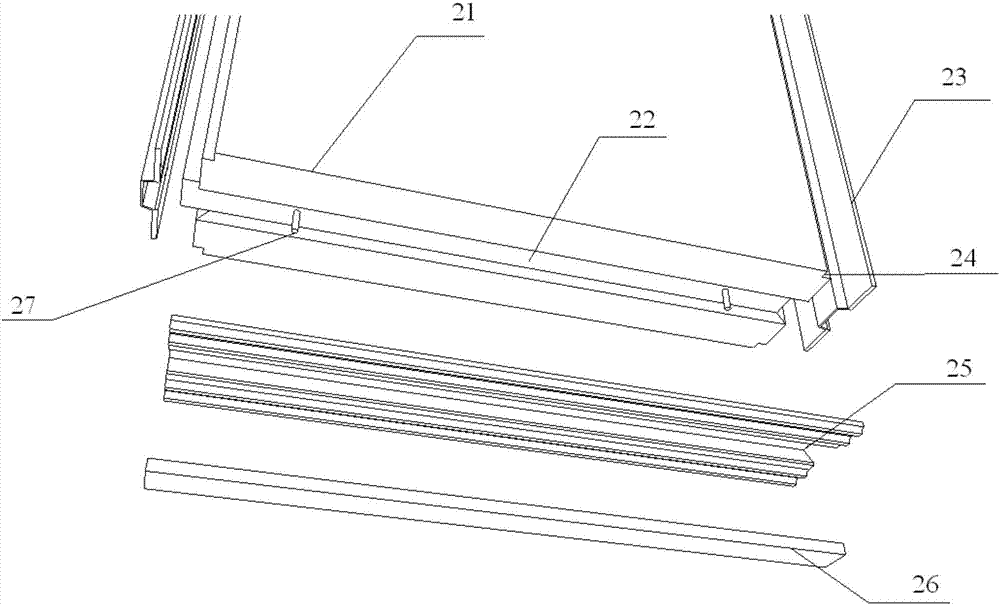

[0024] The second part is the prefabricated partition panel 2, such as image 3 and Figure 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com